Advancements in Food Waste Recycling Technologies in South Africa: Novel Approaches for Biofertilizer and Bioenergy Production—A Review

Abstract

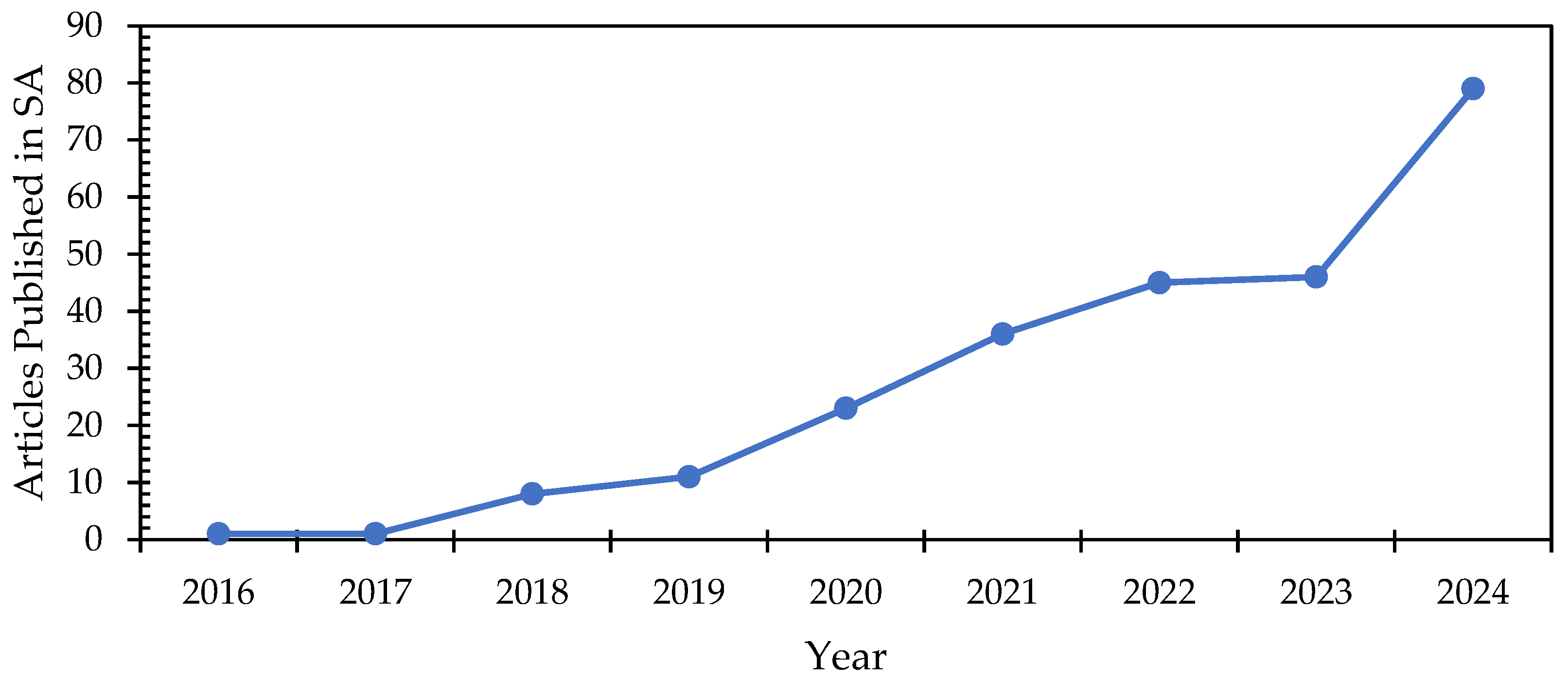

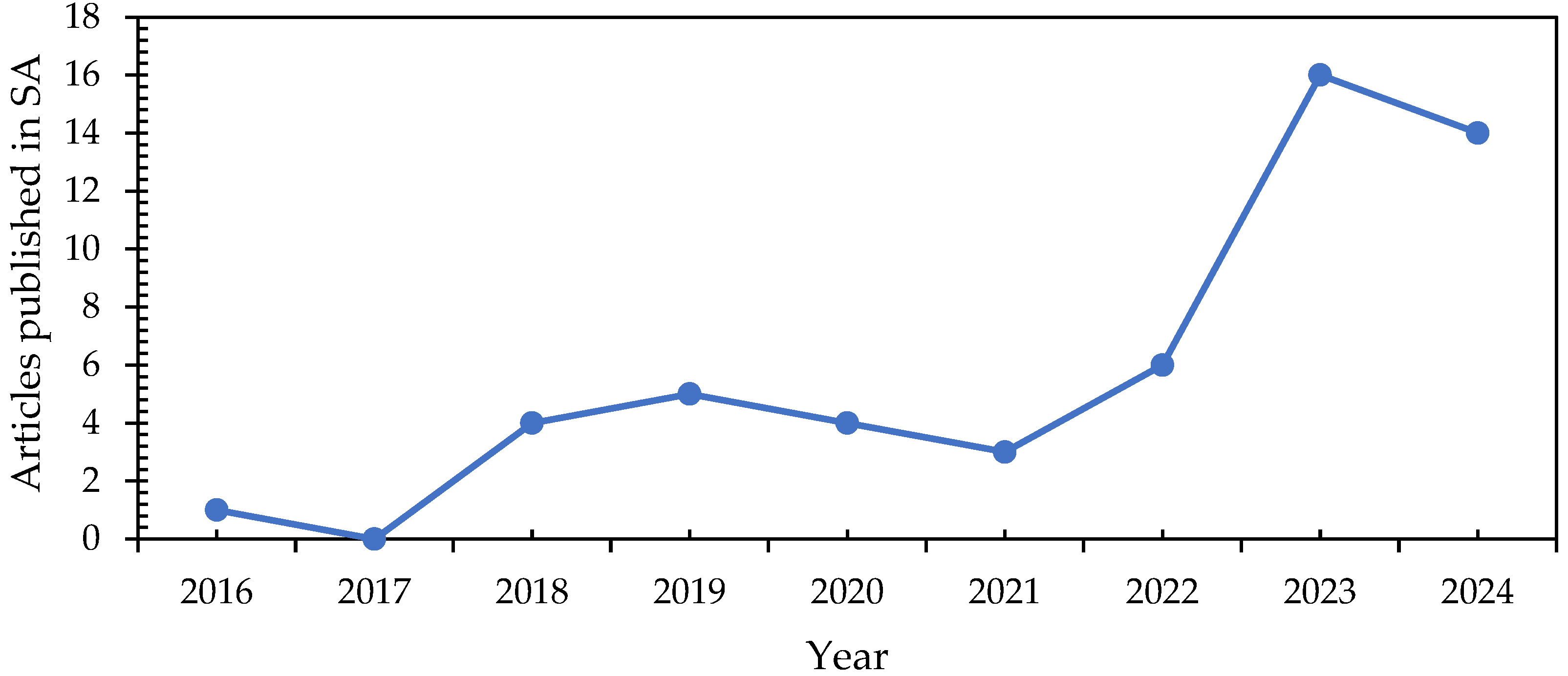

1. Introduction

2. Municipal Food Waste Management and Barriers

3. Generation and Composition of Food Waste

3.1. Global Perspective of Food Waste Generation and Composition

3.2. South African Perspective of Food Waste Generation and Composition

3.3. Environmental and Social Impacts of Food Waste

4. Valorization Technologies for Food Waste

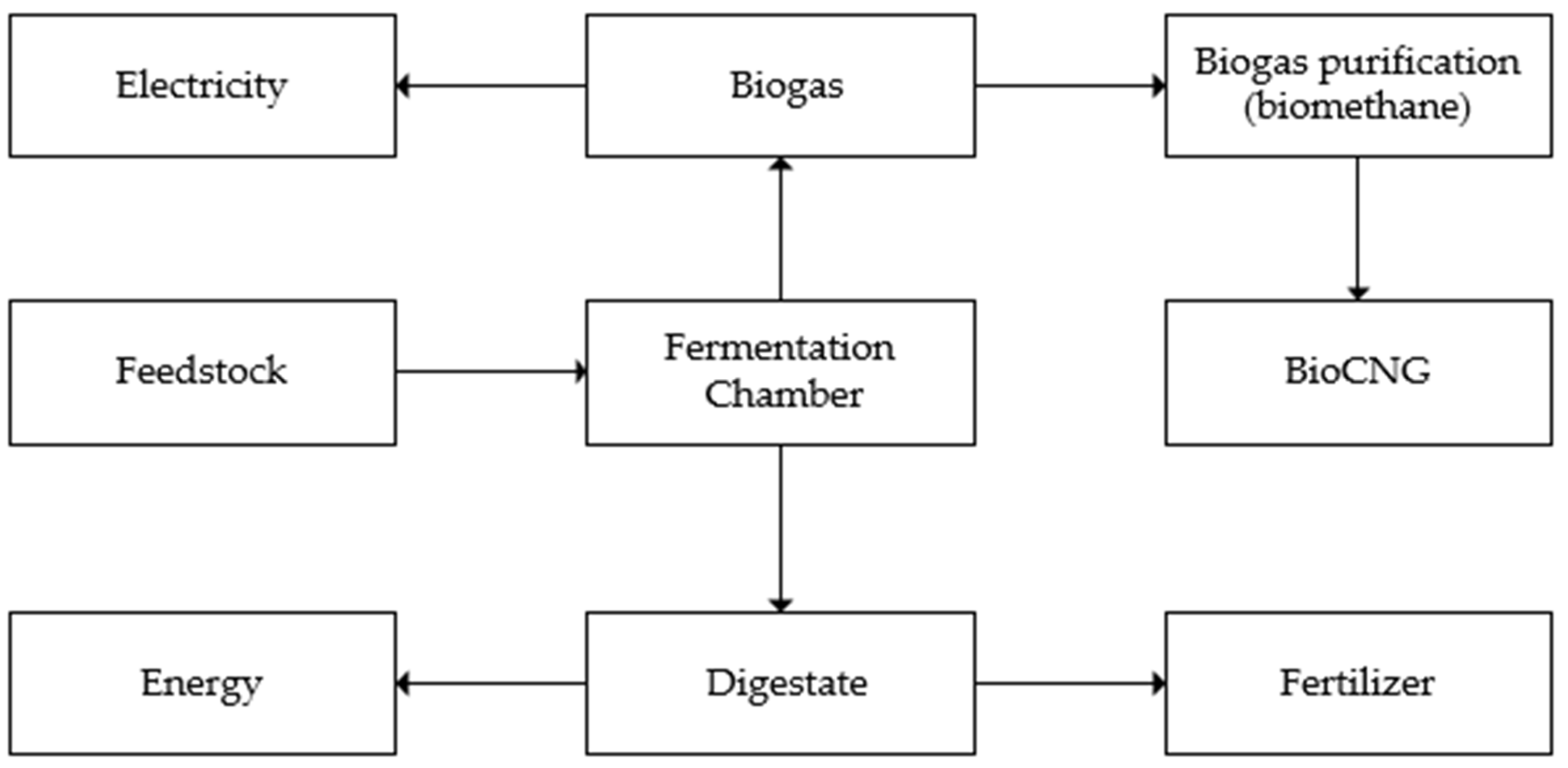

4.1. Anaerobic Digestion (AD)

4.1.1. Life Cycle Assessment of Anaerobic Digestion of Food Waste for Biofertilizer and Biogas Production

4.1.2. Evaluation of Anaerobic Digestion of Food Waste for Biofertilizer and Biogas Generation

4.2. Composting

4.2.1. Life Cycle Assessment of Composting Food Waste for Biofertilizer and Biogas Production

4.2.2. Evaluation of Composting of Food Waste for Biofertilizer and Biogas Generation

4.3. Pyrolysis

4.3.1. Life Cycle Assessment of Pyrolysis of Food Waste for Biofertilizer and Biogas Production

4.3.2. Evaluation of Pyrolysis of Food Waste for Biofertilizer and Biogas Generation

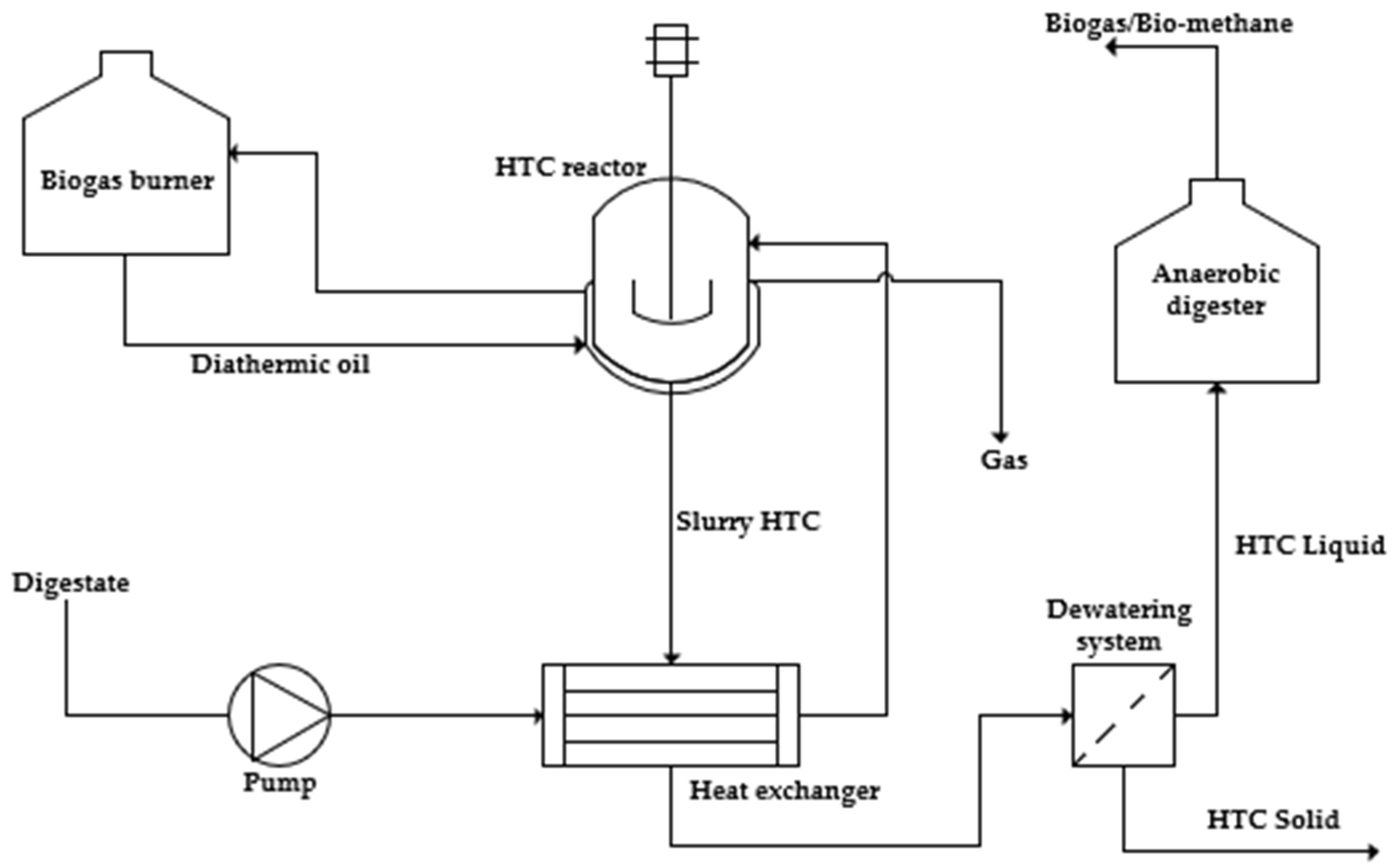

4.4. Heat Treatment Technologies

4.4.1. Hydrothermal Carbonization (HTC)

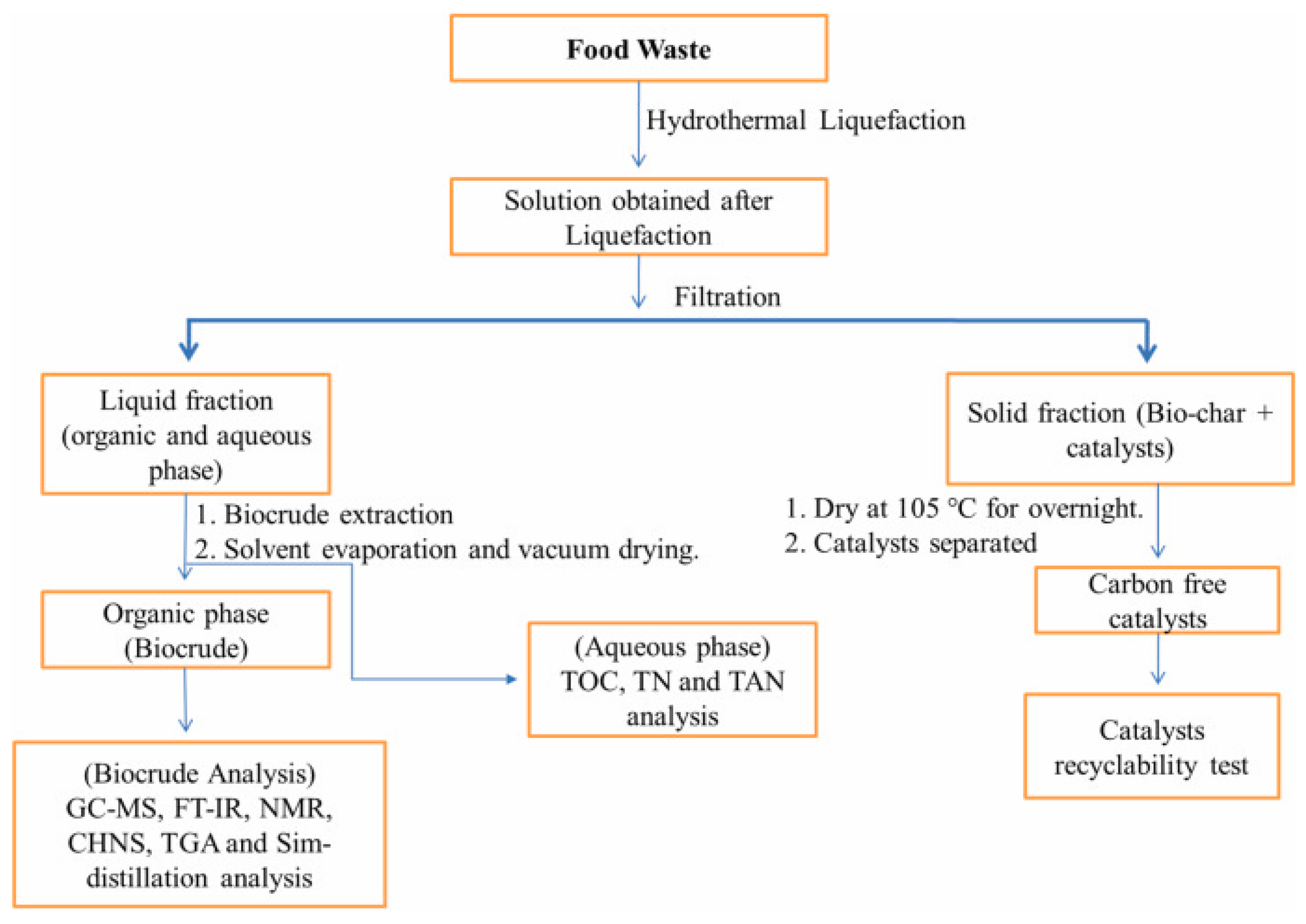

4.4.2. Hydrothermal Liquefaction (HTL)

4.5. Nutrient Recovery from Digestate

4.6. Struvite Precipitation

4.7. Ammonia Stripping and Electrochemical Stripping

4.8. Membrane Separation

4.9. Production of Fertilizer Form Biowaste Material

5. Challenges and Limitations

6. Research Gap and Future Perspectives

- Developing standardized safety and quality benchmarks for manure- and food waste-derived biofertilizers to support regulatory approval and market entry.

- Evaluating the socio-economic and environmental impacts of biofertilizer use in small-scale and commercial farming systems.

- Designing implementation frameworks with clearly defined institutional roles, accountability mechanisms, and performance indicators.

- Investigating financial models and incentive structures that can mobilize public and private investment in food waste valorization technologies.

- Exploring behavioral and policy interventions that promote public awareness, recognition, and participation in food conservation and waste reduction initiatives.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sarker, A.; Ahmmed, R.; Ahsan, S.; Rana, J.; Ghosh, M.K.; Nandi, R. A comprehensive review of food waste valorization for the sustainable management of global food waste. Sustain. Food Technol. 2024, 2, 48–69. [Google Scholar]

- Jiang, H.; Deng, F.; Luo, Y.; Xie, Z.; Chen, Y.; Zhou, P.; Liu, X.; Li, D. Hydrothermal carbonization of corn straw in biogas slurry. J. Clean. Prod. 2022, 353, 131682. [Google Scholar] [CrossRef]

- Rosenberg, M. Thoughts about food security, food loss and waste and what has to be done. AIMS Agric. Food 2021, 6, 797–798. [Google Scholar] [CrossRef]

- Capanoglu, E.; Nemli, E.; Tomas-Barberan, F. Novel approaches in the valorization of agricultural wastes and their applications. J. Agric. Food Chem. 2022, 70, 6787–6804. [Google Scholar] [CrossRef]

- Pérez, S.; Giraldo, S.; Forgionny, A.; Flórez, E.; Acelas, N. Eco-friendly reuse of agricultural wastes to produce biocomposites with high potential in water treatment and fertilizers. Biomass Convers. Biorefinery 2024, 14, 8537–8547. [Google Scholar] [CrossRef]

- Mokotong, D.; Ribeiro, R.V. Community Health Impact Assessment for the Proposed Multisand General Waste Management Facility Project; Niara Environmental Consultants (Pty) Ltd.: Johannesburg, South Africa, 2023. [Google Scholar]

- Sahathu, R. An Evaluation of the Waste Management Cycle Utilised by Fresh Produce Market Informal Traders in Durban, KwaZulu-Natal. Ph.D. Thesis, University of KwaZulu-Natal, KwaZulu-Natal, South Africa, 2021. [Google Scholar]

- Ndobe, F.N. The Impacts of Landfill Management Site a on Grass, Soil, and Surface Water: A Preliminary Study in Kwazulu-Natal, South Africa. Master’s Thesis, University of the Witwatersrand, Johannesburg, South Africa, 2023. [Google Scholar]

- Skrzypczak, D.; Trzaska, K.; Mironiuk, M.; Mikula, K.; Izydorczyk, G.; Polomska, X.; Wiśniewski, J.; Mielko, K.; Moustakas, K.; Chojnacka, K. Recent innovations in fertilization with treated digestate from food waste to recover nutrients for arid agricultural fields. Environ. Sci. Pollut. Res. 2024, 31, 41563–41585. [Google Scholar] [CrossRef]

- Parfitt, J.; Barthel, M.; Macnaughton, S. Food waste within food supply chains: Quantification and potential for change to 2050. Philos. Trans. R. Soc. B Biol. Sci. 2010, 365, 3065–3081. [Google Scholar] [CrossRef]

- Saba, B.; Bharathidasan, A.K.; Ezeji, T.C.; Cornish, K. Characterization and potential valorization of industrial food processing wastes. Sci. Total Environ. 2023, 868, 161550. [Google Scholar] [CrossRef]

- Adeleke, O.; Akinlabi, S.; Jen, T.-C.; Dunmade, I. Towards sustainability in municipal solid waste management in South Africa: A survey of challenges and prospects. Trans. R. Soc. S. Afr. 2021, 76, 53–66. [Google Scholar] [CrossRef]

- Kharola, S.; Ram, M.; Kumar Mangla, S.; Goyal, N.; Nautiyal, O.P.; Pant, D.; Kazancoglu, Y. Exploring the green waste management problem in food supply chains: A circular economy context. J. Clean. Prod. 2022, 351, 131355. [Google Scholar] [CrossRef]

- Kharola, S.; Ram, M.; Goyal, N.; Mangla, S.K.; Nautiyal, O.P.; Rawat, A.; Kazancoglu, Y.; Pant, D. Barriers to organic waste management in a circular economy. J. Clean. Prod. 2022, 362, 132282. [Google Scholar] [CrossRef]

- Kassim, F.O.; Thomas, C.L.P.; Afolabi, O.O.D. Integrated conversion technologies for sustainable agri-food waste valorization: A critical review. Biomass Bioenergy 2022, 156, 106314. [Google Scholar] [CrossRef]

- Chojnacka, K.; Moustakas, K.; Mikulewicz, M. Valorisation of agri-food waste to fertilisers is a challenge in implementing the circular economy concept in practice. Environ. Pollut. 2022, 312, 119906. [Google Scholar] [CrossRef] [PubMed]

- Vaneeckhaute, C.; Lebuf, V.; Michels, E.; Belia, E.; Vanrolleghem, P.A.; Tack, F.M.; Meers, E. Nutrient recovery from digestate: Systematic technology review and product classification. Waste Biomass Valorization 2017, 8, 21–40. [Google Scholar] [CrossRef]

- Wang, L.; Chi, Y.; Du, K.; Zhou, Z.; Wang, F.; Huang, Q. Hydrothermal treatment of food waste for bio-fertilizer production: Regulation of humus substances and nutrient (N and P) in hydrochar by feedwater pH. Waste Biomass Valorization 2023, 14, 2767–2781. [Google Scholar] [CrossRef]

- Vaishnavi, M.; Kumar, K.S.; Gopinath, K.P. Comparative studies on catalytic hydrothermal liquefaction of mixed household waste into bio crude. Biomass Convers. Biorefinery 2023, 13, 14253–14265. [Google Scholar] [CrossRef]

- Bayat, H.; Dehghanizadeh, M.; Jarvis, J.M.; Brewer, C.E.; Jena, U. Hydrothermal liquefaction of food waste: Effect of process parameters on product yields and chemistry. Front. Sustain. Food Syst. 2021, 5, 658592. [Google Scholar] [CrossRef]

- Shah, A.A.; Sharma, K.; Haider, M.S.; Toor, S.S.; Rosendahl, L.A.; Pedersen, T.H.; Castello, D. The Role of Catalysts in Biomass Hydrothermal Liquefaction and Biocrude Upgrading. Processes 2022, 10, 207. [Google Scholar] [CrossRef]

- Dhalsamant, K.; Dalai, A.K. Optimization and characterization of biocrude produced from hydrothermal liquefaction of food waste. Sustain. Energy Fuels 2025, 9, 2119–2136. [Google Scholar] [CrossRef]

- Fleaca, C.; Severin, I. Comparative analysis of organizational performance using the EFQM Excellence Model: The sustainability perspective. Cogn. Sustain. 2024, 3, 34–49. [Google Scholar] [CrossRef]

- Reike, D.; Vermeulen, W.J.; Witjes, S. Conceptualization of circular economy 3.0: Synthesizing the 10R hierarchy of value retention options. In Towards a Circular Economy; Springer: Cham, Switzerland, 2022; pp. 47–69. [Google Scholar] [CrossRef]

- Debrah, J.K.; Teye, G.K.; Dinis, M.A.P. Barriers and challenges to waste management hindering the circular economy in Sub-Saharan Africa. Urban Sci. 2022, 6, 57. [Google Scholar] [CrossRef]

- Davis, J. Food waste in the United States. Ballard Brief 2022, 2022, 7. [Google Scholar]

- Meena, M.D.; Dotaniya, M.L.; Meena, B.L.; Rai, P.K.; Antil, R.S.; Meena, H.S.; Meena, L.K.; Dotaniya, C.K.; Meena, V.S.; Ghosh, A.; et al. Municipal solid waste: Opportunities, challenges and management policies in India: A review. Waste Manag. Bull. 2023, 1, 4–18. [Google Scholar] [CrossRef]

- Melikoglu, M.; Lin, C.S.K.; Webb, C. Analysing global food waste problem: Pinpointing the facts and estimating the energy content. Cent. Eur. J. Eng. 2013, 3, 157–164. [Google Scholar] [CrossRef]

- Dou, Z.; Toth, J.D. Global primary data on consumer food waste: Rate and characteristics—A review. Resour. Conserv. Recycl. 2021, 168, 105332. [Google Scholar] [CrossRef]

- Withanage, S.V.; Dias, G.M.; Habib, K. Review of household food waste quantification methods: Focus on composition analysis. J. Clean. Prod. 2021, 279, 123722. [Google Scholar] [CrossRef]

- Chhandama, M.V.L.; Chetia, A.C.; Satyan, K.B.; Supongsenla, A.; Ruatpuia, J.V.L.; Rokhum, S.L. Valorisation of food waste to sustainable energy and other value-added products: A review. Bioresour. Technol. Rep. 2022, 17, 100945. [Google Scholar] [CrossRef]

- Mbazima, S.J.; Masekameni, M.D.; Mmereki, D. Waste-to-energy in a developing country: The state of landfill gas to energy in the Republic of South Africa. Energy Explor. Exploit. 2022, 40, 1287–1312. [Google Scholar] [CrossRef]

- Dlamini, N.; Rampedi, I.; Kwenda, P. Assessing how load-shedding affects the generation of household food waste in Merafong City Local Municipality, South Africa. Dev. South. Afr. 2025, 42, 1–18. [Google Scholar] [CrossRef]

- Roy, P.; Mohanty, A.K.; Dick, P.; Misra, M. A review on the challenges and choices for food waste valorization: Environmental and economic impacts. ACS Environ. Au 2023, 3, 58–75. [Google Scholar] [CrossRef]

- Scarlat, N.; Motola, V.; Dallemand, J.F.; Monforti-Ferrario, F.; Mofor, L. Evaluation of energy potential of Municipal Solid Waste from African urban areas. Renew. Sustain. Energy Rev. 2015, 50, 1269–1286. [Google Scholar] [CrossRef]

- Cudjoe, D.; Nketiah, E.; Obuobi, B.; Adu-Gyamfi, G.; Adjei, M.; Zhu, B. Forecasting the potential and economic feasibility of power generation using biogas from food waste in Ghana: Evidence from Accra and Kumasi. Energy 2021, 226, 120342. [Google Scholar] [CrossRef]

- Tayyab, A.; Ahmad, Z.; Mahmood, T.; Khalid, A.; Qadeer, S.; Mahmood, S.; Andleeb, S.; Anjum, M. Anaerobic co-digestion of catering food waste utilizing Parthenium hysterophorus as co-substrate for biogas production. Biomass Bioenergy 2019, 124, 74–82. [Google Scholar] [CrossRef]

- Joshi, S.M.; Gogate, P.R. Intensifying the biogas production from food waste using ultrasound: Understanding into effect of operating parameters. Ultrason. Sonochem. 2019, 59, 104755. [Google Scholar] [CrossRef]

- Yentekakis, I.V.; Goula, G. Biogas management: Advanced utilization for production of renewable energy and added-value chemicals. Front. Environ. Sci. 2017, 5, 7. [Google Scholar] [CrossRef]

- Mkhize, N.; Mjoli, N.S.; Khumalo, S.M.; Tettteh, E.K.; Mahlangu, T.P.; Rathilal, S. Enhanced Biogas Production through Anaerobic Co-Digestion of Agricultural Wastes and Wastewater: A Case Study in South Africa. Int. J. Energy Prod. Manag. 2023, 8, 123–131. [Google Scholar] [CrossRef]

- Tshemese, Z.; Deenadayalu, N.; Linganiso, L.Z.; Chetty, M. An overview of biogas production from anaerobic digestion and the possibility of using sugarcane wastewater and municipal solid waste in a South African context. Appl. Syst. Innov. 2023, 6, 13. [Google Scholar] [CrossRef]

- Chow, W.L.; Chong, S.; Lim, J.W.; Chan, Y.J.; Chong, M.F.; Tiong, T.J.; Chin, J.K.; Pan, G.-T. Anaerobic co-digestion of wastewater sludge: A review of potential co-substrates and operating factors for improved methane yield. Processes 2020, 8, 39. [Google Scholar] [CrossRef]

- Awosusi, A.; Sethunya, V.; Matambo, T. Synergistic effect of anaerobic co-digestion of South African food waste with cow manure: Role of low density-polyethylene in process modulation. Mater. Today Proc. 2021, 38, 793–803. [Google Scholar] [CrossRef]

- Ravi, B. Investigating the Use of Anaerobic Fungi to Enhance the Hydrolysis of Lignocellulose in Lab Scale Biodigesters. Master’s Thesis, University of Guelph, Guelph, ON, Canada, 2017. [Google Scholar]

- Saady, N.M.C.; Massé, D.I. Impact of organic loading rate on psychrophilic anaerobic digestion of solid dairy manure. Energies 2015, 8, 1990–2007. [Google Scholar] [CrossRef]

- Armah, E.K. Anaerobic Co-Digestion of Agricultural Biomass with Industrial Wastewater for Biogas Production. Ph.D. Thesis, Durban University of Technology, Durban, South Africa, 2021. [Google Scholar]

- Prabhu, M.S.; Mutnuri, S. Anaerobic co-digestion of sewage sludge and food waste. Waste Manag. Res. 2016, 34, 307–315. [Google Scholar] [CrossRef]

- Nuanual, S.; Thanarak, P.; Maneechot, P.; Artkla, R. Life Cycle Assessment of Anaerobic Digestion of Food Waste in the Presence of Manure Concerned Global Warming Potential. GMSARN Int. J. 2024, 18, 340–347. [Google Scholar]

- Martín-Sanz-Garrido, C.; Revuelta-Aramburu, M.; Santos-Montes, A.M.; Morales-Polo, C. A Review on Anaerobic Digestate as a Biofertilizer: Characteristics, Production, and Environmental Impacts from a Life Cycle Assessment Perspective. Appl. Sci. 2025, 15, 8635. [Google Scholar] [CrossRef]

- Zhao, Z.; Qi, S.; Wang, R.; Li, H.; Song, G.; Li, H.; Yin, Q. Life cycle assessment of food waste energy and resource conversion scheme via the integrated process of anaerobic digestion and hydrothermal carbonization. Int. J. Hydrogen Energy 2024, 52, 122–132. [Google Scholar] [CrossRef]

- Hanafiah, M.M.; Ansari, I.; Chelvam, K. Life cycle assessment of anaerobic digestion systems: An approach towards sustainable waste management. In Renewable Energy Technologies for Energy Efficient Sustainable Development; Springer: Heidelberg, Germany, 2022; pp. 391–414. [Google Scholar]

- Alengebawy, A.; Ran, Y.; Osman, A.I.; Jin, K.; Samer, M.; Ai, P. Anaerobic digestion of agricultural waste for biogas production and sustainable bioenergy recovery: A review. Environ. Chem. Lett. 2024, 22, 2641–2668. [Google Scholar] [CrossRef]

- Mahish, P.K.; Verma, D.K.; Ghritlahare, A.; Arora, C.; Otero, P. Microbial bioconversion of food waste to bio-fertilizers. Sustain. Food Technol. 2024, 2, 689–708. [Google Scholar] [CrossRef]

- Rashid, M.I.; Shahzad, K. Food waste recycling for compost production and its economic and environmental assessment as circular economy indicators of solid waste management. J. Clean. Prod. 2021, 317, 128467. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, Y.; Yuan, Z. Improving food waste composting efficiency with mature compost addition. Bioresour. Technol. 2022, 349, 126830. [Google Scholar] [CrossRef]

- Yaser, A.Z.; Lamaming, J.; Suali, E.; Rajin, M.; Saalah, S.; Kamin, Z.; Safie, N.N.; Aji, N.A.S.; Wid, N. Composting and anaerobic digestion of food waste and sewage sludge for campus sustainability: A review. Int. J. Chem. Eng. 2022, 2022, 6455889. [Google Scholar] [CrossRef]

- Mataba, A.L.; Msuya, N.; Katima, Z. Production of Biofertilizer from Fruit and Garden Waste. Tanzan. J. Eng. Technol. 2024, 43, 158–168. [Google Scholar] [CrossRef]

- Le Pera, A.; Sellaro, M.; Bencivenni, E. Composting food waste or digestate? Characteristics, statistical and life cycle assessment study based on an Italian composting plant. J. Clean. Prod. 2022, 350, 131552. [Google Scholar] [CrossRef]

- Sampaio, I.C.F.; da Silva Quinto, A.S.; de Moura, I.V.L.; Cezar, K.S.; Franco, M.; de Almeida, P.F. The role of composting in sustainable agriculture and waste management. In Progress in Hydrogen Energy, Fuel Cells, Nano-Biotechnology and Advanced, Bioactive Compounds; Springer: Heidelberg, Germany, 2024; pp. 417–432. [Google Scholar]

- Sayara, T.; Basheer-Salimia, R.; Hawamde, F.; Sánchez, A. Recycling of organic wastes through composting: Process performance and compost application in agriculture. Agronomy 2020, 10, 1838. [Google Scholar] [CrossRef]

- Yang, J.; Tang, S.; Song, B.; Jiang, Y.; Zhu, W.; Zhou, W.; Yang, G. Optimization of integrated anaerobic digestion and pyrolysis for biogas, biochar and bio-oil production from the perspective of energy flow. Sci. Total Environ. 2023, 872, 162154. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Tsang, Y.F.; Lin, K.-Y.A.; Kwon, E.E.; Lee, J. Employment of biogas as pyrolysis medium and chemical feedstock. J. CO2 Util. 2022, 57, 101877. [Google Scholar] [CrossRef]

- Xu, F.; Ming, X.; Jia, R.; Zhao, M.; Wang, B.; Qiao, Y.; Tian, Y. Effects of operating parameters on products yield and volatiles composition during fast pyrolysis of food waste in the presence of hydrogen. Fuel Process. Technol. 2020, 210, 106558. [Google Scholar] [CrossRef]

- Su, G.; Ong, H.C.; Fattah, I.M.R.; Ok, Y.S.; Jang, J.-H.; Wang, C.-T. State-of-the-art of the pyrolysis and co-pyrolysis of food waste: Progress and challenges. Sci. Total Environ. 2022, 809, 151170. [Google Scholar] [CrossRef]

- Lin, J.; Ma, R.; Luo, J.; Sun, S.; Cui, C.; Fang, L.; Huang, H. Microwave pyrolysis of food waste for high-quality syngas production: Positive effects of a CO2 reaction atmosphere and insights into the intrinsic reaction mechanisms. Energy Convers. Manag. 2020, 206, 112490. [Google Scholar] [CrossRef]

- Kadlimatti, H.; Mohan, B.R.; Saidutta, M. Bio-oil from microwave assisted pyrolysis of food waste-optimization using response surface methodology. Biomass Bioenergy 2019, 123, 25–33. [Google Scholar] [CrossRef]

- Lee, Y.-E.; Shin, D.-C.; Jeong, Y.; Kim, I.-T.; Yoo, Y.-S. Effects of pyrolysis temperature and retention time on fuel characteristics of food waste feedstuff and compost for co-firing in coal power plants. Energies 2019, 12, 4538. [Google Scholar] [CrossRef]

- Opatokun, S.A.; Kan, T.; Al Shoaibi, A.; Srinivasakannan, C.; Strezov, V. Characterization of food waste and its digestate as feedstock for thermochemical processing. Energy Fuels 2016, 30, 1589–1597. [Google Scholar] [CrossRef]

- Zhao, J.; Zhao, J.; Wang, Z.; Lin, S.; Yan, B.; Chen, G.; Zhou, W. Life cycle assessment of anaerobic digestion coupled co-pyrolysis for treatment of food waste. Bioresour. Technol. 2025, 421, 132145. [Google Scholar] [CrossRef]

- Gahane, D.; Biswal, D.; Mandavgane, S.A. Life Cycle Assessment of Biomass Pyrolysis. BioEnergy Res. 2022, 15, 1387–1406. [Google Scholar] [CrossRef]

- Orlandella, I.; Fiore, S. Life Cycle Assessment of the Production of Biofertilizers from Agricultural Waste. Sustainability 2025, 17, 421. [Google Scholar] [CrossRef]

- Pradhan, S.; Parthasarathy, P.; Mackey, H.R.; Al-Ansari, T.; McKay, G. Food waste biochar: A sustainable solution for agriculture application and soil–water remediation. Carbon Res. 2024, 3, 41. [Google Scholar] [CrossRef]

- Hämäläinen, A.; Kokko, M.; Tolvanen, H.; Kinnunen, V.; Rintala, J. Towards the implementation of hydrothermal carbonization for nutrients, carbon, and energy recovery in centralized biogas plant treating sewage sludge. Waste Manag. 2024, 173, 99–108. [Google Scholar] [CrossRef]

- Mikusińska, J.; Kuźnia, M.; Czerwińska, K.; Wilk, M. Hydrothermal carbonization of digestate produced in the biogas production process. Energies 2023, 16, 5458. [Google Scholar] [CrossRef]

- Cao, Z.; Hülsemann, B.; Wüst, D.; Oechsner, H.; Lautenbach, A.; Kruse, A. Effect of residence time during hydrothermal carbonization of biogas digestate on the combustion characteristics of hydrochar and the biogas production of process water. Bioresour. Technol. 2021, 333, 125110. [Google Scholar] [CrossRef]

- González-Arias, J.; Sánchez, M.E.; Cara-Jiménez, J.; Baena-Moreno, F.M.; Zhang, Z. Hydrothermal carbonization of biomass and waste: A review. Environ. Chem. Lett. 2022, 20, 211–221. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, S.; Cui, D.; Zhou, H.; Wu, D.; Pan, S.; Xu, F.; Wang, Z. Co-hydrothermal carbonization of organic solid wastes to hydrochar as potential fuel: A review. Sci. Total Environ. 2022, 850, 158034. [Google Scholar] [CrossRef]

- Ho, T.T.-T.; Nadeem, A.; Choe, K. A review of upscaling hydrothermal carbonization. Energies 2024, 17, 1918. [Google Scholar] [CrossRef]

- Mannarino, G.; Sarrion, A.; Diaz, E.; Gori, R.; De la Rubia, M.A.; Mohedano, A.F. Improved energy recovery from food waste through hydrothermal carbonization and anaerobic digestion. Waste Manag. 2022, 142, 9–18. [Google Scholar] [CrossRef]

- McGaughy, K.; Toufiq Reza, M. Hydrothermal carbonization of food waste: Simplified process simulation model based on experimental results. Biomass Convers. Biorefinery 2018, 8, 283–292. [Google Scholar] [CrossRef]

- Saengsuriwong, R.; Onsree, T.; Phromphithak, S.; Tippayawong, N. Biocrude oil production via hydrothermal liquefaction of food waste in a simplified high-throughput reactor. Bioresour. Technol. 2021, 341, 125750. [Google Scholar] [CrossRef] [PubMed]

- Tito, E.; Marcolongo, C.A.; Pipitone, G.; Monteverde, A.H.A.; Bensaid, S.; Pirone, R. Understanding the effect of heating rate on hydrothermal liquefaction: A comprehensive investigation from model compounds to a real food waste. Bioresour. Technol. 2024, 396, 130446. [Google Scholar] [CrossRef]

- Ahmed Ebrahim, S.; Robertson, G.; Jiang, X.; Baranova, E.A.; Singh, D. Catalytic hydrothermal liquefaction of food waste: Influence of catalysts on bio-crude yield, asphaltenes, and pentane soluble fractions. Fuel 2022, 324, 124452. [Google Scholar] [CrossRef]

- Biswas, B.; Rahman, T.; Adhikari, S. Mono-and bi-metal catalytic hydrothermal liquefaction of food waste: Screening the process parameter on product yield and characterizations. J. Clean. Prod. 2024, 471, 143398. [Google Scholar] [CrossRef]

- Wang, T.; Dai, Y.; Shang, H.; Si, B.; Sanginova, O.; Yu, Y. Life cycle assessment of integrated hydrothermal liquefication of food waste with biological process toward bio-oil production. Biomass Convers. Biorefinery 2025, 15, 14075–14088. [Google Scholar] [CrossRef]

- Barampouti, E.M.; Mai, S.; Malamis, D.; Moustakas, K.; Loizidou, M. Exploring technological alternatives of nutrient recovery from digestate as a secondary resource. Renew. Sustain. Energy Rev. 2020, 134, 110379. [Google Scholar] [CrossRef]

- Trotta, S.; Adani, F.; Fedele, M.; Salvatori, M. Nitrogen and phosphorus recovery from cow digestate by struvite precipitation: Process optimization to maximize phosphorus recovery. Results Eng. 2023, 20, 101478. [Google Scholar] [CrossRef]

- Aldaach, H.; Zaki, M.T.; Orner, K.D. Improving Prediction of Nutrient Recovery via Struvite Precipitation from Organic Waste Digestate. Environ. Eng. Sci. 2025, 42, 53–67. [Google Scholar] [CrossRef]

- Kumar, R.; and Pal, P. Assessing the feasibility of N and P recovery by struvite precipitation from nutrient-rich wastewater: A review. Environ. Sci. Pollut. Res. 2015, 22, 17453–17464. [Google Scholar] [CrossRef] [PubMed]

- Corona, F.; Hidalgo, D.; Martín-Marroquín, J.M.; Antolín, G. Study of the influence of the reaction parameters on nutrients recovering from digestate by struvite crystallisation. Environ. Sci. Pollut. Res. 2021, 28, 24362–24374. [Google Scholar] [CrossRef] [PubMed]

- Sangeetha, V.; Devasena, M.; Nambi, I.M.; Dwarakanathan, S. Crystallization of struvite family crystals from cow urine: Analysis, characterization, and effects of crystallization method, retention time, rate of mixing, and competing ions. Biomass Convers. Biorefinery 2024, 14, 2357–2368. [Google Scholar] [CrossRef]

- Yang, D.; Chen, Q.; Liu, R.; Song, L.; Zhang, Y.; Dai, X. Ammonia recovery from anaerobic digestate: State of the art, challenges and prospects. Bioresour. Technol. 2022, 363, 127957. [Google Scholar] [CrossRef]

- Aung, S.L.; Choi, J.; Cha, H.; Woo, G.; Song, K.G. Ammonia-selective recovery from anaerobic digestate using electrochemical ammonia stripping combined with electrodialysis. Chem. Eng. J. 2024, 479, 147949. [Google Scholar] [CrossRef]

- Tao, W.; Ukwuani, A.T.; Agyeman, F. Recovery of ammonia in anaerobic digestate using vacuum thermal stripping–acid absorption process: Scale-up considerations. Water Sci. Technol. 2018, 78, 878–885. [Google Scholar] [CrossRef]

- Ghyselbrecht, K.; Monballiu, A.; Somers, M.; Sigurnjak, I.; Meers, E.; Appels, L.; Meesschaert, B. Stripping and scrubbing of ammonium using common fractionating columns to prove ammonium inhibition during anaerobic digestion. Int. J. Energy Environ. Eng. 2018, 9, 447–455. [Google Scholar] [CrossRef]

- Walker, M.; Iyer, K.; Heaven, S.; Banks, C. Ammonia removal in anaerobic digestion by biogas stripping: An evaluation of process alternatives using a first order rate model based on experimental findings. Chem. Eng. J. 2011, 178, 138–145. [Google Scholar] [CrossRef]

- Nowak, M.; Czekała, W. Sustainable Use of Digestate from Biogas Plants: Separation of Raw Digestate and Liquid Fraction Processing. Sustainability 2024, 16, 5461. [Google Scholar] [CrossRef]

- Chew, K.W.; Chia, S.R.; Yen, H.-W.; Nomanbhay, S.; Ho, Y.-C.; Show, P.L. Transformation of biomass waste into sustainable organic fertilizers. Sustainability 2019, 11, 2266. [Google Scholar] [CrossRef]

- Zielińska, M.; Bułkowska, K. Use of Membrane Techniques for Removal and Recovery of Nutrients from Liquid Fraction of Anaerobic Digestate. Membranes 2025, 15, 45. [Google Scholar] [CrossRef] [PubMed]

- Ivanović, N.; Vučinić, A.; Marinković, V.; Krajnović, D.; Ćurčić, M. Towards Sustainable Food Waste Management in Serbia: A Review of Challenges, Gaps, and Future Perspectives. Sustainability 2025, 17, 2961. [Google Scholar] [CrossRef]

- Ndambi, O.A.; Pelster, D.E.; Owino, J.O.; De Buisonjé, F.; Vellinga, T. Manure management practices and policies in sub-Saharan Africa: Implications on manure quality as a fertilizer. Front. Sustain. Food Syst. 2019, 3, 29. [Google Scholar] [CrossRef]

- Teenstra, E.; Vellinga, T.V.; Aektasaeng, N.; Amatayakul, W.; Ndambi, A.; Pelster, D.E.; Germer, L.; Jenet, A.; Opio, C.; Andeweg, K. Global Assessment of Manure Management Policies and Practices. Wageningen UR Livestock Research: Wageningen, The Netherlands, 2014. [Google Scholar]

- Cordeiro, C.M.; Sindhøj, E. Situating the discourse of recycled nutrient fertilizers in circular economy principles for sustainable agriculture. Front. Sustain. 2024, 5, 1465752. [Google Scholar] [CrossRef]

- Bruulsema, T. Nutrient stewardship: Taking 4R further. Crops Soils 2022, 55, 34–40. [Google Scholar] [CrossRef]

- Zhang, J.; He, W.; Wei, Z.; Chen, Y.; Gao, W. Integrating green manure and fertilizer reduction strategies to enhance soil carbon sequestration and crop yield: Evidence from a two-season pot experiment. Front. Sustain. Food Syst. 2025, 8, 1514409. [Google Scholar] [CrossRef]

- Gram, G.; Roobroeck, D.; Pypers, P.; Six, J.; Merckx, R.; Vanlauwe, B. Combining organic and mineral fertilizers as a climate-smart integrated soil fertility management practice in sub-Saharan Africa: A meta-analysis. PLoS ONE 2020, 15, e0239552. [Google Scholar] [CrossRef]

- Dubeux Jr, J.; Sollenberger, L.; Mathews, B.; Scholberg, J.; Santos, H. Nutrient cycling in warm-climate grasslands. Crop Sci. 2007, 47, 915–928. [Google Scholar] [CrossRef]

- Kiss, N.É.; Tamás, J.; Szőllősi, N.; Gorliczay, E.; Nagy, A. Assessment of composted pelletized poultry litter as an alternative to chemical fertilizers based on the environmental impact of their production. Agriculture 2021, 11, 1130. [Google Scholar] [CrossRef]

- Fowles, T.M.; Nansen, C. Insect-based bioconversion: Value from food waste. In Food Waste Management: Solving the Wicked Problem; Springer: Heidelberg, Germany, 2019; pp. 321–346. [Google Scholar]

| Phase | Description | Key Microorganisms | Primary Products | References |

|---|---|---|---|---|

| Hydrolysis | Rate-limiting step is materials rich in fiber | Clostridium Bacillus Vulgaris Vibrio Bacteroides Staphylococcus | Fatty acids Amino acids Sugars | [44,45] |

| Acidogenesis | During hydrolysis, soluble organic matter is transformed by acid-forming bacteria known as acidogens into organic acids such as acetate, butyrate, and propionate, along with alcohol, hydrogen, and carbon dioxide | Escherichia Bacillus Lactobacillus Staphylococcus Pseudomonas Veollonella Sarcina Desulfobacter | Soluble organic acids are formed | [46] |

| Acetogenesis | Acetates are formed as a series of organic acids | Clostridium Syntrophonas wolfeii Synrophomonas wolinii | Acetic acid, hydrogen, carbon dioxide | [46] |

| Methanogenesis | Metane and carbon dioxide are produced from acetic acid, hydrogen, and carbon dioxide | Acetogens or hydrogenotrophs | Methane | [46,47] |

| Advantages | Disadvantages | Cost-Effectiveness | Sustainability | References |

|---|---|---|---|---|

| (1) Converts organic waste into renewable biogas and nutrient-rich digestate. (2) Reduces greenhouse gas emissions compared to landfilling. (3) Supports circular economy and energy independence. (4) Enhances soil health when digestate is properly treated. | (1) Performance varies with feedstock composition and contamination. (2) Requires skilled operation and monitoring. (3) Digestate may contain pathogens or heavy metals if not properly treated. (4) Regulatory classification as livestock waste can limit use. | (1) Capital costs are high for full-scale AD plants. (2) Operational costs can be offset by energy recovery and fertilizer sales. (3) More cost-effective when integrated with composting or nutrient recovery systems. (4) Economies of scale improve viability. | (1) Strong potential to reduce reliance on synthetic fertilizers. (2) Life cycle assessment shows a reduced environmental footprint when digestate is post-treated. (3) Promotes resilient agroecosystems. | [49,52,53] |

| Property | Property Value | Required Range |

|---|---|---|

| Moisture content (%) | 36 | 30 to 60 |

| pH | 7.1 | 5.0–8.0 |

| Temperature (°C) | 35 | 30–40 |

| Potassium (ppm) | 5770 | 1000–35,000 |

| Lead (ppm) | 60 | <300 |

| Cadmium (ppm) | 2 | <15 |

| Advantage | Disadvantage | Cost-Effectiveness | Sustainability | References |

|---|---|---|---|---|

| (1) Simple, low-tech process suitable for small and large scales. (2) Produces stable, nutrient-rich organic fertilizer. (3) Reduces landfill burden and methane emissions. (4) Enhances soil structure and microbial health. | (1) Limited biogas production compared to anaerobic digestion. (2) Requires careful control of moisture, aeration, and temperature. (3) May emit odors and attract pests if poorly managed. (4) Compost quality varies with feedstock. | (1) Low capital and operational costs, especially for decentralized systems. (2) Minimal energy input compared to other valorization methods. (3) Cost-effective for municipalities and rural communities. (4) Revenue potential from compost sales. | (1) Supports nutrient recycling and soil carbon sequestration. (2) Promotes agroecological resilience and food security. | [53,59,60] |

| Biomass | Conditions | Reactor | Yield | Relevant Result and Observation | References |

|---|---|---|---|---|---|

| Food waste | 700–900 °C, 100–250 mL/min, N2, H2 | Fixed-bed reactor | 68.77% (at max temp) |

| [63,64] |

| Food waste | 800–1200 W, 2 h, CO2/N2 | Microwave reactor | 67.90% |

| [64,65] |

| Food waste | 320–480 °C, 30 min, N2 | Microwave reactor | 30.24% |

| [64,66] |

| Food waste | 300–600 W, N2 | Microwave reactor | - |

| [64] |

| Food waste feedstuff/Food waste compost | 300–500 °C, 15–60 °C/min, N2 | Fixed-bed reactor | 32.80% |

| [64,67] |

| Raw food waste/Food waste digestate | 300–700 °C, 10 or 60 °C/min, N2 | Fixed-bed reactor | 52.2–60.3% |

| [64,68] |

| Advantage | Disadvantage | Cost-Effectiveness | Sustainability | References |

|---|---|---|---|---|

| (1) Converts food waste into biochar, bio-oil, and syngas with high energy density. (2) Biochar improves soil fertility, water retention, and carbon sequestration. (3) Operates under oxygen-limited conditions, minimizing combustion losses. | (1) High capital and operational costs compared to biological. (2) Requires precise temperature control and feedstock pre-treatment. (3) Limited nutrient recovery unless biochar is enriched. (4) Potential release of toxic compounds if poorly managed. | (1) Economically viable when integrated with energy recovery systems. (2) Biochar has a growing market value in agriculture and carbon credit schemes. (3) Cost-intensive for small-scale applications without subsidies or co-products. | (1) Biochar application reduces greenhouse gas emissions and enhances soil carbon storage. (2) Syngas and bio-oil offer renewable energy alternatives. (3) Scalable for urban and industrial food waste streams. | [53,72] |

| Source of Biomass | Processing Treatment into Fertilizer | Parameters Monitored and Their Resulting Effects |

|---|---|---|

| Chicken manure, compost | Azotobacter-based microbial treatment | Biological yield: The highest biological yield is attained when livestock manure is utilized. Gain yield: Improved nutritional conditions from organic manure lead to greater biomass accumulation and enhanced plant height. |

| Solid dairy manure | Surface applied and incorporated using a cultivator implement | Bacterial diversity: Manure amendments promoted higher bacterial diversity and provided more sustained effects than granular urea nitrogen treatments. |

| Livestock: chicken, pig and pigeon | Supplemented with non-organic nutrient sources | Aggregate stability: Stability declined, while the concentration of biological binding agents rose. |

| Food waste and cattle manure | -- | Soil properties: Leaching and soil erosion led to reductions in total nitrogen and organic carbon levels within the soil. Yield: A compost blend containing equal parts food waste and cattle manure resulted in increased maize yield. |

| Olive mill waste | Subjected to manual or mechanical mixing and periodically irrigated to maintain optimal moisture levels. | Agronomic: Crop yields achieved with compost were on par with those obtained using chemical fertilizers. Humic content showed no notable variation between compost and chemical fertilizer treatments. |

| Food waste: rice, cabbage, pork | High-temperature aerobic reactor with dynamic operational parameters. | Composting process: After 96 h of fermentation, the composting process reached stable pH and electrical conductivity levels, indicating the formation of mature organic fertilizer. The constant agitation and friction inside the bioreactor fostered optimal conditions for microbial proliferation. |

| Bakery industry sludge | Left for decomposition and vermicomposted for three months. | Vermicomposting demonstrates strong remediation potential, making it effective for stabilizing metal-rich soils and lowering contaminant levels. It serves as a valuable approach for managing ecotoxicity in soils polluted with heavy metals. |

| Region | Description | Policy Framework Support | Circular Economic Impact | Sustainable Agricultural | Ref. |

|---|---|---|---|---|---|

| Sub-Saharan Africa | Manure management practices and policies in sub-Saharan Africa: implications on manure quality as a fertilizer | Limited policy coherence; weak enforcement. Supports AU Agenda 2063 goals for soil health. | Improved manure handling promotes nutrient recycling. | Enhances crop yields and soil fertility. | [101] |

| Asia, Africa and Latin America | Global assessment of manure policies; identifies barriers and opportunities. | Varies by country; need for integrated policies. | Promotes integrated manure management. | Improves food security and reduces methane emissions. | [102] |

| Europe | Recycled nutrient fertilizers face adoption barriers due to contamination concerns. | Supports EU Circular Economy Action Plan. | Encourages waste valorization and nutrient recovery. | Reduces reliance on synthetic fertilizers. | [103] |

| Global | Nutrient stewardship: Taking 4R further | Supports national climate strategies. Aligned with AU climate goals. | Promotes efficient nutrient use and carbon sequestration. | Improves resilience and reduces emissions. | [104] |

| China | Green manure and reduced fertilizer improve soil carbon and yield. | Supports China’s sustainable agriculture goals. | Enhances organic matter recycling. | Boosts soil fertility and carbon sequestration. | [105] |

| Africa | Combining organic and mineral fertilizers as a climate-smart integrated soil fertility management practice in sub-Saharan Africa: A meta-analysis | Supports national soil health strategies and AU Agenda 2063 | Promotes local production and trade of organic fertilizers. | Reverses soil degradation and boosts productivity. | [106] |

| Global | Nutrient cycling in warm-climate grasslands. | Supports national nutrient management policies. Indirect alignment with AU soil health goals. | Highlights nutrient recycling in grazing systems. | Supports ecosystem modeling and sustainability. | [107] |

| Europe/USA | Assessment of composted pelletized poultry litter as an alternative to chemical fertilizers based on the environmental impact of their production | Supports EU Green Deal. | Reduces pollution and supports waste valorization. | Improves soil health and reduces nitrate leaching. | [108] |

| Europe | Insect-based bioconversion: value from food waste | Supports waste management policies. | Creates circular bio-products. | Reduces pollution and enhances farm income. | [109] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mngadi, S.Z.; Tetteh, E.K.; Khumalo, S.M.; Rathilal, S. Advancements in Food Waste Recycling Technologies in South Africa: Novel Approaches for Biofertilizer and Bioenergy Production—A Review. Energies 2025, 18, 5396. https://doi.org/10.3390/en18205396

Mngadi SZ, Tetteh EK, Khumalo SM, Rathilal S. Advancements in Food Waste Recycling Technologies in South Africa: Novel Approaches for Biofertilizer and Bioenergy Production—A Review. Energies. 2025; 18(20):5396. https://doi.org/10.3390/en18205396

Chicago/Turabian StyleMngadi, Samukelo Zwelokuthula, Emmanuel Kweinor Tetteh, Siphesihle Mangena Khumalo, and Sudesh Rathilal. 2025. "Advancements in Food Waste Recycling Technologies in South Africa: Novel Approaches for Biofertilizer and Bioenergy Production—A Review" Energies 18, no. 20: 5396. https://doi.org/10.3390/en18205396

APA StyleMngadi, S. Z., Tetteh, E. K., Khumalo, S. M., & Rathilal, S. (2025). Advancements in Food Waste Recycling Technologies in South Africa: Novel Approaches for Biofertilizer and Bioenergy Production—A Review. Energies, 18(20), 5396. https://doi.org/10.3390/en18205396