1. Introduction

Recent decades have witnessed continuous environmental concerns due to massive economic activities and operations [

1]. The main cause of industrial pollution is the massive usage of coal and fossil fuel despite environmental regulations and standards in production processes [

2]. Stakeholders (such as shareholders and consumers) are pressing organizations to reduce harmful impacts [

3,

4]. In order to achieve sustainability, sustainable development calls for the implementation of innovative business models across all economic sectors [

5]. Trade and business sectors should be environmentally responsible as they are key disruptors of natural sustainability [

6]. Growing interest in ecology, fostering sustainability, and environmental stewardship has aroused the interest in energy consumption [

7]. To achieve sustainable development and strong economic growth, energy plays a crucial role for any nation. The best energy practices must be implemented as soon as possible in emerging nations like China to boost economic development and competitive advantages in the business environment [

8]. Many countries’ economic development depends on industries that pollute the environment for survival, and they lack basic infrastructure in market development [

9]. However, this situation became more acute due to inadequate regulatory requirements, discharging high levels of environmental contamination and hazardous waste [

10].

In recent years, the Chinese government has implemented plenty of energy policies to encourage environmental sustainability and green growth. Energy efficiency and reducing environmental pollution in large corporations are top priorities of the nation [

11,

12]. In an effort to reduce energy consumption, China has closed low-capacity oil and coal plants, which resulted in 18.8% carbon reduction. Forest cover increased by 23.4%, water pollution dropped to 98%, and air quality in major cities significantly improved [

13]. China is a prime example of a nation that entirely focuses on minimizing environmental pollution through stringent laws, policies, and rules to save biodiversity, protect the environment, and foster long-term economic prosperity [

14,

15]. But despite all these efforts, China ranked 56th out of 163 countries in a sustainable development report, with an overall score of 72.4 [

16]. Also, the country’s economic growth still mainly depends on an extensive growth model that releases high levels of pollution, waste, and emissions. Similarly, China economic growth mainly depends on the tremendous growth of the manufacturing industry, and revenue of the sector increased at an average annual rate of 25% between 1990 and 2014. But the manufacturing sector’s phenomenal progress has caused environmental issues in the shape of high energy consumption and extreme greenhouse gas emissions [

17].

There are limited studies on how firms can improve energy efficiency through various policies in the domestic setting [

18,

19]. Also, stakeholder pressure has compelled the majority of enterprises to adopt sustainable strategies and sustainable development models [

20]. The scant amount of prior research has demonstrated the internal and external factors influencing the firm’s likelihood to adopt green business (e.g., [

21]. A significant amount of research has mostly concentrated on developed nations with better environmental performance and higher sustainable growth [

22,

23]. The implementation of policies for energy efficiency in developing nations are surprisingly low due to environmental issues [

24,

25]. Based on the literature analysis, more research is required in developing nations due to poor environmental practices, performance, and institutional constraints [

23]. There are unexplored areas for further exploration because only specific factors were examined in the literature [

18]—for instance, the role of top management [

26], strategic planning [

27], environmental knowledge and awareness [

28], and resources [

29] on green energy adoption. Previous studies have applied various multi-criteria decision making methods (MCDM) to identify factors promoting energy efficiency, such as developing energy planning using the fuzzy TOPSIS technique [

30], prioritizing strategies for increasing energy efficiency by using a combined AHP-TOPSIS approach [

31], achieving energy efficiency through the implementation of fuzzy-AHP, ranking sustainable energy policies in the context of Turkey [

32], creating energy storage alternatives through the integration of Fuzzy AHP-TOPSIS [

33], and selecting renewable energy practices using fuzzy TOPSIS [

34]. These studies have only checked the impact of individual factors on firm energy performance. However, the overall influence of all these factors on energy efficiency through a well-established framework is missing. Also, the relative importance of each factor in the prior literature has been neglected. Moreover, the presentation of energy efficiency policies on the basis of the importance level in the previous studies is also missing.

To fill these potential research gaps, the current study proposed the ISM model to present all influential policies for achieving energy efficiency in the Chinese manufacturing sector on a hierarchical basis. The ISM-MICMAC approach is suitable for examining energy efficiency in Chinese manufacturing, given its ability to model complex interdependencies and identify key strategies. The ISM and MICMAC approach helps to rank and analyze the relationship between various strategies along with their driving power and dependencies, which are important for decision makers to prioritize the most important policies. The Interpretive Structural Modeling (ISM) approach is the most powerful technique because it is an expert-based technique compared to other traditional public questionnaire-based methods [

35]. The objectives of the study are as follows:

To identify the critical policies for achieving energy efficiency in the manufacturing sector;

To analyze the contextual relationship among identified policies;

To develop hierarchy model of policies on the basis of importance;

To identify highly driving and dependent policies in the manufacturing sector.

The reminder of this paper is segregated into following parts.

Section 2 presents the literature on energy policies of companies.

Section 3 introduces ISM methodology in a detailed explanation.

Section 4 highlights the study’s results and presents an analysis of the study.

Section 5 presents the implications of the research.

Section 6 presents conclusions, limitations, and future research work.

2. Literature Review

The overexploitation of natural resources such as land, air, and forests, along with the depletion of finite resources like minerals, ores, and fossil fuels, has a direct impact on biodiversity [

36,

37]. The Paris Pact and the Kyoto Protocol both aim to minimize carbon emissions and overall resource consumption [

38]. Manufacturing firms have incorporated green practices to create opportunities for sustainable production and growth [

2]. There are many industrial sectors that implement plenty of green practices for improving energy performance. One of the most important ways to reduce carbon emission is adopting “energy efficiency practices”, which have drawn the attention of various academicians. Through an energy control system, manufacturing firms can minimize waste and pollution by reducing natural resource consumption, reusing and recycling waste, as well as reducing emissions [

39]. Nowadays, customers are urging industries to produce goods and processes that are innovative or environmentally beneficial [

40,

41]. Some researchers pointed out some important practices that reduce energy consumption within firms, such as information technology [

42], foreign direct investment (FDI) [

43], new business opportunities [

44], green value chain [

45], environmental-based performance [

46], and corporate green environments [

6]. Thus, different researchers conducted analyses, applying either questionnaire-based survey [

19], structural equation modeling (SEM) [

47,

48], an analytic network process [

49], literature-based processes [

50,

51], etc.

China is the world’s sole manufacturing superpower. However, a large number of Chinese manufacturing companies rely on low-cost labor and obsolete manufacturing methods, and their productivity and innovation are below average. Therefore, decreasing the environmental effect and achieving sustainable development requires advanced manufacturing techniques and developments [

52]. Energy planning is a complicated process for designing and assessing potential future energy solutions; hence, efficient energy policies have not been fully implemented in the manufacturing sector [

53]. Chinese manufacturing sectors are expanding with an exponential growth rate, and the sector relies on fossil fuel and other traditional production methods. Reduced energy cost and production cost are significant factors that encourage manufacturing companies to invest in green energy technologies [

24]. Compared to other businesses, the manufacturing sector is mainly responsible for the enormous energy consumption and environmental destruction. Globally, the manufacturing sector is responsible for almost 40% of carbon dioxide emissions and 40% of energy consumption [

54].

Through the implementation of energy strategies, organizations may enhance their performance by reducing energy costs to gain competitive, innovative, and efficient technology [

55]. The successful execution of energy approaches facilitates the manufacturing sector in determining an alternate route for long-term expansion that would result in a win–win situation for the environment, society, and economy [

56]. The integration of all three sustainability factors—social, economic, and environmental—is known as the triple bottom line (3BL), and firms can balance their operations by focusing on each factor. Taking into account the benefits of energy efficient utilization, the current study also identified various strategies to promote sustainable business. The Chinese concept of economic development supports the dual objectives of global sustainable development goals, which are the sustainable preservation of natural resources and raising the quality of life of people [

57]. This study used extensive literature to extract pertinent factors suitable for the research objectives. To search for reliable sources and materials, primary keywords have been employed, such as green, sustainable, energy policies, green manufacturing, energy policies and green manufacturing, and energy policies in developing countries. This study used keywords associated with energy policies utilizing internet search engines, including Elsevier, Emerald, Taylor & Francis, WILEY, and Google Scholar. Following the process, twelve strategies were shortlisted from a literature review. The policies of reducing carbon emission and energy saving in manufacturing sector are explained in detail in this section.

2.1. Strategic Planning

Strategic planning (SP) transforms strategic decision making procedures into logically organized processes that enable management to properly conform to an appropriate strategic course for the entire organization [

58]. Decision makers must create new strategic plans for green manufacturing, industry re-structuring, and high-quality manufacturing. Such planning can strengthen a company’s areas of weaknesses or create new pathways [

59]. Through strategic planning, manufacturing companies not only reduce environmental pollution but also gain a good reputation and corporate image [

2].

2.2. Organizational Culture

A strong corporate culture gives a high priority to sustainability and encourages staff members to participate in eco-friendly practices and creative problem-solving, which leads to the development of sustainable initiatives that support the company’s environmental goals [

60,

61]. The organizational effectiveness of a manufacturing company and its focus on industry advancements are significantly impacted by its culture [

62].

2.3. Environmental Awareness

Environmental awareness inside and outside the company is vital for green manufacturing adoption [

63]. The top management’s commitment and dedication regarding the formulation of corporate strategies to protect the natural environment helps achieve business sustainability [

64,

65].

2.4. Executives’ Support

The creative and novel ideas introduced by top leadership play a critical role in devising energy control systems in the manufacturing sector. Leaders who prioritize innovation and sustainability can inspire organizational change, allocate resources toward eco-friendly initiatives, and embed sustainability into the company’s culture and strategy [

6,

66].

2.5. Team Effort

Enhancing energy efficiency and promoting green manufacturing depends on the collective efforts of team members [

67]. Although leadership offers guidance and vision, teams throughout an organization must work together, be committed, and execute sustainability plans to produce real benefits [

6].

2.6. Resources

Green growth and sustainable development depend on the creation of new knowledge. Organizations can boost innovation performance by encouraging creative behavior through resources, infrastructure, and assets [

68]. A significant body of evidence confirms that financial, people, physical, and technical resources are the tangible resources required to carry out green manufacturing operations [

69,

70]. The intangible resources are non-physical assets and skills that contribute to an organization’s competitive advantage and overall value [

71].

2.7. Green HRM

Green Human Resource Management (Green HRM) practices—such as green hiring, green selection, and green promotion—can assist firms in adopting sustainable energy technologies [

72,

73]. Manufacturing firms require sophisticated technologies for green manufacturing, and GHRM can train employees for continuous improvements in energy efficiency [

72].

2.8. Green Financing

Green financing provides the necessary capital for businesses to implement eco-friendly projects. A manufacturing company can secure green loans to upgrade to energy-efficient machinery, reducing carbon emissions [

74]. Green financing fosters the development and usage of new energy sources, green growth, and ecological agriculture [

75].

2.9. Green Capabilities

Green capabilities mean the capacity of businesses to develop, integrate, and reorganize their skills in order to thrive in current fast-paced, fiercely competitive markets. Previous research has identified four categories of capabilities: relational, organizational, knowledge-based, and strategic [

76]. Effective technology capabilities may help businesses expedite the production of new products, adjust their operations to changing operating circumstances, and foster open innovation to enhance organizational growth and productivity [

77,

78].

2.10. Market Competition

Market competition in international markets is a powerful determinant of green business adoption. The degree of competition a company faces in global markets usually estimates how proactively it implements sustainable practices [

79]. To achieve advantage in fiercely competitive marketplaces, companies may feel pressured to innovate and differentiate themselves through distinct green initiatives [

76]. Also, the market competition of the products depends on prices in developing countries, and customers prefer products that are affordable.

2.11. Green Marketing

Green marketing also assists businesses in identifying and satisfying the customer demand associated with market trends [

80,

81]. As customers are environmentally conscious, they need green products, so companies can increase sales by marketing sustainable products. Firms can also improve environmental performance and respond to multiple stakeholders by focusing on areas like green financing, production, and marketing [

82].

2.12. Green Production

Green manufacturing and production emphasize environmental friendly methods such as employing renewable resources, reducing emissions, and limiting waste [

73]. Businesses may attract eco-conscious customers by reducing their environmental impact through these strategies [

83].

After the identification of relevant policies, a mix methodological approach consisting of interpretive structural modeling (ISM) and cross-impact matrix multiplication applied to classification (MICMAC) was concurrently applied. ISM can empirically investigate factors [

84], while the MICMAC approach [

85] evaluates the dependence and driving power of each factor.

3. Research Methodology

This study applied the ISM model to the implementation of policies to minimize waste and energy in the manufacturing sector. In this study, the literature survey serves as a foundation of the research methodology because the initial step (factors identification) starts from previous literature. The literature has discovered that there are various strategies leading to energy efficiency in the firms. The goal of this study is to improve knowledge of how the identified factors relate to one another and develop a hierarchy form. Four companies were chosen from the manufacturing sectors, including pharmaceutical, cement, leather, and textile, which are main cause of pollution and energy consumption [

86,

87]. The proposal was sent to 26 companies, 8 of which agreed to participate in the study and 4 of which were ultimately chosen based on their experience in concerned area. While we initially contacted 26 companies to ensure a broad outreach, only 4 met the specific criteria required for our study. These criteria included the following: (1) active implementation of sustainability initiatives, (2) proven track records in strategic energy management, and (3) willingness to provide in-depth data necessary for ISM-MICMAC analysis. The ISM approach receives responses from professional experts rather than public, so eight experts were asked for their opinions to develop relationship among the policies. The questionnaire was sent through emails and personal visits to obtain responses. Along with ISM analysis, MICMAC approach was incorporated to examine the contextual relationships among identified strategies. The ISM approach is a well-recognized technique for determining the relationships between particular elements that form a problem statement [

88]. A number of researchers [

2,

88,

89] have applied ISM by examining the factors that promote and inhibit the adoption of green innovations. The studies with applied ISM approach in different contexts are highlighted in

Table 1.

Taken into consideration the successful operationalization of ISM in environmental and sustainable field, current study also identifies policies for improving energy efficiency through ISM approach in Chinese manufacturing sector. The methodological approach consists of following parts:

Phase 1: Factors that influence energy efficiency are investigated through vast literature review.

Phase 2: Establishment of structural self-interaction matrix (SSIM).

Phase 3: Formulation of initial reachability matrix from previous step.

Phase 4: Using transitivity principles, the initial reachability matrix (IRM) is examined for transitivity.

Phase 5: The final reachability matrix (FRM) is constructed and then separated into several categories.

Phase 6: By removing transitivity nodes and dividing levels, the directed graph is obtained.

Phase 7: The ISM framework is completed after validations and inconsistency checks.

3.1. Structural Self-Interaction Matrix (SSIM)

A contextual relationship of “facilitates to” is selected in order to investigate the criterion. This process indicates how one criterion supports another. An SSIM has been created based on this contextual connection. Pairwise relationships between strategies are shown via SSIM. Four symbols were used to represent the system of these relationships between factors to accomplish this task; if factor “i” assists in achieving “j”, the symbol “V” is used; if factor “j” contributes in achieving “i”, the symbol “A” is used. Moreover, “X” is used if “i” and “j” support one another. Lastly, if factors “i” and “j” have no relationship with each other, the sign “O” is used. To obtain feedback, eight experts participated in the questionnaire survey, which is minimum requirement of ISM technique [

103]. Two experts were selected with an academic background, and six specialists had over ten years of manufacturing experience on decision-making panel. Experts in academia had backgrounds in both energy efficiency research and sustainable energy technologies. The selection of experts was purely based on their strong theoretical and practical knowledge of energy efficiency and working experience of more than eight years. The profile of experts is presented in

Table 2. The same experts’ opinions were taken into consideration once again in order to strengthen the contextual relationship between the previously established strategies. To minimize bias and maintain internal consistency, a panel facilitator organized the brainstorming sessions. Each expert was given a structural self-interaction matrix (SSIM) sheet with no notation to indicate the contextual relationship between different strategies. Following a discussion of the results with all of the experts, a final matrix representing their consensus was developed. The final SSIM was revised and approved based on the expert’s feedback (V, A, X, and O), as shown in

Table 3.

3.2. Initial Reachability Matrix (IRM)

In this procedure, the SSIM matrix is transformed into an initial reachability matrix, which is a binary matrix. The following principles determine how the SSIM matrix is converted into binary digits (0 and 1):

(a) If the SSIM entry is V, then (i,j) will be recognized as 1 and (j,i) as 0.

(b) If the SSIM entry is A, then (i,j) will be recognized as 0 and (j,i) as 1.

(c) If the SSIM entry is X, then (i,j) will be recognized as 1 and (j,i) as 1.

(d) If the SSIM entry is O, then (i,j) will be recognized as 0 and (j,i) as 0.

The initial reachability matrix (IRM) is formed with the help of these guidelines, which are displayed in

Table 4.

3.3. Final Reachability Matrix (FRM)

By applying the transitivity principle to the reachability matrix, the final reachability matrix (FRM) is obtained. According to this concept, if factor A is connected to factor B and factor B is connected to factor C, then factor C should be connected to factor A. Every factor’s driving and dependent powers are determined by the FRM. Dependency power shows how much a given component is impacted by other elements, whereas driving power indicates how many factors are influenced by a certain factor. Driving power also establishes the influence of a particular factor over other aspects of the system. The driving power of a factor is determined by adding the row values, whereas the dependency power of a factor is determined by adding the values. The dependent power of a factor is determined by adding the values in the column that correspond to that factor in the FRM, while the driving power of any factor is obtained by adding the row values of that factor. Further, the driving power and dependent power factors are used to draw MICMAC analysis. The outcomes of FRM are shown in

Table 5.

3.4. Level Partitions

Following the formation of the FRM and the computation of each factor’s driving and dependent powers, the factors are divided into several levels based on their final reachability matrix’s (FRM) results. Both antecedent and reachable sets are determined based on the final reachability matrix. The factor that can directly or indirectly affect are included in the reachability set. The same level is assigned to the factors that correspond to the same intersection and reachability set.

At the top of the hierarchy are factors whose intersection set relates to the reachability set. In such cases, level 1 is assigned to the factors whose intersection and reachability set have the same values. The process is repeated for the remaining factors to create the whole hierarchy after a factor has been assigned to a level and eliminated from additional analysis. After this process, 7 levels were created from all 12 elements (

Table 6,

Table 7,

Table 8,

Table 9,

Table 10,

Table 11 and

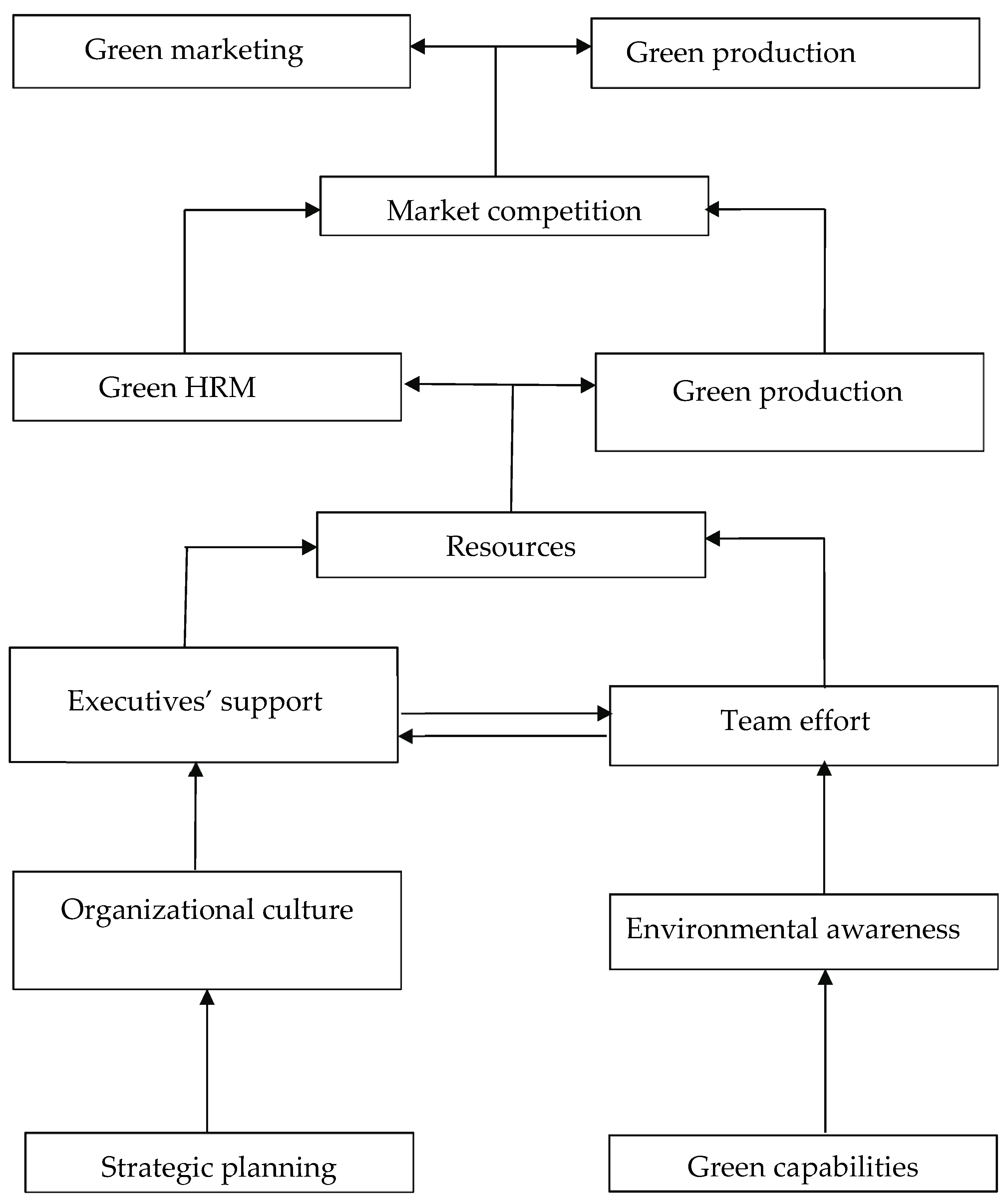

Table 12). The ISM model is constructed through factor partitioning. According to this ISM model, elements in the medium level are slightly significant, while those at the top level are least significant. On the other hand, bottom-level elements are considered very significant.

3.5. MICMAC Analysis

The MICMAC approach was developed to analyze complex systems in a systematic way [

85]. Factors are classified via MICMAC analysis according to their pertinent driving and dependence power, which is illustrated in

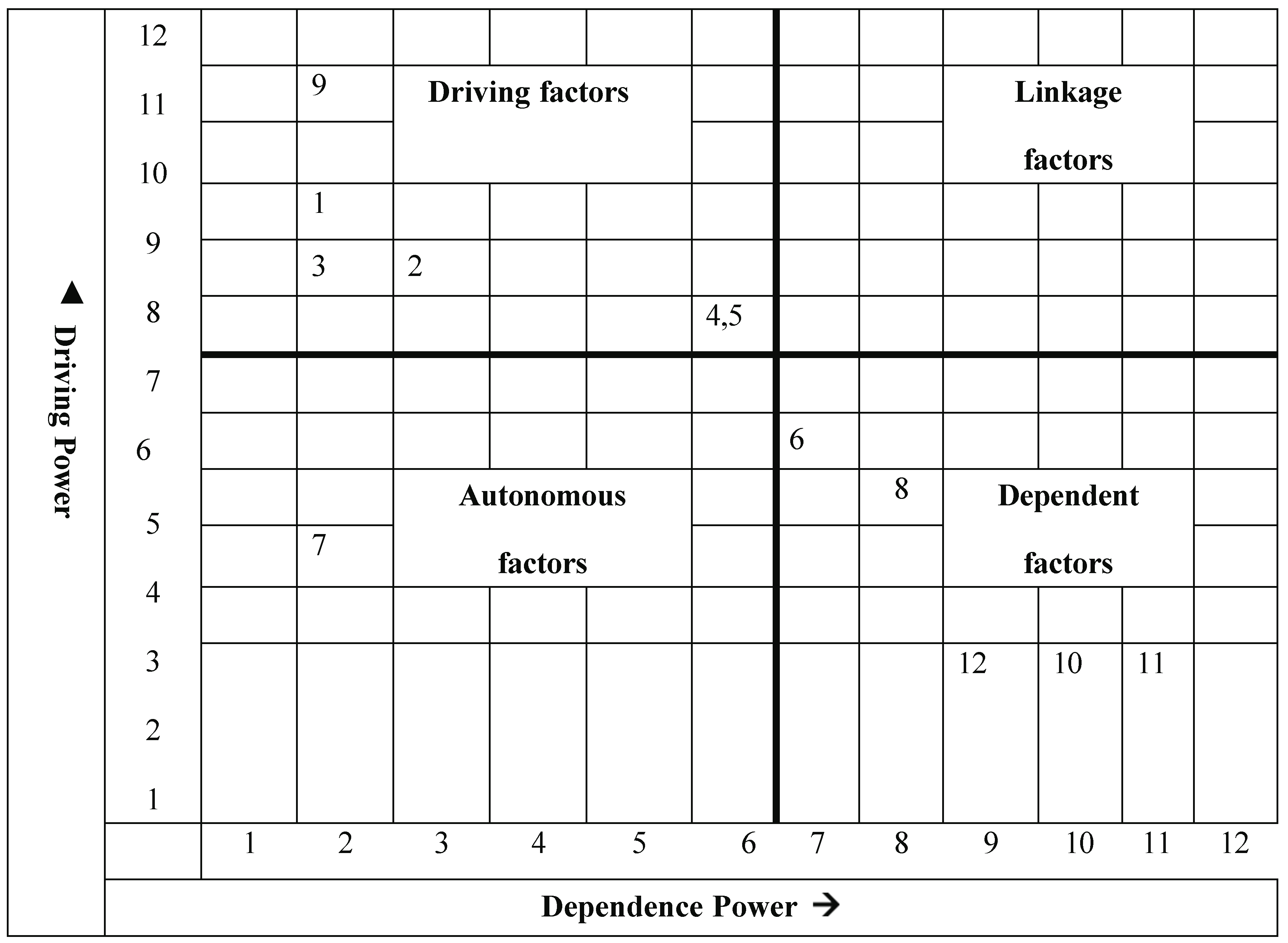

Figure 1.

Four quadrants are used to categorize the crucial strategies of energy efficiency:

3.5.1. Autonomous Factors

The lower left side of the graphical diagram represents autonomous factors. Both driving and dependency power are low for the variables in this group. In this cluster, only one factor “green HRM” exists, and this factor is not connected with the system.

3.5.2. Dependent Factors

Although dependent factors exhibit high driving power, they possess strong dependency power. These factors appear in the lower right section of the diagram and are typically influenced along with other factors. This cluster consists of factors like resources, green financing, market competition, green marketing, and green production.

3.5.3. Linkage Factors

Linkage factors show strong dependence power and driving. These elements are frequently distinguished by their dynamic nature and interdependence within a system. This category of factors is often seen in the diagram in the top right corner. There are no linkage factors (policies) in this cluster.

3.5.4. Independent Factors

Independent factors exhibit high driving power but low dependence power. This cluster comprises policies, strategic planning, organizational culture, environmental awareness, executives’ support, team effort, and green capabilities. These policies play important roles in decision making process.

4. Study Results

With rising average global temperatures, the possibility of more droughts and increased intensity of natural disasters will likely occur, such as hurricanes and typhoons. Companies must evaluate their impact, develop best practices and approaches, and raise awareness about sustainability [

6]. The limited studies regarding energy efficiency policies compels us to identify various policies in the manufacturing sector. The study initially explored twelve strategies, which were further confirmed by an expert panel. This study’s major contribution is the application of the ISM MICMAC approach. The ISM explains the importance of different elements with the help of a seven-level hierarchy structure (

Figure 2).

The results show that strategies at the 7th level of “strategic planning” and “green capabilities” are the most critical policies that drive manufacturing firms toward energy consumption. The previous literature documented that strategic planning helps businesses improve energy efficiency by setting clear goals, identifying areas for improvement, and allocating resources effectively [

50,

104]. Strategic planning enables businesses to assess current energy usage and implement energy-efficient technologies and waste-reduction policies. The study results, compared to the European commission and member states, also reported that strategic planning assists the country’s cost energy efficiency potential [

105]. The study based on Palestinian manufacturing SMEs also corroborates that strategic planning is a key factor influencing sustainable performance [

27]. It is also equally important to consider the magnitude of the influence of green capabilities on energy efficiency because green capabilities and green capabilities have the same degree of importance in improving energy efficiency. As a few authors claim, firms with strong green capabilities gain a competitive advantage by building trust with stakeholders [

48,

106].

This study identified two strategies, “organizational culture” and “environmental awareness”, on the next level. A company’s capacity to incorporate energy efficiency behaviors is strongly influenced by its organizational culture. Green organizational culture ensures employees enact environmental and sustainable practices within organizations, which is supported by [

61,

107]. Similarly, awareness campaigns regarding pollution reduction have a positive impact on the usage of sophisticated technologies. In shaping sustainable organizational culture, the CEO’s strong sense of responsibility and environmental awareness are mandatory [

108,

109].

At the fifth level, this study found that two strategies, namely, “executives’ support” and “team effort”, play decisive roles in firms’ energy control systems. Some studies suggest that visionary leaders are more likely to embrace advanced technologies and develop eco-friendly products to minimize environmental impacts [

110]. Such executives with an innovative mindset often establish good political ties with the government to acquire necessary resources for green business settings [

111,

112]. The implementation of green business is also a challenging task, and their adoption requires diverse skills and expertise of team members [

113].

At the fourth level, this study identified that the strategy of “resources” is beneficial for energy efficient utilization. Without financial and trained human resources, businesses may not attain sustainable growth. Competent workers can create and execute eco-friendly procedures, and businesses may require investment in training initiatives, renewable energy sources, and sustainable technology [

61,

70,

114]. Resources can reduce energy consumption in firms by implementing energy-efficient technologies, such as LED lighting and smart HVAC systems.

Accordingly, strategies at level three identified that “green HRM” and “green financing” are playing integral roles in sustainable business operations. Employee recruitment and selection mostly depend on green values, and many firms pay handsome incentives and packages for adopting green energy technologies [

115,

116]. Manufacturing firms use green financing for the training and development of employees to support the creation and implementation of sustainability-focused programs [

74].

This study found that “market competition”, lying in level two, is also crucial for energy efficiency schemes. Competitors can make a huge difference by adopting eco-friendly practices, setting industry benchmarks, encouraging others to innovate, and improving their environmental performance [

117]. By encouraging companies to develop and incorporate eco-friendly solutions to obtain a competitive advantage, market rivalry influences the adoption of sustainable green practices. Firms adopt energy-saving technologies and practices to lower production costs and offer competitive pricing.

Finally, this study found that “green marketing” and “green production” have less of an impact on energy reduction programs in companies. Green marketing has an impact on the adoption of sustainable green practices by increasing customer knowledge and educating customers about eco-friendly goods and services. It raises awareness of sustainability by highlighting the positive social and environmental effects related to green decisions [

118]. The results largely corroborate the existing research because many manufacturing companies adopt green business practices to produce goods and services that minimize environmental impacts during production. Nowadays, customers are very conscious about environmental impact; green production not only lessens the environmental impact, but it can also satisfy customers’ demands [

119,

120].

5. Implications of the Study

Efficient energy consumption in the manufacturing sector is a transformative step toward sustainable development. The hierarchy structure of 12 key strategies and the MICMAC approach’s visual presentation are basic keys to understanding how these policies interact and affect energy consumption in the manufacturing sector. These strategies can also be used to develop policies in the relevant fields. The results of this study show that a dependent relationship has a significant impact and driving force on other elements of the system. For example, strategic planning and green capabilities possess the highest driving power, which lessens environmental degradation through energy-saving initiatives within the manufacturing sector. Strategic planning enables businesses to connect their objectives with sustainable development through the identification of opportunities for resource efficiency, waste reduction, and the integration of renewable energy. This strategic framework not only sets clear performance benchmarks but also establishes mechanisms for monitoring and evaluation that drive industrial upgrading and push manufacturers toward cleaner production methods [

121]. Green competencies in the form of knowledge of sustainable sourcing, energy efficiency, and environmentally friendly product design serve as the foundation for improving energy performance. Manufacturing companies can lower production costs, lessen their impact on the environment, and provide value-added goods that satisfy consumers’ increasing demand for sustainability by developing these competencies [

122]. Furthermore, green capabilities enhance stakeholder trust and create opportunities for incentives or collaborations by promoting a favorable business image. Policymakers should give special focus to strategic planning and green capabilities in energy consumption. The ISM model also depicts that factors having higher driving power, like organizational culture and environmental awareness, have an influential role in energy efficiency. Executives’ support and team effort play a dynamic role in green energy adoption. Resources, green HRM, and green financing are positioned in the middle of ISM hierarchy levels, which serve as a bridge between top and lower-level strategies in the energy efficiency system. Many firms hesitate to invest in energy-efficient technologies due to high costs. China and other emerging nations are still in the early stages of sustainable energy adoption. In emerging nations, adopting sustainable energy in manufacturing firms is challenging because of a lack of awareness, resistance to change, high costs, and rigid laws [

123].

The government should provide green financing to manufacturing firms to reduce their dependency on fossil fuel prices, which can maintain energy price fluctuations [

74]. Similarly, training employees on the efficient use of resources, such as energy-saving office equipment, smart lighting, and renewable energy systems, can be beneficial [

124]. Also, firms should conduct awareness programs, workshops, and e-learning courses on energy conservation [

125]. The payback period of green investment is slow, so companies are hesitant to invest in green energy technologies. Government support in the shape of incentives can play a crucial role in incorporating renewable energy technologies, which will assist firms in controlling environmental pollution during the production process [

126]. The Chinese government should also focus on incentivizing industries located in developed regions that are particularly vulnerable to climate change [

127]. This will help them overcome financial barriers, reduce payback periods, and align corporate strategies with sustainability goals [

31]. Finally, green marketing and green production have less driving power and high dependency power. These factors have very little impact on efficient energy consumption; therefore, government officials and practitioners usually neglect them in policymaking. Once the manufacturing sector reduces energy consumption, it can achieve economic aspects through lower operational costs and improved profitability, fostering competitiveness and job creation. Socially, it promotes sustainable practices, enhances corporate responsibility, and improves public health by reducing pollution. Environmentally, it decreases greenhouse gas emissions, conserves natural resources, and mitigates climate change, contributing to a greener and more sustainable future.

6. Conclusions, Limitations, and Future Research Directions

Decreasing carbon emissions and energy consumption are becoming popular trends in manufacturing companies [

128,

129]. Organizations are using various policy tools to achieve energy efficiency worldwide [

130,

131]. Especially in the context of manufacturing, the role of incentives is crucial in encouraging green energy practices [

132]. Leading firms now use corporate social and environmental responsibility as a competitive advantage [

133]. China’s manufacturing industry is becoming one of the largest in the world, contributing to global carbon emissions and environmental degradation [

24]. The Chinese government must incorporate policies in the manufacturing sector to save operational costs and energy [

2]. There is a constant need to identify a set of strategies enhancing the energy performance of the Chinese manufacturing sector. Taking the case of the Chinese manufacturing sector, this study initially identified 12 strategies from prior literature and then developed contextual relationships among strategies through the application of ISM. The ISM-based model was structured to meet the study objectives. The ISM-MICMAC approach helps achieve energy efficiency in the manufacturing sector by systematically identifying and structuring key influencing factors, analyzing their interdependencies, and prioritizing them for effective decision making. This ISM model assists practitioners in determining which policies need the most attention in adopting green business.

The ISM model shows seven layers of hierarchy structure based on the importance levels from bottom to top. The bottom-level strategies are most significant, and their role in reducing energy consumption is more appealing. The interpretation of these elements, with the help of a well-established approach, gives insights to practitioners into how these factors could facilitate green energy implementation. The results find that strategic planning and green capabilities lying at the bottom level are the most critical strategies among others that drive manufacturing companies toward energy conservation. Many authors claim that strategic planning assists businesses in defining clear sustainability goals and allocating resources efficiently [

105]. Regardless of size, systematic strategic planning (SSP) can assist any business in enhancing its social, environmental, and economic performance separately or collectively [

134,

135]. Systematic strategic planning also supports firms in creating value and dominating their competitive position in the market [

136]. Additionally, it provides leaders with the right plans and strategies to implement the goal of achieving long-term competitive advantages [

134]. According to the resource-based view (RBV) theory, a company’s distinctive assets—both real and intangible—and green capabilities enable it to achieve sustainable performance [

137]. The results also prove that green culture and awareness campaigns can expedite manufacturing firms’ inclinations toward energy savings. Strategies like executives’ support, team effort play, and resources found in the middle can play a supportive role between top- and bottom-level strategies in the ISM model. Their role in influencing energy efficiency adoption is medium level. Two elements cannot always have the same relationship, since some have a significant impact on the other, while others might have a weak relationship. For example, green marketing and green production have a weak impact on energy efficiency adoption. The MICMAC analysis was used to analyze the driving and dependence power of strategies. On the basis of MICMAC analysis, the factors were divided into three quadrants—autonomous, driving, and dependence.

This study has certain limitations that need to be highlighted. The study’s ISM model is based on expert personal views, which may be biased due to their personal judgments [

74]. The study may not obtain the same results in different settings because of the diverse opinions of experts. However, statistical validations are required for the suggested ISM-based model. The current study only considered 12 strategies that are common in manufacturing sectors while developing the ISM Model by researching the literature; however, this may not be the comprehensive list of strategies affecting energy consumption. The study is based on the Chinese manufacturing sector, which restricts applicability to other sectors and nations. Therefore, future studies should explore a comprehensive list of factors in other sectors.