Potential Effects of Various Optical Filtration Layers on the Techno-Economic Performance of Solar Photovoltaic/Thermal Modules: Status and Prospects

Abstract

1. Introduction

2. Optical Filtration Layer Based on Spectral Splitting Theory in the PV/T Modules

2.1. Absorptive-Based Optical Filtration Layer Technology

2.2. Reflective-Based Optical Filtration Layer Technology

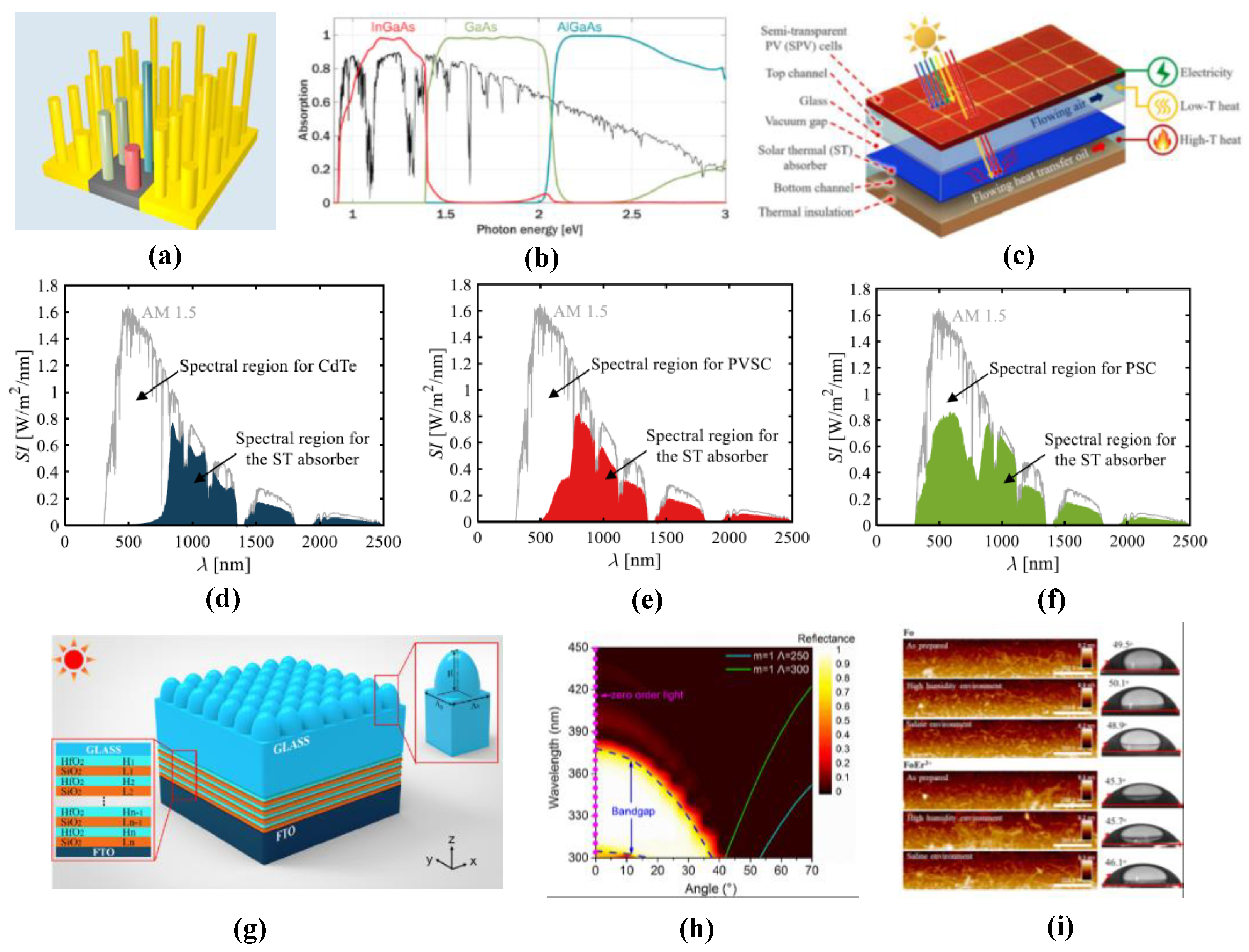

2.3. Refractive-Based Optical Filtration Layer Technology

2.4. Diffractive-Based Optical Filtration Layer Technology

3. Different Types of Optical Filtration Layers

3.1. Nanofluid Optical Filtration Layer

3.2. Liquid Luminescent Down-Shifting Optical Filtration Layer

3.3. Water Optical Filtration Layer

3.4. Colored Optical Filtration Layer

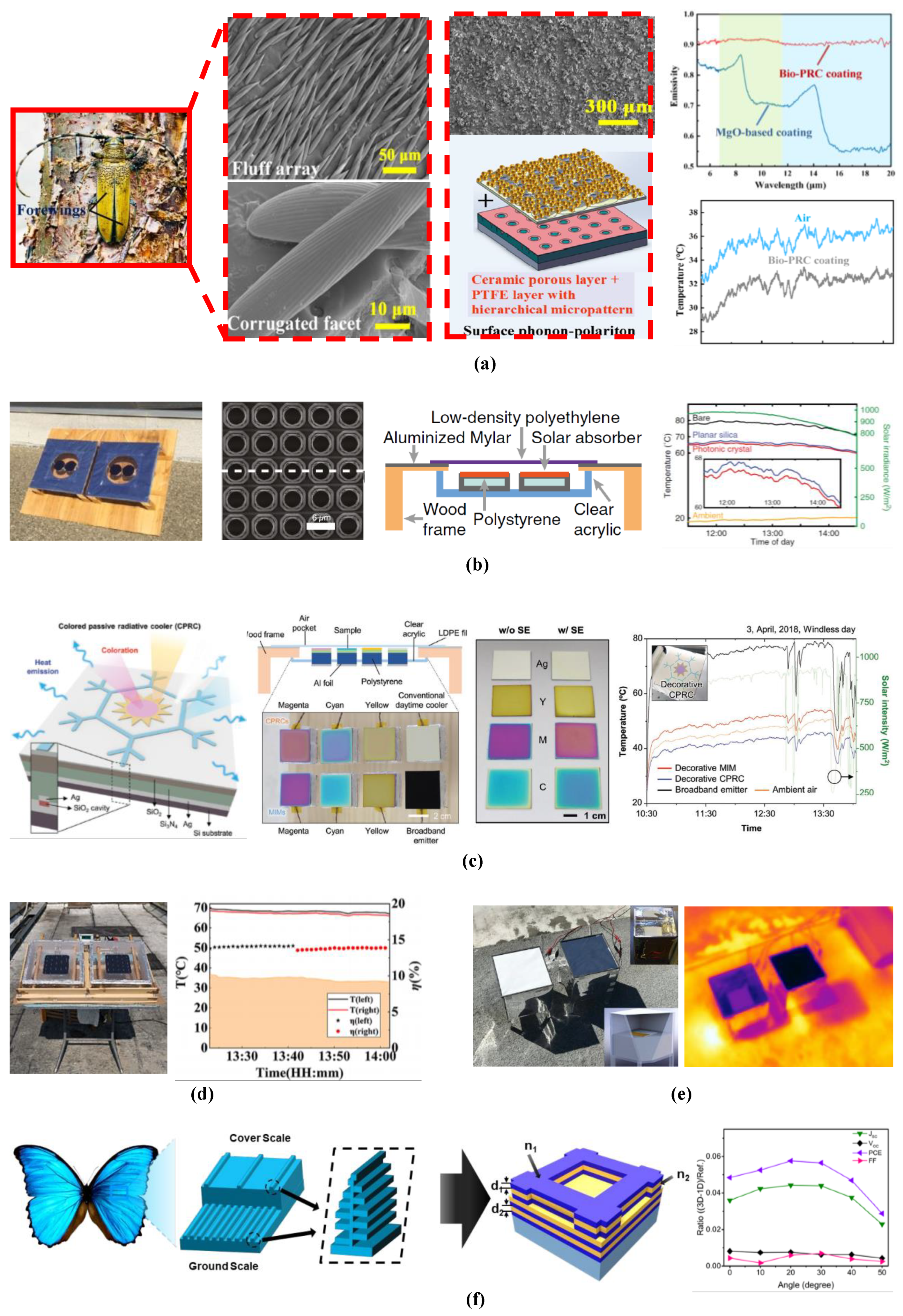

3.5. Radiative Cooling Optical Filtration Layer

3.6. Other Types of Optical Filtration Layer

3.7. Summary

4. Economic Assessments of PV/T System with Various Optical Filtration Layers

5. Techno-Economic Challenges of PV/T Module with Optical Filtration Layers

- Currently, four types of PV/T modules with solid and liquid optical filtration layers—absorptive, refractive, reflective, and diffractive—have been studied both experimentally and numerically. Notably, only absorptive optical filters can function dually as spectral filters and working fluid media (e.g., nanofluids), while the others are typically solid. The performance of such PV/T systems can be tuned by adjusting the dimensions, materials, and thermal properties of the optical layers. Some promising liquids, such as HB650@ propylene glycol (PG), Ag@SiO2@ ethylene glycol (EG), TiO2@ SiO2, and C-dots @ polyvinylpyrrolidone, exhibit excellent optical and thermal properties, high stability, and cost-effectiveness for long-term use. In contrast, solid optical layers serve only as filters, and their optical and thermal stability require further investigation. Despite the effectiveness of many composite materials, few studies have focused on the long-term performance of solid optical filters.

- Reflective and absorptive optical filtration layers have been extensively explored and applied in the PV/T modules. Currently, much less work has been committed to the development and testing of refractive- and diffractive-based optical filtration layers for PV/T utilization. However, diffractive- and refractive-based optical filtration layers are attractive in the CPV/T modules for large-scale deployment, since they are able to serve as sunlight splitters and concentrators simultaneously, which is a promising field for future investigation. Furthermore, current PV/T modules with selectively reflective optical filtration layers still have limited dimensions, which acts as a non-trivial impediment to the large-scale actual employment. Henein, a cost-effective and scalable optical filtration layer needs to be developed as a vital prerequisite for the PV/T with reflective filters.

- The thermal properties of refractive, diffractive, and reflective optical filtration layers are dissimilar from those of fluid-based absorptive ones. Solid phase optical filters usually exhibit low absorptivity; hence, they harvest little sunlight in the form of heat, whereas their low thermal expansions are also comparatively common, contributing to decreasing the thermal stresses. In the meantime, it is demonstrated that the liquid filtration layer filters with a high heat capacity contribute to transporting more heat per unit flow rate to the PV/T module. Nevertheless, the thermal fluid with a high heat capacity also has thermal inertia, as well as a start-up or transient time for achieving a desired temperature. Additionally, liquid-based optical filters in the PV/T modules have high thermal conductivity, which is conducive to attaining a homogeneous fluid temperature distribution for high electrical and thermal effectiveness output.

- More consideration should be given to the effects of exterior conditions, such as temperature, pressure, and magnetic field, on the stability of nanofluids. In particular, when the operating temperature is greater than 200 °C, it is a big challenge to sustain the nanofluid stability.

- One major challenge for nanofluid optical filtration layers in actual utilization is the long-time dispersion stability. Hence, more extensive investigations on stabilization approaches should be conducted in terms of ameliorating the usability of nanofluid in PV/T modules. Further exploration and optimization of concentration, dimension, thickness, and shape in nanoparticles should be implemented to realize the optimum filter based on the transmittance that most suits the PV cell.

- The price of composite material is dependent on the process of material preparation. Thus, in order to select the best nanofluid applied to the PV/T module from the financial viewpoint, a long-term and complete financial assessment involving initial cost and post-maintenance is required to be conducted to guarantee its market competitiveness. However, there is a limited number of studies on investigating the financial usefulness of PV/T modules with optical filtration layers. It is demonstrated that there is a shortage of exploration on optical analyses of some nano-materials, including NiFe2O4, Cu, MgO, Cr, and ionic liquids.

6. Conclusions

- Only the PV/T module with absorptive filters could be integrated with optical filtration layers, which are typically made of solid materials. The performance of the PV/T modules with optical filtration layers could be regulated by altering the dimensions, material, and fluid thermal properties.

- The PV/T modules with optical filtration layers achieve higher thermal and electrical performance compared to conventional PV/T or standalone PV modules. By spectrally splitting incoming sunlight, these systems enable more efficient utilization of different bandwidths by the thermal collector and PV cell. The incorporation of nanomaterials further enhances thermo-optical properties, improving overall system performance. Optical efficiencies of reflective and refractive concentrators can reach approximately 80% at a concentration ratio of 10. However, performance degrades significantly at higher concentrations—for instance, decreasing to around 30% at a concentration ratio of 20.

- Absorptive and reflective filters have been widely studied in PV/T systems, whereas refractive and diffractive types remain less explored. The latter are particularly suitable for concentrated PV/T applications due to their dual function as spectral splitters and sunlight concentrators, making them promising for large-scale deployment. Results demonstrate that the refractive and diffractive filters can direct 50–60% of incoming sunlight to PV cells, achieving up to 70% energy conversion efficiency within the 600–1125 nm range. Moreover, reflective filters exhibit higher irradiance non-uniformity, with peak-to-average ratios reaching 4.99 and 5.23 at the top and middle of the sub-cell, respectively.

- Nanofluid-based filters can reduce PV surface temperature by 6–45%, contributing to overall system efficiencies of 80–85%. Using luminescent imidazole-phenanthroline as an LDS layer, optical, thermal, and electrical efficiencies can reach approximately 60%, 90%, and 80%, respectively.

- InGaP modules effectively reflect light beyond 865 nm, while CdTe modules exhibit semi-transparency in the visible and infrared regions. These properties inspire innovative optical filter designs tailored for PV/T systems. Additionally, novel composites like Mg2SiO4:Er3+ and Fo:Er3+ can achieve transmittance up to 88% in the Vis–NIR range.

- Different designs and materials entail varying initial costs, which must be considered during the design phase to ensure high overall energy efficiency. Material selection and system design should aim for a sufficiently high efficiency improvement to achieve a lower LCOE compared to conventional modules. The PBP for these systems typically ranges from 4 to 6 years.

7. Future Direction

- For the future development of PV/T modules with optical filtration layers, more research investigations should be made in these fields.

- Future research should focus on analyzing illumination unevenness in PV/T modules employing refractive and reflective optical filters, especially when integrated with secondary optical elements, as well as evaluating other factors causing heterogeneity, such as partial shading.

- The long-term operational stability of optical filtration layers also requires thorough assessment, as degradation of optical and thermal properties over time affects system durability. Further investigation should include long-term testing of nanofluids under varying concentrations, high temperatures, and magnetic fields to evaluate their impact on PV/T energy output.

- Composite materials with high heat capacity and thermal conductivity must be further developed to enhance the optical, electrical, and thermal performance of PV/T systems sustainably. Moreover, considering the environmental toxicity of nanomaterials, further research on the safe handling of nanofluids is essential for the practical deployment of integrated PV/T systems.

- The cost of working fluids and the additional expenses required to maintain stability under high solar radiation must be evaluated under varying conditions of temperature, concentration, and exposure time. Future studies should also examine the exergy performance, environmental impact, and social implications of optical filtration layer-based PV/T systems.

- Standardized testing procedures and performance metrics are essential to enable reliable technology benchmarking, guide R&D, and support commercialization. Priority should be shown to spectrally resolved testing, unified hybrid efficiency metrics—such as exergy-based standards—and durability criteria for optical materials. Reproducible test methods are also critical for industry adoption and certification, enabling investors and policymakers to objectively assess system eligibility for subsidies and incentives.

- A systems engineering approach addressing durability, environmental resilience, thermal management, and manufacturability should be adopted. Accelerated testing, long-term outdoor trials, and scalable integration methods are needed to realistically evaluate and implement optical filtering technologies in practical PVT applications.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Ck | thermal conductivity enhancement coefficient |

| Cμ | viscosity enhancement coefficient |

| Mo | turbulent flow to whole thermal performance of nanofluid |

| μ | dynamic viscosity (Pas) |

| μnf | dynamic viscosity of the nanofluid (Pas) |

| μbf | dynamic viscosity of the base fluid (Pas) |

| K | thermal conductivity (W/mK) |

| Knf | thermal conductivity of the nanofluid (W/mK) |

| Kbf | thermal conductivity of the base fluid (W/mK) |

| ρ | density (kg/m3) |

| ρnf | density of the nanofluid (kg/m3) |

| ρbf | density of the base fluid (kg/m3) |

| Cp | specific heat capacity (J/kgK) |

| Cpnf | specific heat capacity at constant pressure of the nanofluid (J/kgK) |

| Cpbf | specific heat capacity at constant pressure of the base fluid (J/kgK) |

Abbreviations

| AFM | atomic force microscopy |

| AR | anti-reflective |

| BMES | biomimetic moth-eye structure |

| Bio-PRC | biomass and passive radiation cooling |

| CPC | compound parabolic concentrator |

| CNT | carbon nanotube |

| CPRC | colored passive radiative cooling |

| CPV/T | concentrator photovoltaic/thermal |

| DM | dichroic mirrors |

| DOE | diffractive optical elements |

| DPP | dynamic payback period |

| EG | propylene glycol |

| EQE | external quantum efficiency |

| EVA | ethylene-vinyl acetate |

| IR | infrared light |

| ITOEG | indium tin oxide–ethylene glycol |

| LCC | life-cycle cost |

| LCOE | least cost of energy |

| LDS | luminescent down-shifting |

| LSC | luminescent solar concentrator |

| MF | merit function |

| MIM | metal–insulator–metal |

| MPF | multilayer polymer film |

| NPV | net present value |

| MWCNT | multi-walled carbon nanotube |

| ORC | organic Rankine cycle |

| PCE | power conversion efficiency |

| PCM | phase change material |

| PG | propylene glycol |

| PMMA | polymethyl methacrylate |

| PMS | photon management structure |

| PPF | price-performance factor |

| PSC | polymer solar cell |

| PVSC | perovskite solar cells |

| CdTe | cadmium telluride |

| PTFE | polytetrafluoroethylene |

| QD | quantum dots |

| SM | spectral match |

| SPR | polyhedral specular reflector |

| SWR | solar weighted reflectance |

| SWT | solar weighted transmittance |

| PV | photovoltaic |

| PV/T | photovoltaic/thermal |

| PV/TE | PV-thermo-electric |

| UV | ultraviolet |

| VIS | visible |

| 1D | one-dimensional |

| 2D | two-dimensional |

| 3D | three-dimensional |

References

- Amin, A.; Yusoff, N.Y.B.M.; Peng, S.; Magazzino, C.; Sharif, A.; Kamran, H.W. Driving Sustainable Development: The Impact of Energy Transition, Eco-Innovation, Mineral Resources, and Green Growth on Carbon Emissions. Renew. Energy 2025, 238, 121879. [Google Scholar] [CrossRef]

- Wang, P.P.; Huang, G.H.; Li, Y.P.; Luo, B.; Li, Y.F. Unveiling China’s Household CO2 Emissions with Disaggregated Energy Sectors: An Affinity-Propagation Multi-Regional Input-Output Model. Renew. Energy 2025, 238, 121929. [Google Scholar] [CrossRef]

- Siow, L.; Lee, J.; Ooi, E.H.; Lau, E.V. Application of Graphene and Graphene Derivatives in Cooling of Photovoltaic (PV) Solar Panels: A Review—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S136403212400011X (accessed on 26 January 2025).

- Ai, S.; Wang, Y.; Li, T.; Chen, Y.; He, C. The Different Dimensional Desalinating Evaporator Independent on Solar Absorber Available to Transferring Random Spectrum into Full-Wavelength Solar Utilization—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/abs/pii/S2542529323002262 (accessed on 26 January 2025).

- Rahmatian, M.; Sayyaadi, H.; Ameri, M. A Novel Thermoelectrical Model for Dye-Sensitized Solar Cells for Consideration of the Effects of Solar Irradiation, Wavelength, and Surface Temperature. Sol. Energy 2023, 266, 112140. [Google Scholar] [CrossRef]

- Falope, T.; Lao, L.; Hanak, D.; Huo, D. Hybrid Energy System Integration and Management for Solar Energy: A Review. Energy Convers. Manage X 2024, 21, 100527. [Google Scholar] [CrossRef]

- Terashima, K.; Sato, H.; Ikaga, T. PV/T Solar Panel for Supplying Residential Demands of Heating/Cooling and Hot Water with a Lower Environmental Thermal Load—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S0378778823006382 (accessed on 26 January 2025).

- Herrando, M.; Kai Wang, K.; Huang, G.; Otanicar, T.; Mousa, O.B. A Review of Solar Hybrid Photovoltaic-Thermal (PV-T) Collectors and Systems—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S0360128523000023 (accessed on 26 January 2025).

- Mojumder, J.C.; Mitchell, T.R.; Aminossadati, S.M.; Leonardi, C.R. Numerical Investigation of the Effect of Nanoparticle Aggregation on the Performance of Concentrated Photovoltaic-Solar Thermal Collectors with Spectral Filtering—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S1359431123019737 (accessed on 26 January 2025).

- Jiang, T.; Zou, T.; Wang, G.; Wang, B.; Chen, Z. Preparation and Application Study in a Novel Solar PV/Thermal System of Indium Tin Oxide Nanofluid Optical Filter. Energy Rep. 2022, 8, 5668–5677. [Google Scholar] [CrossRef]

- Fazal, M.A.; Rubaiee, S. Progress of PV Cell Technology: Feasibility of Building Materials, Cost, Performance, and Stability. Sol. Energy 2023, 258, 203–219. [Google Scholar] [CrossRef]

- Huang, G.; Curt, S.R.; Wang, K.; Markides, C.N. Challenges and Opportunities for Nanomaterials in Spectral Splitting for High-Performance Hybrid Solar Photovoltaic-Thermal Applications: A Review. Nano Mater. Sci. 2020, 2, 183–203. [Google Scholar] [CrossRef]

- Jiao, Y.; Xing, M.; Estellé, P. Efficient Utilization of Hybrid Photovoltaic/Thermal Solar Systems by Nanofluid-Based Spectral Beam Splitting: A Review. Sol. Energy Mater. Sol. Cells 2024, 265, 112648. [Google Scholar] [CrossRef]

- Hao, X.; Zhou, Y.; Wang, Q.; Gao, N.; Wang, X.; Chen, G. Prospective Study of a Novel Heat Pump System with Solar Energy Spectral Beam Splitting. Renew. Energy 2023, 217, 119209. [Google Scholar] [CrossRef]

- Guo, J. Maximizing Uninterrupted Solar Electricity in Spectral-Splitting Photovoltaic-Thermal Systems Integrated with CO2 Battery. J. Energy Storage 2023, 66, 107402. [Google Scholar] [CrossRef]

- Abdelrazik, A.S. The Potential of Liquid-Based Spectrally-Selective Optical Filtration and Its Use in Hybrid Photovoltaic/Thermal Solar Systems. Sol. Energy 2023, 249, 569–605. [Google Scholar] [CrossRef]

- Pan, H.-Y.; Chen, X.; Xia, X.-L. A Review on the Evolvement of Optical-Frequency Filtering in Photonic Devices in 2016–2021. Renew. Sustain. Energy Rev. 2022, 161, 112361. [Google Scholar] [CrossRef]

- Hong, W.; Li, B.; Li, H.; Niu, X.; Li, Y.; Lan, J. Recent Progress in Thermal Energy Recovery from the Decoupled Photovoltaic/Thermal System Equipped with Spectral Splitters. Renew. Sustain. Energy Rev. 2022, 167, 112824. [Google Scholar] [CrossRef]

- Ko, J.H.; Yoo, Y.J.; Lee, Y.; Jeong, H.-H.; Song, Y.M. A Review of Tunable Photonics: Optically Active Materials and Applications from Visible to Terahertz. iScience 2022, 25, 104727. [Google Scholar] [CrossRef]

- Kumar, S.; Chander, N.; Gupta, V.K.; Kukreja, R. Progress, challenges and future prospects of plasmonic nanofluid based direct absorption solar collectors—A state-of-the-art review. Sol. Energy 2021, 227, 365–425. [Google Scholar] [CrossRef]

- Kumar, M.; Kumar, S.; Singh, S. A critical review of concentrating and nanofluid-based hybrid PV/T systems utilizing beam splitting technique: Progress, challenges, and way forward. Environ. Sci. Pollut. Research 2023, 36, 84850–84873. [Google Scholar] [CrossRef]

- Yazdanifard, F.; Ameri, M.; Ebrahimnia-Bajestan, E. Performance of nanofluid-based photovoltaic/thermal systems: A review. Renew. Sustain. Energy Rev. 2017, 76, 323–352. [Google Scholar] [CrossRef]

- Jackson, E.D. Areas for Improvement of the Semiconductor Solar Energy Converter. Trans. Intern. Conf. Use Sol. Energy-Sci. Basis 1955, 5, 122. [Google Scholar]

- Adam, S.A.; Ju, X.; Zhang, Z.; Abd El-Samie, M.M.; Xu, C. Theoretical Investigation of Different CPVT Configurations Based on Liquid Absorption Spectral Beam Filter. Energy 2019, 189, 116259. [Google Scholar] [CrossRef]

- Han, X.; Xue, D.; Zheng, J.; Alelyani, S.M.; Chen, X. Spectral Characterization of Spectrally Selective Liquid Absorption Filters and Exploring Their Effects on Concentrator Solar Cells. Renew. Energy 2019, 131, 938–945. [Google Scholar] [CrossRef]

- Han, X.; Tu, L.; Sun, Y. A Spectrally Splitting Concentrating PV/T System Using Combined Absorption Optical Filter and Linear Fresnel Reflector Concentrator. Sol. Energy 2021, 223, 168–181. [Google Scholar] [CrossRef]

- Ma, Y.; Han, X.; Chen, Z.; Khosa, A.A. Performance Analysis of a Nanofluid Spectral Splitting Concentrating PV/T System with Triangular Receiver Based on MCRT-FVM Coupled Method. Appl. Therm. Eng. 2024, 239, 122096. [Google Scholar] [CrossRef]

- Abd El-Samie, M.M.; Li, W.; Xu, C.; Ju, X. Influence of Thermal and Optical Criteria of Spectral Fluid Filters for Hybrid Concentrated Photovoltaic/Thermal Systems. Int. J. Heat Mass Transf. 2021, 174, 121303. [Google Scholar] [CrossRef]

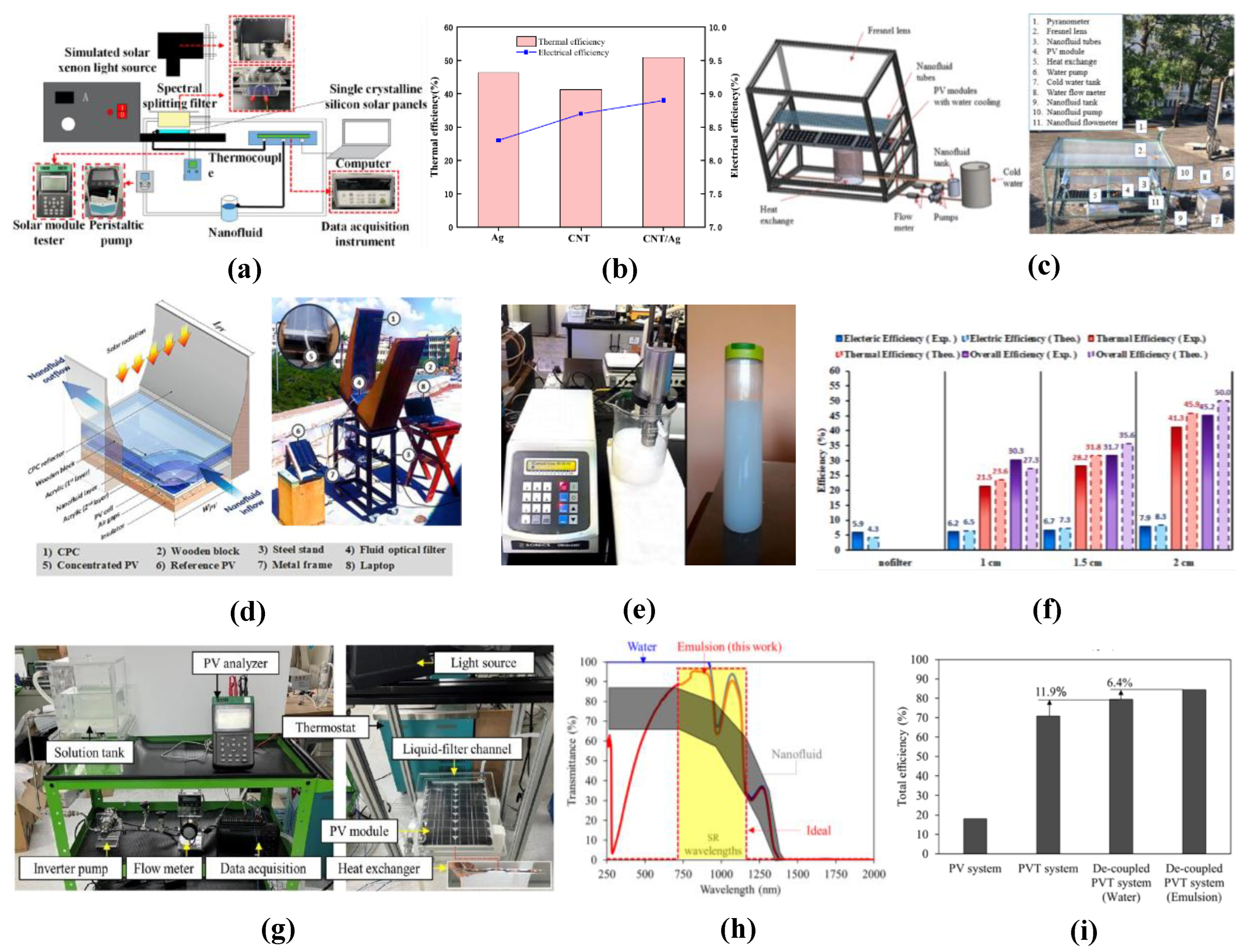

- Elharoun, O.; Tawfik, M.; El-Sharkawy, I.I.; Zeidan, E. Experimental Investigation of Photovoltaic Performance with Compound Parabolic Solar Concentrator and Fluid Spectral Filter. Energy 2023, 278, 127848. [Google Scholar] [CrossRef]

- Alnajideen, M.; Min, G. Hybrid Photovoltaic-Thermoelectric System Using a Novel Spectral Splitting Solar Concentrator. Energy Convers. Manag. 2022, 251, 114981. [Google Scholar] [CrossRef]

- Li, J.; Yang, Z.; Han, X.; Ge, Y.; Wang, Y.; Dong, Q.; Huang, C.; Li, H.; Chen, P.; Lin, R. Thermodynamic Investigation of Spectral Splitting Hybrid System Integrated Cassegrain Concentrator and Mid/Low-Temperature Solar Thermochemical Storage. Renew. Energy 2023, 217, 119152. [Google Scholar] [CrossRef]

- Zambrano-Mera, D.F.; Espinoza-González, R.; Villarroel, R.; Rosenkranz, A.; Carvajal, N.; Pintor-Monroy, M.I.; Montaño-Figueroa, A.G.; Arellano-Jiménez, M.J.; Quevedo-López, M.; Valenzuela, P.; et al. Optical and Mechanical Properties of Zr-Oxide Doped TiO2/SiO2 Anti-Reflective Coatings for PV Glass Covers. Sol. Energy Mater. Sol. Cells 2022, 243, 111784. [Google Scholar] [CrossRef]

- Kandil, A.A.; Awad, M.M.; Sultan, G.I.; Salem, M.S. Enhancing Photovoltaic Performance through Solar Radiation Splitting: A Beam Splitter-Assisted Hybrid Approach with 2-D Tracking and PCM Integration. J. Energy Storage 2024, 75, 109692. [Google Scholar] [CrossRef]

- Stefancich, M.; Zayan, A.; Chiesa, M.; Rampino, S.; Roncati, D.; Kimerling, L.; Michel, J. Single Element Spectral Splitting Solar Concentrator for Multiple Cells CPV System. Opt. Express OE 2012, 20, 9004–9018. [Google Scholar] [CrossRef]

- Zhao, H. Refractive Index Dependent Optical Property of Carbon Dots Integrated Luminescent Solar Concentrators. J. Lumin. 2019, 211, 150–156. [Google Scholar] [CrossRef]

- Liu, G.; Mazzaro, R.; Sun, C.; Zhang, Y.; Wang, Y.; Zhao, H.; Han, G.; Vomiero, A. Role of Refractive Index in Highly Efficient Laminated Luminescent Solar Concentrators. Nano Energy 2020, 70, 104470. [Google Scholar] [CrossRef]

- Saura, J.M.; Rodrigo, P.M.; Almonacid, F.M.; Chemisana, D.; Fernández, E.F. Experimental Characterisation of Irradiance and Spectral Non-Uniformity and Its Impact on Multi-Junction Solar Cells: Refractive vs. Reflective Optics. Sol. Energy Mater. Sol. Cells 2021, 225, 111061. [Google Scholar] [CrossRef]

- Wu, J.; Tu, J.; Li, L.; Xiao, X.; Hu, K.; Yu, S.; Xie, Y.; Yang, Y.; Wu, H. Gradient Refractive Index-Based Broadband Antireflective Coatings and Application in Silicon Solar Modules. Surf. Interfaces 2022, 30, 101918. [Google Scholar] [CrossRef]

- Kim, W.; Cho, D.; Hong, S.; Lee, W. Implementation of Various Colors in Cu (in, Ga) Se2 Thin-Film Solar Cells by Diffractive Nanostructures—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S0927024823002131 (accessed on 26 January 2025).

- Gün, B.N.; Yüce, E. Wavefront Shaping Assisted Design of Spectral Splitters and Solar Concentrators|Scientific Reports. Available online: https://www.nature.com/articles/s41598-021-82110-w (accessed on 26 January 2025).

- Huang, Q.; Wang, J.; Hu, J.; Xu, H. The Analysis of High Efficiency Multi-Junction Solar Cells Architecture Using a Diffractive Optical Element as the Spectrum Splitting Solar Concentrator|Atlantis Press. Available online: https://www.atlantis-press.com/proceedings/ifeesd-16/25857132 (accessed on 26 January 2025).

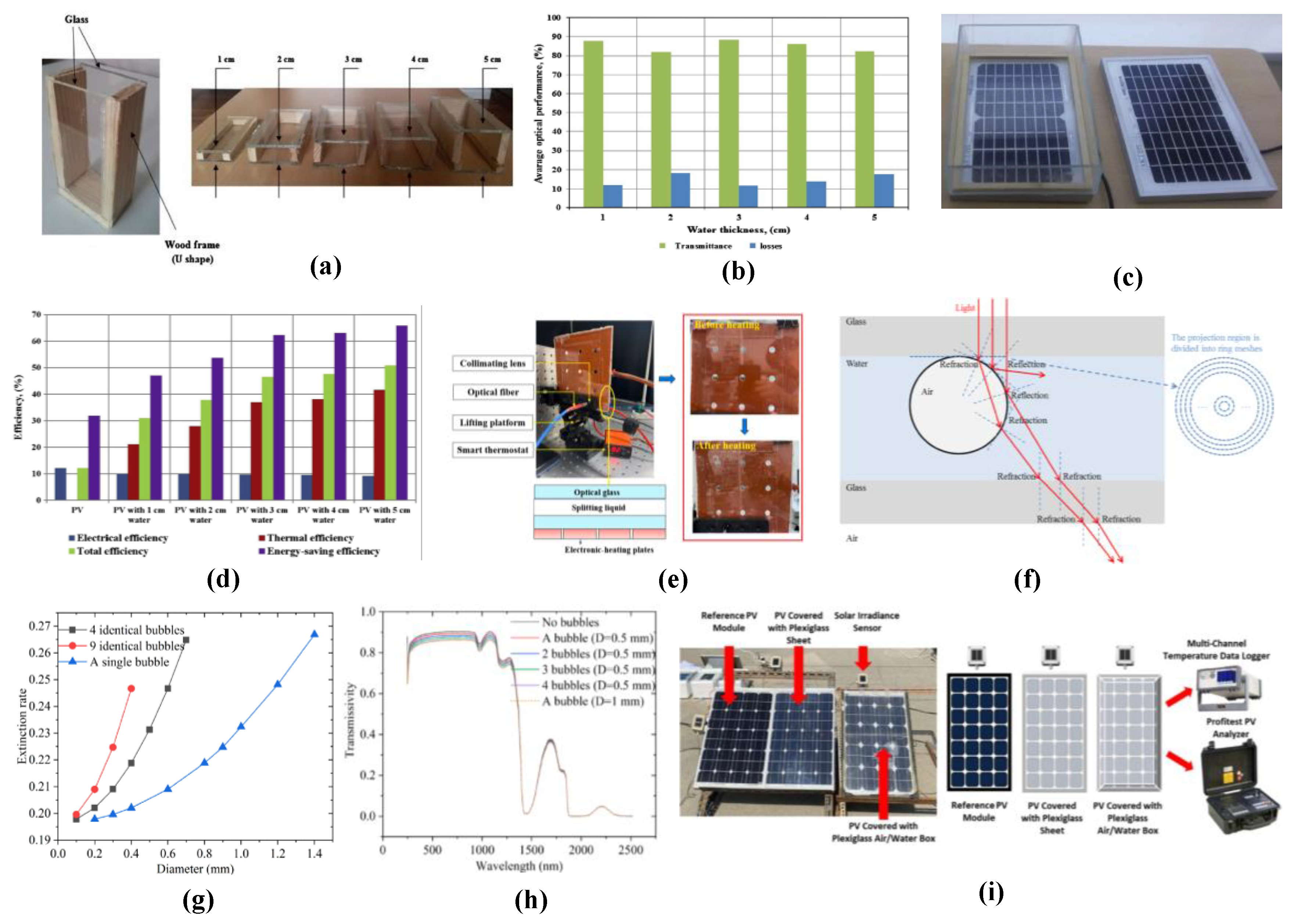

- Xia, X.; Cao, X.; Li, N.; Yu, B.; Liu, H.; Ji, J. Study on a Spectral Splitting Photovoltaic/Thermal System Based on CNT/Ag Mixed Nanofluids. Energy 2023, 271, 127093. [Google Scholar] [CrossRef]

- Meraje, W.C.; Huang, C.-C.; Barman, J.; Huang, C.-Y.; Kuo, C.-F.J. Design and Experimental Study of a Fresnel Lens-Based Concentrated Photovoltaic Thermal System Integrated with Nanofluid Spectral Splitter. Energy Convers. Manag. 2022, 258, 115455. [Google Scholar] [CrossRef]

- Elharoun, O.; Tawfik, M.; El-Sharkawy, I.I.; Zeidan, E. Experimental and Numerical Study of Photovoltaic Performance Integrated with a Nanofluid-Based Optical Filter and a Compound Parabolic Concentrator. Energy Convers. Manag. 2023, 291, 117278. [Google Scholar] [CrossRef]

- Lee, J.W.; Song, M.S.; Jung, H.S.; Kang, Y.T. Development of Solar Radiation Spectrum-Controlled Emulsion Filter for a Photovoltaic-Thermal (PVT) System. Energy Convers. Manag. 2023, 287, 117087. [Google Scholar] [CrossRef]

- Huaxu, L.; Fuqiang, W.; Dong, Z.; Ziming, C.; Chuanxin, Z.; Bo, L.; Huijin, X. Experimental Investigation of Cost-Effective ZnO Nanofluid Based Spectral Splitting CPV/T System. Energy 2020, 194, 116913. [Google Scholar] [CrossRef]

- Hashemian, M.; Jafarmadar, S.; Khalilarya, S.; Faraji, M. Energy Harvesting Feasibility from Photovoltaic/Thermal (PV/T) Hybrid System with Ag/Cr2O3-Glycerol Nanofluid Optical Filter. Renew. Energy 2022, 198, 426–439. [Google Scholar] [CrossRef]

- Han, X.; Chen, X.; Wang, Q.; Alelyani, S.M.; Qu, J. Investigation of CoSO4-Based Ag Nanofluids as Spectral Beam Splitters for Hybrid PV/T Applications. Sol. Energy 2019, 177, 387–394. [Google Scholar] [CrossRef]

- Han, X.; Zhao, X.; Huang, J.; Qu, J. Optical Properties Optimization of Plasmonic Nanofluid to Enhance the Performance of Spectral Splitting Photovoltaic/Thermal Systems. Renew. Energy 2022, 188, 573–587. [Google Scholar] [CrossRef]

- Abdelrazik, A.S.; Al-Sulaiman, F.A.; Saidur, R. Optical Behavior of a Water/Silver Nanofluid and Their Influence on the Performance of a Photovoltaic-Thermal Collector. Sol. Energy Mater. Sol. Cells 2019, 201, 110054. [Google Scholar] [CrossRef]

- Abdelrazik, A.S.; Saidur, R.; Al-Sulaiman, F.A. Investigation of the Performance of a Hybrid PV/Thermal System Using Water/Silver Nanofluid-Based Optical Filter. Energy 2021, 215, 119172. [Google Scholar] [CrossRef]

- Zhang, C.; Shen, C.; Wei, S.; Zhang, Y.; Sun, C. Flexible Management of Heat/Electricity of Novel PV/T Systems with Spectrum Regulation by Ag Nanofluids. Energy 2021, 221, 119903. [Google Scholar] [CrossRef]

- Du, M.; Tang, G.H.; Wang, T.M. Exergy Analysis of a Hybrid PV/T System Based on Plasmonic Nanofluids and Silica Aerogel Glazing. Sol. Energy 2019, 183, 501–511. [Google Scholar] [CrossRef]

- Klampaftis, E.; Ross, D.; McIntosh, K.R.; Richards, B.S. Enhancing the Performance of Solar Cells via Luminescent Down-Shifting of the Incident Spectrum: A Review. Sol. Energy Mater. Sol. Cells 2009, 93, 1182–1194. [Google Scholar] [CrossRef]

- Alexandre, M.; Chapa, M.; Haque, S.; Mendes, M.J.; Águas, H. Optimum Luminescent Down-Shifting Properties for High Efficiency and Stable Perovskite Solar Cells|ACS Applied Energy Materials. Available online: https://pubs.acs.org/doi/abs/10.1021/acsaem.9b00271 (accessed on 26 January 2025).

- Yang, D.; Liang, H.; Liu, Y.; Hou, M.; Kan, L.; Yang, Y.; Zang, Z. A Large-Area Luminescent Downshifting Layer Containing an Eu3+ Complex for Crystalline Silicon Solar Cells. Dalton Trans. 2020, 49, 4725–4731. [Google Scholar] [CrossRef] [PubMed]

- Singh, J.; Kumar, A.; Jaiswal, A.; Suman, S.; Jaiswal, R.P. Luminescent Down-Shifting Natural Dyes to Enhance Photovoltaic Efficiency of Multicrystalline Silicon Solar Module. Sol. Energy 2020, 206, 353–364. [Google Scholar] [CrossRef]

- Razzaq, S.; Asghar, A.; Lou, C.; Diao, H.; Huang, S.; Yin, Y. Influence of Down-Shifting Particle’s Size on Monocrystalline Silicon Solar Cells. J. Alloys Compd. 2022, 907, 164512. [Google Scholar] [CrossRef]

- Coldrick, K.; Walshe, J.; Doran, J.; Amarandei, G. Evaluation of the Photon Contributions to the Solar Energy Conversion for Organic Luminescent Down-Shifting Liquid Beam Splitters in Hybrid Photovoltaic-Thermal (PVT) Applications Using Raytracing Monte Carlo Simulations. Sol. Energy Mater. Sol. Cells 2023, 254, 112201. [Google Scholar] [CrossRef]

- Walshe, J.; Carron, P.M.; McCormack, S.; Doran, J.; Amarandei, G. Organic Luminescent Down-Shifting Liquid Beam Splitters for Hybrid Photovoltaic-Thermal (PVT) Applications. Sol. Energy Mater. Sol. Cells 2021, 219, 110818. [Google Scholar] [CrossRef]

- Al-Shohani, W.A.M.; Sabouri, A.; Al-Dadah, R.; Mahmoud, S.; Butt, H. Experimental Investigation of an Optical Water Filter for Photovoltaic/Thermal Conversion Module. Energy Convers. Manag. 2016, 111, 431–442. [Google Scholar] [CrossRef]

- Al-Shohani, W.A.M.; Al-Dadah, R.; Mahmoud, S. Reducing the Thermal Load of a Photovoltaic Module through an Optical Water Filter. Appl. Therm. Eng. 2016, 109, 475–486. [Google Scholar] [CrossRef]

- Lin, J.; Liu, H.; Ju, X.; Liu, S.; Xu, C.; Ju, X. Investigation of Bubbles on the Performance of an Optical Water Filter for a Photovoltaic/Thermal System. Appl. Therm. Eng. 2022, 213, 118643. [Google Scholar] [CrossRef]

- Almarzooqi, N.K.; Ahmad, F.F.; Hamid, A.K.; Ghenai, C.; Farag, M.M.; Salameh, T. Experimental Investigation of the Effect of Optical Filters on the Performance of the Solar Photovoltaic System. Energy Rep. 2023, 9, 336–344. [Google Scholar] [CrossRef]

- Gupta, M.; Dubey, A.K.; Kumar, V.; Mehta, D.S. Experimental Study of Combined Transparent Solar Panel and Large Fresnel Lens Concentrator Based Hybrid PV/Thermal Sunlight Harvesting System. Energy Sustain. Dev. 2021, 63, 33–40. [Google Scholar] [CrossRef]

- Ben Amara, M.; Balghouthi, M. Colored Filter’s Impact on the Solar Cells’ Electric Output under Real Climatic Conditions for Application in Building Integrated Photovoltaics. J. Build. Eng. 2023, 76, 107276. [Google Scholar] [CrossRef]

- Wang, G.; Chen, X.; Lin, J.; Xu, C.; Ju, X. Experimental Study on a Concentrating Solar Photovoltaic/Thermal System Using Different Fluid Spectral Beam Filters. J. Clean. Prod. 2023, 429, 139549. [Google Scholar] [CrossRef]

- Chawrey, S.; Kumar, S.; Chander, N.; Kumar, N. Thermal management of a mono-crystalline PV/T system using gold plasmonic nanofluid based optical filter. Mater. Today Proc. 2023, 84, 57–60. [Google Scholar] [CrossRef]

- Eisler, C.N.; Flowers, C.A.; Warmann, E.C.; Lloyd, J.V.; Espinet-Gonzalez, P.; Darbe, S. The Polyhedral Specular Reflector: A Spectrum-Splitting Multijunction Design to Achieve Ultrahigh (>50%) Solar Module Efficiencies|IEEE Journals & Magazine|IEEE Xplore. Available online: https://ieeexplore.ieee.org/abstract/document/8485376 (accessed on 26 January 2025).

- Cho, D.-H.; Lee, W.-J.; Hwang, T.-H.; Chung, Y.-D. Reflective Color Filters Deposited via ZnS Single-Target Sputtering for Colorful Solar Cell Applications. Ceram. Int. 2023, 49, 30586–30591. [Google Scholar] [CrossRef]

- Rudzikas, M.; Donėlienė, J.; Bužavaitė-Vertelienė, E.; Balevičius, Z.; Leuvrey, C.; Šetkus, A. Design and Investigation of 1D Photonic Crystal Based Structures for BIPV Cell Colorization by Sol-Gel Dipping Technology. Sol. Energy 2023, 250, 285–294. [Google Scholar] [CrossRef]

- Su, W.; Cai, P.; Darkwa, J.; Hu, M.; Kokogiannakis, G.; Xu, C.; Wang, L. Review of Daytime Radiative Cooling Technologies and Control Methods. Appl. Therm. Eng. 2023, 235, 121305. [Google Scholar] [CrossRef]

- Xie, B.; Liu, Y.; Xi, W.; Hu, R. Colored Radiative Cooling: Progress and Prospects. Mater. Today Energy 2023, 34, 101302. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Y.; Zou, Y.; Chen, G.; Ouyang, J.; Jia, D.; Zhou, Y. Biologically Inspired Scalable-Manufactured Dual-Layer Coating with a Hierarchical Micropattern for Highly Efficient Passive Radiative Cooling and Robust Superhydrophobicity. ACS Appl. Mater. Interfaces 2021, 13, 21888–21897. [Google Scholar] [CrossRef]

- Zhu, L.; Raman, A.P.; Fan, S. Radiative Cooling of Solar Absorbers Using a Visibly Transparent Photonic Crystal Thermal Blackbody|PNAS. Available online: https://www.pnas.org/doi/abs/10.1073/pnas.1509453112 (accessed on 26 January 2025).

- Kiyaee, S.; Saboohi, Y.; Moshfegh, A.Z. A New Designed Linear Fresnel Lens Solar Concentrator Based on Spectral Splitting for Passive Cooling of Solar Cells. Energy Convers. Manag. 2021, 230, 113782. [Google Scholar] [CrossRef]

- Lee, G.; Kim, Y.; Kim, H.; Yoo, Y.; Song, Y. Colored, Daytime Radiative Coolers with Thin-Film Resonators for Aesthetic Purposes—Lee—2018—Advanced Optical Materials—Wiley Online Library. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/adom.201800707 (accessed on 26 January 2025).

- Cui, X.; Sun, X.; Zhou, L.; Wei, X. Thermal and Electrical Performance Analysis of Monofacial Double-Glass Photovoltaic Module with Radiative Cooling Coating on the Rear Surface. Sol. Energy 2023, 264, 111986. [Google Scholar] [CrossRef]

- Torgerson, E.; Hellhake, J. Polymer Solar Filter for Enabling Direct Daytime Radiative Cooling—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0927024819306476 (accessed on 26 January 2025).

- Jo, S.; Woo, J.; Shim, H.; Seo, S. Angle-Insensitive Transmission and Reflection of Nanopatterned Dielectric Multilayer Films for Colorful Solar Cells|ACS Applied Materials & Interfaces. Available online: https://pubs.acs.org/doi/abs/10.1021/acsami.0c06303 (accessed on 26 January 2025).

- Kecebas, M.A.; Menguc, M.P.; Kosar, A.; Sendur, K. Passive Radiative Cooling Design with Broadband Optical Thin-Film Filters. J. Quant. Spectrosc. Radiat. Transf. 2017, 198, 179–186. [Google Scholar] [CrossRef]

- Dorodnyy, A.; Alarcon-Lladó, E.; Shklover, V.; Hafne, C. Efficient Multiterminal Spectrum Splitting via a Nanowire Array Solar Cell|ACS Photonics. Available online: https://pubs.acs.org/doi/full/10.1021/acsphotonics.5b00222 (accessed on 26 January 2025).

- Huang, G.; Markides, C.N. Spectral-Splitting Hybrid PV-Thermal (PV-T) Solar Collectors Employing Semi-Transparent Solar Cells as Optical Filters. Energy Convers. Manag. 2021, 248, 114776. [Google Scholar] [CrossRef]

- Zheng, L.; Xuan, Y. Suppressing the Negative Effect of UV Light on Perovskite Solar Cells via Photon Management. Sol. Energy 2018, 173, 1216–1224. [Google Scholar] [CrossRef]

- Zampiva, R.Y.S.; Kaufmann, C.G.; Acauan, L.H.; Seeger, R.L.; Bonatto, F.; Boeira, C.D.; Santos, W.Q.; Jacinto, C.; Figueroa, C.A.; Dorneles, L.S.; et al. Luminescent Anti-Reflection Coatings Based on Er3+ Doped Forsterite for Commercial Silicon Solar Cells Applications. Sol. Energy 2018, 170, 752–761. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, H.; Xiong, Y.; Yao, Y.; Lv, H.; Xue, X.; Xu, C. Performance Investigation on an Agricultural Photovoltaic Thermal System Based on Spectral Separation. Renew. Energy 2024, 221, 119720. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, F.; Zhang, W.; Li, M.; Liu, W.; Ali Abaker Omer, A.; Zheng, J.; Zhang, X.; Liu, W. Spectral-Splitting Concentrator Agrivoltaics for Higher Hybrid Solar Energy Conversion Efficiency. Energy Convers. Manag. 2023, 276, 116567. [Google Scholar] [CrossRef]

- Abdelgaied, M.; Attia, M.E.H.; Kabeel, A.E.; Zayed, M.E. Improving the Thermo-Economic Performance of Hemispherical Solar Distiller Using Copper Oxide Nanofluids and Phase Change Materials: Experimental and Theoretical Investigation—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0927024822000204 (accessed on 26 January 2025).

- Al-Waeli, A.H.A.; Sopian, K.; Kazem, H.A.; Chaichan, M.T. Nanofluid Based Grid Connected PV/T Systems in Malaysia: A Techno-Economical Assessment—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/abs/pii/S2213138817300280 (accessed on 26 January 2025).

- Said, Z.; Ghodbane, M.; Boumeddane, B. Energy, Exergy, Economic and Environmental (4E) Analysis of a Parabolic Trough Solar Collector Using MXene Based Silicone Oil Nanofluids—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0927024822000563 (accessed on 26 January 2025).

- Kenfack, A.Z.; Nematchoua, M.K.; Simo, E.; Talla Konchou, F.A.; Babikir, M.H.; Pekarou Pemi, B.A.; Chara-Dackou, V.S. Techno-Economic and Environmental Analysis of a Hybrid PV/T Solar System Based on Vegetable and Synthetic Oils Coupled with TiO2 in Cameroon. Heliyon 2024, 10, e24000. [Google Scholar] [CrossRef] [PubMed]

- Adun, H.; Adedeji, M.; Ruwa, T.; Senol, M.; Kavaz, D.; Dagbasi, M. Energy, Exergy, Economic, Environmental (4E) Approach to Assessing the Performance of a Photovoltaic-Thermal System Using a Novel Ternary Nanofluid—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/abs/pii/S2213138821008183 (accessed on 26 January 2025).

- Abadeh, A.; Rejeb, O.; Sardarabadi, M.; Menezo, C.; Passandideh-Fard, M.; Jemni, A. Economic and Environmental Analysis of Using Metal-Oxides/Water Nanofluid in Photovoltaic Thermal Systems (PVTs). Energy 2018, 159, 1234–1243. [Google Scholar] [CrossRef]

- Hemmat Esfe, M.; Alirezaie, A.; Toghraie, D. Thermal Conductivity of Ethylene Glycol Based Nanofluids Containing Hybrid Nanoparticles of SWCNT and Fe3O4 and Its Price-Performance Analysis for Energy Management. J. Mater. Res. Technol. 2021, 14, 1754–1760. [Google Scholar] [CrossRef]

- Hemmat Esfe, M.; Alidoust, S.; Toghraie, D. Comparison of the Thermal Conductivity of Hybrid Nanofluids with a Specific Proportion Ratio of MWCNT and TiO2 Nanoparticles Based on the Price Performance Factor. Mater. Today Commun. 2023, 34, 105411. [Google Scholar] [CrossRef]

- Alirezaie, A.; Hajmohammad, M.H.; Hassani Ahangar, M.R.; Hemmat Esfe, M. Price-Performance Evaluation of Thermal Conductivity Enhancement of Nanofluids with Different Particle Sizes. Appl. Therm. Eng. 2018, 128, 373–380. [Google Scholar] [CrossRef]

- Navarro, M.E.; Palacios, A.; Jiang, Z.; Avila, A.; Qiao, G.; Mura, E.; Ding, Y. Effect of SiO2 Nanoparticles Concentration on the Corrosion Behaviour of Solar Salt-Based Nanofluids for Concentrating Solar Power Plants. Sol. Energy Mater. Sol. Cells 2022, 247, 111923. [Google Scholar] [CrossRef]

- Yan, C.; Liang, J.; Zhong, X.; Li, C.; Chen, D.; Wang, Z.; Li, S.; Xu, J.; Wang, H.; Li, Y.; et al. BN White Graphene Well-Dispersed Solar Salt Nanofluids with Significant Improved Thermal Properties for Concentrated Solar Power Plants. Sol. Energy Mater. Sol. Cells 2022, 245, 111875. [Google Scholar] [CrossRef]

- Farooq, S.; Vital, C.V.P.; Tikhonowski, G.; Popov, A.A.; Klimentov, S.M.; Malagon, L.A.G.; de Araujo, R.; Kabashin, A.V.; Rativa, D. Thermo-Optical Performance of Bare Laser-Synthesized TiN Nanofluids for Direct Absorption Solar Collector Applications. Sol. Energy Mater. Sol. Cells 2023, 252, 112203. [Google Scholar] [CrossRef]

| Item | Innovation | Key Findings |

|---|---|---|

| Kumar et al. [20] |

|

|

| Kumar et al. [21] |

|

|

| Yazdanifard et al. [22] |

|

|

| Current paper |

|

|

| Authors | Methodology | Optical Layer Dimension | Optical Fluid Type | Filtered Wavelength Range | Findings and Proclaimed Outcomes |

|---|---|---|---|---|---|

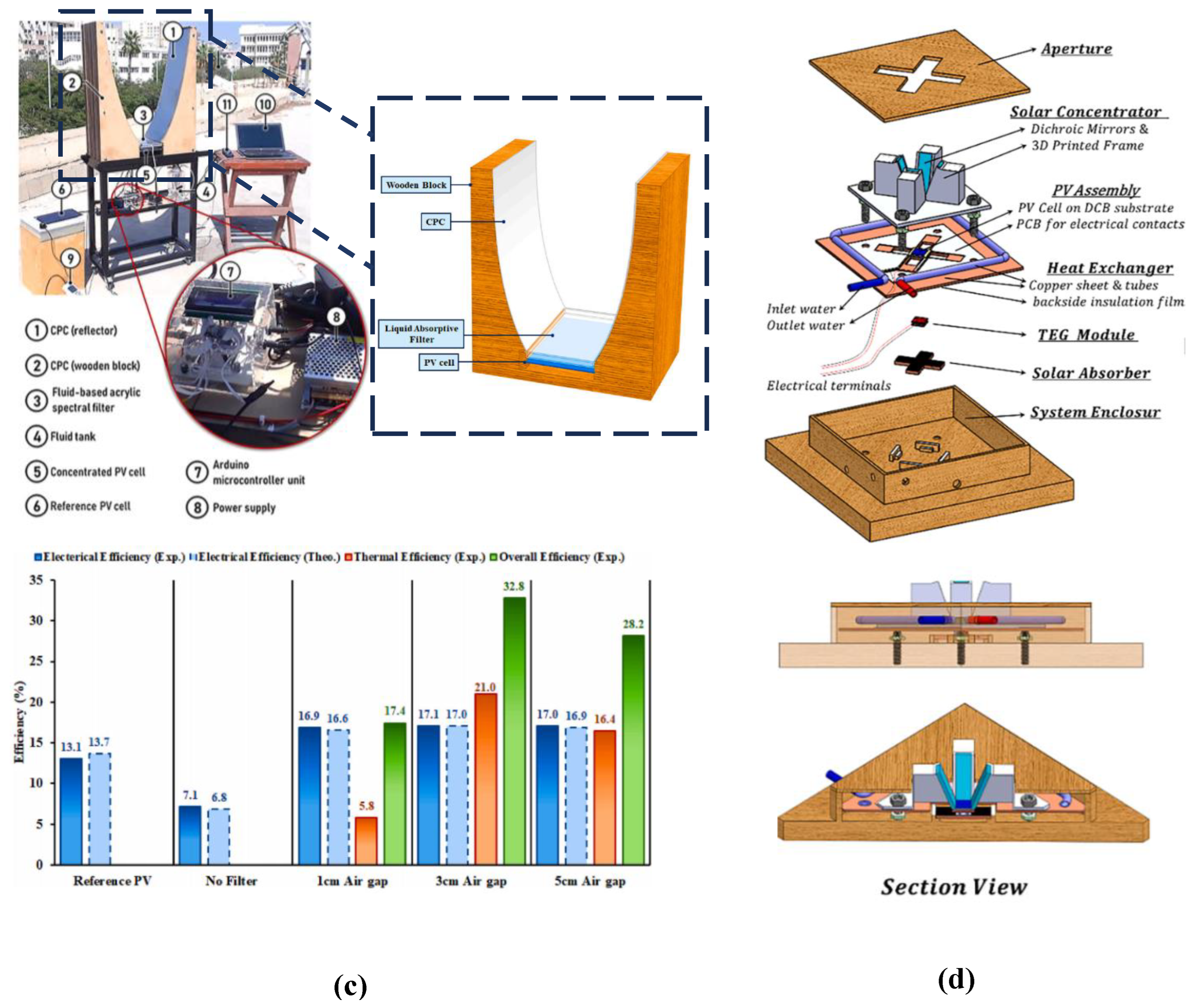

| Meraje et al. [43] | Experimental and numerical study | The area and thickness are 0.84 m2 and 0.005 m | ZnO@ EG and water | 400–1100 nm |

|

| Elharoun et al. [44] | Experimental and numerical study | Nanofluid layer thickness is setup as 1, 1.5 and 2 cm | ZnO@ water | 400–2500 nm |

|

| Liang et al. [45] | Experimental study | The dimension of Fresnel lens is 900 × 300 mm2 | ZnO@ glycol | 1100 nm |

|

| Jiang et al. [10] | Experimental study | The dimension is 200 (L) × 100 (W) × 1500 (H) with thickness of 1.0 mm | Indium tin oxide @ EG | 380–1100 nm |

|

| Hashemian et al. [47] | Experimental study | The dimension is 110 (L) × 150 (W) × 10 (H) mm | Ag/Cr2O3 @ glycerol | 650–1075 nm |

|

| Han et al. [48,49] | Experimental study | The size is 90 (L) × 70 (W) × 10 (H) mm | Ag/CoSO4@ PG | 325–670 nm |

|

| Abdelrazik et al. [50,51] | Experimental and numerical study | The size of optical lengths is defined as 2 (L) × 5 (W) × 10 (H) mm | Ag@ water | 250–1400 nm |

|

| Zhang et al. [52] | Numerical study 2D Monte Carlo method | The thickness is setup as 10 mm | TiO2@ Ag | 700–1100 nm |

|

| Du et al. [53] | Numerical study based on 1D Monte Carlo method | The size is 1m length with 0.02m thickness | TiO2@ Ag | 550–1100 nm |

|

| Alexandre et al. [55] | Numerical study | The thickness layer is 1.5 cm | TiO2 | 350–900 nm |

|

| Yang et al. [56] | Experimental and numerical study | LDS layer is 17 × 17 cm2 | PLQY@ Eu3+ | 250–700 nm |

|

| Singh et al. [57] | Experimental study | The diameters vary from 3 to 30 µm | Yttrium aluminum garnet (YAG: Ce3+) | 300–1100 nm |

|

| Almarzooqi et al. [64] | Experimental study | A plexiglass sheet of dimensions 0.645 × 0.54 × 0.01 m | Water | 350–1100 nm |

|

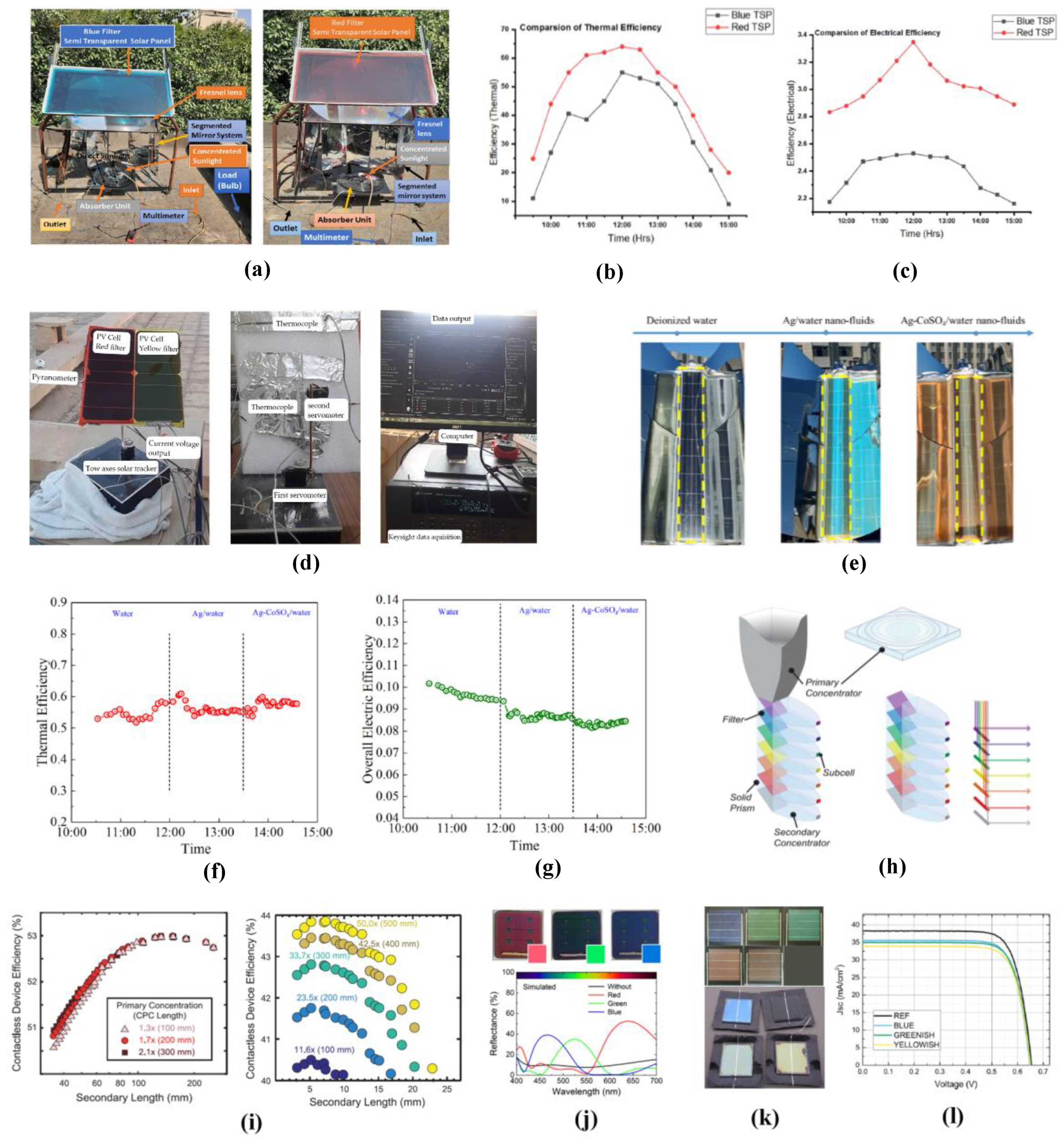

| Gupta et al. [65] | Experimental study | The radius of Fresnel lens is 100 cm with 0.4 cm thickness | Bule and red filter semi-TSP | 350–1100 nm |

|

| Amara and Balghouthi [66] | Experimental study | The optical dimension is 0.125 × 0.125 m | Bule, red and yellow filter semi-TSP | 400–1200 nm |

|

| Eisler et al. [69] | Experimental study | The optical dimension is 649 × 407 × 5 mm | Polyhedral specular reflector | 700–1200 nm |

|

| Zhu et al. [75] and Kiyaee et al. [76] | Experimental and numerical study | A single lens is setup as 20 × 10 cm | SiO2 @ polymethyl methacrylate | 600–1150 nm |

|

| Cui et al. [78] | Experimental study | The size is 156 × 156 mm2 | SiO2@ TPX | 250–2500 nm |

|

| Torgerson and Hellhake [79] | Experimental study | The dimension is defined as 15 × 15 × 250 cm | Polyethylene | 350–1100 nm |

|

| Kecebas et al. [81] | Experimental study | N/A | SiO2, TiO2 and Al2O3 | 800–1300 nm |

|

| Huang and Markides [83] | Numerical study | The dimension is 1000 × 1000 × 10 mm | N/A | 300–900 nm |

|

| Different Types | Advantages | Disadvantages |

|---|---|---|

| Nanofluid optical filtration layers |

|

|

| liquid (LDS) optical filtration layer |

|

|

| Water optical filtration layer |

|

|

| Radiative cooling optical filtration layer |

|

|

| Colored optical filtration layer |

|

|

| Item | Equation |

|---|---|

| PPF for laminar flow | |

| PPF for turbulent flow | |

| Laminar flow to whole thermal performance of nanofluid | |

| Turbulent flow to whole thermal performance of nanofluid |

| Authors | Nation and Region | Annual System Energy Obtained | Initial Capital | Operating Expense | Present Worth Factor | Inflation Rate | Annual Operating and Maintenance Cost | Working Fluid Price | Methods | NPV | PBP |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Hu et al. [86] | China | 67.45 MW | √ | √ | √ | × | × | √ | LCC | √ | 3.18 years |

| Zhang et al. [87] | China | 201 kWh/m2 | √ | √ | √ | × | √ | √ | LCOE | × | 5.6 years |

| Abdelgaied et al. [88] | Egypt | 1296–2336 L/m2 | √ | √ | √ | √ | √ | √ | LCC | × | × |

| Al-Waeli et al. [89] | Malaysia | 47.25 MWh | √ | √ | × | √ | √ | √ | LCC + COE | √ | 7–8 years |

| Kenfack et al. [91] | Cameroon | 121.91 kWh | √ | √ | × | √ | √ | √ | COE | √ | 5.97 years |

| Adun et al. [92] | Turkey | 979,547 kWh | √ | √ | × | √ | √ | √ | LCOE | × | 2.63 years |

| Abadeh et al. [93] | Iran | 10 kW | √ | √ | √ | √ | √ | √ | PPF | × | 4–5 years |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, Y.; Sun, Z.; Wang, S. Potential Effects of Various Optical Filtration Layers on the Techno-Economic Performance of Solar Photovoltaic/Thermal Modules: Status and Prospects. Energies 2025, 18, 4689. https://doi.org/10.3390/en18174689

Cui Y, Sun Z, Wang S. Potential Effects of Various Optical Filtration Layers on the Techno-Economic Performance of Solar Photovoltaic/Thermal Modules: Status and Prospects. Energies. 2025; 18(17):4689. https://doi.org/10.3390/en18174689

Chicago/Turabian StyleCui, Yuanlong, Ziyan Sun, and Shanshan Wang. 2025. "Potential Effects of Various Optical Filtration Layers on the Techno-Economic Performance of Solar Photovoltaic/Thermal Modules: Status and Prospects" Energies 18, no. 17: 4689. https://doi.org/10.3390/en18174689

APA StyleCui, Y., Sun, Z., & Wang, S. (2025). Potential Effects of Various Optical Filtration Layers on the Techno-Economic Performance of Solar Photovoltaic/Thermal Modules: Status and Prospects. Energies, 18(17), 4689. https://doi.org/10.3390/en18174689