Abstract

The development of Digital Twin (DT) technology in Battery Management Systems (BMSs) presents a transformative approach for maintenance, monitoring, and predictive diagnostics, especially in the demanding field of space applications. DTs, through their three-layer structure, provide an accurate and dynamic virtual representation of the physical entity, continuously updated via bidirectional data exchange provided by the communication link. Given the promising capabilities of the DT approach in real-time applications, its integration into BMSs is straightforward, as it can enhance monitoring and prediction of nonlinear electrochemical systems, such as space-grade lithium-ion batteries, supporting the mitigation of ageing effects under the unique constraints of the space environment. Despite notable progress in BMS technologies, the choice of estimation techniques consistent with the DT paradigm remains insufficiently defined. This survey examines the state of the art with the aim of bridging the conceptual framework of DTs and existing battery management algorithms, identifying the methodologies most suitable in accordance with DT architectures and principles. The scope of this paper is to provide researchers and engineers with a comprehensive overview of the advancements, key enabling technologies, and implementation strategies for Digital Twins in space BMSs, ultimately contributing to more reliable and efficient space missions.

1. Introduction

The Electrical Power Subsystem (EPS) is one of the most critical components of a satellite, as it provides essential electrical power to its various subsystems, ensuring the functionality of the satellite throughout its mission. The EPS typically comprises three components: (i) solar panels, (ii) batteries, and (iii) the Battery Management System (BMS). The solar panels generate electricity when the satellite is exposed to sunlight, powering the satellite and charging its batteries. The batteries, in turn, supply power when the satellite is in the shadow of the Earth or during orbital maneuvers, attitude adjustments, or other periods without sunlight. Finally, BMS monitors and manages battery performance, maintaining optimal operational conditions for safe and reliable power delivery [1]. The EPS is particularly vulnerable to harsh and unpredictable space conditions. Failures in the power subsystem can severely impact the satellite, as an inability to supply sufficient power could lead to a critical failure of the mission. Statistical analyses have shown that approximately 21% of satellite malfunctions can be attributed to EPS faults, underlining the importance of robust power systems [2]. Batteries, in particular, exhibit highly nonlinear behavior in terms of performance degradation and failure mechanisms. Due to their complex electrochemical characteristics, batteries are strongly influenced by operational conditions. Thus, in the context of space missions, where each mission presents unique operational profiles, energy storage systems must be carefully tailored and periodically monitored to ensure both mission success and long-term reliability [3]. For these reasons, BMSs are employed to monitor battery health and ensure safe operations. BMS technologies in sectors such as electric vehicles (EVs) can provide an accurate estimation of monitoring fundamental parameters such as State of Charge (SOC), State of Health (SOH), and Remaining Useful Life (RUL), also thanks to the possibility of regular calibration and maintenance operations performed on the ground [4].

In contrast, satellite BMSs often lack the capabilities to process real-time information due to hardware constraints [5,6]. Moreover, in situ maintenance is infeasible in space environments, making continuous and reliable monitoring of battery state essential. Given the importance of EPS for satellite missions and the limitations of current BMSs, there is a pressing need for more advanced, intelligent algorithms necessary for optimal battery management. In this frame, emerging digital methodologies offer promising solutions to overcome these challenges in battery management, from manufacturing and assembly to operation and recycling [7]. One particularly promising approach is the Digital Twin (DT) concept, which involves creating a live digital replica of the physical BMSs. The DT employs multi-scale models, real-time data processing, and a two-way data connection with the physical system to simulate and predict battery behavior accurately. Especially in space where missions operate under extreme conditions and human intervention is impractical, implementing a reliable DT can enable predictive maintenance, satellite operations optimization, and mitigating risks. In [7], a systematic review on Digital Twin batteries has been proposed, which highlights potential use cases, enabling technologies, and implementation requirements in terms of hardware and software. Moreover, recent advances have focused on practical implementations: the use of real-time data has enabled the construction of cloud-based DT models with two-way dynamic mapping between physical batteries and their virtual replicas [8], while data-driven approaches that combine semi-empirical models with deep learning and metaheuristic optimization have demonstrated high accuracy in predicting discharge capacity [9]. Recent works have started to extend Digital Twin applications to battery management in space scenarios. A CubeSat EPS Digital Twin was experimentally validated, demonstrating real-time synchronization with the physical system and the potential for predictive maintenance and hardware-in-the-loop testing [10]. Other studies established executable DT frameworks for satellite fault diagnosis and health management, leading to space–ground platforms for real-time monitoring and decision support [11]. This strategy allows for a more adaptive and comprehensive battery management system, offering a path forward for improved satellite reliability through enhanced SOC, SOH, and RUL monitoring and estimation.

Accurate monitoring of these metrics is essential to prevent overcharging, overheating, and unexpected power interruptions. Despite their importance, SOC, SOH, and RUL estimation in lithium-ion batteries presents numerous challenges. These metrics are influenced by factors like algorithm complexity, battery model design, computational burden, noise sensitivity, and temperature variations, which complicate their accurate and reliable monitoring [12]. In recent years, several scholars have conducted review studies on SOC, SOH, and RUL estimation. Collectively, these studies highlight the progress that has been made in the field, while also identifying gaps and challenges that remain to be filled.

For instance, different reviews have provided detailed comparisons and classification of techniques for SOC, SOH, and RUL estimation, systematically categorizing and analyzing different algorithms in terms of precision, advantages, disadvantages, and characteristics.

In [13], techniques, models, and algorithms used in lithium-ion battery state estimation and RUL prediction have been summarized, providing a comparison of various methods. In [14], a comprehensive analysis of various promising techniques to estimate SOH is systematically categorized and analyzed in terms of accuracy, advantages, disadvantages, and characteristics. Similarly, in [15], a classification of methodologies for estimating and predicting lithium-ion power battery SOH is proposed, dividing the methods into model-based, data-driven, and hybrid approaches, comparing the different SOH estimation and prediction methods. In contrast, ref. [16] provides a comparative analysis of signal-based SOH estimation techniques, categorizing them based on voltage, current, and thermal data, while also highlighting their performance metrics and limitations. In [17], a comprehensive review of current SOH prediction techniques conducted by systematically introducing the aging mechanisms of batteries is presented. The study begins with the aging mechanism of Li-ion batteries, analyzes the micro- and macro-level factors leading to battery aging. Other surveys have focused on advanced data-driven approaches. For example, a thorough classification of Artificial Neural Networks (ANNs) has been presented in [18], detailing their applications for SOH, SOC, and RUL estimation, along with a taxonomy of architectures such as feedforward, convolutional, and recurrent neural networks. Similarly, ref. [19] evaluates the integration of Deep Learning (DL) methodologies for BMSs, emphasizing their ability to capture nonlinear degradation patterns and process high-dimensional datasets. Additionally, ref. [20] presents a comprehensive survey of data-driven methods for predicting and managing the battery SOH in electric vehicles. The review highlights the importance of high-quality data, model generalization, and the role of synthetic datasets in enhancing reliability, illustrating the potential of interdisciplinary approaches to advance SOH diagnostics. In [21], it is shown how cloud computing and Artificial Intelligence (AI) can enhance BMSs for electric vehicles and energy storage compared to traditional BMSs, which face limitations due to onboard constraints. Cloud-based AI overcomes these challenges by leveraging extensive data processing capabilities, improving state estimation, safety, and thermal management.

A relevant effort toward space is [22], which provides insights into battery health management in space applications, emphasizing how the specificities of such applications—such as operational conditions and work profiles—can affect aging and its quantification. Existing reviews mainly focus on methodological classifications or general BMS framework characterization, without regard to the coupling with the Digital Twins concept. Despite the significant advancements in BMS technologies and the development of sophisticated methodologies for estimating critical parameters like SOH, SOC, and RUL, the selection of estimation techniques that align with the DT concept is not yet well defined. The aim of this work is to bridge this gap by establishing a clear and comprehensive definition of the Digital Twin within the context of lithium-ion batteries, which represent the dominant choice for space applications. This involves not only mapping existing battery management algorithms, but also identifying and evaluating the methodologies best suited for estimating SOH, SOC, and RUL in a way that aligns with the architecture and principles of a DT. The rest of this paper is organized in the following manner: Section 2 explores the fundamental principles of lithium-ion battery degradation mechanisms, detailing the micro and macro factors influencing performance; Section 3 provides a comprehensive overview of Digital Twin technology, including its definition and applications in BMSs for space; Section 4 classifies and evaluates methodologies for DT implementation in BMSs; Section 5 compares the different approaches in terms of their adaptability to the DT framework. Finally, Section 6 concludes the paper with insights and recommendations for future research and practical applications.

2. Li-Ion Battery Degradation Mechanisms

To ensure the success of its mission, reliable EPS is essential to supply energy to both the operational bus and payload. When solar panels are unable to deliver sufficient power, batteries become critical. Failure to deliver power can result in mission interruption or even satellite loss. Consequently, ensuring that batteries operate dependably and have a long lifespan in the challenging space environment is vital [23]. In this frame, lithium-ion batteries (LIBs) have become the preferred choice for various space missions due to higher energy density, increased cell voltage, absence of memory effect, and reduced self-discharge rate. These advantages make Li-ion batteries highly favorable for satellite applications, powering over 98% of newly manufactured satellites [24]. Lithium-ion cells are complex electrochemical systems that exhibit dynamic and nonlinear behaviors as they undergo repeated charge and discharge cycles. As LIBs cycle through charging and discharging, various side reactions may occur, resulting in degradation processes which can lead to a reduction in efficiency over time. The following sections will delve into the operational principles of lithium-ion batteries, explore the micro and macro degradation mechanisms, identify common anomalies and degradation mechanisms, and examine the specific considerations for LIBs in space applications.

2.1. Working Mechanism of Li-Ion Batteries

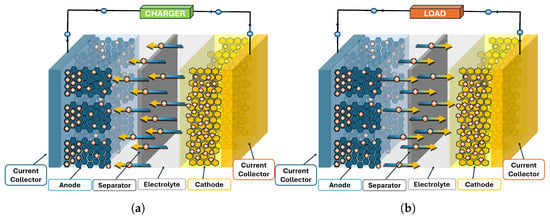

Lithium-ion batteries consist of four primary components: the anode and cathode (electrodes), a separator, and an electrolyte. Each of these parts plays a crucial role in defining the characteristics and overall performance of the battery. In a lithium-ion battery, the movement of lithium ions between the anode and cathode occurs during charging and discharging, a process referred to as intercalation and deintercalation. During discharging (deintercalation phase), lithium ions are released from the anode into the electrolyte, while electrons flow through an external circuit to generate usable electrical power. Concurrently, lithium ions are inserted into the cathode. This movement is driven by the concentration gradient of lithium ions, creating a potential difference that enables current generation. Conversely, during charging, lithium ions migrate from the cathode back to the anode, reversing the previous process. Figure 1a,b show the Li-ion motion, respectively, during the charge and discharge process. The electrolyte acts as the medium facilitating the movement of lithium ions between the electrodes. The separator is a barrier that prevents direct contact between the anode and cathode, thereby avoiding short circuits [25]. Overall, the working mechanism of lithium-ion batteries is characterized by the controlled movement of lithium ions and electrons, facilitated by carefully selected materials and design features to optimize performance and longevity.

Figure 1.

Li-ion motion during the charge (a) and discharge (b) process.

2.2. Micro Degradation Mechanisms

Energy conversion through the intercalation and deintercalation of lithium ions within electrode materials leads to side reactions that irreversibly affect the battery performances [17]. Two main microscale degradation modalities can be identified: Loss of Lithium Inventory (LLI) and Loss of Active Material (LAM) [16]. Both phenomena are driven by distinct yet interrelated electrochemical and mechanical processes.

Loss of Lithium Inventory represents a significant cause of degradation in lithium-ion batteries, primarily occurring through irreversible side reactions that gradually consume lithium during charge and discharge cycles. The loss of available lithium is mainly caused by the following:

- The formation of a Solid Electrolyte Interface (SEI):When lithium reacts with the electrolyte, a solid layer forms on the electrode. This consumes some of the lithium ions, reducing the total amount available for intercalation. This leads to electrode isolation and deactivation, ultimately reducing capacity [26].

- Electrolyte decomposition during the charge and discharge cycles, particularly at the electrode interface, leads to reduction reactions, consuming both the electrolyte and its solvent [15]. Moreover, this process can generate impurities in the electrolyte that usually catalyze the occurrence of side reactions further aggravating lithium loss [25].

- Another key mechanism is lithium plating, where instead of intercalating into the electrode, lithium forms a metallic layer on its surface. While some plated lithium may be stripped off during discharge, a portion often reacts with the electrolyte, forming more SEI that isolates the metal lithium that is no longer available for cycling [27].

While LLI focuses on the irreversible consumption of lithium ions, LAM refers to the gradual degradation and loss of the electrode material itself, rendering portions of the electrode incapable of participating in the electrochemical process. This process can be caused form different reasons, including the following:

- Particle cracking within the electrode is induced by the repeated expansion and contraction of active material particles during cycling. Over time, this mechanical fatigue leads to fractures in the electrode, reducing the number of active sites available for lithium-ion intercalation [27]. Moreover, the fracturing of electrode particles exposes fresh surfaces that exacerbate lithium consumption, contributing to both further SEI formation and lithium plating.

- Another type of LAM can occur when the active material begins to peel away due to mechanical stress. This process reduces the surface area available for lithium intercalation, contributing to a gradual loss of capacity [17].

2.3. Space Environment and Macro Degradation Mechanisms

The mission profile and the impact of the harsh space environment play a critical role in the degradation of lithium-ion batteries used in satellites. During its life cycle, an Earth-orbiting satellite experiences shadow phases in which the use of batteries is required. The duration of these phases varies depending on the satellite’s orbital altitude, which is determined by the mission type [22].

These orbits are generally classified into three types: Low Earth Orbit (LEO), Medium Earth Orbit (MEO), and Geostationary Earth Orbit (GEO). LEO satellites, which complete rapid orbital cycles, approximately 65 min in sunlight and 35 min in eclipse, go through frequent shallow charge and discharge phases, with a Depth of Discharge (DOD) below 40% [3]. MEO satellites remain in sunlight for most of their orbit but encounter daily eclipses of up to 70 min during equinoxes. In contrast, GEO satellites are exposed to sunlight almost continuously, except during brief daily eclipses near the equinoxes (approximately 70 min per orbit). During these short intervals, the batteries undergo deep discharges (60–80% DOD), which places significant stress on them [28]. The different operational conditions of the LEO, MEO, and GEO satellites lead to notable contrasts in battery degradation and performance. Moreover, each space mission is also characterized by unique mission profiles, which cause different long-term degradation modes of the batteries. Several critical macro-level factors, including charge/discharge rate, DOD, and cut-off voltage, impact the performance and lifespan in specific ways. In addition, environmental conditions also significantly influence battery degradation in space, due to factors such as radiation, vacuum, extreme temperatures, and vibrations [23]. The key macro factors that contribute to the micro degradation mechanism are the following:

- Radiation: It can impact the cathode materials, resulting in an increase in grain size due to irradiation, enforcing the capacity loss. Furthermore, the radiation-induced electrolyte decomposition may also play a role in the degradation process. Experiments on Li-ion batteries show cathode grain coarsening and electrolyte decomposition under high irradiation, with capacity losses of up to 8–10% at doses of several Mrad [29,30]

- Vacuum: This condition significantly impacts battery performance, leading to electrolyte leakage and outgassing phenomena [22]. Outgassing involves gas formation within the battery, which can escape and contaminate sensitive satellite components. Additionally, batteries can suffer from electrolyte leakage or swelling, particularly in pouch cells, when exposed to vacuum conditions [31]. Thermal-vacuum tests at typically show negligible mass variation and capacity changes within 5% [23].

- Temperature: High temperatures can exceed the tolerance limits of most commercial lithium-ion batteries [32], leading to processes such as lithium loss, active material reduction, and SEI film formation [33]. Conversely, the extremely low temperatures in space can compromise battery functionality by lowering electrolyte conductivity, causing electrode passivation, lithium-ion depletion, and slowing electrochemical reactions [34,35]. Research indicates that low temperatures affect battery life more intensively than high temperatures.In particular, sub-zero cycling has been reported to significantly shorten battery lifetime compared with elevated temperature conditions [35]. For instance, cycling at low temperature can increase the aging rate by about one order of magnitude compared to room temperature, significantly reducing service life [36].

- Vibrations: During satellite launch, vibrations constitute another factor that can impact battery functionality, inducing LAM or mechanical damage to battery packs. Orientation-dependent tests reported capacity losses up to 9.5% in cylindrical cells under radial-axis vibration, while prismatic and pouch formats showed smaller but non-negligible degradation [23,37].

- Charge/Discharge Rate: High-rate discharges increase the formation of passivation films, elevate internal resistance, and cause more heat generation, which accelerates ageing [38,39]. Moreover, if the battery experiences high charging rates, which can lead to uneven SEI formation, the lithium consumption is increased [40]. Research on various loading modes for lithium-ion storage batteries has revealed that the charge/discharge cycle at a current of 1 C is the most resource-efficient, with test results indicating that this mode best preserves battery life compared to others [41].

- Depth of Discharge (DOD): Higher DOD (percentage of a battery’s capacity used during each cycle) can lead to localized damage due to phase transitions in the battery materials. Lowering the DOD can reduce stress on the battery, extending its life [42]. However, the effects of DOD are relatively minor compared to other factors like temperature and charge rate [43].

- Cut-off voltage: High charging cut-off voltages (overcharging) cause irreversible degradation by promoting lithium metal deposition and reducing electrode capacity due to excessive polarization [35]. Low discharge cut-off voltages (over-discharge), lead to an increase in side reactions and a decrease in the active material of the battery, which accelerates the ageing [17]. In some cases, adjusting the cut-off voltage led to significantly better capacity retention after numerous cycles, extending the service life [44].

The mission profile combined with the space environment conditions can induce unique failure modes or contribute simultaneously to broader degradation processes [45], underscoring the importance of a comprehensive understanding to better manage battery health and optimize operational conditions.

2.4. Li-Ion Battery Anomalies

In the context of lithium-ion batteries, especially those employed in high-stakes environments such as space missions, understanding and classifying anomalies is crucial for ensuring performance, safety, and longevity. A classification is proposed linking each anomaly type to potential causes rooted in micro and macro degradation mechanisms:

- Capacity fade refers to the gradual decline in a lithium-ion battery’s ability to hold a charge [46]. This phenomenon can be significantly influenced by several factors. When a battery experiences overcharging, overdischarging, or high temperatures, lithium plating, SEI film formation, and side reactions occur [46,47,48]. These processes lead to irreversible Loss of Active Material and faster capacity degradation. Conversely, when the battery operates under undercooling conditions, the lithium diffusion in the graphite can be decreased, causing a quick fade in capacity [49]. Moreover, increased cycling rates can accelerate capacity degradation due to the Loss of Lithium Inventory and the growth of the SEI layer on the electrode surface [47]. Also, vacuum and radiation can cause a discharge capacity reduction in battery cells. To assess battery suitability for space, a leak test is typically performed [50,51].

- Increased Internal Resistance hinders efficient charge and discharge cycles, reducing overall battery performance [46]. In the charging and discharging processes, excessive working temperatures can result in increased internal resistance if the rate of heat generation significantly outpaces the rate of heat dissipation [32]. The over-discharge affects electron transport and hides the deintercalation of the lithium ions, resulting in a progressive increase in the internal resistance [52]. Furthermore, SEI thickening and lithium plating at the microlevel impede ion and electron flow within the battery [53].

- Thermal Runaway is a critical anomaly in lithium-ion batteries characterized by an uncontrollable self-sustaining exothermic reaction. This phenomenon typically triggered by internal short circuits, overcharging, high-rate cycling, or exposure to elevated external temperatures. Once initiated, it involves electrolyte decomposition, SEI breakdown, cathode degradation, and flammable gas release, which accelerate heat generation and can ultimately result in fires, explosions, and catastrophic failure of the cell [44]. Recent research has advanced the understanding of thermal runaway mechanisms, thermal stability of cell components, and mitigation strategies, including flame-retardant electrolytes, high-resistance separators, and external protection layers. Experimental studies have shown that these materials can delay thermal runaway onset and safety valve rupture, significantly enhancing emergency response [54,55].

- Internal Short Circuits can occur as a result of lithium plating, which promotes the growth of lithium dendrites [46]. As the battery temperature rises, it further activates side reactions such as SEI film decomposition and cathode material degradation, potentially leading to sudden failures like internal short circuits [56]. Additionally, high-rate charging and discharging can generate exothermic side reactions that heighten the risk of internal short circuits [44,46]. The risks of internal short circuits within cells are also enforced by the vibrational environment that characterizes space applications.

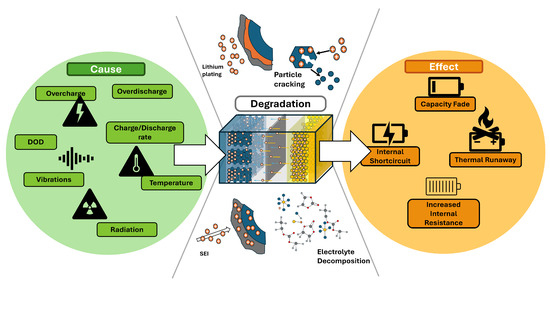

It is essential to recognize that a single fault can arise from multiple degradation mechanisms, while a single degradation mechanism can lead to various anomalies, as shown in Figure 2. In space missions, lithium-ion batteries are exposed to multiple simultaneous stressors, including low and high temperatures, high charge/discharge rates, vacuum, radiation, and thermal cycling. The combination of these factors can drastically accelerate degradation. Low temperatures coupled with high C-rates promote lithium plating, SEI instability, and increased internal resistance, leading to faster capacity fade [57]. Similarly, vacuum and thermal cycling exacerbate structural deformation, irreversible lithium loss, and internal temperature gradients [58], while radiation exposure further damages electrolyte, binder, and electrode interfaces, increasing polarization and side reactions [59]. High-temperature and overcharge conditions can also accelerate electrolyte decomposition and SEI thickening, raising the risk of thermal runaway. Data from CubeSat missions show that chemistries such as NMC (nickel–manganese–cobalt) and NCA (nickel–cobalt–aluminum) are particularly sensitive to these coupled environmental constraints, whereas LFP (lithium iron phosphate) cells demonstrate greater resilience [60]. These synergistic multi-factor effects are critical to consider in the management of space batteries, as they can significantly reduce lifespan compared to single-stressor scenarios.

Figure 2.

Degradation mechanisms and their cause and effects in lithium-ion batteries.

A summary of such interconnections, underscoring the complexity of battery behavior, is reported in Table 1.

Table 1.

Relationships between causes, mechanisms, and anomalies in lithium-ion battery degradation.

3. Digital Twin in Space Battery Management

3.1. Battery Management System Description

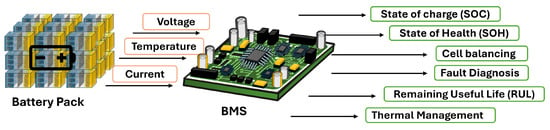

A Battery Management System is a vital technology responsible for monitoring and controlling the performance of battery systems [21]. BMS technology plays a crucial role in various applications, ranging from electric vehicles to renewable energy systems, portable electronics, and satellites. Although BMS configurations may differ depending on the application, their core functionalities ensure optimal operating conditions and stabilize battery operations by processing data from sensors and implementing control algorithms in real time [61]. The BMS enables the tracking of the SOC and SOH of batteries, diagnoses potential faults, manages thermal conditions, and balances cell charges by continuously analyzing voltage, current, temperature, and other parameters. Together, these features, summarized in Figure 3, ensure efficient energy use, enable predictive maintenance, and enhance the reliability and lifespan of batteries.

Figure 3.

Battery Management System (BMS) key features.

- State of Charge (SOC): This index represents a measure of the stored charge. SOC is generally defined as follows:where represents the battery’s capacity in its current state, while denotes the capacity when the battery is fully charged. Accurate SOC monitoring is crucial for maintaining optimal battery performance and efficiently managing charging, ensuring battery longevity and reliability [21].

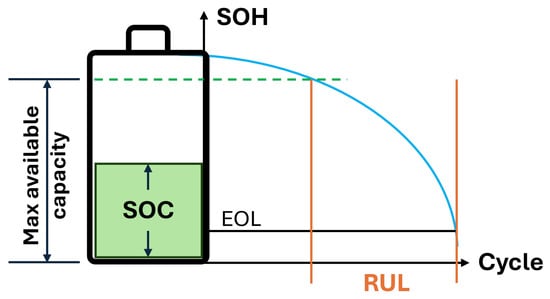

- State of Health (SOH): An index that measures the degradation state of the battery with respect to the beginning of life (BOL) conditions. Typically, end of life (EOL) is reached when the battery’s SOH decreases to 80% [21]. SOH can be mathematically defined as follows:where represents the current full charge capacity and denotes the battery’s nominal capacity. Accurate SOH estimation is essential for several reasons: it aids in predicting RUL, and it informs adaptive charging strategies that help prevent further degradation [21]. Several definitions of SOH exist, including capacity-based, internal resistance-based [15], and many others depending on the definition of the Heath Index (HI) [62,63,64,65]. The capacity-based SOH definition is usually adopted as the primary metric due to its ability to reflect usable energy and the overall aging of the battery. Internal resistance- and HI-based SOH definitions can be used as complementary metrics for real-time monitoring or the early detection of degradation when direct capacity measurement is not feasible.

- Remaining Useful Life (RUL): The index refers to the number of charge/discharge cycles remaining until the battery reaches its end of life [21]. Continuous charging and discharging lead to capacity degradation, eventually requiring battery replacement when the capacity falls to 70–80% of its initial value [66]. Estimating RUL is critical for ensuring reliable and safe operation for proactive maintenance, minimizing unexpected breakdowns, and enhancing the overall lifespan of the battery system. A graphical representation of the RUL is reported in Figure 4.

Figure 4. Schematic representation of a battery’s Remaining Useful Life (RUL), indicating the number of charge/discharge cycles remaining until and of life State of Health (SOH) value is reached.

Figure 4. Schematic representation of a battery’s Remaining Useful Life (RUL), indicating the number of charge/discharge cycles remaining until and of life State of Health (SOH) value is reached. - Fault Diagnosis: The BMS is responsible for the detection and control of faults by means of different integrated algorithms [67]. The system prevents overcharging, deep discharging, short circuits, and thermal runaway by monitoring key parameters and incorporating controllers, actuators, and sensors [68,69].

- Thermal Management: Temperature plays a significant role in the battery’s lifespan [70], as operating outside the recommended thermal range can degrade the battery’s materials and reduce its efficiency. By maintaining a balanced temperature, as determined by the manufacturer, the system helps preserve battery life and functionality.

- Cell balancing: This comprises balancing circuitry and a control strategy to maintain charge uniformity among cells. The balancing process can be either passive, dissipating excess charge as heat, or active, transferring energy from high to low SOC cells. Effective cell balancing optimizes battery capacity utilization, prolongs lifespan by reducing uneven wear, enhances safety by preventing overcharging and overheating, ensures consistent performance, and reduces maintenance needs by promoting balanced cell usage throughout the pack [21].

3.2. The Digital Twin Concept

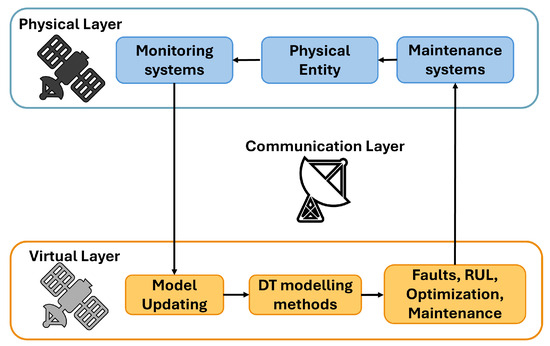

Digital Twins are sophisticated technological frameworks that represent a physical system through a virtual counterpart, enabling continuous monitoring and predictive insights [71]. Initially introduced by NASA and the U.S. Air Force for aerospace applications, specifically for enhancing the safety and reliability of Air Force vehicles [72], DT applications have significantly expanded across various industries and sectors, playing a vital role in real-time operations that inform engineering and operational decisions. Unlike a single technology or model, the DT’s scheme encompasses diverse modeling methods, each adapted to the requirements of specific scenarios. Such a comprehensive scheme aims to mirror every observable feature of the physical asset, allowing it to capture all data obtainable through direct inspection [73]. In fact, despite the various available definitions and interpretations of DT underscoring its versatility and adaptability, they all converge on the core function of accurately emulating a physical entity to monitor its current state and predict future behavior [74]. To describe the structure of a DT, it is essential to understand its purpose: creating a real-time, accurate link between the physical and virtual worlds. A typical DT scheme, shown in Figure 5, comprises three primary components:

Figure 5.

Digital Twin (DT) closed-loop scheme.

- The physical layer is the real-world object or system monitored by the DT, typically equipped with sensors and other monitoring devices to capture real-time data. These sensors track various attributes—such as temperature, pressure, or motion—and enable comprehensive data collection and processing, forming the data foundation of the DT [75]. Moreover, the physical entity continuously sends updated status data to the DT, which returns diagnostic insights and optimized commands, ensuring the physical side adapts to changes in real time [76].

- The virtual layer is the digital replica of the physical entity, consisting of several models which replicate the state and behavior of the physical layer, using the recorded data for dynamic reconfiguration and model coupling [77]. The virtual component performs data processing and analysis, making it the intelligence core of the DT, enabling diagnosis, fault detection, and RUL prediction. Virtual models can be constructed using physics-based methods or data-driven models powered by Machine Learning (ML) and AI, which are essential for quick adaptation and analysis in data-rich environments [47,78].

- The communication layer between the physical and virtual layers operates bidirectionally, allowing a continuous exchange of information. Real-time condition data from the physical layer is transmitted to the digital layer, allowing it to dynamically mirror the state of its physical counterpart and support advanced diagnostic and prognostic functions. Conversely, the digital layer can send feedback or optimization parameters back to the physical layer, facilitating predictive maintenance, performance adjustments, and system optimization based on analyzed data. Therefore, the bidirectional data connection is a fundamental feature of the communication layer, ensuring real-time synchronization and an accurate reflection of operational conditions [71].

Broadly, a DT functions as a “living” model, constantly updating to reflect real-time conditions through a dynamic loop of communication with its physical twin. This closed-loop interaction empowers the DT to perform critical tasks. The DT uncovers hidden patterns within system data, aiding in predictive and prescriptive strategies for fault prevention and operational improvements [47]. Throughout the entire lifecycle of the physical asset, DTs play a vital role. In the design phase, they simulate potential design impacts, pinpoint structural weaknesses, and explore deterioration prevention strategies. During production, they perform diagnostics to preempt faults and ensure optimal operation. In service, DTs provide predictive models that deliver accurate state estimations, enabling efficient, data-driven maintenance [79].

3.3. Applications of Digital Twin in BMSs

The adoption of lithium-ion batteries as the third generation of satellite power storage devices marked a significant advancement in space missions. However, as explained in Section 2, LIBs experience performance degradation due to capacity fading and complex irreversible electrochemical reactions. This degradation, compounded by repeated charge-discharge cycles and the unique mission conditions, can compromise operational safety and even lead to catastrophic failures if unmitigated. A comprehensive statistical analysis of 1584 Earth-orbiting satellites between 1990 and 2008 underscores the influence of battery failures on overall satellite reliability [80]. The study reveals an increase in battery-related failures over time, with cumulative battery failure contributions to satellite malfunctioning reaching 4% in the first 30 days of satellite operation, 2% in the first year of operation, 10% in 5 years of operation, 6% in 10 years of operation, and 14 % in 15 years of operation. Satellite failure data shows a clear need to enhance battery reliability and longevity. Therefore, a well-equipped BMS is essential to accommodate the unique challenges posed by the harsh and variable space environment.

Despite significant advancements in terrestrial BMS technologies and a growing interest in the development of efficient and innovative BMSs tailored for space applications, their use in spacecraft remains limited. Currently, onboard BMS systems primarily serve as general-purpose controllers rather than specialized tools designed to fully optimize battery performance [81]. For this reason, the European Space Agency’s (ESA) Technology Development Elements (TDE) program has introduced a novel BMS concept designed specifically for spacecraft. This advanced system goes beyond conventional monitoring and measurement functions to include parameter calculations that can effectively extend the lifespan of spacecraft batteries through active management. In this context, the scientific community has increasingly focused on advanced battery monitoring techniques for various space applications. Due to the constraints in computing power and data storage, a common trend is the development of novel intelligent algorithms to perform advanced optimization tasks to ensure safety and reliability. In particular, researchers have intensified their focus on integrating DT technology into a BMS, which represents a significant advancement over traditional approaches to battery monitoring and management, especially in cases where resources are limited, such as on space missions. A primary benefit of DTs lies in their ability to digest vast amounts of historical and real-time sensor data, such as voltage, current, and temperature readings, allowing to dynamically update and refine predictive models. Conventional BMS approaches, typically based on equivalent circuit or empirical models, offer stable control and fault protection but have limited capability in predictive maintenance, particularly under the complex conditions of space operation. Single-model predictive methods can achieve accurate short-term predictions but often lack robustness when operating beyond the conditions represented in their calibration datasets [82]. In contrast, a DT-based BMS integrates real-time data acquisition, bidirectional communication, allowing the virtual twin to continuously adjust its parameters to reflect actual operating conditions. This integration improves monitoring accuracy, enhances prediction reliability, and ensures adaptability to radiation, vacuum, and thermal cycling typical of orbital environments. Through online learning and adaptive modeling, DTs provide a better battery life estimation, improved fault detection and optimized maintenance strategies under varying operating conditions [21]. This approach enables enhanced operational assessments compared to conventional models, which often rely on fixed parameters and fail to capture the complex nonlinear and coupled behaviors intrinsic to lithium-ion batteries [8,9].

Additionally, DTs overcome the computational limitations of onboard BMSs by employing algorithms that leverage cloud infrastructure or other external resources, thus enabling more accurate state estimations that traditional BMS processors, constrained by limited memory and CPU capacity, cannot feasibly implement [7]. Furthermore, Digital Twins can act as surrogate models, enabling forecasting and evaluation of different operational strategies while significantly reducing computational costs. This is particularly valuable when dealing with applications—as in the space field—where real-time decision-making and resource efficiency are essential for performance, reliability, and longevity [83]. An advanced multi-layer networked architecture for BMSs that coordinates cloud, edge, and device-level operations are proposed in [8] to overcome the limitations of conventional BMSs, allowing the use of high-performance algorithms. Additional effort has been dedicated to developing a novel method for predicting lithium-ion battery discharge capabilities through a practical Digital Twin model that integrates ML with semi-empirical structures [9]. Digital Twins have also been designed for the CubeSats electrical power system [10]. Its accuracy has been confirmed through real-time comparisons with the physical system, demonstrating the feasibility of using Digital Twins to simulate CubeSat behavior throughout a full orbital cycle. Finally, the Digital Twin-based fault diagnosis and health management approach for satellite systems has also been addressed [11]. These approaches support the creation of a space–ground platform for monitoring, diagnosing, and maintaining satellite power systems, underscoring the potential of Digital Twins in satellite health management. Despite the scarcity of DT applications for space BMSs showcased in the literature, numerous successful implementations of the Digital Twin technology can be found in BMSs of other fields. These applications highlight the versatility and effectiveness of Digital Twins in enhancing system performance and reliability.

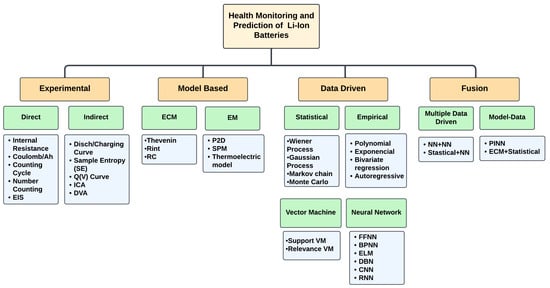

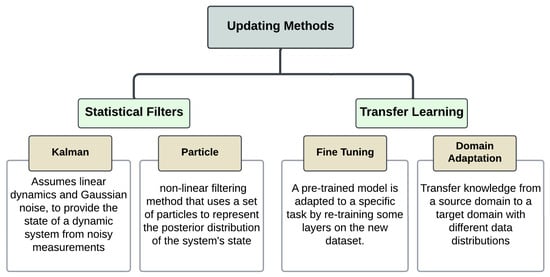

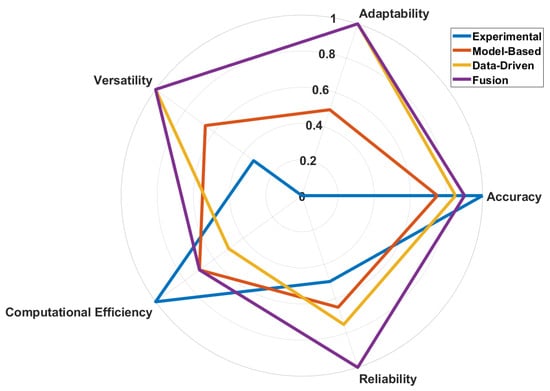

4. Classification of Methods for DT of BMSs

In the evolving landscape of Battery Management Systems, understanding the mechanisms of degradation in lithium-ion batteries is essential for developing an efficient Digital Twin. The estimation of key parameters, SOC, SOH, and RUL, plays a crucial role in optimizing battery performance and longevity. The following section categorizes these methods into four primary groups: experimental, model-based, data-driven, and fusion. Given the core capability of Digital Twins to continuously update models, a review of the main updating methodologies is presented. The objective of this section is indeed to provide a comprehensive overview of how different techniques contribute to the understanding and management of battery degradation, assessing their effectiveness on the DT of the BMS.

4.1. Experimental Methods

The degradation mechanisms of lithium-ion batteries can be evaluated through dedicated laboratory testing, which provides insights into their aging behavior under controlled conditions. These experimental methods can be categorized into direct and indirect measurement techniques.

4.1.1. Direct Measurements

The direct measurement method is used to characterize the degradation mechanism by measuring the battery health state indicators directly. The direct measurement technique can be applied in several ways:

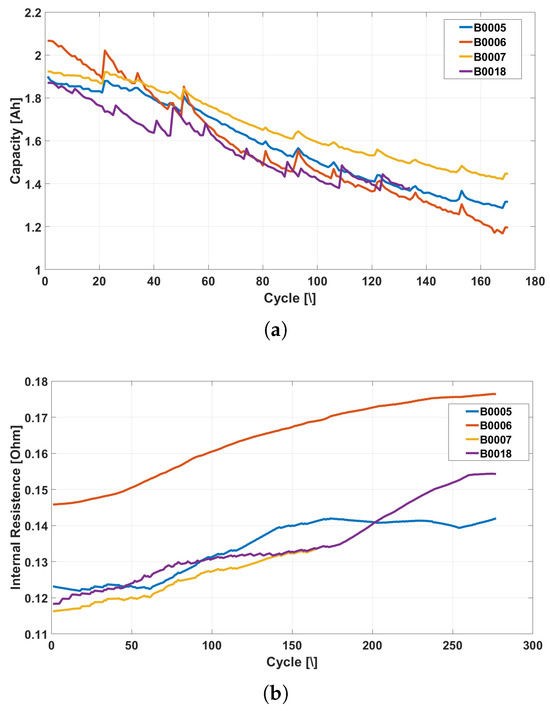

- Internal Resistance: The degradation process is reflected by an increasing trend in internal resistance. Therefore, tracking the changes in resistance over time is well suited to real-time SOH monitoring due to its low computational demands [84,85,86]. In Figure 6b, the increasing trend of the internal resistance over the cycles is reported. Techniques such as pulse current tests further refine resistance measurements by assessing ohmic and polarization resistances under various conditions, thus capturing the impact of temperature and SOC [87,88].

- Coulomb counting, or ampere-hour (Ah) counting: Following the capacity behavior over the cycles (see Figure 6a), it is possible to characterize the degradation mechanism. SOH and SOC can be estimated by measuring the total charge transferred into or out of the battery [89]. The Coulomb counting method has limitations and potential errors in practical applications. Factors such as temperature, charge and discharge rates, and usage patterns can impact its accuracy. Consequently, it is often necessary to combine coulometric counting with other evaluation methods for a more reliable assessment of battery life [17]. Recent improvements include integrating Coulomb counting with Differential Voltage Analysis (DVA) for more accurate, real-time SOH estimation and combining it with weighted ampere-hour methods to enhance precision [90].

- Cycle number counting estimates SOH by comparing the manufacturer’s specified total life cycle count with the current cycle count. This method mainly records complete discharges. For partial cycles, conversion coefficients are used to standardize different depths into equivalent full cycles, which can be obtained through experimental testing [91]. To address the partial cycles, Saxena et al. [92] propose a model which analyzes capacity loss in relation to mean SOC and ΔSOC.

- Electrochemical Impedance Spectroscopy (EIS) is a strong laboratory tool to study the electrochemical process inside the battery, and it can be used as a diagnostic tool [93,94]. However, its utility is limited by cost, calibration complexity, and testing requirements, which restrict potential use onboard spacecraft [17]. To overcome these challenges, alternative real-time impedance measurement methods are emerging, including techniques based on initial charging voltage responses and SOH estimation through impedance-related indicators [62,95,96]. Recent advances also focus on optimizing EIS test parameters and adopting faster diagnostic methods [97].

Figure 6.

Trends of capacity (a) and internal resistance (b) over cycles for cells B0005, B0006, B0007, and B0018 from the NASA lithium-ion battery dataset [98].

4.1.2. Indirect Measurements

Indirect measurement techniques can determine degradation paths by extrapolating health indices derived from direct measurements. Indirect methods encompass various advanced techniques:

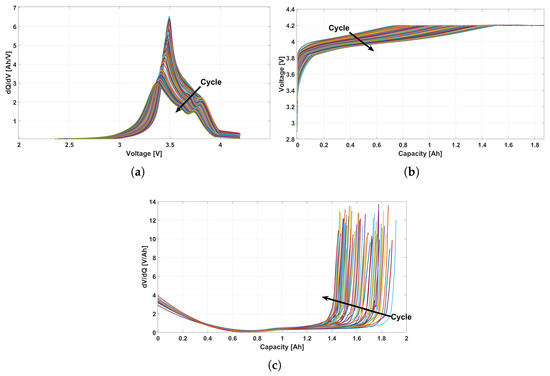

- Incremental Capacity Analysis (ICA) is valuable for diagnosing battery SOH by correlating peak features with battery capacity, particularly in high-current and random usage patterns [99,100]. In Figure 7a, the incremental capacity as a function of voltage shows the decreasing behavior of the curve as the number of cycles increases. The ICA’s dependence on low-noise, constant-current profiles limits real-world applicability. To counter this, methods such as model-free fitting and high current-rate adaptations enable ICA under noisy conditions, enhancing accuracy in Battery Management Systems [101,102,103,104,105].

Figure 7. Incremental Capacity Analysis (ICA) (a), capacitance-voltage curve (b), and Differential Voltage Analysis (DVA) (c) over cycles for cell B0005 from the NASA lithium-ion battery dataset [98].

Figure 7. Incremental Capacity Analysis (ICA) (a), capacitance-voltage curve (b), and Differential Voltage Analysis (DVA) (c) over cycles for cell B0005 from the NASA lithium-ion battery dataset [98]. - Sample Entropy (SE) is used to assess battery health by quantifying the complexity and predictability of time-series data. Recent enhancements include improved capacity estimators using voltage sequences under the Hybrid Pulse Power Characterization (HPPC) profile [106]. Additionally, sample entropy is utilized to estimate the remaining capacity of lithium-ion batteries by analyzing surface temperature dynamics during the charging process [107]. To reduce the computational demands of the sample entropy technique, various approaches have been proposed, including a fuzzy entropy-based SOH estimator [108] and a method utilizing fusion weights from multi-scale sample entropy [109].

- Q(V) Curve analysis is another method for SOH estimation, focusing on the evolution of the capacitance-voltage Q(V) curve across cycles; Figure 7a. In this context, Deng et al. [110] propose a voltage segmentation strategy that incorporates filtering techniques for non-monotonic curves, resulting in low estimation errors.

- Charging/Discharging Curve: As batteries degrade, their charging and discharging curves change, serving as valuable indicators for SOH evaluation. Many researchers have focused on constant-voltage (CV) charging data, finding a strong correlation with the SOH [111,112]. In [113], a novel SOH estimator that utilizes partial CV charging data is proposed. This approach incorporates a curve reconstruction method to accurately predict the capacity. Additionally, a dynamic characteristic of the charging current has been shown to be a robust parameter related to battery aging [114]. Another approach focuses on health indicators derived from discharge curves, examining the effects of depth-of-discharge, current, and temperature on the health indicator [64].

- Differential Voltage Analysis (DVA): The distance between curves in the DV curves (Figure 7c) quantifies electricity participation in two-phase transitions, aiding capacity fading analysis [93]. Innovative techniques use the DV curve to accurately detect degradation mechanisms and the end of life of cells in efficient online applications [115,116]. DVA can be combined with other experimental techniques, such as the Coulomb counting method for precise SOH calculation [90], or ICA to improve the reliability of SOC estimation [117].

To investigate the aging behavior of batteries, extensive laboratory testing is essential. However, many experimental procedures face challenges in real-world applications, primarily due to the need for sophisticated equipment and the significant differences between controlled laboratory environments and actual operating conditions. Despite these limitations, laboratory experiments represent an invaluable resource for studying aging mechanisms, as they provide a theoretical foundation.

4.2. Model-Based Methods

Model-based methods rely on battery models that represent the internal electrochemical dynamics of the battery, making assumptions based on these models to estimate essential battery management system parameters. Techniques within this category include Equivalent Circuit Models and electrochemical methods.

4.2.1. Electrochemical Methods (EMs)

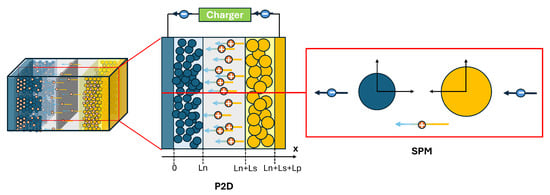

The electrochemical model primarily investigates the electrochemical reactions within the battery. These models offer a sophisticated means of simulating lithium-ion battery behaviors, which is essential for predicting the state of the battery. The Pseudo-Two-Dimensional (P2D) model conceptualizes a lithium battery as a system comprising positive and negative electrodes, a separator, and an electrolyte containing numerous spherical solid particles. The P2D model, widely recognized for its detailed representation of battery processes, utilizes partial differential equations to capture charge and mass conservation in both the solid and electrolyte phases. Due to its high accuracy, this model has seen extensive application across various studies [118,119,120,121]. Despite its high accuracy, the P2D model is computationally intensive, presenting challenges for real-time applications. This has led to the development of simplified models like the Single Particle Model (SPM), which reduces computational demands by approximating each electrode as a single spherical particle and assuming uniform lithium-ion concentration in the electrolyte [122,123,124]. However, the SPM’s neglect of electrolyte dynamics and mechanical responses can reduce its accuracy, a limitation that has been addressed by incorporating additional degradation mechanisms such as Solid Electrolyte Interphase layer formation, lithium plating, particle cracking, and active material losses. For instance, models integrating these degradation phenomena have been shown to significantly enhance predictive capabilities [125,126,127]. Furthermore, incorporating temperature dynamics into models has been proven to greatly enhance prediction accuracy and capture true degradation patterns [128,129,130,131]. In Figure 8, a representation of the P2D model and SPM model is reported.

Figure 8.

Representation of the Pseudo-Two-Dimensional (P2D) model and Single Particle Model (SPM).

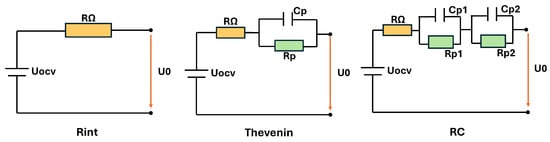

4.2.2. Equivalent Circuit Models (ECMs)

Model-based techniques employing Equivalent Circuit Models (ECMs) are pivotal in managing lithium-ion batteries, balancing computational efficiency with accuracy. ECMs simplify the complex electrochemical processes within batteries into a network of resistors, capacitors, and voltage sources, allowing for the real-time estimation of crucial parameters such as SOC, capacity, and internal resistance. Several ECM configurations, including the Resistance-Capacitance (RC) model, Thevenin model, and Rint model (see Figure 9 and their modified versions, have been developed to capture various dynamic behaviors of Li-ion batteries [132]. By modeling the battery with essential components like resistors, inductors, and capacitors, the ECM framework effectively captures the electrochemical dynamics crucial for monitoring battery condition. Its simplicity lends itself to real-time applications, allowing online parameter updates that reflect the battery’s evolving state under various operating conditions [133]. Several enhancements to classical ECM approaches have been proposed in the literature. For instance, a multi-time scale RC model combined with wavelet analysis advances the accuracy of battery dynamic characterization across varying operational state [134]. Additionally, recursive estimation methods allow targeted parameter adjustments to capture distinct fast and slow battery dynamics [135]. Further refinements to ECMs address SOH tracking by employing algorithms like Kalman and particle filters, which iteratively update model parameters to adapt to real-time performance variations. These adaptive filter-based methods provide a powerful approach to SOH and SOC estimation, allowing automatic adjustments that keep up with aging processes and operational changes [136,137,138,139]. The online capabilities of ECMs have increased interest in applications like satellite systems. In space applications, where maintaining consistent telemetry quality is challenging, ECMs have been adapted to account for variable temperature conditions and limited sample resolution [131,140,141]. More advanced ECMs, such as the half-cell model, attempt to increase the physical interpretability of the model by representing individual electrode characteristics, yielding detailed information on battery aging. Further refinements include a Pseudo-Two-P2D approach, linking ECM parameters with electrochemical characteristics for more precise modeling under diverse conditions [142]. However, these approaches introduce additional computational demands, highlighting a compromise between model granularity and efficiency that is critical in applications requiring real-time responsiveness [143].

Figure 9.

Schematic representation of Equivalent Circuit Models (ECMs). The Rint model includes a resistor RΩ to represent the internal resistance. The Thevenin model adds an additional resistor (Rp) and capacitor (Cp) to account for transient effects. Finally, the RC model employs multiple RC branches to capture more complex transient dynamics [132].

In conclusion, the model-based approaches offer valuable insights into how electrochemical degradation impacts battery health over time. Although model-based methods provide significant advantages, including lower data requirements and resilience to external conditions, their inherent complexity, due to the intricate physical and mathematical modeling required, makes implementation demanding.

4.3. Data-Driven Methods

Data-driven methods rely on the use of historical data to build a representation of the battery state. Many recent studies in the literature have adopted data-driven approaches, and four main categories have emerged: Statistical, Empirical, Vector Machine, and Machine Learning.

4.3.1. Statistical Methods

In the field of lithium-ion battery degradation modeling, statistical data-driven approaches have proven effective for predicting states by leveraging their ability to handle uncertainty and variability in experimental data. A primary probabilistic technique included in Bayesian Methods is the Gaussian Process Regression (GPR). GPR, a non-parametric Bayesian technique, can model complex, nonlinear relationships, making it especially useful for applications in diverse fields [144,145,146]. Studies demonstrate the application of GPR for SOH estimation in battery systems, where it quantifies uncertainty and enhances reliability [147,148,149]. Additionally, GPR enables accurate predictions for RUL, underscoring its adaptability and precision in forecasting battery lifespan under various conditions [150]. A variant of Bayesian techniques is the Wiener processes, used in [151] to develop a framework of lithium-ion battery capacity degradation assessment and RUL prediction. Hidden Markov Models (HMMs) are another set of methods used to capture the stochastic relationships inherent in battery degradation processes. In [152], Piao et al. propose an HMM to model the relation between health states and internal resistance changes. Similarly, Niri’s work combines HMMs with a wavelet decomposition approach to address both long- and short-term load predictions, enhancing prediction accuracy under fluctuating operational conditions [153]. Zhao’s work extends the utility of HMMs by integrating a belief rule base to improve SOH prediction accuracy [154]. The Monte Carlo Simulation provides another versatile method for handling the probabilistic nature of lithium-ion battery degradation. By generating multiple simulation scenarios, these techniques capture the variability in battery behavior under different conditions [155,156].

4.3.2. Empirical Methods

Empirical models in battery research are essential for analyzing experimental data to construct mathematical relationships that effectively characterize battery performance and aging behavior. These models typically utilize polynomial and exponential functions to map the aging process, focusing on key parameters such as voltage, aging time, temperature, discharge rate, and depth of discharge [157,158]. The representation of capacity degradation is a critical aspect of these empirical models, often expressed as a function of cycle count. For example, Yu [159] adopts a bi-variate regression to model the relationship between features extracted from controlled charging data and capacity, enhancing the accuracy of capacity predictions. In addition to capacity modeling, research has also focused on developing resistance models that assess battery power capability and health state [160,161]. These models reveal that performance indicators, particularly capacity and resistance, are sensitive to different aging types, including calendar aging (affected by temperature and state-of-charge), cycling aging (influenced by temperature and cycle depth), and radiation aging [162]. To maintain accuracy in the face of dynamic aging processes and fluctuating operational conditions, it is essential for empirical models to be regularly updated. This need is addressed by incorporating various filtering algorithms alongside empirical models to enhance predictions of SOH and RUL, thus improving estimation reliability amid changing parameters [163,164,165,166,167]. These approaches not only contribute to effective battery prognosis, but also align well with the empirical framework, as they leverage techniques to refine health indicators based on the evolving state of the battery.

4.3.3. Vector Machine Methods

The degradation monitoring and prediction of lithium-ion batteries can be formulated as a regression problem. Regression techniques can process large datasets to identify relationships between dependent and independent variables, thereby enabling the construction of predictive models. [168]. Support Vector Regression (SVR), a variant of Support Vector Machines (SVMs), has emerged as a pivotal technique in the estimation of the SOH and RUL of lithium-ion batteries. The effectiveness of SVR is largely attributed to its ability to handle high-dimensional data and perform well in nonlinear regression scenarios, making it particularly suited for complex battery health assessments. Fewer unknown parameters and high sparsity characterize the method [169]. Several studies have underscored the effectiveness of the use of the SVR in conjunction with health indicators. For instance, Z. Chen et al. [170] utilized charging voltage and current data to derive critical features such as energy signals and charge durations, employing SVR to achieve robust SOH predictions. Similarly, Q. Zhao et al. [171] focused on real-time measurable HIs, specifically the time intervals of equal charging and discharging voltage differences, to establish a relationship model between these indicators and battery capacity. Petkovski’s [172] work highlighted the advantage of combining features extracted from different observables. This multifaceted approach enhances the robustness of predictions made using SVR. Furthermore, Pang [173] addressed the challenge of limited sample sizes in satellite applications by proposing an online RUL prediction method based on SVR, establishing a clear relationship between health indicators and battery capacity. Various optimization techniques such as Coyote Optimization Algorithm (COA) and Particle Swarm Optimization (PSO) have been proposed to refine the model’s parameters and enhance the accuracy and computational efficiency of SVR [174,175,176]. Moreover, the adaptability of SVR in complex operational environments has been a focal point in recent research. In [177], the authors develop a self-adaptive health state assessment method that employs Least Squares Support Vector Machines (LS-SVMs), which enable efficient real-time assessments of battery health. Z. Liu [178] proposes a modified SVR kernel designed to handle changes in battery performance over time. Furthermore, studies have sought to enhance estimation strategies through advanced techniques. D. Zhang [179] proposes an integration of Grid Search Cross-Validation with particle filtering and SVR, yielding improved SOH estimations for satellite batteries. Another vector machine technique is the Relevance Vector Machine (RVM). Its foundation in sparse Bayesian theory provides several advantages over traditional SVMs, particularly in handling sparse datasets and controlling overfitting. Research by Widodo et al. [180] highlighted a comparison between SVMs and RVMs, demonstrating that while SVMs are known for their operational simplicity and high accuracy, they suffer from limitations in generalization. In contrast, RVMs demonstrated superior adaptability and robustness, enabling model parameters to be adapted based on operational results. For instance, a method proposed in [181] utilized RVMs alongside a three-parameter capacity degradation model to make reliable extrapolations to failure thresholds with confidence intervals. Zhang [182] et al. proposed a prediction method of battery SOH based on an optimized RVM model for the online application. A method combining dynamic grey correlation with RVM regression prediction demonstrated improved long-term prediction capabilities by updating model parameters in response to new data [183]. Similarly, Song [184] proposes a method involving the RVM and Kalman filter to refine RUL estimates, addressing some of these concerns by allowing the model to dynamically adjust its predictions as new data becomes available.

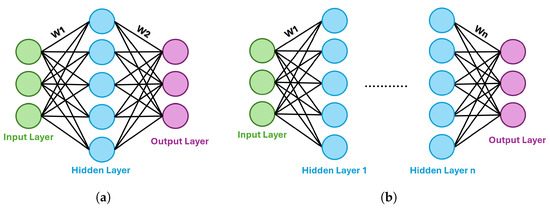

4.3.4. Neural Network

Artificial Neural Networks (ANNs) are a powerful algorithmic framework that learn from data and generalize this learning to new situations, making them crucial for solving complex problems. Recent advancements in ANNs have significantly enhanced the prediction of the SOH, RUL, and SOC of lithium-ion batteries through various data-driven approaches. A typical ANN is structured into three main layers: an input layer, one or more hidden layers, and an output layer. The input layer receives the data, which is then passed through the hidden layers. Each neuron in these hidden layers performs computations based on a weighted linear combination of the input data, followed by an activation function that introduces nonlinearity. This iterative process continues until the output layer generates the final prediction or result. In Figure 10a, a typical representation of an NN structure is depicted. ANNs can be categorized into two primary types based on their architecture: traditional neural networks and DL algorithms. Traditional neural networks include Feedforward Neural Networks (FFNNs), which typically consist of a single hidden layer, as well as their variants, such as Backpropagation Neural Networks (BPNNs) and Extreme Learning Machines (ELMs). They have a relatively simple structure yet possess strong learning capabilities, allowing them to model nonlinear relationships by adjusting the number of neurons and hidden layers [15].

Figure 10.

Typical structures of Artificial Neural Network (ANN) (a) and Deep Neural Network (DNN) (b).

- Feed-Forward Neural Networks are one of the most fundamental and simple types of ANNs. In these networks, information flows in a single direction: from the input layer, through more hidden layers, to the output layer—without any feedback connections. Due to their ability to model complex nonlinear relationships, FFNNs are widely used for monitoring and predicting the performance of lithium-ion batteries. For example, You et al. developed a real-time RUL estimation method using FFNNs based on historical battery data [185]. A notable study used data from a constant current constant voltage (CC-CV) charging experiment to train battery models, achieving accurate SOH predictions [186]. Furthermore, Driscoll employs an FFNN to estimate the SOH of the battery, using the extraction of characteristics from the voltage, current, and temperature profiles observed during charging [187]. In a related effort, Bonfitto introduced an FFNN prediction method combining SOH and SOC estimations, demonstrating that the interdependence of these factors within a recursive framework significantly improves prediction accuracy [188].

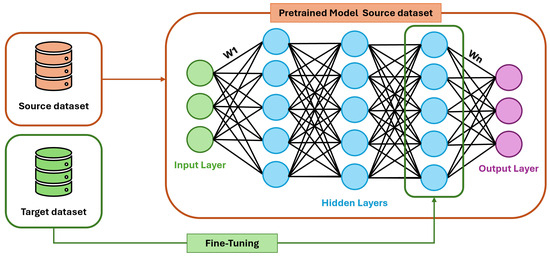

- Backpropagation Neural Networks (BPNNs) are FFNNs trained with a backpropagation algorithm. BPNNs are often enhanced by incorporating optimization algorithms for selecting optimal weights. For instance, H. Li [189] proposed an intelligent Digital Twin model for BMSs, using a BPNN and a whale optimization algorithm (WOA) to estimate and diagnose battery health by leveraging historical battery data from real scenarios. Additionally, M. Wu [190] employed a BPNN in combination with PCA and PSO to optimize the model for more accurate SOH predictions.

- The Extreme Learning Machine (ELM) is a type of single hidden-layer feedforward neural network (SLFN). ELM uses a fast, closed-form solution for the output layer weights, making it computationally efficient. These ANNs are suitable for regression problems in which indirect health indicators that show a strong correlation with capacity are used for estimation [191,192].

Deep learning algorithms incorporate multiple hidden layers (Figure 10b); one or more activation functions pass through these layers as data. This multi-layer approach enhances their ability to extract intricate features from data, making DNNs particularly effective for complex prediction tasks [18]. The foundational structure of DL is the Deep Neural Network (DNN), which encompasses various network architectures such as Deep Belief Networks (DBNs), Convolutional Neural Networks (CNNs), and Recurrent Neural Networks (RNNs).

- Deep Belief Networks (DBNs) consist of multiple layers of restricted Boltzmann machines (RBMs), followed by a layer of backpropagation neural networks (BPNNs). The stacked RBMs are used to extract significant information from the data, while the BPNN is employed for making predictions. In the study by Cao [25], 17 health indicators are extracted during the charging process. These indicators include metrics like charge capacity and sample entropy, which effectively represent the internal thermodynamic reactions of the batteries. The extracted HIs are then employed for capacity estimation using a DBN model.

- Convolutional Neural Networks (CNNs) are structured with convolutional layers, pooling layers, and fully connected layers, distinguishing themselves from traditional fully connected networks by their ability to automatically extract features from raw data. The architecture allows for efficient computation and the handling of large datasets [193]. In the context of SOC estimation, Bhatta [194] demonstrated that a CNN could achieve competitive performance by optimizing hyperparameters such as the number of filters in the convolutional layers. Additionally, J.Yao [195] proposed a CNN method leveraging partial segments of charging and discharging data for capacity estimation, effectively minimizing discrepancies between different battery types and improving accuracy. Despite their advantages, CNNs require a substantial amount of training data and can be computationally intensive. For instance, B. Zhou [196] introduced an attention mechanism within a CNN to enhance prediction accuracy by allowing the model to focus on specific sequence parts. This method proved both time-efficient and accurate in RUL prediction, utilizing a sliding window technique for processing raw data.

- Recurrent neural networks (RNNs) are a class of neural networks designed to process sequential data by incorporating feedback connections. This structure allows the network to retain information from previous time steps, which it uses to influence current predictions. However, when the effective information interval is long, the reverse propagation of the RNN network will produce the phenomenon of gradient disappearance or explosion. To solve these two problems, some scholars propose a long short-term memory (LSTM) neural network, gated recurrent unit (GRU) neural network, Bi-LSTM neural network, and Evolving Elman neural network (EENN) [197]. In this context, different studies propose an LSTM-based approach to RUL and SOH estimation, achieving impressive results, considering the aging characteristics extracted from the voltage, current, and temperature [198,199,200,201,202]. In reference [203], a GRU is established to evaluate the SOC. Additionally, S.Seol et al. [204] employ two recurrent neural network models, LSTM and GRU, evaluating the improvement in SOH estimation accuracy when synthetic data is added to the original dataset. Moreover, S.Yun [205] proposes a Bi-LSTM for SOC estimation, dealing with limited access to the current and voltage data in satellite applications. In another approach, Hong [206] integrates Bi-LSTM with an attention mechanism to predict SOH and compare RUL estimation performance under varied initial conditions. For satellite applications, D. Zhang [207] developed an SOH estimation strategy based on the Evolving Elman Neural Network (EENN) by using the in-orbit discharging voltage data.

Recent research has increasingly centered on the comparative analysis of various neural network methodologies for estimating the SOH and RUL of lithium-ion batteries [208,209]. Venugopal evaluates several models and concludes that DNNs are superior for SOH estimation, whereas LSTM networks are more effective for predicting RUL [210]. Pohlmann enhances SOC estimation through data augmentation techniques, identifying CNNs as the most efficient model in this context [211].

Data-driven methods are powerful tools for developing very accurate estimation and prediction models. Using extensive aging data bypasses the need to directly account for intricate electrochemical changes and fluctuations in active materials within lithium-ion batteries. However, these methods have some limitations in the context of battery health assessments. They require large datasets for effective training and are highly dependent on data quality, making them prone to overfitting, especially when a physical battery model is not incorporated.

4.3.5. Fusion Methods

In recent years, research on monitoring and prediction for lithium-ion batteries has increasingly recognized the benefits of combining various methods to leverage their individual strengths. Two distinct fusion techniques have been prominently highlighted in the literature:

- Data–Data Fusion: This combines multiple data-driven algorithms to improve SOC, SOH, and RUL estimations. Moreover, studies [212,213,214,215] combine the CNN with the LSTM used as a typical encoder-decoder. In [216], the authors take fusion by integrating CNN with LSTM for assessing the battery’s RUL and boosting prediction precision within a reasonable computation time. The CNN is also used in combination with the GRU, enabling the model to effectively extract significant local features while emphasizing their importance during training. For example, Y. Liu [217] uses CNNs to estimate the maximum discharging capacity, which is then used by a GRU to deduce the RUL. To maximize the strengths of each model, Fan et al. [218] proposed a GRU-CNN hybrid model to estimate the SOH under various discharge conditions. Other methodologies, including statistical models, demonstrate powerful results when combined with neural networks. Gao et al. [219] employ an Elman neural network and GPR to model battery aging, with a Bi-LSTM component for capacity error correction. Liu’s [220] research uses LSTM for long-term dependency capture and GPR to assess uncertainty, effectively addressing capacity regeneration phenomena. Che [221] integrates GPR to optimize the health indicator extraction and applies an RNN to directly forecast RUL. Uncertainty quantification is further refined in Kim’s [222] work with a variational LSTM (VarLSTM) model using Monte Carlo dropout to predict battery degradation and RUL with reliable uncertainty estimates.

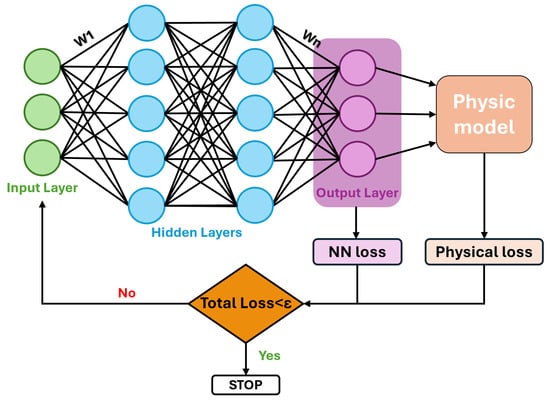

- Model-Data Fusion: Approaches that fuse model-based and data-driven methods have become central to advancing lithium-ion battery health and life predictions. One prominent fusion strategy involves embedding physical constraints directly within neural networks to guide model training and enhance interpretability; Figure 11. For example, J. Ye’s [223] Physics-Informed Neural Network (PINN) incorporates specific physical relationships between health indicators and SOH, creating constraints that guide the learning process and improve prediction accuracy. Similarly, S. Singh [224] embeds Fick’s diffusion law into a PINN, integrating partial differential equations of battery chemistry into the network. This approach allows the model to capture electrochemical dynamics accurately, translating these constraints into the network’s optimization function, which supports SOC and SOH predictions that are rooted in physical principles. Similarly, Y. Wang’s [225] Physics-Informed Recurrent Neural Network (PIRNN) introduces electrochemical impedance constraints in the NN loss function, allowing the network to capture the diffusion dynamics of lithium-ion cells. Another approach focuses on combining physics-based simulated data with experimental observations in a hybrid data structure. T. Hofmann’s [226] study, for instance, trains an LSTM model on a dataset that fuses outputs from a P2D model, lab experiments, and field data from electric vehicles. This hybrid dataset captures various SOH stages, enabling the model to align internal battery states with measurable SOH indicators. Lastly, methods utilize statistical fusion within hybrid architectures to incorporate both physical models and data-driven filtering for noise reduction and uncertainty management. For example, Z. Lyu’s [227] Model-Data Fusion framework integrates a Thevenin model with GPR and particle filtering to estimate SOH dynamically.

Figure 11. Structure of Physics-Informed Neural Network (PINN) incorporating physical principles into the loss function.

Figure 11. Structure of Physics-Informed Neural Network (PINN) incorporating physical principles into the loss function.

To improve accuracy and reliability, many researchers now use hybrid approaches that combine the strengths of different techniques. While some methods offer simplicity and ease of implementation, others provide robustness and resilience to parameter fluctuations; however, they may require extensive datasets or precise calibration. A more versatile and effective prediction model, better suited to real-world operating conditions, can be developed using a fusion strategy [15].

The methodologies used to estimate key parameters such as SOC, SOH, and RUL have been categorized into four primary classes, representing the first level of the classification. Each class is further divided into different approaches, which form the second level of the classification. For each approach, various algorithms are presented, highlighting their common features and differences, forming the third level of the classification. A flowchart in Figure 12 summarizes the classification. Table 2 lists the different approaches, providing a comparison by outlining their respective advantages and disadvantages. Additionally, the possible outputs for each algorithm are specified.

Figure 12.

Classification of methods and algorithms for health monitoring and prediction in Li-ion batteries.

Table 2.

Classification and comparison of health monitoring and prediction of Li-ion batteries.

4.3.6. Datasets