Assessment of the Risks Associated with the Handling and Transportation of Air Shipments Containing Lithium-Ion Batteries

Abstract

1. Introduction

2. Literature Review

2.1. Transport of Lithium-Ion Batteries

2.2. Risk Assessment Methods in Air Transport

3. Analysis of Lithium-Ion Battery Transport Incidents

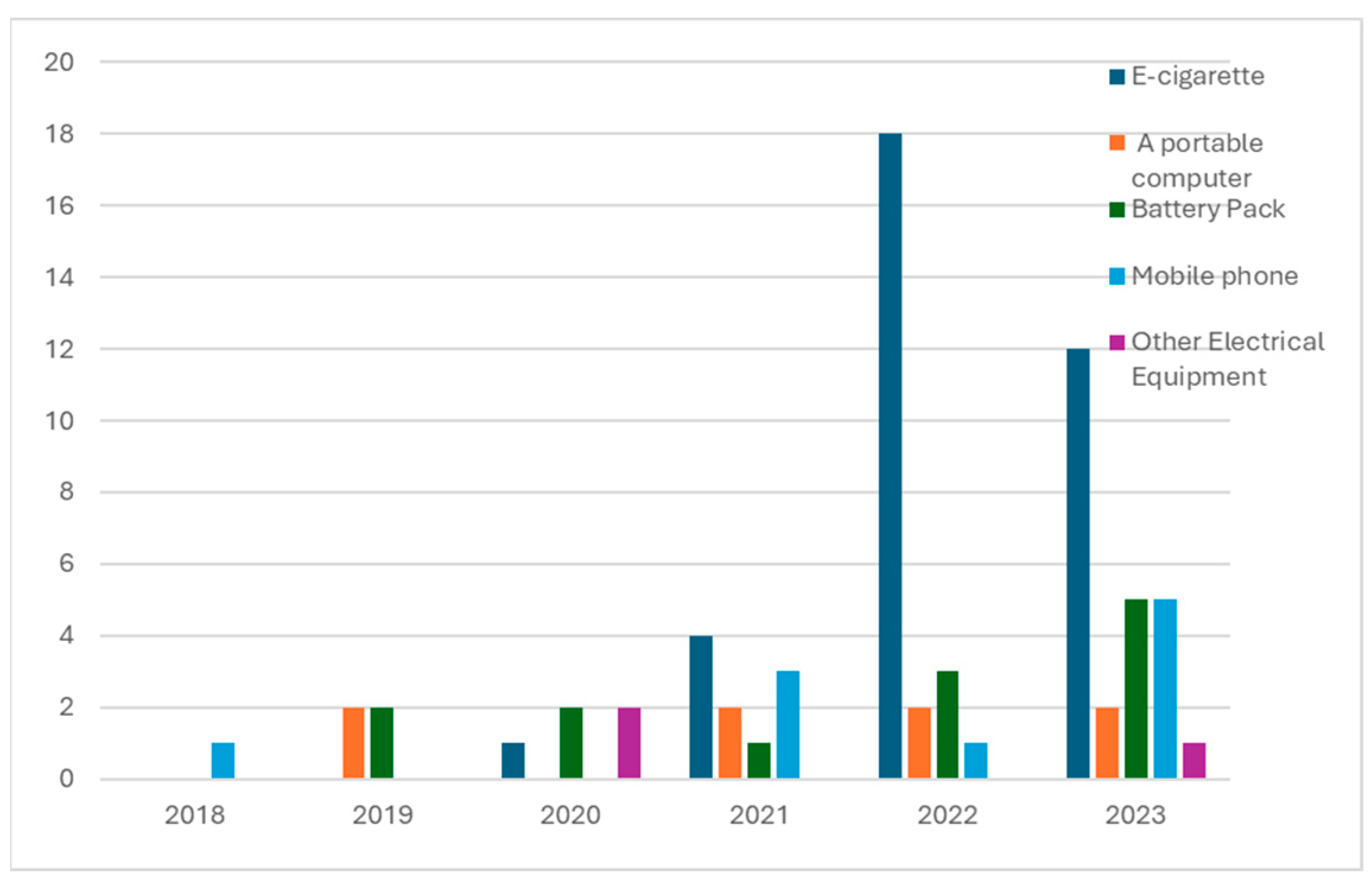

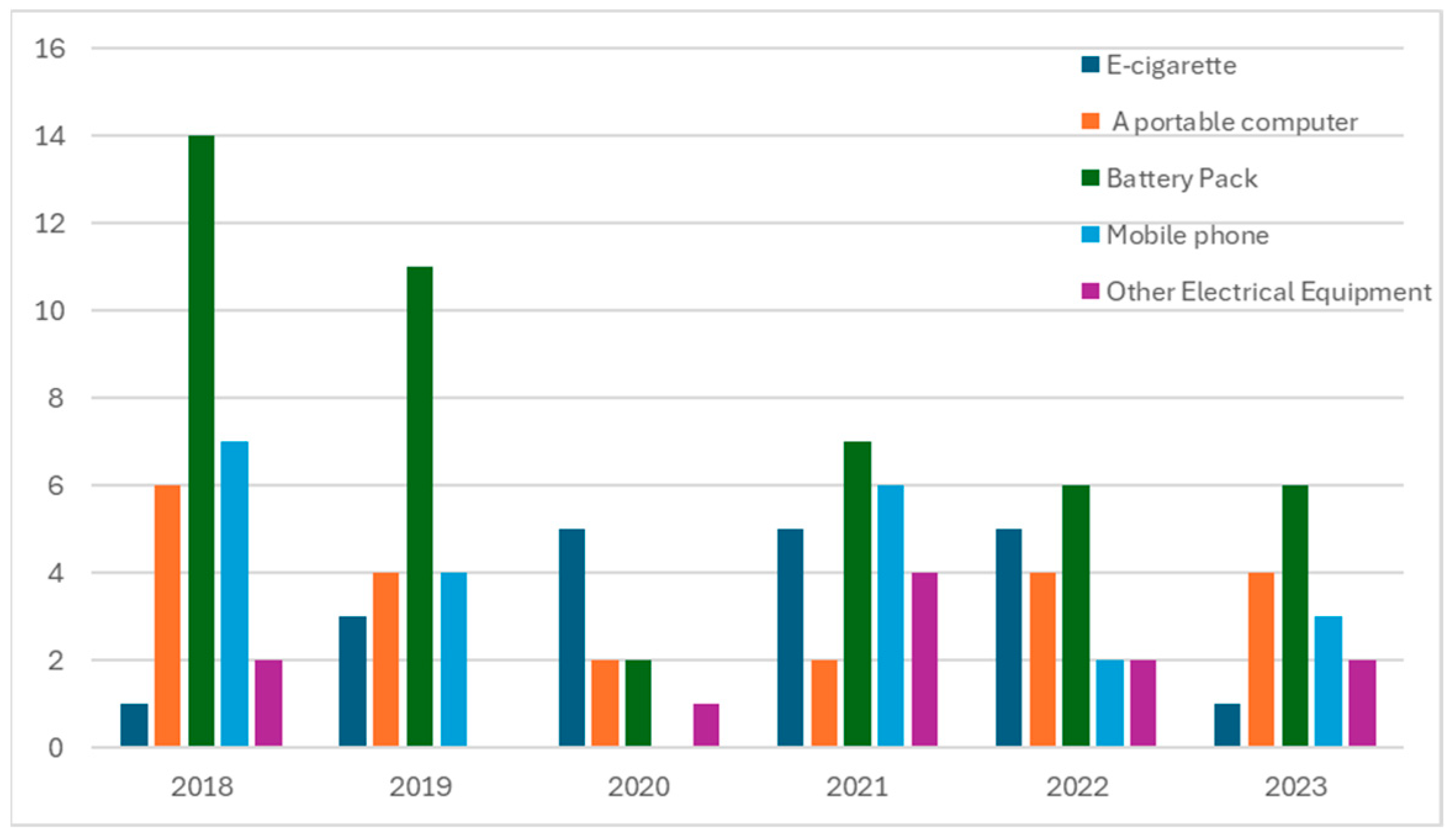

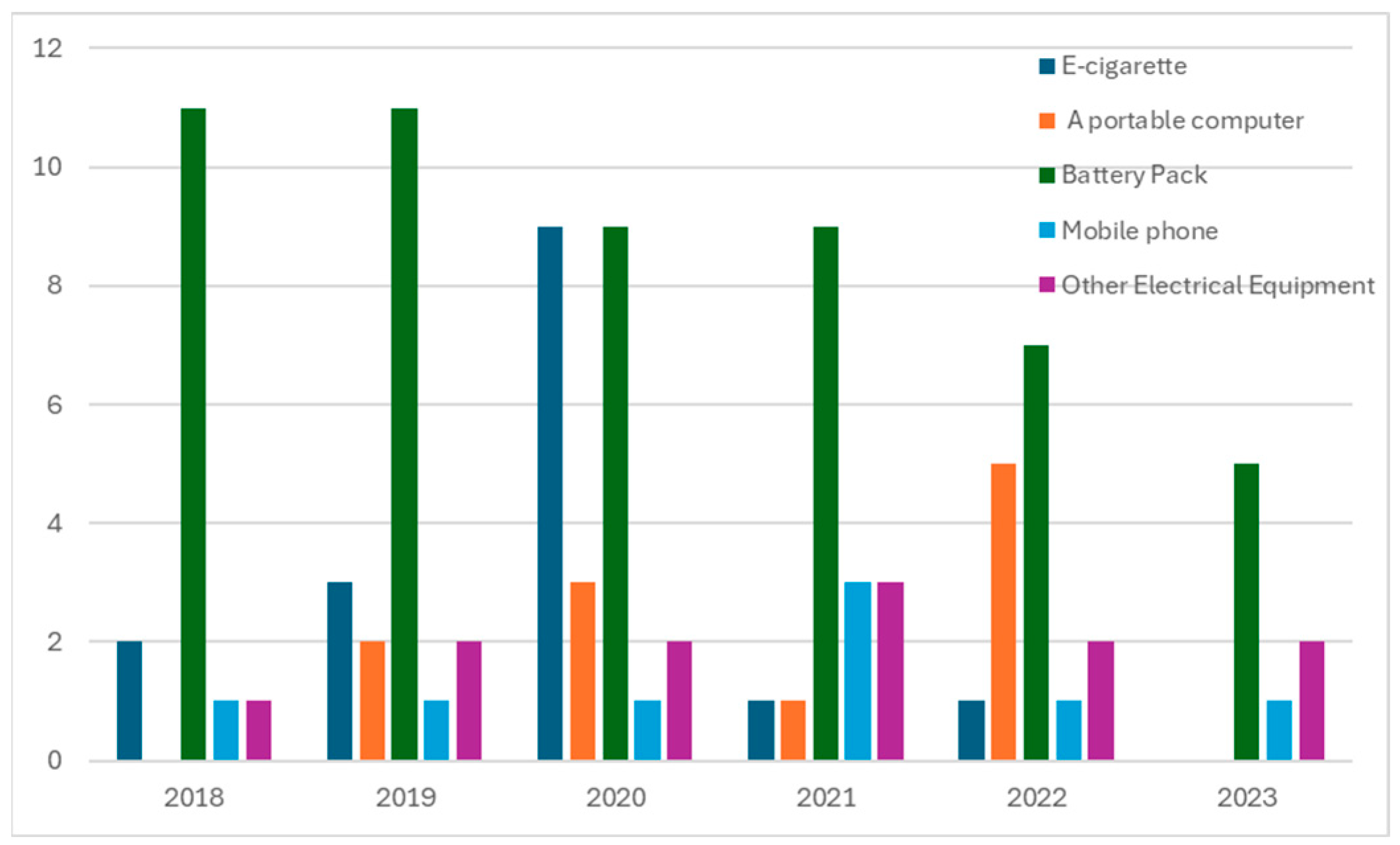

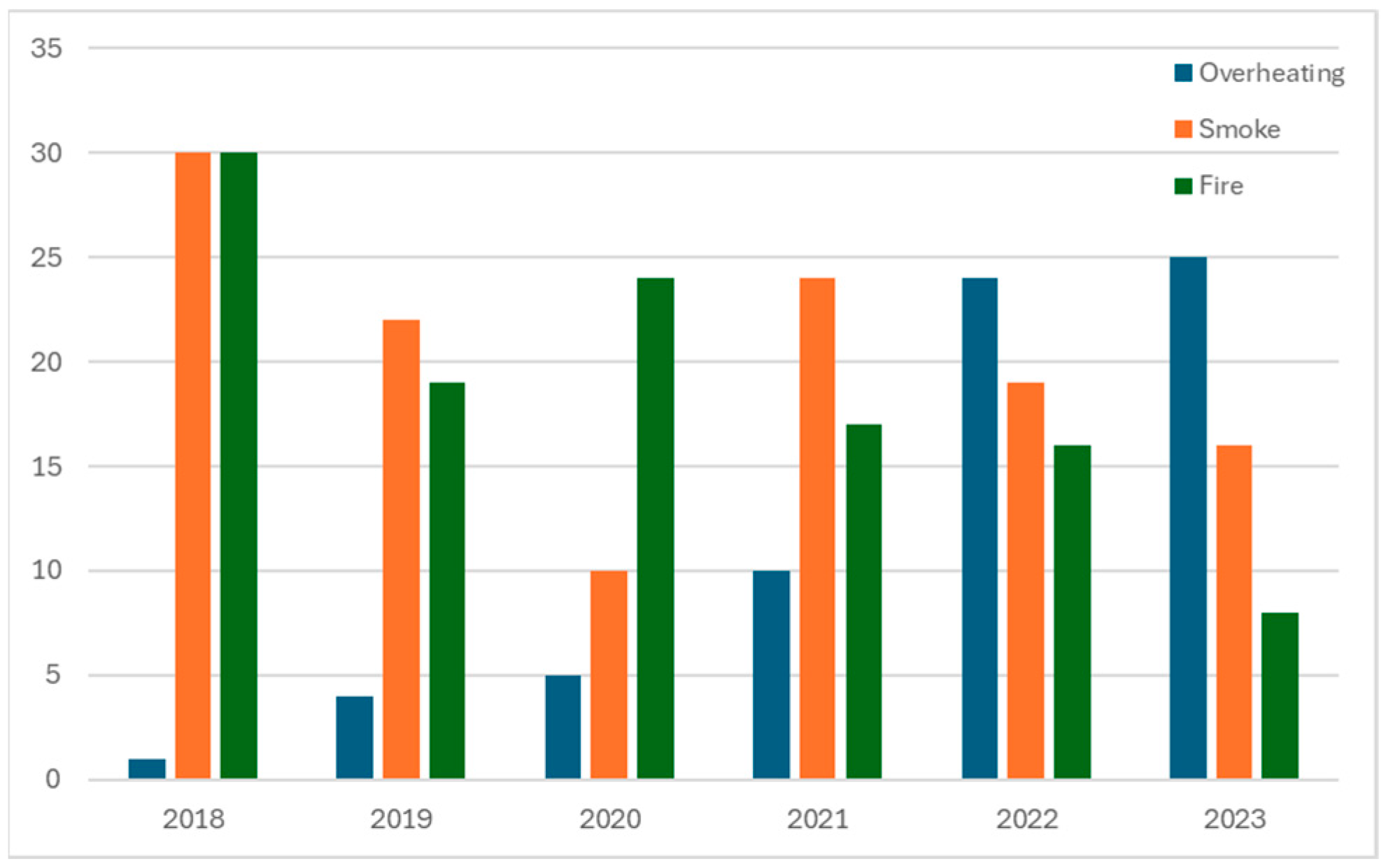

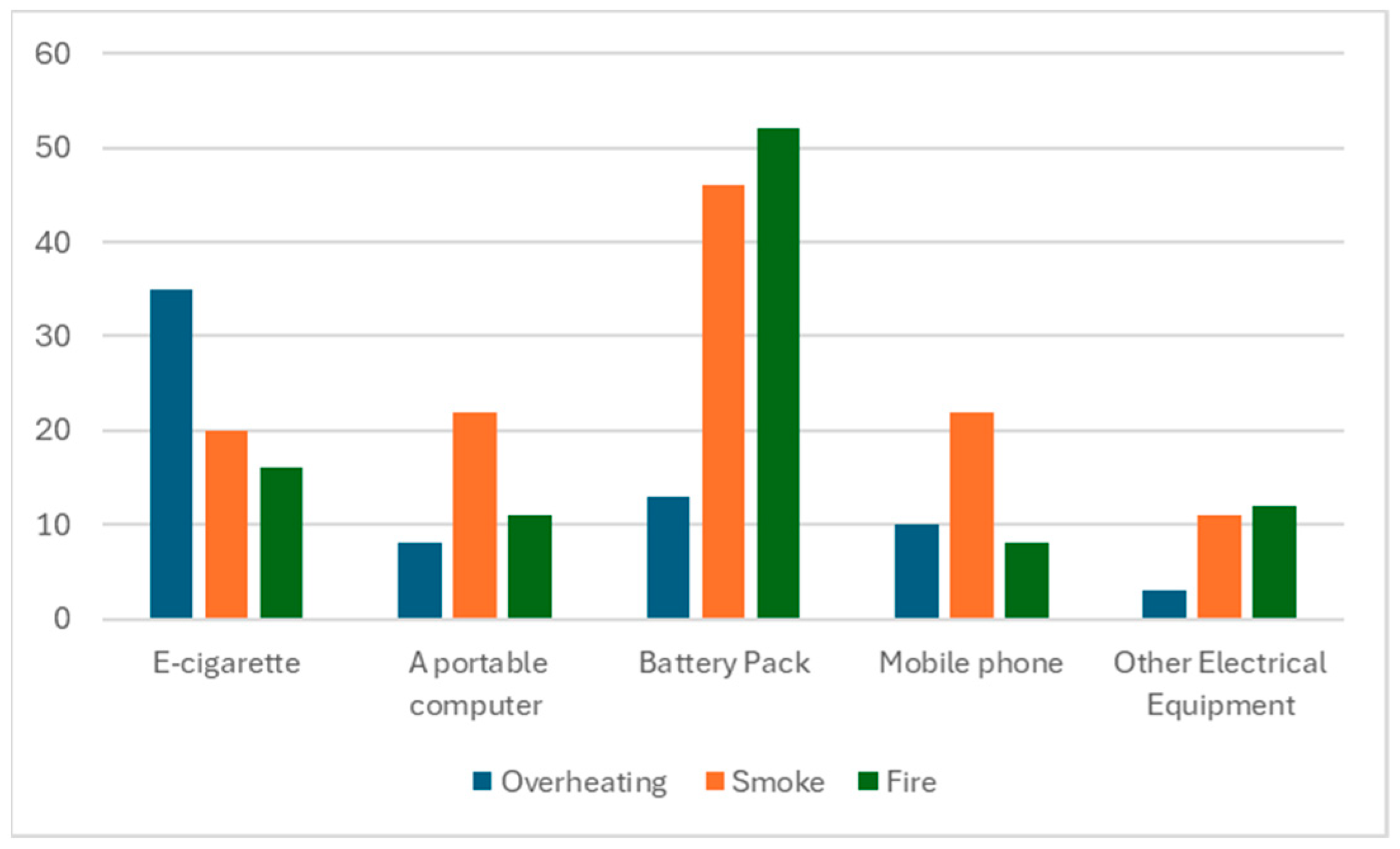

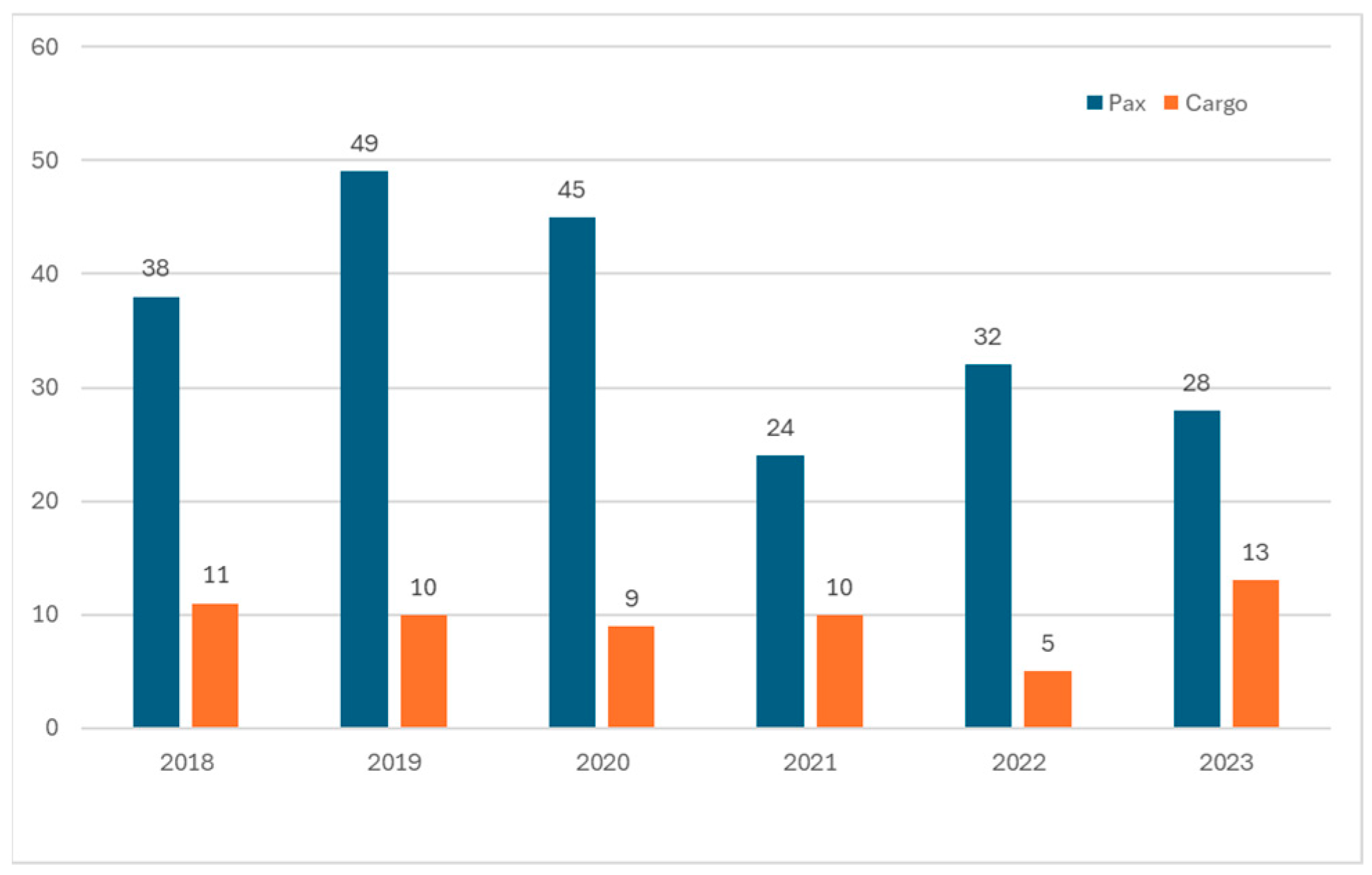

3.1. Federal Aviation Administration Incident Reporting

- -

- E-cigarettes.

- -

- A portable computer.

- -

- Battery pack.

- -

- Mobile phones.

- -

- Other electrical devices.

- -

- Overheating.

- -

- Smoke emitted from the device.

- -

- Fire.

3.2. Analysis of Incidents Involving Lithium-Ion Batteries

3.2.1. Incidents Caused by Battery Overheating

3.2.2. Smoke-Related Incidents

3.2.3. Fire Incidents

3.2.4. Summary of Incidents Involving Lithium-Ion Batteries

3.2.5. Description of Selected Incidents Involving Lithium-Ion Batteries

- -

- Batteries with a capacity of up to 100 Wh or up to two grams of lithium content—in this case, the carrier’s consent is not required.

- -

- Up to 15 devices with batteries of up to 100 Wh in checked baggage or hand luggage.

- -

- Up to two spare batteries with a capacity of over 100 Wh, but not more than 160 Wh, in hand luggage only.

- -

- Up to 20 replacement batteries with a capacity of up to 100 Wh, in hand luggage only.

3.2.6. Incidents and Aircraft Type

4. Risk Assessment of Handling the Transport of Lithium-Ion Batteries

4.1. Identification of Groups of Causes of Incidents

4.2. Identification of Hazards in Handling and Transporting Batteries

4.3. Hazard Identification and Risk Assessment in Battery Handling and Transport

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| FAA | Federal Aviation Administration |

| ACI | Airports Council International |

| IATA | The International Air Transport Association |

| DGR | Dangerous Goods Regulations |

| LBSR | Lithium Battery Shipping Regulations |

| SMS | Safety Management System |

References

- Civil Aviation Auhority. Available online: https://www.ulc.gov.pl/pl/aktualnosci/4430-baterie-litowe-w-podrozy-lotniczej-jak-przewozic-je-bezpiecznie (accessed on 15 September 2024).

- Choi, S.; Lee, K.; Kim, J.; Oh, S.; Joo, J.; Bae, E.; Lee, H.; Kim, M. Early Detection and Suppression of Thermal Runaway in Large-Format Lithium-Ion Batteries: Insights from Experimental Analysis. Energies 2025, 18, 155. [Google Scholar] [CrossRef]

- Quan, T.; Xia, Q.; Wei, X.; Zhu, Y. Recent Development of Thermal Insulating Materials for Li-Ion Batteries. Energies 2024, 17, 4412. [Google Scholar] [CrossRef]

- Meng, D.; Weng, J.; Wang, J. Experimental Investigation on Thermal Runaway of Lithium-Ion Batteries under Low Pressure and Low Temperature. Batteries 2024, 10, 243. [Google Scholar] [CrossRef]

- Ubaldi, S.; Russo, P. Toxicity Assessment of Gas, Solid and Liquid Emissions from Li-Ion Cells of Different Chemistry Subjected to Thermal Abuse. Energies 2024, 17, 4402. [Google Scholar] [CrossRef]

- Ubaldi, S.; Conti, M.; Marra, F.; Russo, P. Identification of Key Events and Emissions during Thermal Abuse Testing on NCA 18650 Cells. Energies 2023, 16, 3250. [Google Scholar] [CrossRef]

- IATA 2023, Dangrerous Goods Regulations (DGR) 2023. Available online: https://www.iata.org/en/publications/dgr/ (accessed on 15 September 2024).

- Civil Aviation Auhority, 2020, Passenger Air Transport in 2020. Available online: https://www.ulc.gov.pl/pl/aktualnosci/5632-przewozy-pasazerskie-w-transporcie-lotniczym-w-2020-roku (accessed on 25 March 2024).

- Kwasiborska, A. Air Transportation of Dangerous Goods “Logistic”, Warsaw; BazTech: Lagos, Nigeria, 2011; Available online: https://yadda.icm.edu.pl/baztech/element/bwmeta1.element.baztech-article-BPL1-0004-0079 (accessed on 25 March 2024).

- ICAO 2011, Annex 18 to the Convension on International Civil Aviation “Safe Transport of Dangerous Goods by Air” 2011. Available online: https://store.icao.int/en/annex-18-the-safe-transport-of-dangerous-goods-by-air (accessed on 25 March 2024).

- IATA 2023, Literium Battery Shipping Regulations (LBSR) 2023. Available online: https://www.iata.org/en/publications/manuals/battery-shipping-regulations/ (accessed on 15 September 2024).

- Williard, N.; Hendricks, C.; Sood, B.; Chung, J.S.; Pecht, M. Evaluation of Batteries for Safe Air Transport. Energies 2016, 9, 340. [Google Scholar] [CrossRef]

- Shen, H.; Zhang, Y.; Wu, Y. A comparative study on air transport safety of lithium-ion batteries with different SOCs. Appl. Therm. Eng. 2020, 179, 115679. [Google Scholar] [CrossRef]

- Ke, Q.; Li, X.; Guo, J.; Cao, W.; Wang, Y.; Jiang, F. The retarding effect of liquid-cooling thermal management on thermal runaway propagation in lithium-ion batteries. J. Energy Storage 2022, 48, 104063. [Google Scholar]

- Mele, M.L.; Bracciale, M.P.; Ubaldi, S.; Santarelli, M.L.; Mazzaro, M.; Di Bari, C.; Russo, P. Thermal Abuse Tests on 18650 Li-Ion Cells Using a Cone Calorimeter and Cell Residues Analysis. Energies 2022, 15, 2628. [Google Scholar] [CrossRef]

- Jiang, Z.Y.; Qu, Z.G.; Zhang, J.F.; Rao, Z.H. Rapid prediction method for thermal runaway propagation in battery pack based on lumped thermal resistance network and electric circuit analogy. Appl. Energy 2020, 268, 115007. [Google Scholar]

- Ping, P.; Wang, Q.; Chung, Y.; Wen, J. Modelling electro-thermal response of lithium-ion batteries from normal to abuse conditions. Appl. Energy 2017, 205, 1327–1344. [Google Scholar] [CrossRef]

- Hwang, J.; Sivasengaran, A.N.; Yang, H.; Yamamoto, H.; Takeuchi, T.; Matsumoto, K.; Hagiwara, R. Improvement of electrochemical stability using the eutectic composition of a ternary molten salt system for highly concentrated electrolytes for Na-ion batteries. ACS Appl. Mater. Interfaces 2021, 13, 2538–2546. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Ouyang, D.; Qian, X.; Yuan, S.; Chang, C.; Zhang, J.; Liu, Y. Early Warning Method and Fire Extinguishing Technology of Lithium-Ion Battery Thermal Runaway: A Review. Energies 2023, 16, 2960. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, T.; Li, W.; Li, T.; Zhang, L.; Zhang, X.; Wang, Z. Engineering of sodium-ion batteries: Opportunities and challenges. Engineering 2023, 24, 172–183. [Google Scholar] [CrossRef]

- Batuecas, E.; Martínez-Cisneros, C.S.; Serrano, D.; Varez, A. Life cycle assessment of lab-scale solid sodium-ion batteries: A sustainable alternative to liquid lithium-ion batteries. J. Energy Storage 2024, 80, 110355. [Google Scholar] [CrossRef]

- Iwan, A.; Bogdanowicz, K.A.; Pich, R.; Gonciarz, A.; Miedziak, J.; Plebankiewicz, I.; Przybyl, W. The Safety Engineering of Sodium-Ion Batteries Used as an Energy Storage System for the Military. Energies 2025, 18, 978. [Google Scholar] [CrossRef]

- Zhang, X.; Zhong, S.; Mahadevan, S. Airport surface movement prediction and safety assessment with spatial–temporal graph convolutional neural network. Transp. Res. Part C Emerg. Technol. 2022, 144, 103873. [Google Scholar] [CrossRef]

- Chikha, P.; Skorupski, J. The risk of an airport traffic accident in the context of the ground handling personnel performance. J. Air Transp. Manag. 2022, 105, 102295. [Google Scholar] [CrossRef]

- Skorupski, J.; Grabarek, I.; Kwasiborska, A.; Czyżo, S. Assessing the suitability of airport ground handling agents. J. Air Transp. Manag. 2020, 83, 101763. [Google Scholar] [CrossRef]

- ICAO 2013, Doc 9859, Safety Management Manual. Available online: https://elibrary.icao.int/product/229751 (accessed on 25 March 2024).

- Krzyżanowski, M.; Manerowski, J.; Gładyś, S. New approach to safety management system in civil aviation. WUT J. Transp. Eng. 2017, 119, 227–238. [Google Scholar]

- Skorupski, J. Ilościowe Metody Analizy Incydentów w Ruchu Lotniczym; Oficyna Wydawnicza Politechniki Warszawskiej/Politechnika Warszawska (PW): Warszawa, Poland, 2018; ISBN 978-83-7814-759-6. Available online: https://www.sklep.pw.edu.pl/produkty/ilosciowe-metody-analizy-incydentow-w-ruchu-lotniczym (accessed on 25 March 2024).

- Wróblewski, D. Zarządzanie Ryzykiem–Przegląd Wybranych Metodyk; Centrum Naukowo-Badawcze Ochrony Przeciwpożarowej im. Józefa Tuliszkowskiego Państwowy Instytut Badawczy: Józefów, Poland, 2015. [Google Scholar]

- Kwasiborska, A.; Stelmach, A. Identification of threats and risk assessment in air transport with the use of selected models and methods. Zesz. Nauk. Szk. Gł. Służ. Pożar. 2023, 86, 77–94. [Google Scholar] [CrossRef]

- Flage, R.; Askeland, T. Assumptions in quantitative risk assessments: When explicit and when tacit? Reliab. Eng. Syst. Saf. 2020, 197, 106799. [Google Scholar] [CrossRef]

- Ketabdari, M.; Giustozzi, F.; Crispino, M. Sensitivity analysis of influencing factors in probabilistic risk assessment for airports. Saf. Sci. 2018, 107, 173–187. [Google Scholar] [CrossRef]

- Chen, M.; Chen, Y.; Ma, S. Identifying safety performance indicators for risk assessment in civil aviation. In Proceedings of the 10th International Conference on Quality, Reliability, Risk, Maintenance, and Safety Engineering (QR2MSE 2020), Shaanxi, China, 8–11 October 2020; Volume 1043, p. 032010. [Google Scholar]

- Bartulović, D.; Steiner, S. Predictive analysis of airport safety performance: Case study of Split Airport. Aerospace 2023, 10, 303. [Google Scholar] [CrossRef]

- Ang, H.; Cai, Q.; Alam, S. A collision risk assessment method for runway threshold management: A case study of Singapore Changi Airport. Case Stud. Transp. Policy 2020, 8, 784–795. [Google Scholar] [CrossRef]

- Kabir, S.; Papadopoulos, Y. Applications of Bayesian networks and Petri nets in safety, reliability, and risk assessments: A review. Saf. Sci. 2019, 115, 154–175. [Google Scholar] [CrossRef]

- Federal Aviation Administratin FAA 2024, Lithium Battery Air Incidents. Available online: https://explore.dot.gov/t/FAA/views/LithiumBatteries/LithiumBatteryIncidents?%3Aembed=y&%3AisGuestRedirectFromVizportal=y (accessed on 1 April 2024).

| Value | Probability | ICAO Description | FAA ARP |

|---|---|---|---|

| 1 | Extremely improbable | Almost inconceivable that the event will occur | Expected to occur < every 100 years |

| 2 | Improbable | Very unlikely to occur | Expected to occur once every 10–100 years or 25 million departures, whichever occurs sooner |

| 3 | Remote | Inlikely to occur, but possible | Expected to occur about once every year or 2.5 million departures, whichever occurs sooner |

| 4 | Occasional | Likely to occur sometimes | Expected to occur about once every month or 250,000 departures, whichever occurs sooner |

| 5 | Frequent | Likely to occur many times | Expected to occur more than once per week or every 2500 departures, whichever occurs sooner |

| Value | Probability | ICAO Description | FAA ARP |

|---|---|---|---|

| A | Catastrophic | Equipment destroyed Multiple deaths | Complete loss of aircraft and/or facilities or fatal injury in passengers(s)/worker(s); or Complete unplanned airport closure and destruction of critical facilities; or Airport facilities and equipment destroyed |

| B | Hazardous | A large reduction in safety margins, physical distress or a workload such that the operators cannot be relief upon to perform their tasks accurately or completely Serious injury Major equipment damage | Severe damage to aircraft and/or serious to passenger(s)/worker(s); or Complete unplanned airport closure, or Major unplanned operations limitations, or Major airport damage to equipment and facilities |

| C | Major | A significant reduction in safety margins, a reduction in the ability if the operators to cope with adverse operationg conditions as a result of an increase in workload or as a result of conditions impairing their efficiency Serious incident Injury to persons | Major damage to aircraft and/or minor injury to passenger(s), or Major unplanned disruption to airport operations, or Serious incident, or Reduction on the airport`s ability to deal with adverse conditions |

| D | Minor | Nuisance Operating limitations Use of emergency procedures Minor incident | Minimal damage to aircraft, or Minor injury to passengers, or Minimal unplanned airport operations limitations, or Minor incident involving the use of airport procedures |

| E | Negligible | Few consequences | No damage to aircraft but minimal injury or discomfort of little risk to passenger(s) or worker(s) |

| Risk Probability | Risk Severity | ||||

|---|---|---|---|---|---|

| Catastrophic A | Hazardous B | Major C | Minor D | Negligible E | |

| Frequent 5 | 5A | 5B | 5C | 5D | 5E |

| Occasional 4 | 4A | 4B | 4C | 4D | 4E |

| Remote 3 | 3A | 3B | 3C | 3D | 3E |

| Improbable 2 | 2A | 2B | 2C | 2D | 2E |

| Extremely improbable 1 | 1A | 1B | 1C | 1D | 1E |

| Name | Number of Incidents | [%] of Incidents |

|---|---|---|

| Self-combustion/overheating | 179 | 65.32 |

| Passenger/agent lack of knowledge | 38 | 13.86 |

| Damage due to a passenger’s fault | 29 | 10.58 |

| Damage during handling | 22 | 8.02 |

| Mechanical damage due to falling | 6 | 2.18 |

| Name | Threat Group | |

|---|---|---|

| 1 | Mechanical damage (during the handling process, e.g., impact, being dropped by a forklift or a lifter). | Damage during handling |

| 2 | Mechanical damage caused by the passenger (in the passenger cabin, e.g., jamming the device between the seats, falling on the floor, or damage in the storage compartment). | Damage due to passenger’s fault |

| 3 | Thermal overload (spontaneous combustion, e.g., in the trunk during an air operation). | Spontaneous ignition |

| 4 | Thermal overload (exposure to harmful solar radiation during storage or handling). | Overheating |

| 5 | Battery overload (cracking/swelling). | Damage during the handling stage |

| 6 | Electrical overload (through deep discharge or the use of a faulty charger by the passenger). | Spontaneous ignition |

| 7 | Transport of batteries that do not meet the technical requirements—manufacturing defect (unknown origin of the battery and/or lack of certification). | Overheating |

| 8 | Lack of awareness of the presence of the battery in the device (about the possession/presence of the battery by the passenger and legal regulations). | Lack of passenger knowledge |

| 9 | Failure to declare the battery as DG (when sent by an agent). | Lack of passenger knowledge |

| 10 | Damaged shipment/battery (thermal escape, explosion, leakage, contamination). Exceeding the permissible limits per package or per passenger. | Lack of passenger knowledge |

| 11 | Carriage of devices not permitted for transport. | Lack of passenger/agent knowledge |

| 12 | Battery not protected against short circuit. | Lack of passenger knowledge or damage during the handling stage |

| 13 | Incorrect subcontracting on behalf of the air operator for handling Dangerous Goods. | Lack of passenger knowledge |

| 14 | Mechanical damage (during the handling process, e.g., impact, being dropped by a forklift or a lifter. | Lack of passenger/agent knowledge |

| Threat | Threat Description | Consequence | Risk | Threat Level | Methods of Controlling/ Eliminating the Threat | |

|---|---|---|---|---|---|---|

| 1 | Mechanical damage | At the stage of the handling process, e.g., impact, dropping by a forklift or lift. | Withdrawal of goods from the shipping process. | 4D | Tolerable | Audit processes and training of handling personnel. |

| 2 | Mechanical damage caused by the passenger | In the passenger compartment, e.g., the device is jammed between the seats, falls to the floor, or is damaged in the glove compartment. | Overheating resulting in smoke or ignition of the device. | 5E | Tolerable | Proper awareness of the threat and warning of the consequences to passengers. Procedures for the crew in the event of an incident. |

| 3 | Thermal overload | Spontaneous combustion, e.g., in the trunk during an aircraft operation. | Fire on board the aircraft. | 2C | Tolerable | Certified luggage racks with appropriate fire categories. Fire training for the crew. |

| 4 | Thermal overload | Exposure to harmful solar radiation during storage or handling. | Ignition resulting in damage to the batch of goods. | 2D | Acceptable | Training in handling hazardous materials, subcontractor and operator procedures, audit. |

| 5 | Battery overcharge | Rupture/swelling. | Battery overheating. | 4D | Tolerable | Procedures for the crew in the case of an emergency, certified racks with the appropriate fire category. Fire training for the crew and handling personnel. |

| 6 | Electrical overload | Due to deep discharge or use of a faulty charger by the passenger. | Overheating, smoke, or ignition. | 5E | Tolerable | Emergency procedures for the crew, fire safety training for staff. |

| 7 | Transport of batteries that do not meet the technical requirements | Battery origin unknown and/or lack of certification. | Possibility of causing a thermal incident. | 5D | Tolerable | Information on the website, sending memos to customers, reminder newsletters. |

| 8 | Lack of awareness of the presence of batteries in the device | About the possession/presence of batteries by the passenger and legal provisions. | Detection of the presence of batteries during security checks when scanning the device. | 5E | Tolerable | Information on the website, sending memos to customers, reminder bulletins |

| 9 | Failure to declare batteries as DG | When dispatched by an agent. | Detection of the presence of batteries during security checks when scanning the device. | 3E | Acceptable | Current control based on the detection of batteries in transported loads, verification of transport documents, security control, consignor’s declaration |

| 10 | Damaged shipment/battery | Thermal runaway, explosion, leak, contamination. | Pollution, environmental contamination. | 4C | Tolerable | Aircraft fire systems, crew procedures in the case of an emergency, certified luggage with the appropriate fire category, fire training for personnel |

| 11 | Exceeding the permissible limits | Exceeding the permissible limits per parcel or per passenger. | Preparation of a rejection checklist or DGOR. | 3E | Acceptable | Act on the transport of hazardous materials by air of 5 August 2022. Introducing the obligation for the sender to perform the following: (a) register with the Civil Aviation Authority as a SENDER. (b) Document training in the field of hazardous materials. |

| 12 | Transport of devices not approved for transport | Lack of verification of incoming goods. | Fire in the trunk without crew access. | 4E | Tolerable | Verification of transport documents, security check, consignor’s declaration, preparation of an acceptance checklist. |

| 13 | Battery not protected against short circuit. | Electrostatic charge causing sparks and may cause a fire. | Smoke, fire. | 4C | Tolerable | Aircraft fire systems, procedures for handling personnel and crew, certified luggage racks with the appropriate fire category. |

| 14 | Irregular subcontracting on behalf of an air carrier for handling Dangerous Goods | Wrong acceptance, damaged shipments, improper handling. | Lack of compliance, financial penalties, DG transport not in accordance with the regulations, service errors ended with DGOR. | 3D | Tolerable | Carrying out inspections and audits, training staff in the handling of hazardous materials. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwasiborska, A.; Ścigaj, S. Assessment of the Risks Associated with the Handling and Transportation of Air Shipments Containing Lithium-Ion Batteries. Energies 2025, 18, 1538. https://doi.org/10.3390/en18061538

Kwasiborska A, Ścigaj S. Assessment of the Risks Associated with the Handling and Transportation of Air Shipments Containing Lithium-Ion Batteries. Energies. 2025; 18(6):1538. https://doi.org/10.3390/en18061538

Chicago/Turabian StyleKwasiborska, Anna, and Sylwia Ścigaj. 2025. "Assessment of the Risks Associated with the Handling and Transportation of Air Shipments Containing Lithium-Ion Batteries" Energies 18, no. 6: 1538. https://doi.org/10.3390/en18061538

APA StyleKwasiborska, A., & Ścigaj, S. (2025). Assessment of the Risks Associated with the Handling and Transportation of Air Shipments Containing Lithium-Ion Batteries. Energies, 18(6), 1538. https://doi.org/10.3390/en18061538