Decision Tree-Based Evaluation and Classification of Chemical Flooding Well Groups for Medium-Thick Sandstone Reservoirs

Abstract

1. Introduction

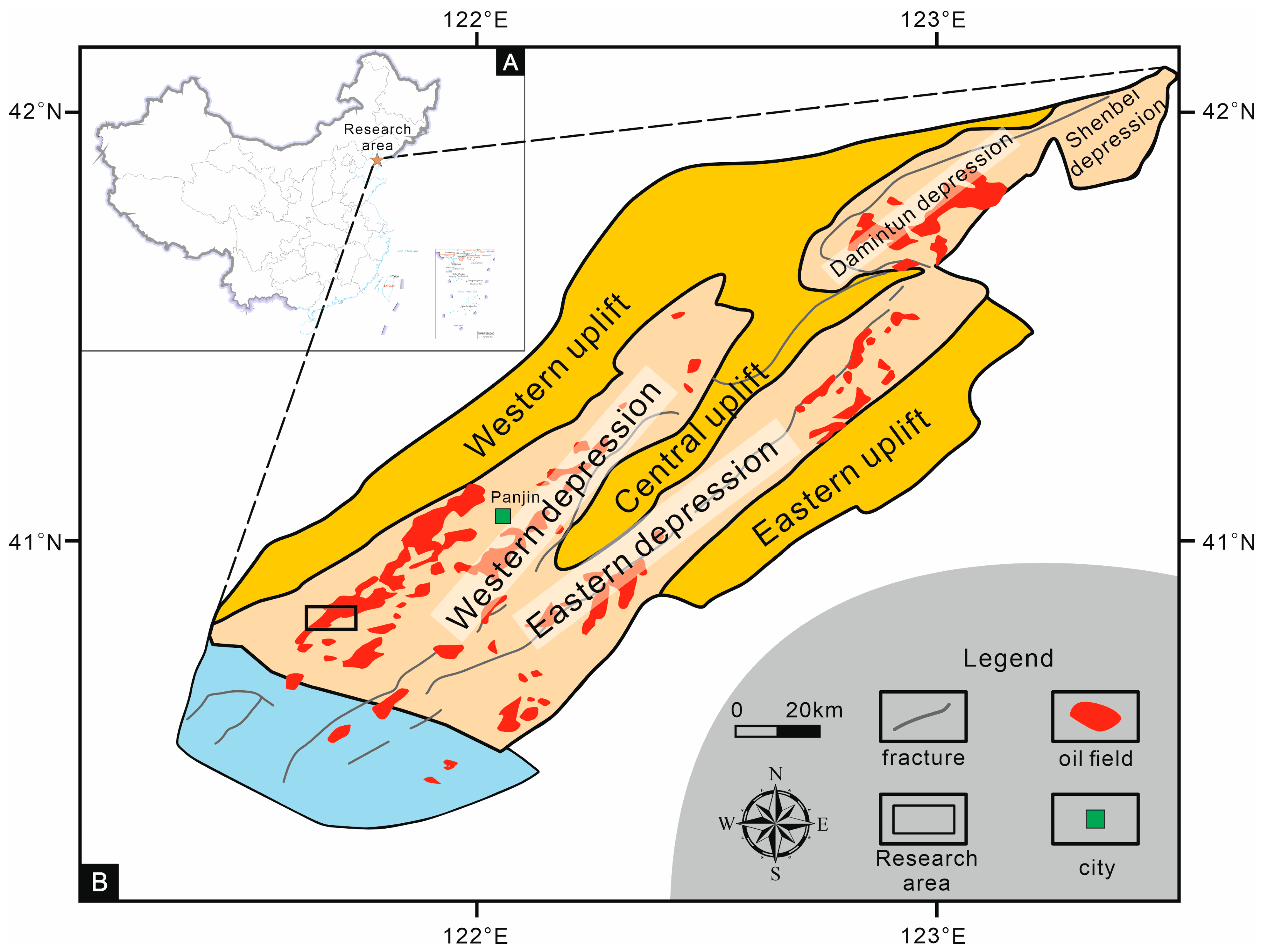

2. Geological Setting

3. Analysis of Influencing Factors on Chemical Flooding Performance and Selection of Classification Criteria

3.1. Interlayer Distribution in the Layer System

3.2. Reservoir Heterogeneity

3.2.1. Vertical Heterogeneity

3.2.2. Planar Heterogeneity

4. Well-Group Classification Evaluation Method and Process

5. Application and Effectiveness

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liao, G.; Wang, Q.; Wang, H.; Liu, W.; Wang, Z. Chemical flooding development status and prospect. Acta Pet. Sin. 2017, 38, 196. [Google Scholar]

- Zhang, C.; Li, C.; Lu, J.; Li, H. Challenges and countermeasures of chemical flooding in Henan Oilfield. Reserv. Eval. Dev. 2020, 10, 1–7. [Google Scholar]

- Tan, F.; Liu, W.; Ma, C.; Cheng, H.; Li, X.; Zhang, C. Classification methods of conglomerate reservoirs based on the adsorption and retention law of surfactant-polymer binary systems. J. Pet. Sci. Eng. 2021, 208, 109195. [Google Scholar] [CrossRef]

- Shen, P.; Yuan, S.; Deng, B.; Song, J.; Shen, K. Quantitative Description of the Effects of Sweep Efficiency and Displacement Efficiency during Chemical Flooding on a Heterogeneous Reservoir. Pet. Sci. 2004, 1, 1957–1961. [Google Scholar]

- Wang, W.; Yang, X.; Wang, J.; Peng, M.; Ma, L.; Xu, M.; Hou, J. Research on the Formulation Design of Nano-Oil Displacement Agents Suitable for Xinjiang Jimusaer Shale Oil. Processes 2023, 11, 2610. [Google Scholar] [CrossRef]

- Chen, W.; Geng, X.; Ding, B.; Liu, W.; Jiang, K.; Xu, Q.; Guan, B.; Peng, L.; Peng, H. A Comparative Study of Surfactant Solutions Used for Enhanced Oil Recovery in Shale and Tight Formations: Experimental Evaluation and Numerical Analysis. Molecules 2024, 29, 3293. [Google Scholar] [CrossRef]

- Podoprigora, D.; Rogachev, M.; Byazrov, R. Surfactant–Polymer Formulation for Chemical Flooding in Oil Reservoirs. Energies 2025, 18, 1814. [Google Scholar] [CrossRef]

- Fang, J.; Sun, J.; Feng, X.; Pan, L.; Bai, Y.; Yang, J. Research and Development of a High-Temperature-Resistant, Gel-Breaking Chemical Gel Plugging Agent and Evaluation of Its Physicochemical Properties. Gels 2025, 11, 350. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, Y.; Zou, J.; Wang, Q.; Wang, Z.; Zhao, Y.; Sun, X. Comprehensive Experimental Study of Steam Flooding for Offshore Heavy Oil Recovery After Water Flooding. Energies 2025, 18, 3140. [Google Scholar] [CrossRef]

- Shanshan, W.; Bin, W.U. Optimization of flooding system under different permeability ratios. China Offshore Oil Gas 2017, 29, 104–108. [Google Scholar]

- Gao, Q.; Ying, Q.; Lu, X. Adaptability between the polymer molecular aggregate and reservoir in the multiple oil-displacing agent. Pet. Geol. Oilfield Dev. Daqing 2018, 37, 104–108. [Google Scholar]

- Li, J.; Liu, W.; Zhou, Y.; Cong, S.; Chen, S.; Du, C.; Yang, Y. Review on the current status of chemical flooding and emulsification. Appl. Chem. Ind. 2018, 47, 1957–1961. [Google Scholar]

- Zhu, Y.; Zhang, Y.; Niu, J.; Liu, W.; Hou, Q. The research progress in the alkali-free surfactant-polymer combination flooding technique. Pet. Explor. Dev. 2012, 39, 371–376. [Google Scholar] [CrossRef]

- Yao, T.Y.; Li, J.T.; Zhou, G.H. Analysis of parameters influencing oil displacement efficiency of oil displacement agent. J. China Univ. Pet. (Ed. Nat. Sci.) 2008, 32, 99–102. [Google Scholar]

- Sun, X. Study on the Development Effect Standard of Classified Well Groups for Polymer Flooding in Class II Reservoirs. IOP Conf. Ser. Earth Environ. Sci. 2020, 526, 012073. [Google Scholar] [CrossRef]

- Zheng, X.; Wang, Y.; Lei, Y.; Zhang, D.; Bao, W.; Huang, S. Research and Application of Deep Profile Control Technology in Narrow Fluvial Sand Bodies. Processes 2025, 13, 289. [Google Scholar] [CrossRef]

- Liu, Y.; Ge, L.; Ma, K.; Chen, X.; Zhu, Z.; Hou, J. Study on Surfactant–Polymer Flooding after Polymer Flooding in High-Permeability Heterogeneous Offshore Oilfields: A Case Study of Bohai S Oilfield. Polymers 2024, 16, 2004. [Google Scholar] [CrossRef]

- Sarbast, R.; Salih, N.; Préat, A. A Critical Overview of ASP and Future Perspectives of NASP in EOR of Hydrocarbon Reservoirs: Potential Application, Prospects, Challenges and Governing Mechanisms. Nanomaterials 2022, 12, 4007. [Google Scholar] [CrossRef]

- Liu, X. Study on classification and adjustment method of chemical flooding well groups for class ii b+ class iii oil reservoirs in area p of daqing oilfield. In Proceedings of the International Field Exploration and Development Conference 2019, Xi’an, China, 16–18 October 2019; pp. 1744–1750. [Google Scholar] [CrossRef]

- Zhang, X.; Cai, Z.; Guan, W.; Zhou, R.; Li, B.; Xing, B. Enhanced oil recovery technology in Class III reservoirs of Daqing Oilfield and its application. Pet. Geol. Oilfield Dev. Daqing 2025, 44, 125–132. [Google Scholar] [CrossRef]

- Zhu, Z.; Li, H.; Gao, G.; Ma, J.; Li, J.; Shu, H. Status and trend of chemical flooding and layered injection technology in Daqing Oilfield. Oil Drill. Prod. Technol. 2022, 44, 642–647. [Google Scholar]

- Zhang, L.; Xu, S.; Jin, K.; Zhang, X.; Liu, Y.; Chen, C.; Liu, R.; Li, M.; Li, J. Study on the Influencing Factors of Oil Bearing and Mobility of Shale Reservoirs in the Fourth Member of the Shahejie Formation in the Liaohe Western Depression. Energies 2024, 17, 3931. [Google Scholar] [CrossRef]

- Zhang, Q.; Pang, Z.; Zhang, J.; Lin, W.; Jiang, S. Qualitative and quantitative characterization of a transitional shale reservoir: A case study from the Upper Carboniferous Taiyuan shale in the eastern uplift of Liaohe Depression, China. Mar. Pet. Geol. 2017, 80, 307–320. [Google Scholar] [CrossRef]

- Qi, J.F.; Li, X.G.; Yu, F.S.; Yu, T.C. Cenozoic structural deformation and expression of the “Tan-Lu Fault Zone” in the West Sag of Liaohe Depression, Bohaiwan basin province, China. Sci. China Earth Sci. 2013, 56, 1707–1721. [Google Scholar] [CrossRef]

- Li, X. Accumulation conditions, key technologies for exploration and development of heavy oil in Huanxiling oilfield, Liaohe depression. Acta Pet. Sin. 2021, 42, 541–560. [Google Scholar] [CrossRef]

- Hu, L.; Fuhrmann, A.; Poelchau, H.S.; Horsfield, B.; Zhang, Z.; Wu, T.; Chen, Y.; Li, J. Numerical simulation of petroleum generation and migration in the Qingshui sag, western depression of the Liaohe basin, northeast China. AAPG Bull. 2005, 89, 1629–1649. [Google Scholar] [CrossRef]

- Pei, L.; Wang, X.; Gao, G.; Liu, W. Geochemical heterogeneity, origin and secondary alteration of natural gas inside and outside buried hills of Xinglongtai area, West Sag, Liaohe Depression, Bohai Bay Basin. J. Pet. Sci. Eng. 2022, 208, 109456. [Google Scholar] [CrossRef]

- MENG, W.G.; Chen, Z.Y.; Li, P.; Guo, Y.; Gao, X.; Hui, X. Exploration theories and practices of buried-hill reservoirs: A case from Liaohe Depression. Pet. Explor. Dev. 2009, 36, 136–143. [Google Scholar] [CrossRef]

- Weigong, M. Continuous Exploration and Discovery Technology and Its Application in Liaohe High Mature Exploration Area. Spec. Oil Gas Reserv. 2020, 27, 1–11. [Google Scholar]

- Zhang, Y.; Gai, C.; Song, B.; Jiang, J.; Wang, Z. The influence of permeability and heterogeneity on chemical flooding efficiency and remaining oil distribution—Based on NMR displacement imaging. Sci. Rep. 2023, 13, 14316. [Google Scholar] [CrossRef]

- Lv, J.; Liao, G.; Liu, W.; Wang, X.; Jing, Y.; Liu, H.; Jiang, R. Effect of Reservoir Heterogeneity on Polymer–Surfactant Binary Chemical Flooding Efficiency in Conglomerate Reservoirs. Polymers 2024, 16, 3405. [Google Scholar] [CrossRef]

- Luo, J.; Hou, Z.; Feng, G.; Liao, J.; Haris, M.; Xiong, Y. Effect of reservoir heterogeneity on CO2 flooding in tight oil reservoirs. Energies 2022, 15, 3015. [Google Scholar] [CrossRef]

- Gupta, A.D.; Pope, G.A.; Sepehrnoori, K.; Shook, M. Effects of reservoir heterogeneity on chemically enhanced oil recovery. SPE Reserv. Eng. 1988, 3, 479–488. [Google Scholar] [CrossRef]

- Anderson, G.A. Simulation of Chemical Flood Enhanced Oil Recovery Processes Including the Effects of Reservoir Wettability; Petroleum and Geosystems Engineering: Austin, TX, USA, 2006. [Google Scholar]

- Flechsig, S.; Yildirim, Ö.; Kenig, E.Y. Sandwich packings: State of the art. ChemBioEng Rev. 2016, 3, 174–185. [Google Scholar] [CrossRef]

- Horváth-Szabó, G.; Czarnecki, J.; Masliyah, J.H. Sandwich structures at oil–water interfaces under alkaline conditions. J. Colloid Interface Sci. 2002, 253, 427–434. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.; Cao, B.; Xie, K.; Cao, W.; Liu, Y.; Zhang, Y.; Wang, X.; Zhang, J. Enhanced oil recovery mechanisms of polymer flooding in a heterogeneous oil reservoir. Pet. Explor. Dev. 2021, 48, 169–178. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Y.; Gao, W.; Xue, X.; Wang, S.; Li, X. Experimental study on variable flow resistance during polymer flooding in vertically heterogeneous reservoirs. Xinjiang Pet. Geol. 2017, 38, 1. [Google Scholar]

- Borovina, A.; Hincapie, R.E.; Clemens, T.; Hoffmann, E.; Wegner, J. Selecting EOR Polymers through Combined Approaches—A Case for Flooding in a Heterogenous Reservoir. Polymers 2022, 14, 5514. [Google Scholar] [CrossRef]

- Zhou, Y.; Yin, D.; Li, Y.; He, J.; Zhang, C. A review of crude oil emulsification and multiphase flows in chemical flooding. Energy Sci. Eng. 2023, 11, 1484–1500. [Google Scholar] [CrossRef]

- Liu, J.; Liu, S.; Zhong, L.; Yuan, S.; Wang, Q.; Wei, C. Study on the emulsification characteristics of heavy oil during chemical flooding. Phys. Fluids 2023, 35, 053330. [Google Scholar] [CrossRef]

- Guo, Y.B.; Yue, X.A.; Fu, J.Y.; Zhang, B. Relevance between emulsification capability and interfacial tension of chemical flooding agents. Energy Fuels 2018, 32, 12345–12350. [Google Scholar] [CrossRef]

- Zhu, Y.; Hou, Q.; Jian, G.; MA, D.; Wang, Z. Current development and application of chemical combination flooding technique. Pet. Explor. Dev. 2013, 40, 96–103. [Google Scholar] [CrossRef]

- Flaaten, A.K.; Nguyen, Q.P.; Pope, G.A. A systematic laboratory approach to low-cost, high-performance chemical flooding. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 20–23 April 2008. [Google Scholar]

| Hierarchical | Parameter | Significance and Impact | Metric | Application Guidance |

|---|---|---|---|---|

| Level 1 | Interlayer Development | Stable interlayers prevent fluid crossflow, ensuring production stability | Interlayer density, J (layers/m) | Optimize perforation strategy to utilize interlayers as flow barriers |

| Level 2 | Vertical Heterogeneity | Property variations cause uneven fluid front advancement, reducing sweep efficiency | Thickness-weighted variation coefficient, Vkh | Implement conformance control (e.g., profile modification, zonal injection) to balance injection profiles |

| Level 3 | Internal Cyclicity | Coarsening-upward: Remaining oil concentrated in low-permeability upper sections | Cyclic pattern type (Coarsening-upward/Fining upward/Compound) | Coarsening-upward: Focus on sweep expansion |

| Fining-upward: Reverse distribution | Fining/Compound: Balance sweep and displacement efficiency | |||

| Level 4 | Connectivity Quality | Controls areal heterogeneity between injectors–producers, governing polymer sweep efficiency | Proportion of connected layers with permeability contrast > threshold | Design polymer MW based on pore-throat radius |

| Predict performance using injector–producer property contrast |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, Z.; Li, M.; Zhang, M.; Yang, C.; Zhao, L.; Zhou, Z.; Zhang, S.; Zheng, C. Decision Tree-Based Evaluation and Classification of Chemical Flooding Well Groups for Medium-Thick Sandstone Reservoirs. Energies 2025, 18, 4672. https://doi.org/10.3390/en18174672

Dong Z, Li M, Zhang M, Yang C, Zhao L, Zhou Z, Zhang S, Zheng C. Decision Tree-Based Evaluation and Classification of Chemical Flooding Well Groups for Medium-Thick Sandstone Reservoirs. Energies. 2025; 18(17):4672. https://doi.org/10.3390/en18174672

Chicago/Turabian StyleDong, Zuhua, Man Li, Mingjun Zhang, Can Yang, Lintian Zhao, Zengyuan Zhou, Shuqin Zhang, and Chenyu Zheng. 2025. "Decision Tree-Based Evaluation and Classification of Chemical Flooding Well Groups for Medium-Thick Sandstone Reservoirs" Energies 18, no. 17: 4672. https://doi.org/10.3390/en18174672

APA StyleDong, Z., Li, M., Zhang, M., Yang, C., Zhao, L., Zhou, Z., Zhang, S., & Zheng, C. (2025). Decision Tree-Based Evaluation and Classification of Chemical Flooding Well Groups for Medium-Thick Sandstone Reservoirs. Energies, 18(17), 4672. https://doi.org/10.3390/en18174672