Deep Reinforcement Learning-Based Optimization of Mobile Charging Station and Battery Recharging Under Grid Constraints

Abstract

1. Introduction

1.1. Motivation and Problem Statement

1.2. Related Work

1.3. Proposed Approach and Contributions

- A decision-making framework that schedules MCSs and EVs charging to maximize profits, reduce grid stress at peak hours, and address demand uncertainty using the DQN algorithm.

- Integration of PV with MCS as an auxiliary source to increase income and minimize reliance on the grid during peak consumption hours.

- Implementation of MCS battery swapping to efficiently respond to more EV charging requests and improve overall service performance.

- Analysis of the impact of MCS battery charging on grid constraints, and the introduction of a scheduling approach to ensure safe and efficient operation.

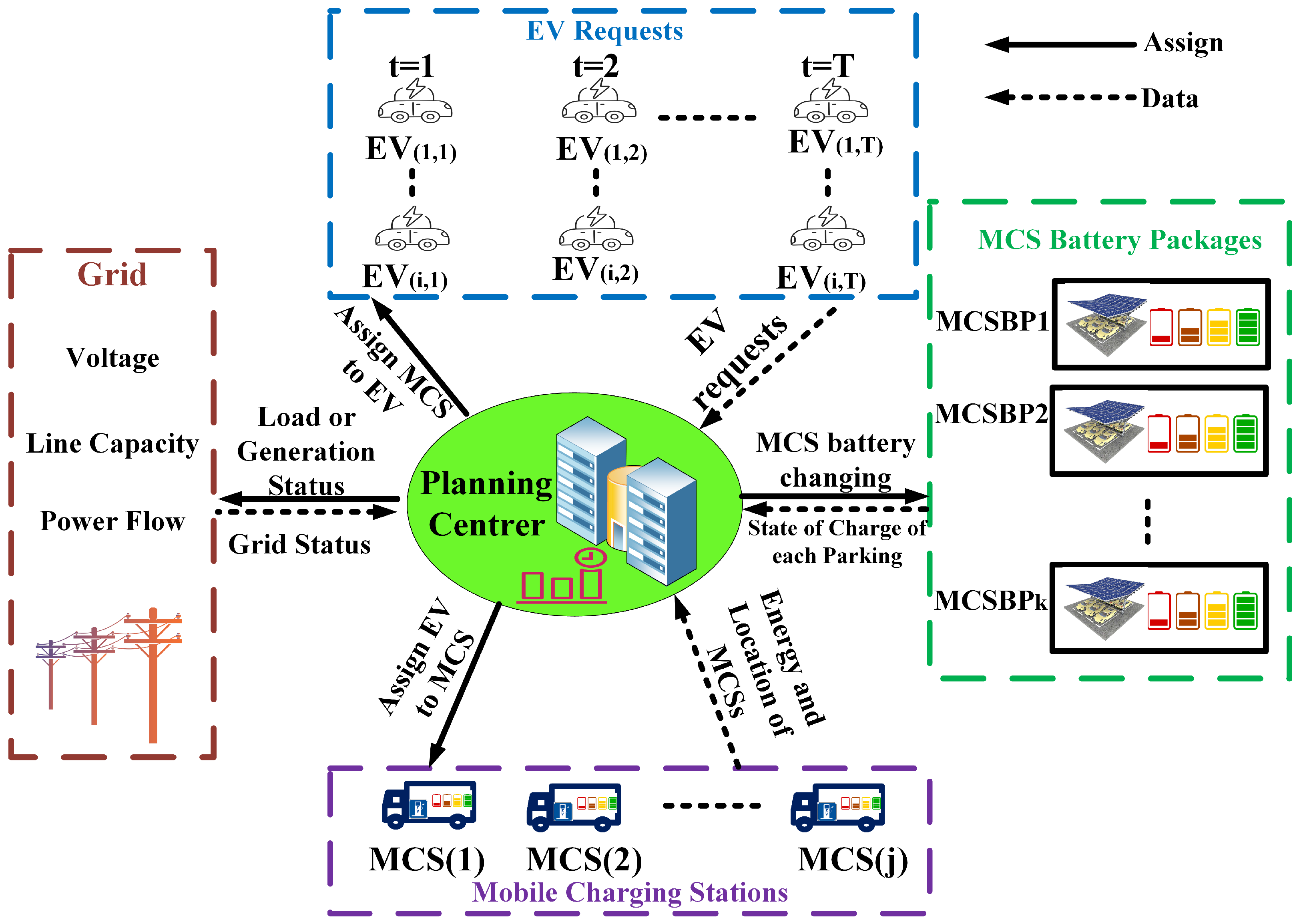

2. Overview

3. Mathematical Model

3.1. Optimizing the Distribution of MCSs to EV Charging Requests

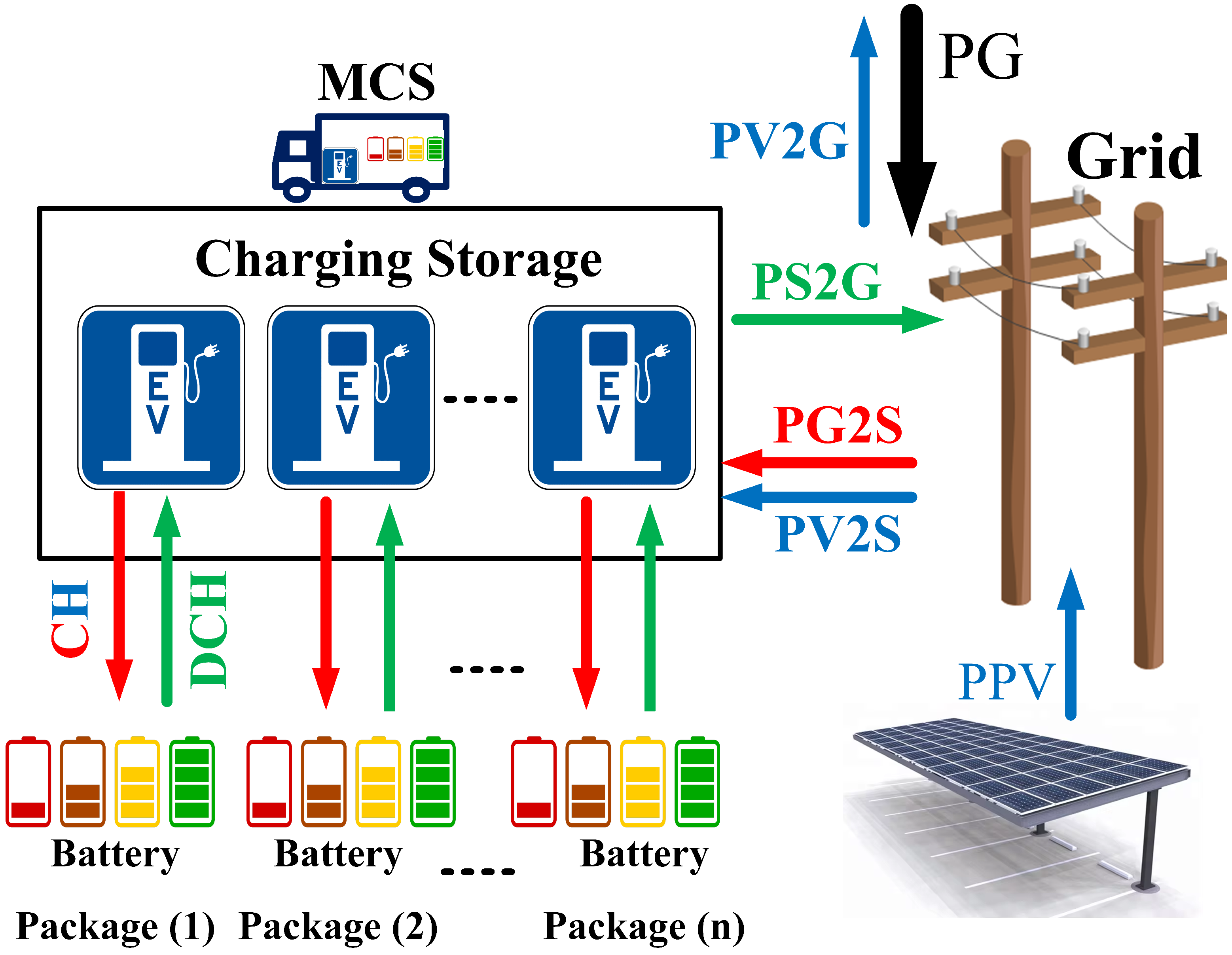

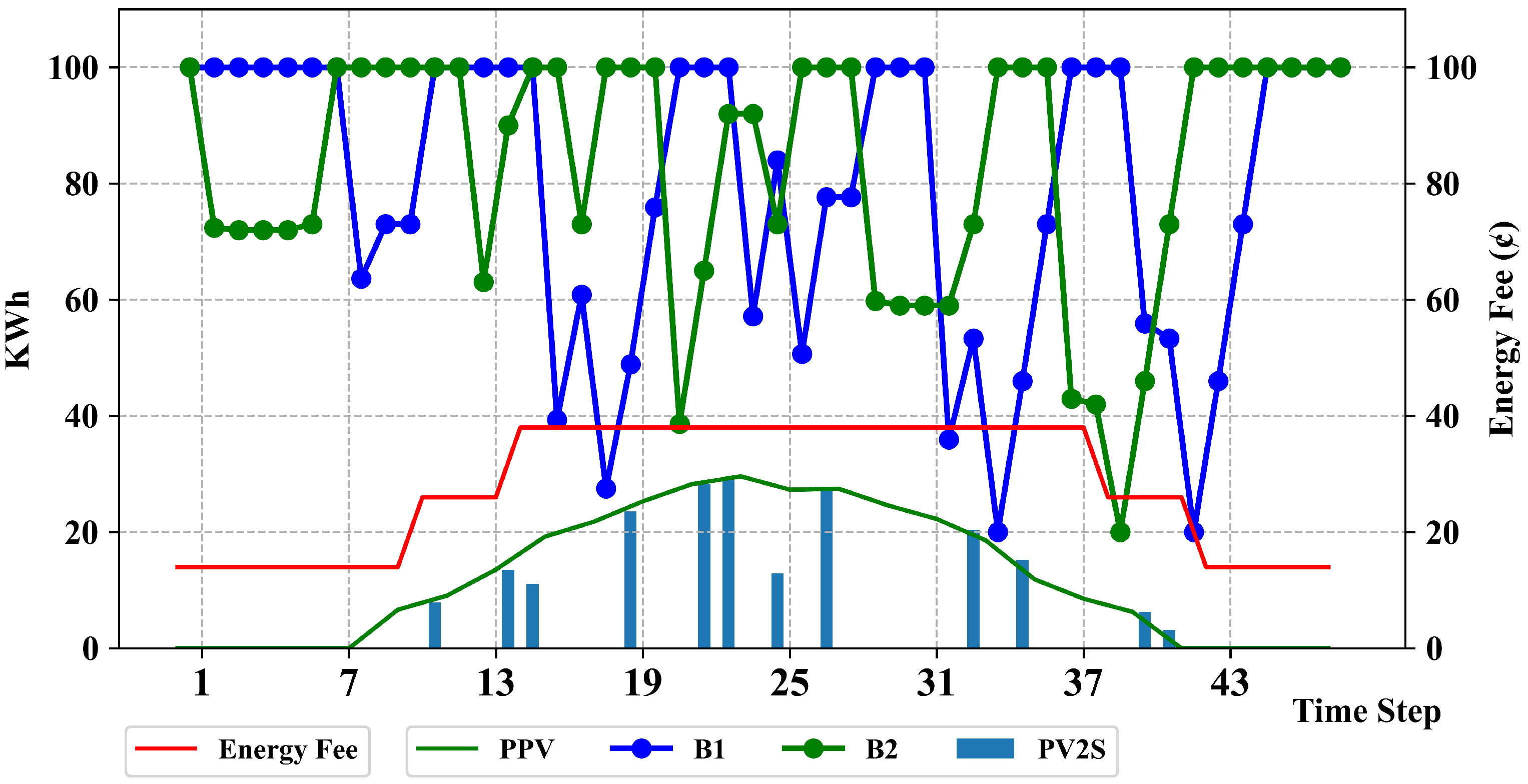

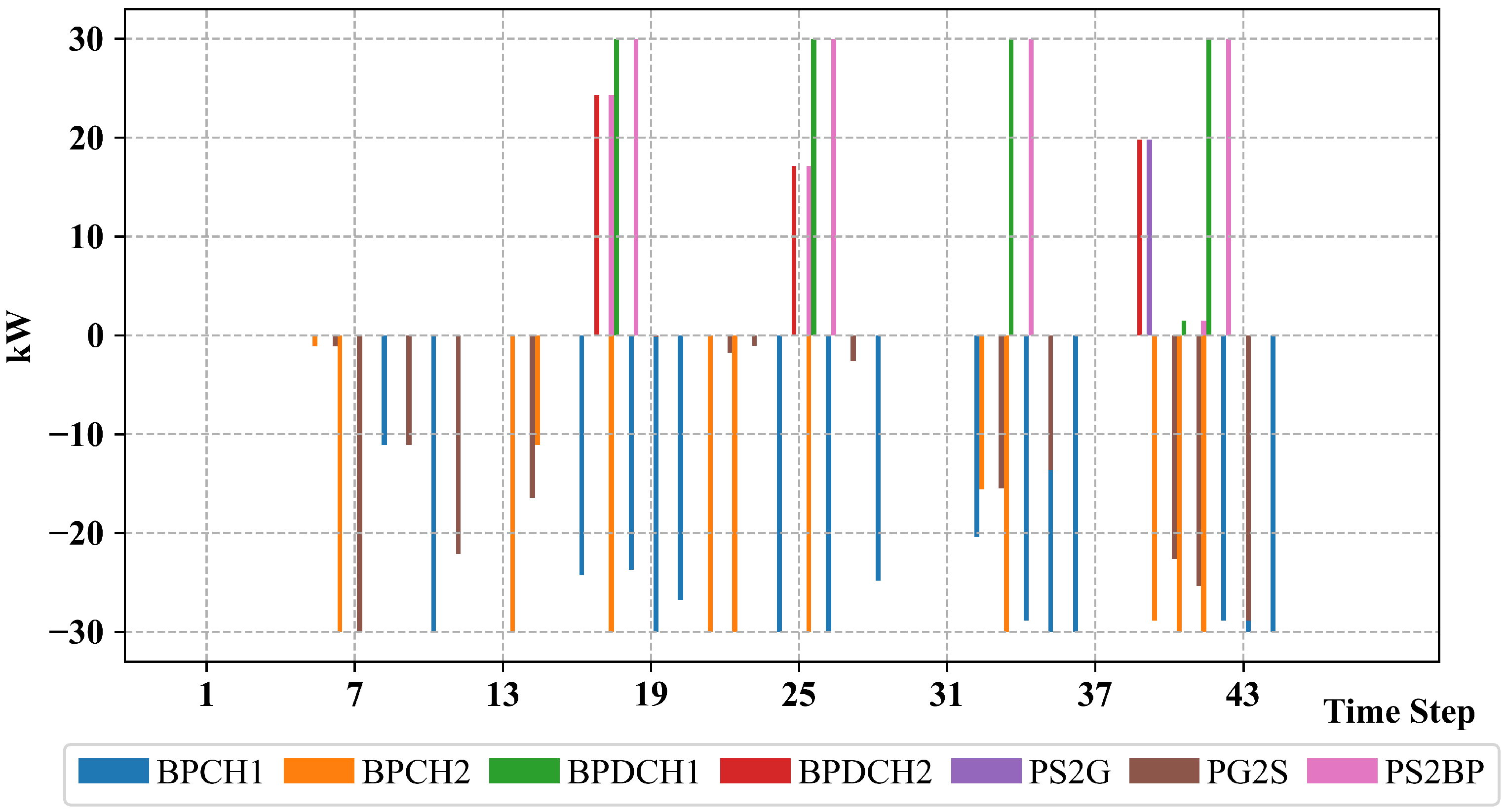

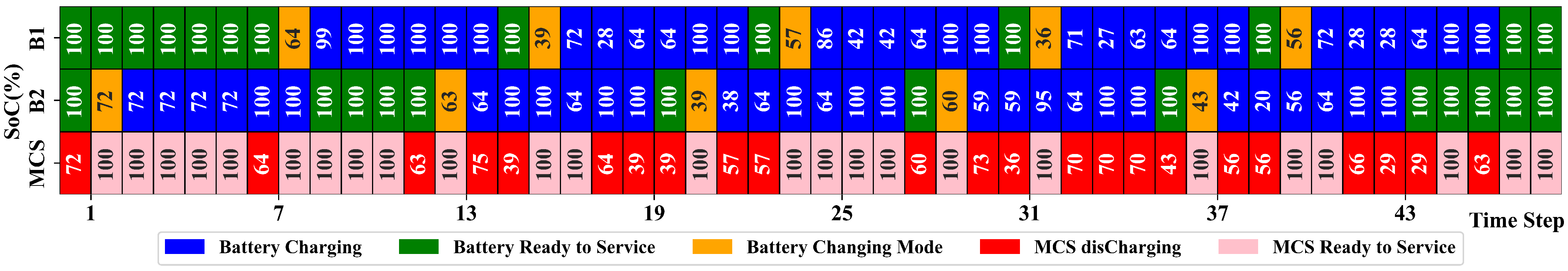

3.2. Charging Optimization at Storage Station

3.2.1. Grid Constraints

3.2.2. PV Constraints

3.2.3. Storage Constraints

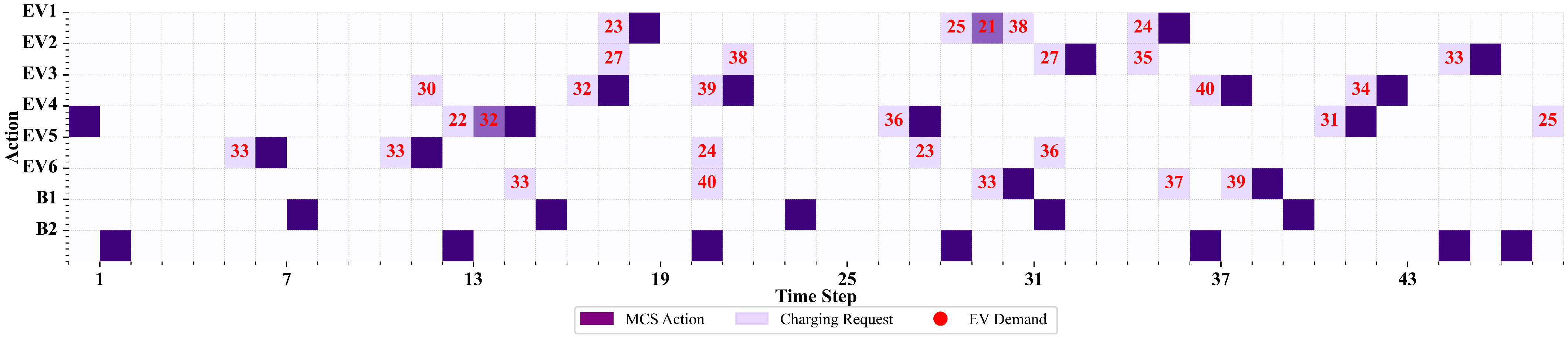

3.3. DQN Approach with New Decision-Making Process and Reward Design

3.3.1. State Design

3.3.2. Action Configuration

3.3.3. Reward Design

- Action 1: MCS does nothing to service the EV or replace its battery (no action).In this situation, according to the system conditions of this decision, the agent has a possible reward or penalty as follows: If the service request is from the EV side, no battery is ready to be replaced and the energy stored in the MCS is able to supply the vehicle’s energy. In this case, the agent will be fined for not providing the power of the EV. If the battery is ready for replacement and the energy stored in the MCS is less than its maximum possible energy, failure of the MCS to refer for battery replacement will result in a penalty. There is a service request from the EV, the battery is ready for replacement, and the energy stored in the MCS is less than the energy requested by that EV, but the MCS does not replace the battery. Failure of the vehicle to refer for battery replacement will result in a penalty; this penalty is twice the first and second cases. If there is no service request from the EV, the battery is not ready for replacement, or there is a service request from the EV, but the amount of energy stored in the MCS is less than the requested energy of the EV, and no battery has announced that it is ready for replacement. In this case, the no agent’s act is correct and it will receive a reward.

- Action 2: The agent selects one of the EVs for servicing ().If the energy available in the MCS is less than the requested energy of the EV, in this case, the agent will be subject to a penalty. If the EV-requested energy is zero, in fact, the EV has no demand. In this case, the agent will be fined. If it is none of the above cases, in this case, the agent will receive a reward due to the correct action.

- Action 3: The agent refers to one of the batteries to replace the battery ().If the battery is not ready for replacement or the energy stored in the MCS is equal to the maximum possible energy, the agent will be fined. If the battery has announced its readiness for replacement (battery readiness has been sent to the control center one time step earlier) and the MCS energy is lower than the maximum MCS value, in this case, the agent will receive a reward due to the correct action.

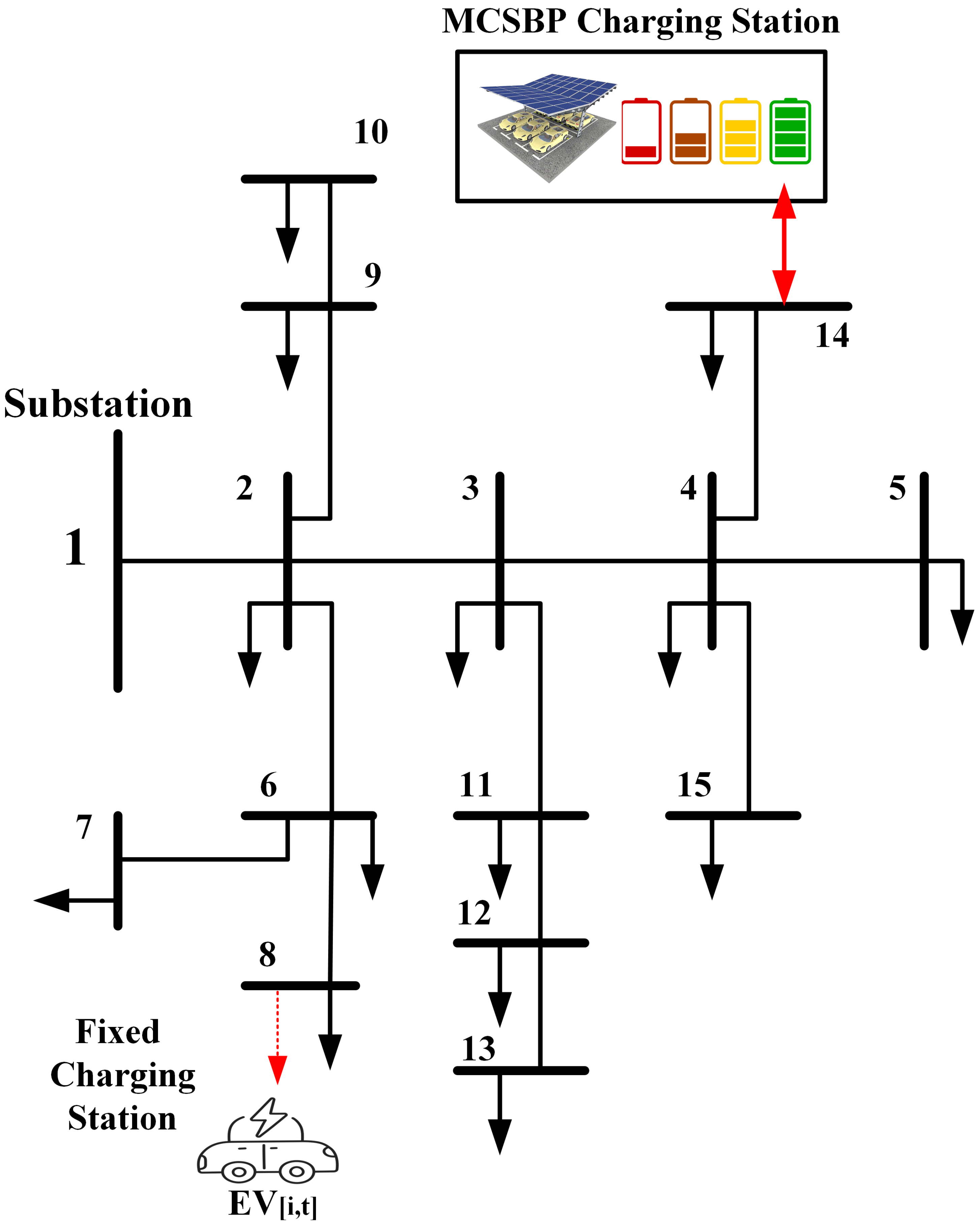

4. Branch Flows Model

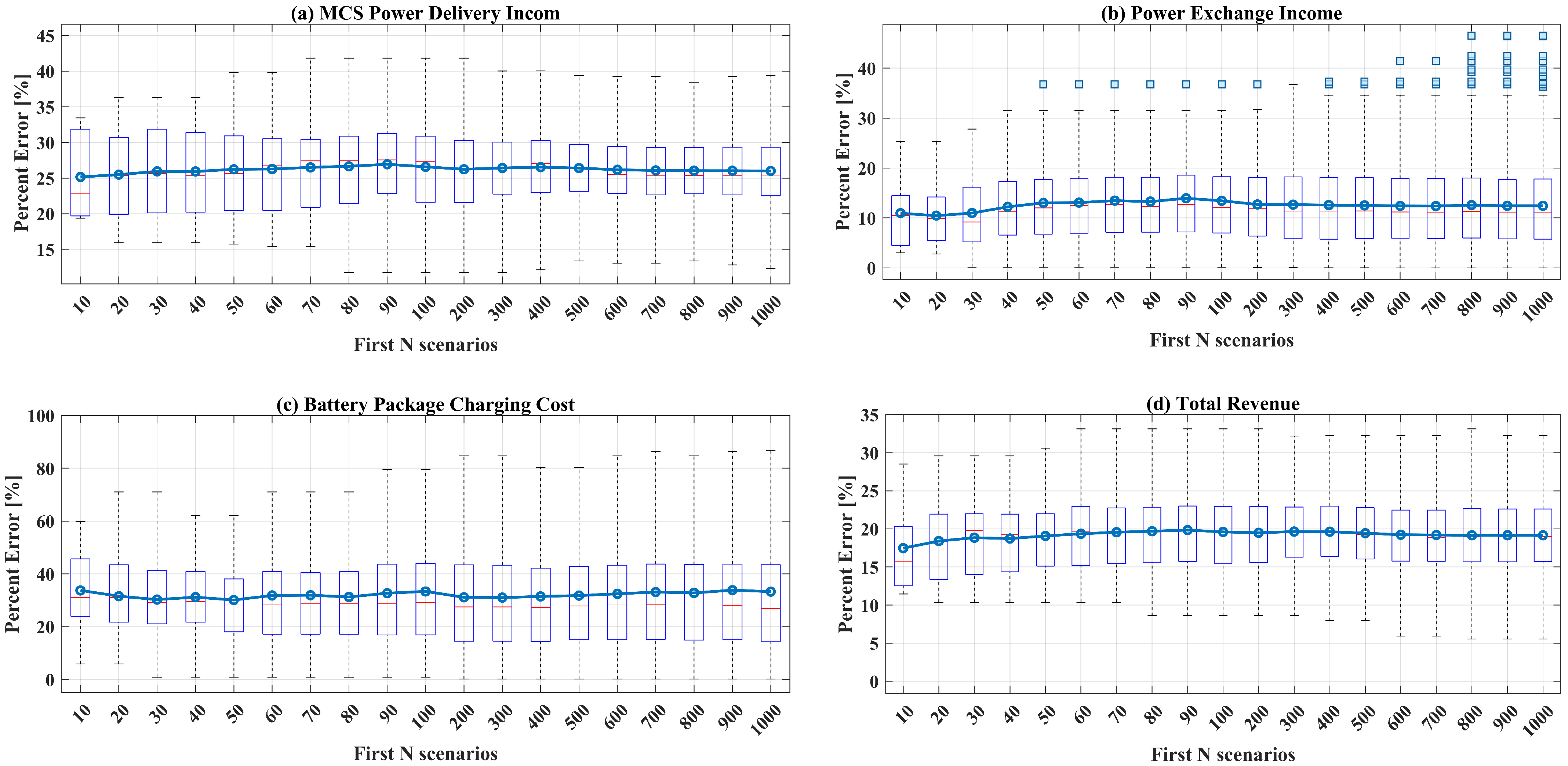

5. Numerical Results and Discussion

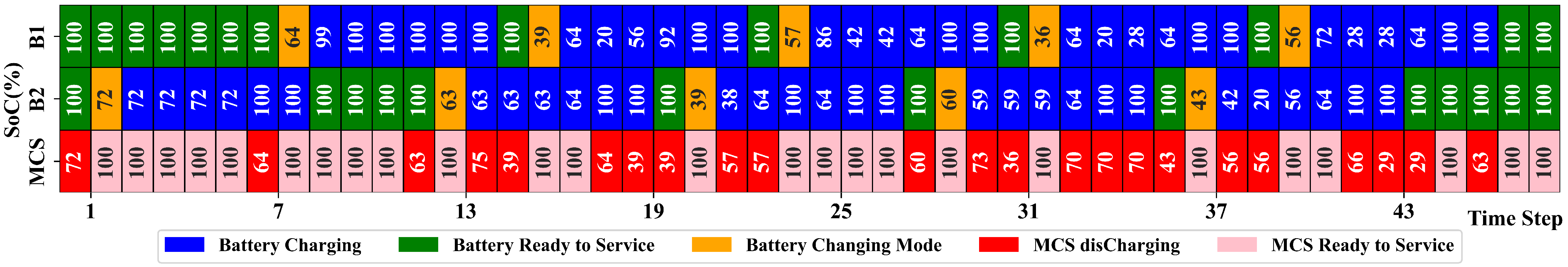

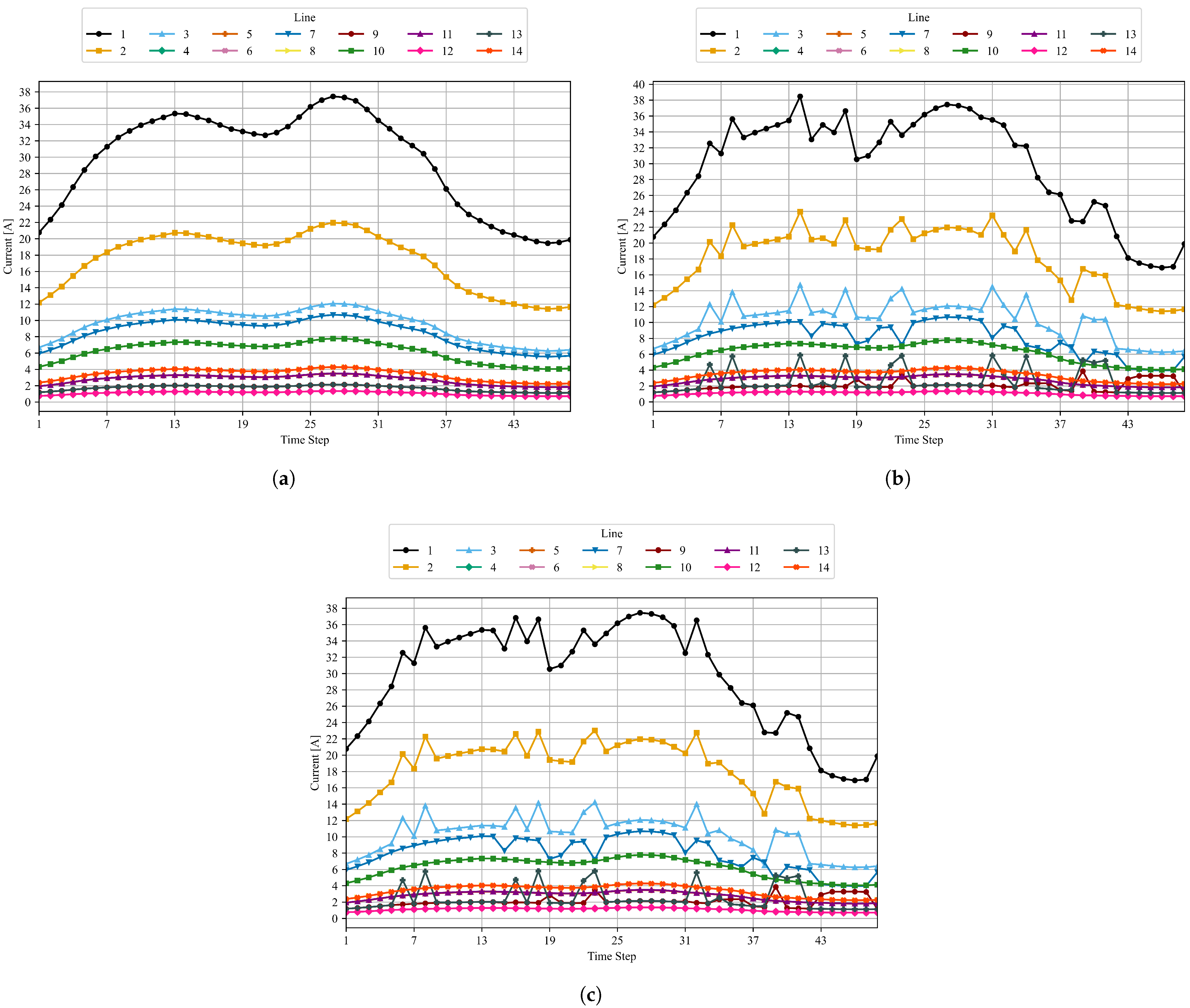

- Case 1: Load flow analysis of the network without considering the presence of the MCS.

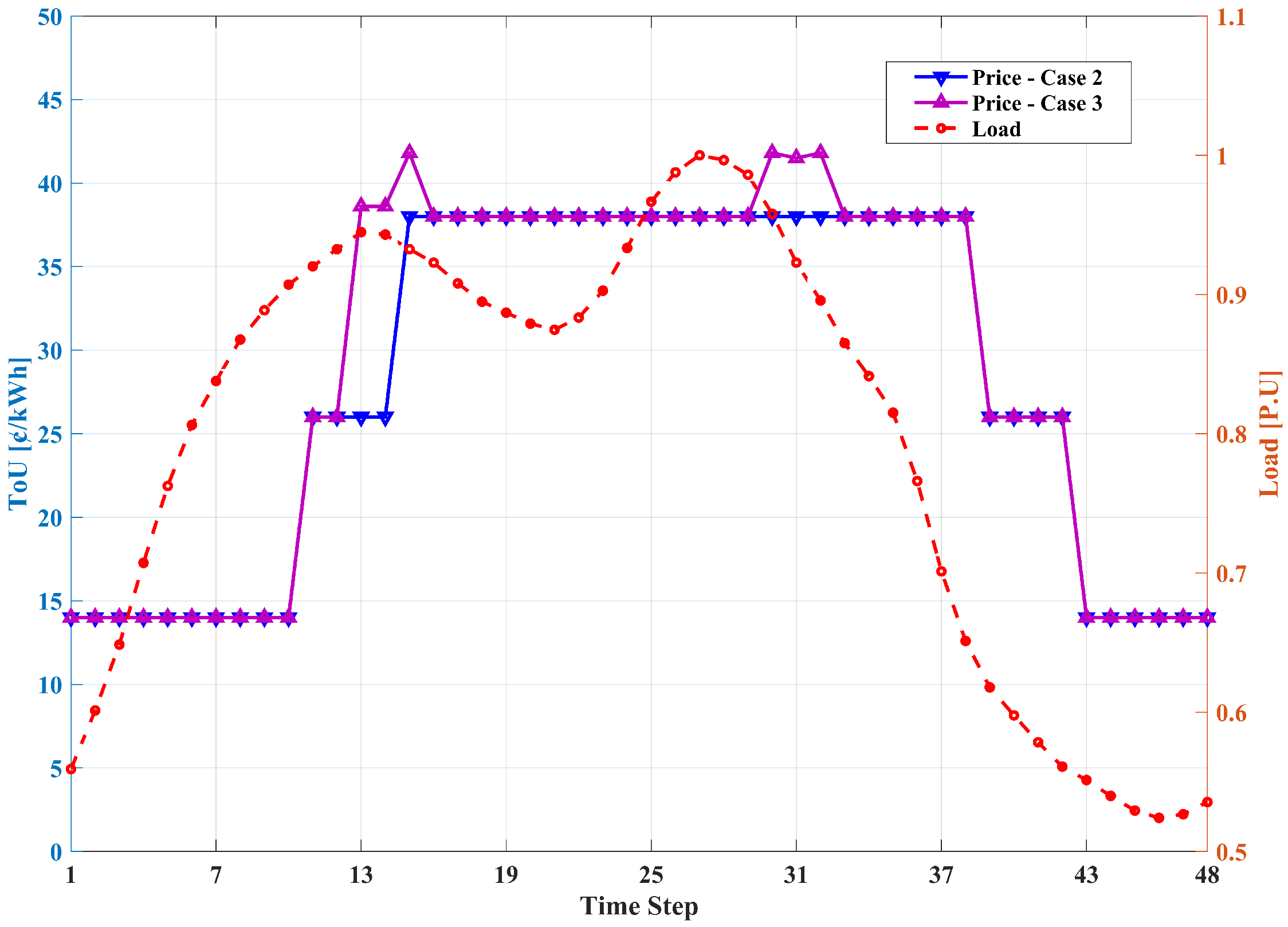

- Case 2: Scheduling of MCS services and charging of associated batteries, without considering the technical constraints of the power grid.

- Case 3: Scheduling of MCS services and battery charging while accounting for the technical constraints of the power grid.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Afshar, S.; Macedo, P.; Mohamed, F.; Disfani, V. Mobile charging stations for electric vehicles—A review. Renew. Sustain. Energy Rev. 2021, 152, 111654. [Google Scholar] [CrossRef]

- Cho, S.; Lim, J.; Won, W.; Kim, J.; Ga, S. Design and optimization of energy supplying system for electric vehicles by mobile charge stations. J. Ind. Eng. Chem. 2024, 138, 481–491. [Google Scholar] [CrossRef]

- Tran, T.K.O.; Le, T.H.T.; Shin, M.J.; Nguyen, V.; Han, Z.; Hong, C.S. Distributed auction-based incentive mechanism for energy trading between electric vehicles and mobile charging stations. IEEE Access 2022, 10, 56331–56347. [Google Scholar] [CrossRef]

- Neumann, T. Green energy fuelling stations in road transport: Poland in the European and global context. Energies 2025, 18, 4110. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, X.; Wei, W.; Peng, T.; Hong, G.; Meng, C. Mobile charging: A novel charging system for electric vehicles in urban areas. Appl. Energy 2020, 278, 115648. [Google Scholar] [CrossRef]

- Afshar, S.; Pecenak, Z.K.; Barati, M.; Disfani, V. Mobile charging stations for EV charging management in urban areas: A case study in Chattanooga. Appl. Energy 2022, 325, 119901. [Google Scholar] [CrossRef]

- Qureshi, U.; Ghosh, A.; Panigrahi, B.K. Scheduling and routing of mobile charging stations with stochastic travel times to service heterogeneous spatiotemporal electric vehicle charging requests with time windows. IEEE Trans. Ind. Appl. 2022, 58, 6546–6556. [Google Scholar] [CrossRef]

- Wang, C.; Lin, X.; He, F.; Shen, M.Z.-J.; Li, M. Hybrid of fixed and mobile charging systems for electric vehicles: System design and analysis. Transp. Res. Part C Emerg. Technol. 2021, 126, 103068. [Google Scholar] [CrossRef]

- Li, H.; Son, D.; Jeong, B. Electric vehicle charging scheduling with mobile charging stations. J. Clean. Prod. 2024, 434, 140162. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, H.; Xu, J.; Wang, P. Providing active charging services: An assignment strategy with profit-maximizing heat maps for idle mobile charging stations. IEEE Trans. Mob. Comput. 2024, 23, 2139–2152. [Google Scholar] [CrossRef]

- Nazari-Heris, M.; Loni, A.; Asadi, S.; Mohammadi-Ivatloo, B. Toward social equity access and mobile charging stations for electric vehicles: A case study in Los Angeles. Appl. Energy 2022, 311, 118704. [Google Scholar] [CrossRef]

- Saboori, H.; Jadid, S. Mobile battery-integrated charging station for reducing electric vehicles charging queue and cost via renewable energy curtailment recovery. Int. J. Energy Res. 2022, 46, 1077–1093. [Google Scholar] [CrossRef]

- Zhao, Z.; Luo, F.; Zhu, J.; Ranzi, G. Multi-stage mobile BESS operational framework to residential customers in planned outages. IEEE Trans. Smart Grid 2023, 14, 3640–3653. [Google Scholar] [CrossRef]

- Aktar, A.K.; Taşcıkaraoğlu, A.; Catalão, J.P.S. Scheduling of mobile charging stations with local renewable energy sources. Sustain. Energy Grids Netw. 2024, 37, 101257. [Google Scholar] [CrossRef]

- Neto, R.C.; Bandeira, C.M.; Azevedo, G.M.S.; Limongi, L.R.; de Carvalho, M.R.S.; Castro, J.F.C.; Rosas, P.A.C.; Venerando, A.C.; Spader, N.; Bueno, E. Mobile charging stations: A comprehensive review of converter topologies and market solutions. Energies 2024, 17, 5931. [Google Scholar] [CrossRef]

- Bokopane, L.; Kusakana, K.; Vermaak, H.; Hohne, A. Optimal power dispatching for a grid-connected electric vehicle charging station microgrid with renewable energy, battery storage and peer-to-peer energy sharing. J. Energy Storage 2024, 96, 112435. [Google Scholar] [CrossRef]

- Ala, A.; Deveci, M.; Bani, E.A.; Sadeghi, A.H. Dynamic capacitated facility location problem in mobile renewable energy charging stations under sustainability consideration. Sustain. Comput. Inform. Syst. 2024, 41, 100954. [Google Scholar] [CrossRef]

- Rani, G.A.; Priya, P.L.; Jayan, J.; Satheesh, R.; Kolhe, M.L. Data-driven energy management of an electric vehicle charging station using deep reinforcement learning. IEEE Access 2024, 12, 65956. [Google Scholar] [CrossRef]

- Wang, K.; Wang, H.; Yang, Z.; Feng, J.; Li, Y.; Yang, J.; Chen, Z. A transfer learning method for electric vehicles charging strategy based on deep reinforcement learning. Appl. Energy 2023, 343, 121186. [Google Scholar] [CrossRef]

- Tang, M.; Zhuang, W.; Li, B.; Liu, H.; Song, Z.; Yin, G. Energy-optimal routing for electric vehicles using deep reinforcement learning with transformer. Appl. Energy 2023, 350, 121711. [Google Scholar] [CrossRef]

- Qiu, D.; Wang, Y.; Hua, W.; Strbac, G. Reinforcement learning for electric vehicle applications in power systems: A critical review. Renew. Sustain. Energy Rev. 2023, 173, 113052. [Google Scholar] [CrossRef]

- Suanpang, P.; Jamjuntr, P. Optimizing electric vehicle charging recommendation in smart cities: A multi-agent reinforcement learning approach. World Electr. Veh. J. 2024, 15, 67. [Google Scholar] [CrossRef]

- Lin, B.; Ghaddar, B.; Nathwani, J. Deep reinforcement learning for the electric vehicle routing problem with time windows. IEEE Trans. Intell. Transp. Syst. 2022, 23, 11528–11538. [Google Scholar] [CrossRef]

- Ahmed, I.; Adnan, M.; Hassan, W. A bidirectional interactive electric vehicles PV grid connected framework for vehicle-to-grid and grid-to-vehicle stability enhancement using hybrid control strategies. Comput. Electr. Eng. 2025, 122, 109983. [Google Scholar] [CrossRef]

- Ullah, Z.; Hussain, I.; Mahrouch, A.; Ullah, K.; Asghar, R.; Ejaz, M.T.; Aziz, M.M.; Naqvi, S.F.M. A survey on enhancing grid flexibility through bidirectional interactive electric vehicle operations. Energy Rep. 2024, 11, 5149–5162. [Google Scholar] [CrossRef]

- Choudhary, D.; Mahanty, R.N.; Kumar, N. Demand management of plug-in electric vehicle charging station considering bidirectional power flow using deep reinforcement learning. Eng. Appl. Artif. Intell. 2025, 139, 109585. [Google Scholar] [CrossRef]

- Choudhary, D.; Mahanty, R.N.; Kumar, N. Plug-in electric vehicle dynamic pricing strategies for bidirectional power flow in decentralized and centralized environment. Sustain. Energy Grids Netw. 2024, 38, 101317. [Google Scholar] [CrossRef]

- Sayed, M.A.; Atallah, R.; Assi, C.; Debbabi, M. Electric vehicle attack impact on power grid operation. Int. J. Electr. Power Energy Syst. 2022, 137, 107784. [Google Scholar] [CrossRef]

- Hernandez-Matheus, A.; Berg, K.; Gadelha, V.; Aragüés-Peñalba, M.; Bullich-Massagué, E.; Galceran-Arellano, S. Congestion forecast framework based on probabilistic power flow and machine learning for smart distribution grids. Int. J. Electr. Power Energy Syst. 2024, 156, 109695. [Google Scholar] [CrossRef]

- Avila-Rojas, A.E.; De Oliveira-De Jesus, P.M.; Alvarez, M. Distribution network electric vehicle hosting capacity enhancement using an optimal power flow formulation. Electr. Eng. 2021, 104, 1337–1348. [Google Scholar] [CrossRef]

- Aggarwal, S.; Singh, A.K.; Rathore, R.S.; Bajaj, M.; Gupta, D. Revolutionizing load management: A novel technique to diminish the impact of electric vehicle charging stations on the electricity grid. Sustain. Energy Technol. Assess. 2024, 65, 103784. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, J.; AL-Wesabi, A.I.; Aboudrar, I.; Shi, Z.; He, Y. Dynamic LADRC and modified indirect P&O algorithm based-power flow management of PV-BESS-grid integrated fast EV charging stations with G2V, V2G and V2H capability. J. Energy Storage 2025, 112, 115505. [Google Scholar]

- Hasanien, H.M.; Alsaleh, I.; Alassaf, A.; Alateeq, A. Enhanced coati optimization algorithm-based optimal power flow including renewable energy uncertainties and electric vehicles. Energy 2023, 283, 129069. [Google Scholar] [CrossRef]

- Sithambaram, M.; Rajesh, P.; Shajin, F.H.; Rajeswari, I.R. Grid connected photovoltaic system powered electric vehicle charging station for energy management using hybrid method. J. Energy Storage 2025, 108, 114828. [Google Scholar] [CrossRef]

- Upadhaya, D.; Biswas, S.; Dutta, S.; Bhattacharya, A. Optimal power flow and grid frequency control of conventional and renewable energy source using evolutionary algorithm based FOPID controller. Renew. Energy Focus 2025, 53, 100676. [Google Scholar] [CrossRef]

- Saini, S.S.; Sharma, K.K. Power enhancement in distributed system to control the bidirectional power flow in electric vehicle. Multimed. Tools Appl. 2023, 83, 54673–54698. [Google Scholar] [CrossRef]

- Mazza, A.; Benedetto, G.; Bompard, E.; Nobile, C.; Pons, E.; Tosco, P.; Zampolli, M.; Jaboeuf, R. Interaction among multiple electric vehicle chargers: Measurements on harmonics and power quality issues. Energies 2023, 16, 7051. [Google Scholar] [CrossRef]

- Maia, G.L., Jr.; Santos, C.C.L.; Nunes, P.R.M.; Castro, J.F.C.; Marques, D.C.; Medeiros, L.H.A.D.; Limongi, L.R.; Brito, M.E.C.; Dantas, N.K.L.; Filho, A.V.M.L.; et al. EV smart-charging strategy for power management in distribution grid with high penetration of distributed generation. Energies 2024, 17, 5394. [Google Scholar] [CrossRef]

- Jia, X.; Xia, Y.; Yan, Z.; Gao, H.; Qiu, D.; Guerrero, J.M.; Li, Z. Coordinated operation of multi-energy microgrids considering green hydrogen and congestion management via a safe policy learning approach. Appl. Energy 2025, 374, 123456. [Google Scholar] [CrossRef]

- Ahmed, I.; Shahid, M.K.; Faisal, T. Deep reinforcement learning based beam selection for hybrid beamforming and user grouping in massive MIMO-NOMA system. IEEE Access 2022, 10, 89519. [Google Scholar] [CrossRef]

- Ngo, A.P.; Thomas, C.; Oikonomou, K.; Nguyen, H.; Nguyen, D. On the comparison of different convexified power flow models in radial network. In Proceedings of the IEEE Kansas Power and Energy Conference (KPEC), Manhattan, KS, USA, 25–26 April 2022; pp. 1–6. [Google Scholar]

- World Bank Group; International Finance Corporation (IFC). Global Solar Atlas. Available online: https://globalsolaratlas.info/ (accessed on 23 September 2025).

- Pettikkattil, J. IEEE 15 Bus Radial System. MATLAB Central File Exchange 2025. Available online: https://www.mathworks.com/matlabcentral/fileexchange/48104-ieee-15-bus-radial-system (accessed on 23 September 2025).

| Optimal | DQN | |

|---|---|---|

| The MCS Power Delivery Incom | USD 787.5 | USD 619 |

| The Power Exchange Income | USD 144.5 | USD 155 |

| The Battery Package Charging Cost | USD −79.5 | USD −44.5 |

| Total Revenue | USD 852.59 | USD 729.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alirezazadeh, A.; Disfani, V. Deep Reinforcement Learning-Based Optimization of Mobile Charging Station and Battery Recharging Under Grid Constraints. Energies 2025, 18, 5337. https://doi.org/10.3390/en18205337

Alirezazadeh A, Disfani V. Deep Reinforcement Learning-Based Optimization of Mobile Charging Station and Battery Recharging Under Grid Constraints. Energies. 2025; 18(20):5337. https://doi.org/10.3390/en18205337

Chicago/Turabian StyleAlirezazadeh, Atefeh, and Vahid Disfani. 2025. "Deep Reinforcement Learning-Based Optimization of Mobile Charging Station and Battery Recharging Under Grid Constraints" Energies 18, no. 20: 5337. https://doi.org/10.3390/en18205337

APA StyleAlirezazadeh, A., & Disfani, V. (2025). Deep Reinforcement Learning-Based Optimization of Mobile Charging Station and Battery Recharging Under Grid Constraints. Energies, 18(20), 5337. https://doi.org/10.3390/en18205337