Comparative Study on the Effects of Diesel Fuel, Hydrotreated Vegetable Oil, and Its Blends with Pyrolytic Oils on Pollutant Emissions and Fuel Consumption of a Diesel Engine Under WLTC Dynamic Test Conditions

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Exhaust Pollutant Emissions

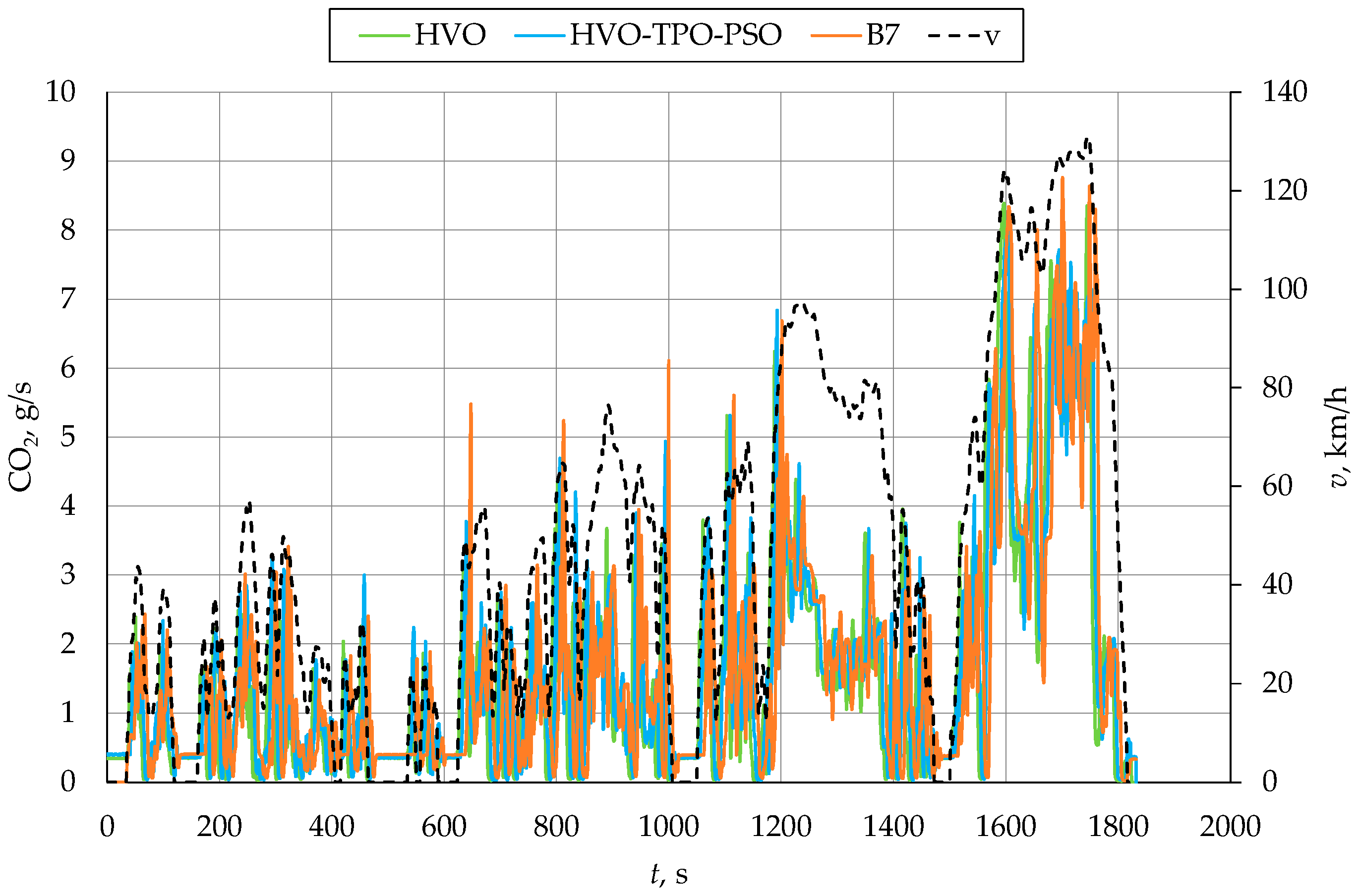

3.1.1. CO2 Emission

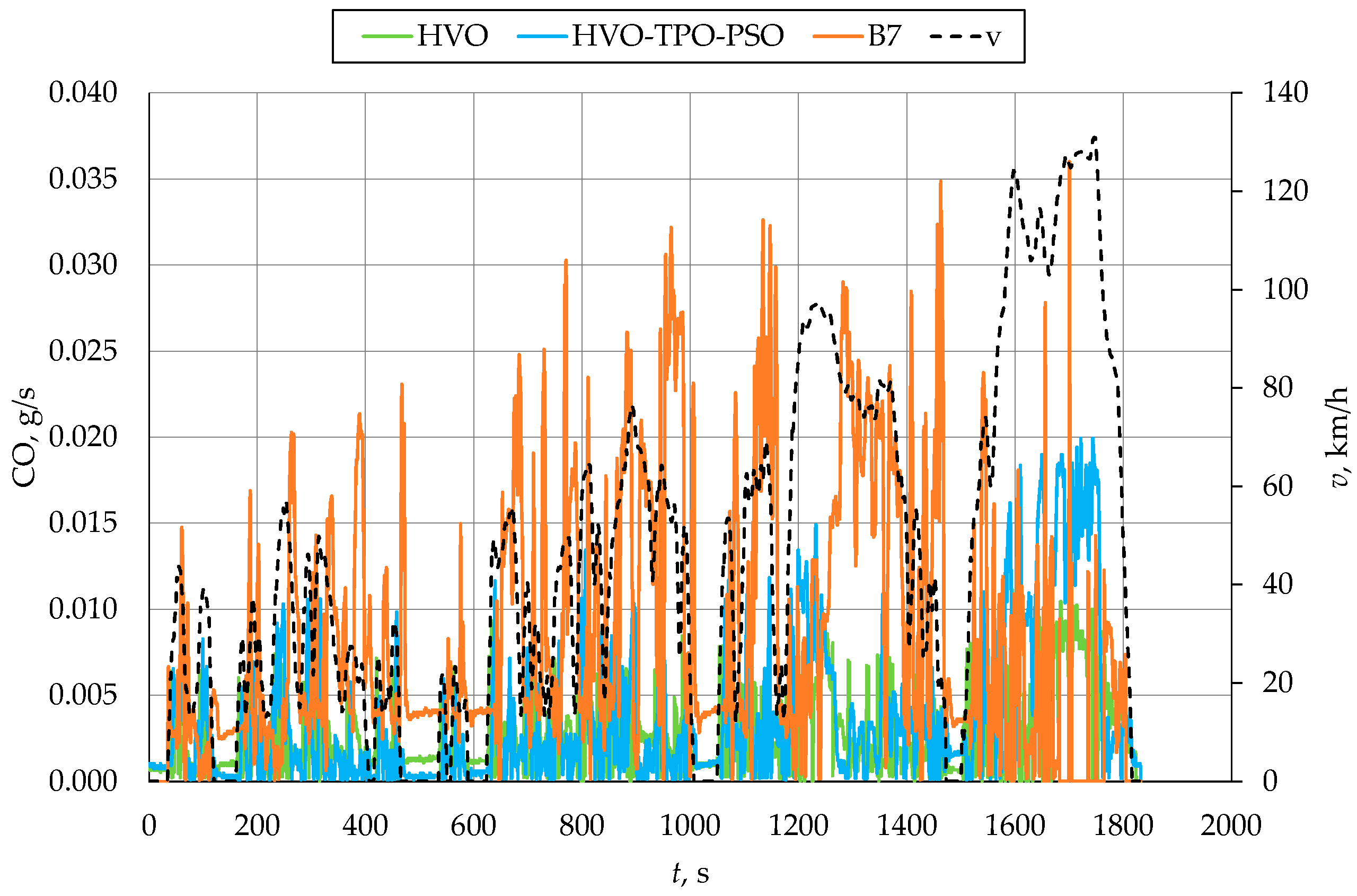

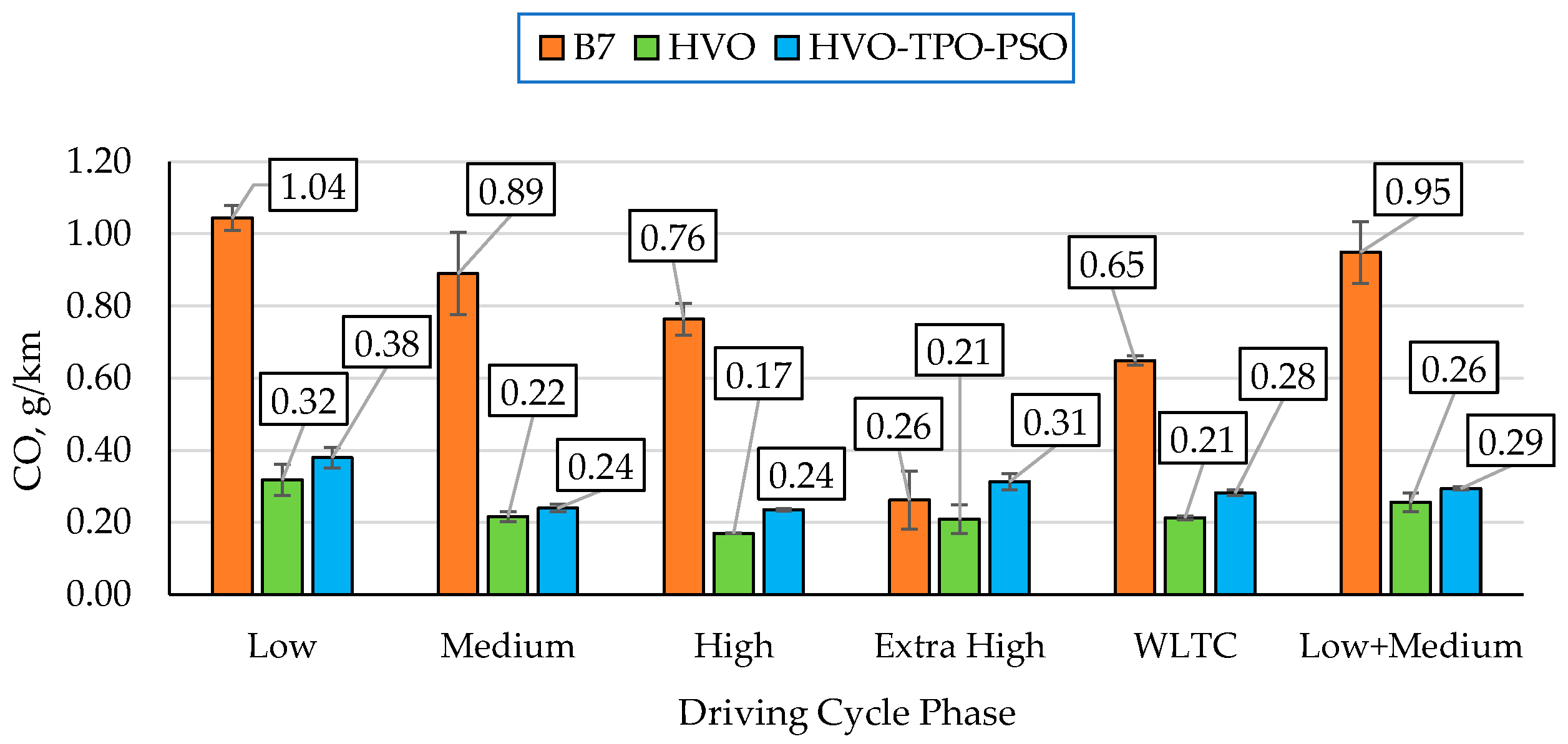

3.1.2. CO Emission

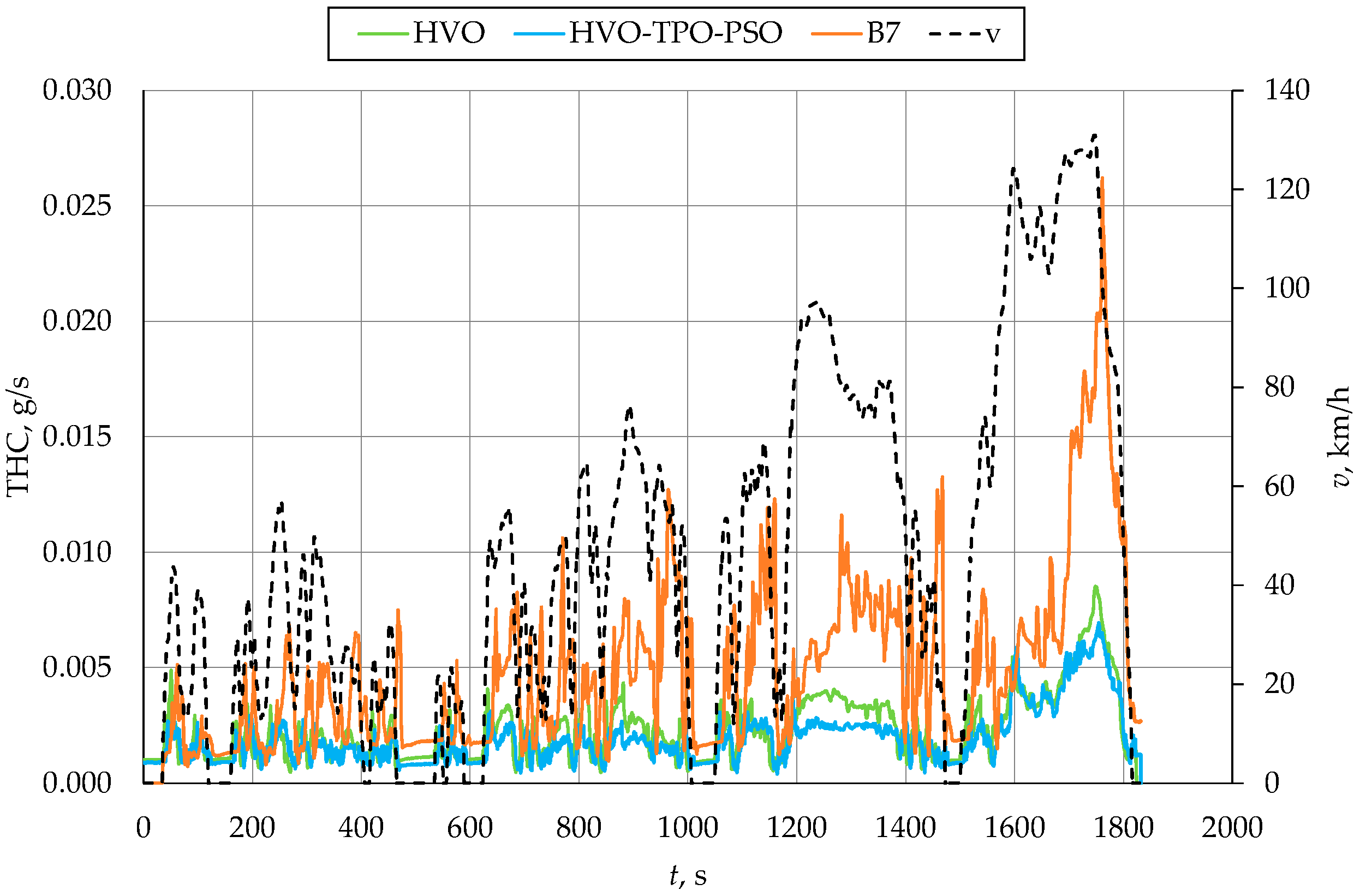

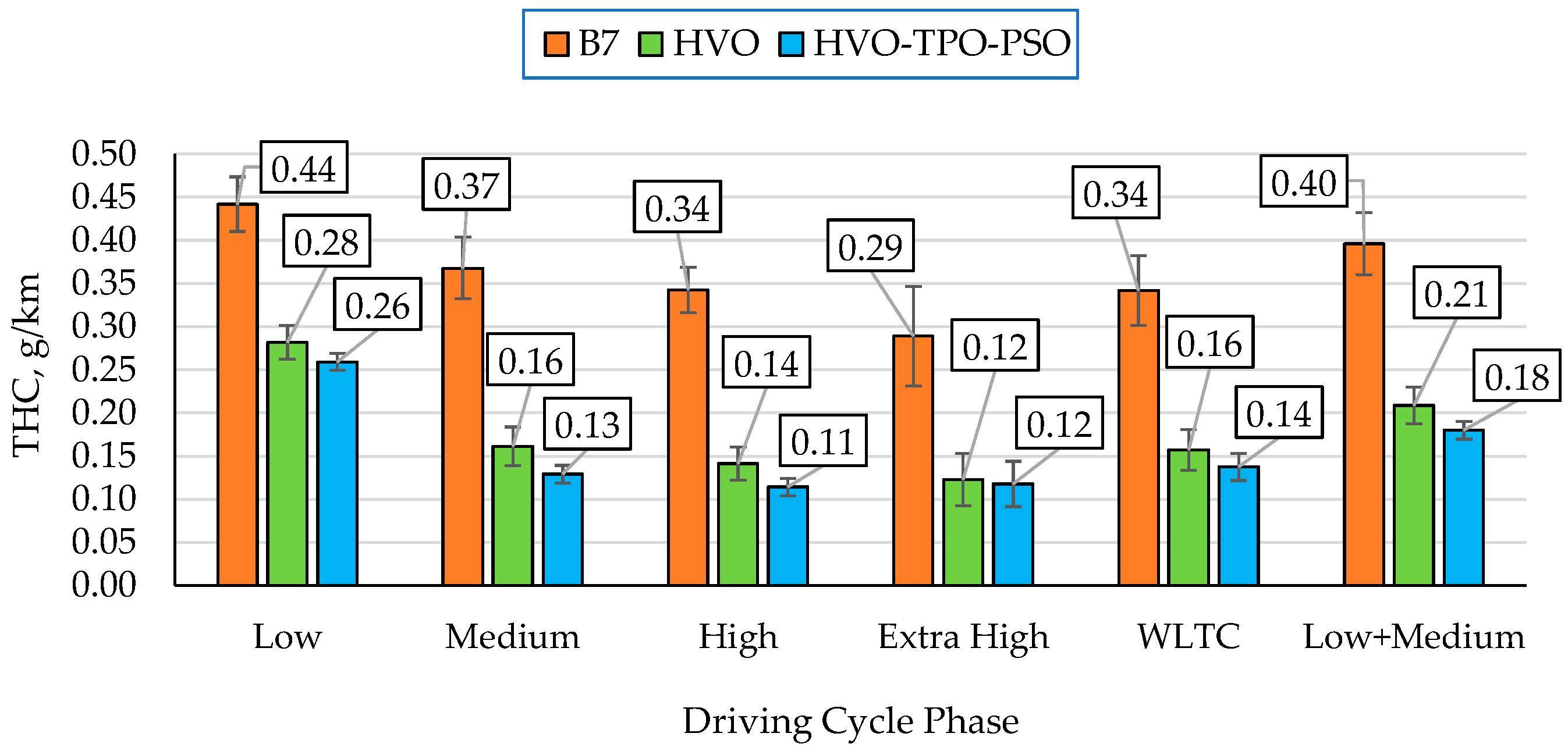

3.1.3. THC Emission

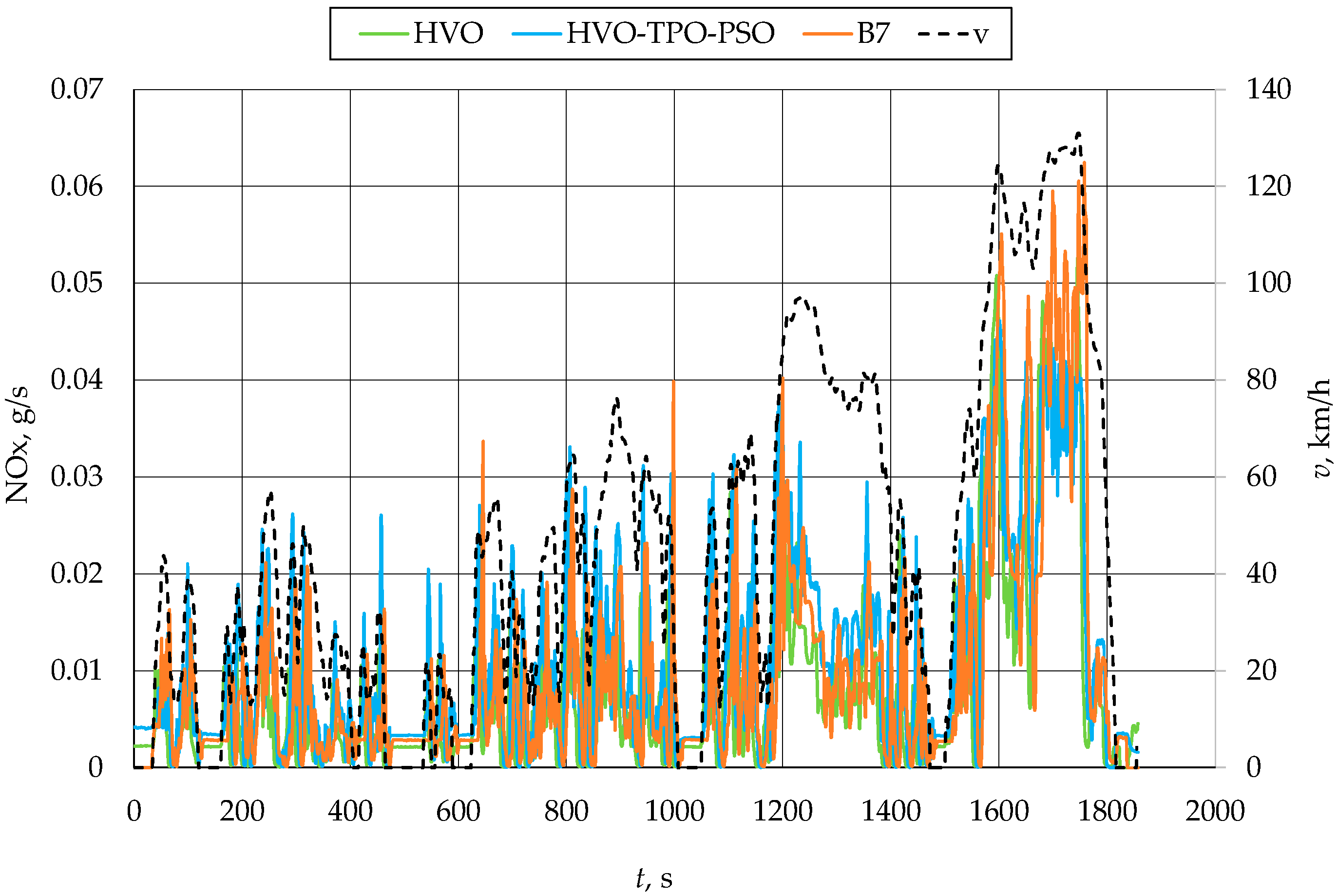

3.1.4. NOx Emission

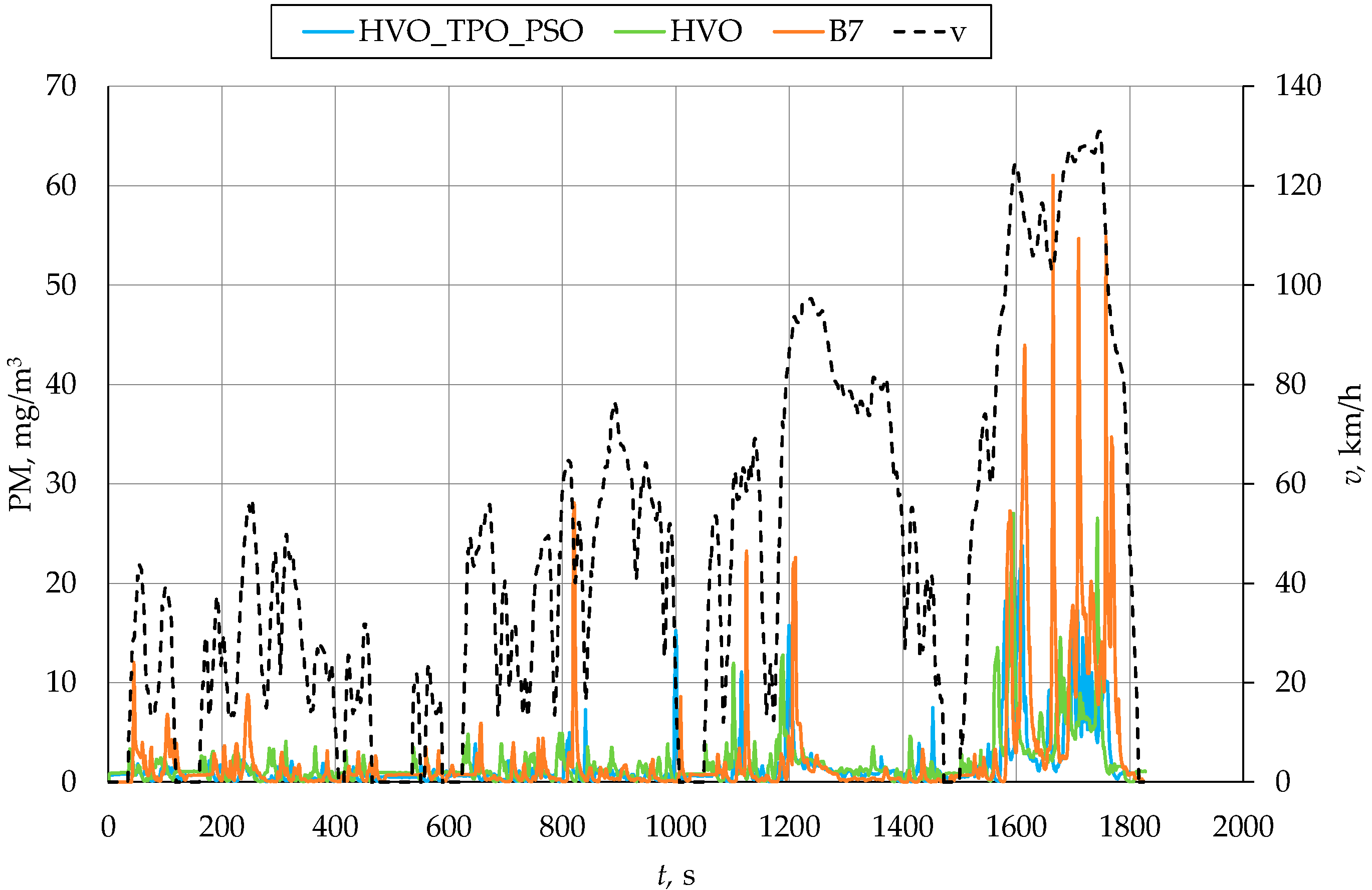

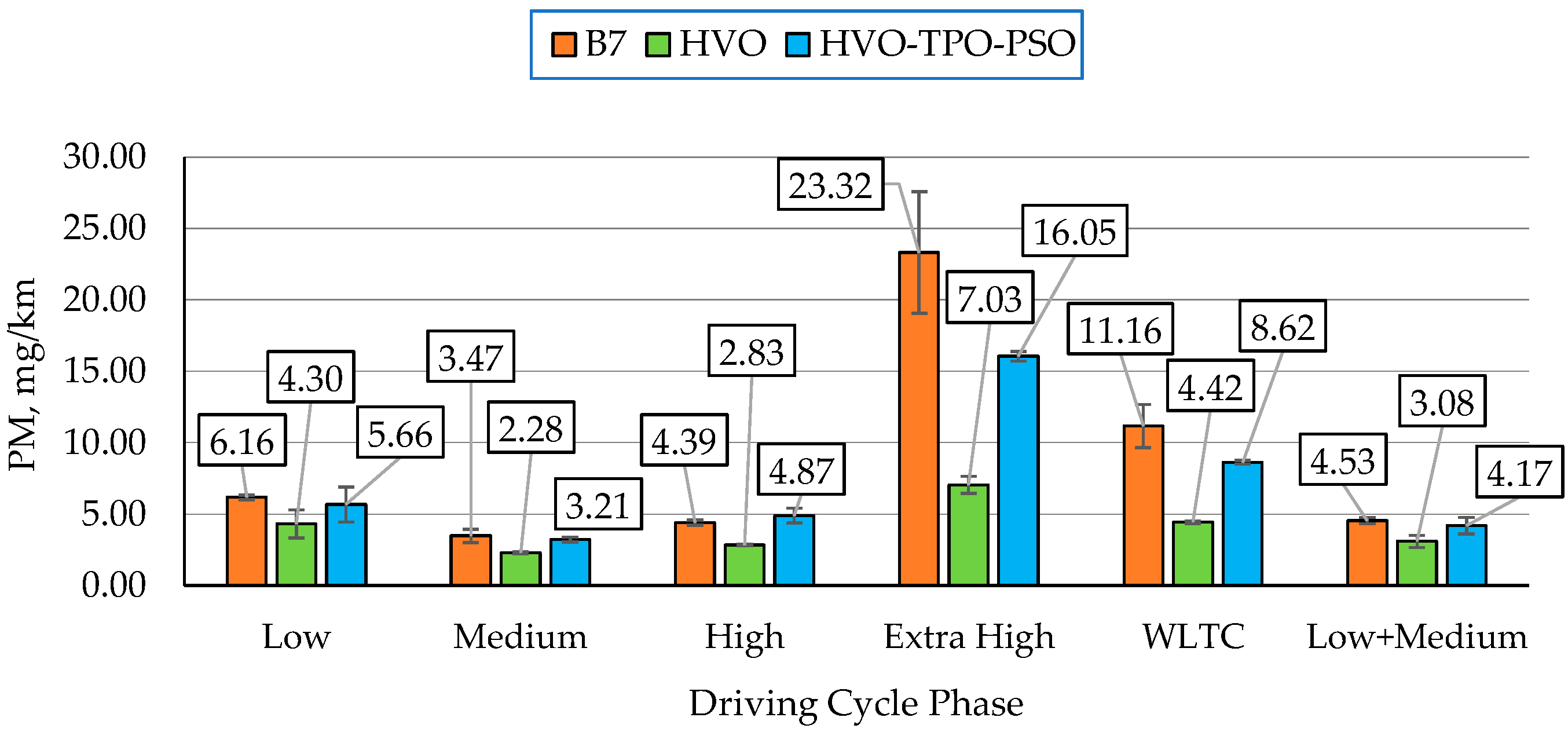

3.1.5. PM Emission

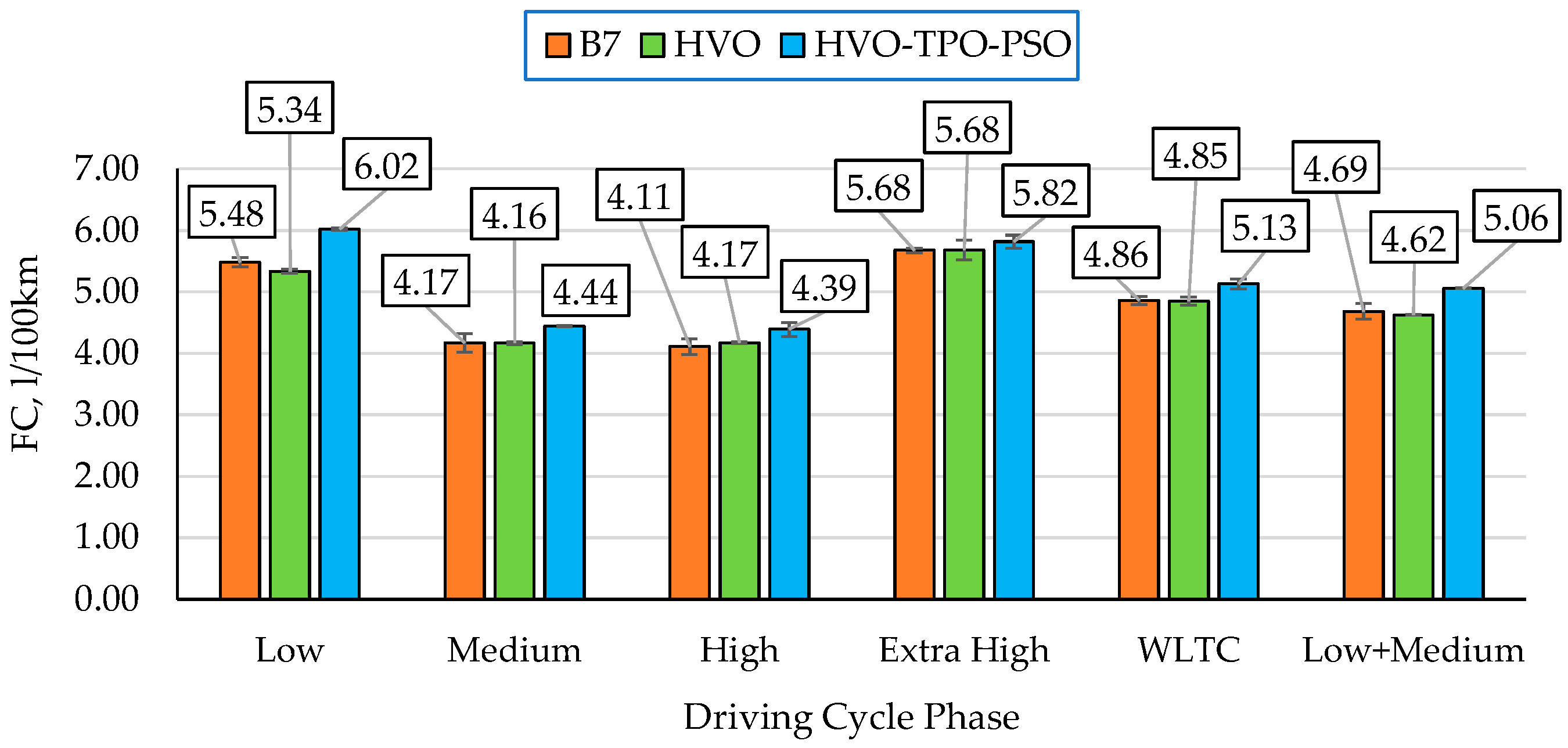

3.2. Fuel Consumption

4. Conclusions

- Replacing the reference fuel B7 with HVO resulted in a reduction of CO2, CO, THC, NOx, and PM emissions in all driving phases of the WLTC 3b cycle. The largest CO2 emission reduction (approximately 9%) was observed in the Low phase, while the smallest reduction (approximately 5%) occurred in the High phase. This effect was likely due to the high cetane number of HVO, its higher calorific value, and its lower carbon and aromatic content compared to B7, all of which promoted more efficient combustion.

- The HVO–TPO–PSO blend exhibited higher CO2 and NOx emissions compared to pure HVO and, in some phases of the cycle, also relative to B7. This was attributed to the lower calorific values and higher aromatic content of TPO and PSO. Nevertheless, PM emissions for HVO–TPO–PSO were lower than for B7 in most driving phases, except for the High phase.

- CO and THC emissions for both HVO and the HVO–TPO–PSO blend were lower than those for B7, with the lowest values obtained for HVO (approximately 0.21 g/km CO for the entire cycle). NOx emissions with HVO were about 22% lower over the entire cycle compared to B7. The HVO–TPO–PSO blend exhibited the highest NOx emissions among the tested fuels in all cycle phases, particularly in the Low phase.

- The greatest reduction in PM emissions was achieved with HVO (approximately 70%) in the Extra High phase of the cycle and about 60% over the entire cycle compared to B7. The addition of TPO and PSO to HVO caused a slight increase in PM emissions relative to HVO; however, PM levels remained lower than those for B7.

- Fuel consumption when using HVO was comparable to that of B7, whereas the HVO–TPO–PSO blend showed a slight increase, particularly in the Low phase of the cycle. This was likely due to the lower calorific value of the pyrolysis oils.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| HVO | Hydrotreated Vegetable Oil |

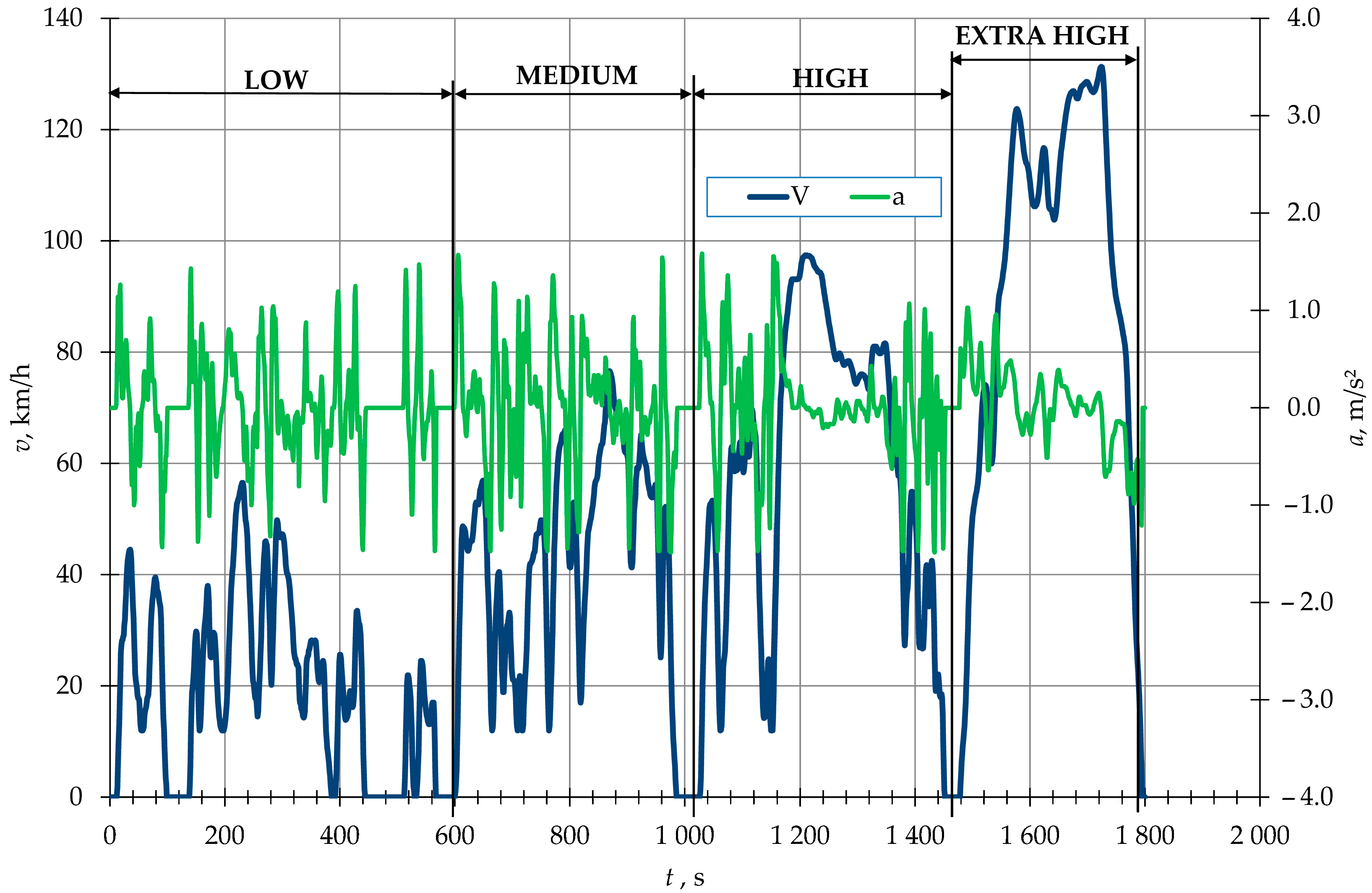

| WLTC | Worldwide Harmonized Light Vehicles Test Cycle |

| CI | Compression Ignition |

| TPO | Tire Pyrolysis Oil |

| PSO | Polystyrene Pyrolysis Oil |

| RDE | Real Driving Emissions |

| CO2 | Carbon Dioxide |

| CO | Carbon Monoxide |

| THC | Total Hydrocarbons |

| NOx | Nitrogen Oxides |

| PM | Particulate Matter |

| FAME | Fatty Acid Methyl Esters |

| B7 | Diesel fuel containing up to 7% biodiesel (FAME) |

| GHG | Greenhouse Gases |

| DF | Diesel Fuel |

| PVO | Pure Vegetable Oil |

| DOC | Diesel Oxidation Catalyst |

| SCR | Selective Catalytic Reduction |

| POB | Palm Oil Biodiesel |

| OME | Oligomeric Methyl Ethers |

| GTL | Gas-to-liquids |

| HDPE | High-Density Polyethylene |

| PP | Polypropylene |

| PS | Polystyrene |

| WPPO | Waste Plastic Pyrolysis Oil |

| BSFC | Brake Specific Fuel Consumption |

| HC | Hydrocarbons |

| NEDC | New European Driving Cycle |

| UDDS | Urban Dynamometer Driving Schedule |

| HHDDT | Heavy Heavy-Duty Diesel Truck |

| NMHC | Non-Methane Hydrocarbons |

| CH4 | Methane |

| CARB | California Air Resources Board |

| ULSD | Ultra-Low Sulfur Diesel |

| HCK | Hydrocracking |

| WLTP | Worldwide Harmonized Light Vehicles Test Procedure |

| B0 | Diesel fuel with 0% biodiesel |

| B7 | Diesel fuel with 7% biodiesel |

| B15 | Diesel fuel with 15% biodiesel |

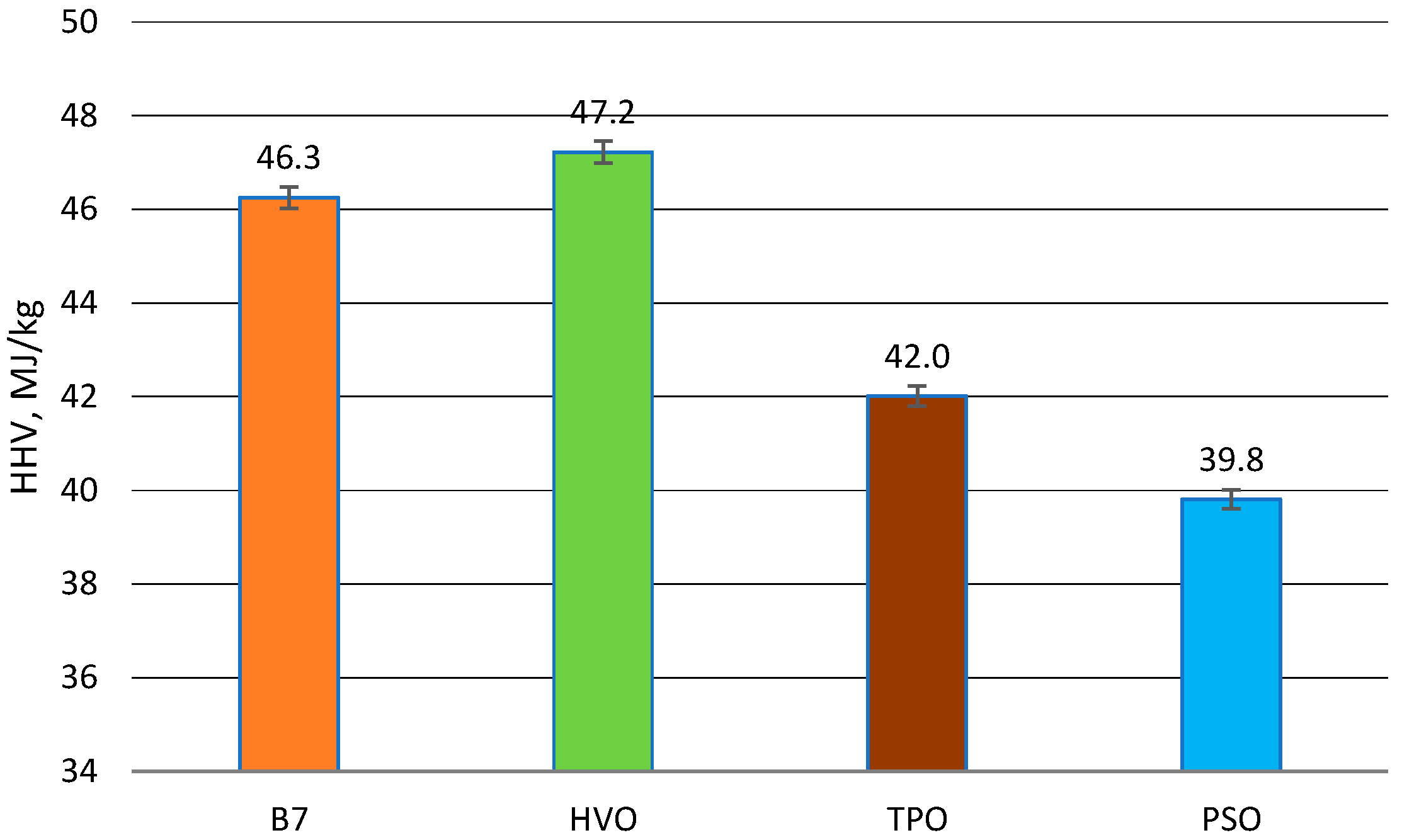

| HHV | Higher Heating Value |

| CFPP | Cold Filter Plugging Point |

| FC | Fuel Consumption |

| HVO–TPO–PSO | Fuel containing 90% HVO, 5% TPO, and 5% PSO (by volume) |

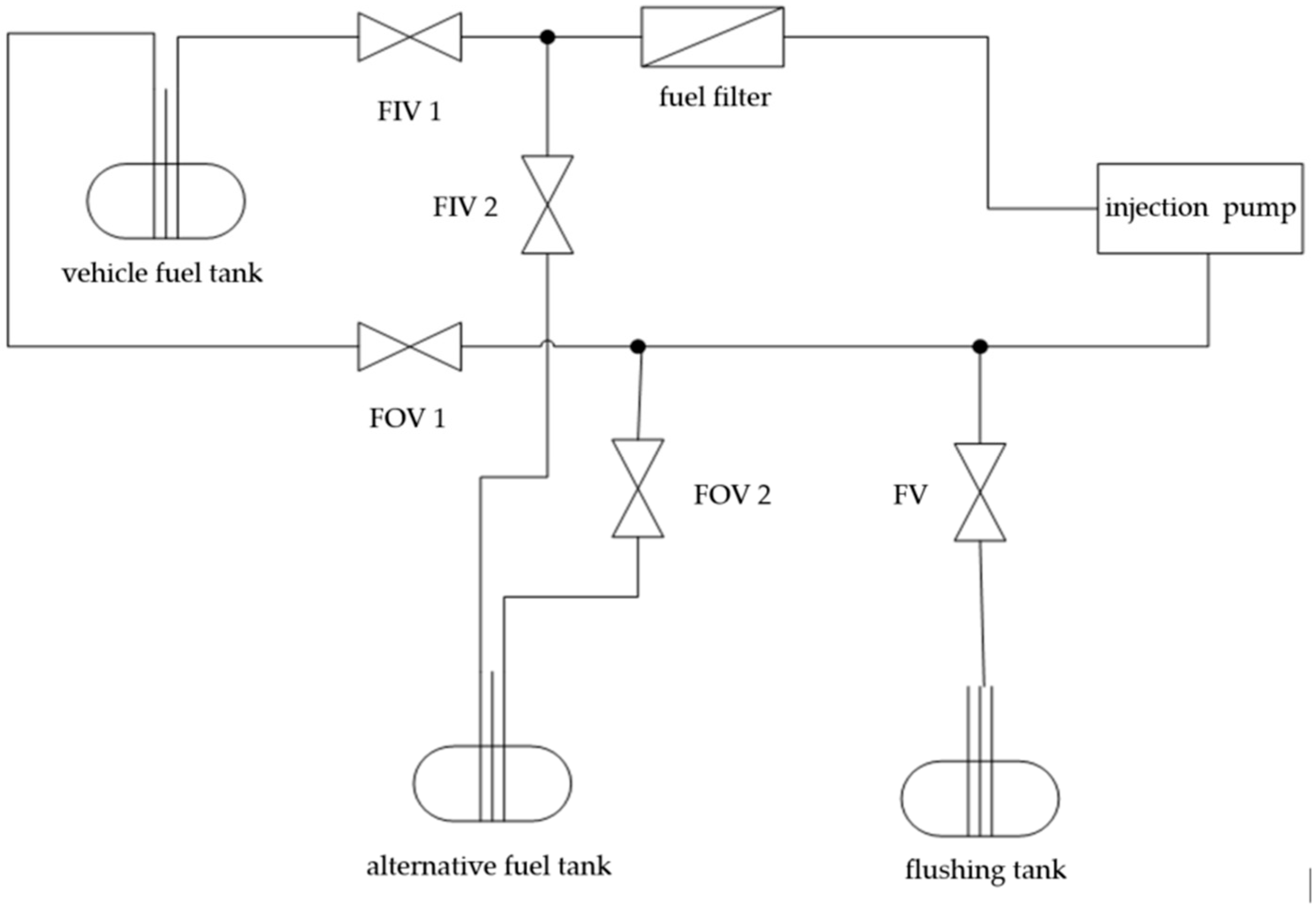

| FIV | fuel inlet valve |

| FOV | fuel outlet valve |

| FV | flush valve |

| v | Speed |

| a | Acceleration |

| d | Distance |

| rd | Dilution ratio |

| qmew,i | Exhaust mass flow rate at time i |

| egas | Mass emission rate of an exhaust gas component |

| ρgas | Density of the exhaust gas component in g/L under standard conditions |

| ci | Soot concentration in the exhaust gas at time i |

| ρo | Density of the exhaust gas under standard conditions |

| Δti | Sampling interval |

References

- Clairotte, M.; Suarez-Bertoa, R.; Zardini, A.A.; Giechaskiel, B.; Pavlovic, J.; Valverde, V.; Ciuffo, B.; Astorga, C. Exhaust emission factors of greenhouse gases (GHGs) from European road vehicles. Environ. Sci. Eur. 2020, 32, 125. [Google Scholar] [CrossRef]

- European Economic and Social Committee. Opinion European Economic and Social Committee CO2 Performance Standards/New Cars; European Economic and Social Committee: Brussels, Belgium, 2022. Available online: https://dm-publicapi.eesc.europa.eu/v1/documents/EESC-2021-04839-00-01-AC-TRA-EN.docx/content (accessed on 15 May 2025).

- Diouf, B. The electric vehicle transition. Environ. Sci. Adv. 2024, 3, 332–345. [Google Scholar] [CrossRef]

- ExxonMobil Energy Demand: Global Outlook. All Energy Types Will Be Needed| ExxonMobil. Available online: https://corporate.exxonmobil.com/sustainability-and-reports/global-outlook/all-energy-types-are-needed (accessed on 15 May 2025).

- Koszalka, G.; Hunicz, J. Comparative study of energy losses related to the ring pack operation in homogeneous charge compression ignition and spark ignition combustion. Energy 2021, 235, 121388. [Google Scholar] [CrossRef]

- British Petroleum. The Energy Outlook Explores the Forces Shaping the Global Energy Transition out to 2040 and the Key Uncertainties Surrounding That Transition; BP Energy Outlook 2019 Edition; BP Energy Outlook 2019; Brunel International NV: Amsterdam, The Netherlands, 2019; pp. 22–24, 72–76, 144, 118. [Google Scholar]

- Bezergianni, S.; Dimitriadis, A. Comparison between different types of renewable diesel. Renew. Sustain. Energy Rev. 2013, 21, 110–116. [Google Scholar] [CrossRef]

- Chiaramonti, D.; Prussi, M. Pure vegetable oil for energy and transport. Int. J. Oil Gas Coal Technol. 2009, 2, 186–198. [Google Scholar] [CrossRef]

- Vásquez, M.C.; Silva, E.E.; Castillo, E.F. Hydrotreatment of vegetable oils: A review of the technologies and its developments for jet biofuel production. Biomass Bioenergy 2017, 105, 197–206. [Google Scholar] [CrossRef]

- Aatola, H.; Larmi, M.; Sarjovaara, T.; Mikkonen, S. Hydrotreated vegetable Oil (HVO) as a renewable diesel fuel: Trade-off between NOx, particulate emission, and fuel consumption of a heavy duty engine. SAE Int. J. Engines 2009, 1, 1251–1262. [Google Scholar] [CrossRef]

- Hunicz, J.; Yang, L.; Rybak, A.; Ji, S.; Gęca, M.S.; Mikulski, M. Comparison of diesel and hydrotreated vegetable oil as the high-reactivity fuel in reactivity-controlled compression ignition. Energy Convers. Manag. 2025, 323, 119264. [Google Scholar] [CrossRef]

- Hunicz, J.; Matijošius, J.; Rimkus, A.; Kilikevičius, A.; Kordos, P.; Mikulski, M. Efficient hydrotreated vegetable oil combustion under partially premixed conditions with heavy exhaust gas recirculation. Fuel 2020, 268, 117350. [Google Scholar] [CrossRef]

- Prokopowicz, A.; Zaciera, M.; Sobczak, A.; Bielaczyc, P.; Woodburn, J. The Effects of Neat Biodiesel and Biodiesel and HVO Blends in Diesel Fuel on Exhaust Emissions from a Light Duty Vehicle with a Diesel Engine. Environ. Sci. Technol. 2015, 49, 7473–7482. [Google Scholar] [CrossRef]

- Bortel, I.; Vávra, J.; Takáts, M. Effect of HVO fuel mixtures on emissions and performance of a passenger car size diesel engine. Renew. Energy 2019, 140, 680–691. [Google Scholar] [CrossRef]

- Millo, F.; Jafari, M.J.; Piano, A.; Postrioti, L.; Brizi, G.; Vassallo, A.; Pesce, F.; Fittavolini, C. A fundamental study of injection and combustion characteristics of neat Hydrotreated Vegetable Oil (HVO) as a fuel for light-duty diesel engines. Fuel 2025, 379, 132951. [Google Scholar] [CrossRef]

- Pirjola, L.; Rönkkö, T.; Saukko, E.; Parviainen, H.; Malinen, A.; Alanen, J.; Saveljeff, H. Exhaust emissions of non-road mobile machine: Real-world and laboratory studies with diesel and HVO fuels. Fuel 2017, 202, 154–164. [Google Scholar] [CrossRef]

- Kuszewski, H.; Jaworski, A.; Mądziel, M. Lubricity of Ethanol–Diesel Fuel Blends—Study with the Four-Ball Machine Method. Materials 2021, 14, 2492. [Google Scholar] [CrossRef]

- Huynh, K.K.; Pham, S.T.; Tieu, K.A.; Wan, S. Tribocatalysis Induced Carbon-Based Tribofilms—An Emerging Tribological Approach for Sustainable Lubrications. Lubricants 2023, 11, 327. [Google Scholar] [CrossRef]

- Parravicini, M.; Barro, C.; Boulouchos, K. Experimental characterization of GTL, HVO, and OME based alternative fuels for diesel engines. Fuel 2021, 292, 120177. [Google Scholar] [CrossRef]

- Kumar, J.S.; Bapu, B.R.R.; Sivasaravanan, S.; Prabhu, M.; Kumar, S.M.; Abubacker, M.A. Experimental studies on emission reduction in a DI diesel engine by using a nano catalyst coated catalytic converter. Int. J. Ambient Energy 2019, 43, 1241–1247. [Google Scholar] [CrossRef]

- Mirkarimi, S.M.R.; Bensaid, S.; Chiaramonti, D. Conversion of mixed waste plastic into fuel for diesel engines through pyrolysis process: A review. Appl. Energy 2022, 327, 120040. [Google Scholar] [CrossRef]

- Faisal, F.; Rasul, M.G.; Ahmed Chowdhury, A.; Schaller, D.; Jahirul, M.I. Uncovering the differences: A comparison of properties of crude plastic pyrolytic oil and distilled and hydrotreated plastic diesel produced from waste and virgin plastics as automobile fuels. Fuel 2023, 350, 128743. [Google Scholar] [CrossRef]

- Zheng, Q.; Li, Z.; Watanabe, M. Production of solid fuels by hydrothermal treatment of wastes of biomass, plastic, and biomass/plastic mixtures: A review. J. Bioresour. Bioprod. 2022, 7, 221–244. [Google Scholar] [CrossRef]

- Ferdoush, M.R.; Aziz, R.A.; Karmaker, C.L.; Debnath, B.; Limon, M.H.; Bari, A.B.M.M. Unraveling the challenges of waste-to-energy transition in emerging economies: Implications for sustainability. Innov. Green Dev. 2024, 3, 100121. [Google Scholar] [CrossRef]

- Bayramoğlu, K.; Nuran, M. Energy, exergy, sustainability evaluation of the usage of pyrolytic oil and conventional fuels in diesel engines. Process Saf. Environ. Prot. 2024, 181, 324–333. [Google Scholar] [CrossRef]

- Bodisco, T.A.; Rahman, S.M.A.; Hossain, F.M.; Brown, R.J. On-road NOx emissions of a modern commercial light-duty diesel vehicle using a blend of tyre oil and diesel. Energy Rep. 2019, 5, 349–356. [Google Scholar] [CrossRef]

- Yaqoob, H.; Tan, E.S.; Ali, H.M.; Ong, H.C.; Jamil, M.A.; Farooq, M.U. Sustainable energy generation from plastic waste: An in-depth review of diesel engine application. Environ. Technol. Innov. 2024, 34, 103467. [Google Scholar] [CrossRef]

- Januszewicz, K.; Hunicz, J.; Kazimierski, P.; Rybak, A.; Suchocki, T.; Duda, K.; Mikulski, M. An experimental assessment on a diesel engine powered by blends of waste-plastic-derived pyrolysis oil with diesel. Energy 2023, 281, 128330. [Google Scholar] [CrossRef]

- Mikulski, M.; Ambrosewicz-Walacik, M.; Hunicz, J.; Nitkiewicz, S. Combustion engine applications of waste tyre pyrolytic oil. Prog. Energy Combust. Sci. 2021, 85, 100915. [Google Scholar] [CrossRef]

- Mustayen, A.G.M.B.; Rasul, M.G.; Wang, X.; Hazrat, M.A.; Islam, M.J.; Negnevitsky, M. Plastic-made diesel (PMD) from pyrolysis via vacuum distillation process—A waste recycling fuel to diesel engine performance and emissions improvement. J. Energy Inst. 2023, 107, 101198. [Google Scholar] [CrossRef]

- Kumar, R.; Mishra, M.K.; Roy, M.K. Effects of Hexane Addition in Waste Plastic Fuel-Biodiesel-Diesel Blends on the Performance and Emission Characteristics of DI Diesel Engine. Automot. Exp. 2022, 5, 416–432. [Google Scholar] [CrossRef]

- Sharma, B.K.; Moser, B.R.; Vermillion, K.E.; Doll, K.M.; Rajagopalan, N. Production, characterization and fuel properties of alternative diesel fuel from pyrolysis of waste plastic grocery bags. Fuel Process. Technol. 2014, 122, 79–90. [Google Scholar] [CrossRef]

- Sunaryo, S.; Sesotyo, P.A.; Saputra, E.; Sasmito, A.P. Performance and fuel consumption of diesel engine fueled by diesel fuel and waste plastic oil blends: An experimental investigation. Automot. Exp. 2021, 4, 20–26. [Google Scholar] [CrossRef]

- Mohan, R.K.; Sarojini, J.; Rajak, U.; Verma, T.N.; Ağbulut, Ü. Alternative fuel production from waste plastics and their usability in light duty diesel engine: Combustion, energy, and environmental analysis. Energy 2023, 265, 126140. [Google Scholar] [CrossRef]

- Muthukumar, K.; Kasiraman, G. Utilization of fuel energy from single-use Low-density polyethylene plastic waste on CI engine with hydrogen enrichment—An experimental study. Energy 2024, 289, 129926. [Google Scholar] [CrossRef]

- Armas, O.; García-Contreras, R.; Ramos, Á.; López, A.F. Impact of Animal Fat Biodiesel, GTL, and HVO Fuels on Combustion, Performance, and Pollutant Emissions of a Light-Duty Diesel Vehicle Tested under the NEDC. J. Energy Eng. 2015, 141, C4014009. [Google Scholar] [CrossRef]

- Karavalakis, G.; Jiang, Y.; Yang, J.; Durbin, T.; Nuottimäki, J.; Lehto, K. Emissions and Fuel Economy Evaluation from Two Current Technology Heavy-Duty Trucks Operated on HVO and FAME Blends. SAE Int. J. Fuels Lubr. 2016, 9, 177–190. [Google Scholar] [CrossRef]

- Birzietis, G.; Pirs, V.; Dukulis, I.; Gailis, M. Effect of commercial diesel fuel and hydrotreated vegetable oil blend on automobile performance. Agron. Res. 2017, 15, 964–970. [Google Scholar]

- Jaroonjitsathian, S.; Saisirirat, P.; Sivara, K.; Tongroon, M.; Chollacoop, N. Effects of GTL and HVO Blended Fuels on Combustion and Exhaust Emissions of a Common-Rail DI Diesel Technology; SAE Technical Paper 2014-01-2763; SAE: Warrendale, PA, USA, 2014. [Google Scholar] [CrossRef]

- Napolitano, P.; Beatrice, C.; Guido, C.; Del Giacomo, N.; Pellegrini, L.; Scorletti, P. Hydrocracked Fossil Oil and Hydrotreated Vegetable Oil (HVO) Effects on Combustion and Emissions Performance of “Torque-Controlled” Diesel Engines; SAE Technical Paper 2015-24-2497; SAE: Warrendale, PA, USA, 2015. [Google Scholar] [CrossRef]

- Mata, C.; Cárdenas, D.; Esarte, C.; Soriano, J.A.; Gómez, A.; Fernández-Yáñez, P.; García-Contreras, R.; Sánchez, L.; Nogueira, J.I.; Armas, O. Performance and regulated emissions from a Euro VI-D hybrid bus tested with fossil and renewable (hydrotreated vegetable oil) diesel fuels under urban driving in Bilbao city, Spain. J. Clean. Prod. 2023, 383, 135472. [Google Scholar] [CrossRef]

- Serrano, L.; Santana, B.; Pires, N.; Correia, C. Performance, Emissions, and Efficiency of Biodiesel versus Hydrotreated Vegetable Oils (HVO), Considering Different Driving Cycles Sensitivity Analysis (NEDC and WLTP). Fuels 2021, 2, 448–470. [Google Scholar] [CrossRef]

- Jaworski, A.; Kuszewski, H.; Balawender, K.; Woś, P.; Lew, K.; Jaremcio, M. Assessment of CH4 Emissions in a Compressed Natural Gas-Adapted Engine in the Context of Changes in the Equivalence Ratio. Energies 2024, 17, 2095. [Google Scholar] [CrossRef]

- Jaworski, A.; Kuszewski, H.; Lew, K.; Wojewoda, P.; Balawender, K.; Woś, P.; Longwic, R.; Boichenko, S. Assessment of the Effect of Road Load on Energy Consumption and Exhaust Emissions of a Hybrid Vehicle in an Urban Road Driving Cycle—Comparison of Road and Chassis Dynamometer Tests. Energies 2023, 16, 5723. [Google Scholar] [CrossRef]

- SENSORS SEMTECH EFM-4. Available online: https://sensors-inc.com/Products/SEMTECH/EFM (accessed on 12 January 2020).

- AVL Micro Soot Sensor. Product Guide. AVL, 2010. Available online: https://www.avl.com (accessed on 15 September 2025).

- HORIBA OBS-2200. Service Manual; HORIBA Ltd.: Kioto, Japan, 2010; Available online: https://www.horiba.com (accessed on 15 September 2025).

- Service Manual AVL-ROADSIM 48; AVL List GmbH: Graz, Austria, 2014; Available online: https://www.avl.com (accessed on 15 September 2025).

- Puškár, M.; Jahnátek, A.; Kádárová, J.; Šoltésová, M.; Kovanič, Ľ.; Krivosudská, J. Environmental study focused on the suitability of vehicle certifications using the new European driving cycle (NEDC) with regard to the affair “dieselgate” and the risks of NOx emissions in urban destinations. Air Qual. Atmos. Health 2019, 12, 251–257. [Google Scholar] [CrossRef]

- Average Age of the EU Vehicle Fleet, by Country. ACEA. Driving Mobility for Europe. 2024. Available online: https://www.acea.auto/figure/average-age-of-eu-vehicle-fleet-by-country/ (accessed on 10 January 2025).

- Autogidas. Volkswagen Polo III 1.9 SDI Specifications. 2012. Available online: https://autogidas.lt/en/auto-katalogas/volkswagen/polo/iii-1.9-sdi-2000-2001-k72196 (accessed on 10 June 2025).

- Hunicz, J.; Rybak, A.; Szpica, D.; Gęca, M.S.; Woś, P.; Yang, L.; Mikulski, M. Waste plastic pyrolysis oils as diesel fuel blending components: Detailed analysis of combustion and emissions sensitivity to engine control parameters. Energy 2024, 313, 134093. [Google Scholar] [CrossRef]

- Adamiak, B.; Andrych-Zalewska, M.; Merkisz, J.; Chłopek, Z. The uniqueness of pollutant emission and fuel consumption test results for road vehicles tested on a chassis dynamometer. Eksploat. Niezawodn. Maint. Reliab. 2025, 27, 1. [Google Scholar] [CrossRef]

- UN Regulation No 154—Uniform Provisions Concerning the Approval of Light Duty Passenger and Commercial Vehicles with Regards to Criteria Emissions, Emissions of Carbon Dioxide and Fuel Consumption and/or the Measurement of Electric Energy Consumption and Electric Range (WLTP) [2021/2039]. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:42021X2039 (accessed on 15 September 2025).

- Ajeeb, W.; Gomes, D.M.; Neto, R.C.; Baptista, P. Life cycle analysis of hydrotreated vegetable oils production based on green hydrogen and used cooking oils. Fuel 2025, 390, 134749. [Google Scholar] [CrossRef]

- Dobrzyńska, E.; Szewczyńska, M.; Pośniak, M.; Szczotka, A.; Puchałka, B.; Woodburn, J. Exhaust emissions from diesel engines fueled by different blends with the addition of nanomodifiers and hydrotreated vegetable oil HVO. Environ. Pollut. 2020, 259, 113772. [Google Scholar] [CrossRef]

- Bohl, T.; Smallbone, A.; Tian, G.; Roskilly, A.P. Particulate number and NOx trade-off comparisons between HVO and mineral diesel in HD applications. Fuel 2018, 215, 90–101. [Google Scholar] [CrossRef]

- Sihlovec, F.; Vrtiška, D.; Šimáček, P. The use of multivariate statistics and mathematically modeled IR spectra for determination of HVO content in diesel blends. Fuel 2025, 379, 132963. [Google Scholar] [CrossRef]

- Bays, J.T.; Gieleciak, R.; Viola, M.B.; Lewis, R.P.; Cort, J.R.; Campbell, K.B.; Coffey, G.W.; Linehan, J.C.; Kusinski, M. Detailed Compositional Comparison of Hydrogenated Vegetable Oil with Several Diesel Fuels and Their Effects on Engine-Out Emissions. SAE Int. J. Fuels Lubr. 2022, 16, 193–220. [Google Scholar] [CrossRef]

- McCaffery, C.; Zhu, H.; Sabbir Ahmed, C.M.; Canchola, A.; Chen, J.Y.; Li, C.; Johnson, K.C.; Durbin, T.D.; Lin, Y.H.; Karavalakis, G. Effects of hydrogenated vegetable oil (HVO) and HVO/biodiesel blends on the physicochemical and toxicological properties of emissions from an off-road heavy-duty diesel engine. Fuel 2022, 323, 124283. [Google Scholar] [CrossRef] [PubMed]

- Smigins, R.; Sondors, K.; Pirs, V.; Dukulis, I.; Birzietis, G. Studies of Engine Performance and Emissions at Full-Load Mode Using HVO, Diesel Fuel, and HVO5. Energies 2023, 16, 4785. [Google Scholar] [CrossRef]

- Jakubowski, M.; Jaworski, A.; Kuszewski, H.; Balawender, K. Performance of a Diesel Engine Fueled by Blends of Diesel Fuel and Synthetic Fuel Derived from Waste Car Tires. Sustainability 2024, 16, 6404. [Google Scholar] [CrossRef]

- Jaworski, A.; Kuszewski, H.; Longwic, R.; Sander, P. Assessment of Self-Ignition Properties of Canola Oil–n-Hexane Blends in a Constant Volume Combustion Chamber and Compression Ignition Engine. Appl. Sci. 2023, 13, 10558. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W.; Gnatowska, R.; Nowak, Ł. Comparative Analysis of the Combustion Stability of Diesel-Methanol and Diesel-Ethanol in a Dual Fuel Engine. Energies 2019, 12, 971. [Google Scholar] [CrossRef]

| Analyzed Parameter | Value |

|---|---|

| Length/Width/Height | 3926 mm/1650 mm/1465 mm |

| Wheelbase | 2454 mm |

| Curb weight | 1083 kg |

| Engine type | Compression-ignition |

| Fuel | Diesel |

| Fuel supply system | Direct injection with mechanical distributor pump |

| Engine displacement | 1896 cm3 |

| Maximum engine power/speed | 47 kW/4200 rpm |

| Maximum torque/speed | 125 Nm/1600 rpm |

| Number of cylinders | 4 |

| Number of valves | 8 |

| Emission standard | Euro 3 |

| Number of gears (manual transmission) | 5 |

| Mileage | ~193,000 km |

| Drive axle | Front |

| Tire size | 165/70 R14 |

| Road load parameters: f0, f1, f2 | 67.24 N, 0.06451 N/(km/), 0.04371 |

| Test mass | 1130 kg |

| Engine designation | T9V/T2Q/T0X/T96 |

| Fuel supply system | Electronically controlled distributor pump |

| Exhaust aftertreatment system | Oxidation catalyst |

| Parameter | B7 | HVO | TPO | PSO |

|---|---|---|---|---|

| Density, g/cm3 (T = 15 °C) | 0.834 | 0.782 | 0.910 | 0.945 |

| Kinematic viscosity, mm2/s (T = 40 °C) | 2.81 | 2.90 | 2.71 | 1.20 |

| Flash point, °C | 63.5 | 64.0 | 54.5 | <23.0 |

| Water content, ppm | 28 | 19 | 870 | 207 |

| HHV, MJ/kg | 46.3 | 47.2 | 42.0 | 39.8 |

| CFPP, °C | −21 | −34 | −19 | −15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jaworski, A.; Kuszewski, H.; Szpica, D.; Woś, P.; Balawender, K.; Ustrzycki, A.; Krzemiński, A.; Jakubowski, M.; Mieczkowski, G.; Borawski, A.; et al. Comparative Study on the Effects of Diesel Fuel, Hydrotreated Vegetable Oil, and Its Blends with Pyrolytic Oils on Pollutant Emissions and Fuel Consumption of a Diesel Engine Under WLTC Dynamic Test Conditions. Energies 2025, 18, 5038. https://doi.org/10.3390/en18185038

Jaworski A, Kuszewski H, Szpica D, Woś P, Balawender K, Ustrzycki A, Krzemiński A, Jakubowski M, Mieczkowski G, Borawski A, et al. Comparative Study on the Effects of Diesel Fuel, Hydrotreated Vegetable Oil, and Its Blends with Pyrolytic Oils on Pollutant Emissions and Fuel Consumption of a Diesel Engine Under WLTC Dynamic Test Conditions. Energies. 2025; 18(18):5038. https://doi.org/10.3390/en18185038

Chicago/Turabian StyleJaworski, Artur, Hubert Kuszewski, Dariusz Szpica, Paweł Woś, Krzysztof Balawender, Adam Ustrzycki, Artur Krzemiński, Mirosław Jakubowski, Grzegorz Mieczkowski, Andrzej Borawski, and et al. 2025. "Comparative Study on the Effects of Diesel Fuel, Hydrotreated Vegetable Oil, and Its Blends with Pyrolytic Oils on Pollutant Emissions and Fuel Consumption of a Diesel Engine Under WLTC Dynamic Test Conditions" Energies 18, no. 18: 5038. https://doi.org/10.3390/en18185038

APA StyleJaworski, A., Kuszewski, H., Szpica, D., Woś, P., Balawender, K., Ustrzycki, A., Krzemiński, A., Jakubowski, M., Mieczkowski, G., Borawski, A., Gęca, M. S., & Rybak, A. (2025). Comparative Study on the Effects of Diesel Fuel, Hydrotreated Vegetable Oil, and Its Blends with Pyrolytic Oils on Pollutant Emissions and Fuel Consumption of a Diesel Engine Under WLTC Dynamic Test Conditions. Energies, 18(18), 5038. https://doi.org/10.3390/en18185038