End-of-Life Strategies for Wind Turbines: Blade Recycling, Second-Life Applications, and Circular Economy Integration

Abstract

1. Introduction

2. Search and Selection Strategy

- (“wind turbine” OR “wind-turbine” OR WTB) AND (blade* OR composite*) AND (recycl* OR “end-of-life” OR EoL OR repurpos* OR “life extension” OR pyrolys* OR solvolys* OR “mechanical recycling” OR supercritical OR “fluidis* bed”)

- (circular* OR “circular economy” OR EPR OR “extended producer responsibility” OR “Digital Product Passport*” OR “green public procurement” OR “end-of-waste”)

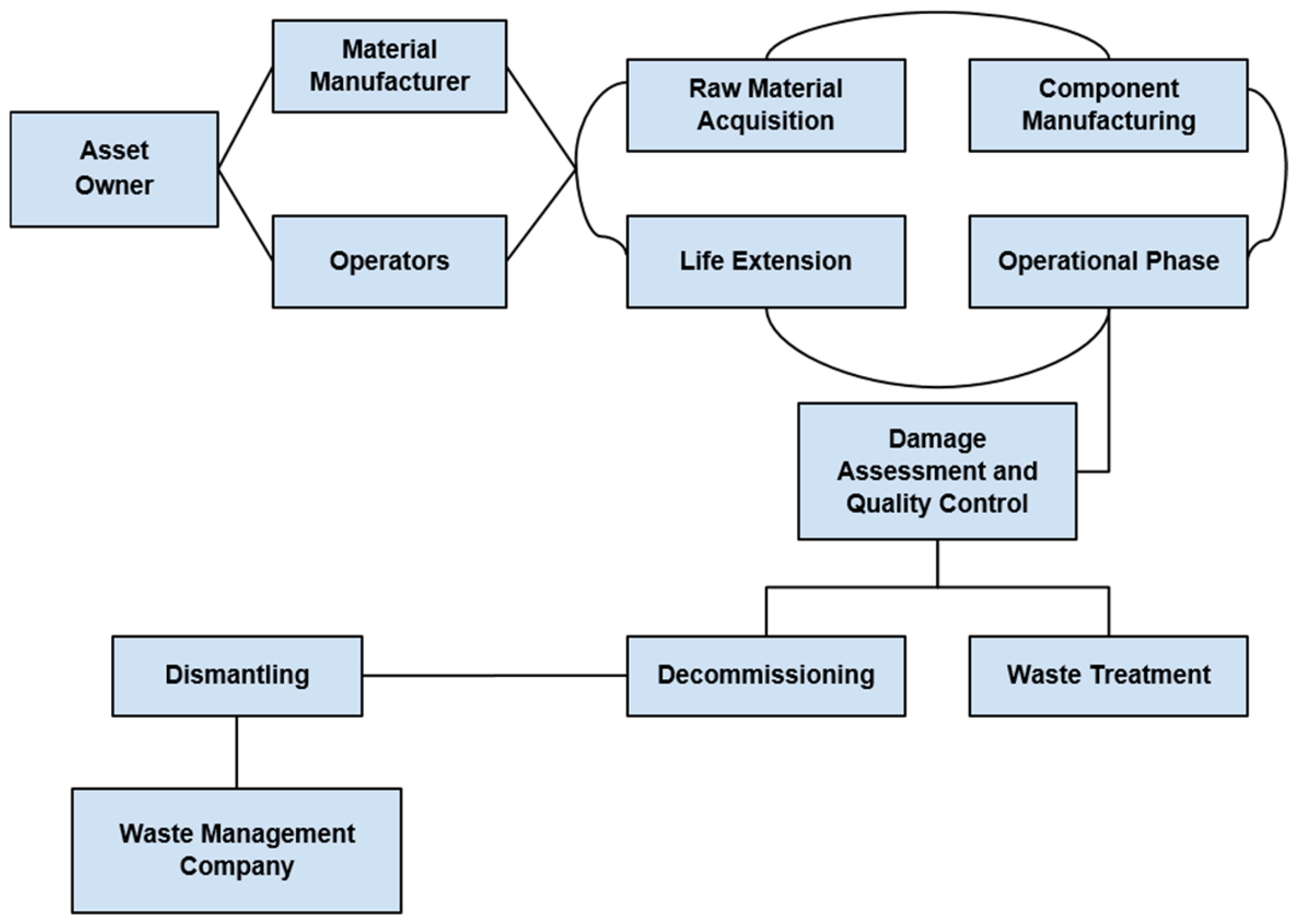

3. Strategies and Methods for Managing End-of-Life Wind Turbine Components

3.1. Methods for Extending the Service Life

3.2. Upcycling and Second Life

- anticipated investment and operational costs;

- potential revenues from recycled materials;

- environmental impacts [28].

3.3. Component Processing Methods

4. Innovative Solutions for Wind Turbine Blade Recycling and Their Implementation Challenges

4.1. Advanced Materials and Functional Reuse

4.2. Applications in Cement, Asphalt, and Infrastructure

4.3. Chemical Processing and Recycling Techniques

4.4. Industrial Deployments and Scalability

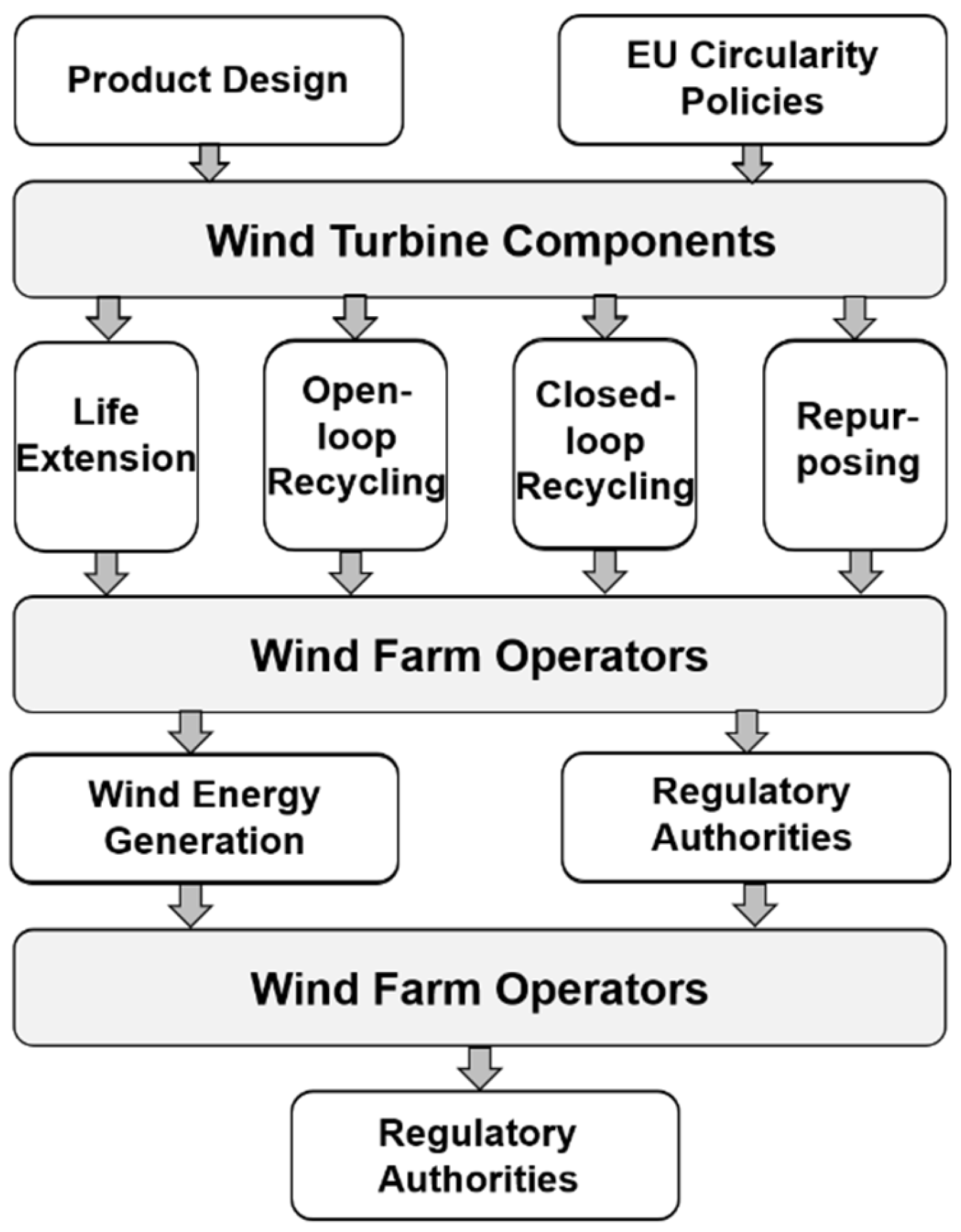

5. Wind Turbine End-of-Life in the Circular Economy: Regulation, Markets, and Finance

5.1. Circular Economy Frameworks and Regulatory Alignment in the EU

5.2. Market-Creation Instruments and Financing

5.3. Circular Design and Digital Traceability

5.4. System Perspective and Feedback Loops

6. Summary and Perspectives

- Segmentation and cutting. Preference should be given to low-dust methods (e.g., water jet cutting) and on-site containment to minimise re-handling. Where dry cutting/grinding is unavoidable, use integrated LEV with point-source capture and shrouded tools [102].

- Dust control. Apply wet suppression where practicable; provide LEV with appropriate filtration (e.g., HEPA for fine particulates); avoid compressed-air cleaning; maintain housekeeping using vacuum systems fitted with HEPA filtration; enclose cutting bays or use temporary curtains to limit fugitive dust [103,104].

- Worker exposure and PPE. Conduct task-specific risk assessment; provide protective clothing, gloves, eye/face protection, and respiratory protective equipment commensurate with measured concentrations; ensure training and fit-testing where respirators are used; institute exposure monitoring/medical surveillance as required by national regulation [105].

- Odour and nuisance. Use temporary enclosures and negative-pressure regimes where needed, particularly in urban settings or during indoor preparation of blade segments [102].

- Waste handling. Collect dust and offcuts into sealed, labelled containers for appropriate downstream processing; do not mix with municipal waste streams [89].

| Sector | Application | Material Type | References |

|---|---|---|---|

| Construction | Concrete additives, cement clinker substitute, fillers in asphalt mixtures, polymer-based construction panels, sound barriers, bridges, urban furniture | Powdered GFRP (Glass Fibre Reinforced Polymer), crushed blade particles, fibre mats, composite laminates | [12,13,16,30,52,61,64,72,96,106] |

| Energy | Co-firing in cement kilns and industrial furnaces, fuel for pyrolysis-based energy recovery systems | Combustible resin matrix, GFRP fragments, pyrolysed solids and liquids | [8,15,18,39,47,99,107] |

| Transport | Fillers for road subbase layers, reinforcement elements in railway infrastructure, noise protection panels | Thermally treated composite aggregates, fibre-reinforced particles, GFRP-derived composites | [34,45,54,76,108] |

| Consumer Goods | Production of urban equipment, sports equipment, furniture, and household items with recycled blade fibres | Composite fibre panels, GFRP powder, reformulated thermoplastics | [16,20,24,90], |

| Public Infrastructure | Playground structures, outdoor shelters, information signs, pedestrian bridges, bus stops | Cut blade segments, surface-treated GFRP panels, laminated composites | [2,32,55,109] |

| Agriculture | Fencing, protective panels, livestock enclosures, wind barriers | Mechanical offcuts, reused composite sheets, reinforced laminates | [33,35,110] |

7. Conclusions

- Wind turbine blades, due to their heterogeneous composite structure, remain the most technically challenging component to recycle. Among available options, chemical recycling—particularly solvolysis—demonstrates the highest potential for fibre recovery with minimal degradation, provided that solvent management and heat integration are engineered to industrial standards and environmental compliance requirements are met.

- Mechanical recycling and second-life applications offer feasible short-term solutions, especially when recovered materials are redirected to the construction sector. Their environmental benefits, however, are often constrained by quality limitations and lack of standardisation. In practice, these routes are most immediately applicable to GFRP, but they entail downcycling; fit-for-purpose standards and product specifications are, therefore, essential to secure predictable performance and market uptake.

- The adoption of bio-based and biodegradable composites may significantly reduce the environmental burden of future blade production. Nonetheless, further research is required to optimise their mechanical performance and economic viability. Priority gaps include long-term durability, fire/UV resistance, and certification pathways, so that design-for-recycling gains do not compromise service integrity.

- Upcycling approaches—such as the transformation of blade segments into infrastructure elements or urban furniture—represent a low-energy alternative to full material recovery, though they currently face social, regulatory, and durability-related barriers. These applications should follow engineering qualification and monitoring protocols, with use targeted to noncritical or moderately loaded elements.

- The integration of circular economy strategies within the wind energy sector necessitates not only technological development but also institutional support. Instruments such as EPR schemes and digital material tracking systems can enhance transparency, accountability, and resource circulation. Equally important are harmonised end-of-waste criteria, recognised quality grades for recovered fibres/polymers, and demand-pull levers (e.g., green public procurement, eco-modulated EPR fees).

- Advancing interdisciplinary research and establishing industrial symbiosis between the wind energy, construction, and waste management sectors are essential to closing material loops and fostering market acceptance of recycled composites. Near-term priorities include standardised fibre quality classes and test methods, transparent gate-to-gate energy balances that include abatement/solvent-recovery penalties, and bankable offtake arrangements to de-risk first-of-a-kind plants.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

List of Abbreviations

| IEA | International Energy Agency |

| EPR | Extended Producer Responsibility |

| WTBs | Wind Turbine Blades |

| GFRP | Glass Fibre Reinforced Polymer |

| EU | European Union |

| RWTBs | Recycled Wind Turbine Blades |

| DDWTs | Direct-Drive Wind Turbine(s) |

| SCADA | Supervisory Control And Data Acquisition |

| ZEBRA | Zero wastE Blade ReseArch, project designing and manufacturing the first 100% recyclable wind turbine blade. |

| SiC | Silicon Carbide |

| PETG | Polyethylene Terephthalate Glycol |

| RCWTB | Re-Crushed Blade Waste |

| FRP | Fibre-Reinforced Polymer |

| CE | Circular Economy |

| CEAP | Circular Economy Action Plan |

References

- Alavi, Z.; Khalipour, K.; Florin, N.; Hadigheh, A.; Hoadley, A. End-of-life wind turbine blade management across energy transition: A life cycle analysis. Resour. Conserv. Recycl. 2025, 213, 108008. [Google Scholar] [CrossRef]

- Sanda, M.G.; Emam, M.; Okawara, S.; Hassan, H. Techno-enviro-economic evaluation of on-grid and off-grid hybrid photovoltaics and vertical axis wind turbines system with battery storage for street lighting application. J. Clean. Prod. 2025, 491, 144866. [Google Scholar] [CrossRef]

- An, J.; Hu, X.; Gong, L.; Zou, Z.; Zheng, L. Fuzzy reliability evaluation and machine learning-based fault prediction of wind turbines. J. Ind. Inf. Integr. 2024, 40, 100606. [Google Scholar] [CrossRef]

- Desalegn, B.; Gebeyehu, D.; Tamrat, B.; Tadiwose, T.; Lata, A. Onshore versus offshore wind power trends and recent study practices in modeling of wind turbines’ life-cycle impact assessments. Clean. Eng. Technol. 2023, 17, 100691. [Google Scholar] [CrossRef]

- Evro, S.; Veith, J.; Akinwale, A.; Tomomewo, O.S. Enhancing floating offshore wind turbine systems through multi-scale coupled modeling. Sustain. Energy Technol. Assess. 2025, 77, 104299. [Google Scholar] [CrossRef]

- León, M.F.G.; Llort, C.B.; Demuytere, C.; Bobba, S.; Tazi, N.; Dewulf, J. Multilayer Material System Analysis of wind turbines: Correlation of stocks and flows in the EU of six metals and two drivetrain technologies. J. Clean. Prod. 2025, 518, 145794. [Google Scholar] [CrossRef]

- Gennitsaris, S.; Sagani, A.; Sofianopoulou, S.; Dedousis, V. Integrated LCA and DEA approach for circular economy-driven performance evaluation of wind turbine end-of-life treatment options. Appl. Energy 2023, 339, 120951. [Google Scholar] [CrossRef]

- Xu, M.; Ji, H.; Meng, X.; Wu, Y.; Meng, X.; Di, J.; Yang, J.; Lu, Q. Recovering glass fibers from waste wind turbine blades: Recycling methods, fiber properties, and potential utilization. Renew. Sustain. Energy Rev. 2024, 202, 114690. [Google Scholar] [CrossRef]

- Liu, T.; Paraskeroulakos, C.; Mughal, U.A.; Tyurkay, A.; Lushnikova, N.; Song, H.; Duyal, C.; Karnick, S.T.; Gauvin, F.; Lima, A.T. Mechanisms and applications of wind turbine blade waste in cementitious composites: A review. Mater. Des. 2025, 251, 113732. [Google Scholar] [CrossRef]

- Eligüzel, İ.M.; Özceylan, E. Closed-loop supply chain network of end-of-life wind turbines mathematical model proposal considering environmental, employment, and cost reduction aspects. Expert. Syst. Appl. 2024, 258, 125193. [Google Scholar] [CrossRef]

- Deeney, P.; Leahy, P.G.; Campbell, K.; Ducourtieux, C.; Mullally, G.; Dunphy, N.P. End-of-life wind turbine blades and paths to a circular economy. Renew. Sustain. Energy Rev. 2025, 212, 115418. [Google Scholar] [CrossRef]

- Zhou, B.; Zhang, M.; Ma, G.; Zhang, R. Evaluation of mechanical properties, durability, and sustainability of concrete reinforced with recycled GFRP fibers: Experiments and optimization. J. Build. Eng. 2025, 111, 113111. [Google Scholar] [CrossRef]

- Zhang, Y.; Cui, S.; Wang, X.; Yang, B.; Zhang, N.; Liu, T. Microstructure and performance of recycled wind turbine blade based 3D printed concrete. Clean. Waste Syst. 2025, 10, 100206. [Google Scholar] [CrossRef]

- Gennitsaris, S.; Sofianopoulou, S. Wind turbine end-of-life options based on the UN Sustainable Development Goals (SDGs). Green Technol. Sustain. 2024, 2, 100108. [Google Scholar] [CrossRef]

- Fresneda-Cruz, A.; Chaine, C.; Bernardes-Figueirêdo, M.; Murillo-Ciordia, G.; Sanz-Martinez, A.; Julián, J. Potentials and limitations of microwave-assisted chemical recycling of fiber-reinforced composites from wind blades. Sustain. Energy Fuels 2024, 8, 4752–4766. [Google Scholar] [CrossRef]

- Tyurkay, A.; Kirkelund, G.M.; Lima, A.T.M. State of the art circular economy practices for end of life wind turbine blades for use in the construction industry. Sustain. Prod. Consum. 2024, 47, 17–36. [Google Scholar] [CrossRef]

- Gast, L.; Meng, F.; Morgan, D. Assessing the circularity of onshore wind turbines: Using material flow analysis for improving end-of-life resource management. Resour. Conserv. Recycl. 2024, 204, 107468. [Google Scholar] [CrossRef]

- Ji, J.; Zhang, C.; Zhang, X.; Chen, Y. Recent research advances in wind turbine thermal management technologies. Renew. Sustain. Energy Rev. 2025, 208, 114983. [Google Scholar] [CrossRef]

- Gbashi, S.M.; Olatunji, O.O.; Adedeji, P.A.; Madushele, N. From academic to industrial research: A comparative review of advances in rolling element bearings for wind turbine main shaft. Eng. Fail. Anal. 2024, 163, 108510. [Google Scholar] [CrossRef]

- Priyadumkol, J.; Muangput, B.; Nanchanthra, S.; Zin, T.; Phengpom, T.; Chokaew, W.; Savajumrat, C.; Promtong, M. CFD modelling of vertical-axis wind turbines using transient dynamic mesh towards lateral vortices capturing and Strouhal number. Energy Convers. Manag. X 2025, 26, 101022. [Google Scholar] [CrossRef]

- Yu, X.; Zhang, Z.; Tang, B.; Ma, J. Non-temporal neural networks for predicting degradation trends of key wind-turbine gearbox components. Renew. Energy 2025, 243, 122438. [Google Scholar] [CrossRef]

- Tartt, K.; Kazemi-Amini, A.M.; Nejad, A.R.; Carrol, J.; McDonald, A. Life extension of wind turbine drivetrains by means of SCADA data: Case study of generator bearings in an onshore wind farm. Results Eng. 2024, 24, 102921. [Google Scholar] [CrossRef]

- Li, X.; Teng, W.; Wang, L.; Hu, J.; Su, Y.; Peng, D.; Liu, Y. Trend-constrained pairing based incremental transfer learning for remaining useful life prediction of bearings in wind turbines. Expert. Syst. Appl. 2025, 263, 125731. [Google Scholar] [CrossRef]

- Ziegler, L.; Gonzalez, E.; Rubert, T.; Smolka, U.; Melero, J.J. Lifetime extension of onshore wind turbines: A review covering Germany, Spain, Denmark, and the UK. Renew. Sustain. Energy Rev. 2018, 82, 1261–1271. [Google Scholar] [CrossRef]

- Natarajan, A.; Dimitrov, N.K.; William Peter, D.R.; Bergami, L.; Madsen, J.; Olesen, N.; Krogh, T.; Nielsen, J.; Sørensen, J.D.; Pedersen, M.; et al. Demonstration of requirements for life extension of wind turbines beyond their design life. In DTU Wind Energy E-Report; Technical University of Denmark: Kongens Lyngby, Denmark, 2020; p. E-0196. ISBN 978-87-93549-64-7. Available online: https://orbit.dtu.dk/en/publications/6ec87362-0f20-41e7-965b-6be7091a131e (accessed on 20 September 2025).

- Arif, Z.U.; Khalid, M.Y.; Sheikh, M.F.; Zolfagharin, A.; Bodaghi, M. Biopolymeric sustainable materials and their emerging applications. J. Environ. Chem. Eng. 2022, 10, 108159. [Google Scholar] [CrossRef]

- Lund, K.W.; Madsen, E.S. State-of-the-art value chain roadmap for sustainable end-of-life wind turbine blades. Renew. Sustain. Energy Rev. 2024, 192, 114234. [Google Scholar] [CrossRef]

- Kramer, K.J.; Abrahamsen, A.B.; Beauson, J.; Hansen, U.E.; Clausen, N.E.; Velenturf, A.P.M.; Schmidt, M. Quantifying circular economy pathways of decommissioned onshore wind turbines: The case of Denmark and Germany. Sustain. Prod. Consum. 2024, 49, 179–192. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, F.; Liang, D.; Lv, G.; Chen, C. A comprehensive review of waste wind turbine blades in China: Current status and resource utilization. J. Environ. Chem. Eng. 2024, 12, 113077. [Google Scholar] [CrossRef]

- Manso-Morato, J.; Hurtado-Alonso, N.; Revilla-Cuesta, V.; Ortega-López, V. Management of wind-turbine blade waste as high-content concrete addition: Mechanical performance evaluation and life cycle assessment. J. Environ. Manag. 2025, 373, 123995. [Google Scholar] [CrossRef]

- Khalid, Y.; Arif, Z.U.; Hossain, M.; Umer, R. Recycling of wind turbine blades through modern recycling technologies: A road to zero waste. Renew. Energy Focus 2023, 44, 373–389. [Google Scholar] [CrossRef]

- Spini, F.; Bettini, P. End-of-Life wind turbine blades: Review on recycling strategies. Compos. B Eng. 2024, 275, 111290. [Google Scholar] [CrossRef]

- Hasheminezhad, A.; Nazari, Z.; Yang, B.; Ceylan, H.; Kim, S. A comprehensive review of sustainable solutions for reusing wind turbine blade waste materials. J. Environ. Manag. 2024, 366, 121735. [Google Scholar] [CrossRef]

- Johst, P.; Lee, S.; Kim, E.; Bae, S.; Böhm, R.; Na, W. Structural integrity assessment of repurposed wind turbine blade composite components with acoustic emission testing and Ib-value analysis. Compos. B Eng. 2025, 301, 112490. [Google Scholar] [CrossRef]

- Ramaswamy, N.; Joshi, B.; Song, G.; Mo, Y.L. Repurposing decommissioned wind turbine blades: A circular economy approach to sustainable resource management and infrastructure innovation. Renew. Sustain. Energy Rev. 2025, 215, 115629. [Google Scholar] [CrossRef]

- Liu, P.; Barlow, C.Y. Wind turbine blade waste in 2050. Waste Manag. 2017, 62, 229–240. [Google Scholar] [CrossRef] [PubMed]

- Beauson, J.; Laurent, A.; Rudolph, D.P.; Jensen, J.P. The complex end-of-life of wind turbine blades: A review of the European context. Renew. Sustain. Energy Rev. 2022, 155, 111847. [Google Scholar] [CrossRef]

- Wang, Y.; Dong, B.; Dai, J.; Lu, G.; Peng, K.; Wang, Y. Value-added recycling strategies for decommissioned wind turbine blades: A review. Renew. Sustain. Energy Rev. 2025, 222, 115950. [Google Scholar] [CrossRef]

- Hao, C.; Zhao, B.; Guo, X.; Zhang, S.; Fei, M.; Shao, L.; Liu, W.; Cao, Y.; Liu, T.; Zhang, J. Mild chemical recycling of waste wind turbine blade for direct reuse in production of thermoplastic composites with enhanced performance. Resour. Conserv. Recycl. 2025, 215, 108159. [Google Scholar] [CrossRef]

- Sobek, S.; Lombardi, L.; Mendecka, B.; Mumtaz, H.; Sajdak, M.; Muzyka, R.; Werle, S. A life cycle assessment of the laboratory—Scale oxidative liquefaction as the chemical recycling method of the end-of-life wind turbine blades. J. Environ. Manag. 2024, 361, 121241. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, Y.; Li, Y.; Wang, Y.; Li, G.; Liu, X. Wind turbine blade recycling: A review of the recovery and high-value utilization of decommissioned wind turbine blades. Resour. Conserv. Recycl. 2024, 210, 107813. [Google Scholar] [CrossRef]

- Wu, W.; Prescott, D.; Remenyte-Prescott, R.; Saleh, A.; Ruano, M.C. An asset management modelling framework for wind turbine blades considering monitoring system reliability. Reliab. Eng. Syst. Saf. 2024, 252, 110478. [Google Scholar] [CrossRef]

- Xu, M.; Ji, H.; Meng, X.; Yang, J.; Wu, Y.; Di, J.; Jiang, H.; Lu, Q. Effects of core materials on the evolution of products during the pyrolysis of end-of-life wind turbine blades. J. Anal. Appl. Pyrolysis 2023, 175, 106222. [Google Scholar] [CrossRef]

- Dai, J.; Lin, K.; Zhu, C.; Wu, Y.; Ruan, J. Sustainable thermal conversion of waste wind turbine blades: Environmental impact and pollutant footprint analysis. Environ. Impact Assess. Rev. 2023, 115, 107999. [Google Scholar] [CrossRef]

- Lee, D.; Kim, J.; Yang, S.B.; Kwon, D. Development of reprocessable structural adhesives based on covalent adaptable networks for wind turbine blade. Compos. B Eng. 2025, 301, 112519. [Google Scholar] [CrossRef]

- Chen, S.; Liu, J.; Lin, Z.; Lin, S.; Li, L.; Chen, Y.; Evrendilek, F.; Li, W.; Huang, W.; Yang, C.; et al. Atmosphere-dependent pyrolytic transformability of glass fiber/epoxy resin composites in waste wind turbine blades. Chem. Eng. J. 2025, 505, 159675. [Google Scholar] [CrossRef]

- Jousef, S.; Eimontas, J.; Stasiulaitiene, J.; Zakarauskas, K.; Striugas, N. Recovery of energy and carbon fibre from wind turbine blades waste (carbon fibre/unsaturated polyester resin) using pyrolysis process and its life-cycle assessment. Environ. Res. 2024, 245, 118016. [Google Scholar]

- De Laurentis, C.; Windemer, R. When the turbines stop: Unveiling the factors shaping end-of-life decisions of ageing wind infrastructure in Italy. Energy Res. Soc. Sci. 2024, 113, 103536. [Google Scholar] [CrossRef]

- Martulli, L.M.; Diani, M.; Sabetta, G.; Bontumasi, S.; Colledani, M.; Bernasconi, A. Critical review of current wind turbine blades’ design and materials and their influence on the end-of-life management of wind turbines. Eng. Struct. 2025, 327, 119625. [Google Scholar] [CrossRef]

- Jani, H.K.; Kachhwaha, S.S.; Nagababu, G.; Das, A. A brief review on recycling and reuse of wind turbine blade materials. Mater. Today Proc. 2022, 62, 7124–7130. [Google Scholar] [CrossRef]

- Royuela, D.; Martínez, J.D.; López, J.M.; Callén, M.S.; García, T.; Verdejo, R.; Murillo, R.; Veses, A. Pursuing the circularity of wind turbine blades: Thermochemical recycling by pyrolysis and recovery of valuable resources. J. Anal. Appl. Pyrolysis 2024, 181, 106657. [Google Scholar] [CrossRef]

- Xu, G.; Liu, M.; Xiang, Y.; Fu, B. Valorization of macro fibers recycled from decommissioned turbine blades as discrete reinforcement in concrete. J. Clean. Prod. 2022, 379, 134550. [Google Scholar] [CrossRef]

- Cheng, Y.; Chen, J.; Deng, B.; Chen, W.; Silva, K.J.; Eddy, L.; Wu, G.; Chen, Y.; Li, B.; Kittrell, C.; et al. Flash upcycling of waste glass fibre-reinforced plastics to silicon carbide. Nat. Sustain. 2024, 7, 452–462. [Google Scholar] [CrossRef]

- Luo, D.; Gao, D.; Chen, N.; Yang, S.; Wang, Q. Upcycling wind turbine blades into durable Super-Hydrophobic coating for High-Efficiency Anti-Icing application. Chem. Eng. J. 2025, 507, 160323. [Google Scholar] [CrossRef]

- Luo, D.; Wang, F.; Li, L.; Cao, Y.; Yang, S.; Wang, Q. Recycling wind turbine blade to fabricate 3D framework for ultra-robust composite with enhanced electromagnetic interference shielding. Compos. B Eng. 2025, 305, 112734. [Google Scholar] [CrossRef]

- Olivera, A.F.; Chica, E.L.; Kolorado, H.A. Evaluation of thermoplastic composites for the manufacture of H-Darrieus wind Turbine blades on a laboratory scale. J. Mater. Res. Technol. 2025, 37, 1310–1323. [Google Scholar] [CrossRef]

- Zhang, W.; Yu, H.; Yin, B.; Akbar, A.; Liew, K.M. Sustainable transformation of end-of-life wind turbine blades: Advancing clean energy solutions in civil engineering through recycling and upcycling. J. Clean. Prod. 2023, 426, 139184. [Google Scholar] [CrossRef]

- Upadhyayula, V.K.K.; Yacout, D.M.M.; Latham, K.G.; Jansson, S.; Rova, U.; Christakopulos, P.; Matsakaus, L. Organosolv lignin carbon fibers and their prospective application in wind turbine blades: An environmental performance assessment. J. Clean. Prod. 2025, 491, 144825. [Google Scholar] [CrossRef]

- Zhou, A.; Zhang, Q.; Chen, P.; Wang, X.; Zhang, Y.; Xu, K.; Deng, S.; Sun, S.; Hu, Z.; Wang, X. Experimental study on the effects of cutting size and reaction temperature on the pyrolysis process and product characteristics of decommissioned wind turbine blades. Sustain. Energy Technol. Assess. 2025, 76, 104293. [Google Scholar] [CrossRef]

- Liu, S.; Guo, J.; Wu, C. Improving the pozzolanic reactivity of recycled powders from retired wind turbine blades by removing the polymer phase through thermal treatment. J. Build. Eng. 2024, 96, 110387. [Google Scholar] [CrossRef]

- Tan, Z.; Guo, Y.; Hu, G.; Chen, R.; Wang, Y.; Yin, B.; Leng, Z. Upcycling waste wind turbine blades into fiber-reinforced asphalt mortar: A chemical recycling approach and performance assessment. Constr. Build. Mater. 2025, 489, 142352. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, M.; Lin, J.; Liu, W.; Chen, L.; Wang, Z.; Sun, B.; Li, X. Exploring recycling strategies for retired wind turbine blades: The impact of policy subsidies and technological investments using a game-theoretic approach. J. Clean. Prod. 2025, 490, 144628. [Google Scholar] [CrossRef]

- Cheng, L.; Chen, R.; Yang, J.; Chen, X.; Yan, X.; Gu, J.; Liu, Z.; Yuan, H.; Chen, Y. Mechanisms, technical optimization, and perspectives in the recycling and reprocessing of waste wind turbine blades: A review. Renew. Sustain. Energy Rev. 2025, 218, 115834. [Google Scholar] [CrossRef]

- Mao, K.; Liu, Q.; Yu, T.; Zhang, S.; Tan, Z.; Zhang, G.; Shi, F.; Cao, P. Analytical modeling of tensile and flexural performance of concrete reinforced with recycled FRP-fiber from wind turbine blades. J. Build. Eng. 2025, 99, 111651. [Google Scholar] [CrossRef]

- Liu, H.; Laflamme, S.; Cardinali, A.; Lyu, P.; Rivero, I.V.; Doyle, S.E.; Wang, K. Enhancing 3D-printed cementitious composites with recycled carbon fibers from wind turbine blades. Constr. Build. Mater. 2025, 472, 140650. [Google Scholar] [CrossRef]

- Walzberg, J.; Hares, R.; Ghosh, T.; Key, A.; Potter, K.; Eberle, A. The inclusion of uncertainty in circularity transition modeling: A case study on wind turbine blade end-of-life management. Sustain. Energy Technol. Assess. 2023, 60, 103569. [Google Scholar] [CrossRef]

- Arkema. ZEBRA Consortium Unveils Second Recyclable Wind Turbine Blade. 2023. Available online: https://www.arkema.com/global/en/media/newslist/news/global/corporate/2023/20231220-zebra-unveils-second-recyclable-wind-turbine-blade/ (accessed on 20 December 2023).

- Siemens Gamesa Renewable Energy, S.A. Siemens Gamesa to Supply 132 RecyclableBlades to RWE’s Sofia Offshore Wind Project. Press Release. 2023. Available online: https://www.siemensgamesa.com/global/en/home/press-releases/022723-siemens-gamesa-press-release-recyclable-blade-offshore-sofia-united-kingdom.html (accessed on 9 March 2023).

- Carbon Conversions, Inc. Our Carbon Fiber Recycling Facility. 2025. Available online: https://carbonconversions.com/facility/ (accessed on 20 September 2025).

- Holcim Ltd. GE Renewable Energy and Holcim Team Up for a More Circular Wind Industry. Media Release. 2021. Available online: https://www.holcim.com/media/media-releases/ge-renewable-energy-and-lafargeholcim-team-a-more-circular-wind-industry (accessed on 10 June 2021).

- Shen, Y.; Aprak, S.E.; Zhu, Y. Recycling and recovery of fiber-reinforced polymer composites for end-of-life wind turbine blade management. Green Chem. 2023, 25, 9644–9658. [Google Scholar] [CrossRef]

- Hurtado-Alonso, N.; Manso-Morato, J.; Revilla-Cuesta, V.; Skaf, M. Strength-based RSM optimization of concrete containing coarse recycled concrete aggregate and raw-crushed wind-turbine blade. Compos. Struct. 2025, 356, 118895. [Google Scholar] [CrossRef]

- Li, L.; Wang, Y.; Wang, M.; Tan, H.; Xiong, X. Collaborative disposal of exhaust gas and waste wind turbine blades: Mechanical properties of recycled glass fibres and economic analysis. J. Clean. Prod. 2024, 471, 143351. [Google Scholar] [CrossRef]

- Liu, P.; Meng, F.; Barlow, C.Y. Wind turbine blade end-of-life options: An economic comparison. Resour. Conserv. Recycl. 2022, 180, 106202. [Google Scholar] [CrossRef]

- Mamanpush, S.H.; Tabatabaei, A.T.; Li, H.; Englund, K. Experimental data on the mechanical and thermal properties of extruded composites from recycled wind turbine blade material. Data Br. 2019, 25, 104253. [Google Scholar] [CrossRef]

- Sorte, S.; Figueiredo, A.; Vela, G.; Oliveira, M.S.A.; Vicente, R.; Relvas, C.; Martins, N. Evaluating the feasibility of shredded wind turbine blades for sustainable building components. J. Clean. Prod. 2024, 434, 139867. [Google Scholar]

- Pender, K.; Romoli, F.; Fuller, J. Lifecycle Assessment of Strategies for Decarbonising Wind Blade Recycling toward Net Zero 2050. Energies 2024, 17, 3008. [Google Scholar] [CrossRef]

- Zhang, A.; Seuring, S. Digital Product Passport for Sustainable and Circular Supply Chain Management: A Structured Review of Use Cases. Int. J. Logist. Res. Appl. 2024, 27, 2513–2540. [Google Scholar] [CrossRef]

- Ahmed, M.Z.; O’Donoghue, C.; McGetrick, P.J. Green Public Procurement in Construction: A Systematic Review. Clean. Responsible Consum. 2024, 15, 100234. [Google Scholar] [CrossRef]

- Yu, Z.; Lim, Y.J.; Williams, T.; Nutt, S. A Rapid Electrochemical Method to Recycle Carbon Fiber Composites Using Methyl Radicals. Green Chem. 2023, 25, 7058–7061. [Google Scholar] [CrossRef]

- Protsenko, A.E.; Shakirova, O.G.; Petrov, V.V. Recycling of Epoxy/Fiberglass Composite Using Supercritical Ethanol with (2,3,5-Triphenyltetrazolium)2[CuCl4] Complex. Polymers 2023, 15, 1559. [Google Scholar] [CrossRef]

- Vázquez-Fernández, J.M.; Abelleira-Pereira, J.M.; García-Jarana, B.; Cardozo-Filho, L.; Sánchez-Oneto, J.; Portela-Miguélez, J.R. Catalytic Hydrothermal Treatment for the Recycling of Composite Materials from the Aeronautics Industry. Appl. Sci. 2024, 14, 9874. [Google Scholar] [CrossRef]

- Mishnaevsky, L., Jr. Sustainable End-of-Life Management of Wind Turbine Blades: Overview of Current and Coming Solutions. Materials 2021, 14, 1124. [Google Scholar] [CrossRef]

- Yu, X.; Zhang, C.; Li, J.; Bai, X.; Yang, L.; Han, J.; Zhou, G. Reuse of Retired Wind Turbine Blades in Civil Engineering. Buildings 2025, 15, 2414. [Google Scholar] [CrossRef]

- Pender, K.; Yang, L. Glass Fibre Composites Recycling Using the Fluidised Bed: A Comparative Study into the Carbon Footprint in the UK. Sustainability 2024, 16, 1016. [Google Scholar] [CrossRef]

- Pender, K.; Yang, L. Waste Glass Fibre Composites Valorization Using the Fluidised Bed: A Global Warming Potential and Economic Assessment. J. Mater. Cycles Waste Manag. 2025, 27, 343–353. [Google Scholar] [CrossRef]

- Åkesson, D.; Krishnamoorthi, R.; Foltynowicz, Z.; Christéen, J.; Kalantar, A.; Skrifvars, M. Microwave pyrolysis as a method of recycling glass fibre from used blades of wind turbines. J. Reinf. Plast. Compos. 2012, 31, 1136–1142. [Google Scholar] [CrossRef]

- Zhang, D.; Song, Q.; Hou, B.; Zhang, M.; Teng, D.; Zhang, Y.; Bie, R.; Yang, H. Experimental Study on Microwave Pyrolysis of Decommissioned Wind Turbine Blades Based on Silicon Carbide Absorbents. Processes 2024, 12, 1065. [Google Scholar] [CrossRef]

- Schindler, A.K.; Duke, S.R.; Galloway, W.B. Co-processing of End-of-Life Wind Turbine Blades in Portland Cement Production. Waste Manag. 2024, 182, 207–214. [Google Scholar] [CrossRef] [PubMed]

- Karavida, S.; Peponi, A. Wind Turbine Blade Waste Circularity Coupled with Urban Regeneration: A Conceptual Framework. Energies 2023, 16, 1464. [Google Scholar] [CrossRef]

- Johst, P.; Bühl, M.; Enderle, C.; Kupfer, R.; Modler, N. Forecasting wind turbine blade waste with material composition and geographical distribution: Methodology and application to Germany. Resour. Conserv. Recycl. 2024, 211, 107876. [Google Scholar] [CrossRef]

- Cheng, X.; Du, B.; He, J.; Long, W.; Su, G.; Liu, J.; Fan, Z.; Chen, W. A review of thermoplastic composites on wind turbine blades. Compos. B Eng. 2025, 299, 112411. [Google Scholar] [CrossRef]

- Yan, Z.; Rahimizadeh, A.; Zhang, Y.; Zhou, Y.; Lessard, L. A finite element model for 3D printed recycled parts from end-of-life wind turbine blades. Compos. Struct. 2023, 320, 117177. [Google Scholar] [CrossRef]

- Wang, H.; Feng, L.; Wang, J.; Zhao, W.; Cheng, L. Analyzing critical core components’ technology opportunities based on multilayer networks from a lifecycle perspective: A case study of offshore wind turbine foundation. J. Clean. Prod. 2024, 477, 143850. [Google Scholar] [CrossRef]

- Zhang, Y.; Van Caneghem, J.; Pontikes, Y.; Granata, G.; Lessard, L.; Van Vuure, A.W. Environmental and economic assessment of mechanical recycling of end-of-life wind turbine blades into rebars and comparison with conventional disposal routes. Compos.-A Appl. Sci. Manuf. 2025, 190, 108711. [Google Scholar] [CrossRef]

- Mumtaz, H.; Sobek, S.; Sajdak, M.; Muzyka, R.; Werle, S. An experimental investigation and process optimization of the oxidative liquefaction process as the recycling method of the end-of-life wind turbine blades. Renew. Energy 2023, 211, 269–278. [Google Scholar] [CrossRef]

- Shen, M.; Guo, Z.; Feng, W. A study on the characteristics and thermal properties of modified regenerated carbon fiber reinforced thermoplastic composite recycled from waste wind turbine blade spar. Compos. B Eng. 2023, 264, 110878. [Google Scholar] [CrossRef]

- Oh, S.Y.; Joung, C.; Lee, S.; Shim, Y.; Lee, D.; Cho, G.; Jang, J.; Lee, J.Y.; Park, Y. Condition-based maintenance of wind turbine structures: A state-of-the-art review. Renew. Sustain. Energy Rev. 2024, 204, 114799. [Google Scholar] [CrossRef]

- Ekici, E.; Yildiz, M.J.; Kalinowska, M.; Wang, J.; Yildiz, G. Co-pyrolysis of waste wind turbine blades in a molten polyolefin medium. J. Anal. Appl. Pyrolysis 2025, 190, 107143. [Google Scholar] [CrossRef]

- Zhang, H.; Du, Y.; Lu, D.; Liu, K.; Zhang, T.; Chen, X.; Liu, H.; Li, L.; Luo, B. Nacre-inspired gradient design and multifunctional wood-based composites using recycled GFRP from decommissioned wind turbine blades. Chem. Eng. J. 2025, 514, 163116. [Google Scholar] [CrossRef]

- Yao, Y.; Cao, Y.; Rao, M.; Yang, J.; Zhang, Y.; Gu, J.; Han, J. Production of green phenol by microwave-assisted catalytic pyrolysis of epoxy-based carbon fiber reinforced plastic from wind turbine blades. J. Energy Inst. 2025, 119, 102005. [Google Scholar] [CrossRef]

- Health and Safety Executive (HSE). Controlling Airborne Contaminants at Work: A Guide to Local Exhaust Ventilation (LEV); HSG258, 3rd ed.; HSE Books: London, UK, 2017; ISBN 978-0-7176-6613-3. [Google Scholar]

- EN 1822-1:2019; High Efficiency Air Filters (EPA, HEPA and ULPA)—Part 1: Classification, Performance Testing, Marking. European Committee for Standardization: Brussels, Belgium, 2019.

- Harney, J.M.; McCague, A.; Cummings, K.J.; Cox-Ganser, J. Evaluation of Styrene and Dust Exposures and Health Effects During Fiberglass-Reinforced Wind Turbine Blade Manufacturing; NIOSH Health Hazard Evaluation Report 2013-0056-3256; CDC/NIOSH: Cincinnati, OH, USA, 2016. [Google Scholar]

- OSHA. 29 CFR 1910.134—Respiratory Protection; Occupational Safety and Health Administration: Washington, DC, USA, 2024. [Google Scholar]

- Liu, T.; Reascos, H.; Mughal, U.A.; Kirkelund, G.M.; Lima, A.T. Improving mortar properties with waste wind turbine blade fibers and superplasticizer. Constr. Build. Mater. 2025, 472, 140864. [Google Scholar] [CrossRef]

- Hurtado-Alonso, N.; Manso-Morato, J.; Revilla-Cuesta, V.; Ortega-López, V.; Skaf, M. Optimization of concrete containing wind-turbine wastes following mechanical, environmental and economic indicators. Clean. Mater. 2025, 16, 100317. [Google Scholar] [CrossRef]

- Ramirez, I.S.; Marquez, F.P.G.; Sánchez, P.J.B.; Gonzalo, A.P. A coustic inspection system with unmanned aerial vehicles for offshore wind turbines: A real case study. Measurement 2025, 251, 117226. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, P.; Yue, J.; Huan, H.; Bi, G.; Zhang, L. Recycling glass fibers from thermoset epoxy composites by in situ oxonium-type polyionic liquid formation and naphthalene-containing superplasticizer synthesis with the degradation solution of the epoxy resin. Compos. B Eng. 2023, 254, 110435. [Google Scholar] [CrossRef]

- Yousef, S.; Kalpokaitė-Dičkuvienė, R. Sustainable mortar reinforced with recycled glass fiber derived from pyrolysis of wind turbine blade waste. J. Mater. Res. Technol. 2024, 31, 879–887. [Google Scholar] [CrossRef]

| Waste Processing Method | Technological Process Outline | Key Advantages | Key Limitations | TRL | References |

|---|---|---|---|---|---|

| Mechanical recycling | Mechanical recycling typically entails cutting, crushing, and milling of composite materials, often in combination with separation techniques such as air classification, magnetic, electrostatic, and hydro-gravitational sorting. The process is environmentally benign, cost-effective, and readily scalable for industrial application; however, it typically leads to a deterioration in the mechanical properties of the recovered materials. | Environmentally benign; cost-effective; readily scalable; uses established separation/milling operations; rapid throughput. | Loss of continuous fibres; property downgrading of recyclate (powders/flour); suitability depends on end-use specifications. | 8–9 | [26,30] |

| Chemical recycling | This method employs chemical reactions to cleave the chemical bonds present within polymer matrices. It encompasses processes such as solvolysis, electrochemical treatments, and supercritical fluid techniques. These approaches facilitate the degradation of cross-linked polymer structures into linear chains or smaller molecules, enabling material recovery and reuse. Although effective, chemical recycling typically demands significant energy input and precise process control to ensure efficiency and environmental compliance. | Depolymerises cross-linked matrices into smaller molecules; enables fibre recovery with higher quality; potential to valorise resin-derived fractions. | Higher energy/operational intensity; solvent/reagent handling; tighter process control and compliance requirements. | 4–6 | [15,39,40] |

| Solvolysis | This process involves the use of solvents, often combined with catalysts or additives, to degrade the resin matrix under controlled temperature and pressure conditions. The treatment breaks down the cross-linked polymer network into linear polymer chains, facilitating the recovery of valuable fibre materials. Solvolysis offers a selective and efficient approach to polymer matrix decomposition, enabling improved recyclability of composite materials while maintaining fibre integrity. | Selective matrix degradation; good fibre surface cleanliness; preserves fibre integrity; potential resin-fraction recovery. | Pressurised solvents/catalysts; corrosion/effluent management; scale-up complexity. | 4–6 | [29,30,41] |

| Electrochemical method | This process involves the degradation of waste materials within an electrolyte solution through electrochemically assisted catalysis. Specifically, the waste is suspended in a sodium chloride (NaCl) solution containing a potassium hydroxide (KOH) catalyst. The applied electric current facilitates catalytic reactions that degrade the polymer matrix, promoting depolymerisation and enabling the recovery of valuable components. This method offers a controlled and efficient approach to polymer degradation under relatively mild conditions. | Mild conditions; controllable degradation of matrix; prospect of lower thermal damage to fibres. | Early-stage maturity; electrolyte stability/management; limited multi-tonne demonstrations. | 3–5 | [42] |

| Supercritical fluid methods | These techniques involve the dissolution and degradation of polymer waste using supercritical or near-supercritical fluids. Various solvents such as water, propanol, potassium phosphate, and diethylene glycol, often combined with catalysts like sodium hydroxide (NaOH), potassium hydroxide (KOH), sulphuric acid, or benzyl alcohol—or sometimes applied without catalysts—have been employed to recover fibres. This approach results in fibres with clean, smooth surfaces, and high tensile strength, making it an effective method for reclaiming valuable composite materials while minimising environmental impact. | Very clean, smooth fibre surfaces; high retained fibre strength; short processing times. | High-pressure equipment/safety; energy demand and CAPEX; solvent make-up/recovery. | 4–6 | [8,21] |

| Thermal recycling | Thermal recycling involves the treatment of waste through pyrolysis, combustion, or other advanced thermal methods. These processes enable the separation of composite components by breaking down the polymer matrix and releasing the reinforcing fibres. Additionally, thermal recycling can recover energy in the form of heat generated during combustion or pyrolysis, contributing to resource efficiency and waste valorisation. | Separates fibre/matrix thermally; enables energy recovery; industrial thermal know-how transferable. | Fibre degradation risk (esp. GFRP); off-gas/emissions control needed; residue removal. | 6–8 | [43,44,45] |

| Pyrolysis | Pyrolysis of wind turbine blade components is typically conducted at temperatures around 600 °C, where thermal decomposition of the resin matrix occurs. This process breaks down the polymeric resin within the composite material, effectively separating the reinforcing fibres while minimising damage to their mechanical properties. Pyrolysis thus enables the recovery of valuable fibres and reduces the volume of composite waste, offering an efficient and sustainable recycling pathway. | Efficient matrix removal; good retention for CFRP fibres; valuable gas/oil co-products. | GFRP fibre property loss; fibre cleaning/post-treatment; tight atmosphere/temperature control. | 6–8 | [32,46,47,48] |

| Fluidised-bed process (thermal pyrolysis variant) | Shredded composite waste is introduced into a fluidised bed of quartz sand and heated to c. 450 °C. Hot air causes thermal decomposition of the polymer matrix. Decomposition products and released fibres are carried by the gas flow and separated in a cyclone; remaining polymer residues are burnt off in an afterburner. The process enables recovery of carbon fibres but is unsuitable for glass fibre composites. | Continuous operation; effective resin removal; suitable for CFRP fibre recovery. | Generally unsuitable for GFRP; media/particle handling; cyclone/afterburner complexity. | 5–7 | [31,49] |

| Microwave-assisted pyrolysis | Microwave-assisted pyrolysis operates at lower temperatures compared to conventional pyrolysis, which significantly reduces thermal degradation of fibre-reinforced composite materials. This milder thermal regime better preserves the recovered fibres’ mechanical performance, positioning microwave pyrolysis as a promising route for recycling composite waste with improved material quality and efficiency. | Lower bulk temperature; shorter cycles; reduced thermal damage to fibres vs. conventional pyrolysis. | Scale-up and field uniformity; need for susceptors/absorbers; process controllability at scale. | 4–6 | [15,50] |

| Combustion | Combustion involves the co-processing of shredded turbine blade materials mixed with other waste streams or co-fired alongside coal in energy recovery facilities. This method enables the recovery of energy content from composite waste, but it typically results in the complete destruction of the composite structure, preventing material reuse. Combustion processes must be carefully managed to control emissions and comply with environmental regulations, ensuring sustainable waste-to-energy conversion. | Highest industrial readiness; full energy recovery; substitution of fuel/raw meal in cement kilns. | No material recovery of fibres; emissions permitting and quality control of clinker feed required. | 9 | [11,14,16,33] |

| Waste Processing Method | Fibre Yield | Energy Consumption (MJ/kg) | Cost | Material Quality | References |

|---|---|---|---|---|---|

| Mechanical recycling | (no continuous fibres; powder product) | 0.17–1.93 | Low | Low (powder; reduced properties) | [9,31,32,41,50] |

| Chemical recycling | High (>90%) | 61–93 | High | Very high (near-virgin fibres; clean surface) | [39,40,41] |

| Solvolysis | High (>90%) | NR | High | Very high (clean fibres; monomer recovery possible) | [1,11,41] |

| Electrochemical method | NR | NR | Medium–high | High (reported case-wise | [32,41] |

| Supercritical fluid methods | High (>90%) | NR | High | Very high (smooth, clean fibres) | [8,32,41] |

| Thermal recycling | Carbon fibre composites: 75.8–77.5%; glass fibre composites: negligible (combustion reported separately) | 3–30 | Medium–high | Carbon fibre composites: medium–high (properties partly retained); glass fibre composites: low (significant strength loss) | [11,44] |

| Pyrolysis | 75.8–77.5% fibres; gas ≤ 12.9%; oil 8.8–18.7% | 3–30 | Medium–high | Carbon fibre composites: medium–high; glass fibre composites: low | [43,46,47,51] |

| Fluidised-bed process (thermal pyrolysis variant) | Carbon fibre composites: fibre recovery feasible; glass fibre composites: unsuitable | NR (operates ~450 °C) | Medium | Carbon fibre composites: medium; glass fibre composites: not applicable | [31,50] |

| Microwave-assisted pyrolysis | NR (reported comparable to conventional pyrolysis) | NR (trend: lower than conventional) | Medium–high | High (reduced thermal damage) | [15] |

| Combustion | 0% (no fibre recovery) | n/a (net energy recovery) | Low–medium | None (material destroyed) | [11,44] |

| Waste Processing Method | CPT (€/t, Band *) | Deployment Status | Expected Revenue Streams | Financing and Policy Instruments | References |

|---|---|---|---|---|---|

| Mechanical recycling | Low (<150) | Industrial | Sale of fillers/powders; gate fees; avoided landfill | EPR take-back fees; green public procurement for recycled content; SME CAPEX grants | [12,30,41,76] |

| Chemical recycling | High (>400) | Pilot/demo | Near-virgin fibre premia; monomer streams | PPPs for first-of-a-kind plants; innovation funds; tax credits for recycled content | [15,32,33,39] |

| Solvolysis | High (>400) | Pilot/demo | High-grade fibres; possible resin/intermediates | EPR eco-modulation; soft loans; carbon contracts for difference (where applicable) | [32,71] |

| Electrochemical method | Med–High (150–400+) | Lab/pilot | Select fibres/oligomers; licencing | R&D grants; pilot-line PPPs | [32,80] |

| Supercritical fluid methods | High (>400) | Pilot | Premium fibres | First-of-a-kind guarantees; green bonds | [81,82,83,84] |

| Thermal recycling | Med–High (150–400) | Demo/industrial (route-dependent) | Oils/gases; CFRP fibre (part-retained) | Industrial decarbonisation funds; energy recovery incentives | [41,44,51] |

| Pyrolysis | Med–High (150–400) | Demo/early industrial | CFRP fibre resale; pyro-oil/gas | Project finance with offtake; EPR; reduced electricity levies | [43,47,59], |

| Fluidised-bed process (thermal pyrolysis variant) | Medium (150–300) | Pilot/demo | CFRP fibres; energy recovery | PPPs; regional waste-to-resources programmes | [83,85,86] |

| Microwave-assisted pyrolysis | Med–High (150–400+) | Pilot | CFRP fibre resale; condensate oil/gas | Innovation grants; pilot guarantees | [15,87,88] |

| Combustion | Low/Negative ** | Industrial | Gate-fee revenue; energy and mineral substitution | Co-processing guidelines; landfill/incineration restrictions | [70,89] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cieślewicz, N.; Pilarski, K.; Pilarska, A.A. End-of-Life Strategies for Wind Turbines: Blade Recycling, Second-Life Applications, and Circular Economy Integration. Energies 2025, 18, 5182. https://doi.org/10.3390/en18195182

Cieślewicz N, Pilarski K, Pilarska AA. End-of-Life Strategies for Wind Turbines: Blade Recycling, Second-Life Applications, and Circular Economy Integration. Energies. 2025; 18(19):5182. https://doi.org/10.3390/en18195182

Chicago/Turabian StyleCieślewicz, Natalia, Krzysztof Pilarski, and Agnieszka A. Pilarska. 2025. "End-of-Life Strategies for Wind Turbines: Blade Recycling, Second-Life Applications, and Circular Economy Integration" Energies 18, no. 19: 5182. https://doi.org/10.3390/en18195182

APA StyleCieślewicz, N., Pilarski, K., & Pilarska, A. A. (2025). End-of-Life Strategies for Wind Turbines: Blade Recycling, Second-Life Applications, and Circular Economy Integration. Energies, 18(19), 5182. https://doi.org/10.3390/en18195182