Abstract

The energy efficiency of water treatment plants (WTPs) plays a key role in the sustainable management of water resources. In the face of increasing water demand, climate change, and increasingly stringent environmental regulations, optimising the energy consumption of treatment processes is becoming a priority for water system operators and decision-makers alike. Water treatment plants, depending on the type of water source served (groundwater, infiltration, surface water), vary considerably in terms of their technological design, which directly affects their energy efficiency and operating costs. According to the International Water Association, the water sector accounts for approximately 4% of global electricity consumption, a significant proportion of which is consumed by water treatment and distribution processes. Electricity is used in many process steps, such as water pumping, aeration, filtration, disinfection, and filter flushing. The energy consumption of a System for Upgrading Water (SUW) depends not only on the quality of taken raw water, but also on the size of the station, used technologies, and operation organisation. This study shows that implementing high-efficiency pumping systems and AI-based optimisation can reduce energy consumption in WTPs by 20–30%. The introduction of membrane filtration in surface water plants has demonstrated a reduction in energy use by up to 50%, while the use of biogas from sludge treatment has cut external energy demand by 15–25%. The results emphasise the potential to reduce CO2 emissions by 10–20% compared to conventional treatment methods. However, achieving significant reductions in energy consumption in SUW requires a comprehensive understanding of the diversity of water facilities, technological processes, and specific energy requirements.

1. Introduction

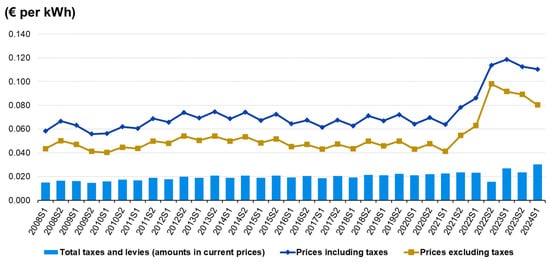

Energy efficiency in water treatment plants (WTPs) plays a key role in the context of rising energy costs, pressure to reduce carbon dioxide emissions, and increasing water demand (Figure 1, Figure 2 and Figure 3). Since the beginning of the 21st century, there has been a significant increase in electricity prices in Europe. Between 2000 and 2024, electricity prices for households in the European Union (EU) have increased, on average, by 70%, from around EUR 0.12/kWh in 2000 to EUR 0.20/kWh in 2024 [1,2,3,4,5,6].

In Poland, this increase was even more pronounced; electricity prices for households rose by around 80% over the same period, reaching EUR 0.18/kWh in 2024. The increase in energy prices has a direct impact on the operational costs of WTPs, where electricity accounts for a significant share of total operating costs. In some cases, energy costs can account for up to 30–40% of the total operating costs of a water treatment plant. Improving energy efficiency therefore becomes a key element of the System for Upgrading Water (SUW) cost-management strategy [7,8,9].

Figure 1.

Energy prices in European Union 2008–2024. S1: first half of the year, S2: second half of the year. Source: own study based on [10].

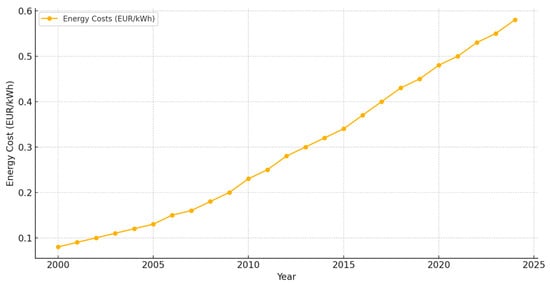

Figure 2 shows the development of electricity costs for water treatment plants (WTPs) over the period of 2000–2024. Since 2000, energy costs have increased from EUR 0.08/kWh to EUR 0.58/kWh in 2024, a sevenfold increase over the period under review. A clear accelerated increase in energy costs has been observed since 2010, linked to global trends of rising energy commodity prices and increased energy demand. The energy crisis of 2020–2022 has further exacerbated this trend, with rising energy prices in 2024 putting SUW in a position to improve energy efficiency [7,9].

Figure 2.

Trends in energy costs for Systems for Upgrading Water 2000–2024. Source: own study based on [10].

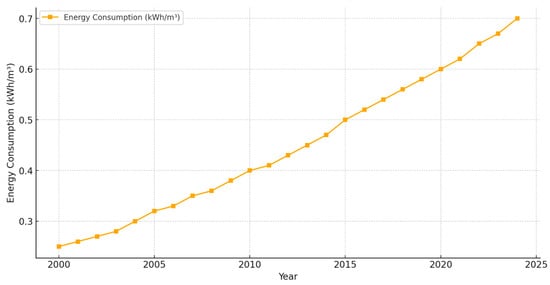

Energy consumption per cubic metre of treated water at the WTP is shown in Figure 3. Energy consumption values have increased from 0.25 kWh/m3 in 2000 to 0.7 kWh/m3 in 2024. This trend is driven by the increasing complexity of technological processes, especially in surface water treatment plants, and the introduction of advanced membrane and disinfection technologies [11,12]. Despite the increase in device efficiency, higher water quality requirements and increased raw water pollution require more energy-intensive processes. Comparing the two charts, we can see that the increase in energy costs and the increase in energy demand overlap, compounding the pressure to optimise WTP processes. Introducing innovative technologies and implementing energy management strategies are key to reducing operating costs and ensuring the future sustainability of water treatment systems [4,5,6].

Figure 3.

Trends in energy consumption in water treatment plants (2000–2024). Source: own study based on [10].

2. Methodology: Data Sources, Validation, and Limitations

The data presented in this study, including figures on energy consumption trends, CO2 emissions from water treatment plants, and efficiency improvements from technological interventions, originate from a combination of primary and secondary sources. To ensure the validity and accuracy of the presented findings, multiple datasets were analysed, cross-referenced, and compared with the existing literature. This study draws upon official reports and statistical data from international organisations such as the International Energy Agency [13], the United Nations Environment Programme [14], and the World Bank [15], and national agencies like Eurostat [10] and the U.S. Environmental Protection Agency [16,17]. These sources provide a base for historical trends evaluation in energy use and emissions in the water sector. In addition to publicly available statistics, the peer-reviewed scientific literature was extensively consulted to compare reported values with empirical studies on water treatment energy consumption and process efficiency. These include comparative analyses of energy use in different water treatment processes, CO2 emissions from municipal water infrastructure, and the impacts of climate change on energy demands in treatment plants. Furthermore, this study incorporates primary data from selected case studies of energy efficiency improvements in water treatment plants, collected from municipal facilities in Europe, North America, and the Middle East. Performance data on renewable energy integration, pressure turbines, and AI-based process optimisation were obtained from utility operators and research collaborations.

The methodology for extrapolating energy consumption and CO2 emissions trends from 2000 to 2024 is based on a combination of statistical modelling, historical data analysis, and predictive forecasting techniques. The primary approach relies on time-series analysis, utilising linear regression and autoregressive integrated moving average (ARIMA) models to estimate future energy demand in water treatment plants. These models incorporate historical consumption patterns, technological advancements, and policy changes to provide a reliable projection of energy use and emissions. The dataset used for these extrapolations consists of historical energy consumption records obtained from international agencies such as the International Energy Agency [13], the United Nations Environment Programme [14], and Eurostat [10], alongside national water utility reports and peer-reviewed studies on water treatment energy demand. To ensure accuracy, the analysis takes into account key influencing factors, including advancements in energy-efficient technologies, shifts in water treatment methods, and regulatory impacts on plant operations. One of the critical elements considered is the increasing adoption of high-efficiency pumps, membrane filtration, and process optimisation, all of which contribute to improved energy performance. The models also integrate the effects of climate policies, carbon pricing, and government incentives for renewable energy in the water sector, which influence the pace of emissions reduction. The reliability of the extrapolated data was tested by comparing model outputs with real-world energy efficiency trends observed in case studies of water treatment plants that have implemented energy-saving strategies over the past two decades. Validation was performed through sensitivity analysis, which assessed the impact of different assumptions on the projected values, ensuring that the forecasts remained within an acceptable margin of uncertainty.

Despite the robustness of the statistical approach, it is important to acknowledge inherent limitations in long-term projections. Energy use in water treatment plants varies significantly based on location, size, and treatment technology. While this study provides global averages, regional disparities, such as energy subsidies in the Middle East and the impact of ageing infrastructure in Eastern Europe, could introduce deviations from these figures. This study also includes projections of energy consumption and CO2 emissions trends for 2024 based on historical data and validated forecasting models. While these projections rely on well-established methodologies, they inherently carry uncertainties due to potential shifts in policies, technological breakthroughs, and unforeseen industry developments. Furthermore, access to proprietary industrial data remains a constraint. Another factor affecting data reliability is variability in reporting standards across water utilities. The manner in which energy consumption data are recorded and disclosed varies depending on the utility operator, regulatory framework, and national reporting requirements. Differences in methodology between datasets may result in minor inconsistencies when comparing figures across regions.

The integration of multiple data sources, combined with rigorous validation techniques, strengthens the reliability of the findings, while the discussion of study constraints provides a framework for understanding the inherent uncertainties in long-term projections.

3. Discussion

The analysis of energy efficiency in water treatment plants highlights the increasing challenges associated with rising energy costs, growing environmental concerns, and stricter regulatory requirements. While technological advancements have significantly improved operational efficiency, the integration of energy-saving strategies remains uneven across different regions and plant scales. This discussion aims to contextualise the findings of this study within the broader framework of global efforts toward sustainable water management.

A key aspect of this discourse is the pressure to reduce carbon dioxide (CO2) emissions. As the water sector remains a significant consumer of energy, its reliance on fossil fuel-based electricity contributes substantially to greenhouse gas emissions. Examining trends in emissions over time and assessing potential mitigation strategies, such as the implementation of renewable energy sources and process optimisation, provides insights into how WTPs can align with international climate goals.

Beyond emissions reduction, regional variations in energy consumption must be considered. Climate adaptation strategies, influenced by geographical location, economic conditions, and water availability, affect the feasibility of implementing energy-efficient solutions. The discussion also explores national and international policies aimed at improving the energy sustainability of WTPs, with particular attention to technological innovations, financial constraints, and public acceptance of emerging treatment methods.

In light of the findings, this section evaluates the impact of these developments on future energy efficiency trends, the challenges associated with the large-scale adoption of novel technologies, and the policy-driven measures necessary to support sustainable water treatment operations. The subsequent subsections provide a detailed examination of key themes, beginning with the imperative to curb CO2 emissions in the water treatment sector.

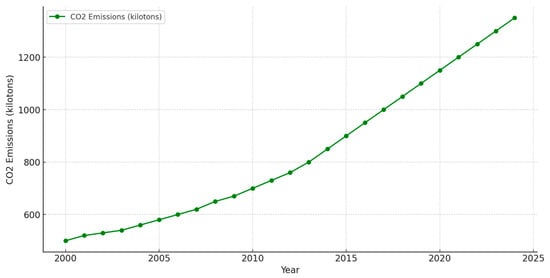

4. Pressure to Reduce CO2 Emissions

Water treatment plants (WTPs) play a key role in the municipal sector, but their operation involves significant environmental impacts, particularly in terms of carbon dioxide (CO2) emissions [18]. The sources of emissions are mainly energy processes, as SUWs consume significant amounts of electricity and most energy in many countries comes from fossil fuels [19]. Between 2000 and 2024, CO2 emissions associated with WTP operations increased from about 500 kilotonnes per year to 1350 kilotonnes, an increase of 170% (Figure 4). The rate of emissions growth accelerated significantly after 2010, due to the increasing energy intensity of technological processes and the increase in water demand [20,21].

Figure 4.

CO2 emissions for water treatment sector. Source: own study based on [4,19].

The increased demand for water is due to dynamic urban development and population growth in urban regions, leading to an increased load on water infrastructure. With this growth, the quality requirements for drinking water are also changing, necessitating the use of more complex technological processes such as membrane filtration or advanced disinfection methods [22]. These processes, while effective in removing contaminants, are significantly more energy-intensive than traditional treatment methods [23]. Membrane filtration, for example, consumes between 0.2 and 0.6 kWh/m3, which, in large stations, translates into hundreds of megawatt hours of additional energy per year [24]. With higher energy consumption, CO2 emissions increase, especially in regions where the dominant share of electricity comes from coal and natural gas [9]. In countries such as Poland, where coal power accounts for more than 70% of the energy mix, emissions associated with SUW operations are particularly high [1].

Increased CO2 emissions are also influenced by more processes related to water recirculation and sludge management [25]. While these operations contribute to efficiency improvements in raw materials and water consumption, they require additional energy. It is estimated that advanced recirculation systems at stations handling more than 100,000 m3/day can increase energy consumption by 10–15%, translating into additional CO2 emissions of 50–70 kilotonnes per year depending on the region [4].

With increasing environmental pressures from international climate agreements such as the Paris Agreement, the water sector faces the challenge of decarbonisation. The use of renewable energy sources such as photovoltaics or biogas, combined with process optimisation, can reduce emissions [26]. For example, photovoltaic installations at large WTPs are capable of supplying up to 30% of the energy demand, reducing CO2 emissions by approximately 400–500 tonnes per year per station with a capacity of 200,000 m3/day [27]. However, the implementation of such solutions faces financial barriers, especially in developing countries where the cost of installing renewable energy sources (RES) in WTPs still remains high.

Data on CO2 emissions at WTP were based on the scientific literature and sector reports that analyse energy intensity and emissions for typical processes used at WTP such as membrane filtration, UV disinfection, coagulation, and flocculation [4,24]. Values for individual years were extrapolated based on technological trends and changes in the energy mix. It was taken into account that CO2 emissions are strongly dependent on the sources of electricity in the energy mix. In regions where fossil fuels predominate, CO2 emissions per unit of energy are higher. These figures are based on reports from the International Energy Agency [1]. An increase in water demand of 1–2% per year has been assumed, as projected by [6]. The increase in the number of customers served and the intensification of technological processes at the WTP influenced the general trend of increasing emissions.

The analysis of the change in CO2 emissions from WTP between 2000 and 2024 clearly shows that the increase in emissions is correlated with increasing water demand and more energy-intensive treatment technologies. In the future, it will be necessary to invest more heavily in the modernisation of infrastructure and the development of lower energy demand technologies in order to meet global climate goals while ensuring access to safe drinking water. The data used to create Figure 4 from the early 2000s (2000–2010) were based on retrospective reports on energy consumption and emissions in SUW [21,28]. Values for later years (2010–2024) were extrapolated from known energy intensity growth trends in SUW.

5. Regional Variability in Energy Consumption and Climate Adaptation Strategies in Water Treatment Plants

Energy consumption in water treatment plants (WTPs) is highly dependent on regional differences in energy costs, climate conditions, and water availability. As climate change intensifies and energy prices fluctuate globally, WTPs must adapt their processes to regional conditions to optimise energy efficiency while maintaining high water quality standards. These regional disparities influence both operational costs and the choice of water treatment technologies, leading to significant variations in energy consumption across different types of WTPs. Electricity prices for municipal and industrial applications vary significantly across the world due to differences in power generation sources, government subsidies, and carbon taxation policies. In many European Union (EU) countries, such as Germany, Denmark, and the Netherlands, electricity prices for industrial consumers exceed EUR 0.15 per kWh, driven by the EU’s strict carbon neutrality goals and the transition toward renewable energy sources [10]. This forces WTPs in these regions to adopt energy-efficient retrofits and renewable energy integration to offset high operational costs. In contrast, North America benefits from lower electricity prices, particularly in regions with large-scale hydropower generation (e.g., Canada, the Pacific Northwest, and the Northeastern U.S.). However, WTPs in certain U.S. states, such as California and New York, experience significantly higher energy costs due to carbon pricing policies and water scarcity issues, necessitating the adoption of desalination and advanced water reuse technologies [17]. In Middle Eastern countries, where water scarcity is extreme, energy-intensive desalination plants dominate the water supply infrastructure [15]. These plants rely on thermal distillation and reverse osmosis (RO) technologies, consuming between 2.5 and 6.0 kWh/m3, which is 3–10 times higher than conventional groundwater treatment [21,23,24]. However, to mitigate costs, some Gulf nations, such as Saudi Arabia and the UAE, are pioneering solar-powered desalination systems, which could significantly reduce fossil fuel dependency [13,28]. Developing regions, particularly in sub-Saharan Africa and South Asia, face the dual challenge of unreliable electricity grids and rising energy costs [15,29,30]. Many WTPs in these areas rely on diesel generators as backup power sources, further increasing their carbon footprint and operational expenses. Recent efforts to integrate off-grid solar energy systems and micro-hydropower solutions in decentralised WTPs offer a promising solution for improving energy resilience in these regions [15,23,28].

Climate change directly influences WTP operations by altering raw water quality and availability, thereby increasing energy consumption due to the need for more advanced treatment processes. These effects vary depending on the region and the source of water. Considering arid and semi-arid regions (the Middle East, Australia, the Southwestern U.S.) prolonged droughts and groundwater depletion increased reliance on energy-intensive desalination and deep groundwater extraction [5,15,31]. In some cases, energy requirements for pumping groundwater from deep aquifers have increased by 20–30% due to declining water tables [11]. On the other hand in cold-climate regions (Canada, Russia, Scandinavia) WTPs need increased energy demand for heating pipelines and maintaining process temperatures. During winter, heating energy consumption can increase by 15–20%, particularly in membrane-based filtration systems where temperature fluctuations affect permeability [25]. Additionally, chemical coagulation and disinfection processes often require higher doses of treatment chemicals in low-temperature conditions, further increasing energy use [26,32]. High turbidity events, algal blooms, and saltwater intrusion in tropical and coastal regions (Southeast Asia, Gulf Coast, Latin America) are common challenges that demand advanced oxidation processes (AOPs), membrane filtration, and activated carbon adsorption [27]. The introduction of these treatment processes has resulted in an increase in energy demand by 10–30% compared to traditional sedimentation and sand filtration systems [21,22]. Other technology is needed in flood-prone areas (Europe, South Asia) where intense rainfall events lead to higher microbial and organic loads in raw water sources, forcing WTPs to enhance ozone disinfection and UV radiation, which can elevate energy consumption by 15–25% during flood seasons [11,12,33].

6. National and Global Energy Efficiency Strategies

The water sector is one of the largest consumers of energy in the municipal economy, and its role in global energy consumption is steadily increasing with the growing demand for potable water and climate change. According to the International Energy Agency [13], the water sector consumes about 4% of global electricity production, which corresponds to emissions of more than 120 megatonnes of CO2 equivalent per year. Much of this energy is used in water treatment and distribution processes, making water treatment plants (WTPs) a key component of the sector’s energy efficiency strategy [4,32,33].

At the global level, the increase in energy consumption in the water sector is driven by rapid urbanisation, industrial intensification, and climatic changes that affect water availability and quality [34]. Particularly evident is the increase in energy consumption in urban regions, where water supply infrastructure has to cope with the challenges of high population density and increasingly polluted water sources [35]. Examples include mega-cities such as London, where water supply systems consume hundreds of gigawatt hours of electricity annually, or cities in India that face water scarcity requiring expensive desalination technologies [16,36,37].

At the local level, energy consumption in the water sector is strongly dependent on the quality of raw water and the treatment technologies used [37,38]. In regions with easy access to groundwater, which requires minimal treatment, energy consumption per unit of water is much lower than in areas using surface or saline water [39]. For example, in the Scandinavian countries, where raw water quality is high, energy consumption is around 0.2–0.4 kWh/m3, while in the Middle East regions, where desalination technologies are widely used, it exceeds 1 kWh/m3 [2,22,40].

An additional challenge is the growing energy demand in developing cities, which face underinvested water supply infrastructure and limited access to efficient technologies [41]. In many cases, energy use in water systems is inefficient, due to outdated pumping systems, water losses in the distribution network, and insufficient process automation [25,31]. In response to these challenges, global initiatives such as the UN Sustainable Development Goals (SDG 6 and SDG 13) are promoting the implementation of energy-efficient solutions in the water sector [3]. These efforts include the development of intelligent energy management systems, infrastructure upgrades, and increasing the share of renewable energy sources in SUW supply [3]. Understanding the dynamics of energy consumption in the water sector and implementing innovative technologies is key to achieving more sustainable use of water and energy resources worldwide [32,33].

Energy efficiency is one of the key elements of modern energy policy at both national and global levels. In the face of growing energy demand, the need to reduce greenhouse gas emissions, and the need to ensure energy security, a strategic approach to energy management is essential [42]. At the national level, many countries are developing their strategies according to local circumstances, using available resources and technologies, while at the global level, universal goals are set, such as the implementation of the Paris Agreement or the Sustainable Development Goals [3,35,37].

At the European Union level, energy efficiency is one of the main pillars of the Green Deal, which aims to achieve climate neutrality by 2050 [35,38,40]. The Energy Efficiency Directive [33,38,43] requires member states to reduce primary energy consumption by at least 32.5% by 2030, compared to 2007 projections [44]. As part of this policy, countries are required to develop long-term strategies for the renovation of buildings, the promotion of energy-efficient technologies in industry, and consumer support for energy efficiency [45].

Poland’s Energy Policy until 2040 (PEP2040) is one example of a national strategy that integrates energy efficiency goals with the development of renewable energy sources and the decarbonisation of the economy [34,36]. The document places particular emphasis on the modernisation of energy infrastructure, including efficiency improvements in the buildings and industry sectors, and the development of distributed energy, including energy clusters [46]. An important element of this strategy is also the deployment of innovative technologies, such as smart grids and energy storage, which can significantly reduce energy losses in transmission and distribution [33,45,46].

One of the key elements of the global strategies is international cooperation under the Paris Agreement, which requires signatories to develop National Action Plans (NDCs) with energy efficiency measures [39,47]. Particular attention is given to the buildings, industry, and transport sectors, where the potential for energy savings is greatest [5]. An important part of global strategies is to promote access to modern technologies in developing countries to reduce their dependence on fossil fuels and reduce the energy intensity of their economies. Initiatives such as Sustainable Energy for All (SEforALL) fund projects that support the development of renewable energy sources, the upgrading of transmission networks, and the improvement of energy efficiency in regions with low levels of energy infrastructure [39,48]. At the global level, key energy efficiency efforts are coordinated by international organisations such as the International Energy Agency [41] and the United Nations Environment Programme [49]. The IEA regularly publishes reports identifying best practices and areas for improvement, highlighting the importance of energy efficiency in reducing CO2 emissions. In its Energy Efficiency 2021 report, the agency highlighted the potential for energy savings in the transport and buildings sectors, indicating that investments in energy efficiency could contribute up to 40% of the emissions reductions required to achieve climate neutrality [39,45].

7. Climate Changes

As mentioned above, climate change has a significant impact on the energy consumption of water treatment plants (WTPs). Climate change affects both the availability of water resources and the technological processes involved in their treatment. In regions affected by prolonged droughts, a reduction in the amount of available surface and groundwater requires an intensification of water harvesting activities, which significantly increases the energy demand for pumping processes. Particularly in such dry areas as the Middle East countries, increasing water demand leads to higher use of energy-intensive desalination technologies [2,38]. Conversely, in regions with abundant rainfall but low water quality, the need for more advanced treatment processes, such as coagulation, flocculation, or membrane filtration, also increases energy costs [50,51].

An escalation in the frequency of extreme weather events, such as floods or hurricanes, affects the quality of surface water, increasing its suspended solids and organic matter content. As a result, water treatment plants have to adapt their technological processes to the new challenges, which require more energy to process water with increased levels of pollution [5,35]. Higher turbidity and the presence of microorganisms in water from regions with variable weather conditions necessitate more frequent filter backwashing and the use of more intensive disinfection methods, such as ozone and UV light, which are more energy-intensive than traditional methods [2].

Changing temperatures also have a direct impact on the technological processes in the WTP. Higher water temperatures increase biological activity, leading to a greater need for disinfection chemicals and additional energy in coagulation and filtration processes [16]. In addition, in cold regions, the need to heat water to protect equipment from freezing increases operating costs in WTP, especially in Scandinavian and Northern countries [52,53].

In the face of climate change, it is necessary to develop technologies that are resilient to changing weather conditions and optimise energy consumption in WTP. The implementation of renewable energy sources, automation of technological processes, and investment in adaptive research are key strategies to reduce the impact of climate change on the water sector [3].

8. Growing Demand for Water

Global water demand is increasing at a rate of about 1% per year as a result of complex demographic, economic, and climatic processes. Since 2000, global water consumption has increased by about 25%, and this trend is expected to continue in the coming decades [6]. The reasons for this increase are multi-faceted and include urban development, population growth, and intensification of agricultural and industrial activities [28,53].

One of the main drivers of growing water demand is urbanisation. In 2000, about 46% of the world’s population lived in urban areas, while, in 2024, this rate rose to 58% [54]. Urbanisation leads to increased water consumption in the municipal sector, associated with infrastructure development, household growth, and rising living standards. In addition, the intensification of industrial activities is intensifying the demand for process water, putting additional stress on existing resources.

Meanwhile, the agricultural sector, which accounts for about 70% of global water use, plays a key role in increasing water demand [55]. The growth in food production in response to an enlarging population and changing consumption patterns, such as higher meat consumption, require greater water use in irrigation systems. It is estimated that since 2000, the acreage of irrigated land has expanded by 15%, corresponding to an additional billion cubic metres of water used annually [55].

Climate change is also affecting the availability of water resources. In many regions, rising temperatures and changes in precipitation lead to a reduction in the amount of renewable water resources per person. Between 2000 and 2024, the global rate of renewable water resources per capita fell by 20%, particularly affecting regions such as sub-Saharan Africa (down 41%) and Central Asia (down 30%) [5,6].

Water treatment plants face escalating challenges in delivering adequate water at the same time as maintaining energy efficiency and environmental protection. The increase in water demand results in an elevated load on the infrastructure, which necessitates the use of more advanced treatment technologies [56]. For example, processes such as membrane filtration, although effective in improving water quality, are more energy-consuming and require more investment [22,23]. Long-term solutions include the optimisation of treatment processes, the implementation of advanced water management systems, and the development of technologies to enable water recycling in the industrial and municipal sectors [8,53,57]. Such approaches are essential to ensure sustainable access to water in light of population growth, urbanisation, and climate change. As UNESCO (2021) [6] points out, the implementation of integrated water resource management strategies can help reduce pressure on available resources—while improving the efficiency of their use.

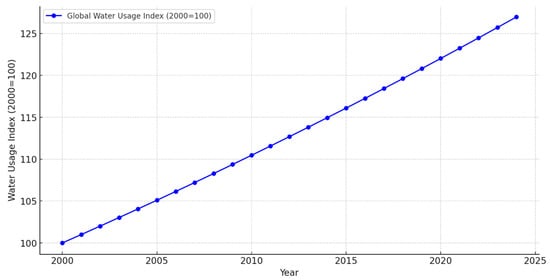

Figure 5 shows an index of global water consumption, based on data from the year 2000, when the consumption value was taken as 100 units. An annual increase of 1% has been taken into account to estimate water consumption in subsequent years. In 2024, global water consumption increased to approximately 126 units, indicating a 26% increase compared to the base year. The data were based on UNESCO [6] reports and the scientific literature, which indicate a stable annual increase in water consumption of 1% [4,34,50]. Extrapolation was made assuming a constant growth rate, taking into account the impact of factors such as population growth, urbanisation, and industrial development. The values of the graph are indexed, allowing for easy comparison of global trends [57].

Figure 5.

Global water use growth 2000–2024. Source: own study based on [6].

9. Factors Influencing Energy Consumption Trends in Water Treatment Plants

Energy consumption in water treatment plants depends on a complex set of technological, environmental, and operational factors [58]. Understanding these relationships is key to improving energy efficiency in the water sector, especially in the context of increasing environmental and economic demands. These factors can be analysed in terms of the quality of the raw water, the treatment technologies used, the size of the station, climatic conditions, and the level of technological advancement of the water [16,23].

9.1. Raw Water Quality and Type

One of the most important determinants of energy consumption at the WTP is the quality and type of raw water. Groundwater, which has a higher quality compared to surface water, requires less intensive treatment processes such as coagulation or membrane filtration [40]. The average energy consumption of groundwater treatment plants is between 0.2 and 0.3 kWh/m3, whereas, for surface water, these values can reach 0.6–0.8 kWh/m3 [35]. These differences are due to the need for more energy-intensive technologies, such as advanced disinfection and membrane filtration in stations serving surface water [11,12,59].

9.2. Applicable Treatment Technologies

The characteristics of the applied technological processes are a key factor influencing the energy consumption of the WTP. Processes such as coagulation, flocculation, membrane filtration, and advanced disinfection methods are more energy-intensive than standard technologies such as sand filtration or chlorination [22,23,24]. For example, membrane filtration consumes between 0.2 and 0.6 kWh/m3, depending on the type of membranes and operating pressure, which is a significantly higher energy cost compared to sand filtration (0.08–0.12 kWh/m3). In addition, coagulation and flocculation processes require intensive mixing, which can increase the energy requirement to 0.15–0.2 kWh/m3 for infiltration and surface water [60].

9.3. Size of the Water Treatment Plant

The scale of operation of a WTP significantly affects energy efficiency. Large stations benefit from economies of scale, resulting in lower specific energy consumption compared to small stations. For large underground water treatment stations, energy consumption averages 0.2 kWh/m3, while, in small stations, it can reach 0.3 kWh/m3 [28,61]. A similar trend is observed for infiltration and surface water, where the difference between large and small stations may be as low as 0.2 kWh/m3. The reason for this phenomenon is the more advanced automation of processes and the use of energy-efficient equipment in larger facilities.

9.4. Climatic and Environmental Conditions

Climate plays an important role in shaping the energy consumption of WTP, influencing the quality of raw water and the need for intensification of technological processes. In regions with high temperature and humidity, surface water is more prone to biological contamination, increasing the need for intensive disinfection and membrane filtration [53,59,62,63]. In colder climates, processes such as aeration may require higher energy inputs due to the reduced efficiency of equipment at low temperatures.

10. Types of Water Treatment Plants

Water treatment plants (WTPs) play a fundamental role in ensuring access to potable water and responding to the needs of local communities and industry. Their diversity arises from the characteristics of the raw water sources served, such as groundwater, infiltration, and surface water, as well as local geographical, social, and economic considerations. Each type of water treatment plant is characterised by unique challenges and opportunities that affect operational efficiency and the ability to adapt to changing environmental and technological conditions [2,4,64].

Groundwater treatment plants are one of the most common types of SUW, especially in rural areas and in regions with rich groundwater resources [65,66]. Groundwater is characterised by its relatively high quality, which allows for reduced treatment processes. This is particularly important in terms of energy efficiency, as the reduced need for intensive processes such as coagulation or membrane filtration reduces operating costs [17,28]. The opportunity for these stations is the ability to keep operating costs low while maintaining high water quality. However, a limitation is the decreasing availability of groundwater resources as a result of over-exploitation and climate change, such as falling groundwater levels [50,53,67]. Furthermore, groundwater contamination, for example, by nitrogen compounds from agricultural activities, may require the introduction of additional technological processes, which increases costs [56].

Infiltration water treatment plants are characterised by the use of a natural treatment process in which surface water flows through layers of soil, acting as a natural filter. Infiltration water, although cleaner than surface water, still requires treatment to remove microorganisms and some chemicals [2]. The opportunity for these stations is the potential to reduce operating costs due to a smaller range of treatment processes compared to surface water. At the same time, natural filtration improves the stability of water quality, which is beneficial for water supply systems. A limitation, however, is the sensitivity to climate change, including a reduction in groundwater levels and an increase in the risk of pollution from agricultural and industrial activities [38,56]. In addition, the ability to maintain the effectiveness of these stations depends on hydrogeological conditions, which can vary from location to location [54,55,61].

The most technologically complex facilities are surface water treatment stations, which handle water from rivers, lakes, and reservoirs. This type of raw water is most susceptible to biological, chemical, and microbiological contamination, requiring advanced technological processes [31,51]. The opportunity for these stations is the potential to provide large volumes of potable water for growing urban agglomerations where local groundwater supplies are insufficient. Modern technologies such as membrane filtration and ozone disinfection produce water of very high quality, meeting even the most rigorous standards [11,23,59,63]. However, such WTPs face the limitation of high operating costs and high energy consumption due to the need for intensive treatment processes [35,64]. In addition, the variability of surface water quality as a result of climate change, such as floods and droughts, provides a significant operational challenge.

In terms of the scale of operation, WTPs can be divided into small, medium, and large units. Small water treatment plants, serving local communities, are characterised by simpler infrastructure and fewer technological requirements. Their advantage is their ability to adapt quickly to local needs, making them effective in rural areas [65]. However, they are constrained by limited financial resources, which inhibit modernisation and the implementation of innovative technologies [39]. Medium-sized water treatment plants, serving larger cities or regions, combine the advantages of scale with the ability to use more advanced technologies. However, their challenge is the need to manage more complex distribution systems, which can lead to water losses and higher operating costs.

The largest water treatment plants, located in large agglomerations, face the challenges of mass production of drinking water. The opportunity for these stations is the ability to benefit from economies of scale, which allows for lower single-unit water production costs. In addition, large budgets make it possible to invest in high-tech technologies, such as energy recovery systems or intelligent process management [8,61]. However, the increasing pressure to reduce greenhouse gas emissions and the need to adapt to changing environmental standards remains a constraint [7,66].

The typology of water treatment plants depends on the type of water sources and the scale of their operation. Each type of WTP offers unique opportunities, but at the same time faces restrictions due to local environmental and economic conditions. The development of these facilities requires an integrated approach that takes into account local needs, financial capacity, and the availability of modern technology. As climate change and urbanisation increase pressure on water resources, the role of WTP in water management will be even more crucial [57,67].

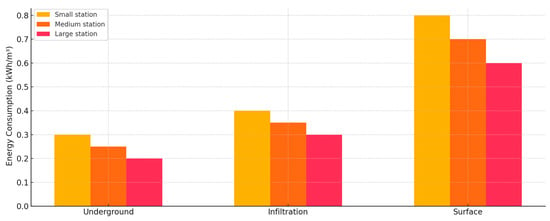

Figure 6 compares the energy consumption of water treatment plants (WTPs) by type and size of water treated: groundwater, infiltration, and surface water. The energy consumption values presented in this study for different types of water treatment plants (groundwater, infiltration, and surface water) are based on an extensive review of the scientific literature and sector reports, ensuring their consistency with established data. Multiple studies have confirmed that energy consumption in WTPs varies depending on the water source, plant scale, and applied treatment technologies (e.g., [21,31,58,68]).

Figure 6.

Energy consumption by water type and station size. Source: own study based on [21,31].

Averaged values of unit energy consumption for different technological processes were provided. These data are comparable as they are based on uniform units (kWh/m3) and refer to typical treatment technologies used in Europe. Regional variations in energy consumption were also taken into account by analysing studies from different geographic areas. For example, WTPs in regions with high energy prices (e.g., Germany and Denmark) have implemented energy-efficient retrofits, resulting in lower energy consumption per unit of water treated despite higher baseline costs [45,69]. Conversely, water treatment plants in the Middle East, where desalination is prevalent, exhibit significantly higher energy demand, often exceeding 2.5 kWh/m3 [23,43]. Groundwater treatment plants have the lowest energy consumption, ranging from 0.2 kWh/m3 in large plants to 0.3 kWh/m3 in small plants. This is due to the high quality of the groundwater, which requires less intensive processes such as aeration and mechanical filtration. These values align with previous reports documenting similar consumption levels for European and North American groundwater treatment plants [31,61].

The influence of scale was also considered by differentiating between small, medium, and large plants. Small WTPs often have higher specific energy consumption due to the lack of automatization and older equipment, with groundwater plants consuming up to 0.3 kWh/m3 and surface water plants reaching 0.8 kWh/m3 [24,65]. Large-scale treatment plants, benefiting from automation and energy-efficient technologies, consistently show lower consumption per cubic metre of water, with groundwater WTPs consuming 0.2 kWh/m3 and surface water WTPs reducing energy usage to around 0.6 kWh/m3 [31,70]. It happens here because of economies of scale and modern technologies such as inverter pumps further reduce energy requirements. For infiltration water, energy consumption is higher, ranging from 0.3 kWh/m3 in large stations to 0.4 kWh/m3 in small ones. This is due to the need for more advanced processes such as coagulation, flocculation, and sedimentation. In small stations, the lack of advanced automation and less efficient chemical dosing systems increase the unit energy demand. The highest energy consumption is observed in surface water treatment plants, where values range from 0.6 kWh/m3 in large plants to 0.8 kWh/m3 in small plants. The high energy demand is due to the high pollution of surface water, which requires complex technological processes such as membrane filtration, intensive coagulation, and advanced disinfection. In small stations, the lack of modern technology and less efficient process management significantly increase energy costs [67,70]. Energy consumption per unit of water in these stations is highest, regardless of the type of water treated. It is 0.3 kWh/m3 for groundwater, 0.4 kWh/m3 for infiltration water, and 0.8 kWh/m3 for surface water. The high values are due to technological limitations, such as the lack of advanced automation, the use of less efficient equipment, and the failure to exploit economies of scale. In medium-sized water treatment plants, these values are moderate and amount to 0.25 kWh/m3 for groundwater, 0.35 kWh/m3 for infiltration water, and 0.7 kWh/m3 for surface water, respectively. Medium-sized stations combine the advantages of large-scale technology with a more flexible operational approach to achieve better energy performance than small-scale stations. Energy efficiency is highest in large stations, with energy consumption of 0.2 kWh/m3 for groundwater, 0.3 kWh/m3 for infiltration water, and 0.6 kWh/m3 for surface water. The improved results are due to economies of scale, the use of modern technology such as high-efficiency pumps, and a more advanced process management system [71].

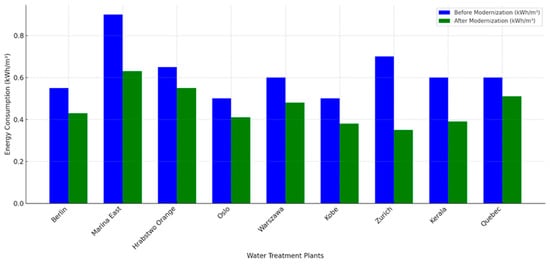

The study findings align with comparative analyses performed in prior research. For example, the energy efficiency improvements achieved through AI-driven process optimisation in Singapore’s Marina East WTP demonstrate reductions of up to 30% in energy consumption, similar to the potential savings reported in [71,72]. Additionally, a review of global case studies indicates that membrane filtration energy demand can be reduced by 15–25% with optimised operational strategies, in agreement with [19,71,73].

The variations observed across different plant sizes, treatment processes, and geographic locations illustrate the complexity of energy consumption trends in WTPs. Nevertheless, by incorporating validated scientific data, official sector reports, and real-world case studies, this study provides a comprehensive and reliable assessment of energy efficiency in water treatment plants.

11. Technological Processes in Different Types of Water Treatment Plants

Technological processes in water treatment plants (WTPs) are fundamental to ensure the quality of drinking water, adapted to the needs of local communities and environmental conditions. The typology of WTPs, based on the type of water being treated (underground, infiltration, surface), determines the range of used technologies, from simple aeration processes to advanced membrane and chemical methods [11,12]. Each of these processes is associated with specific operational challenges, technological constraints, and environmental impacts [24,62].

Groundwater is characterised by relatively good quality, which allows for the standing of simpler technological processes. Aeration, which is one of the basic steps in groundwater treatment plants, is used to remove iron, manganese, and hydrogen sulphide. This process is efficient, but depends on the chemical conditions of the water, such as pH and contaminant concentration [58,67]. The limitation of aeration is the need for precise control of water parameters, which requires specialised equipment and increases operating costs. Mechanic filtration, most often carried out using sand filters, allows for the removal of suspended particles but requires regular flushing of the filters, which entails additional water and energy losses [64,74]. The next stage is disinfection, most often implemented by chlorination or UV radiation. Chlorination, although effective, can lead to the formation of by-products such as trihalomethanes, which are potentially harmful to health [66,75]. Groundwater treatment plants have a natural advantage in terms of lower energy consumption due to the higher quality of the groundwater, which allows for a reduction in the number and intensity of used procedures (Figure 7). However, groundwater contamination risks and the decreasing availability of groundwater resources may require more energy-intensive technologies in the future.

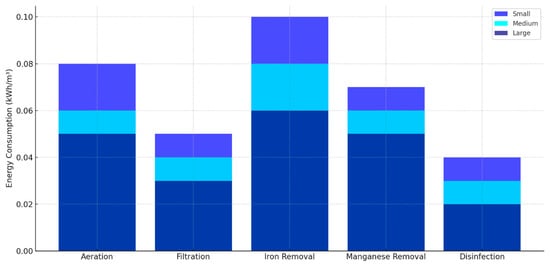

Figure 7.

Energy consumption by process for groundwater. Source: own study.

Figure 7 shows the energy consumption per unit of water for the technical processes typical of groundwater treatment plants: aeration, filtration, removal of iron and manganese, and disinfection. Groundwater is characterised by relatively simple treatment processes, which is reflected in the chart’s energy consumption results. Aeration is the most energy-intensive stage and, in small stations, it reaches 0.08 kWh/m3, due to the limited efficiency of simpler aeration equipment. In large stations, aeration consumes 0.05 kWh/m3, a result of more advanced pressure aerators and better airflow management. Filtration, crucial for the removal of mechanical particles, is a moderately energy-intensive process, with consumption ranging from 0.05 kWh/m3 in small stations to 0.03 kWh/m3 in large stations. This decrease is due to the use of advanced filtration techniques in larger units. The process of iron removal from the water, a key step in groundwater treatment plants, consumes 0.1 kWh/m3 in small plants and 0.06 kWh/m3 in large plants, due to the use of more efficient iron precipitation methods. Similarly, the removal of manganese shows a high energy intensity, especially in small stations, where it is 0.07 kWh/m3, while, in large facilities, it is reduced to 0.05 kWh/m3. The disinfection process, due to its simplicity and lower energy requirements, is the least energy-intensive [32,34]. In small stations, the consumption is 0.04 kWh/m3, while, in large ones, it drops to 0.02 kWh/m3.

Infiltration water treatment plants use natural purification processes whereby the water flowing through the ground layers undergoes pre-filtration. The natural infiltration processes in the ground reduce the energy demand in the initial stages of treatment The processes include coagulation, flocculation, sand filtration, and disinfection. Coagulation and flocculation are particularly important for the removal of fine suspended particles and organic pollutants [52,60]. However, the use of these methods requires precise dosing of chemicals, which increases operational costs and requires advanced automation. Sand filtration is a common technology in infiltration water treatment plants. Although effective in removing mechanical contaminants, it requires frequent filter flushing, leading to increased energy and water consumption [68]. In infiltration, WTPs disinfection in a similar way to stations treating groundwater is based on chlorination or ozonation. Ozonation, although more effective in eliminating pathogens, is much more expensive and energy-intensive than traditional disinfection methods [21,54]. However, subsequent stages, such as coagulation or disinfection, generate significant energy costs, which increase with the degradation of infiltration water quality [21,60]. In this context, optimising chemical dosage and automating processes can result in significant energy savings, but requires investment in advanced monitoring and management systems [52,58].

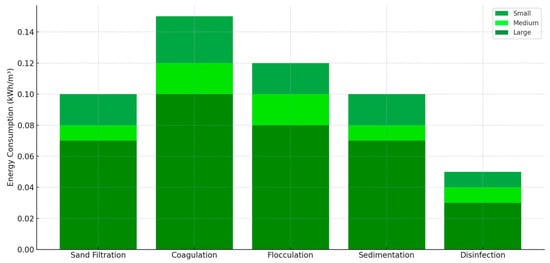

Figure 8 shows the energy demand of the processes used in infiltration water treatment plants: sand filtration, coagulation, flocculation, sedimentation, and disinfection. In the case of infiltration water, processes such as sand filtration, coagulation, flocculation, sedimentation and disinfection have a higher energy demand than groundwater due to more complex technologies [21,57,60]. Sand filtration in small stations consumes 0.1 kWh/m3, while in large stations it drops to 0.07 kWh/m3, due to the use of systems with high hydraulic efficiency. Coagulation is the most energy-intensive process, with consumption in small stations reaching 0.15 kWh/m3, which can be attributed to the need for intensive mixing and the use of large quantities of chemicals. At large stations, consumption in the coagulation process is 0.1 kWh/m3 due to optimised chemical dosage and modern agitators. Flocculation, which is the connecting step between coagulation and sedimentation, also shows high energy consumption in small stations of 0.12 kWh/m3, falling to 0.08 kWh/m3 in large stations. Sedimentation, a key process in the removal of larger particles, has an energy consumption of 0.1 kWh/m3 in small stations and 0.07 kWh/m3 in large stations. Disinfection in stations serving infiltration water is a moderately energy-intensive process, consuming between 0.05 kWh/m3 in small stations and 0.03 kWh/m3 in large stations.

Figure 8.

Energy consumption by process for infiltration water. Source: own study.

Surface water treatment plants use the most advanced technological processes due to the high levels of chemical, biological, and microbiological contaminants present in surface water [76]. The key stages are coagulation, flocculation, sedimentation, membrane filtration, and advanced disinfection. Coagulation and flocculation in stations serving surface water require higher chemical doses due to the presence of organic substances such as humic acids [52,68]. The limitation of these processes is the high cost of the chemicals and the need for precise dosing to avoid over-coagulation phenomena, which can lead to water loss and prolonged sedimentation. Membrane filtration, which is one of the newest technologies, allows the removal of micropollutants, including pathogens, pesticides, and heavy metals. However, it requires high pressure, which translates into significant energy consumption, and, in addition, membranes are prone to fouling (clogging), which increases operating costs [22,23]. Advanced disinfection methods, such as ozonation and UV light, are more effective than traditional chlorination, especially in removing organic compounds and reducing the taste and odour of water [31,75]. However, a limitation is the high energy intensity of these methods and the need for additional monitoring systems to prevent ozone overdose, which could adversely affect water quality and the sustainability of infrastructure. Surface water treatment plants have the highest energy consumption due to the high variability of raw water quality and the need for complex processes [73]. Intensive methods such as membrane filtration and ozone treatment ensure high water quality, but generate significant operating costs due to high energy requirements. It is therefore particularly important in these stations to implement energy-efficient technologies, such as modern membranes with low resistance coefficients and energy recovery systems [22,23,29].

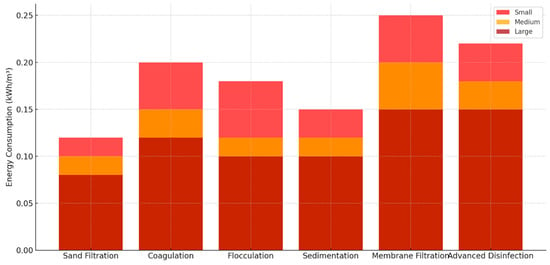

Figure 9 shows the energy consumption for the processes used in surface water treatment plants: sand filtration, coagulation, flocculation, sedimentation, membrane filtration, and advanced disinfection. The most complex technological processes occur in surface water treatment plants, which translates into the highest energy consumption. Sand filtration, although less energy-intensive than other processes, consumes 0.12 kWh/m3 in small stations and 0.08 kWh/m3 in large stations. Coagulation and flocculation are among the most energy-intensive steps, reaching 0.2 kWh/m3 and 0.18 kWh/m3 in small stations and 0.12 kWh/m3 and 0.1 kWh/m3 in large stations, respectively, due to the need for intensive mixing processes and high chemical doses. Sedimentation, necessary to remove larger particles, shows a consumption of 0.15 kWh/m3 in small stations and 0.1 kWh/m3 in large stations. Membrane filtration is the most energy-intensive process in surface water treatment plants, with a consumption of 0.25 kWh/m3 in small plants and 0.15 kWh/m3 in large plants (Lau). The high energy demand in this process is due to the need to maintain high operating pressures. Advanced disinfection, including ozone or UV radiation, generates consumption from 0.22 kWh/m3 in small stations to 0.15 kWh/m3 in large ones, due to the high energy intensity of these methods, but also their effectiveness in elimination of pathogens and organic compounds.

Figure 9.

Energy consumption by process for surface water. Source: own study.

The technological processes used in the various types of water treatment plants are a key factor in determining the energy efficiency of these facilities. The diversity of technologies, from simple aeration and mechanical filtration in groundwater treatment plants to advanced coagulation, flocculation, and membrane filtration in surface water plants, has a direct impact on energy consumption. Each of these processes brings with it specific benefits and challenges, which require careful understanding and optimisation in the context of increasing environmental and economic demands [11,28,55].

12. Sources of Energy Consumption in Water Treatment Plants

Water treatment plants (WTPs) play a crucial role in municipal infrastructure, ensuring the supply of high-quality drinking water. However, these facilities are also significant energy consumers, as their operations rely on various energy-intensive processes. The primary sources of energy demand in WTPs include pumps, aerators, filtration equipment, coagulation and flocculation systems, membrane filtration, and disinfection technologies. Given the high energy consumption of these systems, it is essential to analyse their efficiency, explore opportunities for energy optimisation, and consider the challenges associated with retrofitting WTPs for better energy performance [7,28]. Table 1 summarises the energy consumption of key components in WTPs.

Table 1.

Energy consumption in water treatment plants.

12.1. Pumps Are the Main Source of Energy Consumption

Pump systems dominate the energy structure of WTPs, accounting for 60–80% of total energy consumption [28]. Energy consumption of pumps ranges from 0.15 to 0.3 kWh/m3 of treated water, depending on the type of water, height of the head, operating pressure and length, and characteristics of the piping system [79]. For surface water treatment plants that need to transport water over longer distances and at higher pressures, the energy demand may reach the upper end of this range. An opportunity to reduce the energy consumption of pumping systems is to use modern high-efficiency pumps equipped with inverters. By dynamically adjusting the pump performance to the current demand, energy consumption can be reduced by 20–30% [28,79]. However, a limitation is the cost of retrofitting these systems, especially in small stations with limited financial capacity.

12.2. Aerators and Aeration Processes

Aeration is a key process in groundwater and infiltration treatment plants, where aerators are used to introduce air into the water to remove iron, manganese, carbon dioxide, and hydrogen sulphide compounds. The energy consumption of aerators ranges from 0.05 to 0.15 kWh/m3, depending on the intensity of the process and the design of the device [66]. In small stations, which often use simpler technologies, the energy requirement is higher due to the lower efficiency of the aerators. Modern pressurised aerator systems can reduce energy consumption by up to 20%, and their use is particularly effective in large stations where better process management is possible [70]. A limitation of these devices, however, is their high purchase cost and the need for a high-level control system, which makes their implementation in smaller plants difficult [7,62].

12.3. Filtration Equipment

Filtration is one of the most energy-intensive processes in a WTP, especially for membrane filtration [66]. In infiltration and surface water treatment plants, sand filtration is popular, with energy requirements ranging from 0.08 to 0.12 kWh/m3 [59,74]. This process requires regular backwash of the filters, which generates additional energy costs. Membrane filtration, which is mainly used in stations serving surface water, has an energy consumption of 0.2 to 0.6 kWh/m3 of treated water [28]. The use of low hydraulic resistance membranes and pressure recovery systems can reduce energy requirements by 15–25%, representing a significant opportunity for energy optimisation. However, membrane filtration is associated with high investment costs and the need for frequent membrane servicing, which is a significant limitation to its widespread use [73,80].

12.4. Coagulation and Flocculation Equipment

Coagulation and flocculation are chemical processes commonly used in infiltration and surface water treatment plants. The equipment used in these processes, such as mechanical stirrers, requires energy consumption in the range of 0.1–0.2 kWh/m3 [51,76]. The intensity of mixing and the amount of added chemicals increase the energy demand, especially in stations serving surface water where raw water quality is lower. Automation of chemical dosing systems and optimisation of mixer design can reduce energy consumption by 10–15%. However, these solutions are associated with high implementation costs, which may limit their use in smaller plants [35,38,76].

12.5. Disinfection Equipment

Disinfection is the final stage of water treatment and includes both traditional methods such as chlorination and advanced technologies such as ozonation and UV radiation. Traditional chlorination is relatively energy efficient, with a consumption of 0.01–0.03 kWh/m3. In contrast, ozone and UV radiation, which are mainly used in large surface water treatment plants, have an energy consumption of between 0.1 and 0.3 kWh/m3 [30,66,78]. The use of advanced monitoring and automatisation systems in these processes can improve their energy efficiency, but is associated with high investment costs [77,79].

13. Technological Innovations in Water Treatment Plants

Water treatment plants are critical infrastructure components responsible for ensuring access to clean and safe drinking water. However, they are also among the most energy-intensive municipal facilities, requiring significant amounts of electricity to operate various treatment processes. The increasing global water demand, coupled with growing energy costs and stringent environmental regulations, has driven the need for greater efficiency in energy use and the adoption of innovative technologies in water treatment plants [23,24,68].

Energy consumption in WTPs is influenced by multiple factors, including raw water source, treatment complexity, plant size, operational efficiency, and regulatory standards. Treatment of surface water, which often contains higher levels of organic and chemical contaminants, generally requires more intensive processing than groundwater treatment, leading to higher energy demand per unit of treated water. Similarly, larger WTPs benefit from economies of scale, allowing for better energy optimisation, while smaller plants often face higher relative energy costs due to outdated equipment and limited process control [28,51,57,74].

The primary sources of energy consumption in WTPs include pumps, aerators, filtration systems, coagulation and flocculation processes, and disinfection technologies. Pumps alone account for 60–80% of total energy use, making them a key area for energy-saving initiatives [31]. Filtration, especially in membrane-based processes, also constitutes a major energy burden, with energy demands reaching 0.6 kWh/m3 in some cases [23,64,65,74]. As the global energy landscape shifts toward sustainability, WTPs must integrate high-efficiency equipment, automation, and process optimisation strategies to reduce their environmental impact and operational costs [8,38,77].

Parallel to energy consumption challenges, technological innovations have become a driving force for improving efficiency in water treatment. Emerging solutions such as next-generation membrane filtration, advanced oxidation processes (AOPs), artificial intelligence (AI)-driven process automation, and water recycling technologies are transforming the industry. These advancements reduce energy consumption, enhance treatment effectiveness, and lower the environmental footprint of WTPs [80,81]. However, despite their potential, economic, regulatory, and technical barriers continue to hinder widespread implementation.

Table 2 provides a comprehensive overview of the key sources of energy consumption in WTPs and the most promising technological innovations aimed at improving efficiency. Each category highlights the energy demands, potential energy savings, and major challenges associated with each process or technology. This structured approach allows for a comparative understanding of the energy dynamics within WTPs and the feasibility of integrating new advancements.

Table 2.

Technological innovations in water treatment plants.

13.1. Next-Generation Membrane Filtration

Membrane filtration is one of the most important water treatment technologies, especially in desalination and surface water treatment processes [2,12,73]. In traditional membrane systems, energy intensity and sensitivity to fouling (clogging) are significant limitations [21,51]. The development of graphene-based membranes or their hybrid variants, such as nanocomposite membranes, enables a significant reduction in hydraulic resistance, resulting in a 30–50% reduction in energy consumption. In addition, antimicrobial coatings, such as silver nanoparticles or titanium dioxide, can extend the life of membranes, reducing operating costs and the consumption of cleaning chemicals [37,81]. However, the primary challenge remains high production and implementation costs, which can be up to ten times higher than conventional membranes. Current large-scale desalination and filtration plants still rely on polymeric membranes due to their lower cost and established operational reliability. The total cost of ownership, including membrane replacement cycles, chemical cleaning, and process optimisation, must be carefully evaluated to determine the long-term benefits of graphene-based membranes [87].

Future applications of hybrid membranes include the integration of reverse osmosis technology with membrane-distillation processes, which can increase desalination efficiency even at high levels of organic fouling [78,81]. Such systems are already being tested in plants in Saudi Arabia and Australia, where a 20% reduction in energy costs compared to conventional methods has been achieved [35,70].

13.2. Advanced Oxidation Processes (AOPs)

Advanced oxidation processes (AOPs) are a group of technologies that use highly reactive hydroxyl radicals to degrade complex organic contaminants and microplastics, pharmaceuticals, pesticides, and PFAS compounds [76,83]. Processes such as the combination of ozonation with UV or the Fenton reaction are able to effectively remove difficult-to-treat compounds such as pharmaceuticals, pesticides, or PFAS compounds [84,85]. Additionally, AOPs can be used to degrade toxic disinfection by-products, making them a technology with great potential to ensure the safety of drinking water [83,88]. These processes outperform traditional chlorination and ozonation in terms of contaminant degradation, but they require higher energy inputs and advanced process control systems. The capital costs for AOP systems remain 30–50% higher than conventional disinfection methods, primarily due to reactor complexity, energy demand, and catalyst replacement costs. Despite these economic challenges, long-term operational savings can be achieved by integrating AOPs with on-site renewable energy sources and optimised chemical dosing strategies.

In the future, the development of heterogeneous catalysts, such as iron or cobalt oxide nanoparticles, could significantly increase the efficiency of AOPs, reducing their energy and operational costs [73]. It is estimated that advanced AOP systems can reduce energy consumption in disinfection processes by 20–30% while improving water quality [70].

13.3. Intelligent Water Management Systems: AI and IoT

The integration of artificial intelligence (AI) and the Internet of Things (IoT) in water management is the next step in the transformation of the WTP sector [8,52]. Systems equipped with sensors and machine learning algorithms can monitor water quality in real time, predict changes in water composition, and optimise equipment operation [83]. For example, intelligent chemical dosing systems equipped with AI technologies can reduce chemical consumption by 15–20%, while reducing energy losses in mixing processes [89].

In the future, the integration of water management systems into urban data platforms could enable the dynamic adaptation of treatment processes to changing demand, especially in regions affected by climate change. This approach is being tested in cities such as Singapore and Copenhagen, where intelligent management systems have enabled a 25% reduction in water losses [6].

13.4. Water Recovery and Recycling

In the context of global water scarcity, the development of water recovery and recycling technologies remains a key challenge. Multistage recovery systems, such as reverse osmosis combined with membrane bioreactors (MBRs), enable the reuse of process water in industrial and agricultural processes [86]. Future technologies, such as metathesis electrodialysis, can further improve the energy efficiency of recycling, especially for waters with high salt content [90].

To better illustrate the economic feasibility of emerging technologies, Table 3 compares key cost factors for graphene membranes, AOPs, and conventional water treatment methods, considering implementation, maintenance, and energy consumption.

Table 3.

Key cost factors for graphene membranes, AOPs, and conventional water treatment methods comparison.

Many WTPs operate on an infrastructure that was designed and built decades ago. Adapting this infrastructure to new technologies, such as intelligent management systems or advanced filtration processes, is a challenge technically and in terms of cost [90]. For example, the integration of modern membranes requires not only the installation of new equipment, but also the modification of water transport and storage systems, which generates additional costs and increases implementation time [80]. Furthermore, the implementation of modern technologies requires skilled engineering and technical staff who are able to operate and service the advanced equipment. The lack of adequate training and limited access to knowledge of new technologies, especially in developing countries, is a significant constraint [91]. The introduction of technologies, such as advanced membrane processes or plasma disinfection technologies, requires both specialised skills and adequate research and development (R&D) and regulatory facilities. New technologies will be ahead of the current regulatory framework and water quality standards [65]. The lack of uniform standards for advanced procedures such as AOPs or membrane technologies will hinder their implementation in practice. In addition, differences in national and pan-European regulations may cause difficulties in scaling up innovative solutions [4,5,6,57].

Some new technologies, such as water recycling or the use of biogas, may face public opposition. Lack of confidence in the safety of such solutions, especially in the context of recycled drinking water, may affect their acceptance [6,34,39]. It is necessary to conduct educational initiatives and information campaigns now to bring local communities closer to the benefits of introducing these technologies [56,72,77,84,86].

On the other hand, the cost of implementing advanced technologies such as hybrid membranes, advanced oxidation processes (AOPs), or intelligent management systems is one of the most important constraints [78,83,84]. Graphene membrane technology, although promising significant energy savings, is still in the research and development stage and the cost of producing these membranes remains very high—up to 10 times that of traditional polymeric membranes [12,87]. For a medium-sized station, the cost of upgrading membrane filtration can range from EUR 1 to EUR 3 million [53,90]. Advanced management systems based on artificial intelligence (AI) also require significant financial investments in digital infrastructure, sensors, and control systems. In small- and medium-sized stations, such costs may exceed available operating budgets, making these technologies mainly available to large units [92,93].

The integration of advanced technologies, such as graphene membranes and advanced oxidation processes (AOPs), presents significant opportunities for improving the efficiency of water treatment plants. However, the adoption of these innovations is often constrained by high capital investment, operational costs, and maintenance requirements compared to conventional treatment technologies. A comprehensive evaluation of economic feasibility is essential to assess whether these advancements can be implemented on a large scale while remaining cost-effective.

14. Overview of Technologies and Practises to Improve Energy Efficiency

Improving energy efficiency in water treatment plants (WTPs) is an important step towards sustainability [2]. Due to rising energy costs and increasing environmental pressures, the optimisation of processes and technology in WTP is becoming more and more important [23,34]. The solutions discussed, including modern pump and motor technologies, process optimisation, integration of renewable energy sources (RES), and energy recuperation, offer both significant opportunities and specific limitations. Their potential, limitations, and directions for future development should be especially considered [4,22,94,95].

14.1. Modern Pump and Motor Technologies

Pumps and electric motors are responsible for the largest share of total energy consumption in SUW, accounting for between 60% and 80% [4,25,90]. Traditional pumping systems, used until recently, were characterised by low efficiency (50–65%) and a lack of flexibility in adjusting performance to changing operational conditions. The introduction of pumps with inverters has allowed dynamic speed adjustment to current hydraulic needs, reducing energy consumption by 20–30% compared to older-generation pumps [92]. For large stations handling more than 100,000 m3/day, such a reduction represents savings of 2000–3000 MWh per year, which translates into operating costs of more than EUR 250,000. The opportunities presented by modern pumping technology include not only improving energy efficiency, but also extending the life of the equipment through precise control of its operation. IE4 (Premium Efficiency) and IE5 (Ultra Premium Efficiency) motor technology offer further savings by reducing energy losses due to mechanical resistance, which is particularly important in large stations with high flow rates. Permanent magnet synchronous motors, which achieve efficiencies of more than 98%, are considered the future in the water sector [28]. The limitations of modern pumping systems are mainly due to high initial costs. The cost of upgrading inverter pumps in a medium-sized SUW (50,000 m3/day) can range from EUR 150,000 to EUR 300,000, which is a barrier for many smaller units. In addition, the introduction of new technologies requires specialised staff for both installation and ongoing maintenance of the systems, which is an additional challenge in some regions [4,5,6].

14.2. Technological Processes Optimisation

Traditional processes at the SUW, such as coagulation, flocculation, or filtration, were designed in a standardised manner without taking into account the variability of raw water quality. Fixed operating parameters led to excessive energy and chemical consumption, especially in smaller plants with limited optimisation possibilities [85]. For example, flocculation processes in older systems consumed between 0.15 and 0.2 kWh/m3, while modern technologies allow this value to be reduced to 0.1 kWh/m3 through precise chemical dosing and optimal mixing [33]. Optimisation of membrane filtration, by using membranes with low hydraulic resistance, reduces energy demand by 15–25% [47,95]. For example, in surface water treatment plants with a capacity of 200,000 m3/day, the reduction in energy consumption can reach 1000 MWh per year. Management of water flows in SUWs, such as recirculation of process water or optimisation of filter backwash, offers additional energy savings of 5–10% per year [41,83,96]. Opportunities in process optimisation arise from the further development of intelligent control systems that adjust process parameters in real time to changing operational conditions [97]. These systems can also integrate machine learning algorithms that predict optimal settings based on analysis of historical data. The limitations of process optimisation mainly relate to the cost of implementing advanced control systems and their scalability. For small stations, handling less than 10,000 m3/day, the cost of installing advanced control systems may outweigh the potential savings [93].

14.3. Energy Recuperation