Study on the Effect of Mixed-Phase Icing on the Aerodynamic Characteristics of Wind Turbine Airfoil

Abstract

1. Introduction

2. Numerical Simulation Methods

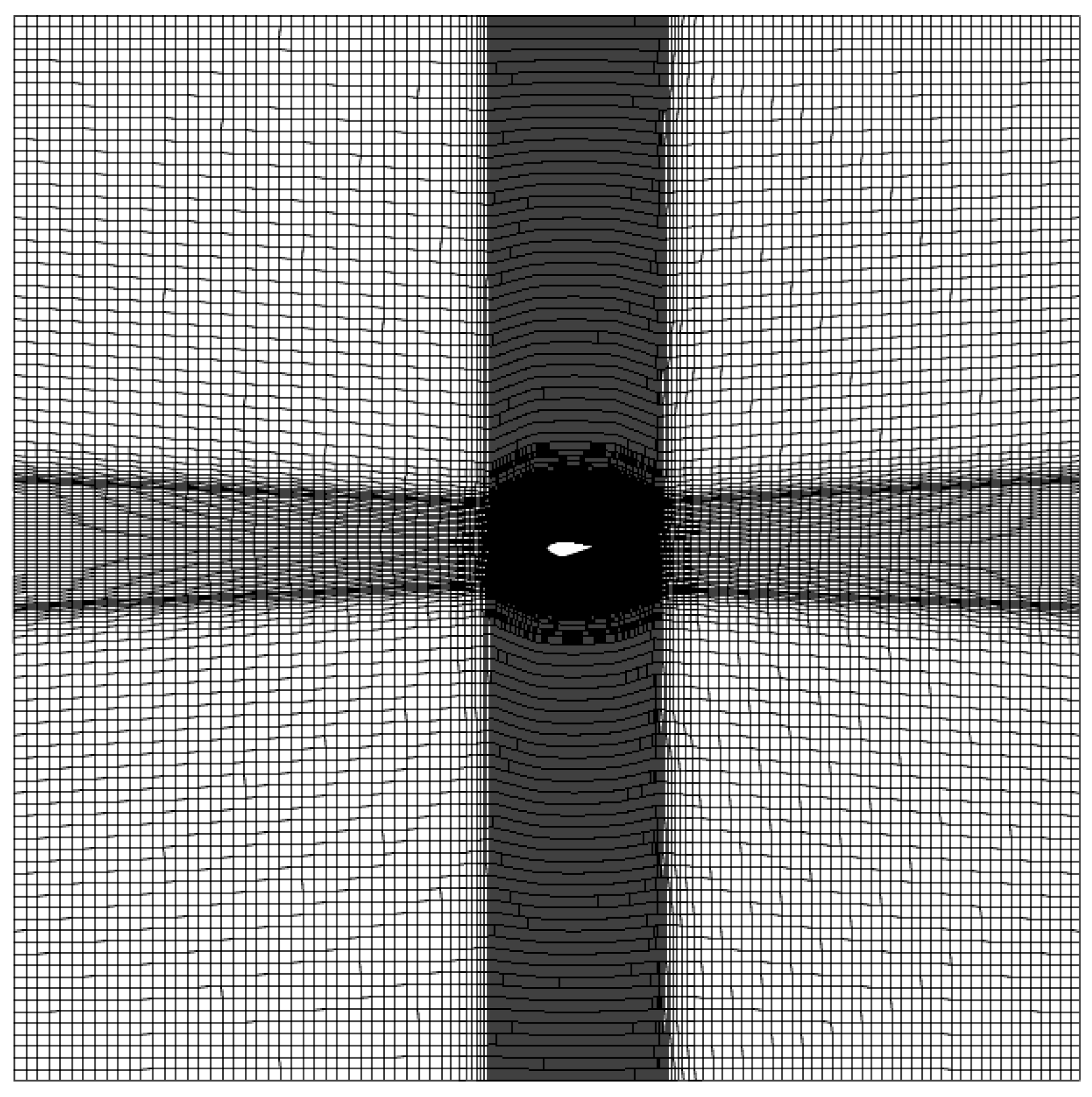

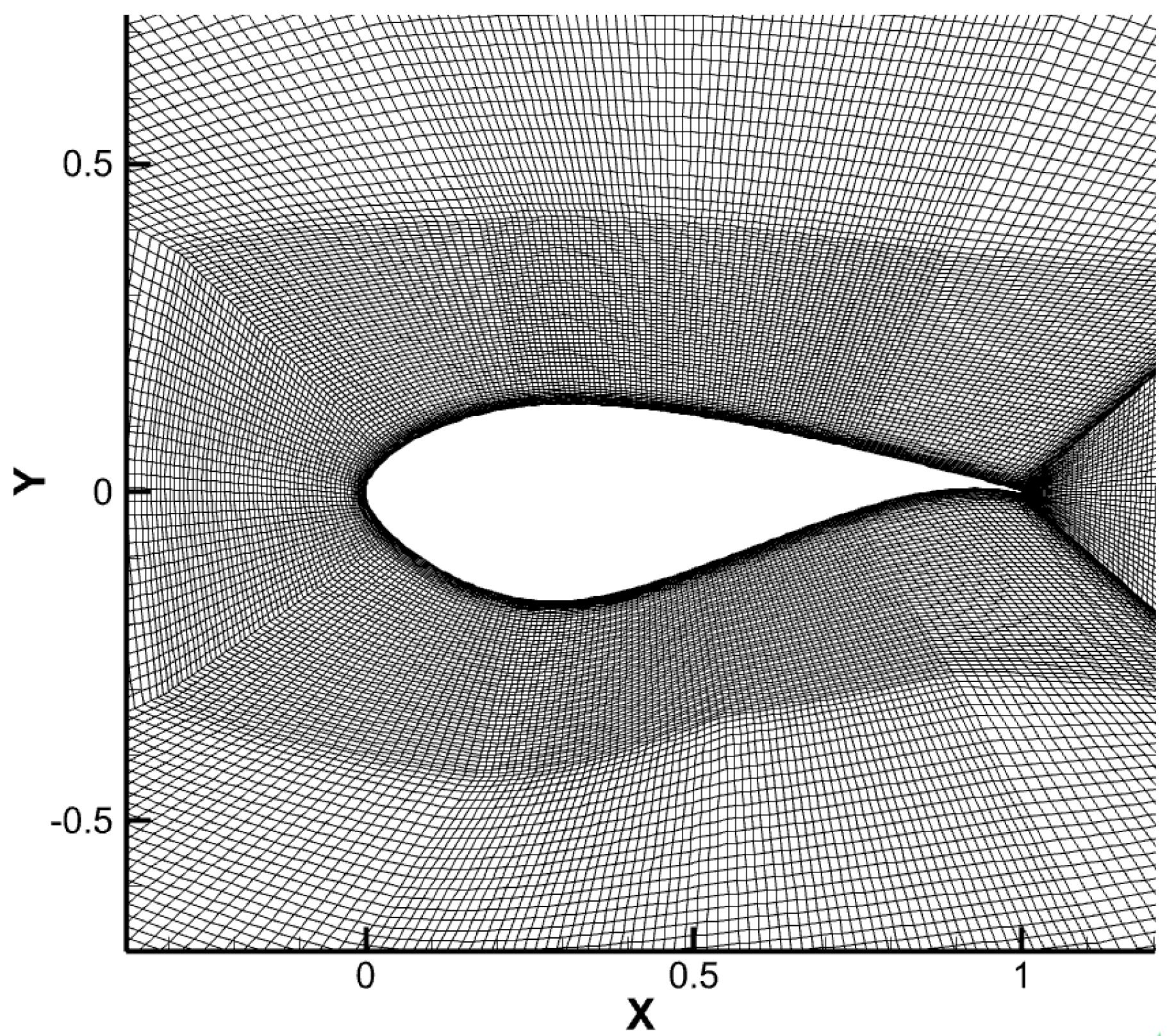

2.1. Grid Generation

2.2. Flow Field Calculation

2.3. Particle Trajectory Calculation

2.4. Ice Accretion Calculation

3. Effect of Icing Growth on Aerodynamic Characteristics

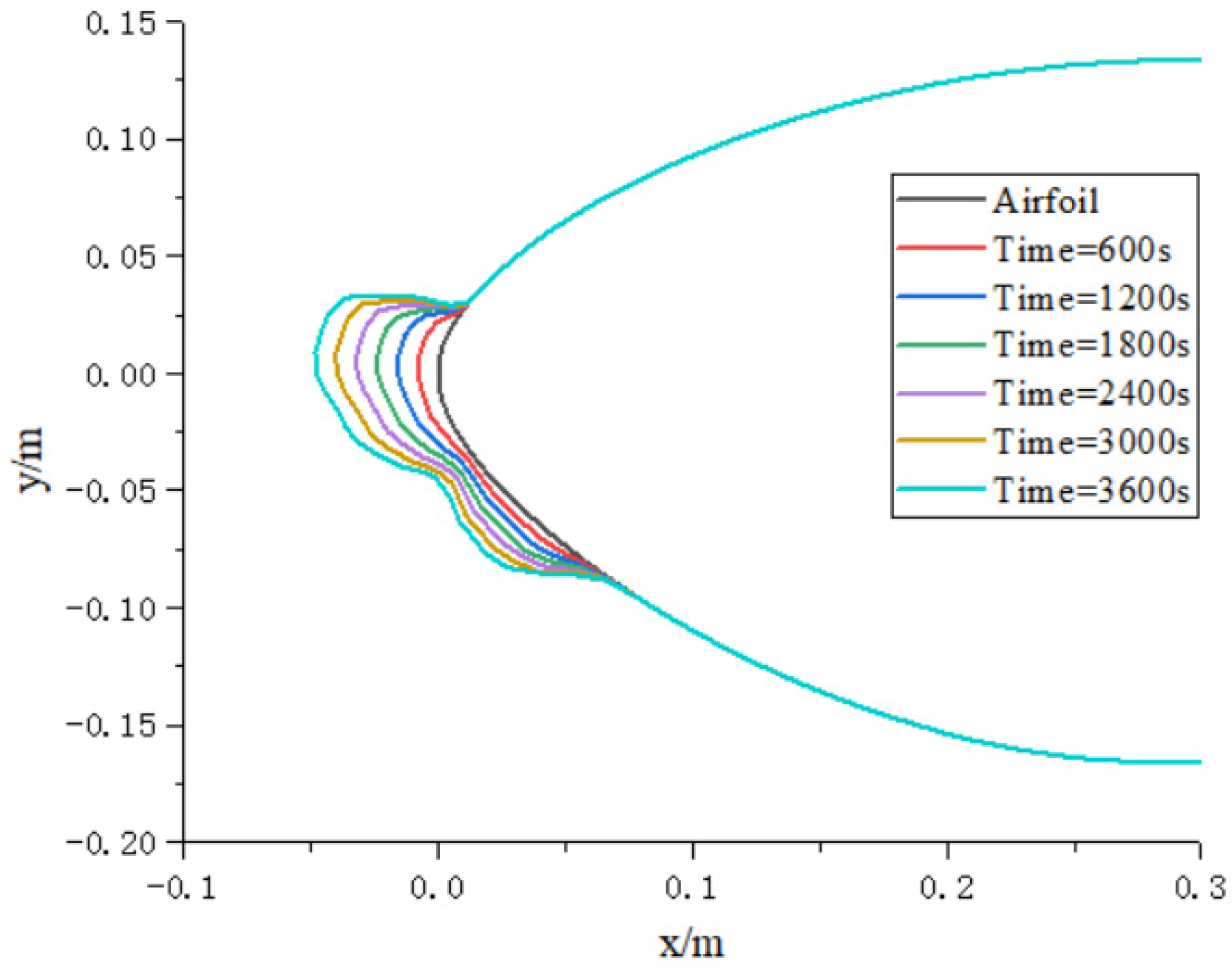

3.1. Ice Shapes Calculation

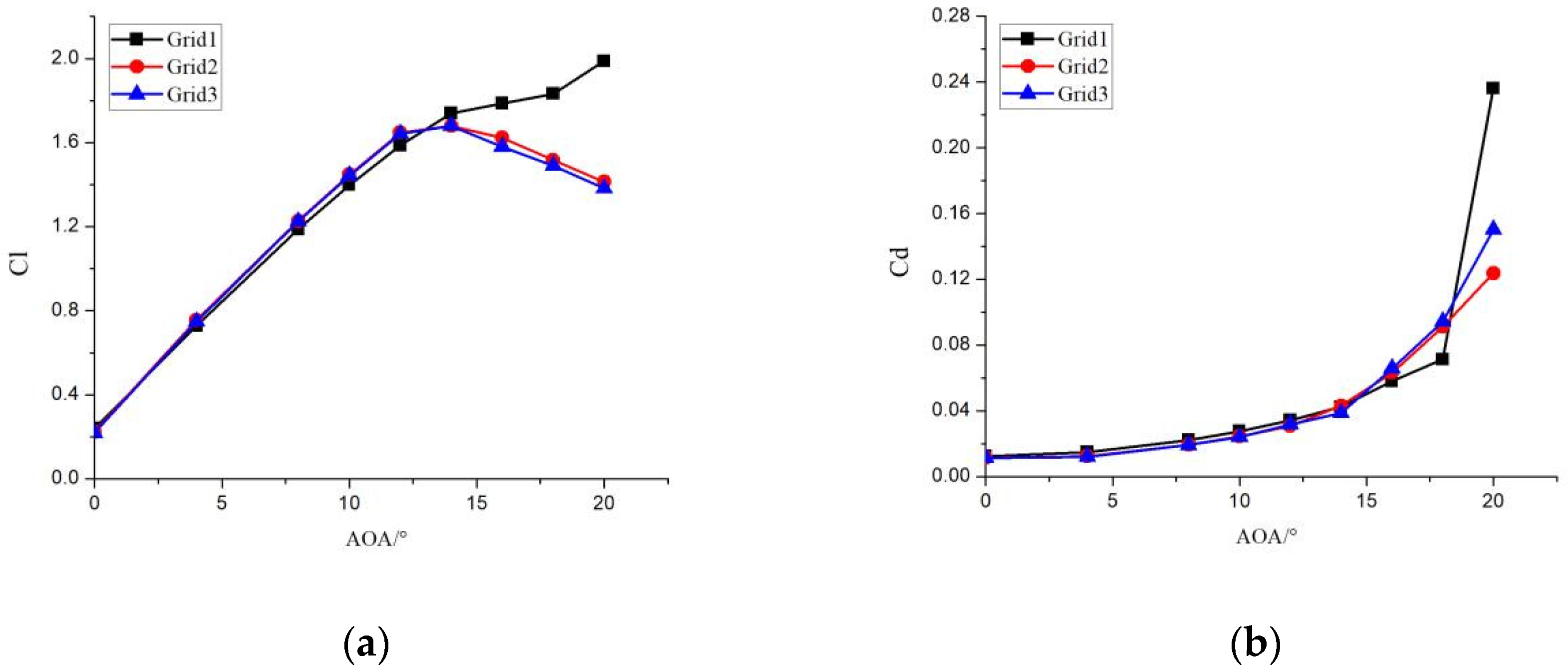

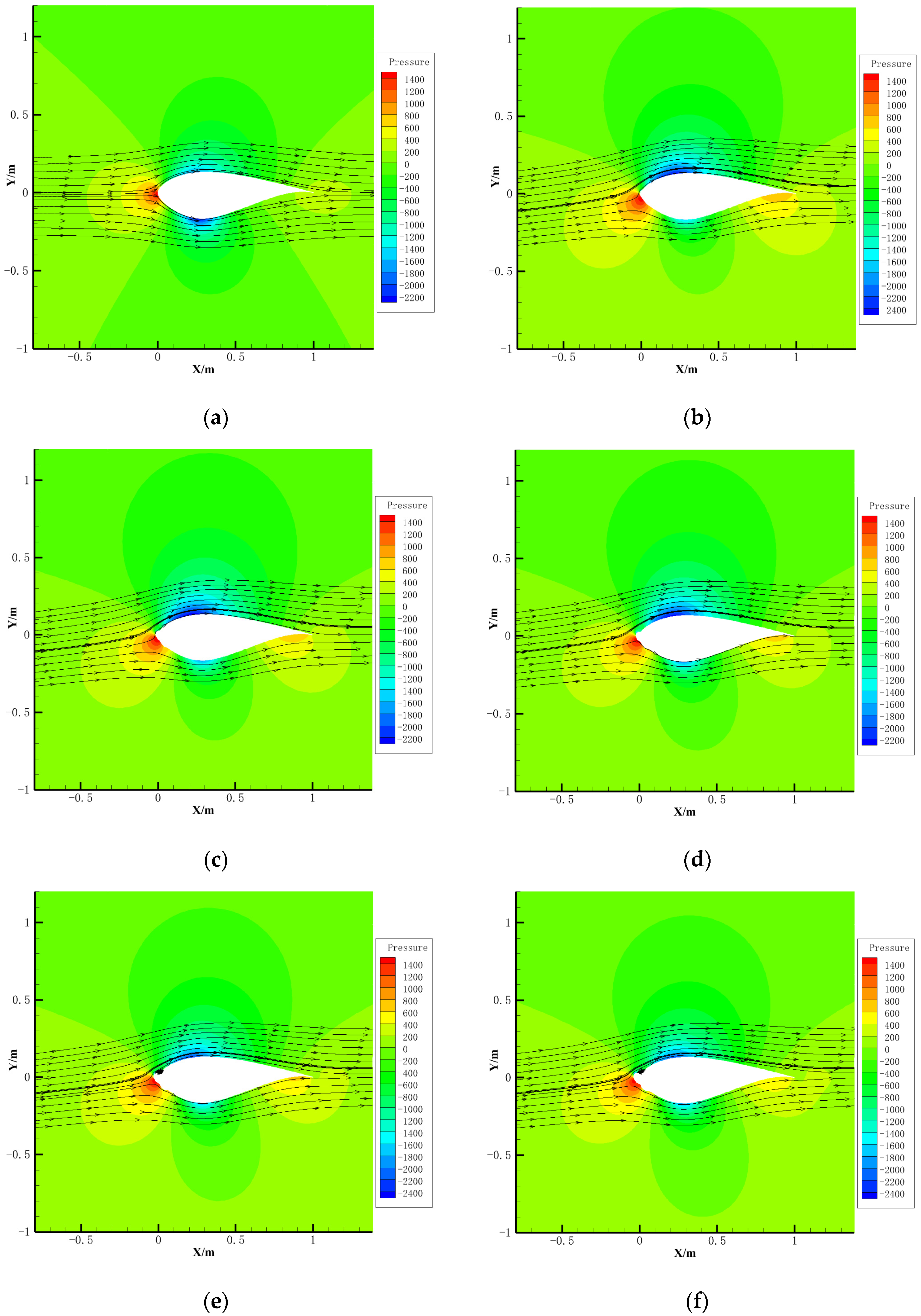

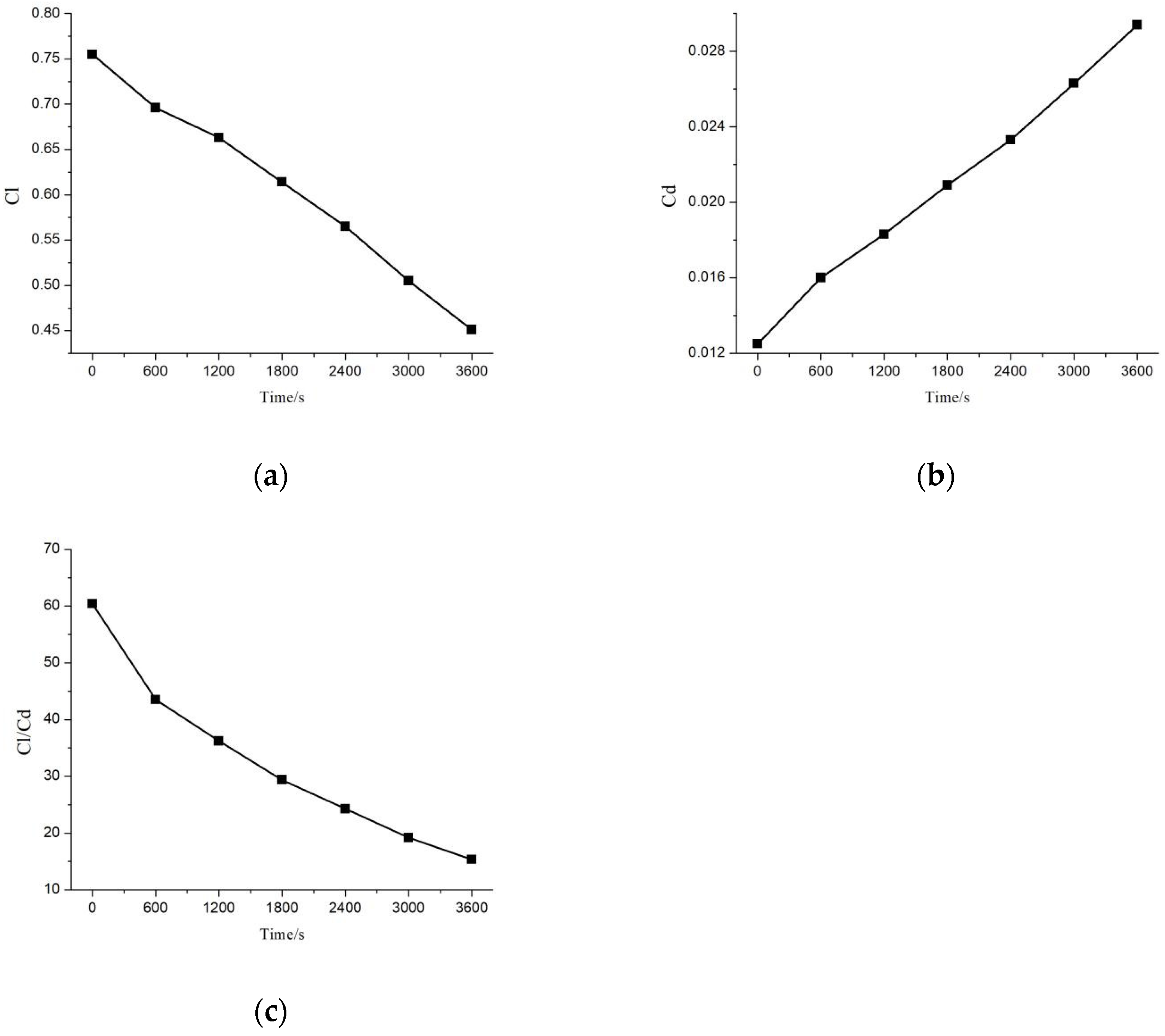

3.2. Aerodynamic Characteristics Calculation

4. Aerodynamic Characteristics of Wind Turbine Airfoil After Icing

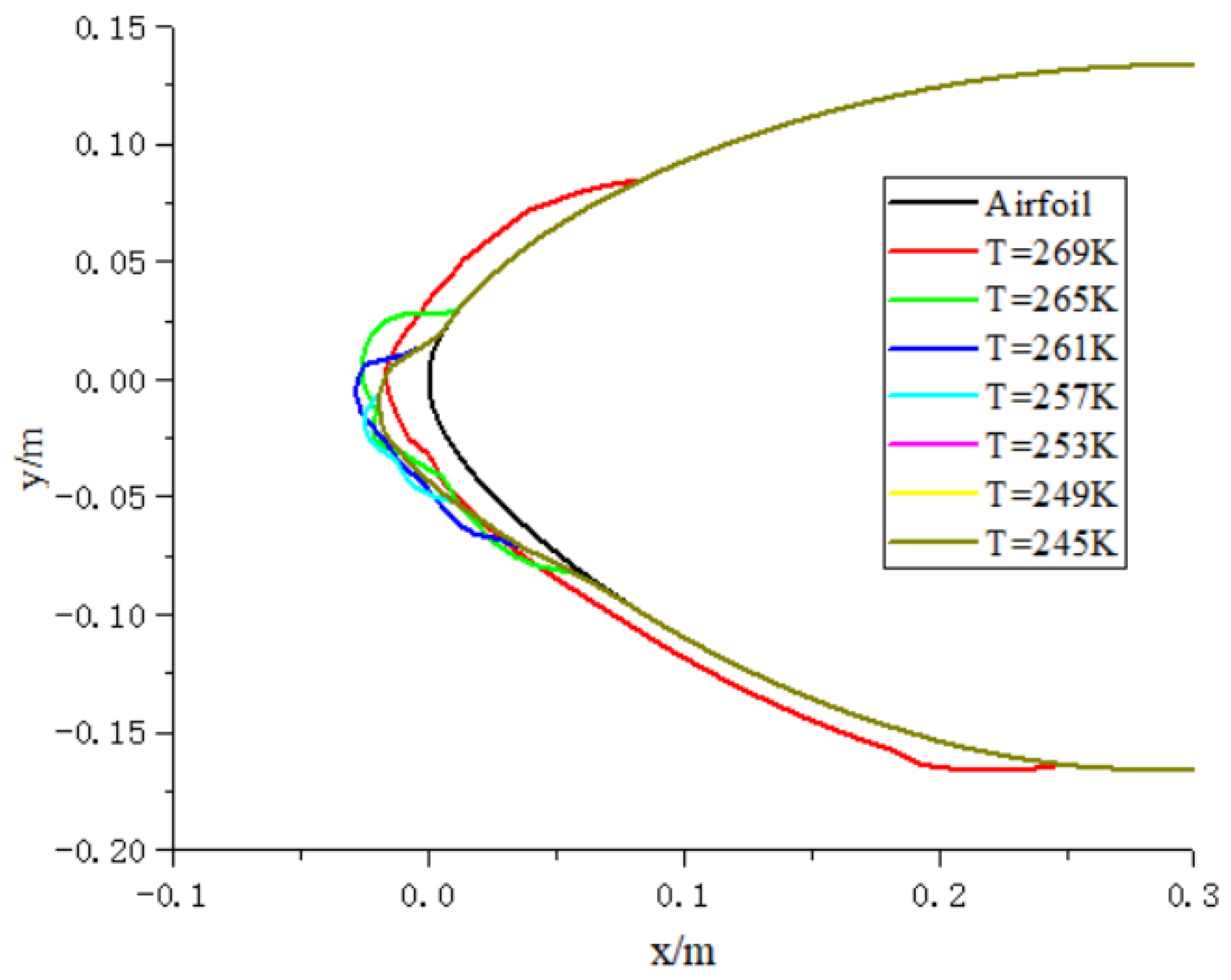

4.1. Icing Characteristics at Different Temperatures

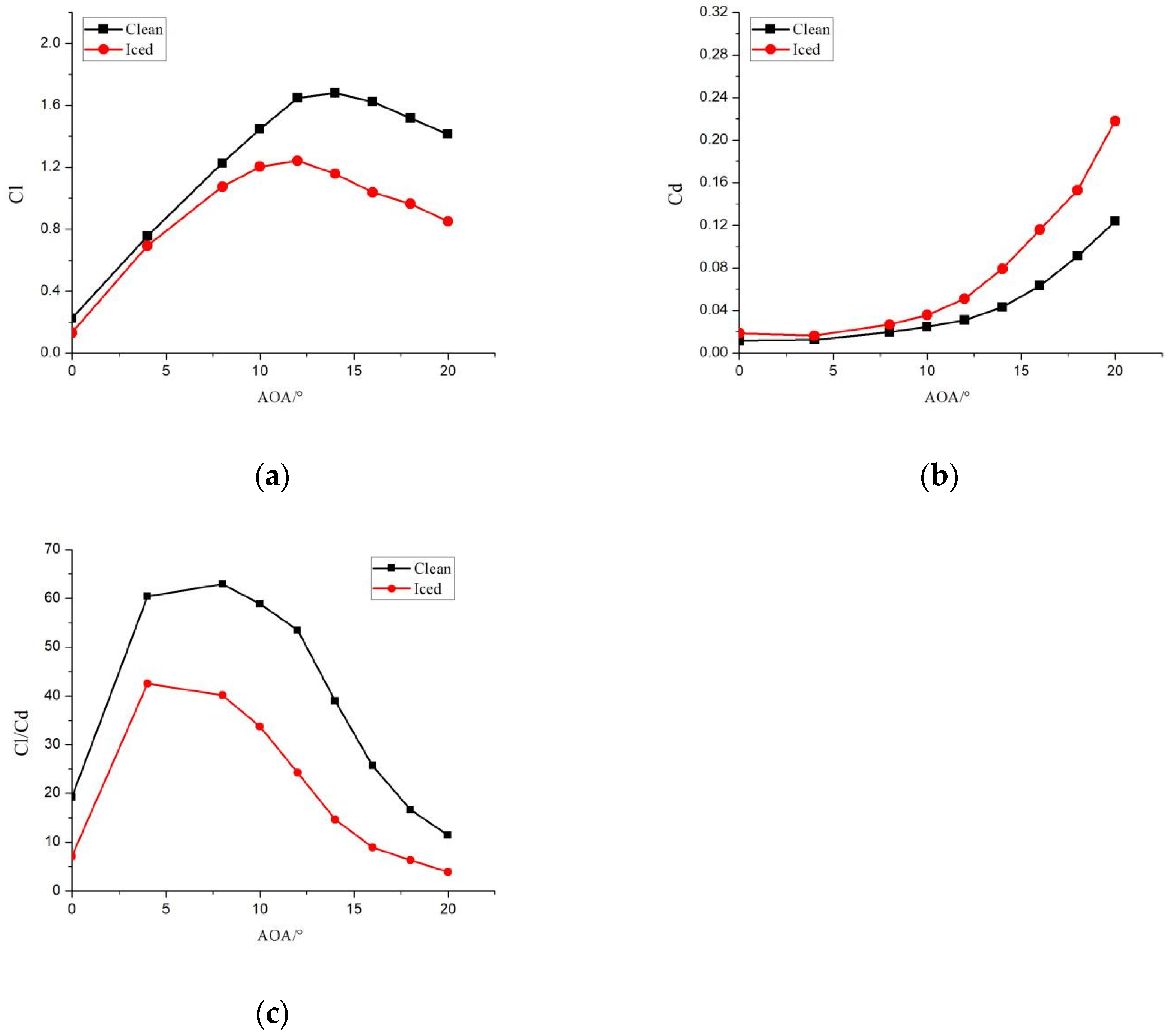

4.2. Aerodynamic Characteristics of Clean Airfoil

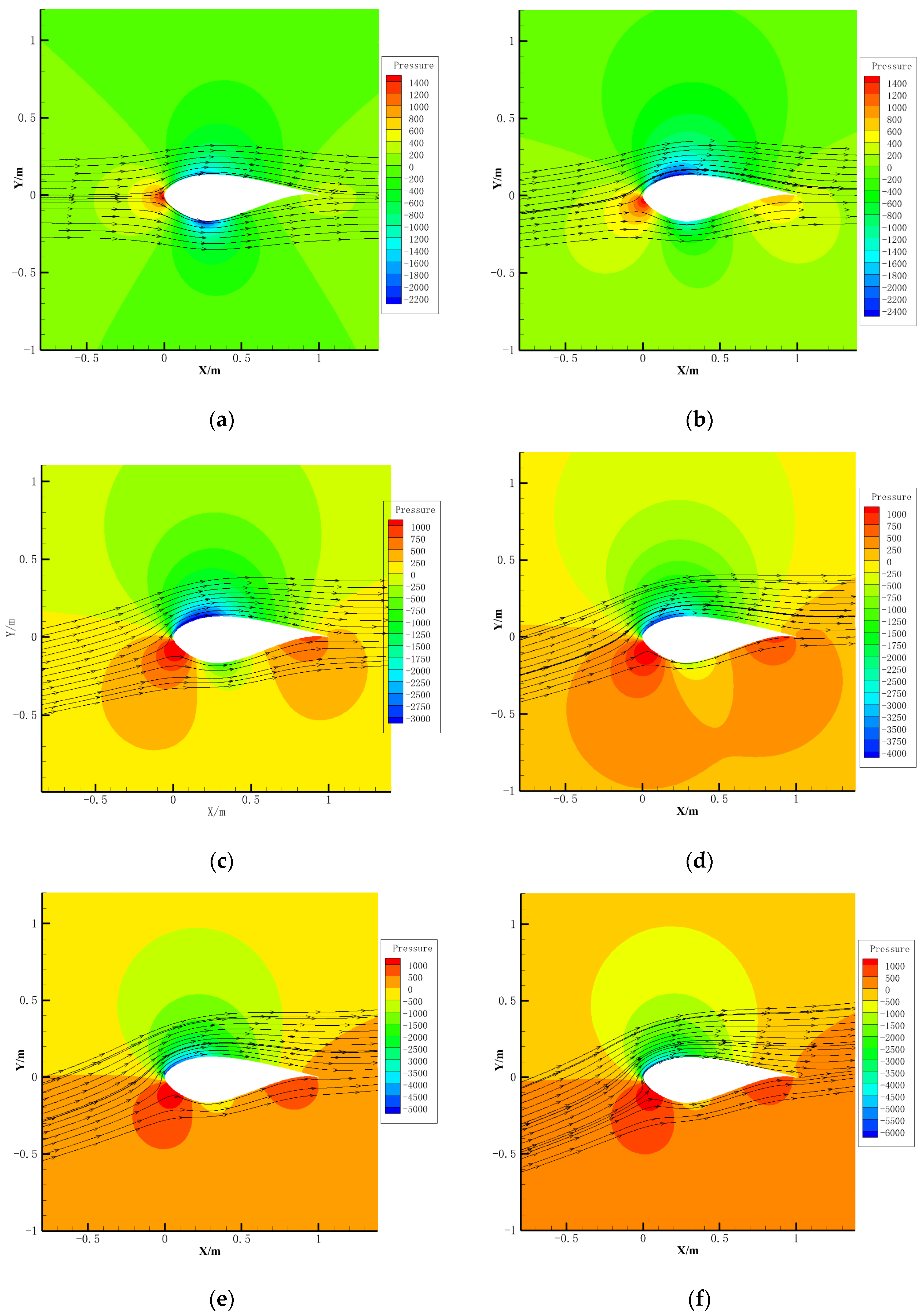

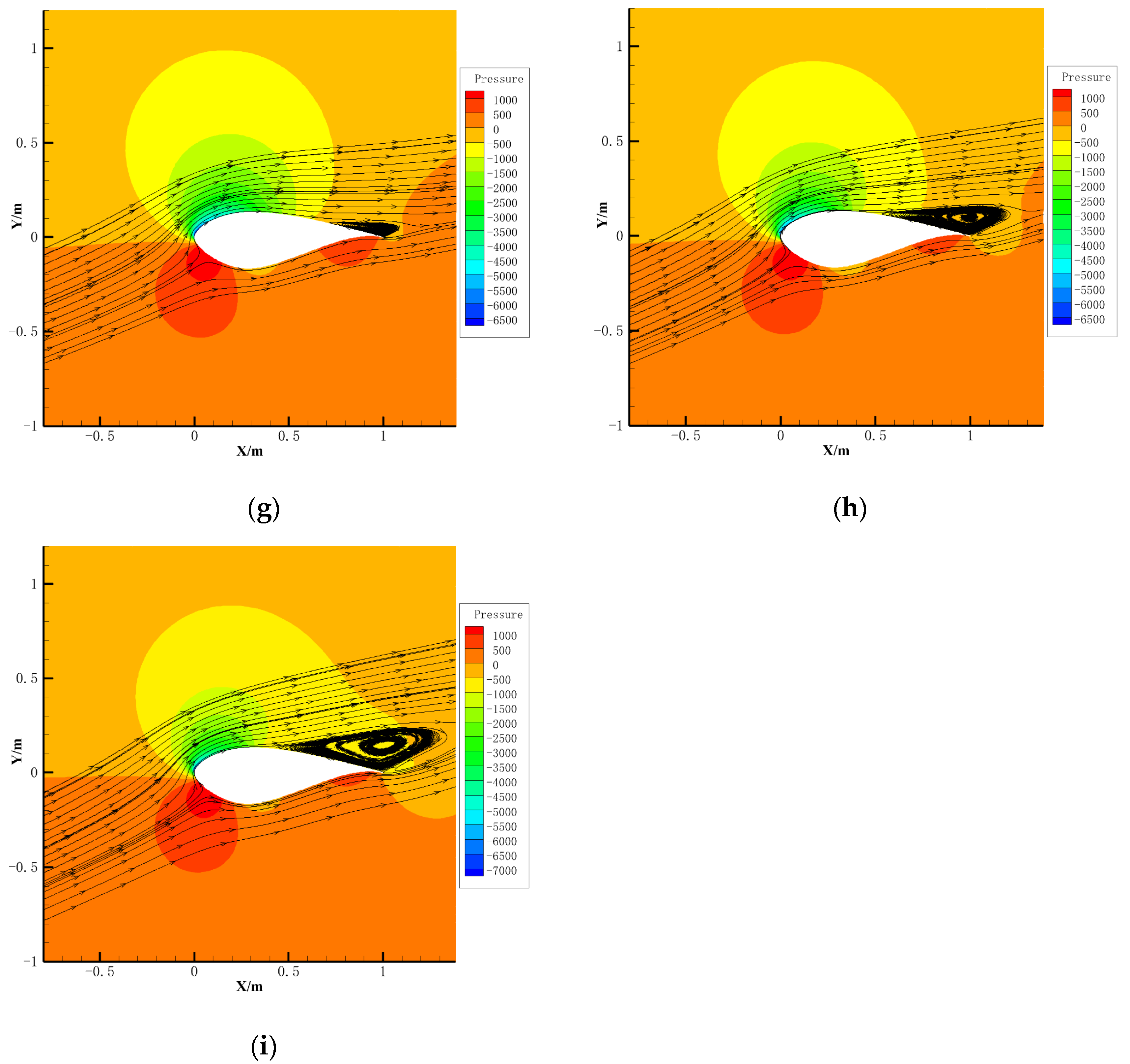

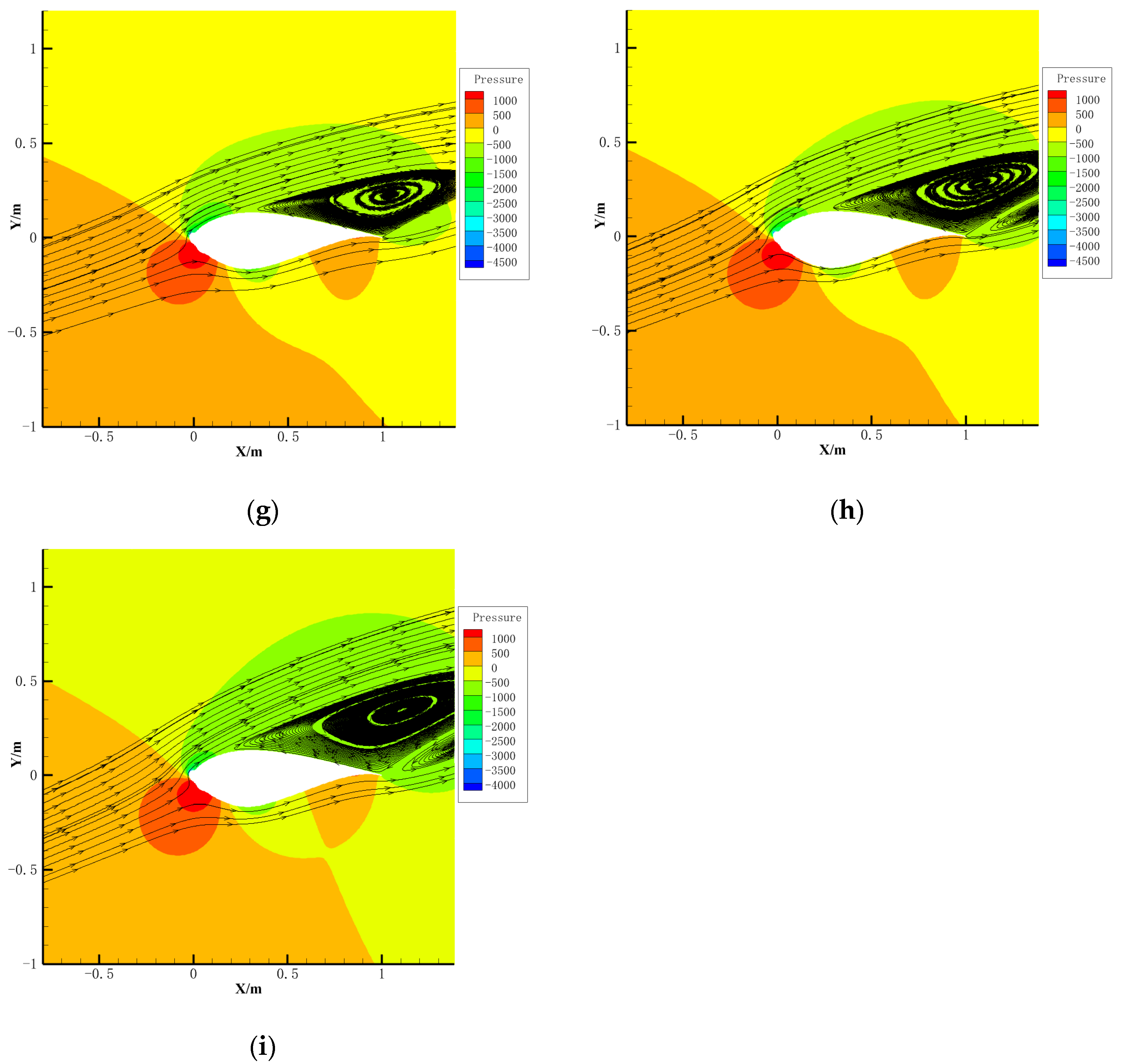

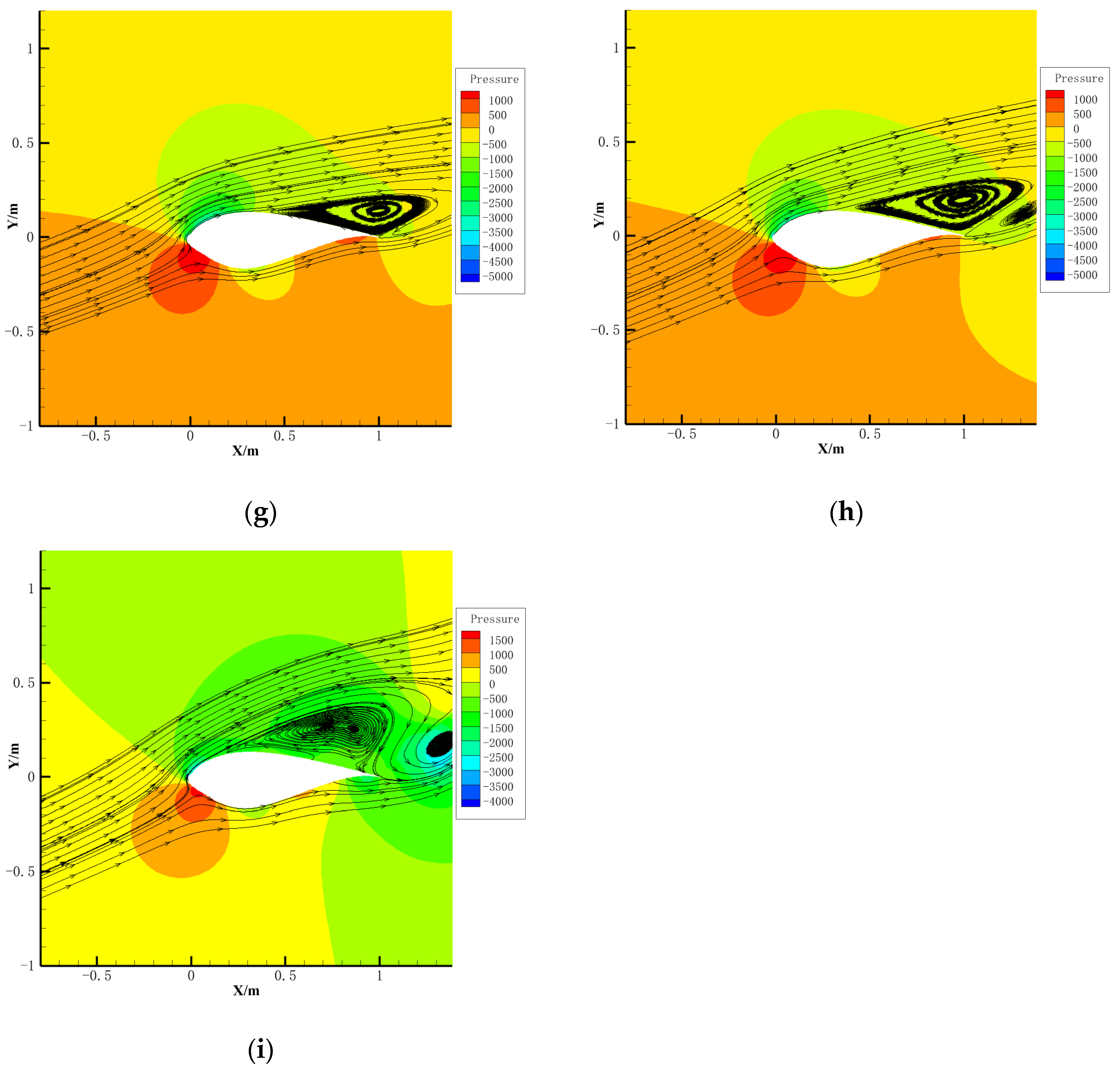

4.3. Aerodynamic Characteristics Under Glaze Ice Condition

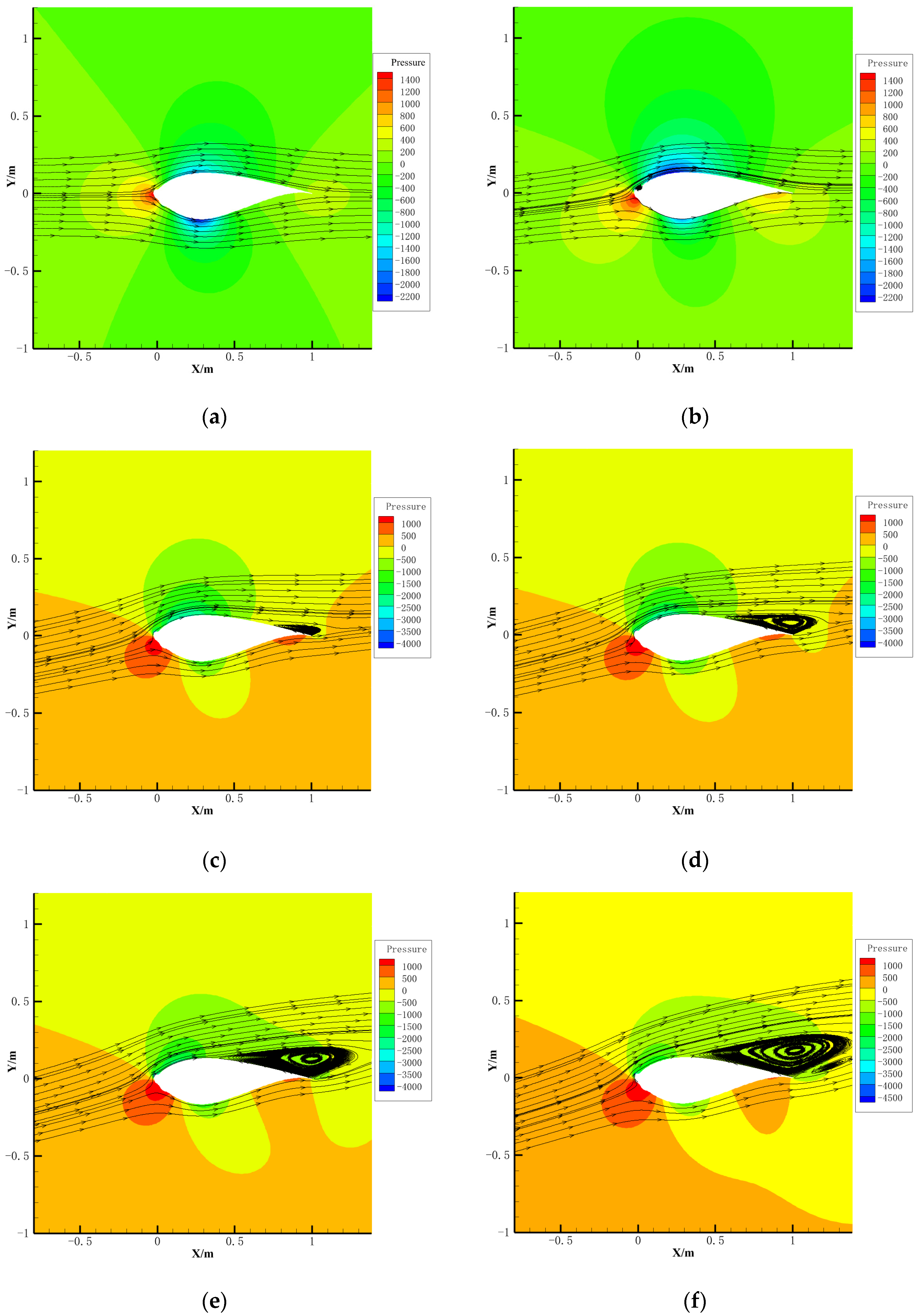

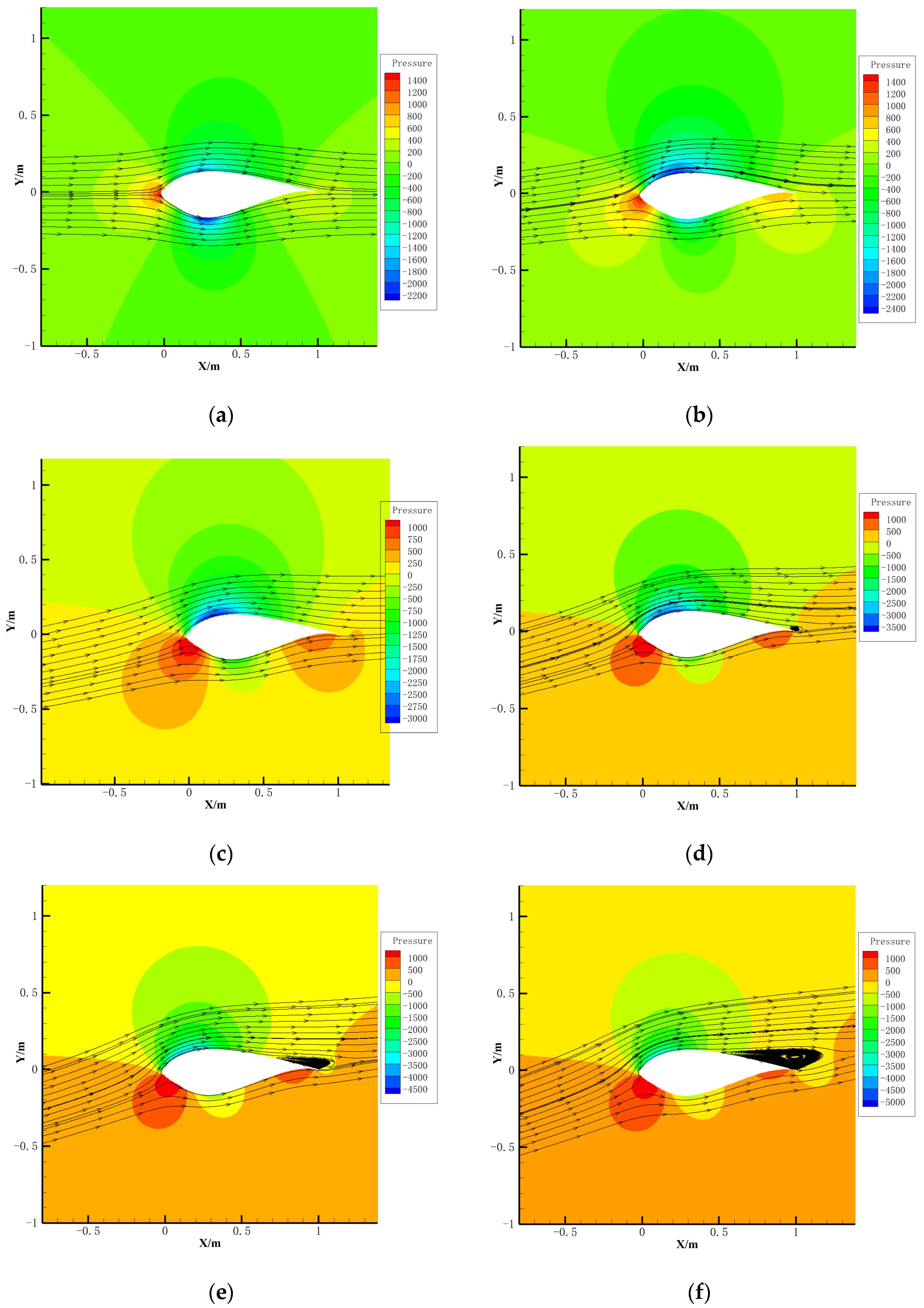

4.4. Aerodynamic Characteristics Under Rime Ice Condition

5. Conclusions

- (1)

- As icing gradually accumulates, the icing thickness gradually increases. The higher the icing temperature, the wider the range of icing on the wind turbine airfoil and the higher the total amount of icing.

- (2)

- The aerodynamic characteristics of the wind turbine airfoil decrease with the icing growth. After 3600 s of icing, the lift coefficient decreases by 40.2%, the drag coefficient increases by 135.2%, and the lift-to-drag ratio decreases by 74.6%.

- (3)

- Under the glaze ice condition, the lift coefficient of the wind turbine airfoil decreases by up to 60.8%, the drag coefficient increases by up to 241.8%, the lift-to-drag ratio decreases by up to 87.9%, and the stall angle of attack advances from 14° to 8°. Under the rime ice condition, lift coefficient decreases by up to 31.0%, drag coefficient increases by up to 83.2%, lift-to-drag ratio decreases by up to 62.4%, and the stall angle of attack is advanced from 14° to 12°.

- (4)

- The harm of icing on the aerodynamic characteristics of the wind turbine airfoil under the glaze ice condition is significantly greater than that in the rime ice condition.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.; Zhang, H.; Zhang, X.; Hu, Q.; Jiang, X. A Review of Wind Turbine Icing and Anti/De-Icing Technologies. Energies 2024, 17, 2805. [Google Scholar] [CrossRef]

- Frohboese, P.; Anders, A. Effects of icing on wind turbine fatigue loads. J. Phys. Conf. Ser. 2007, 75, 01206. [Google Scholar] [CrossRef]

- Gantasala, S.; Luneno, J.C.; Aidanpää, J.O. Influence of Icing on the Modal Behavior of Wind Turbine Blades. Energies 2016, 9, 862. [Google Scholar] [CrossRef]

- Fortin, G.; Perron, J. Wind Turbine Icing and De-icing. In Proceedings of the 47th AIAA Aerospace Sciences Meeting, Orlando, FL, USA, 5–8 January 2009. [Google Scholar]

- Wang, Z.; Zhu, C. Numerical simulation for in-cloud icing of three-dimensional wind turbine blades. Simulation 2018, 94, 31–41. [Google Scholar] [CrossRef]

- Bian, P.; Wang, F.; Wang, L.; Kong, W.; Liu, H. The microscopic contact morphology of ice crystal on substrate and its effect on heterogeneous nucleation/icing. Int. J. Heat Mass Transf. 2023, 209, 124125. [Google Scholar] [CrossRef]

- Tetteh, E.; Loth, E.; Neuteboom, M.O.; Fisher, J. In-flight gas turbine engine icing. AIAA J. 2022, 60, 5610–5632. [Google Scholar] [CrossRef]

- Haggerty, J.; Defer, E.; De Laat, A.; Bedka, K.; Moisselin, J.; Potts, R.; Divito, S. Detecting Clouds Associated with Jet Engine Ice Crystal Icing. Bull. Am. Meteorol. Soc. 2019, 100, 31–40. [Google Scholar] [CrossRef] [PubMed]

- Mason, J.; Strapp, W.; Chow, P. The ice particle threat to engines in flight. In Proceedings of the 44th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 9–12 January 2006. [Google Scholar]

- Addy, H.E.; Veres, J.P. An overview of NASA engine ice-crystal icing research. In Proceedings of the International Conference on Aircraft and Engine Icing and Ground Deicing, Chicago, IL, USA, 13–17 June 2011. [Google Scholar]

- Dezitter, F.; Grandin, A.; Brenguier, J.L.; Hervy, F.; Schlager, H.; Villedieu, P.; Zalamansky, G. HAIC-High Altitude Ice Crystals. In Proceedings of the 5th AIAA Atmospheric and Space Environments Conference, San Diego, CA, USA, 24–27 June 2013. [Google Scholar]

- Bucknell, A.; McGilvray, M.; Gillespie, D.R.; Jones, G.; Reed, A.; Buttsworth, D.R. Heat transfer in the core compressor under ice crystal icing conditions. J. Eng. Gas Turbines Power 2018, 140, 071501. [Google Scholar] [CrossRef]

- Abdelghany, E.S.; Sarhan, H.H.; El Saleh, A.; Farghaly, M.B. High bypass turbofan engine and anti-icing system performance: Mass flow rate of anti-icing bleed air system effect. Case Stud. Therm. Eng. 2023, 45, 102927. [Google Scholar] [CrossRef]

- Al-Khalil, K.; Irani, E.; Miller, D. Mixed phase icing simulation and testing at the cox icing wind tunnel. In Proceedings of the 41st Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 2003. [Google Scholar]

- Currie, T.; Struk, P.; Tsao, J.C.; Fuleki, D.; Knezevici, D. Fundamental study of mixed-phase icing with application to ice crystal accretion in aircraft jet engines. In Proceedings of the 4th AIAA Atmospheric and Space Environments Conference, New Orleans, LA, USA, 25–28 June 2012. [Google Scholar]

- Currie, T.; Fuleki, D.; Mahallati, A. Experimental Studies of Mixed-Phase Sticking Efficiency for Ice Crystal Accretion in Jet Engines. In Proceedings of the 6th AIAA Atmospheric and Space Environments Conference, Atlanta, GA, USA, 16–20 June 2014. [Google Scholar]

- Currie, T.; Fuleki, D. Experimental Results for Ice Crystal Icing on Hemispherical and Double Wedge Geometries at Varying Mach Numbers and Wet Bulb Temperatures. In Proceedings of the 8th AIAA Atmospheric and Space Environments Conference, Washington, DC, USA, 13–17 June 2016. [Google Scholar]

- Struk, P.M.; King, M.C.; Bartkus, T.P.; Tsao, J.C.; Fuleki, D.; Neuteboom, M.; Chalmers, J. Ice crystal icing physics study using a NACA 0012 airfoil at the national research council of Canada’s research altitude test facility. In Proceedings of the 2018 Atmospheric and Space Environments Conference, Atlanta, GA, USA, 25–29 June 2018. [Google Scholar]

- Baumert, A.; Bansmer, S.; Trontin, P.; Villedieu, P. Experimental and numerical investigations on aircraft icing at mixed phase conditions. Int. J. Heat Mass Transf. 2018, 123, 957–978. [Google Scholar] [CrossRef]

- Trontin, P.; Blanchard, G.; Villedieu, P. A comprehensive numerical model for mixed-phase and glaciated icing conditions. In Proceedings of the 8th AIAA Atmospheric and Space Environments Conference, Washington, DC, USA, 13–17 June 2016. [Google Scholar]

- Trontin, P.; Villedieu, P. A comprehensive accretion model for glaciated icing conditions. Int. J. Multiph. Flow 2018, 108, 105–123. [Google Scholar] [CrossRef]

- Nilamdeen, S.; Habashi, W.G. Multiphase approach toward simulating ice crystal ingestion in jet engines. J. Propuls. Power 2011, 27, 959–969. [Google Scholar] [CrossRef]

- Bucknell, A.; McGilvray, M.; Gillespie, D.R.; Jones, G.; Collier, B. A thermodynamic model for ice crystal accretion in aircraft engines: EMM-C. Int. J. Heat Mass Transf. 2021, 174, 121270. [Google Scholar] [CrossRef]

- Malik, Y.A.; Köbschal, K.; Bansmer, S.; Tropea, C.; Hussong, J.; Villedieu, P. Ice accretion compositions in ice crystal icing. Int. J. Heat Mass Transf. 2024, 220, 124910. [Google Scholar] [CrossRef]

- Malik, Y.A.; Bennani, L.; Bansmer, S.; Trontin, P.; Villedieu, P. Experimental and numerical investigation of accretion inception and heat transfer physics in ice crystal icing. Int. J. Heat Mass Transf. 2023, 214, 124364. [Google Scholar] [CrossRef]

- Malik, Y.A.; Karpen, N.; Bonaccurso, E.; Roisma, I.; Hussong, J.; Villedieu, P. Experimental investigation of the accretion and shedding process on a heatable NACA0012 airfoil in ice crystal icing conditions. Cold Reg. Sci. Technol. 2024, 217, 104030. [Google Scholar] [CrossRef]

- Norde, E. Eulerian Method for Ice Crystal Icing in Turbo Fan Engines. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 2017. [Google Scholar]

- Zhang, L.; Liu, Z.; Zhang, M. Numerical simulation of ice accretion under mixed-phase conditions. Proc. Inst. Mech. Eng.—Part G J. Aerosp. Eng. 2016, 230, 2473–2483. [Google Scholar] [CrossRef]

- Jia, W.; Yang, B.; Zheng, M.; Kong, Q. Numerical investigation of ice crystal melting characteristic and icing risk in an axial compressor. Int. J. Turbo Jet-Engines 2024, 41, 139–149. [Google Scholar] [CrossRef]

- Wang, X.; Ru, Y.; Zhao, H.; Wang, Z. Numerical Investigation of Wind Turbine Airfoil Icing and Its Influencing Factors under Mixed-Phase Conditions. Energies 2024, 17, 4993. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, C.; Zhong, W.; Zhao, H. Numerical simulation of ice crystal trajectory and its influencing factors based on Lagrangian method. Appl. Sci. 2023, 13, 4110. [Google Scholar] [CrossRef]

- Wang, Z.; Zhong, W.; Liu, C.; Zhao, H.; Liu, S. Numerical Simulation of Ice Crystal Supercooled Droplet Mixed Phase Icing Based on the Improved Messinger Model. Int. J. Aerosp. Eng. 2023, 1, 6696084. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Ru, Y.; Zhao, H.; Wang, Z. Study on the Effect of Mixed-Phase Icing on the Aerodynamic Characteristics of Wind Turbine Airfoil. Energies 2025, 18, 559. https://doi.org/10.3390/en18030559

Wang X, Ru Y, Zhao H, Wang Z. Study on the Effect of Mixed-Phase Icing on the Aerodynamic Characteristics of Wind Turbine Airfoil. Energies. 2025; 18(3):559. https://doi.org/10.3390/en18030559

Chicago/Turabian StyleWang, Xiang, Yiyao Ru, Huanyu Zhao, and Zhengzhi Wang. 2025. "Study on the Effect of Mixed-Phase Icing on the Aerodynamic Characteristics of Wind Turbine Airfoil" Energies 18, no. 3: 559. https://doi.org/10.3390/en18030559

APA StyleWang, X., Ru, Y., Zhao, H., & Wang, Z. (2025). Study on the Effect of Mixed-Phase Icing on the Aerodynamic Characteristics of Wind Turbine Airfoil. Energies, 18(3), 559. https://doi.org/10.3390/en18030559