Enhanced Oil Recovery Mechanism Mediated by Reduced Miscibility Pressure Using Hydrocarbon-Degrading Bacteria During CO2 Flooding in Tight Oil Reservoirs

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Efficiency of PHDB Degradation of Crude Oil

2.3. Impact of PHDB on MMP

2.4. Core Displacement Tests to Evaluate the EOR

2.5. Analysis Methods and Calculations

3. Results and Discussion

3.1. Efficiency of Crude Oil Degradation by PHDB

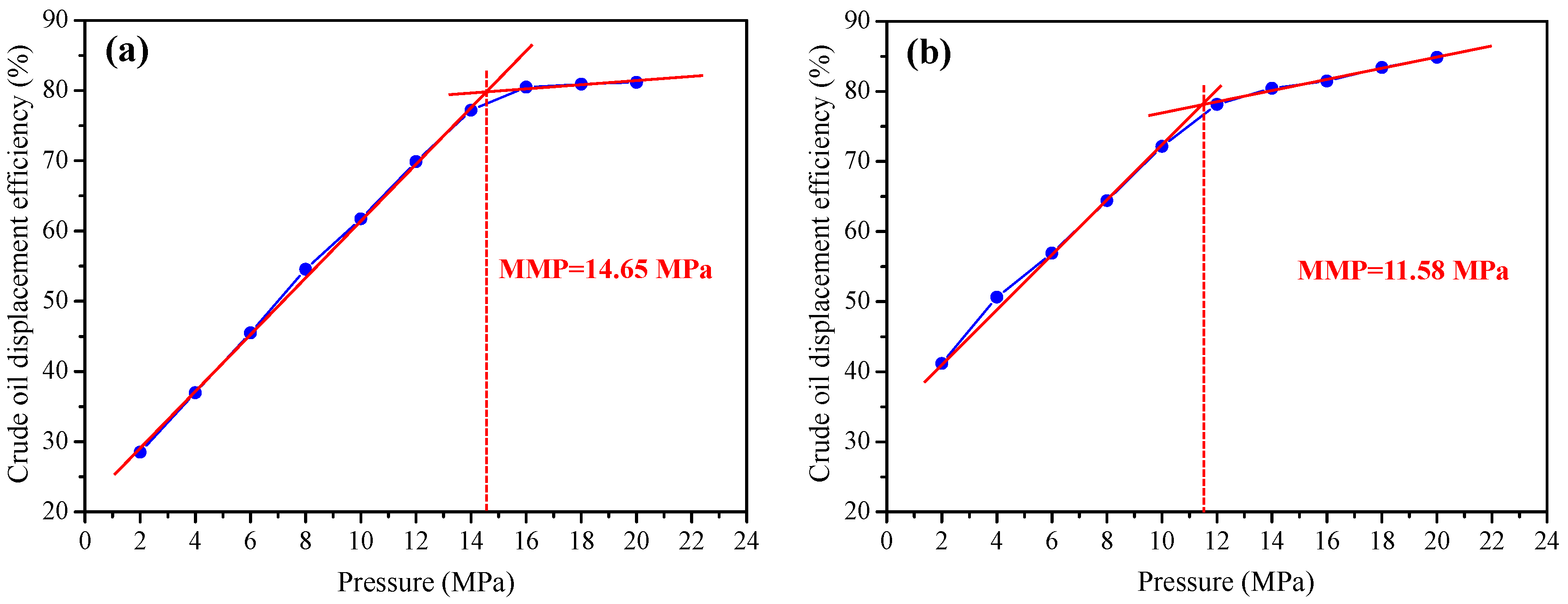

3.2. Evaluation of MMP Reduction by PHDB

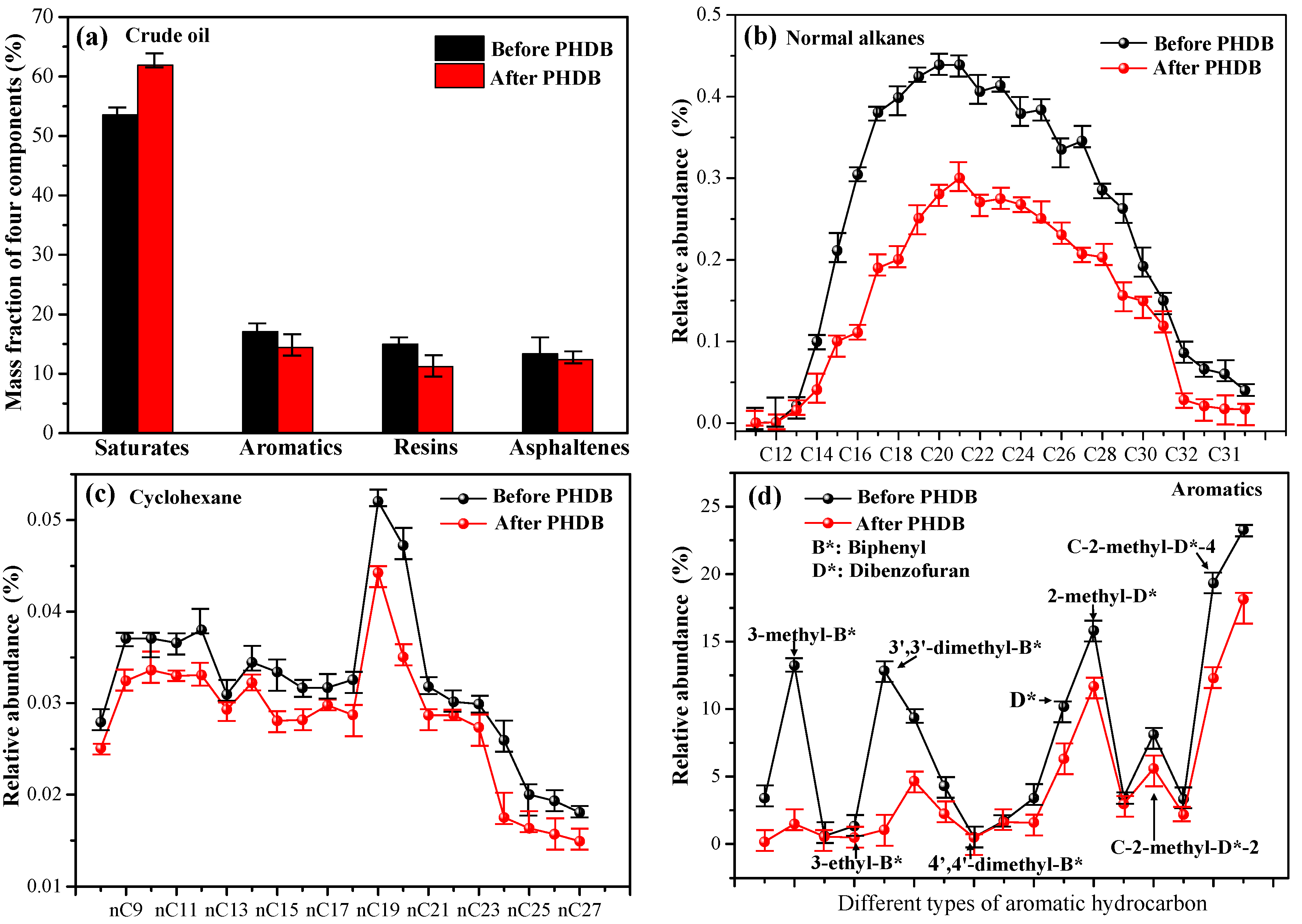

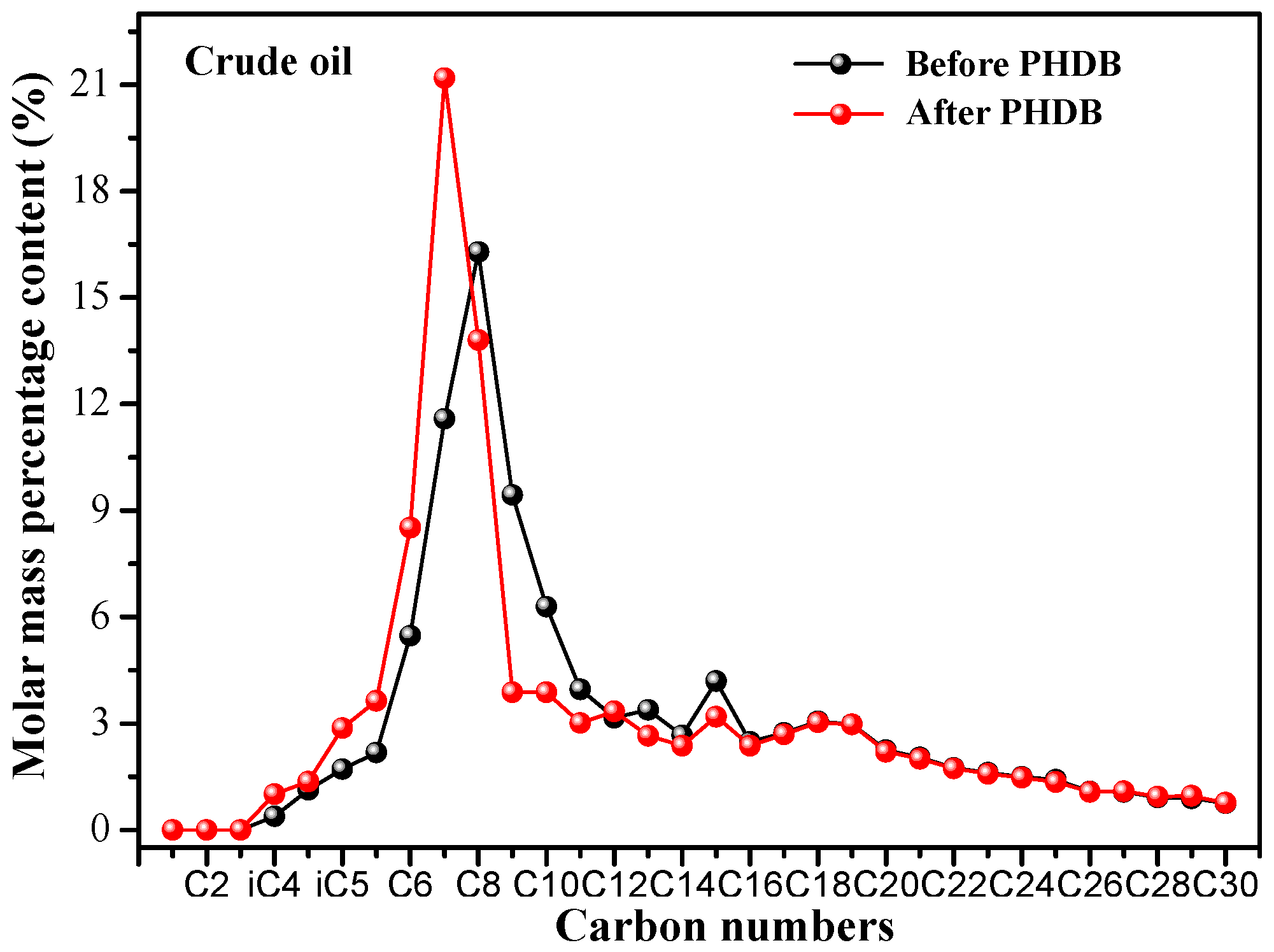

3.3. Change in Crude Oil Composition by PHDB

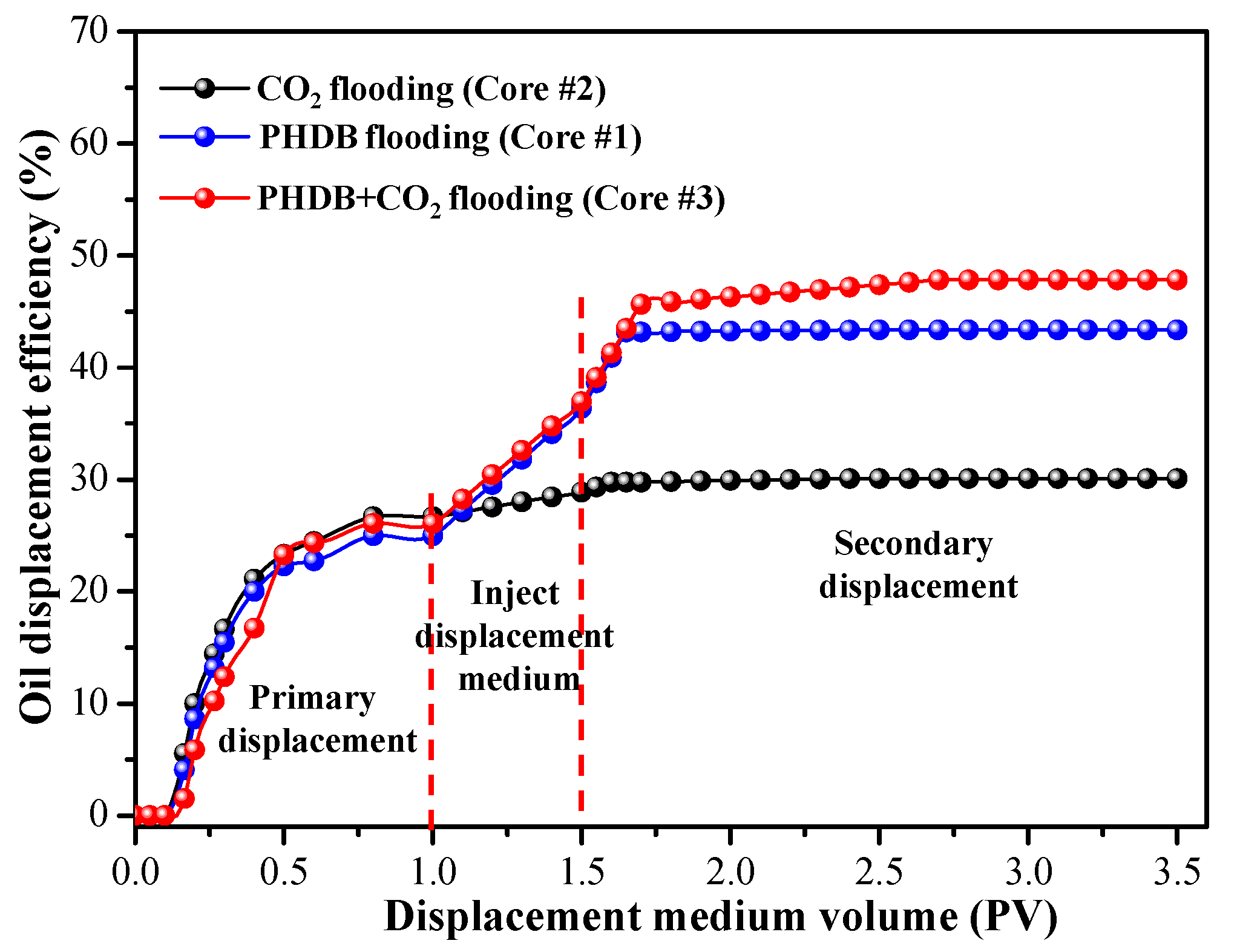

3.4. EOR by PHDB-Enhanced CO2 Flooding

3.5. Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PHDB | Petroleum hydrocarbon-degrading bacteria |

| MMP | Minimum miscibility pressure |

| EOR | Enhanced oil recovery |

| GC-MS | Gas chromatography-mass spectrometry |

| PV | Pore volume |

References

- Liu, K.; He, H.; Yin, D.Y. Theoretical and experimental study on the long-term conductivity of heterogeneous artificial fractures in tight reservoirs. Energy Rep. 2023, 9, 3881–3895. [Google Scholar] [CrossRef]

- Yuan, S.Y. CCUS is the most feasible low-carbon development technology for fossil fuels: Written in the release of “China’s carbon capture, utilization and storage technical evaluation report”. China Sustain. Trib. 2022, 5, 35–37. [Google Scholar]

- Kim, J.M.; Kim, S.Y.; Bae, J.; Shinn, Y.J.; Ahn, E.; Lee, J.W. Analysis of patent trends on the CCUS technologies. Econ. Environ. Geol. 2020, 53, 13–18. [Google Scholar]

- Li, Q.; Li, Q.; Cao, H.; Wu, J.; Wang, F.; Wang, Y. The crack propagation behaviour of CO2 fracturing fluid in unconventional low permeability reservoirs: Factor analysis and mechanism revelation. Processes 2025, 13, 159. [Google Scholar] [CrossRef]

- Wang, T.F.; Wang, L.L.; Meng, X.B.; Chen, Y.; Song, W.; Yuan, C. Key parameters and dominant EOR mechanism of CO2 miscible flooding applied in low-permeability oil reservoirs. Geoenergy Sci. Eng. 2023, 225, 211724. [Google Scholar] [CrossRef]

- Bachu, S. Identification of oil reservoirs suitable for CO2-EOR and CO2 storage (CCUS) using reserves databases, with application to Alberta Canada. Int. J. Greenh. Gas Control. 2016, 44, 152–165. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, J.H.; Zhang, X. A comprehensive review of minimum miscibility pressure determination and reduction strategies between CO2 and crude oil in CCUS processes. Fuel 2025, 235, 134053. [Google Scholar] [CrossRef]

- Cheng, X.L.; Han, H.B.; Li, S.; Yu, H.W. Microscopic characteristics of residual oil indeed-end pores initiated by CO2. Pet. Geol. Recovery Efficie 2020, 27, 50–56. [Google Scholar]

- Han, H.; Li, S.; Chen, X.; Qin, J.; Zeng, B. Main control factors of carbon dioxide on the swelling effect of crude hydrocarbon components. Acta Pet. Sin. 2016, 37, 392–398. [Google Scholar]

- Idem, R.O.; Ibrahim, H.H. Kinetics of CO2-induced asphaltene precipitation from various Saskatchewan crude oils during CO2 miscible flooding. J. Pet. Sci. Eng. 2002, 35, 233–246. [Google Scholar] [CrossRef]

- Orr, F.M.; Silva, M.K. Effect of Oil Composition on Minimum Miscibility Pressure Part 2: Correlation. SPE 1987, 2, 479–491. [Google Scholar] [CrossRef]

- Xi, C.F.; Wang, B.J.; Zhao, F.; Liu, T.; Qi, Z.; Zhang, X.; Tang, J.; Jiang, Y.; Guan, W.; Wang, H.; et al. Oxidization characteristics and thermal miscible flooding of high pressure air injection in light oil reservoirs. Pet. Explor. Dev. 2020, 49, 874–885. [Google Scholar] [CrossRef]

- Xue, L.; Zhang, J.; Chen, G.; Wang, X.; Huang, X.; Li, X.; Wang, Y.; Lu, J. Enhance oil recovery by carbonized water flooding in tight oil reservoirs. Geoenergy Sci. Eng. 2025, 244, 213430. [Google Scholar] [CrossRef]

- Li, G.J.; Fu, M.L.; Hu, J.N.; Lu, S.; Meng, F. Study of thickened CO2 flooding for enhancing oil recovery in Low-Permeability sandstone reservoirs. Fuel 2025, 385, 134148. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Liao, P.L.; Ma, C. A convenient and visualized method to estimate CO2 miscible flooding assistantrising height test and its applications in oilfield chemistry. Oilfield Chem. 2020, 37, 525–530. [Google Scholar]

- Rathmell, J.J.; Stalkup, F.I.; Hassinger, R.C. A laboratory investigation of miscible displacement by carbon dioxide. In Proceedings of the Fall Meeting of The Society of Petroleum Engineers of AIME, New Orleans, LA, USA, 3 October 1971; Society of Petroleum Engineers: Richardson, TX, USA, 1971. [Google Scholar]

- Alston, R.B.; Kokolis, G.P.; James, C.F. CO2 minimum miscibility pressures: A correlation for impure CO2 streams and live oil systems. SPE J. 1985, 25, 268–274. [Google Scholar] [CrossRef]

- Wang, C.J.; Gao, R.M.; Zhao, L. A Method for Reducing the Minimum Miscibility Pressure of CO2 Flooding by Using Microbial Hydrocarbon-Degrading Bacteria. CN107435052A, 5 December 2017. [Google Scholar]

- Zhang, J.; Fang, T.M.; Wang, Y.F.; Wang, L.; Shen, Y.; Liu, B. Molecular dynamics simulation of dissolution of n-alkanes droplets in supereritical carbon dioxide. J. China Univ. Pet. (Ed. Nat. Sci.) 2015, 39, 124–129. [Google Scholar]

- Han, B.; Zhai, Z.W.; Yu, W.D.; Li, K.C.; Ma, X.Q.; Cao, S.W.; Shi, Y.; Bao, X.; Huang, F.; Ren, S.R. Dynamic analysis of minimum miscibility pressure during CO2 flooding reservoirs and its influencing factors. Unconv. Oil Gas 2022, 9, 98–104. [Google Scholar]

- Xu, X.M.; Gui, X.; Zhi, Y. Effects of condensate oil on reducing the minimum miscible pressure of CO2 flooding. J. Naning Tech Univ. (Nat. Sci. Ed.) 2021, 43, 706–712. [Google Scholar]

- Zhu, H.Y.; Li, Y.; Zhou, D.; Xu, Q.Q.; Yin, J.Z. Molecular dynamics study on microstructure of supercritical CO2 microemulsions containing ionic liquids. Colloids Surf. A Physicochem. Eng. Asp. 2020, 603, 125272. [Google Scholar] [CrossRef]

- Lu, H.S.; Gao, Y.; Shan, J.T.; Lei, G.M.; Zhang, Y.L.; Zhang, G.C.; Ye, Z.B. Experimental researches on factors influencing supercritical CO2 extraction effect of crude oil from tight sandy conglomerate. Pet. Reserv. Eval. Dev. 2021, 11, 845–851. [Google Scholar]

- Cui, K.; Zhang, Z.; Zhang, Z.; Sun, S.; Li, H.; Fu, P. Stimulation of indigenous microbes by optimizing the water cut in low permeability reservoirs for green and enhanced oil recovery. Sci. Rep. 2019, 9, 15772–15784. [Google Scholar] [CrossRef] [PubMed]

- Das, K.; Mukherjee, A.K. Crude petroleum-oil biodegradation efficiency of Bacillus subtilis and Pseudomonas aeruginosa strains isolated from a petroleum-oil contaminated soil from North-East India. Bioresour. Technol. 2007, 98, 1339–1345. [Google Scholar] [CrossRef]

- Kostka, J.E.; Prakash, O.; Overholt, W.A.; Green, S.J.; Freyer, G.; Canion, A.; Delgardio, J.; Norton, N.; Hazen, T.C.; Huettel, M. Hydrocarbon-degrading bacteria and the bacterial community response in gulf of Mexico beach sands impacted by the deepwater horizon oil spill. Appl. Environ. Microbiol. 2011, 77, 7962–7974. [Google Scholar] [CrossRef] [PubMed]

- Vieth, A.; Wilkes, H. Deciphering biodegradation effects on light hydrocarbons in crude oils using their stable carbon isotopic composition: A case study from the Gullfaks oil field, offshore Norway. Geochim. Cosmochim. Acta 2006, 70, 651–665. [Google Scholar] [CrossRef]

- Ke, C.; Sun, W.; Li, Y.; Lu, G.M.; Zhang, Q.Z.; Zhang, X.L. Microbial enhanced oil recovery in Baolige Oilfield using an indigenous facultative anaerobic strain Luteimonas huabeiensis sp. Nov. J. Petrol. Sci. Eng. 2018, 167, 160–167. [Google Scholar] [CrossRef]

- Brown, L.R. Microbial enhanced oil recovery (MEOR). Curr. Opin. Microbiol. 2010, 13, 316–320. [Google Scholar] [CrossRef]

- Patel, J.; Borgohain, S.; Kumar, M.; Rangarajan, V.; Somasundaran, P.; Sen, R. Recent developments in microbial enhanced oil recovery. Renew. Sustain. Energy Rev. 2015, 52, 1539–1558. [Google Scholar] [CrossRef]

- Fu, X.G.; Xue, J.L.; Chen, C.; Bai, Y.; Qiao, Y.-L.; Liu, Y.-X.; Hu, X.-M.; Gao, Y.; Yu, H. Systematic adsorption process of petroleum hydrocarbon by immobilised petroleum-degradation bacteria system in degradation pathways. Pet. Sci. 2021, 18, 1543–1550. [Google Scholar] [CrossRef]

- Das, S.; Das, N.; Choure, K.; Pandey, P. Biodegradation of asphaltene by lipopeptide-biosurfactant producing hydrocarbonoclastic, crude oil degrading Bacillus spp. Bioresour. Technol. 2023, 382, 129198. [Google Scholar] [CrossRef]

- Cui, K.; Wang, C.J.; Li, L.; Zou, J.; Huang, W.; Zhang, Z.; Wang, H.; Guo, K. Controlling the hydro-Swelling of smectite clay minerals by Fe(III) reducing bacteria for enhanced oil recovery from low-permeability reservoirs. Energies 2022, 15, 4393. [Google Scholar] [CrossRef]

- SY/T 6573-2016; Experimental Determination Method of Minimum Miscible Pressure-Capillary Method. Petroleum Industry Press: Beijing, China, 2016.

- Wang, X.B.; Chi, C.Q.; Nie, Y.; Tang, Y.-Q.; Tan, Y.; Wu, G.; Wu, X.-L. Degradation of petroleum hydrocarbons (C6–C40) and crude oil by a novel Dietzia strain. Bioresour. Technol. 2011, 102, 7755–7761. [Google Scholar] [CrossRef] [PubMed]

- Li, H.L.; Lai, R.Q.; Jin, Y.L.; Fang, X.; Cui, K.; Sun, S.; Gong, Y.; Li, H.; Zhang, Z.; Zhang, G.; et al. Directional culture of petroleum hydrocarbon degrading bacteria for enhancing crude oil recovery. J. Hazard. Mater. 2020, 390, 122160–122170. [Google Scholar] [CrossRef] [PubMed]

- Abedini, A.; Mosavat, N.; Torabi, F. Determination of minimum miscibility pressure of crude oil-CO2 system by oil swelling/extraction Test. Energy Technol. 2014, 2, 431–439. [Google Scholar] [CrossRef]

- Zhao, S.A.; Pu, W.F.; Li, Y.B.; Jiang, Q. Low-temperature oxidation characteristics and reaction pathways of crude oil within tight shale during air injection. Petroleum 2023, 27, 2405–6561. [Google Scholar] [CrossRef]

- Gao, Y.W.; Wang, W.B.; Jiang, S.J.; Jin, Z.; Guo, M.; Wang, M.; Li, H.; Cui, K. Response Characteristics of the Community Structure and MetabolicGenes of Oil-Recovery Bacteria after Targeted Activation of Petroleum Hydrocarbon-Degrading Bacteria in Low-Permeability Oil Reservoirs. ACS Omega 2024, 9, 33448–33458. [Google Scholar] [CrossRef]

- Yang, Z.H.; Wu, W.; Dong, Z.X.; Lin, M.; Zhang, S.; Zhang, J. Reducing the minimum miscibility pressure of CO2 and crude oil using alcohols. Colloids Suf. A 2019, 568, 105–112. [Google Scholar] [CrossRef]

- Yang, Y.; Zhao, S.M.; Cao, X.P.; Lyu, Q.; Lyu, G.; Zhang, C.; Li, Z.; Zhang, D.; Zheng, W. CO2 high-pressure miscible flooding and storage technology and its application in Shengli Oilfield, China. Pet. Explor. Dev. 2024, 51, 1247–1260. [Google Scholar] [CrossRef]

- Pal Østebø, A. Carbon capture utilization and storage (CCUS) in tight gas and oil reservoirs. J. Nat. Gas Sci. Eng. 2020, 81, 13235. [Google Scholar]

- Chen, J.; Li, T.; Wu, S. Influence of pressure and CO2 content on the asphaltene precipitation and oil recovery during CO2 flooding. Pet. Sci. Technol. 2018, 36, 1–6. [Google Scholar] [CrossRef]

- Li, F.; Gao, X.Q.; Du, J.; Lin, L.; Hou, D.; Luo, J.; Zhao, J. Microscopic mechanism of enhancing shale oil recovery through CO2 flooding-insights from molecular dynamics simulations. J. Mol. Liq. 2024, 410, 125593. [Google Scholar] [CrossRef]

- Zhao, H.F.; Liu, C.D. Research on the mechanism of CO2 miscible flooding and the minimum miscibility pressure. China Pet. Chem. Stand. Qual. 2016, 36, 95–98. [Google Scholar]

- Kumar, N.; Sampaio, M.A.; Ojha, K.; Hoteit, H.; Mandal, A. Fundamental aspects, mechanisms and emerging possibilities of CO2 miscible flooding in enhanced oil recovery: A review. Fuel 2022, 330, 125633. [Google Scholar] [CrossRef]

| Core Number | Pretreatment | Injection Medium | Displacement Medium | Displacement Tests | Objectives |

|---|---|---|---|---|---|

| #1 | Crude oil | Water flooding (7% PHDB) | Water | PHDB flooding | Experimental control |

| #2 | Crude oil | Water flooding (without PHDB) | CO2 | CO2 flooding | CO2 flooding control |

| #3 | Crude oil | Water flooding (7% PHDB) | CO2 | PHDB + CO2 flooding | EOR of PHDB enhanced CO2 flooding |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Li, X.; Xia, J.; Ni, J.; Wang, W.; Jin, G.; Cui, K. Enhanced Oil Recovery Mechanism Mediated by Reduced Miscibility Pressure Using Hydrocarbon-Degrading Bacteria During CO2 Flooding in Tight Oil Reservoirs. Energies 2025, 18, 1123. https://doi.org/10.3390/en18051123

Wang C, Li X, Xia J, Ni J, Wang W, Jin G, Cui K. Enhanced Oil Recovery Mechanism Mediated by Reduced Miscibility Pressure Using Hydrocarbon-Degrading Bacteria During CO2 Flooding in Tight Oil Reservoirs. Energies. 2025; 18(5):1123. https://doi.org/10.3390/en18051123

Chicago/Turabian StyleWang, Chengjun, Xinxin Li, Juan Xia, Jun Ni, Weibo Wang, Ge Jin, and Kai Cui. 2025. "Enhanced Oil Recovery Mechanism Mediated by Reduced Miscibility Pressure Using Hydrocarbon-Degrading Bacteria During CO2 Flooding in Tight Oil Reservoirs" Energies 18, no. 5: 1123. https://doi.org/10.3390/en18051123

APA StyleWang, C., Li, X., Xia, J., Ni, J., Wang, W., Jin, G., & Cui, K. (2025). Enhanced Oil Recovery Mechanism Mediated by Reduced Miscibility Pressure Using Hydrocarbon-Degrading Bacteria During CO2 Flooding in Tight Oil Reservoirs. Energies, 18(5), 1123. https://doi.org/10.3390/en18051123