Abstract

The biogas sector is undergoing development as a result of the growing demand for renewable energy. Methane fermentation allows for the acquisition of energy that is universally usable, while also facilitating the neutralization of problematic waste. Sewage sludge generated as a result of a number of technological processes occurring during wastewater treatment requires appropriate management, and its volume increases every year. In this work, the task was to determine the suitability of sewage sludge for co-digestion with agricultural biomass. The research allowed for the determination of the positive impact of using sewage sludge for fermentation with agricultural biomass. The amount of biogas produced and the methane content were higher compared to the single-component fermentation of agricultural biomass. Mixed sludge had a particularly beneficial effect on fermentation. The largest amount of biogas was obtained from maize silage input and mixed sludge, i.e., 309 Ndm3·k−1 d.m. The methane content in this mixture reached a maximum level of 63%. The least productive was mixture no. 4, consisting exclusively of apple pomace. It produced the smallest amount of biogas (96 Ndm3/kg d.m.) and the process occurred with the greatest delay. The rate of the process was similar for mixtures 3 and 4 for an extended period. In the case of mixture no. 2, there was initially a slightly higher inhibition of the process, but by day 17, it had reached the biogas yield level of mixture 3. The amount of biogas produced for mixtures 2 and 3 was 119 and 133 Ndm3/kg d.m., respectively. From day 22 onwards, the process for all mixtures was coming to an end, with no significant biogas yields observed until the end of the study period. Such a high methane content increases the energy value of biogas, which in practice means a higher yield of electricity and heat from the same amount of feedstock, and thus lower unit costs of energy production. Co-digestion of maize silage, apple pomace, and beet pulp with sewage sludge can be a successful practice in biogas plants.

1. Introduction

An increasingly problematic situation is posing new challenges in the field of energy. The aim is to reduce the consumption of heat and electricity, as well as the costs of their production. Conventional energy carriers, fossil fuels, are becoming more expensive at an alarming rate, and continuous economic development creates an increasing demand for energy. Hence, there is a growing interest in alternative energy sources, such as biogas [1,2,3].

The literature emphasizes that treating sewage sludge as an energy substrate not only reduces the costs of waste disposal but also increases the economic efficiency of biogas installations by reducing the unit cost of energy [4].

The choice of subject for this article was prompted by the observed continuous increase in the amount of sewage sludge, but the authors are aware that mono-digestion is not profitable in every case. The possibility of co-fermentation of sewage sludge, e.g., with agricultural biomass, should be considered. Determining the suitability of the methane fermentation of substrates composed of sewage sludge and typical agricultural masses, such as maize silage and apple pomace, was the final goal of this study.

The adopted goal, work, and results obtained can be a guide for plants generating sewage sludge or agricultural biomass that are looking for a rational management method in the field of energy. In order to protect the environment, it is necessary to change the methods of obtaining energy. Conventional energy sources must be replaced by green ones. Biogas, one of the components of energy obtained from renewable sources, is obtained as a result of methane fermentation. It primarily contains methane and carbon dioxide. Its properties and the genesis of the process are well known and described in the available literature. The basic factors determining the efficiency of fermentation include the composition of the feed in the fermentation chamber, temperature, pH, the presence of selected groups of microorganisms, the fragmentation of substrates, and the presence of process inhibitors.

The resulting biogas can be used to produce electricity and heat. As a result of technological progress, the whole spectrum of possibilities for using this product for energy is at hand, from simple gas boilers to fuel cells [2].

Methane fermentation can be applied to a wide range of substrates of agricultural and non-agricultural origin. This paper’s literature review also includes information on the substrates used in the study, sewage sludge and agricultural biomass. Maize silage, apple pomace, and beet pulp are commonly used raw materials in agricultural biogas plants. This is due to the large area of agricultural land and the developed processing industry.

An upward trend in the amount of sewage sludge has been observed. As waste, they must be managed appropriately, which can be problematic. Most wastewater treatment plants stabilize wastewater in separate digesters [5].

As a result of this process, biogas and digestate are produced, which, after meeting the appropriate standards, can be used for natural purposes. Organic waste without structure, with significant moisture content, and a relatively neutral pH is most suitable for fermentation (Table 1).

Table 1.

Carbon dioxide, methane content, and biogas production from three basic groups of organic compounds.

Carbohydrates are the easiest to ferment, but the amount of biogas and methane content obtained from them is the lowest. Fats and proteins are characterized by higher biogas content; moreover, the CH4/CO2 ratio can reach up to twice as high as in the case of saccharides [6].

From a physicochemical point of view, biogas is a flammable mixture of gases containing mainly methane, carbon dioxide, and nitrogen (Table 2). It is the first of these chemical compounds that determines its calorific value, and thus its usefulness as a fuel [7].

The calorific value of methane is 35.7 MJ/m3. Hence, the energy value of biogas varies depending on the percentage of this chemical compound in the volume of gas in the range of 16–27 MJ/m3.

Biogas may also contain trace amounts of ammonia, siloxanes, hydrogen sulfide, and water vapor. The presence of these contaminants can cause difficulties in its use. The density of biogas is 1.20 kg/m3, which is approximately 20% lighter than air. The auto-ignition temperature is in the range of 650–750 °C, and the explosion limit in air is in the range of 6–12%. The critical pressure oscillates between 7.5–8.9 MPa, and the critical temperature is −82.5 °C [8].

Biogas obtained as a result of fermentation has many applications and, after appropriate treatment, can be used in various installations. It can be used to produce heat in adapted gas boilers and electricity in internal combustion engines or turbines. These processes are characterized by low efficiency, rarely exceeding 40%, therefore biogas should be used in the combustion process in cogeneration engines (CHP—Combined Heat and Power), which produce electricity and heat at the same time [1,9].

The electricity generated in CHP systems can be transferred entirely to the grid or used at the place of generation, so there is no problem with its management. The total efficiency of a CHP system depends on the electrical efficiency of the generator and the possibility of using the heat. The efficiency of electricity production generally increases with the size of the system, reaching 30–40%. In the case of thermal energy, this value is 45–60%; the total efficiency of the CHP system can reach up to 90% [10].

The use of heat obtained in a CHP system is a key challenge for achieving the financial efficiency of biogas plants. Part of the heat energy stream is used to heat the fermentation tanks, but there is a large reserve that needs to be optimally managed [10].

Heat can be used for the plant’s own heating purposes. Other uses include the following:

- sales to the local heating network, which requires the proximity of the heat receiver;

- (heat substation) from the biogas plant;

- investment in a belt dryer that converts the available heat energy into a stream of hot air, which is a medium for the processes of drying digestate or wood biomass [11].

- production of additional electricity, e.g., in the Organic Rankine Cycle (ORC) system, where the heat from cogeneration causes the evaporation of the organic medium, the resulting steam moves the turbine, as a result of which electricity is produced in the correlated generator [10].

- use of thermal energy in a trigeneration system—a CHP system connected to a cooling device, e.g., an absorption cooler powered by heat. Thanks to its use, it is possible to efficiently use heat during the winter season for heating, and in the summer season for air conditioning purposes [12,13].

After enrichment (removal of water, carbon dioxide, and hydrogen sulfide), biogas can be used as fuel for vehicles with an internal combustion engine.

This solution is very popular in Sweden and Switzerland. The gas must be odorized and compressed to a pressure of 200 bar. Biomethane is used in the same engines as natural gas, so it must meet similar quality requirements [10].

Biomethane can be used in liquid form (LBM—liquefied biomethane) or compressed (CBM—compressed biomethane) locally or transported to filling stations. To produce the liquid fraction of biomethane, the gas is cooled and stored at −160 °C. Cars can then be filled with LBM using cryogenic liquid pumps. The advantage of LBM is that the fuel density is higher than that of CBM, and there is the possibility of reducing the size of tanks. On the other hand, the fuel is less stable and requires great care when filling the tanks [10].

Purified biogas—biomethane can be injected into the gas network as a substitute for natural gas. This requires prior enrichment to 95% biomethane, odorization, quantity measurement, and compression. This use of biogas has many benefits. Gas can be supplied to a larger number of customers, improving the local stability of gas supply [9].

Biogas can be used in technological processes. An example is its use as a raw material for producing syngas in the steam reforming process. Like syngas obtained from natural gas reforming, it can be used to produce many chemicals after treatment. As in the previous cases, this use of biogas requires the removal of pollutants, primarily hydrogen sulfide [14,15].

The use of biogas for methanol production can be particularly attractive. The carbon dioxide present in it in this case is not an energy ballast, but a valuable raw material. The obtained methanol can be further processed, e.g., to obtain dimethyl ether (DME), which is used as a solvent, in the dehydration process [15].

Sludge generated by sewage treatment plants requires neutralization, i.e., processing that will change its composition and properties. This effect is achieved by biological, chemical, or thermal transformations. They must prepare the sludge for final management, so they are primarily aimed at reducing the volume, reducing the content of organic compounds, and hygienization [16,17,18].

Due to the limitations in the natural use of sewage sludge, thermal stabilization methods seem to be future-oriented and are becoming increasingly important. These include, m.in:

- Drying (transitional stage, preparing for final use)—combustion in a fluidized bed, in furnaces with a mechanical grate, in rotary furnaces;

- Co-incineration in power facilities and cement plants;

- Alternative methods: pyrolysis, gasification, wet oxidation.

The use of thermal stabilization is supported by knowledge of technical means, full mastery of the foundations of processes, and techniques for cleaning by-products. The suitability of sediments for thermal methods is determined by their chemical composition and fuel properties [4,19,20].

The concept of biomass is understood as “solid or liquid substances of plant or animal origin that are biodegradable, derived from products, waste and residues from agricultural and forestry production and the industry processing their products, and cereal grains that do not meet quality requirements” (Act of 20 February 2015 on Renewable Energy Sources, Journal of Laws No. 2015, item 478).

Agricultural biomass differs from substrates of municipal origin primarily due to its lower composition diversity and the lack of trace toxic substances. Four basic types of agricultural biomass can be assumed due to the source of formation:

- waste biomass from primary agricultural production (manure, slurry, straw);

- waste from the agri-food industry (beet pulp, whey, molasses, etc.)-organic waste from agriculture (food leftovers, kitchen waste from households);

- plant biomass from dedicated energy crops (mainly maize, grasses, cereals).

The use of agricultural biomass in the process of methane fermentation contributes to the reduction of greenhouse gas emissions (primarily methane), of which the agricultural industry is a significant emitter, and to the protection of groundwater. In economic terms, it increases the profitability of agricultural production and the processing industry [7,21].

Table 2.

Percentages of the main components of biogas.

Table 2.

Percentages of the main components of biogas.

| Biogas Component | Content (%) |

|---|---|

| Methane | 45–75 |

| Carbon dioxide | 25–50 |

| Nitrogen | 0–10 |

| Hydrogen sulfide | 0–3 |

| Oxygen | 0–2 |

| Hydrogen | 0–1 |

Source: [21].

Maize silage is one of the most commonly used plant-based substrates for biogas production. Maize as a crop is characterized by versatility of use, high yield, ease, low costs of cultivation, and simple harvesting technology. Varieties dedicated to cultivation for biogas plants are distinguished by a higher content of polysaccharides. The suitability of maize for fermentation is also determined by its ease of ensiling, enabling long-term storage, which is necessary to ensure a constant supply of biomass to the fermentation chamber [22].

As the dry matter content increases, the methane yield decreases, and the ratio of carbon to nitrogen increases. It is assumed that the optimal dry matter content is 28–35%. Such biomass goes through the ensiling process well and is the best raw material for biogas production. In plants that are excessively overgrown, the fiber undergoes lignification, thereby becoming more resistant to hydrolysis and microbial decomposition [23].

In practice, maize silage is most often fermented with other substrates, such as slurry, thanks to which the ratio of carbon to nitrogen is maintained at an appropriate level and the whole process is more stable [24,25].

Apple pomace is a by-product of juice pressing; it accounts for 20–25% of the processed fruit. They are a source of valuable ingredients: carbohydrates, proteins, pectin, fiber, fatty acids, and vitamins; hence, they are used as a feed additive. Due to its high water and carbohydrate content, pomace tends to spoil quickly, so its use in unprocessed form is possible only seasonally [26].

As a substrate for methane fermentation, it has high biogas potential, but it is not used as a monosubstrate. When used as a co-substrate, it increases the efficiency of the process and, at the same time, does not increase the necessary costs incurred for the purchase of another raw material. Fermented with more hydrated material, such as slurry or sewage sludge, they weigh down the mixture with dry matter. The year-round use of apple pomace enables it to undergo a process of preservation ensiling. Due to the high water content, the process can be problematic, but methods for stabilizing it have already been developed. Apple pomace silage is an attractive alternative to maize silage. It can help (in the event of a temporary lack of other material) to maintain the continuity of substrate supply to the fermentation chamber, which is extremely important for the stability of the entire fermentation process [26]

This study aimed to determine the suitability of sewage sludge for methane fermentation by analyzing the quantity and quality of biogas obtained from substrates composed of sewage sludge in co-fermentation with agricultural masses.

The scope of work included collecting samples of individual materials and delivering them to the laboratory of the Faculty of Production and Energy Engineering. After determining the dry matter content, the feedstocks were composed and subjected to 30-day anaerobic fermentation. During the process, the following parameters were recorded: the amount of biogas produced and its content of methane, oxygen, and carbon dioxide.

Batch mixes were made based on sewage sludge and agricultural biomass:

- Mix 1—Primary sludge + maize silage

- Mix 2—Excessive sludge + maize silage

- Mix 3—mixed sludge + maize silage

- Mix 4—Pre-sludge + Apple pomace

- Mix 5—Excess sludge + apple pomace

- Mix 6—Mixed sludge + apple pomace

Agricultural biomass was watered with raw sewage sludge. The dry matter content in the mixes was 10%, and fermentation was carried out under mesophilic conditions (approximately 38 °C).

2. Materials and Methods

Sewage sludge (preliminary, excessive, and mixed) was collected from the Sewage Treatment Plant in the city of Krosno at the turn of September and November. The municipal wastewater treatment plant has a capacity of 35,410 m3/day. It accepts sewage from Krosno and the surrounding municipalities. It is a mechanical and biological treatment plant that utilizes chemical precipitation for phosphorus removal and features a sewage sludge processing line. Following the modernizations implemented in recent years, the plant achieves excellent results in wastewater treatment and meets all environmental requirements. Table 3 and Table 4 present the basic properties of primary and excess sludge in the first half of 2018.

Table 3.

Basic properties of the primary sludge.

Table 4.

Basic properties of mixed sludge.

Maize silage and apple pomace come from the Group of Agricultural Producers Wielopolanka Sp. z o.o, a farm located in the Lesser Poland Voivodeship, about 40 km from the city of Tarnów, near the Dunajec River.

The prepared fermenters were placed in a temperature-controlled chamber. The samples were then subjected to static methane fermentation according to the DIM DIN 38,414 methodology. This involved introducing the substrates into the fermentation chambers, after which the process was conducted until the biogas production decreased by 95% relative to the maximum biogas yield. Each substrate was placed in three fermenters with a volume of 2 dm3, while a fourth fermenter, containing only the inoculum, served as a reference fermenter against which the performance of each of the three fermenters was compared. The mixes were placed in 4 fermenters.

The core of the farm is an industrial pig farm and a fattening facility for cattle of meat breeds. On arable land, the basic sowing is wheat and maize for silage and grain. Grassland is the source of roughage for cattle. The farm uses industrial feed and by-products of the food industry to feed pigs.

The tests were carried out in the biogas laboratory at the Faculty of Production and Energy Engineering of the University of Agriculture in Krakow in accordance with the German DIN 38,414 standard. The process was carried out under static conditions, after the raw materials were fed into the digesters once, and the results were read daily at the same time.

Static methane fermentation in 2 dm3 fermenters is considered the closest approximation to actual fermentation yields. Measuring the biogas volume at atmospheric pressure allows for comparison with results from researchers worldwide, as well as with actual fermentation, in terms of per kilogram of fermentable dry matter.

The following types of substrates were used for the research:

- Agricultural biomass:

- Corn silage

- Apple pomace—sewage sludge:

- Preliminary sewage sludge

- Excessive sewage sludge

- Mixed sewage sludge

First, samples of each substrate, weighing approximately 100 g each, were collected. In order to determine their humidity, the samples were placed in an Elkon 110 convection dryer with forced air circulation at a temperature of approximately 105 °C for 24 h. After this time, they were weighed again and placed in a dryer until no weight loss was recorded. The moisture content of the samples was calculated according to the formula:

where

- fraction moisture (%)-initial sample weight (g),-final sample weight (g).

Based on the calculated moisture content of individual fractions, the masses of the charges were determined according to the equation:

where

- mass of fraction (g),

- dry matter of the fermented fraction (g),

- moisture of the fraction (%).

The composed biomass batch mixes were hydrated with raw sewage sludge, inoculated with inoculum from the digestate of the agricultural biogas plant, and placed in digesters with a capacity of 2 dm3.

The inoculum was obtained from a typical agricultural biogas plant, as the idea of the study was for the tested material to serve as a supplement to the feedstock of an agricultural biogas plant. In other words, the sewage sludge was intended to complement the feedstock in agricultural biogas plants. The inoculum had a pH of 7.6 and a dry matter content of 4%, and its biological activity was high.

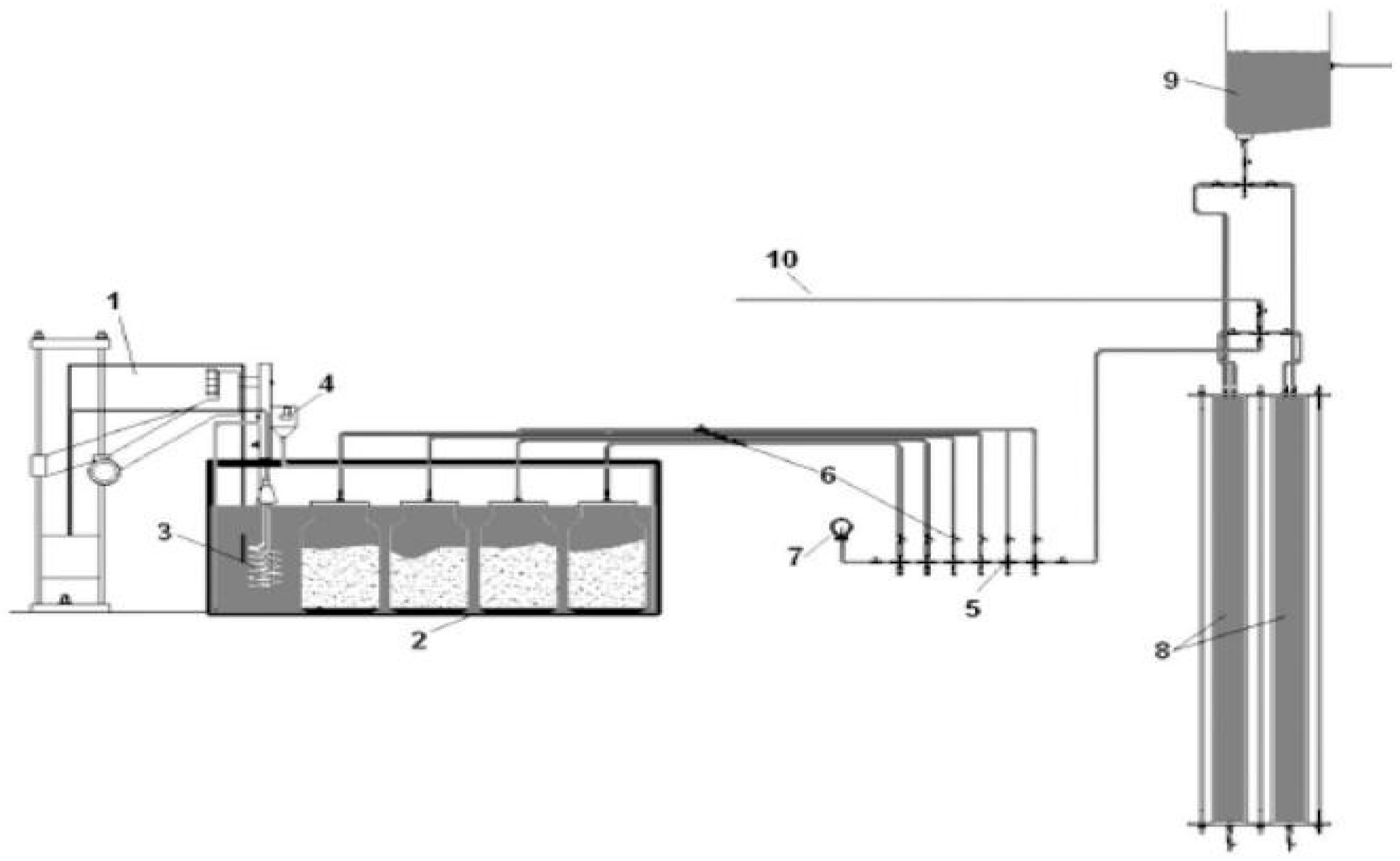

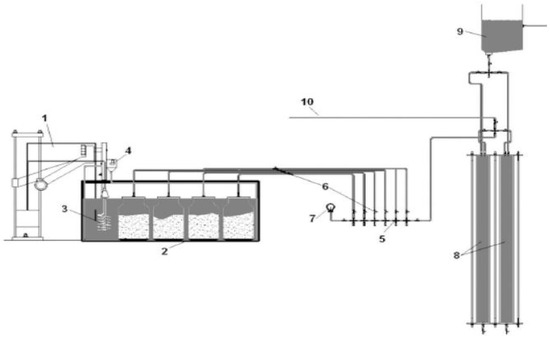

The prepared fermenters were placed in a tank with a controlled temperature environment. The test stand also included a dashboard and a measuring system. A detailed diagram of the test stand is shown in Figure 1.

Figure 1.

Diagram of the test bench. Source: [27].

To the base (1) located next to the tank (2) with the water jacket in which the digesters were located, devices responsible for maintaining constant temperature conditions of the environment were attached. The system was controlled by an electronic ESCO ES-20 thermostat (16A contactor) with an accuracy of 0.2 °C. When the temperature drop was greater than 0.1 °C, the 1500 W water heater (3) was switched on, and the Hanning DPO 25–205 water pump (4) was activated, responsible for the even distribution of heated water in the chamber. If the temperature exceeds by 0.1 °C from the set level, the heater will be automatically switched off and with a 30-s delay of the pump [28,29].

The switchboard (5) consists of serially connected manifolds with shut-off valves and a pressure gauge (6) for measuring pressure in individual measuring branches [29].

The system used to measure the volume (8) consisted of two water-filled columns with drain valves and a tank (9) topping up the fluid level in the columns. The measuring system was connected by a cable (10) to the switchboard and the biogas composition meter [28].

The gas produced during the methane fermentation process was collected in variable-volume tanks for each fermenter. A NANO SENS 60 m was used to measure the moisture content of the produced biogas and to determine its chemical composition. The process output parameters were recorded daily at the same time using the measurement system and automatically saved to a hard drive. Calibrations are carried out by an authorized service or calibration center, as the procedure requires specialized equipment (calibration gases and a pressure regulator). Calibrations are performed regularly, usually every 36 months, as well as in special situations, e.g., after sensor contamination by a high gas concentration.

The measurements were taken for 30 days, and the results were recorded on a computer in the laboratory. The first measurement was recorded on the day the load was placed in the fermenters. During the measurements, the samples were mixed; this treatment increased the intensity of the fermentation process. The temperature of the water in the reservoir was constant and amounted to 38 °C. In the final balance, the amount of biogas separated from the inoculum was deducted.

The batches were designed to load the chamber with a 10% dry matter load. This load ensures that every organic particle is washed with water, ensuring decomposition and avoiding biomass concentration gradients. The third columns of Table 5 and Table 6 provide the exact number of grams of dry matter used for each material.

Table 5.

Physicochemical properties of maize silage feedstocks.

Table 6.

Physicochemical properties of apple pomace feedstocks.

3. Results

The research carried out in the laboratory allowed us to determine the amount of biogas produced and its composition. The composed substrates based on agricultural biomass and sewage sludge were fermented for 30 days without changing the process parameters. The feedstock was inoculated with inoculum from the digestate of the agricultural biogas plant, and the biogas separated from it was deducted in the final balance. The properties of the tested fractions of sewage sludge and maize silage are presented in Table 5.

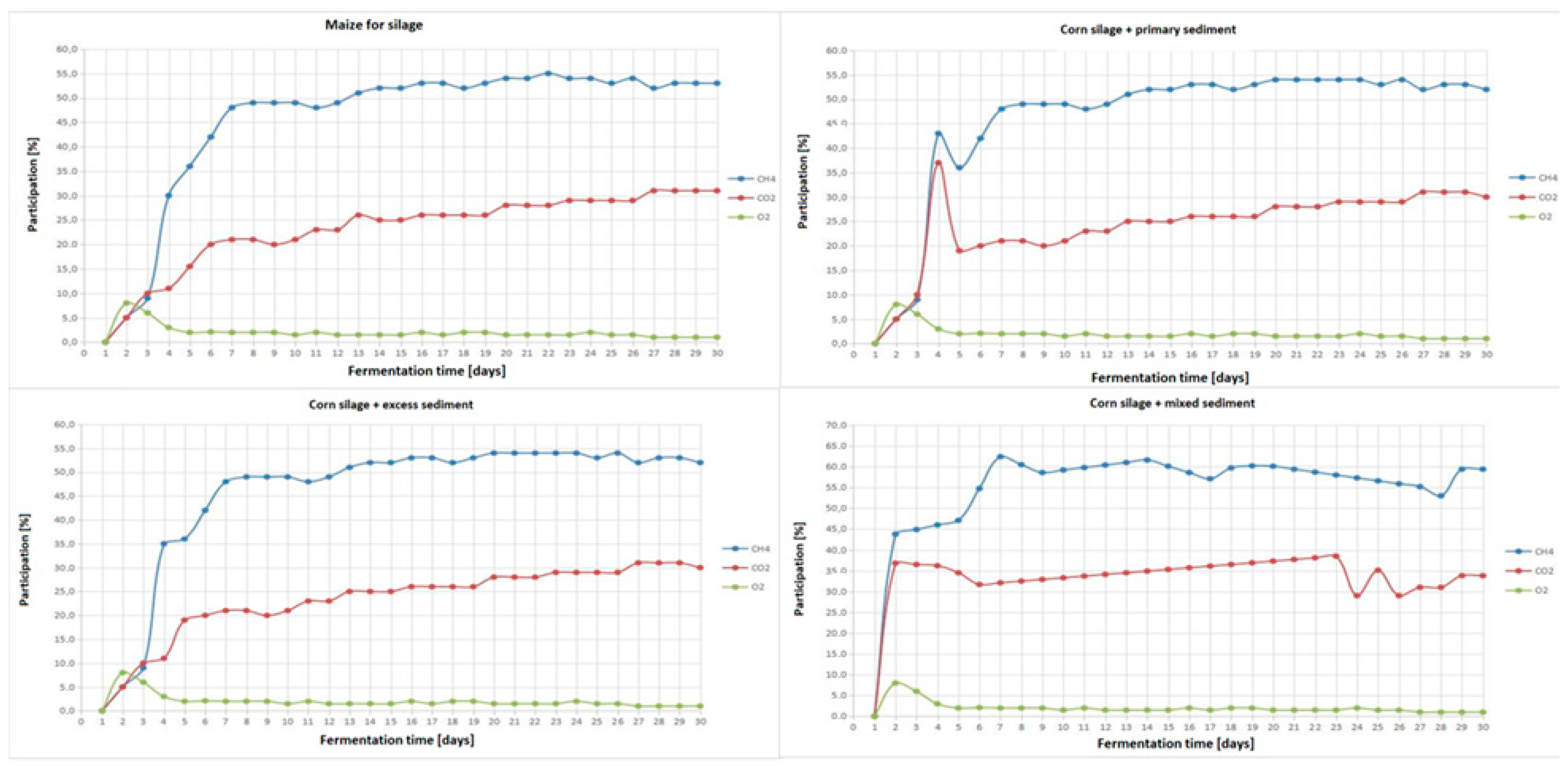

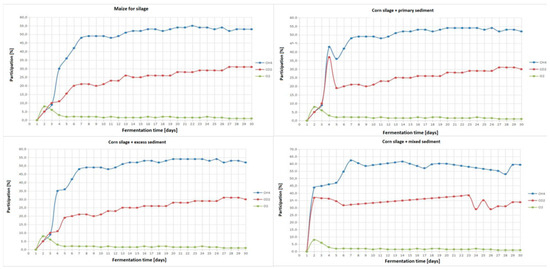

Figure 2 shows the methane, carbon dioxide, and oxygen content of biogas released from maize silage and sewage sludge. In the case of all feedstocks, from the second day onwards, there was a decrease in oxygen content and a gradual increase in the share of methane in biogas. During these two days, the deposit was colonized with methanogenic bacteria. In batch no. 4, from the first day, there was a very dynamic jump in the amount of methane up to 45% (day two). The methane content in the case of the 1, 2, 3 charge reached its highest level of about 55% and oscillated above 50% most of the time. Only input 4 was distinguished by achieving a higher share of methane content in biogas by almost 10% compared to the other feedstocks (on day 7). From day 6 onwards, its level practically did not go below 55%, which is the limit value for other charges. The oxygen content in the biogas from all feedstocks remained at a low, non-inhibiting level. The carbon dioxide present usually did not exceed 40%.

Figure 2.

Composition of the separated biogas from the studied substrates, composed of maize silage and sewage sludge.

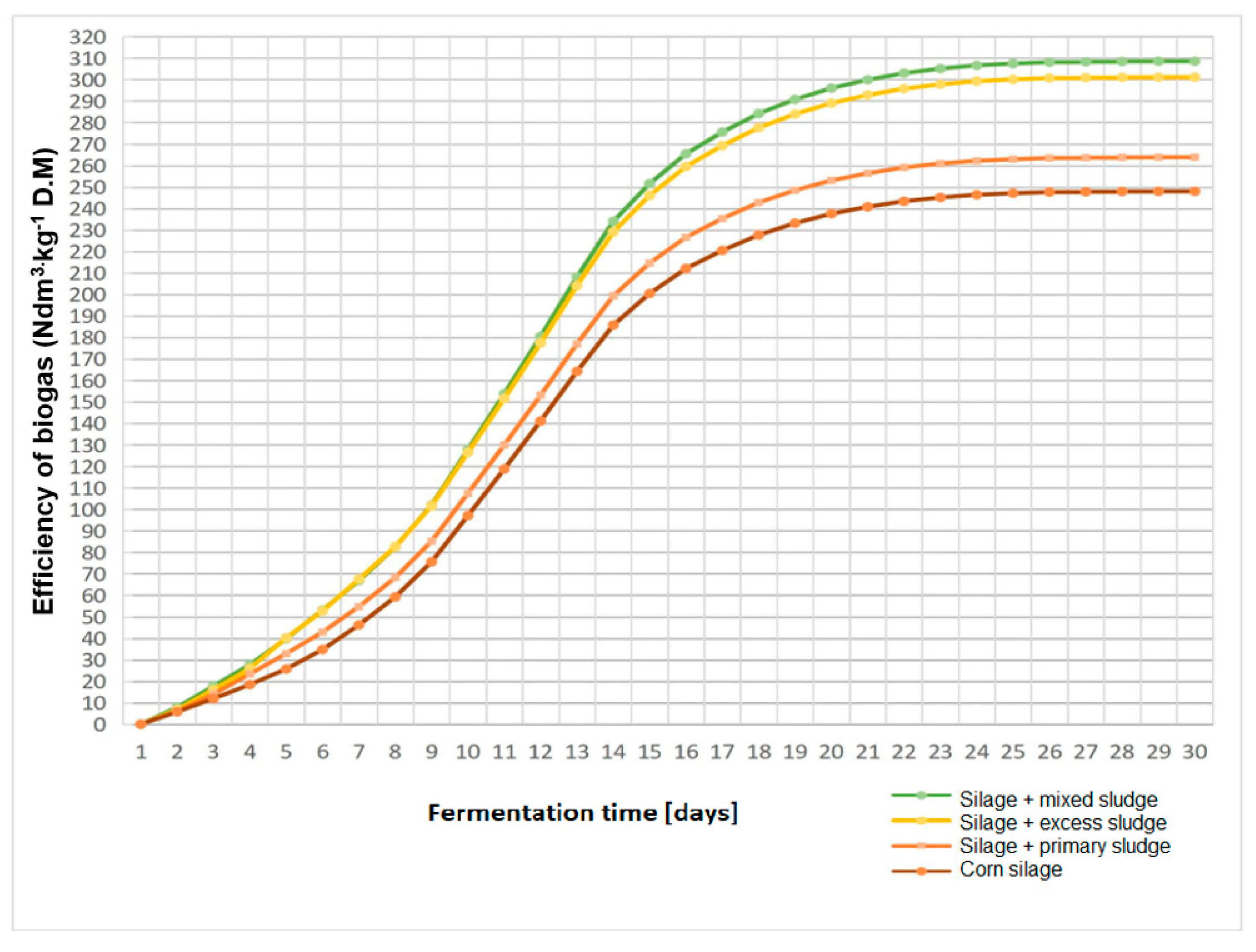

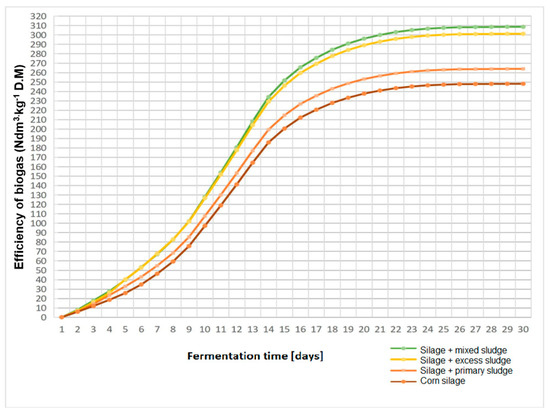

The analysis of the amount of biogas released in relation to dry matter is presented on a summary curve (Figure 3). In the initial phase, feedstock 3 and 4 fermented at the same rate until the 13th day of the process, when the feedstock from maize silage and mixed sludge began to achieve a higher biogas yield, reaching a maximum value of less than 310 Ndm3/kg of dry mass on day 26. This charge turned out to be the best fermenting.

Figure 3.

Summary curve of biogas separation from the studied substrates composed of maize silage and sewage sludge.

The biogas profitability of feed 3 stopped at 301 Ndm3/kg d.m. Fermentation of the maize silage feed (1) had a delay because the material was not hydrated, and the bacteria, not having a suitable environment, multiplied more slowly. Monofermented maize silage gave the lowest biogas yield of 248 Ndm3/kg d.m., consistent with the data available in the literature [6].

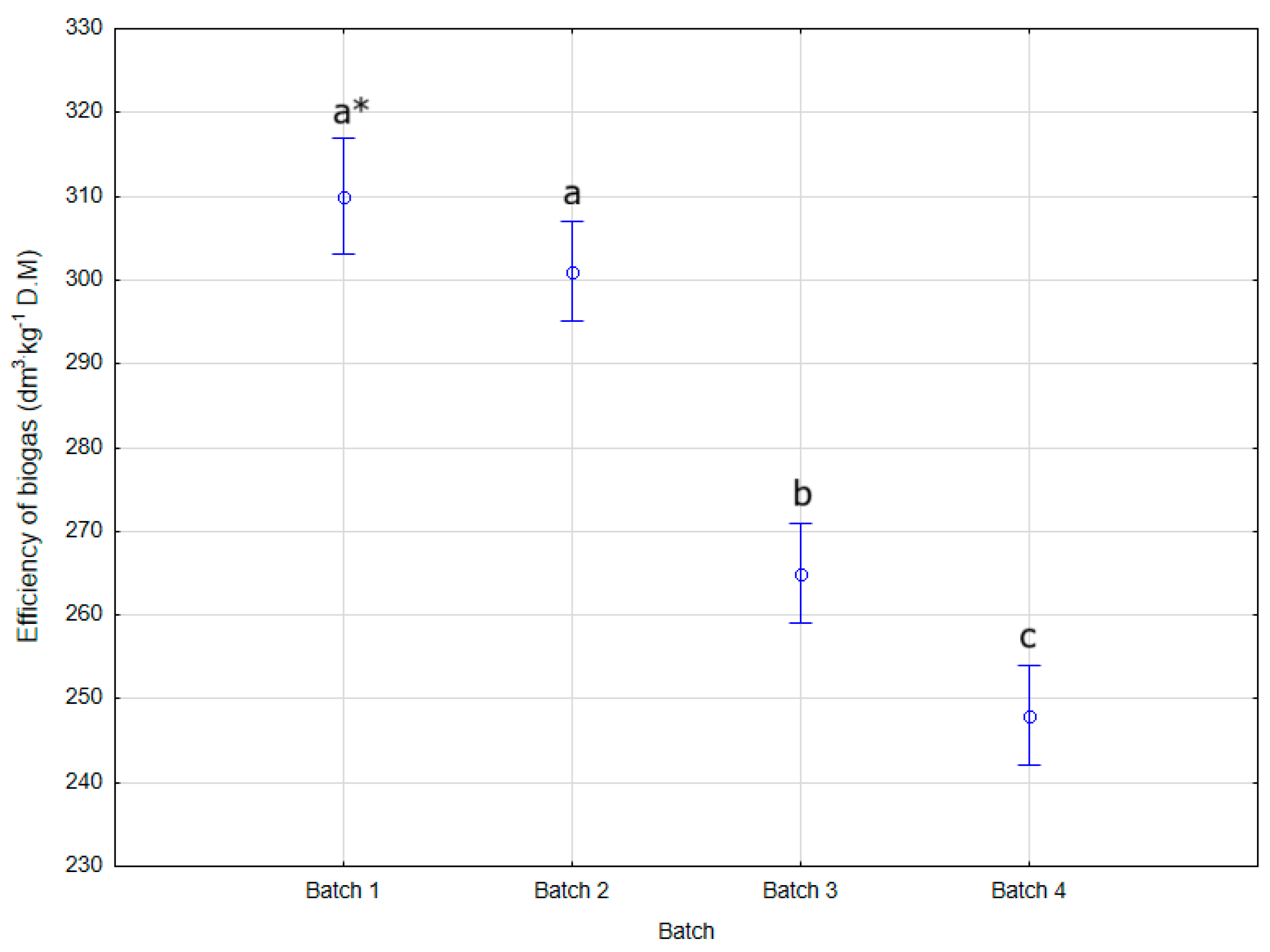

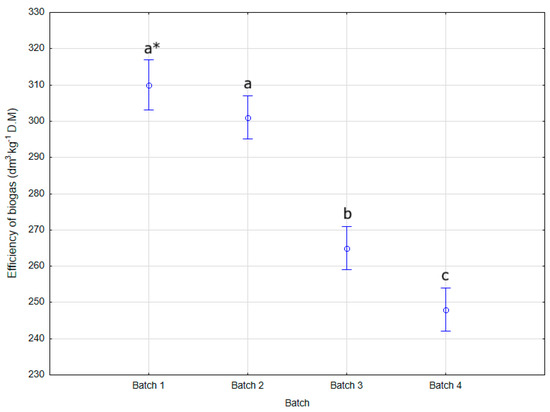

The obtained results were subjected to an analysis of variance (ANOVA). The significance of differences in mean values was determined using Duncan’s test (α ≤ 0.05), and the Statistica 13 software (TIBCO Software Inc., San Ramon, CA, USA) was used for the statistical analysis.

The ANOVA method used for estimating the variance of random factors begins with the construction of a sum of squares and cross-products (SSCP) matrix for independent variables. The remaining sums of squares and cross-products are then calculated for random effects relative to fixed effects, so that random effects are independent of fixed effects, as required by the mixed model.

Subsequently, the residual sums of squares and cross-products for each random factor are divided by their corresponding degrees of freedom to create coefficients that appear in the expected mean squares matrix. Non-zero off-diagonal coefficients in this matrix for random effects indicate confounding that should be taken into account when estimating the population variance for each factor. Based on the data on the wheat.sta file and treating both variety and plot as random effects, the expected mean squares matrix shows that these factors are at least somewhat confounded. The results sheet with the expected mean squares is shown below.

After obtaining a significant F-test value in ANOVA, it is necessary to determine which means differ significantly from each other. Duncan’s test was used to identify significant differences in biogas production intensity between various raw materials during methane fermentation.

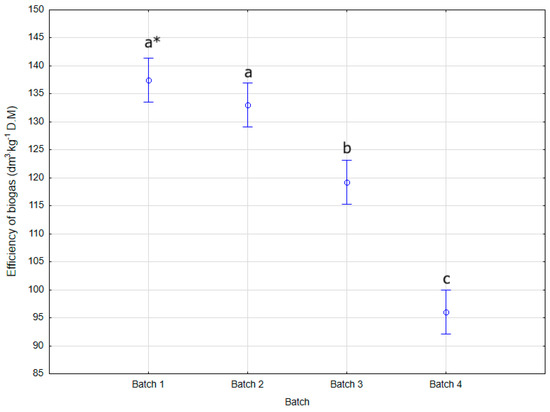

The Dukan test performed indicates that the biogas yield group was within the corn silage and silage feed fractions with the primary sludge system. Instead, corn silage mixed with sludge applied and combined with the appropriate biogas yield groups was distinguished (Figure 4).

Figure 4.

Average biogas yield based on the input composition of sewage sludge fraction mixed with agricultural sludge. * Significant differences in biogas release from different inputs determined by the Duncan test; (a,b,c)-homogeneous groups, alpha = 0.05000. Error: cross-group MS = 304.37, df = 10.000.

Batch No. 2 fermented almost proportionately, achieving a slightly higher result of 264 Ndm3/kg of dry mass. The amount of biogas produced in all feedstocks increased most intensively between the 9th and 16th day of the process, and from the 24th day onwards, the process was stopped.

Table 6 illustrates the properties of composed apple pomace and sewage sludge feedstocks. The initial sludge was characterized by the lowest dry matter content (2.5%). The moisture content of the apple pomace samples was about 90%.

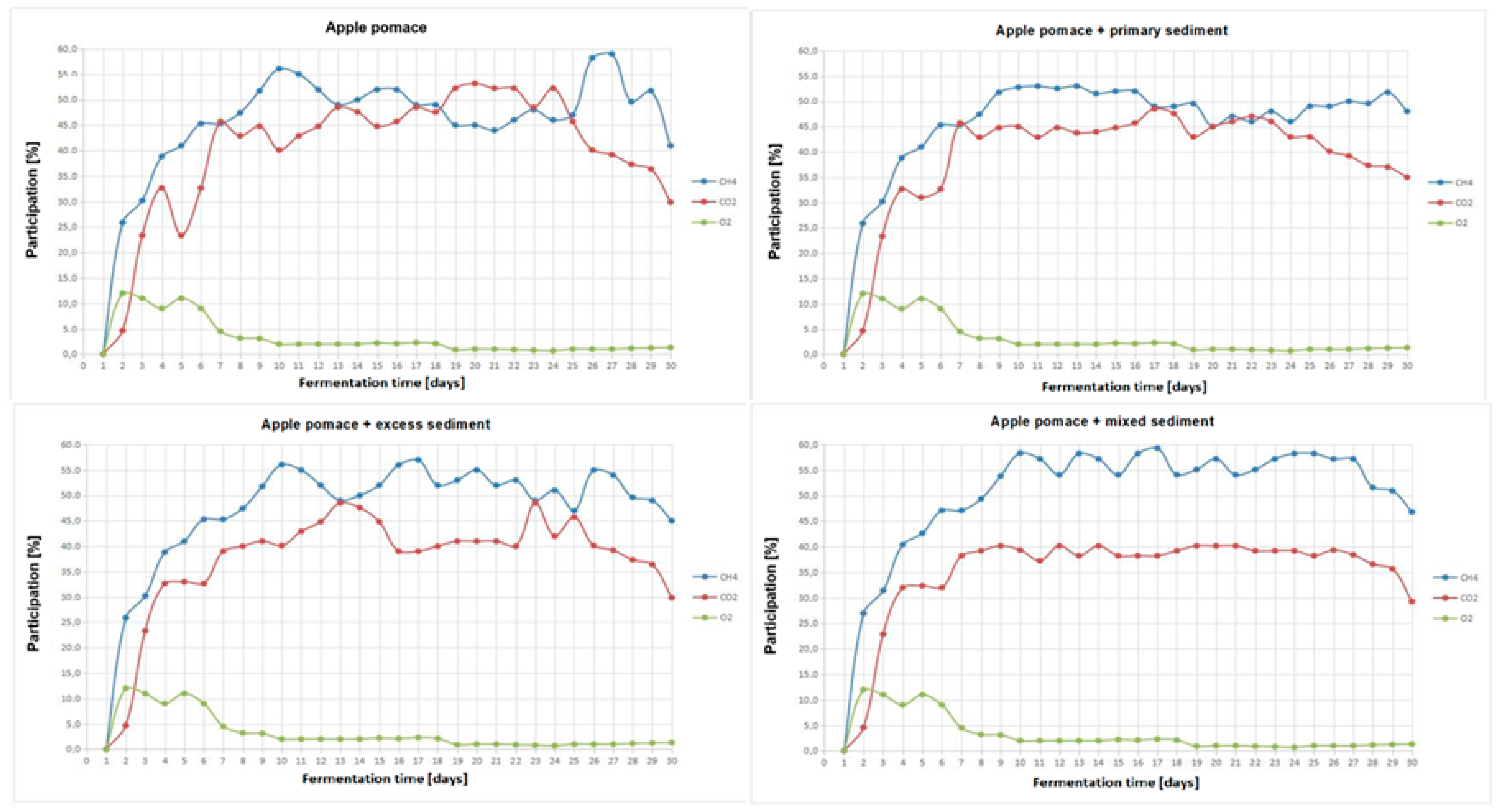

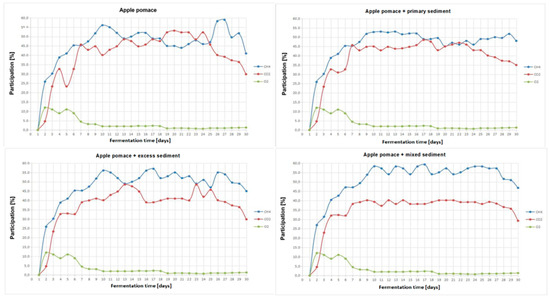

Figure 5 shows the content of basic components of biogas obtained in the co-digestion of sewage sludge and apple pomace. From the very first day, a dynamic increase in the amount of methane in biogas could be observed in all feedstocks. The oxygen content dropped below 10% only after the 5th day and remained at a low level until the end of the process. Biogas from input 2 turned out to be the least methane-rich, and its content did not exceed 55%.

Figure 5.

Composition of the separated biogas from the studied substrates, composed of apple pomace and sewage sludge.

The apple pomace and mixed sludge feedstock was distinguished by the highest methane content, which already exceeded 45% on day 6 and remained in a high range between 50 and 60% from day 8 to 29 of the process. In the case of this feedstock, the carbon dioxide content also stabilized potentially quickly (7th day) and did not exceed 40% by the end of the process.

When fermenting only apple pomace, the carbon dioxide content was variable throughout the fermentation, between 19 and 24 days, its level exceeded the methane content and reached almost 55%.

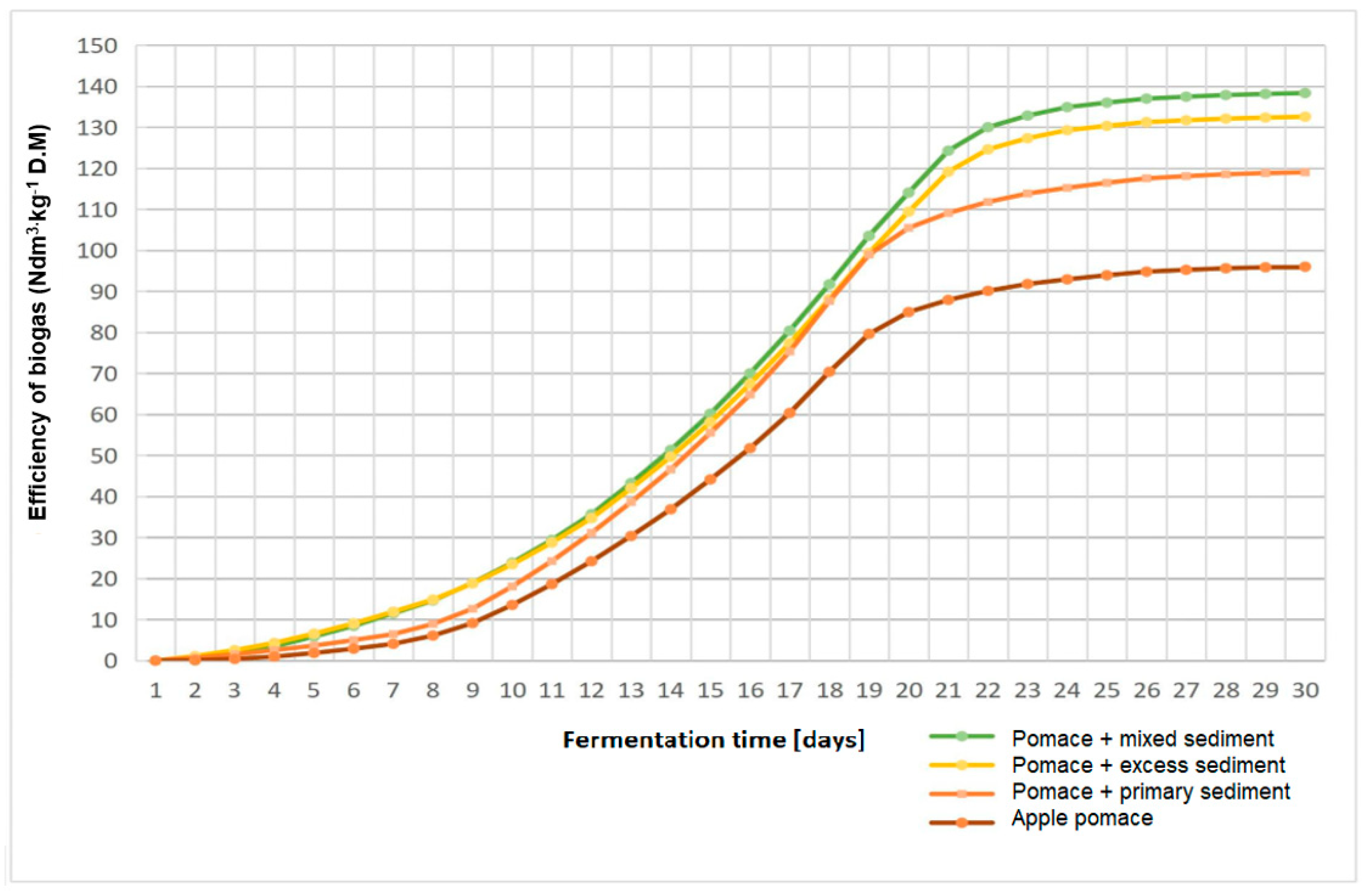

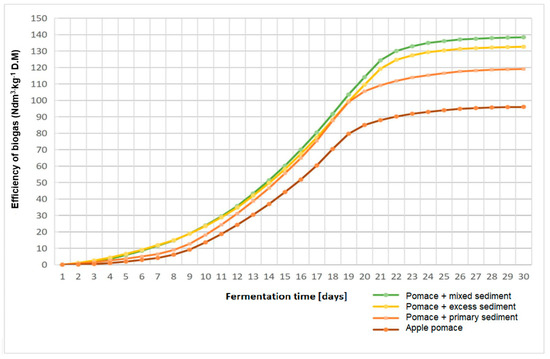

The data presented in Figure 6 allow us to conclude that the fermentation of apple pomace, similar to maize silage, was most significantly influenced by its hydration with mixed sludge. The input composed in this way achieved a biogas yield of 138 Ndm3/kg d.m.

Figure 6.

Summary curve of biogas separation from the studied substrates composed of apple pomace and sewage sludge.

The least productive input was mix No. 4, consisting only of apple pomace. The least biogas was produced from it (96 Ndm3/kg d.m), and the process took place with the greatest delay.

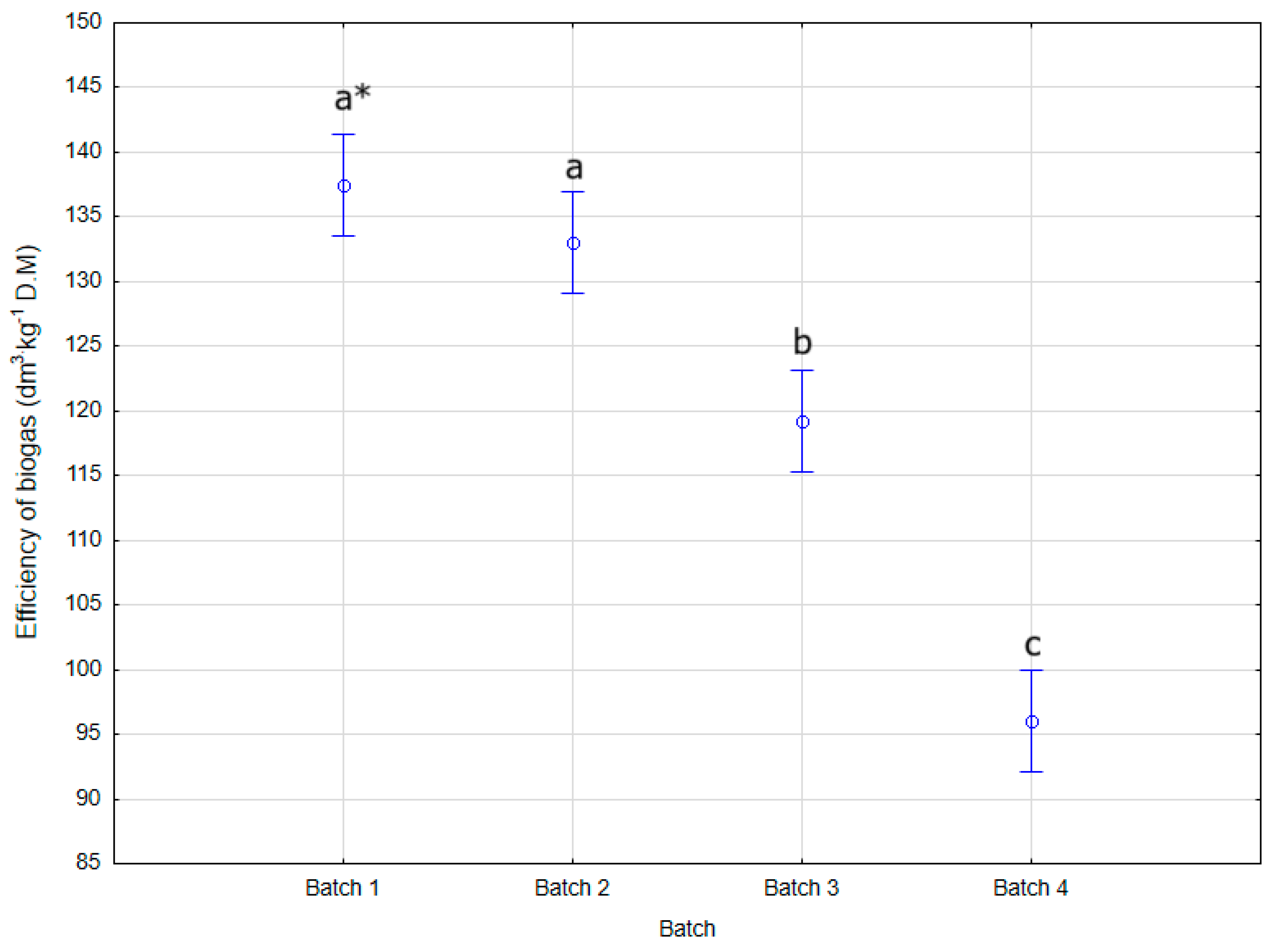

The rate of the process remained constant for batches 3 and 4 for a long time. Mix No. 2 had a slightly higher inhibition of the process at the beginning, and by the time of the 17th day, it had reached the level of biogas profitability of the 3rd batch. The amount of biogas produced for feedstock 2 and 3 was 119 and 133 Ndm3/kg d.m., respectively (Figure 7).

Figure 7.

Average biogas yield based on the input composition of sewage sludge fraction mixed with apple pomace as waste biomass from agri-food processing. * Significant differences in biogas release from different inputs determined by the Duncan test; (a,b,c)—homogeneous groups, alpha = 0.05000. Error: cross-group MS = 304.37, df = 10.000.

The Duncan test showed that homogeneous groups were formed within the fractions with the highest biogas yield, which were the fractions made from apple pomace with both primary and excess sediment. Separate groups with lower biogas yields were formed by the fractions from apple pomace with mixed sediment and the substrate made solely from apple pomace.

4. Discussion

The results of the research clearly indicate that co-digestion of sewage sludge with agricultural biomass leads to increased biogas production and higher methane content compared to monofermentation.

This study aimed to demonstrate the usefulness of sewage sludge in agricultural biogas plants, specifically examining how the addition of sewage sludge affects the fermentation process and whether this type of waste can be successfully utilized in agricultural biogas plants.

The conducted research directly relates to the economy and seeks to answer the question of how to manage sewage sludge by utilizing its physical properties. Agricultural biomass provides a significant amount of energy in biogas plants; however, it requires diluents such as slurry, liquid manure, or water. Sewage sludge contains little organic matter, and its monofermentation is only practical in large wastewater treatment plants. In small treatment plants, even the biogas produced is insufficient to heat the fermenters to 38 °C, and at 40 °C, external energy input is required. Small wastewater treatment plants are therefore forced to dispose of sewage sludge in other ways, often involving long-distance transport. This transport further burdens sludge management with additional CO2 emissions. The research results presented in the article demonstrate that sewage sludge can be successfully utilized in agricultural biogas plants. The sludge is biologically active and does not inhibit fermentation; rather, it serves as an effective diluent. The findings reveal alternative possibilities for managing sewage sludge in small wastewater treatment plants, other than composting and disposal at distant facilities. Many small treatment plants in Europe, in an effort to reduce disposal costs, dewater and compost their sewage sludge. However, this process releases CO2 and CH4 into the atmosphere. While carbon dioxide is a well-known greenhouse gas, methane is particularly harmful, as it persists in the environment for about seven years. This approach is unsustainable and places a considerable burden on the natural environment. The research presented in this article contributes to the ongoing search for optimal biological, environmental, and economic solutions for sewage sludge management.

The addition of agricultural plant biomass to methane fermentation did not cause process inhibition, as sewage sludge is biologically active. The biomass within the sludge consists of clusters of aerobic bacteria, which ensures that each biological particle is homogenized and surrounded by water. The introduction of an inoculum containing anaerobic bacteria, along with the maintenance of appropriate environmental conditions, provided easy access to nutrients, allowing anaerobic bacterial colonies to proliferate. During the decomposition of organic matter, anaerobic bacteria release carbon dioxide and methane. The gas bubbles lift the colonies to the surface of the fermentation bed, forming bubbles on its surface. As the bacterial colonies grow, they come into contact with homogenized biomass particles, colonize them, and initiate the degradation of biomass. This cycle then repeats itself throughout the fermentation process.

This is important not only in terms of technological efficiency, but also in terms of the profitability of biogas plants. Higher methane efficiency means higher energy yields per unit of substrate, which directly translates into lower unit energy cost (LCOE) and improved process profitability. A higher methane content in biogas indicates a higher energy potential of the substrate, which in practice may result in a reduction in the unit costs of electricity and heat production in biogas plants. This means that selecting the right proportions of agricultural biomass and sewage sludge is not only technologically important, but also economically beneficial, increasing the profitability of the entire process. Rathika et al. report in their paper that the LCOE for wastewater treatment plant installations usually depends strongly on local conditions, with mid-point values of ~60–140 €/MWh reported for actual implementations/techno-economic analyses [27,30]

The literature confirms that the increase in methane fermentation efficiency is closely related to its economic justification. Ref. [31] showed that the implementation of additional steps, such as dark fermentation and by-product separation, can increase the profitability of the plant from $19/t_VS to almost $296/t_VS, indicating the huge potential for economic optimization through technological modifications. Similarly, ref. [32] have shown that co-digestion of dewatered sewage sludge with the organic fraction of municipal waste improves not only the energy balance but also the financial balance of waste management plants, making co-digestion an economically beneficial solution.

Another factor influencing the economics of the process is the use of additives. In recent years, increasing attention has been paid to the use of biochar, a solid, carbonaceous product of biomass pyrolysis, which, thanks to its porous structure, supports the growth of methane-producing microorganisms and reduces the effects of inhibitory substances such as ammonia or hydrogen sulfide. Showed that the addition of sewage sludge-derived biochar increases methane yield while enabling an internal rate of return (IRR) above 15%, confirming the financial appeal of this technology [33]. Wasajja et al. (2024) [34] emphasize that in small-scale biogas systems, biochar significantly reduces the operating costs associated with biogas purification, while extending the life of the plant.

From a circular economy perspective, co-digestion of sewage sludge with agricultural biomass offers the dual benefits of producing renewable energy and stabilizing problematic waste. This approach reduces the costs of their external disposal, while providing a stream of valuable energy carriers. Ref. [33] indicated that the integration of waste streams in co-digestion systems can reduce sludge management costs by up to 40%, while increasing the economic sustainability of wastewater treatment plants.

In addition, the higher concentration of methane in biogas translates into a lower cost of energy generated (LCOE), which increases the competitiveness of the installation compared to other renewable energy sources. From an economic perspective, it is also important that co-digestion technology enhances the financial stability of the installation, reducing its susceptibility to fluctuations in the prices of raw materials and electricity. Market analyses show that this approach can particularly strengthen the cost-effectiveness of small and medium-scale biogas plants, which are more sensitive to operating costs than large industrial units.

Comparing the results of our own research with those cited in the literature reports, it can be concluded that the co-fermentation of the studied substrates not only improves the energy balance of the methane fermentation process but also creates favorable economic conditions for the wider application of this technology in practice. For wastewater treatment plants and agricultural biogas plants, this means that waste management costs can be reduced while generating energy in a cost-effective and sustainable manner.

5. Conclusions

Based on the analyzed literature and laboratory tests, the following conclusions can be drawn:

- Sewage sludge can be used with a positive effect for co-digestion with agricultural biomass. The addition of any of them increases the biogas profitability of feedstock in relation to monofermented agricultural biomass.

- The largest amount of biogas produced was obtained by biomass hydrated with mixed sludge. The feedstocks composed in this manner also achieved the highest methane content in the resulting gas composition. Most biogas was produced from maize silage and mixed sludge (309 Ndm3/kg d.m.). The methane content in this mix peaked at 63%.

- In the case of single-component methane fermentation, the literature presents excess sludge as the least desirable substrate for the process, and it is recommended that its amount in the mixed sludge should be as low as possible [7]. In the case of co-fermentation with maize silage and apple pomace, excessive sludge created the opposite of the expected effects—it provided a better environment for the process, increased the biogas yield to a greater extent, and turned out to be a better substrate than the primary sludge.

- Mixes with maize silage are characterized by more than twice the biogas potential compared to apple pomace.

- The primary sludge turned out to be the worst cosubstrate, but it increased the biogas yield in the case of apple pomace to a greater extent than in the case of maize silage, in contrast to the excessive sludge, which gave a better effect in the case of maize silage. This may indicate their different physicochemical properties, compensating for other unfavorable features of agricultural biomass in both cases for fermentation.

Author Contributions

Conceptualization J.S., A.S.-S., A.O.-G. and M.D.; methodology, J.S., A.S.-S., M.D. and A.O.-G.; software, J.S., A.S.-S., A.O.-G. and J.W.; validation, J.S., A.S.-S., A.O.-G. and M.D.; formal analysis, J.S., A.S.-S., A.O.-G.; investigation, J.S., A.S.-S., A.O.-G. and J.W.; resources, J.S., A.S.-S., A.O.-G., J.W. and M.D. data curation, J.S., A.S.-S. and J.W.; writing—original draft preparation, J.S., A.O.-G. and J.W.; S writing—review and editing, A.O.-G. and A.S.-S. visualization, J.S., A.S.-S., A.O.-G.; supervision, J.S., A.O.-G. and A.S.-S.; project administration, A.O.-G. and A.S.-S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bulak, P.; Proc, K.; Pawłowska, M.; Kasprzycka, A.; Berus, W.; Bieganowski, A. Biogas Generation from Insects Breeding Post Production Wastes. J. Clean. Prod. 2020, 244, 118777. [Google Scholar] [CrossRef]

- Vasan, V.; Sridharan, N.V.; Feroskhan, M.; Vaithiyanathan, S.; Subramanian, B.; Tsai, P.C.; Lin, Y.C.; Lay, C.H.; Wang, C.T.; Ponnusamy, V.K. Biogas Production and Its Utilization in Internal Combustion Engines—A Review. Process Saf. Environ. Prot. 2024, 186, 518–539. [Google Scholar] [CrossRef]

- Li, L.; Wu, W.; Giller, P.; O’Halloran, J.; Liang, L.; Peng, P.; Zhao, G. Life Cycle Assessment of a Highly Diverse Vegetable. Multi-Cropping System in Fengqiu County, China. Sustainability 2018, 10, 983. [Google Scholar] [CrossRef]

- Szeląg-Sikora, A.; Niemiec, M.; Sikora, J.; Chowaniak, M. Possibilities of Designating Swards of Grasses and Small-Seed Legumes From Selected Organic Farms in Poland for Feed. In Proceedings of the IX International Scientific Symposium “Farm Machinery and Processes Management in Sustainable Agriculture”, Lublin, Poland, 22–24 November 2017; pp. 365–370. [Google Scholar]

- Zepter, J.M.; Engelhardt, J.; Gabderakhmanova, T.; Marinelli, M. Empirical validation of a biogas plant simulation model and analysis of biogas upgrading potentials. Energies 2021, 14, 2424. [Google Scholar] [CrossRef]

- Komorowska, M.; Niemiec, M.; Sikora, J.; Szeląg-Sikora, A.; Gródek-Szostak, Z.; Findura, P.; Gurgulu, H.; Stuglik, J.; Chowaniak, M.; Atılgan, A. Closed-Loop Agricultural Production and Its Environmental Efficiency: A Case Study of Sheep Wool Production in Northwestern Kyrgyzstan. Energies 2022, 15, 6358. [Google Scholar] [CrossRef]

- Gu, Y.; Li, Y.; Li, X.; Luo, P.; Wang, H.; Wang, X.; Wu, J.; Li, F. Energy self-sufficient wastewater treatment plants: Feasibilities and challenges. Energy Procedia 2017, 105, 3741–3751. [Google Scholar] [CrossRef]

- Limonti, C.; Monteverde, G.; Cecchi, F.; Cavinato, C. Co-Digestion of Dehydrated Sewage Sludge and Organic Fraction of Municipal Solid Waste: Technical and Economic Analysis. Fermentation 2024, 10, 600. [Google Scholar] [CrossRef]

- Derehajło, S.; Tymińska, M.; Skibko, Z.; Borusiewicz, A.; Romaniuk, W.; Kuboń, M.; Olech, E.; Koszel, M. Heavy Metal Content in Substrates in Agricultural Biogas Plants. Agric. Eng. 2023, 27, 315–329. [Google Scholar] [CrossRef]

- Majeed, Y.; Khan, M.U. Waseem, M.; Zahid, U.; Mahmood, F.; Majeed, F.; Sultan, M.; Raza, A. Renewable energy as an alternative source of energy management in agriculture. Energy Represent. 2023, 10, 344–359. [Google Scholar] [CrossRef]

- Sikora, J.; Mruk, B. Quantitative and qualitative analysis of biogas emitted from feedstocks composed on the basis of available fractions on a farm. Infrastruct. Ecol. Rural. Areas 2016, 13, 907–917. Available online: http://www.infraeco.pl/en/art/a_17961.htm (accessed on 19 August 2025).

- Fermentation Methane, Biotechnology Web Portal–ISSN 2080–8682. Available online: http://www.e-biotechnologia.pl/Artykuly/fermentacja-metanowa (accessed on 10 July 2025).

- Biogas as a Renewable Energy Source. Prospects for Energy Production from Biogas in Poland. Available online: https://www.ekologia.pl/srodowisko/biogaz-jako-odnawialne-zrodlo-energii-perspektywy-produkcji-energii-z-biogazu-w-polsce/ (accessed on 10 July 2025).

- Renewable Energy Systems, B.22 Fermentation, Lecture, Ph.D. Marcin Michlski. Available online: https://www.viessmann.edu.pl/wp-content/uploads/T12_SEO-B22__Fermentacja_ (accessed on 10 July 2025).

- Corigliano, O.; Iannuzzi, M.; Pellegrino, C.; D’Amico, F.; Pagnotta, L.; Fragiacomo, P. Enhancing Energy Processes and Facilities Redesign in an Anaerobic Digestion Plant for Biomethane Production. Energies 2023, 16, 5782. [Google Scholar] [CrossRef]

- Śniacecka, N. Investigation on Utilization of Organic Fraction of Municipal Solid Waste. Available online: https://mostwiedzy.pl/pl/publication/badania-nad-zagospodarowaniem-organicznej-frakcji-odpadow-komunalnych,143039-1 (accessed on 19 August 2025).

- Heat from Biogas in Local Drying Installations. Available online: https://magazynbiomasa.pl/cieplo-z-biogazowni/ (accessed on 10 July 2025).

- Kuboń, M.; Niemiec, M.; Klimek-Kopyra, A.; Gliniak, M.; Sikora, J.; Sadowska, U.; Latawiec, A.E.; Kobyłecki, R.; Zarzycki, R.; Kacprzak, A.; et al. Assessment of Greenhouse Gas Emissions in Soybean Cultivation Fertilized with Biochar from Various Utility Plants. Agronomy 2021, 11, 2224. [Google Scholar] [CrossRef]

- Kazimierowicz, J.; Dębowski, M.; Zieliński, M. Innovative Method for Biomethane Production Based on a Closed Cycle of Biogas Upgrading and Organic Substrate Pretreatment—Technical, Economic, and Technological Fundamentals. Energies 2025, 18, 1033. [Google Scholar] [CrossRef]

- Piaskowska-Wasiak, J. Treatment of biological gases for the production of biofuels and biocomponents. Naft. Gaz 2013, 69, 241–255. [Google Scholar]

- Lima, D.; Appleby, G.; Li, L. A Scoping Review of Options for Increasing Biogas Production from Sewage Sludge: Challenges and Opportunities for Enhancing Energy Self-Sufficiency in Wastewater Treatment Plants. Energies 2023, 16, 2369. [Google Scholar] [CrossRef]

- Bień, J.; Bień, B. Management of municipal sewage sludge using thermal methods in the face of the landfill ban after 1 January 2016. Inżynieria Ekol. 2015, 45, 36–43. [Google Scholar] [CrossRef]

- Bužinskienė, R.; Miceikienė, A.; Venslauskas, K.; Navickas, K. Assessment of Energy–Economy and Environmental Performance of Perennial Crops in Terms of Biogas Production. Agronomy 2023, 13, 1291. [Google Scholar] [CrossRef]

- Sikora, J.; Niemiec, M.; Szeląg-Sikora, A.; Kuboń, M.; Olech, E.; Marczuk, A. Gasification of waste from industrial carp processing. Przem. Chem. 2017, 96, 2275–2278. [Google Scholar]

- Czekała, W.; Dach, J.; Dong, R.; Janczak, D.; Malińska, K.; Jóźwiakowski, K.; Smurzyńska, A.; Cieślik, M. Composting potential of the solid fraction of digested pulp produced by a biogas plant. Biosyst. Eng. 2017, 160, 25–29. [Google Scholar] [CrossRef]

- Borowski, S.; Boniecki, P.; Kubacki, P.; Czyżowska, A. Co-digestion of food waste with waste sludge and sewage sludge: Digestion and supernatant quality. Manag. Waste 2018, 74, 158–167. [Google Scholar] [CrossRef]

- Sikora, J.; Niemiec, M.; Szeląg-Sikora, A. Evaluation of the chemical composition of Raw Common Duckweed (Lemna minor L.) and Pulp after methane fermentation. J. Elementol. 2018, 23, 685–695. [Google Scholar] [CrossRef]

- Svazas, M.; Navickas, V. The potential of energy and agriculture synergy—Main directions of development. Energy 2025, 18, 1031. [Google Scholar] [CrossRef]

- Podkówka, W. Agricultural Biogas Renewable Energy Source; Powszechne Wydawnictwo Leśne: Warsaw, Poland, 2012. [Google Scholar]

- Piekutin, J.; Puchlik, M.; Haczykowski, M.; Dyczewska, K. The Efficiency of the Biogas Plant Operation Depending on the Substrate Used. Energies 2021, 14, 3157. [Google Scholar] [CrossRef]

- Sikora, J.; Niemiec, M.; Szeląg-Sikora, A.; Gródek-Szostak, Z.; Kuboń, M.; Komorowska, M. Effect of fat emulsifier addition on the quantity and quality of biogas obtained. Energie 2020, 13, 1825. [Google Scholar] [CrossRef]

- Martinez, E.; Torres, A.; Álvarez, C.; Gómez, M. Techno-Economic and Environmental Assessment of Small- and Medium-Scale Biogas Plants: Enhancing Competitiveness and Financial Stability. Energies 2022, 15, 7394. [Google Scholar] [CrossRef]

- Wojcieszak, D.; Pawłowski, A.; Dammer, K.-H.; Przybył, J. Chemical and Energetical Properties in Methane Fermentation of Morphological Parts of Corn with Different Variety Earliness Standard FAO. Agric. Eng. 2023, 27, 273–287. [Google Scholar] [CrossRef]

- Rathika, K.; Kumar, S.; Yadav, B.R. From pollutant to powerhouse: The untapped potential of sewage sludge and wastewater. EMBO Rep. 2023, 24, e58201. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).