Abstract

The operational efficiency of many industrial processes is greatly affected by condition monitoring, which has become more and more important in the detection and forecast of electrical machine failures. Early identification of possible problems and prompt and precise diagnosis reduce unscheduled downtime, lower maintenance costs, and prevent catastrophic failures. Traditional human-dependent diagnostic techniques are changing as a result of advances in artificial intelligence (AI), opening the door to automated and predictive maintenance plans. This paper provides a detailed examination of artificial intelligence (AI) applications in the prediction of electrical device failures, with a focus on techniques such as fuzzy systems, expert systems, artificial neural networks (ANNs), and complex machine-learning algorithms. These methods use both historical and present data to identify and predict problems and allow timely actions. The study looks at implementation challenges for AI-based diagnostic systems, including data dependencies, processing demands, and model interpretability, in addition to highlighting recent advances such as digital twins, explainable AI, and IoT integration. This review highlights the revolutionary potential of artificial intelligence (AI) in improving the sustainability, efficiency, and dependability of electrical machine systems, especially in the context of rotating machines, by addressing existing constraints and suggesting future research routes.

1. Introduction

Electrical machines are fundamental to a wide range of applications, including power generation and transmission, industrial processes, integration of renewable energy, energy efficiency, electric vehicles, and transportation systems. Generators, a critical type of electrical machine, account for approximately 95% of the world’s electricity production (as reported in the early 2020s [1]), while electric motors consume about 60% of this generated power. The reliability and efficiency of these machines are vital for maintaining operational continuity and minimizing economic losses.

Over the past 15 years, significant research efforts have focused on advancing condition monitoring techniques for electric machine drives. Ensuring reliable operation from a maintenance perspective is crucial, as unexpected failures can lead to severe operational disruptions and substantial financial losses. Traditional maintenance strategies, such as scheduled inspections and reactive repairs, have mainly relied on protective devices such as overcurrent relays to protect equipment. However, these conventional methods have notable limitations. Protective relays typically activate only after severe failures occur, resulting in extensive equipment damage or complete machine failure [2].

Historically, fault detection methods for electrical machines have included vibration analysis, thermography, acoustic emission analysis, motor current signature analysis (MCSA), and partial discharge detection. Although effective to some extent, these methods often require specialized equipment, significant manual interpretation, and periodic maintenance intervals that may not align with the actual machinery degradation timeline. Moreover, these techniques are reactive in nature, identifying faults only after they have developed to a critical stage [3,4].

The advent of artificial intelligence (AI) in defect prediction represents a transformative advancement, enabling proactive fault detection and significantly enhancing system reliability. AI techniques, such as machine learning (ML), deep learning (DL), and data-driven modeling, can process vast amounts of operational data to identify patterns and predict potential failures before they occur. This shift from reactive to predictive maintenance not only minimizes downtime but also extends the operational life of equipment, reduces maintenance costs, and improves safety.

The primary objectives of this paper are as follows:

- To provide a comprehensive overview of how artificial intelligence is utilized for predicting faults in electrical machines.

- To investigate and propose the most effective AI approaches for fault prediction and analyze the current state of AI applications in this field.

- To discuss the various AI techniques implemented to date, their methodologies, and the benefits they offer.

- To address the challenges encountered in deploying AI-based systems and to highlight directions for future research.

Although the focus of this research is primarily on rotating machines, such as motors and generators, a brief overview of fault prediction in static machines, including transformers, is also provided. This comprehensive approach aims to offer insights into enhancing the reliability and efficiency of electrical machine operations through AI-driven fault prediction strategies.

2. Traditional Electrical Machine Faults Clearance

According to [5,6,7], incident-based maintenance (IBM), sometimes referred to as corrective maintenance, is the most traditional and straightforward maintenance technique. It is carried out following a breakdown. This strategy does not require a monitoring system, thus avoiding additional costs. However, it allows the machine to reach a faulty state, rendering it inoperative. This approach is frequently enough for low-cost machines that are simple to fix or replace and when failure has no serious repercussions.

For machines where failures could lead to more serious consequences, alternative strategies are employed, including the following:

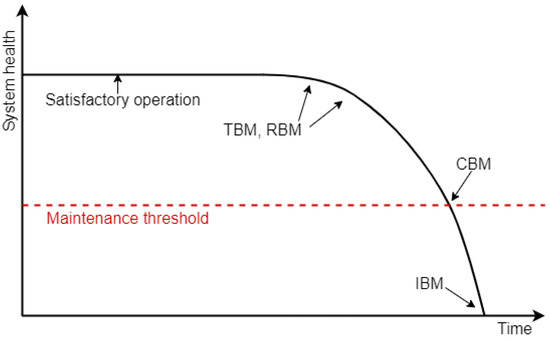

- Time-Based Maintenance (TBM): This is the approach that follows a scheduled maintenance plan, often guided by the bathtub curve (Figure 1). According to [8], TBM is defined as a preventive maintenance strategy in which electrical machines are serviced at regular predetermined intervals, regardless of their current condition. The goal is to reduce the likelihood of equipment failure by performing routine inspections, adjustments, or replacements based on the machine’s operating time or calendar schedule. This approach assumes that failures are time-dependent and can be mitigated through consistent maintenance practices.

Figure 1. Bathtub curve for system health maintenance strategies.

Figure 1. Bathtub curve for system health maintenance strategies. - Condition-Based Maintenance (CBM): This method involves monitoring diagnostic signals to assess the actual condition of the machine in real time. According to [7], CBM is defined as a proactive maintenance approach where the condition of the machine is monitored using parameters such as vibration, temperature, and current. Maintenance is performed only when necessary, based on real-time data, to prevent failures, reduce costs, and improve efficiency

- Risk-Based Maintenance (RBM): This strategy uses risk analysis to evaluate potential hazards, prioritize critical assets or components, and adjust maintenance actions and intervals accordingly [9].

These fundamental maintenance strategies are illustrated in Figure 1, where the condition of the system over time is further analyzed, as discussed in [10].

In electrical rotating machines, the most frequent failures are associated with bearing and stator winding problems. Although rotor winding faults are less common, they tend to have a more significant impact when they occur. The following percentage failures by component for the sample, as reported in [11]:

- Bearing 41%

- Stator 37%

- Rotor 10%

- Others 12%

Therefore, any worldwide conservation, green energy, or alternative energy policy must prioritize the development of more efficient electric machine technologies.

2.1. Dynamic Machines, Common Types of Failures

Despite the relative robustness of rotating electrical machines, research shows that any part can break down, and the probability varies depending on the type and design of the machine, the operating conditions, and the application [12,13].

2.1.1. Bearing Failures

The main cause of bearing failure is lubrication issues, misalignment, contamination, and excessive loads, and this is recorded in the vibration analysis (VA) reports [14]. Power generation [15], cement plants [16], aircraft [17], and civil construction engineering [18] are just a few of the industries and fields that have used the VA method for decades.

The reported disadvantages of VA include high initial costs, the need for expertise, reduced effectiveness for low-speed machines, susceptibility to environmental interference, difficulty detecting certain faults, and ongoing maintenance of equipment [19]. Furthermore, it generates large data volumes, may require complementary methods for deeper insight, and is sensitive to operating conditions, with the risk of false positives or negatives [20].

Detecting bearing faults using temperature logs has limitations, including delayed detection, low sensitivity to early faults, external factor interference, lack of fault specificity, and the potential for false positives. It is also ineffective for continuous monitoring and often identifies issues only after significant damage has occurred [21].

Other traditional methods are temperature logs, lubrication schedules, and replacement history.

2.1.2. Rotor Failures

The causes of rotor failures include mechanical stress, thermal cycling, electrical failures, and manufacturing defects, which can be applied to both larger machines that use roller bearings between the stator and the rotor to help maintain the rotor centering and reduce the air gap, as well as to smaller motors that usually use ball bearings [22,23]. So far, the existing techniques for recording rotor faults are vibration analysis, thermographic images, electrical test results, and repair and replacement logs [24,25,26,27]. The disadvantages of recording rotor faults include delayed or incomplete detection, sensitivity to external factors, high equipment costs, reliance on expertise, and limited coverage of fault types. Vibration analysis and thermography may miss internal issues, electrical tests can be time-consuming, and repair logs are reactive and prone to errors. Combining methods is necessary for comprehensive fault detection [28].

2.1.3. Stator Failures

The stator structure itself is the stationary part of a motor (or generator), responsible for energy conversion or using a magnetic field. It is essential for powering motors and generating electricity in various applications.

The causes of stator failure include the following [29]:

- Inadequate penetration of resin

- Degradation of insulation, causing electrical faults

- Contamination, such as dust, trash, and other particles

- Subpar manufacturing (processes, craftsmanship, etc.)

- Impacts from the environment (power system, lightning, etc.)

- Vibration (fast-tracks the deterioration of insulation)

- Thermal damage (cycles of heating)

The techniques for recording stator failure are insulation resistance measurements, thermal imaging, electrical test reports, and operational logs.

The main drawback of these techniques is their limited scope: Insulation resistance tests and thermal imaging may miss early or internal faults, electrical tests require downtime, and operational logs are reactive and prone to inaccuracies. Combining methods is necessary for comprehensive analysis [30].

Briefly, traditional fault clearance in electrical machines relies on incident-based maintenance (IBM) for post-failure repairs, time-based maintenance (TBM) for scheduled servicing, condition-based maintenance (CBM) for real-time monitoring, and risk-based maintenance (RBM) for prioritizing critical components. The most common failures occur in bearings (41%), stators (37%), and rotors (10%), caused by factors like lubrication issues, insulation degradation, and mechanical stress. Detection methods include vibration analysis, thermal imaging, and electrical tests, but each has limitations. A combination of techniques is essential for effective fault detection and prevention.

2.2. Static Electrical Machine Failures

Compared to rotating electrical machines, transformers have been found to have a lower failure rate than rotating electric motors [31]. Transformers and generators are examples of static electrical machinery that can fail for a number of reasons, including the following.

2.2.1. Insulation Breakdown

The various causes of transformer insulation breakdown are outlined based on research conducted by [32]. These include the following:

- Thermal stress: Overheating can degrade the insulation over time, leading to short circuits or complete failure.

- Electrical stress: High-voltage surges, lightning strikes, or switching operations can cause dielectric breakdown in insulation.

- Aging: Insulation materials deteriorate with time due to environmental factors such as moisture, temperature, and chemical contamination.

2.2.2. Overloading

Continuous operation at or above the machine’s rated capacity can cause overheating, leading to insulation failure, wind damage, or deterioration of the core [33].

2.2.3. Moisture and Contamination

Moisture can seep into the transformer and degrade insulation materials, leading to electrical failure. Dust, dirt, and corrosive contaminants can also affect insulation and cause mechanical or electrical faults [34].

2.2.4. Mechanical Stresses

Vibrations, improper handling, or external forces can damage the core, windings, or other mechanical components of the transformer, leading to insulation damage [35].

2.2.5. Thermal Stress and Overheating

Excess heat due to overloading, poor cooling, or blocked ventilation can damage insulation and winding materials. Transformers and other machines rely on efficient cooling (oil or air) to maintain temperature. A failure in the cooling system can lead to overheating [36].

2.2.6. Electrical Faults

Transformer short circuits in the windings cause severe damage. According to [37], ground faults due to insulation breakdown can result in dangerous leakage currents and permanent failure. Phase-to-phase faults may occur in multiphase machines due to insulation breakdown between phases.

2.2.7. Core Saturation

If the core of a transformer or similar device becomes saturated as a result of high input voltage, it can lead to overheating, inefficient operation, and eventual failure [38].

2.2.8. Harmonics

Non-linear loads can introduce harmonics into the electrical system, causing additional heating and stress on the windings and insulation of the transformer [39].

2.2.9. Improper Installation and Maintenance

Incorrect installation practices, poor connections, or lack of regular maintenance can accelerate wear and lead to premature failure. Neglecting routine inspections can miss early signs of issues such as loose connections, oil contamination, or physical damage [40].

2.2.10. Aging

This is a common natural process in which the materials within a transformer or other machinery, such as insulation, core, and windings, gradually deteriorate over time. Routine maintenance and monitoring are essential to extend their operational lifespan [41].

In summary, static electrical machines like transformers and generators can fail due to various factors, including insulation breakdown from thermal or electrical stress, overloading, moisture, and contamination. Mechanical stresses, overheating, electrical faults, core saturation, and harmonics can also lead to damage. Improper installation, lack of maintenance, and aging further accelerate wear and tear, emphasizing the need for regular inspections to prolong the machine’s lifespan.

3. Existing Fault Analysis Techniques for Rotating Motors

Recent research shows that, to improve the fault analysis techniques for rotating motors, a combination of multiple methods, real-time monitoring, and advanced sensors should be used. Accuracy can be increased by using machine learning for predictive analysis, the Internet of Things (IoT) for ongoing monitoring, and better data analytics. In addition, personnel training, standardized protocols, and robust equipment design are key to more effective and proactive fault detection [3,42,43,44].

3.1. Motor Current Signature Analysis (MCSA)

The concept of motor current signature analysis (MCSA) emerged in the early 1970s, originally proposed as a method to monitor motors in hazardous or harsh environments, such as those found in nuclear power plants.

The condition of the electric motor is evaluated using MCSA, a predictive maintenance technique. It falls under electrical signature analysis (ESA), which is a broader field [45].

ESA also covers motor circuit analysis, which looks at things like phase angle, insulation against ground faults, resistance, impedance, inductance, and current/frequency response [46,47].

MCSA can detect anomalies such as bearing wear, insulation deterioration, and mechanical problems by analyzing electrical current waveforms. By facilitating proactive maintenance interventions and early detection of any issues, this non-intrusive approach helps to avoid unplanned downtime and costly repairs [45,48].

According to the study by [45,49], the MCSA techniques that are the most widely used are instantaneous power signature analysis (IPSA), voltage signature analysis (VSA), current signature analysis (CSA), and the extended park vector approach (EPVA). In Figure 2, a standard stator current monitoring system is displayed.

Figure 2.

System for monitoring stator current.

Using MCSA and according to [50,51], the following issues are detectable:

- Static and/or dynamic air-gap irregularities.Air-gap eccentricity is the term used to describe an uneven distance between the rotor and the stator. There are two types of abnormal air-gap eccentricity: dynamic and static. Figure 3 shows many types of eccentricity that go beyond the normal state [52].

Figure 3. (a) Concentric (normal), (b) Static eccentricity, and (c) Dynamic eccentricity.is eccentricity frequencyis the frequency of the electrical gridR is the number of rotor barss is the slipp is the pole pairs== 1, 3, 5, 5, 7, …The slip is given by (2)where:s is the slip (per unit)is the rotor speedis the synchronous speed

Figure 3. (a) Concentric (normal), (b) Static eccentricity, and (c) Dynamic eccentricity.is eccentricity frequencyis the frequency of the electrical gridR is the number of rotor barss is the slipp is the pole pairs== 1, 3, 5, 5, 7, …The slip is given by (2)where:s is the slip (per unit)is the rotor speedis the synchronous speed - Broken rotor bar or cracked rotor end-rings.As previously mentioned, the MCSA finds damaged end rotor rings or a broken rotor bar. The main causes of broken rotor bars are duty cycles related to DOL starting. When rotor bars are broken, current components in the stator windings can be monitored at frequencies specified by Equation (4) [11].where:is the frequency of the broken rotor baris the grid frequencyp is the number of pole pairs.s is per unit slipk = 1, 2, 3, …

- Stator faults (one or more stator phase winding coils opening or shorting)Shorted turns lead to current imbalance and excessive heat generation in the stator coil. As mentioned in [53,54], motor current signature analysis (MCSA) makes use of the ability of rotating flux waves to generate particular components in the stator windings. The frequencies indicated by Equation (5) can be used to identify current components that are only impacted by shorted turns:where:is the component related to shorted turnis the frequency of the gridn = 1, 2, 3, …

- Abnormal stator winding connection.Abnormal stator winding connections in electrical machines can cause imbalanced currents, distorted magnetic fields, overheating, and excessive vibrations. These issues lead to reduced efficiency, performance degradation, insulation damage, and increased risk of failure or fire. Proper connections and regular monitoring can prevent these consequences and enhance machine reliability. According to [55], the motor current signature analysis (MCSA) detects abnormal stator winding connections by analyzing the motor’s current spectrum. It identifies harmonic distortions, phase imbalances, and fault-specific frequencies caused by connection issues. MCSA is non-invasive, cost-effective, and enables early fault detection, improving machine reliability and reducing downtime.The frequency spectrum of motor current for both normal and problematic stator winding connections is shown in Figure 4 [53]. The normal connection has a smooth peak at the fundamental frequency (50 Hz), while the abnormal connection shows additional harmonic distortions, indicating an issue with the winding.

Figure 4. MCSA frequency spectrum of motor current.

Figure 4. MCSA frequency spectrum of motor current. - Bent shaft (similar to dynamic eccentricity). As seen in Figure 5, this causes a rub between the rotor and the stator, which seriously damages the stator core and windings.

Figure 5. Four types of rolling-element bearing misalignment [56].

Figure 5. Four types of rolling-element bearing misalignment [56]. - Bearing and gearbox failures

Bearing misalignment, as shown in the four ways in Figure 5, is another frequent consequence of improper bearing installation.

The performance of motor current signature analysis (MCSA) decreases under high loads as load variations alter the amplitudes of the fault indicator, reduce the signal-to-noise ratio, and modify the baseline current spectrum. These changes obscure fault-related frequencies, making detection more difficult. Mitigation strategies include adaptive algorithms, advanced signal processing, machine learning, and combining MCSA with additional sensors to improve reliability under varying load conditions.

3.2. AI in Electrical Machines: Notable Implementations and Key Milestones

The application of AI in electrical machines has evolved from basic expert systems to advanced machine-learning algorithms. AI technologies have significantly improved the monitoring, diagnosis, and fault prediction of critical components such as motors, generators, and transformers, improving their reliability and performance. This historical overview traces key milestones and technological advancements in AI, highlighting its role in improving fault diagnosis, maintenance, and operational efficiency in electrical machines.

3.2.1. Machine Learning’s Early Developments (1980s–1990s)

Rule-based expert systems were the main focus of early AI applications in electrical equipment. To identify errors, these systems used human expert knowledge that was encoded into a set of rules. The mid and early 1980s led to the development of the first AI-based diagnostic systems for electric motors and transformers and the implementation of fuzzy logic in expert systems to handle uncertainty and imprecision in fault diagnosis [57].

3.2.2. Support Vector Machine (SVM): Early 1990s

The early AI applications in electrical equipment were mostly focused on rule-based expert systems. These systems used human-expert knowledge encoded in a set of rules to detect faults. It is notably implemented in decision trees for the predictive maintenance and development of condition monitoring systems using machine-learning algorithms.

A 1995 study titled “Support Vector Method for Function Approximation, Regression Estimation, and Signal Processing” by Vladimir N. Vapnik and his colleagues described how they developed SVMs in the early 1990s [58]. The late 1990s saw the emergence of unsupervised learning for anomaly detection in electrical machines.

In this review, according to [59], SVMs are classified into three types: linear SVMs, non-linear SVMs, and support vector regression (SVR).

Despite being less prone to overfitting, SVMs have been found to be computationally intensive and more difficult to comprehend. Neural networks, on the other hand, are more adaptable and scalable. Due to these factors, SVMs may be more effective in a hybrid approach with other algorithms.

3.2.3. The Advent of Neural Networks: 2000s–2010s

Neural networks brought significant advancements in handling complex and non-linear relationships in data. Early applications focused on artificial neural networks (ANNs) for fault diagnosis.

Support vector machines and neural networks differ in that the latter perform a sequence of linear combinations, usually combined with non-linear activation functions across multiple layers, whereas the former send data into a higher-dimensional space where it can be linearly separable [60,61].

3.2.4. Key Milestones

Neural networks are machine-learning methods in artificial intelligence (AI) that date from 1943 with the works of neurophysiologist Warren McCulloch and mathematician Walter. From then on to the 1970s, more developments have been made by different researchers [62].

Later, the backpropagation algorithm, recurrent neural networks, convolutional neural networks, and hardware advancements reignited interest in ANNs. In the 2000s, ANNs were used to detect patterns in vibration and temperature data, and AlexNet was created, which was a deep neural network (a neural network with several layers) [63]. The neural network development process is shown in Figure 6.

Figure 6.

Neural network development process.

Neural networks handle unorganized data, improve accuracy, increase flexibility, and can lead to faster workflows. However, some of the recorded disadvantages of neural networks include the following [64]:

- ‘Black Box nature’: the decision-making process of a machine-learning model. In the case where the NN predicts the wrong output, the user cannot know how or why the NN came up with it. Figure 7 shows the simple neural network diagram.

Figure 7. A simple 2-layer neural network.

Figure 7. A simple 2-layer neural network. - The development of neural networks takes a long period.

- Neural networks require a significant amount of data.

- Neural networks are computationally expensive.

3.2.5. Convolutional Neural Networks (CNNs): 2000s

CNNs are a regularized kind of feedforward neural network that uses filter optimization, sometimes referred to as kernel optimization, to learn features on its own. Text, photos, audio, video, and other types of data have all been processed and used to generate predictions or fault detections using this kind of deep-learning network [65]. CNNs are also applied to analyze thermal imaging data for hotspot detection in transformers.

Convolutional neural networks (CNNs) have several advantages. One advantage is that CNNs have shown remarkable results in various image-related applications such as face recognition, detection of moving targets, and classification of food according to calorie content [66]. Another advantage is that CNNs can process high-dimensional data and share information between layers, enabling efficient data processing [66]. However, CNNs also have some drawbacks. One disadvantage is that CNN design requires experts with knowledge in the domain of another and is a laborious process that involves testing different hyperparameters and configurations [67]. Another disadvantage is that CNNs can consume a significant amount of computational resources and time, especially when using automated neural architecture search methods [68]. Furthermore, deeper CNNs may suffer from information loss, but this can be mitigated by using techniques such as residual structures [69].

3.2.6. Exploration of Recurrent Neural Networks (RNNs): Late 2000s

An RNN is a type of artificial neural network designed to analyze sequential inputs.

RNNs are designed primarily for time series prediction.

RNNs handle data over several time steps, in contrast to feedforward neural networks, which process data in a single pass. Because of this, they are especially well suited for tasks involving time series data, speech, and text [70].

A hidden state, a form of memory that is updated at each time step based on the input being received and the previously preserved hidden state, is maintained by the recurrent unit, which is the core component of an RNN. The network may learn from previous inputs and apply that knowledge to current processing thanks to this feedback loop.

RNNs are frequently used for applications including image captioning, sentiment analysis, natural language processing (NLP), speech recognition, unsegmented handwriting recognition, and neural machine translation [71,72]. The RNN according to Trist’n Joseph is shown in Figure 8.

Figure 8.

Recurrent neural networks according to Trist’n Joseph [73].

In summary, fault analysis in rotating motors has improved with motor current signature analysis (MCSA) and AI-based techniques. MCSA detects faults like bearing wear, rotor damage, and insulation failures through electrical waveforms. AI advancements, including machine learning, neural networks, and deep learning, enhance predictive maintenance, improving accuracy and reducing downtime.

4. AI Techniques in Electrical Machine Fault Prediction and Their Limitations

Artificial intelligence techniques are becoming increasingly prevalent in predicting electrical machine faults, enhancing reliability, minimising downtime, and reducing maintenance costs. Despite their advantages, each technique has its own set of limitations.

4.1. Machine Learning (ML)

The machine-learning (ML) methods used in electrical machine fault prediction are tailored to the unique challenges of fault diagnosis and condition monitoring. Machine learning in electrical machines is challenged by data needs, computational demands, overfitting risks, and integration complexity [3]. These techniques fall into the following categories:

- Supervised Learning:Supervised learning is a branch of machine learning that uses labeled datasets to teach computers to recognize patterns and forecast results. Using previously labeled data, it is used to categorize and forecast faults. Support vector machines (SVMs), random forests, decision trees, and k-nearest neighbors (k-NN) are the algorithms employed [74].Unlike unsupervised learning, supervised learning algorithms receive labeled training to comprehend the relationship between input and output. The major drawback of supervised learning is its dependence on labeled data; labeling large datasets is time-consuming, challenging, and expensive [75,76].

- Unsupervised LearningUnsupervised learning uses machine-learning (ML) techniques to evaluate and classify unlabeled samples. Without human assistance, these algorithms can find hidden patterns and data groupings on their own [77,78].The comparison of ML unsupervised and supervised is summarized in Table 1.

Table 1.

Supervised learning vs. unsupervised learning [79].

Table 1.

Supervised learning vs. unsupervised learning [79].

| Supervised Learning | Unsupervised Learning | |

|---|---|---|

| Objective | To estimate a function that maps inputs to outputs based on input–output pairs. | To create a compact representation of the data and produce creative content from it. |

| Accuracy | Highly precise and dependable. | Less accurate and reliable. |

| Complexity | Simpler method. | Computationally intensive. |

| Classes | There are known numbers of classes. | There are unknown numbers of classes. |

| Output | A target output value (also referred to as the supervisory signal). | Absence of corresponding output values. |

- Reinforcement Learning: Reinforcement learning utilizes a trial-and-error training approach, making it well-suited for dynamic environments where the system incrementally learns optimal maintenance strategies [80]. This method also, when applied to the prediction of electrical machine faults, according to [81], faces challenges such as high computational cost, data requirements, complexity in real-world applications, and training instability.

- Deep Learning:This technique handles large and complex datasets with greater accuracy. Recurrent neural networks (RNNs) for time series data and convolutional neural networks (CNNs) for vibration and image data are examples of deep-learning approaches.Deep learning in electrical machines faces challenges such as high computational costs, data dependency, lack of transparency, overfit risks, and complex deployment and integration [82].

4.1.1. Signal Processing and Feature Extraction

AI algorithms use principal component analysis (PCA), wavelet transform, and fast Fourier transform (FFT) to analyze sensor data, such as current, voltage, vibration, or auditory signals [83,84]. Signal processing and feature extraction in fault prediction for electrical machines face challenges such as complexity in feature selection, sensitivity to noise, limited fault detection scope, and high computational demands [3,81].

According to [76], they also require domain expertise, can introduce data preprocessing issues, and may struggle with real-time applications. In addition, there is a risk of overfitting, loss of temporal information, and model complexity. These are all challenges that constitute future research opportunities

In summary, signal processing techniques such as PCA, wavelet transform, and FFT enhance fault detection in electrical machines by analyzing sensor data. Although effective, they face challenges such as noise sensitivity, complex feature selection, and real-time processing limits. Future research aims to improve accuracy through adaptive and hybrid methods.

4.1.2. Expert Systems

These systems use a knowledge base and inference rules to predict faults, often supplemented by AI for dynamic rule updates. They consist of a set of two rules [85]:

- Rule-Based Systems: To identify errors, these use a set of predetermined rules that are developed from expert knowledge.

- Fuzzy Logic Systems: These can handle uncertainty and imprecision in data, making them effective for complex fault diagnosis scenarios.

Expert systems in electrical machines face limitations such as a restricted scope of predefined knowledge, an inability to learn or adapt, and high development and maintenance costs.

According to [86,87], expert systems often lack flexibility, struggle with complex or ambiguous data, and rely heavily on expert input, which can introduce biases. Furthermore, their processing efficiency decreases with larger rule bases, and integration with modern technologies is a challenge. These limitations highlight the need for advanced solutions, such as hybrid systems, that combine expert knowledge with modern AI techniques [88].

In summary, expert systems for fault prediction in electrical machines use predefined rules and fuzzy logic to detect faults, but face challenges such as limited adaptability, high costs, and reliance on expert input. Rule-based systems can struggle with complex or new fault patterns, and fuzzy logic systems are data-dependent and computationally intensive. As the rule bases expand, the efficiency decreases. To overcome these issues, hybrid systems that combine expert knowledge with AI, such as machine learning, are being explored to enhance flexibility, scalability, and accuracy in fault detection. These systems dynamically update rules and better handle complex, unseen faults.

4.1.3. Fuzzy Logic and Neuro-Fuzzy Systems

Fuzzy logic and neuro-fuzzy systems are ideal techniques for managing uncertain or imprecise data, as they combine human-like reasoning with machine-learning capabilities. Like other techniques, fuzzy logic and neuro-fuzzy systems in electrical machine fault prediction face limitations such as dependence on expert knowledge, difficulty handling complex fault patterns, and scalability challenges with increasing parameters [89,90]. They are data-dependent, computationally intensive, and may struggle with real-time implementation and generalization to unforeseen faults. Additionally, neuro-fuzzy systems suffer from reduced interpretability and require careful parameter optimization. Integration with modern monitoring systems can also be challenging, which limits their effectiveness in advanced fault prediction scenarios [91].

Fuzzy logic and neuro-fuzzy systems are useful for handling uncertain data in electrical machine fault prediction but face challenges like reliance on expert knowledge, difficulty with complex faults, scalability issues, and integration with modern systems. These systems, though effective in cases like motor fault detection, struggle with real-time implementation and reduced interpretability. Future improvements may focus on combining them with deep learning to enhance fault detection and scalability.

4.1.4. Predictive Maintenance with AI

This in turn is also divided into two categories: reinforcement learning, which optimizes maintenance schedules by balancing cost and risk, and digital twins, the AI-driven replicas of electrical machines for real-time fault simulation and prediction.

4.2. Neural Networks (NNs)

A particular kind of machine-learning model that was inspired by the human brain and created to handle complex data and identify patterns is called a neural network (NN) [92].

Neural networks (NNs) are highly effective in fault detection for electrical machines. They analyze sensor data (e.g., vibration, current, temperature) to identify and classify faults such as mechanical, electrical, and thermal issues [93].

NNs also predict potential failures by learning from historical data and provide real-time monitoring, allowing timely maintenance. Techniques like auto-encoders help with anomaly detection, while deep-learning models improve diagnostic accuracy. NNs generally increase the efficiency and dependability of defect detection systems, lowering maintenance expenses and downtime [94].

- Artificial Neural Networks (ANNs): Mimic the structure of the human brain to process complex data. ANNs are effective in recognizing patterns and relationships in machine operational data.

- Convolutional Neural Networks (CNNs): Primarily used in image and signal processing, CNNs can analyze vibration and thermal images to detect anomalies.

- Recurrent Neural Networks (RNNs): Suitable for time series data, RNNs can predict future machine behavior based on historical data.

In summary, AI techniques improve electrical machine fault prediction but face challenges like data dependency, high computational costs, and integration complexity. Machine learning, deep learning, signal processing, expert systems, and neural networks offer advantages but struggle with scalability, real-time application, and adaptability. Hybrid approaches are needed for more reliable fault detection.

5. Future Directions and Methodologies

The integration of artificial intelligence (AI) into electrical machine fault detection is poised to revolutionize predictive maintenance, system diagnostics, and overall machine performance. However, advancing these systems requires more focused research that addresses key challenges and maximizes the potential of AI technologies. The following are specific future research directions, each with targeted goals and methodologies.

5.1. Predictive Maintenance via Enhanced Machine-Learning Models

Improved machine-learning models for predictive maintenance. Future research may include integrating more sophisticated machine-learning models, such as deep-upgrade learning (DRL) and transformers, to improve predictive maintenance techniques. These models can continuously learn from real-time sensor data and provide more accurate predictions of defects. In addition, hybrid models could be developed that combine classical statistical methods and artificial intelligence to solve data scarcity and noise problems. This is done by developing DRL-based models that continuously improve their performance when interacting with new fault data and offer real-time prediction and optimization. The ensemble model uses a balance between interpretation and performance in predicting errors.

5.2. Real-Time Fault Detection in Dynamic Environments

Detecting faults in real time in dynamic settings: Even while real-time error detection is possible with artificial intelligence models, it remains a significant issue, especially in dynamic and unpredictable situations like industrial facilities and electric vehicles. By executing AI algorithms directly on sensor devices (edge devices), research into edge AI technology enables quicker decision-making and less reliance on central cloud systems. Research on lightweight AI algorithms for edge devices with constrained resources (low power, memory) is one area of focus.

Create adaptive algorithms that can modify their parameters and thresholds in real time in response to sensor data in a variety of operational scenarios.

5.3. Digital Twins and AI Integration

Combining AI and digital twins: Digital twins, or virtual replicas of real machinery, present a number of opportunities for predictive maintenance and fault identification. Research should concentrate on incorporating AI models into digital twins so that they can forecast possible errors and suggest remedial action in addition to simulating machine behavior. Large-scale electrical machine simulation can be used with these models to increase fault detection accuracy. The creation of AI-powered digital twins that simulate and predict the behavior of electric devices under diverse operating conditions is a specific field of study.

Examine the applications of the digital twin in closed-loop control systems. In addition to identifying faults, the AI model modifies the operating parameters to stop them.

5.4. Self-Learning Systems and Autonomous Fault Diagnosis

Self-diagnosing faults and self-learning systems: It is possible to use self-learning systems that can continuously adapt to shifting circumstances without requiring significant human involvement. Systems will be able to identify new flaws instantly without the need to label datasets thanks to unsupervised learning and online learning research. The particular lines of inquiry is to enable self-improving fault detection systems and concentrate on deep-learning methods like autoencoders, generative adversarial networks (GANs), and reinforcement learning, reducing reliance on labeled datasets by the use of semi-supervised learning, which allows for fault identification with little human intervention.

5.5. Improved Fault Detection in Renewable Energy Systems

Enhanced identification of faults in renewable energy systems: AI has the potential to greatly enhance defect detection in renewable energy systems, including solar power plants and wind turbines. The integration of IoT sensor networks with AI models and predictive maintenance systems for renewable energy applications could be the subject of future research. Developing artificial intelligence models that can detect problems with renewable energy system components (in this case more focuss is on wind turbine and hydroelectric turbines) and predict their remaining useful life (RUL) is one area of research.

Investigate a hybrid approach that makes more precise forecasts for energy producing systems by fusing physical modeling and artificial intelligence.

5.6. Methodologies for Fault Prediction

To advance fault detection, we will continue to explore a variety of machine-learning methodologies, each targeting specific aspects of the fault prediction task. The methodologies outlined in the following will undergo rigorous testing in our future research.

Future work will focus on ensemble methods (such as boosting or bagging) to improve the robustness of decision tree-based models, particularly when dealing with high-dimensional sensor data. Future research in fault detection for electrical machines using AI could benefit from several key advancements in machine-learning techniques. For instance, in random forests, there is an opportunity to explore the use of feature importance metrics and hyperparameter tuning to improve both the interpretability and precision of these models. This approach can enhance the model’s performance in complex fault detection tasks by identifying the most influential features and optimizing model parameters.

In the case of k-nearest neighbors (k-NN), future research could focus on distance-weighted k-NN techniques. This would improve the model’s sensitivity to local data patterns, which is particularly useful in dealing with imbalanced datasets where certain fault types are underrepresented. By adjusting the model to prioritize closer data points, we can achieve more accurate and reliable fault classifications.

For support vector machines (SVMs), one promising direction is investigating kernel methods that can handle non-linear relationships in sensor data. This is particularly crucial when sensor data exhibit complex patterns that are not easily captured by linear models. Kernel methods allow SVMs to map data into higher dimensions, improving their ability to classify faults that have non-linear characteristics.

In the area of autoencoders for anomaly detection, future work will focus on using deep autoencoders with various loss functions, such as reconstruction error and adversarial loss. These approaches can significantly enhance the model’s ability to detect anomalies in sensor data, making it more effective in identifying previously unseen fault conditions.

Regarding principal component analysis (PCA), future research will likely incorporate kernel PCA and non-linear dimensionality reduction methods. These techniques can better handle complex data structures that are not well-represented by linear models, allowing for more accurate dimensionality reduction and improving fault detection performance.

Moreover, linear regression can be advanced by investigating more sophisticated methods such as ridge regression or Lasso regression. These approaches can improve fault prognosis, especially when predicting the remaining useful life (RUL) of electrical machines. By introducing regularization techniques, these models can better handle noisy data and prevent overfitting, ensuring more accurate and reliable predictions.

By focusing on these specific areas, we aim to significantly advance the state-of-the-art in AI-driven fault detection for electrical machines, ultimately ensuring greater reliability, efficiency, and predictive accuracy in industrial applications.

As summary, future AI research in electrical machine fault detection focuses on improving predictive maintenance, real-time detection, and renewable energy systems using advanced machine learning, edge AI, digital twins, and self-learning models. Enhanced methodologies like ensemble learning, optimized feature selection, and deep learning will boost fault prediction accuracy and system reliability.

6. Conclusions

The integration of AI into electrical machine fault prediction is revolutionizing industrial operations by enhancing reliability, efficiency, and predictive maintenance. AI-driven methods such as supervised learning, unsupervised learning, and deep neural networks offer precise fault detection, allowing industries to anticipate failures, minimize downtime, and optimize operational costs. Additionally, emerging technologies like digital twins provide real-time virtual simulations for predictive analysis, while explainable AI improves trust and transparency in decision-making, making AI-driven diagnostics more accessible and interpretable.

Despite these advancements, challenges persist, including computational complexity, high data dependency, and difficulties in model interpretability. The need for large labeled datasets, vulnerability to sensor noise, and scalability concerns further limit widespread adoption. Addressing these issues requires continued research into hybrid models that combine AI with traditional physics-based approaches, edge computing for real-time processing, and algorithm optimization to enhance efficiency without compromising accuracy.

Looking ahead, AI-driven fault prediction plays a pivotal role in Industry 4.0, enabling smarter, more adaptive, and sustainable manufacturing ecosystems. As AI evolves, integrating self-learning systems, federated learning, and cloud-edge collaboration will further refine fault diagnostics, ensuring more resilient and intelligent electrical machine monitoring systems.

Author Contributions

Conceptualization, M.H. and A.A.A.; methodology, M.H.; software, M.H.; validation, A.A.A. and M.H.; formal analysis, M.H. and A.A.A.; investigation, M.H. and A.A.A.; resources, M.H.; data curation, M.H. and A.A.A.; writing—original draft preparation, M.H.; writing—review and editing, M.H. and A.A.A.; visualization, M.H.; supervision, A.A.A.; project administration, M.H.; funding acquisition, M.H. and A.A.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AI | Artificial Intelligence |

| NN | Neural Network |

| ANN | Artificial Neural Networks |

| RNN | Recurrent Neural Networks |

| TBM | Time-Based Maintenance |

| CBM | Condition-Based Maintenance |

| VA | Vibration Analysis |

| MCSA | Motor Current Signature Analysis |

| ESA | Electrical Signature Analysis |

| IPSA | Instantaneous Power Signature Analysis |

| VSA | Voltage Signature Analysis |

| EPVA | Extended Park Vector Approach |

| NLP | Natural Language Processing |

| SVM | Support Vector Machines |

| CNN | Convolutional Neural Networks |

References

- Ritonja, J. Robust and Adaptive Control for Synchronous Generator’s Operation Improvement. In Automation and Control; IntechOpen: London, UK, 2020. [Google Scholar]

- Reimert, D. Protective Relaying for Power Generation Systems; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Akbar, S.; Vaimann, T.; Asad, B.; Kallaste, A.; Sardar, M.U.; Kudelina, K. State-of-the-art techniques for fault diagnosis in electrical machines: Advancements and future directions. Energies 2023, 16, 6345. [Google Scholar] [CrossRef]

- Mohamed Almazrouei, S.; Dweiri, F.; Aydin, R.; Alnaqbi, A. A review on the advancements and challenges of artificial intelligence based models for predictive maintenance of water injection pumps in the oil and gas industry. SN Appl. Sci. 2023, 5, 391. [Google Scholar]

- Yu, Q.; Zhao, N.; Li, M.; Li, Z.; Wang, H.; Zhang, W.; Sui, K.; Pei, D. A survey on intelligent management of alerts and incidents in IT services. J. Netw. Comput. Appl. 2024, 224, 103842. [Google Scholar]

- Trnka, P.; Trnkova, M. Asset Management of Large Electric Machines through Monitoring of Electric Insulation. Acta Polytech. Hung. 2022, 19, 85–102. [Google Scholar]

- Peng, Y.; Dong, M.; Zuo, M.J. Current status of machine prognostics in condition-based maintenance: A review. Int. J. Adv. Manuf. Technol. 2010, 50, 297–313. [Google Scholar]

- Mydin, M. Key Performance Indicator of Building Maintenance and Its Effect on the Building Life Cycle. Analele Univ. ‘Eftimie Murgu’ 2014, 21, 193. [Google Scholar]

- Arunraj, N.; Maiti, J. Risk-based maintenance policy selection using AHP and goal programming. Saf. Sci. 2010, 48, 238–247. [Google Scholar]

- Haddad, G.; Sandborn, P.A.; Pecht, M.G. An options approach for decision support of systems with prognostic capabilities. IEEE Trans. Reliab. 2012, 61, 872–883. [Google Scholar]

- Benbouzid, M.E.H. A review of induction motors signature analysis as a medium for faults detection. IEEE Trans. Ind. Electron. 2000, 47, 984–993. [Google Scholar]

- Thorsen, O.V.; Dalva, M. Failure identification and analysis for high-voltage induction motors in the petrochemical industry. IEEE Trans. Ind. Appl. 1999, 35, 810–818. [Google Scholar]

- Bell, R.N.; Heising, C.; O’donnell, P.; Singh, C.; Wells, S. Report of large motor reliability survey of industrial and commercial installations. II. IEEE Trans. Ind. Appl. 1985, 21, 865–872. [Google Scholar]

- Liu, Z.; Zhang, L. A review of failure modes, condition monitoring and fault diagnosis methods for large-scale wind turbine bearings. Measurement 2020, 149, 107002. [Google Scholar]

- Chu, T.; Nguyen, T.C.; Yoo, H.; Wang, J. ESP Vibration Prediction Based on Pump Operating Conditions in Laboratory Using Machine Learning. Geoenergy Sci. Eng. 2024, 240, 213039. [Google Scholar]

- Renwick, J.T.; Babson, P.E. Vibration analysis—A proven technique as a predictive maintenance tool. IEEE Trans. Ind. Appl. 1985, IA-21, 324–332. [Google Scholar]

- Gao, P.; Tao, Y.; Zhang, Y.; Jiao, W.; Zhai, J. Vibration analysis and control technologies of hydraulic pipeline system in aircraft: A review. Chin. J. Aeronaut. 2021, 34, 83–114. [Google Scholar]

- Jassim, Z.; Ali, N.; Mustapha, F.; Jalil, N.A. A review on the vibration analysis for a damage occurrence of a cantilever beam. Eng. Fail. Anal. 2013, 31, 442–461. [Google Scholar]

- Martin, G.J. The Disadvantages of Using Measured Vibration Data as Input Levels in a Laboratory Vibration Test. Ph.D. Thesis, California State University, Northridge, CA, USA, 1986. [Google Scholar]

- Al-Haddad, L.A.; Jaber, A.A.; Hamzah, M.N.; Fayad, M.A. Vibration-current data fusion and gradient boosting classifier for enhanced stator fault diagnosis in three-phase permanent magnet synchronous motors. Electr. Eng. 2024, 106, 3253–3268. [Google Scholar]

- Collacott, R. Mechanical Fault Diagnosis and Condition Monitoring; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Wang, Z.; Xuan, J.; Shi, T. Domain reinforcement feature adaptation methodology with correlation alignment for compound fault diagnosis of rolling bearing. Expert Syst. Appl. 2025, 262, 125594. [Google Scholar]

- Wang, Z.; Xuan, J.; Shi, T. An autonomous recognition framework based on reinforced adversarial open set algorithm for compound fault of mechanical equipment. Mech. Syst. Signal Process. 2024, 219, 111596. [Google Scholar]

- Babak, V.; Babak, S.; Zaporozhets, A. Tasks and Main Methods of Statistical Diagnostics of Electric Power Equipment. In Statistical Diagnostics of Electric Power Equipment; Springer: Berlin/Heidelberg, Germany, 2024; pp. 1–50. [Google Scholar]

- Tavner, P. Condition Monitoring of Rotating Electrical Machines; IET: London, UK, 2008; Volume 56. [Google Scholar]

- Saad, N.; Irfan, M.; Ibrahim, R. Condition Monitoring and Faults Diagnosis of Induction Motors: Electrical Signature Analysis; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Scheffer, C.; Girdhar, P. Practical Machinery Vibration Analysis and Predictive Maintenance; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Merizalde, Y.; Hernández-Callejo, L.; Duque-Perez, O. State of the art and trends in the monitoring, detection and diagnosis of failures in electric induction motors. Energies 2017, 10, 1056. [Google Scholar] [CrossRef]

- Gaerke, T.R.; Hernandez, D.C. Root cause analysis of motor stator failures. In Proceedings of the Conference Record of 2013 Annual IEEE Pulp and Paper Industry Technical Conference (PPIC), Charlotte, NC, USA, 23–27 June 2013; pp. 11–16. [Google Scholar]

- Tallam, R.M.; Lee, S.B.; Stone, G.C.; Kliman, G.B.; Yoo, J.; Habetler, T.G.; Harley, R.G. A survey of methods for detection of stator-related faults in induction machines. IEEE Trans. Ind. Appl. 2007, 43, 920–933. [Google Scholar]

- Leffler, J.; Trnka, P. Failures of Electrical Machines—Review. In Proceedings of the 2022 8th International Youth Conference on Energy (IYCE), Eger, Hungary, 6–9 July 2022; pp. 1–4. [Google Scholar] [CrossRef]

- Liu, R.; Jaksts, A. Breakdown processes in transformer insulation under LI voltages. In Proceedings of the IEEE International Conference on Dielectric Liquids, ICDL 2005, Coimbra, Portugal, 26 June–1 July 2005; pp. 75–78. [Google Scholar]

- Gracheva, E.I.; Petrova, R.M.; Sinyukova, T.; Valtchev, S.; Miceli, R.; Caruso, M. Reliability and Overload Capacity of Power Transformers. In Proceedings of the 2023 International Conference on Clean Electrical Power (ICCEP), Terrasini, Italy, 27–29 June 2023; pp. 684–689. [Google Scholar]

- Fofana, I.; Hadjadj, Y. Electrical-based diagnostic techniques for assessing insulation condition in aged transformers. Energies 2016, 9, 679. [Google Scholar] [CrossRef]

- Steurer, M.; Frohlich, K. The impact of inrush currents on the mechanical stress of high voltage power transformer coils. IEEE Trans. Power Deliv. 2002, 17, 155–160. [Google Scholar]

- Soliman, M.H.A. Industrial Power Transformers: Selection, Installation, Advanced Maintenance and Reliability; Mohammed Hamed Ahmed Soliman: Cairo, Egypt, 2024. [Google Scholar]

- Yasid, N.; Alawady, A.; Yousof, M.; Talib, M.; Kamarudin, M. The Effect of short circuit fault in three-phase core-typed transformer. Int. J. Power Electron. Drive Syst. (IJPEDS) 2020, 11, 409–416. [Google Scholar]

- Zhang, R. Transformer Modelling and Influential Parameters Identification for Geomagnetic Disturbances Events. Ph.D. Thesis, The University of Manchester, Manchester, UK, 2012. [Google Scholar]

- Dalila, M.; Khalid, M.; Shah, M.M. Distribution transformer losses evaluation under non-linear load. In Proceedings of the 2009 Australasian Universities Power Engineering Conference, Adelaide, SA, Australia, 27–30 September 2009; pp. 1–6. [Google Scholar]

- Metwally, I.A. Failures, monitoring and new trends of power transformers. IEEE Potentials 2011, 30, 36–43. [Google Scholar]

- Saha, T.K.; Purkait, P. Transformer Ageing: Monitoring and Estimation Techniques; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Gawde, S.; Patil, S.; Kumar, S.; Kamat, P.; Kotecha, K.; Abraham, A. Multi-fault diagnosis of Industrial Rotating Machines using Data-driven approach: A review of two decades of research. Eng. Appl. Artif. Intell. 2023, 123, 106139. [Google Scholar]

- Tama, B.A.; Vania, M.; Lee, S.; Lim, S. Recent advances in the application of deep learning for fault diagnosis of rotating machinery using vibration signals. Artif. Intell. Rev. 2023, 56, 4667–4709. [Google Scholar]

- Drakaki, M.; Karnavas, Y.L.; Tziafettas, I.A.; Linardos, V.; Tzionas, P. Machine learning and deep learning based methods toward industry 4.0 predictive maintenance in induction motors: State of the art survey. J. Ind. Eng. Manag. (JIEM) 2022, 15, 31–57. [Google Scholar]

- Dubravko, M.; He, Z. Brief review of motor current signature analysis. HDKBR Info-CrSNDT J. 2015, 15, 15–26. [Google Scholar]

- Penrose, H.W.; Old Saybrook, C. Motor Circuit Analysis Concept and Principle. In Success by Design; Reliabilityweb.com: Blair, NE, USA, 2004; pp. 1–13. [Google Scholar]

- Syahputra, R.; Purwanto, H.; Wiyagi, R.O.; Mustar, M.Y.; Soesanti, I. Analysis of Induction Motor Performance Using Motor Current Signature Analysis Technique. J. Electr. Technol. UMY 2021, 5, 7–16. [Google Scholar]

- Miljković, D. Review of machine condition monitoring based on vibration data. In Proceedings of the MIPRO 2008, Opatija, Croatia, 26–30 May 2008; pp. 70–75. [Google Scholar]

- Giacotto, A.; Mesquita, A.C.P.; Marques, H.C.; Martinetti, A. Holistic and scalable smart optimization framework for prescriptive maintenance. In Proceedings of the 34th Congress of the International Council of the Aeronautical Sciences, Florence, Italy, 9–13 September 2024. [Google Scholar]

- Penrose, H.W. Practical Motor Current Signature Analysis Taking the Mystery Out of MCSA; ALL TEST Pro, BJM Corp.: New Haven, CT, USA, 2003. [Google Scholar]

- Korde, A. On-line condition monitoring of motors using electrical signature analysis. Recent advances in condition-based plant maintenance. In Proceedings of the Seminar Organized by Indian Institute of Plant Engineers, Chennai, India, 12–13 December 2002. [Google Scholar]

- Al-Sabbagh, Q.S.; Alwan, H.E. Detection of static air-gap eccentricity in three phase induction motor by using artificial neural network (ANN). J. Eng. 2009, 15, 4176–4192. [Google Scholar]

- Thomson, W.T.; Gilmore, R.J. Motor Current Signature Analysis to Detect Faults in Induction Motor Drives-Fundamentals, Data Interpretation, and Industrial Case Histories. In Proceedings of the 32nd Turbomachinery Symposium; Texas A&M University, Turbomachinery Laboratories: College Station, TX, USA, 2003. [Google Scholar]

- Kumar, K.V.; Kumar, S.S. LabVIEW based condition monitoring of induction machines. Int. J. Intell. Syst. Appl. 2012, 4, 56–62. [Google Scholar]

- Thomson, W.T.; Fenger, M. Current signature analysis to detect induction motor faults. IEEE Ind. Appl. Mag. 2001, 7, 26–34. [Google Scholar]

- Schoen, R.R.; Habetler, T.G.; Kamran, F.; Bartfield, R. Motor bearing damage detection using stator current monitoring. IEEE Trans. Ind. Appl. 1995, 31, 1274–1279. [Google Scholar]

- Johnson, W.B.; Rouse, S.H.; Rouse, W.B. An Annotated Selective Bibliography on Human Performance in Fault Diagnosis Tasks; US Army Research Institute for the Behavioral and Social Sciences: Arlington, VA, USA, 1980. [Google Scholar]

- El Dakdouki, A. Hyperbolic Support Vector Machine and Kernel Design. Ph.D. Thesis, Université de Lille 1, Sciences et Technologies, Villeneuve-d’Ascq, France, 2019. [Google Scholar]

- Jovanović, I.; Miljanović, I.; Jovanović, T. Soft computing-based modeling of flotation processes—A review. Miner. Eng. 2015, 84, 34–63. [Google Scholar]

- Shao, Y.; Lunetta, R.S. Comparison of support vector machine, neural network, and CART algorithms for the land-cover classification using limited training data points. ISPRS J. Photogramm. Remote Sens. 2012, 70, 78–87. [Google Scholar]

- Wang, Z.; Li, S.; Xuan, J.; Shi, T. Biologically inspired compound defect detection using a spiking neural network with continuous time–frequency gradients. Adv. Eng. Inform. 2025, 65, 103132. [Google Scholar]

- Foote, K.D. The history of machine learning and its convergent trajectory towards AI. In Machine Learning and the City: Applications in Architecture and Urban Design; John Wiley & Sons: Hoboken, NJ, USA, 2022; pp. 129–142. [Google Scholar]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. ImageNet classification with deep convolutional neural networks. Commun. ACM 2017, 60, 84–90. [Google Scholar]

- Dumitru, C.; Maria, V. Advantages and Disadvantages of Using Neural Networks for Predictions. Ovidius Univ. Ann. Ser. Econ. Sci. 2013, 13, 444. [Google Scholar]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar]

- Li, Z.; Liu, F.; Yang, W.; Peng, S.; Zhou, J. A survey of convolutional neural networks: Analysis, applications, and prospects. IEEE Trans. Neural Netw. Learn. Syst. 2021, 33, 6999–7019. [Google Scholar]

- Zhang, W.; Zhang, T.; Cui, G.; Pan, Y. Intelligent machine fault diagnosis using convolutional neural networks and transfer learning. IEEE Access 2022, 10, 50959–50973. [Google Scholar]

- Elsken, T.; Metzen, J.H.; Hutter, F. Simple and efficient architecture search for convolutional neural networks. arXiv 2017, arXiv:1711.04528. [Google Scholar]

- Khan, A.; Sohail, A.; Zahoora, U.; Qureshi, A.S. A survey of the recent architectures of deep convolutional neural networks. Artif. Intell. Rev. 2020, 53, 5455–5516. [Google Scholar]

- Tealab, A. Time series forecasting using artificial neural networks methodologies: A systematic review. Future Comput. Inform. J. 2018, 3, 334–340. [Google Scholar]

- Graves, A.; Liwicki, M.; Fernández, S.; Bertolami, R.; Bunke, H.; Schmidhuber, J. A novel connectionist system for unconstrained handwriting recognition. IEEE Trans. Pattern Anal. Mach. Intell. 2008, 31, 855–868. [Google Scholar]

- Li, X.; Wu, X. Constructing long short-term memory based deep recurrent neural networks for large vocabulary speech recognition. In Proceedings of the 2015 IEEE International Conference on Acoustics, Speech and Signal Processing (ICASSP), South Brisbane, QLD, Australia, 19–24 April 2015; pp. 4520–4524. [Google Scholar]

- Keating, J. Lynch syndrome: Much progress but many questions remain. N. Z. Med. J. 2018, 131, 8–10. [Google Scholar]

- Nasteski, V. An overview of the supervised machine learning methods. Horiz. B 2017, 4, 56. [Google Scholar]

- Alloghani, M.; Al-Jumeily, D.; Mustafina, J.; Hussain, A.; Aljaaf, A.J. A systematic review on supervised and unsupervised machine learning algorithms for data science. In Supervised and Unsupervised Learning for Data Science; Springer: Cham, Switzerland, 2020; pp. 3–21. [Google Scholar]

- Patil, D.; Rane, N.; Desai, P.; Rane, J. Machine learning and deep learning: Methods, techniques, applications, challenges, and future research opportunities. In Trustworthy Artificial Intelligence in Industry and Society; Deep Science Publishing: New York, NY, USA, 2024; pp. 28–81. [Google Scholar]

- Tirthyani, D.; Kumar, S.; Vats, S. Clustering and Unsupervised Learning. In Recent Trends and Future Direction for Data Analytics; IGI Global: Hershey, PA, USA, 2024; pp. 119–139. [Google Scholar]

- Wang, Z.; Xuan, J.; Shi, T.; Li, Y.F. Multi-label domain adversarial reinforcement learning for unsupervised compound fault recognition. Reliab. Eng. Syst. Saf. 2025, 254, 110638. [Google Scholar]

- Mazibuko, N.; Akindeji, K.; Moloi, K. Perfomance comparison of Machine Learning (ML) based fault detection scheme for a compensated transmission line. In Proceedings of the 2024 IEEE PES/IAS PowerAfrica, Johannesburg, South Africa, 7–11 October 2024; pp. 1–5. [Google Scholar]

- Boulesnane, A. Evolutionary Dynamic Optimization and Machine Learning. In Advanced Machine Learning with Evolutionary and Metaheuristic Techniques; Springer: Berlin/Heidelberg, Germany, 2024; pp. 67–85. [Google Scholar]

- Chen, X.; Wang, M.; Zhang, H. Machine Learning–based Fault Prediction and Diagnosis of Brushless Motors. Eng. Adv. 2024, 4, 130–142. [Google Scholar]

- Kiasari, M.; Ghaffari, M.; Aly, H.H. A Comprehensive Review of the Current Status of Smart Grid Technologies for Renewable Energies Integration and Future Trends: The Role of Machine Learning and Energy Storage Systems. Energies 2024, 17, 4128. [Google Scholar] [CrossRef]

- Arabaci, H.; Mohamed, M.A. A knowledge-based diagnosis algorithm for broken rotor bar fault classification using FFT, principal component analysis and support vector machines. Int. J. Intell. Eng. Inform. 2020, 8, 19–37. [Google Scholar] [CrossRef]

- Bagri, I.; Tahiry, K.; Hraiba, A.; Touil, A.; Mousrij, A. Vibration Signal Analysis for Intelligent Rotating Machinery Diagnosis and Prognosis: A Comprehensive Systematic Literature Review. Vibration 2024, 7, 1013–1062. [Google Scholar] [CrossRef]

- Regulwar, G.B.; Mahalle, A.; Pawar, R.; Shamkuwar, S.K.; Kakde, P.R.; Tiwari, S. Big Data Collection, Filtering, and Extraction of Features. In Big Data Analytics Techniques for Market Intelligence; IGI Global: Hershey, PA, USA, 2024; pp. 136–158. [Google Scholar]

- Mandal, M.C.; Mondal, N.; Ray, A. An expert system based decision-making framework for benchmarking industry in sustainable manufacturing. Benchmarking Int. J. 2024, 26, 1–20. [Google Scholar] [CrossRef]

- Cao, K.; Chen, S.; Yang, C.; Li, Z.; Luo, L.; Ren, Z. Revealing the coupled evolution process of construction risks in mega hydropower engineering through textual semantics. Adv. Eng. Inform. 2024, 62, 102713. [Google Scholar]

- Wang, S.; Xu, K.; Ling, Z. Deep learning-based chip power prediction and optimization: An intelligent EDA approach. Int. J. Innov. Res. Comput. Sci. Technol. 2024, 12, 77–87. [Google Scholar]

- Lu, J.; Ma, G.; Zhang, G. Fuzzy Machine Learning: A Comprehensive Framework and Systematic Review. IEEE Trans. Fuzzy Syst. 2024, 32, 3861–3878. [Google Scholar]

- Fida, K.; Abbasi, U.; Adnan, M.; Iqbal, S.; Mohamed, S.E.G. A comprehensive survey on load forecasting hybrid models: Navigating the Futuristic demand response patterns through experts and intelligent systems. Results Eng. 2024, 23, 102773. [Google Scholar]

- Chen, G.; Yuan, J.; Zhang, Y.; Zhu, H.; Huang, R.; Wang, F.; Li, W. Enhancing Reliability through Interpretability: A Comprehensive Survey of Interpretable Intelligent Fault Diagnosis in Rotating Machinery. IEEE Access 2024, 12, 103348–103379. [Google Scholar]

- Taye, M.M. Understanding of machine learning with deep learning: Architectures, workflow, applications and future directions. Computers 2023, 12, 91. [Google Scholar] [CrossRef]

- Mohd Amiruddin, A.A.A.; Zabiri, H.; Taqvi, S.A.A.; Tufa, L.D. Neural network applications in fault diagnosis and detection: An overview of implementations in engineering-related systems. Neural Comput. Appl. 2020, 32, 447–472. [Google Scholar] [CrossRef]

- Khanam, R.; Hussain, M.; Hill, R.; Allen, P. A comprehensive review of convolutional neural networks for defect detection in industrial applications. IEEE Access 2024, 12, 94250–94295. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).