Decarbonising Sustainable Aviation Fuel (SAF) Pathways: Emerging Perspectives on Hydrogen Integration

Abstract

1. Introduction

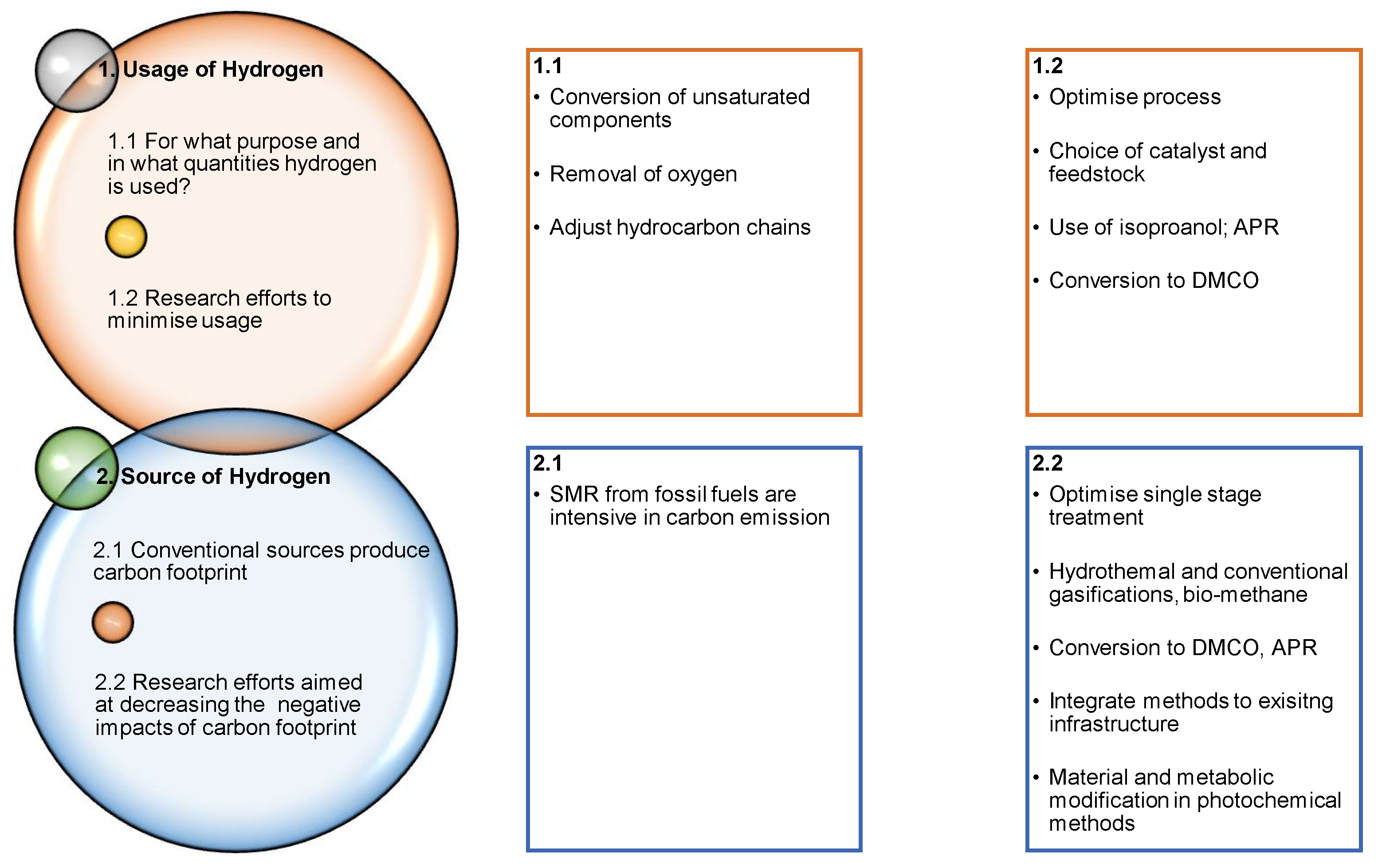

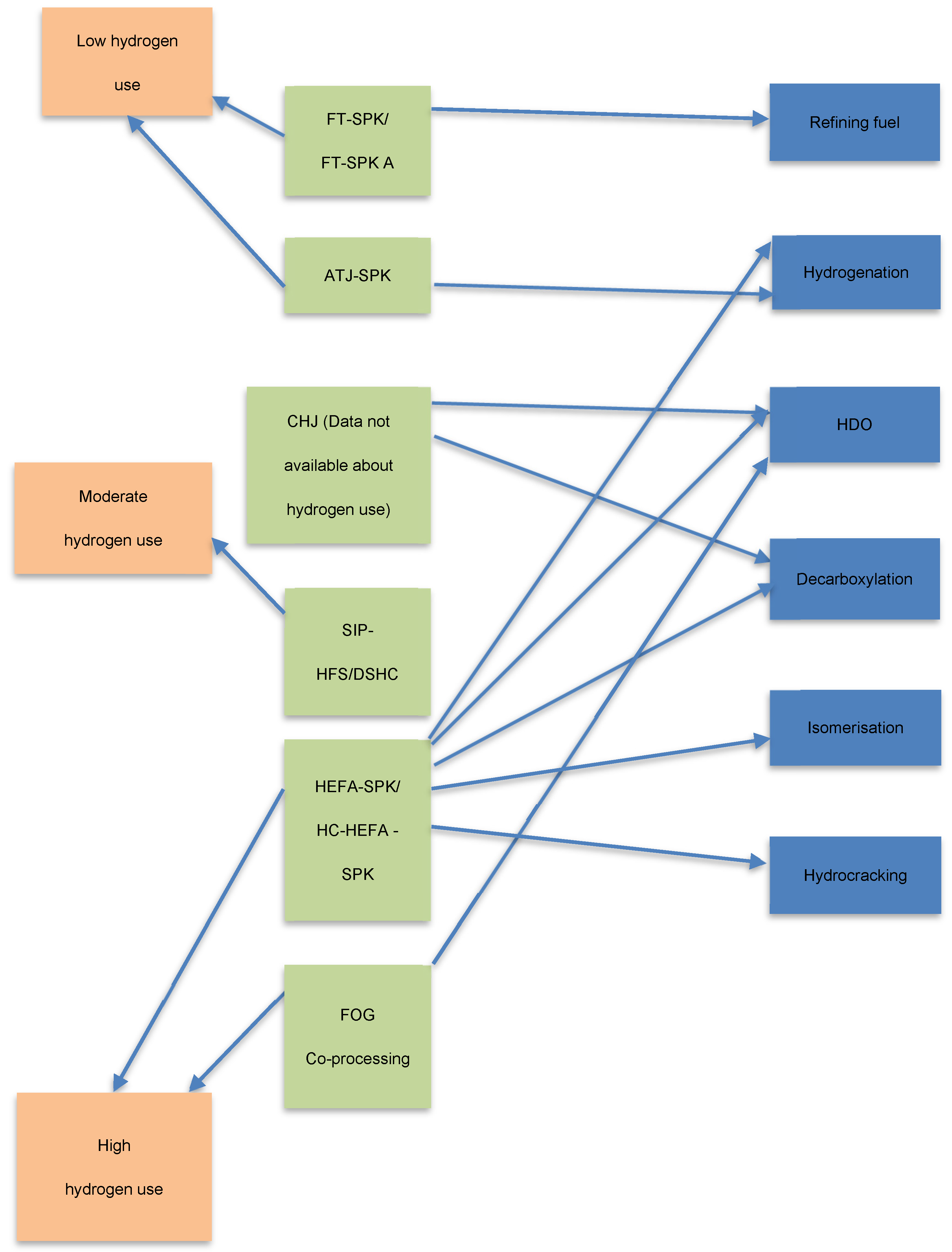

2. Usage of Hydrogen

| Methods | Purpose | Quantity of Hydrogen Normalised (kgH2/kg Feedstock or kgH2/kg Fuel Output) | Remarks |

|---|---|---|---|

| FT-SPK (Synthetic Paraffinic Kerosene) & FT-SPK/A (Synthetic Paraffinic Kerosene with Aromatics) ~Carbon-containing biomass | a. Refining fuel [4,5] | - No use of hydrogen (comparative study in [17]) - 0.01 kgH2/kg feedstock (corn stover) [13] | - Make-up hydrogen is used in the refining of FT product [7] - Theoretically, 0.351 kgH2/kg lignocellulosic biomass for the synthesis of fuel [13] |

| HEFA-SPK & HC-HEFA-SPK (Hydrocarbon) ~Oil-based including algae | a. Hydrogenation [5] b. HDO [13] c. Decarboxylation [5] d. Isomerisation [5] e. Hydrocracking [5] | - For per kg feedstock HDO—0.033 kg; Isomerisation—0.019 kg [9]. Total: 0.052 kgH2/kg feedstock - Hydrotreating and isomerisation/hydrocracking: 0.020 to 0.04 kgH2/kg feedstock (varied feedstock), cross refer [5] - 0.04 kgH2/kg feedstock: oil based feedstock (comparative study [13]) - 0.15 kgH2/kg renewable jet fuel (RJF) (comparative study as referred [17]) - 0.043 kgH2/kg feedstock (soyabean oil) [13] - 0.0317 kgH2/kg feedstock (palm oil), 0.033 kgH2/kg feedstock (macuaba oil) and 0.0377 kgH2/kg feedstock (soyabean oil). Up to 2000 kg/h processing 4 million tonnes of feedstock/annum [12] | - Transform unsaturated triglyceride and fatty acids to saturated compounds [18] - HDO & DCOX convert a saturated substance to linear alkanes of C15 to C18 [19] - Branched alkanes-based liquid fuel produced via isomerisation and hydrocracking [4] - Hydrogen is used to deoxygenate [17] |

| ATJ-SPK ~Alcohol- and sugar-based | a. Hydrogenation [1,4,5,20] | - 0.0016 kgH2/kg feedstock (comparative study [13]) - 0.08 kgH2/kg (RJF) (comparative study as referred [17]) - 0.02 kgH2/kg feedstock (corn stover) [13] | - Paraffins are produced after saturating double bonds in olefins [4] |

| CHJ ~Algae, oil derived from waste and plant | a. Hydrogenation [5,20] b. Decarboxylation [5] c. Hydrotreatment [5] | - | - Hydrogen is used in hydrogenation [4] - Straight, branched and cyclo-olefins are transformed to alkanes [7] |

| SIP-HFS or DSHC (Direct Sugars to Hydrocarbons) ~Lignocellulosic, sugar-based feedstock | a. Hydrotreating [1,4,20] | - 0.0104 kgH2/kg feedstock (from the comparative study [13]) - 0.52 kgH2/kg (RJF) (for a high blending ratio and 0.12 kgH2/kg RJF 10% blending ratio (comparative study as referred [17]) - 0.011 kgH2/kg feedstock (corn stover) [13] | - Sugar-containing feedstocks are modified to farnesene and further transformed to jet fuel [4,17] - Branched molecules are formed after hydroisomerisation and hydrocracking [21] - High hydrogen consumption contributes to GHG emission [17] |

| FOG Co-processing ~Oil-based inputs | a. HDO [4] | - 0.03 kgH2/kg feedstock (for hydro processing) [14] | - Oil-based feedstock deoxygenated in the presence of hydrogen [4] - Hydrogen consumption increases by 7% [14], if lipid-based feedstock blending (waste cooking oil) increases from 10 to 30%. - Saturated feedstocks consume less hydrogen (such as palm oil, animal fats, etc. targeted for renewable diesel) [14] - Lipid feed such as algae oil, camelina oil, linseed oil, etc. with unsaturated fatty acids are suitable for aviation fuels [14] - Different catalyst combinations to be further explored to comprehend its effect on the extent of deoxygenation and the hydrotreatment process apart from CoMo and NiMo catalysts [14]. |

- Low-hydrogen pathways (FT-SPK, ATJ) consume less hydrogen.

- Moderate-hydrogen pathways (DSHC, SIP-HFS) are involved in selective hydrotreating.

- High-hydrogen pathways (HEFA-SPK, HC-HEFA-SPK, FOG) are related to multiple hydrogen-rich upgrading functions, evident as resource-intensive.

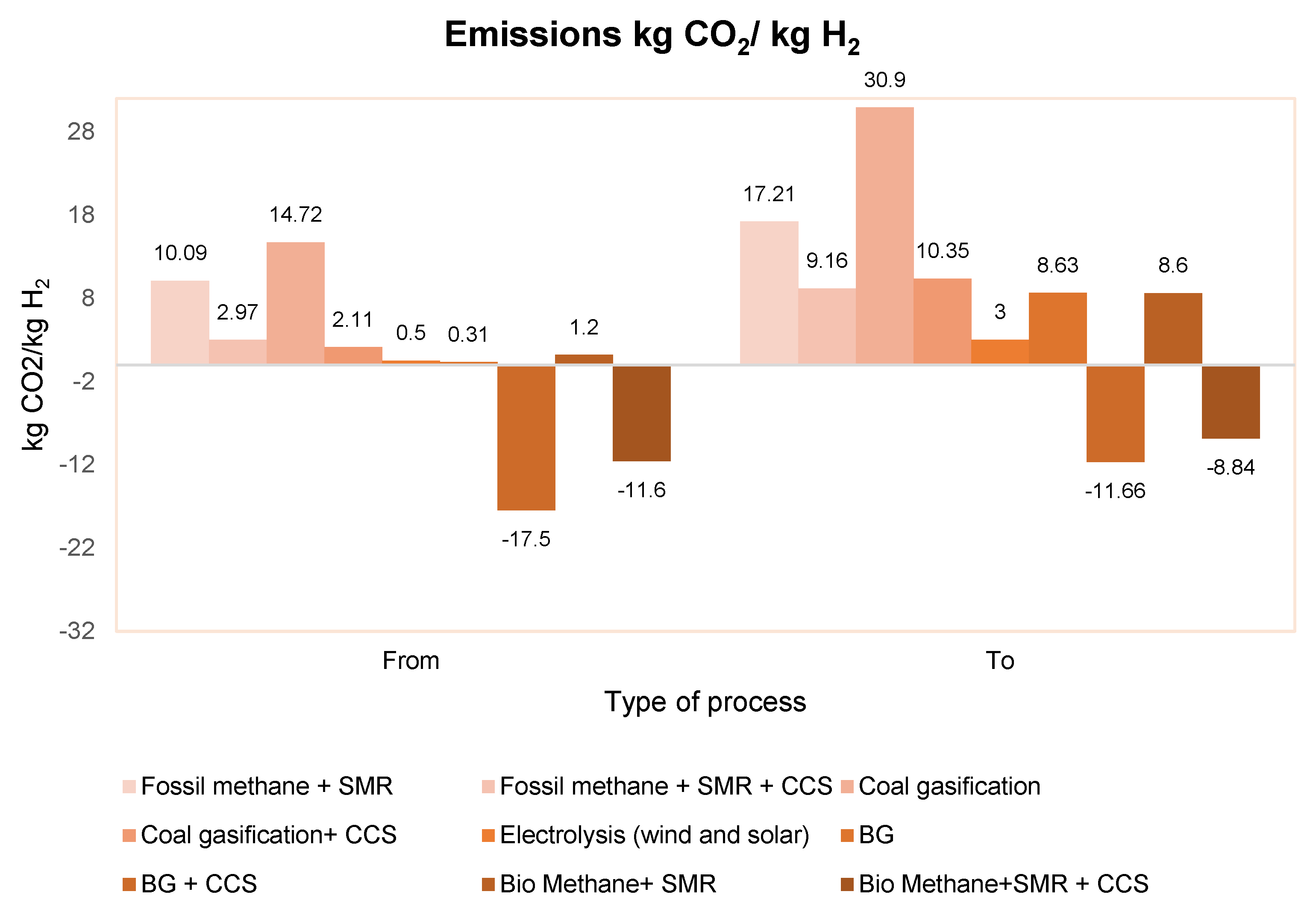

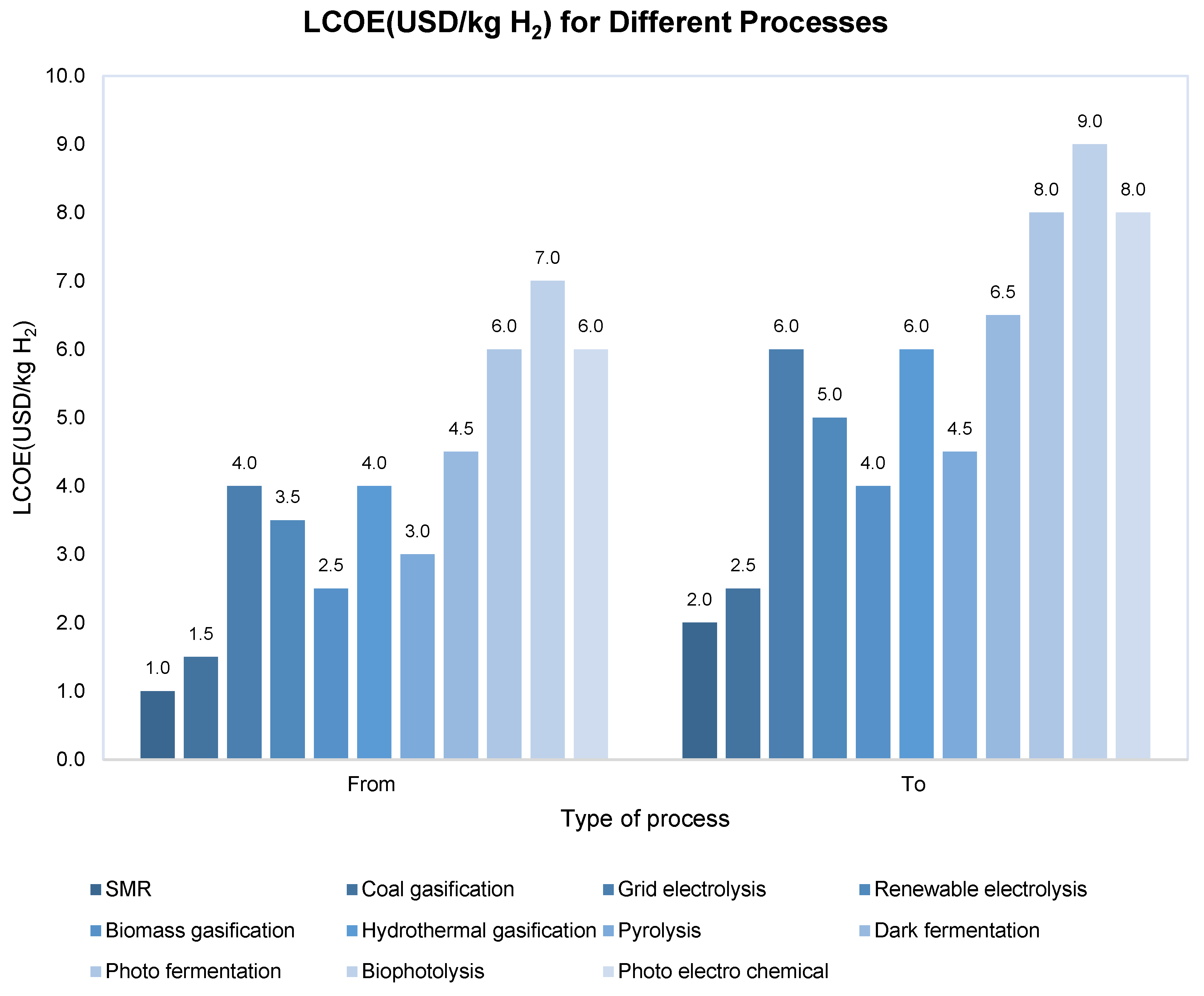

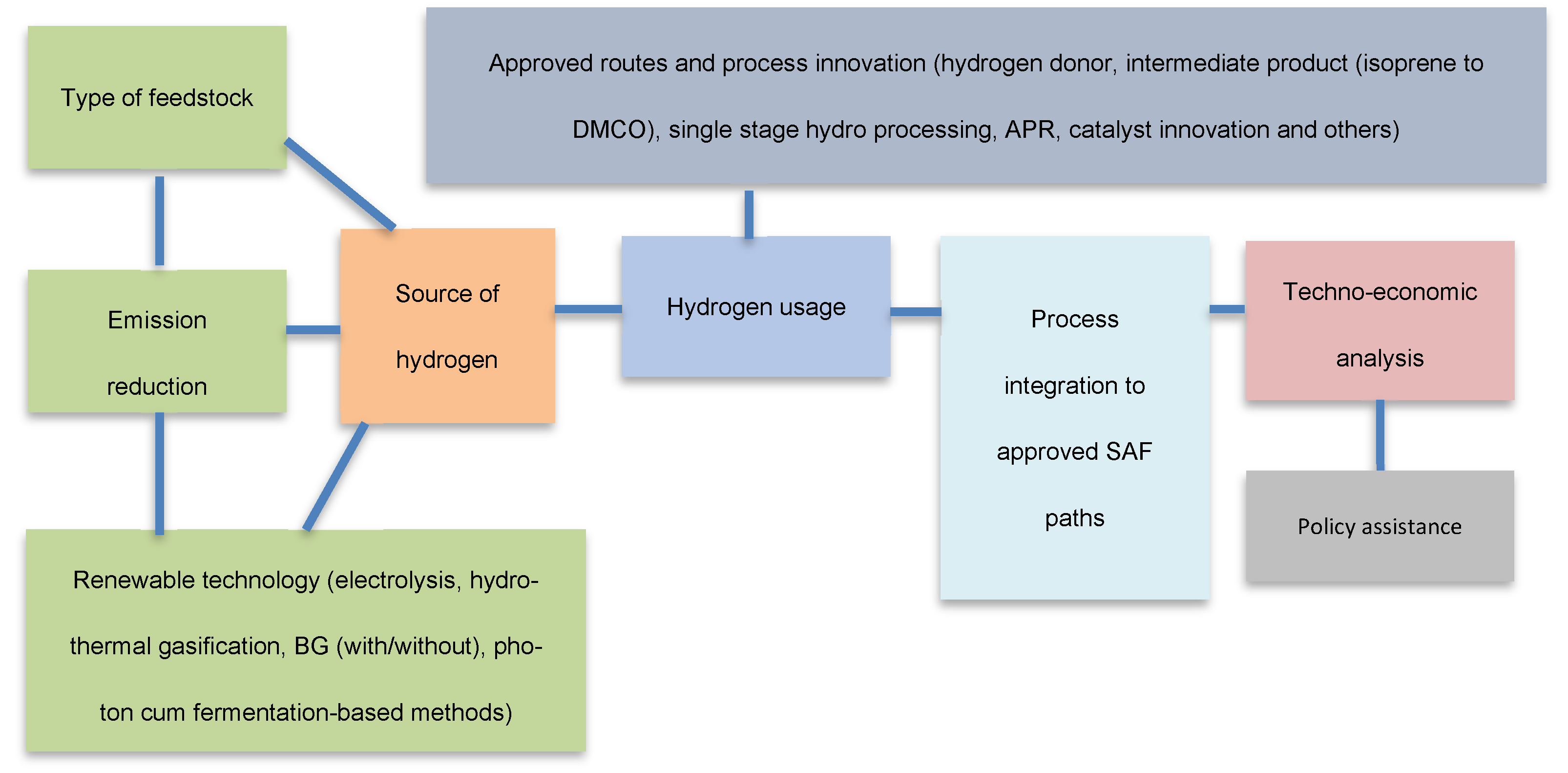

3. Source of Hydrogen

4. Strategy for Alleviating the Issues of the Source of Hydrogen and Usage of Hydrogen

4.1. Conventional Approach Impacting Greenhouse Gas Emission

4.2. Alternative Perspectives Impacting Variability in Hydrogen Usage and Greenhouse Gas Emission

5. Supplementary Opportunities for Future Research and Development

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- International Air Transport Association (IATA). Global Outlook for Air Transport—June 2023, IATA, Geneva 2023. Available online: https://www.iata.org/en/iata-repository/publications/economic-reports/global-outlook-for-air-transport----june-2023/ (accessed on 1 March 2024).

- ASTM D7566-24d; Standard Specification for Aviation Turbine Fuel Containing Synthesized Hydrocarbons. ASTM: West Conshohocken, PA, USA, 2024. [CrossRef]

- ASTM D1655-21c; Standard Specification for Aviation Turbine Fuels. ASTM: West Conshohocken, PA, USA, 2021. [CrossRef]

- Shahriar, F.; Khanal, A. The current techno-economic, environmental, policy status and perspectives of sustainable aviation fuel (SAF). Fuel 2022, 325, 124905. [Google Scholar] [CrossRef]

- Mupondwa, E.; Li, X.; Tabil, L. Biofuels and Biorefining; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Tiwari, R.; Mishra, R.; Choubey, A.; Kumar, S.; Atabani, A.; Badruddin, I.A.; Khan, T.Y. Environmental and economic issues for renewable production of bio-jet fuel: A global prospective. Fuel 2023, 332, 125978. [Google Scholar] [CrossRef]

- Wei, H.; Liu, W.; Chen, X.; Yang, Q.; Li, J.; Chen, H. Renewable bio-jet fuel production for aviation: A review. Fuel 2019, 254, 115599. [Google Scholar] [CrossRef]

- Why, E.S.K.; Ong, H.C.; Lee, H.V.; Gan, Y.Y.; Chen, W.-H.; Chong, C.T. Renewable aviation fuel by advanced hydroprocessing of biomass: Challenges and perspective. Energy Convers. Manag. 2019, 199, 112015. [Google Scholar] [CrossRef]

- Martinez-Hernandez, E.; Ramírez-Verduzco, L.F.; Amezcua-Allieri, M.A.; Aburto, J. Process simulation and techno-economic analysis of bio-jet fuel and green diesel production—Minimum selling prices. Chem. Eng. Res. Des. 2019, 146, 60–70. [Google Scholar] [CrossRef]

- Tao, L.; Milbrandt, A.; Zhang, Y.; Wang, W.-C. Techno-economic and resource analysis of hydroprocessed renewable jet fuel. Biotechnol. Biofuels 2017, 10, 261. [Google Scholar] [CrossRef]

- Geleynse, S.; Brandt, K.; Garcia-Perez, M.; Wolcott, M.; Zhang, X. The Alcohol-to-Jet Conversion Pathway for Drop-In Biofuels: Techno-Economic Evaluation. ChemSusChem 2018, 11, 3728–3741. [Google Scholar] [CrossRef]

- Klein, B.C.; Chagas, M.F.; Junqueira, T.L.; Rezende, M.C.A.F.; Cardoso, T.d.F.; Cavalett, O.; Bonomi, A. Techno-economic and environmental assessment of renewable jet fuel production in integrated Brazilian sugarcane biorefineries. Appl. Energy 2018, 209, 290–305. [Google Scholar] [CrossRef]

- Tanzil, A.H.; Brandt, K.; Wolcott, M.; Zhang, X.; Garcia-Perez, M. Strategic assessment of sustainable aviation fuel production technologies: Yield improvement and cost reduction opportunities. Biomass. Bioenergy 2021, 145, 105942. [Google Scholar] [CrossRef]

- Bezergianni, S.; Dimitriadis, A.; Kikhtyanin, O.; Kubička, D. Refinery co-processing of renewable feeds. Prog. Energy Combust. Sci. 2018, 68, 29–64. [Google Scholar] [CrossRef]

- Chen, J.; Farooqi, H.; Fairbridge, C. Experimental Study on Co-hydroprocessing Canola Oil and Heavy Vacuum Gas Oil Blends. Energy Fuels 2013, 27, 3306–3315. [Google Scholar] [CrossRef]

- Chu, P.L.; Vanderghem, C.; MacLean, H.L.; Saville, B.A. Process modeling of hydrodeoxygenation to produce renewable jet fuel and other hydrocarbon fuels. Fuel 2017, 196, 298–305. [Google Scholar] [CrossRef]

- de Jong, S.; Antonissen, K.; Hoefnagels, R.; Lonza, L.; Wang, M.; Faaij, A.; Junginger, M. Life-cycle analysis of greenhouse gas emissions from renewable jet fuel production. Biotechnol. Biofuels 2017, 10, 64. [Google Scholar] [CrossRef] [PubMed]

- Morgan, T.; Santillan-Jimenez, E.; Harman-Ware, A.E.; Ji, Y.; Grubb, D.; Crocker, M. Catalytic deoxygenation of triglycerides to hydrocarbons over supported nickel catalysts. Chem. Eng. J. 2012, 189–190, 346–355. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, Q.; Zhang, X.; Wang, L.; Li, G. Hydrotreating of C18 fatty acids to hydrocarbons on sulphided NiW/SiO2–Al2O3. Fuel Process. Technol. 2013, 116, 165–174. [Google Scholar] [CrossRef]

- Afonso, F.; Sohst, M.; Diogo, C.M.; Rodrigues, S.S.; Ferreira, A.; Ribeiro, I.; Marques, R.; Rego, F.F.; Sohouli, A.; Portugal-Pereira, J.; et al. Strategies towards a more sustainable aviation: A systematic review. Prog. Aerosp. Sci. 2023, 137, 100878. [Google Scholar] [CrossRef]

- Klein-Marcuschamer, D.; Turner, C.; Allen, M.; Gray, P.; Dietzgen, R.G.; Gresshoff, P.M.; Hankamer, B.; Heimann, K.; Scott, P.T.; Stephens, E.; et al. Technoeconomic analysis of renewable aviation fuel from microalgae, Pongamia pinnata, and sugarcane. Biofuels Bioprod. Biorefining 2013, 7, 416–428. [Google Scholar] [CrossRef]

- Budsberg, E.; Crawford, J.T.; Morgan, H.; Chin, W.S.; Bura, R.; Gustafson, R. Hydrocarbon bio-jet fuel from bioconversion of poplar biomass: Life cycle assessment. Biotechnol. Biofuels 2016, 9, 170. [Google Scholar] [CrossRef]

- Seber, G.; Escobar, N.; Valin, H.; Malina, R. Uncertainty in life cycle greenhouse gas emissions of sustainable aviation fuels from vegetable oils. Renew. Sustain. Energy Rev. 2022, 170, 112945. [Google Scholar] [CrossRef]

- Barbera, E.; Naurzaliyev, R.; Asiedu, A.; Bertucco, A.; Resurreccion, E.P.; Kumar, S. Techno-economic analysis and life-cycle assessment of jet fuels production from waste cooking oil via in situ catalytic transfer hydrogenation. Renew. Energy 2020, 160, 428–449. [Google Scholar] [CrossRef]

- Batten, R.; Galant, O.; Karanjikar, M.; Spatari, S. Meeting sustainable aviation fuel policy targets through first generation corn biorefineries. Fuel 2023, 333, 126294. [Google Scholar] [CrossRef]

- Zulkepli, S.; Juan, J.C.; Lee, H.V.; Rahman, N.S.A.; Show, P.L.; Ng, E.P. Modified mesoporous HMS supported Ni for deoxygenation of triolein into hydrocarbon-biofuel production. Energy Convers. Manag. 2018, 165, 495–508. [Google Scholar] [CrossRef]

- Vásquez, M.C.; Silva, E.E.; Castillo, E.F. Hydrotreatment of vegetable oils: A review of the technologies and its developments for jet biofuel production. Biomass. Bioenergy 2017, 105, 197–206. [Google Scholar] [CrossRef]

- Umenweke, G.C.; Pace, R.B.; Santillan-Jimenez, E.; Okolie, J.A. Techno-economic and life-cycle analyses of sustainable aviation fuel production via integrated catalytic deoxygenation and hydrothermal gasification. Chem. Eng. J. 2023, 452, 139215. [Google Scholar] [CrossRef]

- Pipitone, G.; Zoppi, G.; Pirone, R.; Bensaid, S. Sustainable aviation fuel production using in-situ hydrogen supply via aqueous phase reforming: A techno-economic and life-cycle greenhouse gas emissions assessment. J. Clean. Prod. 2023, 418, 138141. [Google Scholar] [CrossRef]

- Su, G.; Ong, H.C.; Mofijur, M.; Mahlia, T.I.; Ok, Y.S. Pyrolysis of waste oils for the production of biofuels: A critical review. J. Hazard. Mater. 2022, 424, 127396. [Google Scholar] [CrossRef]

- Neuling, U.; Kaltschmitt, M. Techno-economic and environmental analysis of aviation biofuels. Fuel Process. Technol. 2018, 171, 54–69. [Google Scholar] [CrossRef]

- Rosa, L.; Mazzotti, M. Potential for hydrogen production from sustainable biomass with carbon capture and storage. Renew. Sustain. Energy Rev. 2022, 157, 112123. [Google Scholar] [CrossRef]

- Dincer, I.; Acar, C. Review and evaluation of hydrogen production methods for better sustainability. Altern. Energy Ecol. (ISJAEE) 2016, 14–36. [Google Scholar] [CrossRef]

- Abawalo, M.; Pikoń, K.; Landrat, M.; Ścierski, W. Hydrogen Production from Biowaste: A Systematic Review of Conversion Technologies, Environmental Impacts, and Future Perspectives. Energies 2025, 18, 4520. [Google Scholar] [CrossRef]

- Choudhary, T.; Phillips, C. Renewable fuels via catalytic hydrodeoxygenation. Appl. Catal. A Gen. 2011, 397, 1–12. [Google Scholar] [CrossRef]

- Misra, P.; Alvarez-Majmutov, A.; Chen, J. Isomerization catalysts and technologies for biorefining: Opportunities for producing sustainable aviation fuels. Fuel 2023, 351, 128994. [Google Scholar] [CrossRef]

- Shim, J.-O.; Jeon, K.-W.; Jang, W.-J.; Na, H.-S.; Cho, J.-W.; Kim, H.-M.; Lee, Y.-L.; Jeong, D.-W.; Roh, H.-S.; Ko, C.H. Facile production of biofuel via solvent-free deoxygenation of oleic acid using a CoMo catalyst. Appl. Catal. B Environ. 2018, 239, 644–653. [Google Scholar] [CrossRef]

- El-Araby, R.; Abdelkader, E.; El Diwani, G.; Hawash, S.I. Bio-aviation fuel via catalytic hydrocracking of waste cooking oils. Bull. Natl. Res. Cent. 2020, 44, 177. [Google Scholar] [CrossRef]

- Song, M.; Zhang, X.; Chen, Y.; Zhang, Q.; Chen, L.; Liu, J.; Ma, L. Hydroprocessing of lipids: An effective production process for sustainable aviation fuel. Energy 2023, 283, 129107. [Google Scholar] [CrossRef]

- Emmanouilidou, E.; Mitkidou, S.; Agapiou, A.; Kokkinos, N.C. Solid waste biomass as a potential feedstock for producing sustainable aviation fuel: A systematic review. Renew. Energy 2023, 206, 897–907. [Google Scholar] [CrossRef]

- AlNouss, A.; McKay, G.; Al-Ansari, T. A comparison of steam and oxygen fed biomass gasification through a techno-economic-environmental study. Energy Convers. Manag. 2020, 208, 112612. [Google Scholar] [CrossRef]

| Study Description | Research Problem | Emission Benefit | Cost | Opportunity |

|---|---|---|---|---|

| Feasibility of in-situ Catalytic Transfer Hydrogenation (CTH) to generate jet fuel from waste cooking oil in comparison to commercial Hydroprocessed Renewable Jet (HRJ) [24] | a. High cost associated with the use of high-pressure hydrogen (25 to 100 bar) in HRJ/HEFA for proper mixing with oil b. Storage and transportation issue c. Relies on fossil source of hydrogen | a. 100-years GWP is 8% low in CTH without sequestering carbon | a. 95% reduction in capital expenditure (CAPEX) of CTH compared to HRJ b. CTH performs well in term of revenues c. Isopropanol contributes 68% of the total operation and maintenance cost (O&M) | a. CTH profitable despite the large input cost of isopropanol b. Gas compression is costly compared to pumping isopropanol c. CTH operates with a cheaper catalyst (Activated carbon) unlike the nickel-molybdenum-based catalyst in hydrotreating HRJ d. Operates at atmospheric conditions |

| Environmental assessment of first grade biorefinery based on conversion of sugar-based feedstock (corn) to (DMCO) [25] | a. How to produce SAF with the existing commercial first-grade biorefineries? b. To evaluate the environmental performance | a. The obtained average life cycle emissions with and without carbon capture are 36 g CO2 equivalent/MJ and 5 g CO2 equivalent/MJ | __ | a. Corn to DMCO can bridge the SAF targets b. The use of renewable sources of hydrogen could reduce emissions during the hydrogenation of DMCO c. Effectual crop management practices could reduce the land use emissions d. Prospect for economic viability study |

| Study of modified Nickel supported hexagonal mesoporous silica (HMS) in absence of hydrogen to produce renewable fuel [26] | a. To identify the connection between the tested catalyst and to perform deoxygenation (DO) in the absence of hydrogen | a. Improved the DO at 380 °C and free of hydrogen b. 10 wt.% Nickel led to 92.5% conversion and 95.2% selectivity c. Pore size and surface area of HMS played a critical part | __ | a. Ni/HMS is a promising catalyst to produce sustainable oil from non-edible oil feed in the absence of hydrogen |

| Study of the enviro-economic effects for producing SAF from TOFA via catalytic deoxygenation under two scenarios of source of hydrogen—grey hydrogen (Case 1) and using hydrothermal gasification (Case 2) [28] | a. Evaluate the integration of hydrothermal gasification to produce SAF | a. Greenhouse reductions: 94% (Case 2) and 76% (Case 1) | a. Minimum fuel selling price (MSP): USD 0.39/L (Case 2) against USD 0.62/L (Case 1) | a. Economically and environmentally viable b. Can process a variety of waste feedstock such as sewage sludge, agricultural residues, FOG and others c. Optimisation of the process |

| Study of enviro-economic implications on HEFA using in-situ hydrogen via APR [29] | a. To assess the technical, economical and environmental capacity of APR for improving the HEFA process | a. Emission: 54% lower (11.7 g CO2 equivalent/MJ) than in the conventional method | a. MSP: USD 1.84/kg, i.e., 17% lesser than SAF produced using hydrogen generated via electrolysis b. 6.6% higher CAPEX c. Direct manufacturing cost: 22% lower due to the lesser hydrogen demand externally and compression | a. Can be integrated into other approved SAF routes b. Effect of the cost of feedstock, plant capacity and yield of SAF requires further investigation for marketability |

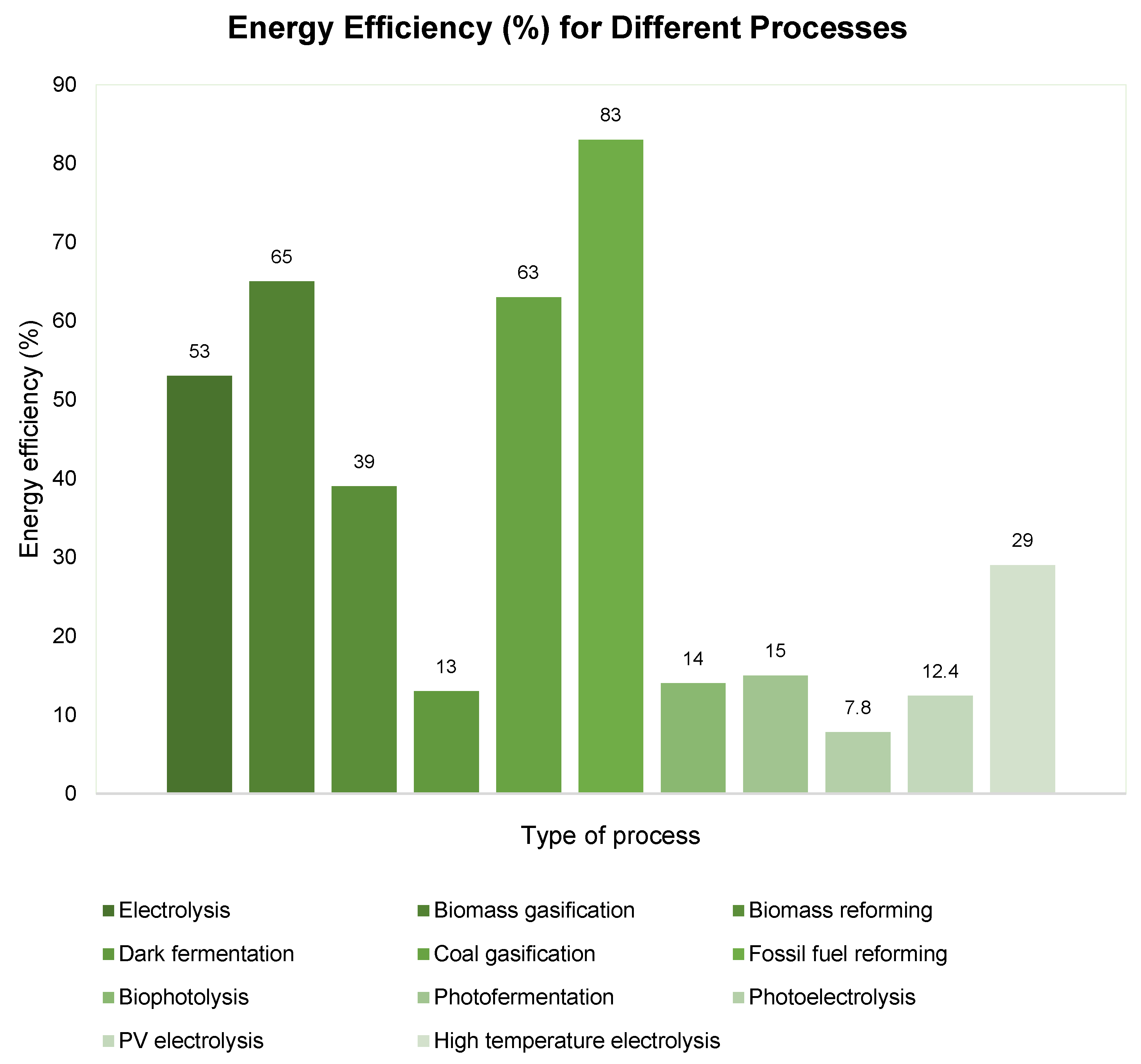

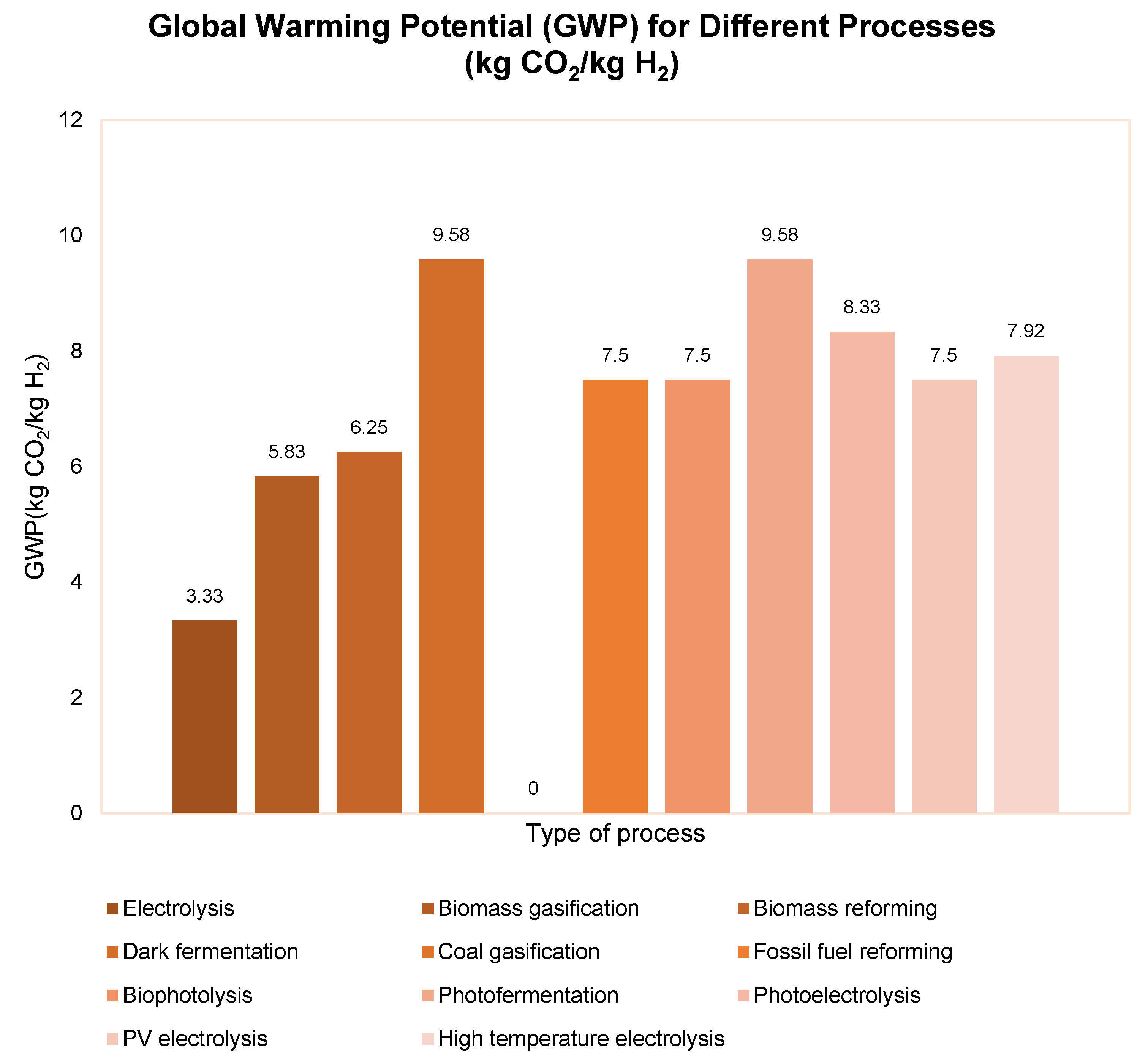

| Study of cost, environmental impact, energy and exergy analysis of producing hydrogen from conventional and renewable sources [33] | a. To compare and evaluate the different technologies depending on efficiencies for energy and exergy, the cost of generation, the warming effect globally and the acidification potential (AP) inclusive of social cost | a. Energy efficiency is greatest in fossil fuel (83%) reforming and lowest in photocatalysis (2%) b. Biomass gasification has the best exergy efficiency (60%) c. Photonic-based hydrogen has almost zero GWP and AP and hence a negligible social cost of carbon (SCC) d. Hydrogen via electrical methods has high GWP and SCC e. Hybrid- and thermal-based production methods perform better | a. Photoelectrochemical hydrogen is expensive (USD 10.36/kg hydrogen) | a. Integrating technologies with minimal environmental impacts can be the source of hydrogen. |

| Analysis of Bioenergy with carbon capture and storage (BECCS) for hydrogen production [32] | a. To identify opportunities for removing carbon dioxide, renewable hydrogen from agricultural residues and other biomass wastes and provide insight for the net zero economy of Europe | a. Biohydrogen Carbon Capture Storage (BHCCS) can produce 12.5 Mtons of low carbon hydrogen and 133 Mtons of CO2 b. Potential location for bio-hydrogen within the desirable range from the suitable industries | a. Opportunity occurs for the use of BECCS |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gogoi Saikia, M.; Baratieri, M.; Menin, L. Decarbonising Sustainable Aviation Fuel (SAF) Pathways: Emerging Perspectives on Hydrogen Integration. Energies 2025, 18, 5742. https://doi.org/10.3390/en18215742

Gogoi Saikia M, Baratieri M, Menin L. Decarbonising Sustainable Aviation Fuel (SAF) Pathways: Emerging Perspectives on Hydrogen Integration. Energies. 2025; 18(21):5742. https://doi.org/10.3390/en18215742

Chicago/Turabian StyleGogoi Saikia, Madhumita, Marco Baratieri, and Lorenzo Menin. 2025. "Decarbonising Sustainable Aviation Fuel (SAF) Pathways: Emerging Perspectives on Hydrogen Integration" Energies 18, no. 21: 5742. https://doi.org/10.3390/en18215742

APA StyleGogoi Saikia, M., Baratieri, M., & Menin, L. (2025). Decarbonising Sustainable Aviation Fuel (SAF) Pathways: Emerging Perspectives on Hydrogen Integration. Energies, 18(21), 5742. https://doi.org/10.3390/en18215742