A Comparative Analysis of Hydrogen Fuel Cells and Internal Combustion Engines Used for Service Operation Vessels Propulsion

Abstract

1. Introduction

1.1. Research Background

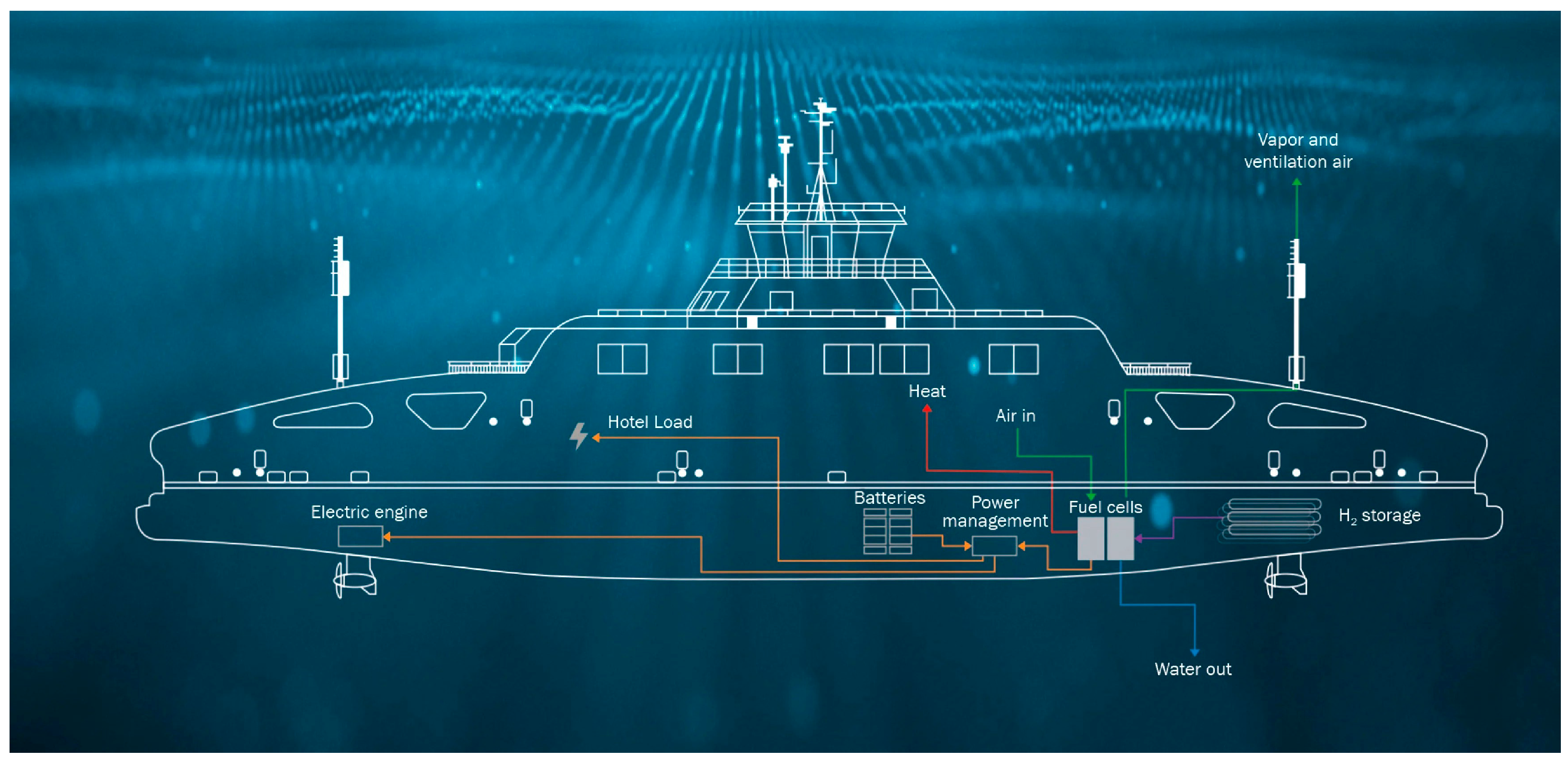

- 2 Ballard FCwave™ (Ballard Power Systems Europe A/S, Hobro, Denmark) hydrogen fuel cells (power 200 kW each);

- Cryogenic tanks from Linde Engineering (Pullach, Germany) (volume 80 m3);

- Electricity storage in the form of batteries (1.36 ÷ 1.5 MWh);

- 2 Scania DI16 75M generators (Scania AB, Södertälje, Sweden) powered by hydrogen and diesel oil (power 500 kW each);

- 2 Schottel SRE 340 LFP thrusters (SCHOTTEL Industries GmbH, Spay/Rhein, Germany).

- Transport and storage of this fuel, which can be transported in gaseous form (compressed hydrogen CH2) in special high-pressure tanks at 700 bar, or in liquid form (liquefied hydrogen LH2) in special tanks at very low temperatures of around −253 °C;

- The use of this fuel in ship propulsion systems, i.e., through direct combustion in internal combustion engines or using hydrogen fuel cells;

- Development of port infrastructure, which is largely lacking worldwide.

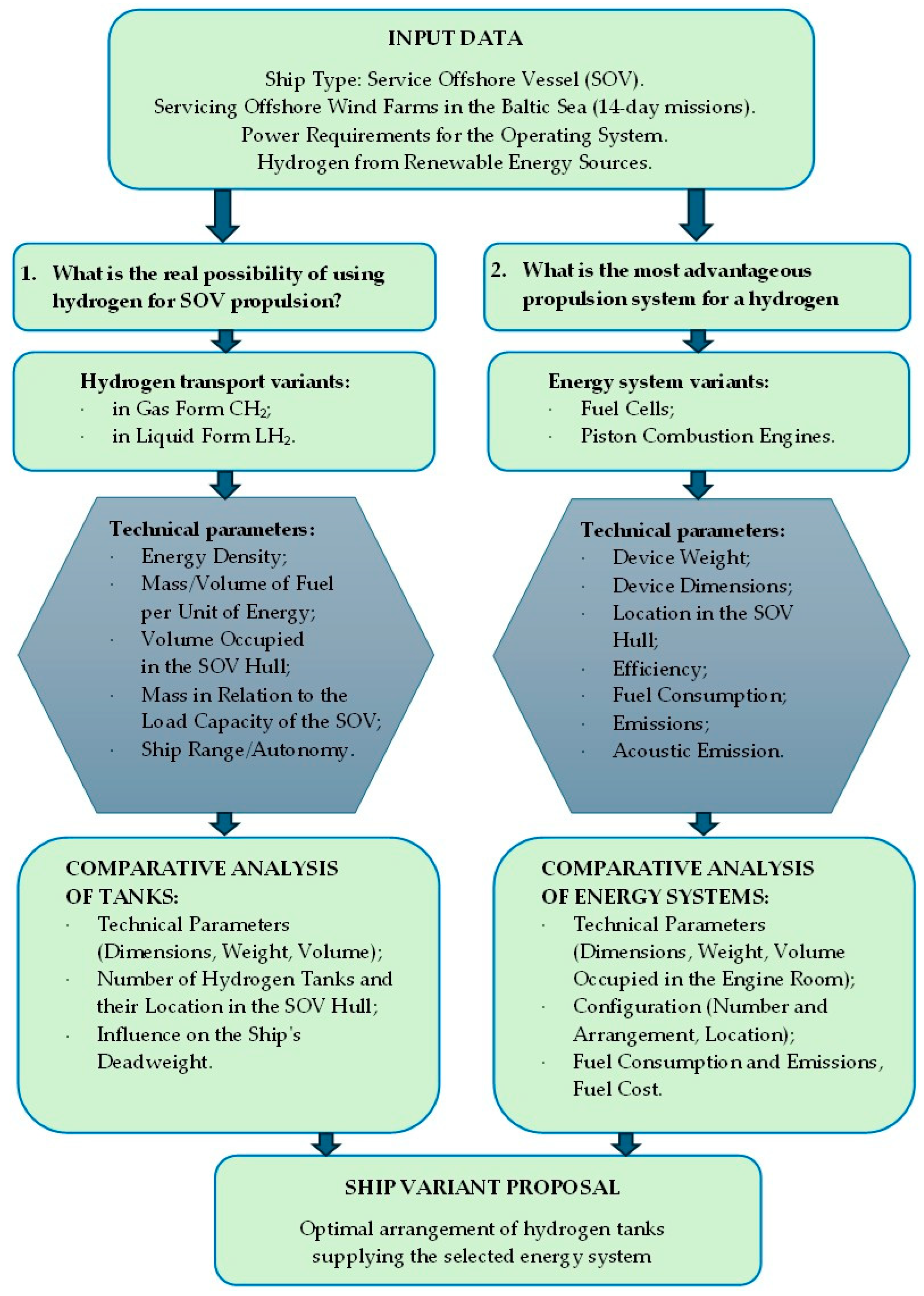

- A comparative analysis of SOV power systems using hydrogen-powered internal combustion engines and hydrogen fuel cells (PEMFCs), with respect to space requirements, mass of the power devices and fuel consumption;

- Evaluation of hydrogen storage methods, including a comparative assessment of liquid hydrogen (LH2) versus compressed hydrogen (CH2), entailing a detailed review of technological challenges and available specialised storage solutions;

- Benchmarking of the results against the reference fuel, marine diesel oil (MDO);

- Assessment of the current regulatory framework and standards for hydrogen, together with an analysis of up-to-date market data, including price variability and projected trends.

1.2. Hydrogen Transport and Storage—Compressed vs. Cryogenic

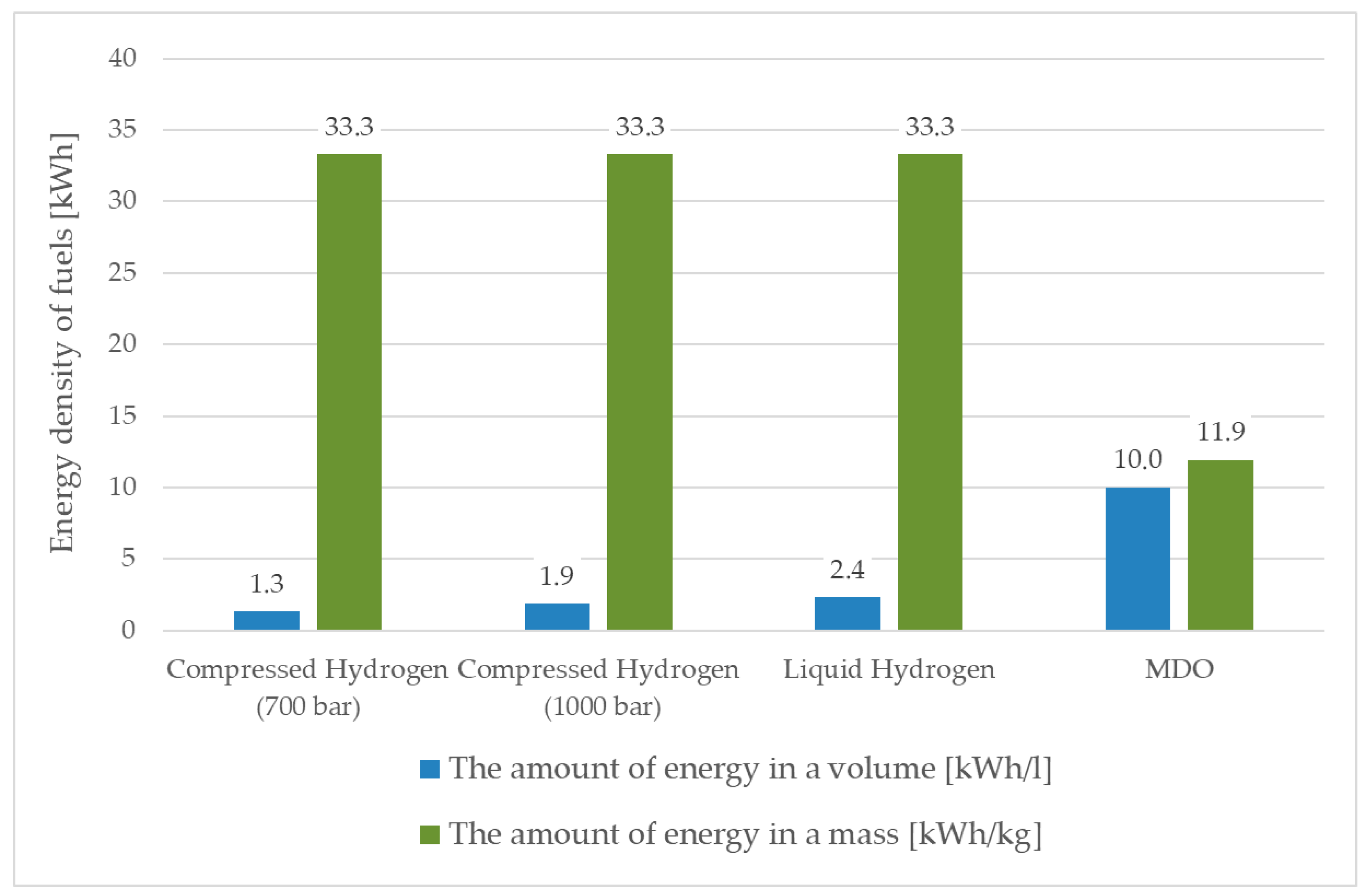

1.2.1. Hydrogen—Properties and Energy Significance

| No. | Property | Compressed Hydrogen (300 bar, 20 °C) | Compressed Hydrogen (700 bar, 20 °C) | Liquid Hydrogen (LH2) (−253 °C) | MDO (40 ÷ 50 °C) |

|---|---|---|---|---|---|

| 1. | Physical condition | Gas | Gas | Cryogenic Liquid | Liquid |

| 2. | Density | 24 kg/m3 | 42 kg/m3 | 70.8 kg/m3 | 875 kg/m3 |

| 3. | Volumetric energy density | 1.3 kWh/L | 2.4 kWh/L | 2.36 kWh/L | 35 ÷ 38 MJ/l |

| 4. | Lower heating value (LHV) | 120 MJ/kg | 42 ÷ 43 MJ/kg | ||

| 5. | High heating value (HHV) | 141.8 MJ/kg | 45 MJ/kg | ||

| 6. | Flash-point | ~585 °C | >60 ÷ 80 °C | ||

| 7. | Evaporation (boil-off) | No | No | 0.2 ÷ 1%/per day | Very low |

1.2.2. Hydrogen Transport—Compressed vs. Cryogenic

- For CH2—Hexagon Purus Maritime (Oslo/Langevåg, Norway), NPROXX (Heerlen, The Netherlands), Luxfer Gas Cylinders (Riverside, CA, USA), Steelhead Composites (Golden, CO, USA), Hyfindr (Stuttgart, Germany), MAHYTEC (Dole, France);

- For LH2—MAN Cryo (Göteborg, Sweden; Augsburg, Germany), Chart Industries (Ball Ground, GA, USA), Linde Engineering (Pullach, Germany).

1.3. Hydrogen Fuel Cells in Ship Propulsion

1.4. Research Aim

- Physical and chemical properties of hydrogen: compressed hydrogen (CH2) and liquefied hydrogen (LH2) were compared in terms of energy density, storage conditions, safety and technological requirements under marine operating conditions on SOVs;

- Selection of power supply technology: available technologies, i.e., PEMFC, SOFC and hydrogen-powered internal combustion engines, were analysed in terms of technical parameters and suitability for the SOV power profile, and possible configurations and their arrangement in the hull were proposed;

- Fuel consumption and storage systems: fuel consumption was estimated for selected operating variants, a suitable tank system for LH2 was selected and compared with CH2, LH2 fuel tanks were laid out on the SOV’s working deck and their impact on the ship’s overall space was assessed;

- Space efficiency: the degree of hull space utilisation was assessed in terms of the volume required for hydrogen storage, indicating the design implications;

- Simplified economic analysis: a preliminary analysis of the costs of using hydrogen as a marine fuel was carried out; due to the limited availability of data (e.g., price of green hydrogen, bunkering infrastructure, component costs), the results are approximate.

2. Initial Assumption and Methodology

2.1. Specifications of the SOV

- Length between perpendiculars, Lbp = 72.0 m;

- Breadth, B = 18.0 m;

- Hull depth, H = 8.9 m;

- Displacement, D = 5004 t;

- Deadweight, DWT = 1005 t;

- Cargo weather deck area, Awd = 620 m2.

- Total power of the energy system, NC = 5400 kW;

- Power of the generator (3 pcs.), NAP = 1800 kW;

- Main propulsion power, NNG = 2800 kW;

- Power of the main azimuth thruster (2 pcs.), Np = 1400 kW;

- Bow tunnel thruster power (2 pcs.), NSS = 1200 kW;

- Bow retractable azimuth thruster power (1 pcs.), NSW = 800 kW.

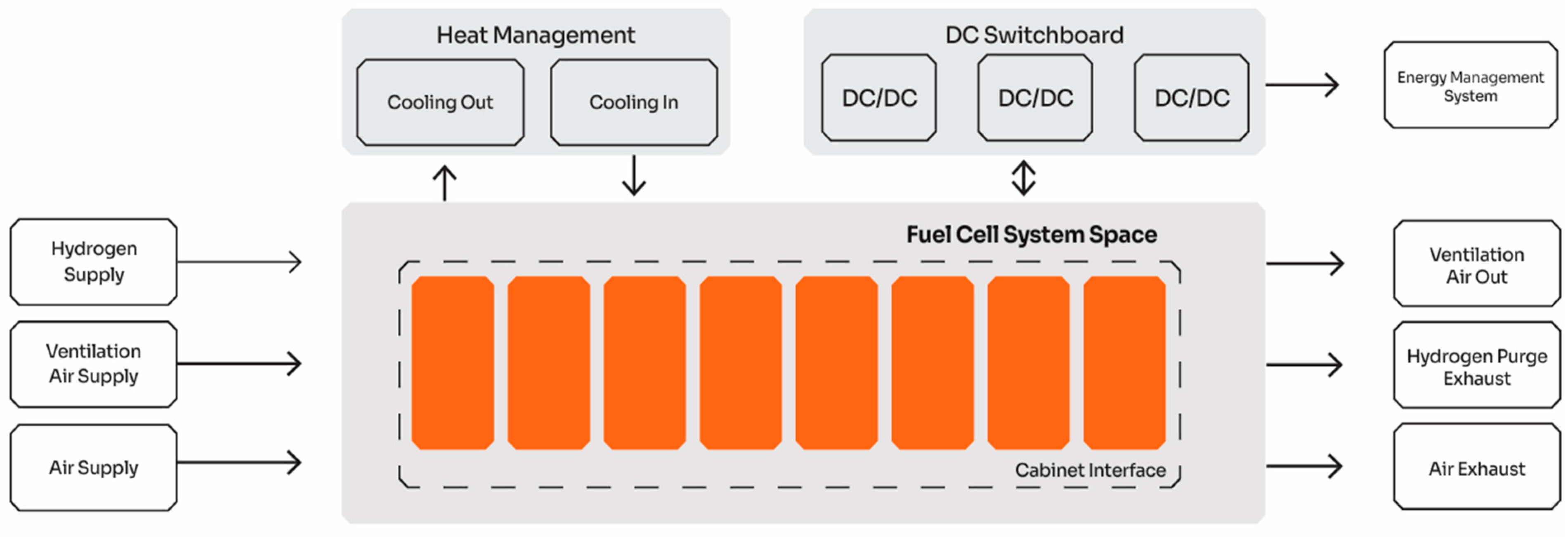

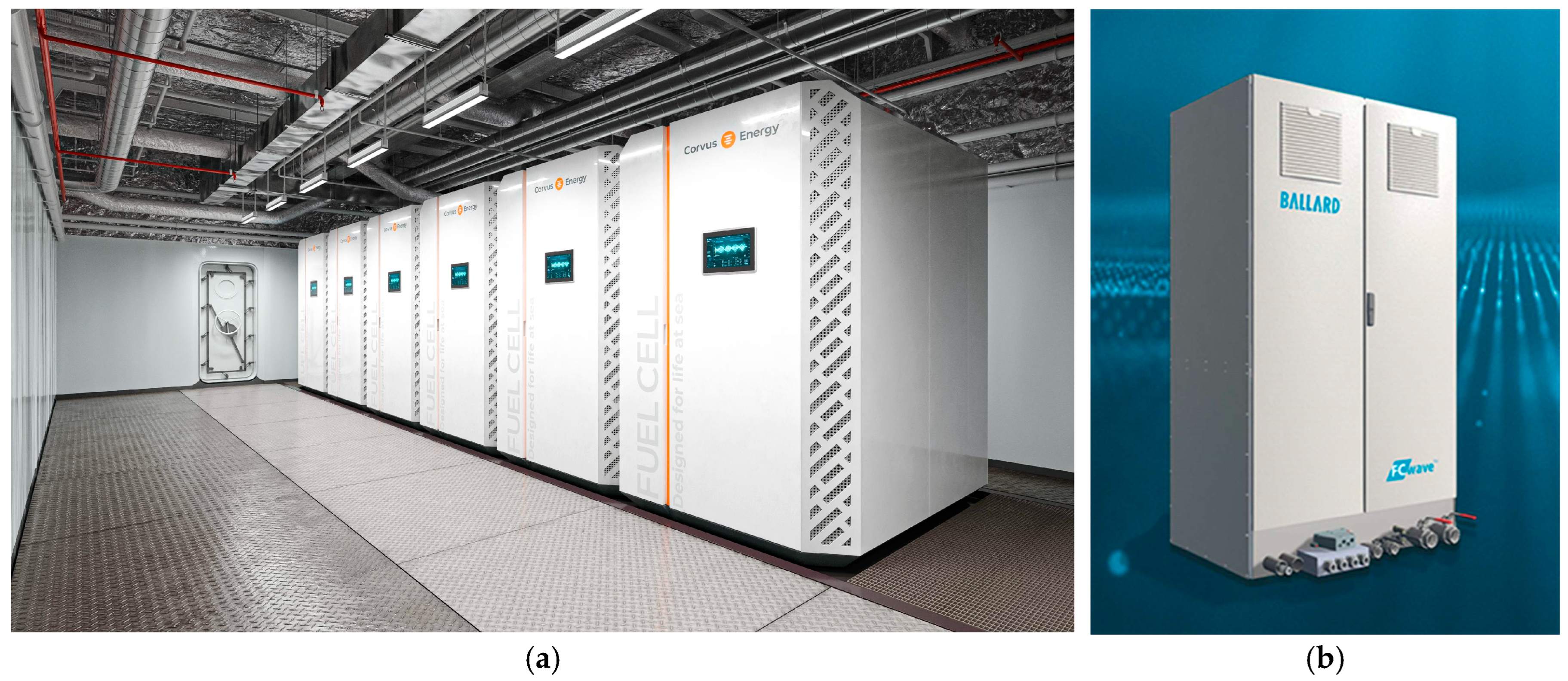

- Ballard’s Power System (Hobro, Denmark)—FCwave™ module;

- Corvus Pelican System (Nesttun, Norway)—Corvus Pelican (FCS) system;

- PowerCell Marine System (Gothenburg, Sweden)—Marine System 225 module.

2.2. Hydrogen Storage and Transport on SOV

- 1.

- A tank in the form of a type IV high-pressure composite cylinder, manufactured by Hexagon Purus, pressure 700 bar at ambient temperature; modular installation of the cylinder with a frame guard on a service vessel.Technical data—H2-70-705X2078 [73]:

- Outside diameter, DCH2 = 705 mm;

- Overall length, LCH2 = 2078 mm;

- Cylinder weight, WCH2 = 264 kg;

- Volume, V = 457 L;

- Hydrogen capacity, VCH2 = 18.4 kg;

- Weight of the hydrogen cylinders, WC+CH2 = 282.4 t;

- Rack weight for 9 pcs CH2 cylinders, WRack CH2 = 238 t acc. [19].

- 2.

- LH2 cryogenic tank—ISO (HYLICS) in a 40 ft stainless steel frame with container dimensions (12.19 m × 2.44 m × 2.59 m), manufactured by Linde Engineering, operating pressure 12.75 bar at a temperature of −253 °C; the tank has vacuum-perlite insulation, optionally with LIN-Shield (liquid nitrogen shield), low boil-off evaporation losses (<0.5%/day).

- Technical data [50]:

- Outside diameter, DLH2 = approx. 2200 mm;

- Overall length, LLH2 = approx. 10,500 mm;

- Usable tank capacity (gross), V = 48.4 m3;

- Weight of liquid hydrogen (LH2 charge), WLH2 = approx. 3040 kg,

- (at 10% loss—for hydrogen density ~70 kg/m3);

- Cryogenic tank weight LH2, WZ = approx. 12,500 kg,

- (fittings, valves, insulation);

- Weight of the steel frame ISO 40 ft, WR = approx. 3000 kg;

- Weight of the tank with frame, WZR = approx. 15,500 kg;

- Total weight (tank, frame and hydrogen), WC = approx. 18,500 kg.

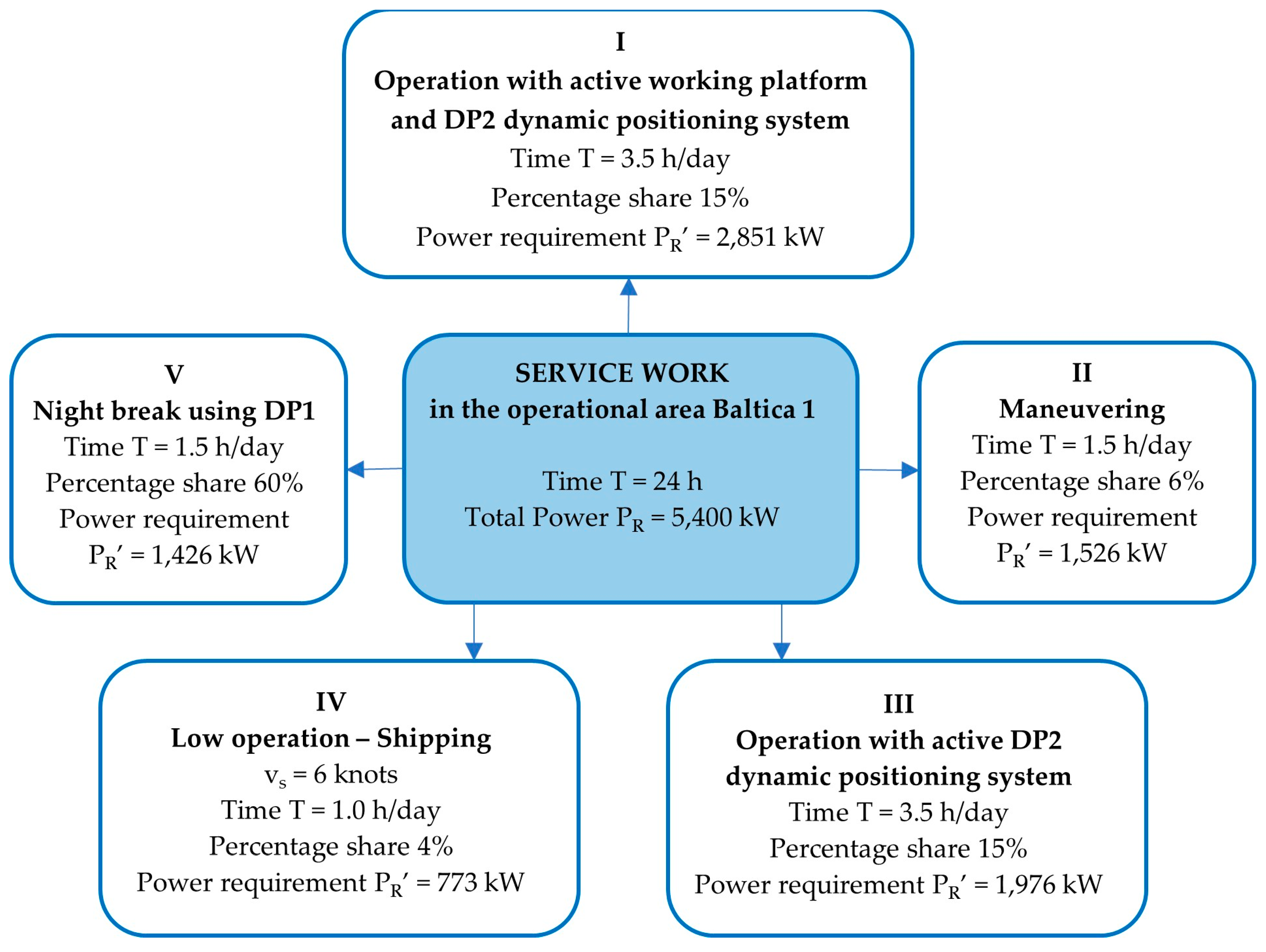

2.3. Operational Profile of Service Vessel Work

- Normal operation: shipping to the working area.

- Service Work in the offshore wind farms in the Baltic Sea.

- Normal operation: shipping to port.

- Stopover in port.

2.4. Research Method

3. Analysis of the SOV Design for the Use of Hydrogen Fuel Cells

3.1. SOV Energy System Specification

3.1.1. Selection of the Hydrogen Fuel Cells

- Ballard’s Power System (Hobro, Denmark)—the FCwave™ module designed to provide emission-free energy for marine vessels, which is the world’s first fuel cell approved by DNV for marine applications. The system is scalable from 200 kW to 1.2 MW to match a wide range of power requirements for vessels operating on short or long, more demanding routes [56].

- Corvus Pelican System (Nesttun, Norway)—the Corvus Pelican fuel cell system (FCS) can serve as the primary or auxiliary power source in vessels. This system is ideal for zero-emission operation for coastal vessels and offshore vessels operating over short distances, as well as vessels that operate on routes where hydrogen fuel is available. The system is scalable from 340 kW to 10 MW [57].

- PowerCell Marine System (Gothenburg, Sweden)—the Marine System 225 module is a compact fuel cell system that is highly efficient and easy to install and maintain. The system allows power scaling from 225 kW to megawatt outputs. It is also flexible in terms of fuel use and can run on reformed renewable fuels [58].

3.1.2. Comparison of Internal Combustion Engines and Fuel Cells

- 2 × 1700 kW (5 × 340 kW);

- 1 × 2040 kW (6 × 340 kW).

- When arranged in rows, the fuel cell modules occupy on average 13.7% (9.3 ÷ 18.5%) more space in the engine room than internal combustion engines. However, fewer fuel cell service devices may contribute to overall reduction in the space required for the entire engine room and easier spatial planning;

- The fuel cell modules used are significantly lower than internal combustion engines, by an average of 24.3% (18.1 ÷ 29.9%), and do not require as much service space over them as combustion engines, which leads to a more optimal layout of the entire engine room in the SOV hull;

- The fuel cell modules used are significantly lighter than internal combustion engines, by an average of 50.6% (20.0 ÷ 73.3%), in particular Ballard’s FCwave™ fuel cells (Ballard Power Systems Europe A/S, Hobro, Denmark), which are 64% lighter than the Wärtsilä engine (Wärtsilä Corporation, Helsinki, Finland), 73% lighter than the BEH2YDRO engine (Anglo Belgian Corporation, Gent, Belgium) and 55% lighter than Corvus fuel cells (Corvus Energy, Nesttun, Norway), which will significantly reduce the total weight of the power plant;

- Fuel cells need fewer installations handling power machinery (no exhaust gas systems, lubrication or start-up systems), which lowers the engine room weight and enables more optimal layout;

- The use of hydrogen fuel cells reduces atmospheric emissions to zero, but limits the possibility of using other types of fuel;

- Modular design of fuel cells allows arranging them more optimally and flexibly in the power plant, and power scaling facilitates the selection of cells and their configuration depending on the electricity demand in different operating states of the SOV.

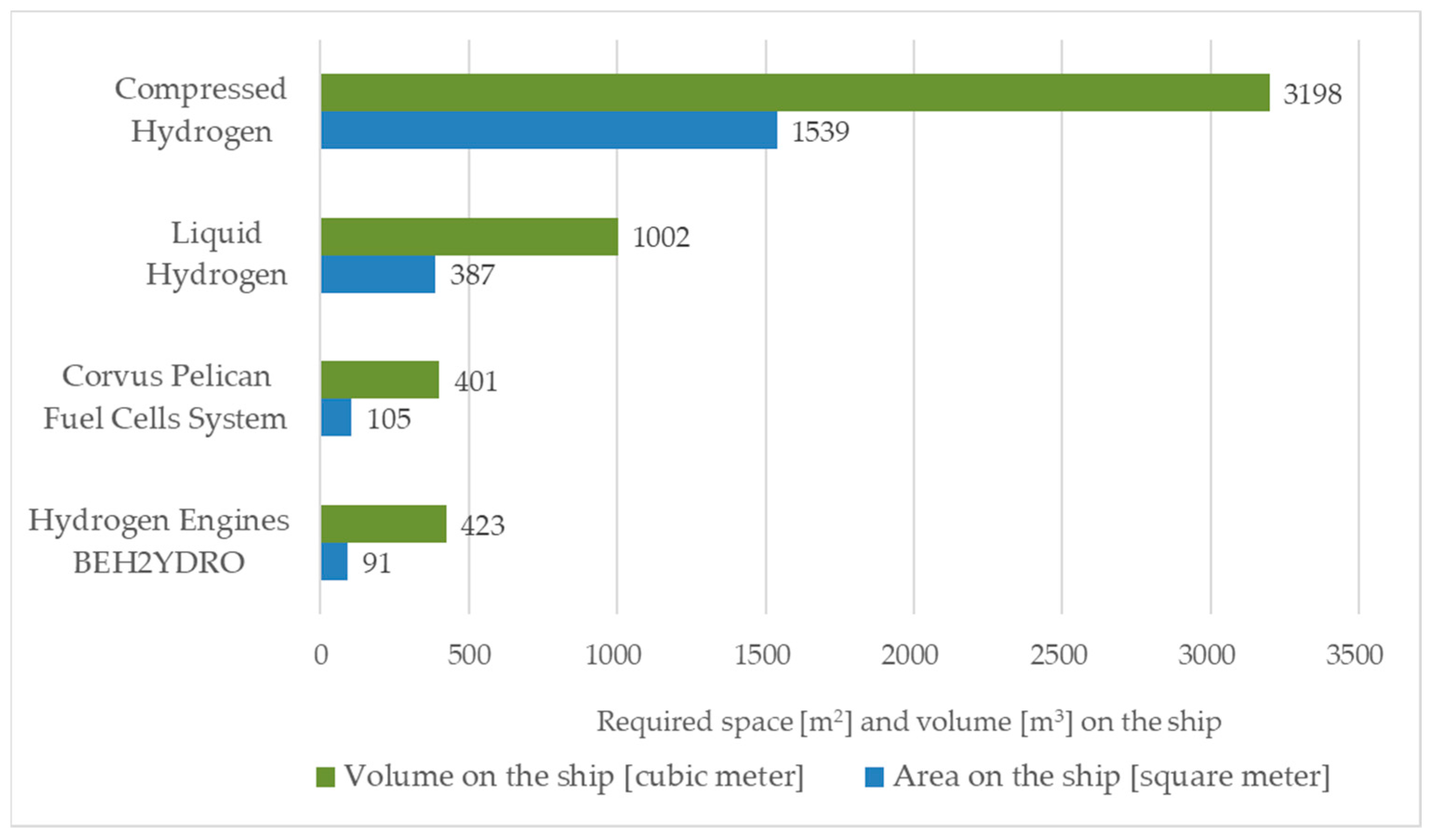

3.2. Analysis of the Hydrogen Supply and the Arrangement of the CH2 and LH2 Tanks in the SOV Hull

3.2.1. Hydrogen Supply—Internal Combustion Engines vs. Fuel Cells

- 1.

- For hydrogen-powered internal combustion engines, the overall efficiency estimated in [19] was assumed to be ηDE = 0.44, with an average load of 80% of the rated power.In addition, the estimated power demand in the assumed SOV operating modes is shown in Figure 6, along with respective duration of each mode.

- 2.

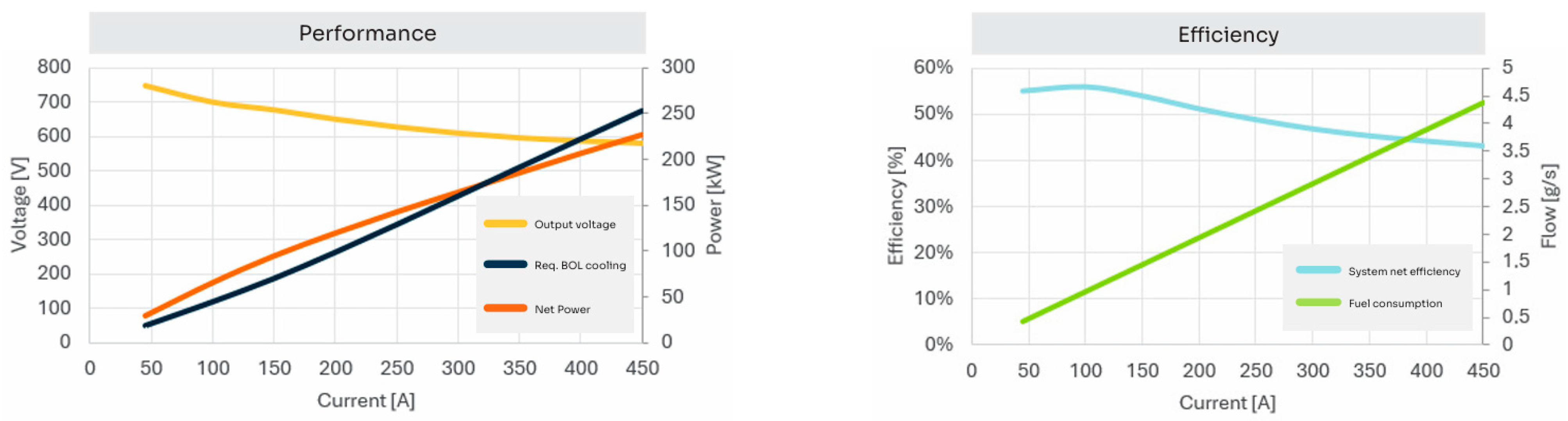

- For hydrogen fuel cells, the maximum overall efficiency specified in the manufacturers’ catalogues was assumed to be ηFC = 0.52 ÷ 0.56, depending on the type of cell (Table 7).In addition, changes in efficiency and fuel consumption depending on the cell power (graphs in Figure 5) were also taken into account; they show that at maximum fuel cell power, their efficiency drops to around 0.42. For further calculations, the fuel cell efficiency was therefore assumed to be ηFC = 0.46, which corresponds to an average cell load of 80% of the rated power.

- Weight of compressed CH2 significantly exceeds the weight of the LH2 system in the entire analysed cruising range, as for 14 days of operation, the weight of the LH2 system (tank with frame) is approx. 244 t, while for CH2 (cylinders with frame) it is as much as 648 t, more than 2.6 times more;

- Volume of LH2 storage systems is more than three times smaller for 14 days than that for compressed hydrogen (LH2—1002 m3, CH2—3198 m3);

- The use of deck space for LH2, ranging from 5% to 62%, represents an efficient utilisation, whereas for CH2, ranging from 18% to 248%, the available deck space is fully utilised and exceeded after approximately four days of operation, rendering the solution impractical for continued service beyond this period.

3.2.2. Hydrogen Storage on SOV—CH2 vs. LH2

- Shortening the length of service missions;

- Developing infrastructure for refuelling hydrogen at sea (e.g., through offshore electrolysers powered by wind farms);

- Integration of energy storage systems in the form of batteries.

3.3. Fuel Costs

- Kfuel CH2, 326,942 $;

- Kfuel LH2, 313,852 $;

- Kfuel MDO, 59,084 $.

4. Results

4.1. Location of Hydrogen Tanks on the Ship

- Maximum number of tanks, 8 ÷ 9 for a 9 ÷ 10 day mission;

- Total fuel reserve MTfuel, 27 ÷ 30 t;

- Fuel volume Vfuel, 385 ÷ 428 m3;

- Full tank weight (with hydrogen), 134.3 t;

- Cryogenic hydrogen tank weight (with hydrogen), 151 ÷ 169.8 t.

4.2. Needed Masses and Volumes of Hydrogen

5. Conclusions

- Indicating technologies that can be realistically implemented on SOVs and identifying limitations that should be considered already at the vessel design stage. At present, the storage of LH2 has greater application potential for service vessels than CH2, as it enables a significant reduction in tank mass and volume.

- Demonstrating that the application of hydrogen fuel cells on SOVs offers substantial operational benefits, as they are characterised by lower weight, modular construction and simpler power plant infrastructure compared to internal combustion engines. This provides designers with greater flexibility in arranging machinery spaces and optimising spatial layouts, thereby increasing the vessel’s usable area.

- Revealing IMO regulatory constraints, including the absence of precise guidelines regarding the location of hydrogen tanks within the ship’s hull, which represents a significant barrier to the design of such vessels. Thus, the results may contribute to confirming the need to accelerate the development of safety standards for hydrogen, which is undoubtedly a future-oriented and zero-emission fuel.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- DNV. Handbook for Hydrogen-Fuelled Vessels, MarHySafe JDP Phase 11st Edition (June 2021). Available online: https://www.dnv.com/maritime/publications/handbook-for-hydrogen-fuelled-vessels-download (accessed on 10 April 2025).

- DNV. Industry Insights Decarbonization Digitalization. Strategies for Meeting Upcoming Decarbonization Targets. Available online: https://www.dnv.com/expert-story/maritime-impact/strategies-for-meeting-upcoming-decarbonization-targets (accessed on 1 May 2025).

- IEA. Global Hydrogen Review 2024. Available online: https://www.iea.org/reports/global-hydrogen-review-2024 (accessed on 10 April 2025).

- Potential of Hydrogen as Fuel for Shipping by ABS. CE DELFT & ARCSILEA. European Maritime Safety Agency EMSA/Hydrogen—2022/2023—4837444, 31 August 2023. Available online: https://emsa.europa.eu/publications/reports/item/5062-potential-of-hydrogen-as-fuel-for-shipping.html (accessed on 10 April 2025).

- IRENA. International Renewable Energy Agency. Available online: https://www.irena.org/Innovation-landscape-for-smart-electrification/Power-to-hydrogen (accessed on 5 June 2025).

- ABI Research. The Tech Intelligence Experts. Available online: https://www.abiresearch.com/press/green-hydrogen-costs-of-production-to-drop-to-us25kg-by-2030-and-us180-by-2040-clearing-the-way-for-heavy-industry-decarbonization (accessed on 5 June 2025).

- De Witte E.—CNB nv. Low Emission Vessel Hydroville. CMB Technologies. De Gerlachekaai 20, Antwerpen, Belgium. 2000. Available online: https://www.hylaw.eu/files/2018-12/2.%20CMB%20Technologies%20-%20HyLaw.pdf (accessed on 10 April 2025).

- NORLED. Available online: https://www.norled.no/en/nyhet/mf-hydra-the-worlds-first/ (accessed on 10 April 2025).

- Ballard Power Systems. Available online: https://blog.ballard.com/marine/worlds-first-liquid-powered-hydrogen-ship-mf-hydra-is-powered-by-ballards-fuel-cells (accessed on 10 April 2025).

- Ballard Website—Ballard’s FCwave™ Receives Type Approval from Lloyd’s Register. Available online: https://blog.ballard.com/marine/ballards-fcwave-receives-type-approval-from-lloyds-register (accessed on 21 July 2025).

- MarineLink. Available online: https://www.marinelink.com/news/osv-operates-green-hydrogen-518041 (accessed on 10 April 2025).

- OffshoreWIND.biz. Available online: https://www.offshorewind.biz/2024/03/19/louis-dreyfus-armateurs-unveils-liquid-hydrogen-sov-concept (accessed on 10 April 2025).

- Vessel Finder. Available online: https://www.vesselfinder.com/pl/vessels/details/9186077 (accessed on 5 May 2025).

- Eidesvik Offshore Website—Viking Energy. Available online: https://eidesvik.no/vessels/viking-energy (accessed on 10 July 2025).

- ShipFC Website—Temporary Suspension for ShipFC Project. Available online: https://shipfc.eu/temporary-suspension-for-shipfc-project (accessed on 10 July 2025).

- Ulstein Website—SX190. Available online: https://ulstein.com/vessels/sx190 (accessed on 10 July 2025).

- Fuel Cells: Addressing the Key Technical Challenges. Part of “Maritime Hybrid, Electric and Fuel Cells” Webinar Week 1–4 June 2020. Roadmap to a Hydrogen Future—ULSTEIN SX190. Available online: https://dvzpv6x5302g1.cloudfront.net/AcuCustom/Sitename/DAM/076/3rd_Fuel_Cells_Addressing_the_key_technical_challenges.pdf (accessed on 10 July 2025).

- Nedstack Website—Zero-Emission Operations in Offshore Construction Market. Available online: https://nedstack.com/en/news/zero-emission-operations-offshore-construction-market (accessed on 10 July 2025).

- Bortnowska, M.; Zmuda, A. The Possibility of Using Hydrogen as a Green Alternative to Traditional Marine Fuels on an Offshore Vessel Serving Wind Farms. Energies 2024, 17, 5915. [Google Scholar] [CrossRef]

- Melideo, D.; Desideri, U. The use of hydrogen as alternative fuel for ship propulsion: A case study of full and partial retrofitting of roll-on/roll-off vessels for short distance routes. Int. J. Hydrogen Energy 2024, 50 Pt B, 1045–1055. Available online: https://www.sciencedirect.com/science/article/pii/S0360319923052503 (accessed on 10 April 2025). [CrossRef]

- Liu, X.; Yang, G.; Sun, B.; Wang, H.; Li, Y.; Wang, R. Assist in GHG Abatement of Offshore Ships: Design and Economic Analysis of an Integrated Utilization Model of hydrogen-powered Ship and Offshore Wind Power. Sustain. Mar. Struct. 2023, 5, 15–25. [Google Scholar] [CrossRef]

- Di Micco, S.; Minutillo, M.; Forcina, A.; Cigolotti, V.; Perna, A. Feasibility analysis of an innovative naval onboard power-train system with hydrogen-based PEMFC technology. E3S Web Conf. 2021, 312, 07009. [Google Scholar] [CrossRef]

- Aziz, M. Liquid Hydrogen: A Review on Liquefaction, Storage. Energies 2021, 14, 5917. Available online: https://www.mdpi.com/1996-1073/14/18/5917 (accessed on 10 April 2025). [CrossRef]

- Levikhin, A.A.; Boryae, A.A. Physical properties and thermodynamic characteristics of hydrogen. Heliyon 2024, 10, e36414. Available online: https://www.sciencedirect.com/science/article/pii/S2405844024124450 (accessed on 10 April 2025). [CrossRef]

- Institution of Gas Engineers and Managers. IGEMHydrogen-CharacteristicsandImplications.pdf. IGEM Technical Paper, August 2022. Available online: https://www.igem.org.uk/resource-report/igem-hydrogen-characteristics-and-implications-technical-paper.html (accessed on 20 March 2025).

- Momirlan, M.; Veziroglu, T.N. The properties of hydrogen as fuel tomorrow in sustainable energy system for a cleaner planet. Int. J. Hydrogen Energy 2005, 30, 795–802. [Google Scholar] [CrossRef]

- Shadidi, B.; Najafi, G.; Yusaf, T. A Review of Hydrogen as a Fuel in Internal Combustion Engines. Energies 2021, 14, 620. Available online: https://www.mdpi.com/1996-1073/14/19/6209 (accessed on 10 April 2025). [CrossRef]

- Yang, N.; Deng, J.; Wang, C.; Bai, Z.; Qu, J. High pressure hydrogen leakage diffusion. Research progress. Int. J. Hydrogen Energy 2024, 50 Pt A, 1029–1046. [Google Scholar] [CrossRef]

- Menon, S.K.; Kumar, A.; Mondal, S. Advancements in hydrogen gas leakage detection sensor technologies and safety measures. Clean Energy 2025, 9, 263–277. [Google Scholar] [CrossRef]

- Van Hoecke, L.; Laffineur, L.; Campe, R.; Perreault, P.; Verbruggen, S.W.; Lenaerts, S. Challenges in the use of hydrogen for maritime applications. Energy Environ. Sci. 2020, 14, 815–843. [Google Scholar] [CrossRef]

- Kanchiralla, F.M.; Brynolf, S.; Malmgren, E.; Hansson, J.; Grahn, M. Life-cycle assessment and costing of fuels and propulsion systems in future fossil-free shipping. Environ. Energy Clim. 2022, 56, 12517–12531. Available online: https://www.researchgate.net/publication/362880292_Life-Cycle_Assessment_and_Costing_of_Fuels_and_Propulsion_Systems_in_Future_Fossil-Free_Shipping (accessed on 20 June 2025). [CrossRef]

- Branwen Ap, D.T.; Stamford, L.; Welflea, A.; Larkin, A. Decarbonising international shipping—A life cycle perspective on alternative fuel options. Energy Convers. Manag. 2024, 299, 117848. [Google Scholar] [CrossRef]

- Nykiel, D.; Zmuda, A.; Abramowski, T.A. Sustainability-Driven Approach to Early-Stage Offshore Vessel Design: A Case Study on Wind Farm Installation Vessels. Sustainability 2025, 17, 2752. [Google Scholar] [CrossRef]

- DNV, IMO CCC 10: Interim Guidelines for Ammonia and Hydrogen as Fuel. Available online: https://www.dnv.com/news/2024/imo-ccc-10-interim-guidelines-for-ammonia-and-hydrogen-as-fuel (accessed on 8 September 2025).

- Advanced Biofuels USA, Practical Guide for Approval of Ammonia or Hydrogen Fuelled Ships Practical Guide for Approval of Ammonia or Hydrogen Fuelled Ships. Available online: https://www.imo.org/en/mediacentre/meetingsummaries/pages/ccc-10th-session.aspx (accessed on 9 September 2025).

- IMO, Sub-Committee on Carriage of Cargoes and Containers (CCC 9), 9th Session, 20–29 September 2023. Available online: https://www.imo.org/en/mediacentre/meetingsummaries/pages/ccc-9th-session.aspx (accessed on 9 September 2025).

- IGF Code (MSC.391(95))—International Code of Safety for Ships Using Gases or Other Low-flashpoint Fuels (SOLAS). Available online: https://puc.overheid.nl/nsi/doc/PUC_80736_14/1/ (accessed on 7 September 2025).

- IMO, MSC.1/Circ.1647 15 June 2022, Interim Guidelines for the Safety of Ships Using Fuel Cell Power Installations. Available online: https://www.register-iri.com/wp-content/uploads/MSC.1-Circ.1647.pdf (accessed on 9 September 2025).

- DNV Handbook. Guidance for Hydrogen-Fuelled Vessels, DNV Class Rules Updates. 2024. Available online: https://www.dnv.com/news/2024/now-available-july-2024-edition-of-the-dnv-class-rules-for-ships-and-offshore-units/ (accessed on 7 September 2025).

- DNV, Practical Guide for Approval of Ammonia- or Hydrogen-Fuelled Ships. Available online: https://www.dnv.com/expert-story/maritime-impact/practical-guide-for-approval-of-ammonia-or-hydrogen-fuelled-ships (accessed on 9 September 2025).

- Bureau Veritas—Rule Notes/NR678 Hydrogen-Fuelled Ships. NR678 Hydrogen-Fuelled Ships|Marine & Offshore. Available online: https://marine-offshore.bureauveritas.com/nr678-hydrogen-fuelled-ships (accessed on 7 September 2025).

- ABS, Advisory on Gas and Other Low Flashpoint Fuels. Available online: https://ww2.eagle.org/content/dam/eagle/advisories-and-debriefs/gas-and-low-flashpoint-fuels-advisory.pdf (accessed on 9 September 2025).

- ISO 21009 (Parts 1 & 2); Static Vacuum-Insulated Cryogenic Vessels. ISO 21009-1:2022—Cryogenic Vessels—Static Vacuum-Insulated Vessels—Part 1: Design, Fabrication, Inspection and Tests. International Organization for Standardization: Geneva, Switzerland. Available online: https://www.iso.org/standard/76098.html (accessed on 7 September 2025).

- Ronevich, J.; San Marchi, C. Materials Performance at Liquid Hydrogen Temperatures. Liquid Hydrogen Technologies Virtual Workshop, 22–23 February 2022. Available online: https://www.energy.gov/sites/default/files/2022-03/Liquid%20H2%20Workshop-SNL.pdf (accessed on 9 September 2025).

- ISO 21011:2008; Cryogenic Vessels—Valves for Cryogenic Service. ISO: Switzerland, Geneva, 2008.

- EN 13445-1:2021; Unfired Pressure Vessels—Part 1: General. CEN: Brussels, Belgium, 2021.

- Kim, M.-S.; Chun, K.W. A Comprehensive Review on Material Compatibility and Safety Standards for Liquid Hydrogen Cargo and Fuel Containment Systems in Marine Applications. J. Mar. Sci. Eng. 2023, 11, 1927. [Google Scholar] [CrossRef]

- Hexagon Purus. Available online: https://hexagonpurus.com/our-solutions/hydrogen-type-4-cylinders (accessed on 21 March 2025).

- Linde Engineering. Available online: https://www.linde-engineering.com/products-and-services/plant-components/liquefied-hydrogen-tank-solutions (accessed on 21 March 2025).

- Linde. Available online: https://www.scribd.com/document/533566986/Day2-1105-Decker-Liquid-hydrogen-distribution-technology-Linde (accessed on 21 March 2025).

- Guan, W.; Chen, L.; Wang, Z.; Chen, J.; Ye, Q.; Fan, H. A 500 kW hydrogen fuel cell-powered vessel: From concept to sailing. Int. J. Hydrogen Energy 2024, 89, 1466–1481. Available online: https://www.sciencedirect.com/science/article/pii/S0360319924041430 (accessed on 21 March 2025). [CrossRef]

- Kołodziejski, M. Review of hydrogen-based propulsion systems in the maritime sector. Arch. Thermodyn. 2024, 44, 335–380. [Google Scholar] [CrossRef]

- Karvounis, P.; Tsoumpris, C.; Boulougouris, E.; Theotokatos, G. Recent advances in sustainable and safe marine engine operation with alternative fuels. Front. Mech. Eng. 2022, 8, 994942. [Google Scholar] [CrossRef]

- Minutillo, M.; Cigolotti, V.; Di Ilio, G.; Bionda, A.; Boonen, E.-J.; Wannemacher, T. Hydrogen-based technologies in maritime sector: Technical analysis and prospective. E3S Web Conf. 2022, 334, 06011. [Google Scholar] [CrossRef]

- Elkafas, A.G.; Rivarolo, M.; Gadducci, E.; Magistri, L.; Massardo, A.F. Fuel Cell Systems for Maritime: A Review of Research Development, Commercial Products, Applications and Perspectives. Processes 2023, 11, 97. [Google Scholar] [CrossRef]

- Ballard Website—FCwave™—Heavy-Duty Marine & Stationary Power Fuel Cell Modules. Available online: https://www.ballard.com/fcwave (accessed on 20 July 2025).

- Corvus Energy Website—Pelican Marine Fuel Cell System. Available online: https://corvusenergy.com/products/corvus-pelican-marine-fuel-cell-system (accessed on 20 July 2025).

- PowerCell Group Website—Introducing Our Marine Power Evolution Marine System 225. Available online: https://powercellgroup.com/solutions/marine-system-225 (accessed on 20 July 2025).

- Nedstack Website—PemGen Mobile. Available online: https://nedstack.com/en/pemgen-solutions/maritime-power-installations/pemgen-mobile (accessed on 20 July 2025).

- Horizon Website—Full Cell Systems. Available online: https://www.horizonfuelcell.com/fuelcellsystems (accessed on 20 July 2025).

- Bloom Energy Website—Hydrogen Fuel Cells for a Decarbonized Future. Available online: https://www.bloomenergy.com/hydrogen-fuel-cells (accessed on 20 July 2025).

- Catalog “Marine System 225”; PowerCell Group: Gothenburg, Sweden, 2025; Available online: https://press.powercellgroup.com/en/marine-system-225 (accessed on 20 July 2025).

- Jia, C.; Liu, W.; He, H.; Chau, K.T. Health-conscious energy management for fuel cell vehicles: An integrated thermal management strategy for cabin and energy source systems. Energy 2025, 333, 137330. [Google Scholar] [CrossRef]

- HydrogenTech Website—Ogniwa Paliwowe SOFC rDSC. Available online: https://hydrogentech.pl/project/ogniwa-paliwowe-sofc-rdsc (accessed on 20 July 2025).

- Łukasiewicz—Instytut Chemii Przemysłowej Im. Prof. Ignacego Mościckiego Website—Własne Ogniwa Paliwowe—Coraz Bliżej. Available online: https://ichp.lukasiewicz.gov.pl/2021/07/19/wlasne-ogniwa-paliwowe-coraz-blizej (accessed on 20 July 2025).

- Klebanoff, L.E.; Caughlan, S.A.M.; Madsen, R.T.; Conard, C.J.; Leach, T.S.; Appelgate, T.B., Jr. Comparative study of a hybrid research vessel utilizing batteries or hydrogen fuel cells. Int. J. Hydrogen Energy 2021, 46, 38051–38072. [Google Scholar] [CrossRef]

- Zhou, Z.; Tao, J. Hydrogen-powered vessels in green maritime decarbonization: Policy drivers, technological frontiers and challenges. Front. Mar. Sci. 2025, 12, 1601617. [Google Scholar] [CrossRef]

- Zéphyr & Borée Website—ZEPH2: CTV Diesel-Hydrogen Hybrid. Available online: https://zephyretboree.com/en/projects/h2ermine (accessed on 9 September 2025).

- FuelCellsWorks Website—Completion of the ZEPH2 Project: Decarbonized Offshore Maintenance Vessel with Hybrid Hydrogen Propulsion. Available online: https://fuelcellsworks.com/news/completion-of-the-zeph2-project-decarbonized-offshore-maintenance-vessel-with-hybrid-hydrogen-propulsion (accessed on 9 September 2025).

- UC San Diego Website—Design of World’s First Hydrogen-Hybrid Research Vessel Approved. Available online: https://today.ucsd.edu/story/design-of-worlds-first-hydrogen-hybrid-research-vessel-approved (accessed on 9 September 2025).

- Mylonopoulos, F.; Durgaprasad, S.; Coraddu, A.; Polinder, H. Lifetime design, operation, and cost analysis for the energy system of a retrofitted cargo vessel with fuel cells and batteries. Int. J. Hydrogen Energy 2024, 91, 1262–1273. [Google Scholar] [CrossRef]

- Bortnowska, M. Projected Reductions in CO2 Emissions by Using Alternative Methanol Fuel to Power a Service Operation Vessel. Energies 2023, 16, 7419. [Google Scholar] [CrossRef]

- Hexagon Purus. Type 4 Infrastructure and Mobility–Hexagon Purus Datasheet. April 2024. Available online: https://hexagonpurus.com/our-solutions/download-our-brochures/datasheets (accessed on 25 March 2022).

- BEH2YDRO Engines Catalog “Information Sheet”; Anglo Belgian Corporation: Gent, Belgium, 2022; Available online: https://www.production.behydro.be/uploads/files/DATASHEETS-Behydro.pdf (accessed on 22 July 2025).

- Engines Catalog “Wärtsilä 20DF”; Wärtsilä Corporation: Helsinki, Finland, 2023; Available online: https://s6ca5bb3203b5f73d.jimcontent.com/download/version/1609518835/module/12717787226/name/Wartsila%2020DF%20Marine%20Engine%20Product%20Guide.pdf (accessed on 22 July 2025).

- KHL Power Division Website—Ballard Wins Type Approval for Marine Fuel Cell Module. Available online: https://www.powerprogress.com/news/ballard-wins-type-approval-for-marine-fuel-cell-module/8019720.article (accessed on 22 July 2025).

- Bunker Ports News Worldwide Website—Rotterdam Bunker Prices. Available online: https://www.bunkerportsnews.com/PortBunkerPrices.aspx?ElementID=93458966-d962-468c-b9ef-1a143bf22d1b (accessed on 29 July 2025).

- Business Analytiq Website—Green Hydrogen Price Index. Available online: https://businessanalytiq.com/procurementanalytics/index/green-hydrogen-price-index (accessed on 29 July 2025).

- eCap Marine Website—Embrace the Future with Zero-Emission Hydrogen Power Generator. Available online: https://ecap-marine.com/products/hydrogen-power-generator.html (accessed on 22 July 2025).

- eCap Marine Website—Battery Energy Storage System—BESS. Available online: https://ecap-marine.com/solutions/battery-energy-storage-system-bess.html (accessed on 22 July 2025).

| No. | Aspect/Criteria | Compressed Hydrogen (CH2) | Liquefied Hydrogen (LH2) |

|---|---|---|---|

| 1. | Volumetric Efficiency | Occupies a large volume | More compact/Higher volumetric density |

| 2. | System Complexity | Relatively simple (no need for cryogenics) | High—requires cooling and insulation |

| 3. | Safety | Can rapidly decompress and ignite/Possible tank explosion | Higher risks due to low temperature/Evaporation may cause flammable gas buildup/Risk of frostbite, material cracking |

| 4. | Applications | Short-range ferries, passenger ships, offshore vessels | Large ocean-going ships, tankers, container ships |

| 5. | Transport Efficiency | Low suitability for long distances/Short-sea shipping | Better for large volumes/Suitable for long endurance at sea |

| 6. | Bunkering | Faster and easier | Slower and more technically demanding |

| 7. | Operating Pressure | Very high: 350–700 bar | Low pressure, but extremely low temperature ~ −253 °C |

| 8. | Tank Construction | Much thicker walls, heavy construction | Thinner tanks, with cryogenic insulation |

| 9. | Tank Mass to Hydrogen Mass Ratio | Up to 14:1 or higher | Around 7:1 or even 5:1 |

| 10. | Infrastructure/Costs | Easy to store/Cheaper storage infrastructure | Complex infrastructure/Higher cost due to complexity of cooling systems and tanks |

| No. | Safety Focus Areas | Liquefied Hydrogen (LH2) |

|---|---|---|

| 1. | Boil-off Gas (BOG) | Hydrogen evaporates due to heat ingress or loss of insulation. Each tank must be equipped with safety valves (PRV—Pressure Relief Valve, TPRD—Thermal Pressure Relief Device) and a gas discharge system designed for extreme scenarios, such as complete vacuum loss. Outlets should be routed to ventilation masts, with priority given to using BOG in internal combustion engines or fuel cells, followed by compression or safe release. |

| 2. | Cryogenics (Tanks) | Vacuum-insulated tanks compliant with ISO 21009 [43] and ISO 21011 [45] are used. Key aspects include vacuum monitoring, prevention of atmospheric moisture condensation and secondary barriers to protect the hull. A defined emergency procedure is also required in the event of insulation failure. |

| 3. | Materials | Steels and alloys must withstand extremely low temperatures (−253 °C) and resist hydrogen embrittlement, i.e., they must not crack under hydrogen exposure. Austenitic stainless steels, such as 304L and 316L (corrosion-resistant, easily weldable and formable), are commonly used. Aluminium and nickel alloys are also applied. All materials must be qualified for cryogenic conditions in accordance with standards such as ISO 21009, EN 13445 [46] and ASME (American Society of Mechanical Engineers). |

| 4. | Detection and Ventilation | Hydrogen sensors must be installed in locations where gas may accumulate. The ventilation system must ensure dilution below the lower explosive limit. Hazard zones and emergency systems must cut off fuel supply upon problem detection. |

| No. | Form of Hydrogen | General Characteristics of Hydrogen Tanks |

|---|---|---|

| 1. | Compressed gas CH2 | High-pressure composite tanks—type IV, highly durable, lightweight compared to steel tanks. They consist of a plastic liner, which serves as an inner container preventing hydrogen permeation but cannot withstand pressure on its own; a main load-bearing layer—usually made of carbon fibre, sometimes with the addition of glass fibre, which absorbs high pressure. Safety features: pressure relief valves, hydrogen detectors. |

| 2. | Cryogenic liquid LH2 | Tanks are usually cylindrical in shape. Their construction is multi-layered: an inner layer (liner) made of low-temperature resistant and hydrogen-tight materials (stainless steel/aluminium alloys); vacuum insulation between the tank walls, consisting of several layers of heat-reflecting metabolised foil; outer shell is made of stainless steel/composite, providing mechanical and environmental protection for the entire structure. Safety features: safety valves, gas ventilation systems, temperature and pressure sensors, emergency gas discharge systems. |

| No. | FC Type | Temperature [°C] | Electrolyte | Typical Fuel | Power Range | Electrical Efficiency | Applications |

|---|---|---|---|---|---|---|---|

| 1. | PEMFC | 60 ÷ 80 110 ÷ 180 | Water-based polymer membrane | Hydrogen | Up to 1 MW (up to 200 kW per module) | 45 ÷ 55% | Backup power, Portable power, Distributed generation, Transportation, Specialty vehicles |

| 2. | SOFC | 500 ÷ 1 000 | Porous ceramic material | Hydrogen, methanol, hydrocarbons | Up to 1 MW (up to 250 kW per module) | 50 ÷ 60% | Auxiliary power, Electric utility, Distributed generation |

| 3. | MCFC | 650 ÷ 800 | Molten carbonate salt | Hydrogen, methanol, hydrocarbons | Up to 1 MW (up to 250 kW per module) | 43 ÷ 55% | Electric utility, Distributed generation |

| 4. | PAFC | 140 ÷ 200 | Phosphoric acid | Hydrogen, LNG, methanol | Up to 11 MW (100 ÷ 400 kW per module) | 30 ÷ 42% | Distributed generation |

| 5. | AFC | 60 ÷ 200 | Potassium hydroxide | Hydrogen | Up to 0.5 MW (up to 100 kW per module) | 40 ÷ 50% | Military and space applications, Backup power, Transportation |

| No. | FC Supplier | Model | Power [kW] | Efficiency [%] | Power Density [kW/tona]/[kW/m3] | Voltage Range [V] | Current Range [A] |

|---|---|---|---|---|---|---|---|

| 1. | PEMFC | ||||||

| 2. | Ballard | FCwave | 200 | 53.5 | 200/102 | 350 ÷ 720 | 0 ÷ 550 |

| 3. | Corvus Energy | Pelican Marine FCS | 340 | ≥50 | 90.7/47.5 | 400 ÷ 750 | - |

| 4. | PowerCell | Marine System 225 | 225 | 56 | 184/104 | 430 ÷ 910 | 45 ÷ 450 |

| 5. | Nedstack | PemGen | 150 | 51 | 176.5/130 | 800 | 0 ÷ 255 |

| 6. | Horizon | VLIII200-50 | 200 | ≥43 | 760/299 | 500 ÷ 750 | 0 ÷ 500 |

| 7. | SOFC | ||||||

| 8. | Bloom Energy | Bloom | 300 | 52 | 19/10.2 | 480 | - |

| No. | Parametr | Fuel Cell Manufacturer | ||

|---|---|---|---|---|

| Ballard’s Power System, FCwave™ | Corvus Pelican Fuel Cell System (FCS) | PowerCell Marine System 225 | ||

| 1. | FC Power NFC [kW] | 200 | 340 | 225 |

| 2. | Dimensions L × W × H [mm] | 1209 × 741 × 2195 | 2160 × 1427 × 2320 | 1165 × 915 × 2032 |

| 3. | Weight WE [t] | 1.0 | 3.75 | 1.22 |

| 4. | Type of Fuel Cell | PEMFC | PEMFC | PEMFC |

| 5. | Fuel type | Hydrogen (H2) | Hydrogen (H2) | Hydrogen (H2) |

| 6. | Hydrogen Inlet Pressure [bar.g] | 3.5 ÷ 6.5 | 5.4 ÷ 14.0 | 3.0 ÷ 8.0 |

| 7. | Output Voltage [V DC] | 350 ÷ 720 | 400 ÷ 750 | 430 ÷ 775 (910) |

| 8. | Maximum Efficiency [%] | 53.5 | 52 | 56 |

| 9. | Marine Certification | DNV, Lloyd’s Register, ABS | DNV | Lloyd’s Register |

| No. | Parameter | Engine Type | Fuel Cell Type | ||

|---|---|---|---|---|---|

| Dual-Fuel Engine (Wärtsilä 9L20DF) | Hydrogen Engine (BEH2YDRO 12DZD H2) | Corvus Pelican Fuel Cell System | Ballard’s Power System, FCwave™ | ||

| 1. | Power NAP [kW] | 3 × 1755 | 3 × 1800 | 3 × 1700 (5 × 340) (plus 1 × 340) | 4 × 1200 (6 × 200) 1 × 600 (3 × 200) |

| 2. | Total Power NC [kW] | 5265 | 5400 | 5440 | 5400 |

| 3. | Dimensions L × B × H [mm] | 6700 × 2010 × 2831 | 6667 × 1850 × 3131 | 7135 × 2160 × 2320 | 7254 × 741 × 2195 |

| 4. | Occupied Area * [m2] | 95.96 | 91.44 | 104.87 | 108.32 |

| 5. | Weight ME [t] | 3 × 25 total 75 | 3 × 33.7 total 101.1 | 16 × 3.75 total 60 | 27 × 1.0 total 27 |

| 6. | Type of Fuel Cell | - | - | PEMFC | PEMFC |

| 7. | Fuel Type | LNG, MDO, HFO | H2, MDO, LFO | Hydrogen (H2) | Hydrogen (H2) |

| 8. | IMO | Tier II or III | Tier III | Zero-emission | Zero-emission |

| No. | Parameter | Fuels | The Ratio of H2 to MDO for: | |||

|---|---|---|---|---|---|---|

| Hydrogen CH2 | Hydrogen LH2 | MDO | CH2 | LH2 | ||

| 1. | Total fuel reserve | 42.46 | 40.76 | 115.85 | 0.37 | 0.35 |

| 2. | Fuel volume Vfuel [m3] | 1056.13 | 599.29 | 137.92 | 7.66 | 4.17 |

| 3. | Emergency Content LHV [MJ/kg] | 120 | 120 | 43 | ||

| 4. | Fuel consumption per hour Gfuel [kg/h] | 97.83 | 93.91 | 266.94 | ||

| 5. | Specific fuel consumption [g/kWh] | 67.93 | 65.22 | 189.59 | ||

| 6. | Density [kg/m3] | 40.2 | 70.85 | 840 | ||

| 7. | Area required for a 14-day mission (tanks + compartments required) [m2] acc. to design analysis | 1539 | 387 | 230 | ||

| No. | Endurance | Hydrogen Volume [m3] | Hydrogen Volume CH2 Minus MDO [m3] | Number of Tanks LH2/ Cylinders CH2 [pcs] | ||

|---|---|---|---|---|---|---|

| LH2 | CH2 | LH2 | CH2 | |||

| 1. | 1 day | 42.7 | 75.4 | 65.7 | 1 | 150 |

| 2. | 3 days | 128.4 | 226.3 | 205.7 | 3 | 449 |

| 3. | 5 days | 213.9 | 377.2 | 342.9 | 5 | 749 |

| 4. | 7 days | 299.6 | 528.1 | 480.1 | 7 | 1048 |

| 5. | 9 days | 385.2 | 678.9 | 617.2 | 8 | 1348 |

| 6. | 11 days | 470.8 | 829.8 | 754.4 | 10 | 1647 |

| 7. | 13 days | 556.4 | 980.7 | 891.6 | 12 | 1947 |

| 8. | 14 days | 599.3 | 1056.1 | 960.1 | 13 | 2096 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bortnowska, M.; Zmuda, A. A Comparative Analysis of Hydrogen Fuel Cells and Internal Combustion Engines Used for Service Operation Vessels Propulsion. Energies 2025, 18, 5104. https://doi.org/10.3390/en18195104

Bortnowska M, Zmuda A. A Comparative Analysis of Hydrogen Fuel Cells and Internal Combustion Engines Used for Service Operation Vessels Propulsion. Energies. 2025; 18(19):5104. https://doi.org/10.3390/en18195104

Chicago/Turabian StyleBortnowska, Monika, and Arkadiusz Zmuda. 2025. "A Comparative Analysis of Hydrogen Fuel Cells and Internal Combustion Engines Used for Service Operation Vessels Propulsion" Energies 18, no. 19: 5104. https://doi.org/10.3390/en18195104

APA StyleBortnowska, M., & Zmuda, A. (2025). A Comparative Analysis of Hydrogen Fuel Cells and Internal Combustion Engines Used for Service Operation Vessels Propulsion. Energies, 18(19), 5104. https://doi.org/10.3390/en18195104