Microscopic Transport During Carbon Dioxide Injection in Crude Oil from Jimsar Oilfield Using Microfluidics

Abstract

1. Introduction

2. Experimental Part

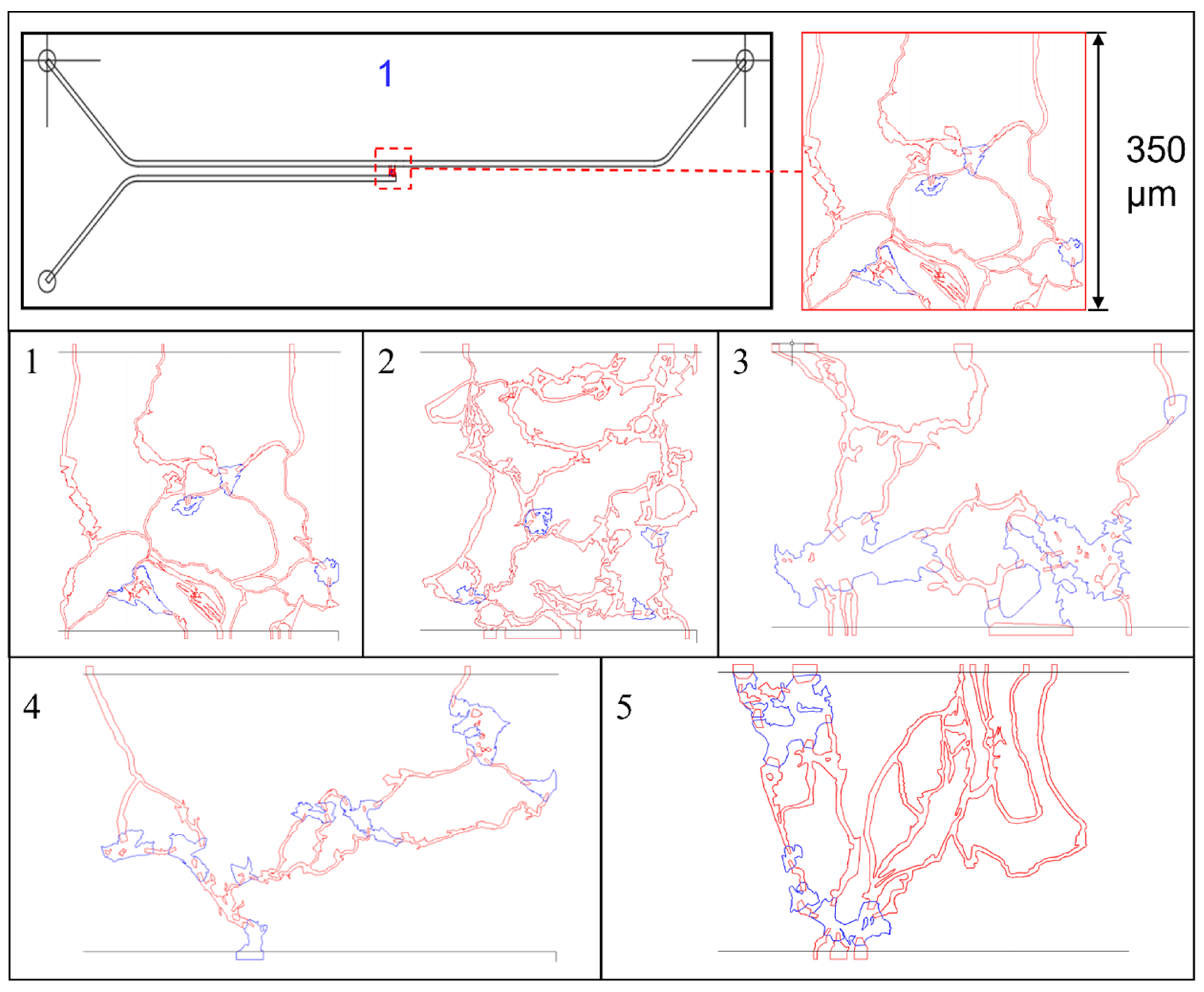

2.1. Chip Design and Preparation

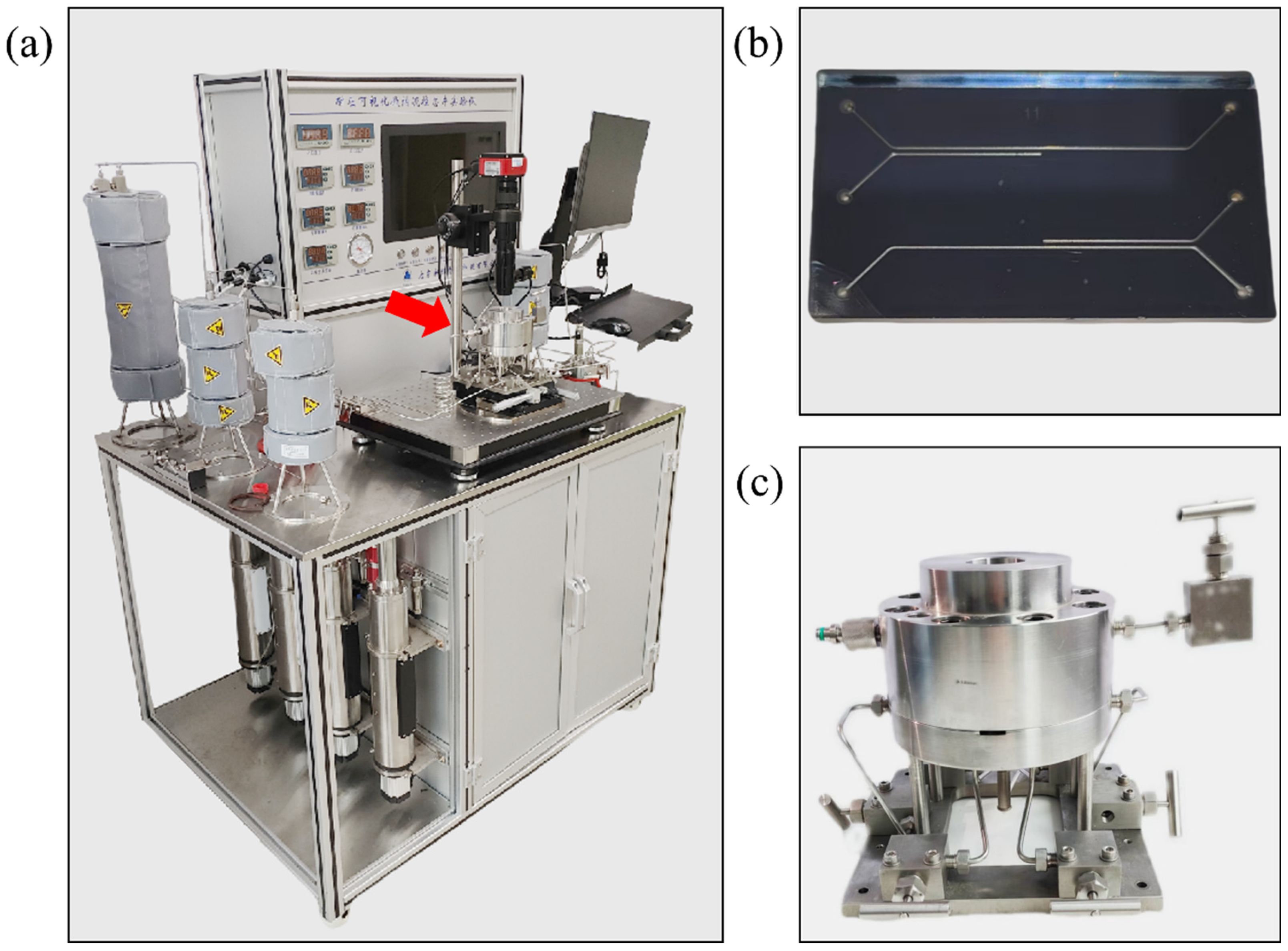

2.2. Experimental Materials and Equipment

2.3. Experimental Program and Procedures

3. Results and Discussion

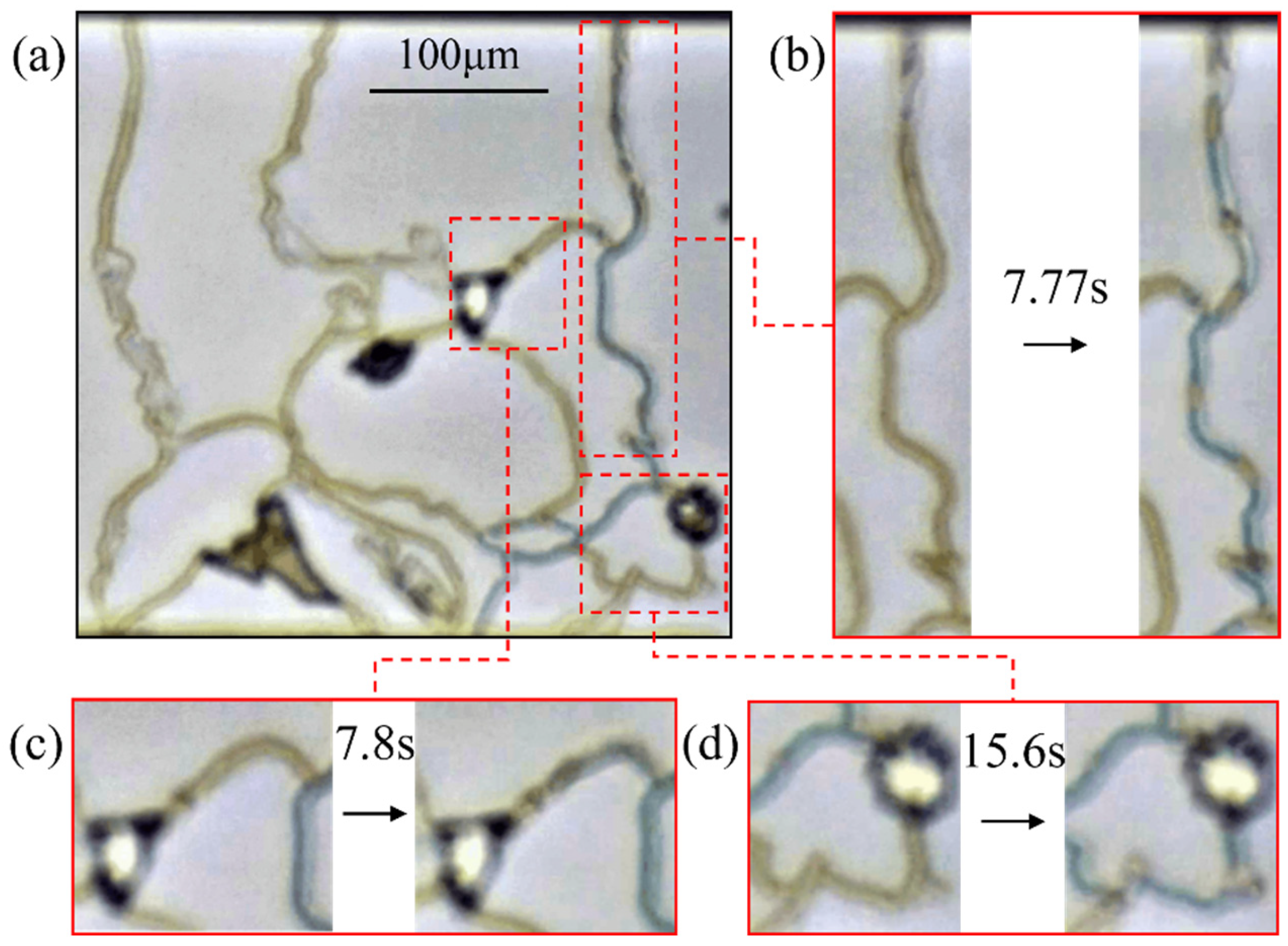

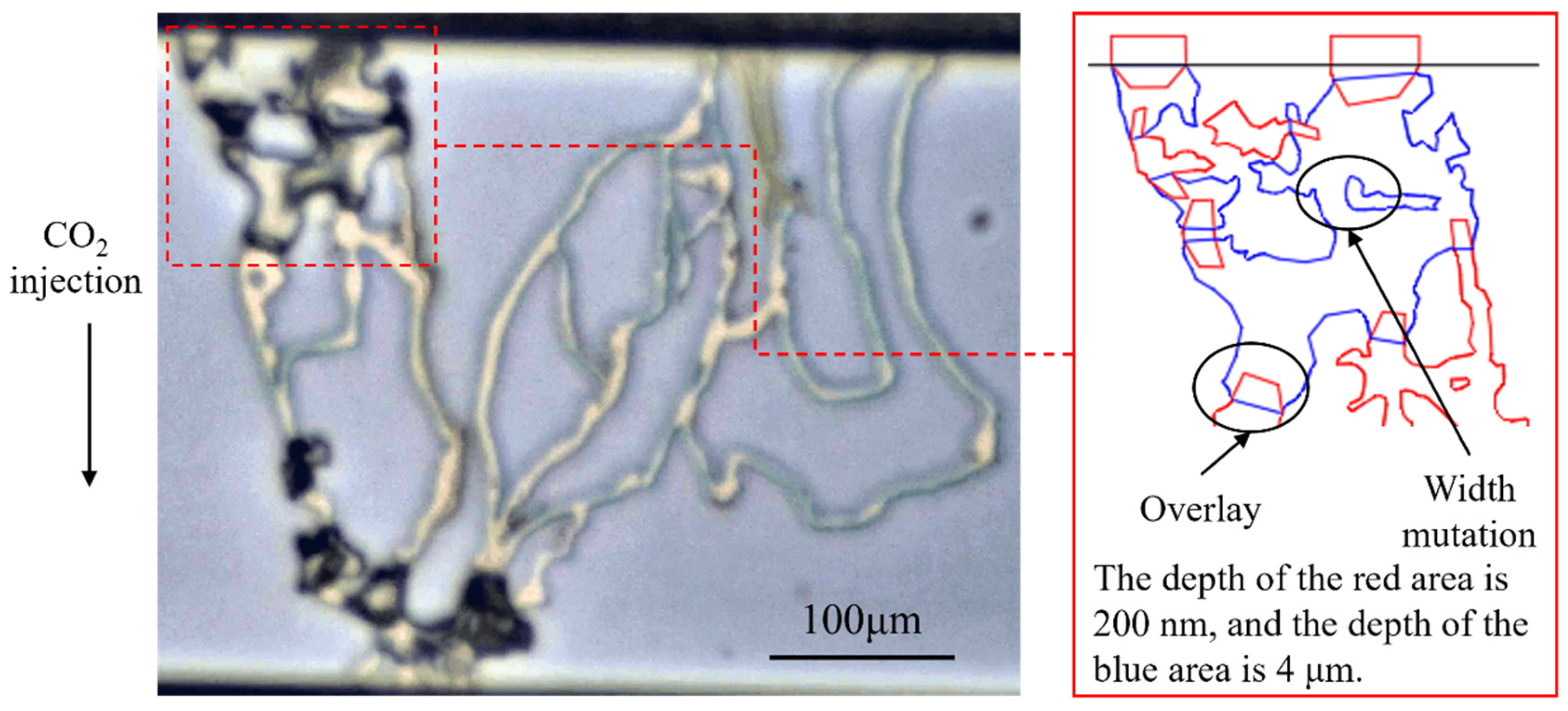

3.1. CO2 Immiscible Flooding Experiments

3.2. Constant Volume Depletion Experiments

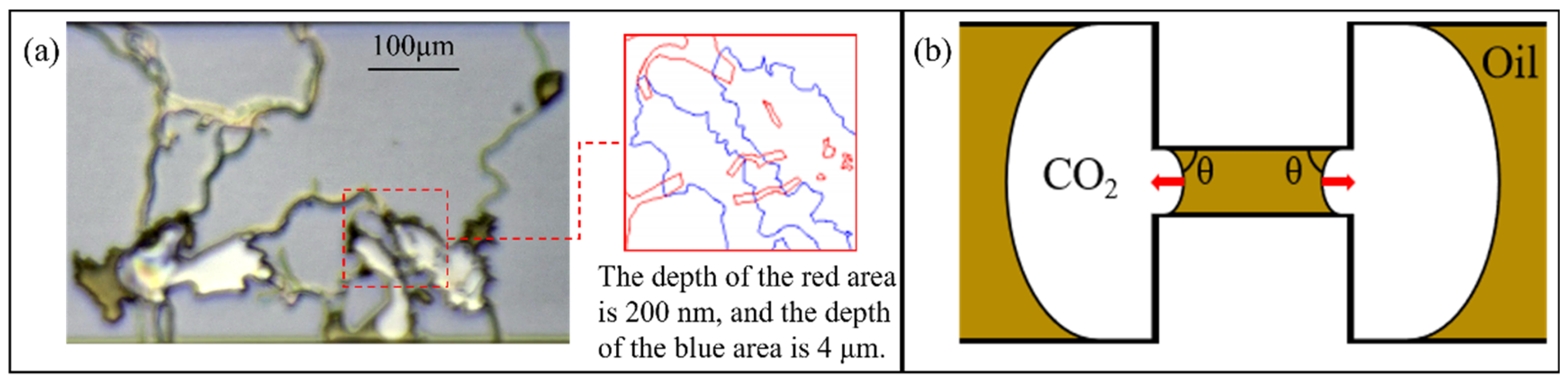

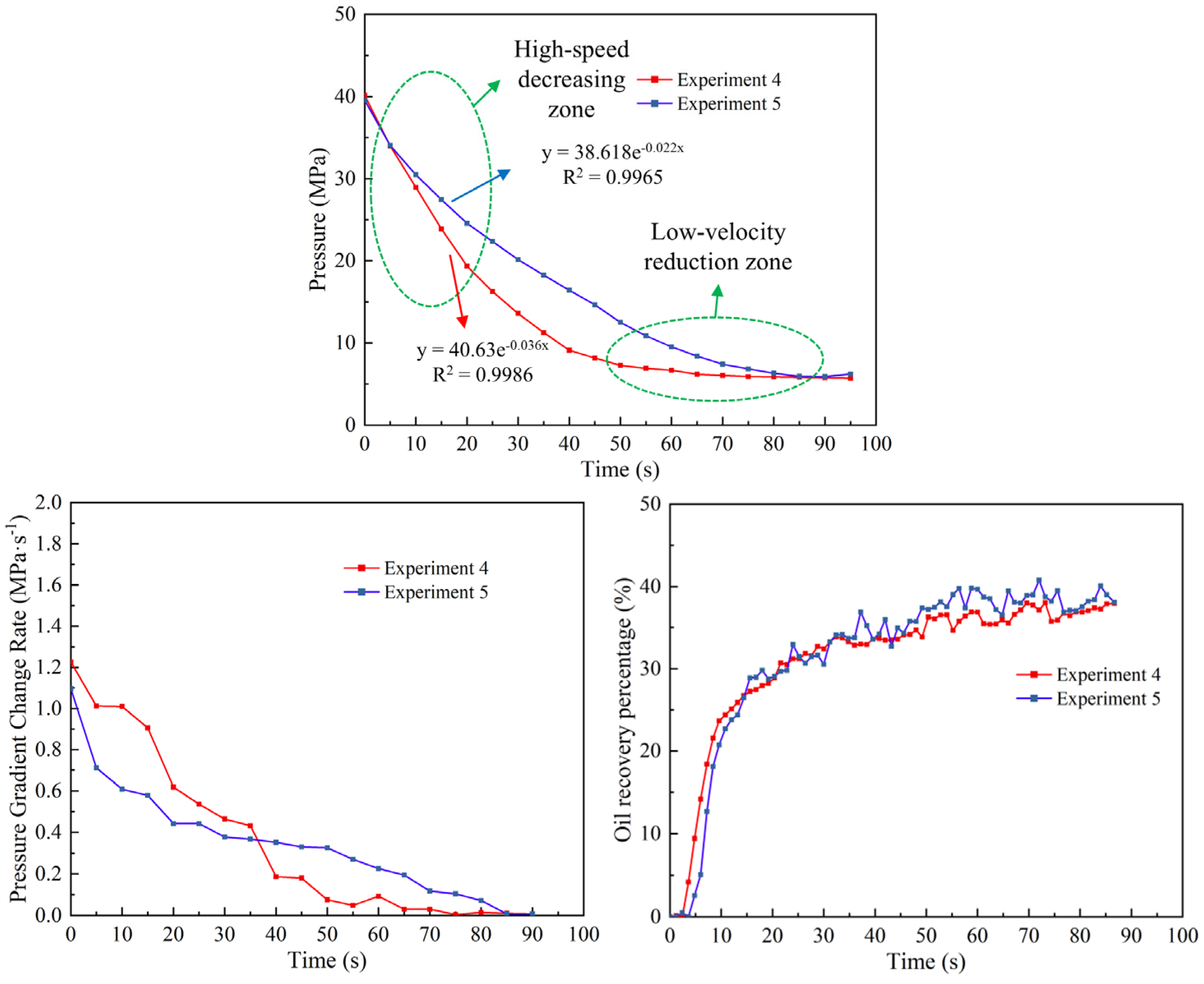

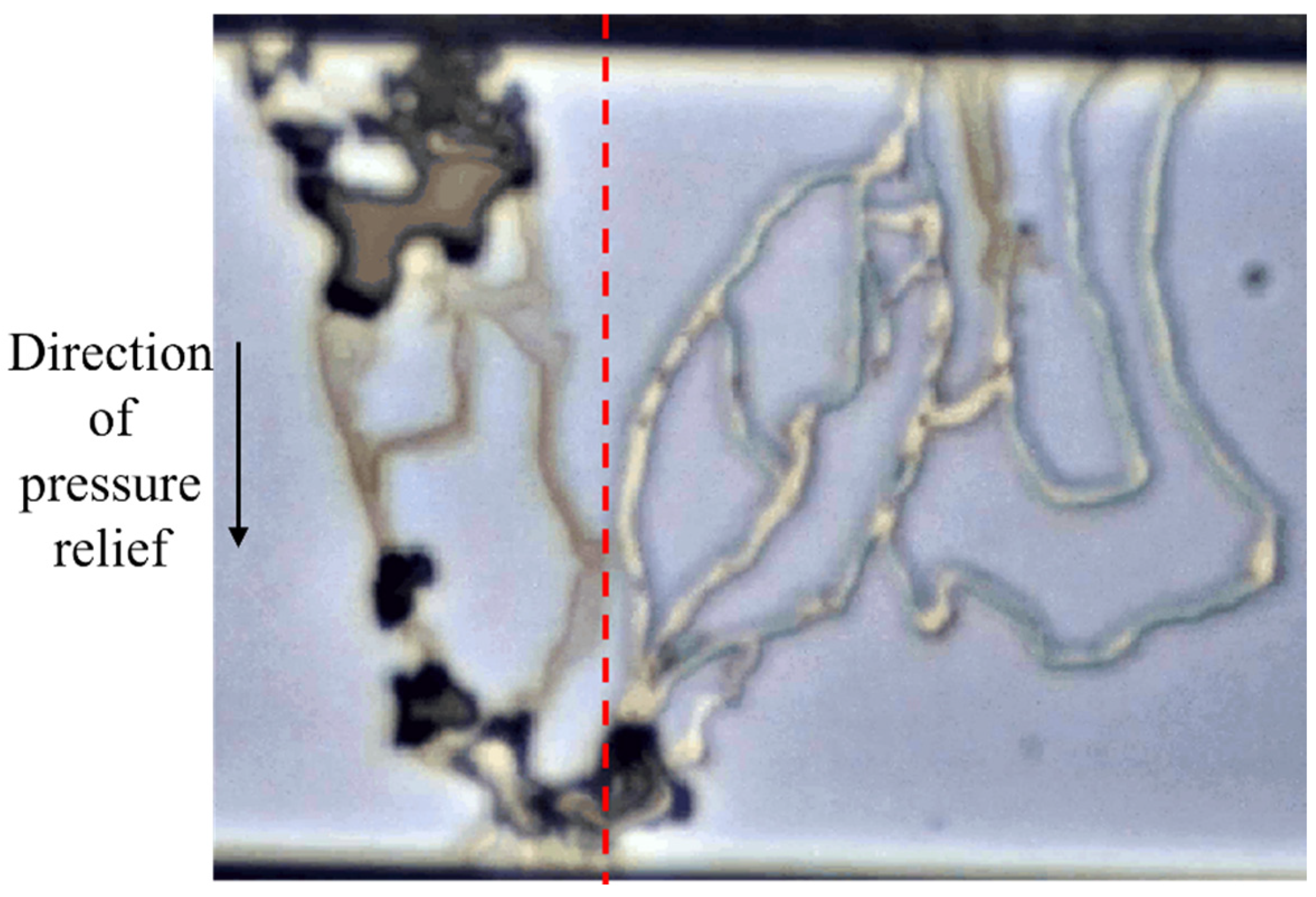

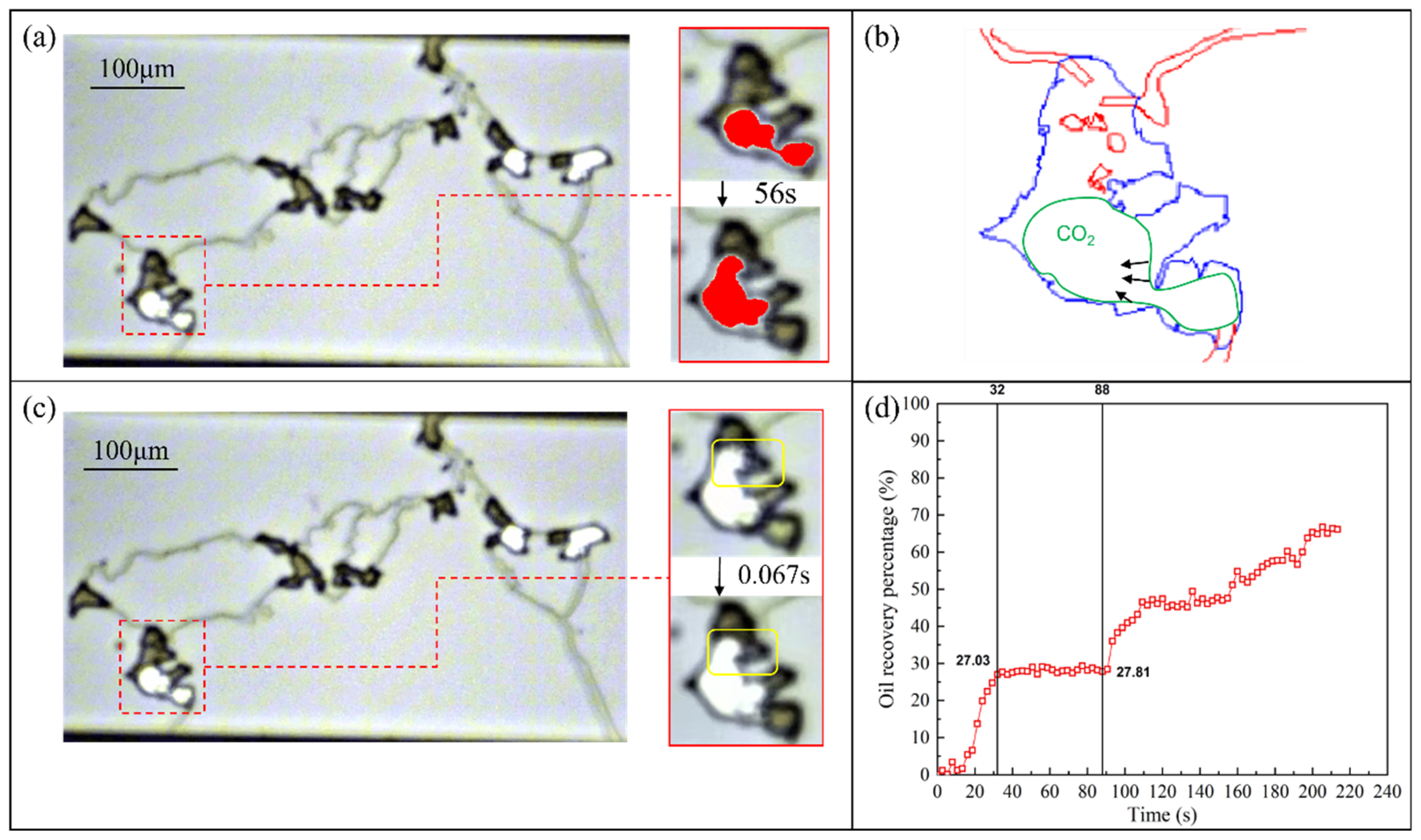

3.3. CO2 Huff-n-Puff Experiments

4. Conclusions

- (1)

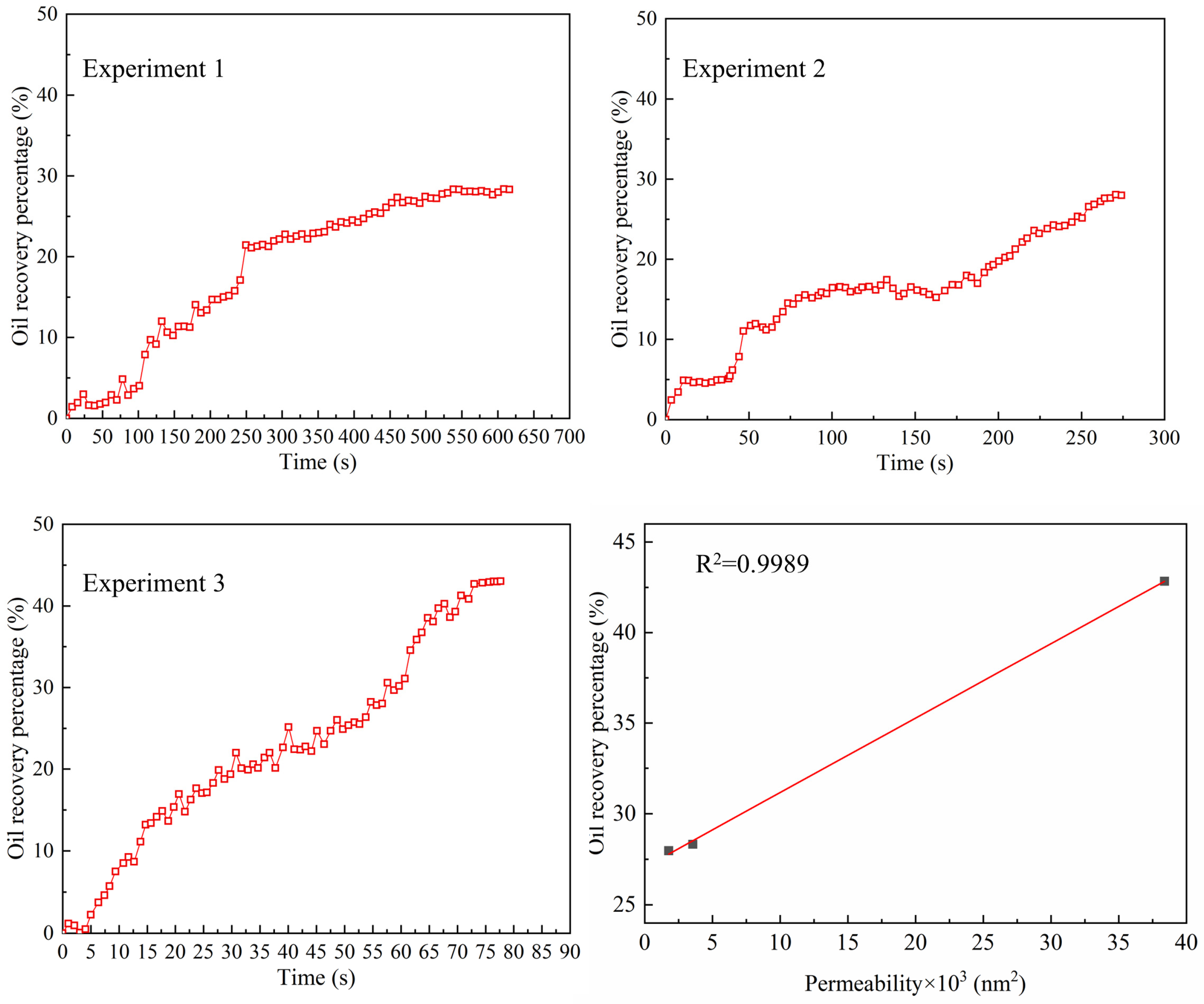

- Pore structure significantly affects crude oil recovery. When fluid flows through large-pore and fine-throat structures, abrupt changes in pore throats increase local resistance, impeding fluid flow. Conversely, homogeneously distributed pore throat structures enhance connectivity and promote fluid flow; experiments showed flow rates in such structures were more than four times higher than those in large-pore and fine-throat configurations. When bubbles pass through constrictions with sudden depth/width reductions, the Jamin effect generates capillary resistance opposing flow direction, reduces bubble velocity, and may prevent entry into these zones, forming dead zones.

- (2)

- In CO2 immiscible flooding experiments, differential flow resistance causes the majority of the crude oil to be displaced through dominant channels, establishing preferential flow pathways. Simultaneously, non-dominant channels exhibit capillary trapping phenomena that result in liquid plugging. In the experiments, the slug flow phenomenon was observed, which impedes fluid transport and reduces displacement efficiency. The capillary number (Ca) at slug flow occurrence points was determined through calculation, simultaneously revealing that lower Ca values correspond to more pronounced liquid slugs.

- (3)

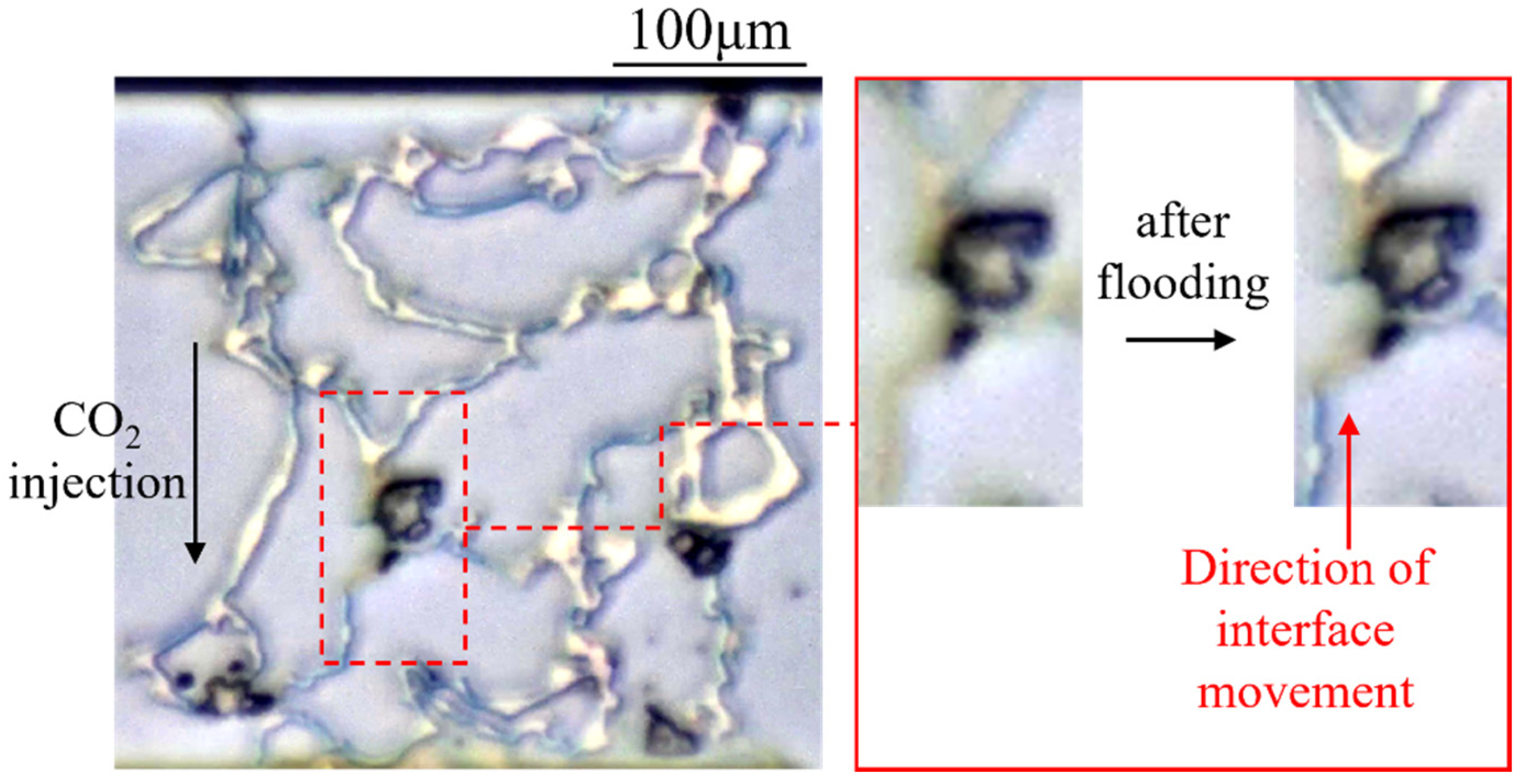

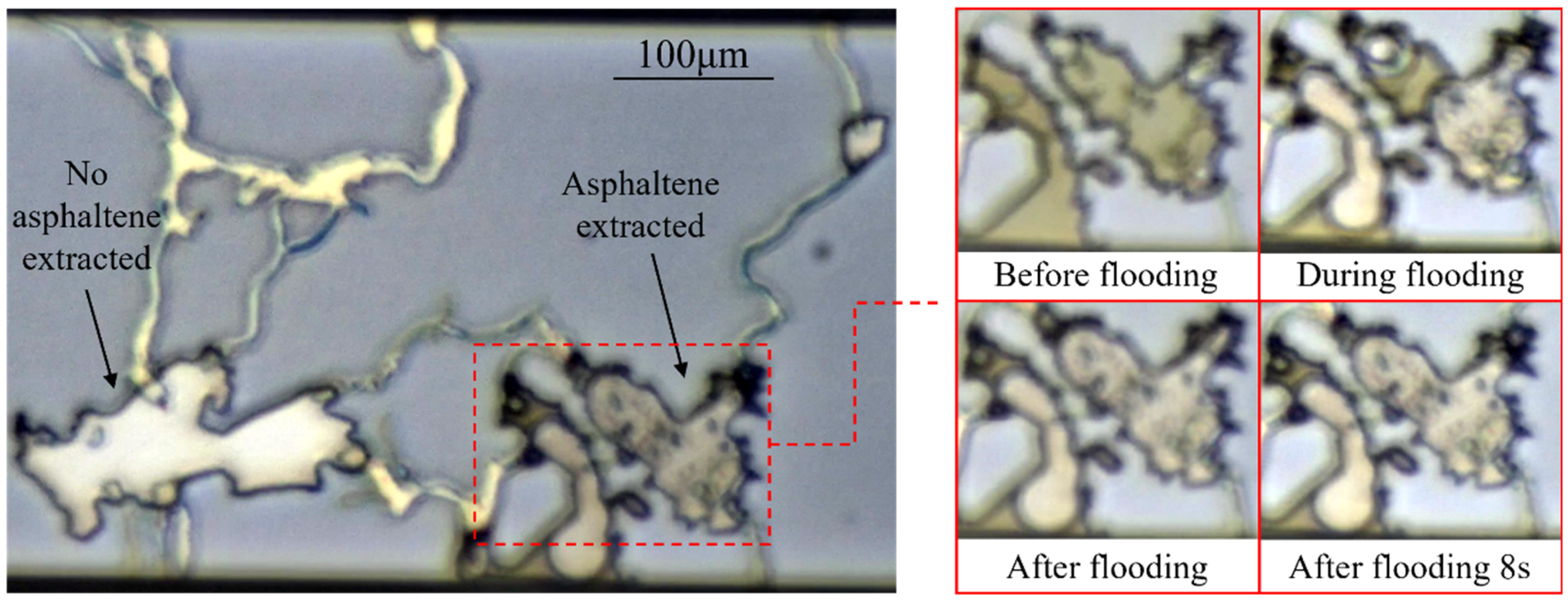

- CO2 exhibits superior extraction capability, enabling extraction of light components from crude oil while partially recovering crude oil resistant to displacement through the extraction mechanism. Extended contact time of CO2 and crude oil intensifies extraction effects, concurrently increasing heavy component content in residual oil. This elevates crude oil viscosity and reduces its deformability, heightening resistance to displacement and thereby reducing macroscopic recovery rates. In the experiments, structural heterogeneity caused a threefold longer contact duration on the chip’s right versus left side, resulting in a 25.6% decrease in macroscopic recovery rate.

- (4)

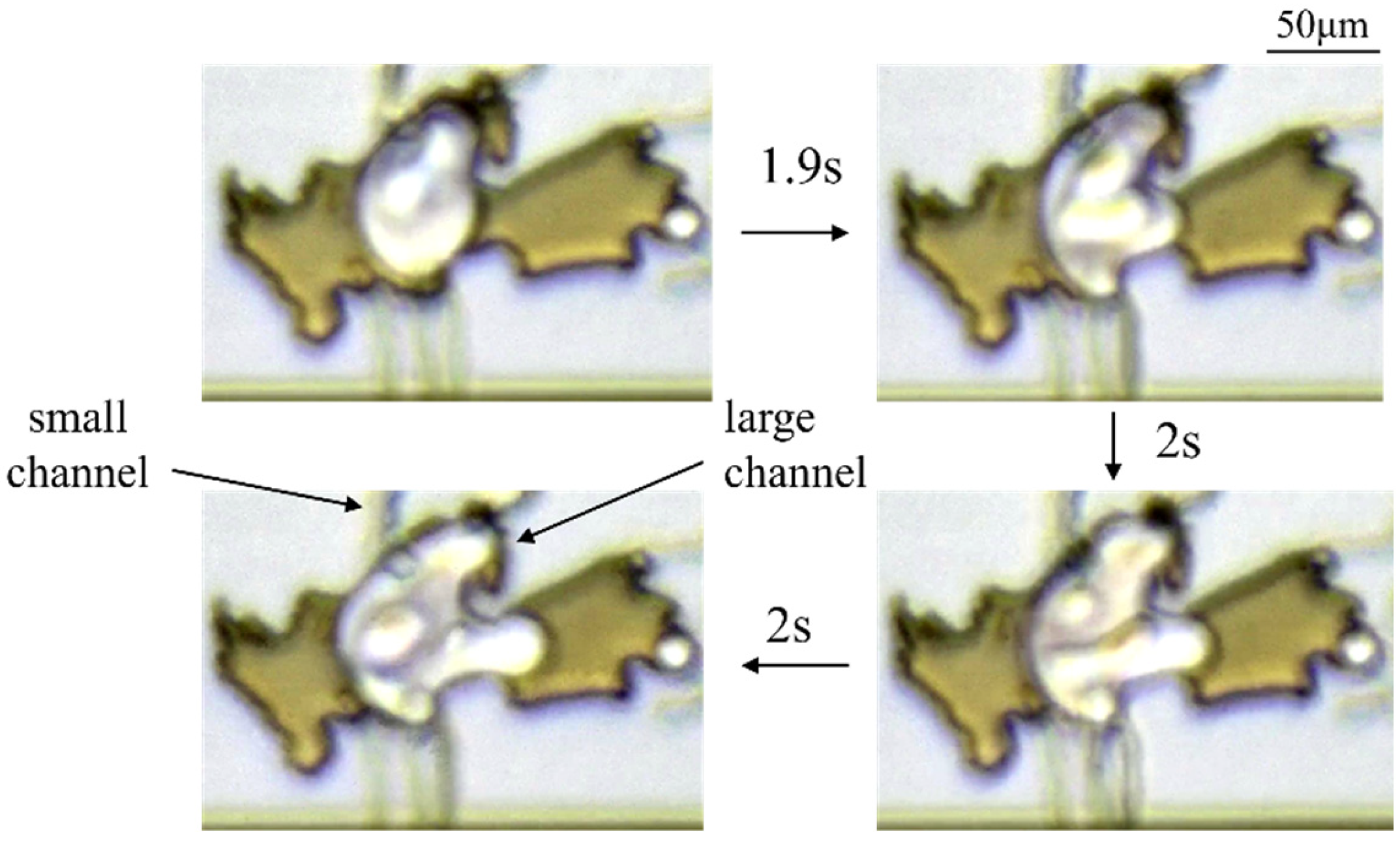

- In the huff-n-puff experiment, rapid pressure reduction triggers desorption of CO2, generating bubbles that grow and expand to displace crude oil from pore spaces. The recovery efficiency correlates with huff-n-puff modes and inlet/outlet cross-sectional areas. In our experiments, it was observed that desorbed bubbles tend to assume spherical configurations due to interfacial tension within pore structures. Subsequent pressure declines cause these bubbles to break through constricted pore throats.

- (5)

- Compared with CO2 immiscible flooding which directly displaces oil from pore structures using CO2, the huff-n-puff process significantly enhances fluid mobility by intensifying interactions of CO2 and crude oil during the soaking period while achieving viscosity reduction through CO2 dissolution. Simultaneously, trapped oil zones occur more frequently in CO2 immiscible flooding than in huff-n-puff experiments, resulting in a lower recovery rate.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, W.; Hu, S.; Hou, L.; Yang, T.; Li, X.; Guo, B.; Yang, Z. Types and Resource Potential of Continental Shale Oil in China and Its Boundary with Tight Oil. Pet. Explor. Dev. 2020, 47, 1–11. [Google Scholar] [CrossRef]

- Zhao, H.; Ning, Z.; Wang, Q.; Zhang, R.; Zhao, T.; Niu, T.; Zeng, Y. Petrophysical Characterization of Tight Oil Reservoirs Using Pressure-Controlled Porosimetry Combined with Rate-Controlled Porosimetry. Fuel 2015, 154, 233–242. [Google Scholar] [CrossRef]

- Ye, D.; Liu, G.; Wang, F.; Gao, F.; Yang, T.; Zhu, J. Fractal Hydrological-Thermal–Mechanical Analysis of Unconventional Reservoir: A Fracture-Matrix Structure Model for Gas Extraction. Int. J. Heat Mass Transf. 2023, 202, 123670. [Google Scholar] [CrossRef]

- Xu, Y.; Lun, Z.; Pan, Z.; Wang, H.; Zhou, X.; Zhao, C.; Zhang, D. Occurrence Space and State of Shale Oil: A Review. J. Pet. Sci. Eng. 2022, 211, 110183. [Google Scholar] [CrossRef]

- Salygin, V.; Guliev, I.; Chernysheva, N.; Sokolova, E.; Toropova, N.; Egorova, L. Global shale revolution: Successes, challenges, and prospects. Sustainability 2019, 11, 1627. [Google Scholar] [CrossRef]

- Chauhan, A.; Salehi, F.; Jalalifar, S.; Clark, S. Two-phase modelling of the effects of pore-throat geometry on enhanced oil recovery. Appl. Nanosci. 2021, 13, 453–464. [Google Scholar] [CrossRef]

- Jia, B.; Su, J. Advancements and Environmental Implications in Oil Shale Exploration and Processing. Appl. Sci. 2023, 13, 7657. [Google Scholar] [CrossRef]

- Sharma, S.; Agrawal, V.; Akondi, R. Role of biogeochemistry in efficient shale oil and gas production. Fuel 2020, 259, 116247. [Google Scholar] [CrossRef]

- Taheri-Shakib, J.; Kantzas, A. A comprehensive review of microwave application on the oil shale: Prospects for shale oil production. Fuel 2021, 305, 121132. [Google Scholar] [CrossRef]

- Cai, J.; Tian, Z.; Zhou, S.; Xiong, Y.; Sun, C.; Zeng, J. Controlling Factor Analysis of Microstructural Property and Storage Capacity of Deep Longmaxi Formation Shale in Sichuan Basin. Energy Fuels 2021, 35, 20092–20102. [Google Scholar] [CrossRef]

- He, W.; Liu, B.; Sun, M.; Wang, L.; Zhang, J.; Yasin, Q.; Tian, S.; Gao, S.; Ukaomah, C.F. Pore Types, Genesis, and Evolution Model of Lacustrine Oil-Prone Shale: A Case Study of the Cretaceous Qingshankou Formation, Songliao Basin, NE China. Sci. Rep. 2022, 12, 17210. [Google Scholar] [CrossRef]

- Lee, T.; Bocquet, L.; Coasne, B. Activated desorption at heterogeneous interfaces and long-time kinetics of hydrocarbon recovery from nanoporous media. Nat. Commun. 2016, 7, 11890. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Hatcherian, J.; Hackley, P.C.; Pomerantz, A.E. Nanoscale geochemical and geomechanical characterization of organic matter in shale. Nat. Commun. 2017, 8, 2179. [Google Scholar] [CrossRef]

- Chen, L.; Jiang, Z.; Jiang, S.; Liu, K.; Yang, W.; Tan, J.; Gao, F. Nanopore Structure and Fractal Characteristics of Lacustrine Shale: Implications for Shale Gas Storage and Production Potential. Nanomaterials 2019, 9, 390. [Google Scholar] [CrossRef]

- Kim, C.; Devegowda, D. Molecular Dynamics Study of Fluid-Fluid and Solid-Fluid Interactions in Mixed-Wet Shale Pores. Fuel 2022, 319, 123587. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, T.; Zhao, Y.; Hu, H.; Wen, S.; Wu, J.; Cao, C.; Wang, Y.; Fan, Y. A Review of Interaction Mechanisms and Microscopic Simulation Methods for CO2-Water-Rock System. Pet. Explor. Dev. 2024, 51, 223–238. [Google Scholar] [CrossRef]

- Sobecki, N.; Nieto-Draghi, C.; Di Lella, A.; Ding, D.Y. Phase behavior of hydrocarbons in nano-pores. Fluid Phase Equilibr. 2019, 497, 104–121. [Google Scholar] [CrossRef]

- Song, Y.; Song, Z.; Zhang, Z.; Chang, X.; Wang, D.; Hui, G. Phase Behavior of CO2-CH4-Water Mixtures in Shale Nanopores Considering Fluid Adsorption and Capillary Pressure. Ind. Eng. Chem. Res. 2022, 61, 5652–5660. [Google Scholar] [CrossRef]

- Qiao, L.; Tan, J.; Li, L.; Ju, Y.; Andreas, B.; David, A.W.; Pathegama, G.R.; Richard, M.; Shu, B.; Hu, C.; et al. The role of supercritical carbon dioxide for recovery of shale gas and sequestration in gas shale reservoirs. Energy Environ. Sci. 2021, 14, 4203–4227. [Google Scholar] [CrossRef]

- Lu, Y.; Gong, T.; Tang, J.; Cheng, Q.; Zhang, C.; Zhao, G.; Liu, B. Evolution of Shale Wetting Properties Under Long-Term CO2/Brine/Shale Interaction: Implications for CO2 Storage in Shale Reservoirs. Gas Sci. Eng. 2024, 126, 205334. [Google Scholar] [CrossRef]

- Yang, K.; Zhou, J.; Xian, X.; Zhou, L.; Zhang, C.; Tian, S.; Lu, Z.; Zhang, F. Chemical-Mechanical Coupling Effects on the Permeability of Shale Subjected to Supercritical CO2-Water Exposure. Energy 2022, 248, 123591. [Google Scholar] [CrossRef]

- Dang, W.; Nie, H.; Zhang, J.; Tang, X.; Jiang, S.; Wei, X.; Liu, Y.; Wang, F.; Li, P.; Chen, Z. Pore-Scale Mechanisms and Characterization of Light Oil Storage in Shale Nanopores: New Method and Insights. Geosci. Front. 2022, 13, 101424. [Google Scholar] [CrossRef]

- Zhao, G.; Yao, Y.; Adenutsi, C.D.; Feng, X.; Wang, L.; Wu, W. Transport Behavior of Oil in Mixed Wettability Shale Nanopores. ACS Omega 2020, 5, 31831–31844. [Google Scholar] [CrossRef] [PubMed]

- Miqueu, C.; Grégoire, D. Estimation of pore pressure and phase transitions of water confined in nanopores with non-local density functional theory. Mol. Phys. 2020, 118, e1742935. [Google Scholar] [CrossRef]

- Sang, Q.; Zhang, S.; Li, Y.; Dong, M.; Bryant, S. Determination of Organic and Inorganic Hydrocarbon Saturations and Effective Porosities in Shale Using Vacuum-Imbibition Method. Int. J. Coal Geol. 2018, 200, 123–134. [Google Scholar] [CrossRef]

- Xia, Y.; Tian, Z.; Xu, S.; Wei, W.; Cai, J. Effects of Microstructural and Petrophysical Properties on Spontaneous Imbibition in Tight Sandstone Reservoirs. J. Nat. Gas Sci. Eng. 2021, 96, 104225. [Google Scholar] [CrossRef]

- Liu, J.; Sheng, J.J.; Wang, X.; Ge, H.; Yao, E. Experimental study of wettability alteration and spontaneous imbibition in chinese shale oil reservoirs using anionic and nonionic surfactants. J. Petrol. Sci. Eng. 2019, 175, 624–633. [Google Scholar] [CrossRef]

- Bakhshian, S.; Hosseini, S.A.; Shokri, N. Pore-Scale Characteristics of Multiphase Flow in Heterogeneous Porous Media Using the Lattice Boltzmann Method. Sci. Rep. 2019, 9, 3377. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, L.; Kang, Q.; Viswanathan, H.S.; Yao, J.; Tao, W. Nanoscale Simulation of Shale Transport Properties Using the Lattice Boltzmann Method: Permeability and Diffusivity. Sci. Rep. 2015, 5, 8089. [Google Scholar] [CrossRef]

- Zhang, T.; Javadpour, F.; Li, J.; Zhao, Y.; Zhang, L.; Li, X. Pore-scale perspective of gas/water two-phase flow in shale. SPE J. 2021, 26, 828–846. [Google Scholar] [CrossRef]

- Lang, D.; Lun, Z.; Lyu, C.; Wang, H.; Zhao, Q.; Sheng, H. Nuclear Magnetic Resonance Experimental Study of CO2 Injection to Enhance Shale Oil Recovery. Pet. Explor. Dev. 2021, 48, 702–712. [Google Scholar] [CrossRef]

- Wang, T.; Wang, L.; Meng, X.; Chen, Y.; Song, W.; Yuan, C. Key Parameters and Dominant EOR Mechanism of CO2 Miscible Flooding Applied in Low-Permeability Oil Reservoirs. Geoenergy Sci. Eng. 2023, 225, 211724. [Google Scholar] [CrossRef]

- Jiménez-Martínez, J.; Porter, M.L.; Hyman, J.D.; Carey, J.W.; Viswanathan, H.S. Mixing in a Three-phase System: Enhanced Production of Oil-wet Reservoirs by CO2 Injection. Geophys. Res. Lett. 2016, 43, 196–205. [Google Scholar] [CrossRef]

- Cao, Z.; Jiang, H.; Zeng, J.; Saibi, H.; Lu, T.; Xie, X.; Zhang, Y.; Zhou, G.; Wu, K.; Guo, J. Nanoscale Liquid Hydrocarbon Adsorption on Clay Minerals: A Molecular Dynamics Simulation of Shale Oils. Chem. Eng. J. 2021, 420, 127578. [Google Scholar] [CrossRef]

- Stone, H.A.; Stroock, A.D.; Ajdari, A. Engineering Flows in Small Devices: Microfluidics Toward a Lab-on-a-Chip. Annu. Rev. Fluid Mech. 2004, 36, 381–411. [Google Scholar] [CrossRef]

- Guo, Y.; Shi, J.; Qiu, J.; Xu, Z.; Bao, B. Visualized investigation of transport and phase behaviors during CO2 huff-n-puff in nanomatrix-fracture tight formations. Fuel 2023, 354, 129344. [Google Scholar] [CrossRef]

- Jensen, K.F. Flow chemistry-Microreaction technology comes of age. Aiche J. 2017, 63, 858–869. [Google Scholar] [CrossRef]

- Qiu, J.; Tang, W.; Bao, B.; Zhao, S. Microfluidic-based in-situ determination for reaction kinetics of hydrogen peroxide decom-position. Chem. Eng. J. 2021, 424, 130486. [Google Scholar] [CrossRef]

- Squires, T.M.; Quake, S.R. Microfluidics: Fluid physics at the nanoliter scale. Rev. Mod. Phys. 2005, 77, 977–1026. [Google Scholar] [CrossRef]

- Yao, C.; Dong, Z.; Zhao, Y.; Chen, G. An online method to measure mass transfer of slug flow in a microchannel. Chem. Eng. Sci. 2014, 112, 15–24. [Google Scholar] [CrossRef]

- Li, L.; Zheng, J.; Shi, Y.; Su, Y.; Hao, Y.; Chen, Z. Mechanisms of Fluid Migration and CO2 Storage in Low Permeability Heavy Oil Reservoirs Using High-Pressure Microfluidic CO2 Flooding Experiment. Energy Fuels 2024, 38, 7997–8008. [Google Scholar] [CrossRef]

- Kolawole, O.; Ispas, I.; Kumar, M.; Weber, J.; Zhao, B.; Zanoni, G. How Can Biogeomechanical Alterations in Shales Impact Caprock Integrity and CO2 Storage? Fuel 2021, 291, 120149. [Google Scholar] [CrossRef]

- Liu, J.; Li, J.; Song, Z.; Shen, A. Flow Characteristics of Shale Oil and Its Geological Controls: A Case Study of the Lucaogou Formation in the Jimsar Sag, Junggar Basin. Pet. Sci. 2025, in press. [Google Scholar] [CrossRef]

- Geng, Y.; Ling, S.; Huang, J.; Xu, J. Multiphase Microfluidics: Fundamentals, Fabrication, and Functions. Small 2020, 16, 1906357. [Google Scholar] [CrossRef]

- Günther, A.; Jensen, K.F. Multiphase Microfluidics: From Flow Characteristics to Chemical and Materials Synthesis. Lab Chip 2006, 6, 1487–1503. [Google Scholar] [CrossRef]

- Weinaug, C.F.; Katz, D.L. Surface tensions of methane-propane mixtures. Ind. Eng. Chem. 1943, 35, 239–246. [Google Scholar] [CrossRef]

- Goual, L.; Sedghi, M.; Zeng, H.; Mostowfi, F.; McFarlane, R.; Mullins, O.C. On the Formation and Properties of Asphaltene Nanoaggregates and Clusters by DC-Conductivity and Centrifugation. Fuel 2011, 90, 2480–2490. [Google Scholar] [CrossRef]

| Experimental Content | Experimental Conditions | |||

|---|---|---|---|---|

| Experiment Number | Temperature (°C) | Pressure (MPa) | Chip Number | |

| Immiscible flooding | Experiment 1 | 85 | 20 | 1 |

| Experiment 2 | 85 | 20 | 2 | |

| Experiment 3 | 85 | 20 | 3 | |

| Constant volume depletion | Experiment 4 | 85 | 40 | 3 |

| Experiment 5 | 85 | 40 | 5 | |

| Huff-n-puff | Experiment 6 | 85 | 40 | 4 |

| Experiment 7 | 85 | 40 | 5 | |

| Experiment 8 | 85 | 40 | 5 | |

| Computed and Measured PARAMETERS | Experiment 1 | Experiment 2 | Experiment 3 |

|---|---|---|---|

| Recovery/% | 28.3 | 27.97 | 42.84 |

| Porosity/% | 10.51 | 19.8 | 15.66 |

| Permeability/nm2 | 3544.36 | 1761.23 | 38,379.89 |

| Computed and Measured Parameters | Experiment 4 | Experiment 5 |

|---|---|---|

| Initial production proportion (%) | 70.45 | 61.6 |

| Ultimate recovery (%) | 37.93 | 39.58 |

| Experimental time (s) | 86.67 | 97.73 |

| Computed and Measured Parameters | Experiment 6 | Experiment 7 | Experiment 8 |

|---|---|---|---|

| Inlet cross-sections (μm2) | 2.284 | 8.488 | 8.488 |

| Outlet cross-sections (μm2) | 2.284 | 15.4962 | 8.488 |

| Permeability (nm2) | 11,872.49 | 8609.26 | 8609.26 |

| Recovery (%) | 66.37 | 71.65 | 50.57 |

| Experimental time (s) | 213 | 2.77 | 29.2 |

| Computed and Measured Parameters | CO2 Immiscible Flooding | Huff-n-Puff | ||||

|---|---|---|---|---|---|---|

| Experiment 1 | Experiment 2 | Experiment 3 | Experiment 6 | Experiment 7 | Experiment 8 | |

| Recovery (%) | 28.3 | 27.97 | 42.84 | 66.37 | 71.65 | 50.57 |

| Permeability (nm2) | 3544.36 | 1761.23 | 38,379.89 | 11,872.49 | 8609.26 | 8609.26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, H.; Wang, J.; Zhang, Y.; Xu, N.; Jiang, Z.; Bao, B. Microscopic Transport During Carbon Dioxide Injection in Crude Oil from Jimsar Oilfield Using Microfluidics. Energies 2025, 18, 4774. https://doi.org/10.3390/en18174774

Guo H, Wang J, Zhang Y, Xu N, Jiang Z, Bao B. Microscopic Transport During Carbon Dioxide Injection in Crude Oil from Jimsar Oilfield Using Microfluidics. Energies. 2025; 18(17):4774. https://doi.org/10.3390/en18174774

Chicago/Turabian StyleGuo, Huiying, Jianxiang Wang, Yuankai Zhang, Ning Xu, Zhaowen Jiang, and Bo Bao. 2025. "Microscopic Transport During Carbon Dioxide Injection in Crude Oil from Jimsar Oilfield Using Microfluidics" Energies 18, no. 17: 4774. https://doi.org/10.3390/en18174774

APA StyleGuo, H., Wang, J., Zhang, Y., Xu, N., Jiang, Z., & Bao, B. (2025). Microscopic Transport During Carbon Dioxide Injection in Crude Oil from Jimsar Oilfield Using Microfluidics. Energies, 18(17), 4774. https://doi.org/10.3390/en18174774