Efficacy of Hybrid Photovoltaic–Thermal and Geothermal Heat Pump System for Greenhouse Climate Control

Abstract

1. Introduction

2. Materials and Methods

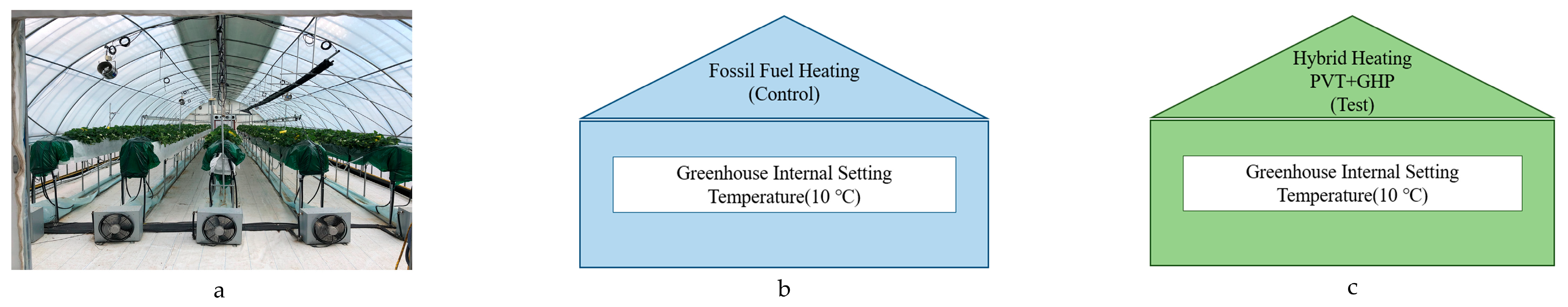

2.1. Overview of the Greenhouse

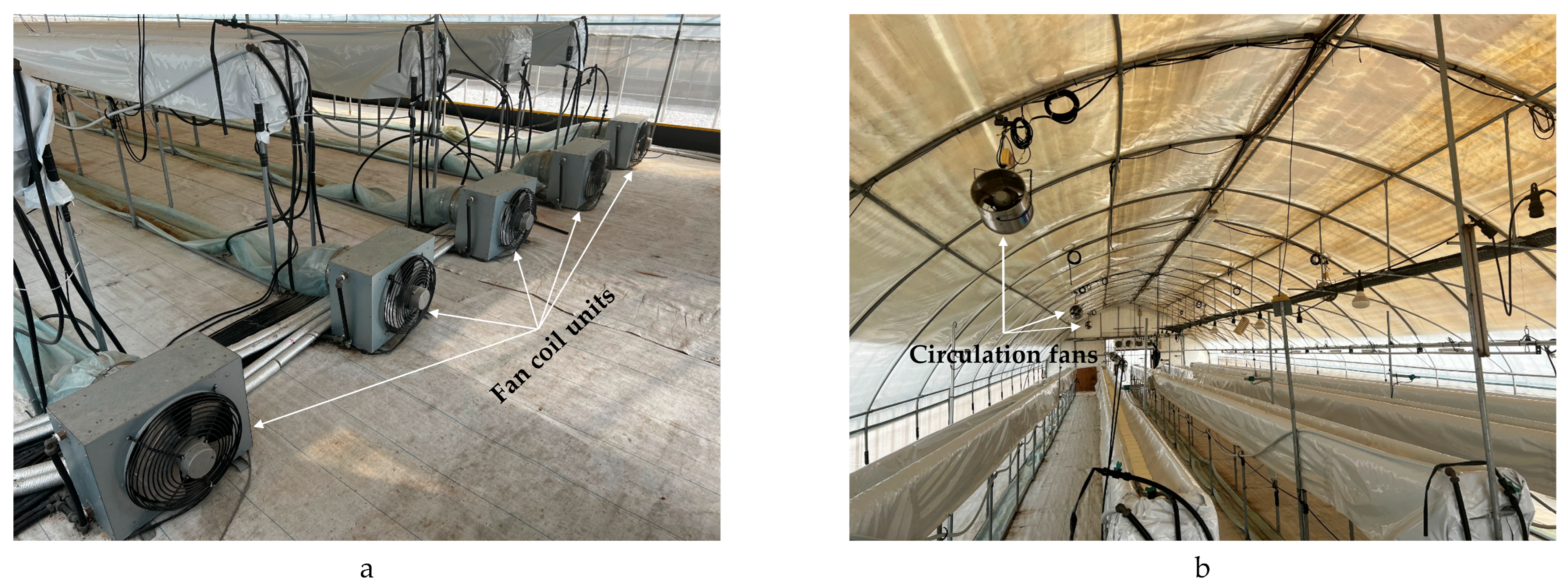

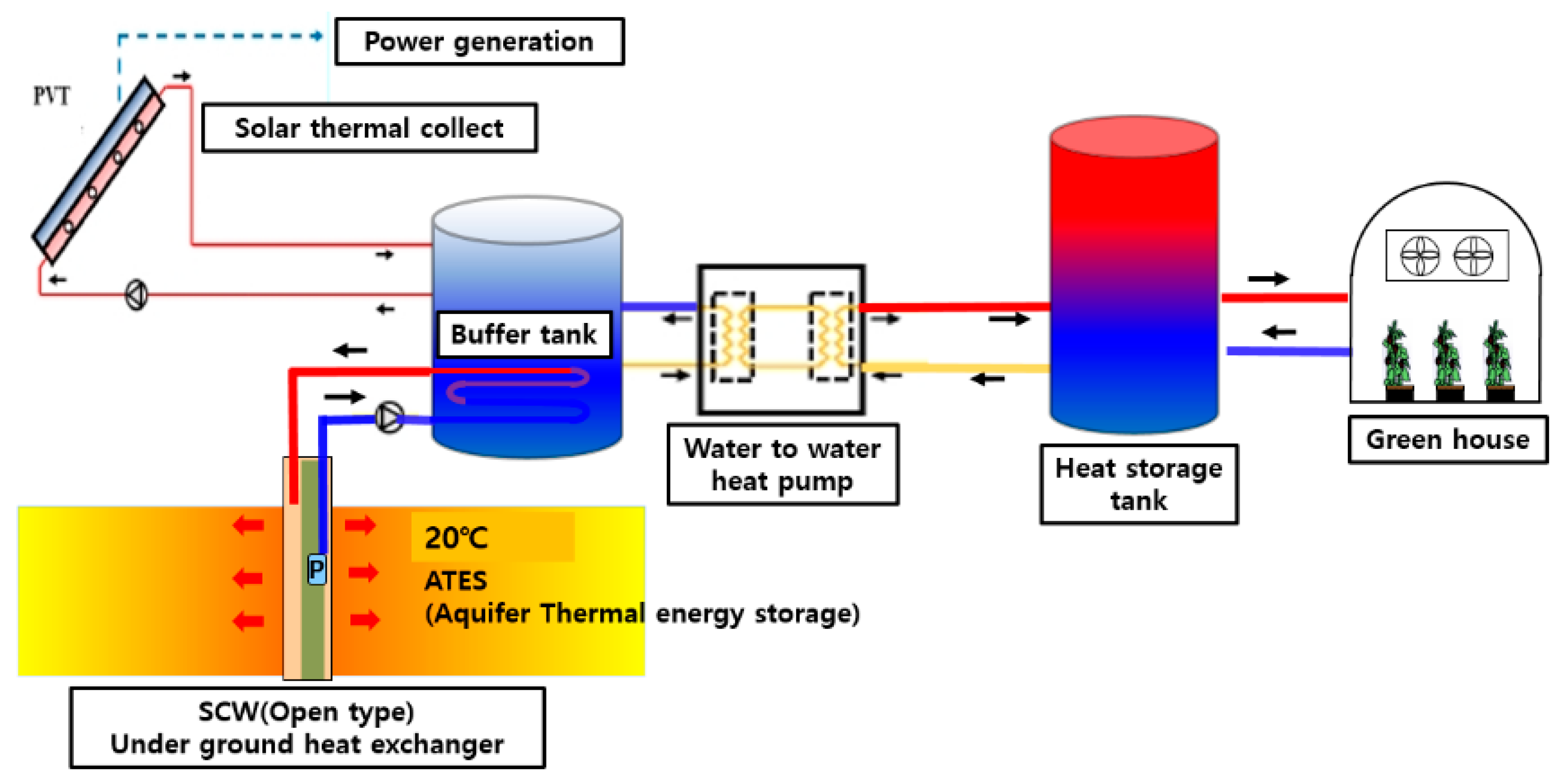

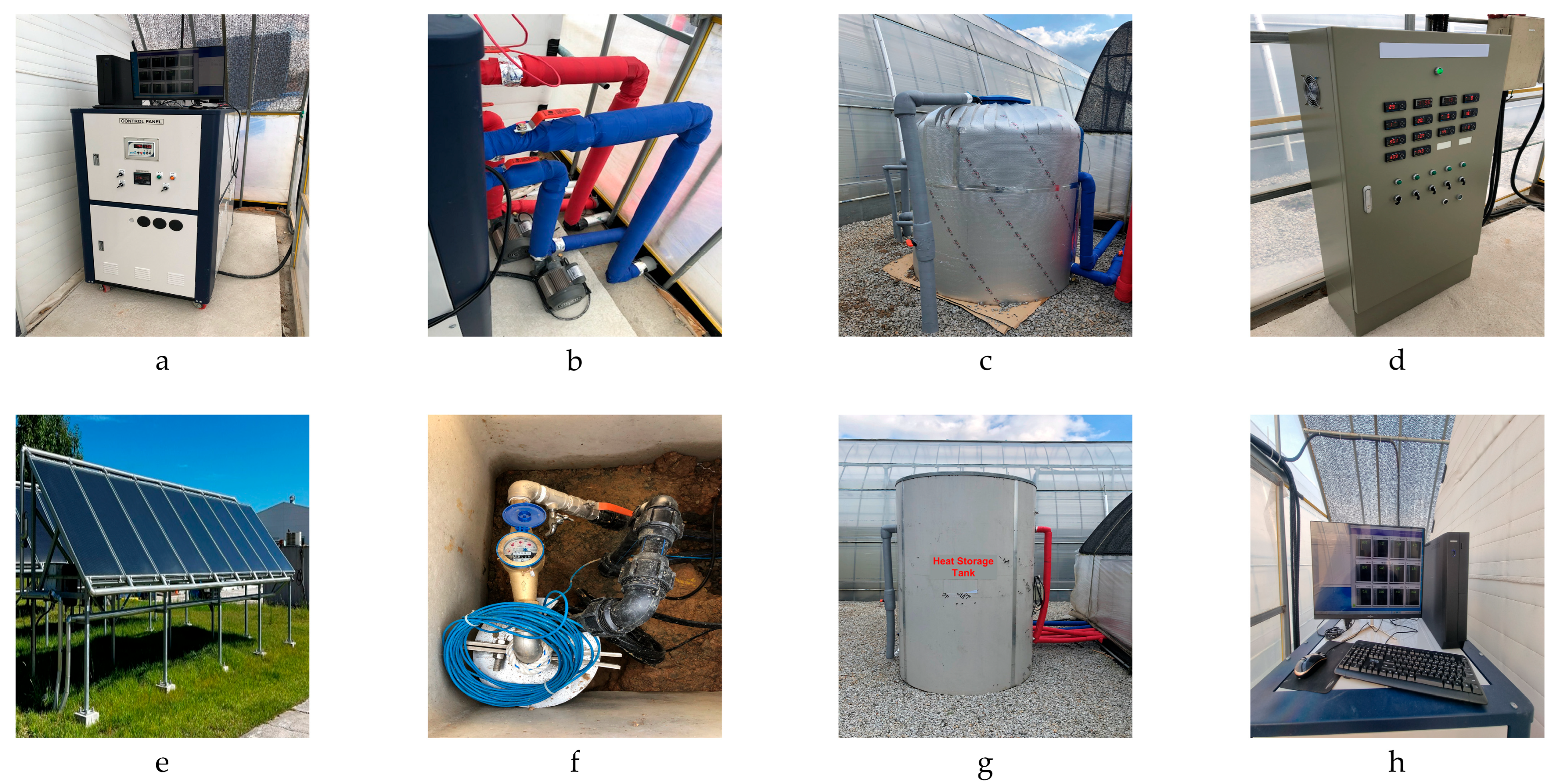

2.2. A Hybrid Thermal Heating and Cooling System Combining PVT Modules and Geothermal Heat

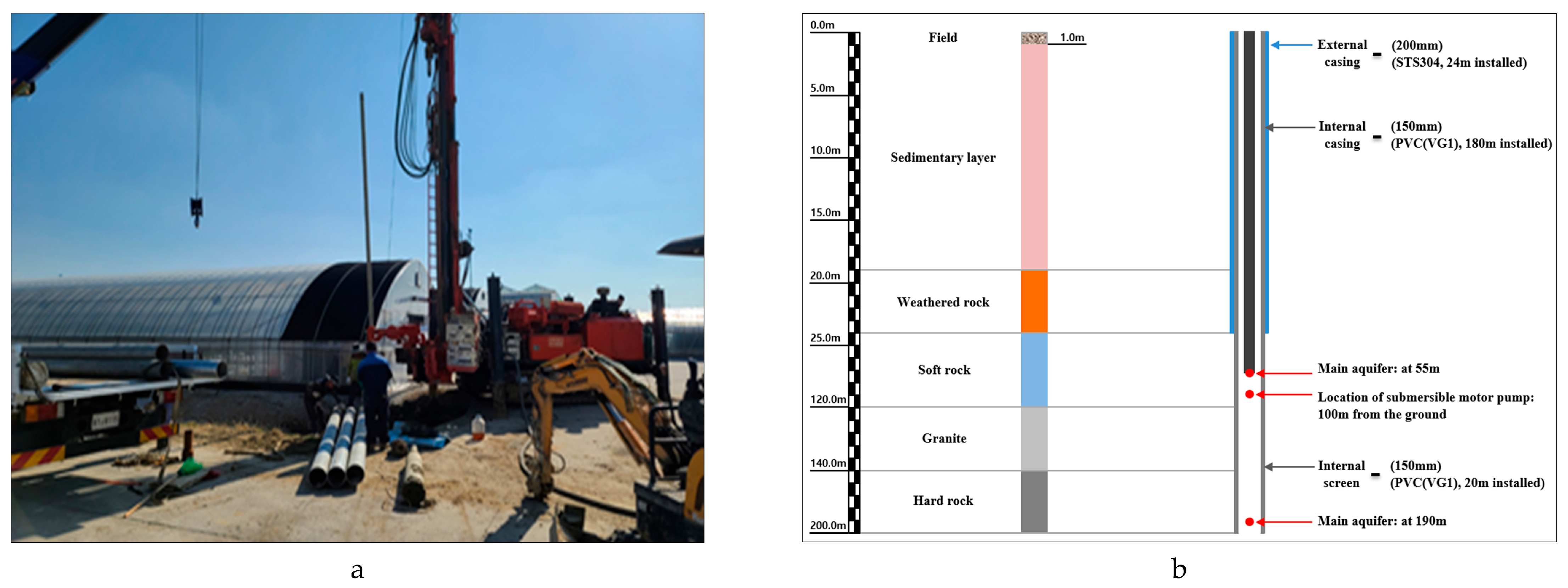

2.2.1. Standing Column Well-Type Open-Loop GHP

2.2.2. Water-to-Water Heat Pump

2.2.3. PVT Module (Reinforced Glass-Covered Type)

2.2.4. Thermal Energy Supply Method

2.2.5. Overview of the Hybrid PVT+GHP System

2.3. Analyses

2.3.1. Heating Load Calculation

2.3.2. Calculating the Capacity of the Storage and Heat Source Tank

2.3.3. Coefficient of Performance (COP) of Hybrid PVT+GHP System

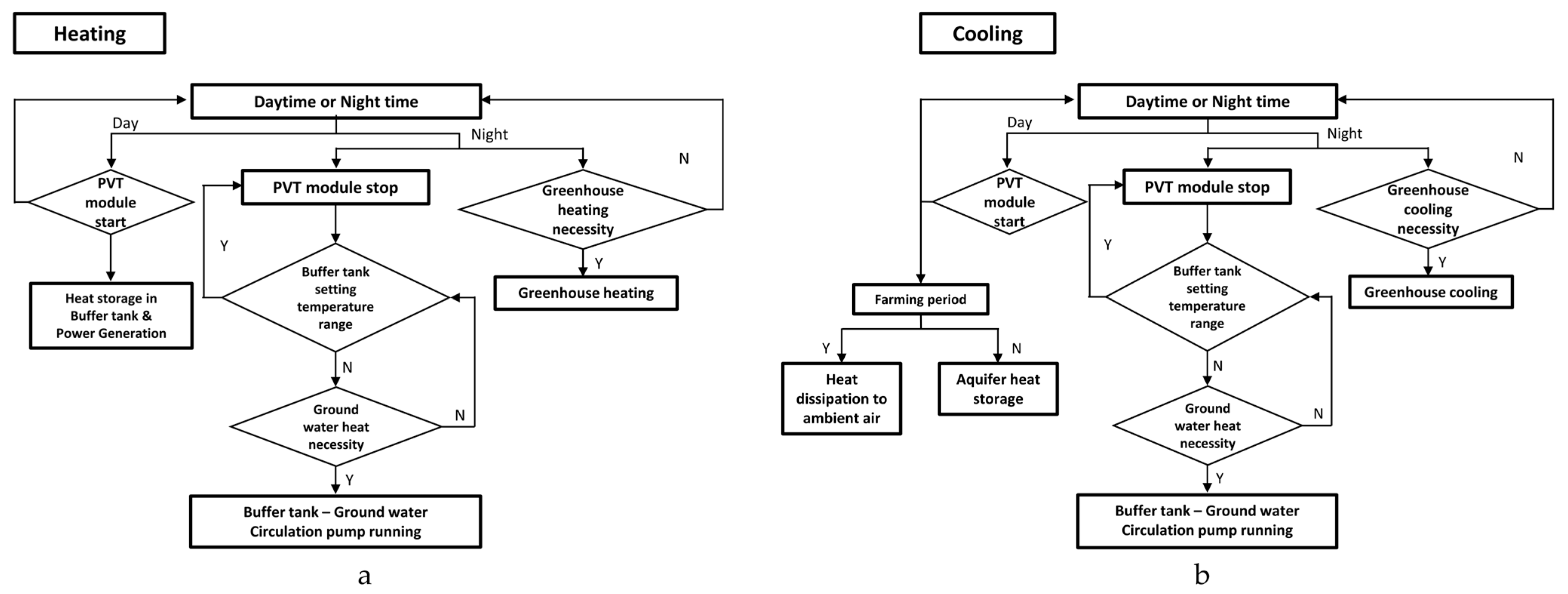

2.3.4. Cooling and Heating Algorithm of Hybrid PVT+GHP System

2.3.5. Measuring Energy Production and Consumption

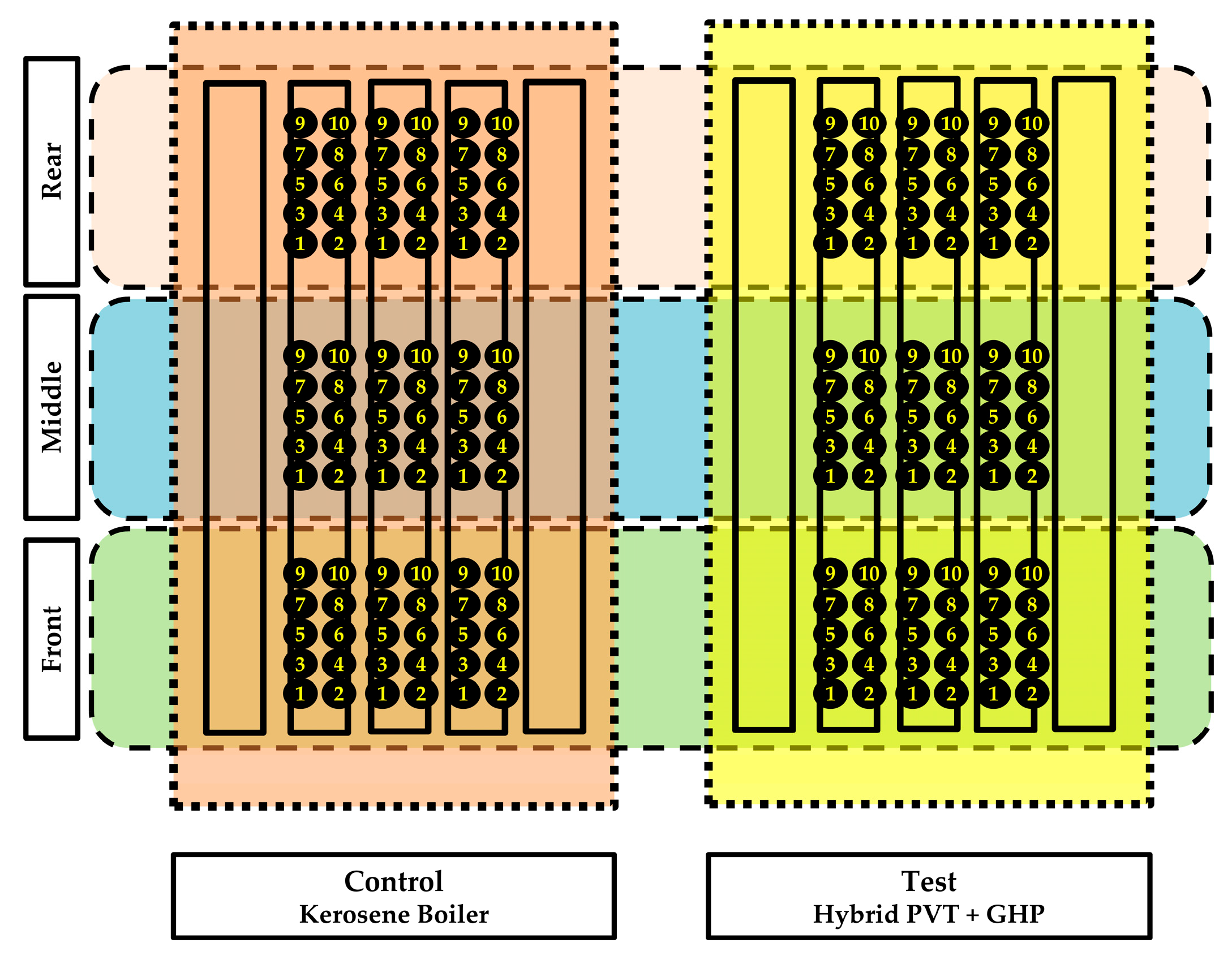

2.3.6. Growth Performance and Yield of Strawberry Plants

2.3.7. Statistical Analysis

3. Results and Discussion

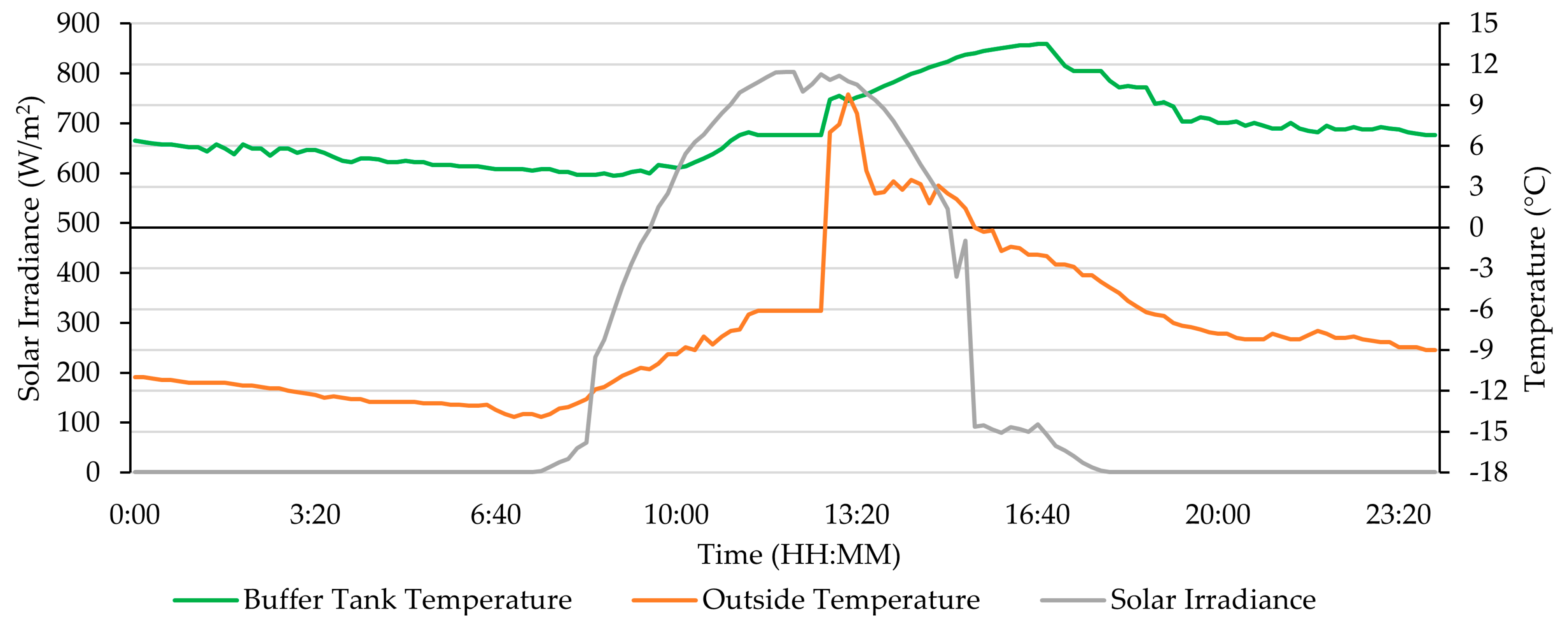

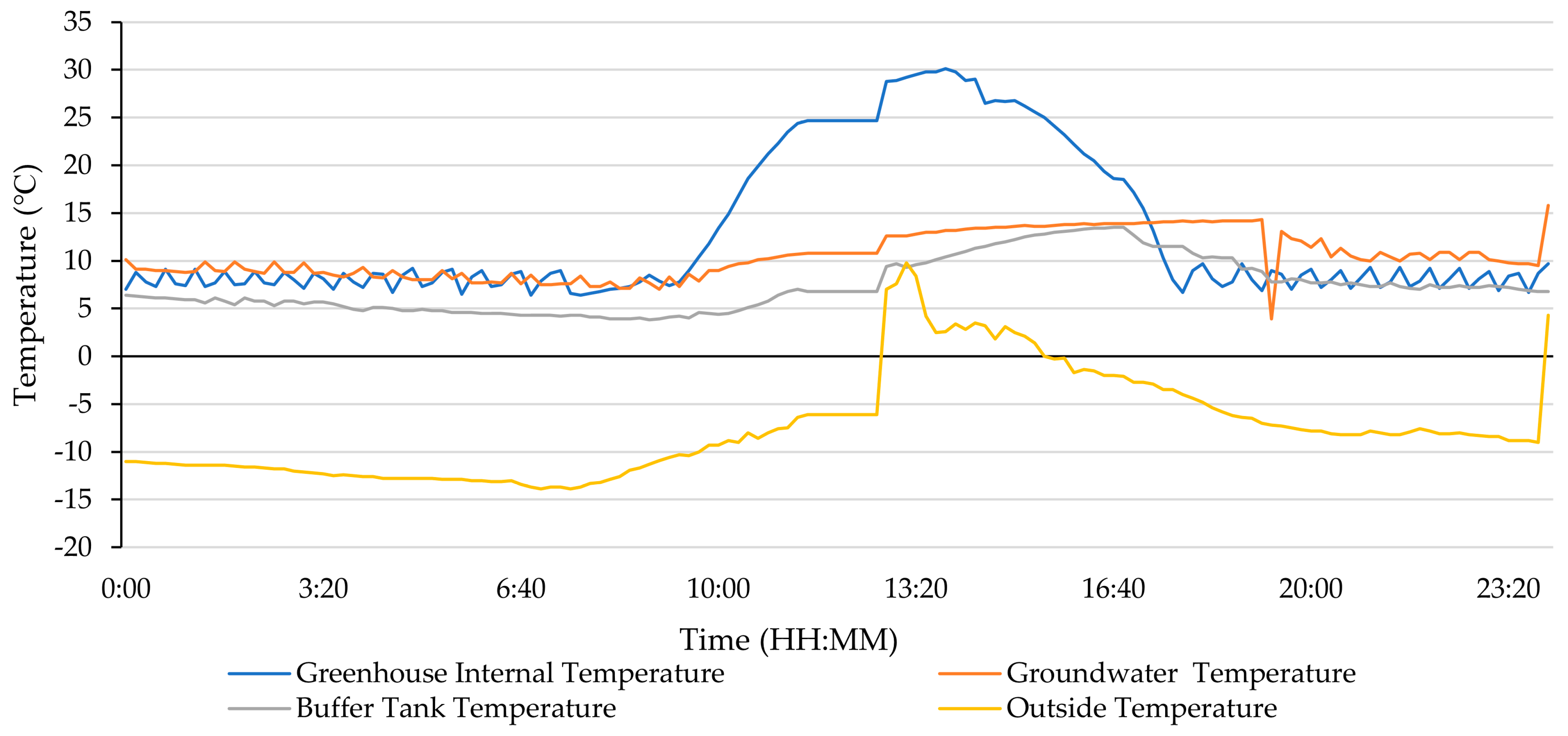

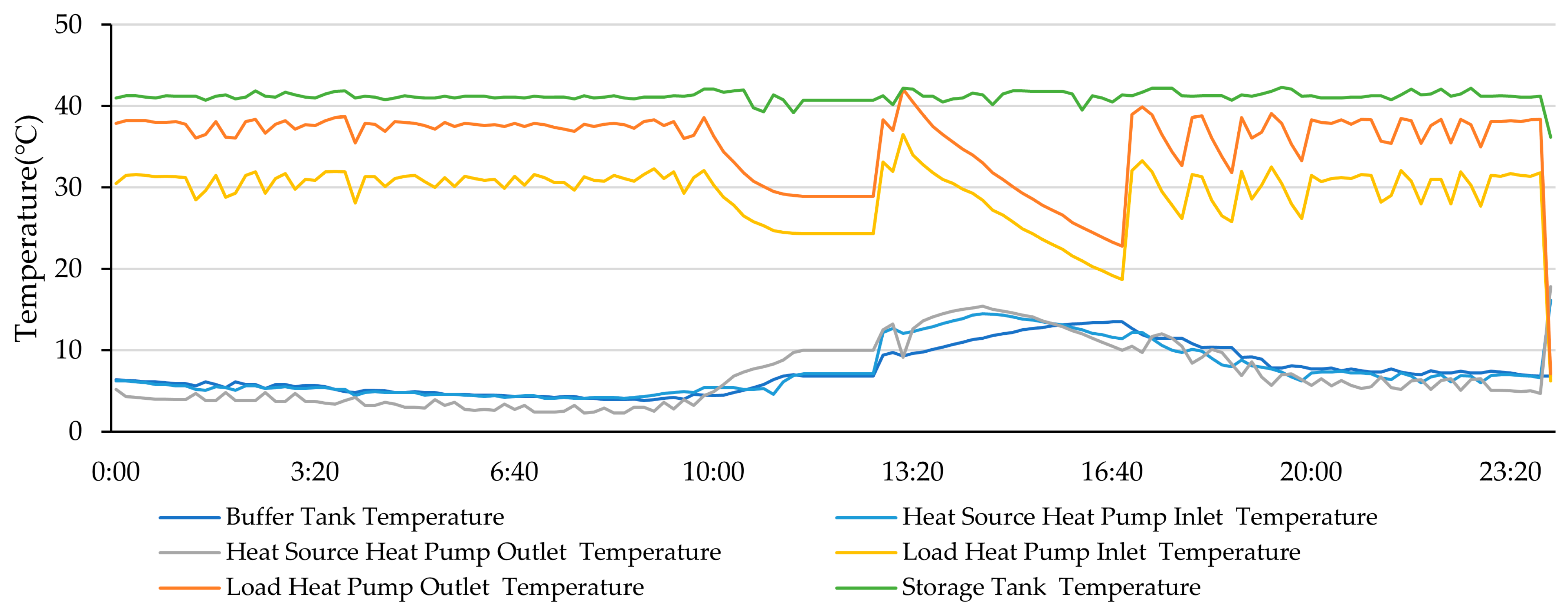

3.1. Analysis of the Specifications of the Testing Instruments and Operating Temperature Ranges

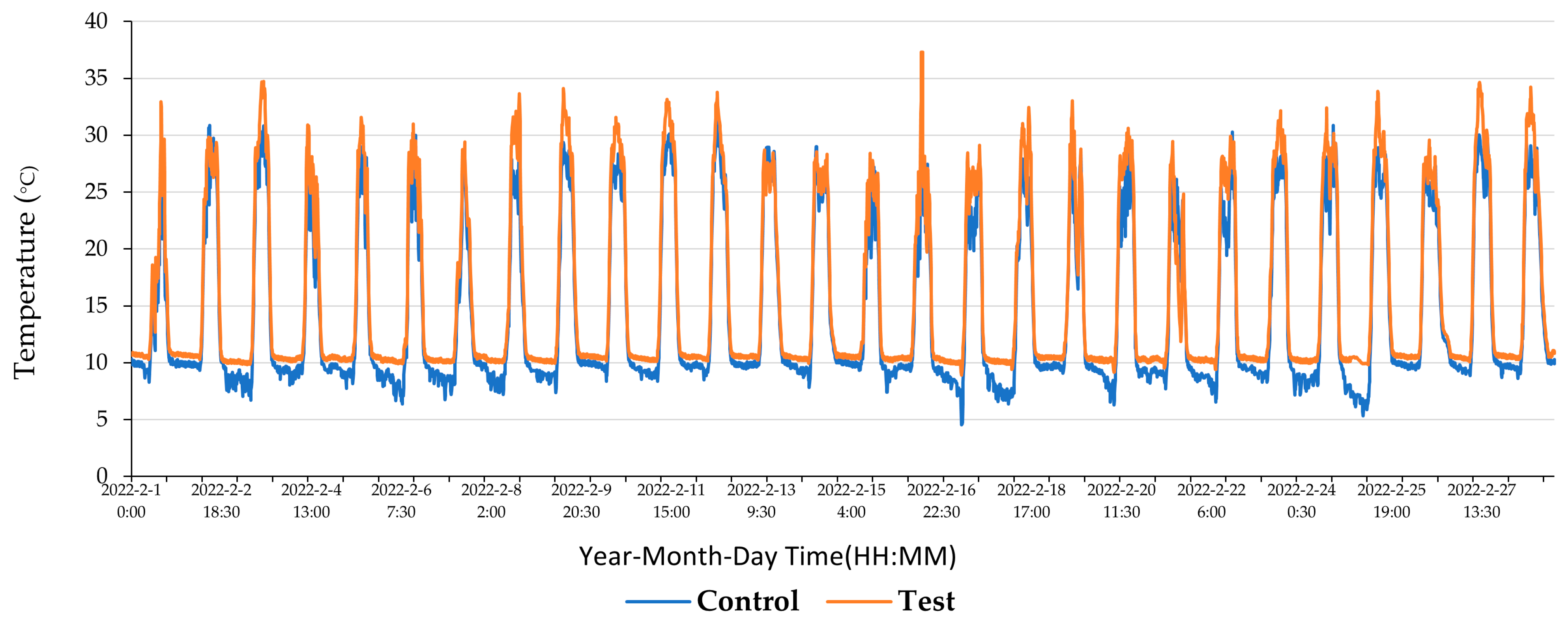

3.2. Comparative Results of Greenhouse Heating Experiments

3.3. COP Analysis Results of the Hybrid PVT+GHP System

3.4. Heating Cost Analysis and Economic Assessment

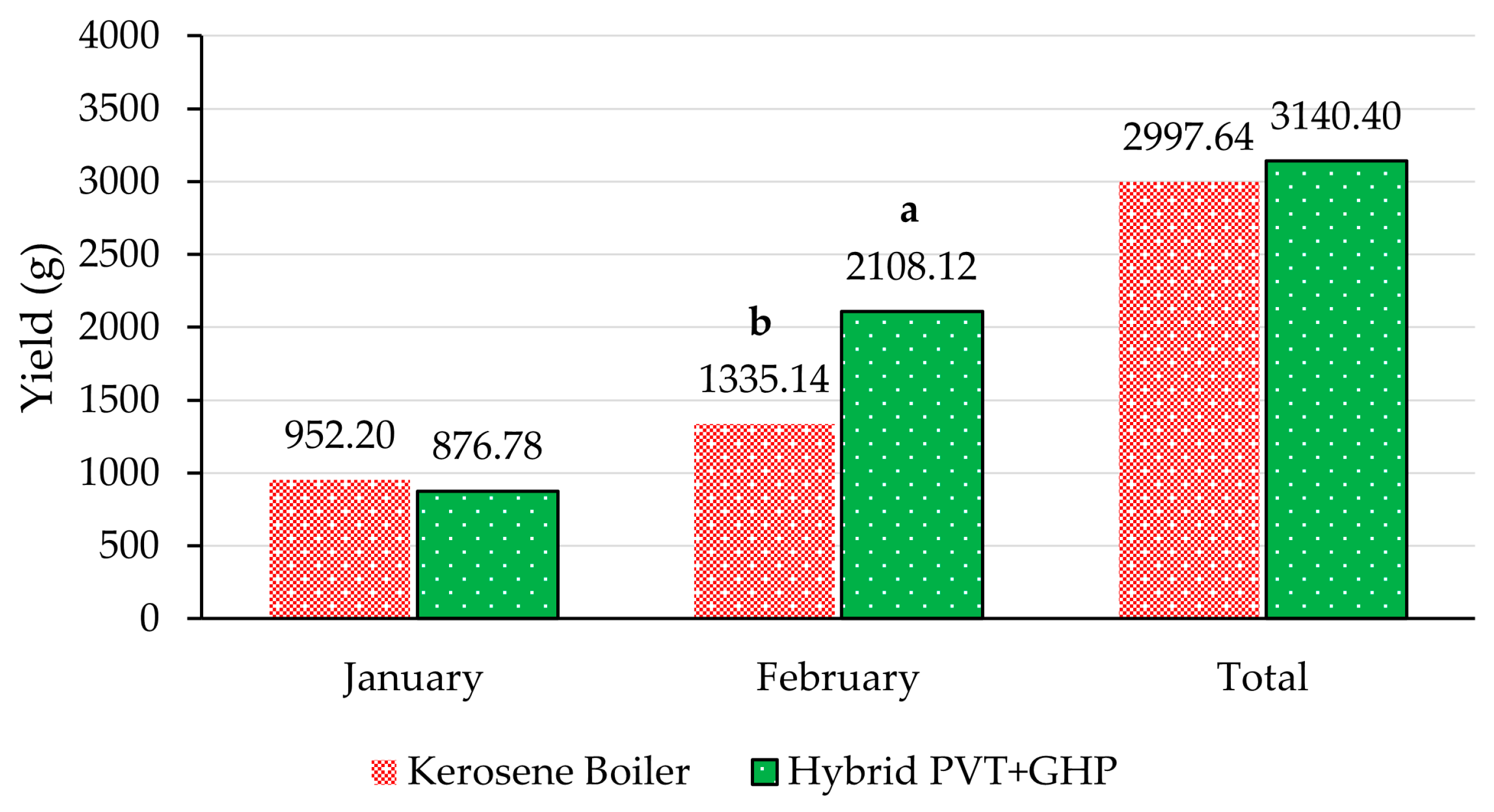

3.5. Comparative Analysis of Strawberry Growth and Yield

3.6. Research Limitations and Recommendations

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ATES | Aquifer thermal energy storage |

| COP | Coefficient of performance |

| ESS | Energy storage system |

| FCU | Fan coil unit |

| GHP | Geothermal heat pump |

| HCF | Heat capacity factor |

| PVT | Photovoltaic–thermal |

| RT | Refrigeration ton |

| SCW | Standing column well |

| STC | Solar thermal collector |

| VCL | Vertical closed loop |

References

- Liu, C. Impact of Global Warming on China’s Agricultural Production. E3S Web Conf. 2022, 352, 03024. [Google Scholar] [CrossRef]

- Sun, Q.; Miao, C.; Hanel, M.; Borthwick, A.G.L.; Duan, Q.; Ji, D.; Li, H. Global Heat Stress on Health, Wildfires, and Agricultural Crops Under Different Levels of Climate Warming. Environ. Int. 2019, 128, 125–136. [Google Scholar] [CrossRef] [PubMed]

- Erickson, P.; Lazarus, M.; Piggot, G. Limiting Fossil Fuel Production as the next Big Step in Climate Policy. Nat. Clim. Change 2018, 8, 1037–1043. [Google Scholar] [CrossRef]

- Gaulin, N.; Le Billon, P. Climate Change and Fossil Fuel Production Cuts: Assessing Global Supply-Side Constraints and Policy Implications. Clim. Policy 2020, 20, 888–901. [Google Scholar] [CrossRef]

- Skovgaard, J.; van Asselt, H. The Politics of Fossil Fuel Subsidies and Their Reform: Implications for Climate Change Mitigation. WIREs Clim. Change 2019, 10, e581. [Google Scholar] [CrossRef]

- Soeder, D.J. (Ed.) Fossil Fuels and Climate Change. In Fracking and the Environment: A Scientific Assessment of the Environmental Risks from Hydraulic Fracturing and Fossil Fuels; Springer International Publishing: Cham, Switzerland, 2021; pp. 155–185. ISBN 978-3-030-59121-2. [Google Scholar]

- van der Ploeg, F.; Withagen, C. Global Warming and the Green Paradox: A Review of Adverse Effects of Climate Policies. Rev. Environ. Econ. Policy 2015, 9, 285–303. [Google Scholar] [CrossRef]

- Wang, T.; Jiang, Z.; Zhao, B.; Gu, Y.; Liou, K.-N.; Kalandiyur, N.; Zhang, D.; Zhu, Y. Health Co-Benefits of Achieving Sustainable Net-Zero Greenhouse Gas Emissions in California. Nat. Sustain. 2020, 3, 597–605. [Google Scholar] [CrossRef]

- da Silva, G.H.R.; Nascimento, A.; Baum, C.D.; Mathias, M.H. Renewable Energy Potentials and Roadmap in Brazil, Austria, and Germany. Energies 2024, 17, 1482. [Google Scholar] [CrossRef]

- Cho, S.; Jeong, Y.-S.; Huh, J.-H. Is South Korea’s 2050 Carbon-Neutral Scenario Sufficient for Meeting Greenhouse Gas Emissions Reduction Goal? Energy Sustain. Dev. 2024, 80, 101447. [Google Scholar] [CrossRef]

- Ha, S.; Tae, S.; Kim, R. A Study on the Limitations of South Korea’s National Roadmap for Greenhouse Gas Reduction by 2030 and Suggestions for Improvement. Sustainability 2019, 11, 3969. [Google Scholar] [CrossRef]

- Nam, H.; Byun, J.; Nam, H. Prediction Greenhouse Gas Emissions from Road Freight Flow in South Korea for Sustainable Transportation Planning. Heliyon 2025, 11, e41937. [Google Scholar] [CrossRef]

- Ministry of Environment. Ministry of Environment Press Release—Revised 2030 Greenhouse Gas Reduction Roadmap and Finalized 2018–2020 Emissions Allocation Plan. Available online: https://www.me.go.kr/home/web/board/read.do?pagerOffset=0&maxPageItems=10&maxIndexPages=10&searchKey=&searchValue=&menuId=286&orgCd=&boardId=886420&boardMasterId=1&boardCategoryId=&decorator (accessed on 8 September 2025).

- Statistic Korea Agricultural Area Survey in 2022. Agricultural Area|Agriculture, Forestry and Fisheries. Press Releases. Available online: http://127.0.0.1/board.es?mid=a20102020000&bid=11707&act=view&list_no=424396 (accessed on 8 September 2025).

- Blom, T.; Jenkins, A.; Pulselli, R.M.; van den Dobbelsteen, A.A.J.F. The Embodied Carbon Emissions of Lettuce Production in Vertical Farming, Greenhouse Horticulture, and Open-Field Farming in The Netherlands. J. Clean. Prod. 2022, 377, 134443. [Google Scholar] [CrossRef]

- Graamans, L.; Baeza, E.; van den Dobbelsteen, A.; Tsafaras, I.; Stanghellini, C. Plant Factories versus Greenhouses: Comparison of Resource Use Efficiency. Agric. Syst. 2018, 160, 31–43. [Google Scholar] [CrossRef]

- Weidner, T.; Yang, A.; Hamm, M.W. Energy Optimisation of Plant Factories and Greenhouses for Different Climatic Conditions. Energy Convers. Manag. 2021, 243, 114336. [Google Scholar] [CrossRef]

- Mun, H.-S.; Lagua, E.B.; Hong, S.-K.; Ryu, S.-B.; Sharifuzzaman, M.; Hasan, M.K.; Kim, Y.-H.; Yang, C.-J. Energy-Efficient Technologies and Strategies for Feasible and Sustainable Plant Factory Systems. Sustainability 2025, 17, 3259. [Google Scholar] [CrossRef]

- Chai, L.; Ma, C.; Ni, J.-Q. Performance Evaluation of Ground Source Heat Pump System for Greenhouse Heating in Northern China. Biosyst. Eng. 2012, 111, 107–117. [Google Scholar] [CrossRef]

- Hassanien, R.H.E.; Li, M.; Dong Lin, W. Advanced Applications of Solar Energy in Agricultural Greenhouses. Renew. Sustain. Energy Rev. 2016, 54, 989–1001. [Google Scholar] [CrossRef]

- Bibbiani, C.; Fantozzi, F.; Gargari, C.; Campiotti, C.A.; Schettini, E.; Vox, G. Wood Biomass as Sustainable Energy for Greenhouses Heating in Italy. Agric. Agric. Sci. Procedia 2016, 8, 637–645. [Google Scholar] [CrossRef]

- Lee, C.-G.; Cho, L.-H.; Kim, S.-J.; Park, S.-Y.; Kim, D.-H. Comparative Analysis of Combined Heating Systems Involving the Use of Renewable Energy for Greenhouse Heating. Energies 2021, 14, 6603. [Google Scholar] [CrossRef]

- Blom, T.; Jenkins, A.; van den Dobbelsteen, A. Synergetic Integration of Vertical Farms and Buildings: Reducing the Use of Energy, Water, and Nutrients. Front. Sustain. Food Syst. 2023, 7, 1227672. [Google Scholar] [CrossRef]

- Sadeghi, H.; Ijaz, A.; Singh, R.M. Current Status of Heat Pumps in Norway and Analysis of Their Performance and Payback Time. Sustain. Energy Technol. Assess. 2022, 54, 102829. [Google Scholar] [CrossRef]

- Song, C.; Li, Y.; Rajeh, T.; Ma, L.; Zhao, J.; Li, W. Application and Development of Ground Source Heat Pump Technology in China. Prot. Control Mod. Power Syst. 2021, 6, 1–18. [Google Scholar] [CrossRef]

- Borland, P.L.; McDonnell, K.; Harty, M. Assessment of the Potential to Use the Expelled Heat Energy from a Typical Data Centre in Ireland for Alternative Farming Methods. Energies 2023, 16, 6704. [Google Scholar] [CrossRef]

- Fan, S.; Li, A.; ter Heijne, A.; Buisman, C.J.N.; Chen, W.-S. Heat Potential, Generation, Recovery and Utilization from Composting: A Review. Resour. Conserv. Recycl. 2021, 175, 105850. [Google Scholar] [CrossRef]

- Martin, M.; Weidner, T.; Gullström, C. Estimating the Potential of Building Integration and Regional Synergies to Improve the Environmental Performance of Urban Vertical Farming. Front. Sustain. Food Syst. 2022, 6, 849304. [Google Scholar] [CrossRef]

- Pertry, I.; Bleyaert, P.; Demyttenaere, P.; Demeulemeester, M. Agrotopia, a Living Lab for High-Tech Urban Horticulture Within Europe. Acta Hortic. 2018, 1215, 153–158. [Google Scholar] [CrossRef]

- Korea Forest Service. Available online: https://english.forest.go.kr/kfsweb/kfs/subIdx/Index.do?mn=UENG (accessed on 9 September 2025).

- Oh, J.; Suh, D.H. Exploring the Import Allocation of Wood Pellets: Insights from Price and Policy Influences Under the Renewable Portfolio Standard. For. Policy Econ. 2024, 161, 103180. [Google Scholar] [CrossRef]

- Korea Forest Service. Korea Forest Service–Forest In Korea > Korean Forests at a Glance. Available online: https://english.forest.go.kr/kfsweb/kfi/kfs/cms/cmsView.do?cmsId=FC_001679&mn=UENG_01_03 (accessed on 8 September 2025).

- Self, S.J.; Reddy, B.V.; Rosen, M.A. Geothermal Heat Pump Systems: Status Review and Comparison with Other Heating Options. Appl. Energy 2013, 101, 341–348. [Google Scholar] [CrossRef]

- Ma, Y. Deep Geothermal Resources in China: Potential, Distribution, Exploitation, and Utilization. Energy Geosci. 2023, 4, 100209. [Google Scholar] [CrossRef]

- Marrasso, E.; Roselli, C.; Sasso, M.; Tariello, F. Global and Local Environmental and Energy Advantages of a Geothermal Heat Pump Interacting with a Low Temperature Thermal Micro Grid. Energy Convers. Manag. 2018, 172, 540–553. [Google Scholar] [CrossRef]

- Neuberger, P.; Adamovský, R. Analysis of the Potential of Low-Temperature Heat Pump Energy Sources. Energies 2017, 10, 1922. [Google Scholar] [CrossRef]

- Putriyana, L.; Daud, Y.; Saha, B.B.; Nasruddin, N. A Comprehensive Data and Information on Low to Medium Temperature Geothermal Resources in Indonesia: A Review. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 58. [Google Scholar] [CrossRef]

- Zheng, J.; Sun, L.; Xu, X.; Long, X.; Gao, T.; Xia, E.; Li, B.; Li, S.; Wang, J.; Mo, Z.; et al. Feasibility of Shallow Geothermal Energy for Industrial Heating Using High-Temperature Heat Pumps in Sichuan Province, China. Energy Sustain. Dev. 2025, 88, 101785. [Google Scholar] [CrossRef]

- Anifantis, A.S.; Pascuzzi, S.; Scarascia-Mugnozza, G. Geothermal Source Heat Pump Performance for a Greenhouse Heating System: An Experimental Study. J. Agric. Eng. 2016, 47, 164–170. [Google Scholar] [CrossRef]

- Blázquez, C.S.; Borge-Diez, D.; Nieto, I.M.; Maté-González, M.Á.; Martín, A.F.; González-Aguilera, D. Geothermal Heat Pumps for Slurry Cooling and Farm Heating: Impact and Carbon Footprint Reduction in Pig Farms. Sustainability 2022, 14, 5792. [Google Scholar] [CrossRef]

- Ghiasi, M.; Wang, Z.; Mehrandezh, M.; Paranjape, R. Enhancing Efficiency through Integration of Geothermal and Photovoltaic in Heating Systems of a Greenhouse for Sustainable Agriculture. Sustain. Cities Soc. 2025, 118, 106040. [Google Scholar] [CrossRef]

- Khashehchi, M.; Thangavel, S.; Rahmanivahid, P.; Heidari, M.; Moazzeni, T. Study and Analysis of Low-Level Geothermal Heat Pumps in Oman. In Highly Efficient Thermal Renewable Energy Systems; CRC Press: Boca Raton, FL, USA, 2024. [Google Scholar]

- Liu, Z.; Wang, W.; Chen, Y.; Wang, L.; Guo, Z.; Yang, X.; Yan, J. Solar Harvest: Enhancing Carbon Sequestration and Energy Efficiency in Solar Greenhouses with PVT and GSHP Systems. Renew. Energy 2023, 211, 112–125. [Google Scholar] [CrossRef]

- Boahen, S.; Lee, K.H.; Cho, S.; Choi, J.M. A Study on the Evaluation of the Annual Energy Consumption for a Geothermal Heat Pump System with Open Loop and Closed Loop Ground Heat Exchangers. Int. J. Air-Cond. Refrig. 2017, 25, 1750024. [Google Scholar] [CrossRef]

- Murr, R.; Faraj, J.; Hage, H.E.; Khaled, M. Renewable Energy as an Auxiliary to Heat Pumps: Performance Evaluation of Hybrid Solar-Geothermal-Systems. Int. J. Thermofluids 2024, 24, 100922. [Google Scholar] [CrossRef]

- Kazaz, O.; Abu-Nada, E. Exploiting Light-Matter Interactions in Multifunctional Nanocomposite Core–Shell Materials for Advanced Utilization of Full-Spectrum Solar Energy. Energy Convers. Manag. 2025, 343, 120210. [Google Scholar] [CrossRef]

- Carmona, M.; Palacio Bastos, A.; García, J.D. Experimental Evaluation of a Hybrid Photovoltaic and Thermal Solar Energy Collector with Integrated Phase Change Material (PVT-PCM) in Comparison with a Traditional Photovoltaic (PV) Module. Renew. Energy 2021, 172, 680–696. [Google Scholar] [CrossRef]

- Ariffin, M.R.; Shafie, S.; Hassan, W.Z.W.; Azis, N.; Ya’acob, M.E. Conceptual Design of Hybrid Photovoltaic-Thermoelectric Generator (PV/TEG) for Automated Greenhouse System. In Proceedings of the 2017 IEEE 15th Student Conference on Research and Development (SCOReD), Wilayah Persekutuan Putrajaya, Malaysia, 13–14 December 2017; pp. 309–314. [Google Scholar]

- Mohd Shatar, N.; Abdul Rahman, M.A.; Muhtazaruddin, M.N.; Shaikh Salim, S.A.Z.; Singh, B.; Muhammad-Sukki, F.; Bani, N.A.; Mohd Saudi, A.S.; Ardila-Rey, J.A. Performance Evaluation of Unconcentrated Photovoltaic-Thermoelectric Generator Hybrid System under Tropical Climate. Sustainability 2019, 11, 6192. [Google Scholar] [CrossRef]

- Shatar, N.M.; Abdul Rahman, M.A.A.; Shaikh Salim, S.A.Z.; Ariff, M.H.M.; Muhtazaruddin, M.N.; Badlisah, A.K.A. Design of Photovoltaic-Thermoelectric Generator (PV-TEG) Hybrid System for Precision Agriculture. In Proceedings of the 2018 IEEE 7th International Conference on Power and Energy (PECon), Kuala Lumpur, Malaysia, 3–4 December 2018; pp. 50–55. [Google Scholar]

- Fudholi, A.; Zohri, M.; Jin, G.L.; Ibrahim, A.; Yen, C.H.; Othman, M.Y.; Ruslan, M.H.; Sopian, K. Energy and Exergy Analyses of Photovoltaic Thermal Collector with ∇-Groove. Sol. Energy 2018, 159, 742–750. [Google Scholar] [CrossRef]

- Jia, Y.; Alva, G.; Fang, G. Development and Applications of Photovoltaic–Thermal Systems: A Review. Renew. Sustain. Energy Rev. 2019, 102, 249–265. [Google Scholar] [CrossRef]

- Mojumder, J.C.; Chong, W.T.; Ong, H.C.; Leong, K.Y.; Abdullah-Al-Mamoon. An Experimental Investigation on Performance Analysis of Air Type Photovoltaic Thermal Collector System Integrated with Cooling Fins Design. Energy Build. 2016, 130, 272–285. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, W.; Zhai, X.; Qian, C.; Chen, X. Feasibility and Performance Study of the Hybrid Ground-Source Heat Pump System for One Office Building in Chinese Heating Dominated Areas. Renew. Energy 2017, 101, 1131–1140. [Google Scholar] [CrossRef]

- Khammayom, N.; Maruyama, N.; Chaichana, C.; Hirota, M. Impact of Environmental Factors on Energy Balance of Greenhouse for Strawberry Cultivation. Case Stud. Therm. Eng. 2022, 33, 101945. [Google Scholar] [CrossRef]

- Kim, S.; Jo, J.S.; Luk, V.; Kim, S.K.; Kim, D.S. Estimating the Impact of Environmental Management on Strawberry Yield Using Publicly Available Agricultural Data in South Korea. PeerJ 2023, 11, e15390. [Google Scholar] [CrossRef]

- Rural Development Administration. Rural Development Administration, Korea Smart Greenhouse Special Exhibition: Smart City Comprehensive Portal. Smart City Korea. 2018. Available online: https://smartcity.go.kr/en/2018/08/14/%EB%86%8D%EC%B4%8C%EC%A7%84%ED%9D%A5%EC%B2%AD-%ED%95%9C%EA%B5%AD%ED%98%95-%EC%8A%A4%EB%A7%88%ED%8A%B8-%EC%98%A8%EC%8B%A4-%ED%8A%B9%EB%B3%84-%EC%A0%84%EC%8B%9C%ED%9A%8C-%EA%B0%9C%EC%B5%9C/ (accessed on 11 September 2025).

- Moon, J.; Lee, S.; Kang, Y.; Lee, S. Development of Greenhouse Heating Technology Using Riverbank Filtered Water. 2011. Available online: https://kiss.kstudy.com/Detail/Ar?key=3582884 (accessed on 30 September 2025).

- Moon, J.P.; Kang, G.C.; Kim, H.G.; Lee, T.S.; Oh, S.S.; Jin, B.O. Effects of the Cooling and Heating System with Seasonal Thermal Storage in Alluvial Aquifer on Greenhouse Heating. J. Korean Soc. Agric. Eng. 2017, 59, 127–135. [Google Scholar]

- Lee, Y.; Song, J.; Hong, H. Long-Term Performance Analysis of a Photovoltaic Thermal–Ground Source Heat Pump (PVT–GSHP) System in Heating-Dominated Climates. J. Build. Eng. 2025, 112, 113772. [Google Scholar] [CrossRef]

- Menzel, C.M. Temperatures Above 30oC Decrease Leaf Growth in Strawberry under Global Warming. J. Hortic. Sci. Biotechnol. 2024, 99, 507–530. [Google Scholar] [CrossRef]

| Contents | Value |

|---|---|

| Width | 7.0 m |

| Side height | 1.5 m |

| Center height | 3.8 m |

| Length | 25 m |

| Cover and Insulation | PO film (0.10 mm) |

| Multi-layer insulation curtain | 5 layers |

| Cultivation area | 5 raised beds |

| Parameters | Specifications | Note | |

|---|---|---|---|

| Manufacturing company | E-MAX System Co., Ltd. | ||

| Size | 1040 × 2003 × 58 (mm) | Area 2.08 m2 | |

| Generation output 1 | 875 W/Module, 44 W/m2 | Based on product specifications: 530 W/m2 | |

| Heat output | Average output 2 | 6.56 MJ/m2 | Based on product specifications: 7.64 MJ/m2 |

| Heat collection 3 | |||

| Components | Details |

|---|---|

| Cell | Single crystal, 72 cells |

| Heat sink plate | Titanium-coated aluminum absorber |

| Permeable glass | AR-coated low-iron tempered glass |

| Heat collecting tube | Serpentine seamless copper tube |

| Manufacturing method | Cell-absorber mechanical lamination |

| Other functions | Natural air circulation, overheating protection device |

| Division | 10 a | 20 a | 30 a | 50 a |

|---|---|---|---|---|

| Greenhouse area (m2) | 990 | 1980 | 2970 | 4950 |

| Greenhouse surface area (m2) | 1386 | 2772 | 4158 | 6930 |

| Heating load of greenhouse (kcal/h *) | 99,644 | 199,287 | 298,931 | 498,218 |

| Heating load of greenhouse (kW *) | 116 | 232 | 348 | 579 |

| Components | Specification | Temperature Range | Remarks | |

|---|---|---|---|---|

| PVT | Area 18 m3 | Electricity: 3 kW Heat: 7.9 kW | 0~80 °C | Electricity: 3 kW × 3.5 h = 10.5 kWh/day Heat: 7.9 kW × 3.5 h = 27.65 kWh/day |

| Heat Pump | 7.5 RT (26.38 kW) | 4~50 °C | Heat source side = 1.7 °C, load side = 6.5 °C | |

| Heat Storage Tank | 5 m3 | 40~45 °C | ||

| Buffer Tank | 2 m3 | 4~35 °C | ||

| Geothermal Well (Groundwater) | 100 L/min | Depth 200 m | 10~20 °C | |

| Heat Supply | PVT Electricity Produced | Heat Stored in Aquifer Thermal Energy Storage | Electricity Usage | ||||

|---|---|---|---|---|---|---|---|

| PVT | Geothermal | PVT | Greenhouse | Heat Pump | Geothermal Pump | ||

| Heating mode | 2568 | 8685 | 815 | 5160 | 1812 | ||

| Cooling mode | 448 | 1266 | 2418 | 1501 | 695 | ||

| Inter-season (Spring, Fall) | 2576 | 7441 | 1287 | ||||

| Subtotal 1 | 11,253 | 815 | 5160 | 1812 | |||

| Total | 11,253 | 3839 | 11,125 | 6661 | 3794 | ||

| Collection Periods | Values | Kerosene Boiler | Hybrid PVT+GHP | SEM | p-Value |

|---|---|---|---|---|---|

| 16 November 2021 | Crown Diameter (cm) | 15.27 | 16.47 | 0.355 | 0.020 |

| Height (cm) | 26.56 | 25.39 | 0.409 | 0.047 | |

| Petiole Length (cm) | 12.74 | 11.70 | 0.262 | 0.007 | |

| Leaf Length (cm) | 12.29 | 11.86 | 0.220 | 0.176 | |

| Leaf Width (cm) | 10.04 | 10.12 | 0.154 | 0.715 | |

| Number of Leaves (n) | nd | nd | nd | nd | |

| 13 December 2021 | Crown Diameter (cm) | 14.96 | 16.82 | 0.355 | <0.001 |

| Height (cm) | 26.49 | 25.09 | 0.363 | 0.009 | |

| Petiole Length (cm) | 12.71 | 11.69 | 0.253 | 0.006 | |

| Leaf Length (cm) | 12.18 | 11.43 | 0.191 | 0.008 | |

| Leaf Width (cm) | 10.06 | 9.85 | 0.151 | 0.316 | |

| Number of Leaves (n) | 5.27 | 5.67 | 0.146 | 0.057 | |

| 28 December 2021 | Crown Diameter (cm) | 14.76 | 15.32 | 0.283 | 0.172 |

| Height (cm) | 26.60 | 23.29 | 0.379 | <0.001 | |

| Petiole Length (cm) | 12.56 | 11.30 | 0.251 | 0.001 | |

| Leaf Length (cm) | 11.97 | 10.26 | 0.194 | <0.001 | |

| Leaf Width (cm) | 10.00 | 8.93 | 0.180 | <0.001 | |

| Number of Leaves (n) | 5.90 | 5.83 | 0.147 | 0.750 | |

| 11 January 2022 | Crown Diameter (cm) | 15.60 | 15.53 | 0.296 | 0.864 |

| Height (cm) | 26.34 | 15.15 | 0.562 | <0.001 | |

| Petiole Length (cm) | 12.57 | 10.76 | 0.225 | <0.001 | |

| Leaf Length (cm) | 11.79 | 9.38 | 0.195 | <0.001 | |

| Leaf Width (cm) | 9.82 | 8.87 | 0.144 | <0.001 | |

| Number of Leaves (n) | 7.03 | 6.47 | 0.242 | 0.103 | |

| 8 February 2022 | Crown Diameter (cm) | 14.45 | 13.65 | 0.328 | 0.088 |

| Height (cm) | 20.41 | 19.33 | 0.603 | 0.214 | |

| Petiole Length (cm) | 10.16 | 9.41 | 0.347 | 0.130 | |

| Leaf Length (cm) | 8.64 | 8.47 | 0.269 | 0.657 | |

| Leaf Width (cm) | 7.17 | 6.71 | 0.229 | 0.165 | |

| Number of Leaves (n) | 8.03 | 6.27 | 0.258 | <0.001 | |

| 22 February 2022 | Crown Diameter (cm) | 14.42 | 13.89 | 0.387 | 0.339 |

| Height (cm) | 15.45 | 18.30 | 0.417 | <0.001 | |

| Petiole Length (cm) | 7.31 | 9.07 | 0.256 | <0.001 | |

| Leaf Length (cm) | 7.08 | 8.07 | 0.195 | 0.001 | |

| Leaf Width (cm) | 5.86 | 6.46 | 0.180 | 0.022 | |

| Number of Leaves (n) | 5.83 | 6.67 | 0.299 | 0.054 | |

| 7 March 2022 | Crown Diameter (cm) | 14.06 | 14.36 | 0.361 | 0.564 |

| Height (cm) | 16.00 | 16.91 | 0.436 | 0.147 | |

| Petiole Length (cm) | 7.79 | 8.72 | 0.312 | 0.041 | |

| Leaf Length (cm) | 7.23 | 7.26 | 0.189 | 0.931 | |

| Leaf Width (cm) | 6.09 | 5.96 | 0.185 | 0.604 | |

| Number of Leaves (n) | 6.50 | 7.50 | 0.320 | 0.031 | |

| Differences 1 | Crown Diameter (%) | −7.92 | −12.85 | ||

| Height (%) | −39.75 | −33.40 | |||

| Petiole Length (%) | −38.81 | −25.51 | |||

| Leaf Length (%) | −41.14 | −38.83 | |||

| Leaf Width (%) | −39.29 | −41.12 | |||

| Number of Leaves (%) | 23.42 | 32.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, C.G.; Kang, G.C.; Jang, J.K.; Yun, S.-W.; Moon, J.P.; Mun, H.-S.; Lagua, E.B. Efficacy of Hybrid Photovoltaic–Thermal and Geothermal Heat Pump System for Greenhouse Climate Control. Energies 2025, 18, 5386. https://doi.org/10.3390/en18205386

Lee CG, Kang GC, Jang JK, Yun S-W, Moon JP, Mun H-S, Lagua EB. Efficacy of Hybrid Photovoltaic–Thermal and Geothermal Heat Pump System for Greenhouse Climate Control. Energies. 2025; 18(20):5386. https://doi.org/10.3390/en18205386

Chicago/Turabian StyleLee, Chung Geon, Geum Choon Kang, Jae Kyung Jang, Sung-Wook Yun, Jong Pil Moon, Hong-Seok Mun, and Eddiemar Baguio Lagua. 2025. "Efficacy of Hybrid Photovoltaic–Thermal and Geothermal Heat Pump System for Greenhouse Climate Control" Energies 18, no. 20: 5386. https://doi.org/10.3390/en18205386

APA StyleLee, C. G., Kang, G. C., Jang, J. K., Yun, S.-W., Moon, J. P., Mun, H.-S., & Lagua, E. B. (2025). Efficacy of Hybrid Photovoltaic–Thermal and Geothermal Heat Pump System for Greenhouse Climate Control. Energies, 18(20), 5386. https://doi.org/10.3390/en18205386