Energy-Saving and Detailed Techno-Economic Assessment of the CO2 Avoided Cost for Emerging Designs of a Solvent-Based CO2 Capture Facility

Abstract

1. Introduction

1.1. Background

1.2. Modeling and Costing Objectives

2. Materials and Methods

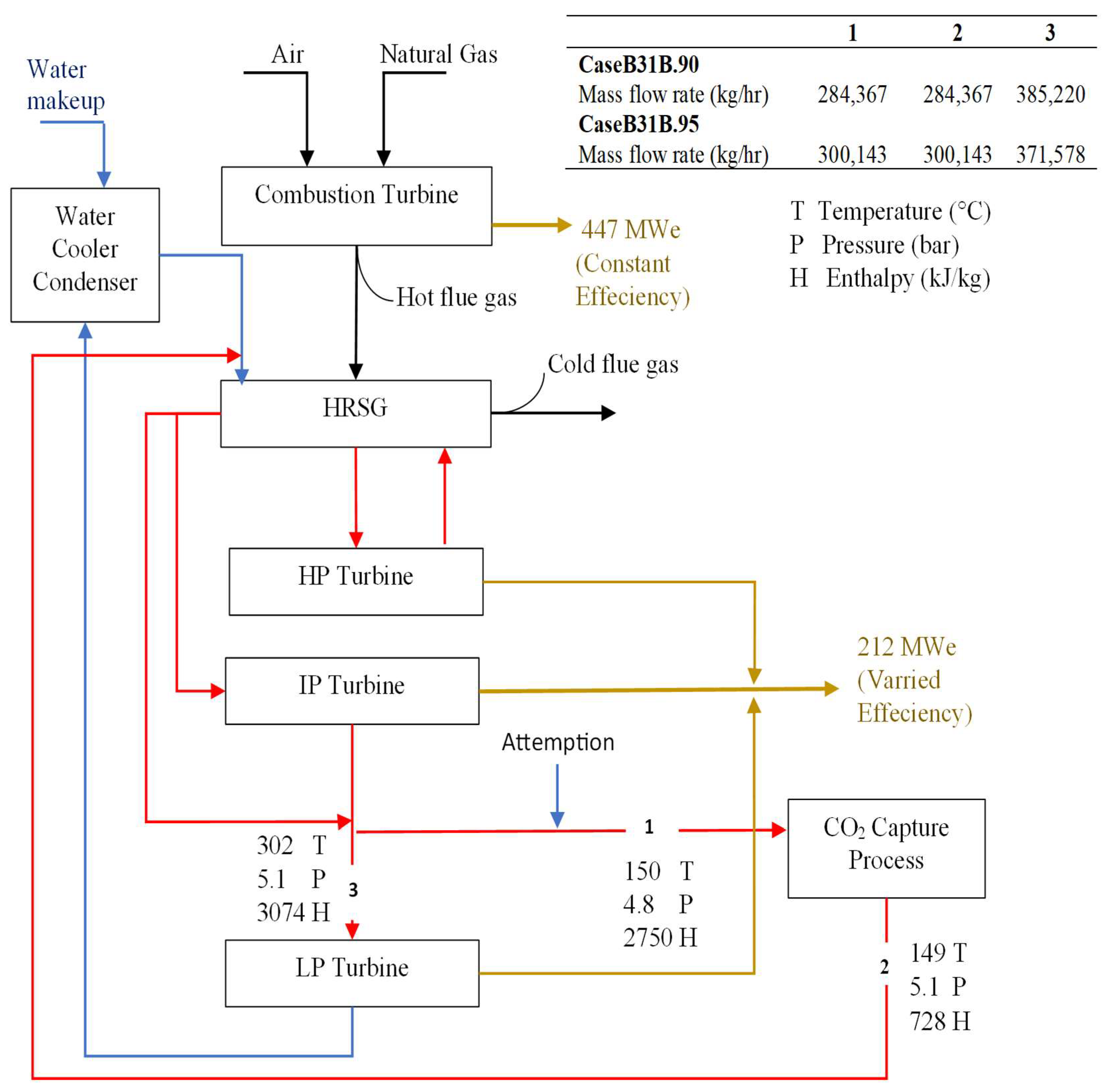

2.1. Simulation Model

2.2. Cost Model

3. Results and Discussions

3.1. Baseline Design

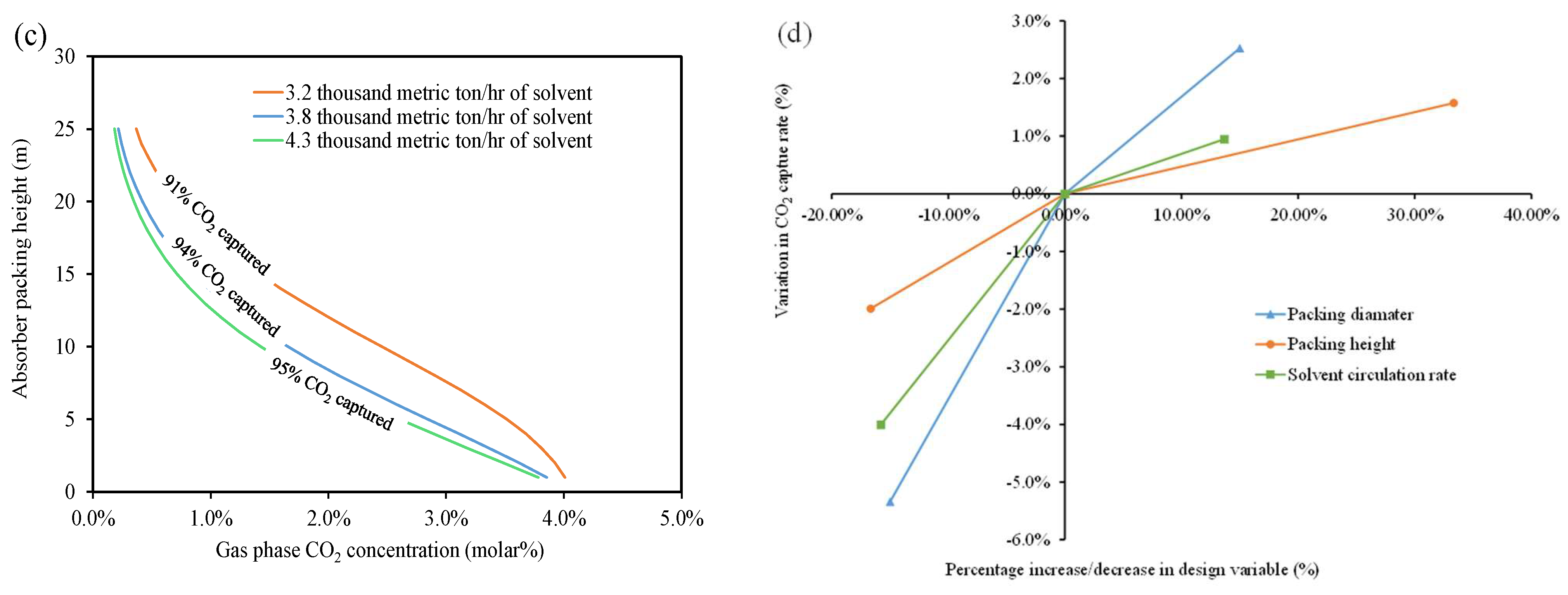

3.1.1. Influence of Design Parameters on CO2 Capture Performance

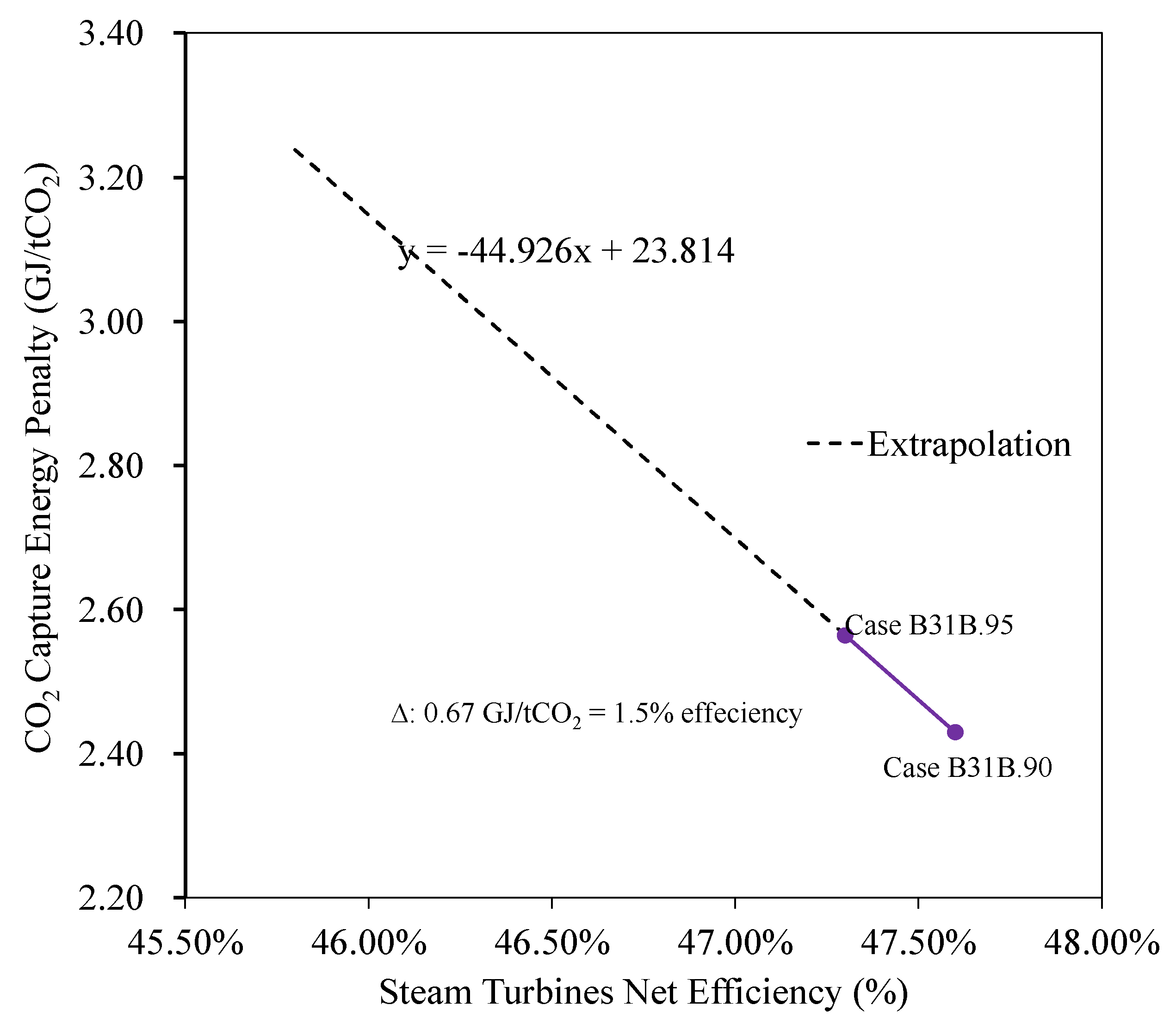

3.1.2. Optimization of Baseline Design

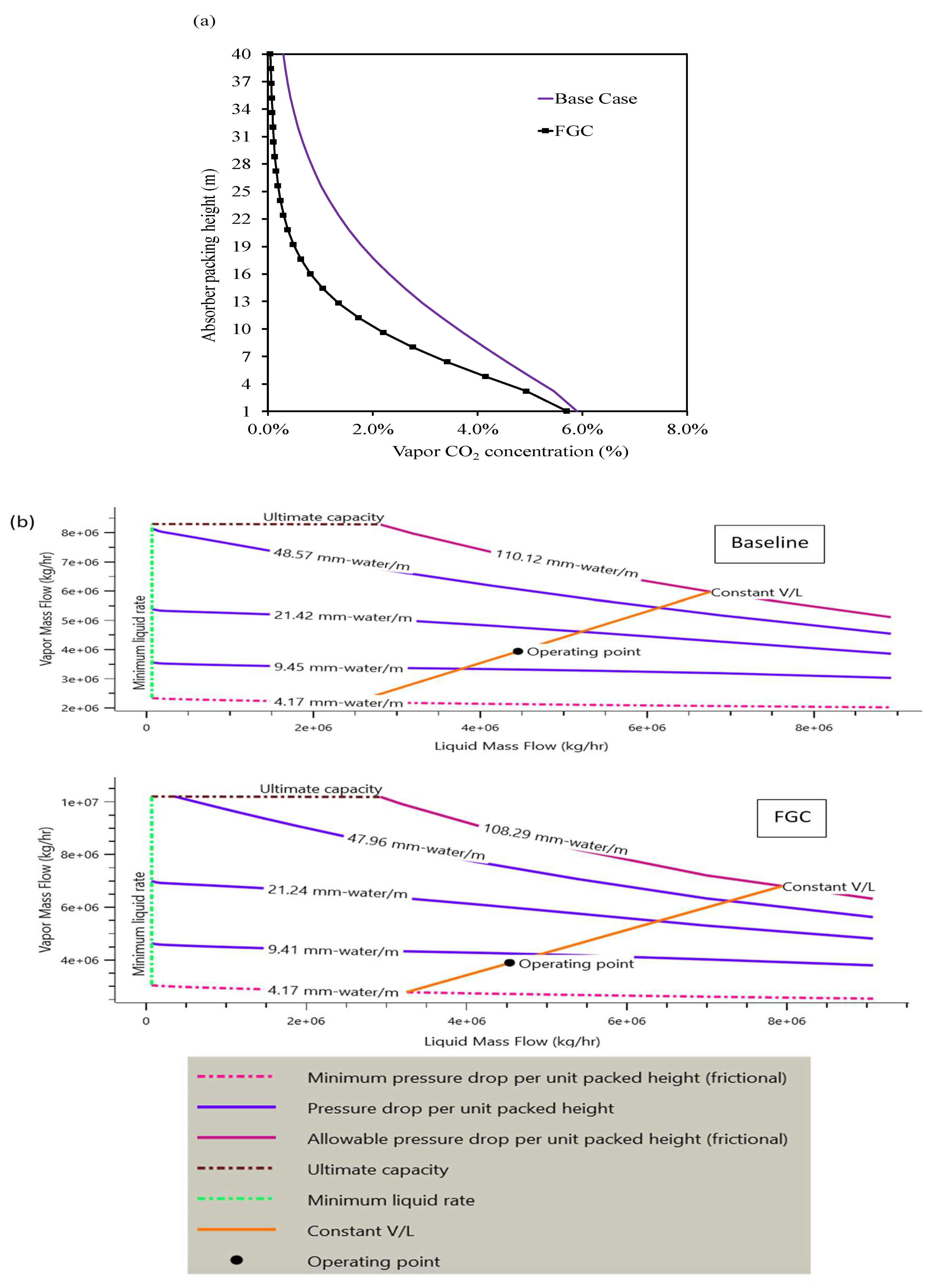

3.2. Design Performance of LVC and FGC Configurations

3.3. Energy Saving of LVC and FGC Configurations

3.4. Capital Investment of LVC and FGC Configurations

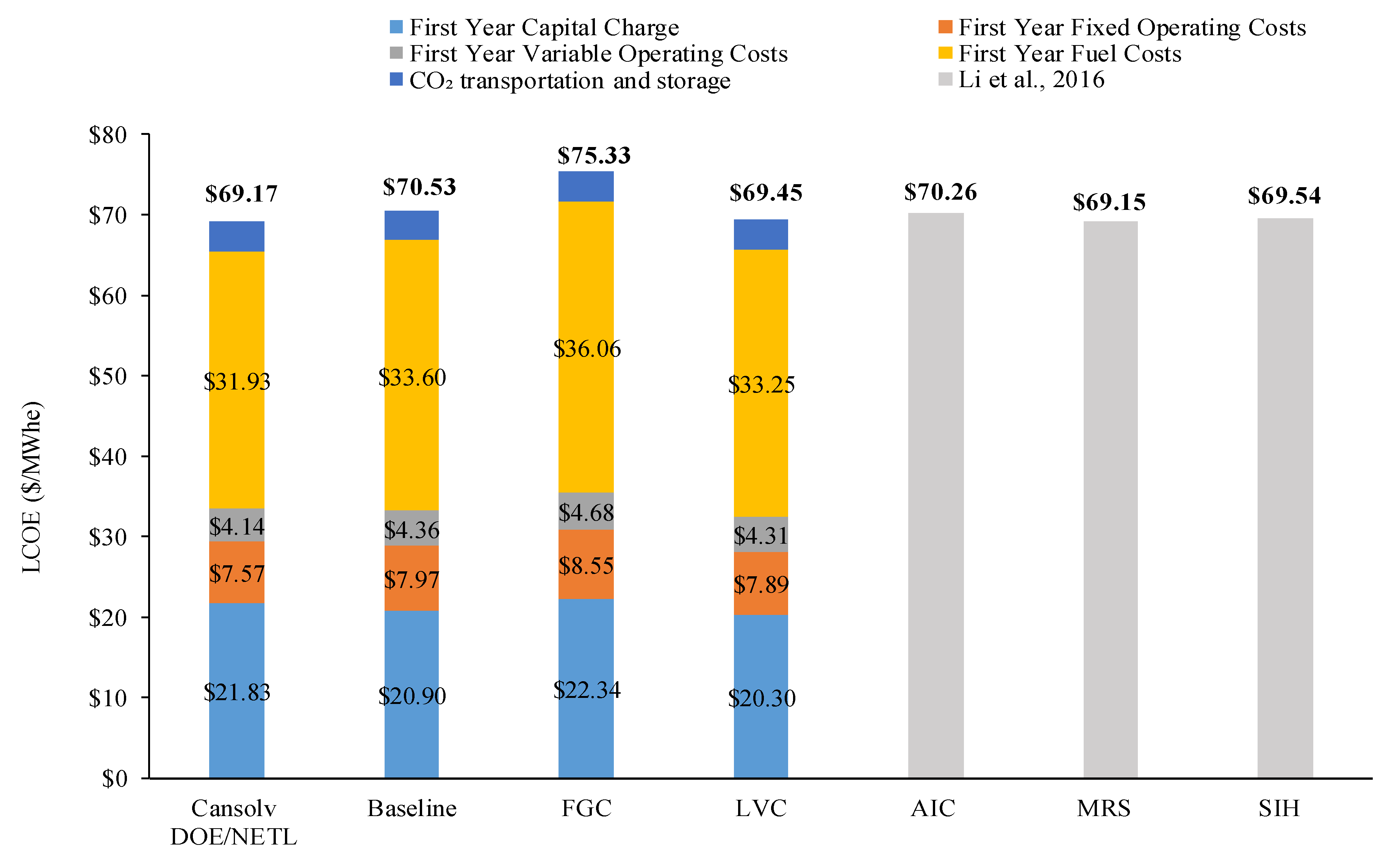

3.5. LCOE and CO2 Avoided Cost for FGC and LVC Versus Literature Configurations

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kabir, M.; Habiba, U.E.; Khan, W.; Shah, A.; Rahim, S.; Rios-Escalante, P.R.D.L.; Farooqi, Z.-U.; Ali, L.; Shafiq, M. Climate change due to increasing concentration of carbon dioxide and its impacts on environment in 21st century; a mini review. J. King Saud Univ.-Sci. 2023, 35, 102693. [Google Scholar] [CrossRef]

- Nunes, L.J.R. The Rising Threat of Atmospheric CO2: A Review on the Causes, Impacts, and Mitigation Strategies. Environments 2023, 10, 66. [Google Scholar] [CrossRef]

- Soeder, D.J. Fossil Fuels and Climate Change. In Fracking and the Environment; Springer International Publishing: Cham, Switzerland, 2021; pp. 155–185. [Google Scholar] [CrossRef]

- Niu, M.; Xie, J.; Liang, S.; Liu, L.; Wang, L.; Peng, Y. Simulation of a new biomass integrated gasification combined cycle (BIGCC) power generation system using Aspen Plus: Performance analysis and energetic assessment. Int. J. Hydrogen Energy 2021, 46, 22356–22367. [Google Scholar] [CrossRef]

- Pang, L.; Shao, Y.; Zhong, W.; Liu, H. Oxy-coal combustion in a 30 kWth pressurized fluidized bed: Effect of combustion pressure on combustion performance, pollutant emissions and desulfurization. Proc. Combust. Inst. 2021, 38, 4121–4129. [Google Scholar] [CrossRef]

- Xiang, Y.; Cai, L.; Guan, Y.; Liu, W.; He, T.; Li, J. Study on the biomass-based integrated gasification combined cycle with negative CO2 emissions under different temperatures and pressures. Energy 2019, 179, 571–580. [Google Scholar] [CrossRef]

- Jansen, D.; Gazzani, M.; Manzolini, G.; Dijk, E.V.; Carbo, M. Pre-combustion CO2 capture. Int. J. Greenh. Gas Control 2015, 40, 167–187. [Google Scholar] [CrossRef]

- Koohestanian, E.; Shahraki, F. Review on principles, recent progress, and future challenges for oxy-fuel combustion CO2 capture using compression and purification unit. J. Environ. Chem. Eng. 2021, 9, 105777. [Google Scholar] [CrossRef]

- Wang, M.; Lawal, A.; Stephenson, P.; Sidders, J.; Ramshaw, C. Post-combustion CO2 capture with chemical absorption: A state-of-the-art review. Chem. Eng. Res. Des. 2011, 89, 1609–1624. [Google Scholar] [CrossRef]

- Liang, Z.; Rongwong, W.; Liu, H.; Fu, K.; Gao, H.; Cao, F.; Zhang, R.; Sema, T.; Henni, A.; Sumon, K.Z.; et al. Recent progress and new developments in post-combustion carbon-capture technology with amine based solvents. Int. J. Greenh. Gas Control 2015, 40, 26–54. [Google Scholar] [CrossRef]

- Li, K.; Leigh, W.; Feron, P.; Yu, H.; Tade, M. Systematic study of aqueous monoethanolamine (MEA)-based CO2 capture process: Techno-economic assessment of the MEA process and its improvements. Appl. Energy 2016, 165, 648–659. [Google Scholar] [CrossRef]

- Ding, X.; Chen, H.; Li, J.; Zhou, T. Comparative techno-economic analysis of CO2 capture processes using blended amines. Carbon Capture Sci. Technol. 2023, 9, 100136. [Google Scholar] [CrossRef]

- Bai, L.; Zhao, D.; Zhong, X.; Dong, S.; Liu, H. Techno-economic analysis of CO2 absorption into a promising blended amine of DEEA-HMDA. Authorea 2022, preprint. [Google Scholar] [CrossRef]

- Nilavuckkarasi, R.K.; Muthumari, P.; Ambedkar, B.; Moniha, M. Carbon-rich solvent regeneration in solvent-based post-combustion CO2 capture process (PCCC): Process intensification by megasonics. Chem. Eng. Process.-Process Intensif. 2020, 151, 107913. [Google Scholar] [CrossRef]

- Fernandez, E.S.; Bergsma, E.J.; de Miguel Mercader, F.; Goetheer, E.L.V.; Vlugt, T.J.H. Optimisation of lean vapour compression (LVC) as an option for post-combustion CO2 capture: Net present value maximisation. Int. J. Greenh. Gas Control 2012, 11, S114–S121. [Google Scholar] [CrossRef]

- Le Moullec, Y.; Kanniche, M. Screening of flowsheet modifications for an efficient monoethanolamine (MEA) based post-combustion CO2 capture. International J. Greenh. Gas Control 2011, 5, 727–740. [Google Scholar] [CrossRef]

- Vinjarapu, S.H.B.; Neerup, R.; Larsen, A.H.; Villadsen, S.N.B.; von Solms, N.; Jensen, S.; Karlsson, J.L.; Kappel, J.; Lassen, H.; Blinksbjerg, P.; et al. Pilot-scale CO2 capture demonstration of heat integration through split flow configuration using 30 wt % MEA at a Waste-to-Energy facility. Sep. Purif. Technol. 2024, 345, 127311. [Google Scholar] [CrossRef]

- Rezazadeh, F.; Gale, W.F.; Rochelle, G.T.; Sachde, D. Effectiveness of absorber intercooling for CO2 absorption from natural gas fired flue gases using monoethanolamine solvent. Int. J. Greenh. Gas Control 2017, 58, 246–255. [Google Scholar] [CrossRef]

- Gerdes, K.; Summers, W.; Wimer, J. Quality Guidelines for Energy System Studies: Cost Estimation Methodology for NETL Assessments of Power Plant Performance; DOE/NETL-2011/1455, 1513278; U.S. Department of Energy Office of Scientific and Technical Information: Oak Ridge, TN, USA, 2011. [CrossRef]

- Schach, M.-O.; Schneider, R.; Schramm, H.; Repke, J.-U. Techno-Economic Analysis of Postcombustion Processes for the Capture of Carbon Dioxide from Power Plant Flue Gas. Ind. Eng. Chem. Res. 2010, 49, 2363–2370. [Google Scholar] [CrossRef]

- Bejan, A.; Tsatsaronis, G.; Moran, M.J. Thermal Design and Optimization; A Wiley-Interscience Publication; Wiley: New York, NY, USA, 1996. [Google Scholar]

- Peters, M.S. Plant Design and Economics for Chemical Engineers; McGraw-Hill: New York, NY, USA, 2003; Available online: http://archive.org/details/plantdesignecono0000pete_u8k1 (accessed on 10 May 2025).

- Schmitt, T.; Leptinsky, S.; Turner, M.; Zoelle, A.; White, C.W.; Hughes, S.; Homsy, S.; Woods, M.; Hoffman, H.; Shultz, T.; et al. Cost and Performance Baseline for Fossil Energy Plants Volume 1: Bituminous Coal and Natural Gas to Electricity. Available online: https://netl.doe.gov/projects/files/CostAndPerformanceBaselineForFossilEnergyPlantsVolume1BituminousCoalAndNaturalGasToElectricity_101422.pdf (accessed on 24 September 2023).

- Carbon Dioxide Capture from Existing Coal-Fired Power Plants; DOE/NETL-401/120106; Office of Systems Analyses and Planning Division. Carbon Dioxide Capture from Existing Coal-Fired Power Plants: Oak Ridge, TN, USA, 2006. Available online: https://www.osti.gov/biblio/20923766 (accessed on 10 May 2025).

- Herzog, H. Lessons Learned from CCS Demonstration and Large Pilot Projects. 2016. Available online: https://sequestration.mit.edu/bibliography/CCS%20Demos.pdf (accessed on 19 April 2025).

- Kennedy, G.W.A. Parish Post-Combustion CO2 Capture and Sequestration Demonstration Project (Final Technical Report); DOE-PNPH-03311; Petra Nova Power Holdings LLC.: Thompsons, TX, USA, 2020. [Google Scholar] [CrossRef]

- Just, P.E. Shell Cansolv deploying CCS worldwide. In Proceedings of the Second Post-Combustion Capture Conference (PCCC2), Bergen, Norway, 17–20 September 2013. [Google Scholar]

- Aboudheir, A. An Optimum Solution for Coal Power Plants to Reduce CO2 Emissions. 2019. Available online: https://www.engineering.pitt.edu/contentassets/f4be457906164980bfec191246d45549/2019.9.5-ahmed-aboudheir.pdf (accessed on 19 April 2025).

- Carbon Dioxide Capture Handbook. Available online: https://www.netl.doe.gov/sites/default/files/netl-file/Carbon-Dioxide-Capture-Handbook-2015.pdf (accessed on 19 April 2025).

| Simulated Design | Cansolv Design at SaskPower (b) | Kansai Mitsubishi Design at Petra Nova (e) | ||||

|---|---|---|---|---|---|---|

| Design Parameters | Absorber | Stripper | Absorber | Stripper | Absorber | Stripper |

| Flue gas flow rate (106 Nm3/h) | 3.43 (a) | 0.65 | 1.4 | |||

| Packing height (m) | 25 | 18 | 21 | 12 | 31 | 49 |

| Diameter (m) | 20 | 13.6 | 11 | 8 | 12 | 8 |

| Gas Velocity at the inlet of absorber (m/s) (c) | 3.04 | 1.90 | 3.47 | |||

| Percent approach to flood (%) | 69.8 | 59.5 | Proprietary (d) | Proprietary (d) | ||

| Packing material | Sulze Mellapark 125Y | Sulzer Mellapark 252Y | Proprietary (d) | |||

| Solvent circulation rate (metric tons/h) | 4320 | Proprietary (d) | ||||

| MEA concentration (wt.%) | 27 | Proprietary (d) | ||||

| Variable Boundaries | Initial Value | Final/Optimal Value | |

|---|---|---|---|

| Objective function variables | |||

| Min: Solvent circulation rate (metric tons/kg) | 2500 ≤ X ≤ 4320 | 4320 | 2820 |

| Manipulated variables | |||

| Packing diameter (m) | 17 ≤ X ≤ 23 | 20 | 23 |

| Packing height (m) | 20 ≤ X ≤ 40 | 25 | 40 |

| Constraints | |||

| CO2 capture rate (%) | =95 | 95.5 | 95 |

| Approach to column flooding (%) | ≤70 | 68.9 | 45 |

| MEA concentration (wt.%) | =30 | 27 | 30 |

| Baseline Design | FGC | LVC | Cansolv | |

|---|---|---|---|---|

| Reboiler duty (GJ/tCO2) | 4.47 | 3.33 | 3.78 | 2.6 |

| LP steam turbine efficiency (%) | 43.04 | 45.59 | 44.59 | 47.30 |

| Steam turbine output (MWe) | 177 | 198 | 190 | 212 |

| CO2 capture power consumption (MWe) | 30.1 | 92.0 | 34.8 | 33.3 |

| Lean solvent pump (kWe) | 12 | 95 | 24 | - |

| Rich solvent pump (kWe) | 63 | 0 | 63 | - |

| Wash water pump (kWe) | 2 | 2 | 2 | - |

| Flue gas blower (kWe) | 11,150 | 11,150 | 11,150 | - |

| CO2 compression (kWe) | 18,900 | 18,900 | 18,900 | 18,900 |

| FGC compressor (kWe) | - | 100,549 | - | |

| FGC expander (kWe) | - | −38,670 | - | - |

| LCV compressor (kWe) | - | - | 4633 | - |

| Total Gross Power (MWe) | 654 | 675 | 667 | 689 |

| Net power plant power (MWe) | 608 | 566 | 615 | 640 |

| Equipment ($M) | BEC ($M) | EPC ($M) | Contingency ($M) | Total ($M) | |

|---|---|---|---|---|---|

| Baseline design | |||||

| Absorption tower | 64.6 | 132.4 | 19.8 | 57.8 | 210.1 |

| Stripper tower | 22.1 | 47.3 | 7.1 | 20.7 | 75.1 |

| Stripper condenser | 0.8 | 4.5 | 0.7 | 2.0 | 7.2 |

| Stripper reboiler | 0.3 | 0.8 | 0.1 | 0.3 | 1.3 |

| Stripper reflux drum | 0.079 | $0.3 | 0.057 | 0.1 | 0.6 |

| Stripper reflux pump | 0.011 | 0.067 | 0.010 | 0.029 | 0.1 |

| Lean solvent cooler | 0.4 | 1.9 | 0.3 | 0.8 | 3.0 |

| Lean solvent pump | 0.1 | 0.8 | 0.1 | 0.3 | 1.3 |

| Rich solvent pump | 0.1 | 0.9 | 0.1 | 0.3 | 1.4 |

| Stripper exhaust water pump | 0.007 | 0.068 | 0.010 | 0.029 | 0.1 |

| Rich/lean solvent heat exchanger | 1.1 | 4.6 | 0.7 | 2.0 | 7.3 |

| Wash water recycle pump | 0.008 | 0.068 | 0.010 | 0.030 | 0.1 |

| Wash water recycle cooler | 0.020 | 0.1 | 0.017 | 0.051 | 0.2 |

| Total Investment ($) | 307.9 | ||||

| FGC design | |||||

| + Flue gas compressor | 3.6 | 7.6 | 1.1 | 3.3 | 12.0 |

| + Flue gas cooler | 0.4 | 3.1 | 0.5 | 1.3 | 5.0 |

| + Turbo-expander | 0.3 | 1.1 | 0.1 | 0.5 | 1.8 |

| Total Investment ($) | 326.7 | ||||

| LVC design | |||||

| + Flue gas compressor | 0.5 | 1.5 | 0.2 | 0.6 | 2.4 |

| + Flash separator | 0.4 | 1.5 | 0.2 | 0.6 | 2.5 |

| Total Investment ($) | 312.9 | ||||

| NGCC w/o CCS ($) | 674.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bellal, A.; Ben Moussa, F.; Bellal, S.E. Energy-Saving and Detailed Techno-Economic Assessment of the CO2 Avoided Cost for Emerging Designs of a Solvent-Based CO2 Capture Facility. Energies 2025, 18, 5608. https://doi.org/10.3390/en18215608

Bellal A, Ben Moussa F, Bellal SE. Energy-Saving and Detailed Techno-Economic Assessment of the CO2 Avoided Cost for Emerging Designs of a Solvent-Based CO2 Capture Facility. Energies. 2025; 18(21):5608. https://doi.org/10.3390/en18215608

Chicago/Turabian StyleBellal, Abdelmalek, Fatah Ben Moussa, and Seif Eddine Bellal. 2025. "Energy-Saving and Detailed Techno-Economic Assessment of the CO2 Avoided Cost for Emerging Designs of a Solvent-Based CO2 Capture Facility" Energies 18, no. 21: 5608. https://doi.org/10.3390/en18215608

APA StyleBellal, A., Ben Moussa, F., & Bellal, S. E. (2025). Energy-Saving and Detailed Techno-Economic Assessment of the CO2 Avoided Cost for Emerging Designs of a Solvent-Based CO2 Capture Facility. Energies, 18(21), 5608. https://doi.org/10.3390/en18215608