Optimization Scheduling of Hydrogen-Integrated Energy Systems Considering Multi-Timescale Carbon Trading Mechanisms

Abstract

1. Introduction

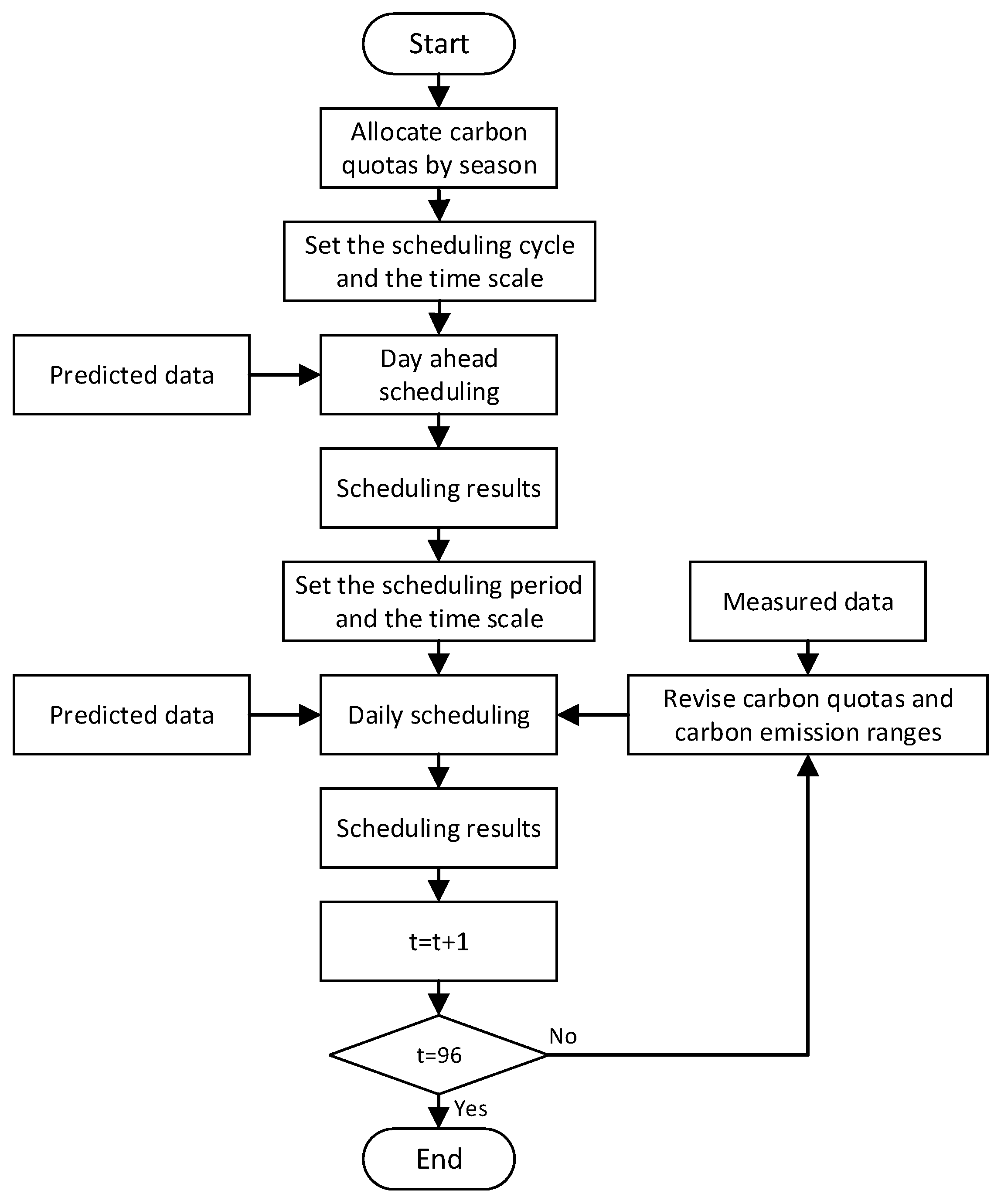

- A multi-timescale carbon trading mechanism is introduced, designed to enhance both day-ahead and intra-day scheduling processes.

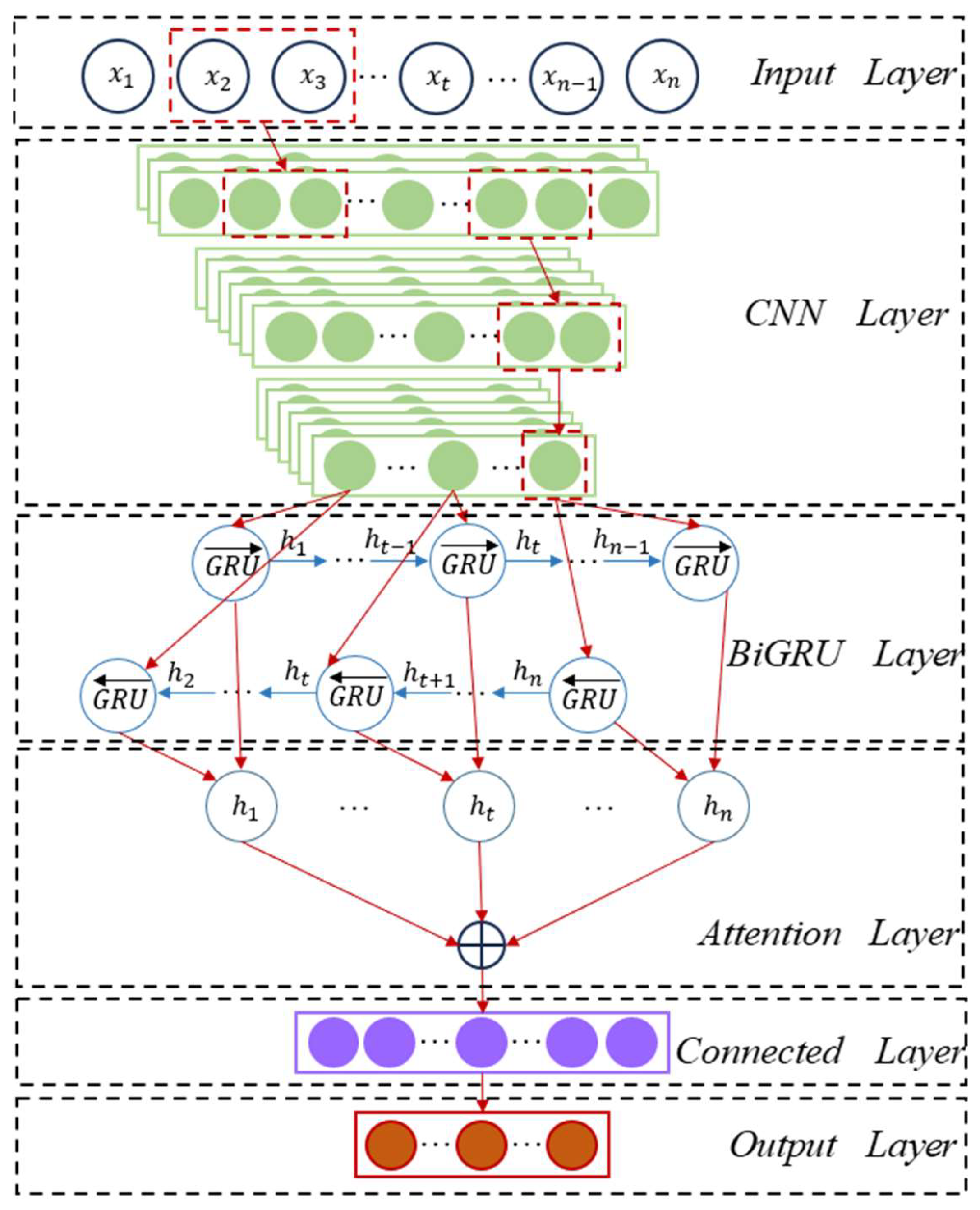

- A novel forecasting approach based on the IVY-CNN-BiGRU-Attention model is proposed to improve load prediction accuracy.

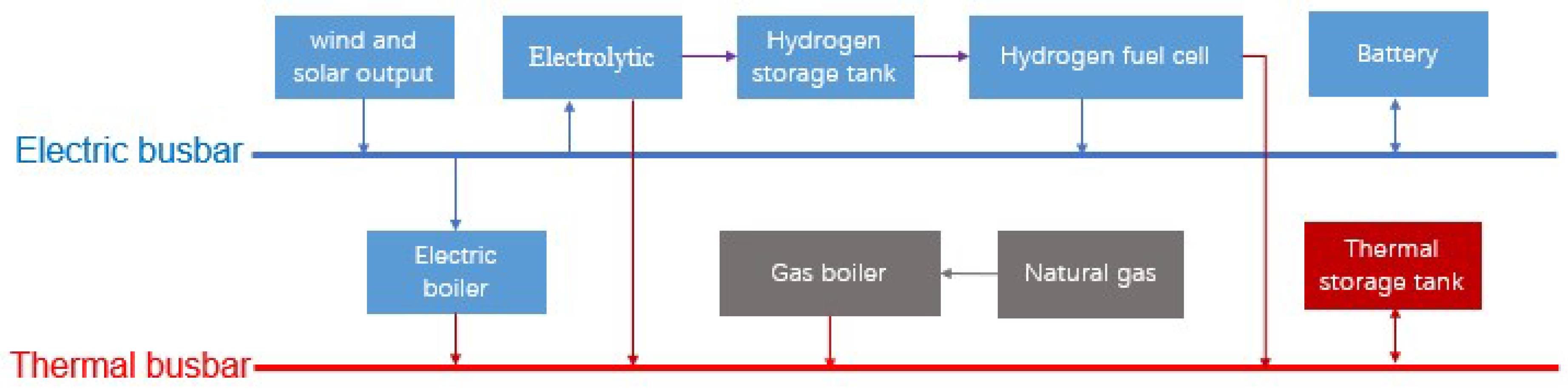

2. Integrated Energy System Structure

3. Multi-Timescale Carbon Trading Mechanism

3.1. Tiered Carbon Trading Cost Model

3.2. Multi-Timescale Carbon Quota Allocation

3.3. Multi-Timescale Carbon Quota and Carbon Emission Interval Adjustment Mechanism

4. Multi-Timescale Optimization Scheduling Model

4.1. Day-Ahead Scheduling Model

4.2. Intra-Day Scheduling Model

4.3. Constraint Conditions

- Electric power balance constraint

- b.

- Thermal power balance constraint

- c.

- Power upper and lower limit constraints of electric boilers and fuel boilers.

- d.

- Battery constraints

- e.

- Power constraints for electric boilers and gas boilers

- f.

- Hydrogen storage tank constraints

4.4. Multi-Time Scale Scheduling Solution Method

4.5. Prediction Method Based on IVY-CNN-BiGRU-Attention

5. Results and Discussion

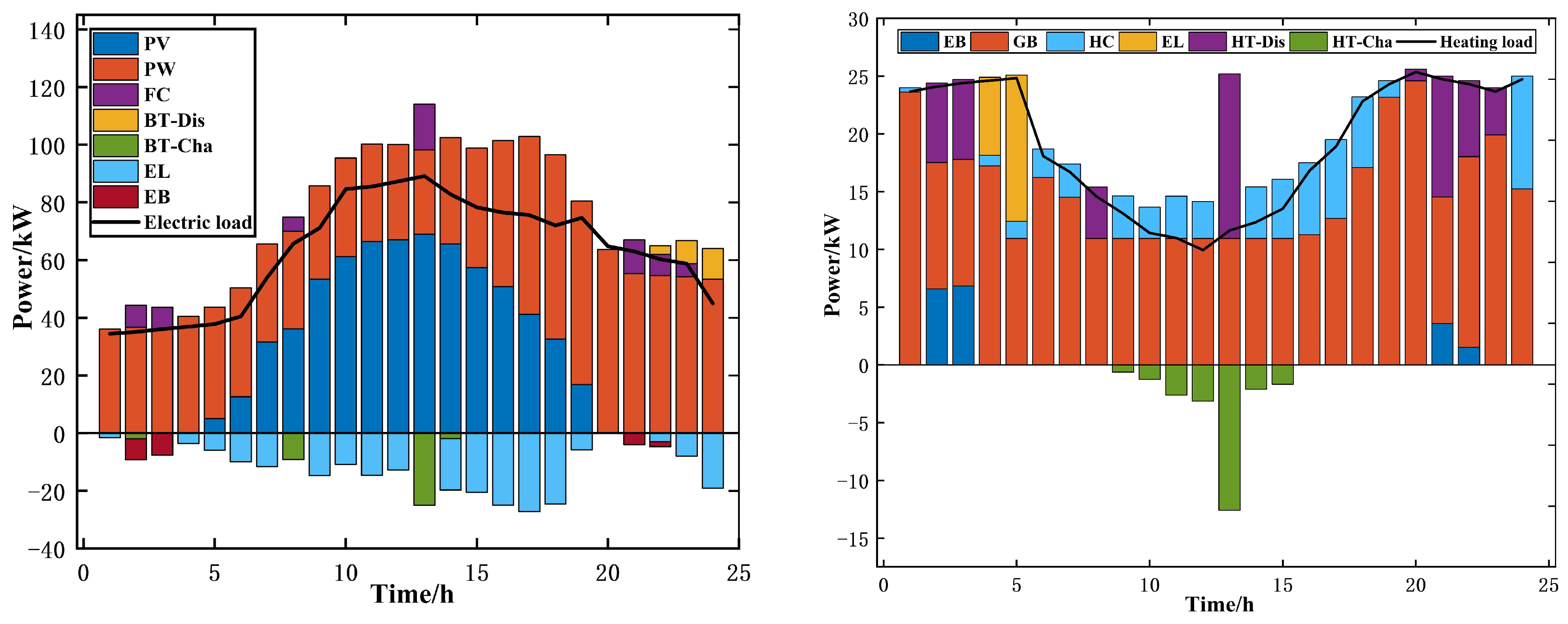

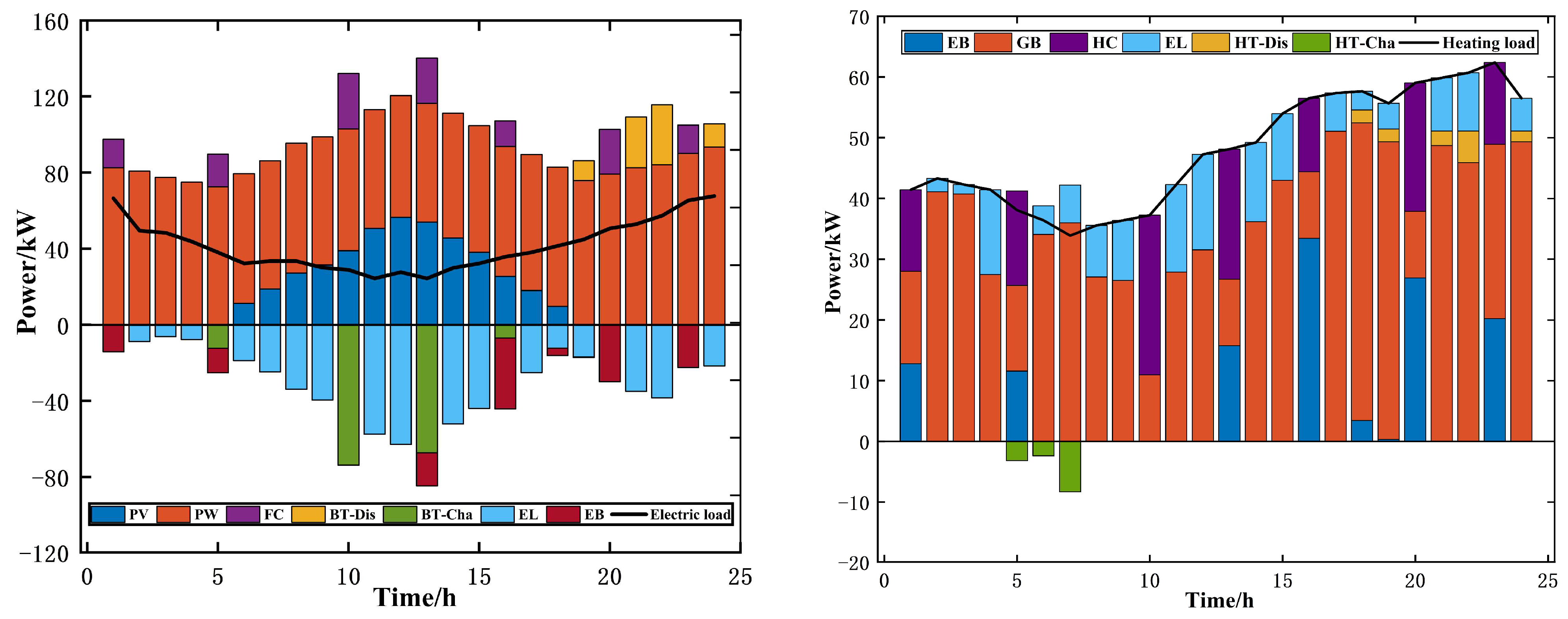

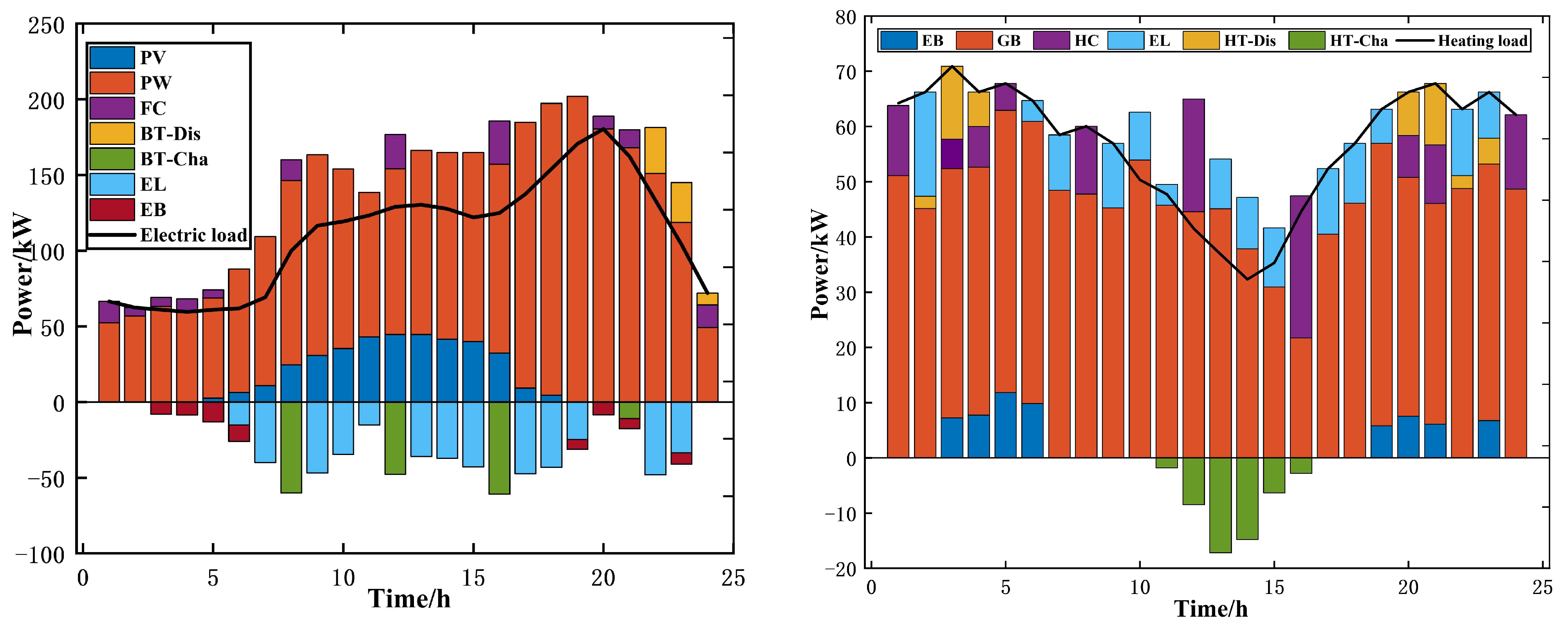

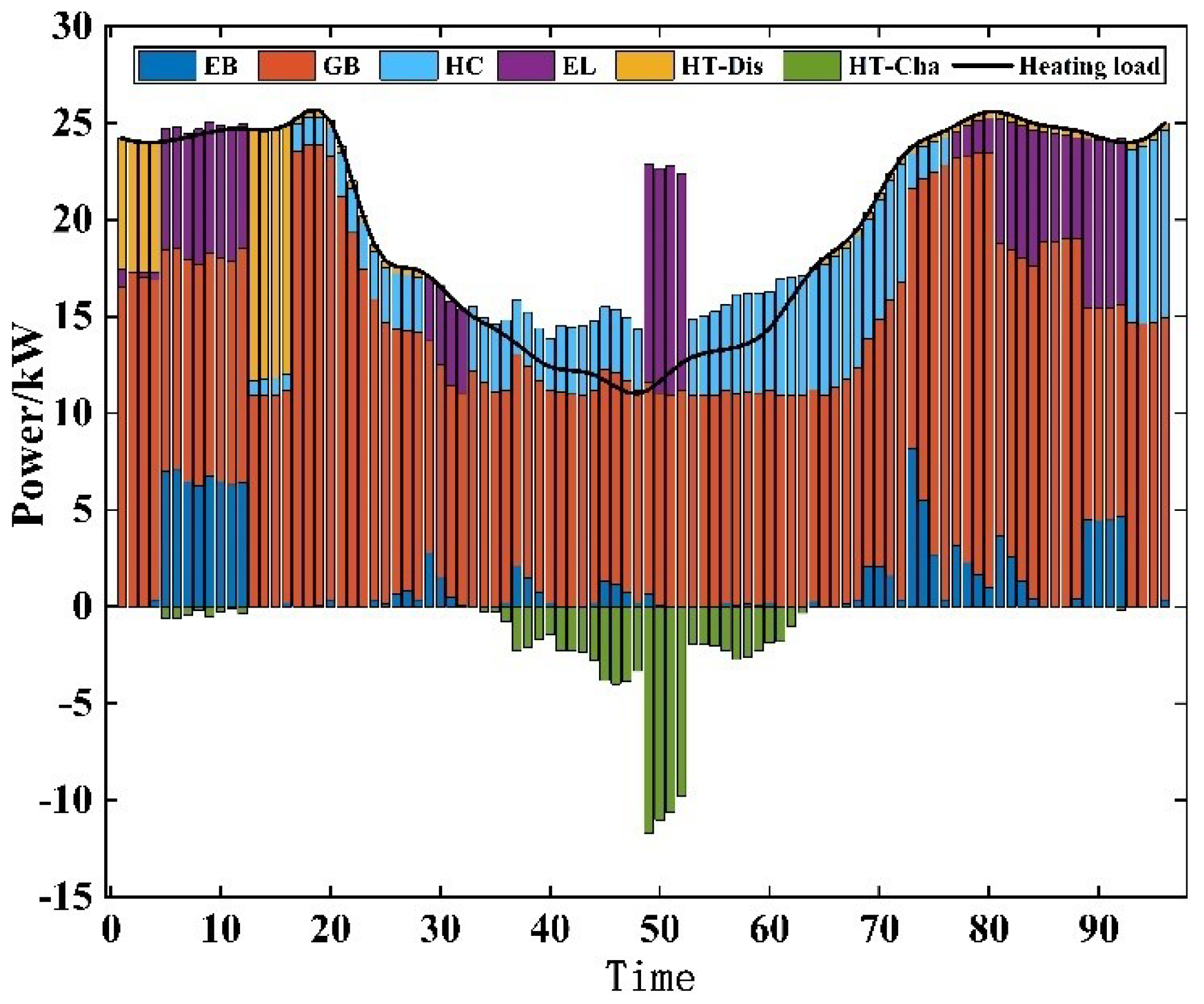

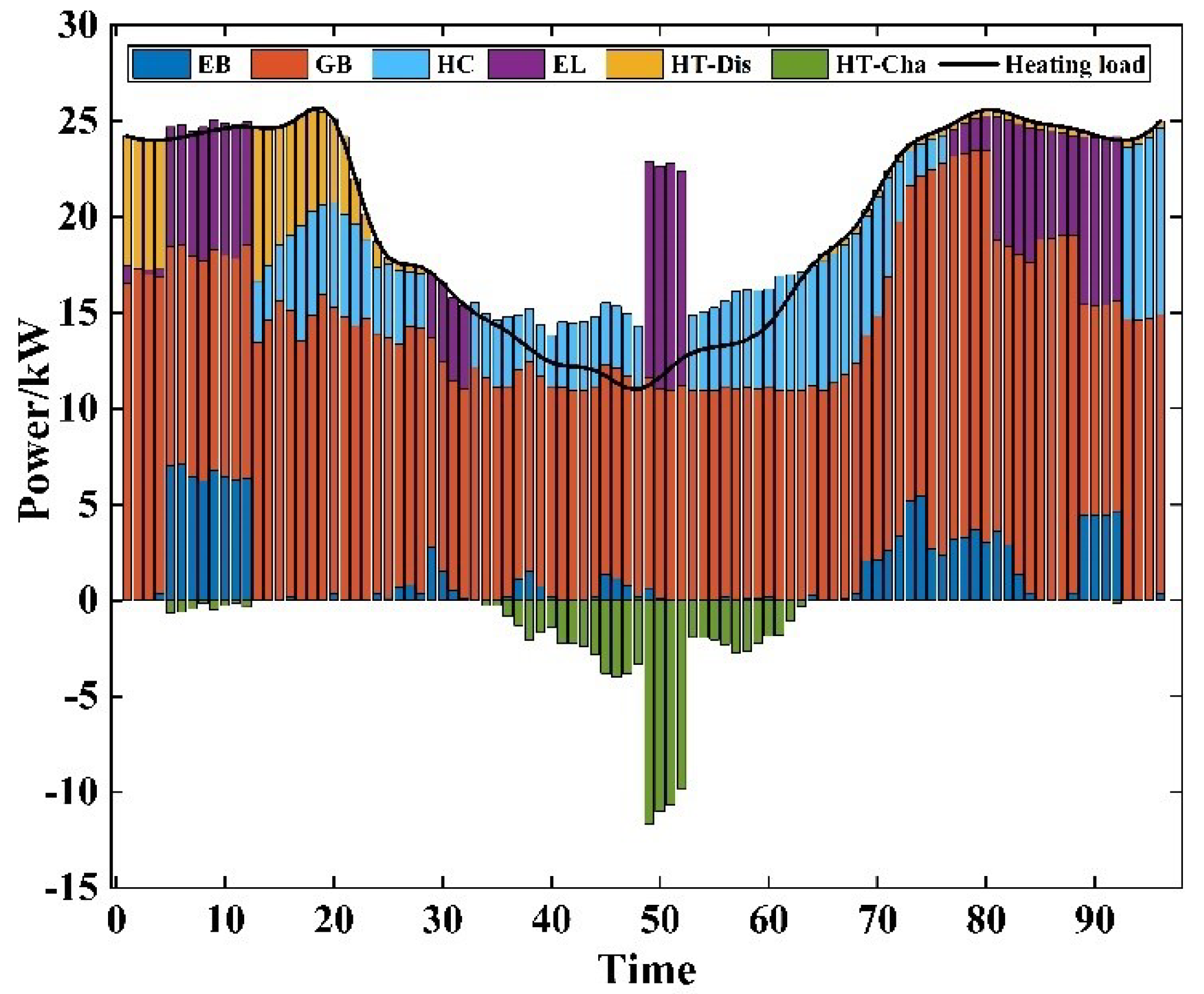

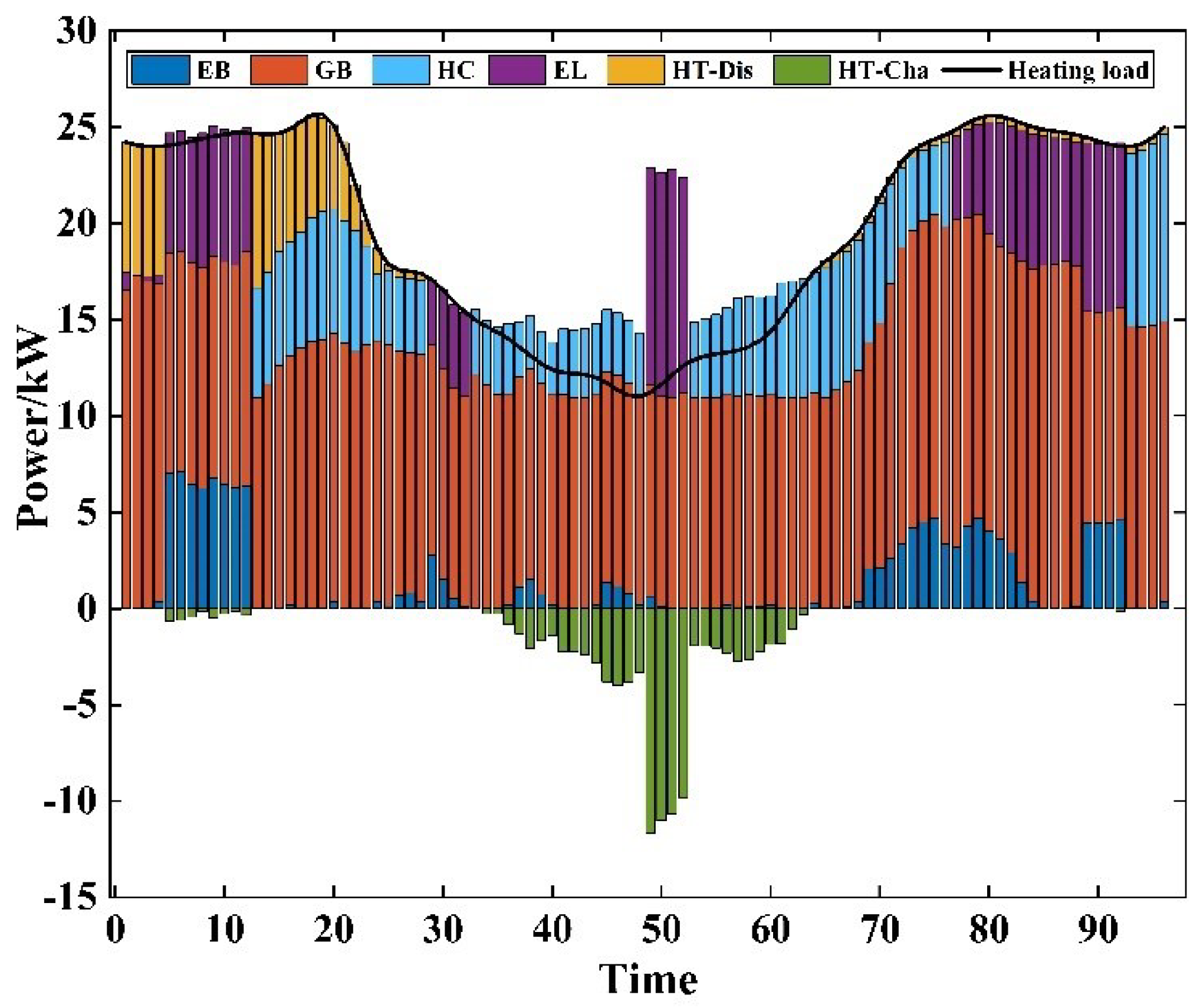

5.1. Model Intra-Day Scheduling Results Analysis

5.2. Feasibility Analysis of the Seasonal Carbon Quota Mechanism

6. Conclusions

- A novel prediction model based on IVY-CNN-BiGRU-Attention is introduced, effectively capturing temporal dependencies and patterns in multivariate time series data. By combining the strengths of convolutional neural networks (CNNs), bidirectional gated recurrent units (BiGRUs), and attention mechanisms, this model significantly enhances the accuracy and reliability of predictions, which improves operational efficiency in the scheduling process for integrated energy systems.

- The paper also introduces a multi-timescale carbon trading mechanism that dynamically adjusts carbon emission quotas and trading intervals. This approach effectively controls carbon trading costs, mitigating risks associated with the uncertainty in carbon emissions. The dynamic nature of this mechanism offers a resilient and cost-effective solution for managing carbon emissions over time.

- Additionally, the proposed multi-timescale carbon trading mechanism integrates seamlessly with the flexible regulation capabilities of renewable energy within the system. By optimizing the synergy between carbon trading and renewable energy utilization across different timescales, the framework significantly improves the efficiency of energy resource allocation. This approach not only reduces carbon emissions but also promotes sustainable energy use. It provides a promising pathway for achieving an optimal balance between economic performance and environmental sustainability in modern energy systems.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kong, F.; Ren, H. Advances in Green Energy, Environment and Carbon Neutralization. Energies 2025, 18, 1016. [Google Scholar] [CrossRef]

- Li, J.; Zhu, M.; Lu, Y.; Huang, Y.; Wu, T. A Review of Optimal Scheduling for Integrated Energy Systems. Power Grid Technol. 2021, 45, 2256–2272. [Google Scholar]

- Zhang, N.; Wang, H.; Song, K.; Cheng, M.; Zhang, M.; Li, P. Research on dynamic optimal control of integrated energy system based on multi energy demand response. Electr. Meas. Instrum. 2023, 60, 16–24. [Google Scholar]

- Yang, M.; Liu, Y. Research on multi-energy collaborative operation optimization of integrated energy system considering carbon trading and demand response. Energy 2023, 283, 129117. [Google Scholar] [CrossRef]

- Yue, M.; Lambert, H.; Pahon, E.; Roche, R.; Jemei, S.; Hissel, D. Hydrogen energy systems: A critical review of technologies, applications, trends and challenges. Renew. Sustain. Energy Rev. 2021, 146, 111180. [Google Scholar] [CrossRef]

- Kong, L.; Cai, G.; Li, L.; Ji, R.L. Online Energy Regulation Strategy and Experimental Platform Development for Wind-Solar-Hydrogen Integrated Energy Systems. Trans. China Electrotech. Soc. 2018, 33, 3371–3384. [Google Scholar]

- Farahani, S.S.; Bleeker, C.; van Wijk, A.; Lukszo, Z. Hydrogen-based integrated energy and mobility system for a real-life office environ-ment. Appl. Energy 2020, 264, 114695. [Google Scholar] [CrossRef]

- Cai, Q.; Xiao, Y.; Zhu, Y. Day-Ahead Economic Coordination Scheduling Model for Electrothermal Microgrids Considering Power-to-Hydrogen and Fuel Cells. Electr. Power Autom. Equip. 2021, 41, 107–112. [Google Scholar]

- Eslamipoor, R. A two-stage stochastic planning model for locating product collection centers in green logistics networks. Clean. Logist. Supply Chain. 2022, 6, 100091. [Google Scholar] [CrossRef]

- Yu, X. Research on the Optimal Configuration and Operation of an Integrated Energy System with Hydrogen Storage and Heat Storage in Industrial Parks. Master’s Thesis, North China Electric Power University, Beijing, China, 2020. [Google Scholar]

- Ni, L.; Wang, Y.; Xue, H.; Yu, A. Stochastic-Robust Hybrid Planning for Electro-Hydrogen Integrated Energy Storage Stations Considering Multi-Time-Scale Uncertainties. Energy Storage Sci. Technol. 2023, 12, 846–856. [Google Scholar]

- Du, Y.; Tan, Z. Multi-Time-Scale Coordinated Operation Optimization of Electro-Hydrogen Energy Systems Based on Nash Bargaining. Power Syst. Technol. 2024, 48, 2745–2753. [Google Scholar]

- Chicco, G.; Mancarella, P. Assessment of the green-house gas emissions from cogeneration and trigeneration systems. Part I: Models and indicators. Energy 2008, 33, 410–417. [Google Scholar] [CrossRef]

- Mancarella, P.; Chicco, G. Assessment of the greenhouse gas emissions from cogeneration and trigeneration systems. Part II: Analysis techniques and application cases. Energy 2008, 33, 418–430. [Google Scholar] [CrossRef]

- Pan, C.; Hou, X.; Jin, T.; Wang, B.; Wang, G.; Gu, Y. Low carbon research of integrated energy system considering the uncertainty of carbon trading and renewable energy. Electr. Meas. Instrum. 2024, 61, 8–16. [Google Scholar]

- Kothe, A.-K.; Kuptel, A.; Seidl, R. Simulating Personal Carbon Trading (PCT) with an Agent-Based Model (ABM): Investigating Adaptive Reduction Rates and Path Dependence. Energies 2021, 14, 7497. [Google Scholar] [CrossRef]

- Zhao, B.; Liu, G.; Han, D. Multi-Time-Scale Low-Carbon Optimal Scheduling of Integrated Energy Systems Considering Hydrogen Energy Coupling and Tiered Carbon Trading. J. Electr. Power Sci. Technol. 2023, 38, 35–46. [Google Scholar]

- Li, T.; Hu, Z.; Chen, Z.; Liu, S. Multi-Time-Scale Low-Carbon Operation Optimization Strategy for Integrated Energy Systems Considering Electric-Gas-Thermal-Hydrogen Demand Response. Electr. Power Autom. Equip. 2023, 43, 16–24. [Google Scholar]

- Liang, J.; Zhang, G.; Li, F.; Xie, C.; Wang, T. Low-Carbon Optimal Scheduling of Integrated Energy Systems Considering Hydrogen Energy Storage, Ammonia Production, and Carbon Capture. Electr. Power Autom. Equip. 2024, 44, 16–23. [Google Scholar]

- Laimon, M.; Yusaf, T. Towards energy freedom: Exploring sustainable solutions for energy independence and self-sufficiency using integrated renewable energy-driven hydrogen system. Renew. Energy 2024, 222, 119948. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, H.; He, Y.; Xu, B.; Zhang, M.; Ding, M. Optimization Scheduling Method for Hydrogen Energy Integrated Energy Systems Based on Deep Reinforcement Learning. Autom. Electr. Power Syst. 2024, 48, 132–141. [Google Scholar]

- Eslamipoor, R. An optimization model for green supply chain by regarding emission tax rate in incongruous vehicles. Model. Earth Syst. Environ. 2023, 9, 227–238. [Google Scholar] [CrossRef]

- Chen, H.; Wu, Q.; Han, C. Carbon Price Point and Interval-Valued Prediction Based on a Novel Hybrid Model. Energies 2025, 18, 1054. [Google Scholar] [CrossRef]

- Jeong, S.; Kim, B.; Cha, S.; Seo, K.; Chang, H.; Lee, J.; Kim, Y.; Noh, J. Real-Time CNN Training and Compression for Neural-Enhanced Adaptive Live Streaming. IEEE Trans. Pattern Anal. Mach. Intell. 2024, 46, 6023–6039. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Li, Y.F.; Huang, H.Z.; Deng, Z.; Huang, Z. A novel method based on CNN-BiGRU and AM model for bearing fault diagnosis. J. Mech. Sci. Technol. 2024, 38, 3361–3369. [Google Scholar] [CrossRef]

- Ren, J.J.; Wei, H.; Zou, Z.L.; Hou, T.T.; Yuan, Y.L.; Shen, J.Q.; Wang, X.M. Ultra-short-term power load forecasting based on CNN-BiLSTM-Attention. Power Syst. Prot. Control. 2022, 50, 108–116. [Google Scholar]

- Li, G.; Lin, C.; Li, Y. Probabilistic Forecasting of Provincial Regional Wind Power Considering Spatio-Temporal Features. Energies 2025, 18, 652. [Google Scholar] [CrossRef]

- Du, M.; Zhang, Z.; Ji, C. Prediction for Coastal Wind Speed Based on Improved Variational Mode Decomposition and Recurrent Neural Network. Energies 2025, 18, 542. [Google Scholar] [CrossRef]

- Ghasemi, M.; Zare, M.; Trojovský, P.; Rao, R.V.; Trojovská, E.; Kandasamy, V. Optimization based on the smart behavior of plants with its engineering applications: Ivy algorithm. Knowl. Based Syst. 2024, 295, 111850. [Google Scholar] [CrossRef]

| Device Type | Device Parameter | Value |

|---|---|---|

| Gas Boiler | Maximum Power | 55 kW |

| Minimum Power | 10 kW | |

| Upward Ramp Power | 5 kW | |

| Downward Ramp Power | 10 kW | |

| Electric Boiler | Maximum Power | 55 kW |

| Minimum Power | 0 | |

| Upward Ramp Power | 5 kW | |

| Downward Ramp Power | 10 kW | |

| Fuel Cell | Conversion Efficiency | 0.9 |

| Maximum Output Power | 300 kW·h | |

| Maximum Capacity | 300 kW·h | |

| Energy Storage Battery | Charge/Discharge Efficiency | 0.9/0.9 |

| Maximum Output Power | 300 kW | |

| Maximum Capacity | 300 kW·h | |

| Thermal Storage Tank | Charge/Discharge Efficiency | 0.9/0.9 |

| Maximum Output Power | 250 kW | |

| Maximum Capacity | 450 kW·h | |

| Thermal Storage Tank | Hydrogen Production Efficiency | 0.25 |

| Maximum Output Power | 150 kW | |

| Installed Capacity | 100 kW·h |

| Scenario | Operation and Maintenance Cost | Fuel Cost | Carbon Emission Cost | Penalty Cost | Total Cost |

|---|---|---|---|---|---|

| Scenario 1 | 223.56 | 169.98 | 39.28 | 17.96 | 450.78 |

| Scenario 2 | 214.78 | 159.34 | 43.79 | 11.28 | 429.19 |

| Scenario 3 | 210.47 | 156.29 | 41.40 | 8.87 | 413.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Song, Y.; Fan, H. Optimization Scheduling of Hydrogen-Integrated Energy Systems Considering Multi-Timescale Carbon Trading Mechanisms. Energies 2025, 18, 1612. https://doi.org/10.3390/en18071612

Zhao J, Song Y, Fan H. Optimization Scheduling of Hydrogen-Integrated Energy Systems Considering Multi-Timescale Carbon Trading Mechanisms. Energies. 2025; 18(7):1612. https://doi.org/10.3390/en18071612

Chicago/Turabian StyleZhao, Jingjing, Yangyang Song, and Haocheng Fan. 2025. "Optimization Scheduling of Hydrogen-Integrated Energy Systems Considering Multi-Timescale Carbon Trading Mechanisms" Energies 18, no. 7: 1612. https://doi.org/10.3390/en18071612

APA StyleZhao, J., Song, Y., & Fan, H. (2025). Optimization Scheduling of Hydrogen-Integrated Energy Systems Considering Multi-Timescale Carbon Trading Mechanisms. Energies, 18(7), 1612. https://doi.org/10.3390/en18071612