Hydrogen-Powered Engines: A Study on Selected Technological and Emissions Issues

Abstract

1. Introduction

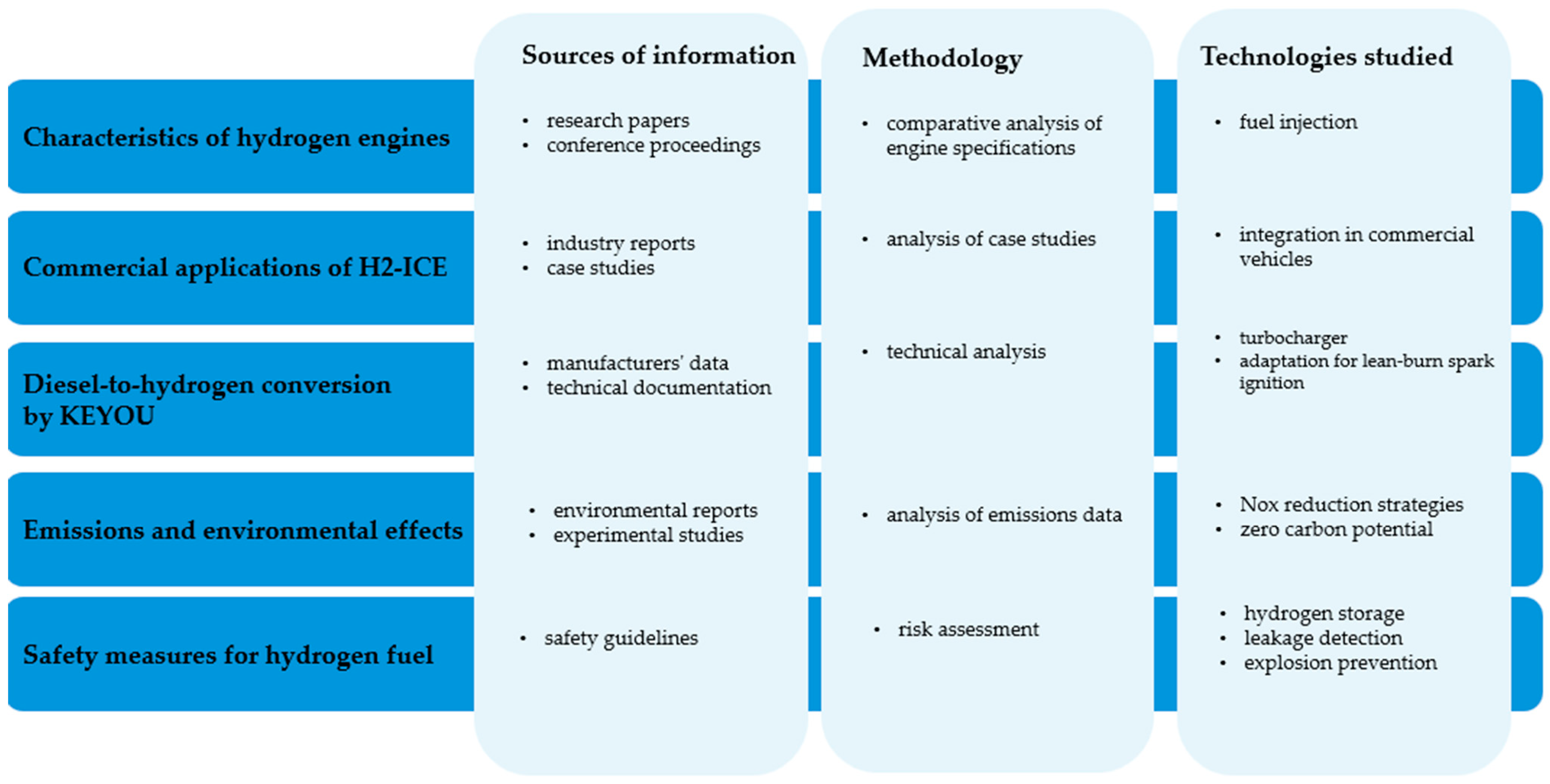

2. Materials and Methods

- Examination of recent innovations in hydrogen-powered internal combustion engine technology, such as advanced injection systems and turbocharging techniques;

- Analysis of the reduction in harmful emissions and the potential of hydrogen engines to meet stringent environmental standards;

- Investigation of the unique properties of hydrogen fuel and the safety strategies required to mitigate the risks associated with its use.

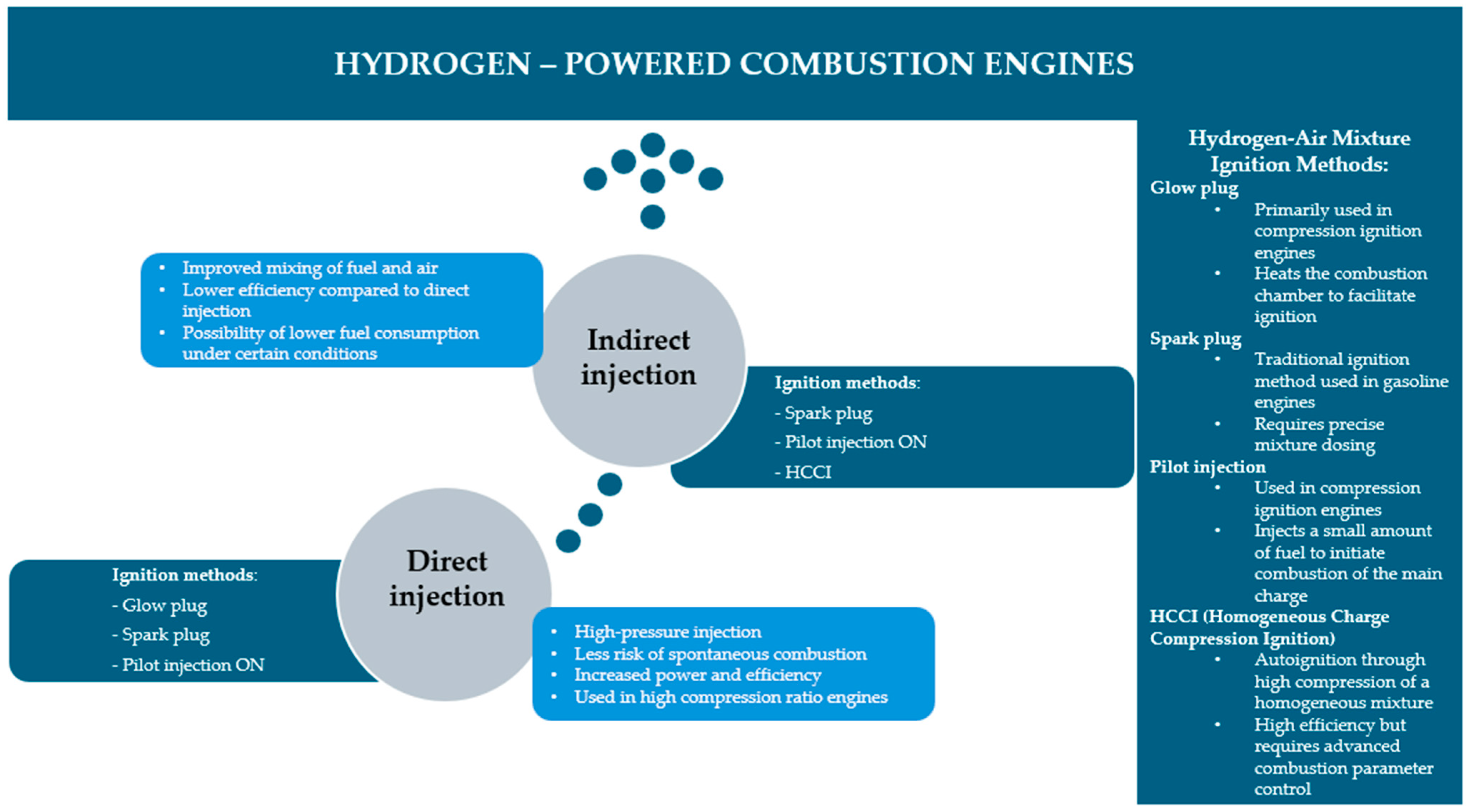

3. Characteristics of Hydrogen-Powered Engine

- Wide flammability range;

- Low ignition energy;

- Short flame extinction distance at the wall;

- High auto-ignition temperature;

- High flame speed at stoichiometric ratio;

- High diffusivity;

- Very low density.

4. Selected Hydrogen-Powered Engines Used in Commercial Vehicles

- A high-pressure common-rail direct-injection system into the cylinder combined with dual-channel turbocharging technology to achieve both homogeneous and stratified combustion;

- A platform that is highly adaptable to different levels of fuel purity and can run on fuels prepared from gray hydrogen, green hydrogen, hydrogen produced from methanol, and other means;

- The low power consumption per liter of hydrogen-powered engines, using a platform in the YC16H hydrogen-powered engine that has a particularly high power-to-weight ratio in its class when powered by diesel;

- An engine control system and a high-performance air handling system that can achieve both equivalent stoichiometric combustion and lean combustion and can adjust fuel injection pressure and air intake volume for different fuels.

- It has a 2 L turbocharged engine;

- It is equipped with what the company calls intelligent water injection, enabling high levels of performance;

- The prototype is the first racing engine that AVL Racetech has developed and built in-house;

- AVL’s racing engine uses only low poor combustion and achieves performance levels of around 150 kW per liter, unlike other hydrogen internal combustion engines, which tend to operate at high levels of excess air (low poor combustion), meaning they generate relatively less performance.

- Radiator and valve: High performance of the radiator and precise control of the EGR stage.

- Injection system: pressure and injectors: optimized H2 injection process for good mixture homogenization throughout the operating range.

- Engine map strategy: controlling the quality and quantity of H2 dosage throughout the operating range along with EGR strategy.

- H2 pressure control system: electronically adjustable pressure valve: accurate and fast flow control changes throughout the operating range.

- Ignition system: ignition module and plugs: ignition voltage and energy adjusted according to ignition conditions.

- Timing system: valves and valve seats made of special materials for maximum durability, because H2 has no lubricating properties.

- Piston junction system: piston and rings to ensure high mixture homogenization and avoid abnormal combustion and low lubricating oil penetration.

- Supercharging system: turbocharger: special requirements due to the low enthalpy of the exhaust gas for high supercharging and high torque; + E-supercharging.

- Exhaust aftertreatment system: simple (SCR), efficient, low cost.

5. KEYOU’s Concept—Switching from Diesel Combustion to a Supercharged and Lean-Burn Spark-Ignition Engine

- In line with the CO2 emission limit for commercial vehicles, the European Union has classified the hydrogen-powered internal combustion engine as a “zero-emission vehicle”. This enables manufacturers of traditional engines and existing technologies in the existing production infrastructure to meet the new stringent CO2 emission requirements and toxic component standards for the commercial vehicle sector, providing an attractive alternative to electric vehicles and fuel cells.

- In hydrogen-powered engines, exhaust aftertreatment systems are less extensive than in conventional internal combustion engines. The smaller number of components leads to a significant reduction in the cost of the end product.

- Supercharged hydrogen-fueled engines achieve higher power and torque compared to conventional spark-ignition and compression-ignition engines.

- The environmental performance of hydrogen-fueled internal combustion engines is greater than that of other types of propulsion. The technology is also sustainable and clean, as it does not consume rare earth elements, and above all, far fewer (toxic) raw materials are required for production.

6. Emissions of Exhaust Constituents of Hydrogen-Fueled Internal Combustion Engines

7. Safety Measures Related to the Use of Hydrogen as a Fuel

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Algayyim, S.J.; Saleh, K.; Wandel, A.P.; Fattah, I.M.; Yusaf, T.; Alrazen, H.A. Influence of natural gas and hydrogen properties on internal combustion engine performance, combustion, and emissions: A review. Fuel 2024, 362, 130844. [Google Scholar] [CrossRef]

- Bhagat, R.N.; Sahu, K.B.; Ghadai, S.K.; Kumar, C.B. A review of performance and emissions of diesel engine operating on dual fuel mode with hydrogen as gaseous fuel. Int. J. Hydrogen Energy 2023, 48, 27394–27407. [Google Scholar] [CrossRef]

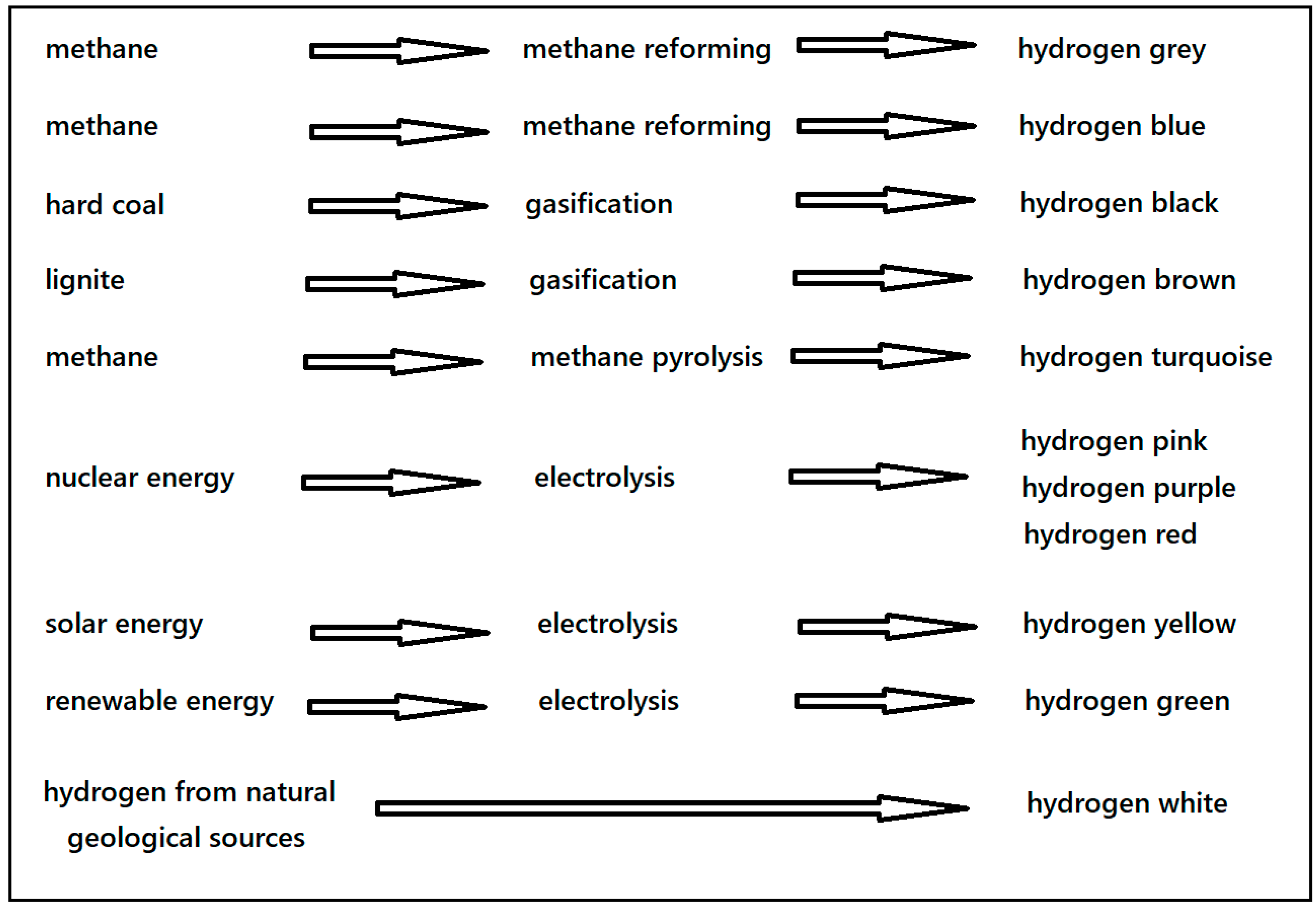

- Mohideen, M.M.; Subramanian, B.; Sun, J.; Ge, J.; Guo, H.; Radhamani, A.V.; Ramakrishna, S.; Liu, Y. Techno-economic analysis of different shades of renewable and non-renewable energy-based hydrogen for fuel cell electric vehicles. Renew. Sustain. Energy Rev. 2023, 174, 113153. [Google Scholar] [CrossRef]

- Tüccar, G.; Uludamar, E. Emission and engine performance analysis of a diesel engine using hydrogen enriched pomegranate seed oil biodiesel. Int. J. Hydrogen Energy 2018, 43, 18014–18019. [Google Scholar] [CrossRef]

- El-Hadary, M.I.; Senthilraja, S.; Zayed, M.E. A hybrid system coupling spiral type solar photovoltaic thermal collector and electrocatalytic hydrogen production cell: Experimental investigation and numerical modeling. Process Saf. Environ. Prot. 2023, 170, 1101–1120. [Google Scholar] [CrossRef]

- Matthews, H.D.; Tokarska, K.B.; Rogelj, J.; Smith, C.J.; MacDougall, A.H.; Haustein, K.; Mengis, N.; Sippel, S.; Forster, P.M.; Knutti, R. An integrated approach to quantifying uncertainties in the remaining carbon budget. Commun. Earth Environ. 2021, 2, 7. [Google Scholar] [CrossRef]

- Kalghatgi, G. Is it really the end of internal combustion engines and petroleum in transport? Appl. Energy 2018, 225, 965–974. [Google Scholar] [CrossRef]

- Kannaiyan, K.; Sadr, R. Spray characteristics of natural gas-based alternative jet fuel at high pressure ambient conditions. Fuel 2023, 350, 128409. [Google Scholar] [CrossRef]

- Romagnoli, F.; Blumberga, D.; Pilicka, I. Life cycle assessment of biohydrogen production in photosynthetic processes. Int. J. Hydrogen Energy 2011, 36, 7866–7871. [Google Scholar] [CrossRef]

- Algayyim, S.J.M.; Yusaf, T.; Hamza, N.H.; Wandel, A.P.; Fattah, I.M.R.; Laimon, M.; Rahman, S.M.A. Sugarcane Biomass as a Source of Biofuel for Internal Combustion Engines (Ethanol and Acetone-Butanol-Ethanol): A Review of Economic Challenges. Energies 2022, 15, 8644. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, X.; Liu, L. Feasibility study of hydrogen jet flame ignition of ammonia fuel in marine low speed engine. Int. J. Hydrogen Energy 2023, 48, 327–336. [Google Scholar]

- Machado, P.G.; Teixeira, A.C.; Collaço, F.M.; Mouette, D. Review of life cycle greenhouse gases, air pollutant emissions and costs of road medium and heavy-duty trucks. Wiley Interdiscip. Rev. Energy Environ. 2021, 10, e395. [Google Scholar] [CrossRef]

- Yusaf, T.; Laimon, M.; Alrefae, W.; Kadirgama, K.; Dhahad, H.A.; Ramasamy, D.; Kamarulzaman, M.K.; Yousif, B. Hydrogen Energy Demand Growth Prediction and Assessment (2021–2050) Using a System Thinking and System Dynamics Approach. Appl. Sci. 2022, 12, 781. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, S.; Zhang, Z.; Li, W.; Yuan, T.; Tan, D.; Duan, L.; Yang, G. A comprehensive review on combustion, performance and emission aspects of higher alcohols and its additive effect on the diesel engine. Fuel 2023, 335, 127011. [Google Scholar]

- Pacura, W.; Szramowiat-Sala, K.; Macherzyński, M.; Gołaś, J.; Bielaczyc, P. Analysis of Micro-Contaminants in Solid Particles from Direct Injection Gasoline Vehicles. Energies 2022, 15, 5732. [Google Scholar] [CrossRef]

- Raza, M.; Chen, L.; Leach, F.; Ding, S. A Review of particulate number (PN) emissions from gasoline direct injection (GDI) engines and their control techniques. Energies 2018, 11, 1417. [Google Scholar] [CrossRef]

- Szramowiat, K.; Woodburn, J.; Pacura, W.; Berent, K.; Bielaczyc, P.; Gołaś, J. Engine-generated solid particles—A case study. Combust. Engines 2018, 174, 33–39. [Google Scholar]

- Mehra, K.S.; Pal, J.; Goel, V. A comprehensive review on the atomization and spray characteristics of renewable biofuels. Sustain. Energy Technol. Assess. 2023, 56, 103106. [Google Scholar]

- Loulergue, L.; Schilt, A.; Spahni, R.; Masson-Delmotte, V.; Blunier, T.; Lemieux, B.; Barnola, J.-M.; Raynaud, D.; Stocker, T.F.; Chappellaz, J. Orbital and millennial-scale features of atmospheric CH4 over the past 800,000 years. Nature 2008, 453, 383–386. [Google Scholar]

- Pham, Q.; Chang, M.; Kalwar, A.; Agarwal, A.K.; Park, S.; Choi, B.; Park, S. Macroscopic spray characteristics and internal structure studies of natural gas injection. Energy 2023, 263, 126055. [Google Scholar] [CrossRef]

- Kakaee, A.-H.; Paykani, A.; Ghajar, M. The influence of fuel composition on the combustion and emission characteristics of natural gas fueled engines. Renew. Sustain. Energy Rev. 2014, 38, 64–78. [Google Scholar] [CrossRef]

- Aworanti, O.A.; Agbede, O.O.; Agarry, S.E.; Ajani, A.O.; Ogunkunle, O.; Laseinde, O.T.; Rahman, S.M.A.; Fattah, I.M.R. Decoding Anaerobic Digestion: A Holistic Analysis of Biomass Waste Technology, Process Kinetics, and Operational Variables. Energies 2023, 16, 3378. [Google Scholar] [CrossRef]

- Veza, I.; Afzal, A.; Mujtaba, M.; Hoang, A.T.; Balasubramanian, D.; Sekar, M.; Fattah, I.; Soudagar, M.; El-Seesy, A.I.; Djamari, D.; et al. Review of artificial neural networks for gasoline, diesel and homogeneous charge compression ignition engine. Alex. Eng. J. 2022, 61, 8363–8391. [Google Scholar] [CrossRef]

- Sharma, H.; Mahla, S.K.; Dhir, A. Effect of utilization of hydrogen-rich reformed biogas on the performance and emission characteristics of common rail diesel engine. Int. J. Hydrogen Energy 2022, 47, 10409–10419. [Google Scholar] [CrossRef]

- Chapman, A.; Itaoka, K.; Hirose, K.; Davidson, F.T.; Nagasawa, K.; Lloyd, A.C.; Webber, M.E.; Kurban, Z.; Managi, S.; Tamaki, T.; et al. A review of four case studies assessing the potential for hydrogen penetration of the future energy system. Int. J. Hydrogen Energy 2019, 44, 6371–6382. [Google Scholar] [CrossRef]

- Novella, R.; Pastor, J.; Gomez-Soriano, J.; Sánchez-Bayona, J. Numerical study on the use of ammonia/hydrogen fuel blends for automotive spark-ignition engines. Fuel 2023, 351, 128945. [Google Scholar]

- Plotz, P. Hydrogen technology is unlikely to play a major role in sustainable road transport. Nat. Electron. 2022, 5, 8–10. [Google Scholar] [CrossRef]

- Hermesmann, M.; Müller, T. Green, turquoise, blue, or grey? Environmentally friendly hydrogen production in transforming energy systems. Prog. Energy Combust. Sci. 2022, 90, 100996. [Google Scholar] [CrossRef]

- Smith, A. The Role of Hydrogen in Future Energy Technologies. J. Renew. Energy 2018, 15, 45–58. [Google Scholar]

- Jones, B.; Lee, C. Hydrogen as a Universal Fuel: Current Status and Future Prospects. Int. J. Energy Res. 2020, 28, 101–115. [Google Scholar]

- Wang, X.; Yuan, Y.; Yan, X.; Shen, B.; Long, T. Hydrogen: A Versatile Energy Carrier for the Future. Renew. Sustain. Energy Rev. 2021, 42, 301–320. [Google Scholar]

- Kothari, R.; Buddhi, D.; Sawhney, R. Comparison of environmental and economic aspects of various hydrogen production methods. Renew. Sustain. Energy Rev. 2008, 12, 553–563. [Google Scholar] [CrossRef]

- Younas, M.; Shafique, S.; Hafeez, A.; Javed, F.; Rehman, F. An overview of hydrogen production: Current status, potential, and challenges. Fuel 2022, 316, 123317. [Google Scholar]

- Ahmed, S.F.; Mofijur, M.; Nuzhat, S.; Rafa, N.; Musharrat, A.; Lam, S.S.; Boretti, A. Sustainable hydrogen production: Technological advancements and economic analysis. Int. J. Hydrogen Energy 2022, 47, 37227–37255. [Google Scholar]

- Zainal, B.S.; Ker, P.J.; Mohamed, H.; Ong, H.C.; Fattah, I.; Rahman, S.A.; Nghiem, L.D.; Mahlia, T.M.I. Recent advancement and assessment of green hydrogen production technologies. Renew. Sustain. Energy Rev. 2024, 189, 113941. [Google Scholar]

- Davis, M.; Okunlola, A.; Di Lullo, G.; Giwa, T.; Kumar, A. Greenhouse gas reduction potential and cost-effectiveness of economy-wide hydrogen-natural gas blending for energy end uses. Renew. Sustain. Energy Rev. 2023, 171, 112962. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, X.R.; Li, T.; Zhang, J.; Gao, J.; Sun, Z.Y. Hydrogen and ethanol: Production, storage, and transportation. Int. J. Hydrogen Energy 2021, 46, 27330–27348. [Google Scholar]

- Zhang, T.; Uratani, J.; Huang, Y.; Xu, L.; Griffiths, S.; Ding, Y. Hydrogen liquefaction and storage: Recent progress and perspectives. Renew. Sustain. Energy Rev. 2023, 176, 113204. [Google Scholar]

- Kumar, S.; Arzaghi, E.; Baalisampang, T.; Garaniya, V.; Abbassi, R. Insights into decision-making for offshore green hydrogen infrastructure developments. Process Saf. Environ. Prot. 2023, 174, 805–817. [Google Scholar] [CrossRef]

- Stecuła, K.; Olczak, P.; Kamiński, P.; Matuszewska, D.; Duong Duc, H. Towards sustainable transport: Techno-economic analysis of investing in hydrogen buses in public transport in the selected city of Poland. Energies 2022, 15, 9456. [Google Scholar] [CrossRef]

- Li, Y.; Kool, C.; Engelen, P.J. Analyzing the business case for hydrogen-fuel infrastructure investments with endogenous demand in the Netherlands: A real options approach. Sustainability 2020, 12, 5424. [Google Scholar] [CrossRef]

- Okolie, J.A.; Patra, B.R.; Mukherjee, A.; Nanda, S.; Dalai, A.K.; Kozinski, J.A. Futuristic applications of hydrogen in energy, biorefining, aerospace, pharmaceuticals and metallurgy. Int. J. Hydrogen Energy 2021, 46, 8885–8905. [Google Scholar] [CrossRef]

- Rasul, M.G.; Hazrat, M.A.; Sattar, M.A.; Jahirul, M.I.; Shearer, M.J. The future of hydrogen: Challenges on production, storage and applications. Energy Convers. Manag. 2022, 272, 116326. [Google Scholar] [CrossRef]

- Ueckerdt, F.; Bauer, C.; Dirnaichner, A.; Everall, J.; Sacchi, R.; Luderer, G. Potential and risks of hydrogen-based e-fuels in climate change mitigation. Nat. Clim. Change 2021, 11, 384–393. [Google Scholar]

- Osman, A.I.; Mehta, N.; Elgarahy, A.M.; Hefny, M.; Al-Hinai, A.; Al-Muhtaseb, A.A.H.; Rooney, D.W. Hydrogen production, storage, utilisation and environmental impacts: A review. Environ. Chem. Lett. 2022, 20, 153–188. [Google Scholar] [CrossRef]

- Gandhi, R. Use of Hydrogen in Internal Combustion Engine. Int. J. Eng. Tech. Res. 2015, 3, 207–216. [Google Scholar]

- Stępień, Z.; Urzędowska, W. Tłokowe silniki spalinowe zasilane wodorem—Wyzwania. Naft. Gaz 2021, 77, 830–840. [Google Scholar]

- Yip, H.L.; Srna, A.; Yuen, A.C.Y.; Kook, S.; Taylor, R.A.; Yeoh, G.; Medwell, P.R.; Chan, Q.N. A Review of Hydrogen Direct Injection for Internal Combustion Engines: Towards Carbon-Free Combustion. Appl. Sci. 2019, 9, 4842. [Google Scholar] [CrossRef]

- Stępień, Z. A Comprehensive Overview of Hydrogen-Fueled Internal Combustion Engines: Achievements and Future Challenges. Energies 2021, 14, 6504. [Google Scholar] [CrossRef]

- Hsiung, S.; Lanz, A.; Heffel, J.; Messer, C. Hydrogen Fuel Cell Engines and Related Technologies; Energy Technology Training Center: Palm Desert, CA, USA, 2001. [Google Scholar]

- Samochód na Wodór. Jak Działa i Ile Kosztuje? Available online: https://devil-cars.pl/blog/samochod-na-wodor-jak-dziala-ile-kosztuje (accessed on 5 June 2024).

- Šarkan, B.; Jaśkiewicz, M.; Kubiak, P.; Tarnapowicz, D.; Loman, M. Exhaust Emissions Measurement of a Vehicle with Retrofitted LPG System. Energies 2022, 15, 1184. [Google Scholar] [CrossRef]

- Skov, I.R.; Schneider, N.; Schweiger, G.; Schöggl, J.P.; Posch, A. Power-to-X in Denmark: An analysis of strengths, weaknesses, opportunities and threats. Energies 2021, 14, 913. [Google Scholar] [CrossRef]

- Chodakowska, E.; Nazarko, J.; Nazarko, Ł.; Rabayah, H.S.; Abendeh, R.M.; Alawneh, R. Arima models in solar radiation forecasting in different geographic locations. Energies 2023, 16, 5029. [Google Scholar] [CrossRef]

- Menesy, A.S.; Sultan, H.M.; Habiballah, I.O.; Masrur, H.; Khan, K.R.; Khalid, M. Optimal Configuration of a Hybrid Photovoltaic/Wind Turbine/Biomass/Hydro-Pumped Storage-Based Energy System Using a Heap-Based Optimization Algorithm. Energies 2023, 16, 3648. [Google Scholar] [CrossRef]

- Morales Rojas, A.D.; Quintana, S.H.; Caro, I.D.B. Experimental Study of a Homogeneous Charge Compression Ignition Engine Using Hydrogen at High-Altitude Conditions. Sustainability 2024, 16, 2026. [Google Scholar] [CrossRef]

- Wang, L.; Li, X.; Hong, C.; Guo, P.; Guo, S.; Yang, Z. Research and Development of Hydrogen-Fueled Internal Combustion Engines in China. ACS Omega 2023, 8, 48590–48612. [Google Scholar]

- Yuchai Launches China’s First Operating Hydrogen Engine for CVs. Available online: https://auto.economictimes.indiatimes.com/news/auto-components/yuchai-launches-chinas-first-operating-hydrogen-engine-for-cvs/88630144 (accessed on 4 June 2024).

- Kaiser, S.; White, C.M. PIV and PLIF to evaluate mixture formation in a directinjection hydrogen-fuelled engine. SAE Int. J. Engines 2009, 1, 657–668. [Google Scholar]

- Qian, L.; Wan, J.; Qian, Y.; Sun, Y.; Zhuang, Y. Experimental investigation of water injection and spark timing effects on combustion and emissions of a hybrid hydrogen-gasoline engine. Fuel 2022, 322, 124051. [Google Scholar]

- Verhelst, S.; Wallner, T. Hydrogen-fueled internal combustion engines. Prog. Energy Combust. Sci. 2009, 35, 490–527. [Google Scholar]

- Al-Orabi, A.M.; Osman, M.G.; Sedhom, B.E. Analysis of the economic and technological viability of producing green hydrogen with renewable energy sources in a variety of climates to reduce CO2 emissions: A case study in Egypt. Appl. Energy 2023, 338, 120958. [Google Scholar]

- The Most Effective Technology to Comply with CO2-Legislation: The New Generation of Hydrogen Internal Combustion Engines. Available online: https://klasterwodorowy.pl/images/zdjecia/Pedro%20Bravo_KEYOU.pdf (accessed on 4 June 2024).

- Hydrogen in Powergeneration. Available online: https://www.wartsila.com/energy/sustainable-fuels/hydrogen-in-power-generation (accessed on 4 June 2024).

- Karim, G.A. Hydrogen as a spark ignition engine fuel. Int. J. Hydrogen Energy 2003, 28, 569–577. [Google Scholar]

- Sharma, S.K.; Goyal, P.; Tyagi, R.K. Hydrogen-Fueled Internal Combustion Engine: A Review of Technical Feasibility. Int. J. Perform. Eng. 2015, 11, 491–501. [Google Scholar]

- Faizal, M.; Chuah, L.S.; Lee, C.; Hameed, A.; Lee, J.; Shankar, M. Review of Hydrogen Fuel For Internal Combustion Engines. J. Mech. Eng. Res. Dev. 2019, 42, 35–46. [Google Scholar]

- Benajes, J.; Olmeda, P.; Martín, J.; Carreño, R. A new methodology for uncertainties characterization in combustion diagnosis and thermodynamic modelling. Appl. Therm. Eng. 2014, 71, 389–399. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, Y.; Jiang, Y.; Lu, W.; Liu, W. Effect of compression ratio and miller cycle on performance of methanol engine under medium and low loads. Fuel 2023, 351, 128985. [Google Scholar] [CrossRef]

- Pagliaro, M. Hydrogen-powered boats and ships. In Current Trends and Future Developments on (Bio-) Membranes; Elsevier: Amsterdam, The Netherlands, 2020; pp. 411–419. [Google Scholar]

- Mäkitie, T.; Danebergs, J.; Hanson, J.; Medbø, E.G. Solving the Chicken and Egg Problem in Maritime Hydrogen Value Chains in Western Norway; FME NTRANS Report; Norwegian Centre for Energy Transition Sreategies: Sogndal, Norway, 2021; Volume 3, p. 21. [Google Scholar]

- Aarskog, F.G.; Danebergs, J.; Strømgren, T.; Ulleberg, Ø. Energy and cost analysis of a hydrogen driven high speed passenger ferry. Int. Shipbuild. Prog. 2020, 67, 97–123. [Google Scholar] [CrossRef]

- Jensen, M. HYDROGEN IN THE NORDICS: What’s Going on in Denmark, Iceland, Norway, Sweden? H2 International: Tokyo, Japan, 2021. [Google Scholar]

- Fereidounizadeh, N. Hydrogen Fuel in Sweden, a Comparative Study of Five Countries; Linnaeus University: Växjö, Sweden, 2021. [Google Scholar]

- Alavi-Borazjani, S.A.; Adeel, S.; Chkoniya, V. Hydrogen as a Sustainable Fuel: Transforming Maritime Logistics. Energies 2025, 18, 1231. [Google Scholar] [CrossRef]

- Zasiadko, M. Deutsche Bahn to Become Carbon Neutral by 2050; Railtech: Rotterdam, The Netherlands, 2020; Available online: https://www.railtech.com/policy/2020/09/07/deutsche-bahn-to-become-carbon-neutral-by-2050/ (accessed on 12 January 2022).

- Steffen, A.D. Britain’s Strategy to Decarbonize 15,140 km of Train Lines; Intelligent Living: Bristol, UK, 2020; Available online: https://www.intelligentliving.co/britains-decarbonize-train-lines/ (accessed on 12 January 2022).

- Corcau, J.I.; Dinca, L.; Cican, G.; Ionescu, A.; Negru, M.; Bogateanu, R.; Cucu, A.A. Studies Concerning Electrical Repowering of a Training Airplane Using Hydrogen Fuel Cells. Aerospace 2024, 11, 218. [Google Scholar] [CrossRef]

- Korn, T. The most efficient way for CO2 reduction: The new generation of hydrogen internal combustion engines. In Proceedings of the 41th International Vienna Motor Symposium, Vienna, Austria, 22–24 April 2020. [Google Scholar]

- Albaker, A.; Abbasi, K.R.; Haddad, A.M.; Radulescu, M.; Manescu, C.; Bondac, G.T. Analyzing the Impact of Renewable Energy and Green Innovation on Carbon Emissions in the MENA Region. Energies 2023, 16, 6053. [Google Scholar] [CrossRef]

- Jaradat, M.; Alsotary, O.; Juaidi, A.; Albatayneh, A.; Alzoubi, A.; Gorjian, S. Potential of producing green hydrogen in Jordan. Energies 2022, 15, 9039. [Google Scholar] [CrossRef]

- Saygin, D.; Blanco, H.; Boshell, F.; Cordonnier, J.; Rouwenhorst, K.; Lathwal, P.; Gielen, D. Ammonia Production from Clean Hydrogen and the Implications for Global Natural Gas Demand. Sustainability 2023, 15, 1623. [Google Scholar] [CrossRef]

- Duan, H.; Huang, Y.; Mehra, R.K.; Song, P.; Ma, F. Study on influencing factors of prediction accuracy of support vector machine (SVM) model for NOx emission of a hydrogen enriched compressed natural gas engine. Fuel 2018, 234, 954–964. [Google Scholar]

- Verhelst, S. Recent progress in the use of hydrogen as a fuel for internal combustion engines. Int. J. Hydrog. Energy 2014, 39, 1071–1085. [Google Scholar]

- Eichlseder, H.; Wallner, T.; Freymann, R.; Ringler, J. The Potential of Hydrogen Internal Combustion Engines in a Future Mobility Scenario; SAE Technical Paper 2003-01-2267; SAE International: Warrendale, PA, USA, 2003. [Google Scholar]

- Fan, B.; Pan, J.; Liu, Y.; Zhu, Y.; Pan, Z.; Chen, W.; Otchere, P. Effect of hydrogen injection strategies onmixture formation and combustion process in a hydrogen direct injection plus natural gas port injection rotary engine. Energy Convers. Manag. 2018, 160, 150–164. [Google Scholar] [CrossRef]

- Kumar, V.; Gupta, D.; Naveen, K. Hydrogen Use in Internal Combustion Engine: A Review. Int. J. Adv. Cult. Technol. 2015, 3, 87–99. [Google Scholar]

- Shivaprasad, K.V.; Rejesh, R.; Anteneh Wogasso, W.; Nigatu, B.; Addisu, F. Usage of Hydrogen as a Fuel in Spark Ignition Engine. IOP Conf. Ser. Mater. Sci. Eng. 2018, 376, 012037. [Google Scholar]

- Das, L.M. Exhaust emission characterization of hydrogen-operated engine system: Nature of pollutants and their control techniques. Int. J. Hydrogen Energy 1991, 16, 765–775. [Google Scholar]

- Salimi, F.; Shamekhi, A.H.; Pourkhesalian, A.M. Role of mixture richness, spark and valve timing in hydrogen-fuelled engine performance and emission. Int. J. Hydrogen Energy 2009, 34, 3922–3929. [Google Scholar]

- Wallner, T. Efficiency and Emissions Potential of Hydrogen Internal Combustion Engine Vehicles; SAE Technical Paper 2011-26-0003; The Automotive Research Association of India: Pune, India, 2011. [Google Scholar]

- Luo, Q.H.; Hu, J.B.; Sun, B.G.; Liu, F.S.; Wang, X.; Li, C.; Bao, L.Z. Experimental investigation of combustion characteristics and NOx emission of a turbocharged hydrogen internal combustion engine. Int. J. Hydrogen Energy 2019, 44, 5573–5583. [Google Scholar]

- Natkin, R.J.; Tang, X.; Boyer, B.; Oltmans, B.; Denlinger, A.; Heffel, J.W. Hydrogen IC Engine Boosting Performance and NOx Study; SAE Technical Paper 2003-01-0631; SAE International: Warrendale, PA, USA, 2003. [Google Scholar]

- Sadiq Al-Baghdadi, M.A.R. Effect of compression ratio, equivalence ratio and engine speed on the performance and emission characteristics of a spark ignition engine using hydrogen as a fuel. Renew. Energy 2004, 29, 2245–2260. [Google Scholar] [CrossRef]

- Habib, M.A.; Abdulrahman, G.A.; Alquaity, A.B.; Qasem, N.A. Hydrogen combustion, production, and applications: A review. Alex. Eng. J. 2024, 100, 182–207. [Google Scholar]

- Schrotenboer, A.H.; Veenstra, A.A.; uit het Broek, M.A.; Ursavas, E. A Green Hydrogen Energy System: Optimal control strategies for integrated hydrogen storage and power generation with wind energy. Renew. Sustain. Energy Rev. 2022, 168, 112744. [Google Scholar]

- Guo, S.; Lou, Z.; Huang, F.; Wang, L.; Liu, H.; Hou, Z.; Yang, Z.; Zhang, X. Effect of hydrogen/ammonia mixing ratio on combustion and emission performance of hydrogen engine with different injection timing. Int. J. Hydrogen Energy 2024, 78, 157–168. [Google Scholar]

- Fernández-Tarrazo, E.; Gómez-Miguel, R.; Sánchez-Sanz, M. Minimum ignition energy of hydrogen–ammonia blends in air. Fuel 2023, 337, 127128. [Google Scholar] [CrossRef]

- Das, L.M. Hydrogen-fueled internal combustion engines. Compend. Hydrogen Energy 2016, 3, 177–217. [Google Scholar]

- Zaik, K. Wodór Jako Klucz do Zrównoważonego Rozwoju—Przegląd Oraz Ocena Metod Produkcji. In Współczesne Problemy Ochrony Środowiska i Energetyki; Pikoń, K., Bogacka, M., Eds.; Silesian University of Technology: Gliwice, Poland, 2020; pp. 221–230. [Google Scholar]

- Hosseini, S.E.; Butler, B. An overview of development and challenges in hydrogen powered vehicles. Int. J. Green Energy 2020, 17, 13–37. [Google Scholar] [CrossRef]

- H2 Safety #1. Understanding Hydrogen. Available online: https://seshydrogen.com/technologie-wodorowe-bezpieczenstwo/ (accessed on 4 June 2024).

- Walallawita, R.; Stroh, J.; Sediako, D. The Effect of Hydrogen Embrittlement on Aluminum Alloys Used for Hydrogen-Fueled Internal Combustion Engine. In Proceedings of the 61st Conference of Metallurgists, COM 2022, Montréal, QC, Canada, 21–24 August 2022; Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar]

- Sadiq Al-Baghdadi, M.A.R. An Overview of Hydrogen as an Alternative Fuel. Available online: https://encyclopedia.pub/revision/9798/v1 (accessed on 4 June 2024).

- Szwabowski, S.J.; Hashemi, S.; Stockhausen, W.F.; Natkin, R.J.; Reams, L.; Kabat, D.M.; Potts, C. Ford Hydrogen Engine Powered P2000 Vehicle; SAE Technical Paper 2002-01-0243; SAE International: Warrendale, PA, USA, 2002. [Google Scholar]

- Huang, Y.; Ma, F. Intelligent regression algorithm study based on performance and NOx emission experimental data of a hydrogen enriched natural gas engine. Int. J. Hydrogen Energy 2016, 41, 11308–11320. [Google Scholar] [CrossRef]

- Malakhov, A.A.; Avdeenkov, A.V.; Du Toit, M.H.; Bessarabov, D.G. CFD simulation and experimental study of a hydrogen leak in a semi-closed space with the purpose of risk mitigation. Int. J. Hydrogen Energy 2020, 45, 9231–9240. [Google Scholar] [CrossRef]

- Zhang, C.; Cao, X.; Bujlo, P.; Chen, B.; Zhang, X.; Sheng, X.; Liang, C. Review on the safety analysis and protection strategies of fast filling hydrogen storage system for fuel cell vehicle application. J. Energy Storage 2022, 45, 103451. [Google Scholar] [CrossRef]

- Koo, W.T.; Cho, H.J.; Kim, D.H.; Kim, Y.H.; Shin, H.; Penner, R.M.; Kim, I.D. Chemiresistive hydrogen sensors: Fundamentals, recent advances, and challenges. ACS Nano 2020, 14, 14284–14322. [Google Scholar]

- Darmadi, I.; Nugroho, F.A.A.; Langhammer, C. High-performance nanostructured palladium-based hydrogen sensors—Current limitations and strategies for their mitigation. ACS Sens. 2020, 5, 3306–3327. [Google Scholar]

- Lee, J.; Cho, S.; Cho, H.; Cho, S.; Lee, I.; Moon, I.; Kim, J. CFD modeling on natural and forced ventilation during hydrogen leaks in a pressure regulator process of a residential area. Process Saf. Environ. Prot. 2022, 161, 436–446. [Google Scholar]

- Fuel Cell Vehicle Dismantling Manual. Available online: https://www.toyota-tech.eu/HYBRID/HVDM/EN/DM32B0U_Revised_201507.pdf (accessed on 4 June 2024).

- Stockhausen, W.F.; Natkin, R.J.; Kabat, D.M.; Reams, L.; Tang, X.; Hashemi, S.; Szwabowski, S.J.; Zanardelli, V.P. Ford P2000 Hydrogen Engine Design and Vehicle Development Program; SAE Technical Paper 2002-01-0240; SAE International: Warrendale, PA, USA, 2002. [Google Scholar]

| Properties | H2 | CH4 | C8H18 | C8H20 |

|---|---|---|---|---|

| Carbon content [wt%] | 0 | 75 | 84 | 86 |

| Calorific value [MJ/kg] | 119.7 | 45.8 | 43.9 | 42.5 |

| Density (1 bar, 273 K) [kg/m3] | 0.089 | 0.72 | 730–780 | 830 |

| Volumetric energy content (1 bar, 273 K) [MJ/m3] | 10.7 | 33 | 33,000 | 35,000 |

| Molecular weight [g/mol] | 2.016 | 16.043 | ~110 | ~170 |

| Boiling point [K] | 20 | 111 | 298–488 | 453–633 |

| Minimum ignition energy in air (1 bar, stoichiometric mixture) [mJ]. | 0.02 | 0.29 | 0.24 | 0.24 |

| Stoichiometric fuel/air mass ratio [wt.] | 34.4:1 | 17.2:1 | 14.7:1 | 14.5:1 |

| Flame extinction distance at the wall (1 bar, 298 K, stoichiometric mixture) [mm] | 0.64 | 2.1 | ~2 | – |

| Propagation velocity of laminar flame in air (1 bar, 298 K, stoichiometric mixture) [m/s] | 1.85 | 0.38 | 0.37–0.43 | 0.37–0.43 |

| Diffusion coefficient in air (1 bar, 273 K) [m2/s] | 8.5 × 10−6 | 1.9 × 10−6 | – | – |

| Flammability limits in air [vol%] | 4–76 | 5.3–15 | 1–7.6 | 0.6–5.5 |

| Adiabatic flame temperature (1 bar, 298 K, stoichiometric mixture) [K] | 2480 | 2214 | 2580 | ~2300 |

| Octane number (RON) | 130+ | 120+ | 86–94 | – |

| Cetane number | – | – | 13–17 | 40–55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Markowska, K.; Wittek, K.; Kabiesz, P.; Stecuła, K.; Aydın, B.; Pawlak, S.; Markowska, A. Hydrogen-Powered Engines: A Study on Selected Technological and Emissions Issues. Energies 2025, 18, 1675. https://doi.org/10.3390/en18071675

Markowska K, Wittek K, Kabiesz P, Stecuła K, Aydın B, Pawlak S, Markowska A. Hydrogen-Powered Engines: A Study on Selected Technological and Emissions Issues. Energies. 2025; 18(7):1675. https://doi.org/10.3390/en18071675

Chicago/Turabian StyleMarkowska, Katarzyna, Kamil Wittek, Patrycja Kabiesz, Kinga Stecuła, Barış Aydın, Szymon Pawlak, and Agata Markowska. 2025. "Hydrogen-Powered Engines: A Study on Selected Technological and Emissions Issues" Energies 18, no. 7: 1675. https://doi.org/10.3390/en18071675

APA StyleMarkowska, K., Wittek, K., Kabiesz, P., Stecuła, K., Aydın, B., Pawlak, S., & Markowska, A. (2025). Hydrogen-Powered Engines: A Study on Selected Technological and Emissions Issues. Energies, 18(7), 1675. https://doi.org/10.3390/en18071675