The Stochastic Nature of the Mining Production Process—Modeling of Processes in Deep Hard Coal Mines

Abstract

1. Introduction

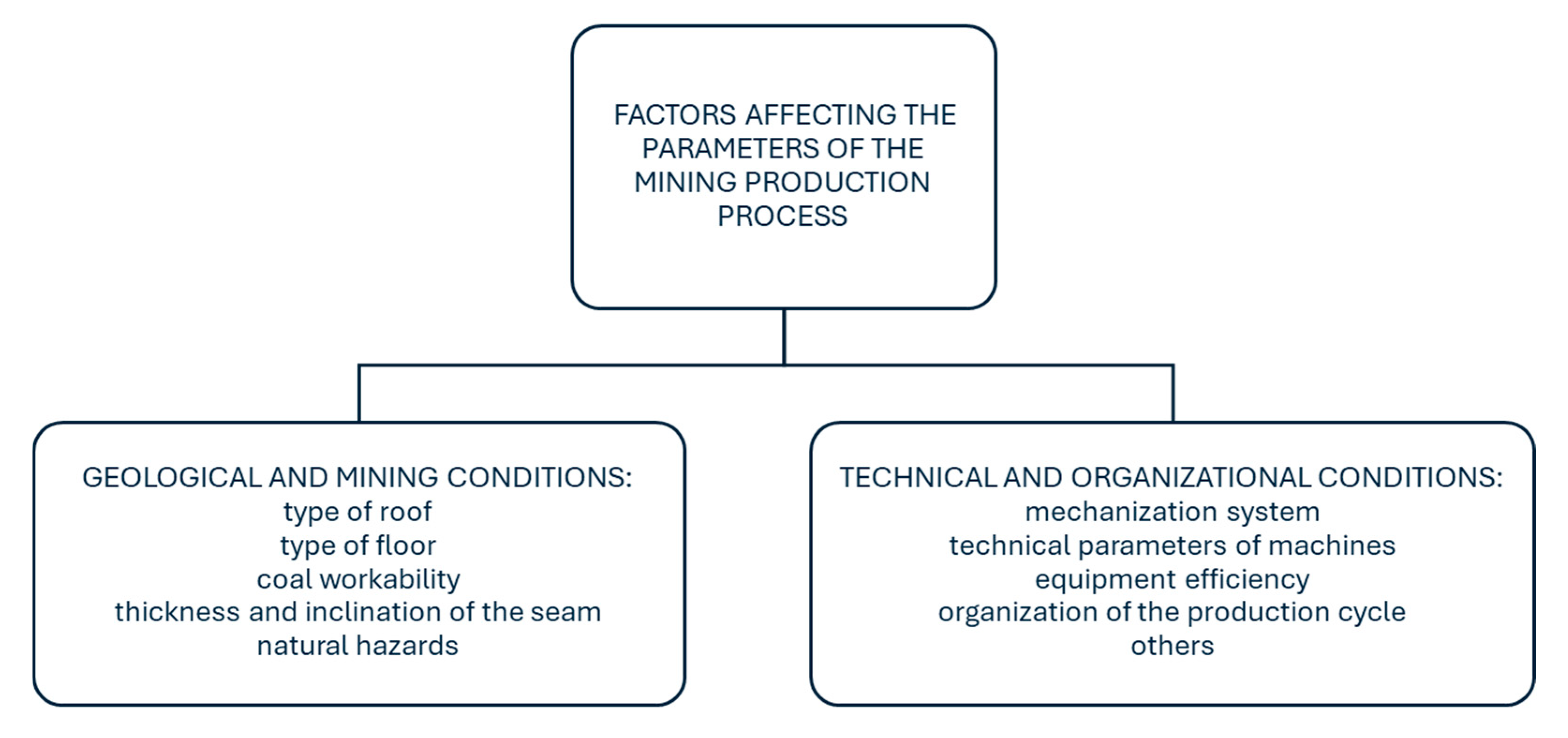

1.1. Factors Influencing the Course of the Production Process Carried out in the Longwall Face

- –

- Type of roof rock;

- –

- Type of floor rock;

- –

- Coal workability;

- –

- Thickness and inclination of the seam;

- –

- Natural hazards.

- –

- Mechanization system;

- –

- Technical parameters of machines;

- –

- Equipment failure rate;

- –

- Organization of the production cycle, which includes the form of work organization, the form of labor organization, and the work system;

- –

- Training and experience of employees.

- –

- Brittle roof rocks, usually forming part of the direct roof, characterized by low cohesion and strength with high deformability, which causes them to fall into the exploited space;

- –

- Stiff roof rocks, with low deformability and high strength, which collapse in blocks behind the exploitation front;

- –

- Plastic roof rocks, capable of significant deformations and bending behind the exploitation front.

- –

- Class I—direct floor composed of weak rock layers susceptible to exfoliation;

- –

- Class II—direct floor consisting of strong rock layers;

- –

- Class III—direct floor consisting of plastic, swelling rocks that are easily extruded into the workings.

- –

- Group I—easily workable seams: f from 0.4 to 1.2;

- –

- Group II—difficult to work seams: f from 1.2 to 2.0;

- –

- Group III—very difficult to work seams: f above 2.0.

- –

- Thin seams—thickness up to 1.5 m;

- –

- Medium seams—thickness from 1.5 to 4.0 m;

- –

- Thick seams—thickness greater than 4.0 m.

- –

- Horizontal or nearly horizontal seams—dip angle between 0° and 5°;

- –

- Gently inclined seams—dip angle between 5° and 30°;

- –

- Steeply inclined seams—dip angle between 30° and 45°;

- –

- Very steep seams—dip angle between 45° and 90°.

- –

- Seams prone to methane and rock outbursts—these include coal seams or their parts where methane content exceeds 8 [m3/Mg] (per ton of pure coal substance) and coal cohesion is less than 0.3, or where methane content exceeds 8 [m3/Mg] and cohesion is at least 0.3, but methane desorption intensity is greater than 1.2 kPa.

- –

- Seams endangered by methane and rock outbursts—these include coal seams or their parts where

- A methane and rock outburst has occurred;

- A sudden methane outflow has occurred;

- Other symptoms indicating increased risk of methane and rock outbursts have been observed.

1.2. Use of Probability Density Functions as Characteristics of Undetermined Process Parameters

- –

- The first stage involves collecting time-study data. In the case of the shearer, the data should include the time it takes to traverse a selected section of the longwall (e.g., a section covering two powered roof support units). After accounting for the support unit spacing and performing the necessary calculations, the observed times are converted into shearer advance speeds. This data can be obtained from supervision and monitoring systems installed in shearers, as well as from operational data collection systems in the mine.

- –

- The second stage involves statistical analysis of these speed values (using, among others, goodness-of-fit tests), which leads to the derivation of a probability density function as an undetermined characteristic of the shearer’s advance speed.

2. Materials and Methods

2.1. Study Site and Data Collection

2.2. Data Preprocessing and Statistical Analysis

2.3. Stochastic Modeling Approach

- Model 1: Identification of the probability distribution of output obtained from longwall faces.

- Model 2: Stochastic model of coal output from a longwall face using unidirectional shearer-based mining technology.

- Model 3: Shift output characteristic accounting for changes in longwall face crew composition.

2.3.1. Identification of the Probability Distribution of Output Obtained from Longwall Faces

- –

- is the elementary probability density function of the variable , representing the time required for the shearer to cut a 1 m section;

- –

- are the elementary probability density functions for tasks or operations performed simultaneously (in parallel) with the cutting shearer, whose execution affects the shearer’s advance.

2.3.2. Stochastic Model of Coal Output from a Longwall Face Using Unidirectional Shearer-Based Mining Technology

2.3.3. Shift Output Characteristic Accounting for Changes in Longwall Face Crew Composition

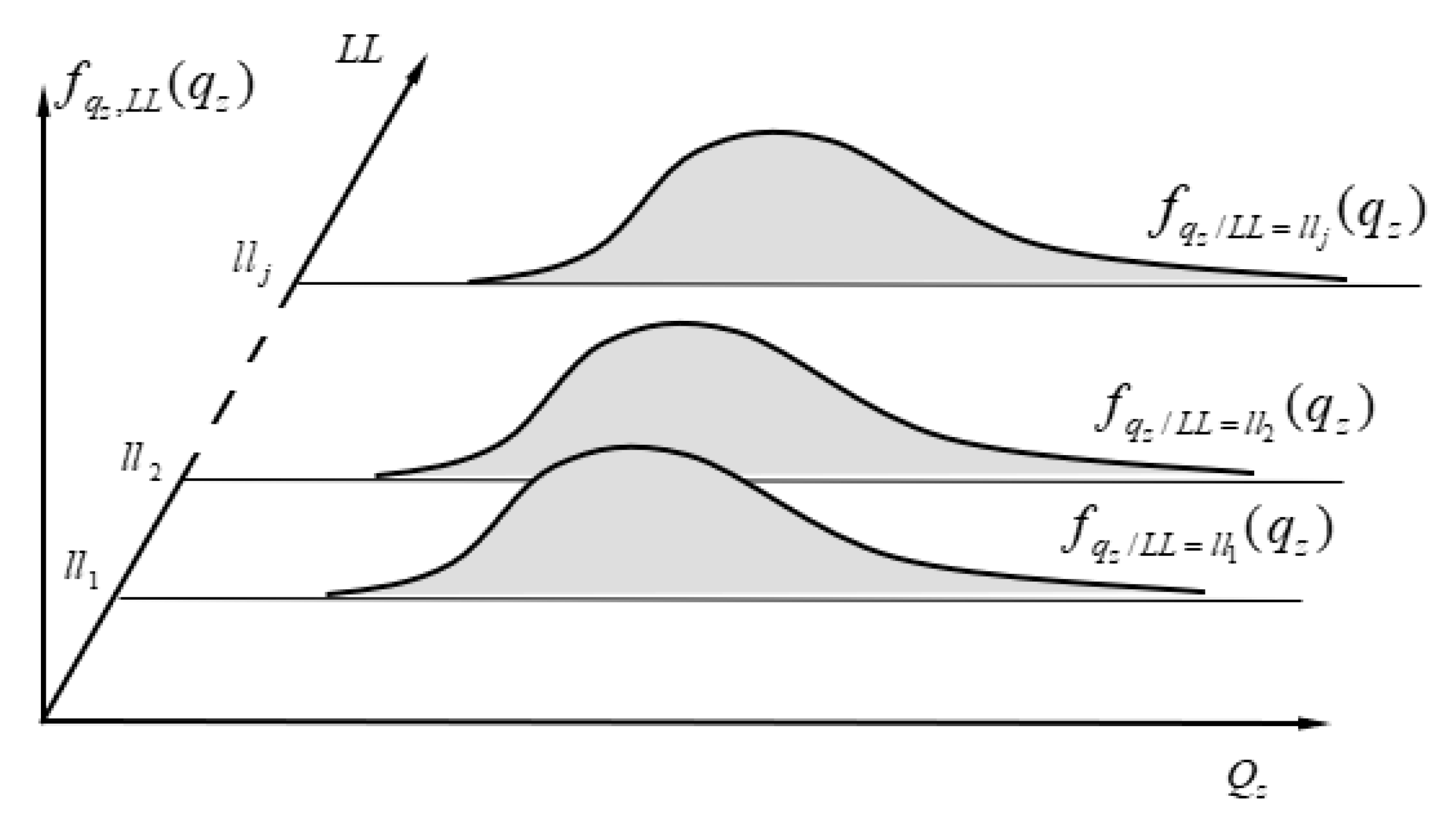

- —marginal probability density function of the variable Qz (shift output);

- —probability that the random variable (crew composition) takes the value .

2.4. Model Validation

- Model 1: Evaluates delay probability by comparing PDFs of the shearer vs. concurrent tasks. Delay probability is expressed as dla każdego zachodzi zależność . The idea of model 1 is presented in Figure 6.

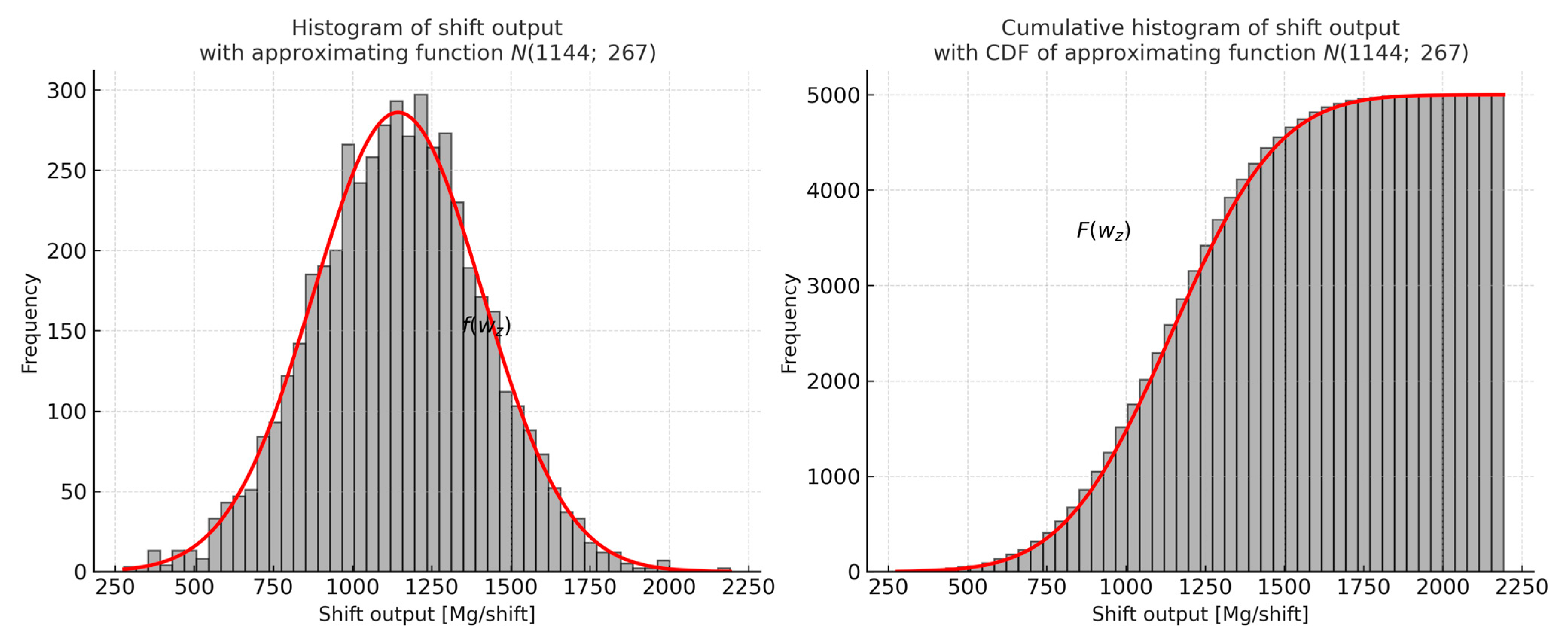

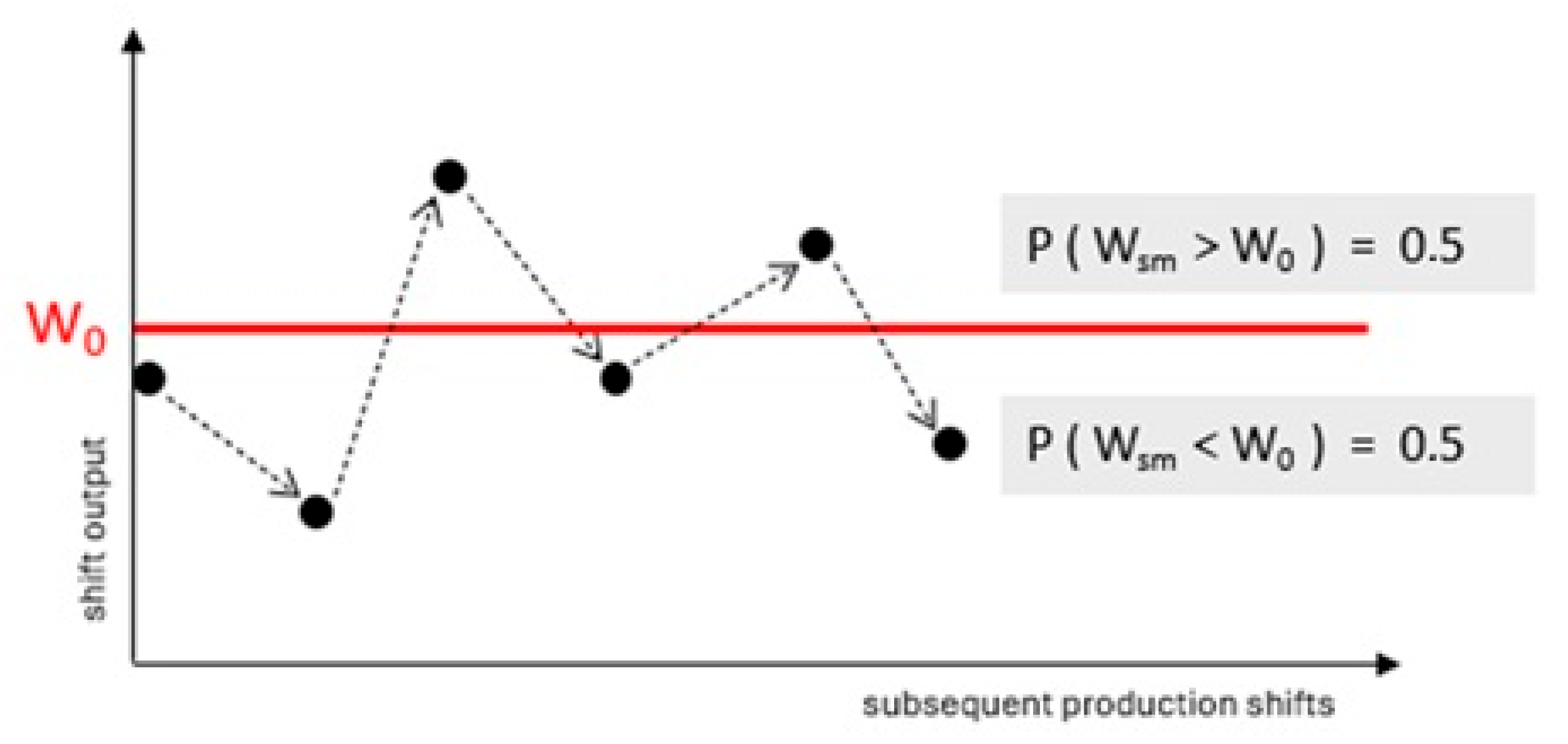

- Model 2: A normal distribution N(1144; 267) describes shift-based output. The cumulative probability corresponds to the median output Mg/shift.

- Model 3: Uses conditional PDFs for each crew composition (LL variants) and computes marginal PDF as

3. Results

3.1. Model 1

3.2. Model 2

3.3. Model 3

4. Discussion

5. Conclusions

- –

- Mining production variability can be effectively described using probabilistic approaches rather than deterministic or regression-based models.

- –

- PDFs derived from field data provide a realistic basis for predicting and planning production.

- –

- The use of conditional and marginal distributions enables analysis of crew impacts and shift variability.

- –

- Production volume is a key element essential to the decision-making process—the proposed method allows for the appropriate preparation of both preparatory and subsequent processing processes.

- –

- Replacing deterministic variables with random variables allows for the simultaneous consideration of multiple factors influencing the duration of an activity in the form of a probability density function. The probability criterion for achieving the assumed module completion time used in the method allows for rational staffing selection, which supports management processes.

- –

- The use of the probability criterion in the method for determining staffing at the longwall face of hard coal mines allows for the stochastic nature of the production process carried out at this face to be taken into account, contributing to effective decision-making.

- –

- It is also possible to support predictive maintenance of machinery.

- –

- Optimization of the mining and logistics process based on current conditions.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Martin, H.; Paschedag, U. Getting up to Speed; World Coal 2005, No. 4; Palladian Publications Ltd.: Farnham, UK, 2005. [Google Scholar]

- Piechota, S. Technika Podziemnej Eksploatacji Złóż i Likwidacji Kopalń; AGH Uczelnianie Wydawnictwa Naukowo-Dydaktyczne: Kraków, Poland, 2008. [Google Scholar]

- Chudek, M.; Wilczyński, S.; Żyliński, R. Podstawy Górnictwa; Wydawnictwo Śląsk: Katowice, Poland, 1979. [Google Scholar]

- Poradnik Górnika, Vol 2; Wydawnictwo Śląsk: Katowice, Poland, 1975.

- Jaszczuk, M.; Kozieł, A. Scenariusze Rozwoju Technologicznego Mechanizacji Podstawowych Procesów Produkcyjnych w Górnictwie Węgla Kamiennego; Monografia, Seria; Innowacyjne Techniki i Technologie Mechanizacyjne: Gliwice, Poland, 2008; Available online: https://sbc.org.pl/Content/817685/Monografia%20%20nr%201.pdf (accessed on 15 September 2025).

- Magda, R.; Woźny, T.; Kowalczyk, B.; Głodzik, S.; Gryglik, D. Racjonalizacja Modelu i Wielkości Kopalni Węgla Kamiennego w Warunkach Gospodarczych Początku XXI Wieku; Nauka i Technika, Uczelniane Wydawnictwa Naukowo-Dydaktyczne: Kraków, Poland, 2002. [Google Scholar]

- Snopkowski, R. Metoda Identyfikacji Rozkładu Prawdopodobieństwa Wydobycia Uzyskiwanego z Przodków Ścianowych Kopalń Węgla Kamiennego; Rozprawy Monografie, AGH: Kraków, Poland, 2000. [Google Scholar]

- Rimélé, A.; Dimitrakopoulos, R.; Gamache, M. A Dynamic Stochastic Programming Approach for Open-Pit Mine Planning with Geological and Commodity Price Uncertainty. Resour. Policy 2020, 65, 101570. [Google Scholar] [CrossRef]

- Dimitrakopoulos, R.; Lamghari, A. Simultaneous Stochastic Optimization of Mining Complexes—Mineral Value Chains: An Overview of Concepts, Examples and Comparisons. Int. J. Min. Reclam. Environ. 2022, 36, 443–460. [Google Scholar] [CrossRef]

- Jiang, Y.; Dimitrakopoulos, R. An Application of Simultaneous Stochastic Optimisation on an Open-Pit Copper Mining Complex with Supply, Recovery, and Market Uncertainties. Int. J. Min. Reclam. Environ. 2024, 39, 74–92. [Google Scholar] [CrossRef]

- van Eyk, L.; Heyns, P.S. A Framework to Define, Design and Construct Digital Twins in the Mining Industry. Comput. Ind. Eng. 2025, 200, 110805. [Google Scholar] [CrossRef]

- Brzychczy, E.; Żuber, A.; van der Aalst, W.M.P. Process Mining of Mining Processes: Analyzing Longwall Coal Excavation Using Event Data. IEEE Trans. Syst. Man Cybern. 2024, 54, 2723–2734. [Google Scholar] [CrossRef]

- Szrek, J.; Jakubiak, J.; Zimroz, R. A Mobile Robot-Based System for Automatic Inspection of Belt Conveyors in Mining Industry. Energies 2022, 15, 327. [Google Scholar] [CrossRef]

- Dąbek, P.; Wróblewski, A.; Wodecki, J.; Bortnowski, P.; Ozdoba, M.; Król, R.; Zimroz, R. Application of the Methods of Monitoring and Detecting the Belt Mistracking in Laboratory Conditions. Appl. Sci. 2023, 13, 2111. [Google Scholar] [CrossRef]

- Dance, A.; Valery, W.; Jankovic, A.; La Rosa, D.; Esen, S. Maintaining the Benefit—How to Ensure Mine to Mill Continues to Work for You; Australasian Institute of Mining and Metallurgy Publication Series; 2007; pp. 215–222. Available online: https://www.scopus.com/pages/publications/58049176805?inward (accessed on 15 September 2025).

- Gackowiec, P.; Podobińska-Staniec, M.; Brzychczy, E.; Kühlbach, C.; Özver, T. Review of Key Performance Indicators for Process Monitoring in the Mining Industry. Energies 2020, 13, 5169. [Google Scholar] [CrossRef]

- Korski, J.; Tobór-Osadnik, K.; Wyganowska, M. Mining machines effectiveness and OEE Indi-cator. IOP Conf. Ser. Mater. Sci. Eng. 2017, 268. [Google Scholar]

- Czaplicka-Kolarz, K.; Burchart-Korol, D.; Turek, M.; Borkowski, W. Model of Eco-Efficiency Assessment of Mining Production Processes. Arch. Min. Sci. 2015, 60, 477–486. [Google Scholar] [CrossRef]

- Fourie, H. Improvement in the overall efficiency of mining equipment: A case study. J. South. Afr. Inst. Min. Metall. 2016, 116, 275–281. [Google Scholar] [CrossRef]

- Singh, A.; Kumar, D.; Hötzel, J. IoT Based information and communication system for en-hancing underground mines safety and productivity: Genesis, taxonomy and open issues. Ad. Hoc. Netw. 2018, 78, 115–129. [Google Scholar] [CrossRef]

- Lin, B.; Wu, W.; Song, M. Industry 4.0: Driving factors and impacts on firm’s performance: An empirical study on China’s manufacturing industry. Ann. Oper. Res. 2019, 329, 47–67. [Google Scholar] [CrossRef]

- Napieraj, A.; Snopkowski, R. Method of the production cycle duration time modeling within hard coal longwall faces. Arch. Min. Sci. 2012, 57, 121–138. [Google Scholar] [CrossRef]

- Sukiennik, M.; Snopkowski, R. Longwall Face Crew Selection with Respect to Stochastic Character of the Production Process—Part 2—Calculation Example. Arch. Min. Sci. 2013, 58, 227–240. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Longwall length | 220 m |

| Longwall height | 4.0–4.4 m |

| Longwall stopway | 1700 m |

| Maximal web | 0.8 m |

| Longwall inclination | 0–2° |

| Thickness of the coal layer in the roof | up to 0.3 m |

| Thickness of the coal layer in the floor | up to 0.2 m |

| Exploitation depth | 710–690 m |

| Parameters | Value |

|---|---|

| Coal seam thickness | 4.0–4.4 m |

| Roof | 0.0–6.2 m clayey shale |

| Basic roof | 37.7–43.2 m multi-grained sandstones |

| Coal seam floor | 1.5–2.4 m clayey shale |

| Coal type | 31.2 |

| Coal specific weight (mean) | 1.35 g/m3 |

| Parameter | Wartość |

|---|---|

| Coal dust explosion hazard | class “A” |

| Methane threat | does not occur |

| Threat of gas and rock outbursts | does not occur |

| Radiation hazard | does not occur |

| Fire hazard | group V |

| Rock burst hazard | level I |

| Water hazards | level I |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Snopkowski, R.; Sukiennik, M.; Napieraj, A. The Stochastic Nature of the Mining Production Process—Modeling of Processes in Deep Hard Coal Mines. Energies 2025, 18, 5383. https://doi.org/10.3390/en18205383

Snopkowski R, Sukiennik M, Napieraj A. The Stochastic Nature of the Mining Production Process—Modeling of Processes in Deep Hard Coal Mines. Energies. 2025; 18(20):5383. https://doi.org/10.3390/en18205383

Chicago/Turabian StyleSnopkowski, Ryszard, Marta Sukiennik, and Aneta Napieraj. 2025. "The Stochastic Nature of the Mining Production Process—Modeling of Processes in Deep Hard Coal Mines" Energies 18, no. 20: 5383. https://doi.org/10.3390/en18205383

APA StyleSnopkowski, R., Sukiennik, M., & Napieraj, A. (2025). The Stochastic Nature of the Mining Production Process—Modeling of Processes in Deep Hard Coal Mines. Energies, 18(20), 5383. https://doi.org/10.3390/en18205383