A Narrative Review of Life Cycle Assessments of Electric Vehicles: Methodological Challenges and Global Implications

Abstract

1. Introduction

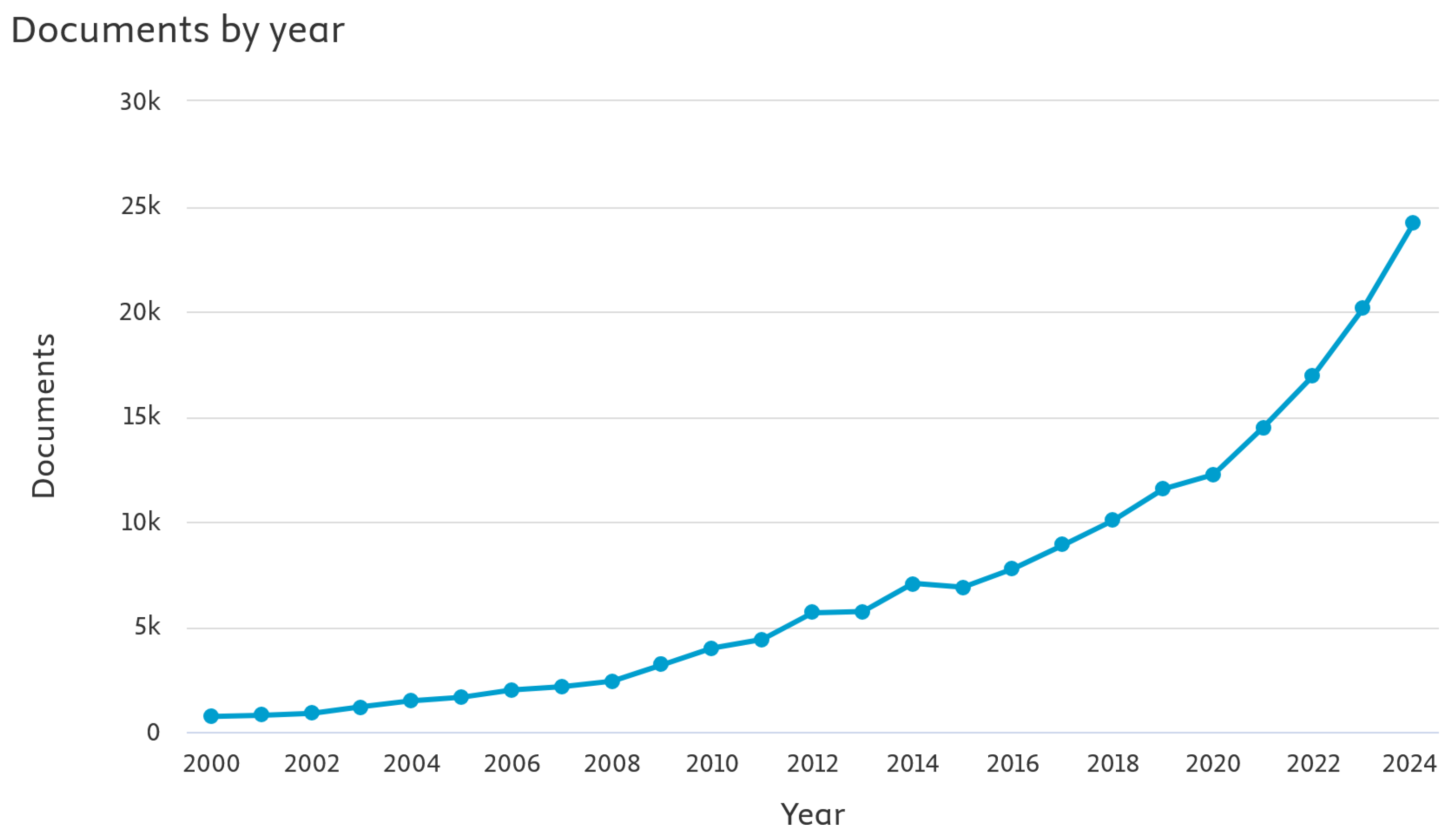

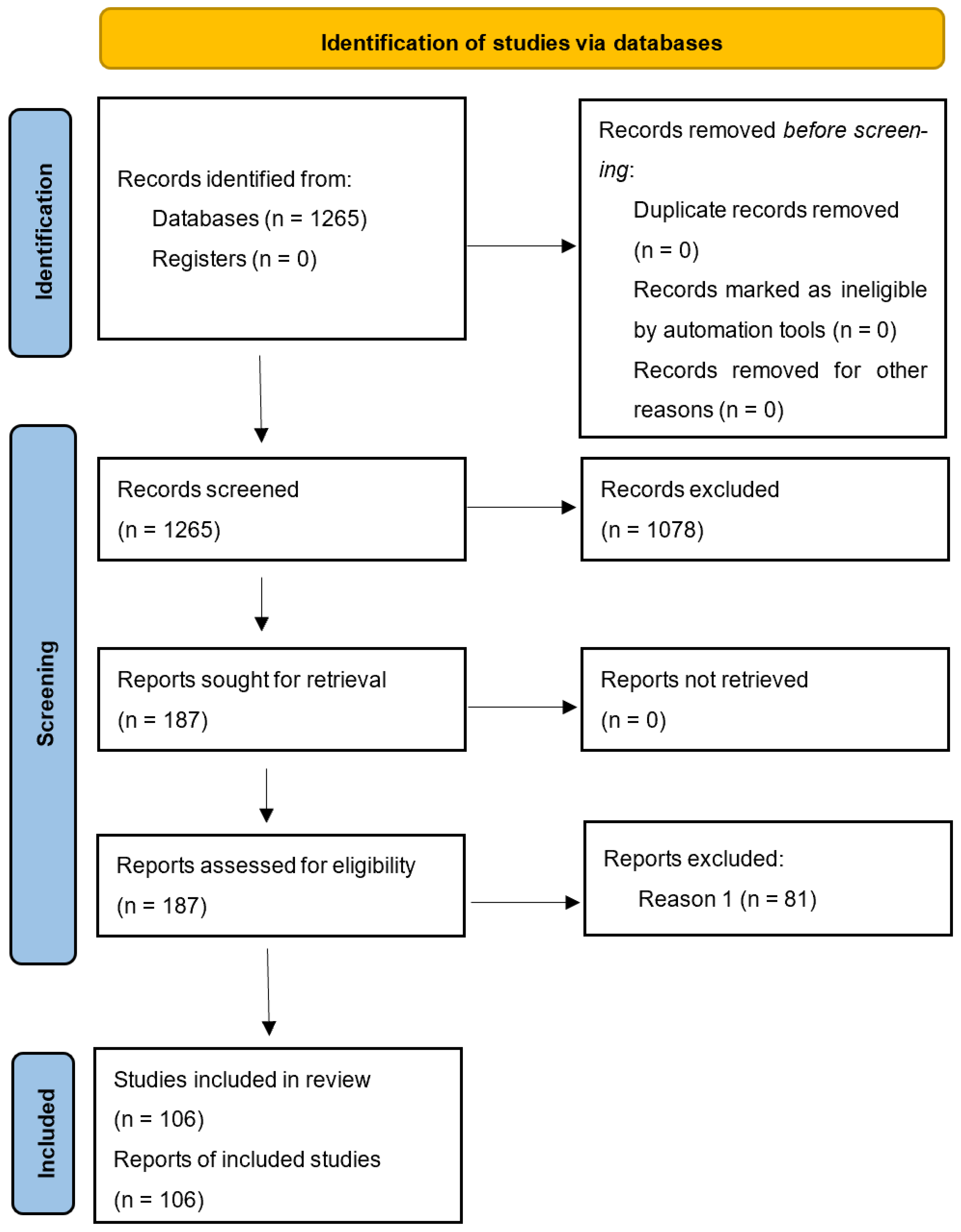

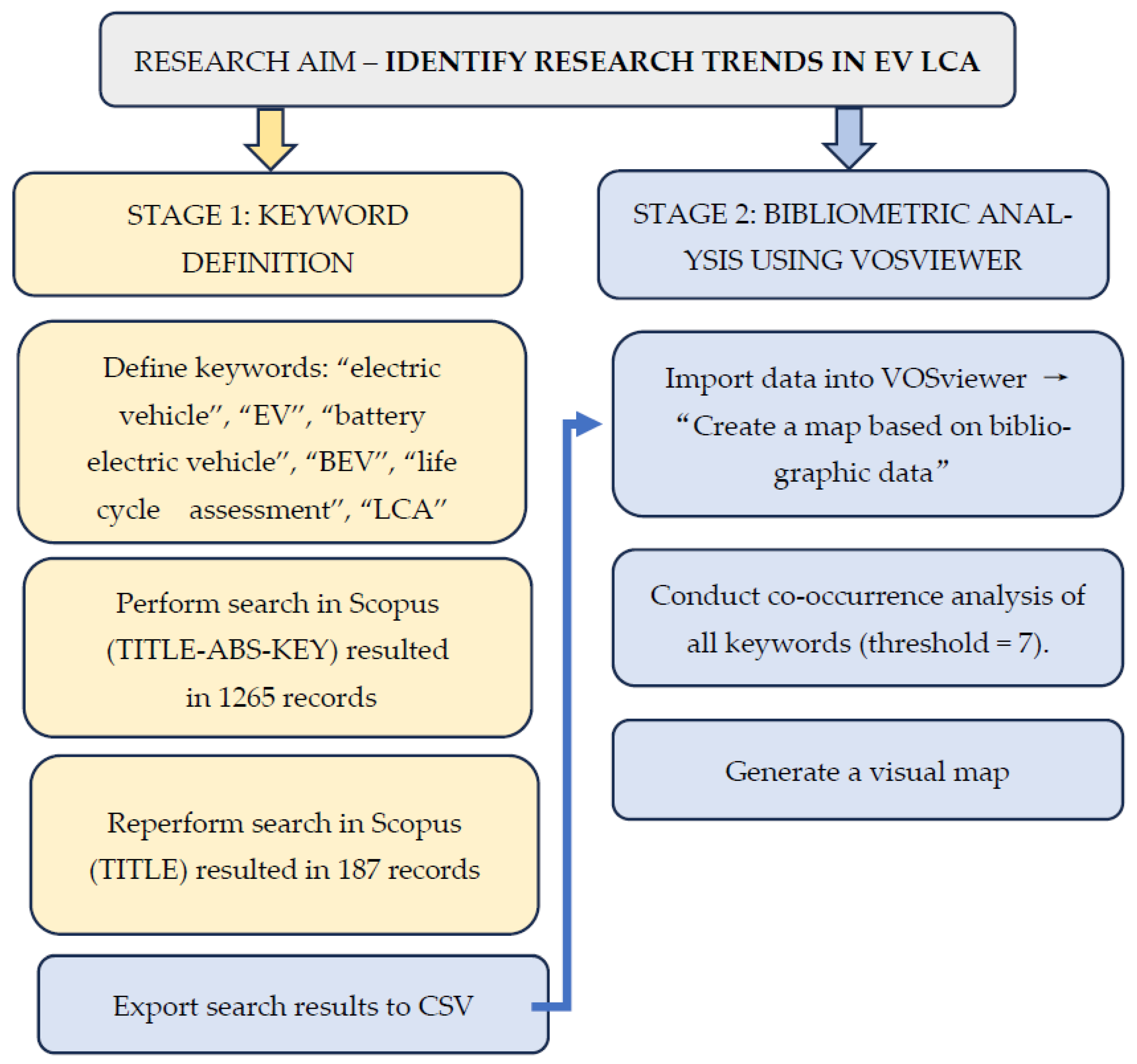

2. Materials and Methods

3. Results

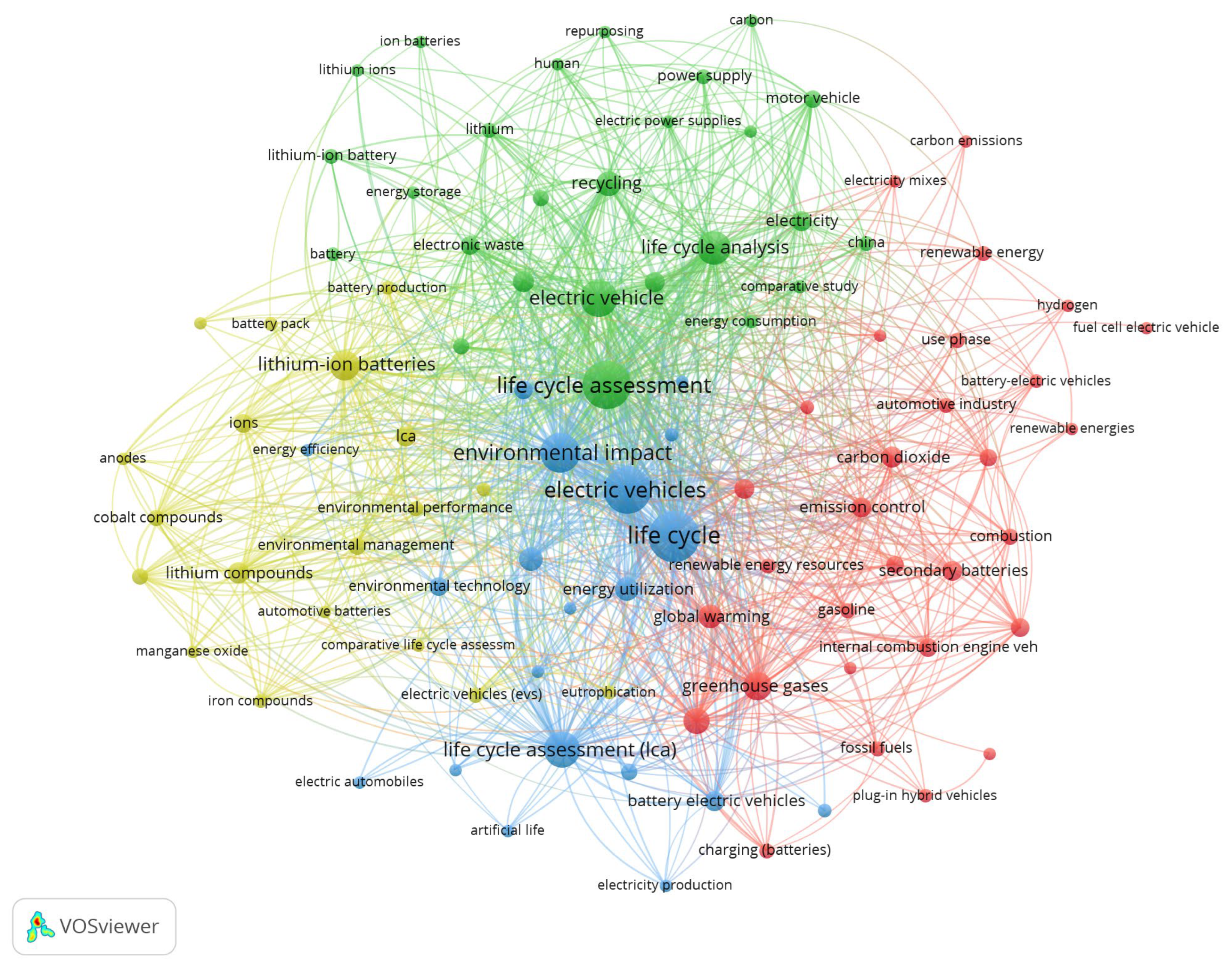

3.1. VOSviewer Analysis

3.2. Regional and Country-Specific LCA of Electric Vehicles

3.3. Literature Analysis on LCA Comparison of Electric Vehicles with Hybrid and Conventional Combustion Engine Vehicles

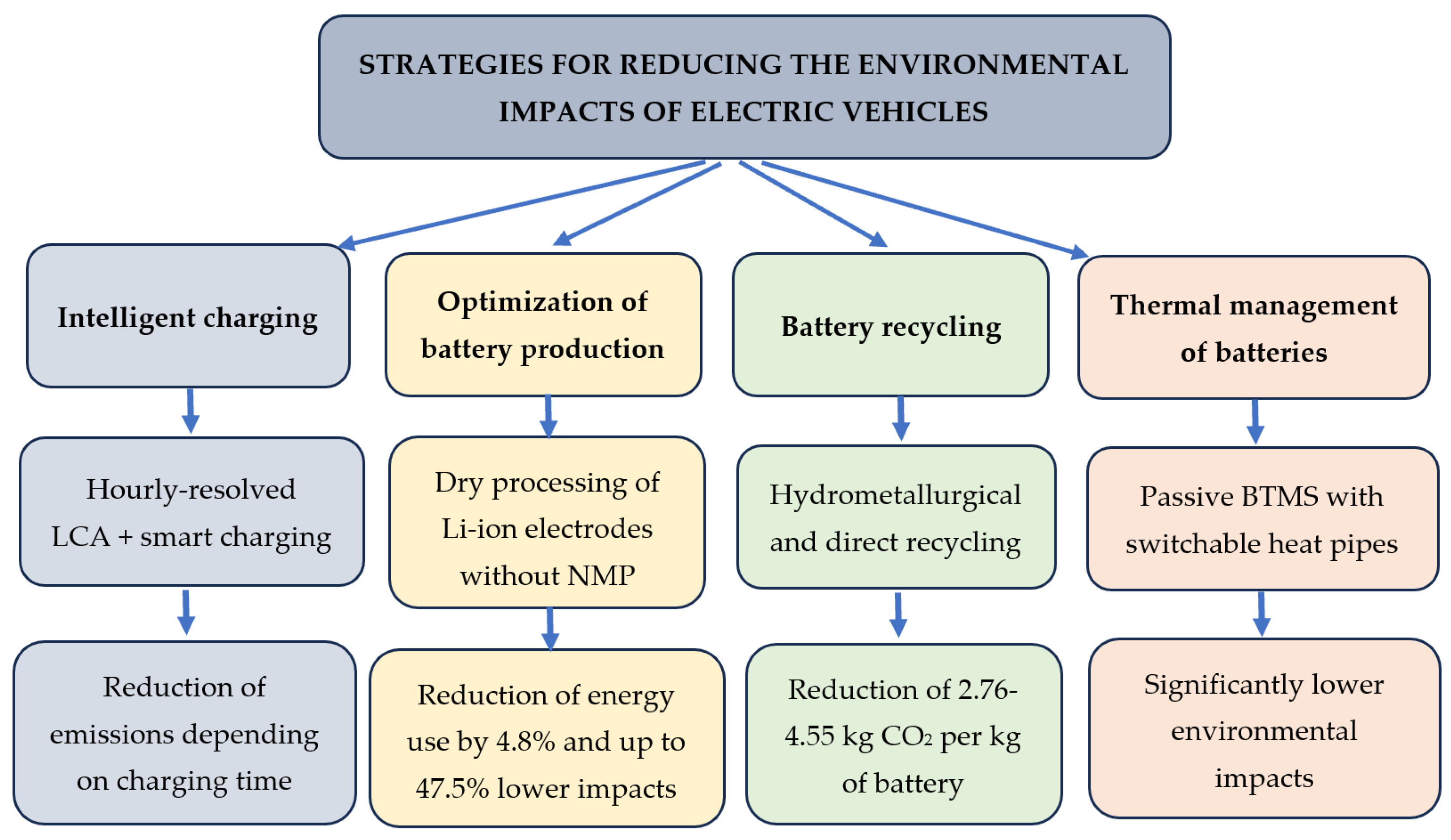

3.4. Strategies for Reducing Environmental Impacts of EVs

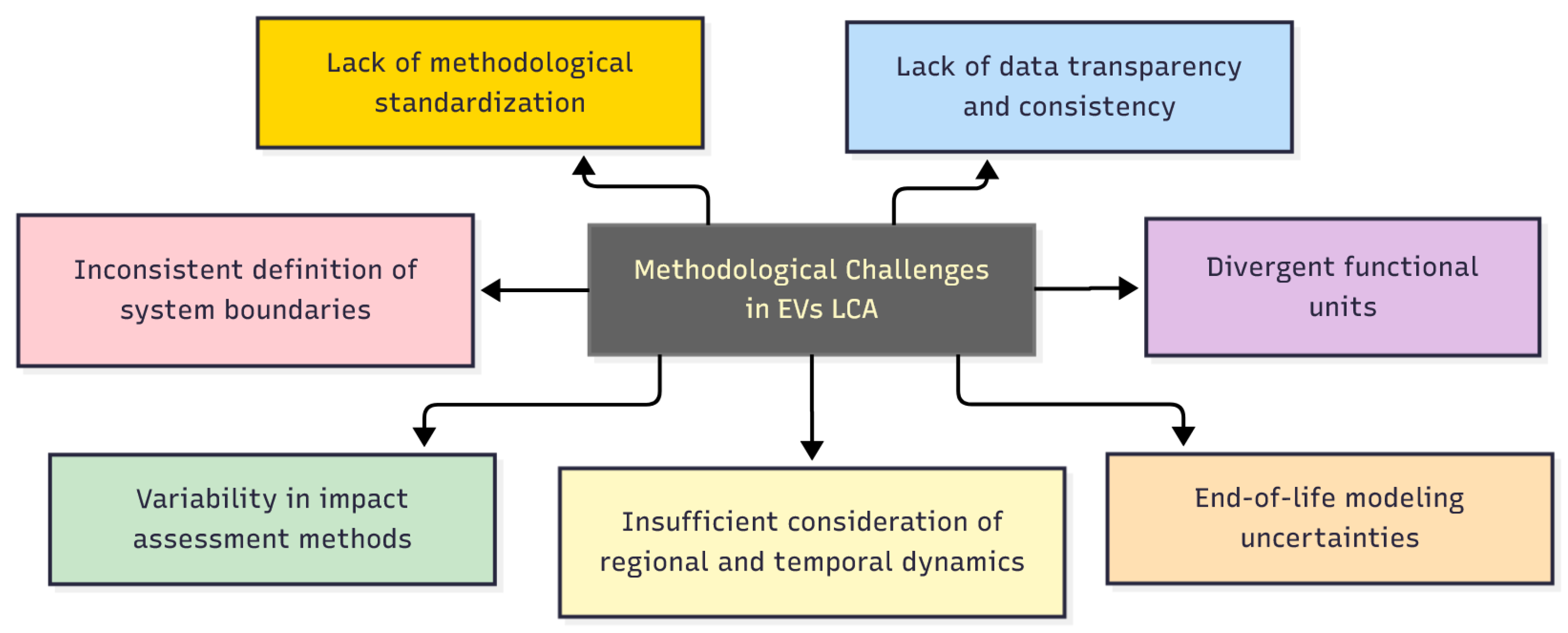

3.5. Methodological Challenges of EVs LCA

4. Discussion

4.1. Thematic Clusters in EV LCA Research

4.2. Comparative Environmental Impacts of EVs and ICEVs

4.3. Battery Production and Emerging Technologies

4.4. Regional Differences and Grid Dependency

4.5. Strategies for Reducing Environmental Impacts

4.6. Suggestions for Standardization of Future LCA Methods

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- European Commission. Transport Decarbonisation. Available online: https://climate.ec.europa.eu/eu-action/transport-decarbonisation_en (accessed on 20 August 2025).

- United States Environmental Protection Agency. Transportation Sector Emissions. Available online: https://www.epa.gov/ghgemissions/transportation-sector-emissions (accessed on 20 August 2025).

- Analyze Search Results. Available online: https://www.scopus.com/term/analyzer.uri?sort=plf-f&src=s&sid=7aa81a23bab49140795fade4792305f2&sot=a&sdt=a&sl=32&s=TITLE-ABS-KEY%28electric+vehicles%29&origin=resultslist&count=10&analyzeResults=Analyze+results (accessed on 20 August 2025).

- Faria, R.; Marques, P.; Moura, P.; Freire, F.; Delgado, J.; De Almeida, A.T. Impact of the Electricity Mix and Use Profile in the Life-Cycle Assessment of Electric Vehicles. Renew. Sustain. Energy Rev. 2013, 24, 271–287. [Google Scholar] [CrossRef]

- Rapa, M.; Gobbi, L.; Ruggieri, R. Environmental and Economic Sustainability of Electric Vehicles: Life Cycle Assessment and Life Cycle Costing Evaluation of Electricity Sources. Energies 2020, 13, 6292. [Google Scholar] [CrossRef]

- Koroma, M.S.; Costa, D.; Philippot, M.; Cardellini, G.; Hosen, M.S.; Coosemans, T.; Messagie, M. Life Cycle Assessment of Battery Electric Vehicles: Implications of Future Electricity Mix and Different Battery End-of-Life Management. Sci. Total Environ. 2022, 831, 154859. [Google Scholar] [CrossRef]

- ISO 14040:2006(En); Environmental Management. Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:14040:ed-2:v1:en (accessed on 15 July 2025).

- ISO 14044:2006(En); Environmental Management. Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:14044:ed-1:v1:en (accessed on 15 July 2025).

- ISO/TS 14048:2002; Environmental Management. Life Cycle Assessment—Data Documentation Format. ISO: Geneva, Switzerland, 2002. Available online: https://www.iso.org/standard/29872.html (accessed on 15 July 2025).

- ISO/TR 14049:2012; Environmental Management—Life Cycle Assessment—Illustrative Examples on How to Apply ISO 14044 to Goal and Scope Definition and Inventory Analysis. ISO: Geneva, Switzerland, 2012. Available online: https://www.iso.org/standard/57110.html (accessed on 15 July 2025).

- ISO 14067:2018; Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification. ISO: Geneva, Switzerland, 2018. Available online: https://www.iso.org/standard/71206.html (accessed on 15 July 2025).

- ISO 14071:2024; Environmental Management—Life Cycle Assessment—Critical Review Processes and Reviewer Competencies. ISO: Geneva, Switzerland, 2024. Available online: https://www.iso.org/standard/86264.html (accessed on 15 July 2025).

- ISO 14072:2024; Environmental Management—Life Cycle Assessment—Requirements and Guidance for Organizational Life Cycle Assessment. ISO: Geneva, Switzerland, 2024. Available online: https://www.iso.org/standard/86265.html (accessed on 15 July 2025).

- Life Cycle Assessment: In-Depth. Available online: https://app.croneri.co.uk/topics/life-cycle-assessment/indepth?section=4146&topic=4153 (accessed on 15 July 2025).

- Kumar, V.; Sharma, Y.; Chadha, P.; Dixit, S.; Jugge, P.; Bobba, P.B. Sustainability in Electric Vehicles: A Bibliometric Analysis of Life Cycle Assessment. In Proceedings of the E3S Web of Conferences, Newcastle, UK, 6 October 2023; EDP Sciences: Les Ulis, France, 2023; Volume 430. [Google Scholar]

- Dolganova, I.; Rödl, A.; Bach, V.; Kaltschmitt, M.; Finkbeiner, M. A Review of Life Cycle Assessment Studies of Electric Vehicles with a Focus on Resource Use. Resources 2020, 9, 32. [Google Scholar] [CrossRef]

- Verma, S.; Dwivedi, G.; Verma, P. Life Cycle Assessment of Electric Vehicles in Comparison to Combustion Engine Vehicles: A Review. Mater. Today Proc. 2021, 49, 217–222. [Google Scholar] [CrossRef]

- Cimprich, A.; Sadayappan, K.; Young, S.B. Lightweighting Electric Vehicles: Scoping Review of Life Cycle Assessments. J. Clean. Prod. 2023, 433, 139692. [Google Scholar] [CrossRef]

- Schulz, M.; Bey, N.; Niero, M.; Hauschild, M. Circular Economy Considerations in Choices of LCA Methodology: How to Handle EV Battery Repurposing? Procedia CIRP 2020, 90, 182–186. [Google Scholar] [CrossRef]

- Schulz-Mönninghoff, M.; Bey, N.; Nørregaard, P.U.; Niero, M. Integration of Energy Flow Modelling in Life Cycle Assessment of Electric Vehicle Battery Repurposing: Evaluation of Multi-Use Cases and Comparison of Circular Business Models. Resour. Conserv. Recycl. 2021, 174, 105773. [Google Scholar] [CrossRef]

- Kim, S.H.; Park, S.H.; Lim, S.R. Identification of Principal Factors for Low-Carbon Electric Vehicle Batteries by Using a Life Cycle Assessment Model-Based Sensitivity Analysis. Sustain. Energy Technol. Assess. 2024, 64, 103683. [Google Scholar] [CrossRef]

- Temporelli, A.; Carvalho, M.L.; Girardi, P. Life Cycle Assessment of Electric Vehicle Batteries: An Overview of Recent Literature. Energies 2020, 13, 2864. [Google Scholar] [CrossRef]

- Lai, X.; Chen, Q.; Tang, X.; Zhou, Y.; Gao, F.; Guo, Y.; Bhagat, R.; Zheng, Y. Critical Review of Life Cycle Assessment of Lithium-Ion Batteries for Electric Vehicles: A Lifespan Perspective. eTransportation 2022, 12, 100169. [Google Scholar] [CrossRef]

- Scrucca, F.; Presciutti, A.; Baldinelli, G.; Barberio, G.; Postrioti, L.; Karaca, C. Life Cycle Assessment of Li-Ion Batteries for Electric Vehicles: A Review Focused on the Production Phase Impact. J. Power Sources 2025, 639, 236703. [Google Scholar] [CrossRef]

- Burchart, D.; Przytuła, I. Review of Environmental Life Cycle Assessment for Fuel Cell Electric Vehicles in Road Transport. Energies 2025, 18, 1229. [Google Scholar] [CrossRef]

- Lavrador, R.B.; Teles, B.A.d.S. Life Cycle Assessment of Battery Electric Vehicles and Internal Combustion Vehicles Using Sugarcane Ethanol in Brazil: A Critical Review. Clean. Energy Syst. 2022, 2, 100008. [Google Scholar] [CrossRef]

- Wang, F.; Deng, Y.; Yuan, C. Life Cycle Assessment of Lithium Oxygen Battery for Electric Vehicles. J. Clean. Prod. 2020, 264, 121339. [Google Scholar] [CrossRef]

- Setyoko, A.T.; Nurcahyo, R.; Sumaedi, S. Life Cycle Assessment of Electric Vehicle Batteries: Review and Critical Appraisal. In Proceedings of the E3S Web of Conferences, Newcastle, UK, 18 December 2023; EDP Sciences: Les Ulis, France, 2023; Volume 465. [Google Scholar]

- Marmiroli, B.; Messagie, M.; Dotelli, G.; Van Mierlo, J. Electricity Generation in LCA of Electric Vehicles: A Review. Appl. Sci. 2018, 8, 1384. [Google Scholar] [CrossRef]

- Nordelöf, A.; Messagie, M.; Tillman, A.M.; Ljunggren Söderman, M.; Van Mierlo, J. Environmental Impacts of Hybrid, Plug-in Hybrid, and Battery Electric Vehicles—What Can We Learn from Life Cycle Assessment? Int. J. Life Cycle Assess. 2014, 19, 1866–1890. [Google Scholar] [CrossRef]

- Vilaça, M.; Santos, G.; Oliveira, M.S.A.; Coelho, M.C.; Correia, G.H.A. Life Cycle Assessment of Shared and Private Use of Automated and Electric Vehicles on Interurban Mobility. Appl. Energy 2022, 310, 118589. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M.; Afshar, S. Eco-Efficiency of Electric Vehicles in the United States: A Life Cycle Assessment Based Principal Component Analysis. J. Clean. Prod. 2019, 212, 515–526. [Google Scholar] [CrossRef]

- Ioakimidis, C.S.; Murillo-Marrodán, A.; Bagheri, A.; Thomas, D.; Genikomsakis, K.N. Life Cycle Assessment of a Lithium Iron Phosphate (LFP) Electric Vehicle Battery in Second Life Application Scenarios. Sustainability 2019, 11, 2527. [Google Scholar] [CrossRef]

- Navas-Anguita, Z.; García-Gusano, D.; Iribarren, D. Prospective Life Cycle Assessment of the Increased Electricity Demand Associated with the Penetration of Electric Vehicles in Spain. Energies 2018, 11, 1185. [Google Scholar] [CrossRef]

- Miao, Y.; Qiu, Z.; Zhang, M.; He, B.; Zhang, X.; Li, M. Integrated Artificial Intelligence and Life Cycle Assessment to Predict Environmental and Economic Impacts for Natural Gas Hybrid Electric Vehicle with Multi-Dimension. J. Phys. Conf. Ser. 2022, 2198, 012016. [Google Scholar] [CrossRef]

- Evtimov, I.; Ivanov, R.; Stanchev, H.; Kadikyanov, G.; Staneva, G. Life Cycle Assessment of Fuel Cells Electric Vehicles. Transp. Probl. 2020, 15, 153–166. [Google Scholar] [CrossRef]

- Olindo, R.; Schmitt, N.; Vogtländer, J. Life Cycle Assessments on Battery Electric Vehicles and Electrolytic Hydrogen: The Need for Calculation Rules and Better Databases on Electricity. Sustainability 2021, 13, 5250. [Google Scholar] [CrossRef]

- Nimesh, V.; Kumari, R.; Soni, N.; Goswami, A.K.; Mahendra Reddy, V. Implication Viability Assessment of Electric Vehicles for Different Regions: An Approach of Life Cycle Assessment Considering Exergy Analysis and Battery Degradation. Energy Convers. Manag. 2021, 237, 114104. [Google Scholar] [CrossRef]

- Burchart-Korol, D.; Jursova, S.; Folęga, P.; Korol, J.; Pustejovska, P.; Blaut, A. Environmental Life Cycle Assessment of Electric Vehicles in Poland and the Czech Republic. J. Clean. Prod. 2018, 202, 476–487. [Google Scholar] [CrossRef]

- Messagie, M.; Boureima, F.; Matheys, J.; Sergeant, N.; Timmermans, J.M.; Macharis, C.; Van Mierlo, J. Environmental Performance of a Battery Electric Vehicle: A Descriptive Life Cycle Assessment Approach. World Electr. Veh. J. 2010, 4, 782–786. [Google Scholar] [CrossRef]

- Bartolozzi, I.; Rizzi, F.; Frey, M. Comparison between Hydrogen and Electric Vehicles by Life Cycle Assessment: A Case Study in Tuscany, Italy. Appl. Energy 2013, 101, 103–111. [Google Scholar] [CrossRef]

- Rovelli, D.; Cornago, S.; Scaglia, P.; Brondi, C.; Low, J.S.C.; Ramakrishna, S.; Dotelli, G. Quantification of Non-Linearities in the Consequential Life Cycle Assessment of the Use Phase of Battery Electric Vehicles. Front. Sustain. 2021, 2, 631268. [Google Scholar] [CrossRef]

- Hawkins, T.R.; Singh, B.; Majeau-Bettez, G.; Strømman, A.H. Comparative Environmental Life Cycle Assessment of Conventional and Electric Vehicles. J. Ind. Ecol. 2013, 17, 53–64. [Google Scholar] [CrossRef]

- Joshi, A.; Sharma, R.; Baral, B. Comparative Life Cycle Assessment of Conventional Combustion Engine Vehicle, Battery Electric Vehicle and Fuel Cell Electric Vehicle in Nepal. J. Clean. Prod. 2022, 379, 134407. [Google Scholar] [CrossRef]

- Unocc Godoy, O.A.; Durand Angeles, B.S.; Silva, F.; Gómez Montoya, J.P. Comparative Life Cycle Analysis for the Carbon Footprint of a Gasoline Vehicle and an Electric Vehicle. In Proceedings of the LACCEI International Multi-Conference for Engineering, Education and Technology, San Jose, Costa Rica, 17–19 July 2024; Latin American and Caribbean Consortium of Engineering Institutions: Boca Raton, FL, USA, 2024. [Google Scholar]

- Shang, H.; Sun, Y.; Huang, D.; Meng, F. Life Cycle Assessment of Atmospheric Environmental Impact on the Large-Scale Promotion of Electric Vehicles in China. Resour. Environ. Sustain. 2024, 15, 100148. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Q.; Gao, L.; Xing, Y.; Chen, Y.; Zhang, S. The Life Cycle Assessment and Scenario Simulation Prediction of Intelligent Electric Vehicles. Energy Rep. 2024, 12, 6046–6071. [Google Scholar] [CrossRef]

- Li, Y.; Ha, N.; Li, T. Research on Carbon Emissions of Electric Vehicles throughout the Life Cycle Assessment Taking into Vehicle Weight and Grid Mix Composition. Energies 2019, 12, 3612. [Google Scholar] [CrossRef]

- Ahmadzadeh, O.; Rodriguez, R.; Getz, J.; Panneerselvam, S.; Soudbakhsh, D. The Impact of Lightweighting and Battery Technologies on the Sustainability of Electric Vehicles: A Comprehensive Life Cycle Assessment. Environ. Impact Assess. Rev. 2025, 110, 107668. [Google Scholar] [CrossRef]

- Huo, H.; Cai, H.; Zhang, Q.; Liu, F.; He, K. Life-Cycle Assessment of Greenhouse Gas and Air Emissions of Electric Vehicles: A Comparison between China and the U.S. Atmos. Environ. 2015, 108, 107–116. [Google Scholar] [CrossRef]

- Kawamoto, R.; Mochizuki, H.; Moriguchi, Y.; Nakano, T.; Motohashi, M.; Sakai, Y.; Inaba, A. Estimation of CO2 Emissions of Internal Combustion Engine Vehicle and Battery Electric Vehicle Using LCA. Sustainability 2019, 11, 2690. [Google Scholar] [CrossRef]

- Zheng, G.; Peng, Z. Life Cycle Assessment (LCA) of BEV’s Environmental Benefits for Meeting the Challenge of ICExit (Internal Combustion Engine Exit). Energy Rep. 2021, 7, 1203–1216. [Google Scholar] [CrossRef]

- Xia, X.; Li, P. A Review of the Life Cycle Assessment of Electric Vehicles: Considering the Influence of Batteries. Sci. Total Environ. 2022, 814, 152870. [Google Scholar] [CrossRef]

- Horesh, N.; Zhou, Y.; Quinn, J. Home Charging for All: Techno-Economic and Life Cycle Assessment of Multi-Unit Dwelling Electric Vehicle Charging Hubs. J. Clean. Prod. 2023, 383, 135551. [Google Scholar] [CrossRef]

- Shafique, M.; Luo, X. Environmental Life Cycle Assessment of Battery Electric Vehicles from the Current and Future Energy Mix Perspective. J. Environ. Manag. 2022, 303, 114050. [Google Scholar] [CrossRef]

- Song, X.; Deng, C.; Shen, P.; Qian, Y.; Xie, M. Environmental Impact and Carbon Footprint Analysis of Pure Electric Vehicles Based on Life Cycle Assessment. Res. Environ. Sci. 2023, 36, 2179–2188. [Google Scholar] [CrossRef]

- Feng, T.; Guo, W.; Li, Q.; Meng, Z.; Liang, W. Life Cycle Assessment of Lithium Nickel Cobalt Manganese Oxide Batteries and Lithium Iron Phosphate Batteries for Electric Vehicles in China. J. Energy Storage 2022, 52, 104767. [Google Scholar] [CrossRef]

- Marques, P.; Garcia, R.; Kulay, L.; Freire, F. Comparative Life Cycle Assessment of Lithium-Ion Batteries for Electric Vehicles Addressing Capacity Fade. J. Clean. Prod. 2019, 229, 787–794. [Google Scholar] [CrossRef]

- Benveniste, G.; Sánchez, A.; Rallo, H.; Corchero, C.; Amante, B. Comparative Life Cycle Assessment of Li-Sulphur and Li-Ion Batteries for Electric Vehicles. Resour. Conserv. Recycl. Adv. 2022, 15, 200086. [Google Scholar] [CrossRef]

- Degen, F.; Mitterfellner, M.; Kampker, A. Comparative Life Cycle Assessment of Lithium-Ion, Sodium-Ion, and Solid-State Battery Cells for Electric Vehicles. J. Ind. Ecol. 2025, 29, 113–128. [Google Scholar] [CrossRef]

- Wang, F.; Deng, Y.; Yuan, C. Comparative Life Cycle Assessment of Silicon Nanowire and Silicon Nanotube Based Lithium Ion Batteries for Electric Vehicles. Procedia CIRP 2019, 80, 310–315. [Google Scholar] [CrossRef]

- Chen, Q.; Lai, X.; Gu, H.; Tang, X.; Gao, F.; Han, X.; Zheng, Y. Investigating Carbon Footprint and Carbon Reduction Potential Using a Cradle-to-Cradle LCA Approach on Lithium-Ion Batteries for Electric Vehicles in China. J. Clean. Prod. 2022, 369, 133342. [Google Scholar] [CrossRef]

- Wu, W.; Cong, N.; Zhang, X.; Yue, Q.; Zhang, M. Life Cycle Assessment and Carbon Reduction Potential Prediction of Electric Vehicles Batteries. Sci. Total Environ. 2023, 903, 166620. [Google Scholar] [CrossRef]

- Yin, R.-S.; Yang, Y.-P.; Yang, Y.; Zhi-Lin, C. Life Cycle Assessment of the Lithium Titanate Batteries Used for Electric Vehicles. China Environ. Sci. 2018, 38, 2371–2381. [Google Scholar]

- De Sio, P.; Gaito, M.; Esperto, V.; Cozzolino, E.; Astarita, A.; Tucci, F. Life Cycle Assessment of a Composite Prototype Battery Enclosure for Electric Vehicles. Sustainability 2025, 17, 1579. [Google Scholar] [CrossRef]

- Shet, K.H.N.; Moholkar, V.S. Comparative Life Cycle Analysis of Hydrogen Fuel Cell Electric Vehicles and Battery Electric Vehicles: An Indian Perspective. Int. J. Hydrogen Energy 2025, 103, 729–739. [Google Scholar] [CrossRef]

- Ankathi, S.K.; Bouchard, J.; He, X. Beyond Tailpipe Emissions: Life Cycle Assessment Unravels Battery’s Carbon Footprint in Electric Vehicles. World Electr. Veh. J. 2024, 15, 245. [Google Scholar] [CrossRef]

- Konrad, J.; Bernt, A.O.; Hofmann, P. Life Cycle Assessment of MHP (Mobile Hydrogen Powersupply), an off-Grid System to Charge Battery Electric Vehicles. Int. J. Life Cycle Assess. 2023, 28, 304–319. [Google Scholar] [CrossRef]

- Deng, Y.; Li, J.; Li, T.; Gao, X.; Yuan, C. Life Cycle Assessment of Lithium Sulfur Battery for Electric Vehicles. J. Power Sources 2017, 343, 284–295. [Google Scholar] [CrossRef]

- Deng, Y.; Li, J.; Li, T.; Zhang, J.; Yang, F.; Yuan, C. Life Cycle Assessment of High Capacity Molybdenum Disulfide Lithium-Ion Battery for Electric Vehicles. Energy 2017, 123, 77–88. [Google Scholar] [CrossRef]

- Fan, T.; Liang, W.; Guo, W.; Feng, T.; Li, W. Life Cycle Assessment of Electric Vehicles’ Lithium-Ion Batteries Reused for Energy Storage. J. Energy Storage 2023, 71, 108126. [Google Scholar] [CrossRef]

- Pinto-Bautista, S.; Baumann, M.; Weil, M. Prospective Life Cycle Assessment of an Electric Vehicle Equipped with a Model Magnesium Battery. Energy Sustain. Soc. 2024, 14, 44. [Google Scholar] [CrossRef]

- Lavigne Philippot, M.; Costa, D.; Cardellini, G.; De Sutter, L.; Smekens, J.; Van Mierlo, J.; Messagie, M. Life Cycle Assessment of a Lithium-Ion Battery with a Silicon Anode for Electric Vehicles. J. Energy Storage 2023, 60, 106635. [Google Scholar] [CrossRef]

- Yang, H.; Hu, X.; Zhang, G.; Dou, B.; Cui, G.; Yang, Q.; Yan, X. Life Cycle Assessment of Secondary Use and Physical Recycling of Lithium-Ion Batteries Retired from Electric Vehicles in China. Waste Manag. 2024, 178, 168–175. [Google Scholar] [CrossRef]

- Accardo, A.; Garofalo, A.; Dotelli, G.; Spessa, E. Prospective LCA of Next-Generation Cells for Electric Vehicle Applications. IEEE Access 2024, 12, 19584–19597. [Google Scholar] [CrossRef]

- Zackrisson, M.; Avellán, L.; Orlenius, J. Life Cycle Assessment of Lithium-Ion Batteries for Plug-in Hybrid Electric Vehicles-Critical Issues. J. Clean. Prod. 2010, 18, 1519–1529. [Google Scholar] [CrossRef]

- Philippot, M.; Smekens, J.; van Mierlo, J.; Messagie, M. Life Cycle Assessment of Silicon Alloy-Based Lithium-Ion Battery for Electric Vehicles. In WIT Transactions on the Built Environment; WITPress: Billerica, MA, USA, 2019; Volume 182, pp. 129–139. [Google Scholar]

- Gottardo, G.; Basso Peressut, A.; Colnago, S.; Latorrata, S.; Piegari, L.; Dotelli, G. LCA of a Proton Exchange Membrane Fuel Cell Electric Vehicle Considering Different Power System Architectures. Energies 2023, 16, 6782. [Google Scholar] [CrossRef]

- Cusenza, M.A.; Guarino, F.; Longo, S.; Mistretta, M.; Cellura, M. Reuse of Electric Vehicle Batteries in Buildings: An Integrated Load Match Analysis and Life Cycle Assessment Approach. Energy Build. 2019, 186, 339–354. [Google Scholar] [CrossRef]

- Nansai, K.; Tohno, S.; Kono, M.; Kasahara, M.; Moriguchi, Y. Life-Cycle Analysis of Charging Infrastructure for Electric Vehicles. Appl. Energy 2001, 70, 251–265. [Google Scholar] [CrossRef]

- Pourrahmani, H.; Xu, C.; Van Herle, J. The Thermodynamic and Life-Cycle Assessments of a Novel Charging Station for Electric Vehicles in Dynamic and Steady-State Conditions. Sci. Rep. 2023, 13, 11159. [Google Scholar] [CrossRef]

- Baumann, M.; Salzinger, M.; Remppis, S.; Schober, B.; Held, M.; Graf, R. Reducing the Environmental Impacts of Electric Vehicles and Electricity Supply: How Hourly Defined Life Cycle Assessment and Smart Charging Can Contribute. World Electr. Veh. J. 2019, 10, 13. [Google Scholar] [CrossRef]

- Kabus, M.; Nolting, L.; Mortimer, B.J.; Koj, J.C.; Kuckshinrichs, W.; De Doncker, R.W.; Praktiknjo, A. Environmental Impacts of Charging Concepts for Battery Electric Vehicles: A Comparison of on-Board and off-Board Charging Systems Based on a Life Cycle Assessment. Energies 2020, 13, 6508. [Google Scholar] [CrossRef]

- Dunn, J.; Ritter, K.; Velázquez, J.M.; Kendall, A. Should High-Cobalt EV Batteries Be Repurposed? Using LCA to Assess the Impact of Technological Innovation on the Waste Hierarchy. J. Ind. Ecol. 2023, 27, 1277–1290. [Google Scholar] [CrossRef]

- Wilson, N.; Meiklejohn, E.; Overton, B.; Robinson, F.; Farjana, S.H.; Li, W.; Staines, J. A Physical Allocation Method for Comparative Life Cycle Assessment: A Case Study of Repurposing Australian Electric Vehicle Batteries. Resour. Conserv. Recycl. 2021, 174, 105759. [Google Scholar] [CrossRef]

- Tao, Y.; You, F. Comparative Life Cycle Assessment of Three Recycling Approaches for Electric Vehicle Lithium-Ion Battery after Cascaded Use. Chem. Eng. Trans. 2020, 81, 1123–1128. [Google Scholar] [CrossRef]

- Mafrici, S.; Accardo, A.; Spessa, E.; Tenconi, A. A Novel Scenario Analysis Framework for the Life Cycle Assessment of Permanent Magnet Synchronous Motors for Electric Vehicles. IEEE Access 2024, 12, 156837–156848. [Google Scholar] [CrossRef]

- Xia, W.; Luo, C.; Cai, L.; Yan, J.; Zhou, X.; Zhang, Y. Environmental Impact Study of the Sightseeing Electric Vehicle Supply Chain Based on the B2C E-Commerce Model and LCA Framework. Energy Inform. 2024, 7, 138. [Google Scholar] [CrossRef]

- Gu, Y.; Tao, R.; Yuan, C.; Zhang, H.C.; Hauschild, M. A Cradle-to-Grave Life-Cycle-Assessment of Dry-Processed Li-Ion Batteries for Electric Vehicles. CIRP Ann. 2025, 74, 73–76. [Google Scholar] [CrossRef]

- Rosenberg, S.; Kurz, L.; Huster, S.; Wehrstein, S.; Kiemel, S.; Schultmann, F.; Reichert, F.; Wörner, R.; Glöser-Chahoud, S. Combining Dynamic Material Flow Analysis and Life Cycle Assessment to Evaluate Environmental Benefits of Recycling—A Case Study for Direct and Hydrometallurgical Closed-Loop Recycling of Electric Vehicle Battery Systems. Resour. Conserv. Recycl. 2023, 198, 107145. [Google Scholar] [CrossRef]

- Illner, M.; Thüsing, K.; Salles, A.; Trettenhann, A.; Albrecht, S.; Winkler, M. Switchable Heat Pipes for Eco-Friendly Battery Cooling in Electric Vehicles: A Life Cycle Assessment. Energies 2024, 17, 938. [Google Scholar] [CrossRef]

- Chen, Q.; Lai, X.; Chen, J.; Huang, Y.; Guo, Y.; Wang, Y.; Han, X.; Lu, L.; Sun, Y.; Ouyang, M.; et al. A Critical Comparison of LCA Calculation Models for the Power Lithium-Ion Battery in Electric Vehicles during Use-Phase. Energy 2024, 296, 131175. [Google Scholar] [CrossRef]

- Lai, X.; Chen, J.; Chen, Q.; Tang, B.; Zheng, Y.; Cheng, E. Investigating the Impact of Electric Vehicle Range on Use-Phase Carbon Footprint: A Life Cycle Assessment Approach. Process Saf. Environ. Prot. 2025, 197, 107044. [Google Scholar] [CrossRef]

- Raugei, M.; Winfield, P. Prospective LCA of the Production and EoL Recycling of a Novel Type of Li-Ion Battery for Electric Vehicles. J. Clean. Prod. 2019, 213, 926–932. [Google Scholar] [CrossRef]

- Held, M.; Schücking, M. Utilization Effects on Battery Electric Vehicle Life-Cycle Assessment: A Case-Driven Analysis of Two Commercial Mobility Applications. Transp. Res. D Transp. Environ. 2019, 75, 87–105. [Google Scholar] [CrossRef]

- Monticelli, M.; Accardo, A.; Bernagozzi, M.; Spessa, E. A Comparative Life Cycle Analysis of an Active and a Passive Battery Thermal Management System for an Electric Vehicle: A Cold Plate and a Loop Heat Pipe. World Electr. Veh. J. 2025, 16, 100. [Google Scholar] [CrossRef]

- Shen, K.; Zhai, Q.; Gu, Y.; Wang, W.; Cao, H.; Hauschild, M.; Yuan, C. Life Cycle Assessment of Lithium Ion Battery from Water-Based Manufacturing for Electric Vehicles. Resour. Conserv. Recycl. 2023, 198, 107152. [Google Scholar] [CrossRef]

- Wong, E.Y.C.; Ho, D.C.K.; So, S.; Tsang, C.W.; Chan, E.M.H. Life Cycle Assessment of Electric Vehicles and Hydrogen Fuel Cell Vehicles Using the Greet Model—A Comparative Study. Sustainability 2021, 13, 4872. [Google Scholar] [CrossRef]

| Vehicle/Battery Type | GHG/CO2 Emissions | Life Cycle Stage | Reference |

|---|---|---|---|

| Li-ion (LIB) | 91.21 kg CO2-eq per kWh | Production | Chen et al. [62] |

| 154.1 kg CO2-eq per kWh | Use | ||

| Lithium-ion LIB | 105 kg CO2-eq per kWh | Production | Wu et al. [63] |

| Lithium-ion (LIB) | 58–92 kg CO2-eq per kWh | Production | Degen et al. [60] |

| Sodium-ion (SIB) | 75–87 kg CO2-eq per kWh | Production | |

| Solid-state (SSB) | 88–130 kg CO2-eq per kWh | Production | |

| LTO EV battery | 1860 kg CO2-eq/kWh | Full life cycle | Yin et al. [64] |

| Prototype composite battery | 1323.9 kg CO2 per battery | Production | De Sio et al. [65] |

| Li–O2 EV battery | 149 g CO2-eq/km | Full life cycle | Wang et al. [27] |

| FCEV (green hydrogen) | 105 g CO2/km | Use phase | Shet K. et al. [66] |

| Various batteries | 10–394 kg CO2-eq/kWh | Production | Ankathi et al. [67] |

| Hydrogen systems | 0.40–1.58 kg CO2-eq/kWh-el | Production and use | Konrad et al. [68] |

| Li-S (next-gen EV) | 158 g CO2-eq/km | Life cycle (use and production) | Deng et al. [69] |

| Battery Chemistry | LCA Approach | Reference |

|---|---|---|

| Lithium-ion batteries (LIBs) | cradle-to-cradle | Chen et al. [62] |

| Lithium-ion battery (NCM811) | cradle-to-cradle | Wu et al. [63] |

| Lithium-ion battery from water-based | cradle-to-grave | Shen et al. [97] |

| Lithium nickel cobalt manganese oxide (NCM) and lithium iron phosphate (LFP) | cradle-to-grave | Feng et al. [57] |

| Lithium iron phosphate (LiFePO4) and lithium manganese oxide (LiMn2O4) | cradle-to-grave | Marques et al. [58] |

| Li-Sulphur and Li-ion: Nickel-Cobalt-Manganese (NCM) | cradle-to-grave | Benveniste et al. [59] |

| Lithium-ion, sodium-ion, and solid-state battery (LIB, SIB, and SSB) | cradle-to-gate | Degen et al. [60] |

| Silicon Nanowire (NMC-SiNW) and Silicon Nanotube (NMC-SiNT) Based Lithium Ion Batteries | cradle-to-gate | Wang et al. [61] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zajemska, M.; Biniek-Poskart, A.; Skibiński, A.; Skrzyniarz, M.; Rzącki, J. A Narrative Review of Life Cycle Assessments of Electric Vehicles: Methodological Challenges and Global Implications. Energies 2025, 18, 5704. https://doi.org/10.3390/en18215704

Zajemska M, Biniek-Poskart A, Skibiński A, Skrzyniarz M, Rzącki J. A Narrative Review of Life Cycle Assessments of Electric Vehicles: Methodological Challenges and Global Implications. Energies. 2025; 18(21):5704. https://doi.org/10.3390/en18215704

Chicago/Turabian StyleZajemska, Monika, Anna Biniek-Poskart, Andrzej Skibiński, Magdalena Skrzyniarz, and Jakub Rzącki. 2025. "A Narrative Review of Life Cycle Assessments of Electric Vehicles: Methodological Challenges and Global Implications" Energies 18, no. 21: 5704. https://doi.org/10.3390/en18215704

APA StyleZajemska, M., Biniek-Poskart, A., Skibiński, A., Skrzyniarz, M., & Rzącki, J. (2025). A Narrative Review of Life Cycle Assessments of Electric Vehicles: Methodological Challenges and Global Implications. Energies, 18(21), 5704. https://doi.org/10.3390/en18215704