The Impact of Brine Saturation and Distribution on Lean Gas Huff-n-Puff EOR Performance of Tight Oil Reservoirs: Examples from the Montney Formation (Canada)

Abstract

1. Introduction

2. Mechanisms of Lean Gas HNP in Tight Oil Reservoirs

3. Materials

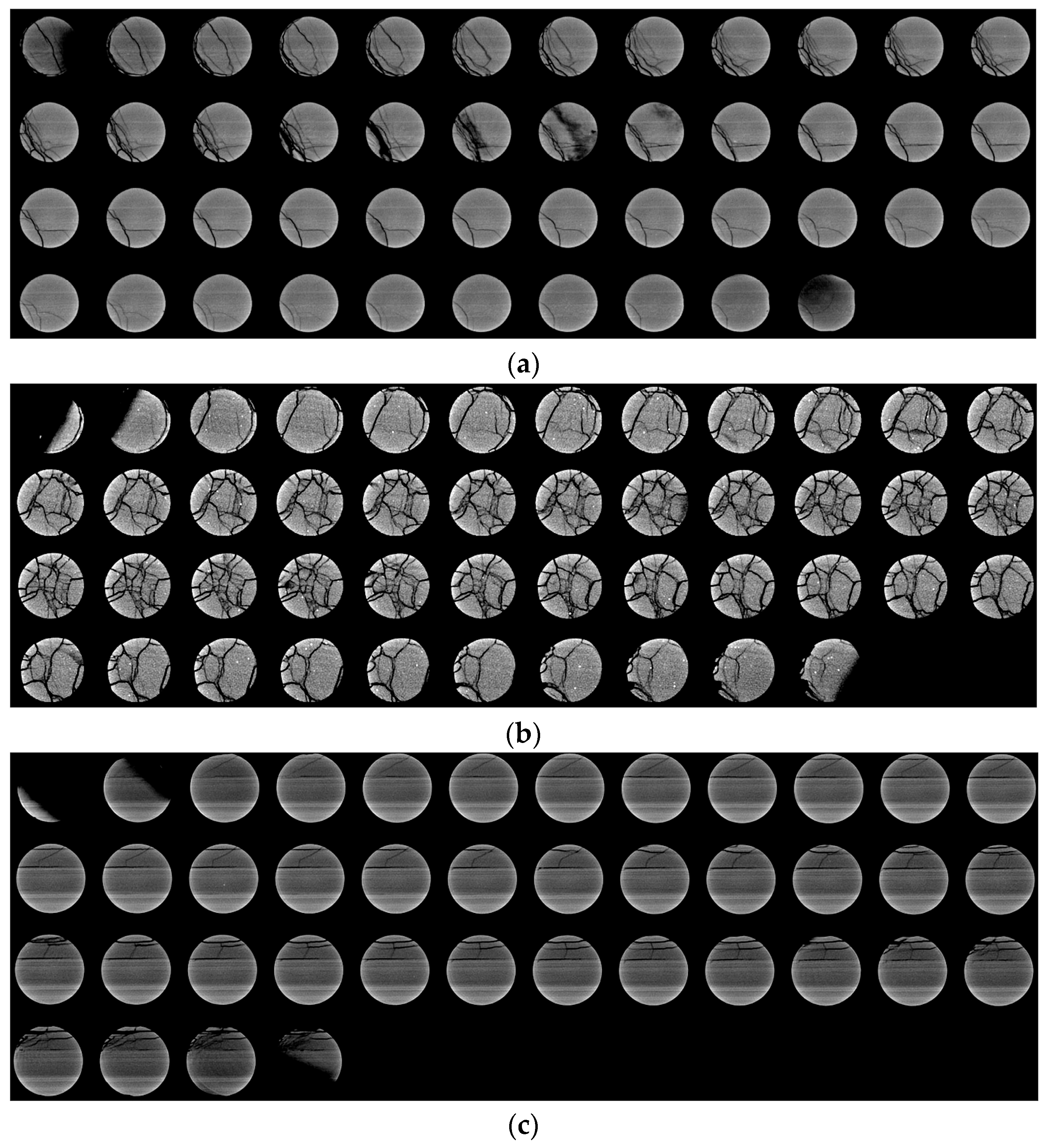

3.1. Rock Samples

3.2. Fluid Samples

4. Experiments

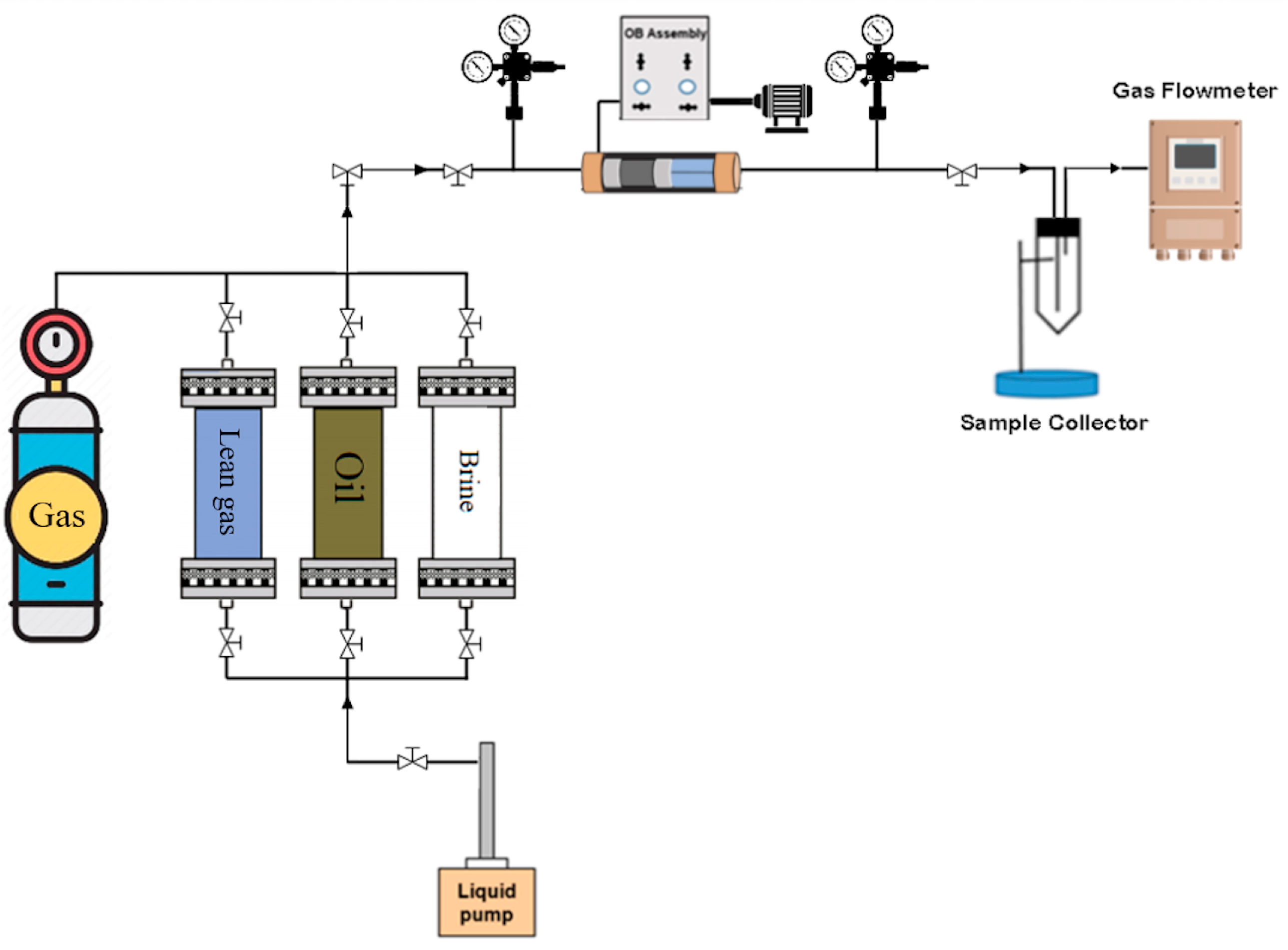

4.1. Experimental Setup

4.2. Experimental Procedures

- Helium porosity measurement—helium porosity of the three intact core plugs was determined by combing helium pycnometry (Micromeritics® Norcross, GA, USA, Accupyc II 1340TM) to obtain a grain density/volume estimate and calipering to estimate bulk density/volume.

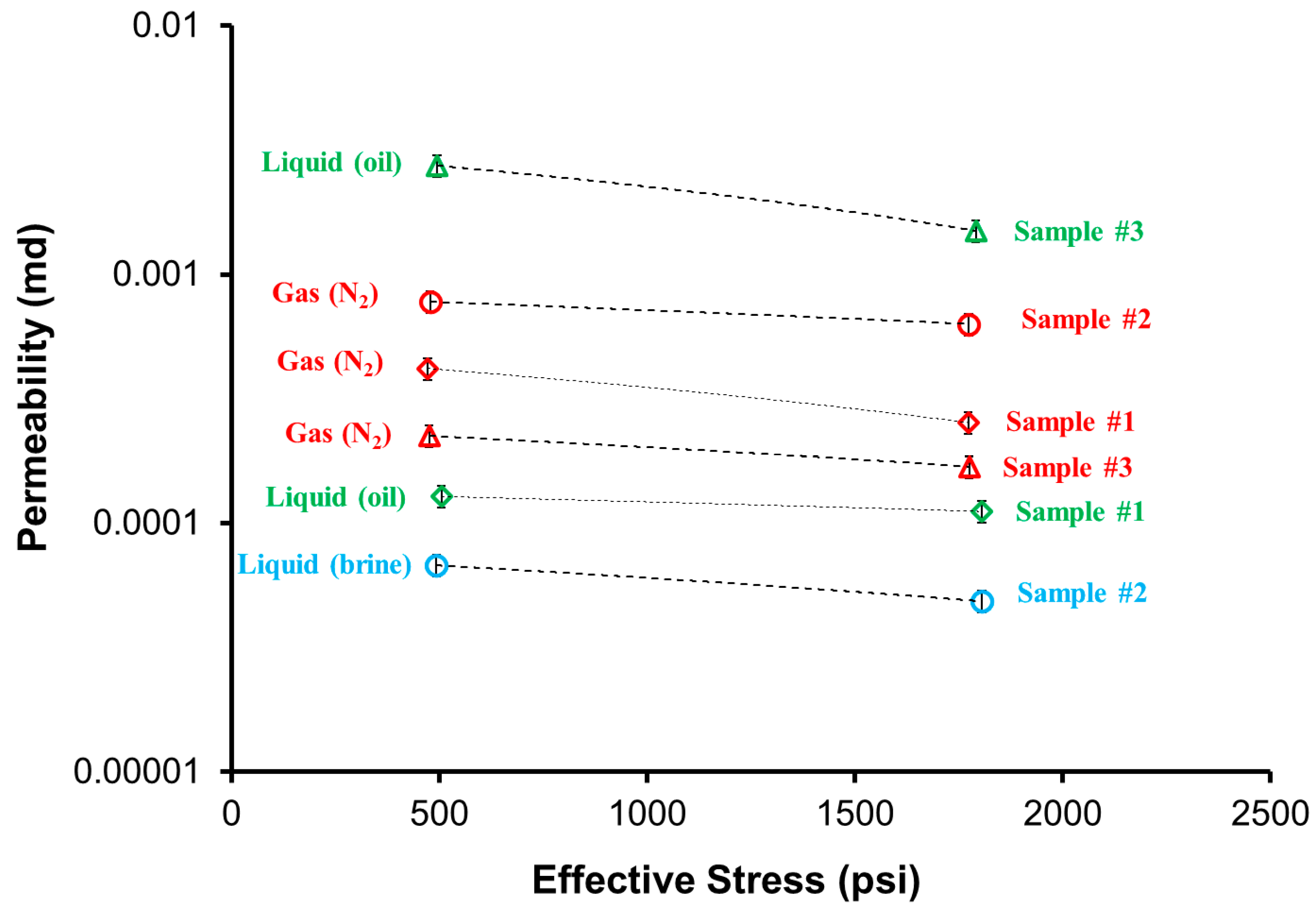

- Gas (N2) permeability measurement—matrix permeability values of the core plugs were determined using the gas (N2) pulse-decay technique (Corelab® Tulsa, OK, USA, PDP-250TM), under different effective stresses (500 and 1800 psi), with mean pore pressures ranging from 200 to 1000 psi to derive the slip-correct gas permeabilities.

- Brine or oil saturation—after evacuating the core plugs for 48 hrs to remove gas, the core plugs were fully saturated with either dead oil (Sample #1 and #3) or brine (Sample #2) under 1500 psi for 5 days. Saturations were calculated from the mass change in the samples before and after saturation.

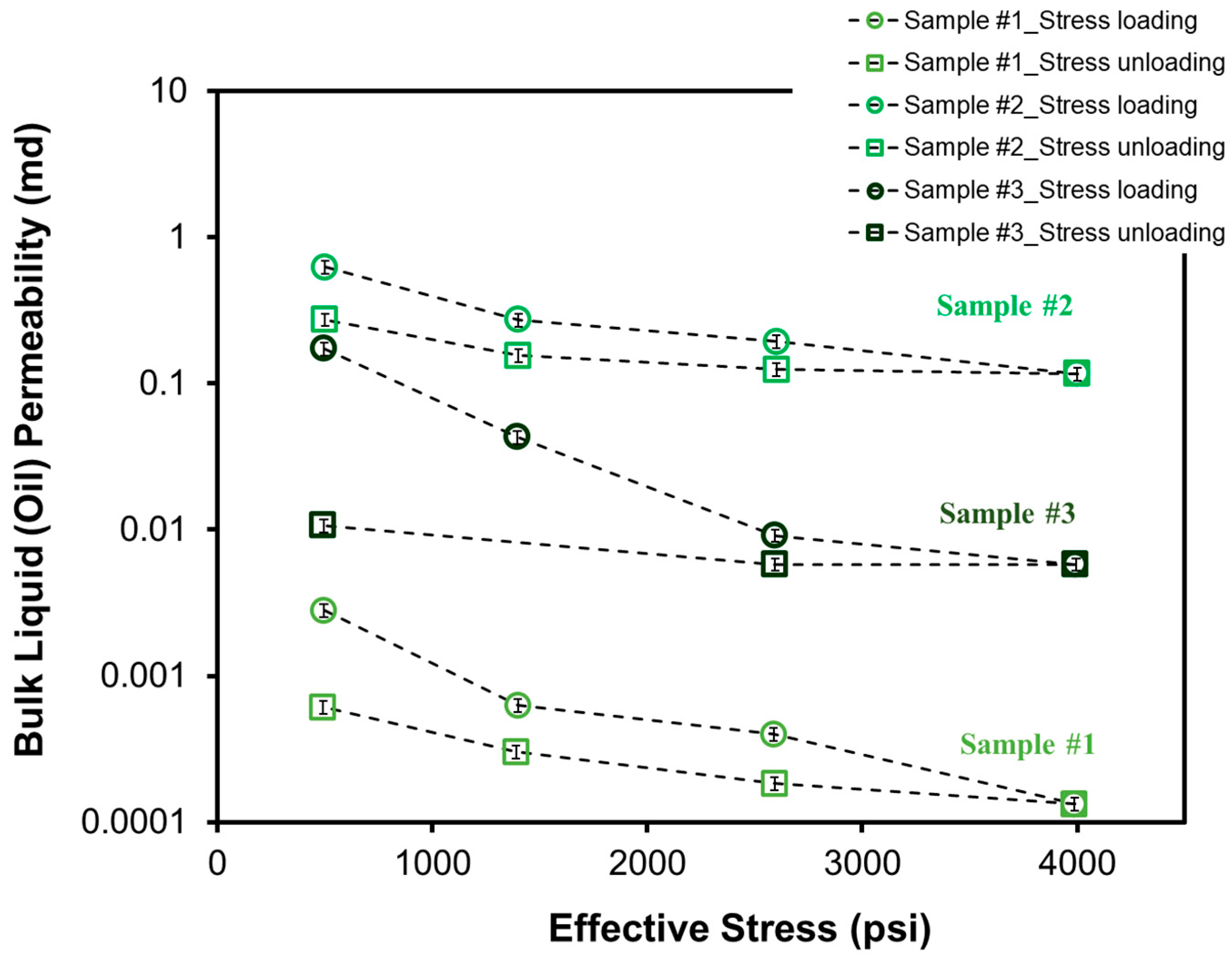

- Liquid permeability measurement—liquid (oil or brine) pulse-decay permeability measurements [31] were conducted on the core plugs (oil for Sample #1 and #3; brine for Sample #2) under the same effective stress conditions used for the previous gas permeability testing.

- Inducing various brine saturations—following the liquid permeability tests, brine (for sample #1 and #3) or crude oil (for sample #2) was flooded into the core samples to achieve different brine saturation levels. The brine saturations were determined from the mass difference in samples before and after saturation, combined with the measured quantities of fluids produced.

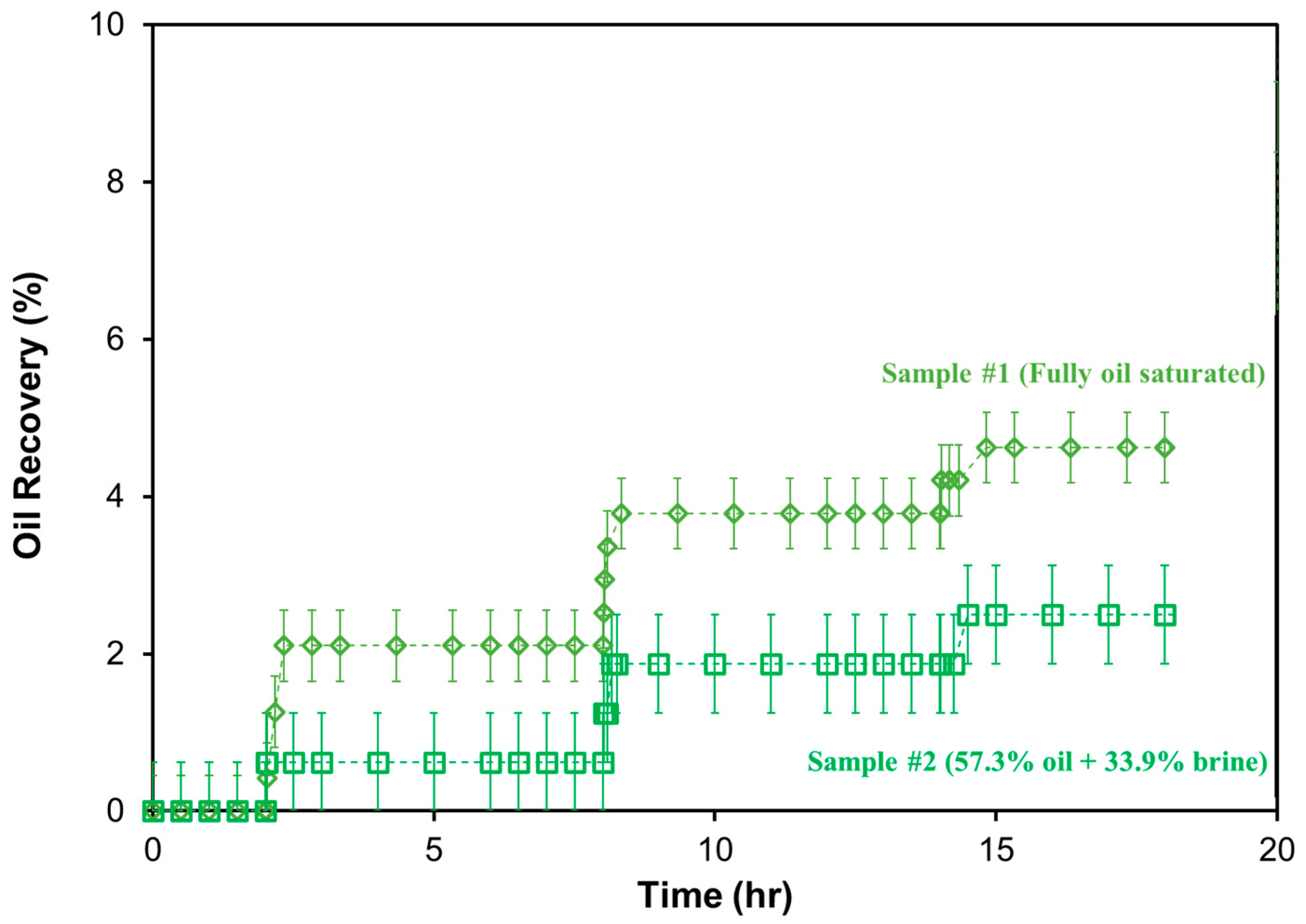

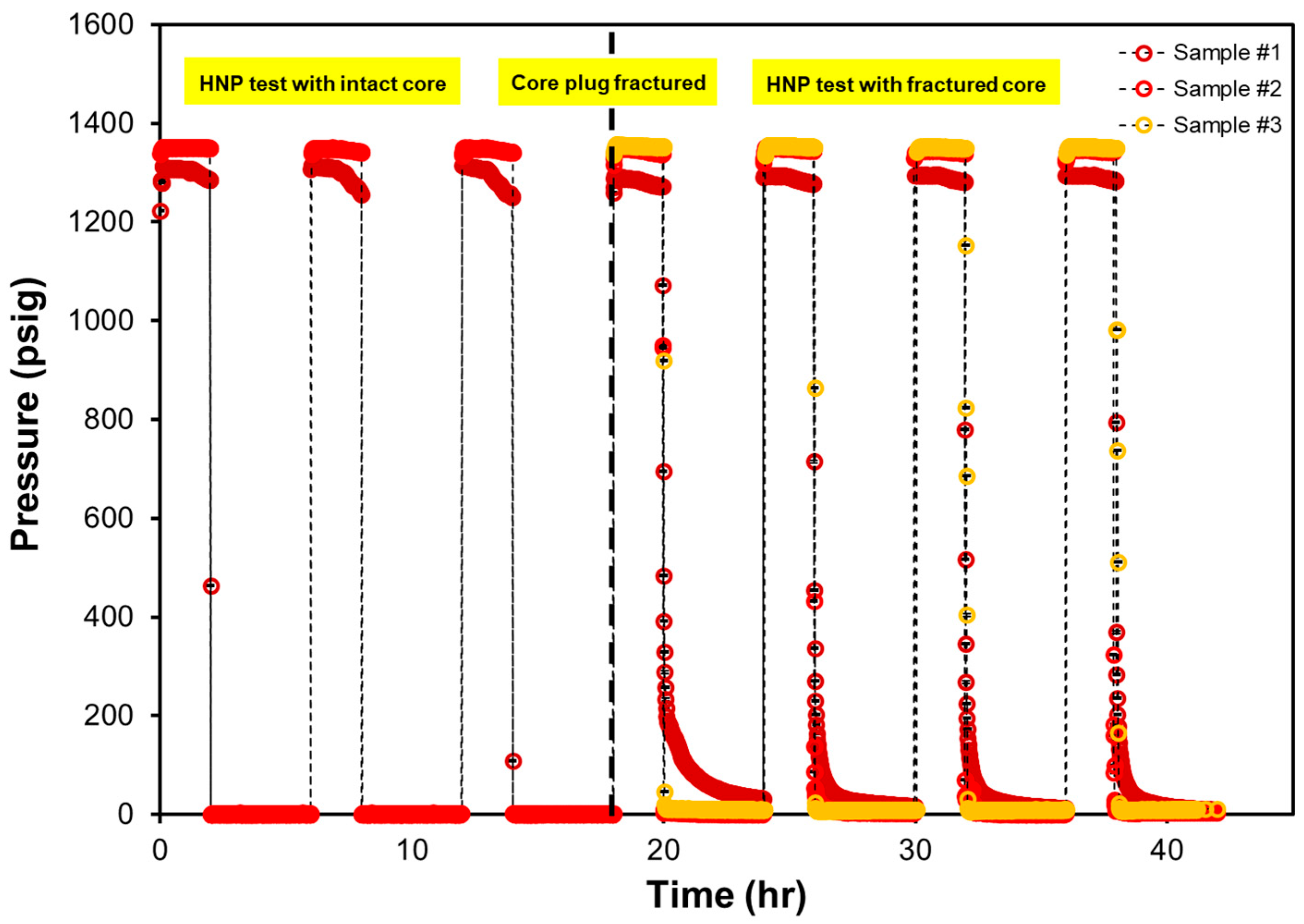

- Lean gas HNP using intact core plugs—for each cycle of lean gas HNP, simplified lean gas was injected into the intact core plugs at a constant pressure (1300 psig) for 1 hr. The core plugs were then soaked with the injected lean gas for another hour, followed by a production period (i.e., atmosphere pressure) for 4 h. Similar HNP scheme was also employed in the previous study [3]. Three cycles of HNP were performed for Sample #1 and Sample #2.

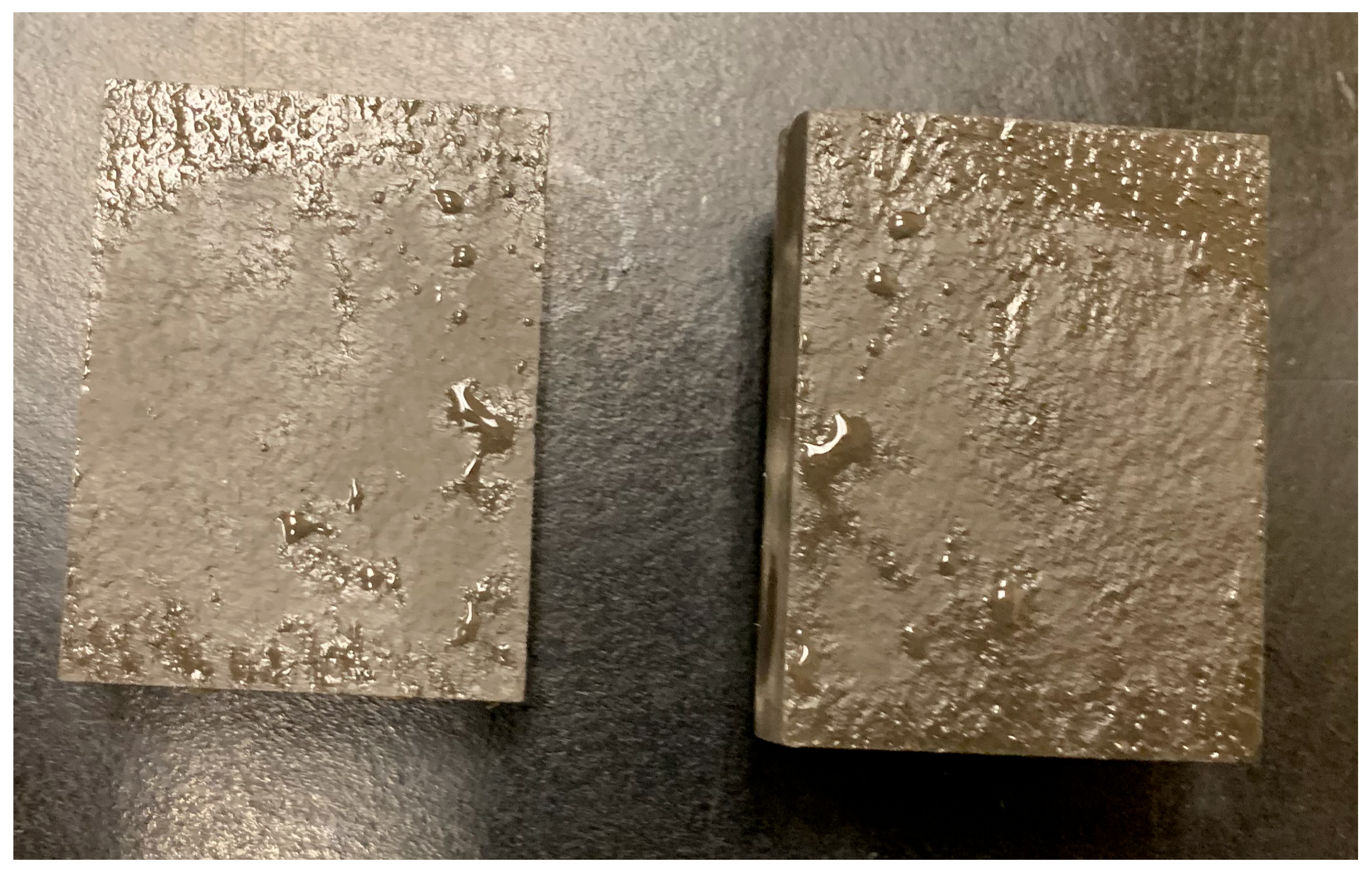

- Fracturing of intact core plugs—after completing the lean gas HNP experiments using the intact core plugs, the core plugs were fractured under stress within the coreholder using the procedure of Ghanizadeh et al. [3]. The axial pressure was increased in a stepwise manner, while the radial pressure was kept constant until the core plugs fractured. Sample #1 and #2 were both fractured using this procedure, while Sample #3 was unintentionally fractured during oil saturation (Step 3). Hence, for Sample #3, the intact core HNP test (Step 6) was skipped and Step 8 was implemented directly.

- Lean gas HNP with fractured core plugs—following Step 7, lean gas HNP experiments were conducted on the fractured core plugs under similar conditions to the intact core HNP tests. Another four HNP cycles were performed for each core sample (Sample #1, #2, and #3).

- Post-test liquid (oil) permeability measurement—after the HNP tests, liquid (oil) permeability was measured again on the fractured core plugs under stress loading (500–4000 psi) and unloading (4000–500 psi) conditions, to evaluate permeability hysteresis.

5. Results

5.1. Matrix Permeability

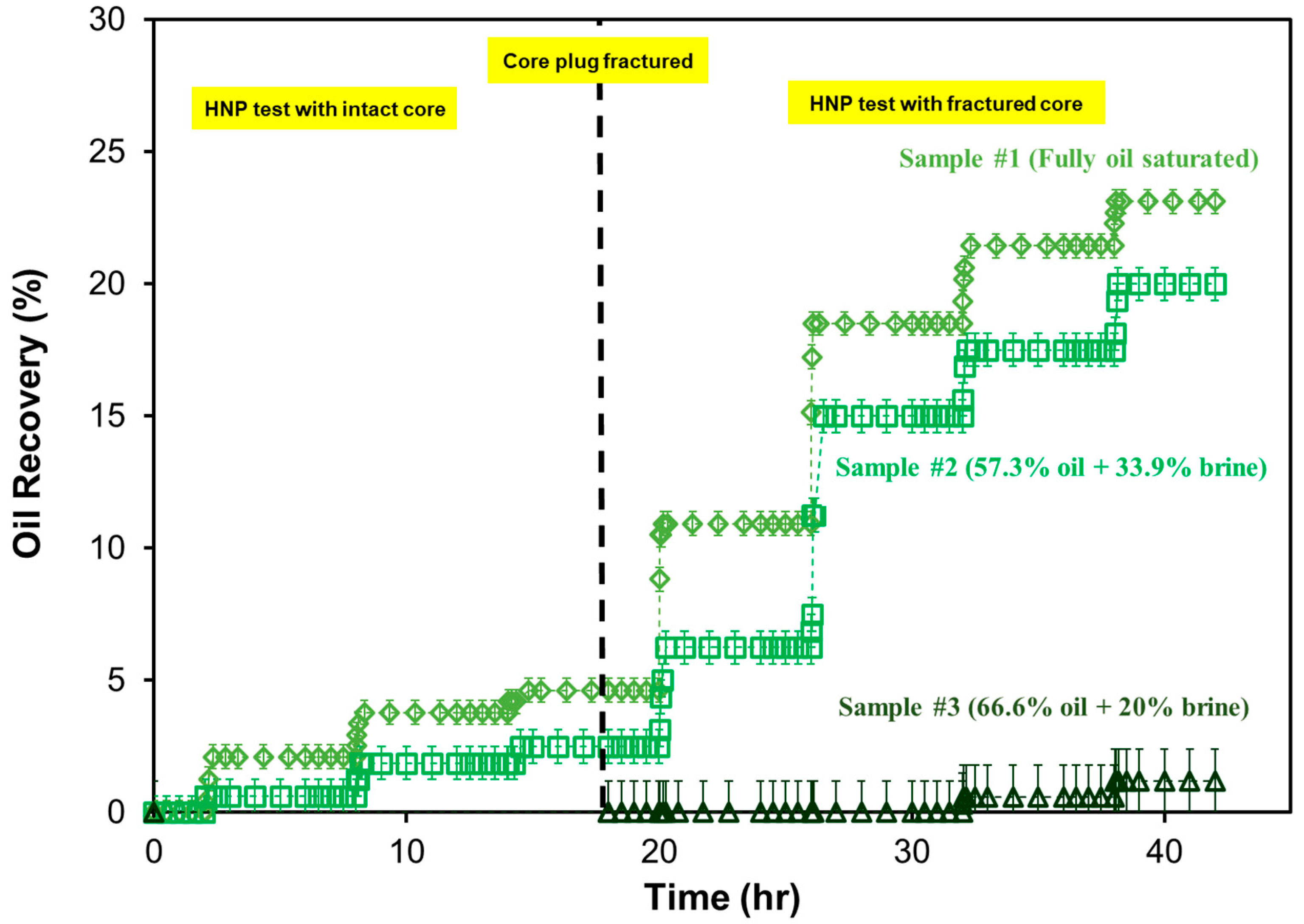

5.2. Lean Gas HNP Recovery

5.3. Post-Test Permeability Evaluation with Fractured Core Plugs

6. Discussion

- (1)

- Low solubility of the main components of the injected lean gas (80% C1 + 20% C2) in brine. For example, Zhao et al. [36] conducted methane solubility tests in brine with salinity up to 234 g/L, which is similar to the Montney Formation brine used in this study (~210 g/L). Those tests yielded a methane solubility of only ~0.00081 mol/mol at 1450 psi and 25 °C. Kim et al. [37] reported that the solubility of ethane in brine was even lower than methane (e.g., 0.00043 mol/mol under 1450 psi and 10 °C). Solubility values of both of these components in brine are orders of magnitude lower than in liquid hydrocarbons (e.g., ~0.015 mol/mol for methane and ~0.053 mol/mol for ethane at 145 psi and 200 °C) [38]. The low solubility of lean gas components in brine reduces gas injectivity into the tight rock matrix when brine is present [39].

- (2)

- Low oil phase relative permeability at high brine saturations. For example, Ghanizadeh et al. [30] reported that oil phase relative permeability decreases from 1 to 0. 3 as water saturation increases from 0% to 41% for a Montney core plug, which in turn limits oil mobility and overall recovery. The brine saturations selected in the current study are within a range that significantly affects oil relative permeability, allowing the impact of brine saturation on oil recovery during lean gas HNP to be evaluated.

7. Conclusions

- Three cycles of lean gas HNP were performed on intact core samples (Sample #1 and #2), resulting in recovery factors of 4.6% and 2.5%, respectively.

- Four additional lean gas HNP cycles were performed on the core plugs (under similar conditions to the intact core plugs) following artificial fracturing. This led to an increase in the recovery factors of 23.1% for Sample #1 and 20% for Sample #2.

- The presence of fractures significantly improves oil recovery by increasing the contact area between injected gas and in-place oil, which enhances mass transfer and fluid flow within the matrix-fracture system.

- Lower brine saturation within the matrix normally contributes to a higher oil recovery during the lean gas HNP process.

- In addition to saturation, water distribution is another critical factor influencing the recovery performance. For the first time, this study quantified the negative effect of heterogeneous brine distribution on recovery performance for lean gas HNP in tight oil reservoirs. It was determined that brine concentrated near fracture surfaces for one of the samples (Sample #3) significantly hindered lean gas diffusion into the matrix and reduced oil recovery (i.e., 1.2% only).

- For reservoirs that have just undergone hydraulic fracturing or waterflooding, appropriate reservoir conditioning and injection strategies should be applied to mitigate the adverse effects of heterogeneous brine distribution on EOR performance.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Song, C.; Yang, D. Experimental and Numerical Evaluation of CO2 Huff-n-puff Processes in Bakken Formation. Fuel 2017, 190, 145–162. [Google Scholar] [CrossRef]

- Hoffman, B.T. Huff-N-Puff Gas Injection Pilot Projects in the Eagle Ford. In Proceedings of the SPE Canada Unconventional Resources Conference, Calgary, AB, Canada, 13–14 March 2018. Paper SPE-189816-MS. [Google Scholar] [CrossRef]

- Ghanizadeh, A.; Song, C.; Hamdi, H.; Clarkson, C.R. Experimental and Computational Evaluation of Cyclic Solvent Injection in Fractured Tight Hydrocarbon Reservoirs. Sci. Rep. 2021, 11, 9497. [Google Scholar] [CrossRef]

- Tang, W.; Sheng, J.J. Huff-n-puff Gas Injection or Gas Flooding in Tight Oil Reservoirs? J. Pet. Sci. Eng. 2022, 208, 109725. [Google Scholar] [CrossRef]

- Milad, M.; Jinin, R.; Sidek, A.; Imqam, A.; Tarhuni, M. Huff-n-Puff Technology for Enhanced Oil Recovery in Shale/Tight Oil Reservoirs: Progress, Gaps, and Perspectives. Energy Fuels 2021, 35, 17279–17333. [Google Scholar] [CrossRef]

- Ma, M.; Zhang, Q.; Emami-Meybodi, H. A Proxy-based Workflow for Screening and Optimizing Cyclic CO2 Injection in Shale Reservoirs. Fuel 2025, 400, 135742. [Google Scholar] [CrossRef]

- Emami-Meybodi, H.; Ma, M.; Zhang, F.; Rui, Z.; Rezaeyan, A.; Ghanizadeh, A.; Hamdi, H.; Clarkson, C.R. Cyclic Gas Injection in Low-Permeability Oil Reservoirs: Progress in Modeling and Experiments. SPE J. 2024, 29, 6217–6250. [Google Scholar] [CrossRef]

- Thomas, F.B.; Piwowar, M.; Noroozi, M.; Gibb, W.; Marin, J.; Zhang, H. Experimental Measurements of Montney and Duvernay Gas-Cycling Enhanced Oil Recovery GCEOR. In Proceedings of the SPE Canada Unconventional Resources Conferences, Virtual, 29 September–2 October 2020. Paper 199994-MS. [Google Scholar] [CrossRef]

- Torabi, F.; Asghari, K. Effect of Operating Pressure, Matrix Permeability and Connate Water Saturation on Performance of CO2 Huff-and-puff Process in Matrix-fracture Experimental Model. Fuel 2010, 89, 2985–2990. [Google Scholar] [CrossRef]

- Sheng, J.J. Critical Review of Field EOR Projects in Shale and Tight Reservoirs. J. Pet. Sci. Eng. 2017, 159, 654–665. [Google Scholar] [CrossRef]

- Zhu, C.; Guo, W.; Wang, Y.; Li, Y.; Gong, H.; Xu, L.; Dong, M. Experimental Study of Enhanced Oil Recovery by CO2 Huff-n-puff in Shales and Tight Sandstones with Fractures. Pet. Sci. 2021, 18, 852–869. [Google Scholar] [CrossRef]

- Liu, F.; Kang, Y.; Zhang, M.; Hu, Y.; Huang, Y.; Li, L.; Pan, H. Comparative Study on the Macroscopic Exploitation and Microscopic Mobilization Characteristics of CO2 and N2 HNP to Enhance Shale Oil Recovery. Energy Fuels 2024, 38, 5974–5987. [Google Scholar] [CrossRef]

- Xia, Y.; Xin, X.; Yu, G.; Wang, Y.; Lei, Z.; Zhang, L. Design of CO2 Huff-n-Puff Parameters for Fractured Tight Oil Reservoirs Considering Geomechanical Effects. Processes 2024, 12, 2777. [Google Scholar] [CrossRef]

- Du, D.; Pu, W.; Jin, F.; Liu, R. Experimental Study on EOR by CO2 Huff-n-puff and CO2 Flooding in Tight Conglomerate Reservoirs with Pore Scale. Chem. Eng. Res. Des. 2020, 156, 425–432. [Google Scholar] [CrossRef]

- Mahzari, P.; Mitchell, T.M.; Jones, A.P.; Oelkers, E.H.; Striolo, A.; Iacoviellom, F.; Shearing, P.R.; Juri, J.E. Novel Laboratory Investigation of Huff-n-puff Gas Injection for Shale Oils under Realistic Reservoir Conditions. Fuel 2021, 284, 118950. [Google Scholar] [CrossRef]

- Wang, L.; Tian, Y.; Yu, X.; Wang, C.; Yao, B.; Wang, S.; Winterfeld, P.H.; Wang, X.; Yang, Z.; Wang, Y.; et al. Advances in Improved/Enhanced Oil Recovery Technologies for Tight and Shale Reservoirs. Fuel 2017, 210, 425–445. [Google Scholar] [CrossRef]

- Song, C.; Ghanizadeh, A.; Younis, A.; Clarkson, C.R. Experimental Evaluation of the Impact of Induced Fractures on Cyclic Solvent Injection Performance in Low-Permeability Hydrocarbon Reservoirs. Fuel 2023, 354, 129327. [Google Scholar] [CrossRef]

- Shilov, E.; Dorhjie, D.B.; Mukhina, E.; Zvada, M.; Kasyanenko, A.; Cheremisin, A. Experimental and Numerical Studies of Rich Gas Huff-n-puff Injection in Tight Formation. J. Pet. Sci. Eng. 2022, 208, 109420. [Google Scholar] [CrossRef]

- Bai, H.; Zhang, Q.; Li, Z.; Li, B.; Zhu, D.; Zhang, L.; Lv, G. Effect of Fracture on Production Characteristics and Oil Distribution during CO2 Huff-n-puff under Tight and Low-permeability Conditions. Fuel 2019, 246, 117–125. [Google Scholar] [CrossRef]

- Zheng, T.; Yang, Z.; Liu, X.; Luo, Y.; Xiao, Q.; Zhang, Y.; Zhao, X. Understanding Immiscible Natural Gas Huff-N-Puff Seepage Mechanism in Porous Media: A Case Study of CH4 Huff-n-Puff by Laboratory Numerical Simulations in Chang-7 Tight Core. Nat. Resour. Res. 2021, 30, 2397–2411. [Google Scholar] [CrossRef]

- Guo, Y.; Shi, Y.; Mohanty, K. Comparison of the Effectiveness of CO2 and Hydrocarbon Gas for Shale Huff ’n’ Puff. SPE J. 2025, 30, 2942–2957. [Google Scholar] [CrossRef]

- Li, H.; Zheng, S.; Yang, D. Enhanced Swelling Effect and Viscosity Reduction of Solvent(s)/CO2/Heavy-oil Systems. SPE J. 2013, 18, 695–707. [Google Scholar] [CrossRef]

- Thomas, F.B.; Noroozi, M.; Apil, R.; White, A. Considerations for Gas Cycling EOR. In Proceedings of the SPE Workshop: The Duvernay Liquid Rich Shale—What Makes It Different and How We Optimize it? Calgary, AB, Canada, 18 October 2017. [Google Scholar]

- Ghedan, S. Global Laboratory Experience of CO2-EOR Flooding. In Proceedings of the SPE/EAGE Reservoir Characterization and Simulation Conference, Dhabi, United Arab Emirates, 19–21 October 2009. Paper SPE 125581. [Google Scholar] [CrossRef]

- Pu, W.; Wei, B.; Jin, F.; Li, Y.; Jia, H.; Liu, P.; Tang, Z. Experimental Investigation of CO2 Huff-n-puff Process for Enhancing Oil Recovery in Tight Reservoirs. Chem. Eng. Res. Des. 2016, 111, 269–276. [Google Scholar] [CrossRef]

- Assef, Y.; Kantzas, A.; Almao, P.P. Numerical Modelling of Cyclic CO2 Injection in Unconventional Tight Oil Resources; Trivial Effects of Heterogeneity and Hysteresis in Bakken Formation. Fuel 2019, 236, 1512–1528. [Google Scholar] [CrossRef]

- Morel, D.; Bourbiaux, B.; Latil, M.; Thiebot, B. Diffusion Effects in Gas Flooded Light Oil Fractured Reservoirs. SPE Adv. Technol. Ser. 1993, 1, 100–109. [Google Scholar] [CrossRef]

- Silva, F.V.; Belery, P. Molecular Diffusion in Naturally Fractured Reservoirs: A Decisive Recovery Mechanism. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 8 October 1989. Paper SPE-19672-MS. [Google Scholar] [CrossRef]

- Ellafi, A.; Jabbari, H. Understanding the Mechanisms of Huff-n-Puff, CO2-EOR in Liquid-Rich Shale Plays: Bakken Case Study. In Proceedings of the SPE Canada Unconventional Resources Conference, Virtual, 29 September–2 October 2020. Paper SPE-200001-MS. [Google Scholar] [CrossRef]

- Ghanizadeh, A.; Song, C.; Clarkson, C.R.; Younis, A. Relative Permeability of Tight Hydrocarbon Systems: An Experimental Study. Fuel 2021, 294, 119487. [Google Scholar] [CrossRef]

- Jone, S.C. A Technique for Faster Pulse-Decay Permeability Measurements in Tight Rocks. SPE Form. Eval. 1997, 12, 19–25. [Google Scholar] [CrossRef]

- Keneti, S.A.R.; Wong, R.C.K. Investigation of Anisotropic Behavior of Montney Shale Under Indirect Tensile Strength Test. In Proceedings of the Canadian Unconventional Resources & International Petroleum Conference, Calgary, AB, Canada, 19–21 October 2010. Paper CSUS/SPE 138104. [Google Scholar]

- Vaisblat, N.; Shokri, A.R.; Ayranci, K.; Harris, N.; Chalaturnyk, R.J. Significance of Rock Compositional Control on Geomechanical Properties and Hydraulic Fracturing of the Montney Formation, Western Canadian Basin. In Proceedings of the Unconventional Resources Technology Conference (URTeC), Brisbane, Australia, 18–19 November 2019. Paper URTEC-198199-MS. [Google Scholar]

- Becerra Rondon, D.M. Geological Characterization and Evaluation of Reservoir Quality in the Montney Formation in West-Central Alberta. Doctoral Thesis, University of Calgary, Calgary, AB, Canada, 2022. Available online: http://hdl.handle.net/1880/114729 (accessed on 10 October 2025).

- Davarpanah, A.; Mirshekari, B. Experimental Study of CO2 Solubility on the Oil Recovery Enhancement of Heavy Oil Reseroirs. J. Therm. Anal. Calorim. 2020, 139, 1161–1169. [Google Scholar] [CrossRef]

- Zhao, Y.; Yu, J.; Shi, H.; Guo, J.; Liu, D.; Lin, J.; Song, S.; Wu, H.; Gong, J. Study of Methane Solubility Calculation Based on Modified Henry’s Law and BP Neural Network. Processes 2024, 12, 1901. [Google Scholar] [CrossRef]

- Kim, Y.S.; Lim, B.D.; Lee, J.E.; Lee, C.S. Solubilities of Carbon Dioxide, Methane, and Ethane in Sodium Chloride Solution Containing Gas Hydrate. J. Chem. Eng. Data 2008, 53, 1351–1354. [Google Scholar] [CrossRef]

- Riazi, M.R.; Vera, J.H. Method to Calculate the Solubility of Light Gases in Petroleum and Coal Liquid Fractions on the Basis of Their P/N/A Composition. Ind. Eng. Chem. Res. 2005, 44, 186–192. [Google Scholar] [CrossRef]

- Soltanian, M.R.; Amoois, M.A.; Cole, D.R.; Darrah, T.H.; Graham, D.E.; Pfiffner, S.M.; Phelps, T.J.; Moortgat, J. Impacts of Methane on Carbon Dioxide Storage in Brine Formations. Groundwater 2018, 56, 176–186. [Google Scholar] [CrossRef]

| No. | Formation | Sample Condition | Gas Type | Porosity (%) | Permeability (md) | Initial Brine Saturation (%) | Cycle No. | Final Recovery (%) | Reference |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Duvernay, Canada | Fractured | CO2 | 3.2 | 0.000125 | 0 | 4 | 45 | [3] |

| Duvernay, Canada | Fractured | Lean Gas | 2.1 | 0.000125 | 0 | 4 | 29 | ||

| 2 | Montney/Duvernay Canada | Fractured | Lean gas | 6 | ~0.0008 | 20 | 7 | ~35 | [8] |

| 3 | Bakken, Canada | Intact | CO2 | 18.6–23.1 | 0.56–0.83 | 35.8–57.1 | 6 | 42.8–63 | [1] |

| 4 | Haynesville Shale USA | Fractured | Lean gas | 8 | 0.0006–0.0009 | ~11 | 7 | 35–50 | [15] |

| 5 | Anonymous | Intact | CO2 | 9.0 | 0.88 | 42.4 | 3 | 37 | [14] |

| 6 | Ordos Basin, China | Intact | CO2 | 9.6 | 0.012 | 0 | 3 | ~70 | [11] |

| Intact | 3.8 | 0.00053 | 3 | ~55 | |||||

| Fractured | 8.9 | 0.018 | 3 | ~78 | |||||

| Intact | 4.3 | 0.00025 | 3 | ~58 | |||||

| 7 | Anonymous, Russia | Intact | Rich gas | 4.1–17.0 | N/A | 0 | 5 | 29–88 | [18] |

| Anonymous, Russia | Fractured | 2.3–10.9 | N/A | 5 | 41–88 | ||||

| 8 | Anonymous | Intact | CO2 | 6.5 | 0.89 | N/A | 1 | 23 | [19] |

| Anonymous | Fractured | 6.8 | 0.89 | 1 | 13 | ||||

| 9 | Ordos Basin, China | Intact | CH4 | 11.4 | 0.145 | 57.7 | 3 | 25 | [20] |

| Rich gas | 11.7 | 0.145 | 60.6 | 3 | 31 | ||||

| 10 | Anonymous | Intact | CO2 | 11.9 | 0.001 | 0 | 6 | 84 | [21] |

| Rich gas | 11.7 | 0.001 | 6 | 74 |

| Quartz (wt.%) | K-Feldspar (wt.%) | Plag. Feldspar (wt.%) | Calcite (wt.%) | Dolomite (wt.%) | Pyrite (wt.%) | Illite (wt.%) | Chlorite (wt.%) |

|---|---|---|---|---|---|---|---|

| 42.03 | 7.82 | 15.9 | 1.69 | 7.59 | 2.3 | 18.47 | 4.2 |

| Sample ID | Depth (m) | Bulk Density (g/cm3) | Grain Density (g/cm3) | Helium Porosity (%) | Pulse-Decay (N2) Gas Permeability (md) 1 |

|---|---|---|---|---|---|

| #1 | 2149.2 | 2.59 | 2.70 | 4.2 | 0.00042 |

| #2 | 2149.2 | 2.61 | 2.73 | 4.4 | 0.00078 |

| #3 | 2156.9 | 2.64 | 2.71 | 2.6 | 0.00022 |

| Fluid | Density (g/cm3) [25 °C, 1 atm] | Viscosity (cP) [25 °C, 1 atm] | Compressibility (psi−1) [25 °C, 1 atm] |

|---|---|---|---|

| Montney Dead Oil | 0.83 | 2.48 | 0.0000052 |

| Fluid | Density (g/cm3) [25 °C, 1 atm] | Viscosity (mPa.s) [25 °C, 1 atm] | Compressibility (psi−1) [25 °C, 1 atm] |

|---|---|---|---|

| Synthetic brine | 1.04 | 0.998 | 0.000003 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, C.; Ghanizadeh, A.; Clarkson, C.R. The Impact of Brine Saturation and Distribution on Lean Gas Huff-n-Puff EOR Performance of Tight Oil Reservoirs: Examples from the Montney Formation (Canada). Energies 2025, 18, 5537. https://doi.org/10.3390/en18205537

Song C, Ghanizadeh A, Clarkson CR. The Impact of Brine Saturation and Distribution on Lean Gas Huff-n-Puff EOR Performance of Tight Oil Reservoirs: Examples from the Montney Formation (Canada). Energies. 2025; 18(20):5537. https://doi.org/10.3390/en18205537

Chicago/Turabian StyleSong, Chengyao, Amin Ghanizadeh, and Christopher R. Clarkson. 2025. "The Impact of Brine Saturation and Distribution on Lean Gas Huff-n-Puff EOR Performance of Tight Oil Reservoirs: Examples from the Montney Formation (Canada)" Energies 18, no. 20: 5537. https://doi.org/10.3390/en18205537

APA StyleSong, C., Ghanizadeh, A., & Clarkson, C. R. (2025). The Impact of Brine Saturation and Distribution on Lean Gas Huff-n-Puff EOR Performance of Tight Oil Reservoirs: Examples from the Montney Formation (Canada). Energies, 18(20), 5537. https://doi.org/10.3390/en18205537