Impact Assessment of Second-Life Batteries and Local Photovoltaics for Decarbonizing Enterprises Through System Digitalization and Energy Management

Abstract

1. Introduction

- Assessment of the impact of SLBs over one year for an enterprise, within the waste management and urban environmental services sector, using digital twins and energy management tools.

- Utilization of a multi-objective optimization strategy for energy management, considering the internal state of the battery. This strategy addresses economic factors (operational costs and battery degradation) and environmental factors.

- The presentation of a methodology that applies to a broad spectrum of enterprises, accommodating various battery and PV sizes, consumption patterns, and prioritization strategies for economic and environmental criteria.

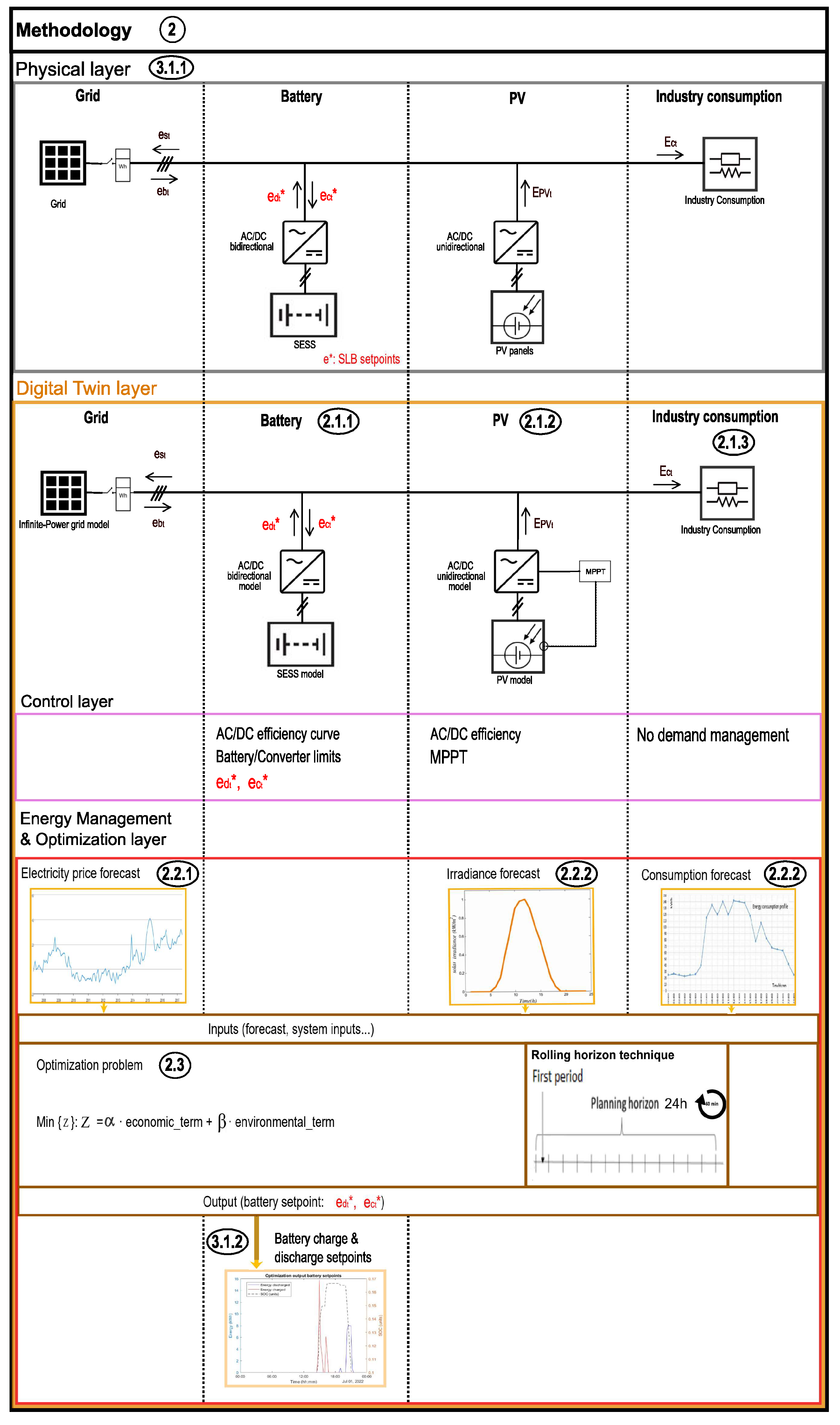

2. Methodology

- Type A: Constant energy consumption throughout the day.

- Type B: High daytime energy consumption and low nighttime consumption.

- Type C: High nighttime energy consumption and low daytime consumption.

- Type D: Peak energy consumption at specific times of the day or week.

2.1. Digital Twin Development

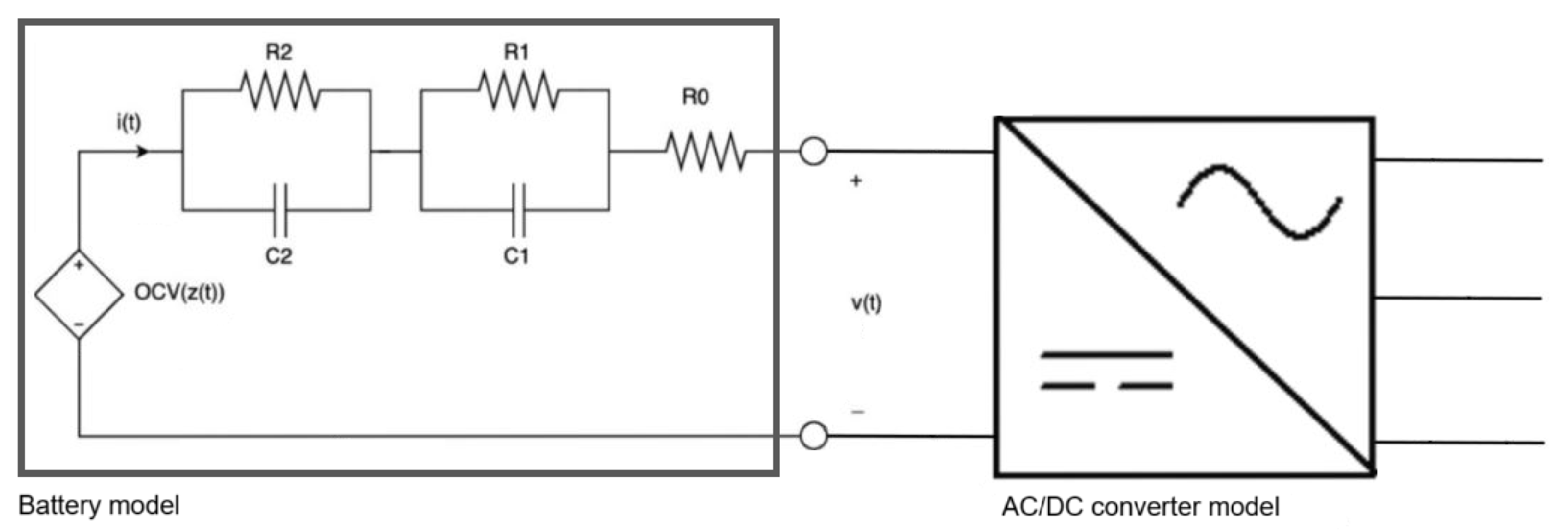

2.1.1. Second-Life Battery System

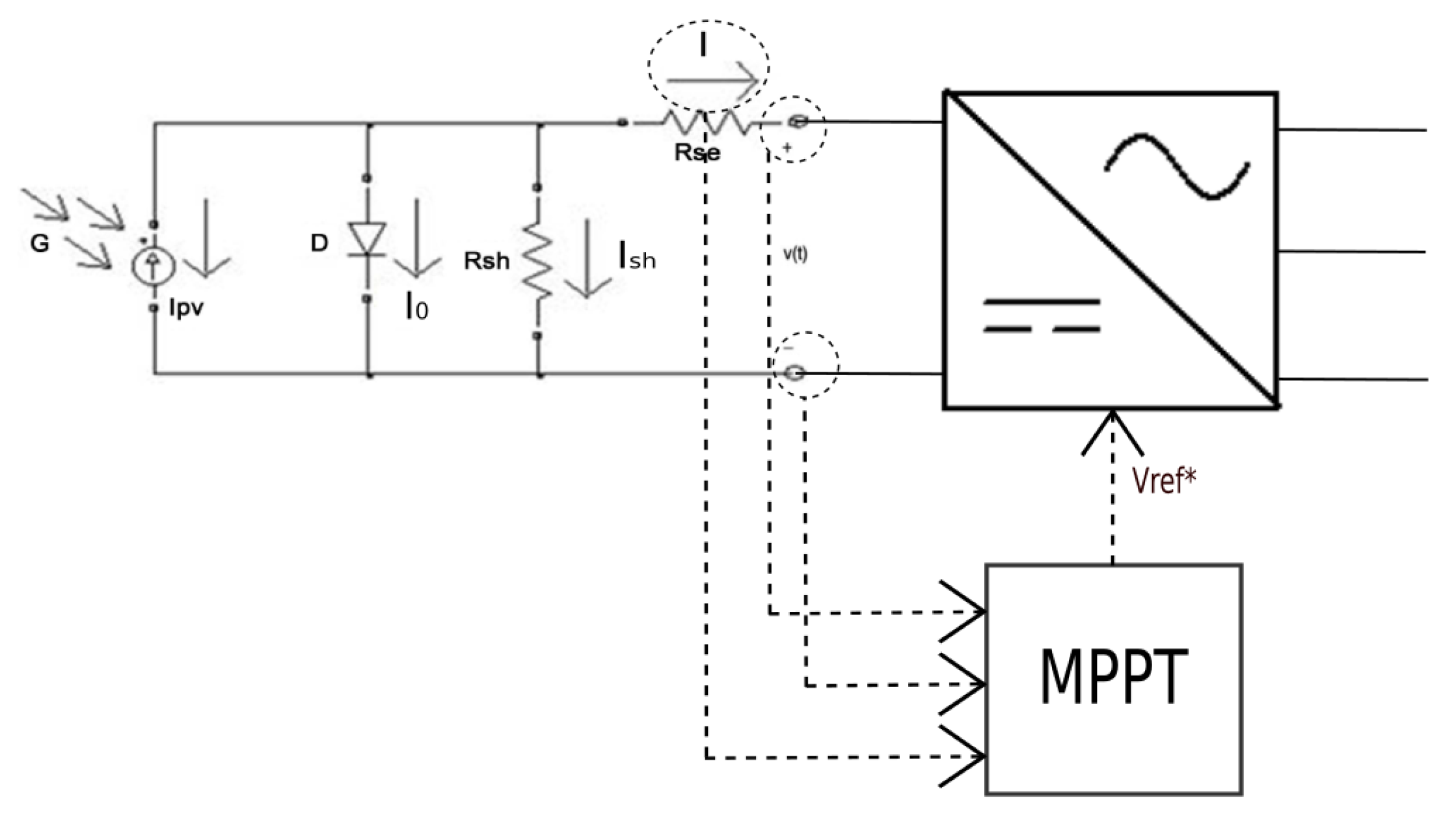

2.1.2. Photovoltaic-Based Power Generation System

2.1.3. Enterprise Loads

2.2. Forecasting Algorithms for Electricity Price, PV Generation, and Load Consumption

2.2.1. Forecast Algorithm for Electricity Price

2.2.2. Forecast Algorithm for PV Generation and Load Consumption

2.3. Optimization Algorithm for the Energy Management of the Enterprise

2.3.1. Input Parameters

- Cost of electricity at time t, , in EUR/kWh.

- Purchased electricity life cycle emission factor at time t, , in kg·CO2eq/kWh.

- Electricity selling price to the grid at time t, , in EUR/kWh.

- Cost of the contracted power, , in EUR/kW-day.

- Photovoltaic energy generated at time t, , in kWh.

- Photovoltaic life cycle emission factor, , in kg·CO2eq/kWh.

- Energy consumption at time t, , in kWh.

- Battery life capacity, , in kWh.

- Battery maximum, nominal, and minimum voltage, , , and , in Volts.

- Battery maximum charge and discharge, and , in Amperes.

- Battery internal resistance, , in ohms (Ω).

- Slope and y-intercept factors of the linear trend in the SOC-OCV characteristic (from 90% to 10% SOC), a and b, in p.u.

- Battery remaining cycles of the second-life application, , in units.

- Battery nominal price , in EUR/kWh.

- Battery price reduction factor for second-life applications, , in p.u.

- Battery life cycle emission factor, , in kg·CO2eq/kWh.

- Battery bi-directional DCDC converter charging and discharging efficiency, and , in p.u.

2.3.2. Decision Variables

- Energy charged by the battery at time t, , in kWh.

- Energy discharged by the battery at time t, , in kWh.

- Energy purchased from the grid at time t, , in kWh.

- Energy sold to the grid at time t, , in kWh.

- Charged power by the battery at time t, , in kW.

- Discharged power by the battery at time t, , in kW.

- Contracted power from the grid, , in kW.

- State of charge of the battery at time t, , in p.u.

- Battery charged current at time t, , in Amperes.

- Battery discharged current at time t, , in Amperes.

- Open circuit voltage of the battery at time t, , in Volts.

- Voltage at the battery terminals at time t, , in Volts.

2.3.3. Objective Function and Constraints

- The system energy balance should be ensured, so

- The maximum power exchanged with the grid must be lower than the contracted power as,and

- In turn, the energy exchanged by the battery is related to its instantaneous power as,and

- The instantaneous power of the battery is, in turn, related to the instantaneous voltage and current. The product and makes the optimization nonlinear. The complexity and optimization time is reduced by simplifying the constraint by calculating the power with a mean voltage value of the battery, . This allows the optimization to remain linear. Therefore, the power constraints are defined as,and

- The voltage at the battery terminals is calculated as,where the open circuit voltage is approximated by a linear trend from the state of charge ,and the state of charge is computed as

- The voltage, current, and state of charge limitations of the battery are stated by,and

- Finally, the state of charge at the final period of the horizon of the optimization should only deviate a fraction from the initial state of charge to ensure the replicability of the method in time. So,and,

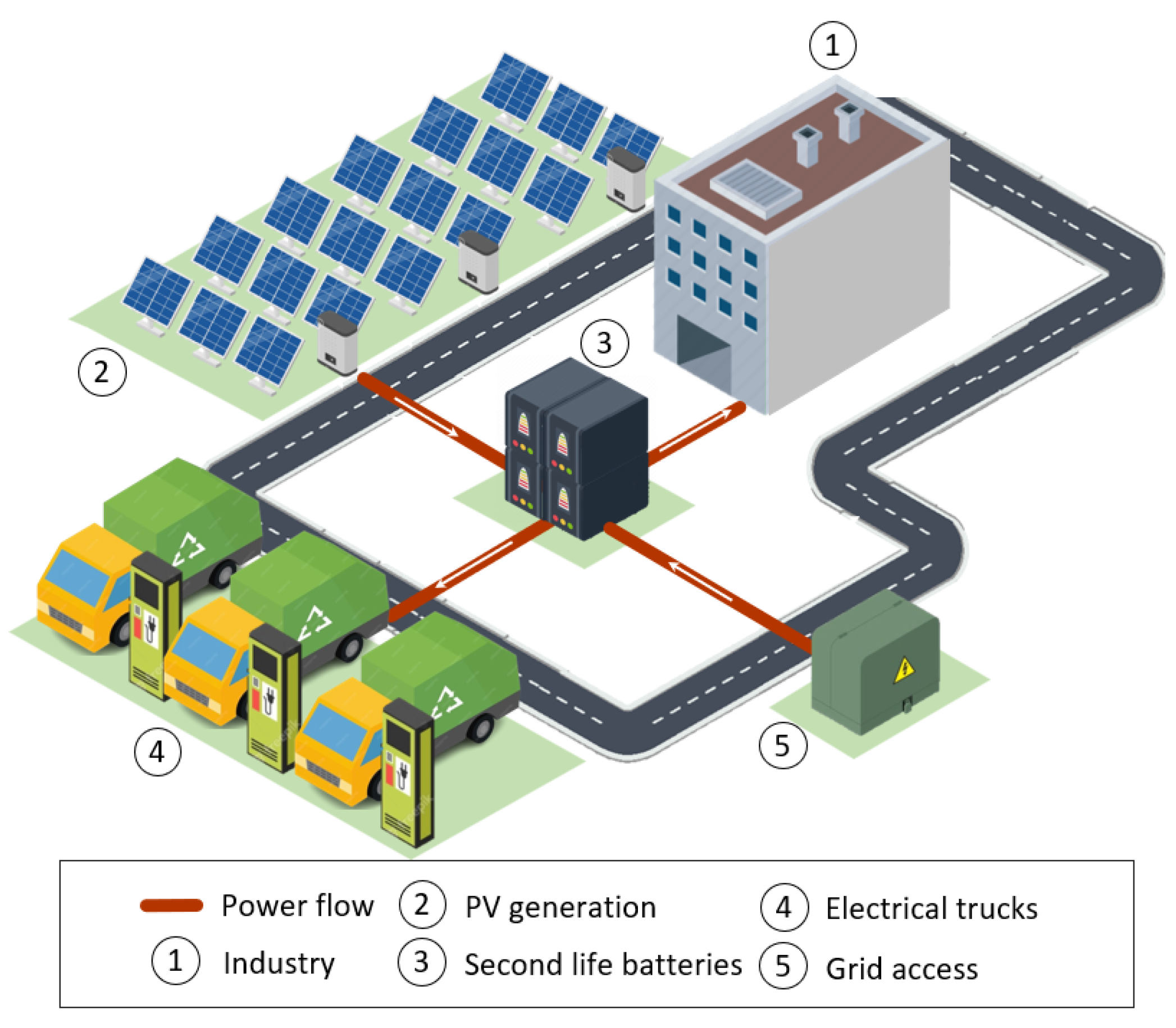

3. Case Study

- Analysis of a specific enterprise, in Section 3.1.

- –

- Description of the enterprise, in Section 3.1.1.

- –

- Results of the specific enterprise analysis, in Section 3.1.2.

- Sensitivity analysis, in Section 3.2.

- –

- Description of the sensitivity analysis methodology, in Section 3.2.1.

- –

- Results of the sensitivity analysis, in Section 3.2.2.

3.1. Enterprise-Specific Analysis

3.1.1. Enterprise Characteristics

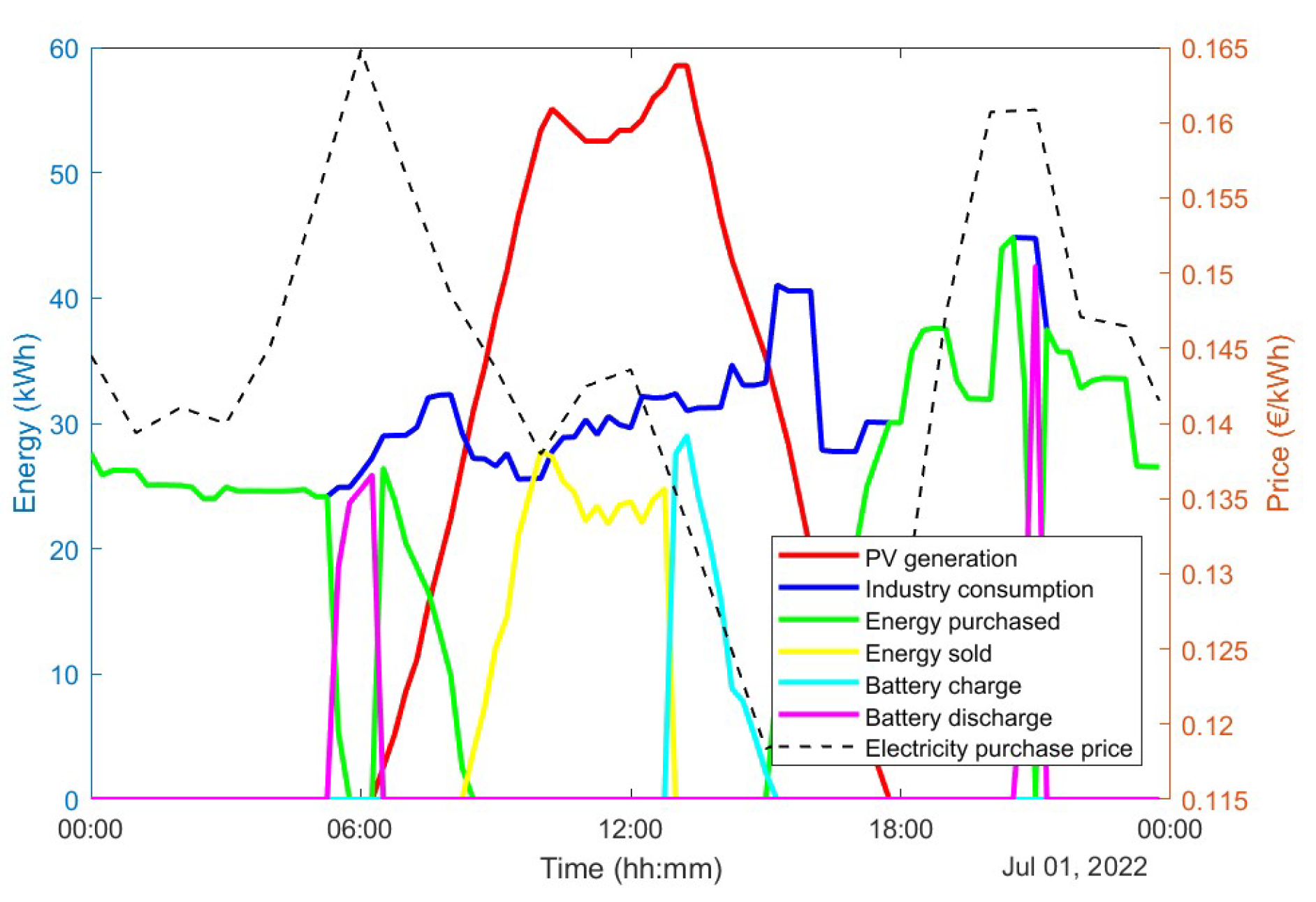

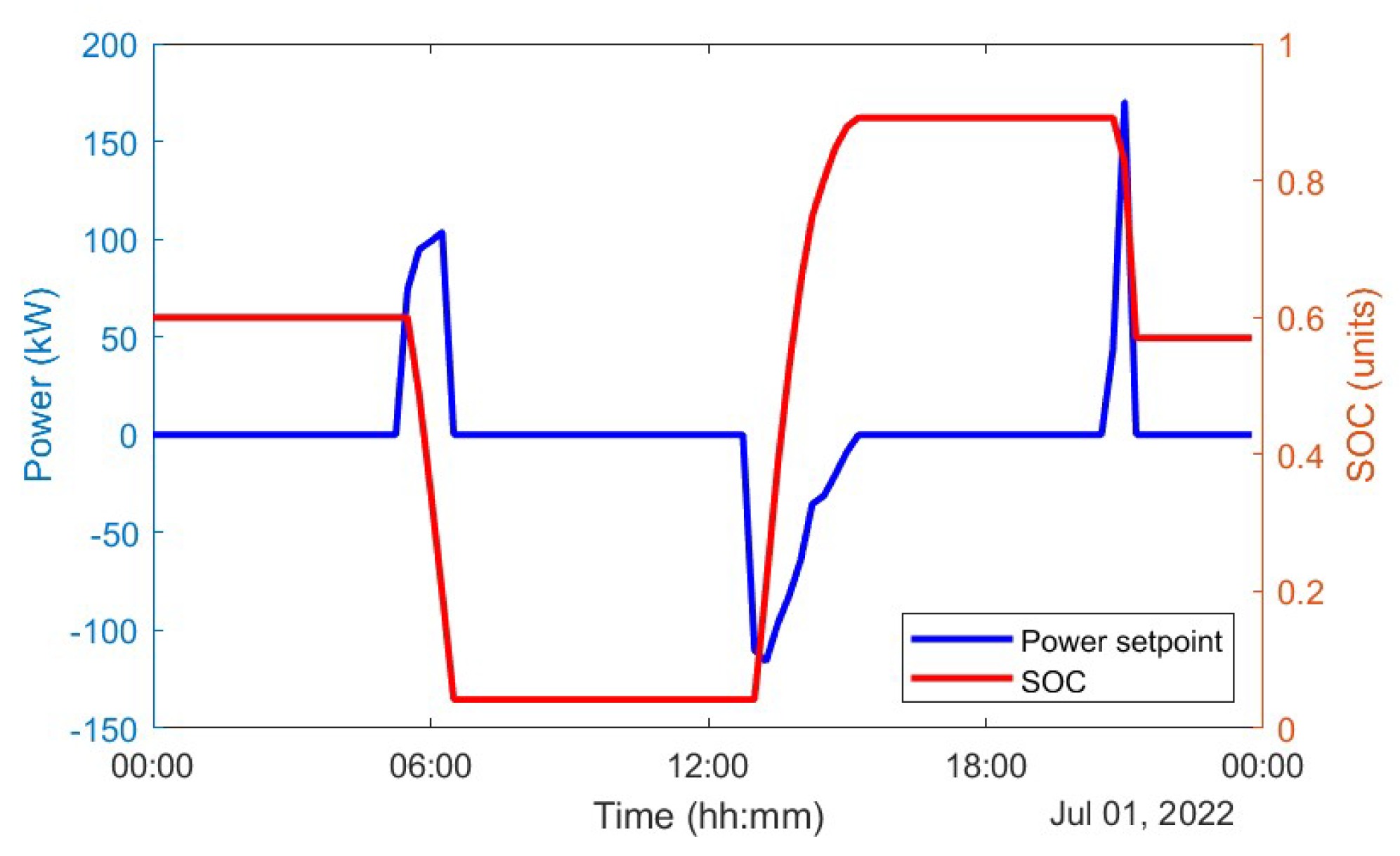

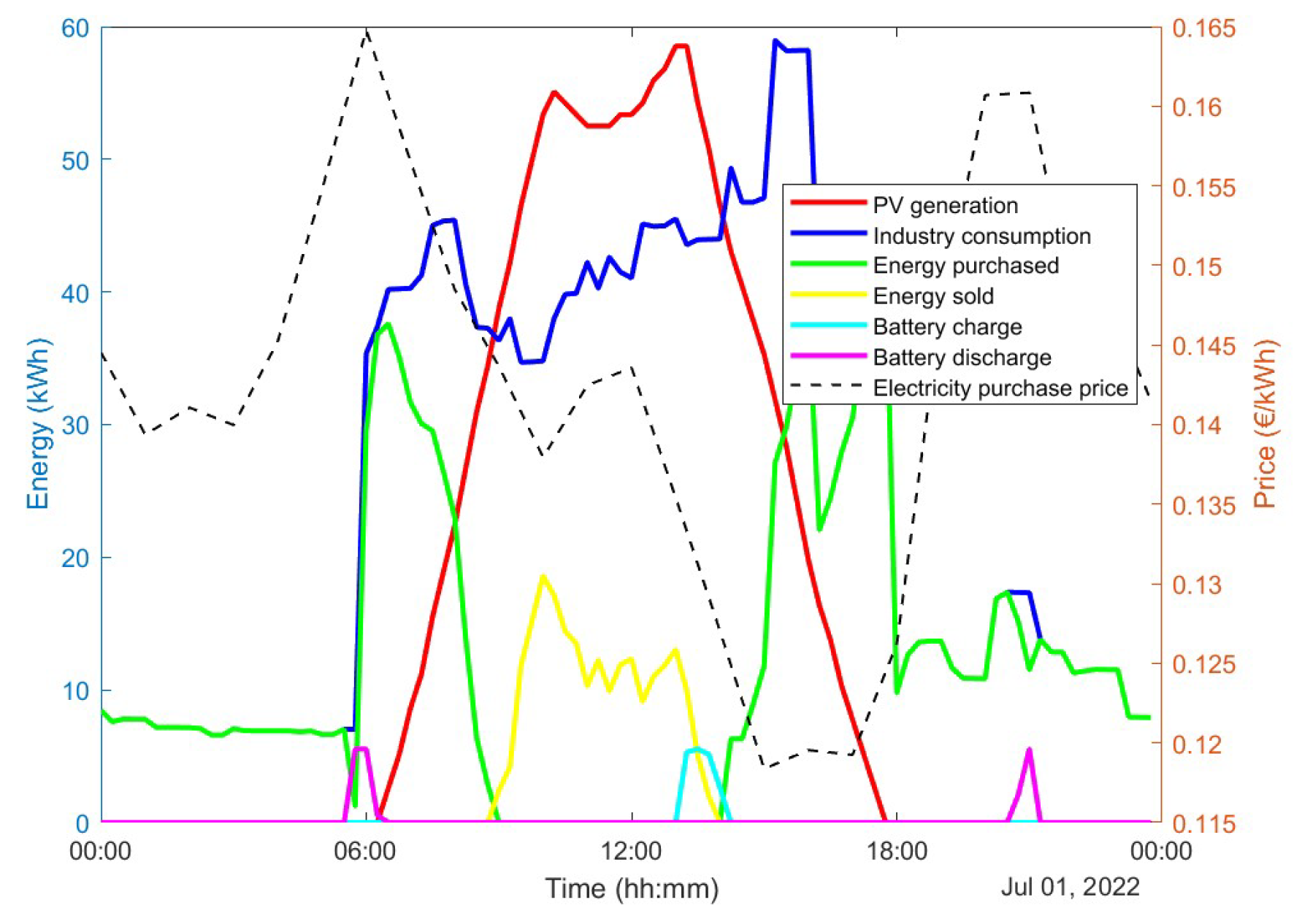

3.1.2. Results for the Selected Enterprise

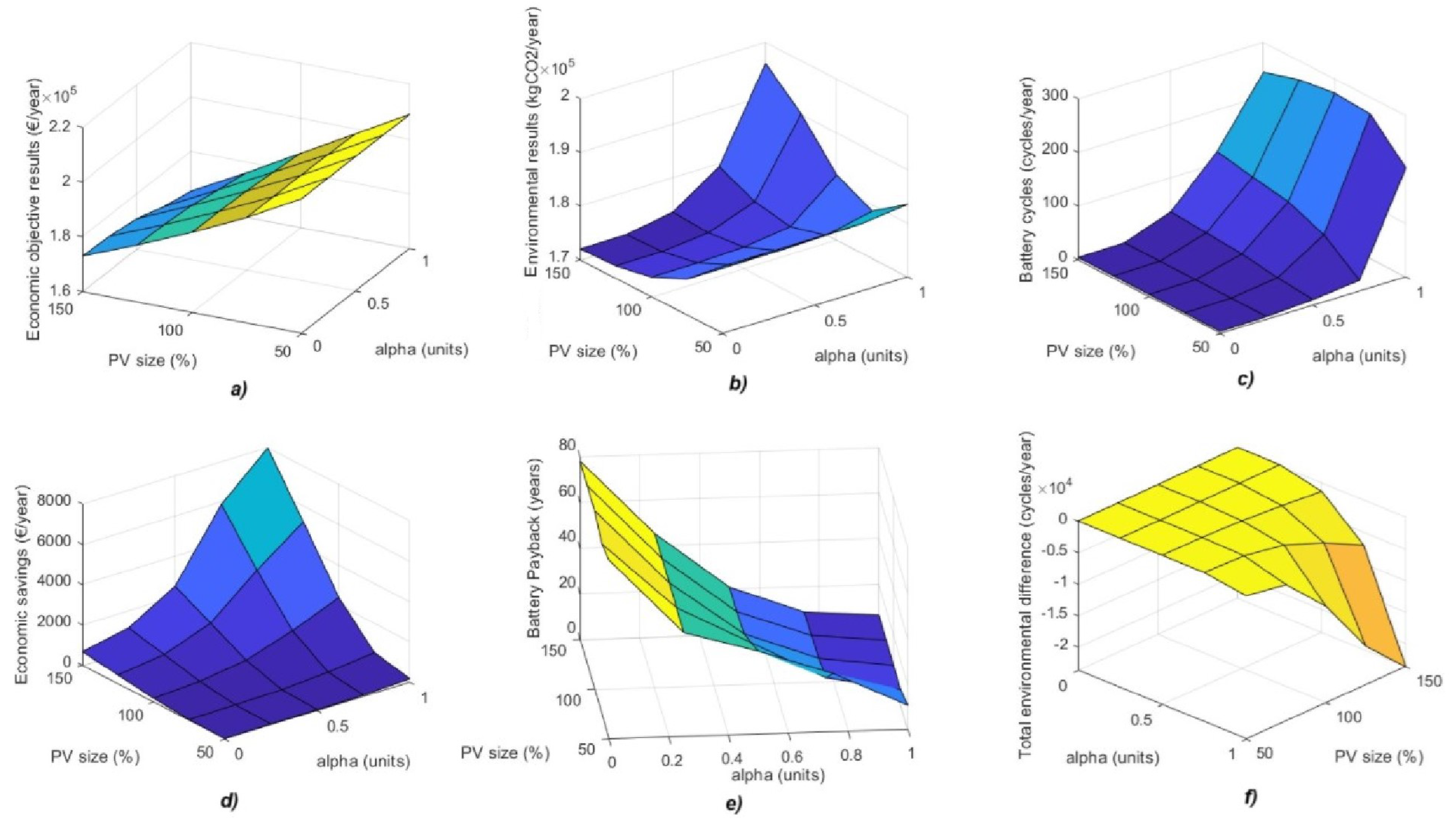

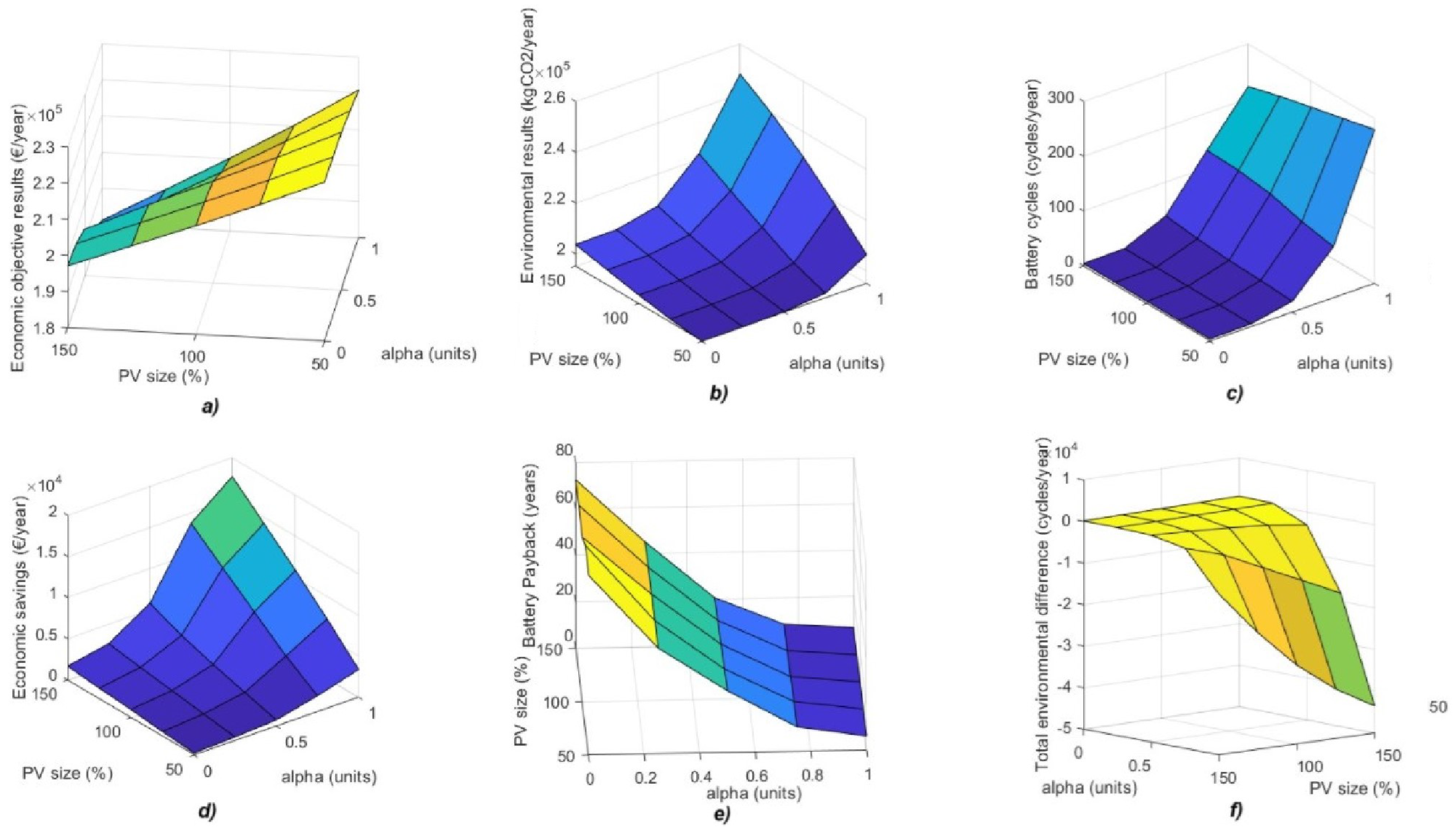

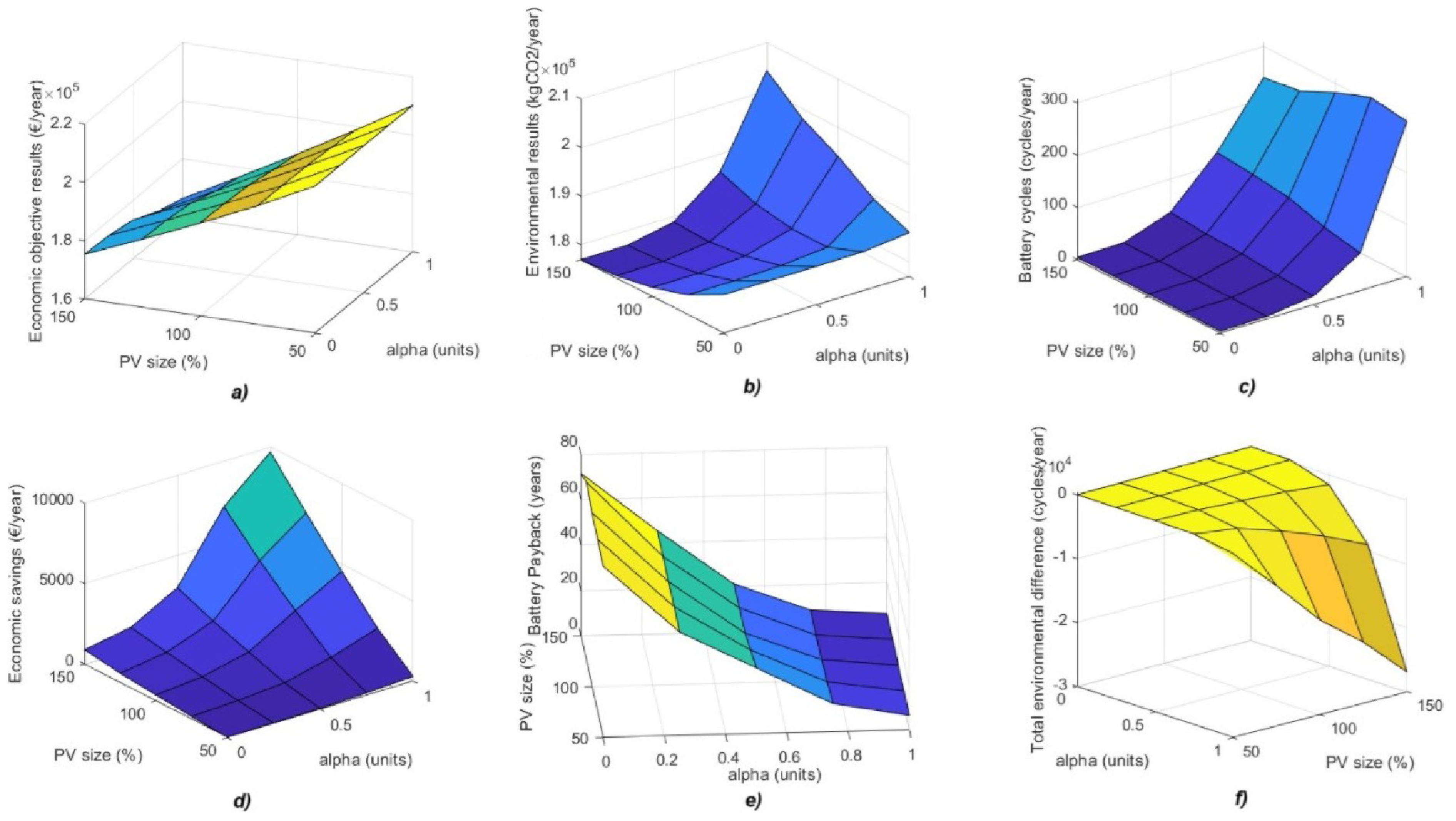

3.2. Sensitivity Analysis for Generalization

3.2.1. Methodology Overview

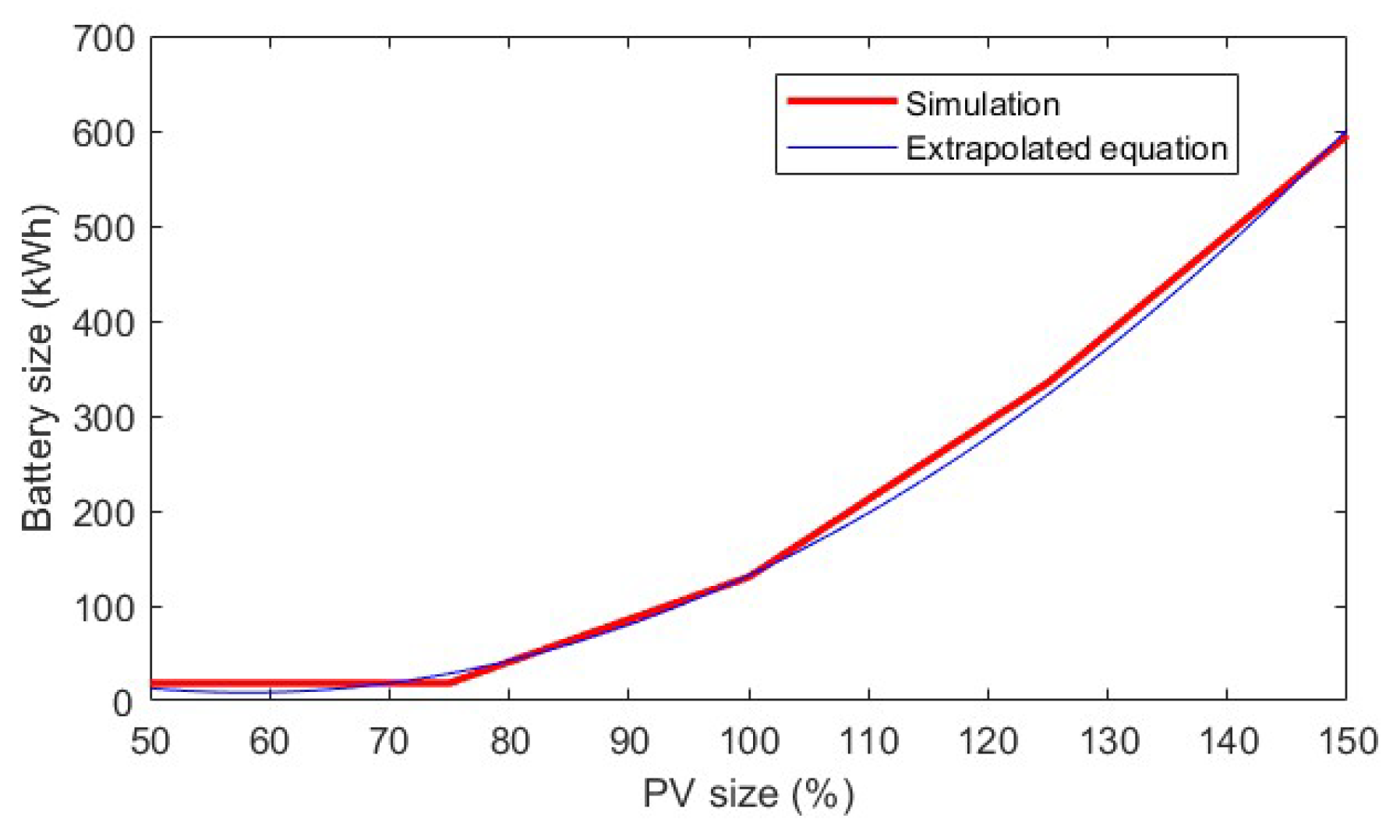

- Power of the PV installation. The power of the photovoltaic installation will range from large powers, corresponding to enterprises with a large surface area and investments in renewable energies, to small powers, corresponding to small enterprises that have not yet been able to invest in renewable energies. The battery pack size will be related to the PV size. The estimation of the SLB energy for the enterprise involves a multi-step process. Initially, using the PV generation from the input value and industrial consumption data, the total surplus energy for each day of the year is computed. Subsequently, the cumulative probability function of the annual surpluses will be plotted, as can be seen in the example in Figure 9. The battery capacity is determined based on the 60th percentile of the annual surplus of the cumulative probability function to optimize the battery pack. This method ensures that the battery can store most of the excess energy generated during high production periods while avoiding the high costs and inefficiencies associated with over-dimensioning for infrequent peaks or periods of low solar irradiance. By capturing and utilizing 60% of the surpluses, this approach balances cost-effectiveness with operational reliability, providing sufficient storage to maximize the use of renewable energy without significantly relying on grid energy.

- Economic criteria versus environmental criteria. Different scenarios will be created to reflect the enterprise’s policies of prioritizing economic versus environmental criteria, or vice versa. These scenarios will be represented by weight variables ( or ), indicating the level of prioritization given to each criterion. The selection of and values depends on the enterprise’s strategic priorities and regulatory environment. Companies prioritizing economic efficiency over environmental impact, focusing on cost reduction and pursuing fast payback periods, would apply > 0.75. In contrast, enterprises in sectors with strong environmental commitments may adopt an environmental policy strategy ( > 0.5), aiming to maximize CO2 reductions at the expense of longer payback periods. Hybrid approaches (0.5 ≤ ≤ 0.75) may be adopted by enterprises balancing financial constraints with social responsibility objectives, especially in regions with incentives for clean energy adoption.

- Industrial consumption type. The type of consumption profile may vary depending on the type of asset that the enterprise generates. This type of consumption profile may affect the appropriateness of incorporating an energy storage system. The following list defines the different types of enterprise consumption profiles that will be simulated to have this general representation.

- –

- Type A: Constant Consumption: These enterprises maintain a relatively consistent level of energy consumption throughout the day and across seasons. They do not exhibit significant consumption peaks during the day or night.

- –

- Type B: High Daytime Consumption: This type of enterprise exhibits high energy consumption during daylight hours and it significantly decreases during the nighttime.

- –

- Type C: High Nighttime Consumption: In contrast to Type A, these enterprises experience high energy consumption during nighttime.

- –

- Type D: Peak Consumption: Enterprises falling into this category have peak energy consumption periods that occur at specific times during the day or week. Outside these peaks, their energy consumption remains low.

3.2.2. Results of Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Environmental Agency, Datahub. Available online: https://www.eea.europa.eu/en/datahub (accessed on 14 February 2025).

- Naseri, F.; Gil, S.; Barbu, C.; Cetkin, E.; Yarimca, G.; Jensen, A.C.; Larsen, P.G.; Gomes, C. Digital twin of electric vehicle battery systems: Comprehensive review of the use cases, requirements, and platforms. Renew. Sustain. Energy Rev. 2023, 179, 113280. [Google Scholar] [CrossRef]

- Kodaira, D.; Jung, W.; Han, S. Optimal Energy Storage System Operation for Peak Reduction in a Distribution Network Using a Prediction Interval. IEEE Trans. Smart Grid 2020, 11, 2208–2217. [Google Scholar] [CrossRef]

- Koltermann, L.; Cortés, M.C.; Figgener, J.; Zurmühlen, S.; Sauer, D.U. Power curves of megawatt-scale battery storage technologies for frequency regulation and energy trading. Appl. Energy 2023, 347, 121428. [Google Scholar] [CrossRef]

- Borkowski, D.; Oramus, P.; Brzezinka, M. Battery energy storage system for grid-connected photovoltaic farm—Energy management strategy and sizing optimization algorithm. J. Energy Storage 2023, 72, 108201. [Google Scholar] [CrossRef]

- Colbertaldo, P.; Parolin, F.; Campanari, S. A comprehensive multi-node multi-vector multi-sector modelling framework to investigate integrated energy systems and assess decarbonisation needs. Energy Convers. Manag. 2023, 291, 117168. [Google Scholar] [CrossRef]

- Li, J.; Li, L.; Yang, R.; Jiao, J. Assessment of the lifecycle carbon emission and energy consumption of lithium-ion power batteries recycling: A systematic review and meta-analysis. J. Energy Storage 2023, 65, 107306. [Google Scholar] [CrossRef]

- Lai, X.; Qiao, D.; Zheng, Y.; Ouyang, M.; Han, X.; Zhou, L. A rapid screening and regrouping approach based on neural networks for large-scale retired lithium-ion cells in second-use applications. J. Clean. Prod. 2019, 213, 776–791. [Google Scholar] [CrossRef]

- Ran, A.; Zhou, Z.; Chen, S.; Nie, P.; Qian, K.; Li, Z.; Li, B.; Sun, H.; Kang, F.; Zhang, X.; et al. Data-Driven Fast Clustering of Second-Life Lithium-Ion Battery: Mechanism and Algorithm. Adv. Theory Simul. 2020, 3, 109. [Google Scholar] [CrossRef]

- Lee, K.; Kum, D. Development of cell selection framework for second-life cells with homogeneous properties. Int. J. Electr. Power Energy Syst. 2019, 105, 429–439. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Z.; Kang, Y.; Zhang, C.; Duan, B. A Quick Screening Approach Based on Fuzzy C-Means Algorithm for the Second Usage of Retired Lithium-Ion Batteries. IEEE Trans. Transp. Electr. 2021, 7, 474–484. [Google Scholar] [CrossRef]

- Jiang, T.; Sun, J.; Wang, T.; Tang, Y.; Chen, S.; Qiu, S.; Liu, X.; Lu, S.; Wu, X. Sorting and grouping optimization method for second-use batteries considering aging mechanism. J. Energy Storage 2021, 44, 103264. [Google Scholar] [CrossRef]

- Sitcharangsie, S. A systematic literature review of the life cycle assessment of electric vehicle components with a second use. In Proceedings of the 2022 International Conference on Data Analytics for Business and Industry (ICDABI), Sakhir, Bahrain, 25–26 October 2022; pp. 223–227. [Google Scholar]

- Li, J.; He, S.; Yang, Q.; Wei, Z.; Li, Y.; He, H. A Comprehensive Review of Second Life Batteries Towards Sustainable Mechanisms: Potential, Challenges, and Future Prospects. IEEE Trans. Transp. Electr. 2022, 9, 4824–4845. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, Y.; Luo, F.; Mu, Y. Hierarchical energy management for community microgrids with integration of second-life battery energy storage systems and photovoltaic solar energy. IET Energy Syst. Integr. 2022, 4, 206–219. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, R.; Zhou, C.; Kang, X.; Chen, Z. Digital twin and cloud-side-end collaboration for intelligent battery management system. J. Manuf. Syst. 2022, 62, 124–134. [Google Scholar] [CrossRef]

- Tanizawa, T.; Suzumiya, T.; Ikeda, K. Cloud-connected battery management system supporting e-mobility. Fujitsu Sci. Tech. J. 2015, 51, 27–35. [Google Scholar]

- Cheng, G.; Wei, W.; Liu, Z. Research on Intelligent Operation and Maintenance System of Battery Based on Digital Twin. In Proceedings of the 2021 2nd International Conference on Computer Engineering and Intelligent Control (ICCEIC), Chongqing, China, 12–14 November 2021; pp. 154–157. [Google Scholar]

- Soleymani, A.; Maltz, W. Real time prediction of Li-Ion battery pack temperatures in EV vehicles. In Proceedings of the International Electronic Packaging Technical Conference and Exhibition, Virtual, 27–29 October 2020; Volume 84041, pp. 1–8. [Google Scholar]

- Baumann, M.; Rohr, S.; Lienkamp, M. Cloud-connected battery management for decision making on second-life of electric vehicle batteries. In Proceedings of the 2018 Thirteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 10–12 April 2018; pp. 1–6. [Google Scholar]

- reLi Energy GmbH Website. Available online: https://www.relienergy.de/ (accessed on 14 February 2025).

- STMicroelectronics AutoDevKit. Available online: https://www.st.com/en/embedded-software/stsw-autodevkit.html (accessed on 14 February 2025).

- Shu, X.; Guo, Y.; Yang, W.; Wei, K.; Zhu, G. Life-cycle assessment of the environmental impact of the batteries used in pure electric passenger cars. Energy Rep. 2021, 7, 2302–2315. [Google Scholar] [CrossRef]

- Schneider, J.; Wolff, S.; Seidenfus, M.; Lienkamp, M. Sizing up sustainability: Influence of battery size and cell chemistry on battery-electric trucks’ life-cycle carbon emissions. Adv. Electr. Eng. Electron. Energy 2024, 9, 100656. [Google Scholar] [CrossRef]

- Cui, J.; Tan, Q.; Liu, L.; Li, J. Environmental Benefit Assessment of Second-Life Use of Electric Vehicle Lithium-Ion Batteries in Multiple Scenarios Considering Performance Degradation and Economic Value. Environ. Sci. Technol. 2023, 57, 8559–8567. [Google Scholar] [CrossRef] [PubMed]

- Kang, H.; Jung, S.; Kim, H.; An, J.; Hong, J.; Yeom, S.; Hong, T. Life-cycle environmental impacts of reused batteries of electric vehicles in buildings considering battery uncertainty. Renew. Sustain. Energy Rev. 2025, 207, 114936. [Google Scholar] [CrossRef]

- Silvestri, L.; Forcina, A.; Silvestri, C.; Arcese, G.; Falcone, D. Exploring the Environmental Benefits of an Open-Loop Circular Economy Strategy for Automotive Batteries in Industrial Applications. Energies 2024, 17, 1720. [Google Scholar] [CrossRef]

- Gharebaghi, M.; Rezaei, O.; Li, C.; Wang, Z.; Tang, Y. A Survey on Using Second-Life Batteries in Stationary Energy Storage Applications. Energies 2025, 18, 42. [Google Scholar] [CrossRef]

- Yucel, M.; Yucel, S. Environmental, Social, and Governance (ESG) Dynamics in the Energy Sector: Strategic Approaches for Sustainable Development. Energies 2024, 17, 6291. [Google Scholar] [CrossRef]

- Díaz-González, F.; Sumper, A.; Gomis-Bellmunt, O. Energy Storage in Power Systems; John Wiley & Sons: Barcelona, Spain, 2016. [Google Scholar]

- Plett, G.L. Battery Management Systems, Volume I: Battery Modeling; Artech House: Norwood, MA, USA, 2015. [Google Scholar]

- Plett, G.L. Battery Management Systems, Volume II: Equivalent-Circuit Methods; Artech House: Norwood, MA, USA, 2015. [Google Scholar]

- Jacob, A.S.; Banerjee, R.; Ghosh, P.C. Trade-off between end of life of battery and reliability in a photovoltaic system. J. Energy Storage 2020, 30, 101565. [Google Scholar] [CrossRef]

- Saravanan, C.; Srinivasan, K. Optimal Extraction of Photovoltaic Model Parameters Using Gravitational Search Algorithm Approach. Circuits Syst. 2016, 7, 3849–3861. [Google Scholar] [CrossRef][Green Version]

- Chellakhi, A.; El Beid, S.; Abouelmahjoub, Y. An improved adaptable step-size P&O MPPT approach for standalone photovoltaic systems with battery station. Simul. Model. Pract. Theory 2022, 121, 102655. [Google Scholar]

- ENF Solar. SUN2000-100KTL-M1 Huawei Technologies. Available online: https://www.enfsolar.com/pv/inverter-datasheet/12848 (accessed on 20 February 2025).

- Wang, M.; Xu, X.; Yan, Z.; Wang, H. An online optimization method for extracting parameters of multi-parameter PV module model based on adaptive Levenberg–Marquardt algorithm. Energy Convers. Manag. 2021, 245, 114611. [Google Scholar] [CrossRef]

- Red Eléctrica de España. ESIOS—Information System of the Electrical System. Available online: https://www.esios.ree.es/en (accessed on 5 June 2024).

- Red Eléctrica de España. Marginal Price Day Ahead Market. Available online: https://www.esios.ree.es/en/analysis/600?vis=1&start_date=09-11-2022T00%3A00&end_date=20-01-2023T23%3A55&compare_start_date=08-11-2022T00%3A00&groupby=hour&geoids=3 (accessed on 5 June 2024).

- Red Eléctrica de España. Daily D+1 Wind Forecast. Available online: https://www.esios.ree.es/es/analisis/1777?vis=1&start_date=10-09-2024T00%3A00&end_date=12-09-2024T23%3A55&compare_start_date=09-09-2024T00%3A00&groupby=hour (accessed on 5 June 2024).

- Red Eléctrica de España. Real Time Nuclear Generation. Available online: https://www.esios.ree.es/es/analisis/549?vis=1&start_date=10-09-2024T00%3A00&end_date=10-09-2024T23%3A55&compare_start_date=09-09-2024T00%3A00&groupby=minutes5 (accessed on 5 June 2024).

- Red Eléctrica de España. Real Time National Combined Cycle Generation. Available online: https://www.esios.ree.es/en/analysis/2041?vis=1&start_date=10-09-2024T00%3A00&end_date=10-09-2024T23%3A55&compare_start_date=09-09-2024T00%3A00&groupby=minutes5 (accessed on 5 June 2024).

- Red Eléctrica de España. CO2 Free Generation. Available online: https://www.esios.ree.es/es/analisis/10006?vis=1&start_date=10-09-2024T00%3A00&end_date=10-09-2024T23%3A55&compare_start_date=09-09-2024T00%3A00&groupby=minutes5 (accessed on 5 June 2024).

- Red Eléctrica de España. Daily D+1 Demand Forecast. Available online: https://www.esios.ree.es/es/analisis/1775?vis=1&start_date=10-09-2024T00%3A00&end_date=12-09-2024T23%3A55&compare_start_date=09-09-2024T00%3A00&groupby=hour (accessed on 5 June 2024).

- Red Eléctrica de España. Forecast of Residual Demand. Available online: https://www.esios.ree.es/es/analisis/10249?vis=1&start_date=10-09-2024T00%3A00&end_date=12-09-2024T23%3A55&compare_start_date=09-09-2024T00%3A00&groupby=minutes15 (accessed on 5 June 2024).

- Saniuk, S.; Rokicki, T.; Milewski, D.; Xing, X.; Cong, Y.; Wang, Y.; Wang, X. The Impact of COVID-19 and War in Ukraine on Energy Prices of Oil and Natural Gas. Sustainability 2023, 15, 14208. [Google Scholar] [CrossRef]

- Sen, P.; Roy, M.; Pal, P. Application of ARIMA for forecasting energy consumption and GHG emission: A case study of an Indian pig iron manufacturing organization. Energy 2016, 116, 1031–1038. [Google Scholar] [CrossRef]

- MathWorks. ARIMA Models in MATLAB. Available online: https://es.mathworks.com/help/econ/arima.html (accessed on 14 February 2025).

- MathWorks. Forecast Method for Time Series Model. Available online: https://es.mathworks.com/help/ident/ref/idmodel.forecast.html (accessed on 14 February 2025).

- Kamath, D.; Shukla, S.; Arsenault, R.; Kim, H.C.; Anctil, A. Evaluating the cost and carbon footprint of second-life electric vehicle batteries in residential and utility-level applications. Waste Manag. 2020, 113, 497–507. [Google Scholar] [CrossRef]

- Wrålsen, B.; O’Born, R. Use of life cycle assessment to evaluate circular economy business models in the case of Li-ion battery remanufacturing. Int. J. Life Cycle Assess. 2023, 28, 554–565. [Google Scholar] [CrossRef]

- Merchante, L.F.S.; Clar, D.; Carnicero, A.; Lopez-Valdes, F.J.; Jimenez-Octavio, J.R. Real-time CO2 emissions estimation in Spain and application to the COVID-19 pandemic. J. Clean. Prod. 2021, 296, 126425. [Google Scholar] [CrossRef] [PubMed]

- Stamford, L.; Azapagic, A. Environmental Impacts of Photovoltaics: The Effects of Technological Improvements and Transfer of Manufacturing from Europe to China. Energy Technol. 2018, 6, 1148–1160. [Google Scholar] [CrossRef]

- Nordin, A.H.M.; Sulaiman, S.I.; Shaari, S. Life cycle impact of photovoltaic module degradation on energy and environmental metrics. Energy Rep. 2022, 8, 923–931. [Google Scholar] [CrossRef]

- European Commission. Joint Research Centre. Photovoltaic Geographical Information System (PVGIS). Available online: https://re.jrc.ec.europa.eu/pvg_tools/es/ (accessed on 14 February 2025).

| Typology | Feature | Source |

|---|---|---|

| Calendar | Hour of the day, work day. | [38] |

| Target Variable Lags | Electricity price shifted by 24, 48, 72, 96, and 168 h. | [39] |

| Electricity generation mix | Wind, nuclear, combined-cycle gas turbine, emission-free generation percentage. | [40,41,42,43] |

| Electricity demand | System predicted demand, System residual demand. | [44,45] |

| Period | MAE | RMSE | |

|---|---|---|---|

| January–March | 28.17 | 40.11 | 0.71 |

| April–June | 23.13 | 33.11 | 0.57 |

| July–September | 19.01 | 25.28 | 0.57 |

| October–December | 20.43 | 26.77 | 0.70 |

| Generation | GWP Range | Median GWP | References |

|---|---|---|---|

| 0.0706–1.4 | 0.14 | [50,51] | |

| 0.013–0.19 | 0.042 | [53,54] |

| Consumption | |

|---|---|

| Electric trucks, gas-powered trucks, | ∼300 kW averaged |

| EV charging points, gas compression points, | |

| and office assets power () | |

| Annual energy consumption () | 2570 MWh |

| Generation | |

| PV installation () | 333 kWp |

| PV inverter power () | 100 kW |

| Number of PV inverters in parallel () | 3 units |

| Annual PV energy generated () | 310 MWh |

| Energy storage system | |

| Capacity () | 166 kWh |

| Power () | 191 kW |

| Cells in series () | 76 |

| Cells in parallel () | 8 |

| Maximum battery voltage () | 304 V |

| Minimum battery voltage () | 212.8 V |

| Rated battery voltage () | 250.2 V |

| Maximum battery current () | 720 A |

| SLB price per kWh () | 90 EUR/kWh |

| SLB price per kWh () | 14,955 EUR |

| Remaining battery cycles () | 1000 cycles |

| Simulation without battery | |

| Objective function: Economic term () | 189.44k EUR/year |

| Economic savings () | 1439 EUR/year |

| Battery cycles () | 97.85 equivalent complete |

| cycles per year | |

| Battery payback (PB) | 4.1 years |

| Objective function: Environmental | 175.13 tones·CO2/year |

| term () | |

| Simulation without battery | |

| Objective function: Environmental | 173.74 tones·CO2/year |

| term () | |

| Environmental impact () | −1393 kg·CO2/year |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borrego-Orpinell, G.; Forero, J.-F.; Caprara, A.; Díaz-González, F. Impact Assessment of Second-Life Batteries and Local Photovoltaics for Decarbonizing Enterprises Through System Digitalization and Energy Management. Energies 2025, 18, 1198. https://doi.org/10.3390/en18051198

Borrego-Orpinell G, Forero J-F, Caprara A, Díaz-González F. Impact Assessment of Second-Life Batteries and Local Photovoltaics for Decarbonizing Enterprises Through System Digitalization and Energy Management. Energies. 2025; 18(5):1198. https://doi.org/10.3390/en18051198

Chicago/Turabian StyleBorrego-Orpinell, Gerard, Jose-Fernando Forero, Adriano Caprara, and Francisco Díaz-González. 2025. "Impact Assessment of Second-Life Batteries and Local Photovoltaics for Decarbonizing Enterprises Through System Digitalization and Energy Management" Energies 18, no. 5: 1198. https://doi.org/10.3390/en18051198

APA StyleBorrego-Orpinell, G., Forero, J.-F., Caprara, A., & Díaz-González, F. (2025). Impact Assessment of Second-Life Batteries and Local Photovoltaics for Decarbonizing Enterprises Through System Digitalization and Energy Management. Energies, 18(5), 1198. https://doi.org/10.3390/en18051198