Investigation of Water-in-Diesel Emulsion Behavior Formulated for Performance Conditions in a Single-Cylinder Diesel Engine

Abstract

1. Introduction

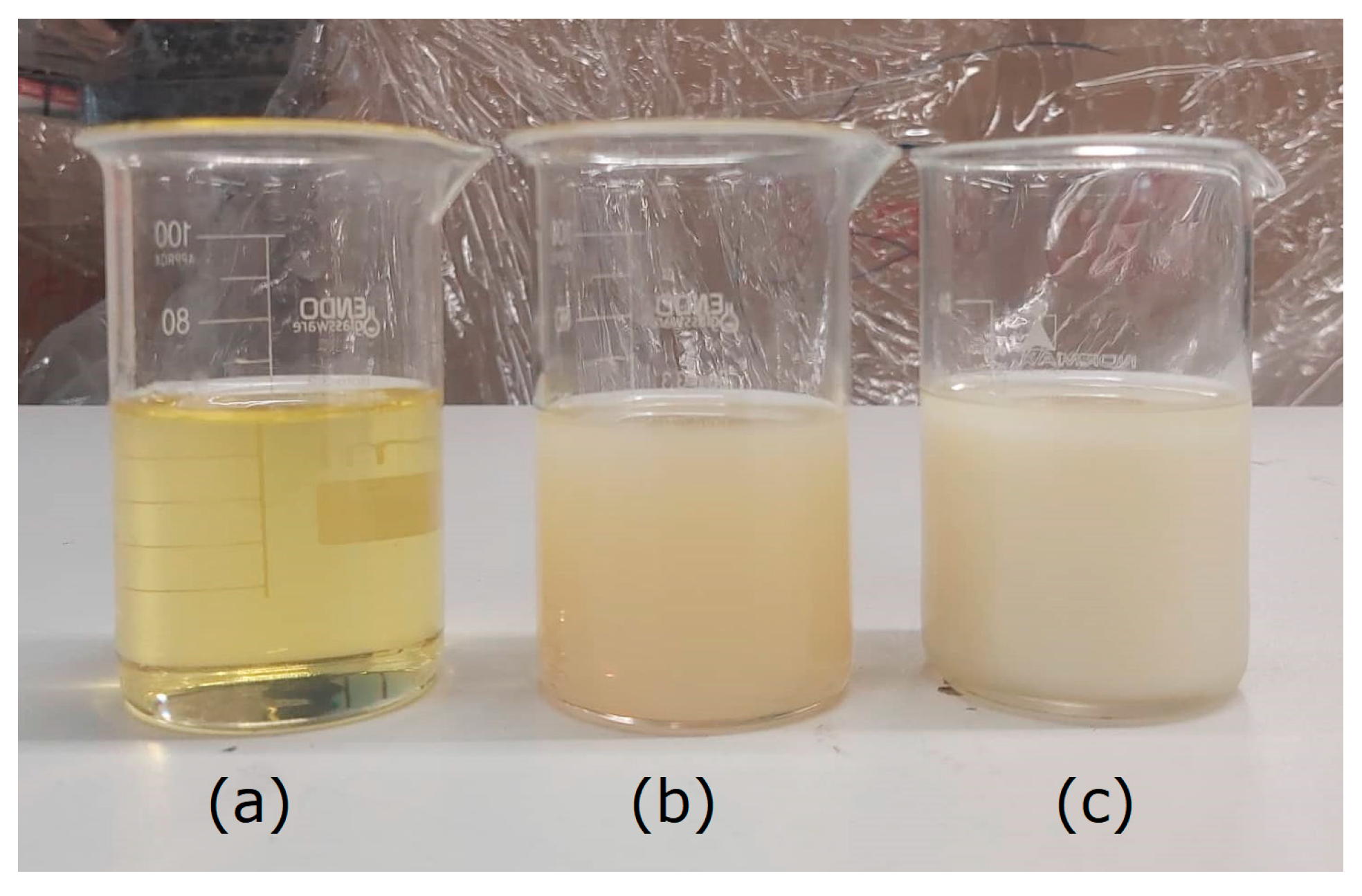

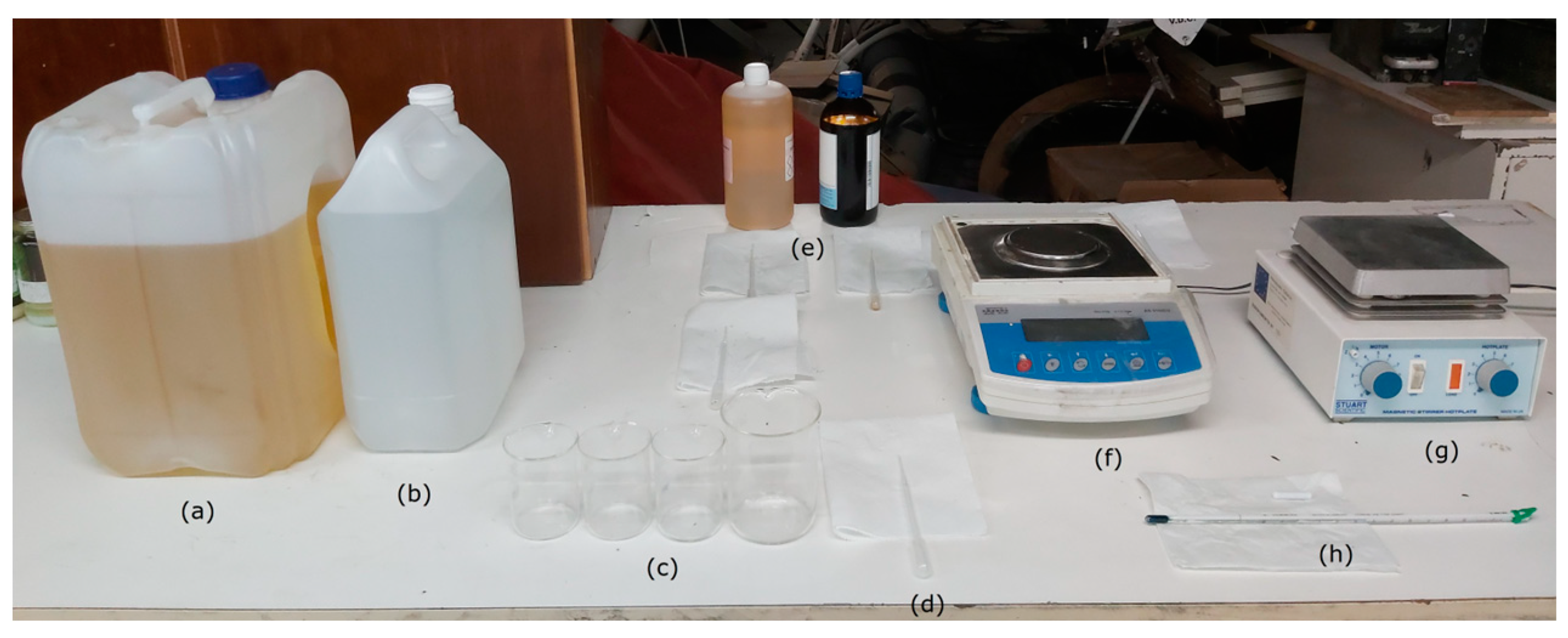

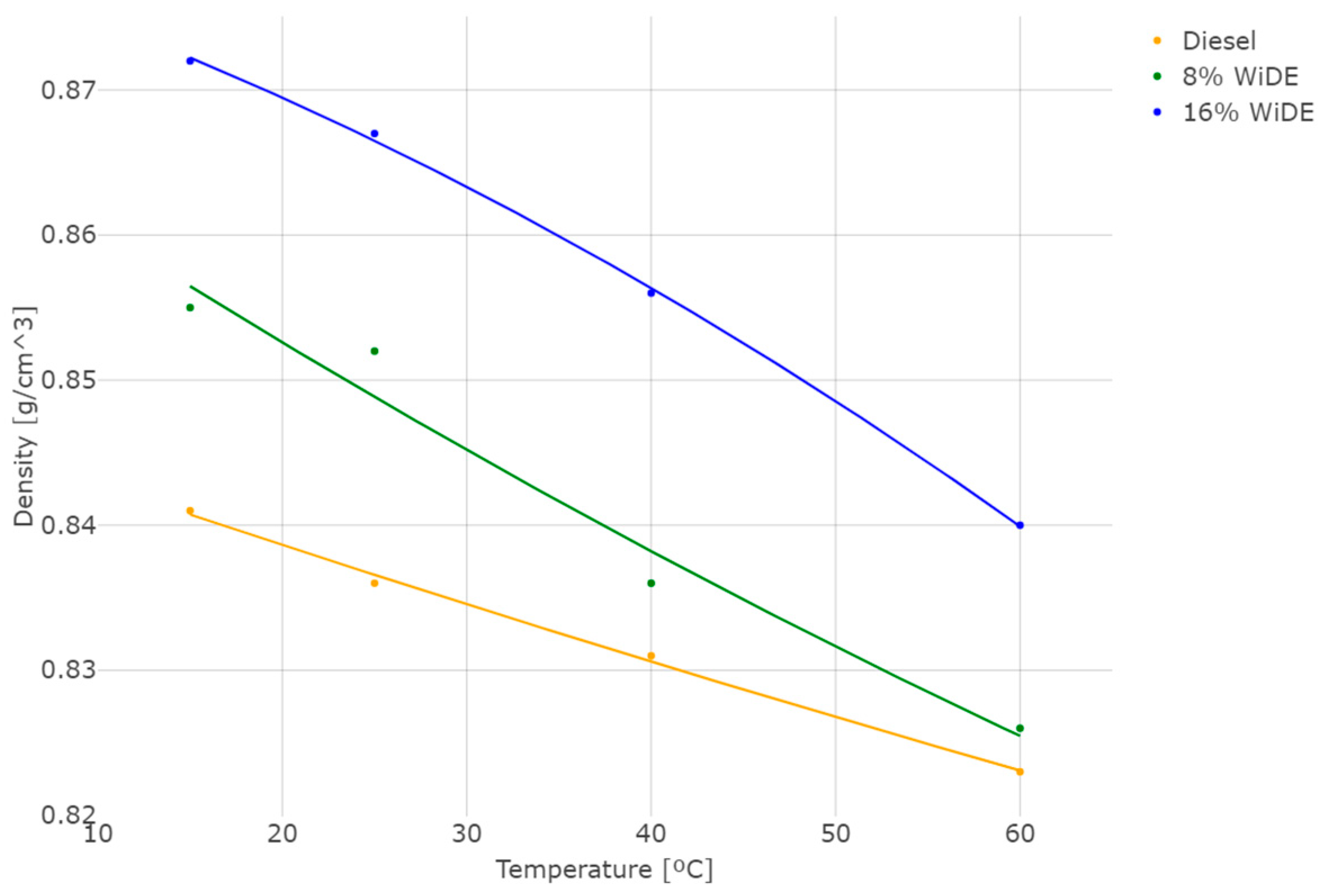

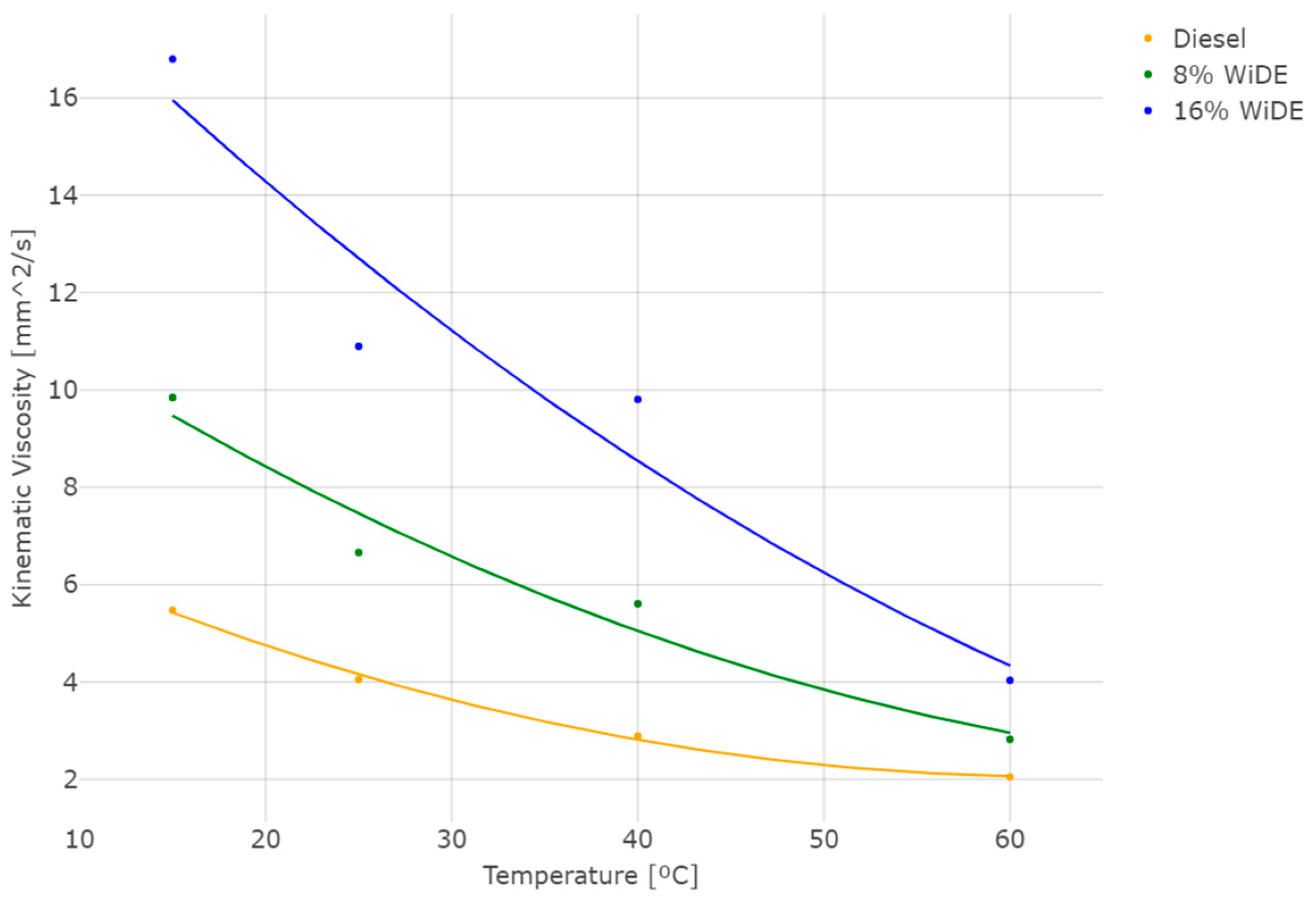

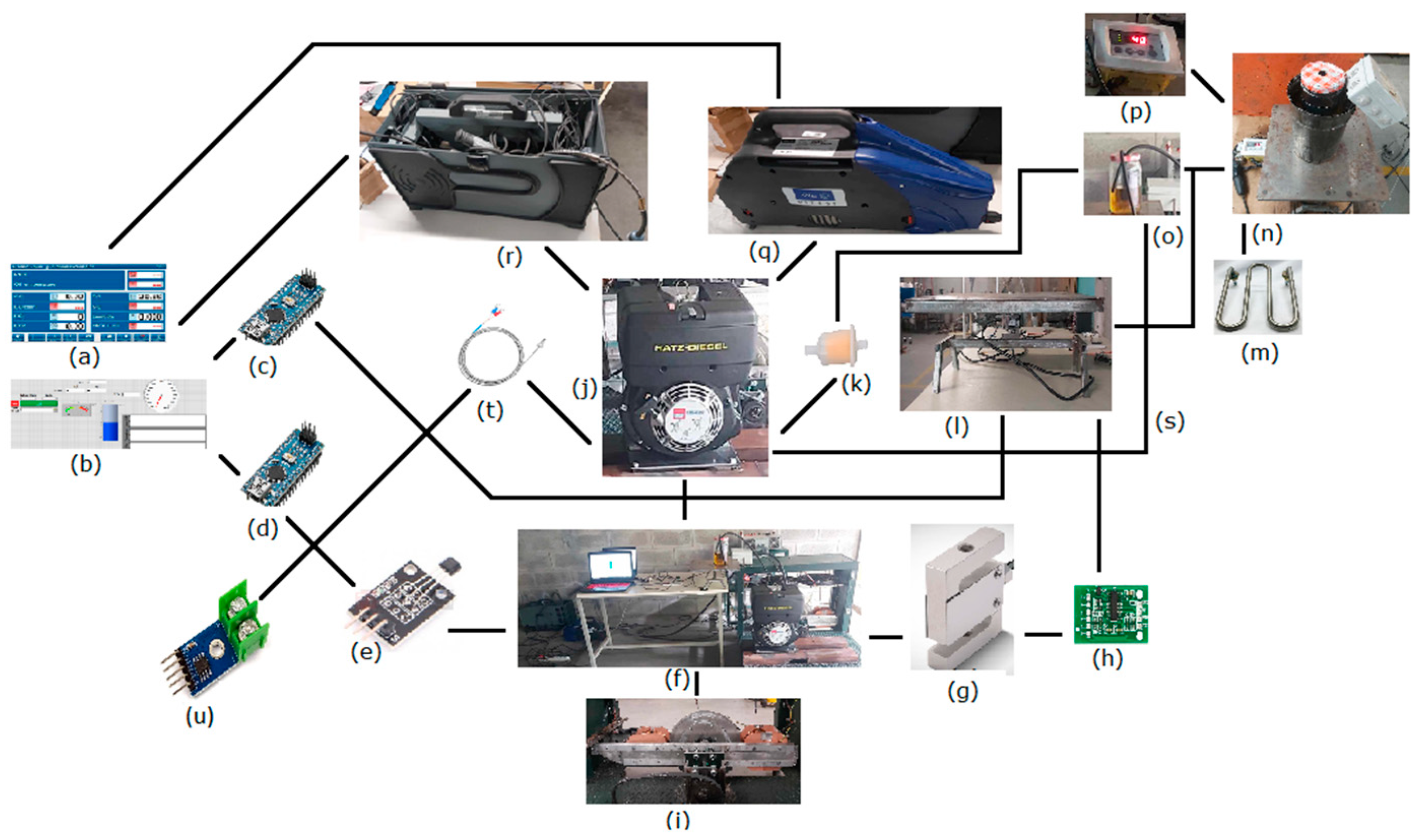

2. Materials and Methods

3. Results and Discussion

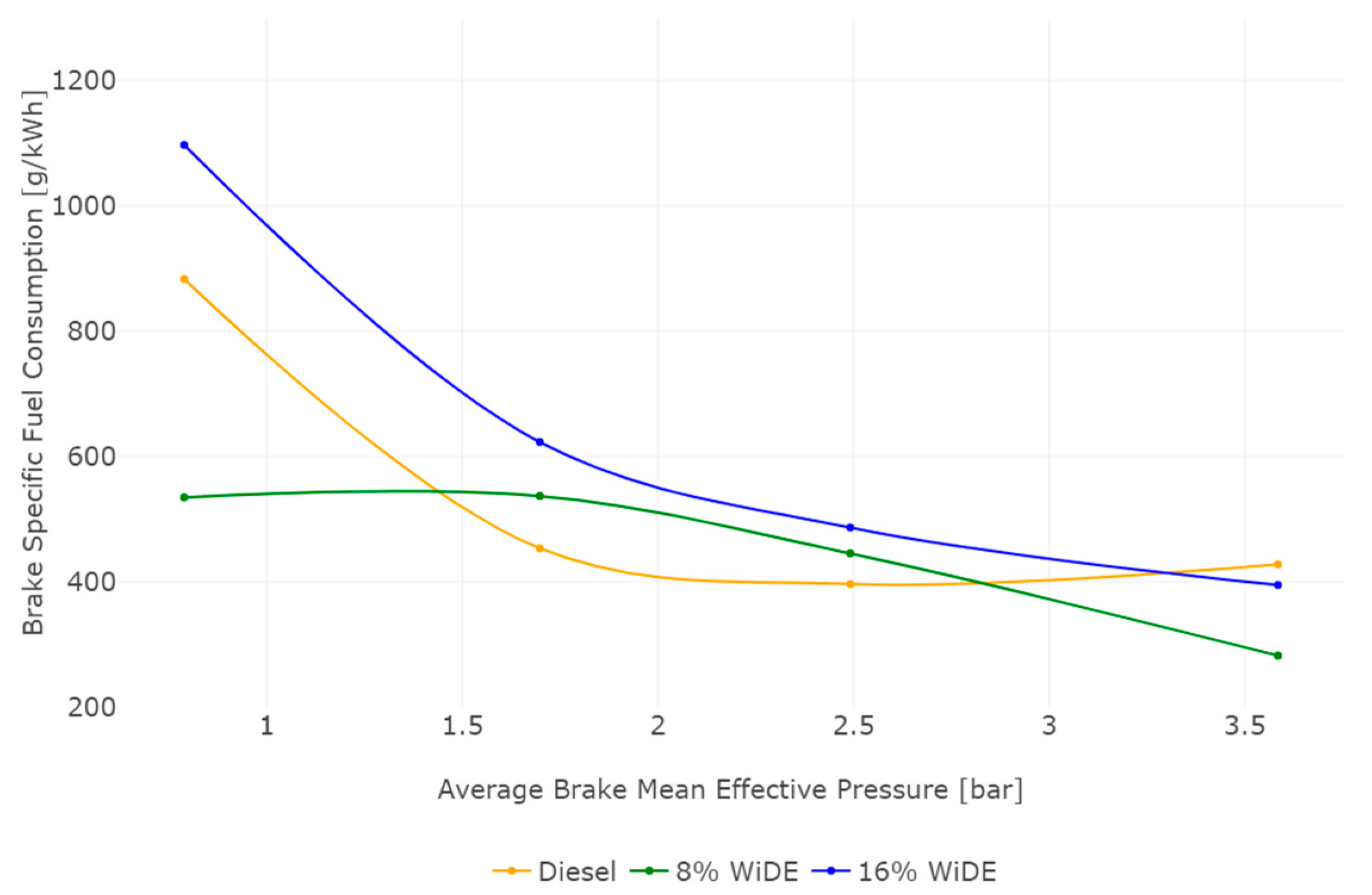

3.1. Brake-Specific Fuel Consumption

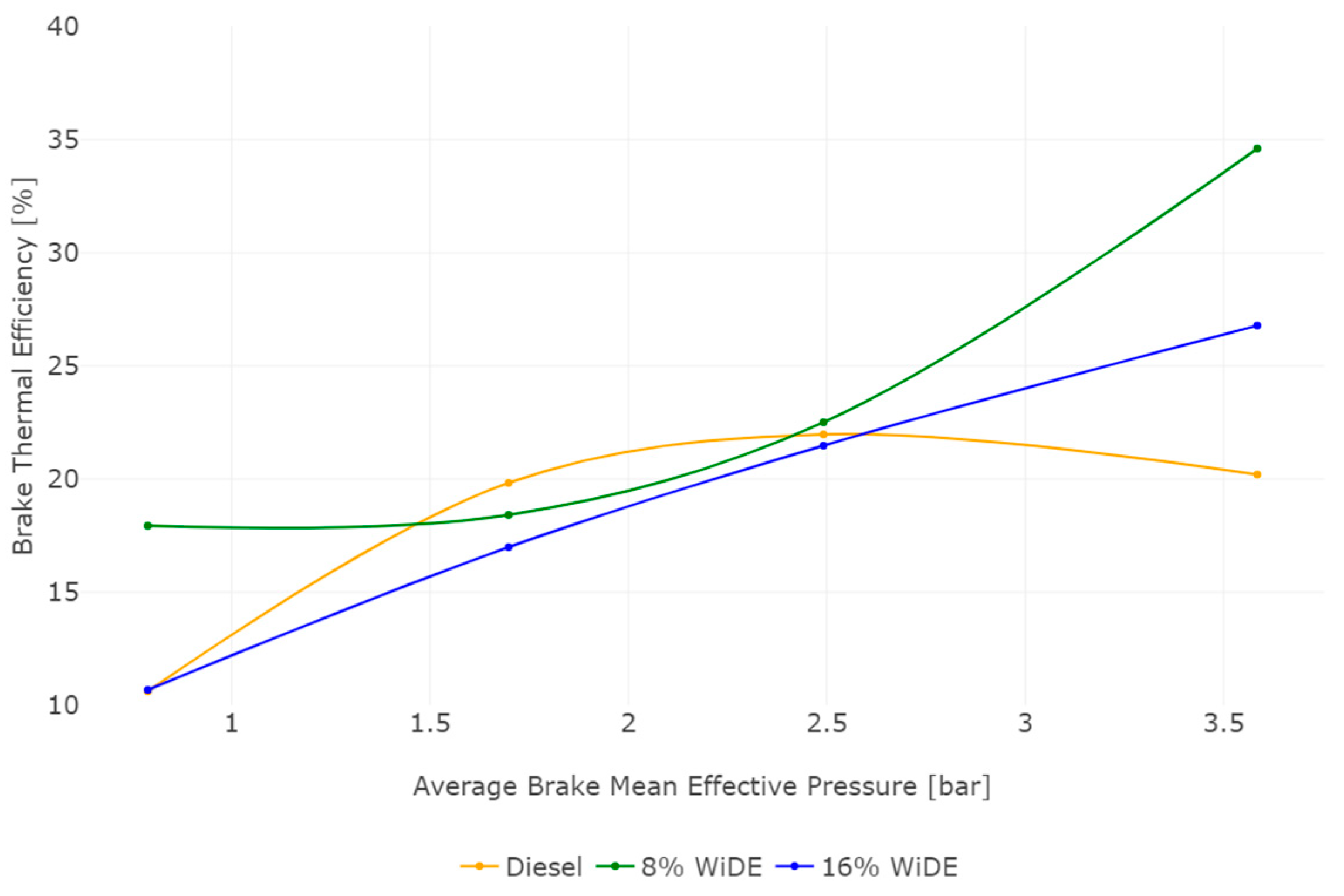

3.2. Brake Thermal Efficiency

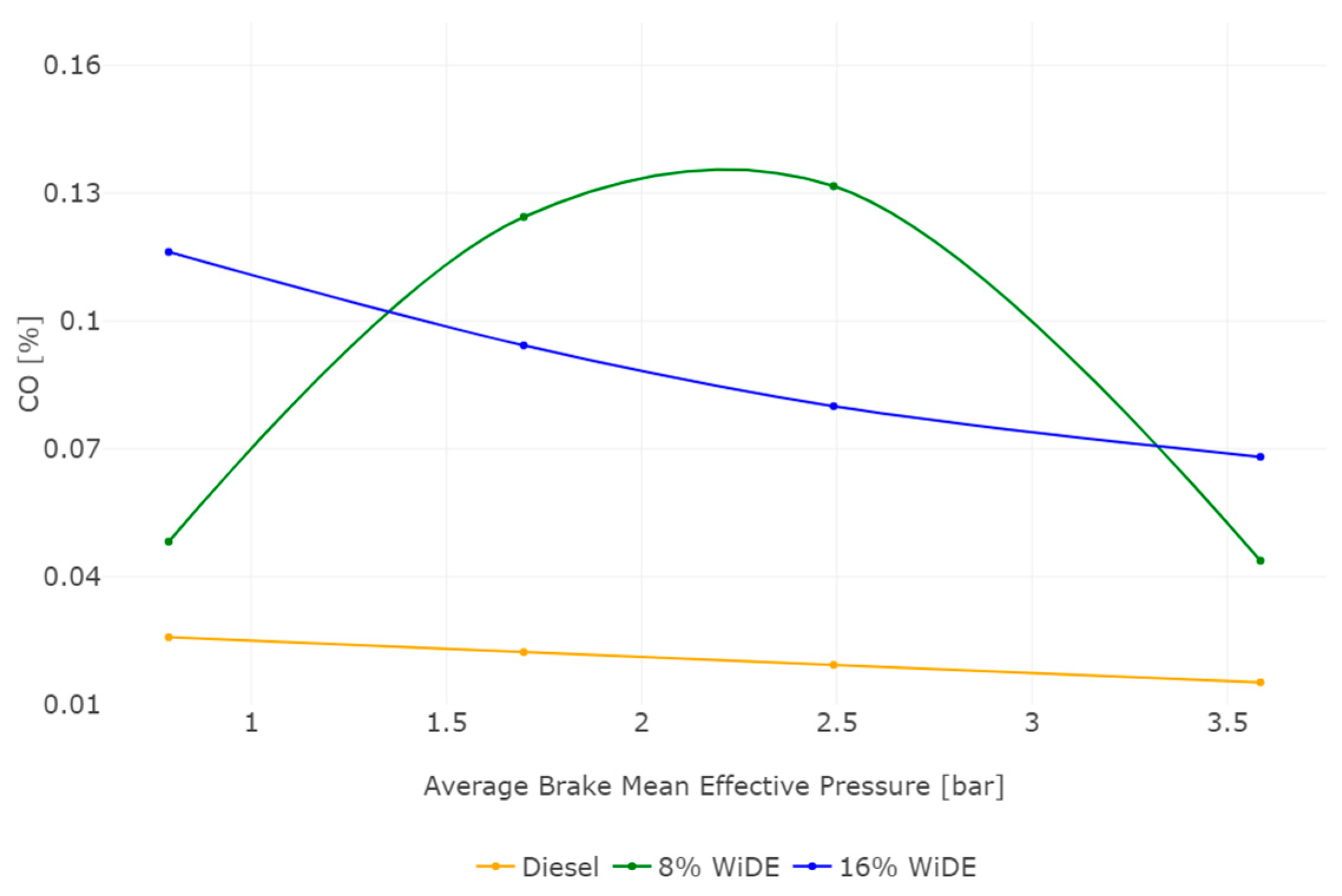

3.3. Carbon Monoxide Emissions

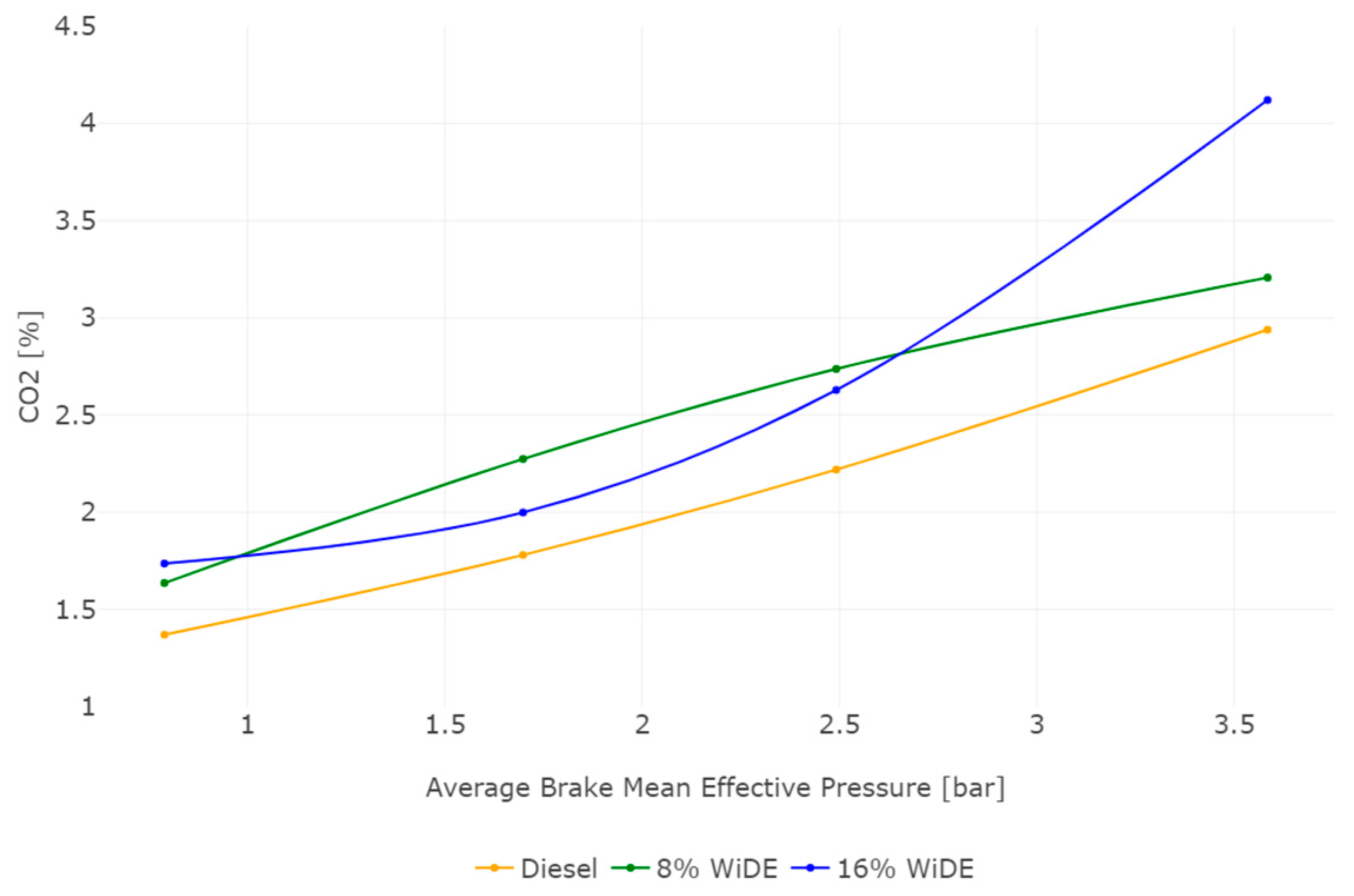

3.4. Carbon Dioxide Emissions

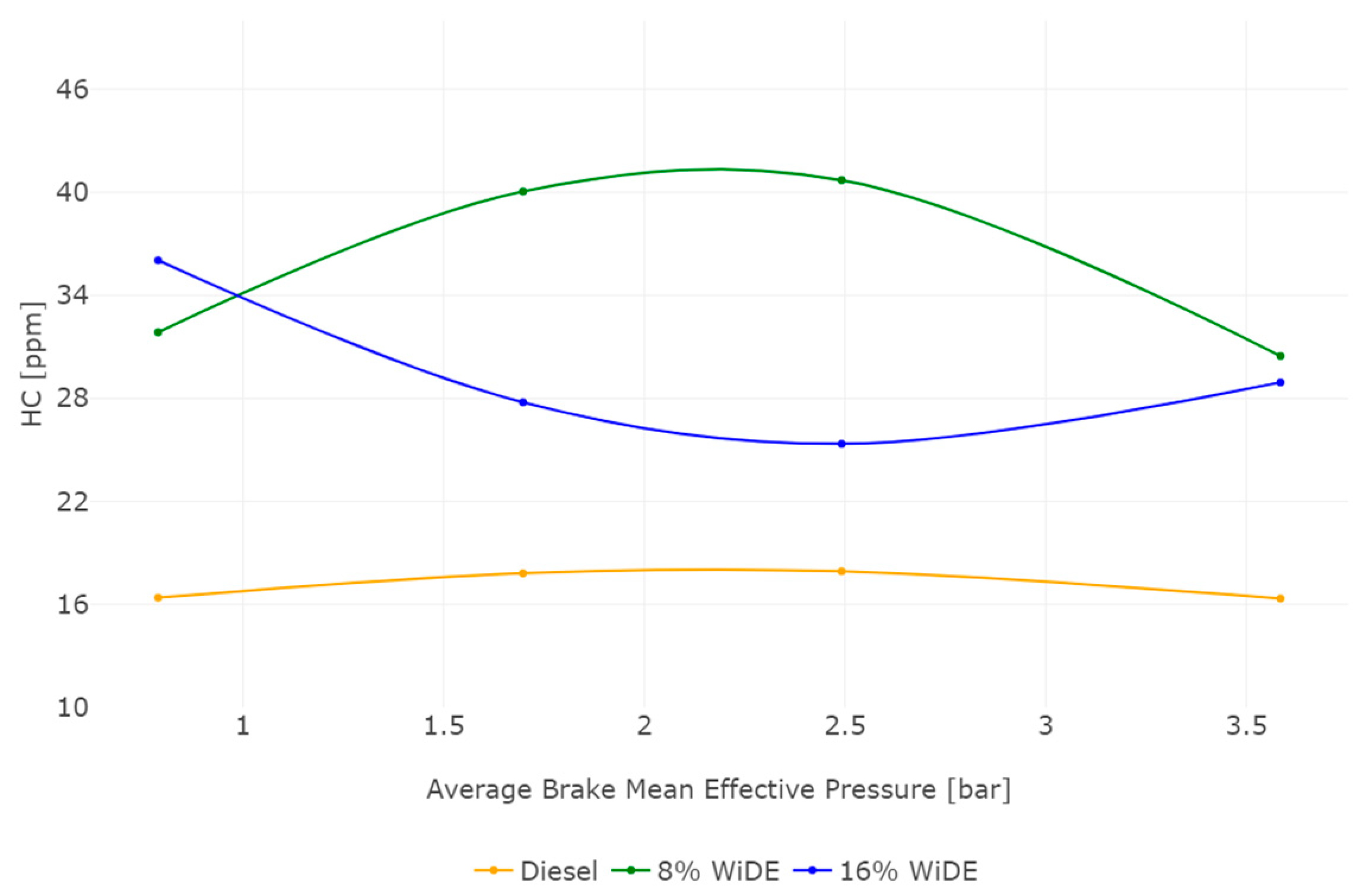

3.5. Hydrocarbon Emissions

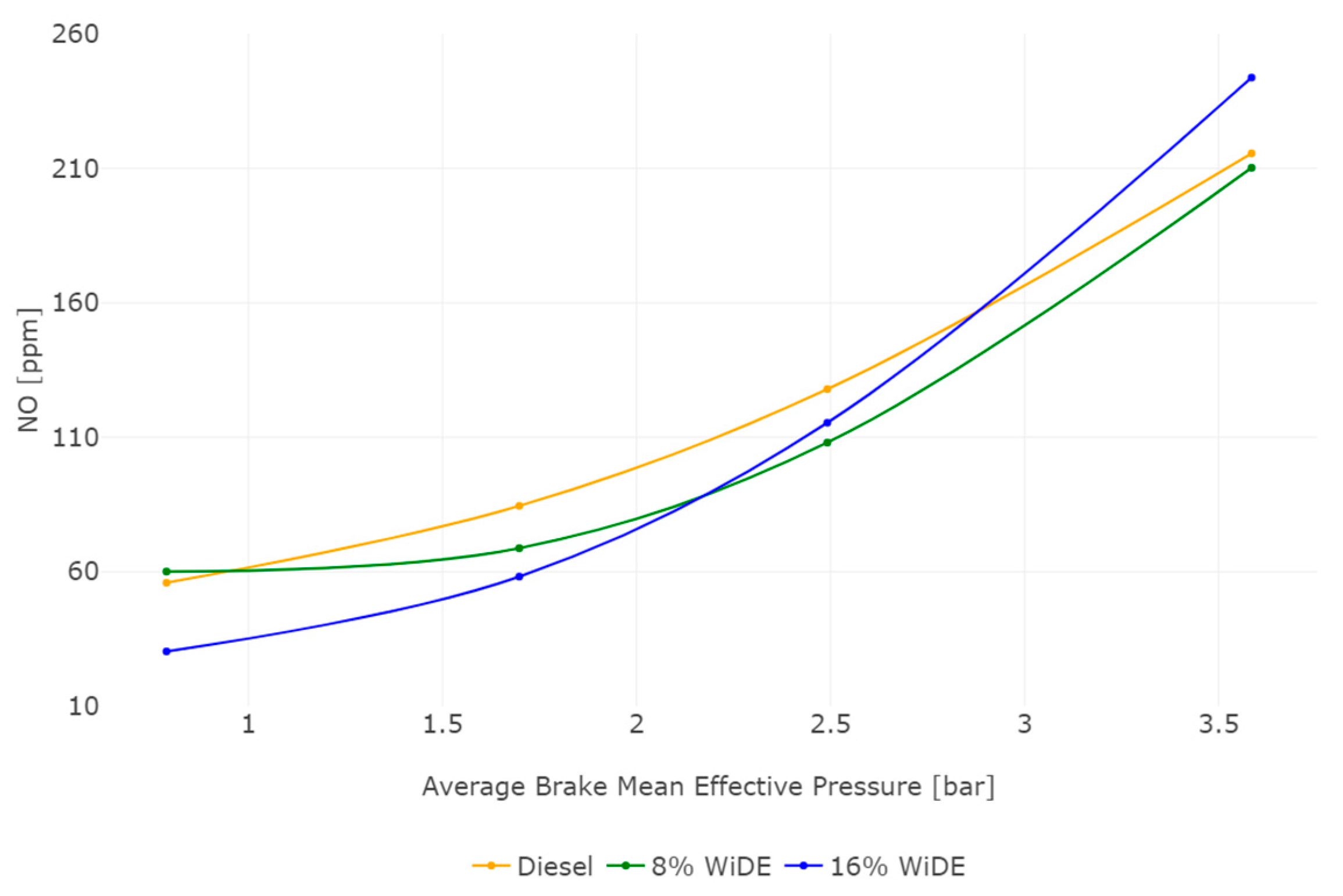

3.6. Nitric Oxide Emissions

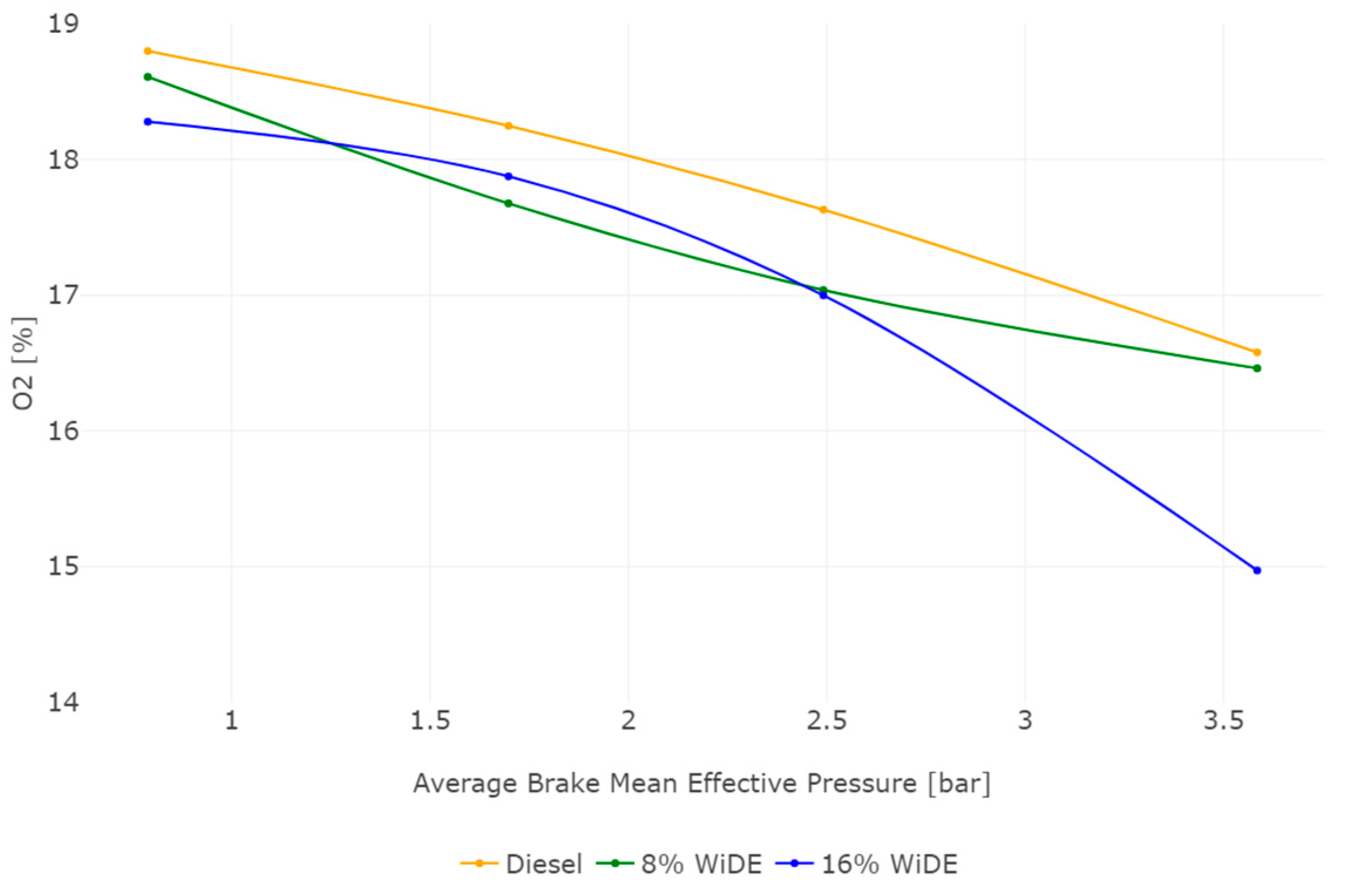

3.7. Oxygen Emissions

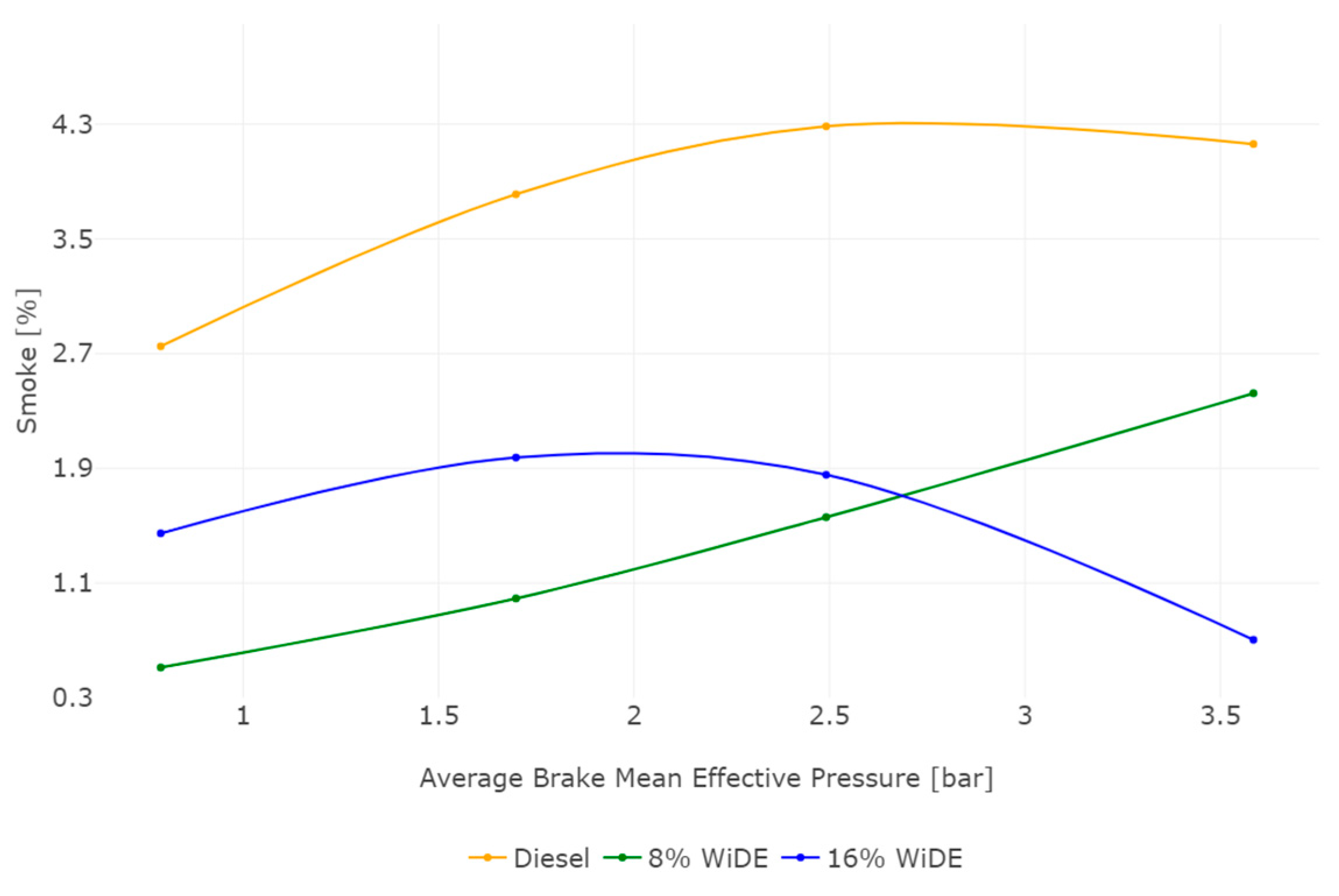

3.8. Smoke Emissions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BMEP | brake mean effective pressure |

| BSFC | brake-specific fuel consumption |

| BTE | brake thermal efficiency |

| CI | compression-ignition |

| CO | carbon monoxide |

| CO2 | carbon dioxide |

| DI | direct injection |

| HC | hydrocarbons |

| LHV | lower heating value |

| NO | nitric oxide |

| NOx | nitrogen oxides |

| PM | particulate matter |

| O2 | oxygen |

| WiDE | water-in-diesel emulsion |

References

- Jayabal, R. Ammonia as a Potential Green Dual Fuel in Diesel Engines: A Review. Process Saf. Environ. Prot. 2024, 188, 1346–1354. [Google Scholar] [CrossRef]

- Jin, C.; Wei, J. The Combined Effect of Water and Nanoparticles on Diesel Engine Powered by Biodiesel and Its Blends with Diesel: A Review. Fuel 2023, 343, 127940. [Google Scholar] [CrossRef]

- Sonachalam, M.; Manieniyan, V.; Senthilkumar, R.; Ramis, M.K.; Warimani, M.; Kumar, R.; Kedia, A.; Khan, T.M.Y.; Almakayeel, N. Experimental Investigation of Performance, Emission, and Combustion Characteristics of a Diesel Engine Using Blends of Waste Cooking Oil-Ethanol Biodiesel with MWCNT Nanoparticles. Case Stud. Therm. Eng. 2024, 61, 105094. [Google Scholar] [CrossRef]

- Liao, J.; Wang, Z.; Hu, J.; Yan, F.; Wu, Y.; Cai, Z.; Zheng, S.; Li, S.; Peng, H. Investigation of the Effect of Different Structure Parameters and Operating Factors on the Integrated Exhaust Aftertreatment System for Diesel Engines and Parameter Importance Analysis. J. Clean. Prod. 2024, 447, 141257. [Google Scholar] [CrossRef]

- Bhagat, R.N.; Sahu, K.B.; Ghadai, S.K.; Kumar, C.B. A Review of Performance and Emissions of Diesel Engine Operating on Dual Fuel Mode with Hydrogen as Gaseous Fuel. Int. J. Hydrogen Energy 2023, 48, 27394–27407. [Google Scholar] [CrossRef]

- Kim, J.; Vallinmaki, M.; Tuominen, T.; Mikulski, M. Variable Valve Actuation for Efficient Exhaust Thermal Management in an Off-Road Diesel Engine. Appl. Therm. Eng. 2024, 246, 122940. [Google Scholar] [CrossRef]

- Farzam, R.; McTaggart-Cowan, G. Hydrogen-Diesel Dual-Fuel Combustion Sensitivity to Fuel Injection Parameters in a Multi-Cylinder Compression-Ignition Engine. Int. J. Hydrogen Energy 2024, 49, 850–867. [Google Scholar] [CrossRef]

- Nadimi, E.; Przybyła, G.; Løvås, T.; Adamczyk, W. Effects of Biodiesel Injector Configuration and Its Injection Timing on Performance, Combustion and Emissions Characteristics of Liquid Ammonia Dual Direct Injection Engine. J. Energy Inst. 2024, 114, 101605. [Google Scholar] [CrossRef]

- Nguyen Manh, D.; Tran Quang, V.; The Luong, N.; Nguyen The, T.; Duy, T.N.; Duc, K.N.; Pham Minh, T. A Simulation and Experiment Study on the Emission Reduction Potential of Light-Duty Diesel Engine Retrofitted with an after-Treatment System: A Case Study. Energy Sources Part A Recover. Util. Environ. Eff. 2024, 46, 674–688. [Google Scholar] [CrossRef]

- Zhang, Z.; Dong, R.; Tan, D.; Duan, L.; Jiang, F.; Yao, X.; Yang, D.; Hu, J.; Zhang, J.; Zhong, W.; et al. Effect of Structural Parameters on Diesel Particulate Filter Trapping Performance of Heavy-Duty Diesel Engines Based on Grey Correlation Analysis. Energy 2023, 271, 127025. [Google Scholar] [CrossRef]

- Zhang, Y.; Xia, C.; Liu, D.; Zhu, Y.; Feng, Y. Experimental Investigation of the High-Pressure SCR Reactor Impact on a Marine Two-Stroke Diesel Engine. Fuel 2023, 335, 127064. [Google Scholar] [CrossRef]

- Liu, W.; Gao, Y.; You, Y.; Jiang, C.; Hua, T.; Xia, B. Nonlinear Model Predictive Control(NMPC) of Diesel Oxidation Catalyst (DOC) Outlet Temperature for Active Regeneration of Diesel Particulate Filter (DPF) in Diesel Engine. Energy 2024, 293, 130658. [Google Scholar] [CrossRef]

- Sekar, M.; Selim, M.Y.E.; Saleh, H.E.; Elgendi, M. Utilization of Hydrogen and Methane as Energy Carriers with Exhaust Gas Recirculation for Sustainable Diesel Engines. Energy Convers. Manag. X 2024, 23, 100618. [Google Scholar] [CrossRef]

- Bui, K.Q.; Perera, L.P.; Emblemsvåg, J. Life-Cycle Cost Analysis of an Innovative Marine Dual-Fuel Engine under Uncertainties. J. Clean. Prod. 2022, 380, 134847. [Google Scholar] [CrossRef]

- Shen, S.; Liu, H.; Liu, Y.; Liu, X.; Hu, H.; Hu, Z.; Wang, T. Dynamic Details inside Water-in-Oil (W/O) Emulsion Droplet and Its Impact on Droplet Evaporation and Micro-Explosion. Fuel 2023, 338, 127254. [Google Scholar] [CrossRef]

- Gowrishankar, S.; Rastogi, P.; Krishnasamy, A.; Basavaraj, M.G.; Kaisare, N.; Aidhen, I.S. Synthesis and Characterization of Emulsion Fuels –Implications to Spray and Engine Studies. Prog. Energy Combust. Sci. 2024, 101, 101133. [Google Scholar] [CrossRef]

- Woo, S.; Lee, K. Effect of Injection Strategy and Water Content on Water Emulsion Fuel Engine for Low Pollutant Compression Ignition Engines. Fuel 2023, 343, 127809. [Google Scholar] [CrossRef]

- Ali, A.; Aziz, A.R.A.; Ismael, M.A.; Alqaed, S. Biosurfactants as an Alternative Eco-Friendly Solution for Water-in-Diesel Emulsions-A Review Paper. Heliyon 2024, 10, e37485. [Google Scholar] [CrossRef] [PubMed]

- Vellaiyan, S. Recent Advancements in Water Emulsion Fuel to Explore Efficient and Cleaner Production from Various Biodiesels: A Retrospective Review. Renew. Sustain. Energy Rev. 2023, 187, 113704. [Google Scholar] [CrossRef]

- Tamam, M.Q.M.; Yahya, W.J.; Abdul Rahman, H.; Ithnin, A.M.; Abd Kadir, H.; Rahman, M.M.; Noge, H.; Koga, T.; Sugeng, D.A. Application of an Inline Mixer to Produce Surfactant-Free Biodiesel-Diesel/Water Emulsion Fuel: An Analysis of Water Droplets Characteristics and Drive Cycle Emissions. Arab. J. Sci. Eng. 2024, 1–14. [Google Scholar] [CrossRef]

- Mahdi, W.N.I.W.; Ithnin, A.M.; Yahya, W.J.; Rashid, M.A.A.; Kadir, H.A.; Sugeng, D.A.; Eiji, K. The Effect of Different In-Line Mixers Producing Emulsifier-Free Bio-Diesel Emulsion on the Diesel Engine Combustion Performance and Exhaust Emission. Fuel 2023, 337, 126886. [Google Scholar] [CrossRef]

- Mohd Tamam, M.Q.; Omi, M.R.T.; Yahya, W.J.; Ithnin, A.M.; Abdul Rahman, H.; Rahman, M.M.; Abd Kadir, H.; Noge, H.; Koga, T.; Hong, C.; et al. Engine Performance and Emissions Evaluation of Surfactant-Free B30 Biodiesel–Diesel/Water Emulsion as Alternative Fuel. Sci. Rep. 2023, 13, 10599. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Yuan, B.; Cao, J.; Huang, Y.; Cheng, X.; Wang, Y.; Zhang, X.; Liu, H. A New Shift Mechanism for Micro-Explosion of Water-Diesel Emulsion Droplets at Different Ambient Temperatures. Appl. Energy 2022, 323, 119448. [Google Scholar] [CrossRef]

- Gowrishankar, S.; Krishnasamy, A. Emulsification–A Promising Approach to Improve Performance and Reduce Exhaust Emissions of a Biodiesel Fuelled Light-Duty Diesel Engine. Energy 2023, 263, 125782. [Google Scholar] [CrossRef]

- Mondal, P.K.; Mandal, B.K. Effect of Fuel Injection Pressure on the Performances of a CI Engine Using Water-Emulsified Diesel (WED) as a Fuel. Energy Sustain. Soc. 2024, 14, 12. [Google Scholar] [CrossRef]

- Ayad, I.; Ghannam, M.T.; Selim, M.Y.E. Experimental Stability Investigation of Different Water-in-Jojoba Biodiesel Emulsions. Fuel 2024, 357, 129782. [Google Scholar] [CrossRef]

- Patel, K.R.; Dhiman, V.D. A Review on Emission and Performance of Water Diesel Micro-Emulsified Mixture-Diesel Engine. Int. J. Environ. Sci. Technol. 2022, 19, 8027–8042. [Google Scholar] [CrossRef]

- Han, D.; Mao, J.; Zhao, J.; Zhang, H.; Yang, X.; Lin, C. Effect of Surfactant Hydrophobic Chain Equivalence on the Oil-Water Interface and Emulsion Stability: A Dissipative Particle Dynamics and Experimental Study. J. Mol. Liq. 2023, 382, 121781. [Google Scholar] [CrossRef]

- Attar, A.; Waghmare, J.; Mane, S. Water in Diesel Emulsion Fuel: Production, Properties, Performance, and Exhaust Emission Analysis. Int. J. Energy Environ. Eng. 2022, 13, 729–738. [Google Scholar] [CrossRef]

- Saha, U.; De, R.; Das, B. Interactions between Loaded Drugs and Surfactant Molecules in Micellar Drug Delivery Systems: A Critical Review. J. Mol. Liq. 2023, 382, 121906. [Google Scholar] [CrossRef]

- Vieira, A.; Simonelli, G.; Carlos, L. Review of the Application of Surfactants in Microemulsion Systems for Remediation of Petroleum Contaminated Soil and Sediments. Environ. Sci. Pollut. Res. 2023, 12, 32168–32183. [Google Scholar] [CrossRef]

- Bello, A.; Ozoani, J.; Adebayo, A.; Kuriashov, D. Rheological Study of Nanoparticle-Based Cationic Surfactant Solutions. Petroleum 2022, 8, 522–528. [Google Scholar] [CrossRef]

- Sazdanić, D.; Krstonošić, M.A.; Ćirin, D.; Cvejić, J.; Alamri, A.; Galanakis, C.M.; Krstonošić, V. Non-Ionic Surfactants-Mediated Green Extraction of Polyphenols from Red Grape Pomace. J. Appl. Res. Med. Aromat. 2023, 32, 100439. [Google Scholar] [CrossRef]

- Ali, A.; Aziz, A.R.A.; Ismael, M.A.; Alqaed, S. The Investigation of Lecithin and Cocamide DEA Biosurfactant Concentrations on Emulsified Biodiesel Fuel Stability, Properties, and the Micro-Explosion Phenomenon. Results Eng. 2024, 23, 102482. [Google Scholar] [CrossRef]

- Marhamati, M.; Ranjbar, G.; Rezaie, M. Effects of Emulsifiers on the Physicochemical Stability of Oil-in-Water Nanoemulsions: A Critical Review. J. Mol. Liq. 2021, 340, 117218. [Google Scholar] [CrossRef]

- Deepak, B.; Ibrahim, M.M. Microemulsion Fuel Formulation from Used Cooking Oil with Carbinol as the Dispersion Phase. Energy Sources Part A Recover. Util. Environ. Eff. 2023, 45, 4107–4126. [Google Scholar] [CrossRef]

- Czerniel, J.; Gostyńska, A.; Jańczak, J.; Stawny, M. A Critical Review of the Novelties in the Development of Intravenous Nanoemulsions. Eur. J. Pharm. Biopharm. 2023, 191, 36–56. [Google Scholar] [CrossRef]

- Kumar, A.; Chen, H.; Yang, S. Modeling Microexplosion Mechanism in Droplet Combustion: Puffing and Droplet Breakup. Energy 2023, 266, 126369. [Google Scholar] [CrossRef]

- Antonov, D.V.; Kuznetsov, G.V.; Razumov, D.S.; Fedorenko, R.M.; Yanovskiy, L.S.; Strizhak, P.A. Puffing and Micro-Explosion Effects in Composite Liquid Fuels in Different Heating Arrangements. Int. J. Heat Mass Transf. 2024, 223, 125273. [Google Scholar] [CrossRef]

- Zhang, H.; Lu, Z.; Wang, T.; Che, Z. Mist Formation during Micro-Explosion of Emulsion Droplets. Fuel 2023, 339, 127350. [Google Scholar] [CrossRef]

- Ismael, M.A.; Aziz, A.R.A.; Mohammed, S.E.; Zainal A, E.Z.; Baharom, M.B.; Hagos, F.Y. Macroscopic and Microscopic Spray Structure of Water-in-Diesel Emulsions. Energy 2021, 223, 120040. [Google Scholar] [CrossRef]

- Sartomo, A.; Santoso, B.; Ubaidillah; Muraza, O. Recent Progress on Mixing Technology for Water-Emulsion Fuel: A Review. Energy Convers. Manag. 2020, 213, 112817. [Google Scholar] [CrossRef]

- Mohd Tamam, M.Q.; Yahya, W.J.; Ithnin, A.M.; Abdullah, N.R.; Kadir, H.A.; Rahman, M.M.; Rahman, H.A.; Abu Mansor, M.R.; Noge, H. Performance and Emission Studies of a Common Rail Turbocharged Diesel Electric Generator Fueled with Emulsifier Free Water/Diesel Emulsion. Energy 2023, 268, 126704. [Google Scholar] [CrossRef]

- Okumuş, F.; Kaya, C.; Kökkülünk, G. NOx Based Comparative Analysis of a CI Engine Fueled with Water in Diesel Emulsion. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 3, 6710–6729. [Google Scholar] [CrossRef]

- Vasistha, V.; Bharj, R.S. Analyzing the Storage Stability of Diesel Emulsified Fuels: A Comparative Standpoint. Energy Sources Part A Recover. Util. Environ. Eff. 2022, 44, 5527–5544. [Google Scholar] [CrossRef]

- Fernandes Serodio, J.C. Method, System, Apparatus and Formulations for Producing Oil-Based Blends and Microemulsions and Nanoemulsions. Worldwide Application No. WO2021090010A1, 14 May 2021. [Google Scholar]

- El Shenawy, E.A.; Elkelawy, M.; Bastawissi, H.A.E.; Shams, M.M.; Panchal, H.; Sadasivuni, K.; Thakar, N. Investigation and Performance Analysis of Water-Diesel Emulsion for Improvement of Performance and Emission Characteristics of Partially Premixed Charge Compression Ignition (PPCCI) Diesel Engines. Sustain. Energy Technol. Assess. 2019, 36, 100546. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, S.; Huang, Y.; Huang, S.; Shi, S.; Cheng, X.; Huang, R. Experimental Investigation on Spray, Evaporation and Combustion Characteristics of Ethanol-Diesel, Water-Emulsified Diesel and Neat Diesel Fuels. Fuel 2018, 231, 438–448. [Google Scholar] [CrossRef]

- Khanjani, A.; Sobati, M.A. Performance and Emission of a Diesel Engine Using Different Water/Waste Fish Oil (WFO) Biodiesel/Diesel Emulsion Fuels: Optimization of Fuel Formulation via Response Surface Methodology (RSM). Fuel 2021, 288, 119662. [Google Scholar] [CrossRef]

- Hassan, Z.U.; Usman, M.; Asim, M.; Kazim, A.H.; Farooq, M.; Umair, M.; Imtiaz, M.U.; Asim, S.S. Use of Diesel and Emulsified Diesel in CI Engine: A Comparative Analysis of Engine Characteristics. Sci. Prog. 2021, 104, 00368504211020930. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Zhang, Z.; Chen, H.; Ji, Z.; Ma, Y.; Sun, F. A Review on Performance, Combustion and Emission of Diesel and Alcohols in a Dual Fuel Engine. J. Energy Inst. 2024, 116, 101760. [Google Scholar] [CrossRef]

- Kim, K.; Lee, W.; Wiersema, P.; Mayhew, E.; Temme, J.; Kweon, C.B.M.; Lee, T. Effects of the Cetane Number on Chemical Ignition Delay. Energy 2023, 264, 126263. [Google Scholar] [CrossRef]

- Liu, J.; Booma Devi, P.; Chinnathambi, A.; Ali Alharbi, S. Mitigating Fossil Fuel Deficiency and Environmental Impacts: Performance Analysis of Scenedesmus Obliquus Microalgae Biodiesel in a Diesel Engine. Fuel 2024, 364, 131033. [Google Scholar] [CrossRef]

- Abdollahi, M.; Ghobadian, B.; Najafi, G.; Hoseini, S.S.; Mofijur, M.; Mazlan, M. Impact of Water–Biodiesel–Diesel Nano-Emulsion Fuel on Performance Parameters and Diesel Engine Emission. Fuel 2020, 280, 118576. [Google Scholar] [CrossRef]

- Rahman, H.A.; Rahman, M.M.; Yahya, W.J.; Kaonain, T.E.; Kadir, H.A. Implementation of a Non-Surfactant Water-in-Diesel Emulsion Fuel in a Common Rail Direct Injection Diesel Vehicle. Int. J. Automot. Technol. 2023, 24, 1349–1358. [Google Scholar] [CrossRef]

- Cengiz, C.; Ozen Unverdi, S. Effect of Early Intake Valve Closing, Exhaust Gas Recirculation and Split Injection on Combustion and Emissions Characteristics of a HDDI Diesel Engine Operating in PCCI Combustion Mode. Fuel 2023, 353, 129079. [Google Scholar] [CrossRef]

- Ağbulut, Ü.; Sarıdemir, S. Synergistic Effects of Hybrid Nanoparticles along with Conventional Fuel on Engine Performance, Combustion, and Environmental Characteristics. Energy 2024, 292, 130267. [Google Scholar] [CrossRef]

- Gowrishankar, S.; Krishnasamy, A. Experimental Investigations on Biodiesel-Water Emulsion as a Potential Fuel for Early and Late Injection Based Premixed Lean Combustion. Energy Convers. Manag. 2022, 273, 116386. [Google Scholar] [CrossRef]

- Neha; Prasad, R.; Singh, S.V. A Review on Catalytic Oxidation of Soot Emitted from Diesel Fuelled Engines. J. Environ. Chem. Eng. 2020, 8, 103945. [Google Scholar] [CrossRef]

- Gautam, P.S.; Vishnoi, P.K.; Gupta, V.K. The Effect of Water Emulsified Diesel on Combustion, Performance and Emission Characteristics of Diesel Engine. Mater. Today Proc. 2022, 52, 1041–1047. [Google Scholar] [CrossRef]

- Vigneswaran, R.; Balasubramanian, D.; Sastha, B.D.S. Performance, Emission and Combustion Characteristics of Unmodified Diesel Engine with Titanium Dioxide (TiO2) Nano Particle along with Water-in-Diesel Emulsion Fuel. Fuel 2021, 285, 119115. [Google Scholar] [CrossRef]

- Ramlan, N.A.; Yahya, W.J.; Ithnin, A.M.; Abd Kadir, H.; Abu Kassim, K.A.; Abdul Rahman, H.; Ezzat Chan, A.F.; Mazlan, N.A.; Abdul Rashid, M.A.; Sugeng, D.A. Emissions and Performance Analysis of Diesel Powered Road Vehicle Equipped with Real-Time Non-Surfactant Emulsion Fuel Supply System. Fuel 2020, 273, 117257. [Google Scholar] [CrossRef]

- Vellaiyan, S. Enhancement in Combustion, Performance, and Emission Characteristics of a Biodiesel-Fueled Diesel Engine by Using Water Emulsion and Nanoadditive. Renew. Energy 2020, 145, 2108–2120. [Google Scholar] [CrossRef]

- Su, X.; Chen, H.; Gao, N.; Ding, M.; Wang, X.; Xu, H.; Zhang, P. Combustion and Emission Characteristics of Diesel Engine Fueled with Diesel/Cyclohexanol Blend Fuels under Different Exhaust Gas Recirculation Ratios and Injection Timings. Fuel 2023, 332, 125986. [Google Scholar] [CrossRef]

- Veza, I.; Irianto; Tuan Hoang, A.; Yusuf, A.A.; Herawan, S.G.; Soudagar, M.E.M.; Samuel, O.D.; Said, M.F.M.; Silitonga, A.S. Effects of Acetone-Butanol-Ethanol (ABE) Addition on HCCI-DI Engine Performance, Combustion and Emission. Fuel 2023, 333, 126377. [Google Scholar] [CrossRef]

- Oh, J.; Im, M.; Oh, S.; Lee, C. Comparison of NOx and Smoke Characteristics of Water-in-Oil Emulsion and Marine Diesel Oil in 400-KW Marine Generator Engine. Energies 2019, 12, 228. [Google Scholar] [CrossRef]

- Elumalai, P.V.; Nambiraj, M.; Parthasarathy, M.; Balasubramanian, D.; Hariharan, V.; Jayakar, J. Experimental Investigation to Reduce Environmental Pollutants Using Biofuel Nano-Water Emulsion in Thermal Barrier Coated Engine. Fuel 2021, 285, 119200. [Google Scholar] [CrossRef]

- Mondal, P.K.; Mandal, B.K. A Comprehensive Review on the Feasibility of Using Water Emulsified Diesel as a CI Engine Fuel. Fuel 2019, 237, 937–960. [Google Scholar] [CrossRef]

- Yin, Z.; Liu, S.; Tan, D.; Zhang, Z.; Wang, Z.; Wang, B. A Review of the Development and Application of Soot Modelling for Modern Diesel Engines and the Soot Modelling for Different Fuels. Process Saf. Environ. Prot. 2023, 178, 836–859. [Google Scholar] [CrossRef]

- Chen, X.; Xi, X.; Zhang, L.; Wang, Z.; Cui, Z.; Long, W. Experimental Study on Nucleation and Micro-Explosion Characteristics of Emulsified Heavy Fuel Oil Droplets at Elevated Temperatures during Evaporation. Appl. Therm. Eng. 2023, 224, 120114. [Google Scholar] [CrossRef]

- Wang, X.; Bu, H.; Chen, H.; Liu, J.; Chen, Z.; Gao, J. Numerical Investigation of Diesel Spray Combustion Characteristics in the Ammonia/Air Atmosphere. J. Energy Inst. 2024, 116, 101718. [Google Scholar] [CrossRef]

- Shen, S.; Sun, K.; Che, Z.; Wang, T.; Jia, M.; Cai, J. Mechanism of Micro-Explosion of Water-in-Oil Emulsified Fuel Droplet and Its Effect on Soot Generation. Energy 2020, 191, 116488. [Google Scholar] [CrossRef]

| Fuels | Lower Heating Value (MJ/Kg) | Lower Heating Value (MJ/L) |

|---|---|---|

| Diesel | 42.53 | 35.77 |

| 8% WiDE | 38.77 | 33.15 |

| 16% WiDE | 35.42 | 30.89 |

| Engine Specifications | Parameters Values |

|---|---|

| Operation cycle | 4-stroke |

| Cylinders | 1 |

| Valves per cylinder | 2 |

| Bore [mm] | 88 |

| Stroke [mm] | 76 |

| Displacement [cm3] | 462 |

| Injection system | DI |

| Injection pressure [bar] | 200 |

| Compression ratio | 20.5:1 |

| Cooling system | Air cooling |

| Rated torque [Nm] | 23.4 |

| Rater power [kW] | 7.3 |

| Measuring Ranges | Accuracy |

|---|---|

| CO: 0–15% vol. | ±0.03% vol. |

| CO2: 0–20% vol. | ±0.5% vol. |

| HCs: 0–30,000 ppm vol. | ±10 ppm vol. |

| O2: 0–25% vol. | ±5% of Maximum |

| NO: 0–5000 ppm vol. | ±1% vol. |

| Opacity | ±0.1% |

| Absorption: 0–99.99 m−1 | ±0.01 m−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, P.; Brójo, F.; Serôdio, R.; Serôdio, J. Investigation of Water-in-Diesel Emulsion Behavior Formulated for Performance Conditions in a Single-Cylinder Diesel Engine. Energies 2025, 18, 934. https://doi.org/10.3390/en18040934

Oliveira P, Brójo F, Serôdio R, Serôdio J. Investigation of Water-in-Diesel Emulsion Behavior Formulated for Performance Conditions in a Single-Cylinder Diesel Engine. Energies. 2025; 18(4):934. https://doi.org/10.3390/en18040934

Chicago/Turabian StyleOliveira, Pedro, Francisco Brójo, Rogério Serôdio, and João Serôdio. 2025. "Investigation of Water-in-Diesel Emulsion Behavior Formulated for Performance Conditions in a Single-Cylinder Diesel Engine" Energies 18, no. 4: 934. https://doi.org/10.3390/en18040934

APA StyleOliveira, P., Brójo, F., Serôdio, R., & Serôdio, J. (2025). Investigation of Water-in-Diesel Emulsion Behavior Formulated for Performance Conditions in a Single-Cylinder Diesel Engine. Energies, 18(4), 934. https://doi.org/10.3390/en18040934