A Damage-Based Fully Coupled DFN Study of Fracture-Driven Interactions in Zipper Fracturing for Shale Gas Production

Abstract

1. Introduction

2. Fully Coupled Hydro–Mechanical–Damage Numerical Model

2.1. Solid Deformation and Damage Evolution

2.2. Normal and Shear Displacements of Fractures

2.3. Fluid Flow in Fractured Porous Media

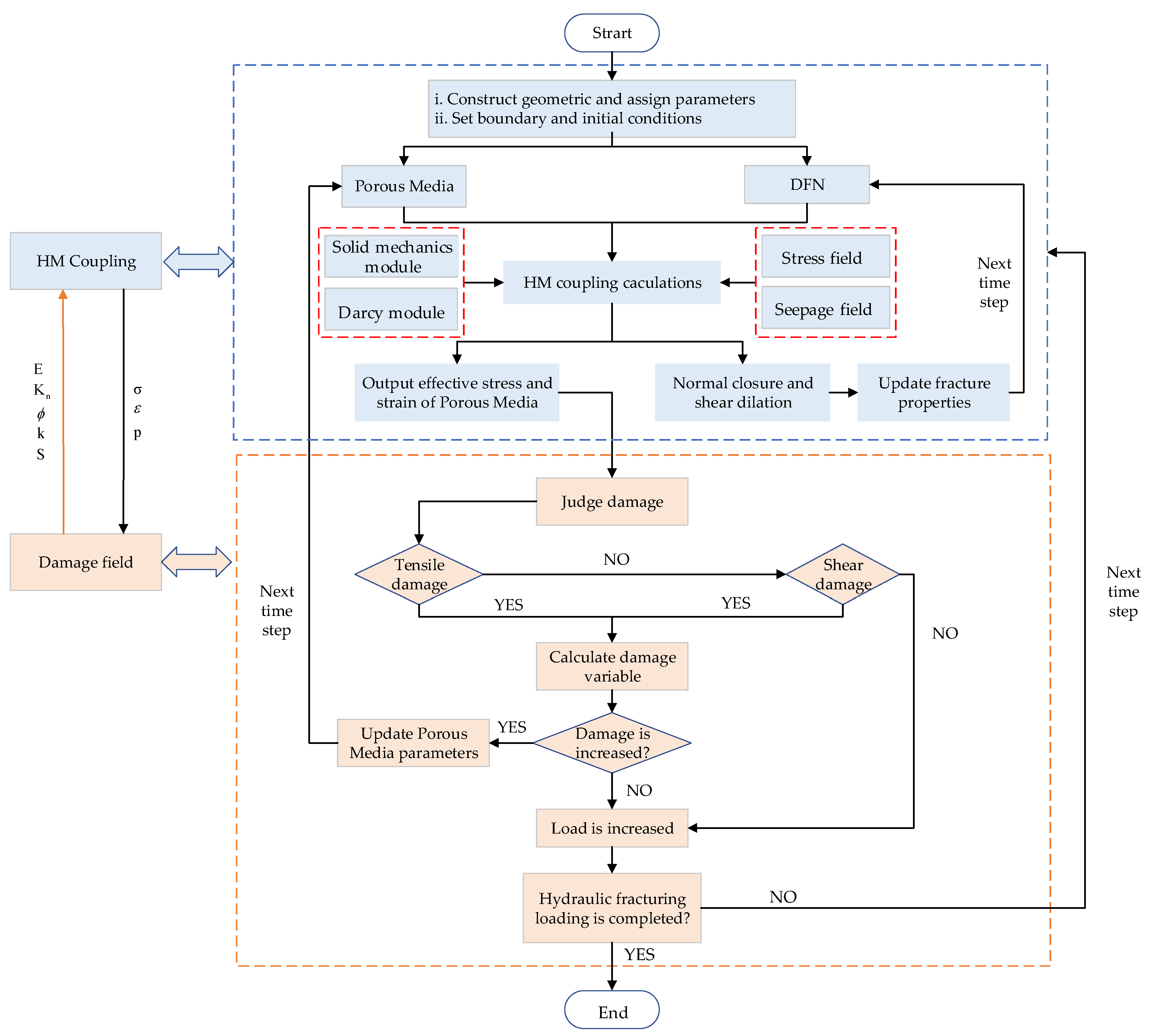

2.4. Model Solution

- (1)

- The geometric model domain of the porous matrix is firstly established, into which a stochastically generated DFN, based on well-logging data, is embedded. Relevant physical parameters are then assigned. Initial and boundary conditions are defined accordingly. In addition, key parameters of the porous matrix and fractures—such as porosity, permeability, and storage coefficient—are defined as functions of local stress or pressure states.

- (2)

- Based on the computed stress and strain fields within the simulation domain, a damage criterion is applied to determine whether tensile or shear damage occurs at Gauss points of the porous matrix Simultaneously, the normal stiffness and aperture of the DFN fractures are updated, along with corresponding permeability and storage coefficient values.

- (3)

- For Gauss points of porous matrix that satisfy the tensile or shear damage criteria, the damage scalar D is calculated using Equations (7) and (8). If D increases, the corresponding parameters within the porous matrix—namely porosity, permeability, and storage coefficient—are updated according to Equations (31)–(33).

- (4)

- If none of the Gauss points satisfy the damage criteria, the loading is incrementally increased, and Steps (2) and (3) are repeated until the hydraulic fracturing process is complete. The simulation is then terminated.

2.5. Model Validation

2.5.1. Comparison with Hydraulic Fracturing Experiment

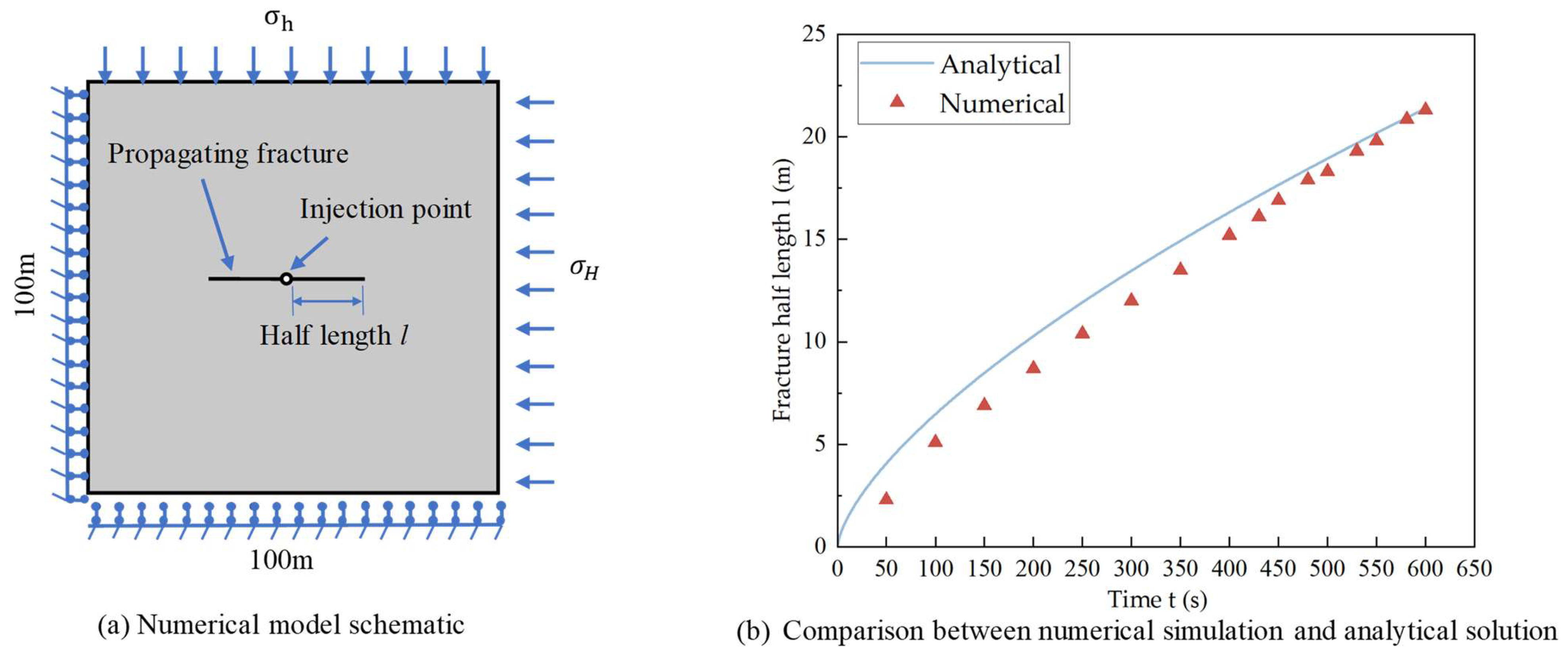

2.5.2. Hydraulic Fracturing in Toughness-Dominated Regime

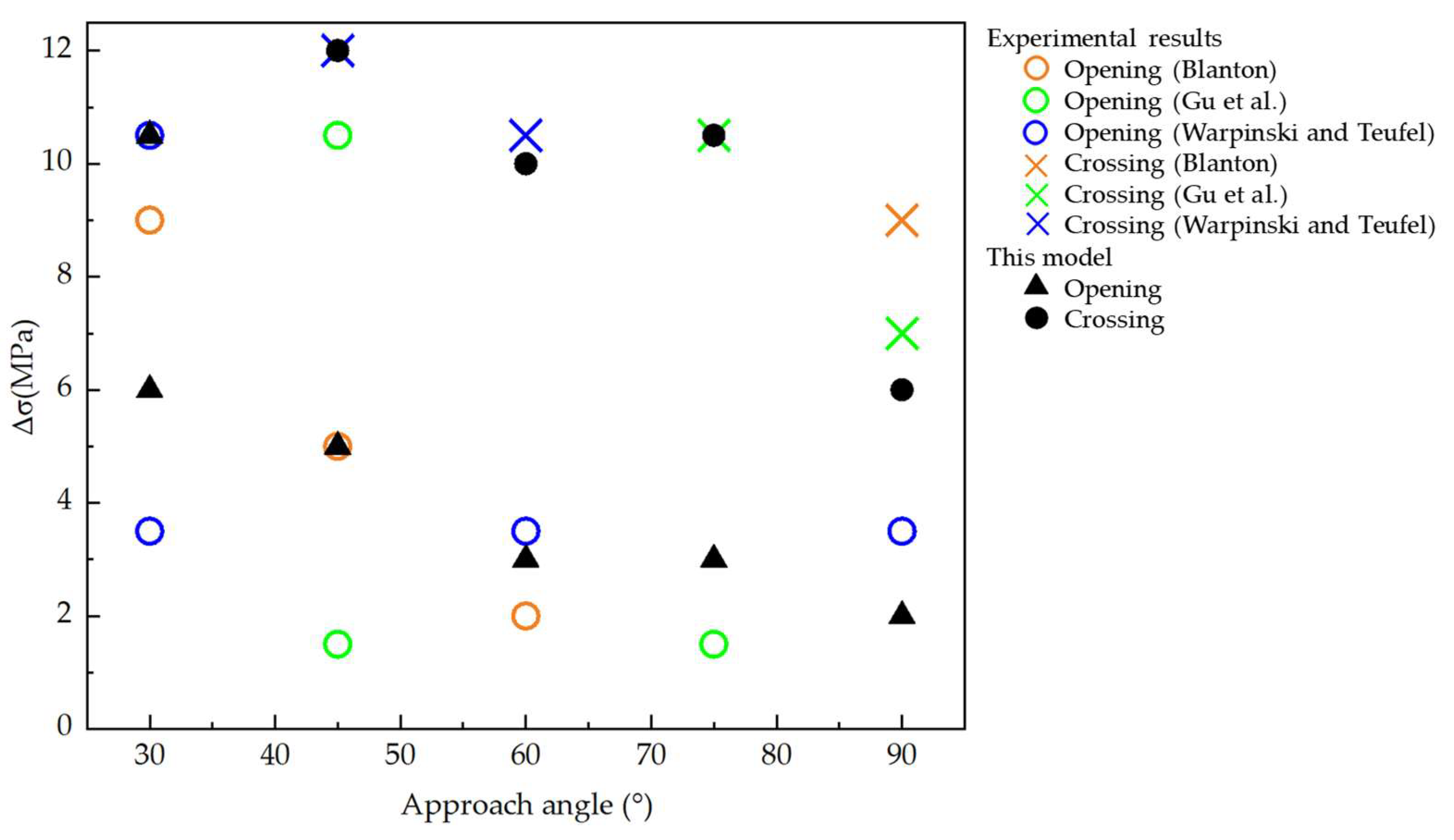

2.5.3. HF-NF Interaction

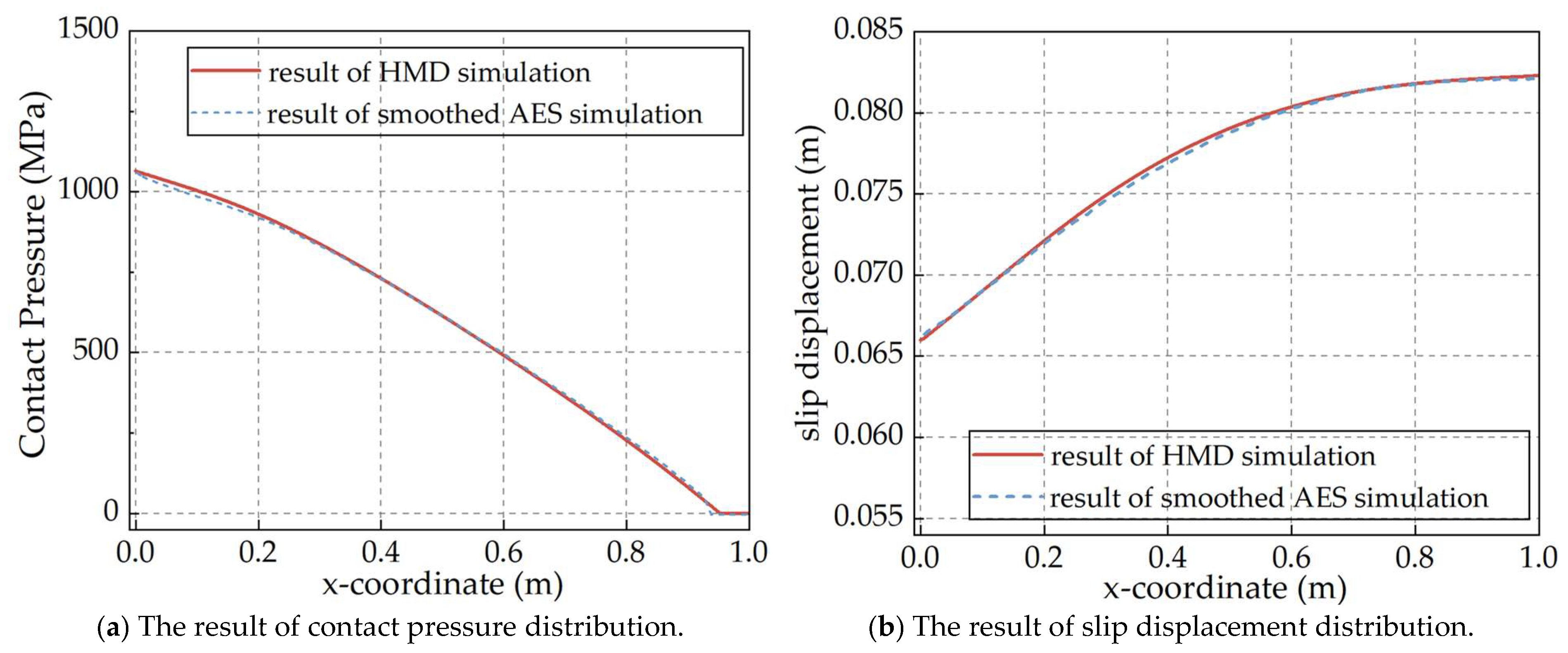

2.5.4. Frictional Contact

3. Case Study

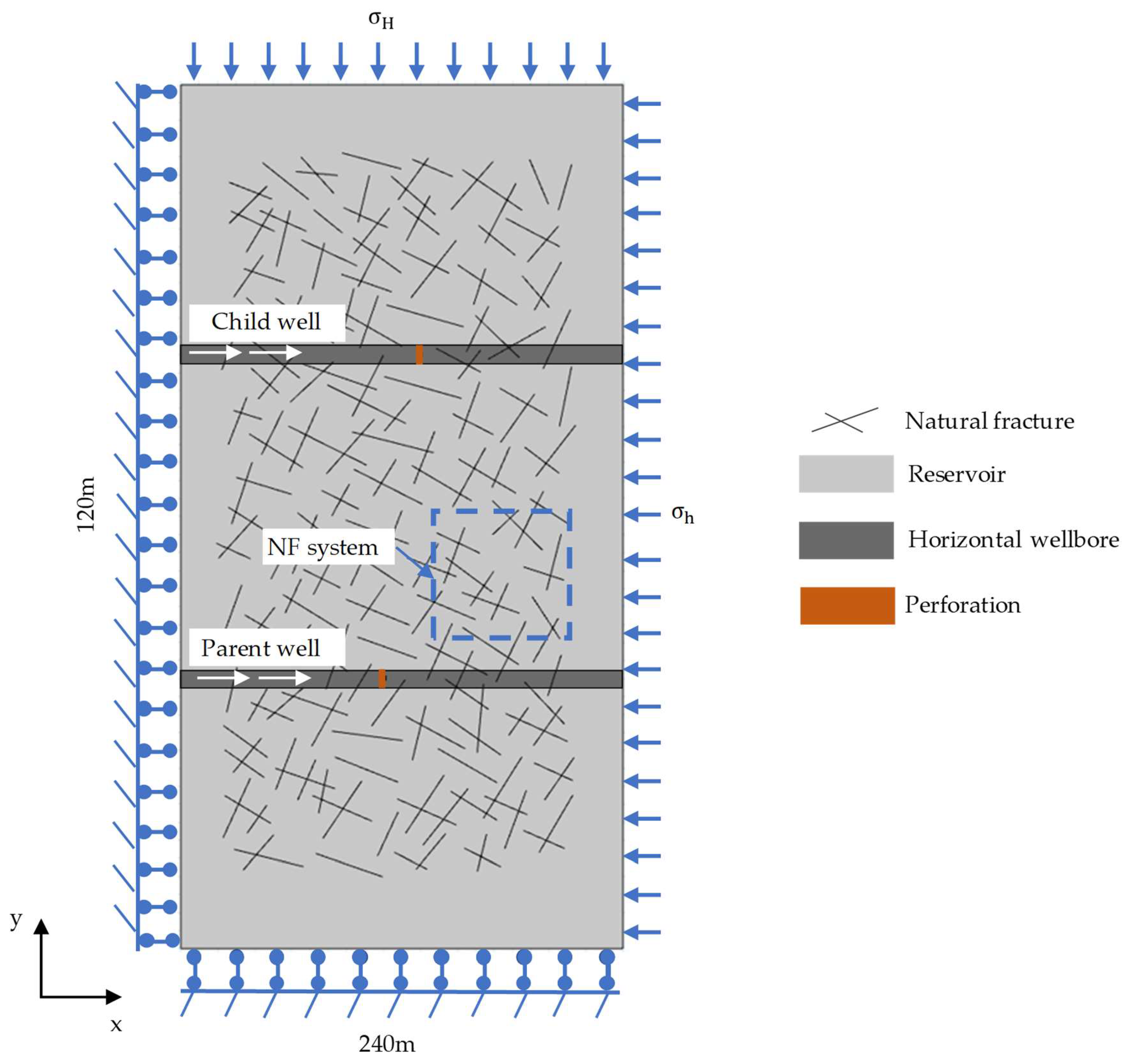

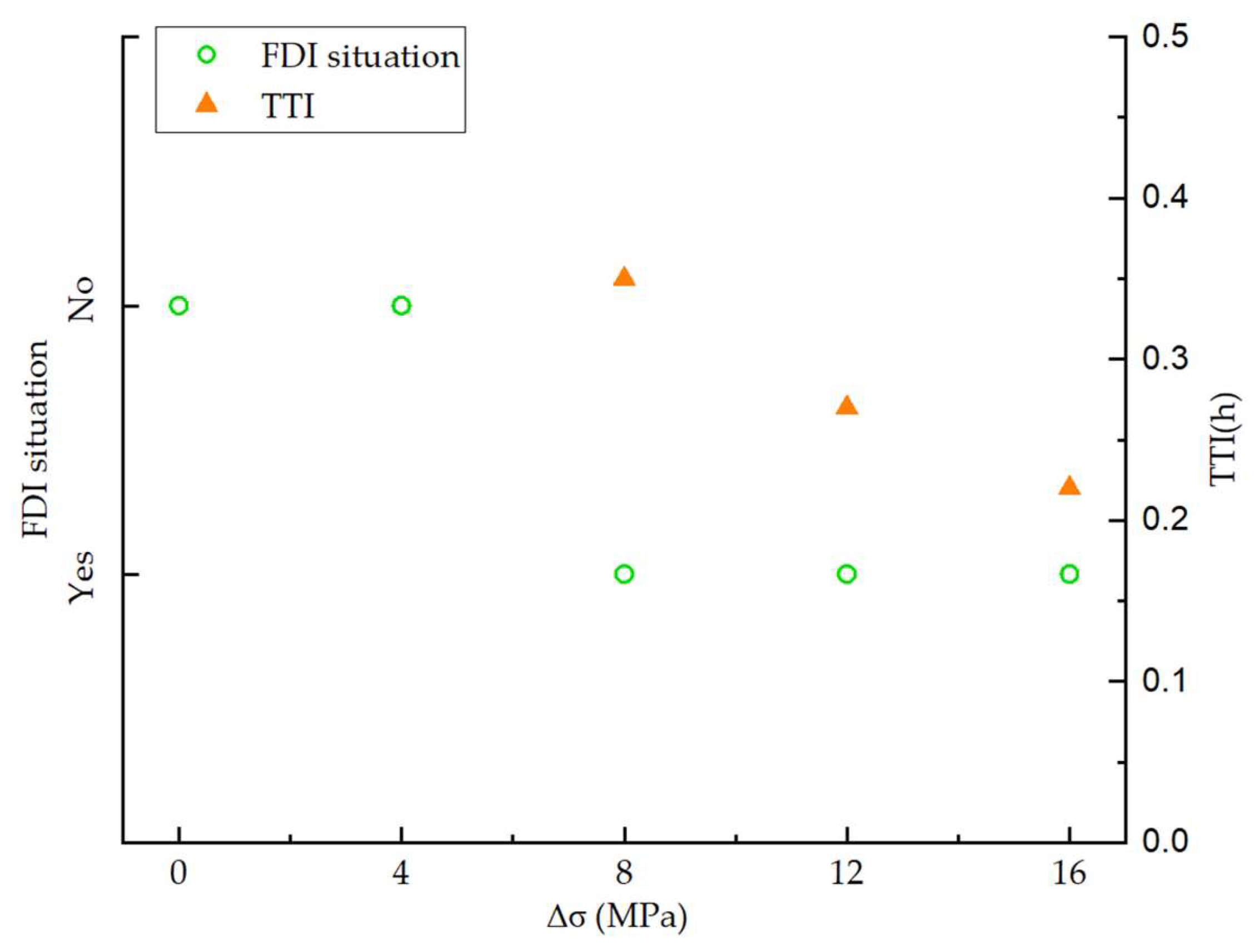

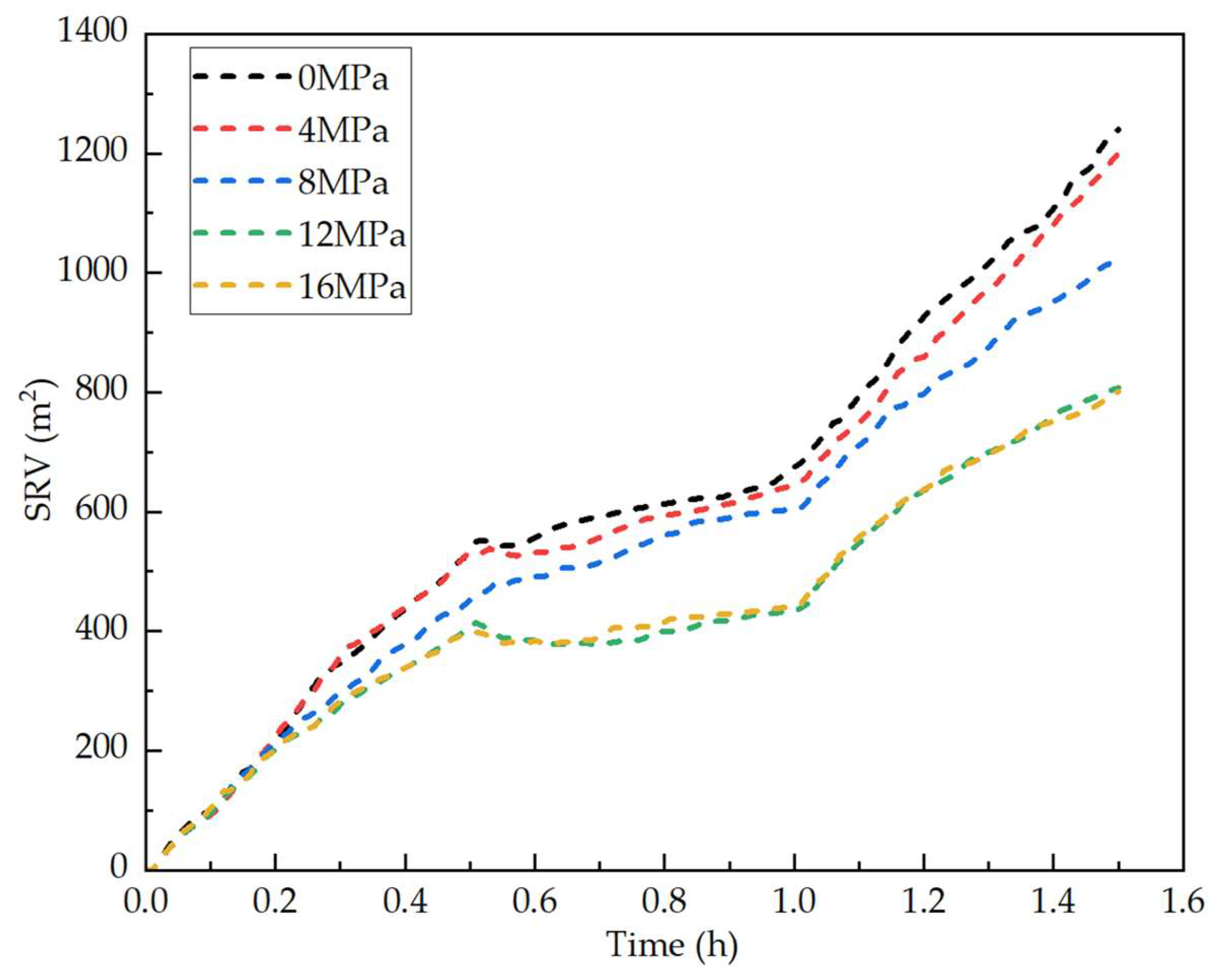

3.1. Horizontal Principal Stress Difference

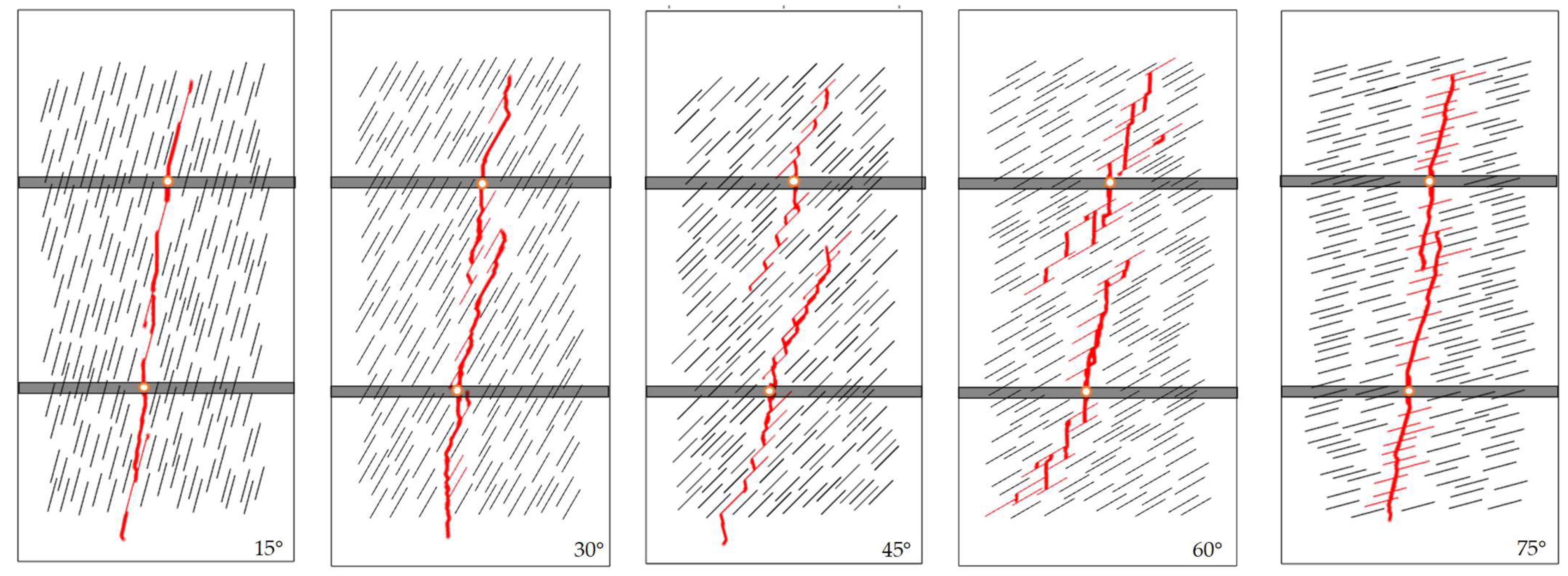

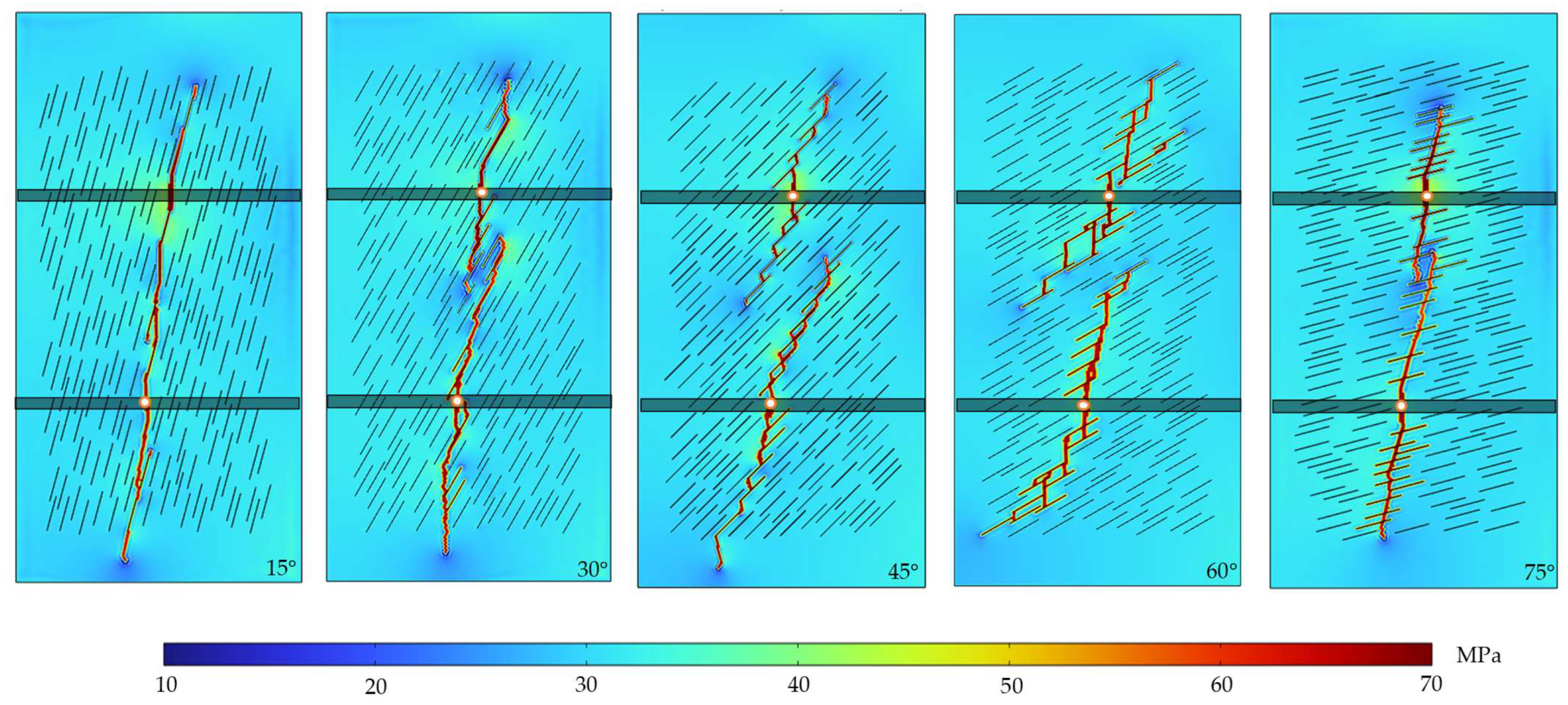

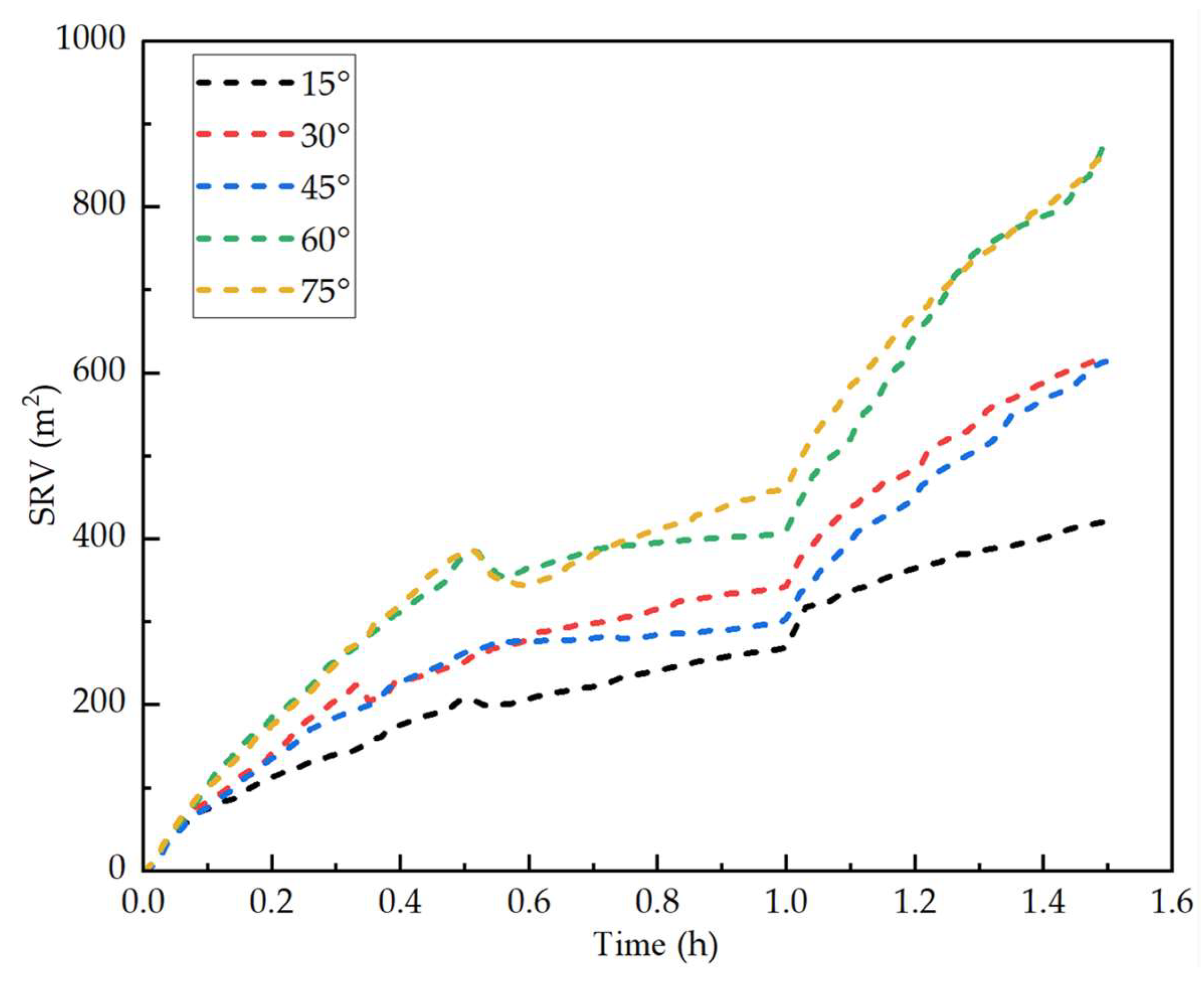

3.2. Approach Angle of Natural Fractures

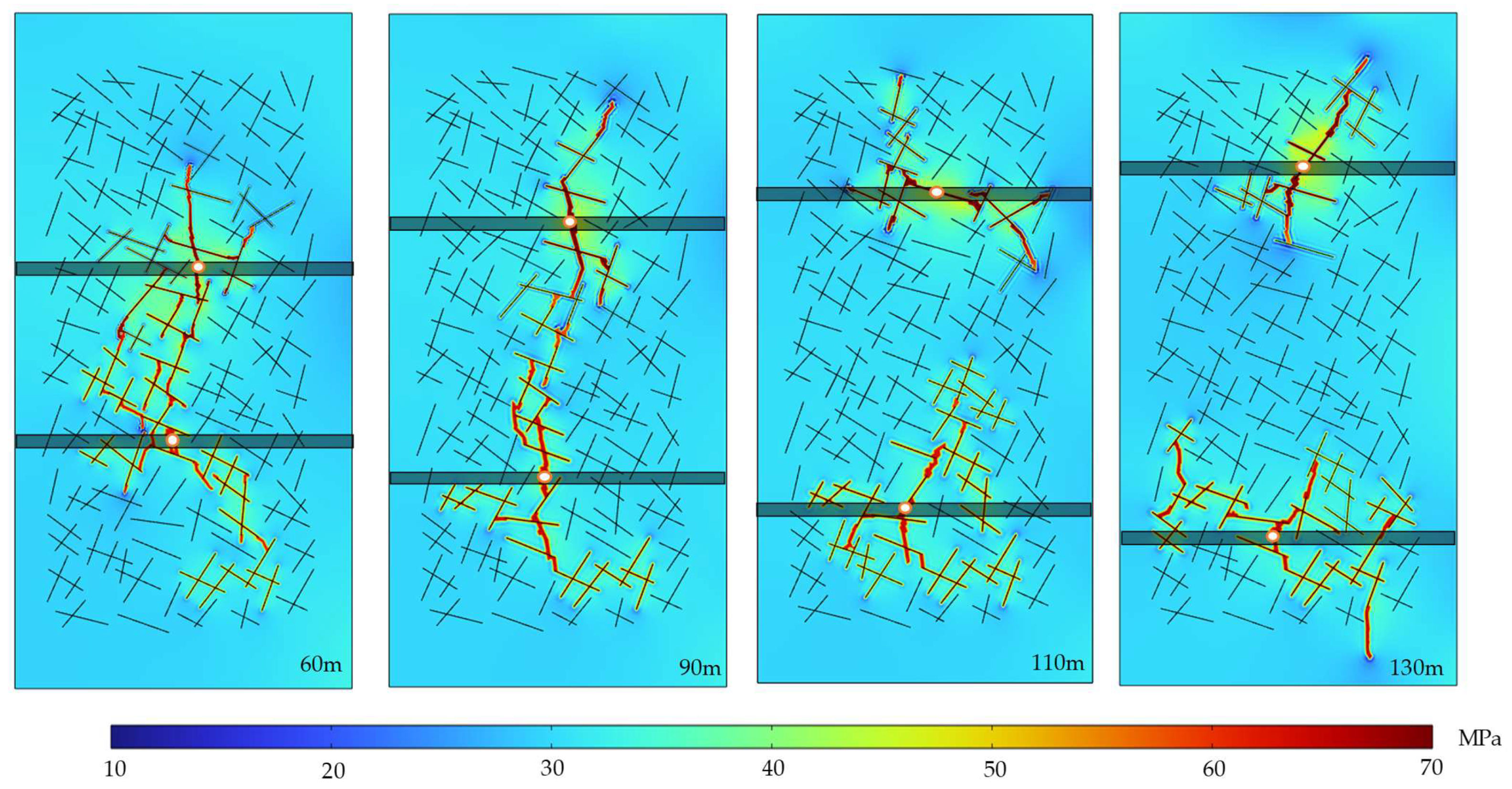

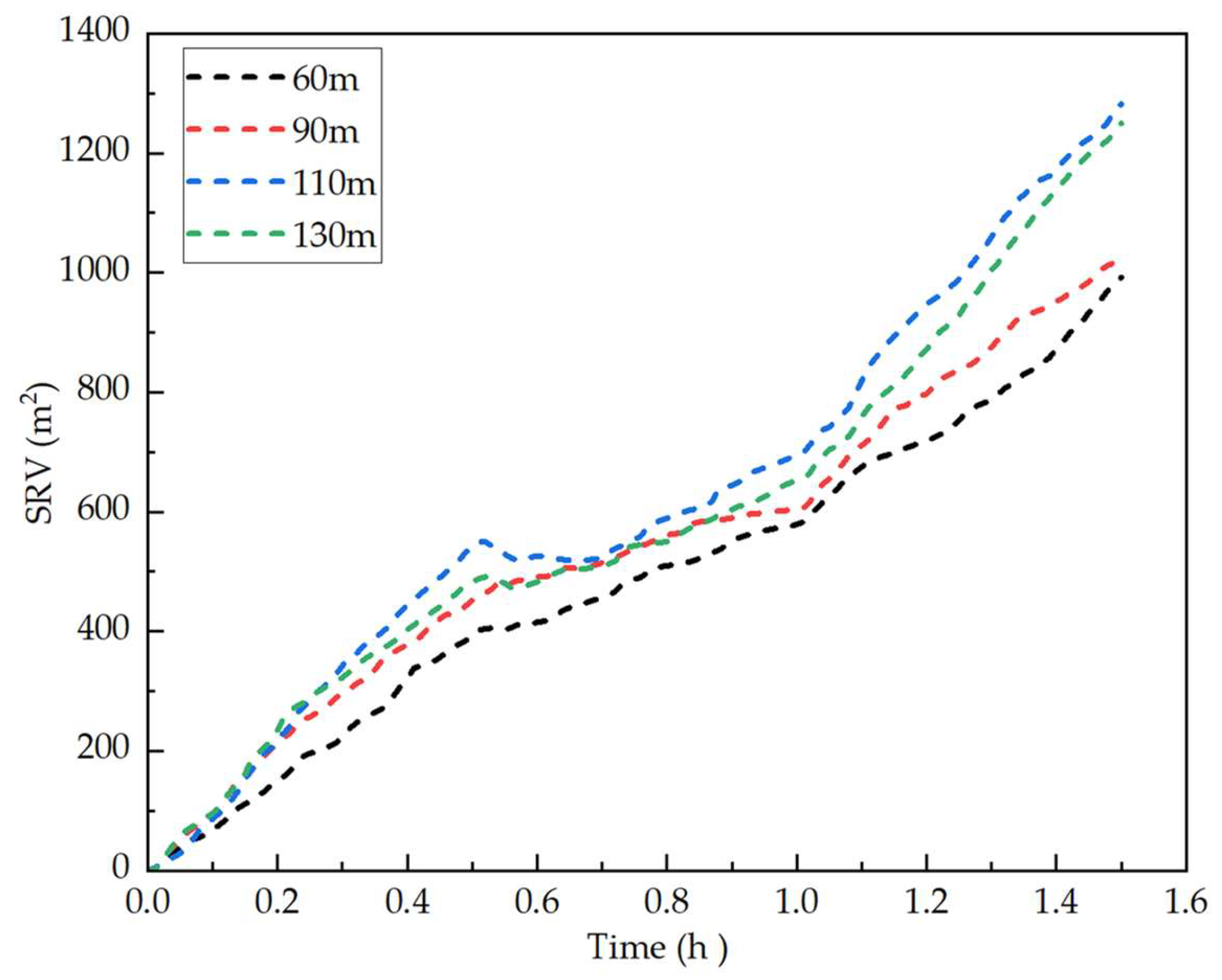

3.3. Well Spacing

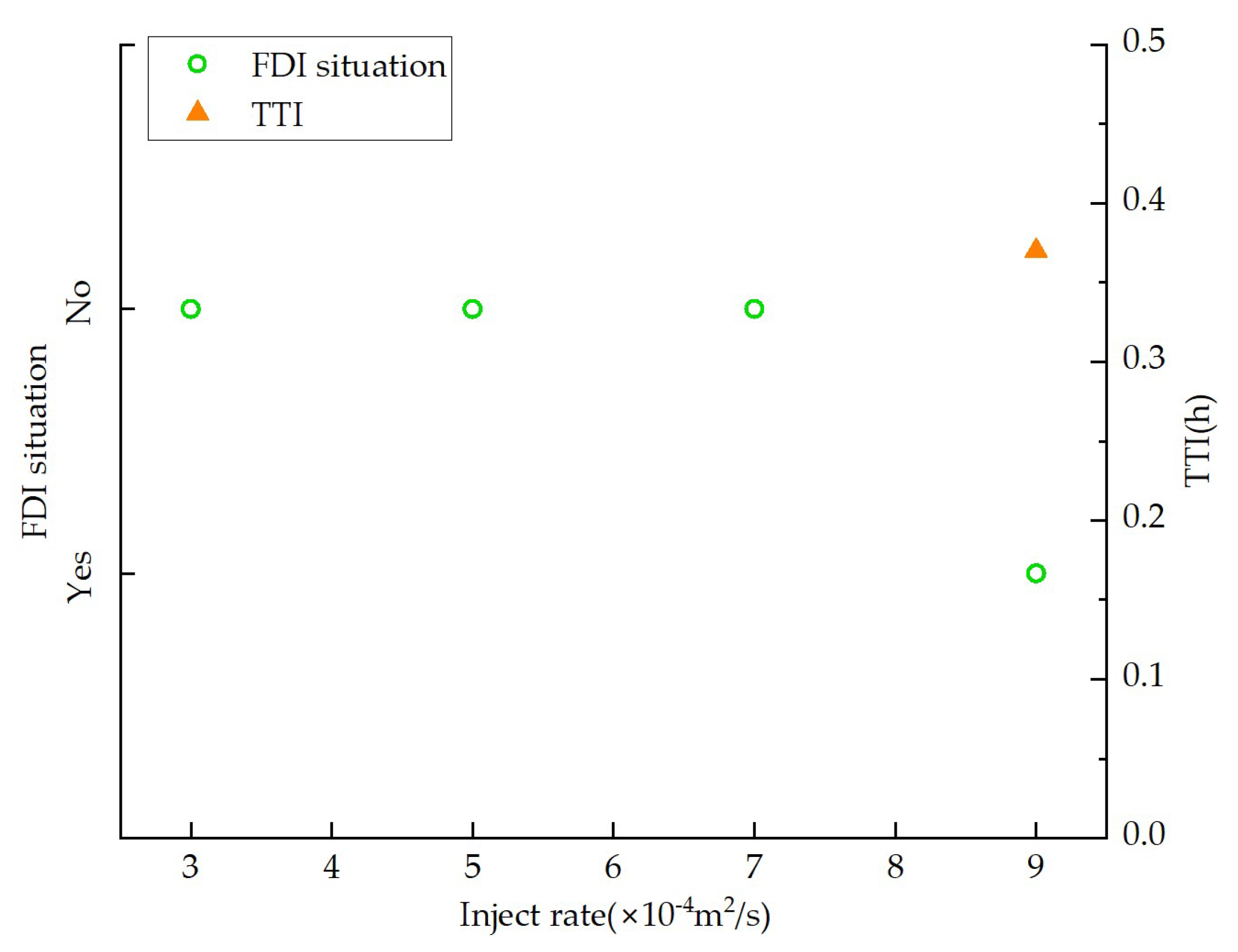

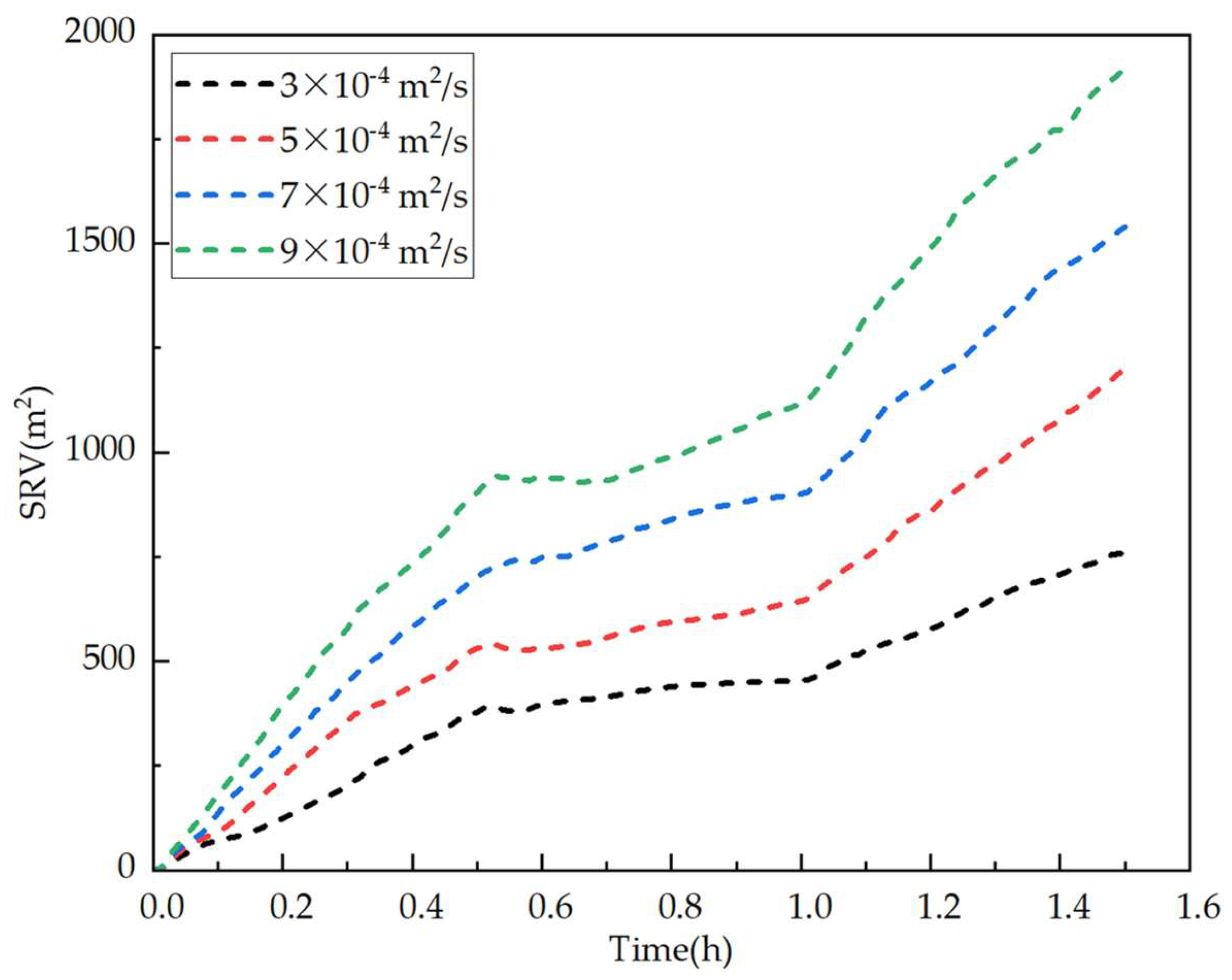

3.4. Injection Rate

4. Conclusions

- When the maximum horizontal stress difference increases to 8 MPa or higher, hydraulic fractures tend to propagate along the direction of the principal stress, forming a “narrow and long” primary fracture structure. At stress differences of 12 MPa and 16 MPa, interwell communication occurs at 0.27 h and 0.22 h after the start of fracturing in the child well, respectively, with a significant reduction in the reservoir stimulation volume.

- Increasing the well spacing from 60 m to 110 m delays interwell communication from 0.08 h after fracturing in the child well to a condition where no interference occurs, resulting in a significant improvement in the SRV. However, when the spacing is further increased to 130 m, although interwell communication is avoided, a larger unstimulated zone forms between wells—resulting in a “unstimulated zone”.

- At an approach angle of 15°, interwell communication occurs at 0.13 h during child well fracturing, with the main fracture path nearly overlapping that of the parent well. In contrast, when the approach angles are 30°, 45°, or 60°, fracture paths exhibit clear deflection and no interwell communication is observed. Moreover, the number of activated natural fractures increases significantly, reaching 16, 20, and 30 respectively.

- At an injection rate of 9 m2/s, the fracture propagation rate increases markedly, and interwell communication occurs at 0.38 h of child well fracturing. In contrast, when the injection rate is 3 m2/s, fracture propagation is significantly constrained, resulting in a smaller SRV and insufficient activation of natural fractures between wells.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| FDIs | Fracture-driven interactions |

| SRV | Stimulated reservoir volume |

| HMD | Hydro–mechanical–damage |

| DFN | Discrete fracture network |

| HF | Hydraulic fracture |

| NF | Natural fracture |

| TTI | Time to interface |

References

- Mukherjee, M.; Vishal, V. Gas transport in shale: A critical review of experimental studies on shale permeability at a mesoscopic scale. Earth-Sci. Rev. 2023, 244, 104522. [Google Scholar] [CrossRef]

- Luo, Z.; Zhang, N.; Zhao, L.; Yuan, X.; Zhang, Y. A novel stimulation strategy for developing tight fractured gas reservoir. Petroleum 2018, 4, 215–222. [Google Scholar] [CrossRef]

- Rammay, M.H.; Awotunde, A.A. Stochastic optimization of hydraulic fracture and horizontal well parameters in shale gas reservoirs. J. Nat. Gas Sci. Eng. 2016, 36, 71–78. [Google Scholar] [CrossRef]

- Qian, B.; Zhang, J.; Zhu, J.; Fang, Z.; Kou, S.; Chen, R. Application of zipper fracturing of horizontal cluster wells in the Changning shale gas pilot zone, Sichuan Basin. Nat. Gas Ind. 2015, 35, 81–84. [Google Scholar] [CrossRef]

- Wu, F.; Yan, Y.; Yin, C. Real-time microseismic monitoring technology for hydraulic fracturing in shale gas reservoirs: A case study from the Southern Sichuan Basin. Nat. Gas Ind. B 2017, 4, 68–71. [Google Scholar] [CrossRef]

- Xiaolun, Y. Investigation on the Fracture-Driven Interactions Mechanism and Preventive Countermeasures in Mahu Area. Ph.D. Thesis, China University of Petroleum, Beijing, China, 2022. [Google Scholar]

- Rafiee, M.; Grover, T. (Eds.) Well spacing optimization in Eagle Ford shale: An operator’s experience. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Austin, TX, USA, 24 July 2017. [Google Scholar]

- Wu, J.; Zeng, B.; Wang, L.; Huang, H.; Pan, Y.; Song, Y.; Nunez, H.; Deng, Q.; Wang, L.; Zhao, H. (Eds.) 3D Integrated G&G Model-Driven Mitigation Workflow on Screenout, Frac Hits and Casing Deformation in Ultradeep Shale Hydraulic Fracturing. In Proceedings of the Society of Petroleum Engineers—SPE Argentina Exploration and Production of Unconventional Resources Symposium, Buenos Aires, Argentina, 20 March 2023; LAUR: Los Alamos, NM, USA, 2023. [Google Scholar]

- Daneshy, A.; Au-Yeung, J.; Thompson, T.; Tymko, D. (Eds.) Fracture shadowing: A direct method for determining of the reach and propagation pattern of hydraulic fractures in horizontal wells. In Proceedings of the Society of Petroleum Engineers—SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 20 February 2012. [Google Scholar]

- Schaeffer, B.; Mcgreaham, L.; Reshetnikov, A. Unconventional parent-child well completion evaluation via microseismic analysis: A Delaware Basin case study. In Seg Technical Program Expanded Abstracts; Society of Exploration Geophysicists: Houston, TX, USA, 2017. [Google Scholar]

- Awada, A.; Santo, M.; Lougheed, D.; Xu, D.; Virues, C. Is That Interference? A Work Flow for Identifying and Analyzing Communication Through Hydraulic Fractures in a Multiwell Pad. SPE J. 2016, 21, 1554–1566. [Google Scholar] [CrossRef]

- Cao, R.; Li, R.; Girardi, A.; Chowdhury, N.; Chen, C. Well Interference and Optimum Well Spacing for Wolfcamp Development at Permian Basin. In Proceedings of the Unconventional Resources Technology Conference, Austin, TX, USA, 24–26 July 2017; pp. 2756–2766. [Google Scholar]

- Cipolla, C.; Mack, M. (Eds.) Reducing Exploration and Appraisal Risk in Low-Permeability Reservoirs Using Microseismic Fracture Mapping. In Proceedings of the Canadian Unconventional Resources and International Petroleum Conference, Calgary, AB, Canada, 19 October 2010; p. SPE-137437-MS. [Google Scholar]

- Cipolla, C.; Mack, M.; Maxwell, S. (Eds.) Reducing Exploration and Appraisal Risk in Low Permeability Reservoirs Using Microseismic Fracture Mapping—Part 2. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Lima, Peru, 1–3 December 2010; p. SPE-138103-MS. [Google Scholar]

- Manchanda, R.; Sharma, M.M.M.; Holzhauser, S. Time-Dependent Fracture-Interference Effects in Pad Wells. SPE Prod. Oper. 2014, 29, 274–287. [Google Scholar] [CrossRef]

- Fatahi, H.; Hossain, M.M.; Sarmadivaleh, M. Numerical and experimental investigation of the interaction of natural and propagated hydraulic fracture. J. Nat. Gas Sci. Eng. 2017, 37, 409–424. [Google Scholar] [CrossRef]

- Zhang, N.; Liu, F.; Jiang, L.; Mo, P.; Xiao, J.; Song, Q.; Luo, Y. Coupled THMC model-based prediction of hydraulic fracture geometry and size under self-propping phase-transition fracturing. Int. J. Coal Sci. Technol. 2024, 11, 78. [Google Scholar] [CrossRef]

- Weng, X.; Chuprakov, D.; Kresse, O.; Prioul, R.; Wang, H. Hydraulic fracture-height containment by permeable weak bedding interfaces. Geophysics 2018, 83, MR137–MR152. [Google Scholar] [CrossRef]

- Cai, Y.; Dahi Taleghani, A. (Eds.) Toward controllable infill completions using frac-driven interactions FDI data. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dubai, United Arab Emirates, 15 September 2021; SPE: Houston, TX, USA, 2021. [Google Scholar]

- Sesetty, V.; Ghassemi, A. Effect of rock anisotropy on wellbore stresses and hydraulic fracture propagation. Int. J. Rock Mech. Min. Sci. 2018, 112, 369–384. [Google Scholar] [CrossRef]

- Zhang, N.; Luo, Z.; Chen, Z.; Liu, F.; Liu, P.; Chen, W.; Wu, L.; Zhao, L. Thermal–hydraulic–mechanical–chemical coupled processes and their numerical simulation: A comprehensive review. Acta Geotech. 2023, 18, 6253–6274. [Google Scholar] [CrossRef]

- Rezaei, A.; Rafiee, M.; Siddiqui, F.; Soliman, M.; Bornia, G. (Eds.) The role of pore pressure depletion in propagation of new hydraulic fractures during Refracturing of horizontal Wells. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 9–11 October 2017; SPE: Houston, TX, USA, 2017. [Google Scholar]

- Seth, P.; Manchanda, R.; Kumar, A.; Sharma, M.M. Analyzing pressure interference between horizontal wells during fracturing. J. Pet. Sci. Eng. 2021, 204, 108696. [Google Scholar] [CrossRef]

- Wang, W.; Yu, W.; Gao, P.; Zeng, B.; Su, Y.; Tang, D.; Huang, H.; Sun, H. Mechanisms and impact patterns of frac hits between shale gas wells. Nat. Gas Ind. 2024, 44, 128–138. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, Y.; Hu, Y.; Zhao, J.; Song, Y.; Shen, C. The law of fracture propagation and intersection in zipper fracturing of deep shale gas wells. Pet. Explor. Dev. 2024, 51, 1316–1326. [Google Scholar] [CrossRef]

- Gupta, I.; Rai, C.; Devegowda, D.; Sondergeld, C.H. Fracture hits in unconventional reservoirs: A critical review. SPE J. 2021, 26, 412–434. [Google Scholar] [CrossRef]

- Liang, Y.; Yang, K.; Yang, Z.; Li, Q.; Chen, Q.; Sun, W. Hydro-mechanical-damage coupling effect of hydraulic fracturing in fractured dual-medium coal masses. Comput. Geotech. 2025, 178, 106909. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, Q.; Zhang, C.; Liao, J.; Lin, H.; Wang, Y. Coupled seepage-damage effect in fractured rock masses: Model development and a case study. Int. J. Rock Mech. Min. Sci. 2021, 144, 104822. [Google Scholar] [CrossRef]

- Jirásek, M.; Bauer, M. Numerical aspects of the crack band approach. Comput. Struct. 2012, 110, 60–78. [Google Scholar] [CrossRef]

- Zhu, W.C.; Tang, C. Micromechanical model for simulating the fracture process of rock. Rock Mech. Rock Eng. 2004, 37, 25–56. [Google Scholar] [CrossRef]

- Tang, C.; Liang, Z.; Zhang, Y.; Chang, X.; Tao, X.; Wang, D.; Zhang, J.; Liu, J.; Zhu, W.; Elsworth, D. Fracture spacing in layered materials: A new explanation based on two-dimensional failure process modeling. Am. J. Sci. 2008, 308, 49–72. [Google Scholar] [CrossRef]

- Zhang, B.; Guo, T.; Qu, Z.; Wang, J.; Chen, M.; Liu, X. Numerical simulation of fracture propagation and production performance in a fractured geothermal reservoir using a 2D FEM-based THMD coupling model. Energy 2023, 273, 127175. [Google Scholar] [CrossRef]

- Simo, J.C.; Hughes, T.J. Computational Inelasticity; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2006; Volume 7. [Google Scholar]

- Wriggers, P.; Laursen, T.A. Computational Contact Mechanics; Springer: Berlin/Heidelberg, Germany, 2006; Volume 2. [Google Scholar]

- Needleman, A. A continuum model for void nucleation by inclusion debonding. J. Appl. Mech. 1987, 54, 525–531. [Google Scholar] [CrossRef]

- Rutqvist, J.; Wu, Y.-S.; Tsang, C.-F.; Bodvarsson, G. A modeling approach for analysis of coupled multiphase fluid flow, heat transfer, and deformation in fractured porous rock. Int. J. Rock Mech. Min. Sci. 2002, 39, 429–442. [Google Scholar] [CrossRef]

- Byerlee, J. Friction of rocks. Pure Appl. Geophys. 1978, 116, 615–626. [Google Scholar] [CrossRef]

- Min, K.-B.; Rutqvist, J.; Tsang, C.-F.; Jing, L. Stress-dependent permeability of fractured rock masses: A numerical study. Int. J. Rock Mech. Min. Sci. 2004, 41, 1191–1210. [Google Scholar] [CrossRef]

- Zhang, F.; Jiang, Z.; Chen, Z.; Yin, Z.; Tang, J. Hydraulic fracturing induced fault slip and casing shear in Sichuan Basin: A multi-scale numerical investigation. J. Pet. Sci. Eng. 2020, 195, 107797. [Google Scholar] [CrossRef]

- Wei, S.; Kao, J.; Jin, Y.; Shi, C.; Xia, Y.; Liu, S. A discontinuous discrete fracture model for coupled flow and geomechanics based on FEM. J. Pet. Sci. Eng. 2021, 204, 108677. [Google Scholar] [CrossRef]

- Zhao, C.; Zhang, Z.; Lei, Q. Role of hydro-mechanical coupling in excavation-induced damage propagation, fracture deformation and microseismicity evolution in naturally fractured rocks. Eng. Geol. 2021, 289, 106169. [Google Scholar] [CrossRef]

- Xia, Y.; Wei, S.; Deng, Y.; Jin, Y. A new enriched method for extended finite element modeling of fluid flow in fractured reservoirs. Comput. Geotech. 2022, 148, 104806. [Google Scholar] [CrossRef]

- Rutqvist, J.; Stephansson, O. The role of hydromechanical coupling in fractured rock engineering. Hydrogeol. J. 2003, 11, 7–40. [Google Scholar] [CrossRef]

- Witherspoon, P.A.; Wang, J.S.; Iwai, K.; Gale, J.E. Validity of cubic law for fluid flow in a deformable rock fracture. Water Resour. Res. 1980, 16, 1016–1024. [Google Scholar] [CrossRef]

- Rutqvist, J.; Noorishad, J.; Tsang, C.F.; Stephansson, O. Determination of fracture storativity in hard rocks using high-pressure injection testing. Water Resour. Res. 1998, 34, 2551–2560. [Google Scholar] [CrossRef]

- Zhu, W.; Wei, C. Numerical simulation on mining-induced water inrushes related to geologic structures using a damage-based hydromechanical model. Environ. Earth Sci. 2011, 62, 43–54. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Oh, B.H. Crack band theory for fracture of concrete. Mater. Struct. 1983, 16, 155–177. [Google Scholar] [CrossRef]

- Jian, Z.; Lichuang, W. Research on pneumatic fracturing applicated to foundation treatment. J. Ground Improv. 2019, 1, 63–78. [Google Scholar]

- Jiao, Y.Y.; Zhang, H.Q.; Zhang, X.L.; Li, H.B.; Jiang, Q.H. A two-dimensional coupled hydromechanical discontinuum model for simulating rock hydraulic fracturing. Int. J. Numer. Anal. Methods Geomech. 2015, 39, 457–481. [Google Scholar] [CrossRef]

- Yang, Y.; Tang, X.; Zheng, H.; Liu, Q.; Liu, Z. Hydraulic fracturing modeling using the enriched numerical manifold method. Appl. Math. Model. 2018, 53, 462–486. [Google Scholar] [CrossRef]

- Lu, M.; Zhu, Z.; Zhou, L.; Ge, X. Numerical simulation of hydraulic fracture propagation in rock masses with pre-existing double fractures using the phase field method. Rock Soil Mech. 2025, 45, 7. [Google Scholar]

- Blanton, T.L. Propagation of hydraulically and dynamically induced fractures in naturally fractured reservoirs. In Proceedings of the SPE Unconventional Resources Conference/Gas Technology Symposium, Louisville, KY, USA, 18 May 1986; SPE: Houston, TX, USA, 1986. [Google Scholar]

- Gu, H.; Weng, X.; Lund, J.; Mack, M.; Ganguly, U.; Suarez-Rivera, R. Hydraulic fracture crossing natural fracture at nonorthogonal angles: A criterion and its validation. SPE Prod. Oper. 2012, 27, 20–26. [Google Scholar] [CrossRef]

- Warpinski, N.; Teufel, L. Influence of geologic discontinuities on hydraulic fracture propagation (includes associated papers 17011 and 17074). J. Pet. Technol. 1987, 39, 209–220. [Google Scholar] [CrossRef]

- Liu, F.; Sun, W.; Li, M.; Shang, X. A smoothed assumed enhanced strain method for frictional contact with constant strain elements. J. Rock Mech. Geotech. Eng. 2024, 16, 4369–4385. [Google Scholar] [CrossRef]

- Zhang, S.; Dong, D.; Liao, Q.; Sun, S.; Huang, S.; Guan, Q.; Zhang, C.; Guo, W.; Jiang, S.; Shi, P. Geological characteristics and resource prospect of deep marine shale gas in the southern Sichuan Basin. Nat. Gas Ind. 2021, 41, 35–45. [Google Scholar]

- Xu, R.-L.; Guo, T.-K.; Xue, X.-J.; Chen, W.-B.; Qu, Z.-Q.; Chen, M.; Hu, Z.-P. Numerical simulation of fracturing and imbibition in shale oil horizontal wells. Pet. Sci. 2023, 20, 2981–3001. [Google Scholar] [CrossRef]

- Lei, Q.; Doonechaly, N.G.; Tsang, C.-F. Modelling fluid injection-induced fracture activation, damage growth, seismicity occurrence and connectivity change in naturally fractured rocks. Int. J. Rock Mech. Min. Sci. 2021, 138, 104598. [Google Scholar] [CrossRef]

- Lin, C.; He, J.; Li, X.; Wan, X.; Zheng, B. An experimental investigation into the effects of the anisotropy of shale on hydraulic fracture propagation. Rock Mech. Rock Eng. 2017, 50, 543–554. [Google Scholar] [CrossRef]

- Yin, P.-F.; Yang, S.-Q.; Ranjith, P.G. Anisotropic mechanical behaviors of shale rock and their relation to hydraulic fracturing in a shale reservoir: A review. Energies 2024, 17, 1761. [Google Scholar] [CrossRef]

- Zhong-xuan, Y.; Luo-yi, Y.; Yang, Y.; Dong, L.; Chao-fa, Z. Overview of fabric anisotropy of soils and constitutive model developments. J. Ground Improv. 2022, 4, 279–288. [Google Scholar]

| Model Properties | Value | Units |

|---|---|---|

| Rock Matrix | ||

| Density | 2650 | |

| Young’s modulus E | 40 | GPa |

| Poisson’s ratio | 0.25 | - |

| Tensile strength | 10 | MPa |

| Compressive strength | 148 | MPa |

| Internal friction angle | 30 | deg |

| Residual strength ratio | 0.1 | - |

| Initial porosity | 0.01 | - |

| Residual porosity | 0.001 | - |

| Initial permeability | 5 × | |

| Biot’s coefficient | 0.8 | - |

| Fractures | ||

| Initial normal stiffness | 50 | GPa/m |

| Shear stiffness | 50 | GPa/m |

| Friction angle | 15 | deg |

| Dilation angle | 3 | deg |

| Residual shear displacement | 5 | mm |

| Initial aperture | 0.1 | mm |

| Residual aperture | 0.01 | Mm |

| Fracturing fluid | ||

| Density | 1000 | |

| Viscosity | ||

| Compressibility | 4.4 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, F.; Mou, Y.; Wen, F.; Yao, Z.; Yi, X.; Xu, R.; Zhang, N. A Damage-Based Fully Coupled DFN Study of Fracture-Driven Interactions in Zipper Fracturing for Shale Gas Production. Energies 2025, 18, 4722. https://doi.org/10.3390/en18174722

Liu F, Mou Y, Wen F, Yao Z, Yi X, Xu R, Zhang N. A Damage-Based Fully Coupled DFN Study of Fracture-Driven Interactions in Zipper Fracturing for Shale Gas Production. Energies. 2025; 18(17):4722. https://doi.org/10.3390/en18174722

Chicago/Turabian StyleLiu, Fushen, Yang Mou, Fenggang Wen, Zhiguang Yao, Xinzheng Yi, Rui Xu, and Nanlin Zhang. 2025. "A Damage-Based Fully Coupled DFN Study of Fracture-Driven Interactions in Zipper Fracturing for Shale Gas Production" Energies 18, no. 17: 4722. https://doi.org/10.3390/en18174722

APA StyleLiu, F., Mou, Y., Wen, F., Yao, Z., Yi, X., Xu, R., & Zhang, N. (2025). A Damage-Based Fully Coupled DFN Study of Fracture-Driven Interactions in Zipper Fracturing for Shale Gas Production. Energies, 18(17), 4722. https://doi.org/10.3390/en18174722