A Comprehensive Review of Well Integrity Challenges and Digital Twin Applications Across Conventional, Unconventional, and Storage Wells

Abstract

1. Introduction

2. History and Evolution of Well Integrity Standards

3. Fundamental Concepts: Well Barrier Philosophy

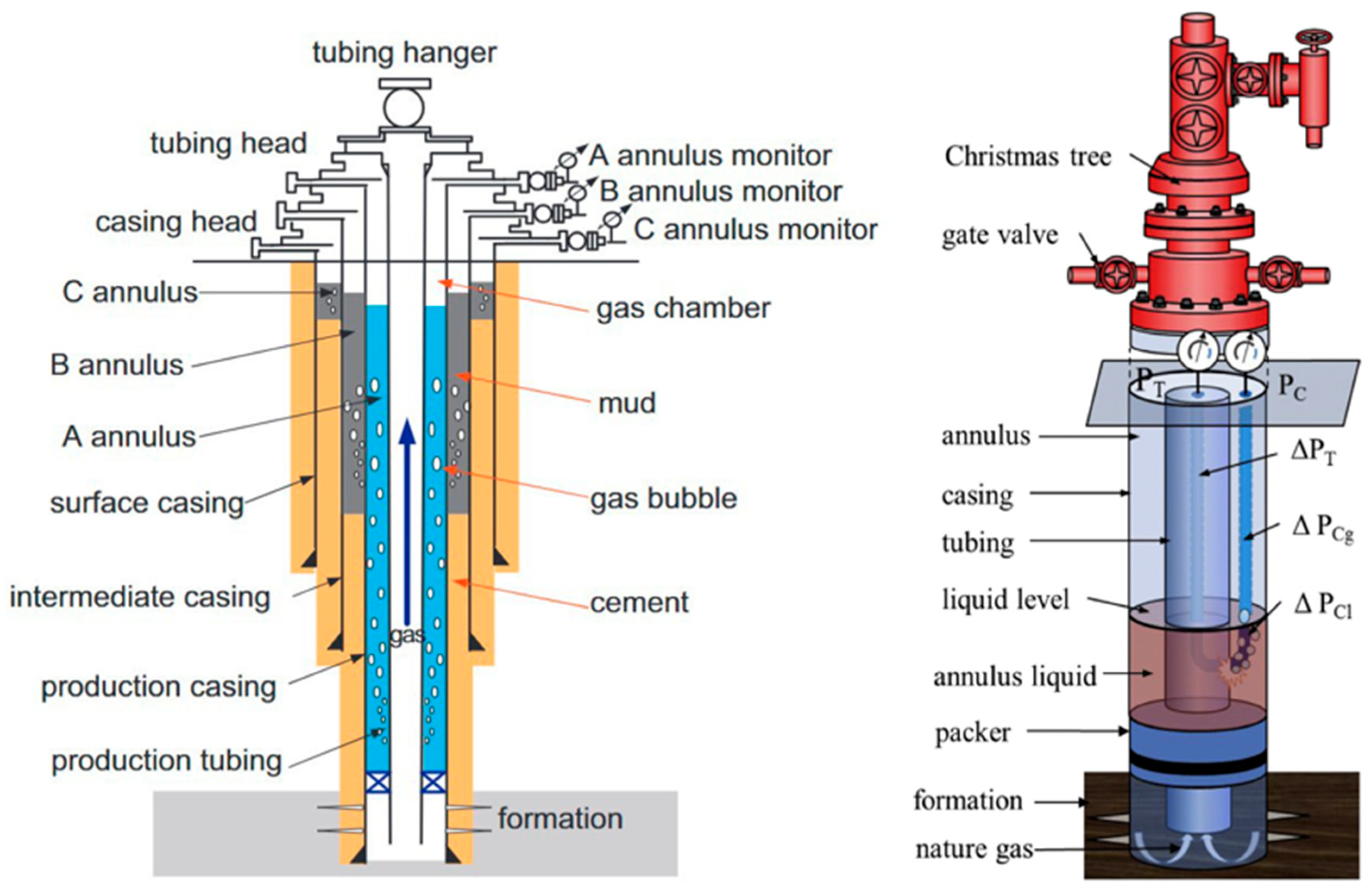

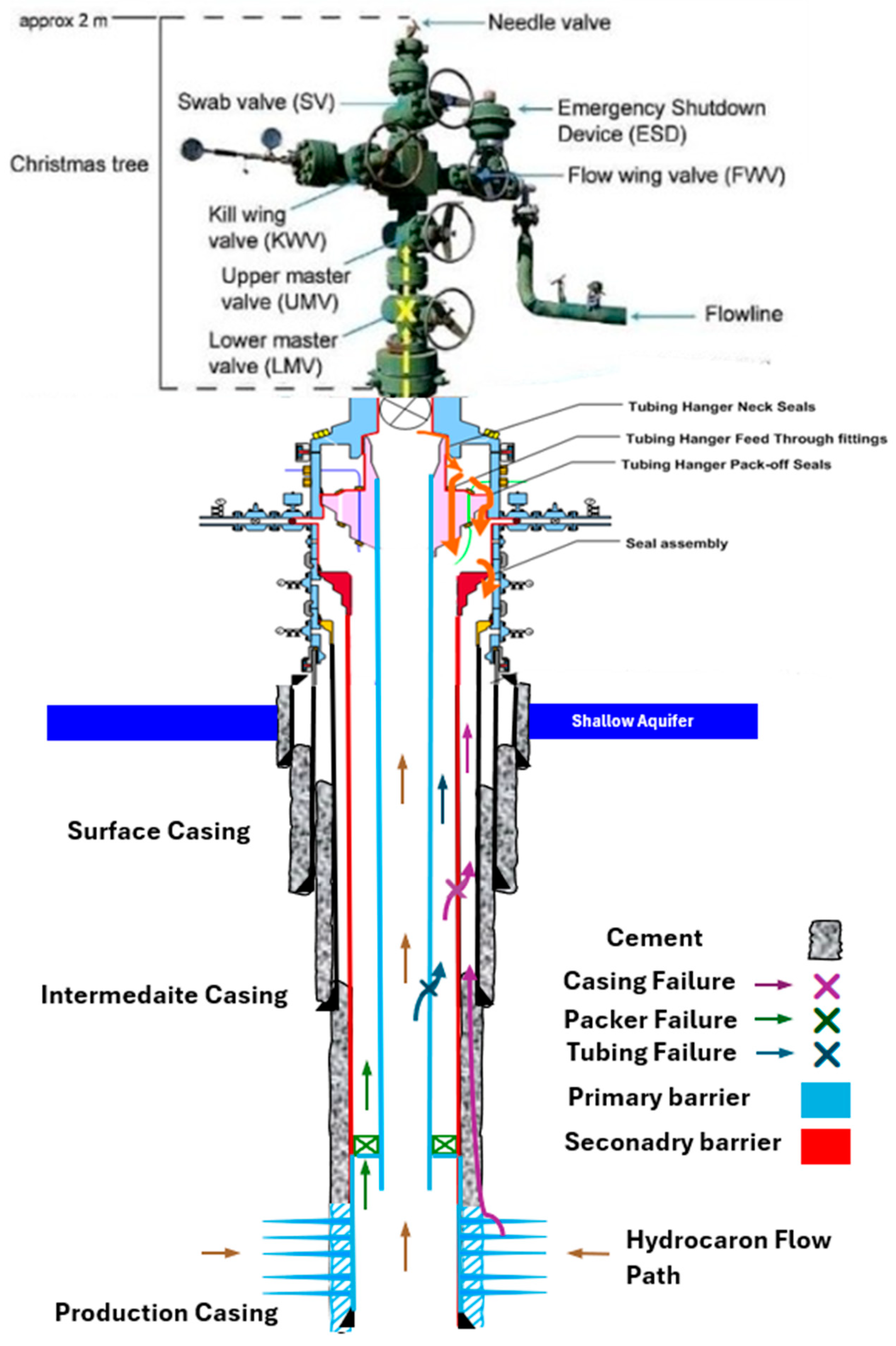

- Primary Barrier: This is the envelope of barrier elements closest to the potential source of inflow (e.g., the reservoir). It is designed to contain wellbore fluids and pressures under normal operating, shut-in, or intervention conditions. Examples include the production tubing, downhole packer seals, subsurface safety valves (DHSVs), and the casing string below the production packer [2,39].

- Secondary Barrier: This envelope provides containment if the primary barrier fails. It typically surrounds the primary barrier and must also be capable of withstanding the maximum anticipated pressures. Examples include the production casing string, the cement sheath providing annular sealing above the packer, annulus safety valves (ASVs), and the wellhead seals and valves [2,39].

- Mechanical Barriers: Including casing and tubing strings themselves, downhole completion equipment like packers and bridge plugs, surface equipment like wellheads and Christmas trees with their associated valves and seals, subsurface safety valves (DHSVs, ASVs), and blowout preventers (BOPs) used during drilling and intervention operations [38].

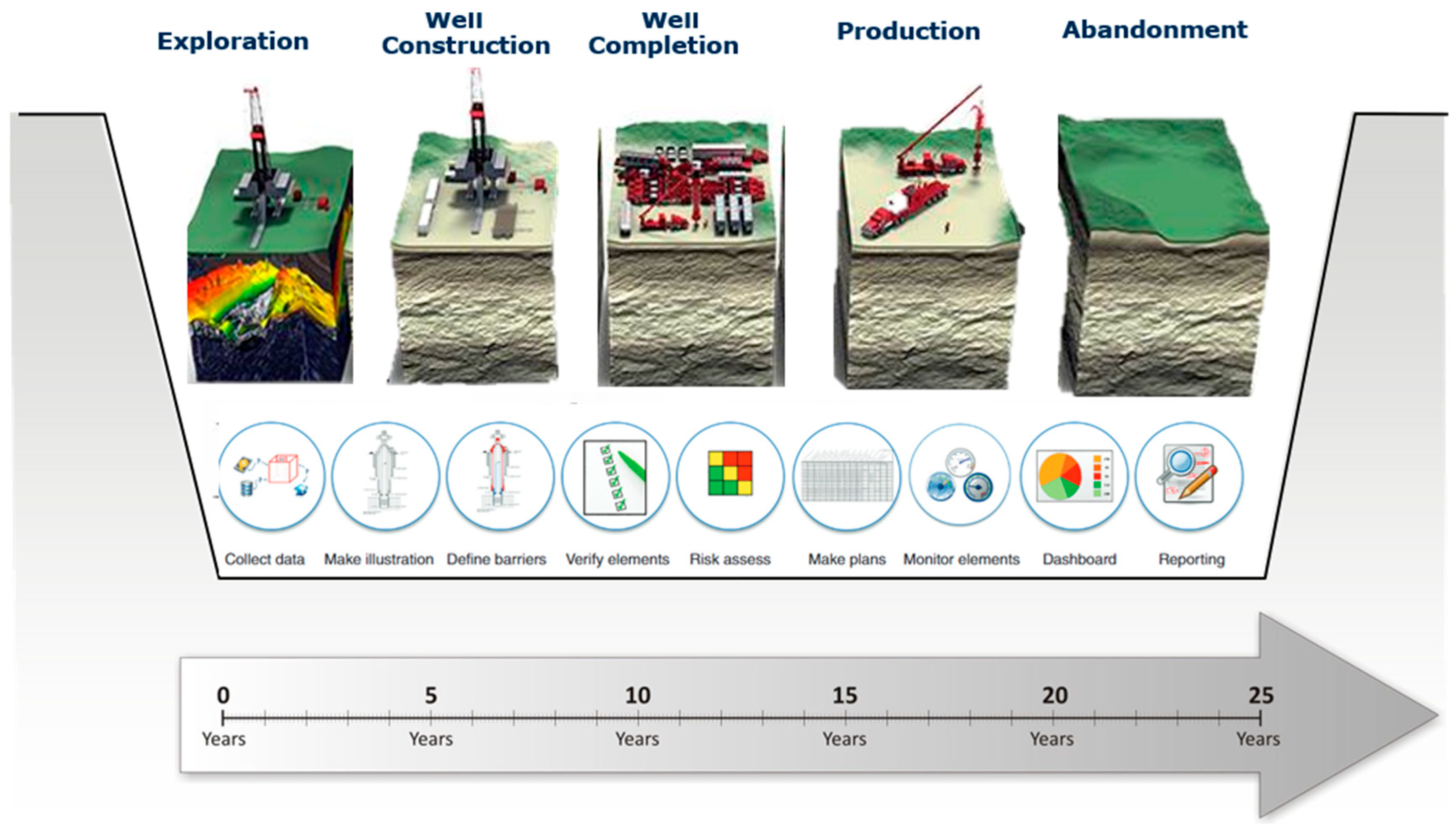

4. Well Integrity Across the Lifecycle

5. Wellhead and Surface Equipment Integrity

6. Failure Mechanisms in Well Integrity

6.1. Mechanical Failures

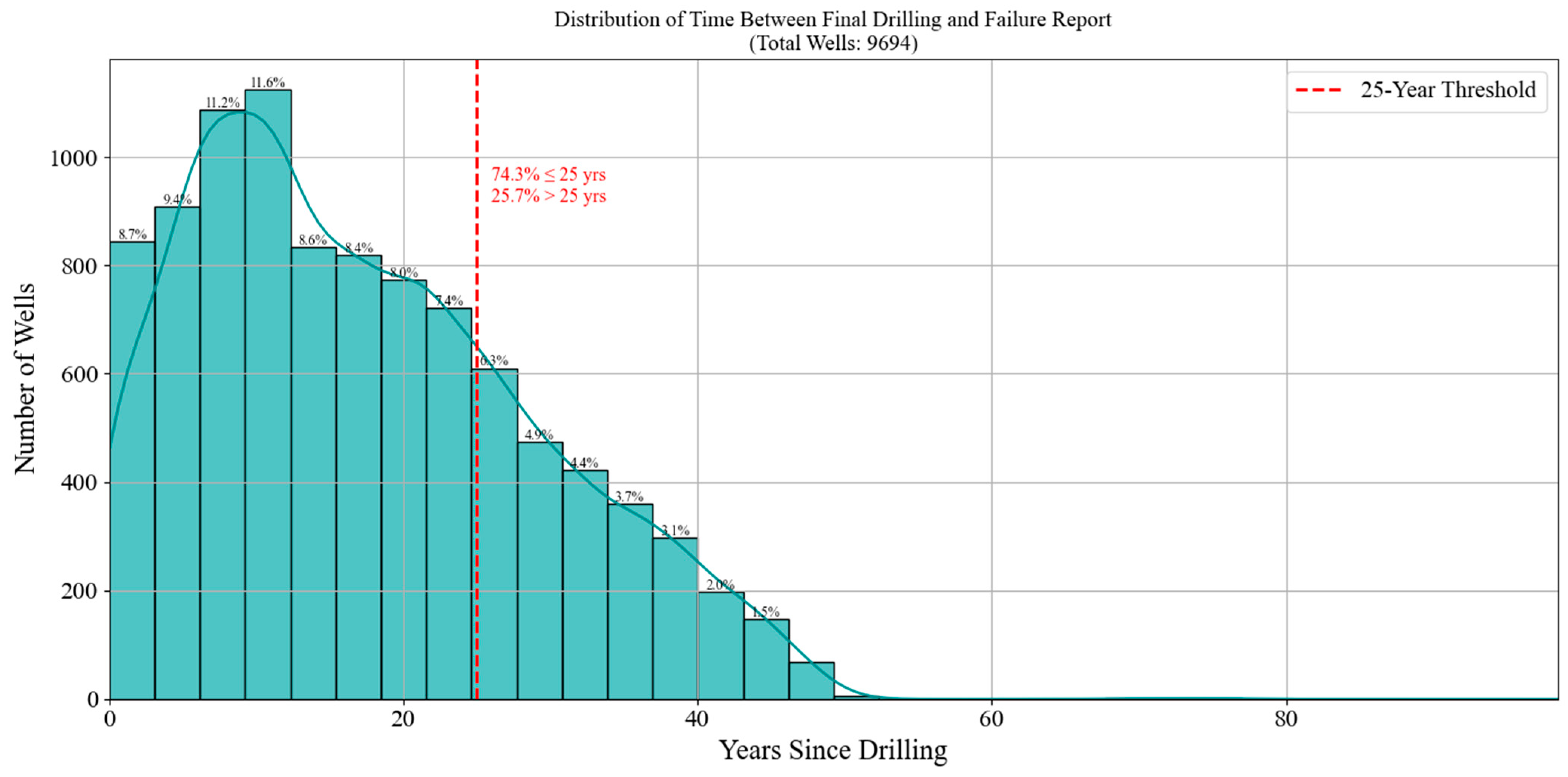

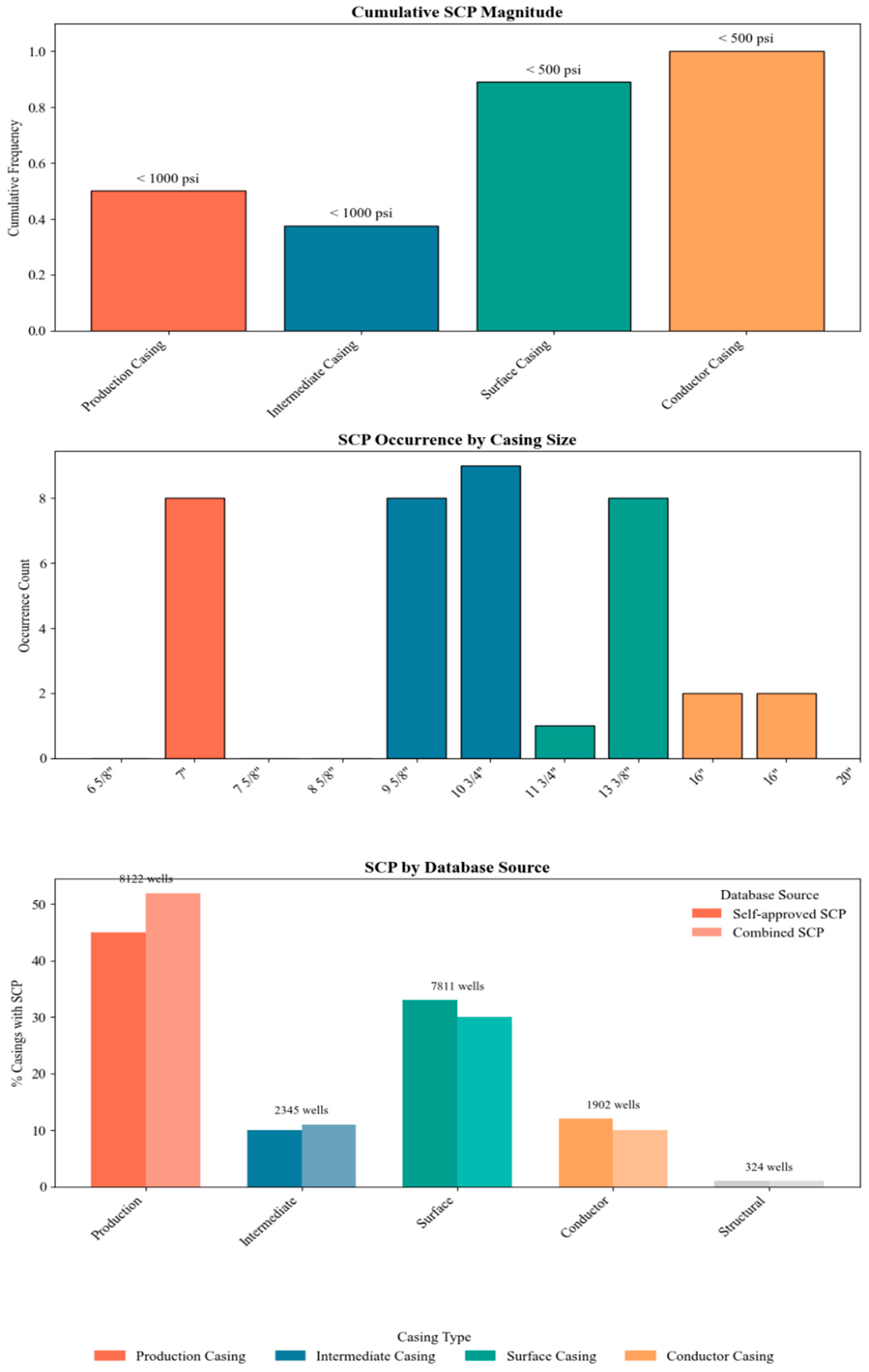

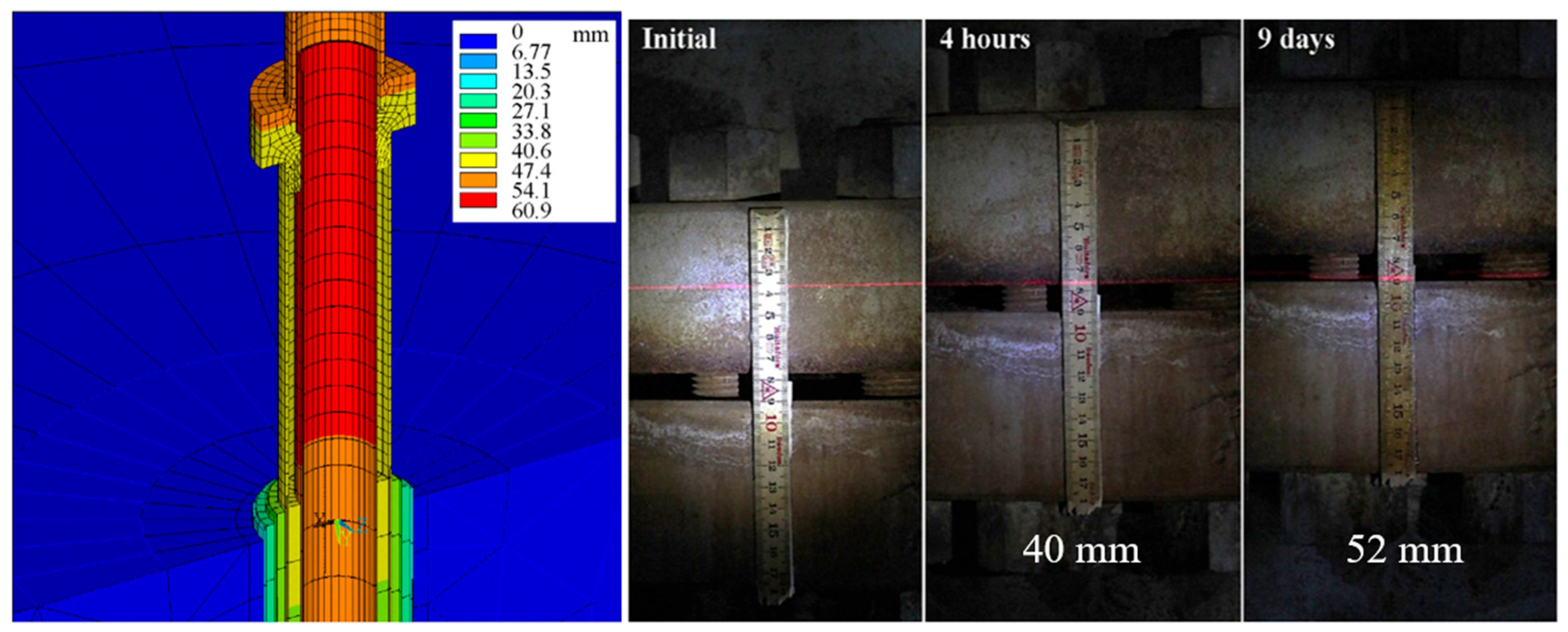

6.1.1. Casing Collapse

6.1.2. Casing Burst

6.1.3. Casing Buckling

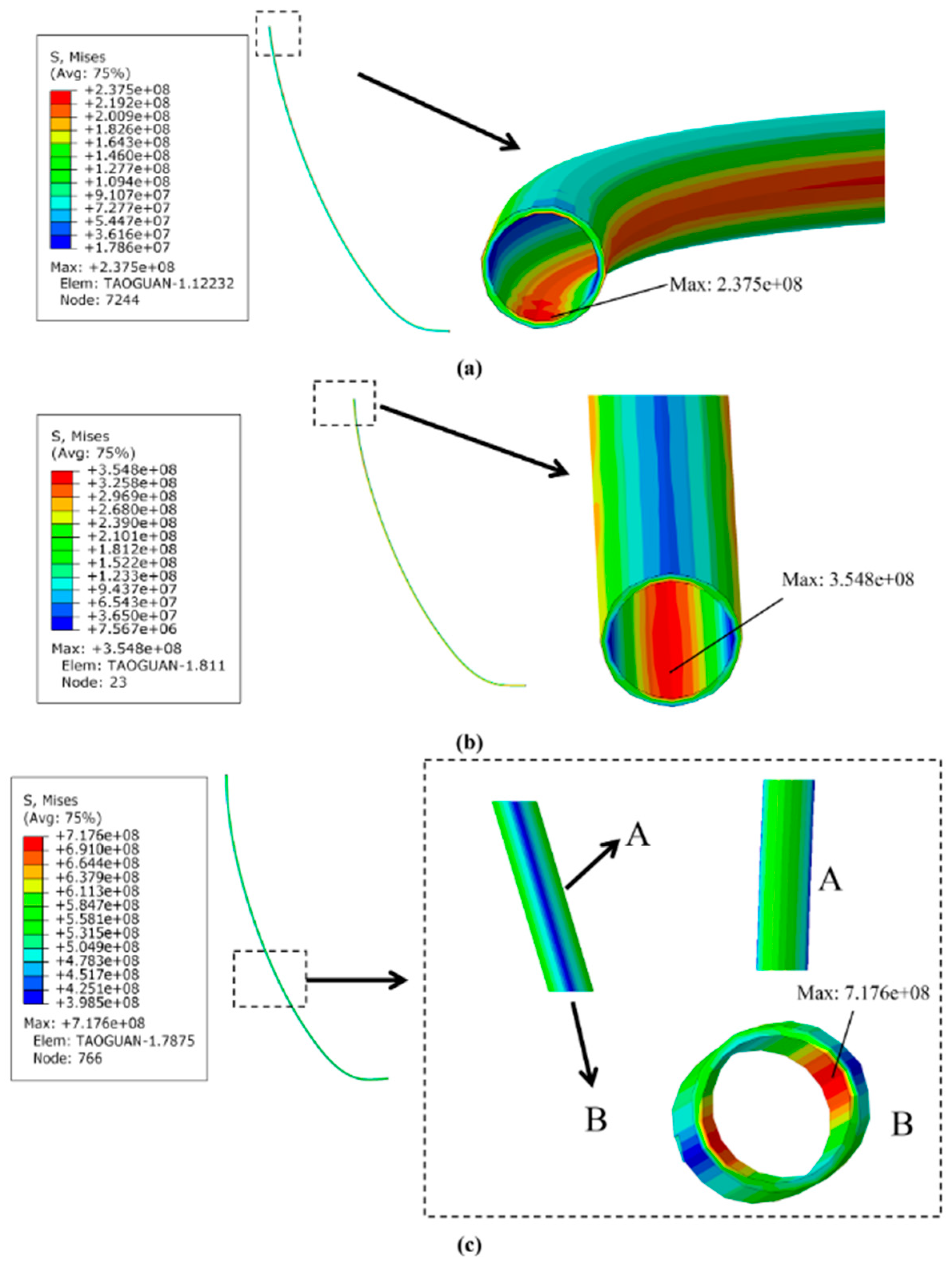

6.1.4. Casing Fatigue

- Optimizing casing design to minimize stress concentrations.

- Improving cement placement and bonding to constrain casing movement.

- Ensuring proper landing tension and make-up torque.

- Using advanced fatigue models to evaluate life cycles.

- Deploying real-time monitoring systems to detect early signs of fatigue degradation.

6.1.5. Casing Erosion and Wear

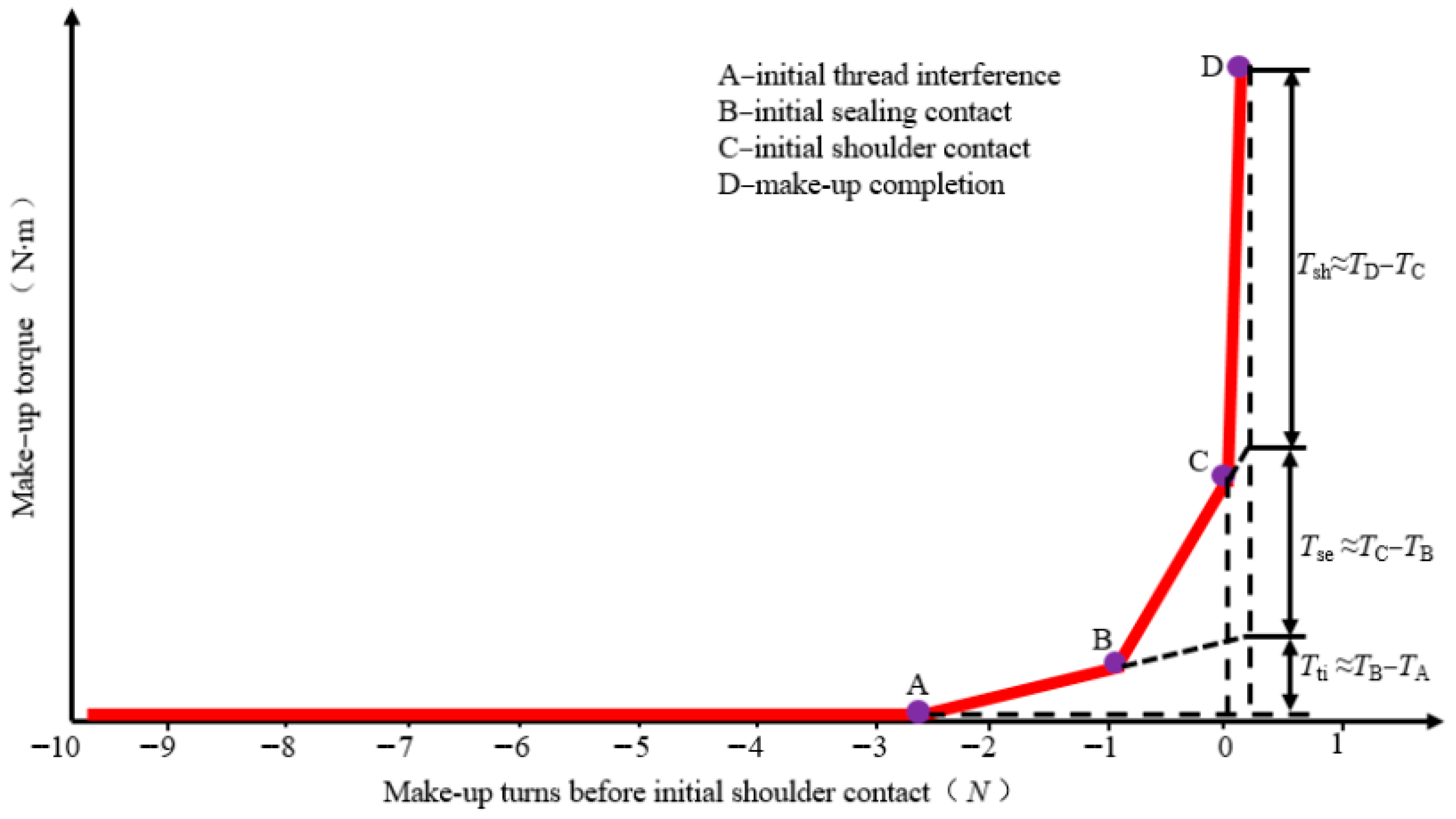

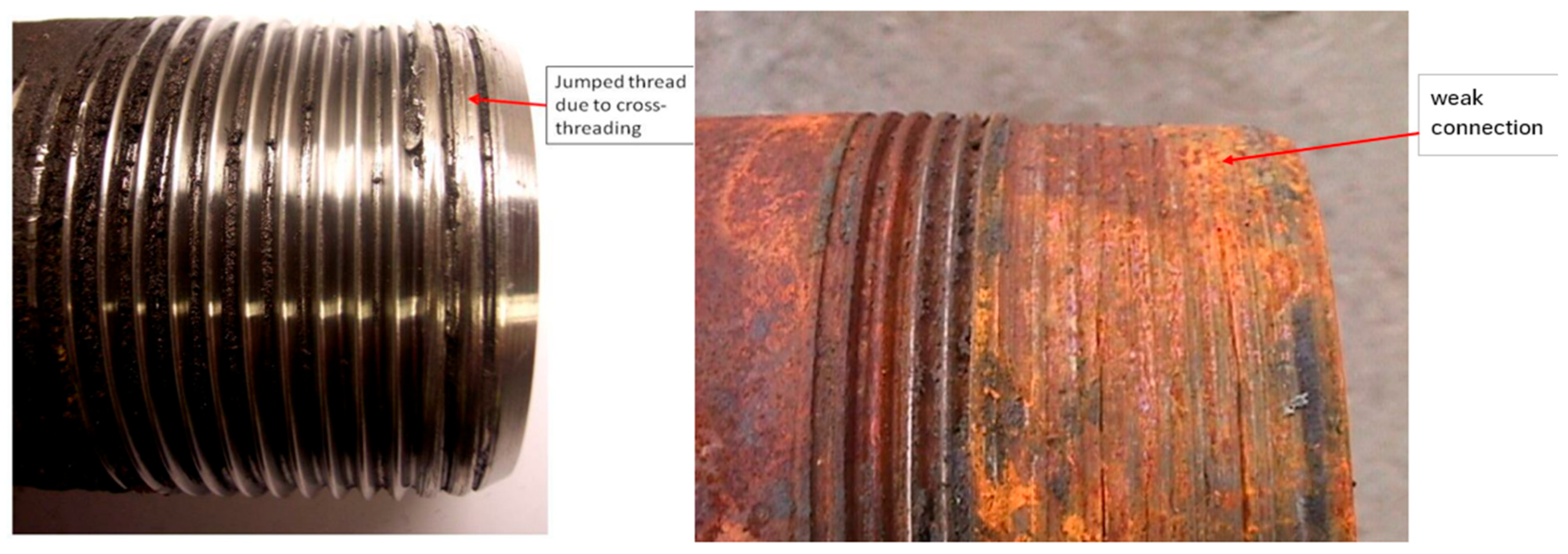

6.1.6. Connection Failure

6.1.7. Installation Damage

6.2. Geochemical Failures

6.2.1. Cement Chemical Degradation

- Carbonation (CO2 Attack): Dissolved CO2 in formation water, injected CO2, or produced fluids containing CO2 can react with the alkaline hydration products of Portland cement, primarily calcium hydroxide (CH) and calcium silicate hydrates (C-S-H) gel [133,134,135].

- ○

- Mechanism: CO2 reacts with CH to form calcium carbonate (CaCO3). This reaction initially reduces permeability in the carbonated zone but also consumes CH, lowering the pH. At lower pH, the primary strength-giving C-S-H gel becomes unstable and decalcifies (calcium is leached out), losing its binding capacity and converting to silica gel. The overall result is a significant loss of strength, increased porosity, and increased permeability in the degraded zone over time.

- ○

- Occurrence: A major concern for long-term integrity in CO2-rich reservoirs (sour/sweet gas), gas storage wells (especially when cushion gas mixes with formation water), and particularly CCS wells where the cement is exposed to high concentrations of wet CO2 for extended periods. The rate of degradation is influenced by CO2 partial pressure, temperature, pressure, water saturation, and flow rate [136,137,138].

- Sulfate Attack: Sulfates (SO42−) present in formation water or injection water can react with the calcium aluminate hydrate phases (formed from C3A hydration) and calcium hydroxide in Portland cement [139].

- ○

- Mechanism: Reactions form expansive minerals like ettringite and gypsum. These expansive minerals generate internal stresses within the cement matrix, leading to expansion, cracking, softening, loss of strength, and loss of bonding [140].

- ○

- Occurrence: Can be an issue in formations with high sulfate concentrations or when using high-sulfate injection water. Using sulfate-resistant Portland cements (API Type II or V, with low C3A content) or non-Portland-based cements designed for sulfate resistance can mitigate this risk.

- Acid Attack (H2S, Organic Acids): Acidic fluids (low pH) can directly dissolve the alkaline hydration products (CH and C-S-H) of Portland cement, leading to increased porosity, permeability, and loss of structural integrity [141]. H2S dissolved in water forms a weak acid, and its presence can accelerate cement degradation. Organic acids present in some reservoir fluids can also be aggressive, particularly at high temperatures.

- Leaching: Flowing formation water (even seemingly non-aggressive water) can slowly dissolve and carry away soluble components of the cement matrix, particularly calcium hydroxide (CH), over very long periods. This process increases porosity and permeability, potentially creating or enlarging leak paths, especially in fractured or already damaged cement. This is a long-term process that can be accelerated by high flow rates or low pH fluids [142].

- Magnesium Attack: Brines rich in magnesium chloride or sulfate can also degrade cement through complex reactions that replace calcium phases with weaker magnesium phases like brucite (Mg(OH)2) and magnesium silicate hydrates, leading to strength loss and increased permeability [143].

6.2.2. Casing Corrosion

- CO2 Corrosion (Sweet): Carbon dioxide (CO2) dissolves in water to form carbonic acid (H2CO3), a weak acid that is highly corrosive to carbon steel [144].

- ○

- Mechanism: Carbonic acid dissociates in water, providing hydrogen ions (H+) for the cathodic reaction. The anodic reaction is the dissolution of iron (Fe). Protective iron carbonate (FeCO3) scales can form on the steel surface, which can significantly reduce corrosion rates if they are dense, adherent, and continuous. However, their stability depends heavily on temperature, pH, CO2 partial pressure, and flow conditions. If the scale is porous, non-adherent, removed by high flow rates or pigging, or disrupted by pitting, rapid localized corrosion (often severe pitting) can occur beneath the scale.

- ○

- Factors: Corrosion rates increase significantly with CO2 partial pressure (higher partial pressure means more dissolved CO2 and lower pH), temperature (up to a certain point, then potentially decreasing at very high temperatures if stable, protective scales form), and flow velocity (inhibiting scale formation or causing erosion of existing scale) [145]. The presence of a free water phase wetting the steel surface is essential for electrochemical corrosion to occur.

- ○

- H2S Corrosion (Sour): Hydrogen sulfide (H2S) is extremely dangerous (toxic, flammable) and highly corrosive [149].

- ○

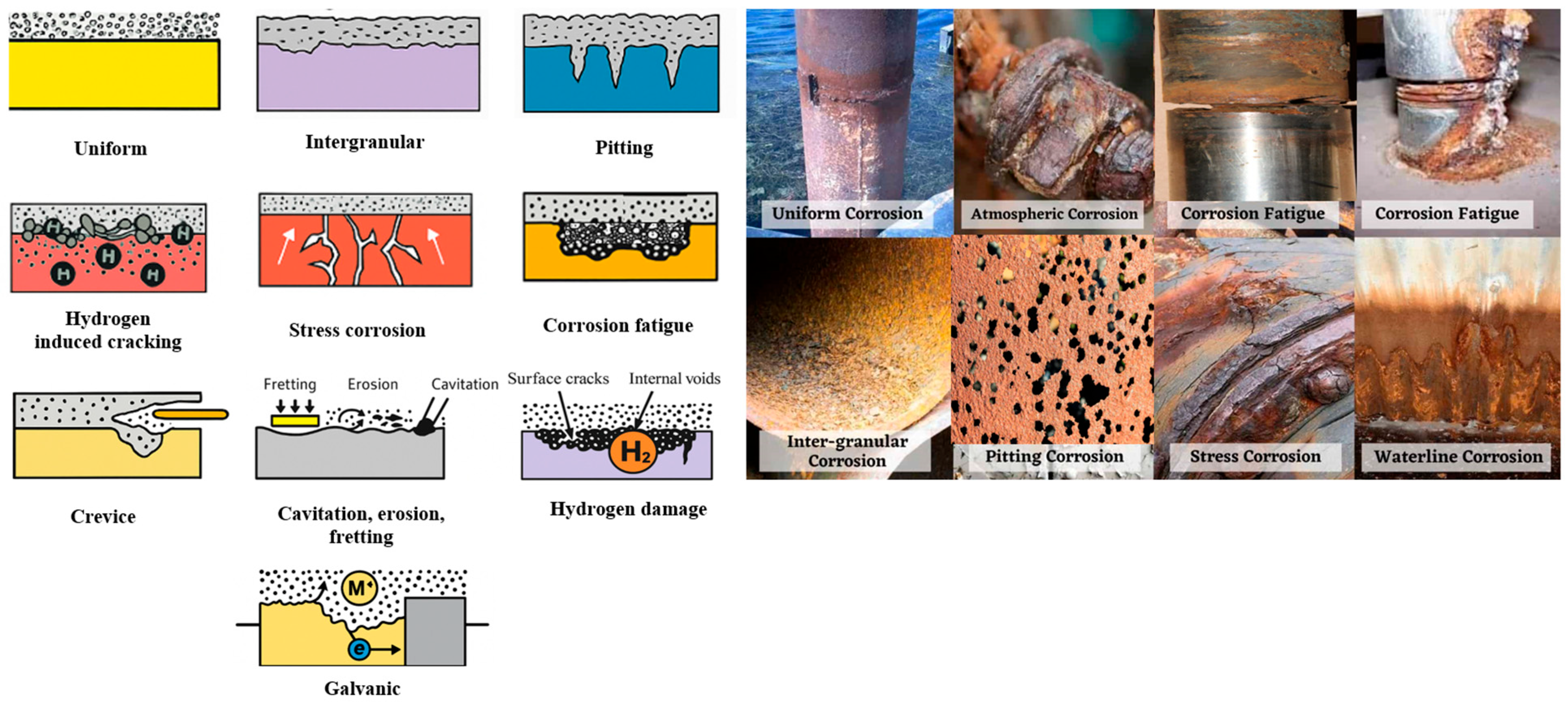

- Mechanism: H2S dissolves in water and acts as a weak acid. It reacts with steel to form iron sulfide (FeS) scales. FeS scales can sometimes be protective, similar to FeCO3, but they are often porous, brittle, non-adherent, or conductive, leading to localized corrosion (pitting, blistering) due to galvanic effects between different FeS phases or between FeS and the underlying steel. Corrosion in well systems presents in various forms, each with distinct mechanisms, damage profiles, and mitigation challenges. Figure 12 provides a dual-view comparison: schematic illustrations (left) depict typical corrosion types—including uniform, pitting, galvanic, stress corrosion, and hydrogen-induced cracking—while field photographs (right) capture real-world manifestations of these failure modes as observed on casing and tubing surfaces. Together, these visuals emphasize the diversity and severity of corrosion-related damage across downhole and topside environments.

- ○

- Sulfide Stress Cracking (SSC): The hydrogen atoms generated during the cathodic reaction in sour environments (especially at low pH) can be absorbed into the steel lattice. In susceptible materials (primarily high-strength steels with certain microstructures or hard weld zones) under tensile stress (applied or residual), these hydrogen atoms can cause embrittlement and sudden, brittle fracture at stresses well below the material’s yield strength [150]. This is SSC, a major, potentially catastrophic, integrity threat. Preventing SSC requires strict adherence to material selection and heat treatment guidelines defined by NACE MR0175/ISO 15156 [151], which specifies limits on steel hardness and structure based on H2S partial pressure, temperature, pH, and chloride concentration (NACE MR0175/ISO 15156). Sulfide stress cracking (SSC) is a critical form of environmentally assisted cracking that occurs when high-strength steels are exposed to H2S-containing environments under tensile stress. The mechanism involves hydrogen generation, absorption into the steel matrix, and accumulation at crack tips and grain boundaries, eventually leading to embrittlement and brittle fracture.

- ○

- Hydrogen Induced Cracking (HIC)/Stepwise Cracking (SWC): Hydrogen atoms can also recombine at internal defects or inclusions within the steel (e.g., manganese sulfide inclusions) to form molecular hydrogen (H2), creating high internal pressures that cause blisters or stepwise internal cracks, particularly in lower-strength steels [150]. This is less common in typical casing/tubing steels manufactured to API standards but is a known threat in certain plate steels used for facilities.

- Oxygen Corrosion: Dissolved oxygen (O2) is a very aggressive corrosive, acting as an efficient cathodic reactant that drives rapid iron dissolution. Fortunately, produced fluids from most reservoirs are typically anaerobic (oxygen-free) [152]. However, oxygen ingress can occur through:

- ○

- Injection fluids (water, polymers, stimulation fluids), if not properly deoxygenated.

- ○

- Leaks in surface equipment or packer/wellhead seals allowing air contact (e.g., in annulus fluids open to atmosphere).

- ○

- Workover or completion fluids are exposed to air. Oxygen corrosion often results in severe, highly localized pitting. Maintaining anaerobic conditions in systems where oxygen is not expected is critical; even small amounts of oxygen can initiate significant corrosion.

- Microbiologically Influenced Corrosion (MIC): Certain types of microorganisms, particularly sulfate-reducing bacteria (SRB) and acid-producing bacteria (APB), can thrive in downhole environments (especially in stagnant zones, under deposits, or in water injection systems if water quality is not controlled) [153].

- ○

- Mechanism: SRB consume sulfate ions and produce H2S as a metabolic byproduct, leading to localized sour corrosion and pitting, often occurring beneath protective biofilms or deposits where oxygen levels are low (anaerobic). APB produces organic acids that can lower local pH and increase corrosion. MIC often causes very rapid, highly localized pitting, which is difficult to predict or monitor with conventional methods.

- ○

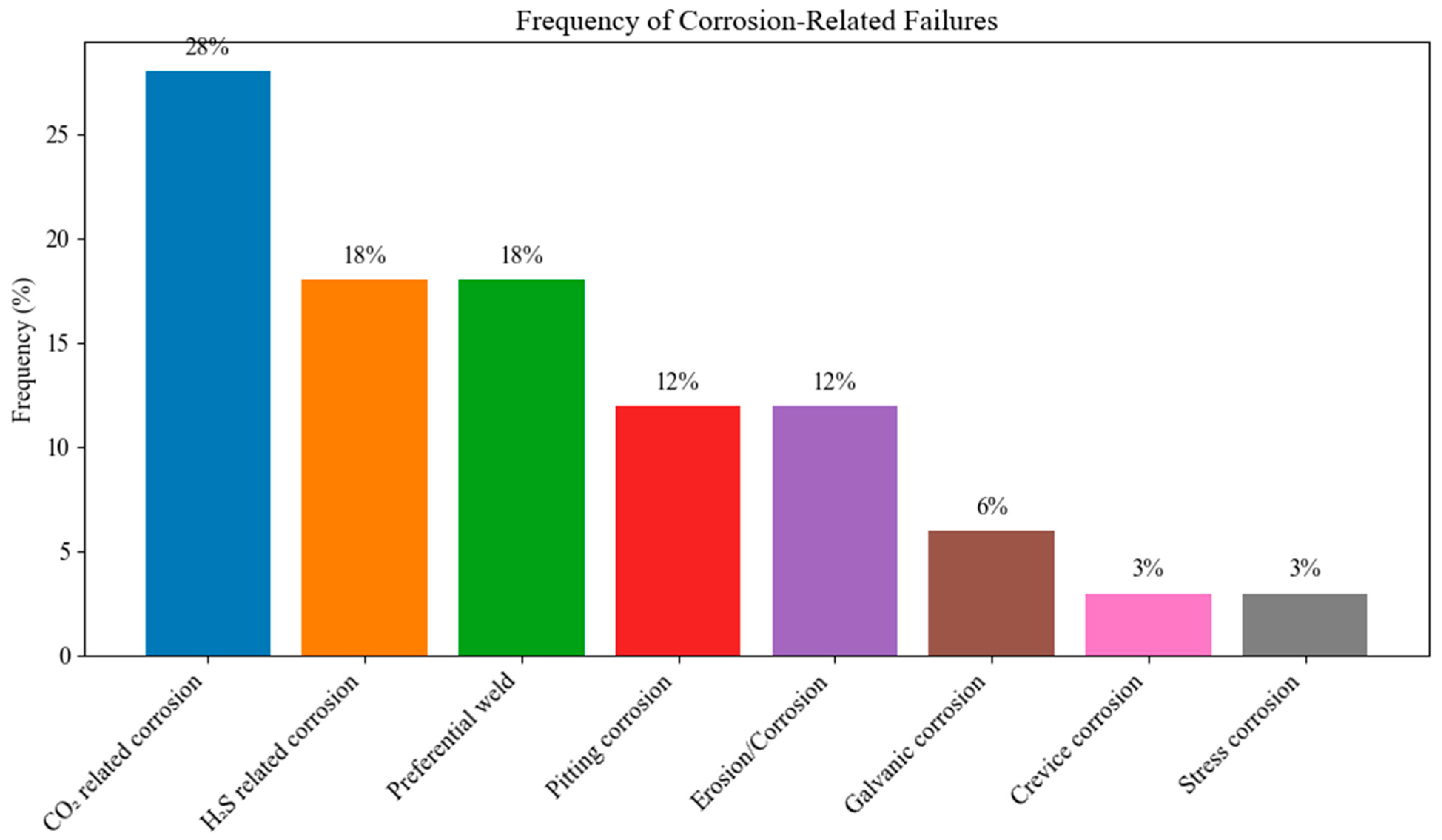

- Detection/Mitigation: Difficult to predict and diagnose. Requires specialized sampling and analysis techniques (molecular methods like quantitative PCR are improving detection). Control involves using biocides (batch or continuous), regular cleaning (pigging) to remove deposits and biofilms, and maintaining flow to prevent stagnation [154]. To understand the practical significance of these corrosion modes, Figure 13 summarizes the relative frequency of corrosion-related failures in oilfield systems. CO2-related corrosion is the leading cause, responsible for 28% of all reported corrosion failures, followed by H2S-related corrosion and preferential weld corrosion, each contributing 18%. Pitting and erosion/corrosion each account for 12%, while galvanic, crevice, and stress corrosion mechanisms collectively represent the remaining 15%. These statistics underscore that 46% of failures are due to acid gas environments, emphasizing the critical need for tailored materials selection, real-time corrosion monitoring, and targeted inhibition strategies in wells exposed to CO2-rich or sour gas conditions.

- ○

- Organic Acid Corrosion: Naturally occurring organic acids (e.g., acetic, propionic) present in some reservoir fluids can contribute to corrosion, particularly at higher temperatures and pressures, although typically less aggressive than CO2 or H2S. Their presence can also influence the pH and stability of protective scales [155].

6.2.3. Hydrogen Embrittlement (HE) and Related Damage

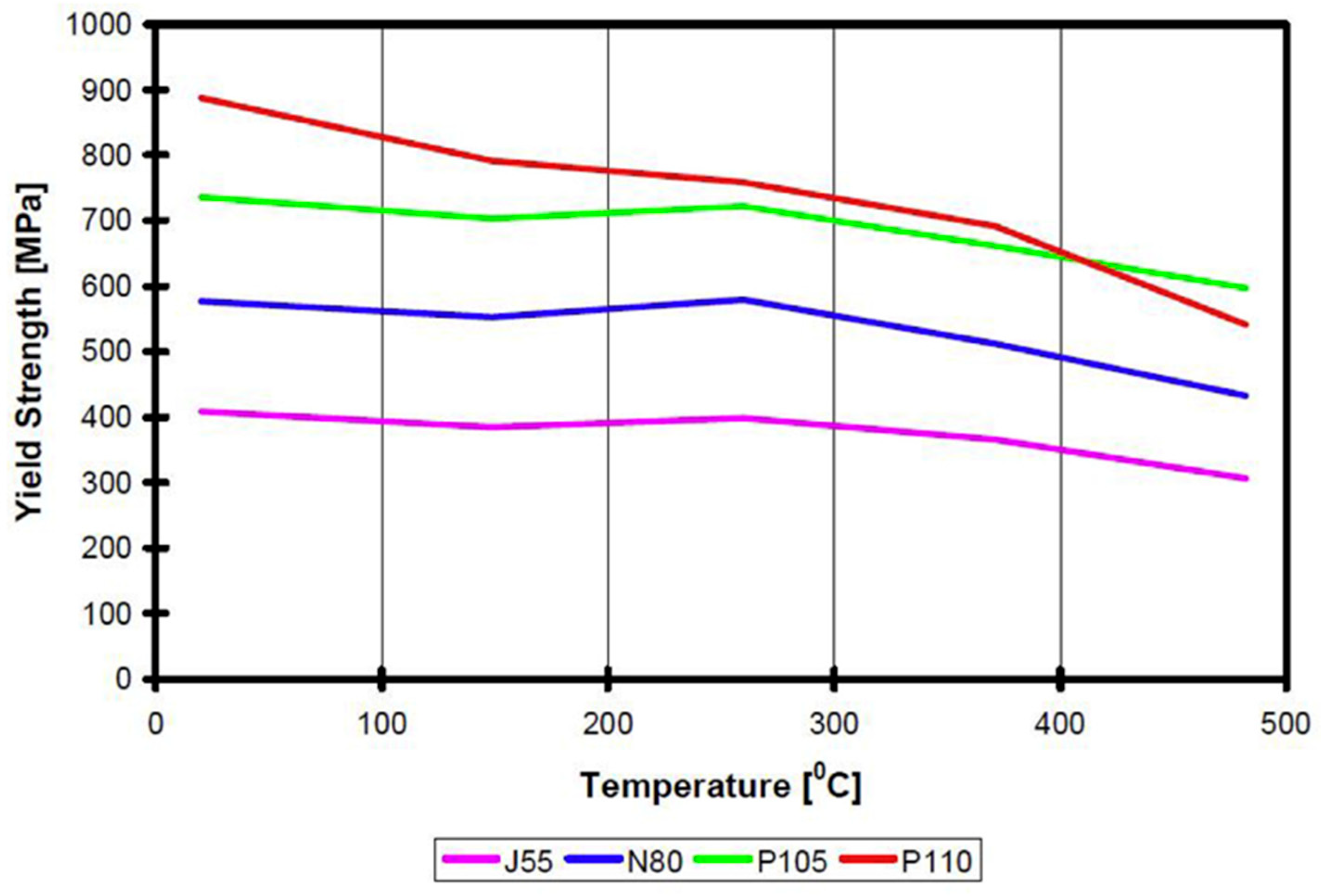

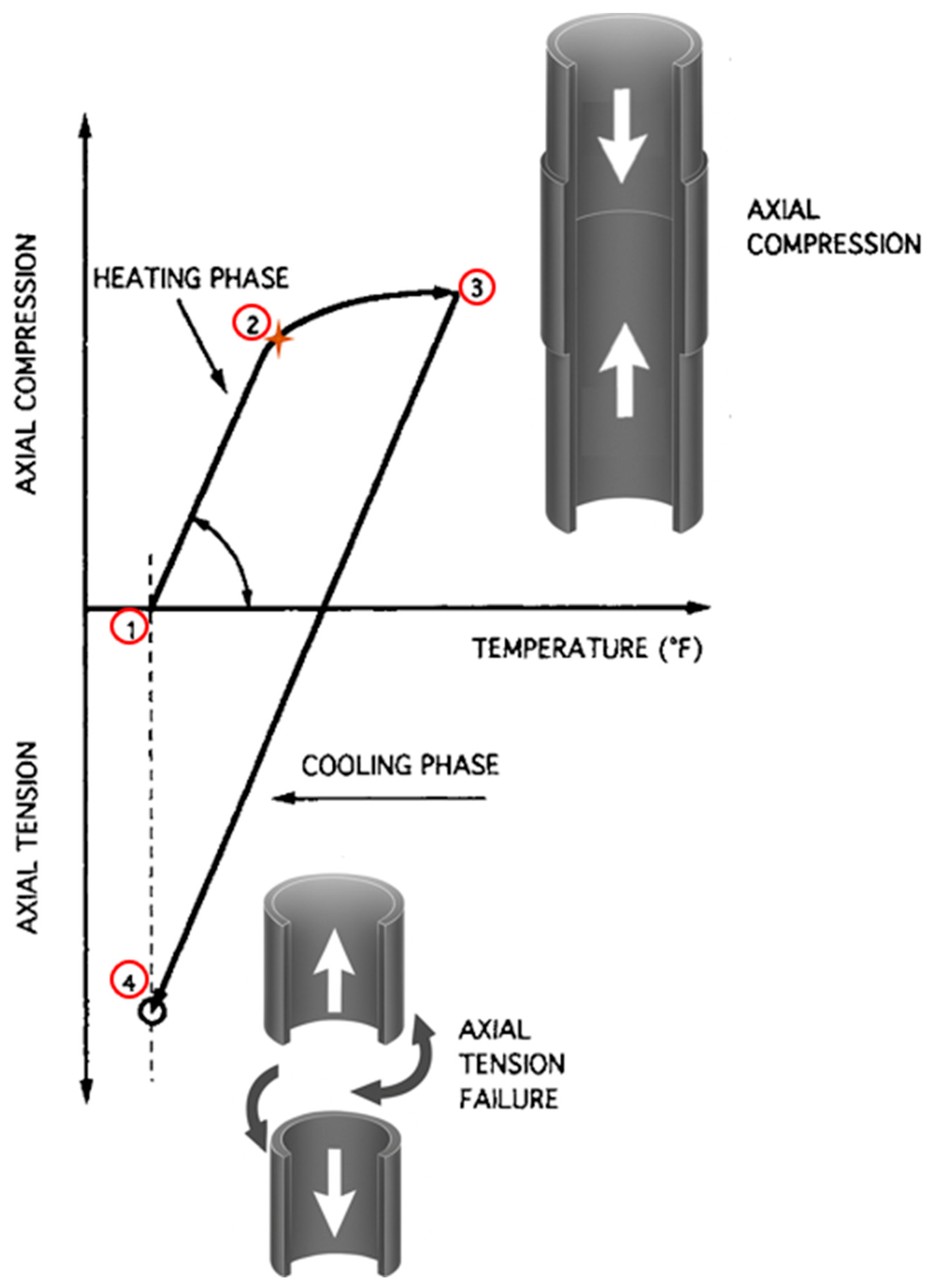

6.3. Thermal and Pressure Cycling Effects

6.4. Erosion and Wear

- Erosion: Erosion is the physical removal of material from a surface by the mechanical action of flowing fluids, especially those containing solid particles (e.g., sand produced from the reservoir, proppant flowback after fracturing, solids in drilling mud or injection water) [172,173,174].

- ○

- Mechanism: High-velocity fluid impingement or abrasive action of particles wears away the metal surface. Typically, occurs at points of high turbulence, flow direction change (bends, elbows, tees), restrictions (chokes, valves, perforation tunnels), or where flow impinges on a surface.

- ○

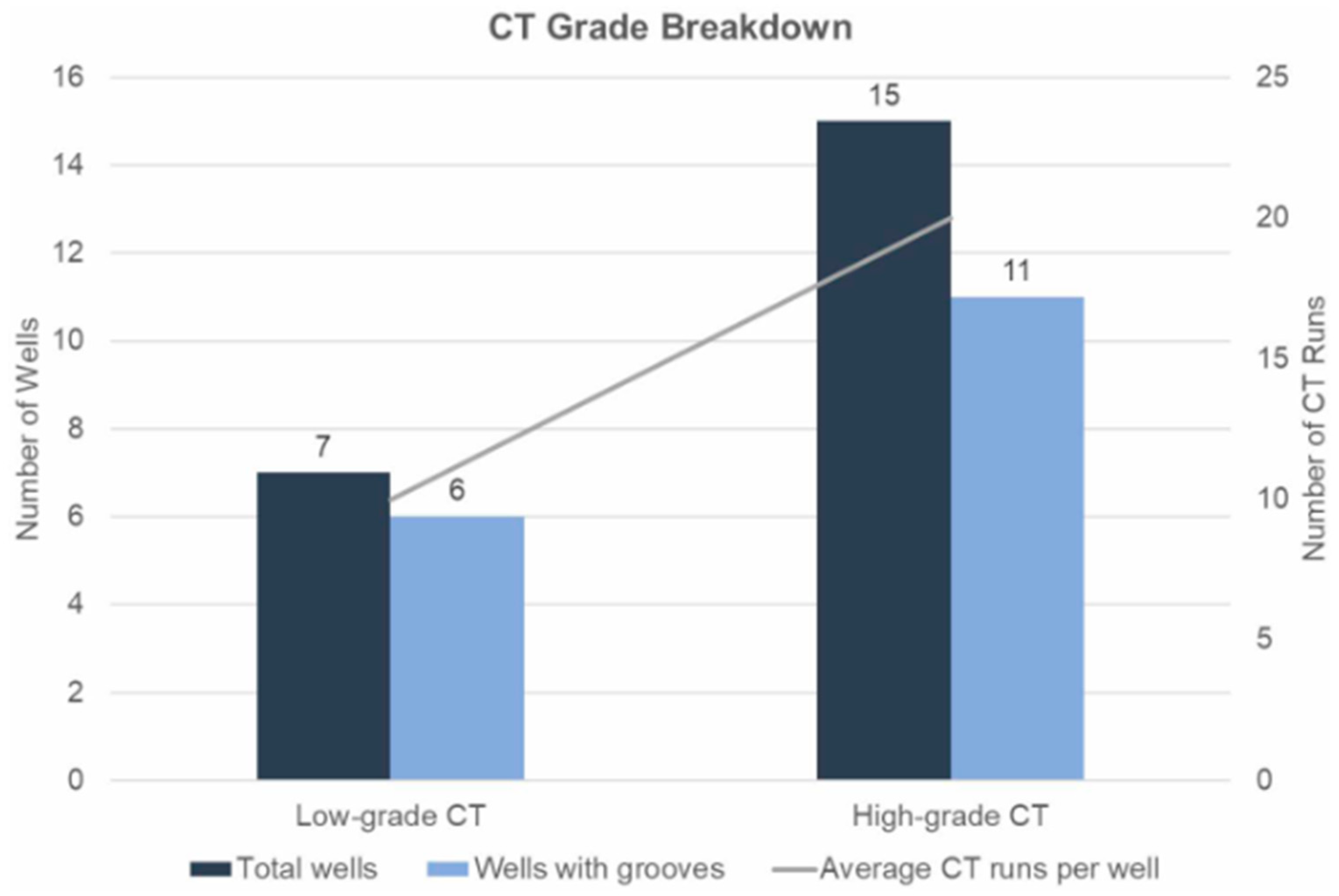

- Factors: Rate increases significantly with flow velocity (often exponentially), particle concentration, particle size/hardness/shape, and impingement angle. High flow rates in production tubing or near perforations are common areas for erosion. Erosive wear from repeated coiled tubing (CT) operations is a significant contributor to wellbore damage, especially when low-grade CT is used or when the number of runs per well is high. Figure 17 compares the number of wells with groove damage for low- and high-grade CT materials. The chart shows that although high-grade CT is more commonly used, it is also associated with a greater number of runs per well and a higher incidence of groove damage—highlighting the cumulative mechanical impact of repeated CT deployment on casing integrity.

- Erosion-Corrosion: This is a highly aggressive synergy where erosion and corrosion act together, resulting in metal loss rates far exceeding the sum of erosion and corrosion acting alone [175].

- ○

- Mechanism: The mechanical action of erosion (or even flow shear stress alone, sometimes called flow-accelerated corrosion) continuously removes any protective corrosion product layers (scales like FeCO3, FeS, or passive films) from the metal surface. This prevents the formation or reformation of these layers, constantly exposing fresh, active metal underneath to the corrosive environment, dramatically accelerating the overall metal loss rate.

- ○

- Occurrence: Common in high-velocity production streams containing both solid particles (sand) and corrosive species (CO2, H2S, organic acids). Particularly aggressive at points of high turbulence or impact (chokes, bends, valves, production nipples, near perforations).

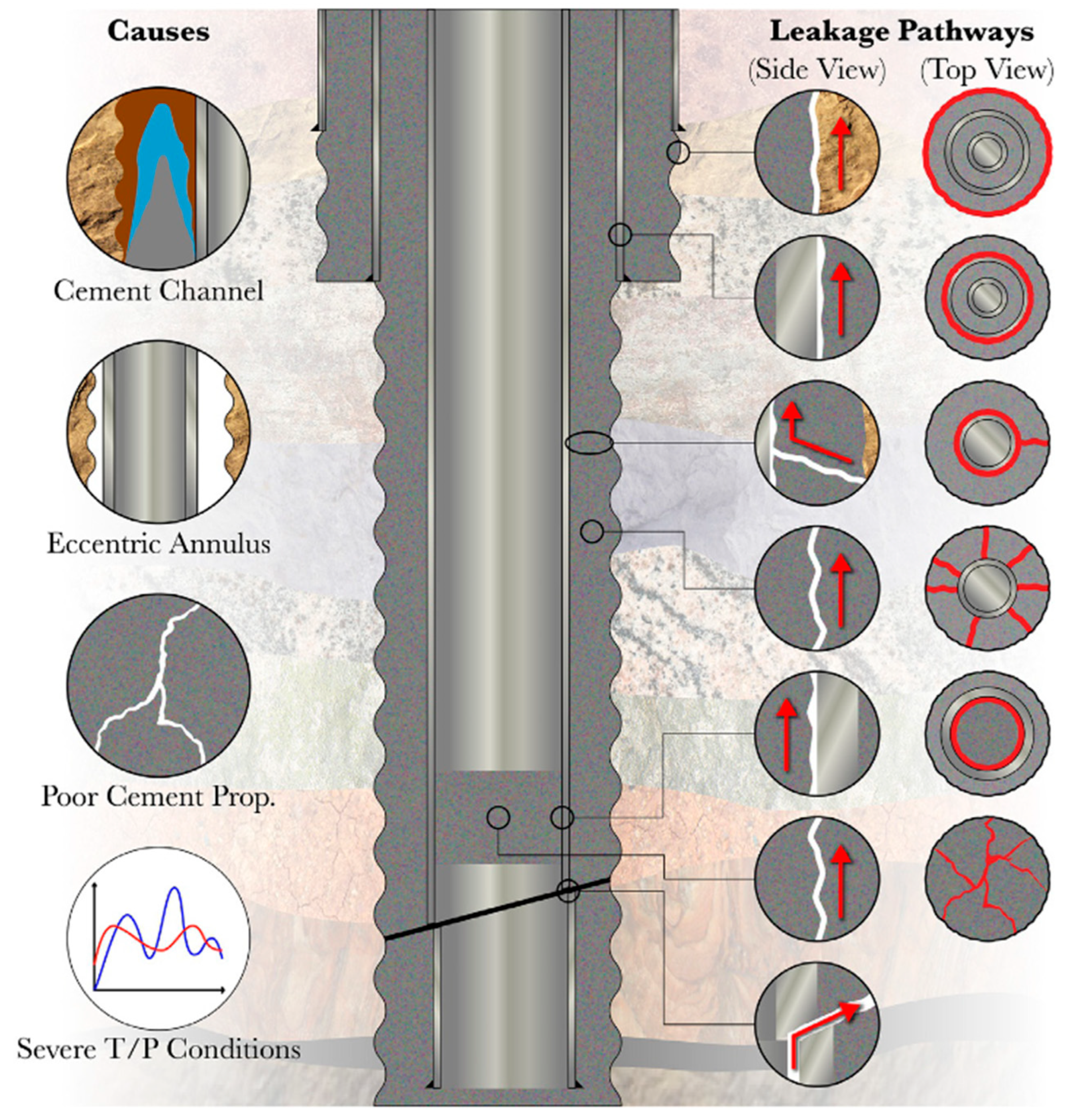

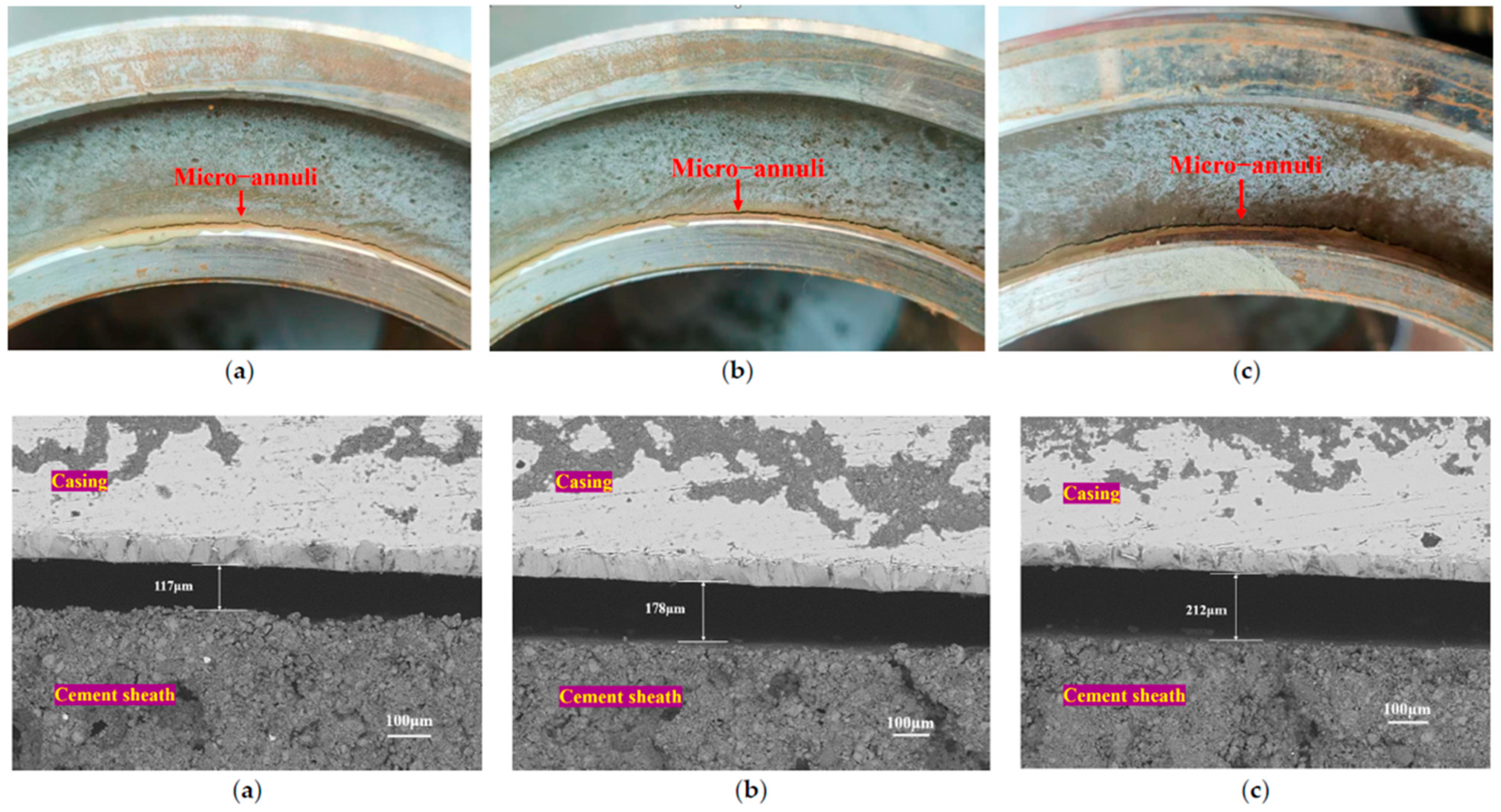

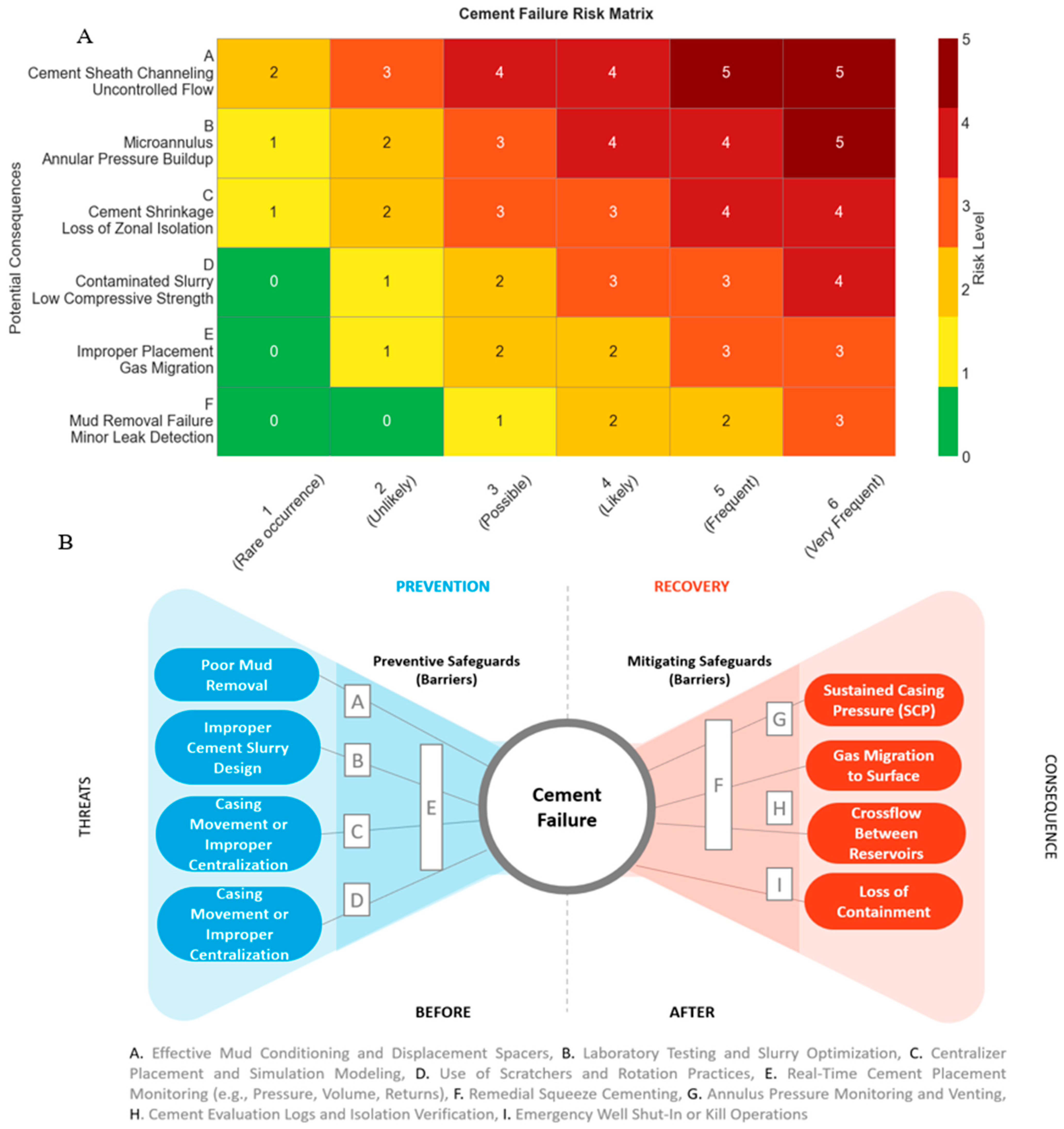

7. Cement Integrity Innovations

Cement Setting and Hydration

- Waiting-on-Cement (WOC) Time: This is the minimum period required for the cement to develop adequate compressive strength before proceeding with subsequent operations (e.g., nippling down the BOP, drilling out the shoe track, or perforating). WOC time depends on the slurry design, wellbore temperature, and the operational strength requirement—such as supporting casing weight, ensuring zonal isolation, or enabling pressure testing. Reference [192] provides standardized procedures for testing and reporting the compressive strength of well cements but does not prescribe a specific minimum threshold. In practice, thresholds such as 50 psi (0.34 MPa) for basic mechanical support or 500 psi (3.45 MPa) for formation integrity tests and leak-off tests are commonly used based on operational or regulatory requirements.

- Strength Development: Cement strength continues to increase beyond the minimum WOC time for days or weeks. Final strength and durability depend on full hydration and resistance to degradation over time.

- Bond Strength: The strength of the hydraulic and mechanical bond between the set cement and the casing and formation is critical for zonal isolation and structural support. Bond strength develops as the cement sets and is heavily influenced by the effectiveness of mud removal, centralization, and shrinkage control during placement.

8. Geomechanics of the Wellbore System

9. Digital Twin and Real-Time Integrity Monitoring

9.1. Digital Twin Technologies in Well Integrity Management

- Static data: as-built well designs, casing and tubing specifications, formation properties, material properties, well logs (e.g., caliper logs for cement design), and cementing job parameters.

- Dynamic data: sensor-derived real-time pressure, temperature, and flow rates, DTS/DAS readings, casing load records during drilling, cement bond logs, pressure test outcomes, corrosion monitoring data, and operational telemetry [20].

- Visualization platforms: interactive dashboards and 3D models presenting KPIs, alerts, and real-time diagnostics for field engineers and asset managers [209].

- Design/Construction: casing design, makeup torque values, steel/cement properties, centralizer placement, and pre-job simulations.

- Drilling and Cementing: caliper logs for hole geometry, real-time ECDs, cement slurry density/yield, pressure test logs, and cement bond log evaluations.

- Operations: downhole sensors capturing pressure/temperature, load histories on casing and tubing, periodic NDT/inspection reports, and intervention history.

- Abandonment: plug placement verification, pressure isolation tests, and long-term monitoring setups.

9.2. Technical Challenges and Readiness of Digital Twins

- Data interoperability: integrating diverse data types (e.g., DAS, E-log, cement bond logs) across vendors and lifecycle stages.

- Model calibration and validation: real-world conditions often deviate from assumptions in simulations, requiring regular updates and data assimilation.

- Sensor reliability and coverage: downhole sensors are expensive and can fail, limiting spatial and temporal resolution.

- AI interpretability: black-box predictions from ML can be difficult to explain or trust without physical validation or explainable AI.

- Cybersecurity and data governance: securing massive data flows and defining access across stakeholders is critical, especially for cross-operator collaborations.

- Low for fully autonomous digital twins with real-time control capabilities.

- Moderate for predictive integrity tools and scenario-based simulation.

- High for dashboard-based visualization and data aggregation platforms [202].

10. Smart Monitoring and AI for Integrity

Integration Monitoring Tools

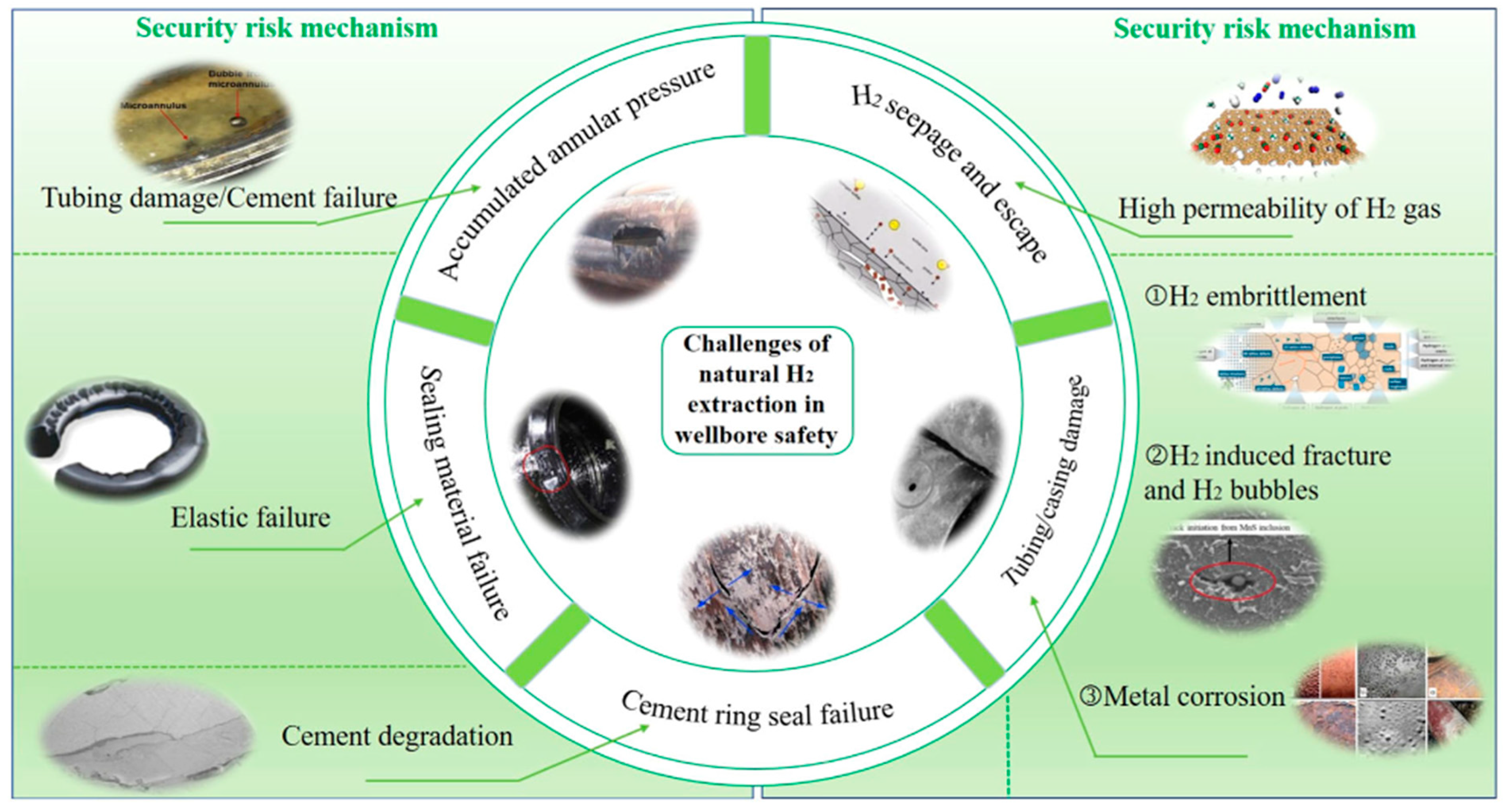

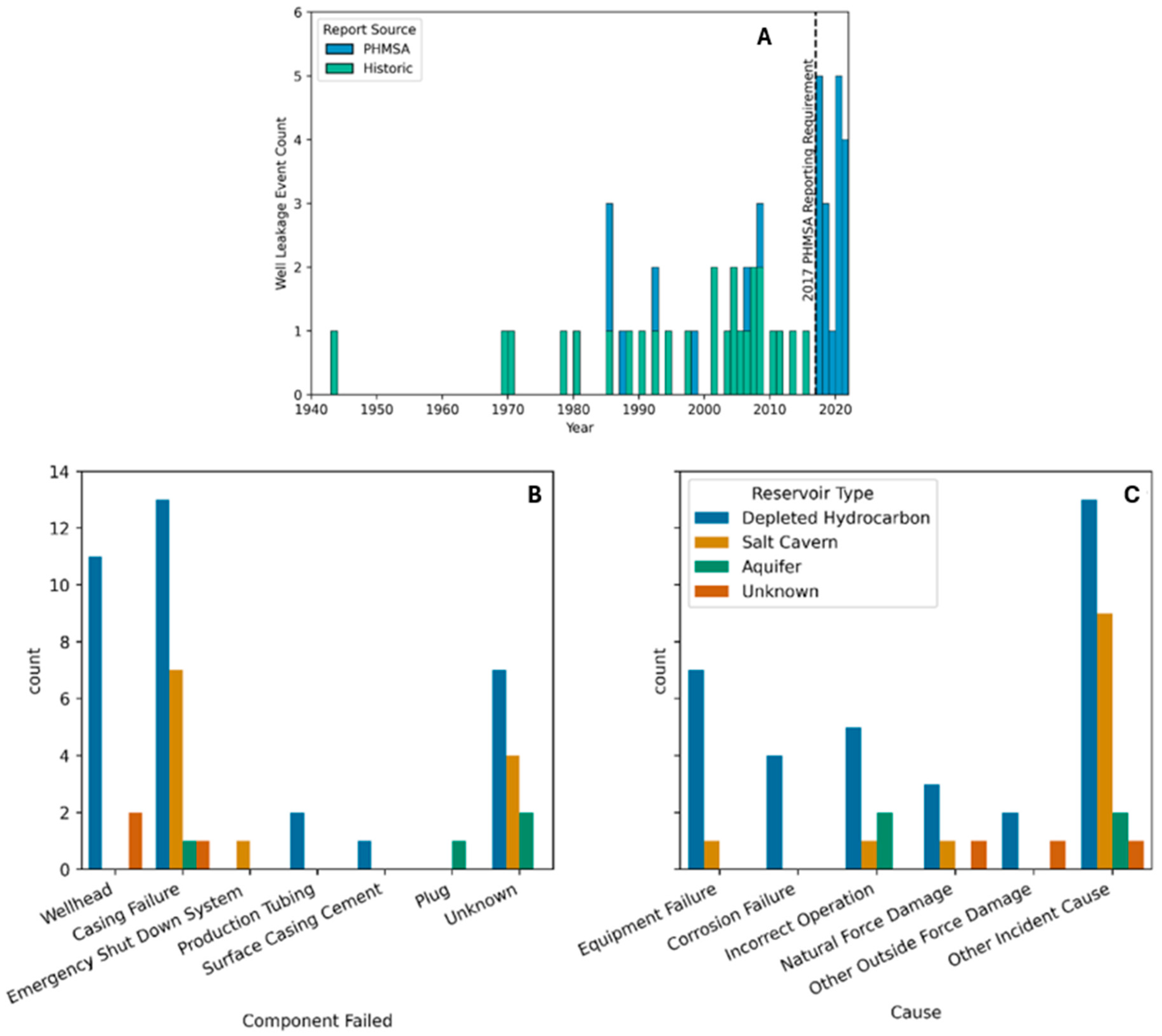

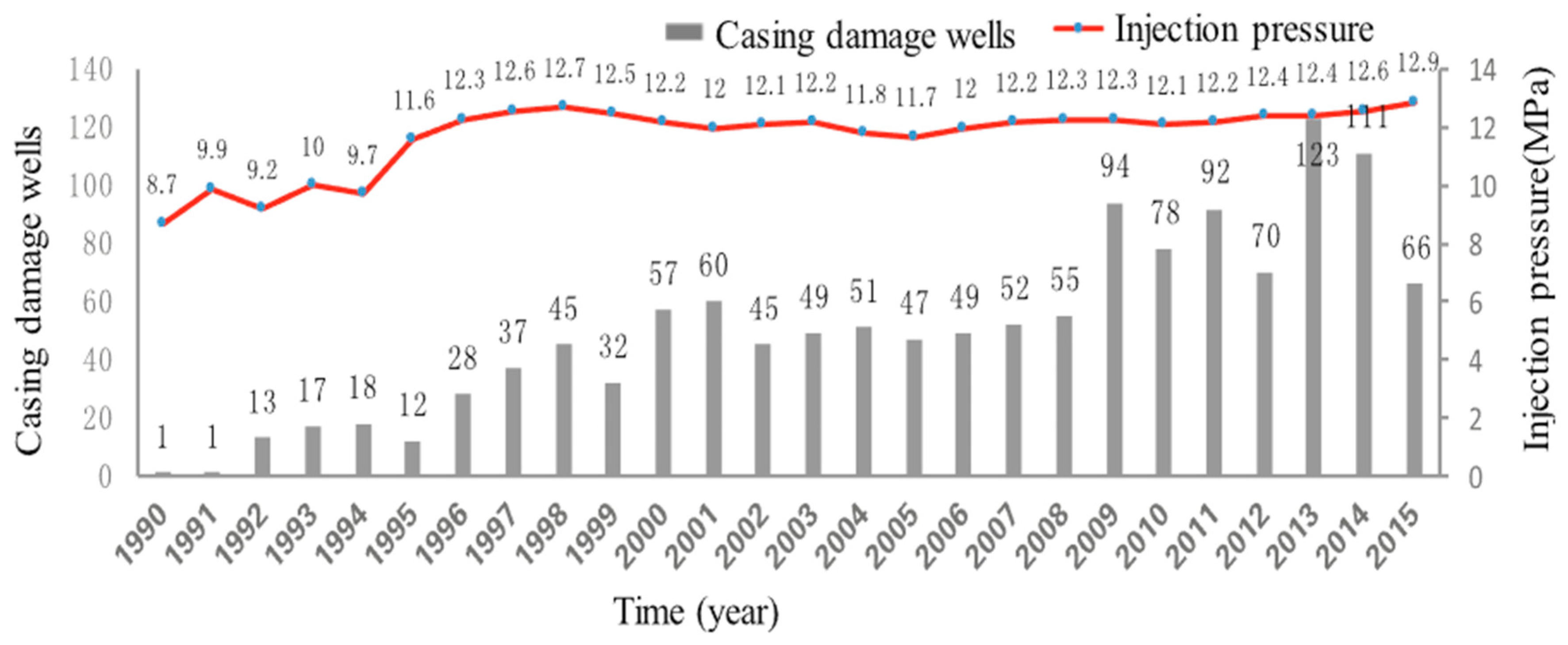

11. Storage Integrity in CO2, H2, and CH4 Injection Wells

- Enhanced Oil Recovery:

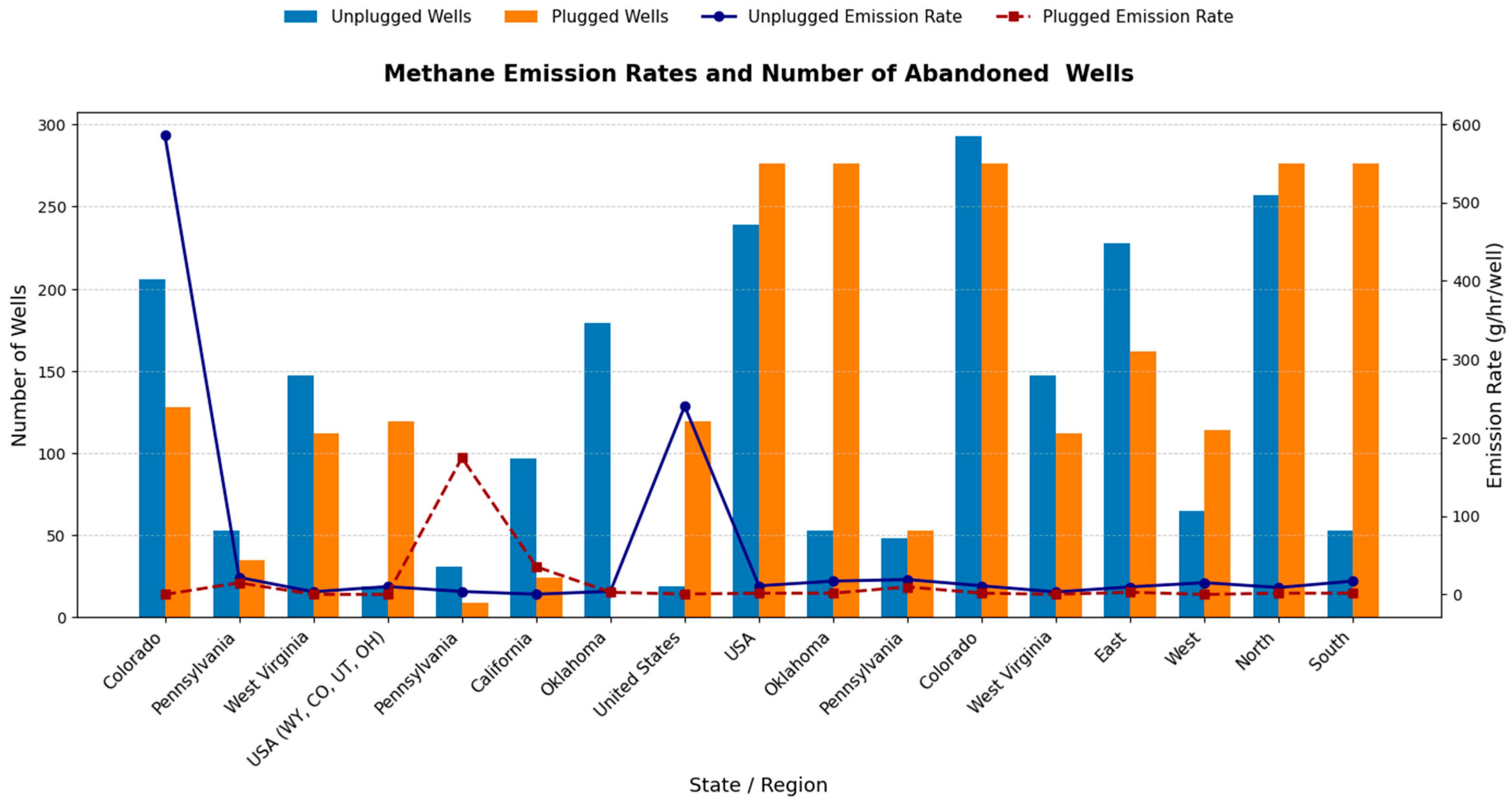

12. Legacy and Orphaned Wells

13. Simulation Tools and Integrity Modeling

14. Design and Operational Recommendations

15. Conclusions

16. Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Oziegbe Iriogbe, H.; Ebeh, C.O.; Onita, F.B. Well integrity management and optimization: A review of techniques and tools. Int. J. Sch. Res. Rev. 2024, 5, 79–87. [Google Scholar] [CrossRef]

- ISO/TS 16530-2; Well Integrity. Part 2: Well Integrity for the Operational Phase. ISO: Geneva, Switzerland, 2014. Available online: https://www.iso.org/standard/57056.html (accessed on 26 April 2025).

- Ibukun, M.; Elyan, E.; Amish, M.; Njuguna, J.; Oluyemi, G.F. A Review of Well Life Cycle Integrity Challenges in the Oil and Gas Industry and Its Implications for Sustained Casing Pressure (SCP). Energies 2024, 17, 5562. [Google Scholar] [CrossRef]

- Maury Fernandez, D.; Emadi, H.; Hussain, A.; Thiyagarajan, S.R. A holistic review on wellbore integrity challenges associated with underground hydrogen storage. Int. J. Hydrogen Energy 2024, 57, 240–262. [Google Scholar] [CrossRef]

- Dusseault, M.B.; Gray, M.N.; Nawrocki, P.A. Why Oilwells Leak: Cement Behavior and Long-Term Consequences. In Proceedings of the International Oil and Gas Conference and Exhibition in China, IOGCEC, Beijing, China, 7–10 November 2000; pp. 623–630. [Google Scholar] [CrossRef]

- Skogdalen, J.E.; Utne, I.B.; Vinnem, J.E. Developing safety indicators for preventing offshore oil and gas deepwater drilling blowouts. Saf. Sci. 2011, 49, 1187–1199. [Google Scholar] [CrossRef]

- King, G.E.; Valencia, R.L. Environmental Risk and Well Integrity of Plugged and Abandoned Wells. In Proceedings of the SPE Annual Technical Conference and Exhibition, Amsterdam, The Netherlands, 27–29 October 2014; Volume 6, pp. 4852–4868. [Google Scholar] [CrossRef]

- Yakoot, M.S.; Elgibaly, A.A.; Ragab, A.M.S.; Mahmoud, O. Well integrity management in mature fields: A state-of-the-art review on the system structure and maturity. J. Pet. Explor. Prod. 2021, 11, 1833–1853. [Google Scholar] [CrossRef]

- Fleckenstein, W.W.; Eustes, A.W.; Miller, M.G. Burst-Induced Stresses in Cemented Wellbores. SPE Drill. Complet. 2001, 16, 74–82. [Google Scholar] [CrossRef]

- Kiran, R.; Teodoriu, C.; Dadmohammadi, Y.; Nygaard, R.; Wood, D.; Mokhtari, M.; Salehi, S. Identification and evaluation of well integrity and causes of failure of well integrity barriers (A review). J. Nat. Gas. Sci. Eng. 2017, 45, 511–526. [Google Scholar] [CrossRef]

- Nygaard, R.; Salehi, S.; Weideman, B.; Lavoie, R. Effect of Dynamic Loading on Wellbore Leakage for the Wabamun Area CO2-Sequestration Project. J. Can. Pet. Technol. 2014, 53, 69–82. [Google Scholar] [CrossRef]

- Alberdi-Pagola, P.; Fischer, G. Review of Integrity Loss Detection and Quantification Due to Cracking in Cemented Wells. SPE J. 2023, 28, 965–982. [Google Scholar] [CrossRef]

- Vrålstad, T.; Skorpa, R.; Werner, B. Experimental Studies on Cement Sheath Integrity During Pressure Cycling. In Proceedings of the SPE/IADC Drilling Conference, The Hague, The Netherlands, 5–7 March 2019. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, D.; Wang, J. New Model for Prediction of Sustained Casing Pressure of Deepwater Wells. In Proceedings of the 30th International Ocean and Polar Engineering Conference, Virtual, 11–16 October 2020. [Google Scholar]

- Davies, R.J.; Almond, S.; Ward, R.S.; Jackson, R.B.; Adams, C.; Worrall, F.; Herringshaw, L.G.; Gluyas, J.G.; Whitehead, M.A. Oil and gas wells and their integrity: Implications for shale and unconventional resource exploitation. Mar. Pet. Geol. 2014, 56, 239–254. [Google Scholar] [CrossRef]

- NORSOK D-010; Well Integrity in Drilling and Well Operations. Standards Norway: Oslo, Norway, 2021. Available online: https://online.standard.no/en/norsok-d-010-2021 (accessed on 26 April 2025).

- Solovyeva, V.A.; Almuhammadi, K.H.; Badeghaish, W.O. Current Downhole Corrosion Control Solutions and Trends in the Oil and Gas Industry: A Review. Materials 2023, 16, 1795. [Google Scholar] [CrossRef]

- Arjomand, E.; Bennett, T.; Nguyen, G.D. Evaluation of cement sheath integrity subject to enhanced pressure. J. Pet. Sci. Eng. 2018, 170, 1–13. [Google Scholar] [CrossRef]

- Jackson, R.B.; Vengosh, A.; Darrah, T.H.; Warner, N.R.; Down, A.; Poreda, R.J.; Osborn, S.G.; Zhao, K.; Karr, J.D. Increased stray gas abundance in a subset of drinking water wells near Marcellus shale gas extraction. Proc. Natl. Acad. Sci. USA 2013, 110, 11250–11255. [Google Scholar] [CrossRef]

- Semwogerere, D.; Sangesland, S.; Vatn, J.; Pavlov, A.; Colombo, D. Well integrity and late life extension—A current industry state of practice and literature review. Geoenergy Sci. Eng. 2025, 244, 213419. [Google Scholar] [CrossRef]

- API STD 65-2; Isolating Potential Flow Zones During Well Construction. API Publishing Services: Washington, DC, USA, 2010.

- Askari, M.; Aliofkhazraei, M.; Jafari, R.; Hamghalam, P.; Hajizadeh, A. Downhole corrosion inhibitors for oil and gas production—A review. Appl. Surf. Sci. Adv. 2021, 6, 100128. [Google Scholar] [CrossRef]

- Patel, H.; Salehi, S.; Ahmed, R.; Teodoriu, C. Review of elastomer seal assemblies in oil & gas wells: Performance evaluation, failure mechanisms, and gaps in industry standards. J. Pet. Sci. Eng. 2019, 179, 1046–1062. [Google Scholar] [CrossRef]

- Jaculli, M.A.; Mendes, R.P.; Miura, K. Methodology for Assessing Wellhead Integrity During Its Life Cycle. In Proceedings of the ASME 2020 39th International Conference on Ocean, Offshore and Arctic Engineering, Virtual, 3–7 August 2020. [Google Scholar]

- Salem, A.M.; Yakoot, M.S.; Mahmoud, O. A novel machine learning model for autonomous analysis and diagnosis of well integrity failures in artificial-lift production systems. Adv. Geo-Energy Res. 2022, 6, 123–142. [Google Scholar] [CrossRef]

- Sun, B.; Zhang, M.; Sun, Q.; Zhong, J.; Shao, G. Review on natural hydrogen wells safety. Nat. Commun. 2025, 16, 369. [Google Scholar] [CrossRef]

- Patel, H.; Salehi, S. Development of an Advanced Finite Element Model and Parametric Study to Evaluate Cement Sheath Barrier. J. Energy Resour. Technol. Trans. ASME 2019, 141, 1–21. [Google Scholar] [CrossRef]

- Yakoot, M.S.; Ragab, A.M.S.; Mahmoud, O. Machine Learning Application for Gas Lift Performance and Well Integrity. In Proceedings of the Society of Petroleum Engineers—SPE Europec Featured at 82nd EAGE Conference and Exhibition, EURO, Amsterdam, The Netherlands, 18–21 October 2021. [Google Scholar] [CrossRef]

- Law, R. The Ekofisk Bravo Blowout, 1977. In Oil Spill Science and Technology; Gulf Professional Publishing: Largo, FL, USA, 2011; pp. 1107–1108. [Google Scholar] [CrossRef]

- Olberg, T.; Gilhuus, T.; Leraand, F.; Haga, J. Re-Entry and Relief Well Drilling To Kill an Underground Blowout in a Subsea Well: A Case History of Well 2/4-14. In Proceedings of the SPE/IADC Drilling Conference, Amsterdam, The Netherlands, 11–14 March 1991; pp. 775–783. [Google Scholar] [CrossRef]

- Pettersen, G.; Ytredal, E.B. The Snorre A Incident 28 November 2004: Lessons Learned. In Proceedings of the SPE International Health, Safety & Environment Conference, Abu Dhabi, United Arab Emirates, 2–4 April 2006. SPE Reprint Series. [Google Scholar] [CrossRef]

- Hayes, J. Operator competence and capacity—Lessons from the Montara blowout. Saf. Sci. 2012, 50, 563–574. [Google Scholar] [CrossRef]

- Stacey, A.; Ersdal, G. Structural Integrity Management of Ageing Offshore Structures: A Regulatory Perspective. In Ageing and Life Extension of Offshore Facilities; ASME: New York, NY, USA, 2022; pp. 5–20. [Google Scholar] [CrossRef]

- Johansen, I.L.; Rausand, M. Barrier management in the offshore oil and gas industry. J. Loss Prev. Process Ind. 2015, 34, 49–55. [Google Scholar] [CrossRef]

- Tangstad, J.R. Assessment of Dynamic Barriers in Oil/Gas Well Operations: Vurdering av Dynamiske Barrierer i Olje/Gass Brønner. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2014; p. 104. [Google Scholar]

- API RP90. Available online: https://www.api.org/products-and-services/standards/important-standards-announcements/90-1 (accessed on 26 April 2025).

- API RP 96; Deepwater Well Design and Construction. API: Washington, DC, USA, 2013. Available online: https://www.apiwebstore.org/standards/96?utm_term=api%20rp%2096&utm_campaign=US+Brand&utm_source=bing&utm_medium=ppc&hsa_acc=4890137417&hsa_cam=11564532636&hsa_grp=1355700341218503&hsa_ad=&hsa_src=o&hsa_tgt=kwd-84732449229502:loc-4126&hsa_kw=api%20rp%2096&hsa_mt=e&hsa_net=adwords&hsa_ver=3&msclkid=b62f7a421336112d1bde124cfdb36c01 (accessed on 26 April 2025).

- ISO 16530-1; Petroleum and Natural Gas Industries—Well Integrity—Part 1: Life Cycle Governance. ISO: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/63192.html (accessed on 26 April 2025).

- Anunciação Jaculli, M.; Choueri, N.; da Mata, C.R.; Aparecida Silva Leite, A.G.; Pelaquim Mendes, J.R.; Colombo, D. Well safety and integrity evaluation of offshore wells: A review of past, present, and future. J. Pet. Sci. Eng. 2022, 212, 110329. [Google Scholar] [CrossRef]

- Well Life Cycle Integrity Guidelines—Issue 4. Available online: https://oeuk.org.uk/product/well-life-cycle-integrity-guidelines-issue-4/ (accessed on 19 April 2025).

- Zhang, Q.; Lian, Z.; Lin, T. Prediction of residual burst strength of worn casing by theoretical and numerical modelling. Int. J. Press. Vessel. Pip. 2020, 188, 104195. [Google Scholar] [CrossRef]

- The Lakeview Gusher. Available online: http://www.sjvgeology.org/history/lakeview.html (accessed on 19 April 2025).

- Oil & Gas: Fire in the Desert|TIME. Available online: https://time.com/archive/6623264/oil-gas-fire-in-the-desert/ (accessed on 19 April 2025).

- Soto, L.A.; Botello, A.V.; Licea-Durán, S.; Lizárraga-Partida, M.L.; Yáñez-Arancibia, A. The environmental legacy of the Ixtoc-I oil spill in Campeche Sound, southwestern Gulf of Mexico. Front. Mar. Sci. 2014, 1, 116502. [Google Scholar] [CrossRef]

- Whyte, D.; Tucker, E. Regulating Safety, Regulating Profit: Cost-Cutting, Injury and Death in the British North Sea After Piper Alpha; Routledge: Abingdon, UK, 2016; pp. 186–210. [Google Scholar]

- Tingay, M.R.P.; Rudolph, M.L.; Manga, M.; Davies, R.J.; Wang, C.-Y. Initiation of the Lusi mudflow disaster. Nat. Geosci. 2015, 8, 493–494. [Google Scholar] [CrossRef]

- Response to the Montara Wellhead Platform Incident|Australian Maritime Safety Authority. Available online: https://www.amsa.gov.au/marine-environment/incidents-and-exercises/response-montara-wellhead-platform-incident (accessed on 19 April 2025).

- Gibson, M. HPHT Field Development Experience Transfer. In Proceedings of the Society of Petroleum Engineers-IADC/SPE Asia Pacific Drilling Technology Conference, Singapore, 22–24 August 2016. [Google Scholar] [CrossRef]

- CSB Issues Final Report on Fatal Gas Well Blowout—ProQuest. Available online: https://www.proquest.com/openview/78d16680837e9cc9810d62a81bdb570c/1?cbl=47267&pq-origsite=gscholar (accessed on 19 April 2025).

- Gao, B.; Wang, L.; Hu, T. Testing String Dynamics When Jarring Stuck Packer. In Proceedings of the 29th International Ocean and Polar Engineering Conference, Honolulu, HI, USA, 16–21 June 2019. [Google Scholar]

- Vrålstad, T.; Saasen, A.; Fjær, E.; Øia, T.; Ytrehus, J.D.; Khalifeh, M. Plug & abandonment of offshore wells: Ensuring long-term well integrity and cost-efficiency. J. Pet. Sci. Eng. 2019, 173, 478–491. [Google Scholar] [CrossRef]

- Mohammed, A.I. An Investigation of Casing Structural Integrity in Shale Gas Horizontal Wells During Hydraulic Fracturing Using FEA and Machine Learning Algorithms. Ph.D. Thesis, Robert Gordon University, Aberdeen, UK, 2021. [Google Scholar]

- Alsubaih, A.A.; Nygaard, R. Shale Instability of Deviated Wellbores in Southern Iraqi Fields. Master’s Thesis, Missouri University of Science and Technology, Rolla, MO, USA, 2016. [Google Scholar]

- Godwin, W.H.; Cole, W.F. Drilling Hazards; Springer: Cham, Switzerland, 2018; pp. 244–248. [Google Scholar] [CrossRef]

- Nelson, E.B.; Guillot, D. Well Cementing, 2nd ed.; Schlumberger: Athens, TX, USA, 2006. [Google Scholar]

- Ma, L.; Zhang, K.; Xie, J.; Yuan, L.; Geng, H.; Ning, K.; Ma, L.; Zhang, K.; Xie, J.; Yuan, L.; et al. Research Progress and Prospect of Well Integrity Technology. J. Power Energy Eng. 2020, 8, 45–54. [Google Scholar] [CrossRef]

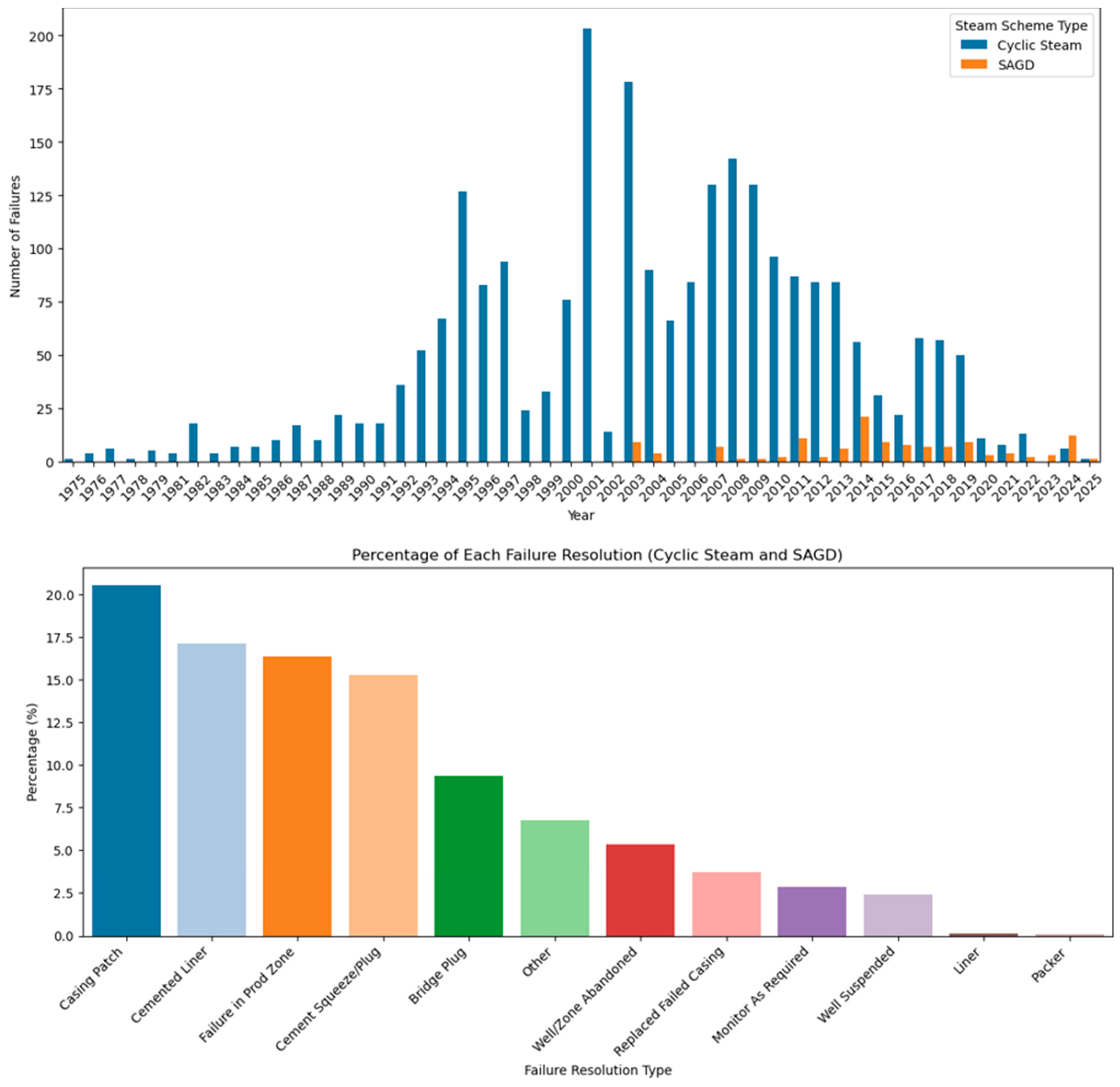

- Wu, J.; Knauss, M.E.; Kritzler, T. Casing Failures in Cyclic Steam Injection Wells. In Proceedings of the Society of Petroleum Engineers—IADC/SPE Asia Pacific Drilling Technology Conference 2008—“Drilling Technology to Access Future Energy Demand and Environmental Challenges”, Jakarta, Indonesia, 25–27 August 2008; pp. 26–32. [Google Scholar] [CrossRef]

- Strazisar, B.; Kutchko, B.; Huerta, N. Chemical Reactions of Wellbore Cement Under CO2 Storage Conditions: Effects of Cement Additives. Energy Procedia 2009, 1, 3603–3607. [Google Scholar] [CrossRef]

- Eme, C.; Dosunmu, A.; Nweke, F.; Udom, G.; Anyanwu, C.; Charles, E. Caprock Integrity Analysis during Hydraulic Fracturing For Produced Water Disposal: A Case Study in Niger-Delta. IOSR J. Appl. Geol. Geophys. 2019, 7, 17–24. [Google Scholar] [CrossRef]

- Zhang, K.; Liu, X.F.; Wang, D.B.; Zheng, B.; Chen, T.H.; Wang, Q.; Bai, H.; Yao, E.D.; Zhou, F.J. A review of reservoir damage during hydraulic fracturing of deep and ultra-deep reservoirs. Pet. Sci. 2024, 21, 384–409. [Google Scholar] [CrossRef]

- Settari, A. Reservoir Compaction. J. Pet. Technol. 2002, 54, 62–69. [Google Scholar] [CrossRef]

- Khalifeh, M.; Saasen, A. Introduction to Permanent Plug and Abandonment of Wells; Springer Nature: Dordrecht, The Netherlands, 2020; Volume 12. [Google Scholar] [CrossRef]

- Alberta Energy Regulator General Well Data|Alberta Energy Regulator. Available online: https://www.aer.ca/data-and-performance-reports/activity-and-data/lists-and-activities/general-well-data (accessed on 26 July 2025).

- Wang, Y.; Liu, K.; Gao, D. Investigation of the interface cracks on the cement sheath stress in shale gas wells during hydraulic fracturing. J. Pet. Sci. Eng. 2021, 205, 108981. [Google Scholar] [CrossRef]

- Zhu, H.; Lin, Y.; Zeng, D.; Zhang, D.; Chen, H.; Wang, W. Mechanism and prediction analysis of sustained casing pressure in “A” annulus of CO2 injection well. J. Pet. Sci. Eng. 2012, 92–93, 1–10. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, L.; Fan, J.; Zhang, X.; Liu, D.; Wang, D. A leakage diagnosis testing model for gas wells with sustained casing pressure from offshore platform. J. Nat. Gas. Sci. Eng. 2018, 55, 276–287. [Google Scholar] [CrossRef]

- Xu, R.; Wojtanowicz, A.K. Pressure buildup test analysis in wells with sustained casing pressure. J. Nat. Gas. Sci. Eng. 2017, 38, 608–620. [Google Scholar] [CrossRef]

- Wojtanowicz, A.K.; Nishikawa, S.; Rong, X. Diagnosis and Remediation of Sustained Casing Pressure in Wells; Final Report; Louisiana State University: Baton Rouge, LA, USA, 2021. [Google Scholar]

- Bourgoyne, A.T.; Stuart Scott, L.L.; Wojciech Manowski, L. A Review of Sustained Casing Pressure Occurring on the Ocs. Available online: https://www.bsee.gov/sites/bsee.gov/files/tap-technical-assessment-program/008de.pdf (accessed on 29 April 2025).

- Jónsson, M.Þ.; Pálsson, H.; Karlsdóttir, S.N. Structural Analysis of the Casings in High-Temperature Geothermal Wells. In Proceedings of the Deep Roots of Geothermal Systems (DRG) Final Meeting, Reykjavik, Iceland, 14 December 2017. [Google Scholar]

- Akpan, E.G. Wellhead Fatigue Response Affected by Seabed Interaction. Master’s Thesis, Memorial University of Newfoundland, St. John’s, NL, Canada, 2018. [Google Scholar]

- Sotoodeh, K. A Review of Valve Stem Sealing to Prevent Leakage from the Valve and Its Effect on Valve Operation. J. Fail. Anal. Prev. 2021, 21, 9–16. [Google Scholar] [CrossRef]

- Davies, D.; Al-Khelaiwi, F.; Muradov, K.; Qing, Y.; Rafiei, Y.; Aggrey, G.; Al-Mutairi, F. Applications of permanent sensors for real-time well management. Leading Edge 2008, 27, 1654–1661. [Google Scholar] [CrossRef]

- Farhadiroushan, M.; Parker, T.R.; Shatalin, S.; Chen, Z.; Gillies, A.; Aghayev, R.; Pérez, D.; Maxwell, J.; Milne, C. Integrated Distributed Strain Sensing for Wellbore and Reservoir Monitoring. In Distributed Acoustic Sensing in Borehole Geophysics; Wiley: Hoboken, NJ, USA, 2024; pp. 17–28. [Google Scholar] [CrossRef]

- Kaldal, G.S.; Jonsson, M.T.; Palsson, H.; Karlsdottir, S.N. Structural modeling of the casings in high temperature geothermal wells. Geothermics 2015, 55, 126–137. [Google Scholar] [CrossRef]

- Evans, G.W.; Harriman, D.W. Laboratory Tests on Collapse Resistance of Cemented Casing. In Proceedings of the Fall Meeting of the Society of Petroleum Engineers of AIME, San Antonio, TX, USA, 8–11 October 1972. [Google Scholar] [CrossRef]

- Yudovich, A.; Chin, L.Y.; Morgan, D.R. Casing Deformation In Ekofisk. In Proceedings of the Annual Offshore Technology Conference, Houston, TX, USA, 2–5 May 1988; pp. 63–72. [Google Scholar] [CrossRef]

- El-Sayed, A.A.H.; Khalaf, F. Resistance of Cemented Concentric Casing Strings Under Nonuniform Loading. SPE Drill. Eng. 1992, 7, 59–64. [Google Scholar] [CrossRef]

- Rodriguez, W.J.; Fleckenstein, W.W.; Eustes, A.W. Simulation of Collapse Loads on Cemented Casing Using Finite Element Analysis. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 5–8 October 2003. [Google Scholar] [CrossRef]

- Fleckenstein, W.W.; Eustes, A.W.; Rodriguez, W.J.; Berger, A.; Sanchez, F.J. AADE-05-NTCE-14 Cemented Casing: The True Stress Picture. Available online: https://www.aade.org/application/files/9215/7304/0396/AADE-05-NTCE-14_Fleckenstein.pdf (accessed on 16 May 2025).

- Fernandes, A.A.; Vanni, G.S.; Martinello, I.A.; de Souza Terra, F.; Sales, I.M.; Guedes, J.; da Silva Vasconcelos, K. Evolving well control procedures with MPD on floaters. In Proceedings of the Society of Petroleum Engineers—IADC/SPE Managed Pressure Drilling and Underbalanced Operations Conference and Exhibition, MPDU, Amsterdam, The Netherlands, 9–10 April 2019. [Google Scholar] [CrossRef]

- Tabatabaei, M.; Taleghani, A.D.; Ahmadi, M. Partial Annular Cracks around Cemented Casing Interfaces. In Proceedings of the 50th U.S. Rock Mechanics/Geomechanics Symposium, Houston, TX, USA, 26–29 June 2016. [Google Scholar]

- Berger, A.; Fleckenstein, W.W.; Eustes, A.W.; Thonhauser, G. Effect of Eccentricity, Voids, Cement Channels, and Pore Pressure Decline on Collapse Resistance of Casing. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 26–29 September 2004. [Google Scholar] [CrossRef]

- Ahmed, S.; Salehi, S. Failure mechanisms of the wellbore mechanical barrier systems: Implications for well integrity. J. Energy Resour. Technol. Trans. ASME 2021, 143, 073007. [Google Scholar] [CrossRef]

- Yuan, Z.; Schubert, J.; Teodoriu, C.; Gardoni, P. HPHT Gas Well Cementing Complications and its Effect on Casing Collapse Resistance. In Proceedings of the Society of Petroleum Engineers—SPE Oil and Gas India Conference and Exhibition, Mumbai, India, 28–30 March 2012; pp. 537–556. [Google Scholar] [CrossRef]

- Sun, R.; Yin, X.; Wang, B.; Zhang, G. Simultaneous inversion of petrophysical parameters based on Metropolis sampling algorithm. In Proceedings of the Society of Exploration Geophysicists International Exposition and 84th Annual Meeting SEG, Denver, CO, USA, 26–31 October 2014; pp. 2611–2615. [Google Scholar] [CrossRef]

- Huang, W.; Gao, D. A theoretical study of the critical external pressure for casing collapse. J. Nat. Gas. Sci. Eng. 2015, 27, 290–297. [Google Scholar] [CrossRef]

- Abdideh, M.; Hedayati Khah, S. Analytical and Numerical Study of Casing Collapse in Iranian Oil Field. Geotech. Geol. Eng. 2018, 36, 1723–1734. [Google Scholar] [CrossRef]

- Bastola, A.; Wang, J.; Mirzaee-Sisan, A.; Njuguna, J. Predicting Hydrostatic Collapse of Pipes Using Finite Element Analysis. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, San Francisco, CA, USA, 8–13 June 2014; p. V06AT04A048. [Google Scholar] [CrossRef]

- Fang, J.; Wang, Y.; Gao, D. On the collapse resistance of multilayer cemented casing in directional well under anisotropic formation. J. Nat. Gas. Sci. Eng. 2015, 26, 409–418. [Google Scholar] [CrossRef]

- Li, C.; Samuel, R. Casing Integrity: Modeling Strength Degradation. In Proceedings of the SPE/IADC Drilling Conference, Fort Worth, TX, USA, 1–3 March 2016. [Google Scholar] [CrossRef]

- Nawathe, S.; Panico, M.; Baker, D.; Huang, W. Effect of Residual Stresses on Causing Sour Burst Pressure. In Proceedings of the Corrosion 2016, Vancouver, BC, Canada, 6–10 March 2016. [Google Scholar]

- Dall’Acqua, D.; Hodder, M.; Kaiser, T.M.V. Burst and Collapse Responses of Production Casing in Thermal Applications. SPE Drill. Complet. 2013, 28, 93–104. [Google Scholar] [CrossRef]

- Kalil, I.A.; McSpadden, A.R. Casing Burst Stresses in Particulate-Filled Annuli: Where Is the Cement? SPE Drill. Complet. 2012, 27, 473–485. [Google Scholar] [CrossRef]

- Kuanhai, D.; Xie, P.; Yue, Y.; Dezhi, Z.; Qiong, L.; Yuanhua, L. Study on the effect of interface failure between casing and cement sheath on casing stress under non-uniform in-situ stress. Appl. Math. Model. 2021, 91, 632–652. [Google Scholar] [CrossRef]

- Lubinski, A.; Althouse, A.W.S. Helical Buckling of Tubing Sealed in Packers. J. Pet. Technol. 1962, 14, 655–670. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, D.; Fang, J. Mechanical characteristics analysis of casing-cement ring-formation multilayer composite system. Yingyong Lixue Xuebao/Chin. J. Appl. Mech. 2014, 31, 387–392. [Google Scholar] [CrossRef]

- Njuguna, J. Flutter prediction, suppression and control in aircraft composite wings as a design prerequisite: A survey. Struct. Control Health Monit. 2007, 14, 715–758. [Google Scholar] [CrossRef]

- Wu, J.; Knauss, M.E. Casing Temperature and Stress Analysis in Steam-Injection Wells. In Proceedings of the International Oil and Gas Conference and Exhibition in China 2006—Sustainable Growth for Oil and Gas 2006, Beijing, China, 5–7 December 2006; Volume 1, pp. 509–517. [Google Scholar] [CrossRef]

- Mitchell, S.; Moore, N.B.; Franks, J.; Liu, G.; Xiang, Y. Comparing the Results of a Full-Scale Buckling-Test Program to Actual Well Data: New Semiempirical Buckling Model and Methods of Reducing Buckling Effects. SPE Drill. Complet. 2011, 26, 578–596. [Google Scholar] [CrossRef]

- Menand, S.; Bjorset, A.; Macresy, L. A New Buckling Model Successfully Validated with Full-Scale Buckling Tests. In Proceedings of the 2011 AADE National Technical Conference & Exhibition, Houston, TX, USA, 12–14 April 2011; 3p. [Google Scholar] [CrossRef]

- Yan, W.; Zou, L.; Li, H.; Deng, J.; Ge, H.; Wang, H. Investigation of casing deformation during hydraulic fracturing in high geo-stress shale gas play. J. Pet. Sci. Eng. 2017, 150, 22–29. [Google Scholar] [CrossRef]

- Lian, Z.; Yu, H.; Lin, T.; Guo, J. A study on casing deformation failure during multi-stage hydraulic fracturing for the stimulated reservoir volume of horizontal shale wells. J. Nat. Gas. Sci. Eng. 2015, 23, 538–546. [Google Scholar] [CrossRef]

- Liu, W.; Yu, B.; Deng, J. Analytical method for evaluating stress field in casing-cement-formation system of oil/gas wells. Appl. Math. Mech. (Engl. Ed.) 2017, 38, 1273–1294. [Google Scholar] [CrossRef]

- Dusseault, M.B.; Bruno, M.S.; Barrera, J. Casing Shear: Causes, Cases, Cures. In Proceedings of the International Oil & Gas. Conference and Exhibition in China, IOGCEC, Beijing, China, 2–6 November 1998; Volume 1, pp. 337–345. [Google Scholar] [CrossRef]

- Gao, L.; Hsu, C.T.T. Fatigue of Concrete under Uniaxial Compression Cyclic Loading. Mater. J. 1998, 95, 575–581. [Google Scholar] [CrossRef]

- Lim, T.K.; Koska, R.; Tellier, E. Overcoming Installation Challenges to Wellhead and Conductor Fatigue. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Nantes, France, 9–14 June 2013; Volume 4B. [Google Scholar] [CrossRef]

- Payne, M.L. Fatigue Failure of API a-Round Casings in Drilling Service. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 3–6 October 1993. [Google Scholar]

- Liu, Z.; Samuel, R.; Gonzales, A.; Kang, Y. Analysis of Casing Fatigue Failure During Multistage Fracturing Operations. In Proceedings of the Society of Petroleum Engineers—Abu Dhabi International Petroleum Exhibition and Conference, ADIPEC, Abu Dhabi, United Arab Emirates, 11–15 November 2018. [Google Scholar] [CrossRef]

- Teodoriu, C.; Falcone, G. Comparing completion design in hydrocarbon and geothermal wells: The need to evaluate the integrity of casing connections subject to thermal stresses. Geothermics 2009, 38, 238–246. [Google Scholar] [CrossRef]

- Asbill, W.T.; Pattillo, P.D.; Rogers, W.M. Investigation of API 8 Round Casing Connection Performance—Part I: Introduction and Method of Analysis. J. Energy Resour. Technol. 1984, 106, 130–136. [Google Scholar] [CrossRef]

- Zhu, X.; Peng, P.; Jing, J.; Song, W. Research on casing erosion in reservoir section of gas storage wells based on Gas-solid Two-phase flow. Eng. Fail. Anal. 2022, 142, 106688. [Google Scholar] [CrossRef]

- Ji, N.; Wang, Z.; Jiang, W.; Wang, P.; Long, Y.; Wang, Z. Erosive wear behavior of casing steel during hydraulic fracturing operation in shale gas well. In Proceedings of the Fifth International Conference on Mechanical Engineering and Materials (ICMEM 2024), Nanchang, China, 5 March 2025; Volume 13547, pp. 444–450. [Google Scholar] [CrossRef]

- Ogunsesan, O.A.; Hossain, M.; Iyi, D.; Dhroubi, M.G. CFD modelling of pipe erosion due to sand transport. In Numerical Modelling in Engineering; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2019; pp. 274–289. [Google Scholar] [CrossRef]

- Clark, H.M.I. A comparison of the erosion rate of casing steels by sand-oil suspensions. Wear 1991, 150, 217–230. [Google Scholar] [CrossRef]

- Lin, T.; Zhang, Q.; Lian, Z.; Chang, X.; Zhu, K.; Liu, Y. Evaluation of casing integrity defects considering wear and corrosion—Application to casing design. J. Nat. Gas. Sci. Eng. 2016, 29, 440–452. [Google Scholar] [CrossRef]

- Mao, L.; Cai, M.; Wang, G. Effect of rotation speed on the abrasive–erosive–corrosive wear of steel pipes against steel casings used in drilling for petroleum. Wear 2018, 410–411, 1–10. [Google Scholar] [CrossRef]

- Mohammed, A.I.; Oyeneyin, B.; Atchison, B.; Njuguna, J. Casing structural integrity and failure modes in a range of well types—A review. J. Nat. Gas. Sci. Eng. 2019, 68, 102898. [Google Scholar] [CrossRef]

- Noshi, C.I.; Noynaert, S.F.; Schubert, J.J. Casing Failure Data Analytics: A Novel Data Mining Approach in Predicting Casing Failures for Improved Drilling Performance and Production Optimization. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 24–26 September 2018. [Google Scholar] [CrossRef]

- Porcaro, R.R.; Cândido, L.C.; Trindade, V.B.; De Faria, G.L.; Godefroid, L.B. Evaluation of standard API casing connections and parametric API Buttress improvement by finite element analysis. Mater. Res. 2017, 20, 130–137. [Google Scholar] [CrossRef]

- WestCan Oilfield Supply Home—WestCan Oilfield Supply. Available online: https://www.westcanoilfield.com/ (accessed on 24 June 2025).

- Jacobs, T. An Unconventional Challenge Can Casing Failures During Hydraulic Fracturing Be Stopped? J. Pet. Technol. 2020, 72, 26–32. [Google Scholar] [CrossRef]

- GATE Energy Common Failures in Oil and Gas Wells—GATE Energy. Available online: https://www.gate.energy/the-brainery/gat2004-gkp-2018-09/common-failures-in-oil-and-gas-wells (accessed on 26 July 2025).

- Xie, J.; Tao, G. Analysis of Casing Connections Subjected to Thermal Cycle Loading. In Proceedings of the 2010 SIMULIA Customer Conference, Providence, RI, USA, 25–27 May 2010; Dassault Systèmes: Providence, RI, USA, 2010; pp. 1–16. [Google Scholar]

- ISO/PAS 12835; Qualification of Casing Connections for Thermal Wells (First Edition). International Organization for Standardization: Geneva, Switzerland, 2013.

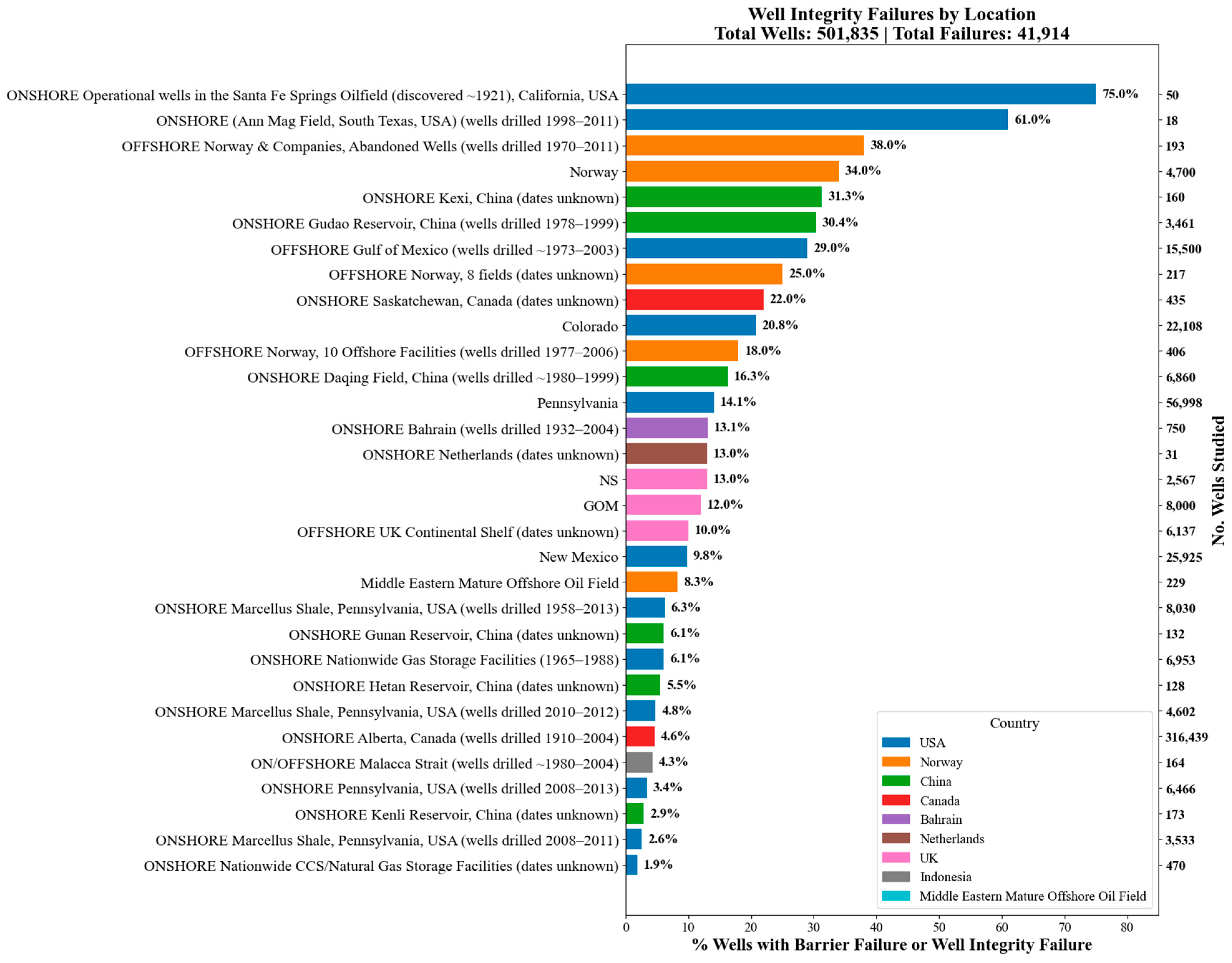

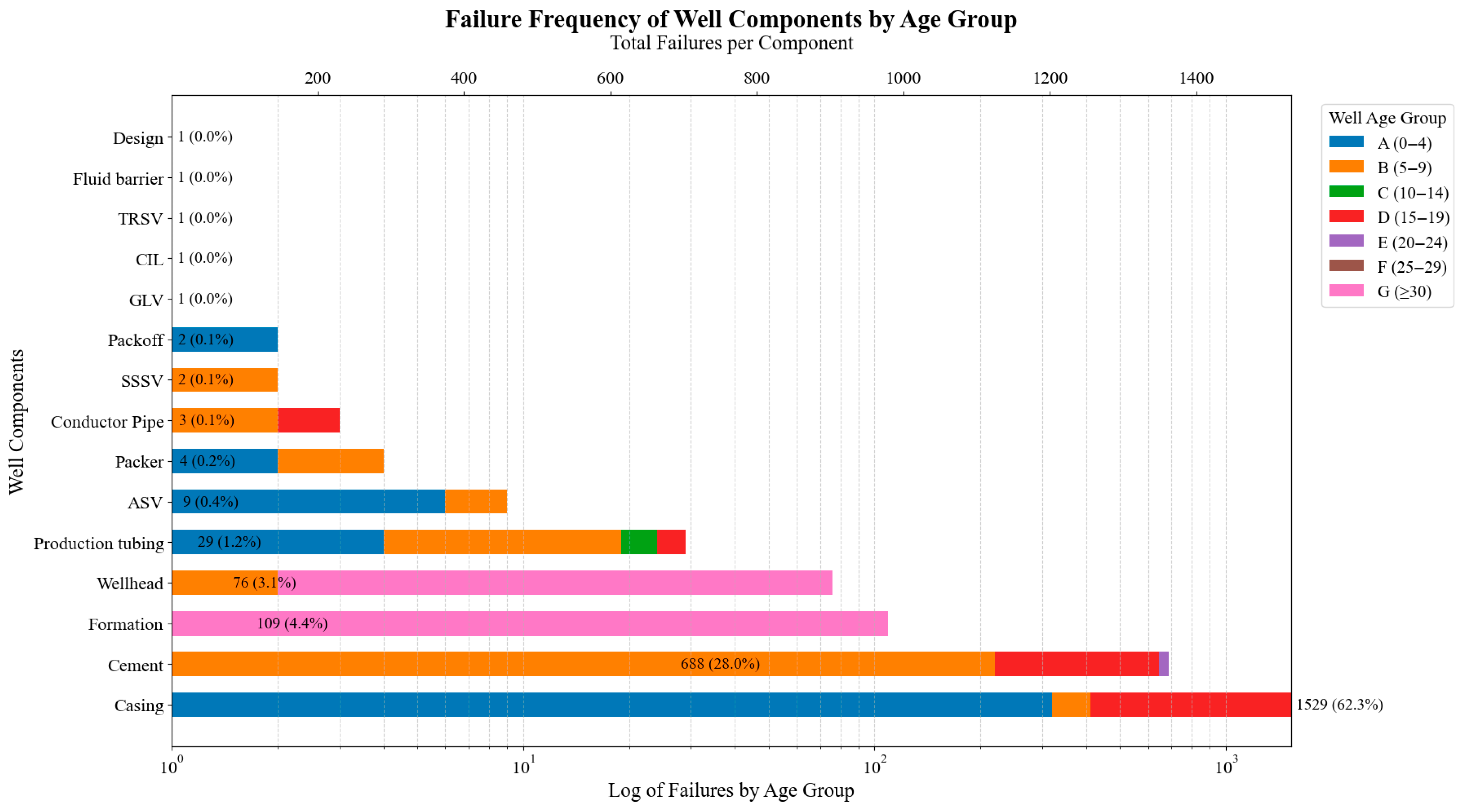

- King, G.E.; King, D.E. Environmental Risk Arising From Well-Construction Failure—Differences Between Barrier and Well Failure, and Estimates of Failure Frequency Across Common Well Types, Locations, and Well Age. SPE Prod. Oper. 2013, 28, 323–344. [Google Scholar] [CrossRef]

- Yang, B.; Xu, H.; Xiang, S.; Zhang, Z.; Su, K.; Yang, Y. Effects of Make-Up Torque on the Sealability of Sphere-Type Premium Connection for Tubing and Casing Strings. Processes 2023, 11, 256. [Google Scholar] [CrossRef]

- Quigley, M.S.; Lewis, D.B.; Boswell, R.S. Field Measurements of Casing Tension Forces. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 25–28 September 1994; pp. 357–364. [Google Scholar] [CrossRef]

- Yamada, K.; Furui, K. Efficient Integration Method of Large-Scale Reservoir Compaction and Small-Scale Casing Stability Models for Oilfield Casing Failure Analysis. In Proceedings of the Society of Petroleum Engineers—SPE Asia Pacific Oil and Gas Conference and Exhibition, APOGCE, Brisbane, Australia, 23–25 October 2018. [Google Scholar] [CrossRef]

- Cirimello, P.G.; Otegui, J.L.; Carfi, G.; Morris, W. Failure and integrity analysis of casings used for oil well drilling. Eng. Fail. Anal. 2017, 75, 1–14. [Google Scholar] [CrossRef]

- API RP 5C5; Recommended Practice on Procedures for Testing Casing and Tubing Connections (3rd ed.). American Petroleum Institute: Washington, DC, USA, 2017.

- ISO 13679; Petroleum and Natural Gas Industries—Procedures for Testing Casing and Tubing Connections (Second Edition). International Organization for Standardization: Geneva, Switzerland, 2019.

- Alsubaih, A.; Sepehrnoori, K.; Delshad, M. Development and Optimization of Self-Healing Cement for CO2 Injection and Storage Wells: Enhancing Long-Term Wellbore Integrity in Extreme Subsurface Conditions. Appl. Sci. 2025, 15, 5428. [Google Scholar] [CrossRef]

- Omosebi, O.; Maheshwari, H.; Ahmed, R.; Shah, S.; Osisanya, S.; Hassani, S.; DeBruijn, G.; Cornell, W.; Simon, D. Degradation of well cement in HPHT acidic environment: Effects of CO2 concentration and pressure. Cem. Concr. Compos. 2016, 74, 54–70. [Google Scholar] [CrossRef]

- Kutchko, B.G.; Strazisar, B.R.; Dzombak, D.A.; Lowry, G.V.; Thauiow, N. Degradation of well cement by CO2 under geologic sequestration conditions. Environ. Sci. Technol. 2007, 41, 4787–4792. [Google Scholar] [CrossRef]

- Omosebi, O.A.; Ahmed, R.M.; Shah, S.N. Mechanisms of Cement Degradation in HPHT Carbonic Acid Environment. In Proceedings of the SPE International Symposium on Oilfield Chemistry, Montgomery, TX, USA, 3–5 April 2017; pp. 448–468. [Google Scholar] [CrossRef]

- Omosebi, O.; Maheshwari, H.; Ahmed, R.; Shah, S.; Osisanya, S.; Santra, A.; Saasen, A. Investigating temperature effect on degradation of well cement in HPHT carbonic acid environment. J. Nat. Gas. Sci. Eng. 2015, 26, 1344–1362. [Google Scholar] [CrossRef]

- Gaurina-Međimurec, N. the influence of CO2 on well cement. Rud.-Geološko-Naft. Zb. 2010, 22, 19–25. [Google Scholar]

- Al-Dulaijan, S.U.; Maslehuddin, M.; Al-Zahrani, M.M.; Sharif, A.M.; Shameem, M.; Ibrahim, M. Sulfate resistance of plain and blended cements exposed to varying concentrations of sodium sulfate. Cem. Concr. Compos. 2003, 25, 429–437. [Google Scholar] [CrossRef]

- Pouya, J.; Neji, M.; De Windt, L.; Péralès, F.; Socié, A.; Corvisier, J. Mineralogical Evolution and Expansion of Cement Pastes in a Sulfate-Confined Environment. Minerals 2022, 13, 1. [Google Scholar] [CrossRef]

- Mackay, E. Effect of Very Low Ph on Degradation of Class G Cement: Implications for CO2 Geological Storage. In Proceedings of the 14th Greenhouse Gas Control Technologies Conference Melbourne, Melbourne, Australia, 21–25 October 2018. [Google Scholar]

- Duchesne, J.; Bertron, A. Leaching of Cementitious Materials by Pure Water and Strong Acids (HCl and HNO3). In Performance of Cement-Based Materials in Aggressive Aqueous Environments; RILEM State-of-the-Art Reports; Springer: Dordrecht, The Netherlands, 2013; Volume 10, pp. 91–112. [Google Scholar] [CrossRef]

- Poole, T.S.; Wakeley, L.D.; Cameron, L.; Young Structures Laboratory. Individual and Combined Effects of Chloride, Sulfate, and Magnesium Ions on Hydrated Portland-Cement Paste; U.S. Government Printing Office: Washington, DC, USA, 1994. [Google Scholar] [CrossRef][Green Version]

- Porcayo-Calderon, J.; Canto, J.; Martinez-de-la-Escalera, L.M.; Neri, A. Sweet Corrosion Inhibition by CO2 Capture. Molecules 2022, 27, 5209. [Google Scholar] [CrossRef] [PubMed]

- Obot, I.B.; Sorour, A.A.; Verma, C.; Al-Khaldi, T.A.; Rushaid, A.S. Key parameters affecting sweet and sour corrosion: Impact on corrosion risk assessment and inhibition. Eng. Fail. Anal. 2023, 145, 107008. [Google Scholar] [CrossRef]

- de Waard, C.; Lotz, U.; Milliams, D.E. Predictive Model for CO2 Corrosion Engineering in Wet Natural Gas Pipelines. In Proceedings of the Corrosion 1991, Cincinnati, OH, USA, 11–15 March 1991. [Google Scholar] [CrossRef]

- Olsen, S.; Halvorsen, A.M.; Lunde, P.G.; Nyborg, R. CO2 Corrosion Prediction Model—Basic Principles. In Proceedings of the Corrosion 2005, Houston, TX, USA, 3–7 April 2005. [Google Scholar]

- Olsen, S. CO2 Corrosion Prediction by Use of the NORSOK M-506 Model—Guidelines and Limitations. In Proceedings of the Corrosion 2003, San Diego, CA, USA, 16–21 March 2003; pp. 1–12. [Google Scholar] [CrossRef]

- Sotoodeh, K. Material selection and corrosion. In Subsea Valves and Actuators for the Oil and Gas Industry; Gulf Professional Publishing: Largo, FL, USA, 2021; pp. 421–457. [Google Scholar] [CrossRef]

- Muthukumar, N. Petroleum Products Transporting Pipeline Corrosion-A Review. In The Role of Colloidal Systems in Environmental Protection; Elsevier: Amsterdam, The Netherlands, 2014; pp. 527–571. [Google Scholar] [CrossRef]

- NACE MR0175/ISO 15156; Petroleum and Natural Gas Industries—Materials for Use in H2S-Containing Environments in Oil and Gas Production (3 Parts). International Organization for Standardization: Geneva, Switzerland, 2001.

- Yan, X.; Wang, Y.; Du, Q.; Jiang, W.; Li, R. Research progress on factors affecting oxygen corrosion and countermeasures in oilfield development. In Proceedings of the 2nd International Conference on Biofilms (ChinaBiofilms 2019), Guangzhou, China, 10–13 October 2019. [Google Scholar] [CrossRef]

- Telegdi, J.; Shaban, A.; Trif, L. Microbiologically influenced corrosion (MIC). In Trends in Oil and Gas. Corrosion Research and Technologies: Production and Transmission; Woodhead Publishing: Cambridge, UK, 2017; pp. 191–214. [Google Scholar] [CrossRef]

- Kannan, P.; Su, S.S.; Mannan, M.S.; Castaneda, H.; Vaddiraju, S. A Review of Characterization and Quantification Tools for Microbiologically Influenced Corrosion in the Oil and Gas Industry: Current and Future Trends. Ind. Eng. Chem. Res. 2018, 57, 13895–13922. [Google Scholar] [CrossRef]

- Scribner, L.A. Corrosion by Organic Acids. In Proceedings of the Corrosion 2001, Houston, TX, USA, 11–16 March 2001. [Google Scholar]

- Kadhim, M.G.; Ali, D.M.T. A Critical Review on Corrosion and its Prevention in the Oilfield Equipment. J. Pet. Res. Stud. 2017, 7, 162–189. [Google Scholar] [CrossRef]

- Dubois, J.; Grau, E.; Tassaing, T.; Dumon, M. On the CO2 sorption and swelling of elastomers by supercritical CO2 as studied by in situ high pressure FTIR microscopy. J. Supercrit. Fluids 2018, 131, 150–156. [Google Scholar] [CrossRef]

- Young, D.; Sevre, A.K.; Smith, P.E.; Al-Madlouh, M.; Gjelstad, G. Effects of Rapid Gas Decompression on Swellable Rubber and Common Oilfield Rubber Compounds. In Proceedings of the SPE/IADC Middle East Drilling Technology Conference and Exhibition, Muscat, Oman, 24–26 October 2011; pp. 738–744. [Google Scholar] [CrossRef]

- Zhou, C.; Ye, B.; Song, Y.; Cui, T.; Xu, P.; Zhang, L. Effects of internal hydrogen and surface-absorbed hydrogen on the hydrogen embrittlement of X80 pipeline steel. Int. J. Hydrogen Energy 2019, 44, 22547–22558. [Google Scholar] [CrossRef]

- Dwivedi, S.K.; Vishwakarma, M. Hydrogen embrittlement in different materials: A review. Int. J. Hydrogen Energy 2018, 43, 21603–21616. [Google Scholar] [CrossRef]

- Song, J.; Curtin, W.A. A nanoscale mechanism of hydrogen embrittlement in metals. Acta Mater. 2011, 59, 1557–1569. [Google Scholar] [CrossRef]

- Laadel, N.E.; El Mansori, M.; Kang, N.; Marlin, S.; Boussant-Roux, Y. Permeation barriers for hydrogen embrittlement prevention in metals—A review on mechanisms, materials suitability and efficiency. Int. J. Hydrogen Energy 2022, 47, 32707–32731. [Google Scholar] [CrossRef]

- Banerjee, T.; Ji, K.; Xia, W.; Ouyang, G.; Del Rose, T.; Hlova, I.Z.; Ueland, B.; Johnson, D.D.; Wang, C.Z.; Balasubramanian, G.; et al. Machine-learning and first-principles investigation of lightweight medium-entropy alloys for hydrogen-storage applications. Int. J. Hydrogen Energy 2025, 154, 149916. [Google Scholar] [CrossRef]

- Banerjee, T.; Balasubramanian, G. Hydrogen diffusion induced dislocation transformations in a nickel superalloy. Fuel 2025, 384, 134064. [Google Scholar] [CrossRef]

- Zhou, N.; Deng, K.; Lin, Y.; Yan, K.; Li, C.; Li, H.; Xie, P. A prediction method of wellhead movement with consideration of interface debonding. Geoenergy Sci. Eng. 2024, 239, 212919. [Google Scholar] [CrossRef]

- Alberdi-Pagola, P.; Fischer, G. Quantification of Casing Expansion-Induced Cracking in Oilwell Cement Sheaths. SPE J. 2024, 29, 714–724. [Google Scholar] [CrossRef]

- Yang, Z.; Sun, R.; Liu, Z. Casing tensile stress distribution in the bending section of a well during hydraulic fracturing. J. Pet. Explor. Prod. Technol. 2023, 13, 1361–1378. [Google Scholar] [CrossRef]

- De Andrade, J.; Sangesland, S.; Todorovic, J.; Vrålstad, T. Cement Sheath Integrity During Thermal Cycling: A Novel Approach for Experimental Tests of Cement Systems. In Proceedings of the Society of Petroleum Engineers—SPE Bergen One Day Seminar, Bergen, Norway, 22 April 2015; pp. 377–392. [Google Scholar] [CrossRef]

- Han, X.; Feng, F.; Zhang, J. Study on the whole life cycle integrity of cement interface in heavy oil thermal recovery well under circulating high temperature condition. Energy 2023, 278, 127873. [Google Scholar] [CrossRef]

- Allahvirdizadeh, P. A review on geothermal wells: Well integrity issues. J. Clean. Prod. 2020, 275, 124009. [Google Scholar] [CrossRef]

- Rahman, S.S.; Chilingarian, G.V. (Eds.) Chapter 4: Casing Design for Special Applications. In Developments in Petroleum Science; Elsevier: Amsterdam, The Netherlands, 1995; Volume 42, pp. 177–257. [Google Scholar] [CrossRef]

- Arefi, B.; Settari, A.; Angman, P. Simulation of Erosion in Drilling Tools for Oil and Gas Industry. In Proceedings of the Canadian International Petroleum Conference, CIPC, Calgary, AB, Canada, 8–10 June 2004. [Google Scholar] [CrossRef]

- Venkatesh, E.S. Erosion Damage in Oil and Gas Wells. In Proceedings of the SPE Rocky Mountain Regional Meeting, Billings, MT, USA, 19–21 May 1986. [Google Scholar] [CrossRef]

- Thomas, M.; Laronge, M.A.; Ward, A. The Basics and Not So Basics of Water Corrosion Processes Altered by Flow Changes. In Proceedings of the CORROSION 99, San Antonio, TX, USA, 25–30 April 1999. [Google Scholar]

- Rao, P.; Mulky, L. Erosion-Corrosion of Materials in Industrial Equipment: A Review. ChemElectroChem 2023, 10, e202300152. [Google Scholar] [CrossRef]

- Campos, J.; Keong, A.; Liu, Z.; Tomczak, D.; Kleppan, T.; Soerensen, M. Understanding Mechanisms of Wellbore Abrasion During Coiled Tubing Intervention. In Proceedings of the Society of Petroleum Engineers—SPE/ICoTA Well Intervention Conference and Exhibition, CTWI, The Woodlands, TX, USA, 19–20 March 2024. [Google Scholar] [CrossRef]

- Al-Yami, A.S.; Alqam, M.H.; Riefky, A.; Shafqat, A.U. Self Healing Durable Cement; Development, Lab Testing, and Field Execution. In Proceedings of the SPE/IADC Middle East Drilling Technology Conference and Exhibition, Abu Dhabi, United Arab Emirates, 29–31 January 2018. [Google Scholar] [CrossRef]

- Liu, G. Introduction to cementing engineering. In Applied Well Cementing Engineering; Gulf Professional Publishing: Largo, FL, USA, 2021; pp. 1–15. [Google Scholar] [CrossRef]

- Segre, N.; Galves, A.D.; Rodrigues, J.A.; Joekes, I. Tire rubber-cement composites: Effect of slag on properties. Cerâmica 2006, 52, 283–292. [Google Scholar] [CrossRef]

- Wray, B.; Bedford, D.; Leotaud, L.; Hunter, B. The Application of High-Density Elastic Cements to Solve HPHT Challenges in South Texas: The Success Story. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 4–7 October 2009; Volume 1, pp. 135–151. [Google Scholar] [CrossRef]

- Reddy, B.R.; Liang, F.; Fitzgerald, R. Self-Healing Cements that Heal without Dependence on Fluid Contact. In Proceedings of the SPE International Symposium on Oilfield Chemistry, The Woodlands, TX, USA, 20–22 April 2009; Volume 1, pp. 430–436. [Google Scholar] [CrossRef]

- Chandra Sekhara Reddy, T.; Ravitheja, A.; Sashidhar, C. Micromechanical Properties of Self-Healing Concrete with Crystalline Admixture and Silica Fume. ACI Mater. J. 2020, 117, 63–74. [Google Scholar] [CrossRef]

- Billmeyer, F.W. A Textbook of Polymer Science (Chemistry and Technology of Polymer): (Processing and Applications); John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1984. [Google Scholar]

- Torsæter, M.; Todorovic, J.; Lavrov, A. Structure and debonding at cement–steel and cement–rock interfaces: Effect of geometry and materials. Constr. Build. Mater. 2015, 96, 164–171. [Google Scholar] [CrossRef]

- Gorokhova, L.; Parry, A.; Flamant, N. Comparing Soft-String and Stiff-String Methods Used to Compute Casing Centralization. SPE Drill. Complet. 2014, 29, 106–114. [Google Scholar] [CrossRef]

- Trudel, E.; Frigaard, I.A. Stochastic modelling of wellbore leakage in British Columbia. J. Pet. Sci. Eng. 2023, 220, 111199. [Google Scholar] [CrossRef]

- Gray, K.E.; Podnos, E.; Becker, E. Finite-Element Studies of Near-Wellbore Region During Cementing Operations: Part I. SPE Drill. Complet. 2009, 24, 127–136. [Google Scholar] [CrossRef]

- Lavrov, A.; Torsæter, M. Properties of Well Cement. In Physics and Mechanics of Primary Well Cementing; SpringerBriefs in Petroleum Geoscience and Engineering; Springer: Cham, Switzerland, 2016; pp. 9–23. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, Y.; Wang, Y.; Feng, Y. Experimental and Numerical Simulation Investigation of Cement Sheath Integrity during Multi-Stage Fracturing in Offshore Tight Oil Reservoir. J. Mar. Sci. Eng. 2024, 12, 814. [Google Scholar] [CrossRef]

- Pang, X.; Sun, L.; Chen, M.; Xian, M.; Cheng, G.; Liu, Y.; Qin, J. Influence of curing temperature on the hydration and strength development of Class G Portland cement. Cem. Concr. Res. 2022, 156, 106776. [Google Scholar] [CrossRef]

- Cao, Z.; Liu, J.; Xiao, J.; Zhang, J.; Xu, Y. Strength characteristics and energy evolution of cement stone under true-triaxial loading conditions. Constr. Build. Mater. 2024, 432, 136690. [Google Scholar] [CrossRef]

- API RP 10B-2; Recommended Practice for Testing Well Cements. API: Washington, DC, USA, 2024.

- Li, Z.; Vandenbossche, J.M.; Iannacchione, A.T.; Brigham, J.C.; Kutchko, B.G. Theory-Based Review of Limitations With Static Gel Strength in Cement/Matrix Characterization. SPE Drill. Complet. 2016, 31, 145–158. [Google Scholar] [CrossRef]

- Mugharbil, M.; Al Khunaizi, M. Significance of Smart and Integration System Solutions in Maintaining Well Integrity. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, MEOS, Sanabis, Bahrain, 28 November–1 December 2021. [Google Scholar] [CrossRef]

- Zhang, Y.; Jung, Y.; Freifeld, B.; Finsterle, S. Using distributed temperature sensing to detect CO2 leakage along the injection well casing. Int. J. Greenh. Gas. Control 2018, 74, 9–18. [Google Scholar] [CrossRef]

- Liu, S.; Yuan, W. Numerical Simulation of Casing Tensile Failure in Water Injection Wells. In Proceedings of the International Field Exploration and Development Conference 2021, Qingdao, China, 16–18 September 2021; Springer Series in Geomechanics and Geoengineering; Springer: Singapore, 2022; pp. 119–132. [Google Scholar] [CrossRef]

- Hu, G.; Deng, S.; Wang, D. Effect of Fault Slip on the Casing Passability of Horizontal Shale Oil and Gas Wells. SPE Drill. Complet. 2023, 38, 370–380. [Google Scholar] [CrossRef]

- Tuo, Y.; Yu, H.; Lian, Z.; Lin, T.; Wang, H. Impact of fault slip induced by water injection on casing deformation: A numerical study. Pet. Sci. Technol. 2024, 43, 1744–1767. [Google Scholar] [CrossRef]

- Straw, M.; Mistry, R.; Lewis, S.; Straw, N.; Aglave, R.; Kolak, D. Predictive Digital Twin for Performance and Integrity. In Proceedings of the Annual Offshore Technology Conference, Houston, TX, USA, 2–5 May 2022; Volume 11. [Google Scholar] [CrossRef]

- Anjos, J.L.; Aranha, P.E.; Martins, A.L.; Oliveira, F.L.; Joségoncalves, C.; Silva, D.R.; Dudek, C.L.; Lima, C.B. Digital Twin for Well Integrity with Real Time Surveillance. In Proceedings of the Annual Offshore Technology Conference, Houston, TX, USA, 4–7 May 2020. [Google Scholar] [CrossRef]

- Haavik, K.E. On the Use of Low-Frequency Distributed Acoustic Sensing Data for In-Well Monitoring and Well Integrity: Qualitative Interpretation. SPE J. 2023, 28, 1517–1532. [Google Scholar] [CrossRef]

- Haavik, K.E. Annuli Liquid-Level Surveillance Using Distributed Fiber-Optic Sensing Data. SPE J. 2024, 29, 1195–1209. [Google Scholar] [CrossRef]

- dos Santos, M.V.; Rosa, R.M.D.; de Oliveira, L.A.; Newmar, C.; da Silva, F.R.G.; Fasolin, K.; Girardi, V.; Rosenbach, L.I.N.C.; de Araújo, J.P.N.; Aranha, P.E.; et al. Development and Deployment of Digital Twin for Production and Well Integrity. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 3–5 October 2022. [Google Scholar] [CrossRef]

- Gu, C.; Xu, T.; Lye, J.; Ødegård, S.I.; Cao, J. A Journey Towards Safer and Faster Drilling: Real-Time Advisory With Digital Twins and AI. In Proceedings of the ASME 2024 43rd International Conference on Ocean, Offshore and Arctic Engineering, Singapore, 9–14 June 2024. [Google Scholar] [CrossRef]

- Yang, Y.; Li, L.; Qu, J.; Gogoi, U.; Liu, T.; Lei, S.; Hu, B.; Liao, H.; Wang, B.; Pan, Y.; et al. Using an Optimal Digital Twin to Integrate Geoengineering Solutions and ML-Assisted Diagnostics in an Underground Gas Storage System. In Proceedings of the Society of Petroleum Engineers—Mediterranean Offshore Conference, MOCE, Alexandria, Egypt, 20–22 October 2024. [Google Scholar] [CrossRef]

- Ma, S.; Flanigan, K.A.; Bergés, M. State-of-the-art review and synthesis: A requirement-based roadmap for standardized predictive maintenance automation using digital twin technologies. Adv. Eng. Inform. 2024, 62, 102800. [Google Scholar] [CrossRef]

- Mohanraj, E.; Eniyavan, N.; Sidarth, S.; Sridharan, S. Digital Twins for Automotive Predictive Maintenance. In Proceedings of the 7th International Conference on Inventive Computation Technologies, ICICT, Lalitpur, Nepal, 24–26 April 2024; pp. 1579–1584. [Google Scholar] [CrossRef]

- Lachvajderová, L.; Trebuňa, M.; Kádárová, J. Unlocking Industry Potential: The Evolution and Impact of Digital Twins. Acta Mech. Slovaca 2024, 28, 46–51. [Google Scholar] [CrossRef]

- Busollo, C.; Mauro, S.; Nesci, A.; Scimmi, L.S.; Baronio, E. Development of a Digital Twin for Well Integrity Management in Underground Gas Storage Fields. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dubai, United Arab Emirates, 21–23 September 2021. [Google Scholar] [CrossRef]

- Aranha, P.E.; De Souza, C.O.; Ferrarezi, L.F.; Valore, F.; De Oliveira, F.L.; Dos Santos, M.V.; Donatti, C.N.; Mendes, H.U.S.; Dearaújo, J.P.N.; Souza Neto, S.L. Look Ahead: Optimization of Well Operations Using Real Time Digital Twin for Well Integrity. In Proceedings of the Annual Offshore Technology Conference, Houston, TX, USA, 5–8 May 2025. [Google Scholar] [CrossRef]

- Abdo, E.; Baronio, E.; Mauro, S.; Troise, M.; Salamina, L. Case Study of the Use of a Digital Twin for Leak Detection and Quantification in Underground Gas Storage Wells. SPE J. 2023, 28, 2415–2424. [Google Scholar] [CrossRef]

- Cherubini, A.; Richard, S.; Jestin, C.; Calbris, G.; Lanticq, V. Real-Time Downhole Monitoring Using DAS and DTS: A New Technology for Leak Detection and Well Integrity. In Proceedings of the International Petroleum Technology Conference, IPTC, Bangkok, Thailand, 1–3 March 2023. [Google Scholar] [CrossRef]

- Prasad, U.; Wu, L.; Hanif, A. Value of Downhole Drilling Data for Real-Time Formation Evaluation and Early Decision Making. In Proceedings of the Offshore Technology Conference Brasil, OTCB, Rio de Janeiro, Brazil, 24–26 October 2023. [Google Scholar] [CrossRef]

- Soroush, M.; Mohammadtabar, M.; Roostaei, M.; Hosseini, S.A.; Fattahpour, V.; Mahmoudi, M.; Keough, D.; Tywoniuk, M.; Mosavat, N.; Cheng, L.; et al. Downhole Monitoring Using Distributed Acoustic Sensing: Fundamentals and Two Decades Deployment in Oil and Gas Industries. In Proceedings of the Society of Petroleum Engineers—SPE Conference at Oman Petroleum and Energy Show, OPES, Muscat, Oman, 21–23 March 2022. [Google Scholar] [CrossRef]

- Aditama, P.; Koziol, T.; Dillen, M. Development of an Artificial Intelligence-Based Well Integrity Monitoring Solution. In Proceedings of the Society of Petroleum Engineers—ADIPEC, Abu Dhabi, United Arab Emirates, 31 October–3 November 2022. [Google Scholar] [CrossRef]

- Saminathan, R.; Nashali, A.Y.A.; Haqawi, A.A.A.; Marappan, S.; Natesan, S.P.; Shakeel, F. Role of artificial intelligence (AI) and machine learning (ML) in the corrosion monitoring processes. Zaštita Mater. 2024, 65, 473–480. [Google Scholar] [CrossRef]

- Al-Hajji, H.; Onikoyi, A. Well Integrity Solutions Using Intelligent Field Remote Surveillance and Monitoring Systems. In Proceedings of the International Petroleum Technology Conference, IPTC, Riyadh, Saudi Arabia, 21–23 February 2022. [Google Scholar] [CrossRef]

- Jasem, M.; Fabian, O.; Dawson, G.; Silari, M.; Al Junaibi, B.; Challagundla, S.; Noble, S.; Al Sawadi, O.; Rodriguez, J.; Mylnikov, P.; et al. Transforming Production Phase WIMS to a Game Changer Smart Well Integrity Monitoring System with Real Time Automated Engineering Analytics. In Proceedings of the Society of Petroleum Engineers—ADIPEC, Abu Dhabi, United Arab Emirates, 31 October–3 November 2022. [Google Scholar] [CrossRef]

- Zhalilov, A.; Toktorbaev, A. Combining Robustness and Explainability in Developing Safe Artificial Intelligence Systems. Бюллетень науки и практики 2024, 10, 167–171. [Google Scholar] [CrossRef]

- Hamad, M.; Steinhorst, S. Security Challenges in Autonomous Systems Design. arXiv 2023, arXiv:2312.00018. [Google Scholar] [CrossRef]

- Coelho de Souza Padilha, S.T.; da Silva Araujo, R.G. New Approach on Cement Evaluation for Oil and Gas Reservoirs Using Ultrasonic Images. In Proceedings of the Latin American and Caribbean Petroleum Engineering Conference, Rio de Janeiro, Brazil, 30 August–3 September 1997. [Google Scholar] [CrossRef]

- Bybee, K. Well-Integrity Operations at Prudhoe Bay, Alaska. J. Pet. Technol. 2007, 59, 64–66. [Google Scholar] [CrossRef]

- Crow, W.; Carey, J.W.; Gasda, S.; Brian Williams, D.; Celia, M. Wellbore integrity analysis of a natural CO2 producer. Int. J. Greenh. Gas. Control 2010, 4, 186–197. [Google Scholar] [CrossRef]

- Van Kuijk, R.; Zeroug, S.; Froelich, B.; Allouche, M.; Bose, S.; Miller, D.; Le Calvez, J.L.; Schoepf, V.; Pagnm, A. A Novel Ultrasonic Cased-Hole Imager for Enhanced Cement Evaluation. In Proceedings of the 2005 International Petroleum Technology Conference, Doha, Qatar, 21–23 November 2005; pp. 855–868. [Google Scholar] [CrossRef]

- Zeghlache, M.L.; Bazaid, A.; Hill, F.; Guergueb, N. Comprehensive Casing Corrosion Inspection Using Multi-Frequency Array EM Technology. In Proceedings of the Society of Petroleum Engineers—SPE International Oilfield Corrosion Conference and Exhibition, OFCS, Virtual, 16–17 June 2021; pp. 16–17. [Google Scholar] [CrossRef]

- Griston, S. Evaluation of Radioactive Tracer Surveys for Steam Injection Wells. In Proceedings of the SPE California Regional Meeting, Ventura, CA, USA, 4–6 April 1990. [Google Scholar] [CrossRef]

- Alaref, O.; Rourke, M.; Khabibullin, M.; Yakupov, A. Comprehensive Well Integrity Solutions in Challenging Environments Using Latest Technology Innovations. In Proceedings of the Offshore Technology Conference Asia, OTCA, Kuala Lumpur, Malaysia, 22–25 March 2016; pp. 791–799. [Google Scholar] [CrossRef]

- Jalan, S.N.; Al-Humoud, J.; Al-Sabea, S.; Gazi, N.; Al-Azmi, K.; Al-Haddad, S.; Abdulrazzaq, E.; Al-Baghli, F.; Khalil, M.; Zaki, H.; et al. Well Integrity: Application of Ultrasonic Logging, Production Logging and Corrosion Logs for Leak Detection in Wells—A Case Study. In Proceedings of the Society of Petroleum Engineers—Kuwait Oil and Gas Show and Conference, KOGS, Kuwait City, Kuwait, 8–10 October 2013; pp. 134–140. [Google Scholar] [CrossRef]

- Galli, G.; Pirrone, M.; Pirola, N.; Parodi, L.; Guiducci, M.; Kozlowski, M. Exploring the Downhole Waterways: Identification of the Sneaky Path of Water Through the Well Completion. In Proceedings of the SPWLA 63rd Annual Logging Symposium, Stavanger, Norway, 11–15 June 2022. [Google Scholar] [CrossRef]

- Pehlke, T.; Simpson, G.; Roberts, A.; Maxwell, T.; Chu, J. High-Resolution Acoustic Imaging Deployed for Mapping Permanent Fiber Optic Lines. In Proceedings of the Society of Petroleum Engineers—SPE Hydraulic Fracturing Technology Conference and Exhibition, HFTC, The Woodlands, TX, USA, 6–8 February 2024. [Google Scholar] [CrossRef]

- Varma, E.; Piccone, G.; Alhammadi, A.; Salah, M.; Emam, A.; Azher, M.; Al Hammadi, M.M.; Alshehhi, H.M.A.J.; Mohamad, A.A.; Marwat, Q.; et al. Rigless Well Intervention Using Tubing Patch Technology Helps Restore Inactive Wells. In Proceedings of the Society of Petroleum Engineers—ADIPEC, Abu Dhabi, United Arab Emirates, 4–7 November 2024. [Google Scholar] [CrossRef]

- Wu, X.; Dai, L.; Chang, Q.; Qiuhao, S.; Shiau, B.J. Study of Controlling Parameters of In-Situ CO2 EOR Using Numerical Simulations. In Proceedings of the SPE Western Regional Meeting, Anchorage, AK, USA, 22–25 May 2023. [Google Scholar] [CrossRef]

- Hussain, S.; Ahmed, Z.; Zakir, M.M.; Iqbal, M.; Wu, J.J.; Wu, X. Role of Temperature on the Performance of In-Situ CO2 EOR. In Proceedings of the Society of Petroleum Engineers—SPE/PAPG Pakistan Section Annual Technical Symposium and Exhibition, PATS, Islamabad, Pakistan, 7–8 November 2023. [Google Scholar] [CrossRef]

- Al Maqbali, Q.; Hussain, S.; Mask, G.; Xingru, W. Numerical Simulation of In-Situ CO2 Mineralization in Mafic Basaltic Formations in Southwest Oklahoma. In Proceedings of the Society of Petroleum Engineers—SPE Oklahoma City Oil and Gas Symposium, OKOG, Oklahoma City, OK, USA, 17–19 April 2023. [Google Scholar] [CrossRef]

- Duguid, A.; Radonjic, M.; Scherer, G.W. Degradation of cement at the reservoir/cement interface from exposure to carbonated brine. Int. J. Greenh. Gas. Control 2011, 5, 1413–1428. [Google Scholar] [CrossRef]

- Syed, T.; Cutler, T.; de Janeiro, R. Well Integrity Technical and Regulatory Considerations for CO2 Injection Wells. In Proceedings of the Safety and Environment in Oil and Gas Exploration and Production, Rio de Janeiro, Brazil, 12–14 April 2010. SPE 125839. [Google Scholar]

- Sweatman, R.E.; Santra, A.; Kulakofsky, D.S.; Calvert, D.G.J. Effective Zonal Isolation for CO2 Sequestration Wells. In Proceedings of the SPE International Conference on CO2 Capture, Storage, and Utilization, San Diego, CA, USA, 2–4 November 2009; pp. 8–22. [Google Scholar] [CrossRef]

- Durongwattana, N.; Toempromraj, W.; Jedsadawaranon, P.; Sompopsart, S. Well Integrity remediation—A Challenge for Swellable Technology. In Proceedings of the International Petroleum Technology Conference, IPTC, Bangkok, Thailand, 15–17 November 2011; pp. 7–9. [Google Scholar] [CrossRef]

- Papavinasam, S. Corrosion Control in the Oil and Gas Industry; ScienceDirect: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Van Der Schijff, O.J.; Budiansky, N.; Latanision, R.M. Hydrogen Damage and Embrittlement. In ASM Handbook; Failure Analysis and Prevention; ASM International: Almere, The Netherlands, 2021; pp. 518–532. [Google Scholar] [CrossRef]

- Aftab, A.; Hassanpouryouzband, A.; Martin, A.; Kendrick, J.E.; Thaysen, E.M.; Heinemann, N.; Utley, J.; Wilkinson, M.; Haszeldine, R.S.; Edlmann, K. Geochemical Integrity of Wellbore Cements during Geological Hydrogen Storage. Environ. Sci. Technol. Lett. 2023, 10, 551–556. [Google Scholar] [CrossRef]

- Al Dandan, E.; Hossain, M.M. Understanding of Geochemical Reactions in Hydrogen-Injected Wells: Cement Integrity for Safe Underground Hydrogen Storage. In Proceedings of the International Petroleum Technology Conference, IPTC, Dhahran, Saudi Arabia, 12–14 February 2024. [Google Scholar] [CrossRef]

- Al-Yaseri, A.; Fatah, A.; Zeng, L.; Al-Ramadhan, A.; Sarmadivaleh, M.; Xie, Q. On hydrogen-cement reaction: Investigation on well integrity during underground hydrogen storage. Int. J. Hydrogen Energy 2023, 48, 35610–35623. [Google Scholar] [CrossRef]

- Hussain, A.; Al-Hadrami, H.; Emadi, H.; Altawati, F.; Thiyagarajan, S.R.; Watson, M. Experimental Investigation of Wellbore Integrity of Depleted Oil and Gas Reservoirs for Underground Hydrogen Storage. In Proceedings of the Annual Offshore Technology Conference, Houston, TX, USA, 2–5 May 2022. [Google Scholar] [CrossRef]

- Sammer, T.; Kostoglou, N.; Ravi, K.; Raith, J.G. Hydrogen induced changes in the phase composition and micro-structure of downhole cements: Fundamental research within the context of underground hydrogen storage. Int. J. Hydrogen Energy 2024, 89, 1166–1175. [Google Scholar] [CrossRef]

- Tarkowski, R.; Uliasz-Misiak, B. Towards underground hydrogen storage: A review of barriers. Renew. Sustain. Energy Rev. 2022, 162, 112451. [Google Scholar] [CrossRef]

- Zivar, D.; Kumar, S.; Foroozesh, J. Underground hydrogen storage: A comprehensive review. Int. J. Hydrogen Energy 2021, 46, 23436–23462. [Google Scholar] [CrossRef]

- Nagumo, M.; Takai, K. The predominant role of strain-induced vacancies in hydrogen embrittlement of steels: Overview. Acta Mater. 2019, 165, 722–733. [Google Scholar] [CrossRef]

- Khalilidermani, M.; Knez, D.; Zamani, M.A.M. Empirical Correlations between the Hydraulic Properties Obtained from the Geoelectrical Methods and Water Well Data of Arak Aquifer. Energies 2021, 14, 5415. [Google Scholar] [CrossRef]

- Kirchheim, R. Solid solution softening and hardening by mobile solute atoms with special focus on hydrogen. Scr. Mater. 2012, 67, 767–770. [Google Scholar] [CrossRef]

- Alsubaih, A.; Sepehrnoori, K.; Delshad, M. Environmental Impacts of Orphaned and Abandoned Wells: Methane Emissions, and Implications for Carbon Storage. Appl. Sci. 2024, 14, 11518. [Google Scholar] [CrossRef]