Optimization of Grid-Connected and Off-Grid Hybrid Energy Systems for a Greenhouse Facility

Abstract

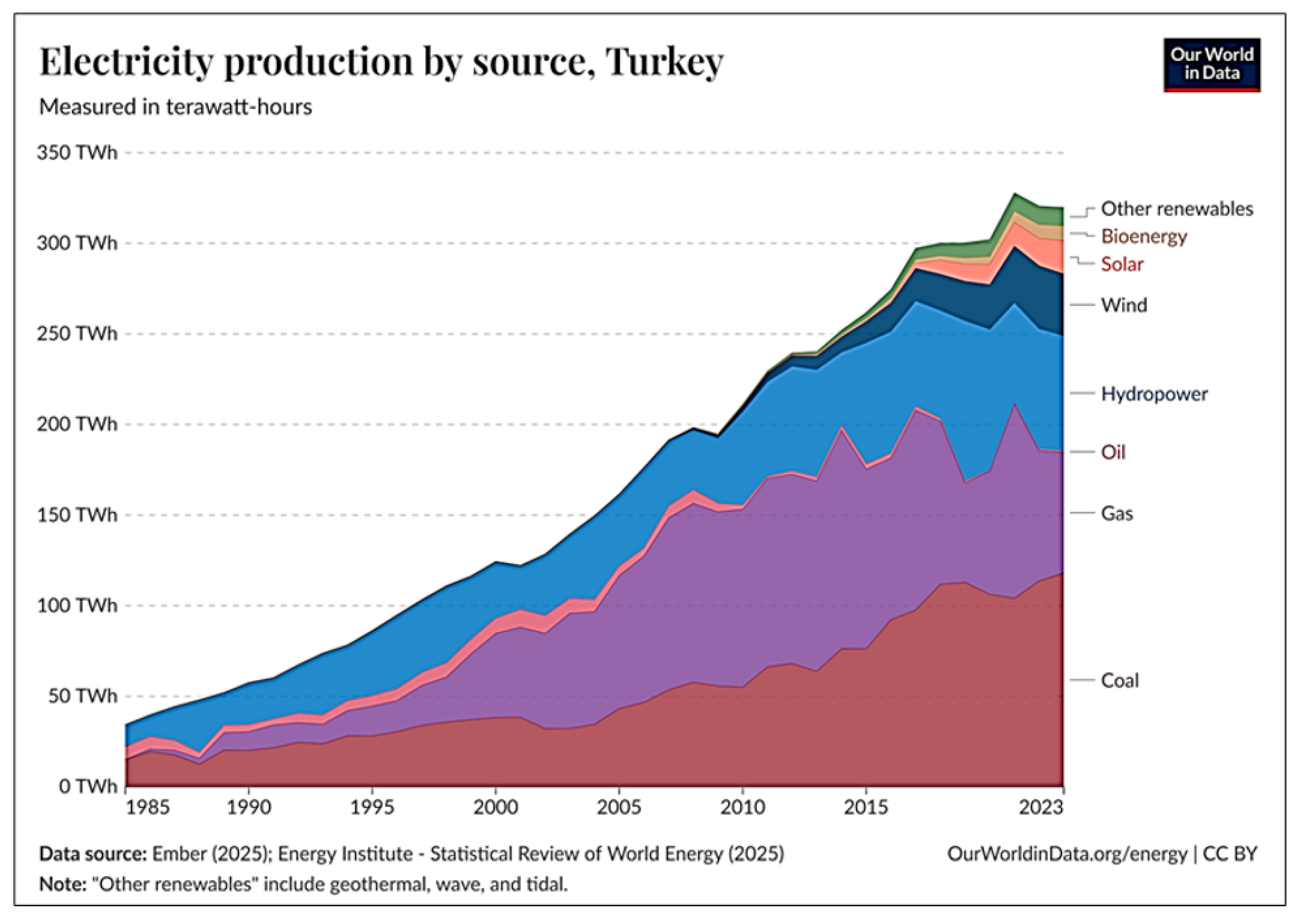

1. Introduction

1.1. Renewables in Agriculture

1.2. Studies Focusing on Renewable Energy Optimization Strategies

1.3. Objectives of This Study

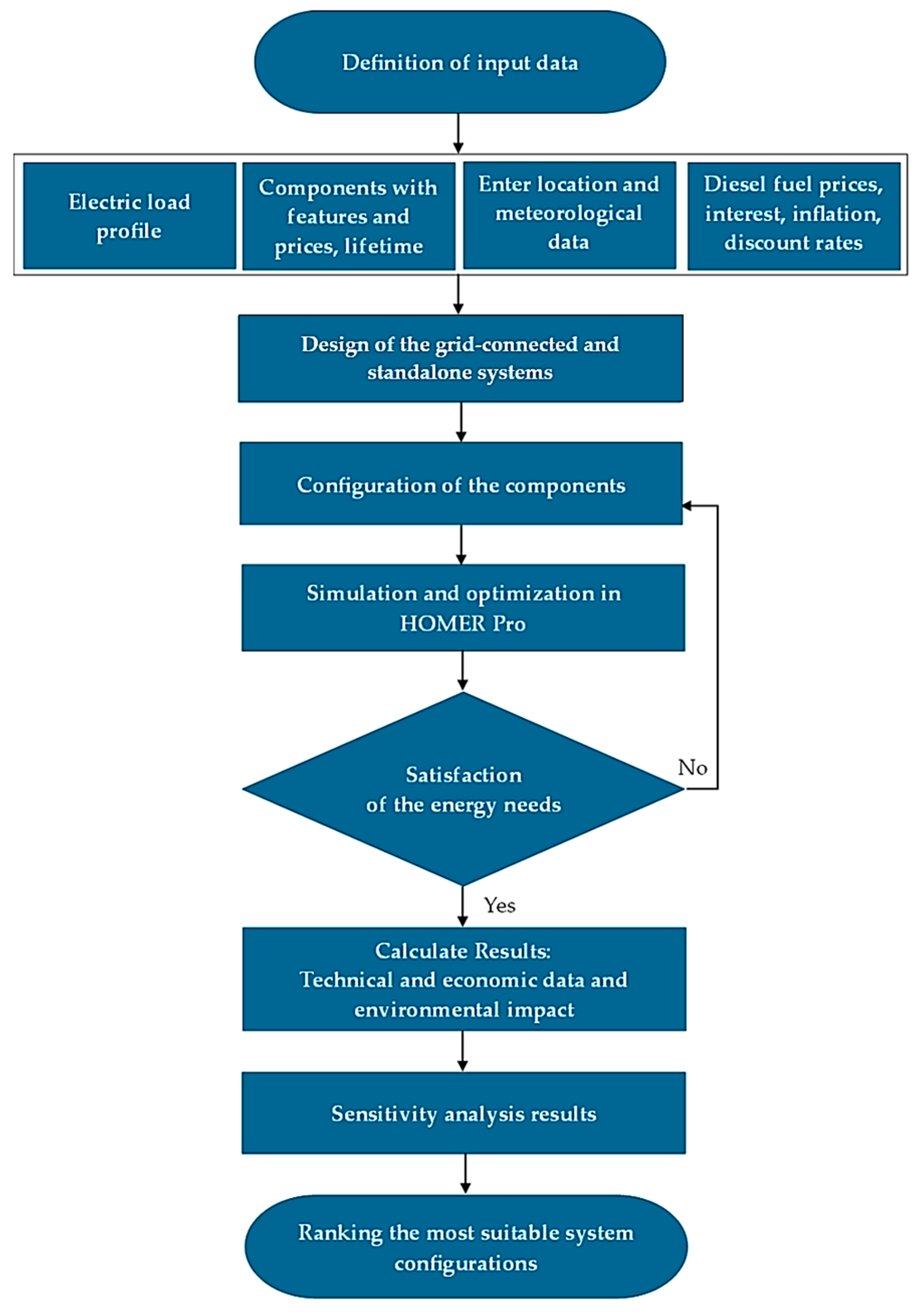

2. Materials and Methods

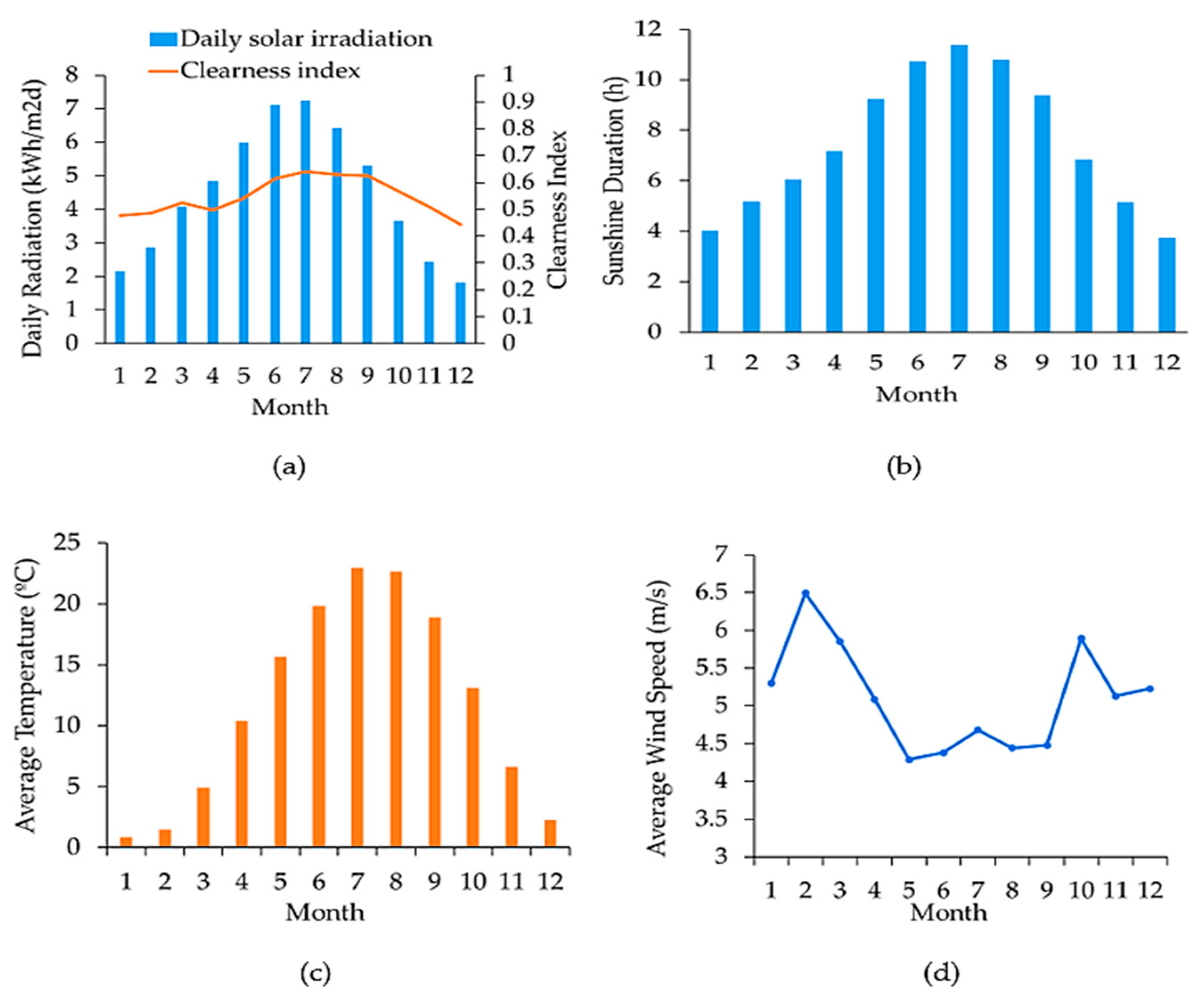

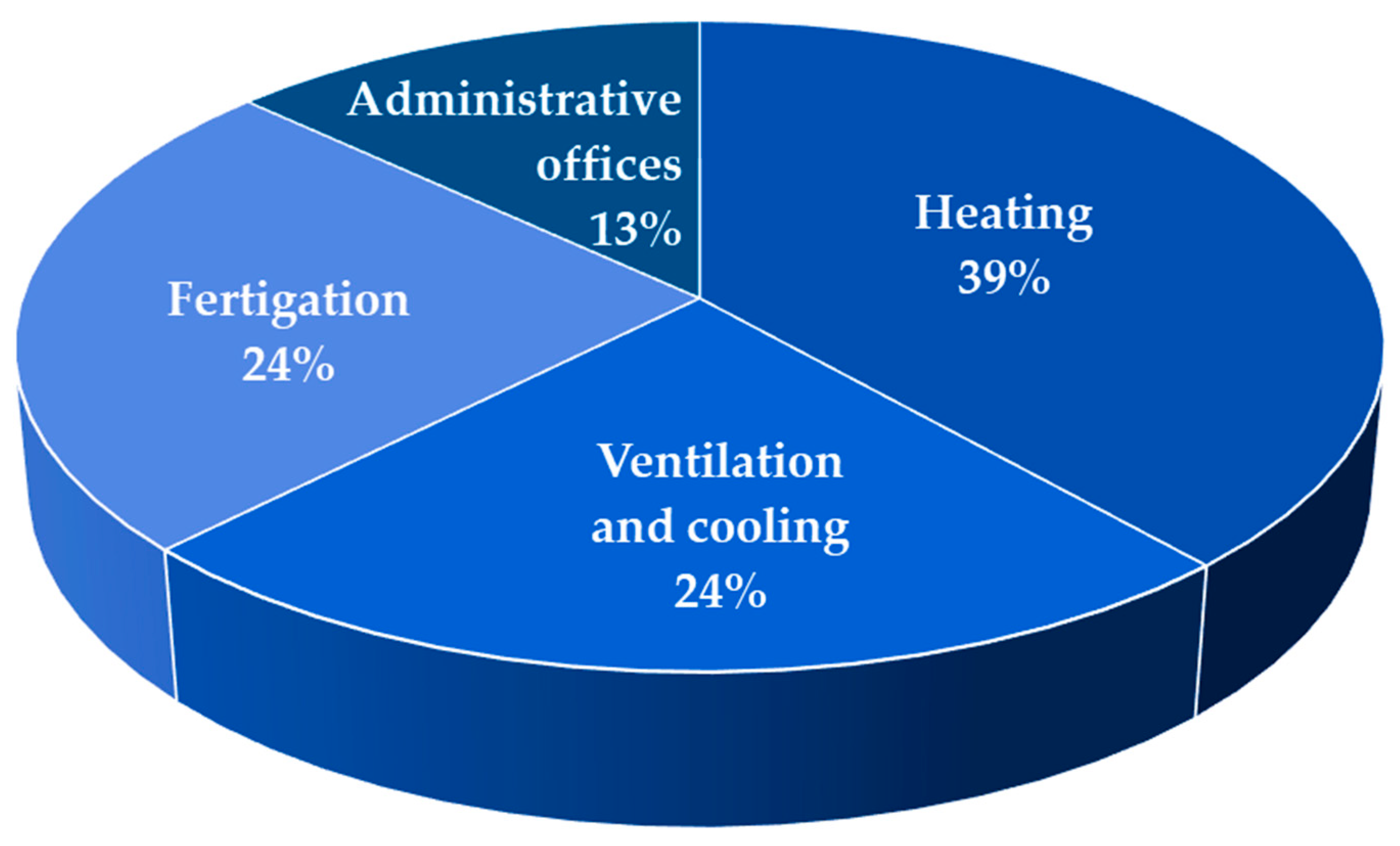

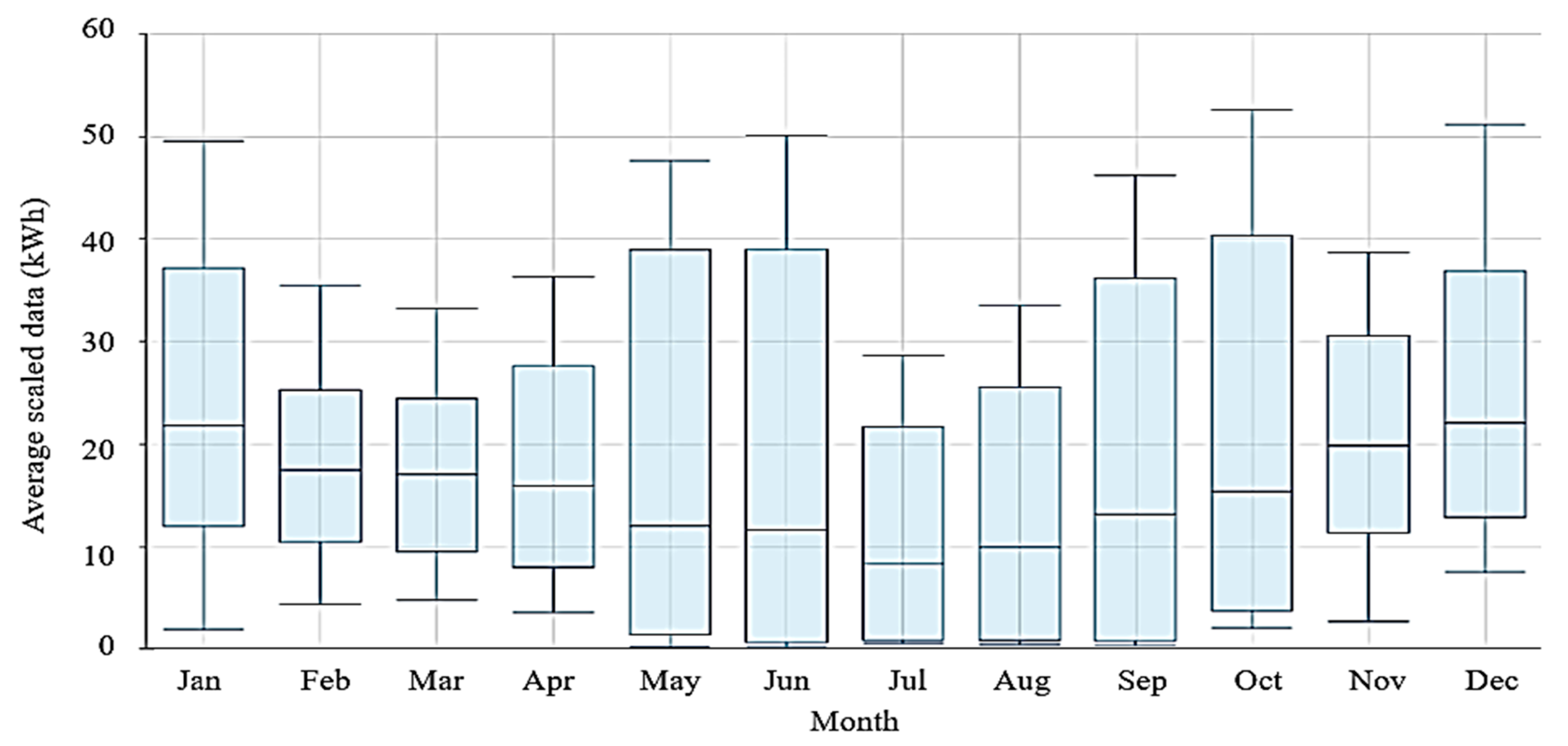

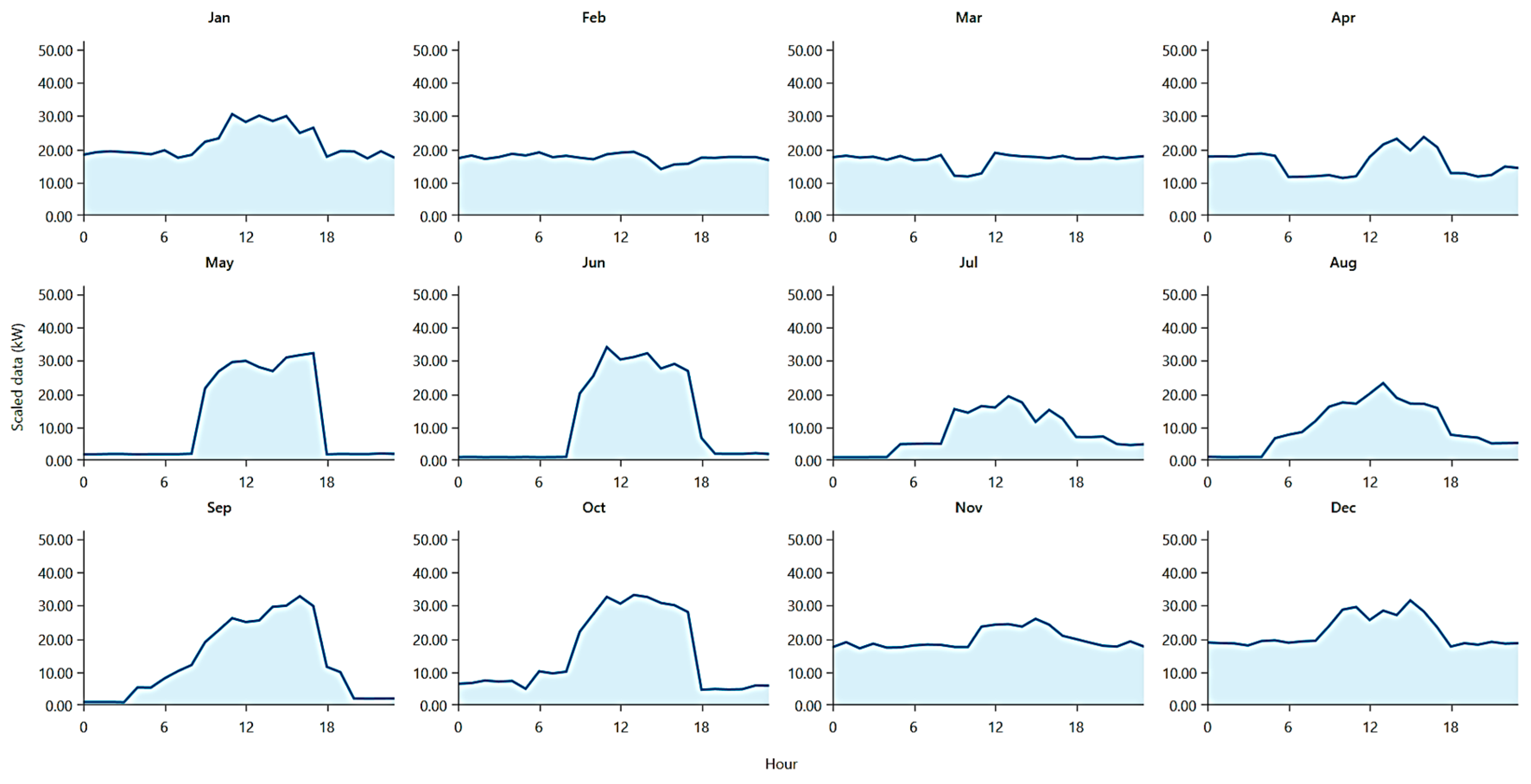

2.1. Site and System Design Parameters

2.2. Mathematical Modeling of Energy Systems

2.2.1. HOMER Pro Software

2.2.2. Photovoltaic Systems

2.2.3. Wind Turbine Systems

2.2.4. Diesel Generator Systems

2.2.5. Battery Storage

2.2.6. Inverter

2.2.7. Grid (G)

2.3. Economic Analysis

2.3.1. The Net Present Cost (NPC)

2.3.2. Levelized Cost of Energy (LCOE)

3. Results

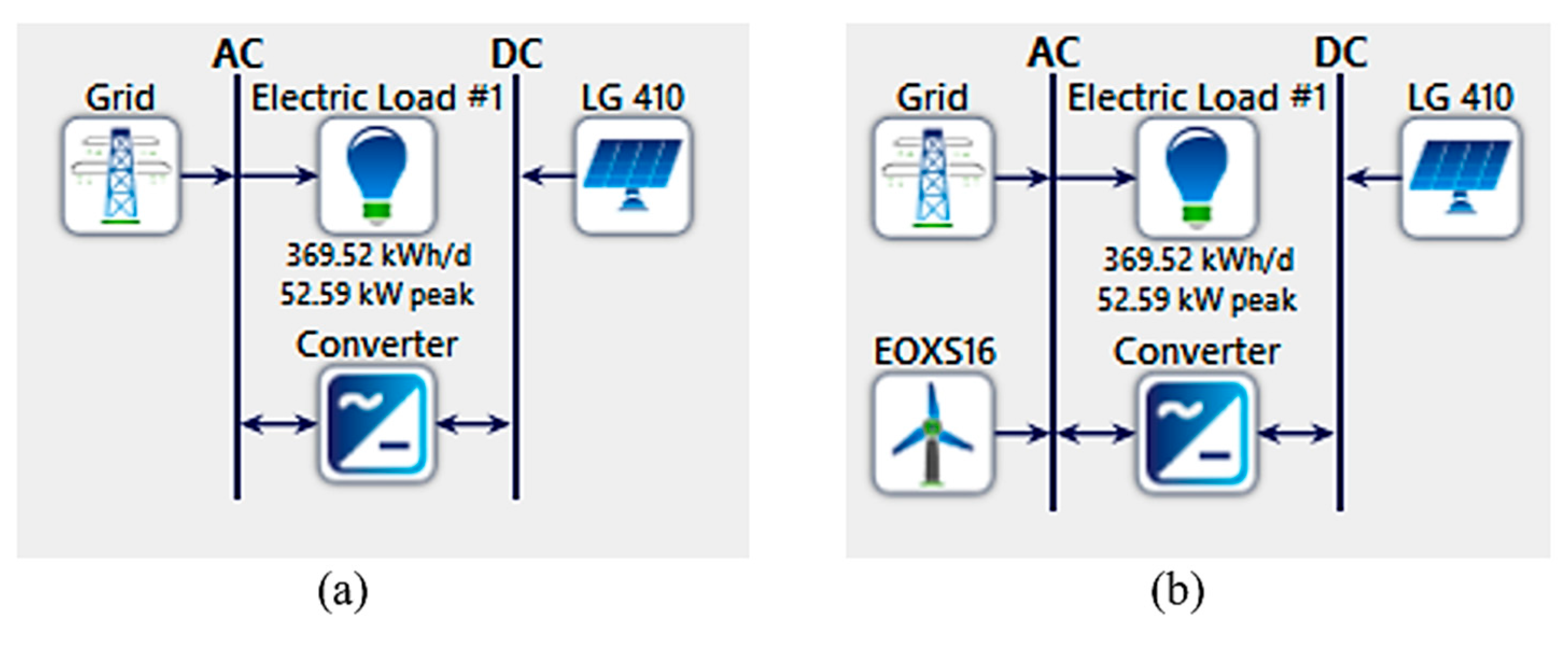

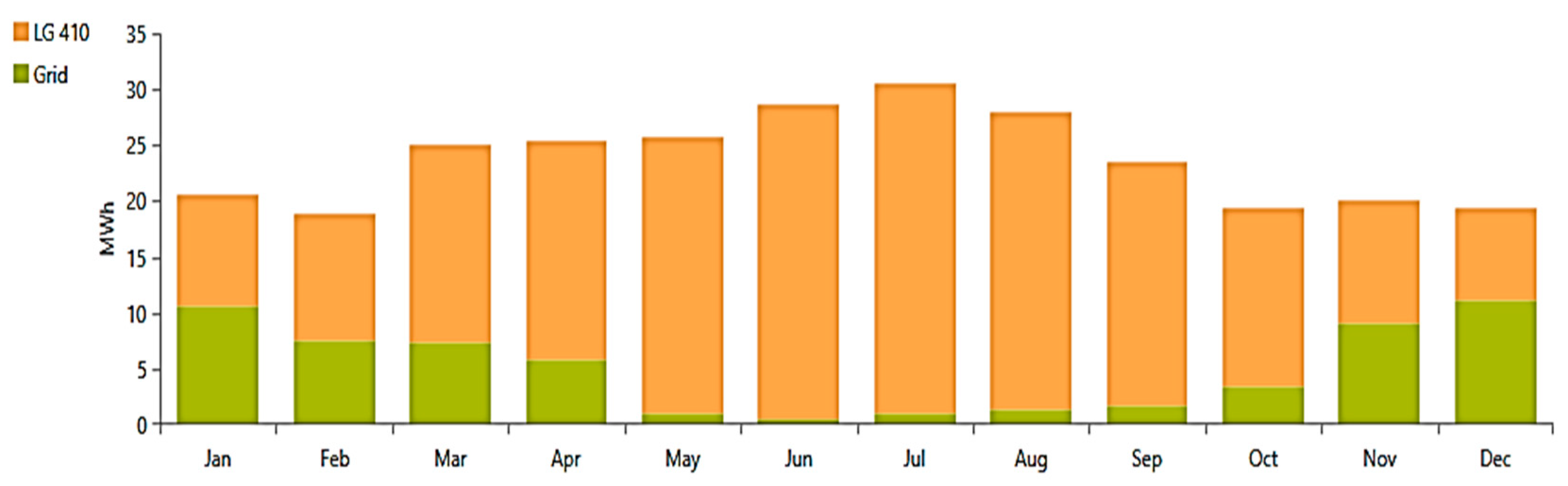

3.1. Analysis of Grid-Connected Systems

- i.

- Economic Analysis: Among the examined configurations, [G/PV] was the most cost-effective design, with the lowest NPC (USD 282,492) and LCOE (USD 0.0401/kWh), and a moderate annual operating cost of USD 4601. However, systems such as [G/PV/WT/B], [G/PV/B], and [G/WT/B] incur higher NPCs (USD 624,729, USD 506,112, and USD 785,724, respectively) and higher LCOEs (USD 0.0845/kWh, USD 0.0718/kWh, and USD 0.2100/kWh) due to heavy reliance on photovoltaic generation and battery storage. The [G/PV] and [G/PV/WT] configurations, with integrated PV components and low maintenance needs, offer the lowest operating costs (USD 4601 and USD 5127 per year, respectively). By contrast, the wind turbine-based [G/WT/B] system includes two turbines, resulting in a much higher annual operating cost (USD 20,007) due to the intensive maintenance requirements.

- ii.

- Environmental Impact: [G/PV] was the most economically viable configuration, offering both low LCOE and substantial environmental benefits. Even though [G/PV/WT/B] requires higher investment, it achieves the highest CO2 emission reductions, making it ideal for environmentally focused regions. However, its high initial capital cost may limit broader applicability. [G/PV/WT], which shares similar PV and WT components but excludes batteries, offers a cost-effective alternative with comparable emissions; in contrast, wind-dominated systems such as [G/WT] and [G/WT/B] fail to significantly reduce carbon emissions, rendering them less suitable for modern energy demands.

- [G/PV] system: The grid is the primary energy source, and PV panels supply additional energy and export any surplus solar generation back to the grid. Due to its low maintenance requirements, this system has the lowest operating costs. Its lifespan corresponds to that of the PV panels. One challenge, however, is that the system’s performance is dependent on daily solar irradiation and sunlight availability.

- Environmental Impact: [G/PV] was the most economically viable configuration, offering both low LCOE and substantial environmental benefits. Even though [G/PV/WT/B] requires higher investment, it offers the highest CO2 emission reductions, making it ideal for environmentally focused regions. However, its high initial capital cost may limit broader applicability. [G/PV/WT], which shares similar PV and WT components but excludes batteries, presents a cost-effective alternative with comparable emissions. In contrast, wind-dominated systems such as [G/WT] and [G/WT/B] fail to significantly reduce carbon emissions, rendering them less suitable for modern energy demands.

Sensitivity Analysis for Grid-Connected Systems

3.2. Standalone Systems

- i.

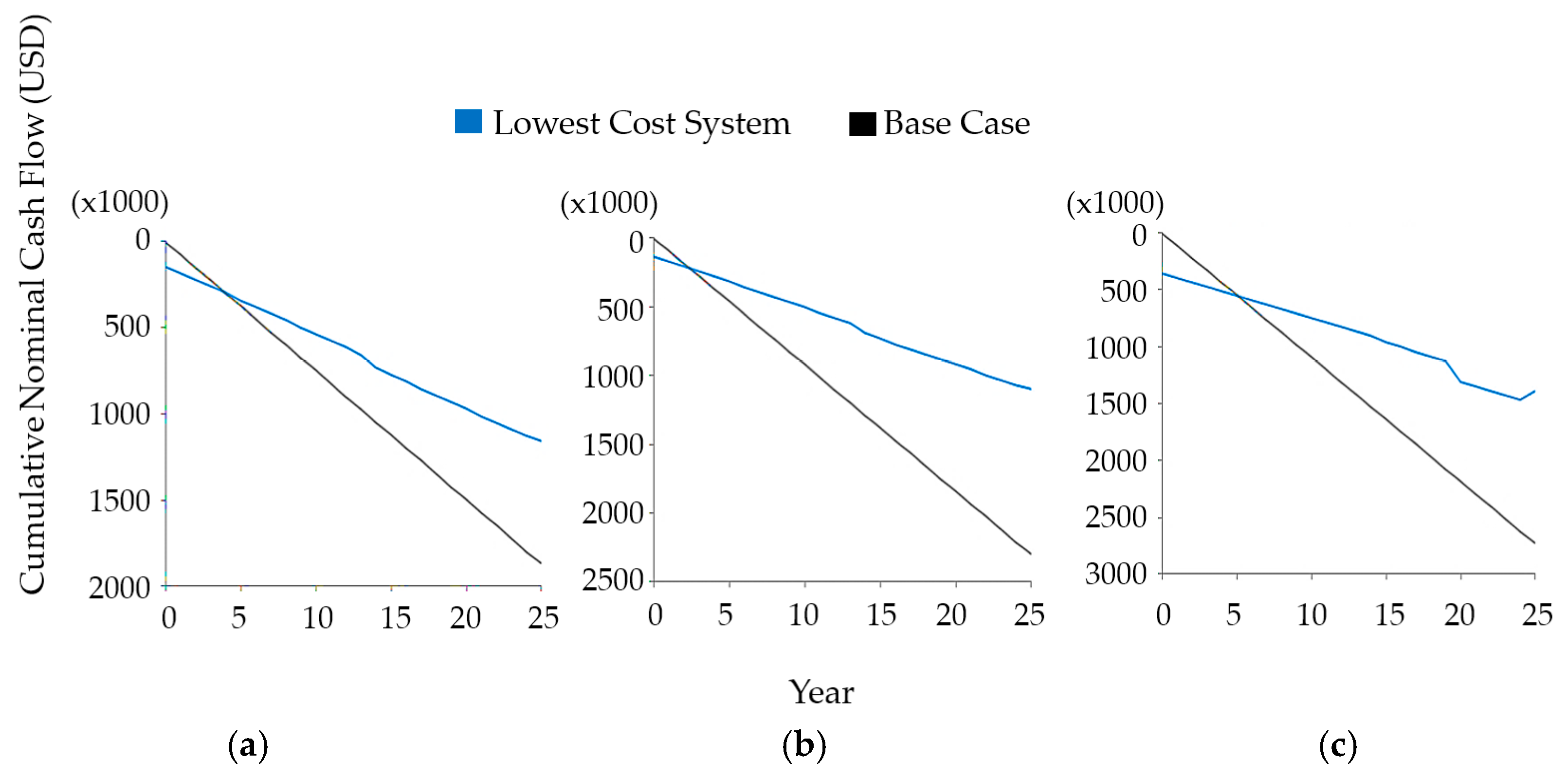

- Economic Analysis: The cost of the most economical configuration, [Gen/PV/B] (USD 1.19 million), is approximately three times lower than the most expensive system, [WT/B] (USD 4.52 million). The significantly higher cost of the [WT/B] system stems from its reliance on 12 wind turbines. Generator-based systems such as [Gen/PV] and [Gen/PV/WT] (USD 1.85 million and USD 1.92 million, respectively) fall into the mid-range cost category; however, their environmental benefits are notably limited.From the perspective of energy production cost, the system with the lowest LCOE is [Gen/PV/B], with a value of 0.342 USD/kWh. In contrast, even though it is designed to achieve zero emissions, the [WT/B] system has the highest LCOE at 1.370 USD/kWh due to its high capital investment requirements. This underscores the inevitable trade-off between environmental sustainability and financial feasibility (Table 7).On the other hand, PV-integrated configurations such as [Gen/PV/B] and [Gen/PV/WT/B] offer the lowest operational costs, attributed to their low fuel consumption (20,363 L/year and 17,574 L/year, respectively) and reduced maintenance needs (USD 39,321 and USD 37,155, respectively). On the other hand, the [WT/B] system has the highest operational cost (USD 100,917) due to the substantial maintenance requirements of its 12 wind turbines.

- ii.

- Environmental Impact: Configurations such as [Gen/PV/B] and [Gen/PV/WT/B], which provide both low LCOE and considerable environmental benefits, emerge as the most cost-effective alternatives. Despite their higher financial costs, the [PV/WT/B], [PV/B], and [WT/B] systems represent more suitable options for regions prioritizing environmental sustainability thanks to their zero-emission advantages. However, the substantial capital investments required by these systems may limit widespread adoption. However, generator-based systems such as [Gen], [Gen/PV], [Gen/WT], and [Gen/PV/WT] fail to yield meaningful reductions in carbon emissions, which makes them inadequate for meeting contemporary energy demands.

- [Gen/PV/B] system: The system is primarily powered by the generator, with solar PV offering additional supply. Surplus solar energy is directed to the battery, and a inverter facilitates AC–DC conversion to decrease diesel usage. Despite these features, challenges persist, notably the dependence on diesel, relatively high operating costs, and constrained storage capacity.

- [Gen/PV/WT/B] system: This hybrid system integrates wind generation to complement solar PV and reduce diesel dependency, particularly during nighttime or low-sunlight conditions. The generator ensures supply during peak load events. Key advantages include enhanced system reliability, reduced operational costs, and minimized environmental impact; however, it requires sophisticated control systems and is sensitive to local wind conditions.

- [Gen/WT/B] system: As illustrated in Figure 13c, this configuration combines a diesel generator, wind turbine, inverter, and battery. The turbine decreases fuel consumption, while the generator compensates for reduced wind availability. Benefits include fuel economy and improved environmental performance, although challenges stem from intermittent wind resources and constrained battery storage.

Sensitivity Analysis for Standalone Systems

4. Discussion

5. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- REN21. Renewables 2024 Global Status Report Collection. Renewables 2024 Global Status Report. A Comprehensive Annual Overview of The State of Renewable Energy. 2024. Available online: https://www.ren21.net/gsr-2024/modules/energy_supply/01_global_trends/ (accessed on 4 May 2025).

- Anadolu Agency. Ekonomi. 2024. Available online: https://www.aa.com.tr/tr/ekonomi/dunya-elektrik-uretiminde-yenilenebilirin-payi-ilk-kez-yuzde-30u-asti-turkiyede-yuzde-42ye-ulasti/3213124 (accessed on 4 May 2025). (In Turkish).

- SHURA. Türkiye Enerji Dönüşümü Görünümü 2023. SHURA Enerji Dönüşümü Merkezi Raporu. 2024. Available online: https://shura.org.tr/wp-content/uploads/2024/04/SHURA-2024-04-Rapor-outlook-2023-2.pdf (accessed on 5 May 2025).

- GEPA. Solar Energy Potential Atlas. 2025. Available online: https://gepa.enerji.gov.tr/ (accessed on 5 May 2025).

- Republic of Türkiye Ministry of Energy and Natural Resources. Wind Energy Potential Map-REPA. 2025. Available online: https://enerji.gov.tr/bilgi-merkezi-enerji-ruzgar (accessed on 4 May 2025).

- Republic of Türkiye Ministry of Energy and Natural Resources. Elektrik Piyasas1 Yenilenebilir Enerji Kaynakları Destekleme Mekanizması (YEKDEM) Listesi. 2021. Available online: https://enerji.gov.tr/eigm-yenilebilir-enerji-uretim-faaliyetleri-lisansli-elektrik-uretimi (accessed on 5 May 2025).

- EPDK. Lisanslı Elektrik Üretimi. 2023. Available online: https://www.epdk.gov.tr/Detay/Icerik/3-0-0-122/yenilenebilir-enerji-kaynaklari-destekleme-mekanizmasi-yekdem (accessed on 5 May 2025).

- SHURA. Net Sıfır 2053: Enerji Sektörü için Politikalar. 2023. Available online: https://shura.org.tr/wp-content/uploads/2024/01/SHURA-2023-11-Rapor-Enerji-Sektoru-icin-Politikalar_Ocak2024.pdf (accessed on 5 May 2025).

- EPDK. Elektrik Piyasası Sektör Raporu Aralık 2023. 2024. Available online: https://www.epdk.gov.tr/Detay/Icerik/3-0-23/elektrikaylik-sektor-raporlar (accessed on 11 April 2025).

- EMBER. Electricity Production by Source, Turkey. Energy Institute—Statistical Review of World Energy. 2025. Available online: https://ember-energy.org/data/yearly-electricity-data/ (accessed on 4 May 2025).

- TEİAŞ. Power of Energy. Electricity Transmission in Türkiye. 2025. Available online: https://www.teias.gov.tr/en-US (accessed on 4 May 2025).

- Republic of Türkiye Ministry of Energy and Natural Resources. Bilgi Merkezi. Elektrik. 2025. Available online: https://enerji.gov.tr/bilgi-merkezi-enerji-elektrik (accessed on 4 May 2025).

- ETKB. Türkiye Ulusal Enerji Planı. 2022. Available online: https://enerji.gov.tr/Media/Dizin/EIGM/tr/Raporlar/TUEP/T%C3%BCrkiye_Ulusal_Enerji_Plan%C4%B1.pdf (accessed on 7 May 2025).

- SBB. OnN İkinci Kalkınma Planı (2024–2028). 2023. Available online: https://www.sbb.gov.tr/wp-content/uploads/2023/12/On-Ikinci-Kalkinma-Plani_2024-2028_11122023.pdf (accessed on 12 May 2025).

- REN21. Renewables in Energy Demand: Global Trends. Market Developments and Investment Trends. 2024. Available online: https://www.ren21.net/gsr-2024/modules/energy_demand (accessed on 12 May 2025).

- IEA. World Energy Balances. 2023. Available online: https://www.iea.org/data-and-statistics/data-product/world-energy-balances (accessed on 12 May 2025).

- IEA. SEK 380 Million: Temporary Tax Reduction on Agricultural Diesel—Policies. 2023. Available online: https://www.iea.org/policies/17497-sek-380-milliontemporary-tax-reduction-on-agricultural-diesel (accessed on 20 April 2023).

- IEA. 2023 Price Crisis Response Policies—Policies. 2023. Available online: https://www.iea.org/policies/17484-2023-price-crisis-response-policies (accessed on 11 May 2023).

- Puri, M.; Kojakovic, A.; Rincon, L.; Gallego, J.; Vaskalis, I.; Maltsoglou, I. The Small-Scale Fisheries and Energy Nexus: Opportunities for Renewable Energy Interventions; Food and Agriculture Organization of the United Nations: Rome, Italy, 2023. [Google Scholar] [CrossRef]

- Ambuko, J.; Owino, W. Toward Sustainable Transformation Through Postharvest Management: Lessons from Kenya’s Mango Value Chain, in International Food Policy Research Institute. In Food Systems Transformation in Kenya: Lessons Past and Policy Options for the Future; SAGE Publishing: Thousand Oaks, CA, USA, 2023; pp. 433–468. [Google Scholar] [CrossRef]

- Dawnbreaker and Department of Energy. Market Research Study—Agrivoltaics; Department of Energy: Washington, DC, USA, 2022. Available online: https://science.osti.gov/-/media/sbir/pdf/Market-Research/SETO---Agrivoltaics-August-2022-Public.pdf (accessed on 4 May 2025).

- European Commission. Agriculture and Rural Development. Common Agricultural Policy for 2023–2027—28 CAO Strategic Plans at a Glance. 2022. Available online: https://agriculture.ec.europa.eu/system/files/2022-12/csp-at-a-glance-eu-countries_en.pdf (accessed on 11 May 2025).

- European Economic and Social Committee. Decarbonisation of the Fishing Fleet. 2023. Available online: https://www.eesc.europa.eu/en/our-work/opinions-information-reports/opinions/decarbonisation-fishing-fleet (accessed on 14 May 2025).

- Schindele, S.; Trommsdorff, M.; Schlaak, A.; Obergfell, T.; Bopp, G.; Reise, C.; Braun, C.; Weselek, A.; Bauerle, A.; Högy, P.; et al. Implementation of agrophotovoltaics: Techno-economic analysis of the price-performance ratio and its policy implications. Appl. Energy 2020, 265, 114737. [Google Scholar] [CrossRef]

- Rahman, A.; Sharma, A.; Postel, F.; Goel, S.; Kumar, K.; Laan, T. Agrivoltaics in India: Challenges and Opportunities for Scale-up; International Institute for Sustainable Development (IISD): Winnipeg, MB, Canada, 2023; Available online: http://www.jstor.org/stable/resrep49783 (accessed on 14 May 2025).

- Ferreira, R.F.; Lameirinhas, R.A.M.; Bernardo, C.P.C.V.; Torres, J.P.N.; Santos, M. Agri-PV in Portugal: How to combine agriculture and photovoltaic production. Energy Sustain. Dev. 2024, 79, 101408. [Google Scholar] [CrossRef]

- NREL. Agrivoltaics. Solar Market Research and Analysis. 2023. Available online: https://www.nrel.gov/solar/market-research-analysis/agrivoltaics.html (accessed on 13 March 2024).

- Meza, E. Turkey Launches Agrivoltaics Research Project, pv magazine International, 27 December 2023. Available online: https://www.pv-magazine.com/2023/12/27/turkey-launches-agrivoltaics-research-project (accessed on 4 April 2025).

- ESMAP. Energy Sector Management Assistance Program. Energy Storage for Mini Grids: Status and Projections of Battery Deployment. 2023. Available online: https://www.esmap.org/Energy_Storage_for_Mini_Grids (accessed on 4 April 2025).

- ESMAP. Energy Sector Management Assistance Program. Accelerating the Productive Use of Electricity: Enabling Energy Access to Power Rural Economic Growth. 2023. Available online: http://documents.worldbank.org/curated/en/099092023192023389/P1751521d3f58f6f1307c1499619e141b8baef6de8dd (accessed on 6 April 2025).

- EAP. Energizing Agriculture Programme, Results. 2024. Available online: https://energizingagricultureprogramme.org/results (accessed on 1 February 2024).

- AEP. Africa Energy Portal, Renewable Energy. 2022. Available online: https://africa-energy-portal.org/news/uganda-engie-commissions-600-kwp-solar-mini-grid-lolwe-island (accessed on 6 April 2025).

- Ali, S.; Zheng, Z.; Aillerie, M.; Sawicki, J.-P.; Péra, M.-C.; Hissel, D. A Review of DC Microgrid Energy Management Systems Dedicated to Residential Applications. Energies 2021, 14, 4308. [Google Scholar] [CrossRef]

- Farkhani, J.S.; Zareein, M.; Najafi, A.; Melicio, R.; Rodrigues, E.M.G. The Power System and Microgrid Protection—A Review. Appl. Sci. 2020, 10, 8271. [Google Scholar] [CrossRef]

- HOMER Energy LLC. HOMER Pro 3.14 User Manual; HOMER Energy LLC: Boulder, CO, USA, 2020; Available online: https://homerenergy.com/products/pro/docs/index.html (accessed on 18 February 2025).

- Sambhi, S.; Sharma, H.; Kumar, P.; Fotis, G.; Vita, V.; Ekonomou, L. Techno-economic optimization of an off-grid hybrid power generation for SRM IST, Delhi-NCR campus. Energies 2022, 15, 7880. [Google Scholar] [CrossRef]

- Ali, M.F.; Hossain, M.A.; Julhash, M.M.; Ashikuzzaman, M.; Alam, M.S.; Sheikh, M.R.I. A Techno-Economic Analysis of a Hybrid Microgrid System in a Residential Area of Bangladesh: Optimizing Renewable Energy. Sustainability 2024, 16, 8051. [Google Scholar] [CrossRef]

- Kangaji, L.M.; Raji, A.; Orumwense, E. Optimizing Sustainability Offshore Hybrid Tidal-Wind Energy Storage Systems for an Off-Grid Coastal City in South Africa. Sustainability 2024, 16, 9139. [Google Scholar] [CrossRef]

- Seedahmed, M.M.A.; Ramli, M.A.M.; Bouchekara, H.R.E.H.; Milyani, A.H.; Rawa, M.; Budiman, F.N.; Muktiadji, R.F.; Hassan, S.M.U. Optimal Sizing of Grid-Connected Photovoltaic System for a Large Commercial Load in Saudi Arabia. Alex. Eng. J. 2022, 61, 6523–6540. [Google Scholar]

- Dalton, G.J.; Lockington, D.A.; Baldock, T.E. Feasibility analysis of stand-alone renewable energy supply options for a large hotel. Renew. Energy 2008, 33, 1475–1490. [Google Scholar] [CrossRef]

- Wahid, S.S.A.; Arief, Y.Z.; Mubarakah, N. Optimization of Hybrid Renewable Energy in Malaysia Remote Rural Area Using HOMER Software. In Proceedings of the International Conference on Electrical, Telecommunication and Computer Engineering (ELTICOM), Medan, Indonesia, 16–17 September 2019; pp. 111–115. [Google Scholar]

- Dinçsoy, M.E. Modelling and Optimization of Medium-Sized Hotel’s Electrical Energy with Hybrid Systems. Master’s Thesis, İstanbul Technical University, İstanbul, Türkiye, 2010. [Google Scholar]

- Himri, Y.; Stambouli, A.B.; Draoui, B.; Himri, S. Techno-economical study of hybrid power system for a remote village in Algeria. Energy 2008, 33, 1128–1136. [Google Scholar] [CrossRef]

- Özcan, H. Modeling and Analysıs of A Hybrid Energy System. Master’s Thesis, İstanbul Technical University, İstanbul, Türkiye, 2009. [Google Scholar]

- Adaramola, M.S. Viability of grid-connected solar PV energy system in Jos, Nigeria. Int. J. Electr. Power Energy Syst. 2014, 61, 64–69. [Google Scholar] [CrossRef]

- Ngan, M.S.; Tan, C.W. Assessment of economic viability for PV/wind/diesel hybrid enegry system in southern Peninsular Malaysia. Renew. Sustain. Energy Rev. 2012, 16, 634–647. [Google Scholar] [CrossRef]

- Suresh, V.; Muralidhar, M.; Kiranmayi, R. Modelling and optimization of an off-grid hybrid renewable energy system for electrification in a rural area. Energy Rep. 2020, 6, 594–604. [Google Scholar] [CrossRef]

- Olatomiwa, L.; Blanchard, R.; Mekhilef, S.; Akinyele, D. Hybrid renewable energy supply for rural healthcare facilities: An approach to quality healthcare delivery. Sustain. Energy Technol. Assess. 2018, 30, 121–138. [Google Scholar] [CrossRef]

- Tudorache, T.; Morega, A. Optimum Design of Wind/PV/Diesel/Batteries Hybrid Systems. In Proceedings of the International Conference on Modern Power Systems, Cluj-Napoca, Romania, 12–14 November 2008; pp. 261–264. [Google Scholar]

- Muh, E.; Tabet, F. Comparative Analysis of Hybrid Renewable Energy Systems for off-Grid Applications in Southern Cameroons. Renew. Energy 2019, 135, 41–54. [Google Scholar] [CrossRef]

- Ahmad, J.; Imran, M.; Khalid, A.; Iqbal, W.; Ashraf, S.R.; Adnan, M.; Ali, S.F.; Khokhar, K.S. Techno Economic Analysis of a Wind-Photovoltaic-Biomass Hybrid Renewable Energy System for Rural Electrification: A Case Study of Kallar Kahar. Energy 2018, 148, 208–234. [Google Scholar] [CrossRef]

- Byrne, J.; Glover, L.; Hegedus, S.; VanWicklen, G. The Potential of Solar Electric Applications for Delaware’s Poultry Farms; Final Report; Center for Energy and Environmental Policy, University of Delaware: Newark, DE, USA, 2005. [Google Scholar]

- Dağtekin, M. Tecno-ekonomic Feasibility Analysis of Solar Energy Use in Cooling of Broiler Poultry Houses. J. Agric. Fac. Ç.Ü. 2012, 27, 11–20. [Google Scholar]

- Erensoy, K.; Altan, A.; Bayraktar, Ö. Characteristics of Energy Usage and Energy Savings Opportunities in Environmentally Controlled Egg Production Houses. In Proceedings of the 9. National Animal Science Congress 2015, Konya, Türkiye, 2–5 September 2015. [Google Scholar]

- Mandal, S.; Das, B.K.; Hoque, N. Optimum Sizing of a Stand-Alone Hybrid Energy System for Rural Electrification in Bangladesh. J. Clean. Prod. 2018, 200, 12–27. [Google Scholar] [CrossRef]

- Das, B.K.; Hoque, N.; Mandal, S.; Pal, T.K.; Raihan, A. A Techno-Economic Feasibility of a Stand-Alone Hybrid Power Generation for Remote Area Application in Bangladesh. Energy 2017, 134, 775–788. [Google Scholar] [CrossRef]

- Ashok, S. Optimised model for community-based hybrid energy system. Renew. Energy 2007, 32, 1155–1164. [Google Scholar] [CrossRef]

- González, A.; Riba, J.-R.; Rius, A.; Puig, R. Optimal sizing of a hybrid grid-connected photovoltaic and wind power system. Appl. Energy 2015, 154, 752–762. [Google Scholar] [CrossRef]

- Kamel, S. The economics of hybrid power systems for sustainable desert agriculture in Egypt. Energy 2005, 30, 1271–1281. [Google Scholar] [CrossRef]

- Khare, V.; Nema, S.; Baredar, P. Solar–wind hybrid renewable energy system: A review. Renew. Sustain. Energy Rev. 2016, 58, 23–33. [Google Scholar] [CrossRef]

- Nandi, S.K.; Ghosh, H.R. A wind–PV-battery hybrid power system at Sitakunda in Bangladesh. Energy Policy 2009, 37, 3659–3664. [Google Scholar] [CrossRef]

- Rehman, S.; Al-Hadhrami, L.M. Study of a solar PV–diesel–battery hybrid power system for a remotely located population near Rafha, Saudi Arabia. Energy 2010, 35, 4986–4995. [Google Scholar] [CrossRef]

- Shaahid, S.M.; Elhadidy, M.A. Technical and economic assessment of grid-independent hybrid photovoltaic–diesel–battery power systems for commercial loads in desert environments. Renew. Sustain. Energy Rev. 2007, 11, 1794–1810. [Google Scholar] [CrossRef]

- Shezan, S.A.; Julai, S.; Kibria, M.A.; Ullah, K.R.; Saidur, R.; Chong, W.T.; Akikur, R.K. Performance analysis of an off-grid wind-PV (photovoltaic)-diesel-battery hybrid energy system feasible for remote areas. J. Clean. Prod. 2016, 125, 121–132. [Google Scholar] [CrossRef]

- Sediqi, M.M.; Furukako, F.; Lotfy, M.E.; Yona, A.; Senjyu, T. Optimal Economical Sizing of Grid-Connected Hybrid Renewable Energy System. Energy Power Eng. 2017, 11, 244–253. [Google Scholar]

- Olatomiwa, L.; Mekhilef, S.; Ismail, M.S.; Moghavvemi, M. Energy management strategies in hybrid renewable energy systems: A review. Renew. Sustain. Energy Rev. 2016, 62, 821–835. [Google Scholar] [CrossRef]

- Fragaki, A.; Markvart, T.; Laskos, G. All UK electricity supplied by wind and photovoltaics—The 30–30 rule. Energy 2019, 169, 228–237. [Google Scholar] [CrossRef]

- Tijani, H.O.; Tan, C.W.; Bashir, N. Techno-economic analysis of hybrid photovoltaic/diesel/battery off-grid system in northern Nigeria. J. Renew. Sustain. Energy 2014, 6, 033103. [Google Scholar] [CrossRef]

- Türkdoğan, S.; Dilber, S.; Çam, B. Economic and Technical Investigation of the Feasibility of Off-Grid Hybrid Energy Systems for a Farmhouse. Sinop Univ. J. Nat. Sci. 2018, 3, 52–65. [Google Scholar] [CrossRef]

- Oladigbolu Jamiu, O.; Ramli Makbul, A.M.; Al-Turki Yusuf, A. Feasibility Study and comparative analysis of hybrid renewable power system for off-grid rural electrification in a typical remote village located in Nigeria. IEEE Access 2020, 8, 171643–171663. [Google Scholar] [CrossRef]

- Rallo, H.; Casals, L.C.; De La Torre, D.; Reinhardt, R.; Marchante, C.; Amante, B. Lithium-ion battery 2nd life used as a stationary energy storage system: Ageing and economic analysis in two real cases. J. Clean. Prod. 2020, 272, 122584. [Google Scholar] [CrossRef]

- Arabi-Nowdeh, S.; Nasri, S.; Saftjani, P.B.; Naderipour, A.; Abdul-Malek, Z.; Kamyab, H.; Jafar-Nowdeh, A. Multi-criteria optimal design of hybrid clean energy system with battery storage considering off- and on-grid application. J. Clean. Prod. 2021, 290, 125808. [Google Scholar] [CrossRef]

- Li, C.; Zhou, D.; Wang, H.; Lu, Y.; Li, D. Techno-economic performance study of stand-alone wind/diesel/battery hybrid system with different battery Technologies in the cold region of China. Energy 2020, 192, 116702. [Google Scholar] [CrossRef]

- Al-Sharafi, A.; Sahin, A.Z.; Ayar, T.; Yilbas, B.S. Techno-economic analysis and optimization of solar and wind energy systems for power generation and hydrogen production in Saudi Arabia. Renew. Sustain. Energy Rev. 2017, 69, 33–49. [Google Scholar] [CrossRef]

- Haratian, M.; Tabibi, P.; Sadeghi, M.; Vaseghi, B.; Poustdouz, A. A Renewable Energy Solution for Stand-Alone Power Generation: A Case Study of KhshU Site-Iran. Renew. Energy 2018, 125, 926–935. [Google Scholar] [CrossRef]

- Ariyo, B.O.; Akorede, M.F.; Omeiza, I.O.A.; Amuda, S.A.Y.; Oladeji, S.A. Optimisation Analysis of a Stand-Alone Hybrid Energy System for the Senate Building, University of Ilorin, Nigeria. J. Build. Eng. 2018, 19, 285–294. [Google Scholar] [CrossRef]

- Ayhan, D. Building Mounted Solar-Wind Hybrid Electric Power System Analysis. Master’s Thesis, Marmara University Institute of Science and Technology, İstanbul, Türkiye, 2011; p. 28552482. [Google Scholar]

- Riahi, J.; Vergura, S.; Mezghani, D.; Mami, A. Intelligent control of the microclimate of an agricultural greenhouse powered by a supporting pv system. Appl. Sci. 2020, 10, 1350. [Google Scholar] [CrossRef]

- Cossu, M.; Yano, A.; Murgia, L.; Ledda, L.; Deligios, P.; Sirigu, A.; Chessa, F.; Pazzona, A. Effects of the photovoltaic roofs on the greenhouse microclimate. Acta Hortic. 2017, 1170, 461–468. [Google Scholar] [CrossRef]

- Adam, D.; Apaydin, G. Grid connected solar photovoltaic system as a tool for green house gas emission reduction in Turkey. Renew. Sustain. Energy Rev. 2016, 53, 1086–1091. [Google Scholar] [CrossRef]

- Li, C.; Wang, H.; Miao, H.; Ye, B. The economic and social performance of integrated photovoltaic and agricultural greenhouses systems: Case study in China. Appl. Energy 2017, 190, 204–212. [Google Scholar] [CrossRef]

- Hassanien, R.H.E.; Ming, L. Influences of greenhouse-integrated semi-transparent photovoltaics on microclimate and lettuce growth. Int. J. Agric. Biol. Eng. 2017, 10, 11–22. [Google Scholar] [CrossRef]

- Lalwani, M.; Kothari, D.P.; Singh, M. Investigation of solar photovoltaic simulation softwares. Int. J. Appl. Eng. Res. 2010, 1, 585–601. [Google Scholar]

- NASA POWER Data Access Viewer. Available online: https://power.larc.nasa.gov/data-access-viewer/ (accessed on 22 October 2023).

- Amole, A.O.; Oladipo, S.; Olabode, O.E.; Makinde, K.A.; Gbadega, P.A. Analysis of Grid/Solar Photovoltaic Power Generation for Improved Village Energy Supply: A Case of Ikose in Oyo State Nigeria. Renew. Energy Focus 2023, 44, 186–211. [Google Scholar] [CrossRef]

- HOMER Pro 2023. HOMER Pro Manual. Available online: https://support.ul-renewables.com/homer-manuals-pro/index.html (accessed on 20 October 2023).

- Mulumba, A.N.; Farzaneh, H. Techno-economic analysis and dynamic power simulation of a hybrid solar-wind-battery-flywheel system for off-grid power supply in remote areas in Kenya. Energy Convers. Manag. X 2023, 18, 100381. [Google Scholar] [CrossRef]

- Prum, M.; Goh, H.H.; Zhang, D.; Dai, W.; Kurniawan, T.A.; Goh, K.C. Optimizing hybrid energy systems for remote communities in Asia’s least developed countries. Heliyon 2024, 10, e29369. [Google Scholar] [CrossRef] [PubMed]

- Das, B.K.; Alotaibi, M.A.; Das, P.; Islam, M.; Das, S.K.; Hossain, A. Feasibility and techno-economic analysis of stand-alone and grid-connected PV/Wind/Diesel/Batt hybrid energy system: A case study. Energy Strategy Rev. 2021, 37, 100673. [Google Scholar] [CrossRef]

- Wang, Y.; He, X.; Liu, Q.; Razmjooy, S. Economic and technical analysis of an HRES (Hybrid Renewable Energy System) comprising wind, PV, and fuel cells using an improved subtraction-average-based optimizer. Heliyon 2024, 10, e32712. [Google Scholar] [CrossRef] [PubMed]

- Tajouo, G.F.; Kapen, P.T.; Koffi, F.L.D. Techno-economic investigation of an environmentally friendly small-scale solar tracker-based PV/wind/Battery hybrid system for off-grid rural electrification in the mount bamboutos, Cameroon. Energy Strategy Rev. 2023, 48, 101107. [Google Scholar] [CrossRef]

- Oladigbolu, J.O.; Ramli, M.A.M.; Al-Turki, Y.A. Techno-economic and sensitivity analyses for an optimal hybrid power system which is adaptable and effective for rural electrification: A case study of Nigeria. Sustainability 2019, 11, 4959. [Google Scholar] [CrossRef]

- Agajie, T.F.; Fopah-Lele, A.; Ali, A.; Amoussou, I.; Khan, B.; Elsisi, M.; Mahela, O.P.; Álvarez, R.M.; Tanyi, E. Optimal sizing and power system control of hybrid solar PV-biogas generator with energy storage system power plant. Sustainability 2023, 15, 5739. [Google Scholar] [CrossRef]

- Lata-García, J.; Zamora Cedeño, N.; Ampuño, G.; Jurado, F.; Swarupa, M.L.; Maliza, W. Optimization and evaluation of a stand-alone hybrid system consisting of solar panels, biomass, diesel generator, and battery bank for rural communities. Sustainability 2024, 16, 9012. [Google Scholar] [CrossRef]

- EPDK. Yenilenebilir Enerji Kaynaklarının Elektrik Enerjisi Üretimi Amaçlı Kullanımına İlişkin Kanun. 2024. Available online: https://www.epdk.gov.tr/Detay/Icerik/23-2-3/mevzuat (accessed on 12 May 2025).

- EPIAS. The Prices to be Applied for the Power Plants Commissioned Between 01.07.2021 and 31.12.2030 That Rely on Renewable Energy Sources with RES Certificate. Energy Exchange Company. 2025. Available online: https://www.epias.com.tr/en/announcements/the-prices-to-be-applied-for-the-power-plants-commissioned-between-01-07-2021-and-31-12-2030-that-rely-on-renewable-energy-sources-with-res-certificate-22/ (accessed on 8 June 2025).

- Sarıaslan, H. Yatırım Projelerinin Hazırlanması ve Değerlendirilmesi; Planlama-Analiz-Fizibilite: Turhan Kitapevi, Ankara, 1990; 240 s. (In Turkish) [Google Scholar]

- Yılmaz, U.; Demirören, A.; Zeynelgil, H.L. Investigation of the Potential for Electrical Energy Production with Renewable Energy Sources in Gökçeada. J. Polytech. 2010, 13, 215–223. [Google Scholar]

- CEIC. Turkey Central Bank Discount Rate. View Turkey’s Turkey Central Bank Discount Rate from 1970 to 2023 in the Chart. 2023. Available online: https://www.ceicdata.com/en/turkey/saving-discount-rate-and-interbank-rate/central-bank-discountrate#:~:text=Turkey%20Central%20Bank%20Discount%20Rate%20data%20was%20reported%20at%209.750 (accessed on 19 May 2025).

- Yokoyama, R.; Niimura, T.; Saito, N. Modeling and evaluation of supply reliability of microgrids including PV and wind power. In Proceedings of the 2008 IEEE Power and Energy Society General Meeting-Conversion and Delivery of Electrical Energy in the 21st Century, Pittsburgh, PA, USA, 20–24 July 2008; IEEE: Berkeley, CA, USA; pp. 1–5. [Google Scholar]

- Woldegiyorgis, T.A.; Asmare, E.; Benti, N.E.; Asefa, S.K.; Assamnew, A.D.; Desalegn, G.A.; Chekol, F.; Anose, F.A.; Mossie, S.Y. Techno-economic feasibility analysis of a hybrid wind-PV-diesel energy system for Kiltu village, Oromia, Ethiopia using HOMER pro. Environ. Res. Commun. 2025, 7, 055004. [Google Scholar] [CrossRef]

- Samatar, A.M.; Mekhilef, S.; Mokhlis, H.; Kermadi, M.; Alshammari, O. Performance analysis of hybrid off-grid renewable energy systems for sustainable rural electrification. Energy Convers. Manag. X 2024, 24, 100780. [Google Scholar] [CrossRef]

- Eze, V.H.U.; Mwenyi, J.S.; Ukagwu, K.J.; Eze, M.C.; Eze, C.E.; Okafor, W.O. Design analysis of a sustainable techno-economic hybrid renewable energy system: Application of solar and wind in Sigulu Island, Uganda. Sci. Afr. 2024, 26, e02454. [Google Scholar] [CrossRef]

- Kumar, P.H.; Alluraiah, N.C.; Gopi, P.; Bajaj, M.; Kumar, S.; Kalyan, C.N.S.; Blazek, V. Techno-economic optimization and sensitivity analysis of off-grid hybrid renewable energy systems: A case study for sustainable energy solutions in rural India. Results Eng. 2025, 25, 103674. [Google Scholar] [CrossRef]

| Component | Technical Specifications | ||

|---|---|---|---|

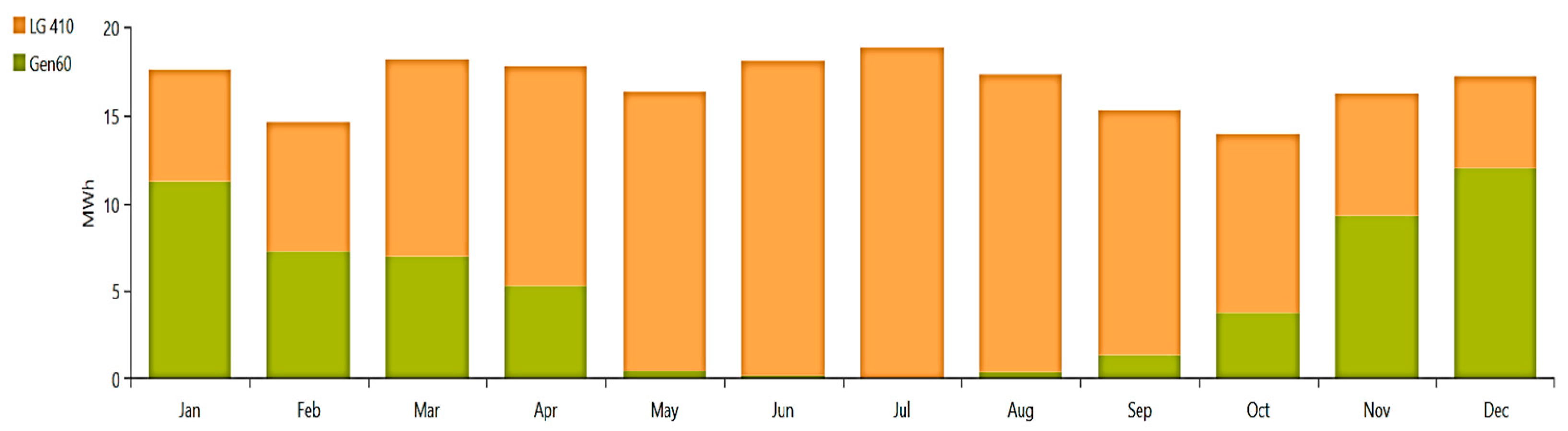

| Panel (PV)  | Model: LG410N2W-V5 Rated capacity: 410 W Panel type: monocrystalline-Si Open circuit voltage (Voc): 49.5 V Short circuit current (Isc): 10.55 A Power tolerance: 0/3% Module efficiency: 19.8% Lifetime: 25 years |  | |

| Wind Turbine (WT)  | Model: Eocycle EOX S-16 Rated capacity: 30 kW Rotor diameter: 15.8 m Cut-in/out wind speed: 2.75/20 m/s Hub height: 23.8 m Lifetime: 30 years | Average wind speed (m/s) | Gross output (kWh/yr) |

| 4.0 | 41,140 | ||

| 4.5 | 55,910 | ||

| 5.0 | 70,920 | ||

| 5.5 | 85,460 | ||

| 6.0 | 99,000 | ||

| 6.5 | 111,200 | ||

| 77.0 | 121,860 | ||

| 7.5 | 130,870 | ||

| Inverter | Model: TommaTech Hybrid Rated capacity: 60 kW Rated AC output current: 87 A Grid connection form: 3-Phase Max. efficiency: 97.60 MPPT efficiency: >99% Lifetime: 15 years |  | |

| Generator (Gen) | Model: Generic Gen60 Fuel: Diesel Rated capacity: 60 kW Fuel curve intercept: 2.80 L/h Fuel curve slope: 0.253 L/h kW Minimum load ratio: 25% CO emission: 17.79 g/L Particulate matter: 0.0712 g/L Lifetime: 15,000 h |  | |

| Battery (B) | Model: SAFT/Kinetic 28S24M Chemistry: Li-ion Nominal voltage: 720 V Nominal capacity: 55 kWh Maximum capacity: 76.4 Ah Capacity Ratio: 0.927 Rate constant (1/h): 0.989 Roundtrip efficiency: 97% Maximum charge current: 82 A Maximum discharge current: 200 A Maximum charge rate: 1 A/Ah Initial state of charge: 100% Minimum state of charge: 5% Throughput: 240,000 kWh Lifetime: 20 years |  | |

| Architecture | Cost | System | Grid | |||||

|---|---|---|---|---|---|---|---|---|

| NPC (USD) | LCOE (USD/kWh) | Operating Cost (USD/yr) | Initial Capital (USD) | Renewable Fraction (%) | Reduction of CO2 (%) | Energy Purchased (kWh) | Energy Sold (kWh) | |

| G/PV | 282,492 | 0.0401 | 4601 | 164,009 | 77.8 | 54.94 | 60,771 | 138,638 |

| G/PV/WT | 401,065 | 0.0542 | 5127 | 269,012 | 82.4 | 62.50 | 50,559 | 152,683 |

| G/WT | 445,910 | 0.1260 | 13,237 | 105,000 | 17.7 | 16.39 | 112,772 | 2152 |

| G/PV/B | 506,112 | 0.0718 | 10,954 | 224,013 | 77.8 | 54.94 | 60,771 | 138,642 |

| G/PV/WT/B | 624,729 | 0.0845 | 11,499 | 328,581 | 82.4 | 62.51 | 50,581 | 152,148 |

| G/WT/B | 785,724 | 0.2100 | 20,007 | 270,455 | 33.5 | 28.48 | 96,464 | 10,098 |

| Component | Capital (USD) | Replacement (USD) | O&M (USD) | Salvage (USD) | Total (USD) |

|---|---|---|---|---|---|

| Grid (G) | 0.00 | 0.00 | −121,107.18 | 0.00 | −121,107.18 |

| Panel (PV) | 153,414.63 | 0.00 | 232,414.04 | 0.00 | 385,828.68 |

| Inverter | 10,594.35 | 9672.50 | 802.49 | −3298.37 | 17,770.97 |

| System | 164,008.98 | 9672.50 | 112,109.35 | −3298.37 | 282,492.47 |

| Month | Energy Purchased (kWh) | Energy Sold (kWh) | Net Energy Purchased (kWh) | Peak Load (kW) | Energy Charge (USD) | Demand Charge (USD) |

|---|---|---|---|---|---|---|

| January | 10,612 | 3828 | 6784 | 41 | 727.78 | 0 |

| February | 7469 | 6528 | 940 | 33 | 220.85 | 0 |

| March | 7430 | 11,538 | −4109 | 33 | −163.69 | 0 |

| April | 5841 | 12,886 | −7045 | 30 | −418.62 | 0 |

| May | 1022 | 15,568 | −14,546 | 34 | −1085.08 | 0 |

| June | 590 | 18,753 | −18,162 | 23 | −1368.51 | 0 |

| July | 988 | 22,821 | −21,833 | 10 | −1639.57 | 0 |

| August | 1299 | 19,022 | −17,723 | 11 | −1320.93 | 0 |

| September | 1665 | 12,860 | −11,195 | 30 | −817.55 | 0 |

| October | 3511 | 7095 | −3583 | 34 | −202.12 | 0 |

| November | 9176 | 5191 | 3985 | 32 | 486.4 | 0 |

| December | 11,169 | 2548 | 8621 | 38 | 878.58 | 0 |

| Annual | 60,771 | 138,638 | −77,866 | 41 | −4702.46 | 0 |

| Parameter | Minimum | Average | Maximum |

|---|---|---|---|

| Solar scaled average (kWh/m.d) | 2.0 | 4.5 | 7.0 |

| Temperature scaled average (°C) | 1.0 | 11.5 | 25.0 |

| Expected inflation rate (%) | 5 | 10 | 30 |

| Grid power price (USD/kWh) | 0.12 | 0.14 | 0.16 |

| Grid sellback rate (USD/kWh) | 0.10 | 0.14 | 0.18 |

| Power Price (USD/kWh) | Sellback Rate (USD/kWh) | Expected Inflation Rate (%) | NPC (USD) | LCOE (USD/kWh) | IRR (%) | Simple Payback (yr) |

|---|---|---|---|---|---|---|

| 0.10 | 0.8 | 5 | 191,525 | 0.0960 | 18 | 5.5 |

| 10 | 333,462 | 0.0960 | 18 | 5.5 | ||

| 30 | 5.65 M | 0.0960 | - | 25< | ||

| 0.10 | 5 | 191,525 | 0.0960 | 24 | 4.2 | |

| 10 | 333,462 | 0.0960 | 24 | 4.2 | ||

| 30 | 5.65 M | 0.0960 | - | 25< | ||

| 0.14 | 5 | 191,525 | 0.0960 | 34 | 3.0 | |

| 10 | 333,462 | 0.0960 | 34 | 3.0 | ||

| 30 | 5.65 M | 0.0960 | - | 25< | ||

| 0.18 | 5 | 191,525 | 0.0960 | 44 | 2.3 | |

| 10 | 333,462 | 0.0960 | 44 | 2.3 | ||

| 30 | 5.65 M | 0.0960 | - | 25< | ||

| 0.12 | 0.8 | 5 | 239,407 | 0.120 | 19 | 5.2 |

| 10 | 416,827 | 0.120 | 19 | 5.2 | ||

| 30 | 7.06 M | 0.120 | - | 25< | ||

| 0.10 | 5 | 239,407 | 0.120 | 25 | 4.0 | |

| 10 | 416,827 | 0.120 | 25 | 4.0 | ||

| 30 | 7.06 M | 0.120 | - | 25< | ||

| 0.14 | 5 | 239,407 | 0.120 | 35 | 2.9 | |

| 10 | 416,827 | 0.120 | 35 | 2.9 | ||

| 30 | 7.06 M | 0.120 | - | 25< | ||

| 0.18 | 5 | 239,407 | 0.120 | 45 | 2.2 | |

| 10 | 416,827 | 0.120 | 45 | 2.2 | ||

| 30 | 7.06 M | 0.120 | - | 25< | ||

| 0.14 | 0.8 | 5 | 279,308 | 0.140 | 20 | 5 |

| 10 | 486,298 | 0.140 | 20 | 5 | ||

| 30 | 8.24 M | 0.140 | - | 25< | ||

| 0.10 | 5 | 279,308 | 0.140 | 26 | 3.8 | |

| 10 | 486,298 | 0.140 | 26 | 3.8 | ||

| 30 | 8.24 M | 0.140 | - | 25< | ||

| 0.14 | 5 | 279,308 | 0.140 | 36 | 2.8 | |

| 10 | 486,298 | 0.140 | 36 | 2.8 | ||

| 30 | 8.24 M | 0.140 | - | 25< | ||

| 0.18 | 5 | 279,308 | 0.140 | 46 | 2.2 | |

| 10 | 486,298 | 0.140 | 46 | 2.2 | ||

| 30 | 8.24 M | 0.140 | 0.033 | 25 | ||

| 0.16 | 0.8 | 5 | 319,209 | 0.160 | 21 | 4.8 |

| 10 | 555,769 | 0.160 | 21 | 4.8 | ||

| 30 | 9.41 M | 0.160 | - | 25< | ||

| 0.10 | 5 | 319,209 | 0.160 | 27 | 3.7 | |

| 10 | 555,769 | 0.160 | 27 | 3.7 | ||

| 30 | 9.41 M | 0.160 | - | 25< | ||

| 0.14 | 5 | 319,209 | 0.160 | 37 | 2.7 | |

| 10 | 555,769 | 0.160 | 37 | 2.7 | ||

| 30 | 9.41 M | 0.160 | - | 25< | ||

| 0.18 | 5 | 319,209 | 0.160 | 47 | 2.1 | |

| 10 | 555,769 | 0.160 | 47 | 2.1 | ||

| 30 | 9.41 M | 0.160 | 0.069 | 25 |

| Architecture | Cost | System | ||||||

|---|---|---|---|---|---|---|---|---|

| System Type | System Configuration | NPC (USD) | LCOE (USD/kWh) | Operating Cost (USD/yr) | Initial Capital (USD) | Renewable Fraction (%) | Total Fuel (L/yr) | Reduction of CO2 (%) |

| Standalone | Gen/PV/B | 1.19 M | 0.342 | 39,321 | 173,909 | 56.8 | 20,363 | 64.58 |

| Gen/PV/WT/B | 1.22 M | 0.350 | 37,155 | 258,453 | 63.1 | 17,574 | 69.43 | |

| Gen/WT/B | 1.65 M | 0.476 | 53,245 | 283,459 | 32.4 | 31,449 | 45.30 | |

| Gen/PV | 1.85 M | 0.531 | 69,871 | 46,672 | 0 | 52,209 | 9.19 | |

| Gen/PV/WT | 1.92 M | 0.553 | 69,032 | 143,441 | 0 | 49,886 | 13.23 | |

| Gen | 1.92 M | 0.554 | 74,252 | 11,500 | 0 | 57,493 | 0 | |

| Gen/WT | 1.96 M | 0.566 | 71,749 | 116,500 | 0 | 53,402 | 7.12 | |

| PV/WT/B | 2.54 M | 0.759 | 58,950 | 1.02 M | 100 | 0 | 100 | |

| PV/B | 2.80 M | 0.837 | 74,327 | 883,702 | 100 | 0 | 100 | |

| WT/B | 4.52 M | 1.370 | 100,917 | 1.93 M | 100 | 0 | 100 | |

| Component | Capital (USD) | Replacement (USD) | O&M (USD) | Fuel (USD) | Salvage (-) (USD) | Total (USD) |

|---|---|---|---|---|---|---|

| Generator (Gen) | 11,500.00 | 47,430.39 | 2592.14 | 629,308.62 | 3976.55 | 686,854.60 |

| Panel (PV) | 97,697.78 | 0.00 | 148,006.33 | 0.00 | 0.00 | 245,704.11 |

| Battery (B) | 60,000.00 | 37,121.02 | 154,523.93 | 0.00 | 5525.37 | 246,119.59 |

| Inverter | 4710.96 | 4301.04 | 356.84 | 0.00 | 1466.68 | 7902.16 |

| System | 173,908.74 | 88,852.46 | 305,479.24 | 629,308.62 | 10,968.59 | 1,186,580.46 |

| Parameter | Minimum | Average | Maximum |

|---|---|---|---|

| Solar scaled average (kWh/m.d) | 2.0 | 4.5 | 7.0 |

| Temperature scaled average (°C) | 1.0 | 11.5 | 25.0 |

| Diesel fuel price (USD/L) | 1.2 | 1.5 | 1.8 |

| Expected inflation rate (%) | 5 | 10 | 30 |

| Solar Energy (kWh/m2·d) | Fuel Price (USD/L) | Expected Inflation Rate (%) | NPC (USD) | LCOE (USD/kWh) | IRR (%) | Simple Payback (yr) |

|---|---|---|---|---|---|---|

| 2.0 | 1.2 | 5 | 1.11 M | 0.557 | 24 | 4.0 |

| 10 | 1.92 M | 0.554 | 21 | 4.7 | ||

| 30 | 32.0 M | 0.545 | 12 | 7.8 | ||

| 1.5 | 5 | 1.37 M | 0.685 | 28 | 3.5 | |

| 10 | 2.37 M | 0.682 | 26 | 3.7 | ||

| 30 | 39.6 M | 0.673 | 16 | 6.1 | ||

| 1.8 | 5 | 1.62 M | 0.813 | 33 | 3.0 | |

| 10 | 2.81 M | 0.810 | 32 | 3.1 | ||

| 30 | 47.1 M | 0.800 | 15 | 6.2 | ||

| 4.5 | 1.2 | 5 | 1.11 M | 0.557 | 35 | 2.8 |

| 10 | 1.92 M | 0.554 | 32 | 3.1 | ||

| 30 | 32.0 M | 0.545 | 18 | 5.4 | ||

| 1.5 | 5 | 1.37 M | 0.685 | 42 | 2.3 | |

| 10 | 2.37 M | 0.682 | 41 | 2.4 | ||

| 30 | 39.6 M | 0.673 | 23 | 4.3 | ||

| 1.8 | 5 | 1.62 M | 0.813 | 50 | 1.9 | |

| 10 | 2.81 M | 0.810 | 48 | 2.1 | ||

| 30 | 47.1 M | 0.800 | 17 | 5.8 | ||

| 7.0 | 1.2 | 5 | 1.11 M | 0.557 | 40 | 2.5 |

| 10 | 1.92 M | 0.554 | 38 | 2.6 | ||

| 30 | 32.0 M | 0.545 | 21 | 4.6 | ||

| 1.5 | 5 | 1.37 M | 0.685 | 50 | 1.9 | |

| 10 | 2.37 M | 0.682 | 49 | 2.0 | ||

| 30 | 39.6 M | 0.673 | 20 | 4.9 | ||

| 1.8 | 5 | 1.62 M | 0.813 | 60 | 1.7 | |

| 10 | 2.81 M | 0.810 | 55 | 1.8 | ||

| 30 | 47.1 M | 0.800 | 19 | 5.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caglayan, N. Optimization of Grid-Connected and Off-Grid Hybrid Energy Systems for a Greenhouse Facility. Energies 2025, 18, 4712. https://doi.org/10.3390/en18174712

Caglayan N. Optimization of Grid-Connected and Off-Grid Hybrid Energy Systems for a Greenhouse Facility. Energies. 2025; 18(17):4712. https://doi.org/10.3390/en18174712

Chicago/Turabian StyleCaglayan, Nuri. 2025. "Optimization of Grid-Connected and Off-Grid Hybrid Energy Systems for a Greenhouse Facility" Energies 18, no. 17: 4712. https://doi.org/10.3390/en18174712

APA StyleCaglayan, N. (2025). Optimization of Grid-Connected and Off-Grid Hybrid Energy Systems for a Greenhouse Facility. Energies, 18(17), 4712. https://doi.org/10.3390/en18174712