Correction: Ashikhmin et al. Effect of Monodisperse Coal Particles on the Maximum Drop Spreading After Impact on a Solid Wall. Energies 2023, 16, 5291

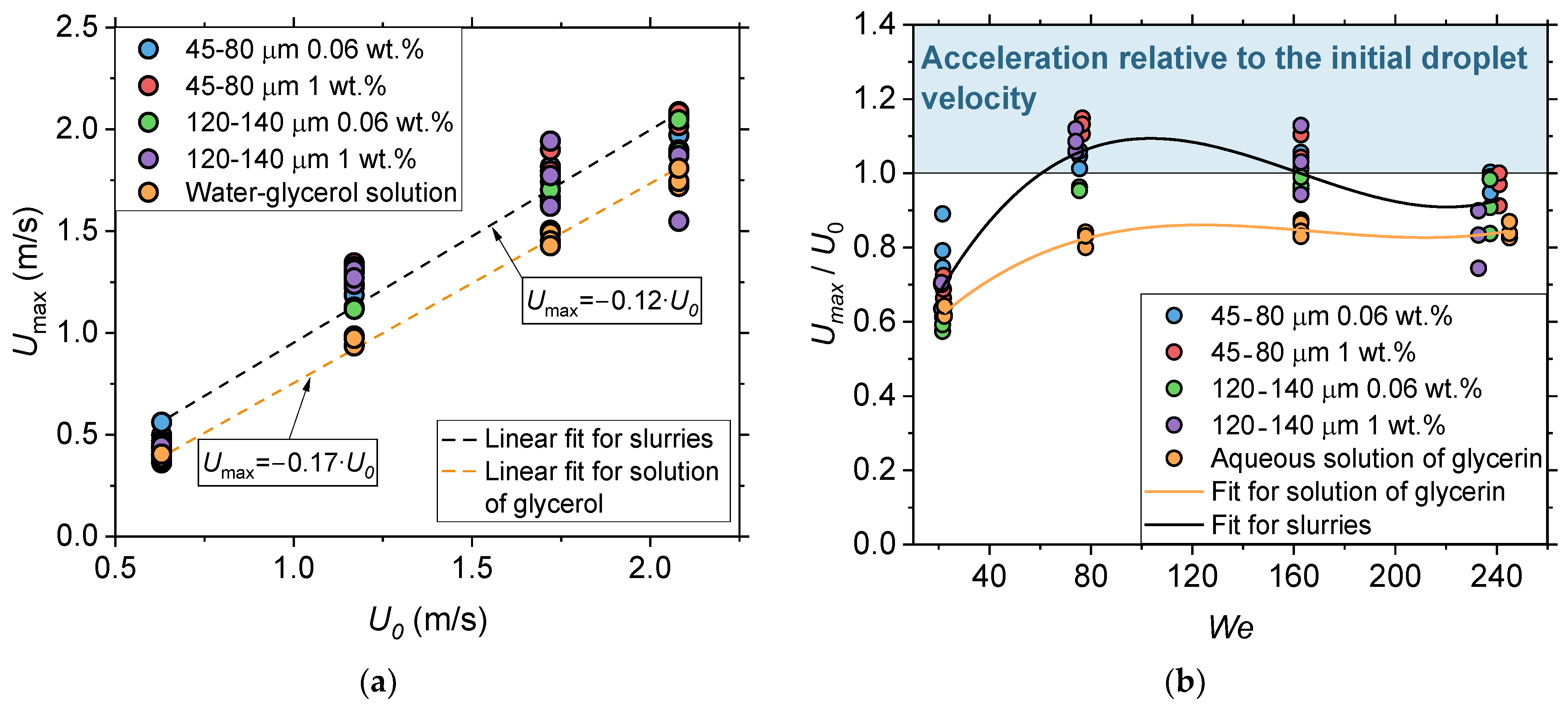

- At We = 20, the particle grinding fineness and concentration strongly affect the internal flow velocities, contributing both to their increase and decrease, depending on the combination of the initial parameters of a slurry. At We = 250, the spreading velocity of the particle-laden drops is approximately twice as high as at We = 20. Given this fact, the inertia-driven spreading of the particle-laden drop is mainly determined by the dynamics of the deformable Taylor rim, and the contribution of solids is insignificant, causing the closeness of the values of the maximum absolute velocity of internal flows for various combinations of the initial parameters of a slurry. Relying on the experimental data obtained by the shadow photography and PIV, the behavior of internal convective flows in the longitudinal section of a particle-laden drop is characterized. It is revealed that the kinetic energy of translational motion of coal particles in a drop compensates for the energy expended by the drop on sliding friction along the wall.

- The behavior of the maximum spreading factor βmax for particle-laden and water–glycerol drops is mainly defined by the initial drop velocity with the constancy of other terms within the Weber number and is governed by the power function of βmax = 0.97We0.2 with a coefficient of determination R2 = 0.95. Further, we revealed the peculiarity of a noticeable increase in the differences in the velocities of internal flows in spreading drops with an increase in Weber number. Finally, as the Weber number grows, an increase in the spreading drop diameter at the maximum absolute velocity of internal flows causes elevated values for the maximum spreading diameter and is described by the expression . In addition, the presence of coal particles causes a general tendency toward a reduction in liquid drop spreading.

Reference

- Ashikhmin, A.; Khomutov, N.; Volkov, R.; Piskunov, M.; Strizhak, P. Effect of Monodisperse Coal Particles on the Maximum Drop Spreading After Impact on a Solid Wall. Energies 2023, 16, 5291. [Google Scholar] [CrossRef]

| Discharge height—2 cm, We ≈ 20 | Coal grinding fineness | Sample name | Coal grinding fineness | Sample name | Number of experiments |

| 45–80 μm | - | 120–140 μm | - | pcs. | |

| Particle concentration, wt.% | 0.06 | Slurry 1 | 0.06 | Slurry 3 | 6 |

| 1 | Slurry 2 | 1 | Slurry 4 | 6 | |

| Discharge height—7 cm, We ≈ 80 | Coal grinding fineness | Sample name | Coal grinding fineness | Sample name | Number of experiments |

| 45–80 μm | - | 120–140 μm | - | pcs. | |

| Particle concentration, wt.% | 0.06 | Slurry 1 | 0.06 | Slurry 3 | 6 |

| 1 | Slurry 2 | 1 | Slurry 4 | 6 | |

| Discharge height—15 cm, We ≈ 160 | Coal grinding fineness | Sample name | Coal grinding fineness | Sample name | Number of experiments |

| 45–80 μm | - | 120–140 μm | - | pcs. | |

| Particle concentration, wt.% | 0.06 | Slurry 1 | 0.06 | Slurry 3 | 6 |

| 1 | Slurry 2 | 1 | Slurry 4 | 6 | |

| Discharge height—22 cm, We ≈ 250 | Coal grinding fineness | Sample name | Coal grinding fineness | Sample name | Number of experiments |

| 45–80 μm | - | 120–140 μm | - | pcs. | |

| Particle concentration, wt.% | 0.06 | Slurry 1 | 0.06 | Slurry 3 | 6 |

| 1 | Slurry 2 | 1 | Slurry 4 | 6 | |

| Total | 48 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ashikhmin, A.; Khomutov, N.; Volkov, R.; Piskunov, M.; Strizhak, P. Correction: Ashikhmin et al. Effect of Monodisperse Coal Particles on the Maximum Drop Spreading After Impact on a Solid Wall. Energies 2023, 16, 5291. Energies 2025, 18, 6375. https://doi.org/10.3390/en18246375

Ashikhmin A, Khomutov N, Volkov R, Piskunov M, Strizhak P. Correction: Ashikhmin et al. Effect of Monodisperse Coal Particles on the Maximum Drop Spreading After Impact on a Solid Wall. Energies 2023, 16, 5291. Energies. 2025; 18(24):6375. https://doi.org/10.3390/en18246375

Chicago/Turabian StyleAshikhmin, Alexander, Nikita Khomutov, Roman Volkov, Maxim Piskunov, and Pavel Strizhak. 2025. "Correction: Ashikhmin et al. Effect of Monodisperse Coal Particles on the Maximum Drop Spreading After Impact on a Solid Wall. Energies 2023, 16, 5291" Energies 18, no. 24: 6375. https://doi.org/10.3390/en18246375

APA StyleAshikhmin, A., Khomutov, N., Volkov, R., Piskunov, M., & Strizhak, P. (2025). Correction: Ashikhmin et al. Effect of Monodisperse Coal Particles on the Maximum Drop Spreading After Impact on a Solid Wall. Energies 2023, 16, 5291. Energies, 18(24), 6375. https://doi.org/10.3390/en18246375