3.1.1. Supercritical Water Gasification

Initial experiments with SCWG began in the late 1970s–early 1980s, when two researchers, Thomason and Modell, started realizing its potential for wet biomass and waste treatment, since wet biomass did not need to be dried before processing, which could be a key economic and technical advantage [

70].

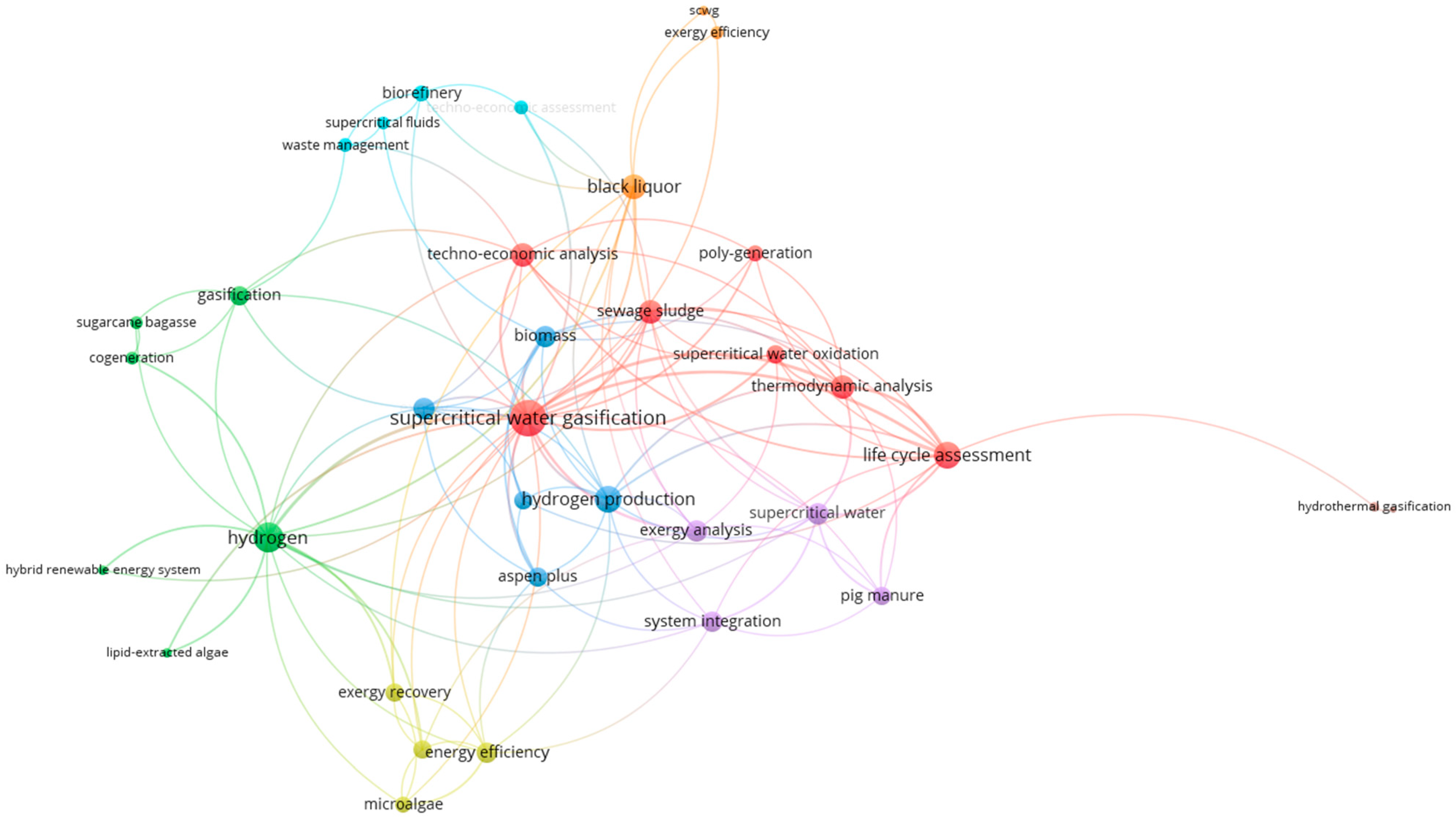

SCWG is a promising thermochemical process that employs water above its critical point (374 °C and 22.1 MPa) as both a reaction medium and a catalyst to convert wet biomass and organic waste into syngas [

71,

72]. Compared to other conversion techniques, SCWG offers higher gasification efficiency and a greater hydrogen yield in the resulting gas products. Importantly, it also minimizes the formation of harmful emissions such as sulfur oxides (SO

x) and nitrogen oxides (NO

x) [

73,

74,

75,

76,

77].

Many factors directly affect the gasification process, including temperature, pressure, organic matter concentration, and feed flow rate, among others.

Table 5 shows how some factors, such as temperature, pressure, feed concentration, and the utilization of a catalyst, can affect the output of the SCWG process.

The composition and structure of the biomass feedstock play a critical role in determining the efficiency, gas yield, and product distribution of the SCWG process.

In this systematic review, the selected articles were categorized based on the types of biomass feedstock used.

3.1.2. Lignocellulosic Biomass

Lignocellulosic biomass is an abundant and renewable resource from plants, which are mainly composed of polysaccharides and lignin. Due to its availability and composition, it holds significant potential as a sustainable alternative to fossil fuels [

78]. Numerous studies have explored its application in supercritical water gasification (SCWG) to produce cleaner syngas, particularly hydrogen-rich gas. Biomass types such as cotton stalks [

27,

45], coconut shells [

42], straw [

51], fir bark [

54], corn stover [

34], bagasse [

13,

36,

69], tomato residues [

44], corn stalks [

68], and ginseng roots [

47] have been examined for energy generation via SCWG.

Aminov et al. [

27] and Aminov et al. [

45] investigated various conversion scenarios for transforming cotton stalks into power and hydrogen. Their findings revealed that integrating SCWG with solar energy resulted in the highest power output (51.48 MW) and superior energy performance.

Sheshdeh et al. [

36], Safari et al. [

13], and Albarelli et al. [

69] focused on valorizing sugarcane bagasse through SCWG. Sheshdeh et al. [

36] assessed five conversion scenarios in Iran using life cycle analysis and found that SCWG integrated systems, especially with solid oxide fuel cells (SOFCs) or combined cycle gas turbines, were environmentally preferable due to higher hydrogen yields. The SCWG–SOFC integration showed the highest energy output (459.51 kWh/functional unit) by utilizing all internal heat. Safari et al. [

13] reported that processing 200 kg of bagasse with 800 kg of water at 700 °C and 300 bar yielded 56 kW of electricity and 8.55 kg of hydrogen, achieving a net efficiency of 44%. Albarelli et al. [

69] employed multi-objective optimization (Pareto points) to determine optimal plant configurations. They found increased energy and exergy efficiency with the increase in bagasse amount, albeit at higher investment costs.

Chen et al. [

34] evaluated the SCWG of corn stover and observed maximum standalone energy and exergy efficiencies of 36.8% and 39.5%, respectively. Integration with an organic Rankine cycle increased energy efficiency to 45.97%. Their study also highlighted the potential of carbon capture and storage (CCS) to reduce global warming potential (GWP) and acidification potential (AP) impacts.

Wang and Jin [

42] analyzed a poly-generation SCWG system using coconut shells to produce gas, biochar, heat, and electricity. The system achieved energy and exergy efficiencies of 60.9% and 58.3%, respectively, under optimal conditions (550 °C, 33% biomass concentration, and 900 kg/h water flow).

Liu et al. [

51] proposed a two-stage SCWG system for straw to boost hydrogen production and efficiency. Their model achieved energy and exergy efficiencies of 54.9% and 56.2%, respectively, which improved to 57.7% and 59.3% with an added organic Rankine cycle. The addition of a CCS reduced carbon emissions by 86.4%.

Ge et al. [

54] conducted a thermodynamic and economic analysis of SCWG using fir bark for poly-generation. With an in situ hydrogen separation (ISHS) rate of 40%, they achieved energy and exergy efficiencies of 73.34% and 72.38% when focusing on hydrogen and electricity. Coupling the process with CCS further reduced the GWP to 5.03 kg CO

2-eq.

Paksung et al. [

44] explored SCWG of tomato residues in rural Japan (Kita-Hiroshima), considering energy, environmental, and economic aspects. Results showed that 1 kg of feedstock could yield 10.45 MJ of energy, supplying 76 MWh of electricity and reducing CO

2 emissions by 13.6 tons compared to natural gas.

Wang et al. [

68] analyzed the SCWG of corn stalk through thermodynamic and life cycle assessment. The process achieved energy and exergy efficiencies of 45.23% and 39.14%, respectively. They found that increasing temperature while reducing slurry concentration and pressure improved environmental performance.

Lastly, Albarelli et al. [

47] studied the SCWG of leftover Brazilian ginseng roots, incorporating energetic, economic, and environmental optimization via Pareto analysis. They reported energy efficiencies above 50%, supporting SCWG as a viable alternative to fossil fuels.

In addition to conventional energy and exergy analysis, environmental impact assessment was also focused on some of these studies. They highlight the importance of CCS as a method to reduce environmental impacts.

Common limitations across these studies include dependency on operating conditions (temperature, pressure, and feed concentration), lack of experimental data, high energy requirements, economic feasibility concerns and investment barriers, and scalability challenges due to system complexity. Additionally, feedstock availability may pose a significant challenge for experimental analysis.

Table 6 presents the optimal operational parameters and main technical limitations for each biomass. It is possible to verify that most of the studies use temperature values between 600 and 700 °C, and pressure between 25 and 30 MPa. These conditions are optimal for maximizing energy efficiency. Reported efficiencies improve substantially when SCWG is integrated with other technologies (solid oxide fuel cells, organic Rankine cycle, or CCS). However, major technical limitations are also highlighted, such as high energy requirements, significant exergy losses in heating and cooling units, complexity of scaling up to industrial levels, and economic barriers due to equipment costs and the logistics of feedstock supply and transportation. Overall, lignocellulosic biomass has strong potential given its abundance, but its feasibility depends heavily on system integration and economic optimization.

3.1.3. Wet Biomass

Wet biomass refers to biological material that contains a significant amount of water. Several studies were conducted to assess the behavior of wet biomass for energy production. Materials such as sewage sludge [

30,

33,

37,

57], aqueous glucose solution [

25,

41,

65], organic wastewater [

39], zootechnical sludge [

58], and kitchen waste [

46,

60,

67] have been used.

Sewage sludge presents a significant environmental challenge, including waste management and environmental pollution issues [

79,

80,

81]. Recent studies have demonstrated the feasibility of SCWG for sewage sludge with promising hydrogen yields and energy efficiencies. Ochieng et al. [

30] compared SCWG with anaerobic digestion (AD), finding SCWG more energy efficient (73.2% vs. 25.8%), though limited by higher costs (1.7 times higher than AD) and resource constraints. Hu et al. [

33] integrated SCWG with CCS, achieving energy and exergy efficiencies of 46.51% and 44.74%, respectively, and a low GWP (0.31 kg CO

2-eq), but the model lacked methane management considerations and relied on a simplified model. Shi et al. [

57] found SCWG had the highest energy and exergy efficiency among several technologies, though it had the worst environmental performance due to the absence of CCS. Zhang et al. [

37] explored a combined SCWG and supercritical water oxidation system, achieving modest energy and exergy efficiencies (~22%), but with high energy requirements and no economic and environmental analysis.

Han [

60] proposed a hybrid SCWG-solar system for remote communities in Fukushima, generating 47.3 MWh of electricity and 2.6 tons of hydrogen per year, with a CO

2 reduction of 21 tons; however, the availability of feed was the biggest limitation. Similarly, Takatsu and Farzaneh [

46] analyzed an SCWG–solar electrolysis system for kitchen waste, estimating an energy production of 47.3 MWh, with a levelized cost of ~56 JPY/kWh for both off-grid mode and grid-tied mode, but lacking experimental validation and environmental assessments.

Yan et al. [

67] tested an integrated hydrothermal carbonization–SCWG system, achieving 27.19% energy efficiency and a 61.77% return on energy investment (higher than standalone SCWG), though it lacked environmental analysis, and the economic analysis was limited (lacks transportation, storage, and some other costs that can highly influence the economic viability of the system).

Qi et al. [

39] studied SCWG integrated with multi-effect evaporation for organic wastewater treatment, with energy efficiency up to 44.88%, exergy efficiency up to 33.89% and a reduced GWP of 5.27 kg CO

2-eq/kg H

2 using CCS. However, the system was energy-intensive and relied on simplified models.

Glucose is commonly used as a model compound for biomass due to experimental limitations with real feedstock [

82]. Recalde et al. [

25] found that SCWG integrated with a reversible solid oxide cell (electrolysis mode or fuel cell mode) presented higher energy and exergy efficiencies (89% and 73%, respectively) than fuel cell mode (42% and 49%, respectively). However, some limitations are needed to reduce the exergy losses, high energy requirement of the system, and scale-up feasibility. In another study, Recalde et al. [

65] also performed a thermodynamic analysis of an integrated SCWG with a solid oxide fuel cell system for the conversion of glucose. Their main findings are that the combined system can achieve energy efficiency and exergy efficiency of 63% and 52%, respectively, although full conversion was only possible under specific conditions (low feed concentration and high temperature). Ondze et al. [

41] evaluated SCWG of glucose using adiabatic and isothermal systems, achieving up to 85% energy efficiency for the adiabatic system and up to 71% energy efficiency for the isothermal system. However, results were highly sensitive to temperature and operational parameters.

Molino et al. [

58] compared SCWG with AD for treating zootechnical sludge. SCWG, with a supercritical steam turbine, showed the highest power output and significantly reduced greenhouse gas emissions. Integration with AD further improved power generation. Yet, the studies relied on simplified models and lacked experimental data.

Table 7 illustrates the optimal operational parameters of SCWG systems using wet biomass such as sewage sludge, aqueous glucose solutions, kitchen waste, zootechnical sludge, and organic wastewater. Operating conditions typically range between 550 and 750 °C and around 25 MPa. Wet biomass is an attractive feedstock because it eliminates the need for drying, which is a costly step in conventional gasification. Despite this promise, wet biomass SCWG faces critical drawbacks. The high water content requires substantial external heat input, making most systems not thermally self-sufficient. Models are often oversimplified, neglecting methane management, waste heat recovery, and transportation logistics. Additionally, economic analyses are limited, with key costs such as storage and distribution often ignored.

3.1.4. Industrial Waste

The pulp and paper industry produces waste streams with low energy value but significant potential for energy and material recovery [

83,

84,

85].

Several studies have explored supercritical water gasification (SCWG) for treating black liquor [

14,

24,

38,

50,

55,

59,

64] and oil palm-derived wastes [

49,

63], with promising results in terms of hydrogen and power generation.

Qiu et al. [

24] conducted a thermodynamic analysis of SCWG with an integrated organic Rankine cycle for black liquor treatment. Under optimal conditions, the system achieved 3342 kW of power and 18.65% energy efficiency. Adding a supercritical CO

2 cycle provided an extra 988.6 kW. Limitations included feed property assumptions, strong dependence on operating conditions, and high energy input. Qi et al. [

59] assessed an auto-thermal SCWG system with a discharge salt utilization unit, reaching energy and exergy efficiencies of 88.16% and 64.10%, respectively. GWP decreased with higher temperatures and lower feed concentrations. However, the system faced operational challenges (discharge salt unit) and modeling simplifications. Liang et al. [

64] compared SCWG and SCWO, finding SCWG superior in energy (41.53%) and exergy efficiency (38.25%) with lower GWP. Yet, the study lacked detailed environmental analysis, economic viability, and heat integration network improvements. Magdeldin and Jarvinen [

55] found that increasing the SCWG system temperature (450 °C to 600 °C) reduced energy output (1.78 MJ to 1.23 MJ). From an economic perspective, the SCWG system could reduce the minimum selling price of pulp by 22%. Limitations included high energy requirements and a lack of environmental assessment.

Darmawan et al. [

14] combined SCWG with syngas chemical looping, achieving 82% net energy efficiency and ~20 MW power output. However, energy losses and model simplifications were not fully addressed. Cao et al. [

38] investigated integrating a black liquor evaporator into SCWG. While exergy efficiency improved, energy efficiency declined with the usage of the evaporator. The study lacked experimental data and discussion on byproducts like CO and CO

2. Cao et al. [

50] simulated a pulping–SCWG system and found air to be a more energy-efficient oxidant than oxygen, with energy outputs of 82.5 MW and 15.9 MW, respectively. System scale-up slightly improved energy efficiency. Key limitations were model simplifications, high energy demand, and operating condition dependency.

Ruya et al. [

49] analyzed an autothermal SCWG process for oil palm waste, reporting up to 70% energy efficiency without a reformer, and 58.3% with one. Limitations included operational dependency, lack of experimental data, and missing environmental impact analysis. Ajiwibowo et al. [

63] integrated SCWG with syngas chemical looping and ammonia synthesis for oil palm residues. Energy efficiency peaked at 29.3% at 35 bar pressure, but power output was lower than energy consumed at low feed concentrations. Challenges included high heating demand and a lack of experimental validation and environmental evaluation.

Table 8 shows the optimal operational parameters of SCWG applied to the industrial residues. The typical operational range is 600–750 °C and 23–40 MPa, with some exceptions. However, the table also reveals persistent limitations. High energy demand is the most common issue, compounded by the operational challenges of handling salts in black liquor and the dependence on thermodynamic assumptions in simulations. Environmental and economic assessments are often incomplete or missing altogether, which limits the reliability of claims regarding industrial feasibility.

3.1.5. Algal Biomass

Among the potential biomass feedstocks, microalgae have shown excellent potential for producing high-value biofuels from a synergetic approach [

75,

86]. Several studies have explored the use of supercritical water gasification (SCWG) for microalgae conversion, particularly in integrated and solar-assisted systems. Onigbajumo et al. [

22] evaluated a solar-driven SCWG system with varying heat exchanger configurations. The optimal setup (with two heat exchangers) achieved high overall energy efficiency (81.26%), thermal energy savings (56.84 MW), intrinsic exergy efficiency (75.44%), and carbon efficiency (98.68%). However, the study was limited by dependency on operating conditions, high costs, and a lack of environmental assessment. Liu et al. [

43] conducted a thermodynamic and environmental analysis of a solar-driven SCWG system for ammonia synthesis and power generation from algae. The system achieved 33.31% energy efficiency and 44.27% exergy efficiency, with a GWP of 0.69 kg CO

2-eq/kg NH

3 and a human health impact indicator of 8.17 × 10

−5. Limitations included model simplifications, high energy demand, lack of economic viability analysis, lack of experimental data, and incomplete environmental analysis.

Nurdiawati et al. [

23] and Nurdiawati et al. [

35] proposed a novel SCWG system integrated with syngas chemical looping for microalgae conversion. Reported efficiencies ranged from 13.3 to 13.7% for power generation, 42.5–45.3% for hydrogen production, and 55.8–59.1% for total energy. However, both studies highlighted challenges related to high implementation costs, lack of experimental validation, and sensitivity to operating conditions.

Aziz M. [

53,

66] developed two integrated systems: one combining SCWG with hydrogen separation, hydrogenation, and a combined cycle, and another with SCWG and a combined cycle for power generation. The systems achieved energy efficiencies of over 60% and 40%, and net electricity outputs of approximately 200 MW and 300 MW, respectively. Key limitations included operational dependency and the absence of economic and environmental analyses.

Rahbari et al. [

32] analyzed an algal SCWG system integrated with photovoltaic-powered electrolysis and steam methane reforming. Energy and exergy efficiencies reached 71% and 45%, respectively, with minimal impact from varying reforming technologies (autothermal reforming and partial oxidation, and dry reforming). Still, the model simplifications, lack of environmental data, and operating condition sensitivity were noted as limitations.

Magdeldin et al. [

56] presented findings from collaborative work on lipid-extracted algae. They concluded that the system found the best performance (at 450 °C and 18 wt% concentration), resulting in energy and exergy efficiencies of 66.46% and 57.39%, respectively. Limitations are the disparity of values with experimental data due to thermodynamic assumptions and the lack of environmental and economic analysis. Magdeldin et al. [

61] showed that integrating SCWG with steam reforming raised efficiencies from 34.18% to 46.17% (energy) and 28.94% to 41.44% (exergy) when compared with the standalone SCWG. Limitations are the dependency on operating conditions, the heat exchanger network needs improvement, and the lack of environmental analysis and experimental data.

Table 9 presents the operating conditions and limitations of SCWG systems treating algal biomass, including both microalgae and lipid-extracted algae. Most studies operate between 600 and 700 °C and 22–28 MPa, though some use lower temperatures. Algal biomass shows high potential in terms of efficiency, especially when integrated with solar-driven and hybrid SCWG systems. Nevertheless, the table also highlights several barriers. System performance is extremely sensitive to operating conditions and reactor design. High energy demand, heat losses, and weak reactor configurations remain obstacles. Moreover, environmental and economic assessments are rarely included, leaving uncertainty about scalability and sustainability.

3.1.6. Agricultural Waste

Agricultural waste is a significant but underutilized resource for renewable energy production. These residues are generated in large volumes and often pose environmental and disposal challenges [

87]. Supercritical water gasification (SCWG) has emerged as a promising technology for converting various agricultural waste into valuable energy products, and several studies have explored its feasibility.

Liu et al. [

48] conducted a thermodynamic and environmental assessment of an auto-thermal SCWG system using chicken manure for ammonia and power production. Their system achieved an energy efficiency of 62.34% and an exergy efficiency of 53.75%, producing 1677.1 kW of net power and 3372.11 kg/h of ammonia. Incorporating CCS reduced the GWP from 4.74 to 3.31 kg CO

2-eq/kg NH

3. However, limitations included the need for feedstock pre-treatment, dependence on operating conditions, and the absence of an economic evaluation. Ma et al. [

28] evaluated four integrated SCWG processes for poultry litter treatment (two focused on energy production, one on hydrogen, and one combining both). The hybrid system for hydrogen and power generation achieved the highest energy and exergy efficiencies (37% and 44%, respectively) when electricity demand was a priority. Limitations involved model simplifications, a lack of economic analysis, and performance sensitivity due to heat losses.

Studies by Wang et al. [

62], Ren et al. [

31], and Guo et al. [

40] focused on the thermodynamic analysis of SCWG of pig manure. Wang et al. [

62] presented a system with energy efficiency exceeding 82%. With CCS, GWP was reduced to 7.4 kg CO

2 per ton of steam. Ren et al. [

31] proposed an auto-thermal system with waste heat recovery, achieving 79.85% energy efficiency and a low GWP of 1.73 kg CO

2-eq/kg H

2. Guo et al. [

40] reported energy and exergy efficiencies of 36.58% and 40.08%, respectively, under optimal conditions. Common limitations across these studies included a lack of economic analysis, incomplete environmental assessments, limited experimental validation, and simplified modeling assumptions.

Molino et al. [

26] combined anaerobic digestion (AD) and SCWG for treating buffalo manure and maize silage. Their experimental study in a full-scale AD plant revealed that integrating SCWG with AD produced 12,174 kWh/day over a 20-day hydraulic retention time (HRT) compared to 12,446 kWh/day from standalone AD at a 35-day HRT. While the combined system demonstrated energy sustainability, it raised environmental concerns. Noted limitations included the need for SCWG process optimization and the absence of detailed economic and environmental analyses.

Table 10 summarizes SCWG studies where agricultural residues were used. Optimal conditions typically revolve around 620 °C and 25 MPa. These feedstocks are widely available and offer an important pathway for decentralized energy systems in rural areas. However, technical limitations are evident. Tar and char formation can cause operational issues such as clogging, while high exergy losses and energy demands persist. Most studies rely on simplified models, with limited experimental validation and almost no detailed economic or environmental analysis. Despite these challenges, agricultural residues remain one of the most practical feedstock categories due to their availability and potential for climate mitigation in rural contexts.

3.1.7. Mixture

Some studies have explored the integration of different biomass feedstocks in SCWG systems to enhance energy recovery and diversify input sources. Ochieng and Sarker [

21] investigated the supercritical water gasification of sewage sludge combined with fast pyrolysis of wood residues (wood chips, birch, spruce, and pinewood) for the co-production of hydrogen, power, and heat. Their energy analysis showed that under optimal conditions, the integrated system produced 684 kW of power, achieving an energy efficiency of 61.2% and an exergy efficiency of 44.9%.

Macri et al. [

52] analyzed the SCWG performance using a diverse feedstock mix, including almond shells, digestate from wastewater treatment, algae, and manure sludge. Their findings indicated similar energetic behavior among almond shells, algae, and manure sludge, suggesting a degree of interchangeability in system performance across these biomass types.

Albarelli et al. [

29] conducted a thermo-economic and environmental evaluation of two biomass extraction technologies (supercritical fluid extraction and low-pressure solvent extraction) integrated with an SCWG system. Their focus was on lipid and protein extraction from wet microalgae and sugarcane bagasse. The sugarcane-based biorefinery produced 112.39 kWh per ton under standard conditions (t sc), which increased to 146.69 kWh/t sc with the addition of low-pressure solvent extraction during microalgae processing. This integration also improved economic performance, yielding a 7.15% increase in profitability when compared to a system without any extraction step.

Common limitations are a lack of experimental data, simplified models and assumptions, and sensitivity to operating conditions.

Table 11 shows the operating conditions for SCWG of mixed feedstocks. Typical operating conditions fall within 25–30 MPa, with some discrepancies in the value of temperature. Mixing different feedstocks has the potential to enhance the system flexibility, reducing the dependency on a single biomass source. However, the complexity of cross-feedstock interactions poses a major challenge. Ash behavior, salt precipitation, and syngas distribution are difficult to model accurately, and most studies rely on simplified assumptions. Moreover, high energy demand and economic evaluation are recurrent barriers.

3.1.8. Discussion and Implications

While multiple studies confirm that lignocellulosic biomass can be efficiently converted into a hydrogen-rich gas through SCWG, the reported energy and exergy efficiencies vary widely. For instance, Safari et al. [

13] reported 44% net efficiency for sugarcane bagasse, whereas Liu et al. [

51] achieved up to 59.3% efficiency for straw when coupled with an organic Rankine cycle. These differences underline the strong influence of system integration, such as coupling with solid oxide fuel cells, organic Rankine cycles, or CCS. However, the reliability of the simulation studies with limited experimental validation raises questions about the real-world performance of these systems. On the other hand, economic and scalability aspects are rarely considered, despite the investment and operational costs being important aspects to consider for lignocellulosic biomass that can be seasonal and geographically dispersed [

88].

Wet biomass represents, in theory, an ideal SCWG feedstock since it avoids costly drying processes. Studies report higher hydrogen yields and improved efficiencies compared to conventional treatment methods such as anaerobic digestion [

30,

58]. However, the energy efficiency is highly variable and dependent on whether the SCWG system is operated standalone or integrated with CCS, solar, or reversible fuel cells [

25,

33,

57]. Although these integrations show promise, most models presented simplify methane management, waste heat recovery, and transportation logistics, which might overestimate the performance of these systems. Another big concern regarding wet biomass (with high water content and low calorific value) is the need to be supplied with sufficient heat to reach reaction temperature, and it is difficult for the system to self-heat without an external heat source. Furthermore, economic viability is rarely addressed beyond preliminary levelized cost analyses, leaving some uncertainties about large-scale applications. Wet biomass could serve as a circular economy solution for the treatment of waste and energy recovery, but a comprehensive LCA and LCC analysis needs to be performed.

Industrial by-products like black liquor and oil palm residues have been explored as SCWG feedstocks, but most analyses are heavily dependent on thermodynamic assumptions, with little experimental validation of byproduct behavior and reactor performance. Moreover, economic and environmental analyses are often incomplete or missing, which weakens claims of industrial feasibility. Despite these limitations, the implications of the consistent energy recovery potential across diverse industrial waste streams suggest that SCWG could complement circular economy strategies for pulp, paper, and palm oil industries. The main implications are that experimental demonstrations and integrated heat and mass balance analysis are needed to validate these potential scenarios.

Microalgae and lipid-extracted algae are also promising SCWG feedstocks in the bio-refinery pathways, producing both hydrogen and high-value byproducts [

22,

43,

56]. However, findings are very sensitive to operational conditions and reactor design, and there is a considerable difference between simulations and experiments [

56].

Agricultural residues have shown promising energy and exergy efficiencies [

48,

62], and the integration with CCS significantly reduces GWP, confirming their role in low-carbon rural energy solutions. Still, most studies rely on simulation models without fully exploring the environmental and economic impacts of these systems, and experimental validation remains scarce. The availability and variability of agricultural waste composition also pose a challenge that has not been sufficiently addressed.

SCWG of mixed feedstocks offers flexibility and resilience by leveraging locally available resources [

21,

52]. Reported efficiencies are encouraging, but only a few studies explore this option due to its complexity, since cross-feedstock is not yet fully understood, particularly regarding ash behavior, salt precipitation, and gas yield distributions.

3.1.10. Future Work

Future research on SCWG should focus on several key areas to advance technology towards large-scale applications. One of the priorities is the development of stable and cost-effective catalysts that can be regenerated and applied across a wide range of biomass feedstocks. This will help reduce energy demand and improve conversion efficiency. In parallel, more comprehensive techno-economic analyses and standardized life cycle assessments are required to properly evaluate the feasibility and environmental performance of SCWG systems at different scales.

Another promising direction lies in system integration. Coupling SCWG with renewable energy sources such as solar or wind, as well as with complementary technologies including solid oxide fuel cells, organic Rankine cycles, and/or carbon capture and storage, can significantly enhance energy recovery and sustainability. Comparative studies that benchmark SCWG against pyrolysis, conventional gasification, and anaerobic digestion are also needed to clarify its role in the broader energy transition.

Moreover, the application of digital tools, including artificial intelligence (AI) and machine learning (ML), offers a promising but underexplored avenue for enhancing process control, efficiency, and scalability. Finally, moving beyond simulation and laboratory-scale experiments, future work should prioritize pilot- and industrial-scale demonstration projects to validate long-term performance, address engineering challenges, and establish the industrial feasibility of SCWG as a competitive biomass-to-energy technology.