1. Introduction

Gas boilers are widely applied in industrial processes including textile, winemaking, papermaking, building materials, metallurgy, and living fields containing heating, bathing, and laundry. The latent heat released by the complete condensation of water vapor generated by natural gas combustion accounts for 11% of the total sensible heat of high-temperature flue gas [

1], and partial or complete utilization of this latent heat is able to significantly improve the efficiency of gas boilers and reduce fuel consumption. China aims to peak carbon dioxide emissions before 2030 and strive to achieve carbon neutrality before 2060. As the global “carbon peaking” targeted date approaches, all industries are transitioning to low carbon [

2,

3]. The use of medium- or low-temperature waste heat is a crucial way to reduce carbon emissions [

4,

5]. Traditional fossil fuel equipment is facing the constraint of a carbon emission index and the pressure of a carbon tax [

6,

7], so energy conservation and carbon reduction are indispensable and urgent. Optimizing conventional gas boilers for gas-fired condensing boilers is conductive to greatly reducing carbon emissions. The necessary point for condensation in a gas boiler is that the water dew point in the exhaust gas is higher than the heated working fluid where the heat can be effectively used [

8]. The water dew point of the exhaust flue gas is related to the air moisture content and excess air coefficient, mostly at 55~58 °C [

9]. The feed water flow of the gas-fired hot water boiler is large. The return water temperature (30~70 °C) is lower or slightly higher than the water dew point of the flue gas, which provides good boundary conditions for the design of various waste heat recovery systems.

When the return water temperature of the gas boiler is close to or greater than the flue gas water dew point, three methods are recommended to promote the condensation of water vapor in the flue gas including increasing the water dew point [

10], introducing low-temperature working fluid [

11], and decreasing the feed water temperature. The waste heat recovery system to improve the water dew point takes the humidification of the combustion air as the design core [

12], so that the water dew point in the exhaust smoke is increased to about 60 °C [

13,

14]. It is mostly used in gas heating boilers with a heating return water temperature of about 50 °C [

15,

16] and the NOx in the exhaust smoke can also be reduced after humidifying the air [

17,

18]. There are two core components: smoke exhaust cooling and a humidity reduction spray tower and air preheating and humidification spray tower [

19]. Increasing the flue gas water dew point can improve the mass transfer driving force of water vapor condensation in the boiler exhaust flue, which creates good boundary conditions for the use of a flue gas condensation heat exchanger. The introduction of low-temperature working fluids includes coupled absorption heat pumps, compression heat pumps [

20,

21], heating low-temperature living/process water, etc. The coupling of the absorption heat pump and gas-fired hot water boiler can be divided into two types: open cycle [

22] and closed cycle [

23,

24]. Both heat pumps can provide 10~30 °C cold water for condensing the flue gas, which also can be used for transferring the condensation heat of the flue gas to boiler feed water. As for boilers that reduce the feed water temperature to 30~40 °C, the feed water temperature has been significantly lower than the flue gas water dew point. Therefore, the tail heating surface only needs to be increased to use about 60% of the water vapor to vaporize the latent heat.

The use of the above systems and devices in a gas boiler enables us to create the conditions for flue gas condensation, but the condensation heat of the flue gas is transferred to the cryogenic working fluid with the help of the direct contact or an interwalled heat exchanger. The condensation heat transfer law of the interwalled heat exchanger was studied in this paper. Considerable endeavors have been devoted to conducting in-depth research on the inter-wall condensing heat exchanger. The relevant factors affecting condensation heat transfer have been dimensionally analyzed. At present, the common condensation heat transfer correlation formula is divided into three types including the types of condensation rate correlation, water vapor condensation amount correlation, and condensation heat transfer coefficient correlation. The condensation rate correlation formula is used to calculate the condensation rate of water vapor under different operating conditions [

25,

26]. The water vapor condensation correlation formula is employed for calculating the transfer of water vapor to the wall under different working conditions [

8], with the Schmidt number Sc and Sherwood number Sh as the core [

27,

28]. The condensation heat transfer coefficient correlation formula is obtained by the addition of a new dimensionless number to the sensible heat convection heat transfer correlation based on the traditional Reynolds number and Plantl number. The dimensionless number includes Ja [

29] describing the ratio of heat of condensation to sensible heat and the relative temperature difference of the condensation process [

30,

31]

[

32].

is the saturation temperature corresponding to the partial pressure

of the inlet water vapor,

is the average wall temperature, and

is the mainstream inlet temperature of the mixed gas. If the

Ln number < 0, the water dew point of the flue gas is less than the wall temperature of the condensing heat exchanger, which represents no condensation phenomenon. If the

Ln number > 0, the water dew point is higher than the wall temperature of the condensing heat exchanger, representing condensation appearing on the wall. The

Ln number is increasing continuously, so the mainstream flue gas temperature is constantly approaching the water dew point. The flue gas is wet and saturated on the

Ln number = 1. In the process of gas boiler flue gas condensation, there are near-wall water vapor condensation and evaporation of small droplets in the mainstream flue gas. The temperature and water dew point of the flue gas continuously change during the condensation, and the RH% of the relative humidity of the mainstream flue gas increases from <50% to nearly 100%. The Schmitt number Sc can only describe the condensation rate of water vapor near the wall, and the condensation rate correlation is difficult to correspond to the drastic change in the water dew point. Therefore, the number of criteria capable of describing the relative temperature difference in the condensation process is more appropriate for this scenario.

At present, the inter-wall gas–liquid condensing heat exchanger widely used in industry and engineering can be divided into a light tube, coil, spiral fin tube [

33], and cast aluminum silicon pin plate [

9] according to the differences in structures. If a variety of condensation heat transfer structures are experimentally obtained, it requires considerable effort, but the pure convective sensible heat transfer correlation formula of different structures is quite mature. Based on previous research, the

Ln number describes the relative temperature difference in the flue gas condensation process, but there is still a missing variable to describe the absolute content of water vapor in the flue gas. After dimensional analysis and comprehensive comparison, an empirical correlation formula for adding condensation heat transfer correction terms on the basis of the traditional sensible heat convection heat transfer correlation formula is proposed in this paper. The paper proposes the P-number to describe the water vapor content in flue gas. Empirically correlated formulas were obtained through experimental analysis, which were verified on condensing heat exchangers of other structures and the experimental results of others [

34].

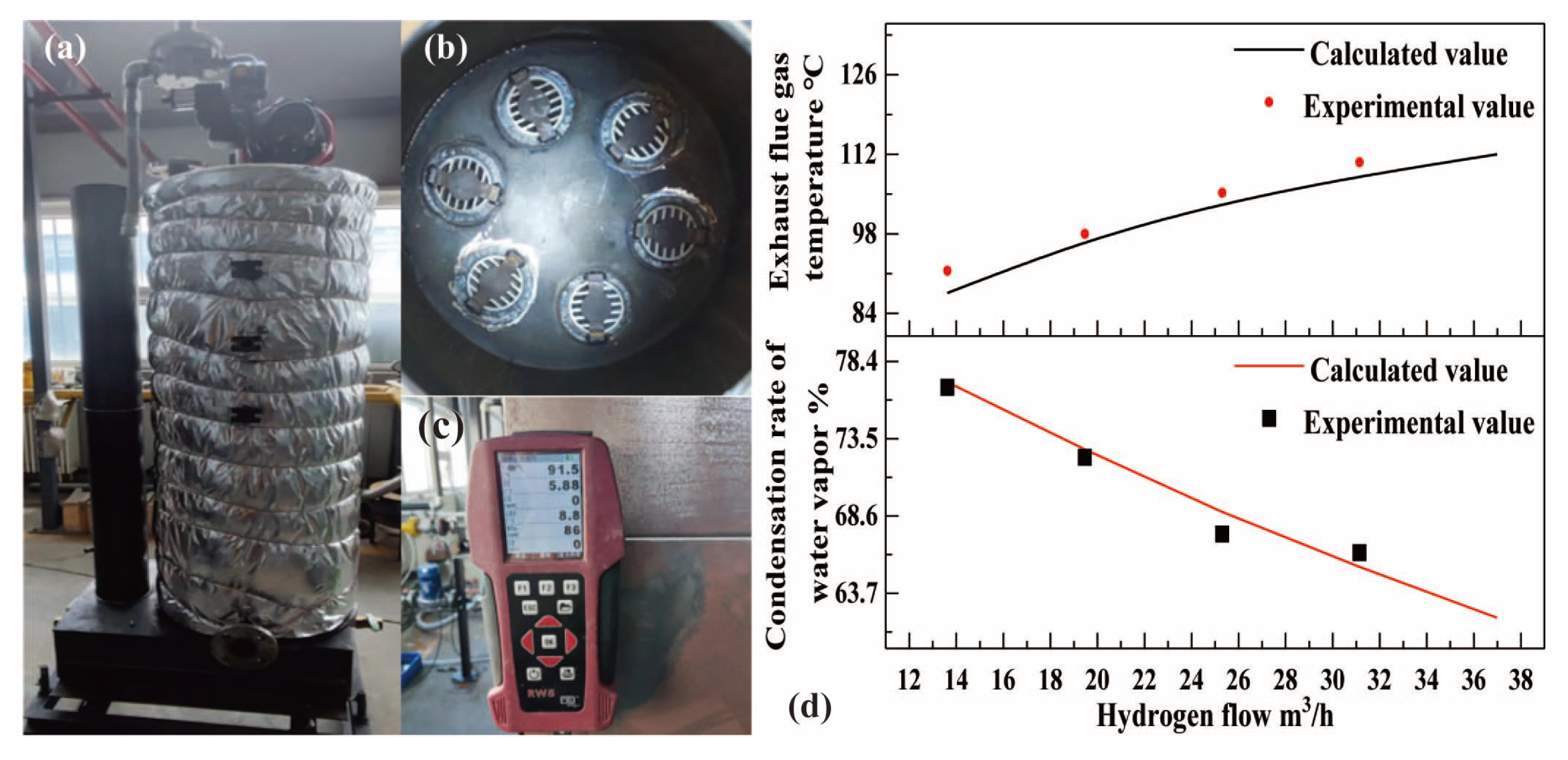

2. Experimental Section

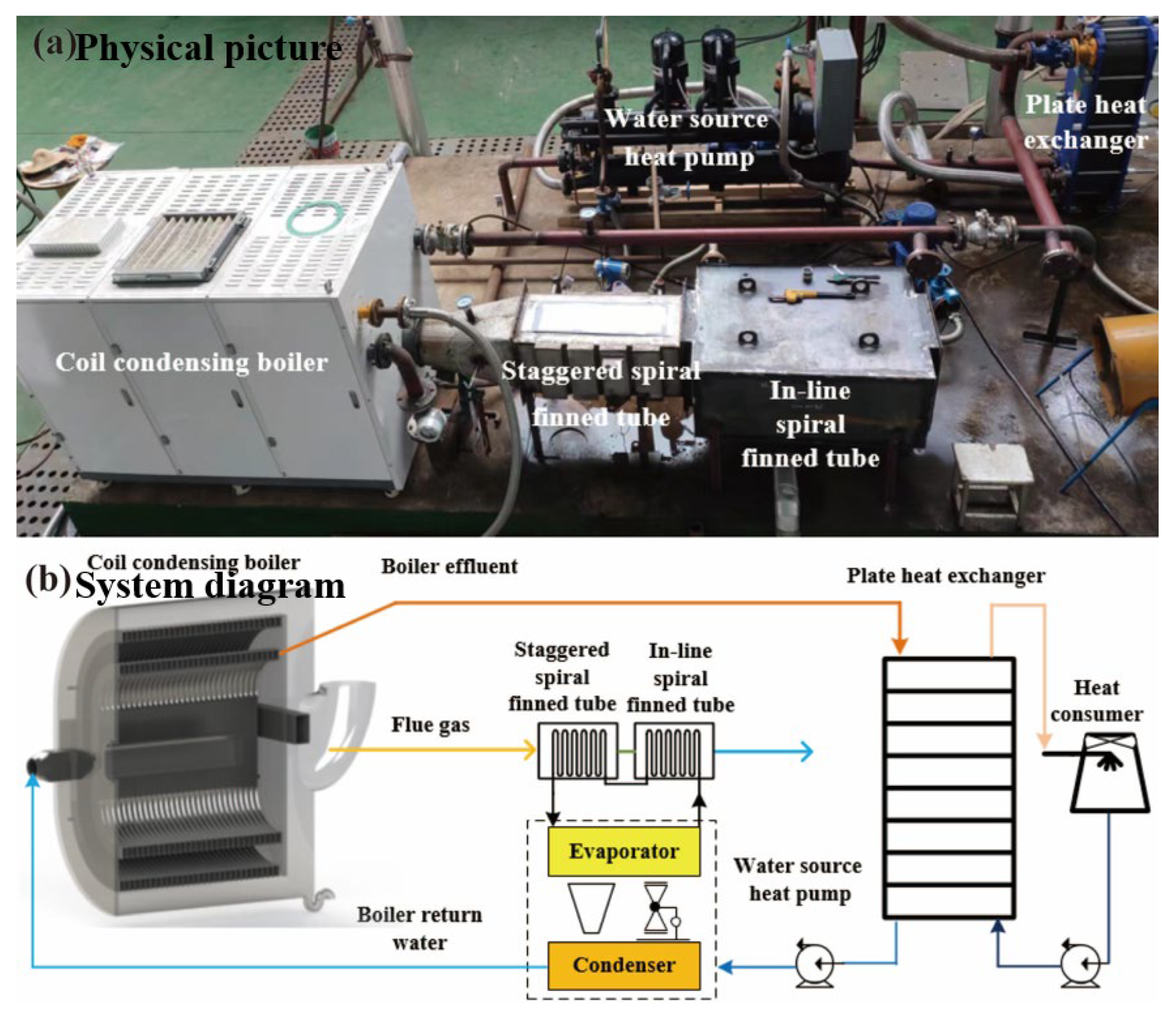

An experimental platform for condensing heat exchangers was built on a 700 kW gas-fired hot water boiler, as shown in

Figure 1. The boiler is followed by a two-stage spiral finned tube flue gas condensation heat exchanger. A 90 kW dual compressor water source heat pump unit outputs cryogenic working fluid as a cold source for condensing heat exchangers. The evaporator of the heat pump is connected in series with the two-stage flue gas condensation heat exchanger to form a closed loop, and the cold water output by the evaporator enters the two-stage flue gas condensation heat exchanger to absorb the waste heat in the exhaust smoke. The waste heat of the recovered flue gas and part of the power consumption of the heat pump are transferred by the heat pump to the condenser. The boiler effluent of a gas-fired hot water boiler first enters the plate heat exchanger to cool down, flows into the heat pump condenser to heat up, and then flows back to the boiler. A mechanically ventilated cooling tower was used to simulate heat users and cool the boiler effluent through a plate heat exchanger.

The temperature measurement thermocouple adopts WZP-230 platinum RTD Pt100 produced by Tiankang Company in Anhui, China, temperature measurement range 0–200 °C, accuracy grade 0.2; the water side flow meter adopts LDG-1011/40 and LDG-1011/65 electromagnetic flow meter produced by Xuner Company in Tianjin, China, pressure resistance 1.6 MPa, and flow range 1 t-h-1~20 t-h-1 and 1 t-h-1~65 t. The gas side flow is measured by LWQ-100/FL/D turbine flowmeter produced by Yinhuan Company in Yuyao, China, with an accuracy of 1.5 and a flow range of 32 m3-h-1 to 620 m3-h-1; the condensate flow is measured by a cylinder with a range of 100 mL and a minimum scale of 1 mL; the flue gas composition analysis is performed by a portable flue gas analyzer from Fischer-Schauffe E30 in Schramberg, Germany, with the instrument accuracy of the oxygen content measurement module being 1.6 MPa and the flow range being 1 t-h-1 to 20 t-h-1 and 1 t-h-1 to 65 t. The measurement accuracy of the oxygen content measurement module is 0.2 level; the flue gas humidity measurement adopts an RS-RJ-K type 4-probe humidity sensor from JD Renke, and the accuracy of the instrument is level 2. The fuel is natural gas. The ambient temperature is recorded during each test, and the boiler load and return water temperature are changed to maintain the temperature and humidity of the flue gas entering the flue gas condensing heat exchanger at the set values. By adjusting the heat size of the heat user, the cooling amplitude of the effluent entering the boiler was changed. The water source heat pump was operated in refrigeration mode to control the temperature of the cryogenic working fluid entering the condensing heat exchanger. The load of the boiler and the excess air coefficient were set to control the flue gas temperature and water vapor gas integration number entering the condensing heat exchanger. During the experiment, the flue gas temperature entering the condensing heat exchanger varied between 50 °C and 120 °C, with the water vapor gas integral number at 9~16%, and the low-temperature working fluid temperature at 10~35 °C to ensure that the experimental working conditions cover most of the gas flue gas condensation heat exchange scenarios. Each working condition test was conducted until the temperature stability of the measuring point at each point after the manual recording of experimental data was achieved, and each test condition was repeated twice to take the average value.

3. Results and Discussions

3.1. Error Analysis

According to the source of error, experimental data errors are classified into direct and indirect errors. The direct error is due to the precision of instrumentation and human observation and other reasons; the direct errors in this experiment include the fact that the temperature error was , the water flow error was , the gas flow error was , the oxygen content error was , the relative humidity error was , and the condensate quality error was . Indirect errors are derived from a direct measurement error; if the errors in the experiment are not related to each other, then the indirect measurement error is the measurement error. From the error transfer formula , is the indirect error, y is the indirect measurement value, and x1,x2,… x6 is the direct measured value of the corresponding physical quantity.

3.2. Experimental Data Processing Methods

During the condensation process, the sensible heat of the flue gas and the latent heat of vaporization of the water vapor were released at the same time, and were calculated according to the flue gas flow, composition, and inlet and outlet flue temperature. The released latent heat of condensation was according to Equation (1):

—the volume of condensate vapor per unit fuel,

, calculated by Equation (9);

—the volume of water vapor at the inlet of the heat exchange section, calculated and measured by hygrometers,

;

—the number of flue gas integrals accounted for by the outlet water vapor of the heat exchange section, calculated and measured by hygrometers;

—the temperature of the water vapor dew point at the outlet of the heat exchange section, calculated and measured by hygrometers, °C;

—the total flue gas volume corresponding to the unit volume of gas,

;

—the latent heat of water vaporization corresponding to the temperature of the inlet cooling water, kJ/kg.

The average convective condensation heat transfer coefficient (

) was calculated according to the heat exchange area, total heat transfer, and logarithmic average heat transfer temperature difference. The average convective condensation heat transfer coefficient (

) on the flue gas side is obtained after removing the thermal resistance of the water side, the thermal resistance of the wall, and the thermal resistance of dirt. However, the average heat transfer coefficient (

) of the fin was not the heat transfer coefficient of the surface of the original fin after the conversion of the wing efficiency. Formulas (3) and (4) were adopted to calculate the pure sensible heat convection heat transfer coefficient (

) of staggered and sequential spiral finned tubes under experimental conditions.

was calculated from Equation (5); the iterative reverse deduction solution was used to gain the original convective condensation heat transfer coefficient (

) of the fin surface with an error of less than 0.001%.

—correction factor for the number of pipe rows along the direction of airflow, when it is over eight rows, take 1;

—correction factors that consider the effect of relative pitch,

;

—thermal conductivity of flue gas at a qualitative temperature,

;

—rib base outer diameter, m;

—rib pitch, m;

—rib height, m;

—flow rate at minimum cross-section,

;

—flue gas motion viscosity coefficient,

; the equivalent of the tube bundle shrinkage cross-section is straight

,

—fin thickness,

.

After calculating

, it is also necessary to consider the rib efficiency, the influence of uneven heat release on the rib surface, the thickness change in the rib along the height direction, and the thermal resistance of dirt to obtain the converted heat release coefficient

.

—surface area of the ribs on the flue gas side, m2; —area of the unribbed part of the flue gas side tube, m2; —total surface area of the flue gas side, m2; —rib efficiency, related to , , —thermal conductivity of fins, ; —influence coefficient that changes along the thickness of the rib blade at height, if there is no change, take 1; —considering the influence coefficient of uneven heat release on the surface of the rib, 0.85 is taken for the cylindrical bottom rib; —pollution coefficient, take 0.85, .

The original convective condensation heat transfer coefficient

is divided into two parts: a sensible heat transfer coefficient and condensation heat transfer according to the ratio of the sensible heat transfer

and latent heat transfer

. Since the flue gas flow velocity and partial pressure

of water vapor have an effect on the sensible heat transfer and latent heat transfer, the moisture pressure coefficient

is introduced to describe its influence on the convective condensation heat transfer process. The outlet flue gas of the gas boiler, the water vapor gas integral number is generally less than 20%, defining the moisture pressure coefficient,

.

is the moisture pressure in the imported flue gas, Pa. The sensible heat strengthening coefficient

is as shown in Equation (6), and the latent heat strengthening coefficient

is as shown in Equation (7):

3.3. Experimental Data Analysis

As shown in

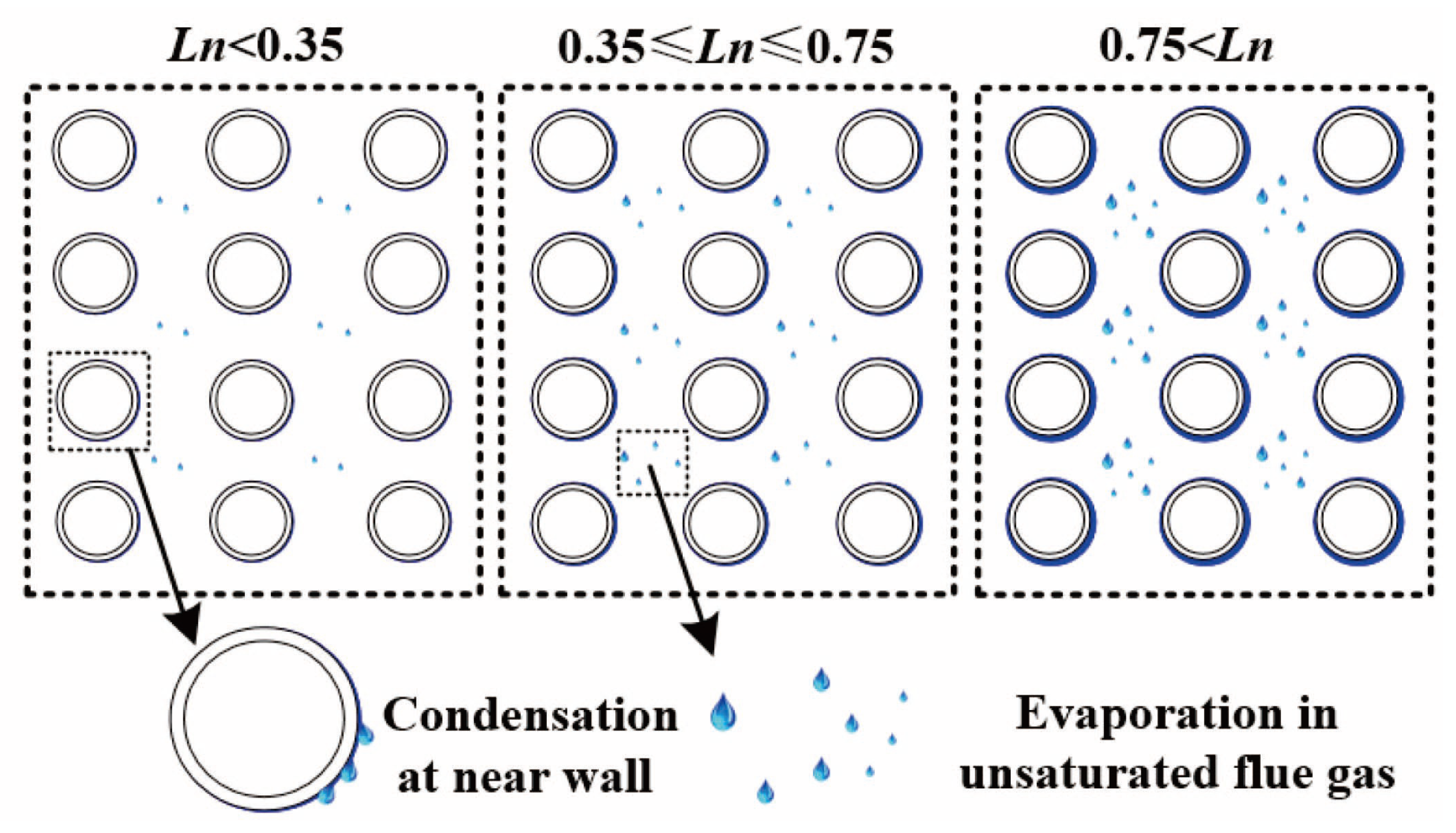

Figure 2, when the flue gas of the gas boiler was cooled, the condensation of water vapor near the wall/wall surface and the evaporation of small droplets in the mainstream flue gas occurred in the meantime. When the exhaust smoke just entered into the condensing heat exchanger, the temperature of the mainstream flue gas was much higher than the water dew point of the flue gas. If the temperature of the condensing heat exchanger wall was lower than the dew point, the water vapor condensed near the wall or the surface of wall. Part of the condensate was blown off the wall by the flue gas, becoming small droplets dispersed in the mainstream flue gas. Since the temperature of the mainstream flue gas was higher than the water dew point, small droplets absorbed heat and evaporated. Part of the water vapor condensed and released heat near the wall or walls, and then absorbed heat and evaporates in the mainstream flue gas, which promoted the cooling of the mainstream flue gas. Therefore, when the exhaust smoke of the gas boiler entered into the condensing heat exchanger, the temperature of the flue gas dropped rapidly, accompanied by a small amount of condensation of water vapor. The water dew point slowly decreased, and the number increased continuously. With the continuous improvement in the

Ln number, more parts of the mainstream flue gas with a temperature close to the dew point of flue gas water were increasing. The condensation at the wall of the condensing heat exchanger improved all the time. The condensate film generated inhibited the sensible heat convection heat transfer between the mainstream flue gas and the heat exchanger wall, and the evaporation of small droplets in the mainstream flue gas continued to weaken. As shown in

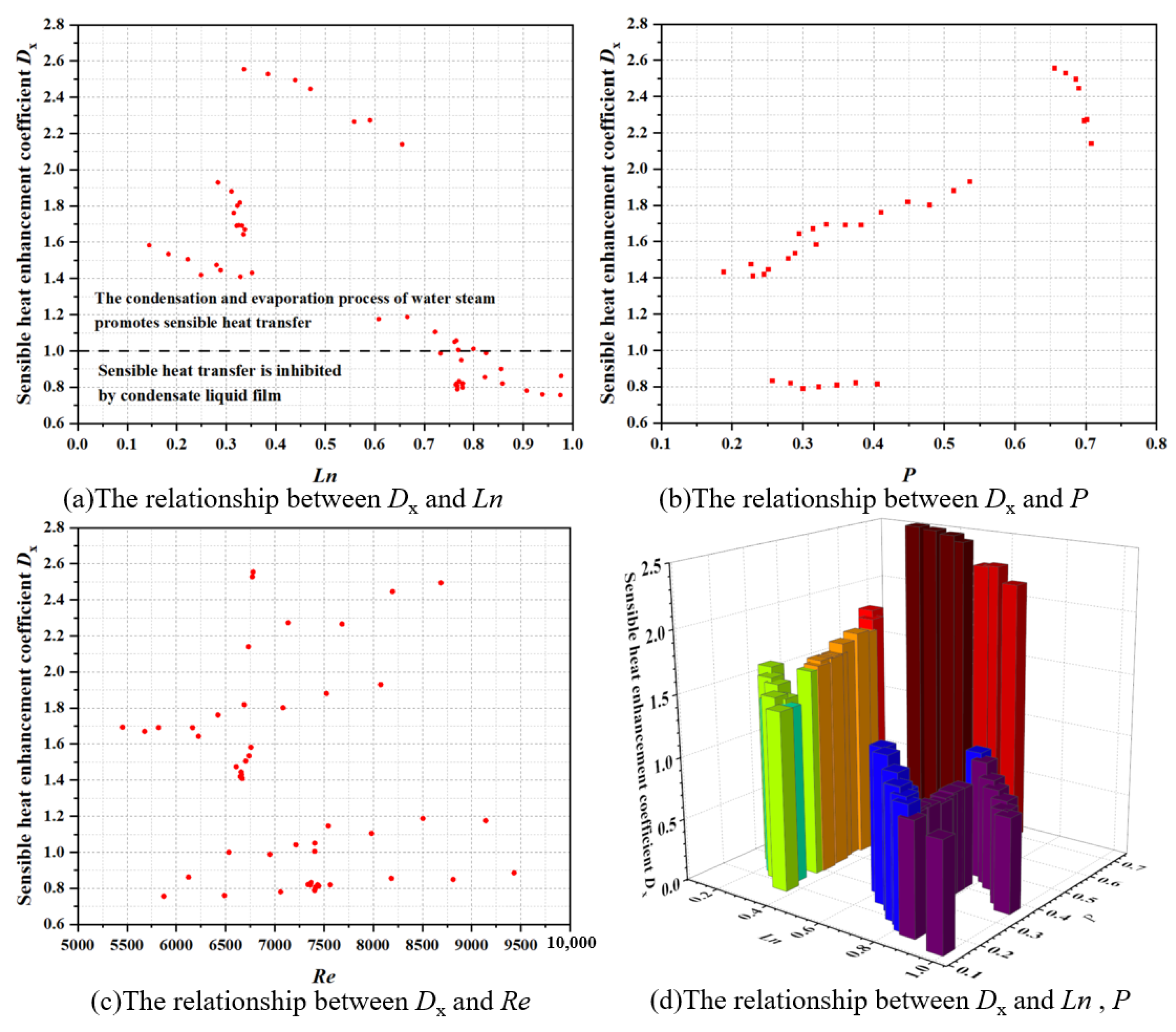

Figure 3a, the process of increasing the number from 0 to 1 promoted and then suppressed the sensible heat strengthening coefficient. When the number was less than 0.75, the condensation of water vapor promoted sensible heat exchange. When the

Ln number was around 0.35, although the condensation of water vapor was less, it was strongly evaporated in the mainstream flue gas. Thus, the water vapor condensation process in this region promoted sensible heat transfer the strongest.

Dx with the same

Ln was distinct, demonstrating that the sensible heat enhancement process was subject to restrictions. As shown in

Figure 3b, with the increase in the

P number, the fraction of water vapor gas, the upper limit of water vapor condensation and the upper limit of water vapor evaporation heat absorption increased, and the maximum value of the sensible heat enhancement coefficient

Dx continued to rise. The

P number was also limited by the

Ln number, so the sensible thermal strengthening coefficient

Dx was different with the same

P number. The influence of the

Re number on sensible heat transfer was irregular. As shown in

Figure 3d, when

Ln < 0.35, the increase in the Ln number and

P number can promote sensible heat transfer. When

Ln > 0.75, the effect of P on

was decreased.

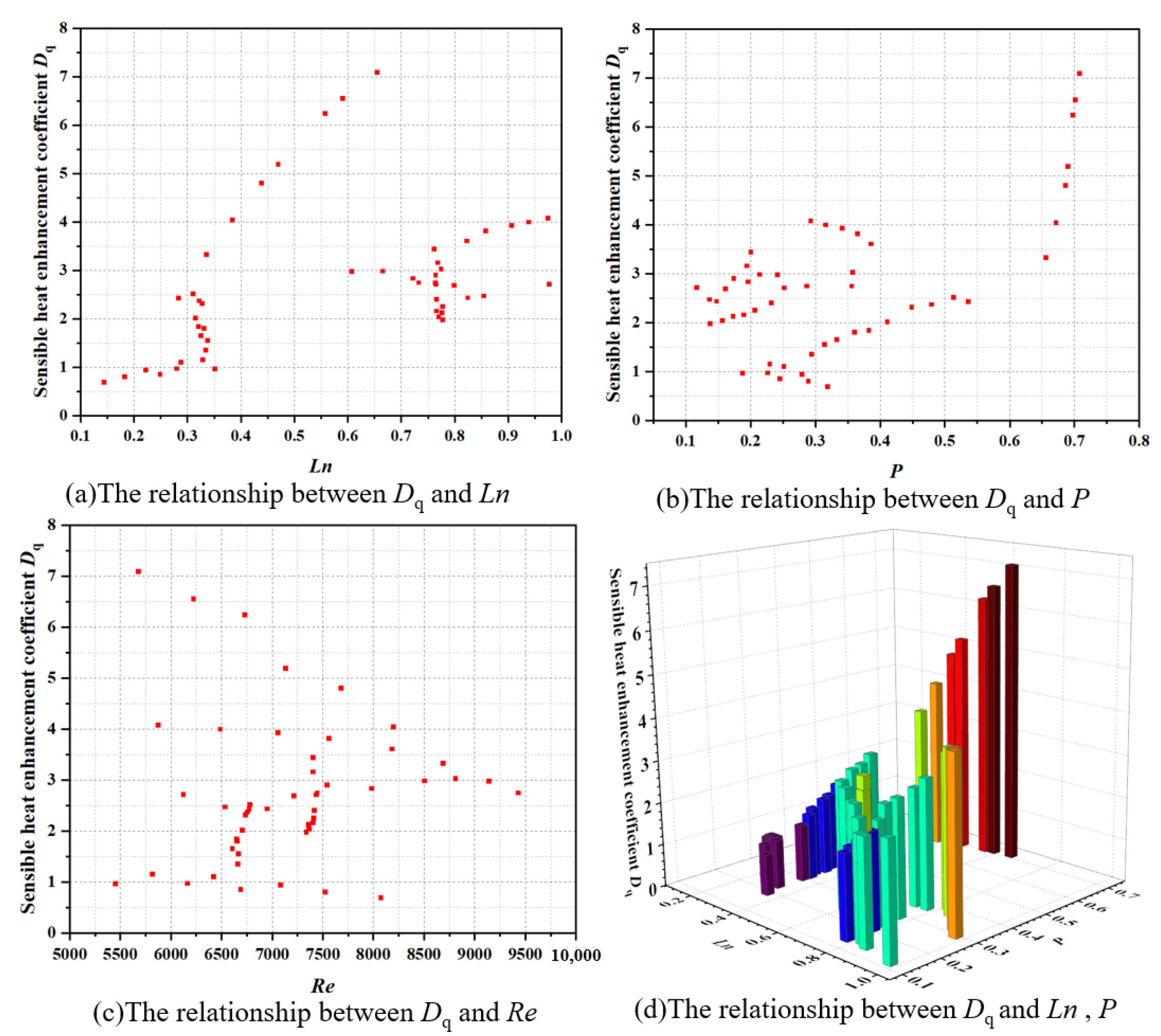

The

Ln number and

P also have a considerable influence on the latent heat strengthening coefficient

Dq. The experimental working conditions were plotted as a scatter plot (

Figure 4). The minimum value of

Dq increased with the increment in the

Ln number, which showed a positive correlation. A high

Ln number means that the flue gas area in the flue gas below the dew point temperature increases. The area where condensation occurs increases, and the secondary evaporation in the main flue gas stream domain after condensation of water vapor is weakened. Both factors work together to promote the increase in

Dq. With the increase in

P, the volume fraction of water vapor, the condensation capacity, and

Dq continue to improve in the flue gas. The influence of

Re on the latent heat transfer process is irregular. At the same time, the influence of

P and

Ln on

Dq was observed, and the influence of

P was greater than the influence of

Ln, while

P determines the upper limit of the condensation strengthening coefficient. The Ln number describes the proportion of water vapor condensed in the flue gas, and the P number represents the total condensation of water vapor.

P and Ln have strongly regular effects on the sensible heat transfer coefficient and latent heat transfer coefficient in the condensation heat transfer process. The sensible heat enhancement coefficient correlation was taken as an example, and the logarithm of both ends is taken to obtain the formula

, which becomes a multiple linear regression solution coefficient. Matlab R2024a’s multiple linear regression function regression was used to fit the experimental data, and the correlation coefficient R

2 was greater than 0.9. Formulas (8) and (9) were obtained (

,

,

).

3.4. The Condensation Heat Transfer Process by Microelement Superposition Method

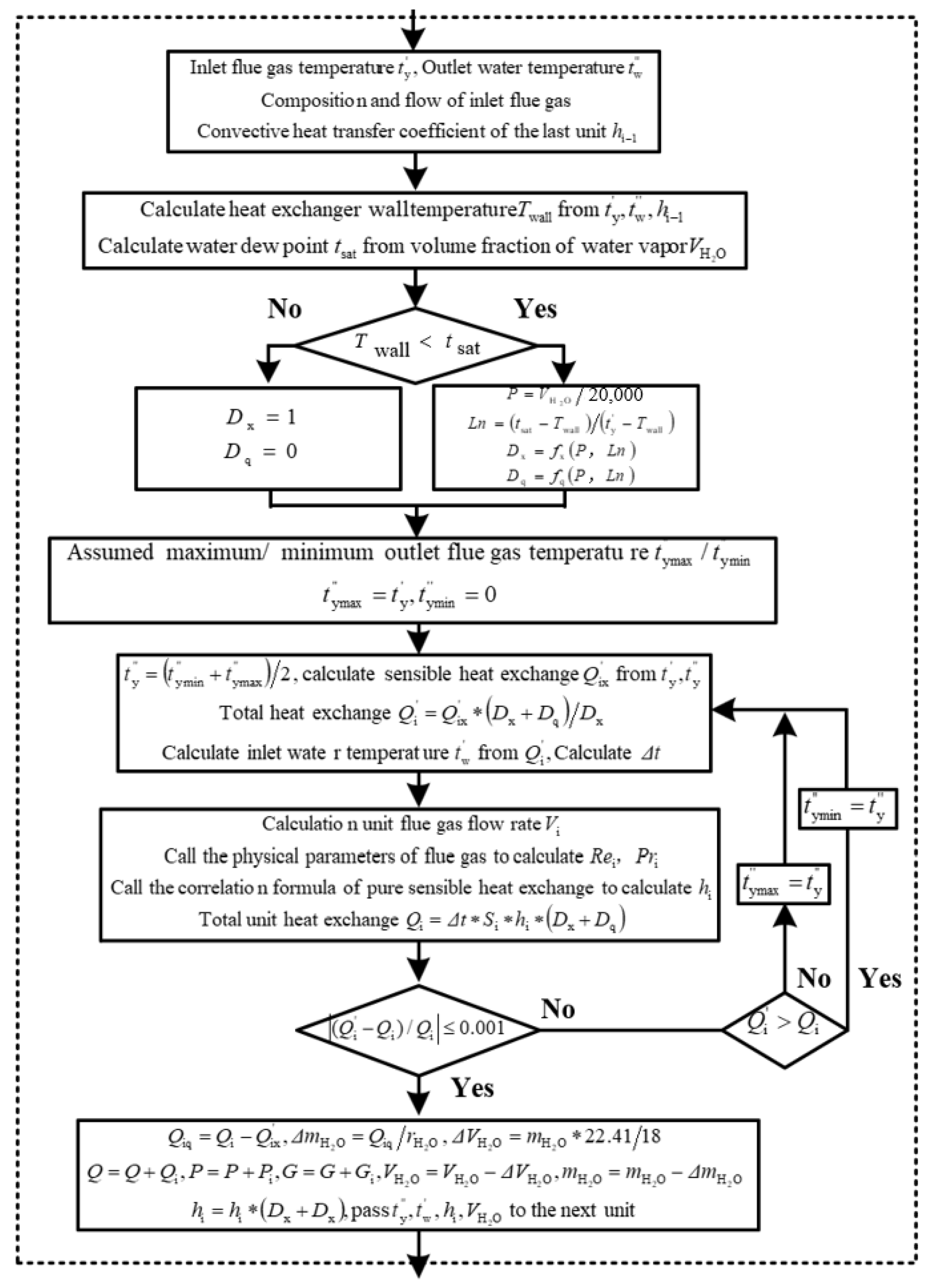

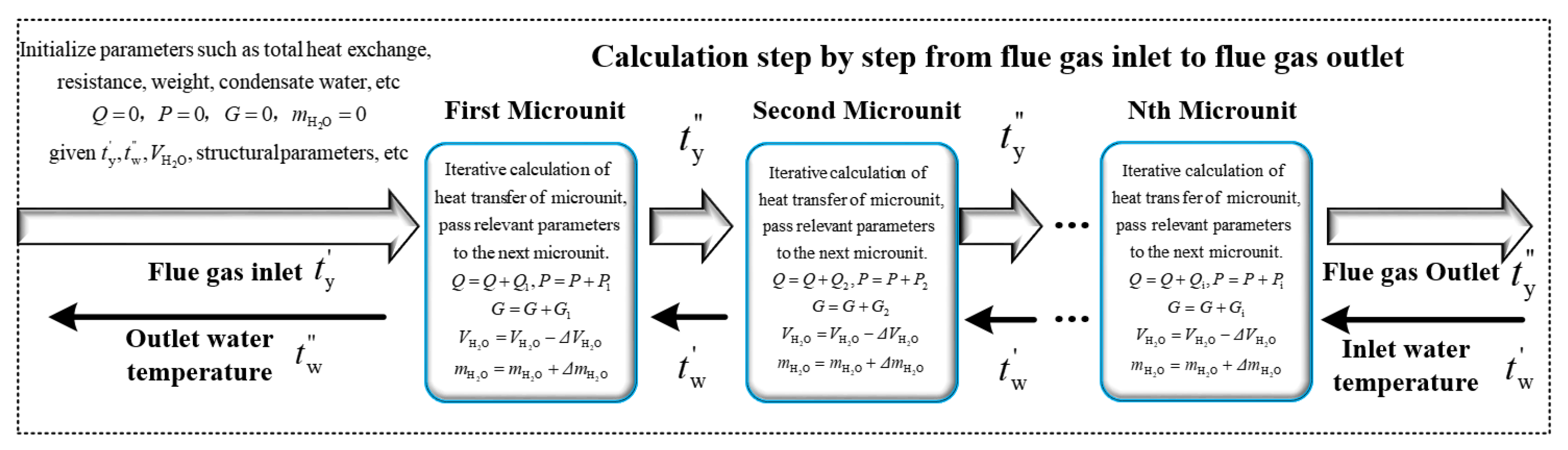

The design of traditional single-phase heat exchangers generally adopts the average method or segmented average method. According to the temperature of the high temperature side and low temperature side of the heat exchange element, the average physical property parameters and heat transfer temperature difference of the working fluid on the high temperature side and the low temperature side were calculated. Then, the average heat transfer coefficient was further calculated to finally determine the required heat exchange area. However, when water vapor condensation occurs in the flue gas, the volume of the flue gas, the integral number of water vapor gas, and the condensation heat transfer coefficient also vary. The latent heat of condensation under the unit temperature drop reached dozens of times the apparent heat, and the heat of condensation and the heat transfer coefficient of condensation would change drastically as the temperature, which brings great challenges to the traditional average method or segmented average method. Even calculating the parameters of each heat exchange unit with a temperature drop of 5 °C introduces huge errors. Therefore, as shown in

Figure 5,when it referred to condensation heat transfer, the design of the microelement superposition method effectively reduced the error caused by the average method or piecewise average method.

Sensible heat strengthening coefficient Dx and latent heat strengthening coefficient Dq were summarized, which were applied to calculate the sensible heat transfer coefficient and latent heat transfer coefficient under condensing conditions on the basis of the traditional sensible heat transfer correlation formula. The condensation heat transfer section was divided into multiple microelements, and the side convective heat transfer coefficient (sum of sensible heat transfer coefficient and latent heat transfer coefficient) of the previous microelement unit was used as the next microelement unit to calculate the side convective heat transfer coefficient of the wall temperature. The condensation that occurs in the calculation unit was determined, and the flue gas physical property parameters of the outlet to the next microelement unit were passed. If condensation occurs, the condensation amount of water vapor in the microelement is calculated so as to accurately obtain the flue gas flow rate, flue gas enthalpy value, and other parameters of the next microelement unit. The flue gas parameters, cooling working fluid parameters, and heat transfer coefficient of the microelement were transferred to the next microelement unit, and the cycle continued.

As shown in

Figure 6, the main calculation program needs to initialize the heat exchange

Q, resistance

P, weight

G, condensate water

, water vapor volume per unit fuel

and so on. After the calculation of each computing microelement unit, the heat exchange

is accumulated to the heat exchange

, the resistance Δ

Pi is accumulated to the resistance Δ

P, the weight

is accumulated to the weight

, the condensate water volume

is accumulated to the condensate volume

, and the water vapor reduction

is accumulated to the water vapor volume

. The outlet flue gas temperature

, inlet water temperature

, and flue gas side convective heat transfer coefficient

are used as the boundary calculation conditions of the next microelement calculation unit until the nth microelement unit. At this time, the outlet temperature

and condensate water volume

are the outlet parameters.

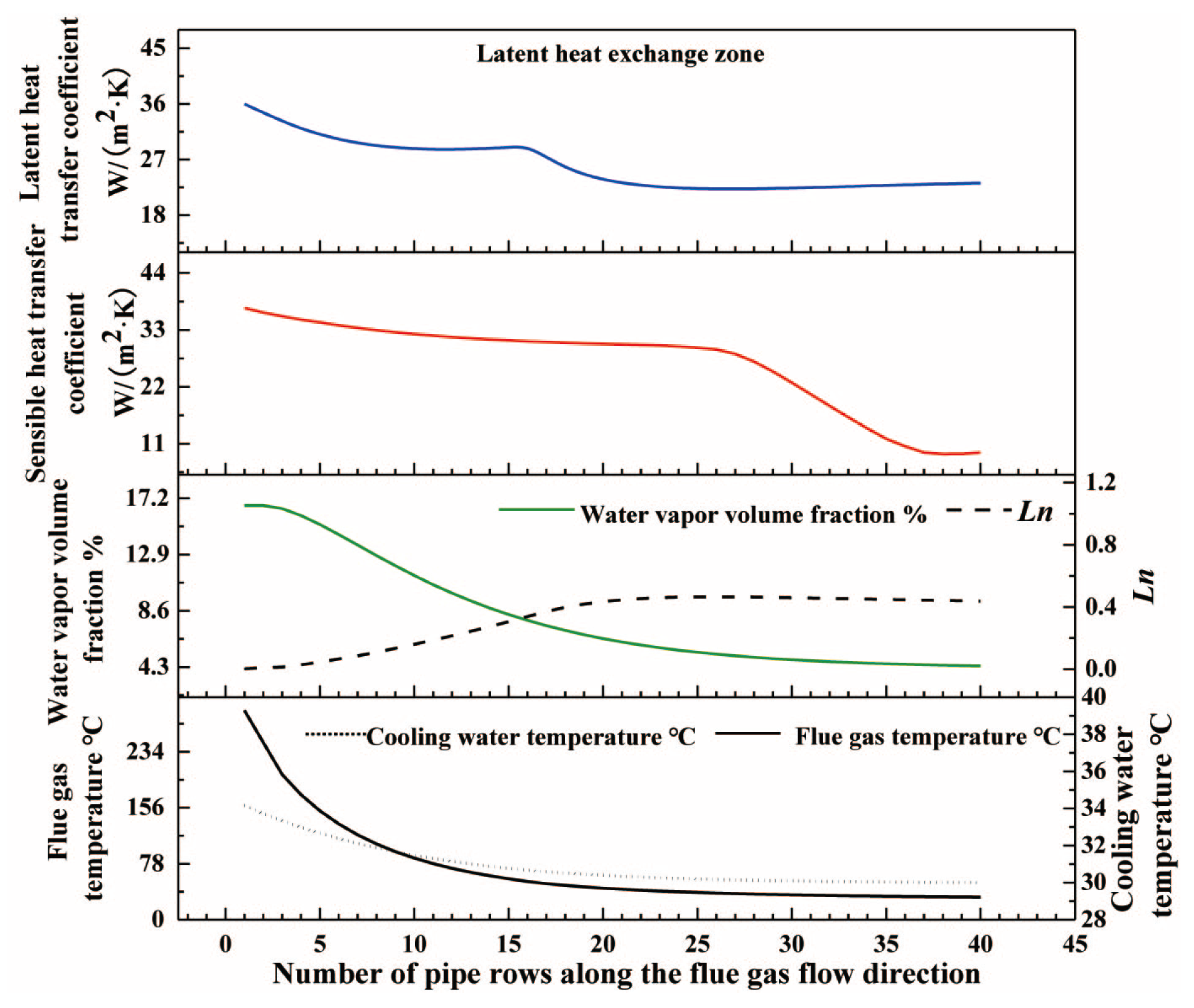

The working conditions of spiral finned condensing heat exchangers for condensing heat exchangers in gas-fired hot water boilers are illustrated in

Figure 7. The sensible heat transfer coefficient exhibited a step shape, the initial condensation remained unchanged, and the sensible heat transfer coefficient began to be suppressed after the Ln number improved. As the water vapor gas integral number decreased, the latent heat transfer coefficient was down, the extrusion of the sensible heat transfer coefficient shrank, and the sensible heat transfer coefficient stopped falling again.

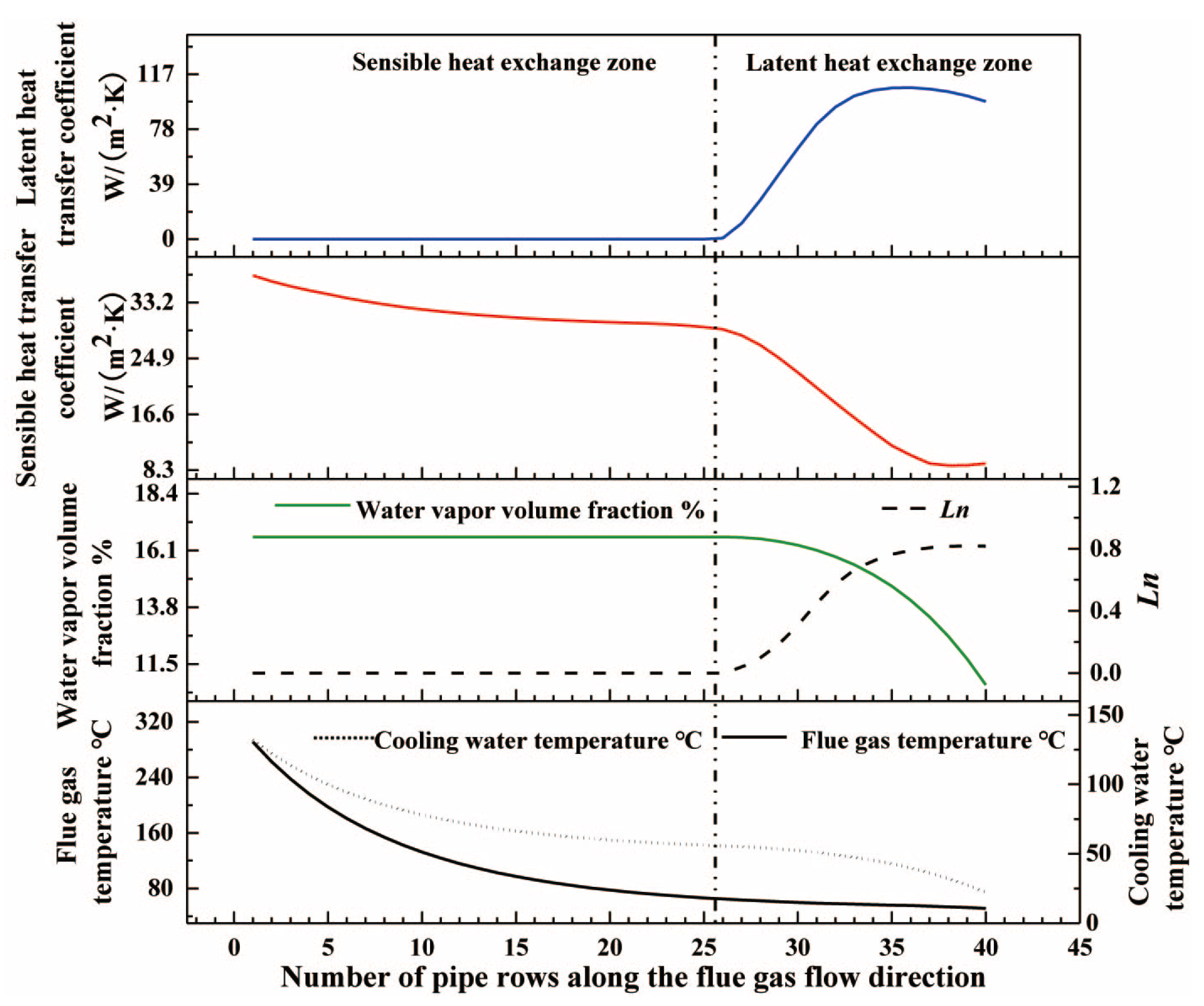

The feed water of the hot water boiler is huge, and the temperature rise of the feed water in the condensing heat exchanger is usually less than 5 °C. The whole process of condensation is generally maintained in the condensing heat exchanger. As shown in

Figure 8, Steam boilers have less water to feed and the feed water temperature quickly rises above the water dew point. After the number of outlets from the condensing heat exchanger, 10 rows are generally condensing heat exchange sections, and condensation begins when the smoke temperature drops to about 80 °C. The stainless steel spiral finned tube is constrained by the fin efficiency, and the total heat transfer coefficient used under vigorous condensing conditions is significantly lower than that of the plain tube structure, which is suitable for pure sensible heat working conditions or the working conditions with an Ln number less than 0.3.

Poškas, R [

34] also studied the condensation of wet flue gas on the surface of a fluorescent tube, and the research results showed that the maximum condensation heat transfer coefficient occurred in rows 6–7 after the start of condensation, which can be mutually confirmed with this example. After condensation occurred in the 26th row, the condensation heat transfer coefficient reached its peak on the left and right sides of the 32nd row. Robert proposed that the condensation heat transfer coefficient is related to the water vapor content in the flue gas and the inlet flue gas temperature. The higher the water vapor content is and the lower the inlet flue gas temperature is, the greater is the condensation heat transfer coefficient. Robert’s research shows that the condensation heat transfer coefficient can reach 4–8 times that of pure sensible heat transfer conditions. Although the calculation expressions are different, the overall heat transfer results are similar.

3.5. Verification of Condensation Heat Transfer Formula

The instruments used for verification are the same as those mentioned above. As a future-oriented zero-carbon energy source, hydrogen energy is gradually replacing some gaseous fuels. Our group designed a condensing hydrogen hot water boiler with a condensed convective heat exchanger element of extruded aluminum inner fin, as shown in

Figure 9b. The error between the calculation and the experimental values is less than 2%, which demonstrates that the condensation heat transfer formula is suitable for hydrogen fuel flue gas and non-spiral fin structures.

4. Conclusions

The condensation heat transfer characteristics of spiral finned tubes were studied by a gas boiler flue gas condensation experiment, and the key parameters affecting condensation heat transfer were analyzed. The condensation of water vapor in the flue gas interacts with the cooling of the flue gas. The increase in

Ln and

P values promotes the enhancement of water vapor condensation, and the condensation heat transfer coefficient can reach about three to eight times that of a sensible heat transfer coefficient. As the

Ln number increases from 0 to 0.35, the promoting effect of sensible heat is enhanced, up to a maximum of 2.5 times. However, from 0.35 to 0.75, the promotion gradually weakens. When the Ln number exceeds 0.75, the sensible heat transfer begins to be suppressed, with a minimum coefficient of 0.7. An empirical correlation formula for the coefficient of modified coefficients of condensation heat transfer sensible heat and latent heat based on the

Ln number and

P number is proposed.

This correlation formula is a modification of the empirical correlation of sensible heat convection heat transfer under condensation heat transfer conditions. Experimental verification was performed on the self-designed and manufactured hydrogen fuel boiler, which validated that the condensation heat transfer calculation correlation in this paper is universal. Since the heat transfer coefficient and flue gas parameters changed drastically with condensation of the flue gas during the condensation heat transfer process, the condensation heat exchange section was divided into multiple microelement units via the microelement superposition method. The calculation range was from the microelement unit at the flue gas outlet to the microelement unit at the flue gas outlet. Each microelement unit first determines whether condensation occurs. If so, the condensation heat transfer correlation method was used to correct the sensible heat convection heat transfer coefficient, so that each microelement unit achieves thermal equilibrium and transmits the relevant parameters to the next microelement unit. The micro-element superposition method improves the design accuracy of condensing heat exchangers, which lay the solid foundation for the wide promotion and application of condensing heat exchangers.