Scaling of Automotive Fuel Cells in Terms of Operating Indicators

Abstract

1. Introduction

1.1. Requirements for Fuel Cells

- The cell designs and their current characteristics (mainly the power density).

- Current losses occurring in cells.

- The scalability of fuel cells.

1.2. Fuel Cells in the Automotive Industry

- A 30% demand for hydrogen in 2030 in the EU, Japan, Korea and the US. These regions could represent up to 60% of the total demand.

- A potential price range for clean hydrogen of USD 1–12/kg H2 (the price variation depends on the end user and geographical region).

1.3. Assessment Capabilities for Fuel Cells

1.3.1. Modern Fuel Cells Research

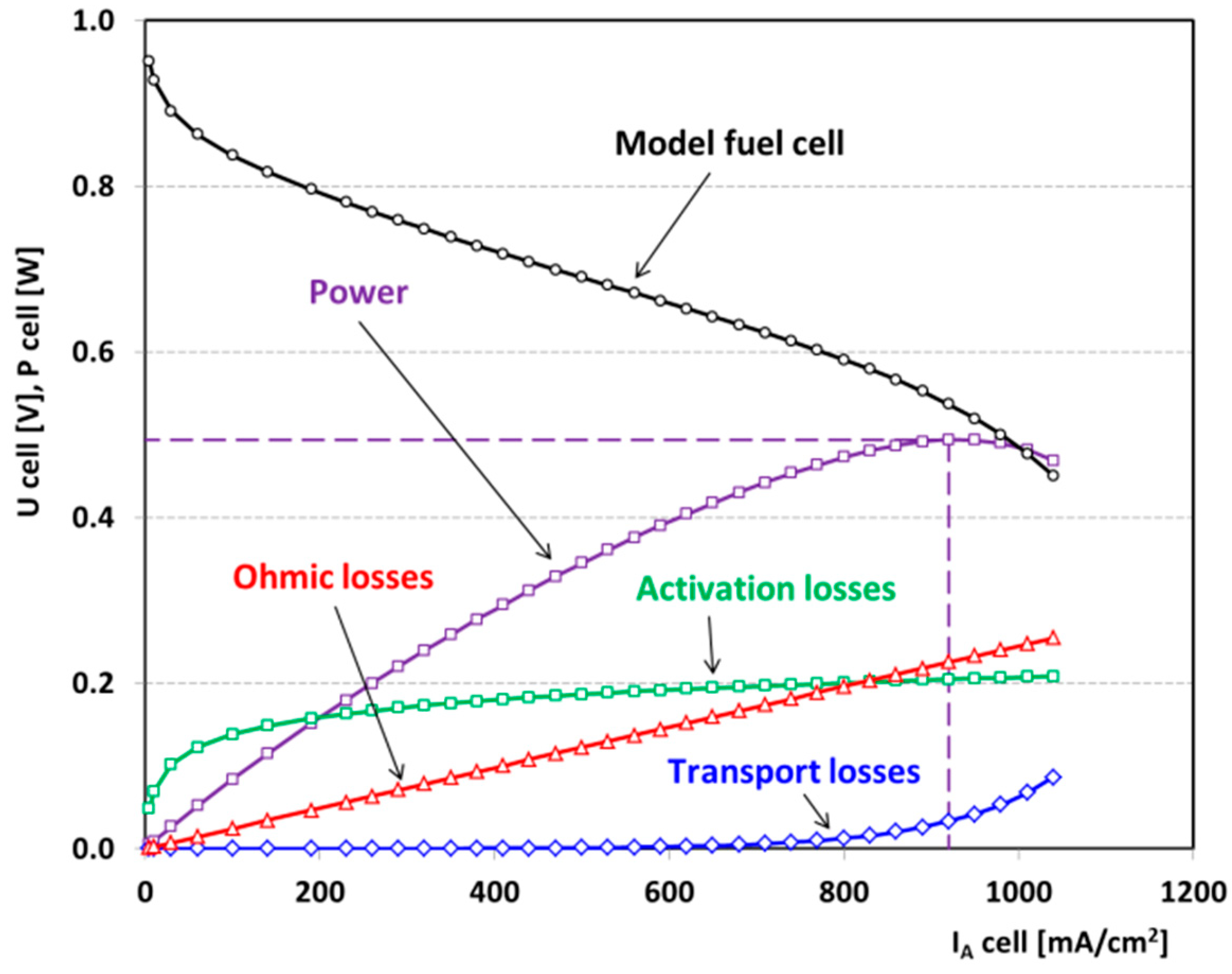

- Voltage activation (activation losses).

- Resistive (ohmic losses).

- Mass transport (transport losses).

1.3.2. Scalability of Fuel Cells

2. Materials and Methods

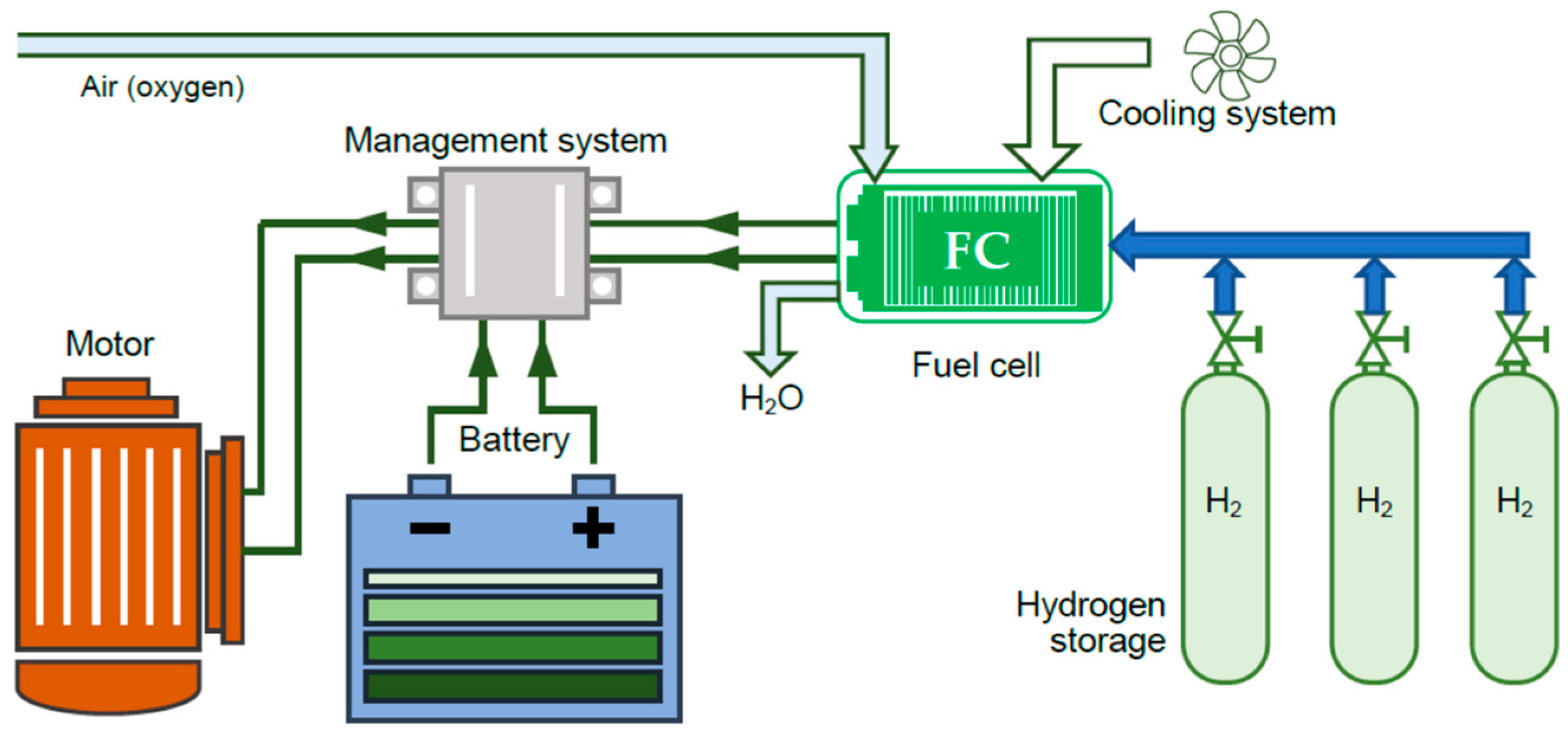

2.1. FCHEV Vehicle

| Component | Parameter | Mirai II Gen. |

|---|---|---|

| Vehicle | mass | 2415 kg |

| top speed | 175 km/h | |

| acceleration 0 to 60 mph | 9.2 s | |

| range (homologation cycle) | 650 km | |

| Fuel cell | type | PEM (polymer electrolyte) |

| power | 128 kW (174 KM) | |

| power density | 5.4 kW/kg; 5.4 kW/dm3 (excl. end plates) | |

| number of cells | 330 | |

| Motor | type | permanent magnet synchronous |

| peak power | 134 kW at 6940 rpm | |

| maximum torque | 300 Nm | |

| maximum speed | 16,500 rpm | |

| Battery | type | Li-Ion |

| capacity | 4 Ah | |

| output | 31.5 kW × 10 s | |

| nominal voltage | 310.8 V (3.7 V × 84) | |

| energy | 1.24 kWh | |

| Hydrogen storage | internal volume | 142.2 dm3 |

| nominal pressure | 70 MPa | |

| mass | 5.6 kg |

2.2. HEL 1.2 kW System

- Driving the vehicle while acquiring basic vehicle operating parameters and data of the fuel cell stack and high-voltage batteries. The authors used specialised TechStream measuring equipment dedicated to Toyota vehicles, enabling data to be retrieved from the OBD system at a frequency of 1 Hz (as required by regulations). For the purposes of this article, only a few measurement values were used: the vehicle speed and electric motor speed and the voltage and current from the electric motor, HV battery, fuel cell, voltage converter data, temperature and pressure at several different points in the hydrogen storage system. The data were read from a single vehicle controller, which was the EV (electric drive) controller.

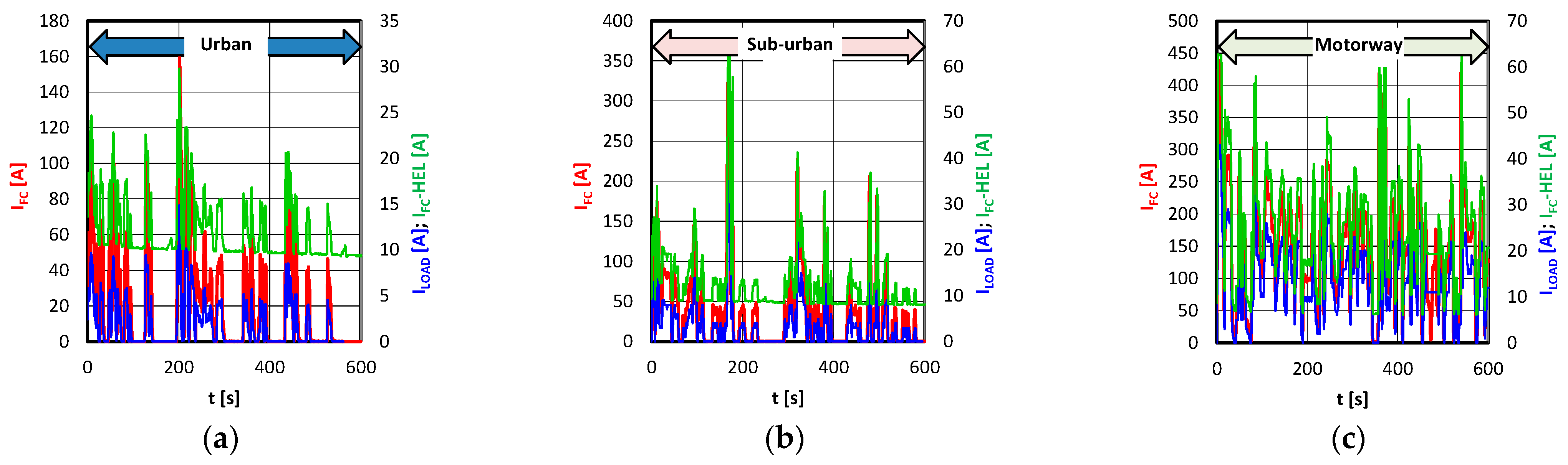

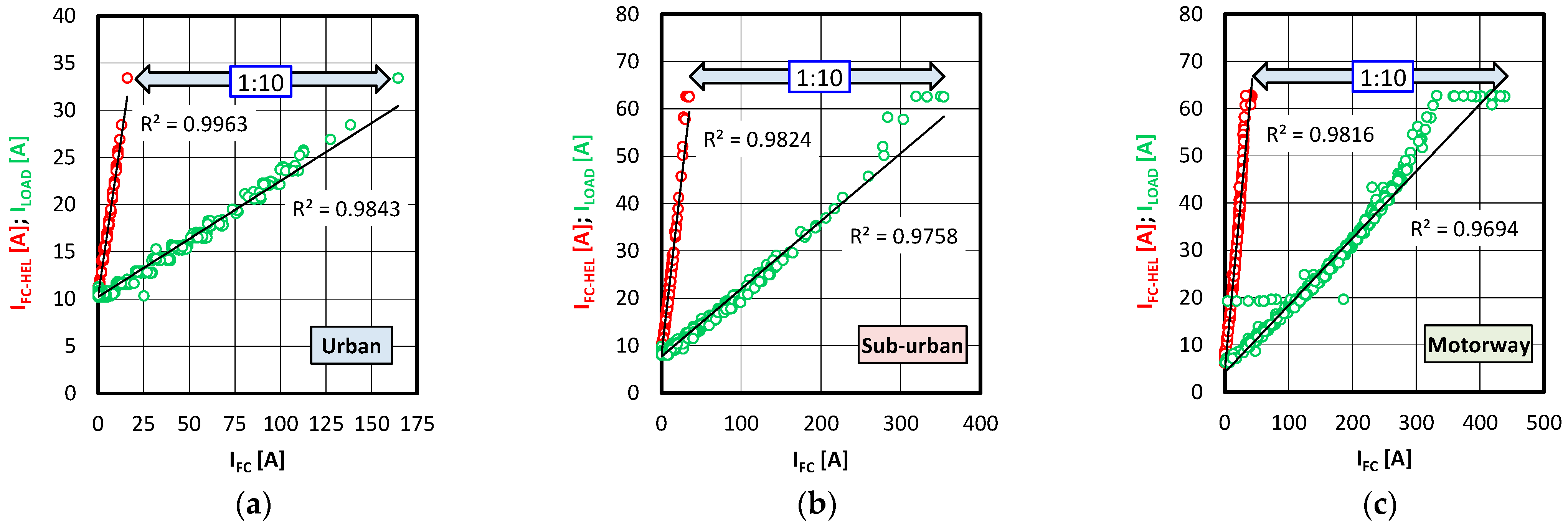

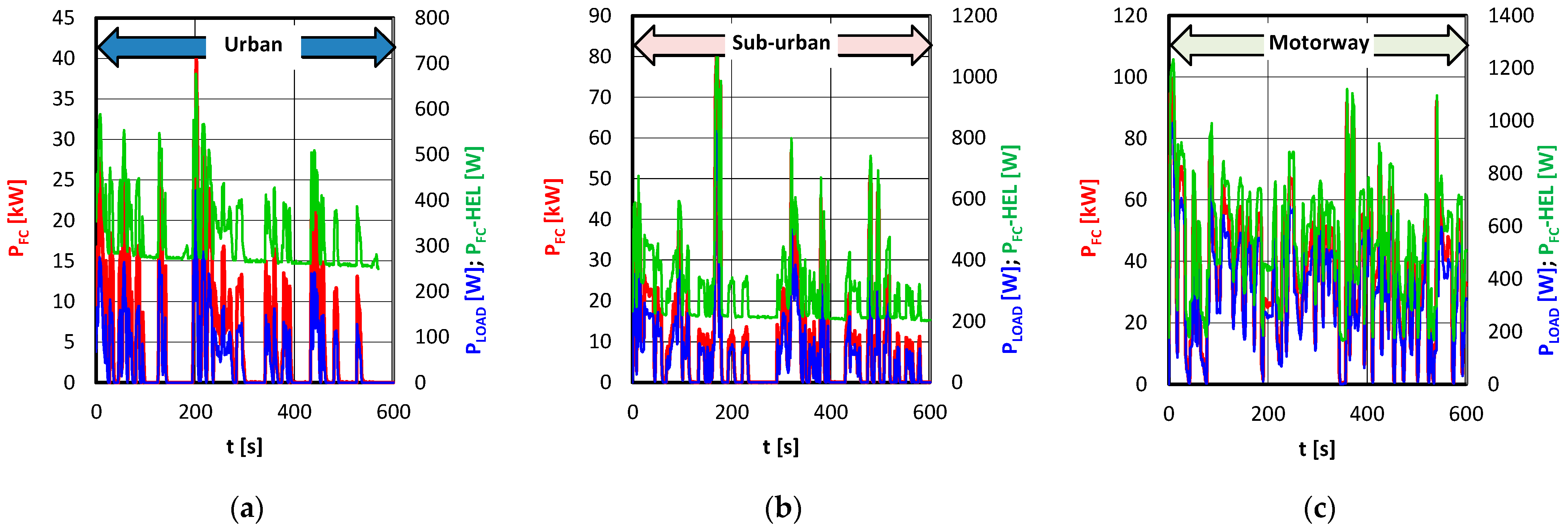

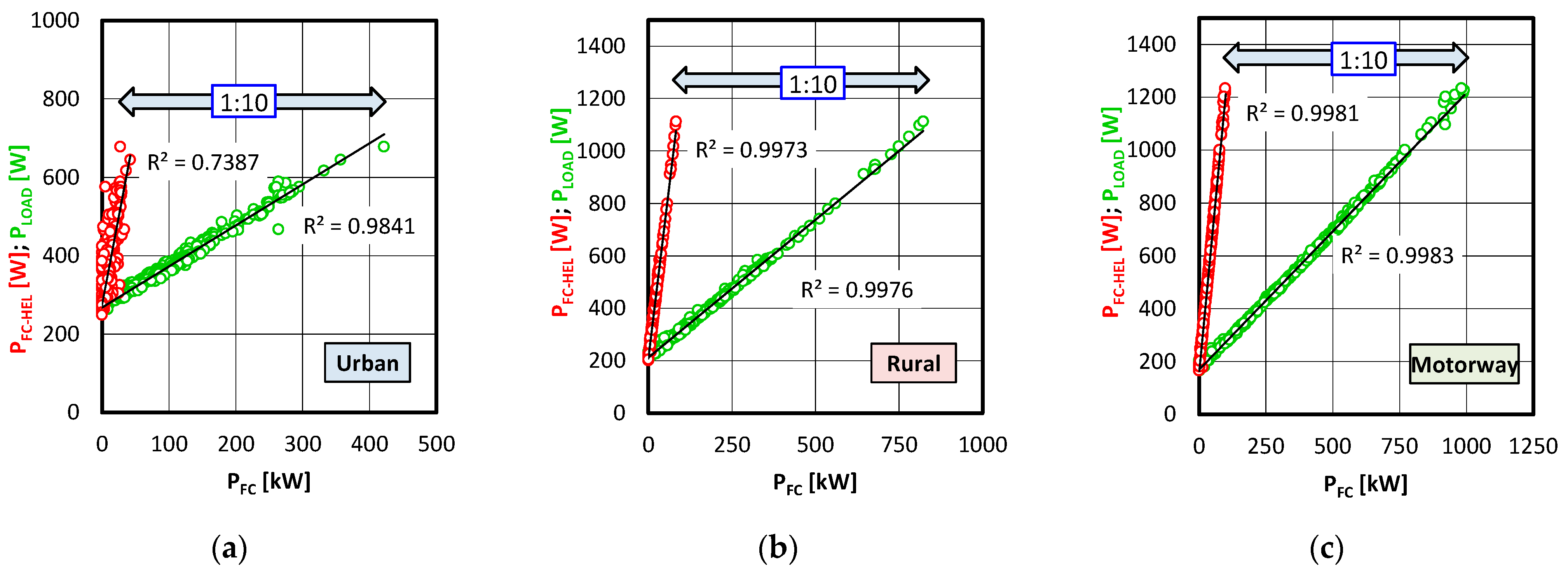

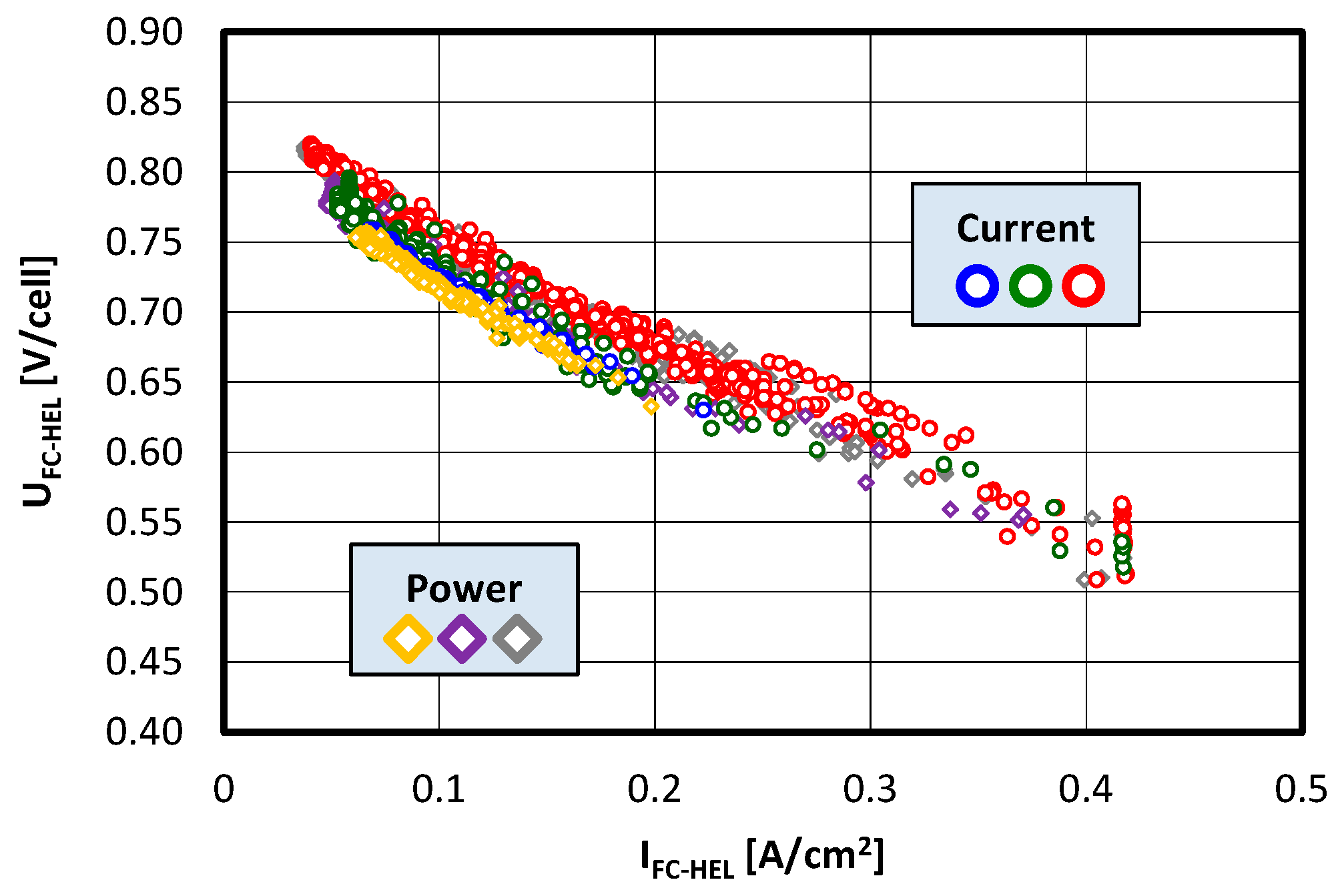

- Due to the use of the HEL system (with a power of 1.2 kW), the cell current and cell power values were scaled down by a factor of 1:100.

- The HEL system allows the load value to be set using a programmable control device. It is possible to obtain a load in the form of current or power.

- The set load is not directly the cell load but the system load (as shown in Figure 4b). This approach means that the scaling will not directly apply to the cell stack (Mirai)–cell stack (HEL), but only to the cell stack (Mirai)–system load (HEL).

3. Results

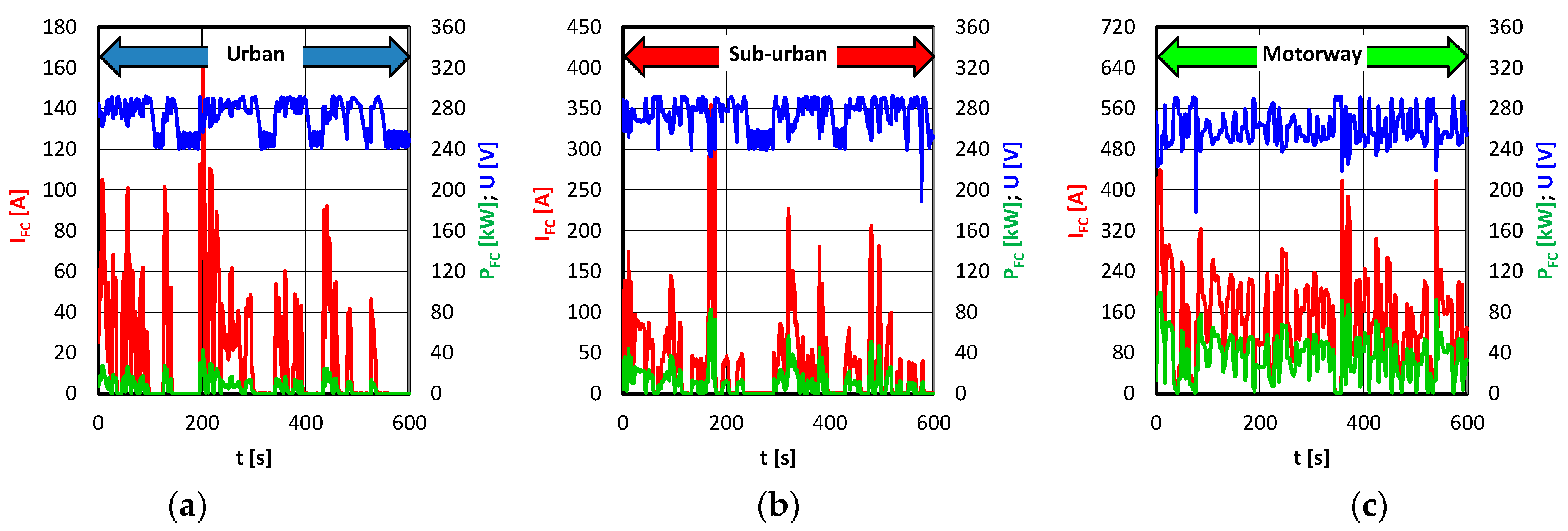

3.1. Results of Road Tests of the Toyota Mirai Vehicle

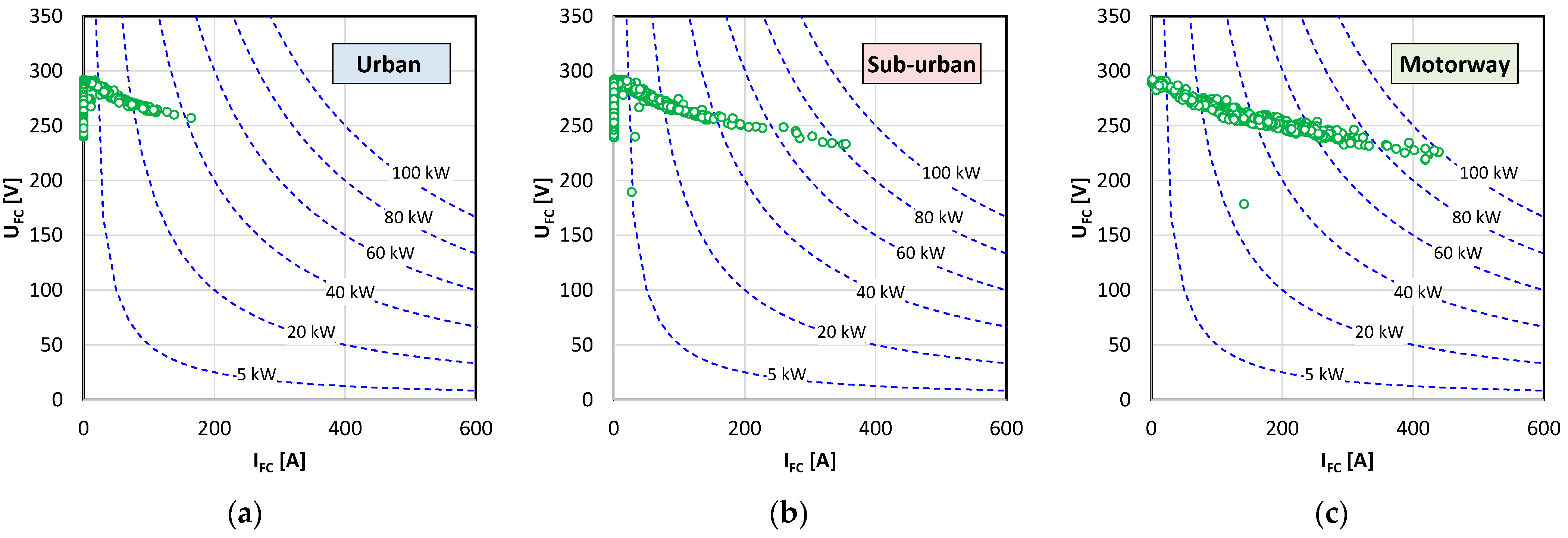

3.2. Fuel Cell Stack Scaling

4. Discussion

5. Conclusions

- In order to compare the characteristics of fuel cells, it is necessary to know the number and ion exchange surface area of such cells in order to evaluate the unit voltage and current of the cell rather than the stack. It is possible to compare cells by presenting the general characteristics of the stacks, but these characteristics are not reliable.

- It is possible to scale fuel cells to laboratory conditions (single cell) while maintaining appropriate conditions (a static test or driving test) or to road conditions, as presented in this study.

- Scaling the current or power of the cell means that the characteristics obtained do not differ from each other. It follows that there is a high degree of independence in the choice of the scaled quantity in order to determine the similarity of the scale.

- Despite certain changes in temperature (Figure 10) during each phase of driving, this does not have a significant impact on cell scaling; this is mainly due to the fact that a hydrogen injection occurs after a three-stage pressure reduction, which significantly stabilises the temperature of the hydrogen.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AC | alternating current |

| AFC | Alkaline Fuel Cell |

| CO2 | carbon dioxide |

| DC | direct current |

| DMFC | Direct Methanol Fuel Cell |

| FC | fuel cell |

| FCEV | fuel cell electric vehicle |

| FCHEV | fuel cell hybrid electric vehicle |

| H2 | hydrogen |

| HDV | heavy-duty vehicles |

| HEL | Hybrid Energy Lab |

| I | current |

| LDV | light-duty vehicles |

| Li-Ion | lithium-ion |

| MCFC | Molten Carbonate Fuel Cell |

| P | power |

| PAFC | Phosphoric Acid Fuel Cell |

| PC | passenger cars |

| PEM | Proton Exchange Membrane |

| RDE | Real Driving Emissions |

| SOFC | solid oxide fuel cell |

| t | time |

| U | voltage |

References

- Von Tettau, P.; Sterlepper, S.; Mauermann, P.; Wick, M.; Tinz, S.; Jesser, M.; Walters, M.; Pischinger, S. Laboratory Assessments Applied to Mass-Produced Automotive Fuel Cells. Int. J. Hydrogen Energy 2024, 52, 1127–1136. [Google Scholar] [CrossRef]

- McKinsey & Company. Hydrogen Scaling Up. A Sustainable Pathway for the Global Energy Transition; McKinsey & Company: New York, NY, USA, 2017. [Google Scholar]

- McKinsey & Company. Hydrogen: Closing the Cost Gap Unlocking Demand for Clean Hydrogen by 2030; McKinsey & Company: New York, NY, USA, 2025. [Google Scholar]

- Ding, D.; Wu, X.-Y. Hydrogen Fuel Cell Electric Trains: Technologies, Current Status, and Future. Appl. Energy Combust. Sci. 2024, 17, 100255. [Google Scholar] [CrossRef]

- Böhm, M.; Fernández Del Rey, A.; Pagenkopf, J.; Varela, M.; Herwartz-Polster, S.; Nieto Calderón, B. Review and Comparison of Worldwide Hydrogen Activities in the Rail Sector with Special Focus on On-Board Storage and Refueling Technologies. Int. J. Hydrogen Energy 2022, 47, 38003–38017. [Google Scholar] [CrossRef]

- Rees, N.V.; Compton, R.G. Carbon-Free Energy: A Review of Ammonia- and Hydrazine-Based Electrochemical Fuel Cells. Energy Environ. Sci. 2011, 4, 1255. [Google Scholar] [CrossRef]

- Luo, Y.; Wu, Y.; Li, B.; Mo, T.; Li, Y.; Feng, S.-P.; Qu, J.; Chu, P.K. Development and Application of Fuel Cells in the Automobile Industry. J. Energy Storage 2021, 42, 103124. [Google Scholar] [CrossRef]

- Das, H.S.; Tan, C.W.; Yatim, A.H.M. Fuel Cell Hybrid Electric Vehicles: A Review on Power Conditioning Units and Topologies. Renew. Sustain. Energy Rev. 2017, 76, 268–291. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, G.; Zhang, X.; Sun, C.; Jiao, K.; Wang, Y. Thermal Management of Polymer Electrolyte Membrane Fuel Cells: A Review of Cooling Methods, Material Properties, and Durability. Appl. Energy 2021, 286, 116496. [Google Scholar] [CrossRef]

- Zhang, G.; Kandlikar, S.G. A Critical Review of Cooling Techniques in Proton Exchange Membrane Fuel Cell Stacks. Int. J. Hydrogen Energy 2012, 37, 2412–2429. [Google Scholar] [CrossRef]

- Wang, Y.; Ruiz Diaz, D.F.; Chen, K.S.; Wang, Z.; Adroher, X.C. Materials, Technological Status, and Fundamentals of PEM Fuel Cells—A Review. Mater. Today 2020, 32, 178–203. [Google Scholar] [CrossRef]

- Wallington, T.J.; Woody, M.; Lewis, G.M.; Keoleian, G.A.; Adler, E.J.; Martins, J.R.R.A.; Collette, M.D. Hydrogen as a Sustainable Transportation Fuel. Renew. Sustain. Energy Rev. 2025, 217, 115725. [Google Scholar] [CrossRef]

- Manzo, D.; Thai, R.; Le, H.T.; Venayagamoorthy, G.K. Fuel Cell Technology Review: Types, Economy, Applications, and Vehicle-to-Grid Scheme. Sustain. Energy Technol. Assess. 2025, 75, 104229. [Google Scholar] [CrossRef]

- Legala, A.; Kubesh, M.; Chundru, V.R.; Conway, G.; Li, X. Machine Learning Modeling for Fuel Cell-Battery Hybrid Power System Dynamics in a Toyota Mirai 2 Vehicle under Various Drive Cycles. Energy AI 2024, 17, 100415. [Google Scholar] [CrossRef]

- Matsunaga, M.; Fukushima, T.; Ojima, K. Powertrain System of Honda FCX Clarity Fuel Cell Vehicle. World Electr. Veh. J. 2009, 3, 820–829. [Google Scholar] [CrossRef]

- Sery, J.; Leduc, P. Fuel Cell Behavior and Energy Balance on Board a Hyundai Nexo. Int. J. Engine Res. 2022, 23, 709–720. [Google Scholar] [CrossRef]

- Wang, Y.; Yuan, H.; Martinez, A.; Hong, P.; Xu, H.; Bockmiller, F.R. Polymer Electrolyte Membrane Fuel Cell and Hydrogen Station Networks for Automobiles: Status, Technology, and Perspectives. Adv. Appl. Energy 2021, 2, 100011. [Google Scholar] [CrossRef]

- Di Pierro, G.; Bitsanis, E.; Tansini, A.; Bonato, C.; Martini, G.; Fontaras, G. Fuel Cell Electric Vehicle Characterisation under Laboratory and In--use Operation. Energy Rep. 2024, 11, 611–623. [Google Scholar] [CrossRef]

- Ballard Power Systems. Fuel Cell Power for Heavy Duty Applications. FCmove-XD; Ballard Power Systems: Burnaby, BC, Canada, 2025. [Google Scholar]

- Dolan, C.; Gangi, J.; Homann, Q.; Fink, V.; Kopasz, J. 2019 Fuel Cell Technologies Market Report; U.S. Department of Energy; Argonne National Laboratory: Lemont, IL, USA, 2020.

- Toyota. JR East, Hitachi and Toyota to Develop Hybrid (Fuel Cell) Railway Vehicles Powered by Hydrogen; Toyota Motor Corporation: Toyota City, Japan, 2020. [Google Scholar]

- Wurzenberger, J.C.; Rašić, D.; Tavcar, G.; Glatz, T.; Mele, I.; Katrasnik, T. FCEV Performance Assessment—Electrochemical Fuel Cell and Battery Modelling on Vehicle Level; SAE International: Warrendale, PA, USA, 2020; 2020–01–0857. [Google Scholar]

- Bagherabadi, K.; Skjong, S.; Pedersen, E. Dynamic Modelling of PEM Fuel Cell System for Simulation and Sizing of Marine Power Systems. Int. J. Hydrogen Energy 2022, 47, 17699–17712. [Google Scholar] [CrossRef]

- Zhang, G.; Wu, L.; Qin, Z.; Wu, J.; Xi, F.; Mou, G.; Wang, Y.; Jiao, K. A Comprehensive Three-Dimensional Model Coupling Channel Multi-Phase Flow and Electrochemical Reactions in Proton Exchange Membrane Fuel Cell. Adv. Appl. Energy 2021, 2, 100033. [Google Scholar] [CrossRef]

- Liu, Y.; Dirkes, S.; Kohrn, M.; Wick, M.; Pischinger, S. A High-Fidelity Real-Time Capable Dynamic Discretized Model of Proton Exchange Membrane Fuel Cells for the Development of Control Strategies. J. Power Sources 2022, 537, 231394. [Google Scholar] [CrossRef]

- Bressel, M.; Hilairet, M.; Hissel, D.; Ould Bouamama, B. Model-Based Aging Tolerant Control with Power Loss Prediction of Proton Exchange Membrane Fuel Cell. Int. J. Hydrogen Energy 2020, 45, 11242–11254. [Google Scholar] [CrossRef]

- Barbir, F. Fuel Cell Electrochemistry. In PEM Fuel Cells; Elsevier: Cambridge, MA, USA, 2005; pp. 33–72. [Google Scholar] [CrossRef]

- Zhang, G.; Yuan, H.; Wang, Y.; Jiao, K. Three-Dimensional Simulation of a New Cooling Strategy for Proton Exchange Membrane Fuel Cell Stack Using a Non-Isothermal Multiphase Model. Appl. Energy 2019, 255, 113865. [Google Scholar] [CrossRef]

- Yoshizumi, T.; Kubo, H.; Okumura, M. Development of High-Performance FC Stack for the New MIRAI; SAE International: Warrendale, PA, USA, 2021; 2021–01–0740. [Google Scholar]

- Jiao, K.; Xuan, J.; Du, Q.; Bao, Z.; Xie, B.; Wang, B.; Zhao, Y.; Fan, L.; Wang, H.; Hou, Z.; et al. Designing the Next Generation of Proton-Exchange Membrane Fuel Cells. Nature 2021, 595, 361–369. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, Y.; Xu, S.; Dong, F. Bibliometric Analysis for Research Trends and Hotspots in Heat and Mass Transfer and Its Management of Proton Exchange Membrane Fuel Cells. Appl. Energy 2023, 333, 120611. [Google Scholar] [CrossRef]

- Philip, N.; Ghosh, P.C. Optimal Sizing of Electrical and Thermal Energy Storage Systems for Application in Fuel Cell Based Electric Vehicles. J. Energy Storage 2024, 83, 110753. [Google Scholar] [CrossRef]

- Leelasupakorn, H.; Kaewchada, A.; Traisantikul, W.; Tiengtrakarnsuk, W.; Limtrakul, S.; Vatanatham, T. Scaleup Effect on Performance of Proton Exchange Membrane Fuel Cell. Chiang Mai J. Sci. 2008, 35, 89–94. [Google Scholar]

- Huang, L.; Ouyang, Q.; Chen, J.; Liu, Z.; Wu, X. A Scalable Segmented-Based PEM Fuel Cell Hybrid Power System Model and Its Simulation Applications. Energies 2023, 16, 6224. [Google Scholar] [CrossRef]

- Zheng, P.; Xie, X.; Zhang, C.; Cai, S.; Pan, J.; Zhang, H.; Yan, M.; Mu, Q. Techno-Economic Assessment Framework for 2.5 MW-Scale Grid-Connected Proton Exchange Membrane Fuel Cell Power Systems: A Case Study in China. Int. J. Hydrogen Energy 2025, 167, 150942. [Google Scholar] [CrossRef]

- Pérez-Trujillo, J.P.; Elizalde-Blancas, F.; Della Pietra, M.; Silva-Mosqueda, D.M.; García Guendulain, J.M.; McPhail, S.J. Thermoeconomic Comparison of a Molten Carbonate Fuel Cell and a Solid Oxide Fuel Cell System Coupled with a Micro Gas Turbine as Hybrid Plants. Energy Convers. Manag. 2023, 276, 116533. [Google Scholar] [CrossRef]

- Luo, L.; Guo, Z.; Cao, H.; Zhang, J.; Wang, H.; Lu, S.; Xiang, Y. Effect of Coolant Flow Field Heat Network Structure on Specific Power and Consistency of the kW-Scale High-Temperature Polymer Electrolyte Membrane Fuel Cells Stack. Int. J. Hydrogen Energy 2025, 166, 150971. [Google Scholar] [CrossRef]

- Pielecha, I.; Szałek, A.; Tchorek, G. Two Generations of Hydrogen Powertrain—An Analysis of the Operational Indicators in Real Driving Conditions (RDC). Energies 2022, 15, 4734. [Google Scholar] [CrossRef]

- Enomoto, K.; Ida, A.; Harada, T.; Takeuchi, H. Development of Safety Performance for FC Stack in the New Toyota FCEV; SAE International: Warrendale, PA, USA, 2022; 2022–01–0686. [Google Scholar]

- Konno, N.; Mizuno, S.; Nakaji, H.; Ishikawa, Y. Development of Compact and High-Performance Fuel Cell Stack. SAE Int. J. Altern. Powertrains 2015, 4, 123–129. [Google Scholar] [CrossRef]

- Soltani, M.; Mohammad Taghi Bathaee, S. Development of an Empirical Dynamic Model for a Nexa PEM Fuel Cell Power Module. Energy Convers. Manag. 2010, 51, 2492–2500. [Google Scholar] [CrossRef]

- Allagui, H.; Mzoughi, D.; Bouaicha, A.; Mami, A. Modeling and Simulation of 1.2 kW Nexa PEM Fuel Cell System. Indian J. Sci. Technol. 2016, 9, 1–8. [Google Scholar] [CrossRef]

- Salim, R.; Nabag, M.; Noura, H.; Fardoun, A. The Parameter Identification of the Nexa 1.2 kW PEMFC’s Model Using Particle Swarm Optimization. Renew. Energy 2015, 82, 26–34. [Google Scholar] [CrossRef]

- Abbade, H.; El Fadil, H.; Lassioui, A.; Intidam, A.; Hamed, A.; El Asri, Y.; Fhail, A.; Hasni, A. Deep Learning-Based Performance Modeling of Hydrogen Fuel Cells Using Artificial Neural Networks: A Comparative Study of Optimizers. Processes 2025, 13, 1453. [Google Scholar] [CrossRef]

- Heliocentris Hybrid Energy Lab. Instruction Heliocentris Academia GmbH; Heliocentris Academia GmbH: Berlin, Germany, 2016. [Google Scholar]

- Czarnigowski, J.; Skiba, K.; Kida, M.; Jakliński, P.A. Simple Dynamic Model of a PEM-Type Fuel Cell. Combust. Engines 2025, 202, 147–153. [Google Scholar] [CrossRef]

- Andrade, T.S.; Thiringer, T. Low Platinum Fuel Cell as Enabler for the Hydrogen Fuel Cell Vehicle. J. Power Sources 2024, 598, 234140. [Google Scholar] [CrossRef]

- Wang, H.; Wang, R.; Sui, S.; Sun, T.; Yan, Y.; Du, S. Cathode Design for Proton Exchange Membrane Fuel Cells in Automotive Applications. Automot. Innov. 2021, 4, 144–164. [Google Scholar] [CrossRef]

- Salim, R.I.; Noura, H.; Nabag, M.; Fardoun, A. Modeling and Temperature Analysis of the Nexa 1.2 kW Fuel Cell System. J. Fuel Cell Sci. Technol. 2015, 12, 061006. [Google Scholar] [CrossRef]

- Sevjidsuren, G.; Uyanga, E.; Bumaa, B.; Temujin, E.; Altantsog, P.; Sang, D. Exergy Analysis of 1.2 kW NexaTM Fuel Cell Module. In Clean Energy for Better Environment; Aydinalp, C., Ed.; InTech: Rijeka, Croatia, 2012; ISBN 978-953-51-0822-1. [Google Scholar]

- Del Real, A.J.; Arce, A.; Bordons, C. Development and Experimental Validation of a PEM Fuel Cell Dynamic Model. J. Power Sources 2007, 173, 310–324. [Google Scholar] [CrossRef]

| Fuel Cell | Unit | Value |

|---|---|---|

| Rated output | W | 1200 |

| No. of cells | – | 36 |

| Area of cell | cm2 | 150 |

| Rated current | A | 60 |

| Operating voltage | V | 18–36 |

| Hydrogen purity | Min. | 4.0 |

| Permissible H2 inlet pressure | bar | 1–15 |

| DC converter | ||

| Max output power | W | 1500 |

| Max output current | ADC | 55 |

| Rated output voltage | VDC | 24 |

| Output voltage range | VDC | 21–30 |

| Max input current | ADC | 60 |

| Input voltage range | VDC | 18–36 |

| Efficiency | % | 96 |

| Inverter | ||

| Continuous output power (50 Hz), 115 VAC (60Hz) | WAC | 1500 |

| Inlet voltage | VDC | 21–30 |

| Output voltage | VAC | 230 |

| Efficiency | % | 93 |

| Electronic Load Module | ||

| Max. continuous power | W | 1200 |

| DC load current | ADC | 0–85 |

| DC load voltage | VDC | 0–80 |

| Battery Module | ||

| Battery set 1 | lead-acid | 24 V, (2 × 12 V), 7.2 Ah |

| Battery set 2 | lead-acid | 24 V, (2 × 12 V), 18 Ah |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pielecha, I.; Pielecha, P. Scaling of Automotive Fuel Cells in Terms of Operating Indicators. Energies 2025, 18, 5513. https://doi.org/10.3390/en18205513

Pielecha I, Pielecha P. Scaling of Automotive Fuel Cells in Terms of Operating Indicators. Energies. 2025; 18(20):5513. https://doi.org/10.3390/en18205513

Chicago/Turabian StylePielecha, Ireneusz, and Piotr Pielecha. 2025. "Scaling of Automotive Fuel Cells in Terms of Operating Indicators" Energies 18, no. 20: 5513. https://doi.org/10.3390/en18205513

APA StylePielecha, I., & Pielecha, P. (2025). Scaling of Automotive Fuel Cells in Terms of Operating Indicators. Energies, 18(20), 5513. https://doi.org/10.3390/en18205513