Investigation into the Multiphase Product Distribution and Evolution During Biomass Pyrolysis Using Wheat Straw and Pine Sawdust

Abstract

1. Introduction

2. Materials and Methods

2.1. Biomass

2.2. TG-DTG

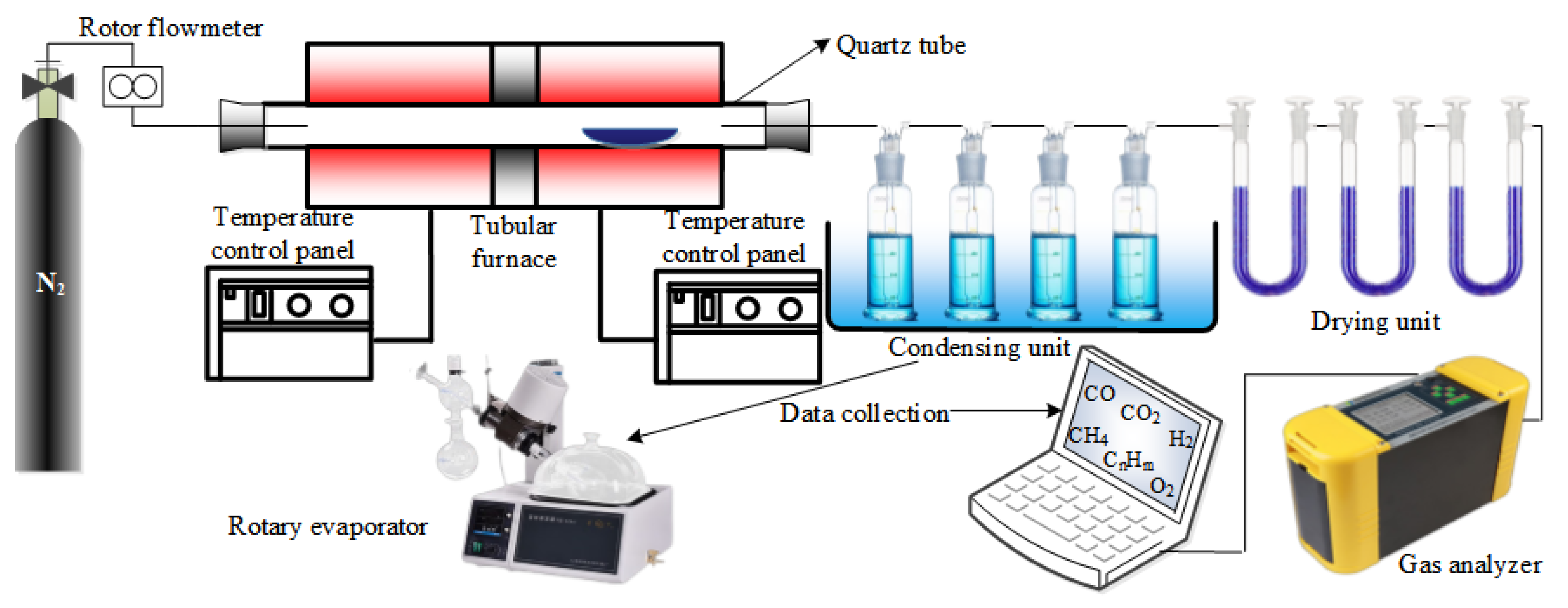

2.3. Tube Furnace Experiment

2.4. FTIR Analysis

2.5. GC-MS Analysis

2.6. Pyrolysis Kinetic Analysis

3. Results and Discussion

3.1. TG-DTG Analysis

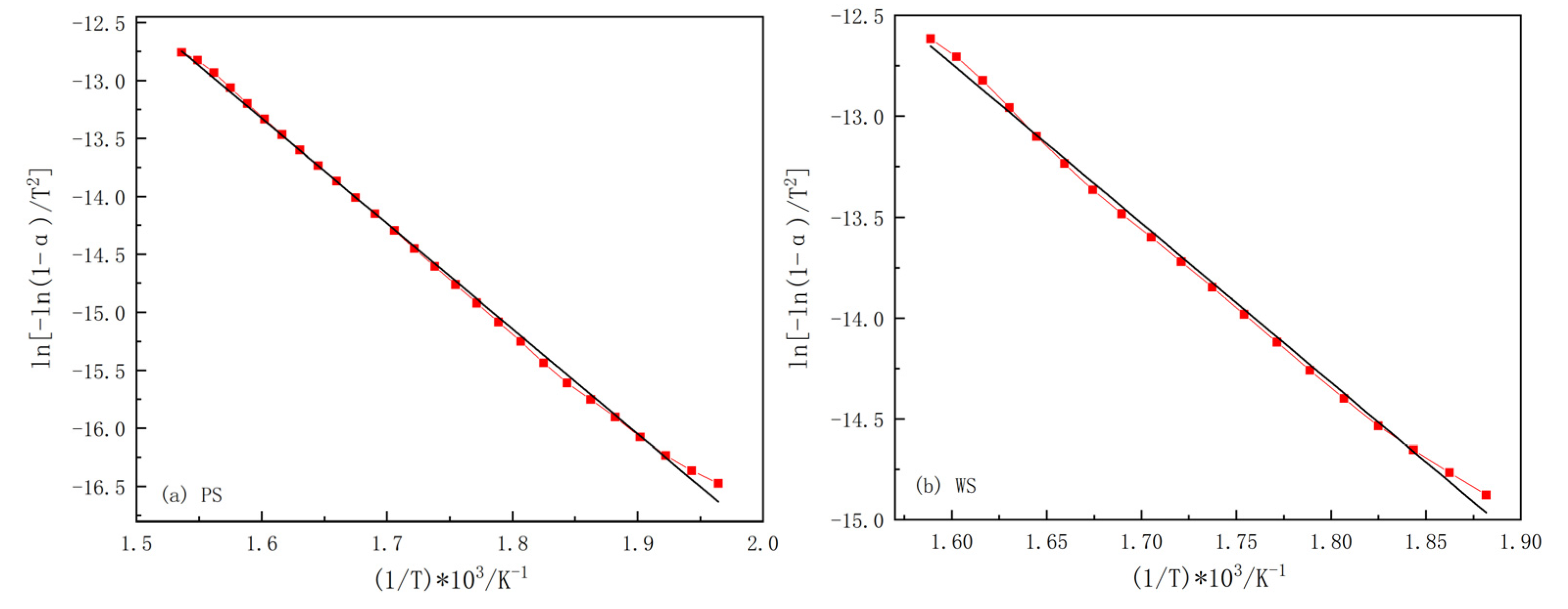

3.2. Activation Energy Analysis

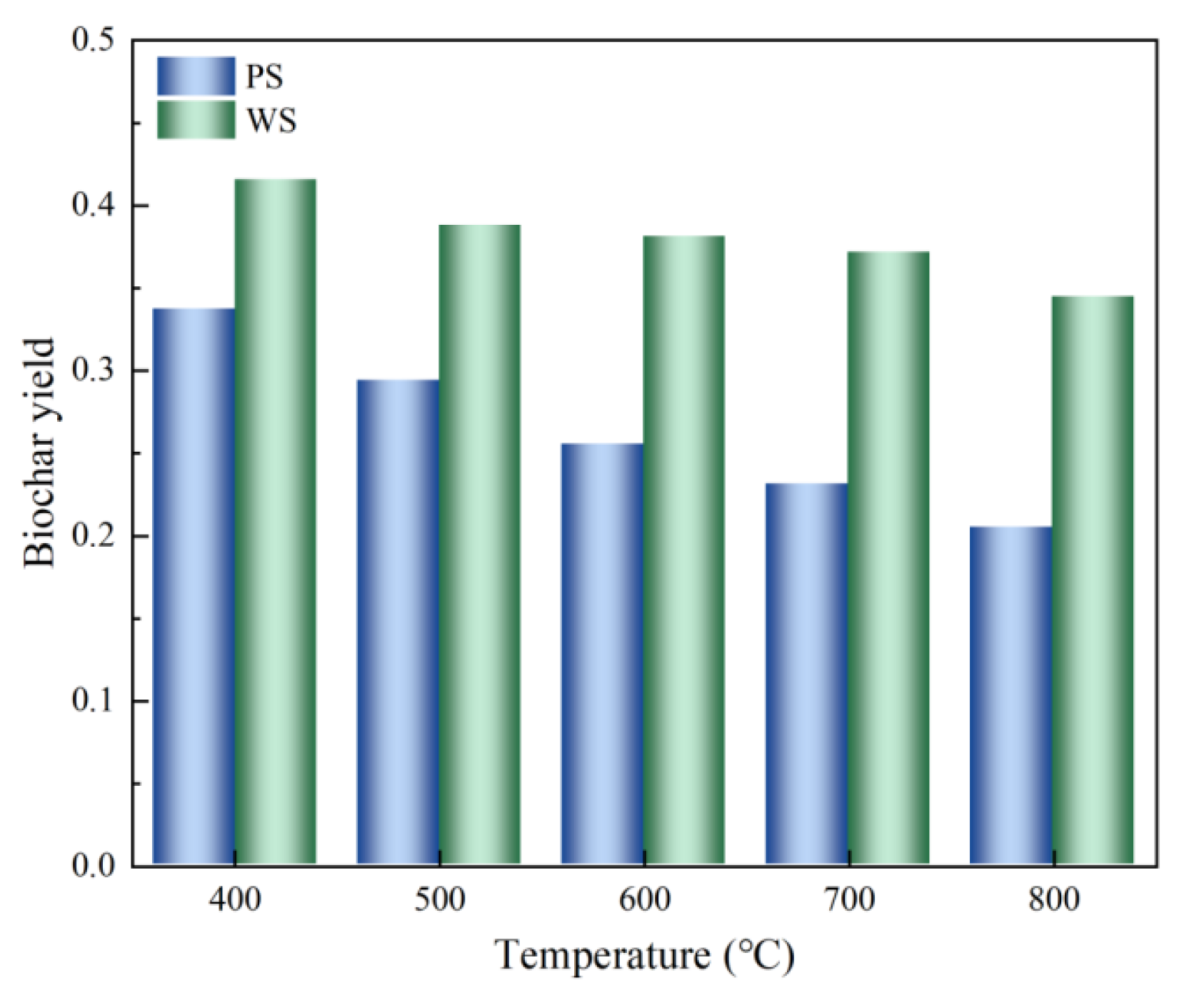

3.3. Analysis of Solid Products

3.3.1. Biochar Yield

3.3.2. FTIR Analysis

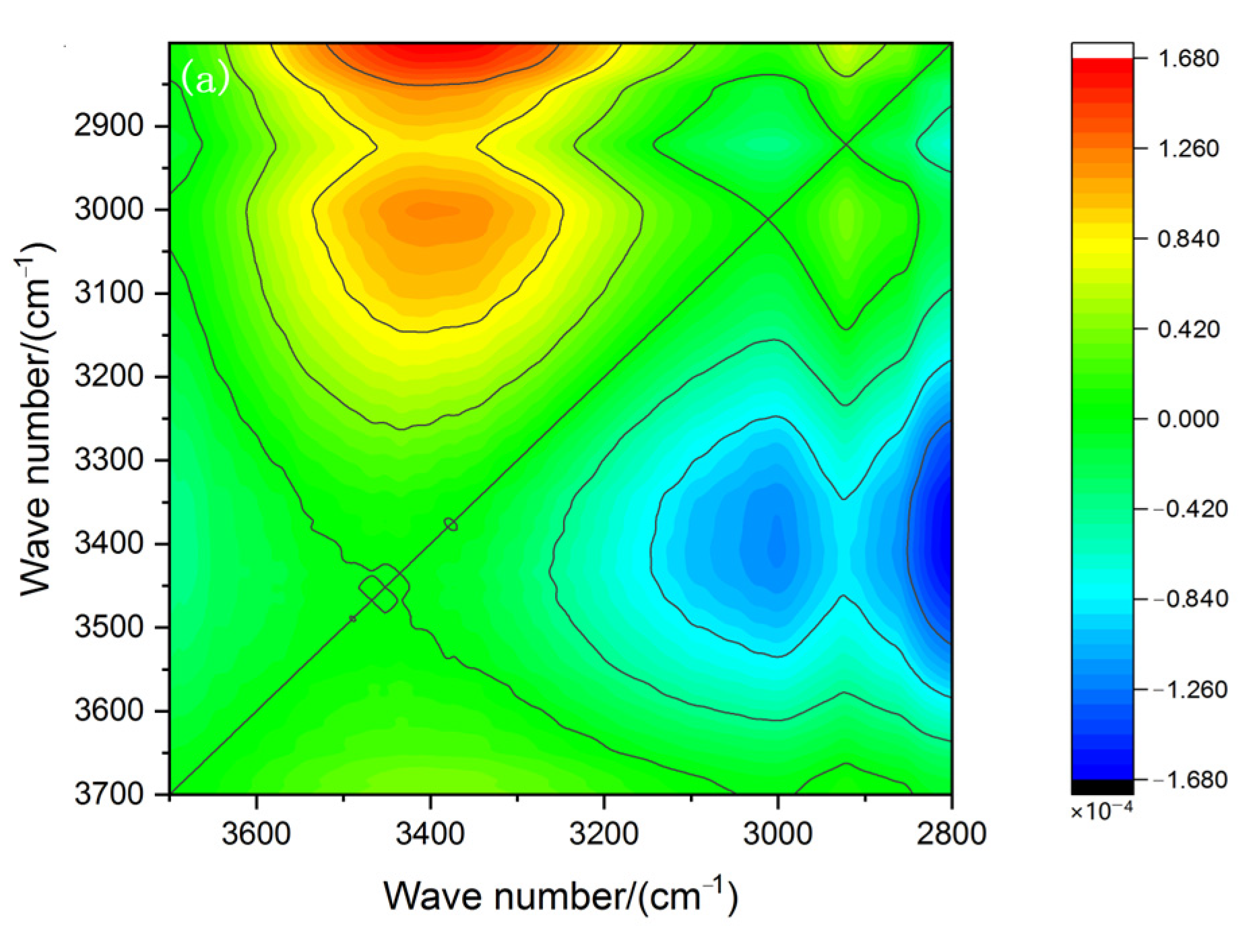

3.3.3. Two-Dimensional Infrared Correlation Spectroscopy Analysis

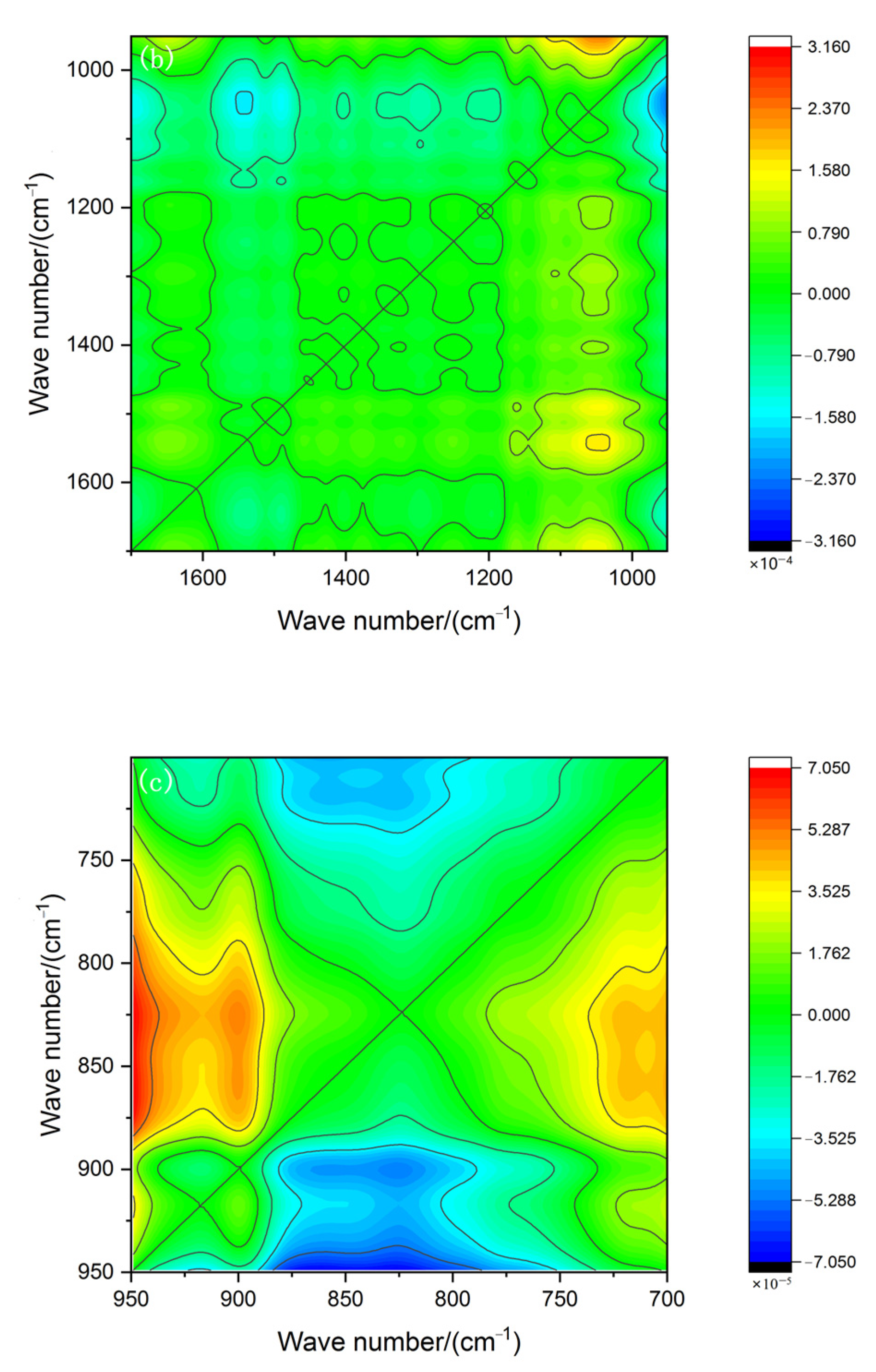

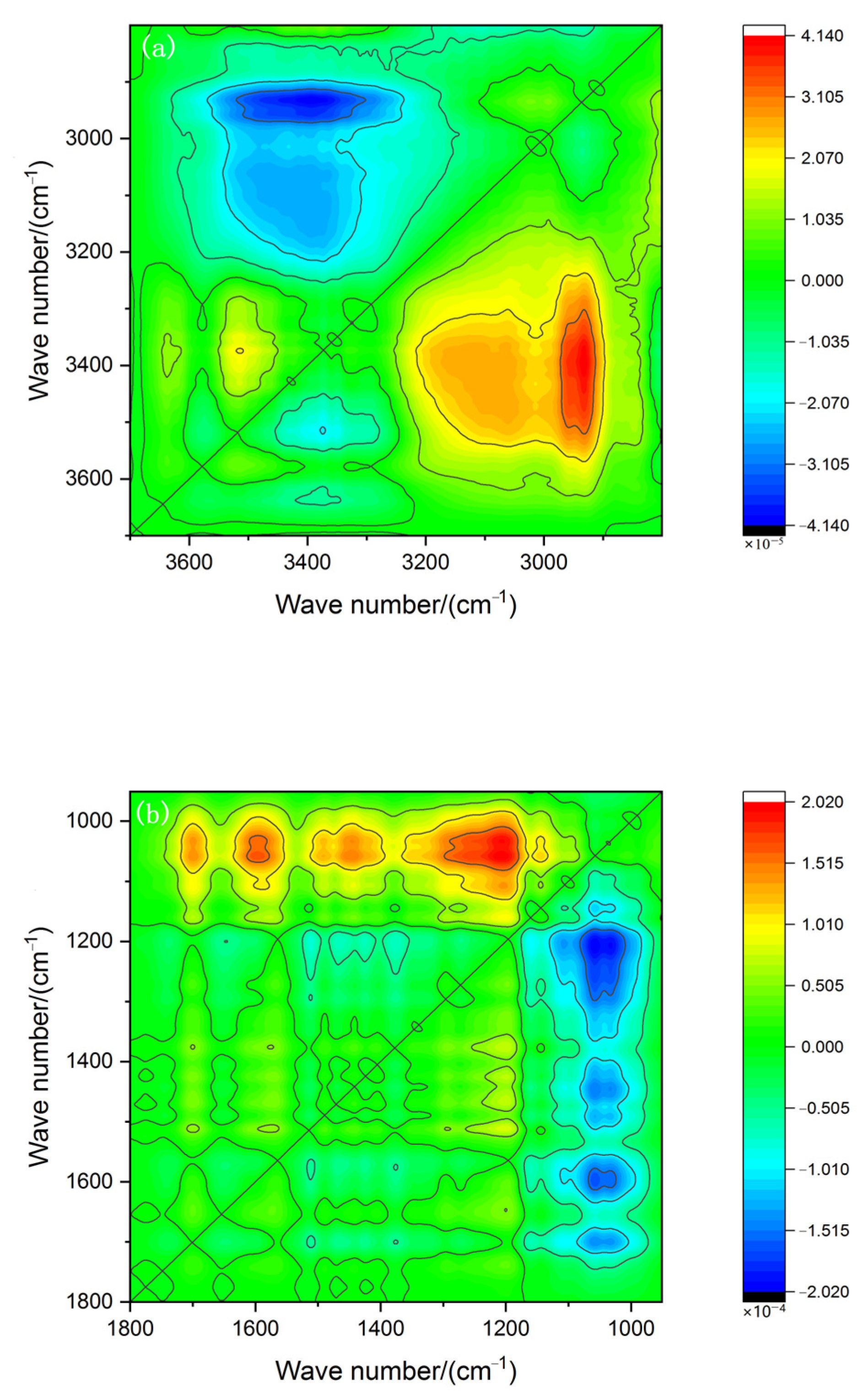

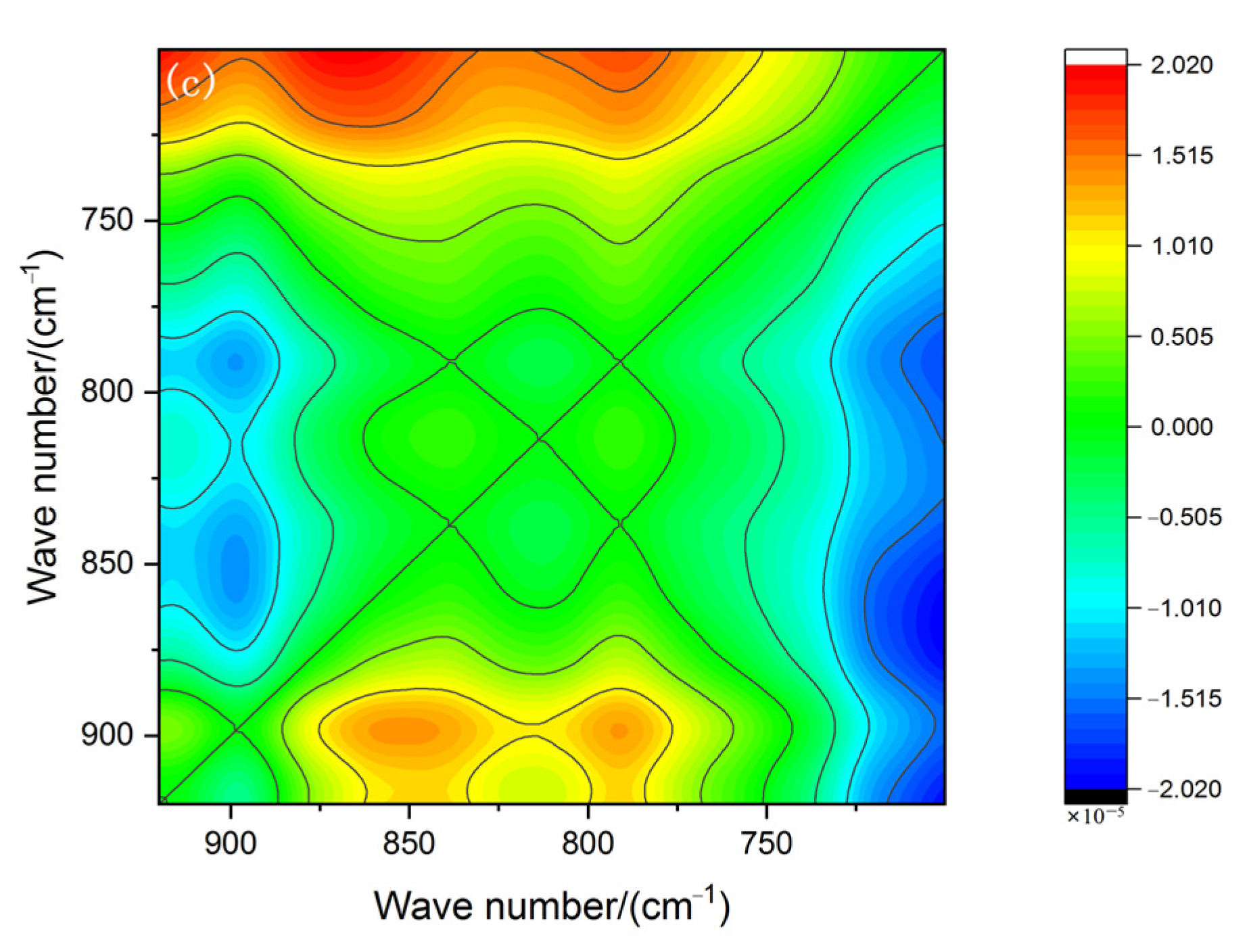

2D-PCIS Analysis of WS

2D-PCIS Analysis of PS

3.4. Biomass Tar Analysis

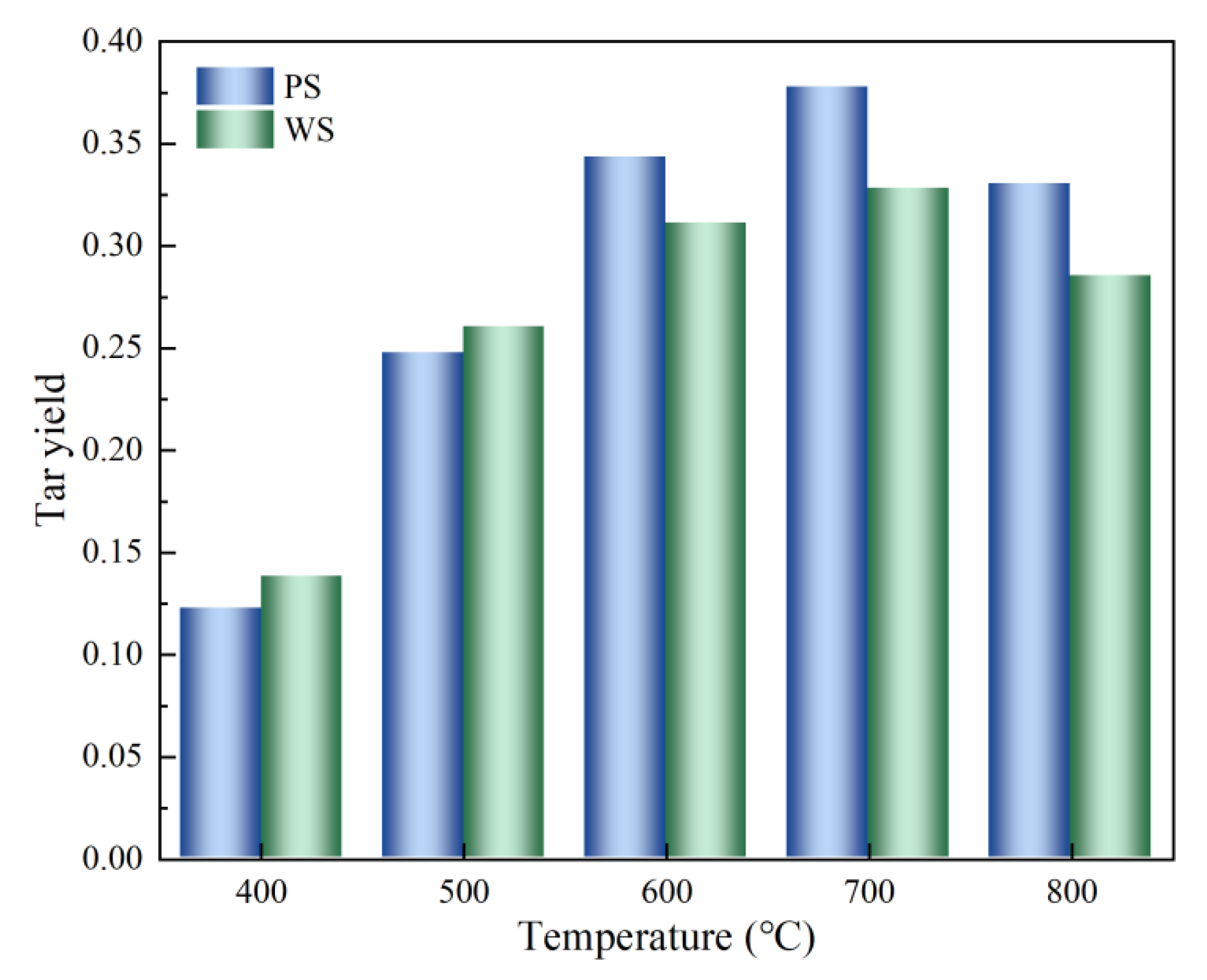

3.4.1. Tar Yield Analysis

3.4.2. Tar Composition Analysis

3.5. Analysis of Gas Product Release Behavior

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Lin, D.; Liu, D.; Xie, X.; Zhang, S.; Li, B. Oxidative Pyrolysis of Typical Volatile Model Compounds Under Low Oxygen Equivalence Ratios During Oxidative Pyrolysis of Biomass. Energies 2025, 18, 2996. [Google Scholar] [CrossRef]

- Mengesha, T.T.; Ancha, V.R.; Nigussie, A.; Afessa, M.M. Effect of Particle Size and Heating Rate on Formation of Polycyclic Aromatic Hydrocarbons During Corn Cob Biomass Pyrolysis. Sustainability 2025, 17, 4962. [Google Scholar] [CrossRef]

- Li, J.; Wang, T.; Hao, T.; Yao, X.; Xu, K.; Liu, J. Application of Biochar Catalysts in Tar Catalytic Reforming: A Review on Preparation, Modification, Deactivation, and Regeneration. Energy 2025, 317, 134734. [Google Scholar] [CrossRef]

- Li, J.; Xu, K.; Yao, X.; Liu, J. Investigation of Biomass Slow Pyrolysis Mechanisms Based on the Generation Trends in Pyrolysis Products. Process Saf. Environ. Prot. 2024, 183, 327–338. [Google Scholar] [CrossRef]

- Daryono, E.; Jimmy; Setyawati, H. Production of Biodiesel Without Catalyst Separation with Palm Oil Interesterification Process Using Essential Oil Biocatalyst. Chem. Chem. Technol. 2025, 356–362. [Google Scholar] [CrossRef]

- Li, J.; Xu, K.; Yao, X.; Liu, J.; Su, D. Study on the Effect of Biochar Catalyst on the Formation of Biomass Slow Pyrolysis Products. Fuel 2025, 392, 134862. [Google Scholar] [CrossRef]

- Dhaundiyal, A. Pyrolysis Kinetics of Pine Waste Based on Ensemble Learning. Energies 2025, 18, 2556. [Google Scholar] [CrossRef]

- Zhao, L.; Li, J.; Xu, K. Analysis of the Pyrolysis and Combustion Behavior and Product Release Characteristics of Chinese Medicine Residue under a Nitrogen/Oxygen Atmosphere. Biomass Bioenergy 2025, 197, 107824. [Google Scholar] [CrossRef]

- Pstrowska, K.; Łużny, R.; Fałtynowicz, H.; Jaroszewska, K.; Postawa, K.; Pyshyev, S.; Witek-Krowiak, A. Unlocking Sustainability: A Comprehensive Review of Up-Recycling Biomass Waste into Biochar for Environmental Solutions. Chem. Chem. Technol. 2025, 19, 211–231. [Google Scholar] [CrossRef]

- Sun, S.; Wan, J.; Fu, H.; Sun, Y.; Shao, F.; Ni, D.; Lu, J. Influence of Pyrolysis on Biomass Structure: Microscopic Deformation Patterns and Chemical Composition Variations. Fuel 2026, 403, 136090. [Google Scholar] [CrossRef]

- Mingzhe, L.; Mcintyre, S.R.; Iacomi, P.; Everden, K.; Williams, P.T.; Zong, S.; Liu, X.; Zhu, X.; Yang, Y.; Li, S.; et al. Biochar Production, Activation, and Applications: A Comprehensive Technical Review. Carbon Capture Sci. Technol. 2025, 16, 100421. [Google Scholar] [CrossRef]

- Ko, H.; Lee, M.; Sen, R. Pyrolysis Characteristics of Empty Fruit Bunches at Different Temperatures and Heating Rates. Energies 2025, 18, 1404. [Google Scholar] [CrossRef]

- Li, J.; Xu, K.; Yao, X.; Liu, J. Slow Pyrolysis Experimental Investigation on the Tar Formation and Its Pyrolysis Behavior Characteristics. Process Saf. Environ. Prot. 2024, 184, 660–671. [Google Scholar] [CrossRef]

- Bi, H.; Wang, C.; Jiang, X.; Jiang, C.; Bao, L.; Lin, Q. Thermodynamics, Kinetics, Gas Emissions and Artificial Neural Network Modeling of Co-Pyrolysis of Sewage Sludge and Peanut Shell. Fuel 2021, 284, 118988. [Google Scholar] [CrossRef]

- Han, Y.; Boateng, A.A.; Qi, P.X.; Lima, I.M.; Chang, J. Heavy Metal and Phenol Adsorptive Properties of Biochars from Pyrolyzed Switchgrass and Woody Biomass in Correlation with Surface Properties Q. J. Environ. Manag. 2013, 118, 196–204. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Wang, F.; Zhang, D.; Deng, H.; Wen, X.; Chen, G. Kinetic and Thermodynamic Analysis of Synergistic Pyrolysis of Salix Psammophila and Plastic Waste. Thermochim. Acta 2025, 751, 180060. [Google Scholar] [CrossRef]

- Kandan, J.A.; Chithra, K. Musa Paradisiaca Peel and Sludge Co-Pyrolysis: Thermal Behavior and Kinetic Analysis. Sustain. Chem. Environ. 2025, 10, 100258. [Google Scholar] [CrossRef]

- Hadou, A.; Belaadi, A.; Alshaikh, I.M.H. Pyrolysis Features of Dracaena Draco Lignocellulosic Fibers: Kinetic and Thermodynamic Analysis at Various Heating Rates through Coats-Redfern Method. Case Stud. Therm. Eng. 2024, 64, 105406. [Google Scholar] [CrossRef]

- Zhu, L.; Zhong, Z. Effects of Cellulose, Hemicellulose and Lignin on Biomass Pyrolysis Kinetics. Korean J. Chem. Eng. 2020, 37, 1660–1668. [Google Scholar] [CrossRef]

- Mansaray, K.G.; Ghaly, A.E. Thermal Degradation of Rice Husks in Nitrogen Atmosphere. Bioresour. Technol. 1998, 65, 13–20. [Google Scholar] [CrossRef]

- Piazza, V.; Batista, R.; Frassoldati, A.; Lietti, L.; Gambaro, C.; Rajendran, K.; Chen, D.; Faravelli, T.; Beretta, A. Unravelling the Complexity of Hemicellulose Pyrolysis: Quantitative and Detailed Product Speciation for Xylan and Glucomannan in TGA and Fixed Bed Reactor. Chem. Eng. J. 2024, 497, 154579. [Google Scholar] [CrossRef]

- Liu, N.; Huang, H.; Feng, J.; Li, R.; Huang, X.; Wu, Y. Effects of Alkali and Alkaline Earth Metals in Biomass on Co-Pyrolysis Characteristics and Product Distribution of Coal and Biomass. Fuel 2025, 389, 134551. [Google Scholar] [CrossRef]

- Zheng, K.; Hu, S.; Gong, Z.; Jia, M.; Xu, K.; Xu, J.; Jiang, L.; Wang, Y.; Su, S.; Xiang, J. Interaction among Cellulose, Hemicellulose and Lignin during Pressurized Pyrolysis: Importance of Deoxygenation and Aromatization Reactions. Energy 2025, 314, 134320. [Google Scholar] [CrossRef]

- Cristina, A.; Araujo, D.; Funke, A.; Margellou, A.; Triantafyllidis, K.; Dahmen, N. Pilot Scale Fast Pyrolysis of Lignin in a Twin-Screw Reactor. Biomass Bioenergy 2025, 200, 108041. [Google Scholar] [CrossRef]

- Guo, Y.; Tan, M.; Zhu, Y.; Yang, W.; Lei, T.; Huang, Z.; Xiao, Z.; Wu, Z.; Li, H. The Effect of Additives on the Storage and Pyrolysis of Biomass: Greenhouse Gas Reduction and Biochar’s Properties Variation. Biomass Bioenergy 2025, 197, 107828. [Google Scholar] [CrossRef]

- Qiu, T.; Li, C.; Zhao, W.; Yasin, M.; Zhang, Y. Microwave-Assisted Pyrolysis of Biomass: Influence of Feedstock and Pyrolysis Parameters on Porous Biochar Properties. Biomass Bioenergy 2025, 193, 107583. [Google Scholar] [CrossRef]

- Tu, R.; Sun, Y.; Wu, Y.; Fan, X.; Jiang, E.; Xu, X. The Fuel Properties and Adsorption Capacities of Torre Fi Ed Camellia Shell Obtained via Different Steam-Torrefaction Reactors. Energy 2022, 238, 121969. [Google Scholar] [CrossRef]

- Song, Y.; Tan, J.; Jin, M.; Liu, Z.; Zhu, J.; El-sayed, M.E.A.; Abdelhafeez, I.A.; Zhang, Y.; Shen, Z. Effect of Pyrolysis Temperature and Heating Rate on the Physicochemical Properties of Alkali Lignin-Derived Biochar: A Comparative Study of Fast and Slow Pyrolysis. J. Anal. Appl. Pyrolysis 2025, 191, 107236. [Google Scholar] [CrossRef]

- Leng, E.; Zhang, Y.; Peng, Y.; Gong, X.; Mao, M.; Li, X.; Yu, Y. In Situ Structural Changes of Crystalline and Amorphous Cellulose during Slow Pyrolysis at Low Temperatures. Fuel 2018, 216, 313–321. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, M.; Yang, H.; Jiang, H.; Chen, Y.; Zhang, S.; Chen, H. Impact of Biomass Constituent Interactions on the Evolution of Char ’ s Chemical Structure: An Organic Functional Group Perspective. Fuel 2022, 319, 123772. [Google Scholar] [CrossRef]

- Liu, R.; Liu, G.; Yousaf, B.; Niu, Z.; Abbas, Q. Novel Investigation of Pyrolysis Mechanisms and Kinetics for Functional Groups in Biomass Matrix. Renew. Sustain. Energy Rev. 2022, 153, 111761. [Google Scholar] [CrossRef]

- Kawamoto, K. Gas and Tar Formation Characteristics in Gasification for Biomass Materials. Chemosphere 2025, 385, 144535. [Google Scholar] [CrossRef]

- Yu, Q.; Brage, C.; Nordgreen, T.; Sjöström, K. Effects of Chinese Dolomites on Tar Cracking in Gasification of Birch. Fuel 2009, 88, 1922–1926. [Google Scholar] [CrossRef]

- Wang, S.; Liu, Q.; Liao, Y.; Luo, Z. A Study on the Mechanism Research on Cellulose Pyrolysis under Catalysis of Metallic Salts. Korean J. Chem. Eng. 2007, 24, 336–340. [Google Scholar] [CrossRef]

- Song, G.; Huang, D.; Ren, Q.; Hu, S.; Xu, J.; Xu, K.; Jiang, L.; Wang, Y.; Su, S.; Xiang, J. Inner-Particle Reaction Mechanism of Cellulose, Hemicellulose and Lignin during Photo-Thermal Pyrolysis Process: Evolution Characteristics of Free Radicals. Energy 2024, 297, 131201. [Google Scholar] [CrossRef]

- Choirun, A.; Zahra, A.; Mudiyanselage, A.; Wimansika, Y.; Zhu, L.; Prakoso, T.; Abudula, A.; Guan, G. Biochar-Assisted Gasification of Raw Biomass: A Review on the Reactivity and Synergistic Effect on Tar Reforming. Resour. Chem. Mater. 2025, 4, 100115. [Google Scholar] [CrossRef]

- Li, J.; Yang, D.; Yao, X.; Zhou, H.; Xu, K. Slow Pyrolysis Experimental Investigation of Biomass Tar Formation and Hydrogen Production by Tar Reforming. Int. J. Hydrogen Energy 2023, 52, 74–87. [Google Scholar] [CrossRef]

- Zheng, K.; Gong, Z.; Hu, S.; Jia, M.; Xu, K.; Xu, J.; Jiang, L.; Wang, Y.; Su, S.; Xiang, J. Investigation of Components Interaction during Pressurized Pyrolysis of Biomass via ReaxFF MD Simulation: Free Radicals Driven Synergistic Deoxygenation and Polymerization Reactions. J. Anal. Appl. Pyrolysis 2025, 190, 107131. [Google Scholar] [CrossRef]

- Abi, A.; Khaled, S.; Hoang, T.; Reza, S.; Abu, S.; Kalam, A. Influence of Combined Catalysts on the Catalytic Pyrolysis Process of Biomass: A Systematic Literature Review. Energy Convers. Manag. 2024, 309, 118437. [Google Scholar] [CrossRef]

- Quan, C.; Feng, S.; Gao, N. Production of Hydrogen-Rich Syngas from Catalytic Reforming of Biomass Gasification Tar Model Compounds Coupled with in-Situ CO2 Capture. Biomass Bioenergy 2025, 193, 107569. [Google Scholar] [CrossRef]

- Arayedh, W.; Van De Steene, L.; Saleh, K.; Daouk, E. Catalyst Deactivation of Biomass-Derived Biochars during Tar Cracking: Role of Porosity. Biomass Bioenergy 2025, 193, 107604. [Google Scholar] [CrossRef]

- Tamiya, H.; Takayama, S.; Mukai, K.; Yagi, J. Effect of Magnetite Addition on Microwave Pyrolysis of Cellulose for Syngas Production. Fuel 2025, 402, 135963. [Google Scholar] [CrossRef]

- Mishra, R.; Shu, C.; Gollakota, A.R.K.; Pan, S. Unveiling the Potential of Pyrolysis-Gasification for Hydrogen-Rich Syngas Production from Biomass and Plastic Waste. Energy Convers. Manag. 2024, 321, 118997. [Google Scholar] [CrossRef]

| Biomass | Proximate Analysis (wt.%) | Ultimate Analysis (wt.%) | ||||||

|---|---|---|---|---|---|---|---|---|

| Moisture | Ash | Volatiles | Fixed Carbon | C | H | O | N | |

| WS | 2.9 | 9.74 | 70.54 | 16.82 | 35.41 | 3.01 | 40.11 | 1.37 |

| PS | 1.67 | 3.86 | 76.42 | 19.05 | 40.65 | 4.13 | 39.8 | 0.72 |

| Biomass | n = 1 | n = 1.1 | n = 1.2 | n = 1.3 | n = 1.4 | n = 1.5 |

|---|---|---|---|---|---|---|

| PS | 0.99841 | 0.9981 | 0.99768 | 0.99717 | 0.99655 | 0.99585 |

| WS | 0.99733 | 0.99651 | 0.99557 | 0.99451 | 0.99334 | 0.99207 |

| Biomass | Fitting Equation | E (kJ·mol−1) | R |

|---|---|---|---|

| PS | Y = −9.07393x + 1.1908 | 75.44 | 0.99841 |

| WS | Y = −7.89386x − 0.11025 | 65.63 | 0.99733 |

| ϕ(v1,v2) | Ψ(v1,v2) | Rules |

|---|---|---|

| + | + | The change in v1 occurs before that in v2. |

| + | − | The change in v2 occurs before that in v1. |

| + | The change trends of v1 and v2 are similar. | |

| − | + | The change in v2 occurs before that in v1. |

| − | − | The change in v1 occurs before that in v2. |

| − | The change trends of v1 and v2 are opposite. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Xu, K.; Yao, X.; Luo, X. Investigation into the Multiphase Product Distribution and Evolution During Biomass Pyrolysis Using Wheat Straw and Pine Sawdust. Energies 2025, 18, 5397. https://doi.org/10.3390/en18205397

Li J, Xu K, Yao X, Luo X. Investigation into the Multiphase Product Distribution and Evolution During Biomass Pyrolysis Using Wheat Straw and Pine Sawdust. Energies. 2025; 18(20):5397. https://doi.org/10.3390/en18205397

Chicago/Turabian StyleLi, Jishuo, Kaili Xu, Xiwen Yao, and Xingyu Luo. 2025. "Investigation into the Multiphase Product Distribution and Evolution During Biomass Pyrolysis Using Wheat Straw and Pine Sawdust" Energies 18, no. 20: 5397. https://doi.org/10.3390/en18205397

APA StyleLi, J., Xu, K., Yao, X., & Luo, X. (2025). Investigation into the Multiphase Product Distribution and Evolution During Biomass Pyrolysis Using Wheat Straw and Pine Sawdust. Energies, 18(20), 5397. https://doi.org/10.3390/en18205397