The previous analysis found the output power of the generator to be 50 W; however, the linear generator is a subsystem of the Stirling engine. Therefore, to complete the assembly of the engine, this linear generator should be connected with the engine and simulated in a single software environment. To accomplish this, SAGE software was used which allows us to connect the generator and engine under one software program and conduct a complete simulation of the engine. The generator cannot be connected with the engine in Maxwell software, as Maxwell only has electrical simulation results, and it cannot solve the mechanical components of the engine.

In this study, mechanical resonance and structural vibration coupling between the generator and the Stirling engine were not explicitly modeled. The use of SAGE software focused solely on simulating the electromechanical characteristics of the linear generator as a subsystem without incorporating detailed dynamics of the entire engine–generator assembly.

It was noted that vibration and mechanical resonance can influence long-term reliability, especially under harsh or variable conditions, such as those in space applications. This aspect is recognized as a limitation of the current study and is intended to be addressed in future work through integrated dynamic modeling or experimental validation.

4.1. SAGE Model of Linear Generator

The 50 W models in Maxwell software comprise different parts, including the geometry of the generator. In the same way, SAGE also includes the parts of a generator, but rather than using 2D symmetry, SAGE has 1D symmetry, and it uses a block that represents backend solving, which performs the analysis by passing the required values. The results computed by SAGE utilize the numerical solvers technique to solve the complex differential equations that govern thermodynamics and mechanical dynamics. These solvers typically use iteration to improve their solutions until the system achieves a stable point or the desired level of accuracy.

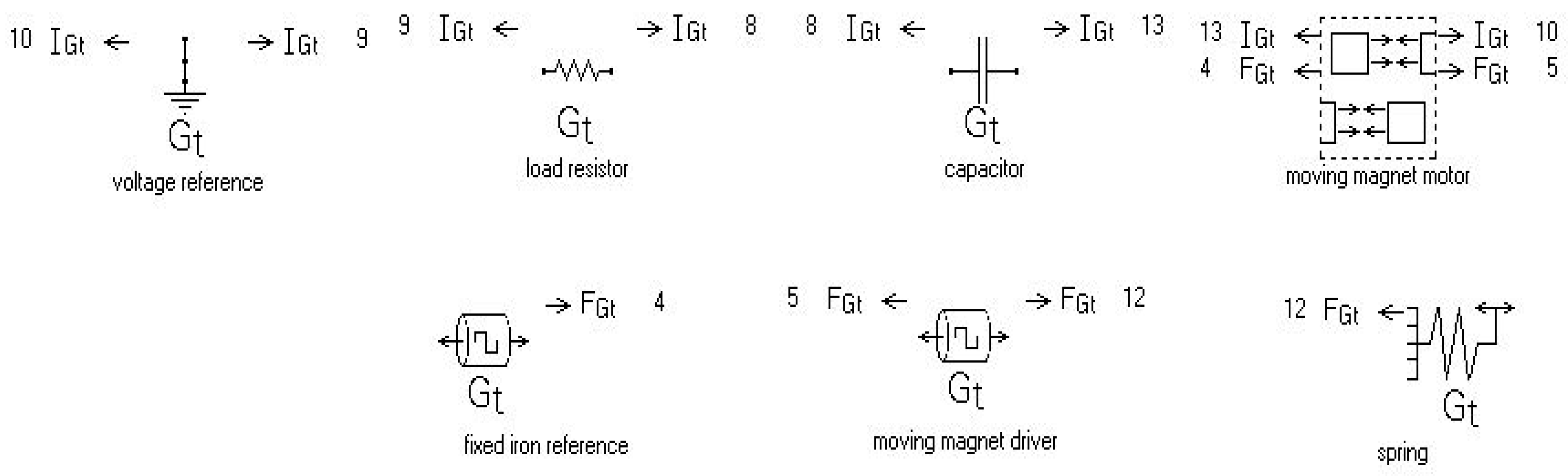

Figure 14 is a representation of an SAGE electromechanical (E-M) model, and the key components include the following:

The block of greatest concern in this paper is the moving magnet motor part of the EM model, as the main parts of the generator are placed under this block, forming a sub-block part of the model shown in

Figure 15.

Moving on, there are necessary parts, like the outer core, inner core, magnet, and coil of the generator under the moving magnet motor block. We took the liberty of passing the values to these sub-blocks so that SAGE can compute the results.

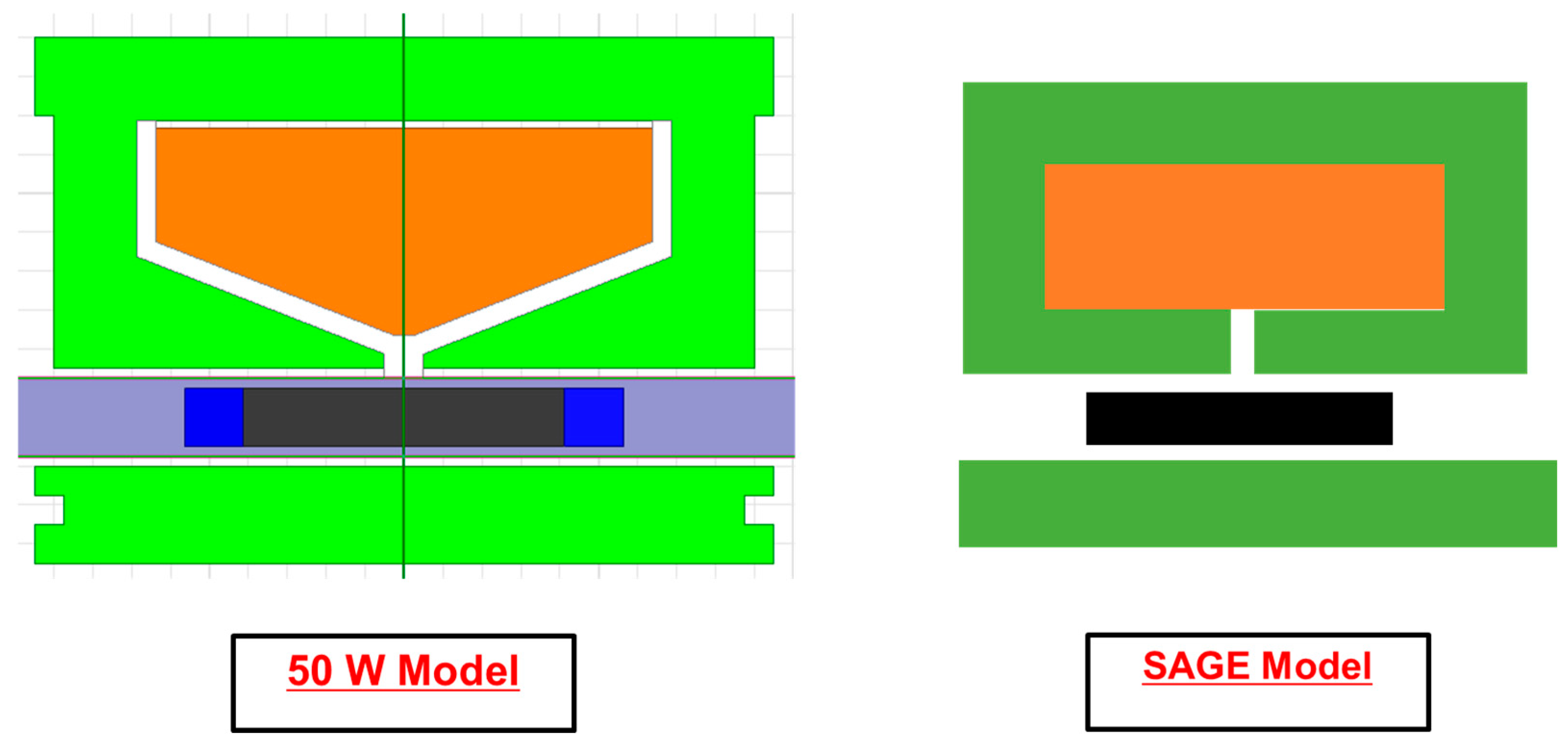

More importantly, SAGE analyzes based on 1-dimensional symmetry. The model that SAGE simulates for analysis is significantly simpler than the actual model. One of the noticeable changes is that the coil design in the Maxwell software is more like the pentagon shape to increase the efficiency of the generator, but SAGE does not account for such geometric detail when solving. Therefore, the inadequacy in creating the particular shape in SAGE software causes the model to deviate from the actual one in Maxwell software. Such a difference is notable in

Figure 16, which shows that the SAGE model is more likely to be considered in SAGE software versus the actual model created using Maxwell software.

4.2. SAGE Model Simulations

As the SAGE model cannot be compared with the current 50 W model because of the different design shape, it was necessary to design a new model similar to the SAGE model. This new model, referred to as the SAGE Maxwell Model and shown in

Figure 17, replicates the SAGE E-M model presented in

Figure 16. The same no-load and load analysis procedures used for the 50 W model were applied to the SAGE Maxwell Model to enable a direct comparison of the results from both software tools.

4.2.1. SAGE Maxwell Model Results

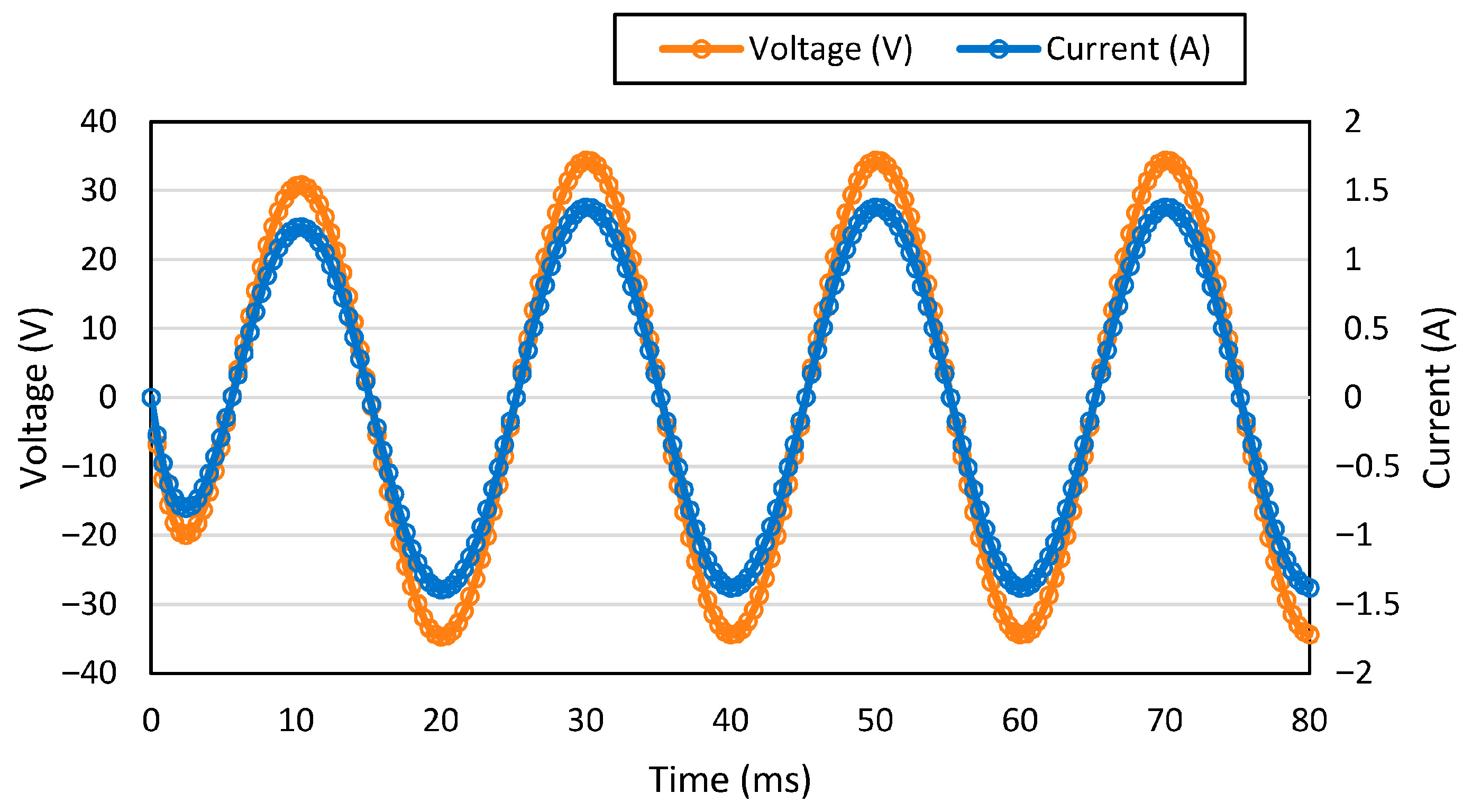

In this section, the results from the load analysis are discussed, as the main goal is to compare the output power results from both software programs. Therefore, in the analysis of the SAGE Maxwell Model, the output power achieved was 45 W.

Table 14 depicts the results, the numerical values, of the SAGE Maxwell model, including power, voltage, and current. The values that are mentioned in

Table 14 are the rms values.

4.2.2. SAGE Results

The parameters and dimensions used for the analysis in SAGE were assigned according to the values mentioned in

Table 14 for the SAGE–Maxwell model. While setting the values, the objective was to ensure consistency with the 50 W model.

The SAGE analysis result yielded an output power of approx. 38 W, as shown in

Table 15.

Other than the 50 W model, there were two more models, namely the SAGE model and the SAGE Maxwell model. The main goal was to compare the results; therefore,

Table 15 shows a comparison of the electrical parameters of these models.

Since the values are not the same in the SAGE–Maxwell model and SAGE model, even while having the same design symmetry, a loss analysis was conducted for both models.

4.2.3. Loss Analysis

The Sage loss analysis results show that the total loss in the SAGE model is approximately 2.5 W, and the total loss of the SAGE Maxwell model is approximately 4 W rms.

The loss comparison between two models shows the difference in the losses by parts in

Table 16.

As shown in

Table 16, the SAGE model loss is around ¾ times less compared to the SAGE Maxwell model. The particular reason is that SAGE did not consider the losses as much as Maxwell did in the FEM analysis, and the analysis of the discrepancy in the output power and the losses is discussed in the next section.

4.3. Analysis of the Discrepancies

Since there was a difference in the power, we conducted a loss comparison of both models, but this still did not provide the reason for the difference in the power. Thus, we checked the material properties used in the SAGE Model with the material used in the SAGE Maxwell Model. The material used for the cores of the SAGE Maxwell Model was 35PN230, whereas the material used in the SAGE model was silicon steel; therefore, for consistency, the SAGE core material was changed to 35PN230, but still, there was no evident change in the output power.

Hence, this analysis concluded that there are two possible reasons for the discrepancy.

- i

Different Modeling Assumptions

- (a)

Maxwell (Electromagnetic Analysis):

Maxwell is an electromagnetic field simulation tool that heavily relies on solving Maxwell’s equations using the Finite Element Method (FEM).

Maxwell calculates the behavior of the electromagnetic fields within the generator based on the geometry and material properties. The FEM divides the geometry into small elements, and the fields are calculated at discrete points. The localized nature of these calculations means that Maxwell can accurately simulate variations in the magnetic flux, eddy currents, and core losses, which directly affect output power [

32].

- (b)

SAGE (System-Level Analysis):

SAGE, a system-level simulation tool, uses lumped parameter models to simulate the electrical, mechanical, and thermodynamic behavior of systems. Regarding the reason for the discrepancy, lumped models simplify the generator into a set of resistances, inductances, and capacitances that represent the overall behavior of the system rather than detailed local interactions. For instance, SAGE might apply Kirchhoff’s laws to simplified circuit models.

These simplifications may omit localized electromagnetic effects (such as skin effect and proximity effect in conductors) and may result in lower predicted power output because of the averaging inherent in these models [

33].

This method of solving in SAGE is known as the Finite Difference Method (FDM). This method involves discretizing the governing differential equations into a grid of points and solving the system iteratively. It is typically simpler and faster for solving problems in structured grids.

- ii

Different Solver Approaches

Maxwell uses FEM to solve for electromagnetic fields by discretizing the domain into finite elements. The fundamental equation solved in this case is the Helmholtz equation [

34] derived from Maxwell’s equations in the frequency domain:

where

E is the electric field,

μ is the permeability,

ϵ is the permittivity,

J is the current density, and

ω is the angular frequency. This allows Maxwell to account for the spatial distribution of currents and fields with high precision.

The FEM method breaks the domain into a mesh of small elements and uses variational methods (such as Galerkin’s method) to approximate the solution. The higher the mesh density, the more accurate the solution, but at the cost of computational time. Maxwell can accurately model transient and dynamic effects, such as eddy currents and non-linear magnetic saturation, which can lead to more precise output power calculations [

35].

- (b)

SAGE’s Simplified Solver:

SAGE, instead of FEM, uses simplified models, often based on analytical equations or semi-empirical relations. For example, it may solve the generator’s electrical performance using the equivalent circuit method:

This method approximates the inductance and resistance of the generator in a time-dependent manner but does not consider spatial variations in the magnetic field. The simplification can result in an underestimation of the output power since localized phenomena like leakage flux and fringing effects are often averaged out or ignored.

The exact equation or a particular method about how SAGE computes results is not mentioned in the literature. While searching thoroughly through the SAGE manual and also looking through previous papers on the SAGE simulation, there was little information about which kind of equation or what solving technique SAGE is based on to compute the E-M model results. Therefore, the discrepancy between both software’s result may be due to both using different solving techniques and the model assumptions used in the software being quite different.