Plugging into Onshore Power Supply System Innovation: A Review from Standards and Patents to Port Deployment

Abstract

1. Introduction

1.1. Background

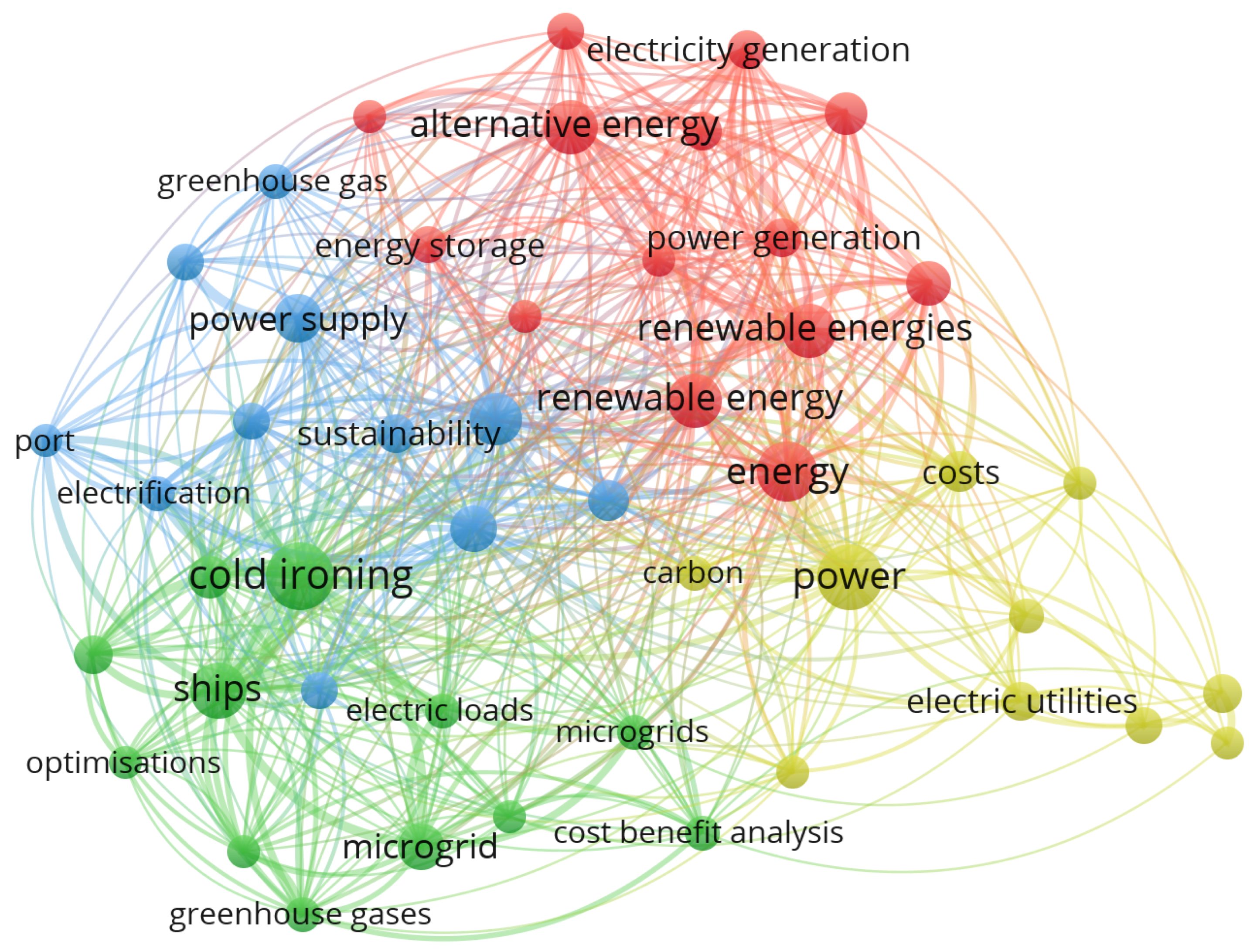

1.2. Methodology

- Database Search: A comprehensive literature search was performed using Scopus, complemented by targeted searches in IEEE Xplore, ScienceDirect, and MDPI Journals. Keywords included: “Onshore Power Supply”, “Shore-to-Ship”, “Cold Ironing”, “High Voltage Shore Connection”, and “Maritime Decarbonization”.

- Selection Criteria: Studies were included if they addressed OPS technologies, shore-to-ship architectures, international standards, patents, or commercial deployments. The excluded criteria involved publications with limited technical content.

- Screening and Data Extraction: From an initial pool of studies (2010–2025), articles were selected based on relevance. Data were extracted on system architectures, energy demand estimation methodologies, technical challenges, and case studies in ports. In the case of patents, the time frame was extended to ensure broader coverage.

- Critical Analysis and Synthesis: The selected studies were compared according to their scope, methodological rigor, and contribution to the development of the OPS system. In addition, patents and commercial solutions were analyzed separately to complement academic findings.

2. OPS Systems Architecture

2.1. Typology and Ship Requirements

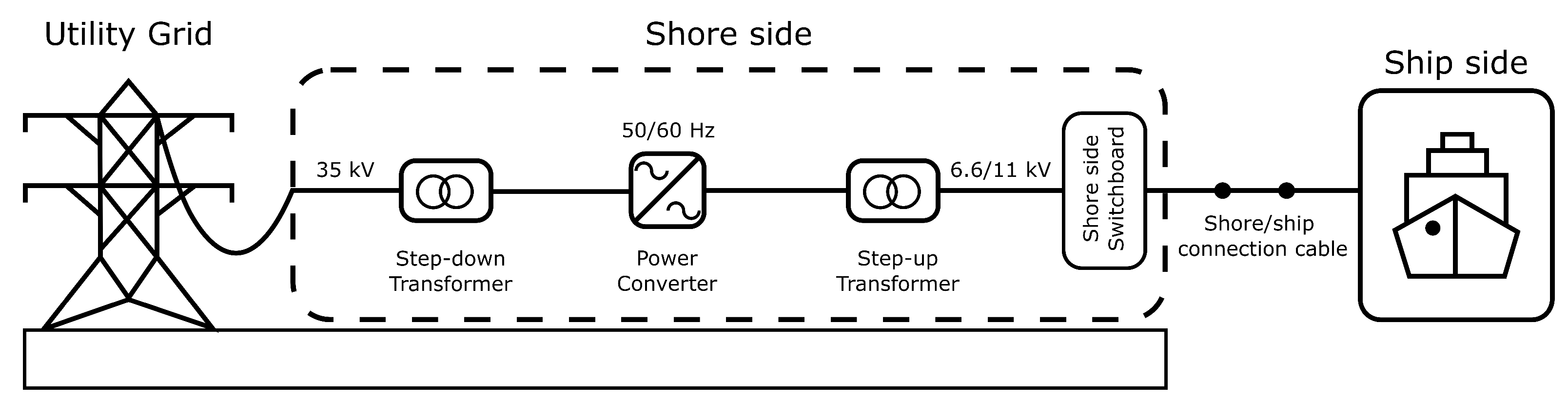

2.2. Shore-to-Ship Architectures

3. Shore-to-Ship Standardization, Incentives and Recommendations

3.1. Main Standards for STS Systems

3.2. Directives and Recommendations

3.3. European Incentives and Research Agendas

- A joint EUR 18.8 million CEF funded project involving Bremerhaven, Gothenburg, Aarhus, and Stockholm to enable shore power for container ships by 2030 [86].

- A EUR 3.2 million grant under the Alternative Fuels Infrastructure Facility (AFIF) awarded to the Port of Antwerp Bruges (Zeebrugge) to install cruise ship OPS starting in 2026 [83].

- European Commission approval of a EUR 570 million Italian national scheme providing up to 100% reduction in general system charges (network fees) for electricity used in shore power systems, valid until 2033 [87].

3.4. Economic Perspective on OPS Deployment

4. Patent Landscape

4.1. Mobility and Connectivity Interfaces

4.2. Power Conversion Topologies and Control

4.3. High-Voltage Integration and Grid Interfacing

5. Ports with Shore Power and Commercial Solutions

6. Conclusions and Development Directions

6.1. Development Directions in OPS

- Transition to DC-based OPS Architectures. Although traditional shore power is highly dependent on transformer-based and static frequency conversion to deliver AC energy at compatible levels, a paradigm shift is underway. The growing presence of DC microgrids onboard ships, often incorporating battery energy storage systems (ESSs), fuel cells, and renewable energy sources (RESs), has accelerated interest in DC-based shore power connections [22,28,29,69]. In particular, multi-distributed architectures provide higher efficiency, fewer conversion losses, and seamless integration with modern onboard systems.

- Advanced Power Electronics and Converter Technologies. Advanced DC-DC converters act as galvanically isolated, voltage-regulating, high-frequency transformers [130]. Future developments must address EMI management and control complexity at high power levels. These technologies will be critical to support hybrid AC/DC operations and integration with renewable energy [26,29,50,131].

- Automation, Digitalization, and AI/ML for Power Management. Automation and digitization are reshaping the way STS systems are operated and maintained. Through smart sensors, condition monitoring, and digital twins, operators can gain real-time insights, allowing predictive maintenance and optimized energy quality [132]. The integration of Artificial Intelligence (AI) and Machine Learning (ML) will enable dynamic power management, fault prediction, and adaptive control of OPS systems, ensuring reliability under varying ship and port demands.

- Wireless Power Transfer (WPT). Another frontier of innovation is the rise of wireless power transfer (WPT), particularly inductive power transfer (IPT), as a safer and more resilient alternative to traditional cabling. For OPS, IPT could eliminate heavy cable handling in large ships, reduce quay congestion, and minimize human error during high-voltage connections. Although prototypes have been tested primarily on ferries and small ships [133,134], scaling up to container ships or cruise ships requires breakthroughs in efficiency and electromagnetic compatibility [93,135,136,137,138,139,140].

- OPS–RES Integration and Hybrid Systems. A dedicated pathway for OPS–RES integration is emerging, where ports combine photovoltaic (PV), wind, and storage systems with OPS infrastructure. Hybrid OPS–RES systems can reduce dependence on the main grid, improve local energy resilience, and contribute to decarbonization [82,141,142]. Optimization strategies include model predictive control, AI-based energy scheduling, and multi-objective optimization for cost and emission reduction.

- Standardization and Interoperability. At the systemic level, standardization is emerging as a key enabler of interoperability and global adoption. Frameworks such as the IEC/IEEE 80005 series [24,57,58,60] support the development of plug-and-play systems that simplify deployment, reduce engineering overhead, and adapt to a wide range of ship types and port layouts. Innovations such as containerized or mobile STS units are also expanding the reach of the technology to smaller or seasonal ports, offering flexibility where it is needed most [22].

- Integration with Smart Grids and Bidirectional Operation. Looking ahead, the convergence of port electrification and smart microgrids is redefining the role of STS systems within the broader energy ecosystem [26]. Ports are beginning to function as active energy hubs, integrating renewable generation, energy storage, and bidirectional grid interaction. In such settings, STS systems can go beyond supplying ships: they can also absorb power from ships equipped with large onboard storage (ship-to-grid, S2G), contributing to local energy resilience [143].

6.2. Multidimensional Integration Challenges

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| AMP | Alternative Maritime Power |

| AC | Alternating Current |

| AE | Auxiliary Engines |

| AFIF | Alternative Fuels Infrastructure Facility |

| AFIR | Alternative Fuels Infrastructure Regulation |

| CARB | California Air Resources Board |

| CEF | Connecting Europe Facility |

| CMS | Cable Management System |

| CO2 | Carbon Dioxide |

| CI | Cold Ironing |

| DC | Direct Current |

| EMI | Electromagnetic Interference |

| EMF | Electromagnetic Field |

| EPA | Environmental Protection Agency |

| ESPO | European Sea Ports Organization |

| ESS | Energy Storage Systems |

| EU STS | European Emissions Trading System |

| GHG | Green House Gas |

| GT | Gross Tonnage |

| HVDC | High-Voltage Direct Current |

| HVSC | High-Voltage Shore Connection |

| IACS | International Association of Classification Societies |

| IAPH | International Association of Ports and Harbors |

| ICCT | International Council on Clean Transportation |

| IEC | International Electrotechnical Commission |

| IEEE | Institute of Electrical and Electronics Engineers |

| IMO | International Maritime Organization |

| IPT | Inductive Power Transfer |

| ISO | International Organization for Standardization |

| IoT | Internet of Things |

| LNG | Liquified Natural Gas |

| LVSC | Low Voltage Shore Connection |

| ML | Machine Learning |

| NOx | Nitrogen Oxides |

| OCIMF | Oil Companies International Marine Forum |

| OPS | Onshore Power Supply |

| PM | Particulate Matter |

| PV | Photovoltaics |

| RES | Renewable Energy Sources |

| Ro/Ro | Roll-on/Roll-off |

| S2G | Ship-to-grid |

| SOx | Sulphur Oxides |

| SSE | Shore-Side Electricity |

| STS | Shore-to-Ship |

| SRIA | Strategic Research and Innovation Agenda |

| TEN-T | Trans-European Transport Network |

| THD | Total Harmonic Distortion |

| VSI | Voltage Source Inverter |

| WPCAP | World Ports Climate Action Program |

| WPT | Wireless Power Transfer |

| ZEWT | Zero Emission Waterborne Transport |

References

- Sæther, S.R.; Moe, E. A green maritime shift: Lessons from the electrification of ferries in Norway. Energy Res. Soc. Sci. 2021, 81, 102282. [Google Scholar] [CrossRef]

- Mallouh, M.A.; Dhou, S.; Zahawi, A.R.A. Decarbonization of Maritime Transport: Is There Light at the End of the Tunnel? Sustainability 2021, 13, 237. [Google Scholar] [CrossRef]

- Abu Bakar, N.N.; Bazmohammadi, N.; Vasquez, J.C.; Guerrero, J.M. Electrification of onshore power systems in maritime transportation towards decarbonization of ports: A review of the cold ironing technology. Renew. Sustain. Energy Rev. 2023, 178, 113243. [Google Scholar] [CrossRef]

- Ejder, E.; Dinçer, S.; Arslanoglu, Y. Decarbonization strategies in the maritime industry: An analysis of dual-fuel engine performance and the carbon intensity indicator. Renew. Sustain. Energy Rev. 2024, 200, 114587. [Google Scholar] [CrossRef]

- Deng, S. A review on carbon emissions of global shipping. Mar. Dev. 2023, 1, 4. [Google Scholar] [CrossRef]

- Metzger, D. Market-based measures and their impact on green shipping technologies. WMU J. Marit. Aff. 2021, 21, 3–23. [Google Scholar] [CrossRef]

- Caprace, J.D.; Marques, C.H.; Assis, L.F.; Lucchesi, A.; Pereda, P.C. Sustainable Shipping: Modeling Technological Pathways Toward Net-Zero Emissions in Maritime Transport (Part I). Sustainability 2025, 17, 3733. [Google Scholar] [CrossRef]

- Williamsson, J.; Costa, N.; Santén, V.; Rogerson, S. Barriers and Drivers to the Implementation of Onshore Power Supply—A Literature Review. Sustainability 2022, 14, 72. [Google Scholar] [CrossRef]

- Uzun, D.; Okumus, D.; Canbulat, O.; Gunbeyaz, S.; Karamperidis, S.; Hudson, D.; Turan, O.; Allan, R. Port Energy Demand Model for Implementing Onshore Power Supply and Alternative Fuels. Transp. Res. Part D Transp. Environ. 2024, 136, 104432. [Google Scholar] [CrossRef]

- German-Galkin, S.; Tarnapowicz, D. Energy Optimization of the ‘Shore to Ship’ System—A Universal Power System for Ships at Berth in a Port. Sensors 2020, 20, 3815. [Google Scholar] [CrossRef]

- Amaral, M.; Amaro, N.; Arsénio, P. Methodology for Assessing Power Needs for Onshore Power Supply in Maritime Ports. Sustainability 2023, 15, 16670. [Google Scholar] [CrossRef]

- Sciberras, E.; Zahawi, B.; Atkinson, D.; Juandó, A.; Sarasquete, A. Cold ironing and onshore generation for airborne emission reductions in ports. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2014, 230, 67–82. [Google Scholar] [CrossRef]

- Le, S.T. Research on Drivers and Barriers to the Implementation of Cold Ironing Technology in Zero Emissions Port. Environ. Health Insights 2024, 18, 2–3. [Google Scholar] [CrossRef]

- Zis, T. Prospects of cold ironing as an emissions reduction option. Transp. Res. Part A Policy Pract. 2018, 119, 82–95. [Google Scholar] [CrossRef]

- Peddi, K.P.; Ricci, S.; Rizzetto, L. Reduction Potential of Gaseous Emissions in European Ports Using Cold Ironing. Appl. Sci. 2024, 14, 6837. [Google Scholar] [CrossRef]

- Nguyen, D.H.; Lin, C.; Cheruiyot, N.; Hsu, J.Y.; Cho, M.Y.; Hsu, S.H.; Yeh, C.K. Reduction of NOx and SO2 Emissions by Shore Power Adoption. Aerosol Air Qual. Res. 2021, 21, 210100. [Google Scholar] [CrossRef]

- Innovation, N. On Shore Power Supply in the Nordic Region Project Report. 2019. Available online: https://pub.nordicinnovation.org/On-Shore-Power-Supply-in-the-Nordic-Region/appendix-iii-technical-aspects-of-on-shore-power-systems.html (accessed on 18 May 2025).

- Fiadomor, R. Assessment of Alternative Maritime Power (Cold Ironing) and Its Impact on Port Management and Operations. Ph.D. Thesis, World Maritime University, Malmö, Sweden, 2009. [Google Scholar]

- Innes, A.; Monios, J. Identifying the unique challenges of installing cold ironing at small and medium ports—The case of aberdeen. Transp. Res. Part D Transp. Environ. 2018, 62, 298–313. [Google Scholar] [CrossRef]

- Li, K.; Du, K. Research on Onshore Power Supply System in Port for Ships. IOP Conf. Ser. Earth Environ. Sci. 2020, 558, 052022. [Google Scholar] [CrossRef]

- Kumar, J.; Kumpulainen, L.; Kauhaniemi, K. Technical design aspects of harbour area grid for shore to ship power: State of the art and future solutions. Int. J. Electr. Power Energy Syst. 2019, 104, 840–852. [Google Scholar] [CrossRef]

- Hsu, S.H.; Tzu, F.M.; Chen, Y.D.; Huang, C.W. Navigating Safety and Compliance in High-Voltage Shore Connection Systems: A Comprehensive Exploration of IEC/IEEE 80005-1 Standards and the Guidelines of Ship Classification Societies. J. Mar. Sci. Eng. 2024, 12, 322. [Google Scholar] [CrossRef]

- Sustainable Ships. Overview of Shore Power Sockets and Plugs—IEC/IEEE 80005. 2024. Available online: https://www.sustainable-ships.org/stories/overview-shore-power-sockets-plugs-2 (accessed on 20 May 2025).

- IEC/IEEE 80005-1:2019; IEC/IEEE International Standard—Utility Connections in Port—Part 1: High Voltage Shore Connection (HVSC) Systems—General Requirements. IEC: Singapore; IEEE: Piscataway, NJ, USA, 2019; pp. 1–78. [CrossRef]

- Sulligoi, G.; Bosich, D.; Pelaschiar, R.; Lipardi, G.; Tosato, F. Shore-to-Ship Power. Proc. oIEEE 2015, 103, 2381–2400. [Google Scholar] [CrossRef]

- Mahdi, H.; Hoff, B.; Østrem, T. A Review of Power Converters for Ships Electrification. IEEE Trans. Power Electron. 2023, 38, 4680–4697. [Google Scholar] [CrossRef]

- Nuchturee, C.; Li, T.; Xia, H. Energy efficiency of integrated electric propulsion for ships—A review. Renew. Sustain. Energy Rev. 2020, 134, 110145. [Google Scholar] [CrossRef]

- Yang, Y.; Jiang, X.; Yu, M.; Ye, S.; Cai, C. A review of key technologies of shore power systems. In Proceedings of the 12th International Conference on Renewable Power Generation (RPG 2023), Shanghai, China, 14–15 October 2023; Volume 2023, pp. 1162–1167. [Google Scholar] [CrossRef]

- Xu, L.; Guerrero, J.M.; Lashab, A.; Wei, B.; Bazmohammadi, N.; Vasquez, J.C.; Abusorrah, A. A Review of DC Shipboard Microgrids—Part I: Power Architectures, Energy Storage, and Power Converters. IEEE Trans. Power Electron. 2022, 37, 5155–5172. [Google Scholar] [CrossRef]

- He, J.; Li, X.; Xu, H.; Zhu, J.; Dai, P.; Chu, H. Review and Discussion on Standards for Shore-to-Ship Power Supply System. In Proceedings of the 4th Annual International Conference on Material Engineering and Application (ICMEA 2017), Wuhan, China, 15–17 December 2017. [Google Scholar] [CrossRef][Green Version]

- Puig, M.; Wooldridge, C.; Michail, N.; Darbra, R.M. Regulatory and technological challenges of shore-side electricity: A review of European ports. Marit. Policy Manag. 2023, 50, 944–962. [Google Scholar] [CrossRef]

- Arduino, G.; Murillo, D.; Ferrari, C. Key factors and barriers to the adoption of cold ironing in Europe. In Proceedings of the Società Italiana di Economia dei Trasporti e della Logistica—XIII Riunione Scientifica, Messina, Italy, 16–17 June 2011. [Google Scholar]

- Winkel, R.; Weddige, U.; Johnsen, D.; Hoen, V.; Papaefthimiou, S. Shore Side Electricity in Europe: Potential and environmental benefits. Energy Policy 2016, 88, 584–593. [Google Scholar] [CrossRef]

- International Maritime Organization. Fourth IMO GHG Study 2020; Technical Report 4; International Maritime Organization: London, UK, 2021. [Google Scholar]

- IEC/IEEE P80005-1 ED2; IEC/IEEE Approved Draft International Standard—Utility Connections in Port—Part 1: High Voltage Shore Connection (HVSC) Systems–General Requirements. IEC: Singapore; IEEE: Piscataway, NJ, USA, 2019; pp. 1–75.

- Sciberras, E.A.; Zahawi, B.; Atkinson, D.J. Electrical characteristics of cold ironing energy supply for berthed ships. Transp. Res. Part D Transp. Environ. 2015, 39, 31–43. [Google Scholar] [CrossRef]

- D’Agostino, F.; Kaza, D.; Schiapparelli, G.P.; Silvestro, F.; Bossi, C.L.; Colzi, F. Assessment of the Potential Shore to Ship Load Demand: The Italian Scenario. In Proceedings of the 2021 IEEE Power & Energy Society General Meeting (PESGM), Washington, DC, USA, 26–29 July 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Khersonsky, Y.; Islam, M.; Peterson, K. Challenges of Connecting Shipboard Marine Systems to Medium Voltage Shoreside Electrical Power. IEEE Trans. Ind. Appl. 2007, 43, 838–844. [Google Scholar] [CrossRef]

- USEPA. Shore Power Technology Assessment at U.S. Ports; Transportation and Climate Division Offce of Transportation and Air Quality U.S. Environmental Protection Agency: Washington, DC, USA, 2022. [Google Scholar]

- Hub, A.E. Shore Power Emissions Calculator. 2021. Available online: https://www.atlasevhub.com/resource/shore-power-emissions-calculator/ (accessed on 3 September 2025).

- Systems, A.P.; Shore Power Converter vs. Generator Cost Comparison Calculator. 2025. Available online: https://aseapower.com/calculator/ (accessed on 3 September 2025).

- EPA. California State Nonroad Engine Pollution Control Standards; Ocean-Going Vessels At-Berth; Notice of Decision. Daily J. United States Gov. 2023, 88, 72461–72476. Available online: https://www.federalregister.gov/documents/2023/10/20/2023-23261/california-state-nonroad-engine-pollution-control-standards-ocean-going-vessels-at-berth-notice-of (accessed on 1 September 2025).

- Gutierrez Saenz, J. Energy Analysis and Cost Estimation of a Potential On-Shore Power Supply System in the Port of Gavle. Master’s Thesis, University of Gävle, Gävle, Sweden, 2019. [Google Scholar]

- Prenc, R.; Vučetić, D.; Cuculić, A. High Voltage Shore Connection in Croatia: Network configurations and formation of the connection point to the Utility power grid. Electr. Power Syst. Res. 2018, 157, 106–117. [Google Scholar] [CrossRef]

- Tarnapowicz, D.; German-Galkin, S. Analysis of the Topology of “Shore to Ship” Systems—-Power Electronic Connection of Ships with Land. New Trends Prod. Eng. 2018, 1, 325–333. [Google Scholar] [CrossRef][Green Version]

- Prousalidis, J.; Antonopoulos, G.; Patsios, C.; Greig, A.; Bucknall, R. Green shipping in emission controlled areas: Combining smart grids and cold ironing. In Proceedings of the 2014 International Conference on Electrical Machines (ICEM), Berlin, Germany, 2–5 September 2014; pp. 2299–2305. [Google Scholar] [CrossRef]

- Strzelecki, R.; Mysiak, P.; Sak, T. Solutions of inverter systems in Shore-to-Ship Power supply systems. In Proceedings of the 2015 9th International Conference on Compatibility and Power Electronics (CPE), Costa da Caparica, Portugal, 24–26 June 2015; pp. 454–461. [Google Scholar] [CrossRef]

- Stromm, K.C.; Danielsson, G.H.; Parqui, W.O.R.; Bernardon, D.P.; Abaide, A.D.R.; Sperandio, M. Reliability-Based Design of a 5 MWp Centralized Solar Photovoltaic Power Plant with Multi-String Inverters. In Proceedings of the 2024 16th Seminar on Power Electronics and Control (SEPOC), Santa Maria, Brazil, 20–23 October 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Su, Y.; Li, S.; Li, B.; Ma, X.; Yao, D.; Zhang, W. Control Strategies for Multi-Terminal DC Transmission System with Special Parallel Topology. In Proceedings of the 2020 4th International Conference on HVDC (HVDC), Xi’an, China, 6–9 November 2020; pp. 164–169. [Google Scholar] [CrossRef]

- Sun, P.; Wickramasinghe, H.R.; Konstantinou, G. AC and DC Fault Analysis in Hybrid Multi-Converter DC Grids. In Proceedings of the 2021 31st Australasian Universities Power Engineering Conference (AUPEC), Perth, Australia, 26–30 September 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Ericsson, P.; Fazlagic, I. Shore-Side Power Supply—A Feasibility Study and a Technical Solution for an On-Shore Electrical Infrastructure to Supply Vessels with Electrical Power While in Port. Master’s Thesis, Charmers University of Technology, Gothenburg, Sweden, 2008. [Google Scholar]

- International Maritime Organisation. Module 5–Ship Port Interface for Energy Efficiency; International Maritime Organisation: London, UK, 2016. [Google Scholar]

- ZEWT Partnership. Zero Emission Waterborne Transport (ZEWT) Partnership: Strategic Research and Innovation Agenda; European Union: Brussels, Brussels, 2023. [Google Scholar]

- IAPH. WPCAP Ports to Focus on OPS, New Fuels and Corridors; IAPH: London, UK, 2023. [Google Scholar]

- SAFETY4SEA. World Port Climate Action Program Focuses on Shore Power, New Fuels and Green Corridors; SAFETY4SEA: Singapore, 2023. [Google Scholar]

- SAFETY4SEA. ESPO: More than Half of European Ports Provide Shore Power; SAFETY4SEA: Singapore, 2024. [Google Scholar]

- IEC/IEEE 80005-2:2016; Utility Connections in Port—Part 2: High and Low Voltage Shore Connection Systems—Data Communication for Monitoring and Control. IEC: Singapore; IEEE: Piscataway, NJ, USA, 2016.

- IEC/IEEE FDIS 80005-3:2014; Utility Connections in Port—Part 3: Low Voltage Shore Connection (LVSC) Systems—General Requirements. IEC: Singapore; IEEE: Piscataway, NJ, USA, 2014.

- IEEE/IEC P80005-3; Utility Connections in Port—Part 4: DC Shore Connection (DCSC) Systems—General Requirements. IEC: Singapore; IEEE: Piscataway, NJ, USA, 2019.

- IEC 62613-2:2016; Plugs, Socket-Outlets and Ship Couplers for High-Voltage Shore Connection Systems (HVSC-Systems)—Part 2: Dimensional Compatibility and Interchangeability Requirements for Accessories to Be Used by Various Types of Ships. IEC: Singapore, 2016.

- IEC 60309-5:2017; Plugs, Socket-outlets and Couplers for Industrial Purposes—Part 5: Dimensional Compatibility and Interchangeability Requirements for Plugs, Socket-Outlets, Ship Connectors and Ship Inlets for Low-Voltage Shore Connection Systems (LVSC). IEC: Singapore, 2017.

- IEC 60092-201:2019; Electrical Installations in Ships—Part 201: System Design—General. IEC: Singapore, 2019.

- IEC 60092-503:2021; Electrical Installations in Ships—Part 503: Special Features—AC Supply Systems with Voltages in the Range of Above 1 kV up to and Including 36 kV. IEC: Singapore, 2021.

- IEC 60146-1-1:2024; Semiconductor Converters—General Requirements and Line Commutated Converters—Part 1-1: Specification of Basic Requirements. IEC: Singapore, 2024.

- IEEE 1662-2023; IEEE Recommended Practice for the Design and Application of Power Electronics in Electrical Power Systems. IEEE: Piscataway, NJ, USA, 2023.

- IEEE Std 1709-2018 (Revision of IEEE Std 1709-2010); IEEE Recommended Practice for 1 kV to 35 kV Medium-Voltage DC Power Systems on Ships. IEEE: Piscataway, NJ, USA, 2018; pp. 1–54. [CrossRef]

- IEEE 45.1-2023; IEEE Recommended Practice for Electrical Installations on Shipboard–Design. IEEE: Piscataway, NJ, USA, 2023.

- Paul, D.; Peterson, K.; Chavdarian, P.R. Designing Cold Ironing Power Systems: Electrical Safety During Ship Berthing. IEEE Ind. Appl. Mag. 2014, 20, 24–32. [Google Scholar] [CrossRef]

- Tarnapowicz, D.; German-Galkin, S. International Standardization in the Design of “Shore to Ship”—Power Supply Systems of Ships in Port. Manag. Syst. Prod. Eng. 2018, 26, 9–13. [Google Scholar] [CrossRef]

- Peterson, K.L.; Chavdarian, P.; Islam, M.; Cayanan, C. Tackling ship pollution from the shore. IEEE Ind. Appl. Mag. 2009, 15, 56–60. [Google Scholar] [CrossRef]

- EMSA. Shore-Side Electricity: Guidance to Port Authorities and Administrations; EMSA: Lisbon, Portugal, 2022. [Google Scholar]

- European Commission. Commission Recommendation of 8 May 2006 on the promotion of shore-side electricity for use by ships at berth in Community ports. Off. J. Eur. Union 2006, 125, 38–42. Available online: https://eur-lex.europa.eu/eli/reco/2006/339/oj (accessed on 16 June 2025).

- COUNCIL DIRECTIVE 2003/96/EC of 27 October 2003 restructuring the Community framework for the taxation of energy products and electricity. Official Journal of the European Union 2003.

- DIRECTIVE 2012/33/EU OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 21 November 2012 amending Council Directive 1999/32/EC as regards the sulphur content of marine fuels. Off. J. Eur. Union 2012, 327, 1–13.

- DIRECTIVE 2014/94/EU OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 22 October 2014 on the deployment of alternative fuels infrastructure. Off. J. Eur. Union 2014, 307, 1–13.

- DIRECTIVE (EU) 2016/802 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 11 May 2016 relating to a reduction in the sulphur content of certain liquid fuels. Off. J. Eur. Union 2016 132, 58–78.

- IMO. Index of MEPC Resolutions and Guidelines related to MARPOL Annex VI. Available online: https://www.imo.org/en/OurWork/Environment/Pages/Index-of-MEPC-Resolutions-and-Guidelines-related-to-MARPOL-Annex-VI.aspx (accessed on 16 June 2025).

- International Council on Clean Transportation. Shore Power Needs and CO2 Emissions Reductions of Ships in European Union Ports: Meeting the Ambitions of the FuelEU Maritime and AFIR; International Council on Clean Transportation: Washington, DC, USA, 2023. [Google Scholar]

- The Maritime Executive. Report: EU Shore Power Regulations Fall Short of Potential; The Maritime Executive: Vero Beach, FL, USA, 2023. [Google Scholar]

- European Commission. Horizon Europe Cluster 5: Climate, Energy and Mobility—Work Programme 2023–2025; European Commission: Brussels, Belgium, 2023. [Google Scholar]

- IACS. Onshore Power Supply; IACS: Kolkata, India, 2024. [Google Scholar]

- European Parliament and Council. Regulation (EU) 2023/1805 of the European Parliament and of the Council of 13 September 2023 on the use of renewable and low-carbon fuels in maritime transport, and amending Directive 2009/16/EC. Off. J. Eur. Union 2023, 234, 48–100.

- European Subsidy for Shore Power in Zeebrugge. 2024. Available online: https://www.maritimeprofessional.com/news/european-subsidy-shore-power-zeebrugge-392826 (accessed on 9 July 2025).

- With new EU Funding, Northern European Ports to Enable Shore Power for Boxships by 2030. 2023. Available online: https://www.offshore-energy.biz/with-new-eu-funding-northern-european-ports-to-enable-shore-power-for-boxships-by-2030/ (accessed on 9 July 2025).

- PTR Onshore Power Supply in Europe: An Overview. 2023. Available online: https://ptr.inc/onshore-power-supply-in-europe-an-overview/ (accessed on 11 July 2025).

- Koch, M. EU Funds Shore-Side Electricity: Bremerhaven Receives More than 5 Million Euros. 2024. Available online: https://www.bremenports.de/en/press/eu-funds-shore-side-electricity-bremerhaven-receives-more-than-5-million-euros (accessed on 11 July 2025).

- EU Okays €570 Million Funding for Italian Shore Power Scheme. 2024. Available online: https://www.offshore-energy.biz/eu-okays-e570-million-funding-for-italian-shore-power-scheme/ (accessed on 9 July 2025).

- European Commission’s DG for Research and Innovation. Horizon Europe Strategic Plan 2025–2027 Analysis; European Commission’s DG for Research and Innovation: Brussels, Belgium, 2024. [Google Scholar]

- Conte, F.; D’Agostino, F.; Kaza, D.; Massucco, S.; Natrella, G.; Silvestro, F. Optimal Management of a Smart Port with Shore-Connection and Hydrogen Supplying by Stochastic Model Predictive Control. In Proceedings of the 2022 IEEE Power & Energy Society General Meeting (PESGM), Denver, CO, USA, 17–21 July 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Costa, P.; Faustino Agreira, C.I.; Pestana, R.; Cao, Y. Green Ports—Shore Power Supply State of the Art. In Proceedings of the 2024 IEEE 22nd Mediterranean Electrotechnical Conference (MELECON), Porto, Portugal, 25–27 June 2024; pp. 1305–1309. [Google Scholar] [CrossRef]

- European Parliament and Council. Regulation (EU) 2023/1804 of 13 September 2023 on the deployment of alternative fuels infrastructure, and repealing Directive 2014/94/EU. Off. J. Eur. Union 2023, 234, 1–45. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX%3A32023R1804 (accessed on 16 June 2025).

- Bao, Q. Movable Shore Power Variable Frequency Power Supply Device. EP2458724A1, 30 May 2012. [Google Scholar]

- Xiao, L.; Han, J. Ship Shore Power Connection Method and System. CN107732900A, 23 February 2018. [Google Scholar]

- Mäkinen, V. Power Connection Between Shore and Ship. WO2013175061A1, 28 November 2013. [Google Scholar]

- Hartig, R.; Schulze Horn, H.; Tigges, K. Ship with a Universal Shore Connection. WO2007060189A1, 31 May 2007. [Google Scholar]

- Pedersen, L.R. System for and a Ship Having a System for Connecting of Shore Power to the Ship While Docked. US7646114B2, 12 January 2010. [Google Scholar]

- Krackhardt, E.C.; Mueller-SCHWENN, H.B. Buoyant Harbor Power Supply. US8482164B2, 9 July 2013. [Google Scholar]

- Wang, X.; Sun, X.; Yang, Y.; Cui, X.; Guo, Z.; Wang, X.; Xu, Y.; Wu, R.; Yang, Y.; Zhang, K.; et al. Shore Power Supply for Medium-Low Voltage Ship. CN202455277U, 26 September 2012. [Google Scholar]

- Xujing, T.; Yedong, X.; Qizgi, Y.; Chengqing, Y.; Yuwei, S.; Xinping, Y.; Chenxing, S.; Yupeng, Y.; Yan, Z. Inland River High Pier Berthing Ship Shore Power Access System and Method. CN108321791A, 24 July 2018. [Google Scholar]

- Bai, L. Landstromversorgungssystem für Schiffe am Kai. DE202014103274U1, 6 August 2014. [Google Scholar]

- Ruixin, X.; Wenwen, W.; Zhaolei, S. Ship Shore Power System. CN105305449B, 9 January 2018. [Google Scholar]

- Jinhang, H.; Ya, M.; Kang, C.; Yuan, X. High-Voltage Shore Power Major Loop and Reverse Power Composite Inhibition Method Therefor. CN108306521A, 20 July 2018. [Google Scholar]

- Yu, W.; Xiaodong, S.; Yeyuan, X.; Jianyang, L.; Hongde, L.; Qi, Q. Shore Power Supply System and Grid-Connection Control Method Thereof. CN106628096A, 10 May 2017. [Google Scholar]

- Xubao, W.; Yuezhong, T.; Feng, W.; Qingcai, J.; Zhongming, Z.; Jun, L.; Jikang, S.; Xingde, H.; Qin, X.; Yue, G.; et al. Shore-Based Frequency Conversion Power Supply System. CN108110753A, 1 June 2018. [Google Scholar]

- Jerry, S.; Raymond, B. System and Method for Electrical Power Conversion. US8610308B2, 17 December 2013. [Google Scholar]

- Vincent, M. System and Method for Connecting to Marine Shore Power. US10153581B2, 11 December 2018. [Google Scholar]

- Fengjian, Z.; Shan, S.; Shu, L.; Zhichao, L.; Jieqing, W.; Zhanhui, Y.; Yan, Z. Ship Shore-Based Variable Frequency Power Supply System. CN105633957A, 1 June 2016. [Google Scholar]

- Xiaosong, Y.; Jinquan, W.; Zhenfei, W.; Ming, X. Shore Power Supply System for Ships and Power Supply Method Thereof. CN101917004B, 24 April 2013. [Google Scholar]

- Mingri, L. Intelligent Environment-Friendly High-Voltage Shore-Power Power-Supply System. CN203434629U, 12 February 2014. [Google Scholar]

- Richard, B.; John, D.; Geoffrey, W. Power Converter for Converting AC Shore Power to Shipboard Use. US5920467A, 6 July 1999. [Google Scholar]

- Zhen, S.; Cheng, Z.; Jian, G.; Yifei, Y.; Baigong, W.; Jing, X.; Zujun, H. Control Method of Ship and Shore Power Grid Connection and Seamless Switching. CN110061527A, 26 July 2019. [Google Scholar]

- Kimmo, R.; Tero, J.; Heikki, B. An Electric Power System for Supplying Electric Energy to a Vessel. EP3229334B1, 12 August 2020. [Google Scholar]

- Hans-Erhard, S.; Manfred, S.; Dieter, W. Distribution Voltage Land Connection for Ships. WO2006079636A1, 3 August 2006. [Google Scholar]

- Jie, G.; Fengqin, W.; Yuxin, S.; Xi, H.; Shanli, Y.; Zixuan, T. Shore-Based Wireless Charging Device for Electric Ship. CN110143144A, 20 August 2019. [Google Scholar]

- Prevljak, N.H. Fit for (Sustainable) Future: Onshore Power Supply Gaining Ground in European Ports. Offshore Energy. 2024. Available online: https://www.offshore-energy.biz/fit-for-sustainable-future-onshore-power-supply-gaining-ground-in-european-ports/ (accessed on 5 July 2025).

- Port of Kiel. Shore Power Terminals at the Port of Kiel. 2023. Available online: https://www.portofkiel.com/blue-port-en-2/landstrom-schiffsantriebe/shore-power.html (accessed on 5 July 2025).

- Ports of Stockholm. Onshore Power Connection for Vessels. 2025. Available online: https://www.portsofstockholm.com/about-us/environmental-work/environmental-measures/onshore-power-connection/ (accessed on 5 July 2025).

- Decker, T.; Sturrup, E. Nationwide Port Emissions Screening for Berthed Vessels: Prioritizing U.S. Port Electrification to Improve Air Quality for Near-Port Communities; International Council on Clean Transportation: Washington, DC, USA, 2024. [Google Scholar]

- Moore, R.; CMA CGM and Shanghai port develop Onshore Power Supply for box ships. Riviera. 2022. Available online: https://www.rivieramm.com/news-content-hub/cma-cgm-and-shanghai-port-develop-onshore-power-supply-for-box-ships-72142 (accessed on 5 September 2025).

- Siemens AG. SINAMICS SM120 CM: Technical Data. Technical Report; Siemens AG, Process Industries and Drives: Nürnberg, Germany, 2016. [Google Scholar]

- Greencisco Industrial Co., Ltd. Marine Shore Frequency Converter (SFC Series)—60 kVA to 400 kVA. 2025. Available online: https://www.greencisco.com/me/show/101/530.html (accessed on 23 May 2025).

- GE Vernova Power Conversion & Storage. MV7000 Press Pack (PP) Medium Voltage Drive—Technical Brochure. Technical Report; GE Vernova: Cambridge, MA, USA, 2022. [Google Scholar]

- Stemmann-Technik GmbH (Wabtec Marine Solutions). ShoreCONNECT—Flexible High-Voltage Onshore Power Supply Interface for Maritime Applications. 2025. Available online: https://www.shoreconnect.com/en/shore-connection (accessed on 23 May 2025).

- Cavotec Group AB. Shore Power Systems for Ports—Cruise Ships, Vessels & Ports; Technical Report; Cavotec Group AB: Stockholm, Sweden, 2023. [Google Scholar]

- Siemens. Sustainable Power Supply For Eco-Friendly Ports; Siemens: Munich, Germany, 2023. [Google Scholar]

- Sun, X.; Qiu, J.; Tao, Y.; Yi, Y.; Zhao, J. Distributed Optimal Voltage Control and Berth Allocation of All-Electric Ships in Seaport Microgrids. IEEE Trans. Smart Grid 2022, 13, 2664–2674. [Google Scholar] [CrossRef]

- Aktas, T.U.; Shi, J.; Lim, G.J.; Prousalidis, J.; D’Agostino, F.; Liang, C. Decarbonization of the Maritime Transportation Systems: Recent Progress, Challenges, and Prospects. In Proceedings of the 2023 IEEE Electric Ship Technologies Symposium (ESTS), Napoli, Italy, 19–21 June 2023; pp. 224–230. [Google Scholar] [CrossRef]

- Campora, U.; Mocerino, L.; Acanfora, M. On the Improvements in Maritime Decarbonization by the Natural Gas-Electric Power System of a Ferry Operating in the Mediterranean Sea. In Proceedings of the 2024 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Napoli, Italy, 19–21 June 2024; pp. 1042–1047. [Google Scholar] [CrossRef]

- Pan, P.; Sun, Y.; Yuan, C.; Yan, X.; Tang, X. Research progress on ship power systems integrated with new energy sources: A review. Renew. Sustain. Energy Rev. 2021, 144, 111048. [Google Scholar] [CrossRef]

- Ismail, A.; Abdel-Majeed, M.S.; Metwly, M.Y.; Abdel-Khalik, A.S.; Hamad, M.S.; Ahmed, S.; Hamdan, E.; Elmalhy, N.A. Solid-State Transformer-Based DC Power Distribution Network for Shipboard Applications. Appl. Sci. 2022, 12, 2001. [Google Scholar] [CrossRef]

- Benevieri, A.; Cosso, S.; Formentini, A.; Marchesoni, M.; Passalacqua, M.; Vaccaro, L. Advances and Perspectives in Multilevel Converters: A Comprehensive Review. Electronics 2024, 13, 4736. [Google Scholar] [CrossRef]

- Wang, B.; Peng, X.; Zhang, L.; Su, P. Real time power management strategy for an all-electric ship using a predictive control model. IET Gener. Transm. Distrib. 2022, 16, 12419. [Google Scholar] [CrossRef]

- IPT-Technology. Wireless Charging System Suits Electric Ferries; Efringen: Kirchen, Germany, 2022; Available online: https://ipt-technology.com/ships-ferries (accessed on 26 May 2025).

- Wartsila. The Evolution of Wireless Charging; Wartsila. Available online: https://www.wartsila.com/insights/article/the-evolution-of-wireless-charging (accessed on 5 June 2025).

- Yu, C.; Zhu, H.; Han, B.; Zhao, W.; Xu, M.; Zhang, Q.; Guo, H. Wireless Power Transfer Technology for Shore-to-Ship Applications. In Proceedings of the 2022 5th International Conference on Power and Energy Applications (ICPEA), Guangzhou, China, 18–20 November 2022; pp. 157–163. [Google Scholar] [CrossRef]

- Guidi, G.; Suul, J.A.; Jenset, F.; Sorfonn, I. Wireless Charging for Ships: High-Power Inductive Charging for Battery Electric and Plug-In Hybrid Vessels. IEEE Electrif. Mag. 2017, 5, 22–32. [Google Scholar] [CrossRef]

- Zhang, H.; Lu, F. Feasibility Study of the High-Power Underwater Capacitive Wireless Power Transfer for the Electric Ship Charging Application. In Proceedings of the 2019 IEEE Electric Ship Technologies Symposium (ESTS), Washington, DC, USA, 14–16 August 2019; pp. 231–235. [Google Scholar] [CrossRef]

- Li, T.; Wu, L.; Chen, Z. Research Overview on Wireless Power Transmission Technology. MATEC Web Conf. 2015, 22, 02021. [Google Scholar] [CrossRef]

- Teeneti, C.R.; Truscott, T.T.; Beal, D.N.; Pantic, Z. Review of Wireless Charging Systems for Autonomous Underwater Vehicles. IEEE J. Ocean. Eng. 2021, 46, 68–87. [Google Scholar] [CrossRef]

- Haque, M.S.; Mohammad, M.; Choi, S. Sensitivity Analysis and Controller Design of High Power LCC-LCC Compensated Wireless Battery Charging For Electric Ship Applications. In Proceedings of the 2020 IEEE Applied Power Electronics Conference and Exposition (APEC), New Orleans, LA, USA, 15–19 March 2020; pp. 3200–3207. [Google Scholar] [CrossRef]

- Yin, J.; Yang, J.; Li, G.; Huo, Q.; Wei, T.; Xin, K. Research on Integration Model of Shore-to-ship Power Supply System with High Proportion Renewable Energy. IOP Conf. Ser. Earth Environ. Sci. 2019, 371, 042056. [Google Scholar] [CrossRef]

- Gutierrez-Romero, J.E.; Esteve-Pérez, J.; Zamora, B. Implementing Onshore Power Supply from renewable energy sources for requirements of ships at berth. Appl. Energy 2019, 255, 113883. [Google Scholar] [CrossRef]

- Frković, L.; Cosic, B.; Puksec, T.; Vladimir, N. Vehicle-to-Ship: Enhancing the Energy Transition of Maritime Transport With the Synergy of All-Electric Vehicles and Ferries. IEEE Trans. Transp. Electrif. 2023, 10, 6010–6023. [Google Scholar] [CrossRef]

| Author/Year | Scope of Study | Main Contributions | Limitations |

|---|---|---|---|

| Abu Bakar et al. (2023) [3] | Electrification of OPS | Comprehensive overview of cold ironing technologies and port decarbonization strategies | Limited coverage of patents and commercial applications |

| Deng (2023) [5] | Carbon emissions from shipping | Synthesized global shipping emission trends | Focused on emissions, limited discussion of OPS |

| Williamsson et al. (2022) [8] | Barriers and drivers of OPS adoption | Identified key barriers (economic, regulatory, technical) | No technical modeling or case validation |

| Sulligoi et al. (2015) [25] | Shore-to-Ship Power systems | Provided state-of-the-art review of OPS technologies | Outdated regarding recent renewable integration |

| Mahdi et al. (2023) [26] | Power converters for ship electrification | Classified converter technologies for shipboard systems | Limited focus on ship side |

| Nuchturee et al. (2020) [27] | Integrated electric propulsion | Analyzed energy efficiency and benefits of integrated propulsion | Limited empirical validation |

| Yang et al. (2023) [28] | Shore power systems | Discussed key technologies of OPS | High-level discussion, less technical depth |

| Xu et al. (2022) [29] | DC shipboard microgrids | Reviewed architectures, storage, and converters for ship electrification | Part I only, not OPS-specific |

| He et al. (2018) [30] | Standards for OPS | Discussed international standards for OPS implementation | Lacked analysis of adoption in practice |

| Puig et al. (2023) [31] | Regulatory and technological challenges in Europe | Identified barriers in European ports for OPS deployment | Geographically limited to Europe |

| Pollutant | Percent Reduction Using Shore Power |

|---|---|

| Carbon Monoxide (CO) | 92% |

| Nitrogen Oxides (NOx) | 98% |

| 59% | |

| 66% | |

| Sulfur Dioxide (SO2) | 73% |

| Carbon Dioxide (CO2) | 26% |

| Ship Type | Average Power Demand [kW] | Peak Power Demand [kW] | Peak Power Demand for 95% Ships [kW] | Frequency | |

|---|---|---|---|---|---|

| 50 Hz | 60 Hz | ||||

| Container ships ( m) | 170 | 1000 | 800 | 63% | 37% |

| Container ships ( m) | 1200 | 8000 | 5000 | 6% | 94% |

| Container ships (total) | 800 | 2000 | 4000 | 26% | 74% |

| RoRo and vehicle ships | 1500 | 2000 | 1800 | 30% | 70% |

| Oil and product tankers | 1400 | 2700 | 2500 | 20% | 80% |

| Cruise ships ( m) | 4100 | 7300 | 6700 | 36% | 64% |

| Cruise ships ( m) | 7500 | 11,000 | 9500 | – | 100% |

| Architecture | Advantages | Disadvantages |

|---|---|---|

| Centralized AC (One central conversion station supplies all terminals via AC lines) |

|

|

| Distributed AC (Multiple local AC conversion units near or on the quays) |

|

|

| Distributed DC (A central AC/DC station feeds DC lines; local DC/AC converters are located at each berth) |

|

|

| Multi-distributed (Multiple AC/DC converters feed a common DC bus supplying several terminals; local DC/AC converters are located at each berth) |

|

|

| Standard | Description | Implementation |

|---|---|---|

| IEC/IEEE 80005-1:2019 [24] | General requirements: high voltage shore side. | Shore |

| IEC/IEEE 80005-2:2016 [57] | Data communication for monitoring and control. | Shore/Ship |

| IEC/IEEE 80005-3:2014 [58] | General requirements: low voltage shore side. | Shore |

| IEC/IEEE 80005-4:2023 [59] | General requirements Direct Current shore connection. | Shore |

| IEC 62613-2:2016 [60] | Dimensional compatibility and interchangeability requirements for accessories to be used by various types of ships. | Connection |

| IEC 60309-5:2017 [61] | Dimensional compatibility and interchangeability requirements for plugs, socket outlets, ship connectors and ship inlets for LVSC systems. | Connection |

| IEC 60092-201:2019 [62] | General system design for electrical installations in ships. | Ship |

| IEC 60092-503:2021 [63] | AC supply systems with voltages in the range of above 1 kV up to and including 36 kV. | Ship |

| IEC 60146-1-1:2024 [64] | Specification of basic requirements for semiconductor power converters. | Converter |

| IEEE 1662-2023 [65] | Onshore and offshore electrical power systems. | Shore/Ship |

| IEEE 1709-2018 [66] | DC power distribution on ships. | Ship |

| IEEE 45.1-2023 [67] | Design of shipboard electrical generation and propulsion. | Ship |

Parameter | High-voltage shore connection (IEC/IEEE 80005-1) | Low-voltage shore connection (IEC/IEEE 80005-3) |

Nominal Voltage | 6.6 kV 11 kV | 400 V 440 V 690 V 230 V also possible for less demanding consumption < 50 kW |

| Voltage Tolerances |

No-Load Conditions: 6% of nominal voltage increase Load Conditions: 3.5% max voltage drop | |

| Nominal Frequency |

50/60 Hz DC for fast DC charging systems | |

| Frequency Tolerances | Continuous tolerance: ±5% | |

| Transient Response |

Voltage: −15% < dV < 20% (1.5 s) Frequency: ±10% (5 s) | |

| Harmonic Distortion |

For no-load conditions, voltage harmonic distortion limits: <3% (single harmonics) <5% (total harmonic distortion) | |

| Voltage variations for DC supply |

Voltage tolerance (continuous): ±10% Voltage cyclic variation deviation: 5% Voltage ripple (RMS over steady DC voltage): 10% | |

| Voltage variations for battery systems |

Components connected to the battery during charging: +30%, −25% Components not connected to the battery during charging: +20%, −25% | |

| Directive/Recommendation | Description | Implementation |

|---|---|---|

| EU Directive 2003/96/EC [73] | Taxation framework for energy products and electricity. | Shore |

| EU Directive 2006/339/EC [72] | Promotion of shore-side electricity to reduce emissions. | Shore |

| EU Directive 2012/33/EC [74] | Limitation of sulphur content in marine fuels. | Ship |

| EU Directive 2014/94/EU [75] | Deployment of alternative fuels infrastructure. | Shore |

| EU Directive 2016/802/EU [76] | Reduction in sulphur content of liquid fuels. | Ship |

| IMO MARPOL Annex VI [77] | Air pollution prevention regulations for ships. | Ship |

| Region | Publication Period | Number of Patents | Main Technological Focus |

|---|---|---|---|

| China (CN) | 2012–2019 | 12 | AC-DC-AC conversion, intelligent control, HV integration. |

| Europe (EP/DE) | 2011–2020 | 3 | Mobile/universal interfaces, MV connection, redundant systems. |

| United States (US) | 1999–2018 | 5 | Automatic connection, scalable topologies. |

| Others (International WO) | 2006–2013 | 3 | Standardized connectors, infrastructure universality. |

| Total | 1999–2020 | 23 | Interfaces, conversion, grid integration. |

| Year | Port Name | Country | Capacity [MW] | Voltage [kV] | Frequency [Hz] | Ship Types |

|---|---|---|---|---|---|---|

| 2010 | San Diego | U.S.A. | 16 | 6.6 & 11 | 60 | Cruise |

| 2010 | San Francisco | U.S.A. | 16 | 6.6 & 11 | 60 | Cruise |

| 2010 | Karlskrona | Sweden | 2.5 | 11 | 50 | ROPAX |

| 2011 | Long Beach | U.S.A. | 16 | 6.6 & 11 | 60 | Cruise |

| 2011 | Oslo | Norway | 4.5 | 11 | 50 | Cruise |

| 2011 | Prince Rupert | Canada | 7.5 | 6.6 | 60 | Cruise |

| 2012 | Rotterdam | Netherlands | 2.8 | 11 | 60 | ROPAX |

| 2012 | Ystad | Sweden | 6.25–10 | 11 | 50 & 60 | Cruise |

| 2013 | Trelleborg | Sweden | 3.5–4.6 | 11 | 50 | ROPAX |

| 2015 | Hamburg | Germany | 12 | 6.6 & 11 | 50 & 60 | Cruise |

| 2019–2023 | Kiel | Germany | 4.5–16 | 6.6 & 11 | 50 & 60 | Ferry & Cruise |

| 2024 | Stockholm | Sweden | Not specified | 0.4 & 0.69 & 6.6 & 11 | 50 & 60 | Cruise |

| Product | Manufacturer | Power [MVA] | Voltage [V] | Efficiency | Key Features |

|---|---|---|---|---|---|

| SINAMICS SM120 [120] (frequency converter) | Siemens | 4–13.3 | 3300–7200 | 98.5% | Scalable design, liquid-cooled, high efficiency, suitable for phased port expansions. |

| SFC Shore Power [121] (frequency converter) | Greencisco | 0.06–0.4 | HV: 6600 LV: 440 | ≥95% | Compact footprint, suitable for small- to medium-scale installations, transformer-integrated. |

| MV7000 [122] (frequency converter) | GE Vernova | 4–48 | 3300–13,800 | 99% | Water or air cooled, suitable for high power applications, compatible with hybridization and storage, low harmonics output. |

| ShoreCONNECT [123] | Wabtec | 6.5–20 | HV: 6600–11,000 LV: Individual cable handling | NA | Available in fixed, mobile, crane-integrated, and fully autonomous configurations; robotic cable handling. |

| PowerFit HV [124] | Cavotec | HV: Up to 7.5 LV: Up to 3.6 | HV: 6600 LV: 380–450 | NA | Wall- or skid-mounted, compact, integrated safety interlocks, ideal for RoRo terminals and ferries. |

| PowerMove [124] | Cavotec | Up to 20 | 6600–11,000 | NA | Containerized and flexible deployment, weatherproof enclosure. |

| PowerAMPReel [124] | Cavotec | 4–8 | HV: Up to 6600 LV: Up to 1000 | NA | Cable management system for OPS, integrated shore power module, designed for harsh marine environments. |

| SIHARBOR [125] | Siemens | 2–16 | 6600–11,000 | NA | Containerized system, plug-and-play operation, air-cooled, integrated power conversion. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jesus, D.; Oliveira, T.; Perdigão, M.; Mendes, A. Plugging into Onshore Power Supply System Innovation: A Review from Standards and Patents to Port Deployment. Energies 2025, 18, 5449. https://doi.org/10.3390/en18205449

Jesus D, Oliveira T, Perdigão M, Mendes A. Plugging into Onshore Power Supply System Innovation: A Review from Standards and Patents to Port Deployment. Energies. 2025; 18(20):5449. https://doi.org/10.3390/en18205449

Chicago/Turabian StyleJesus, Daniel, Tiago Oliveira, Marina Perdigão, and André Mendes. 2025. "Plugging into Onshore Power Supply System Innovation: A Review from Standards and Patents to Port Deployment" Energies 18, no. 20: 5449. https://doi.org/10.3390/en18205449

APA StyleJesus, D., Oliveira, T., Perdigão, M., & Mendes, A. (2025). Plugging into Onshore Power Supply System Innovation: A Review from Standards and Patents to Port Deployment. Energies, 18(20), 5449. https://doi.org/10.3390/en18205449