Research on Active Defense System for Transformer Early Fault Based on Fiber Leakage Magnetic Field Measurement

Abstract

1. Introduction

2. Transformer Magnetic Balance Protection Principle

2.1. Analysis of Leakage Flux Differential Protection Principle

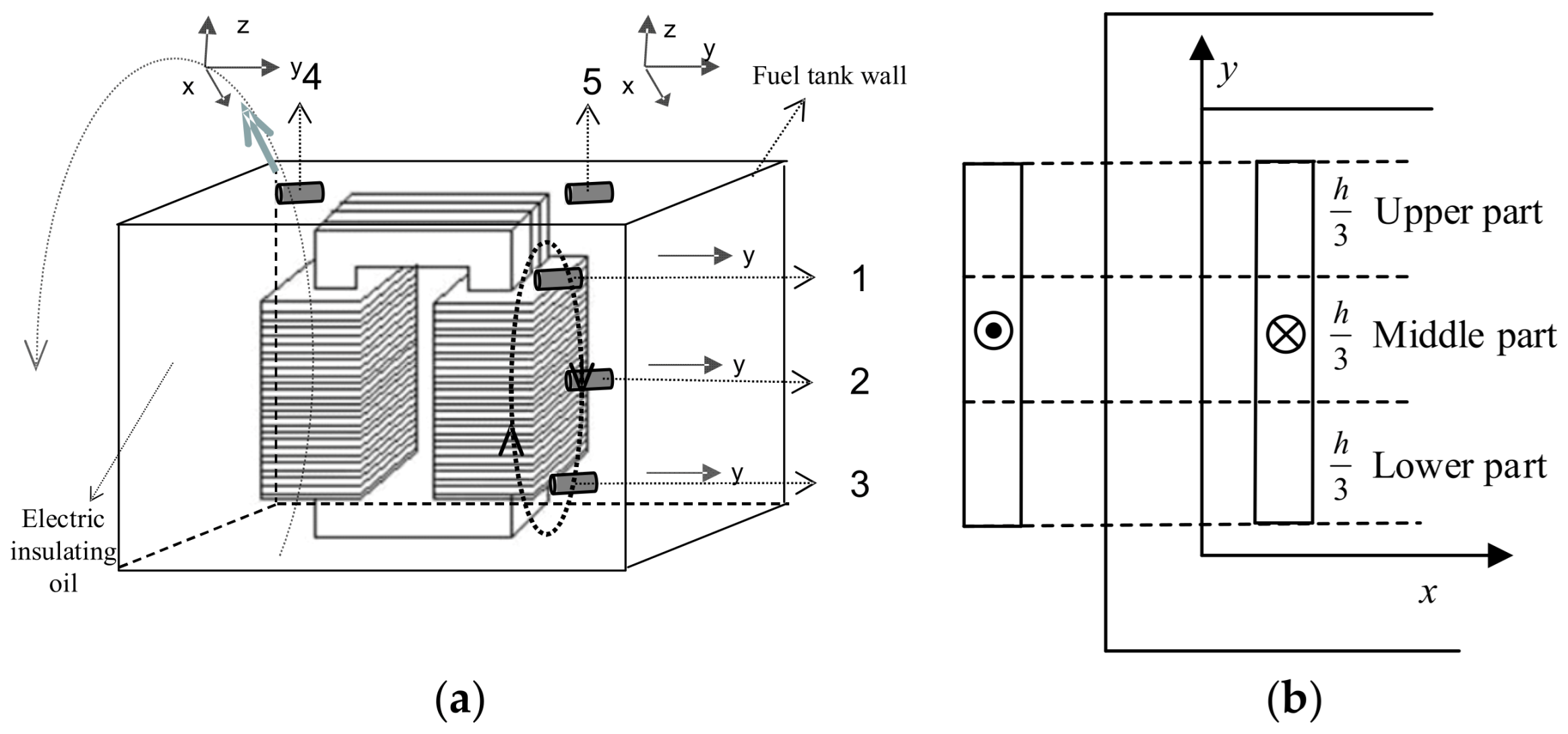

2.2. The Installation Method of the Optical Fiber Leakage Magnetic Field Sensor

2.3. Analysis of Transformer Leakage Flux and Principles of Differential Protection

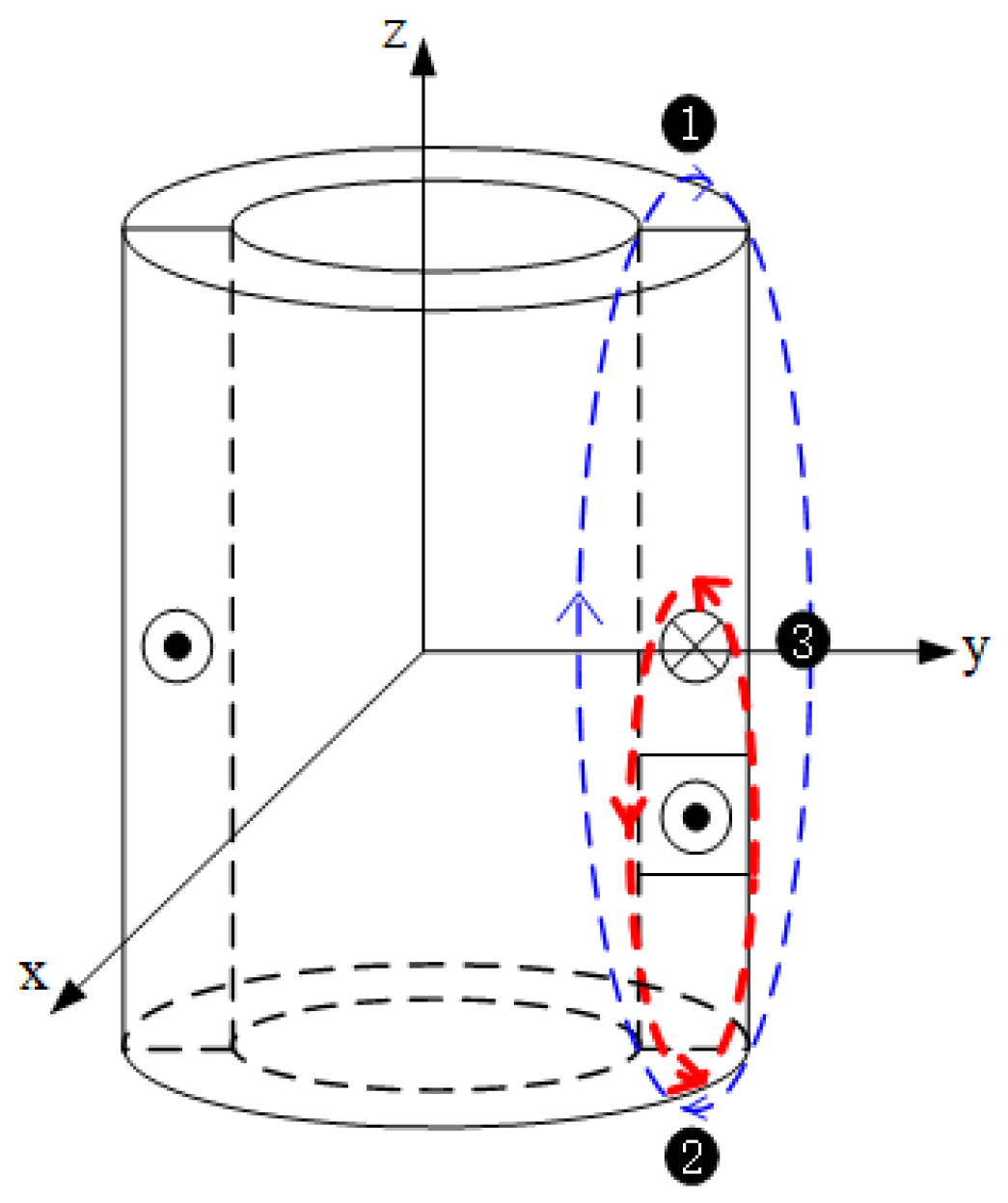

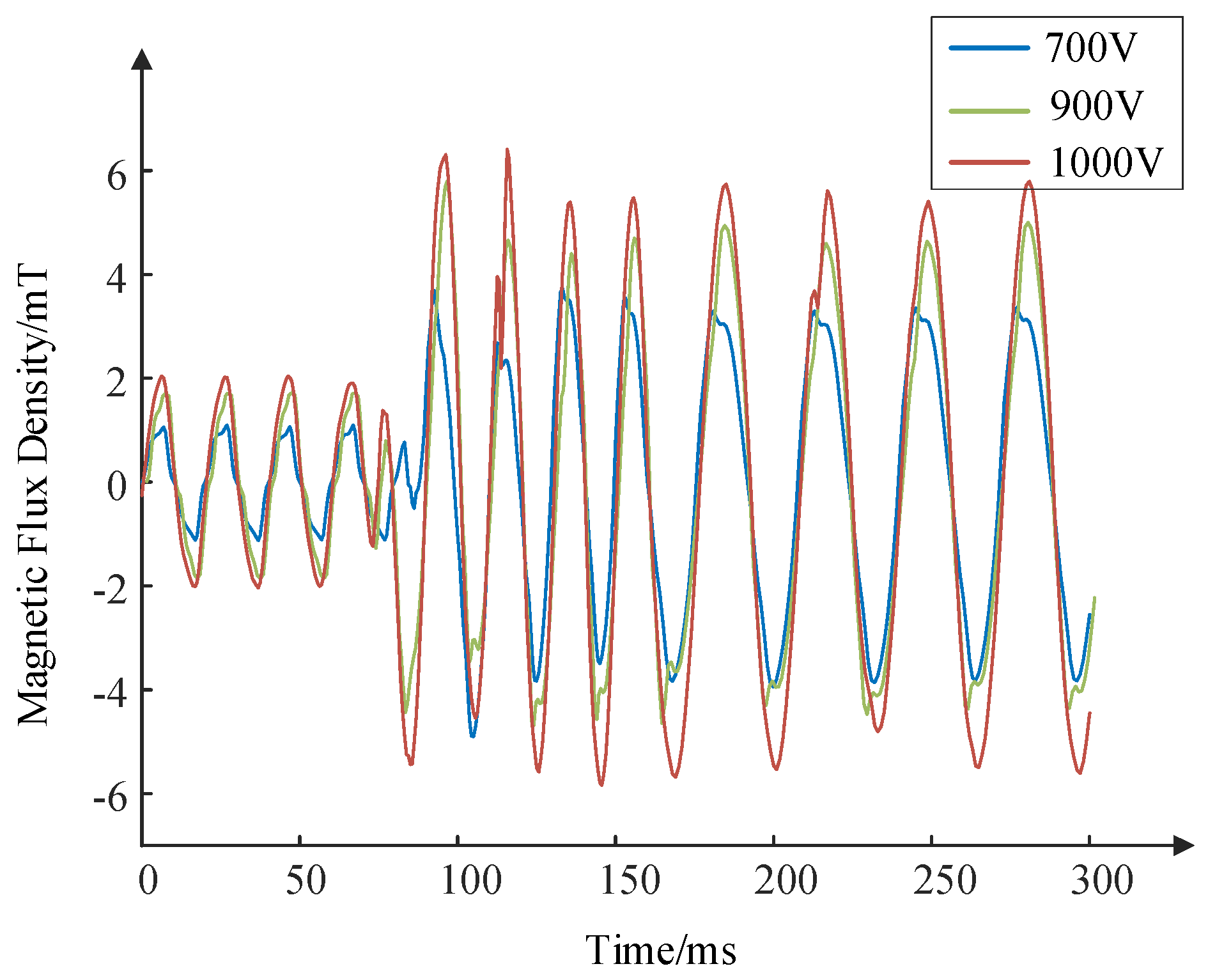

2.3.1. Analytical Calculation of Leakage Magnetic Field Caused by Inter-Turn Short Circuit

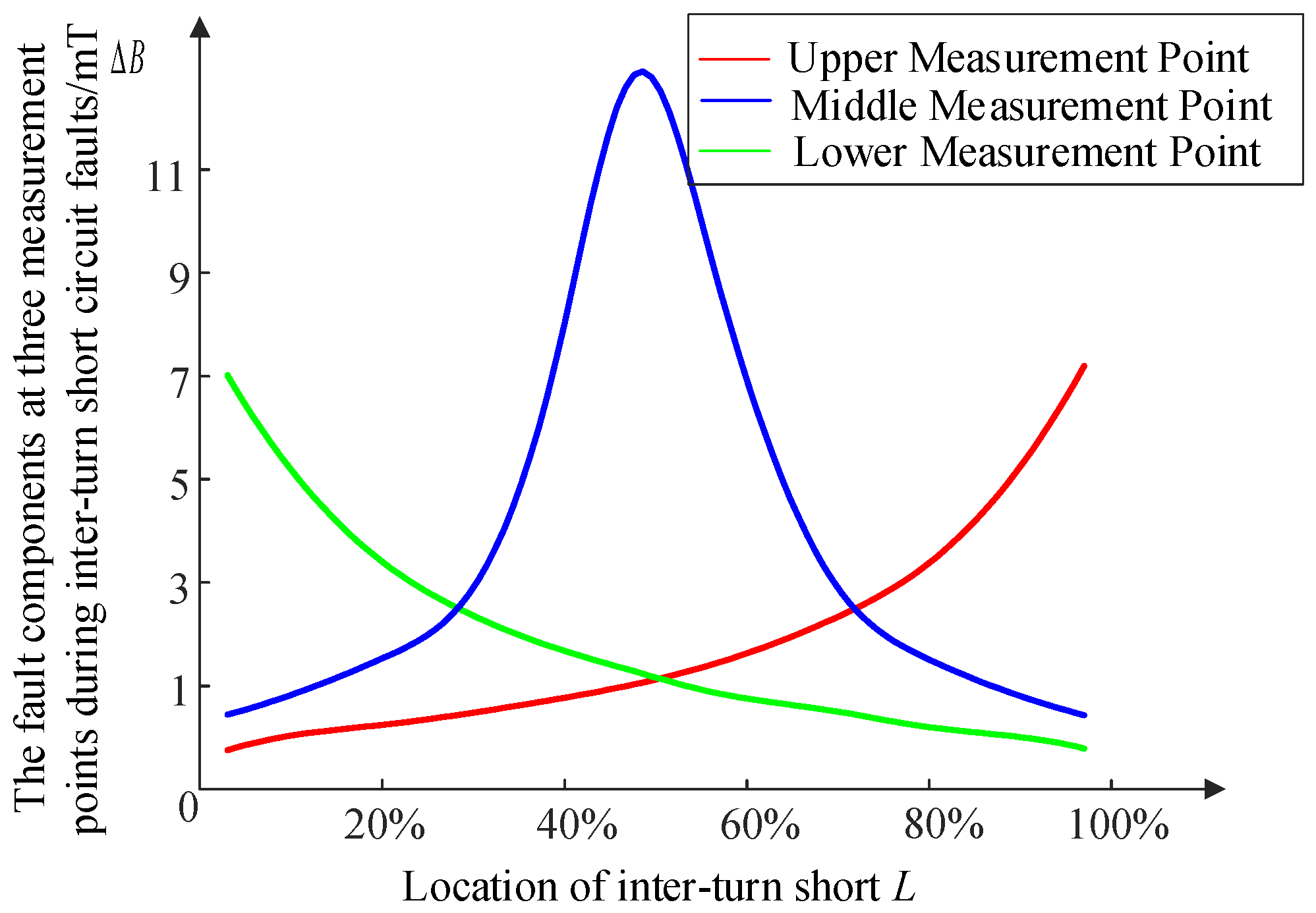

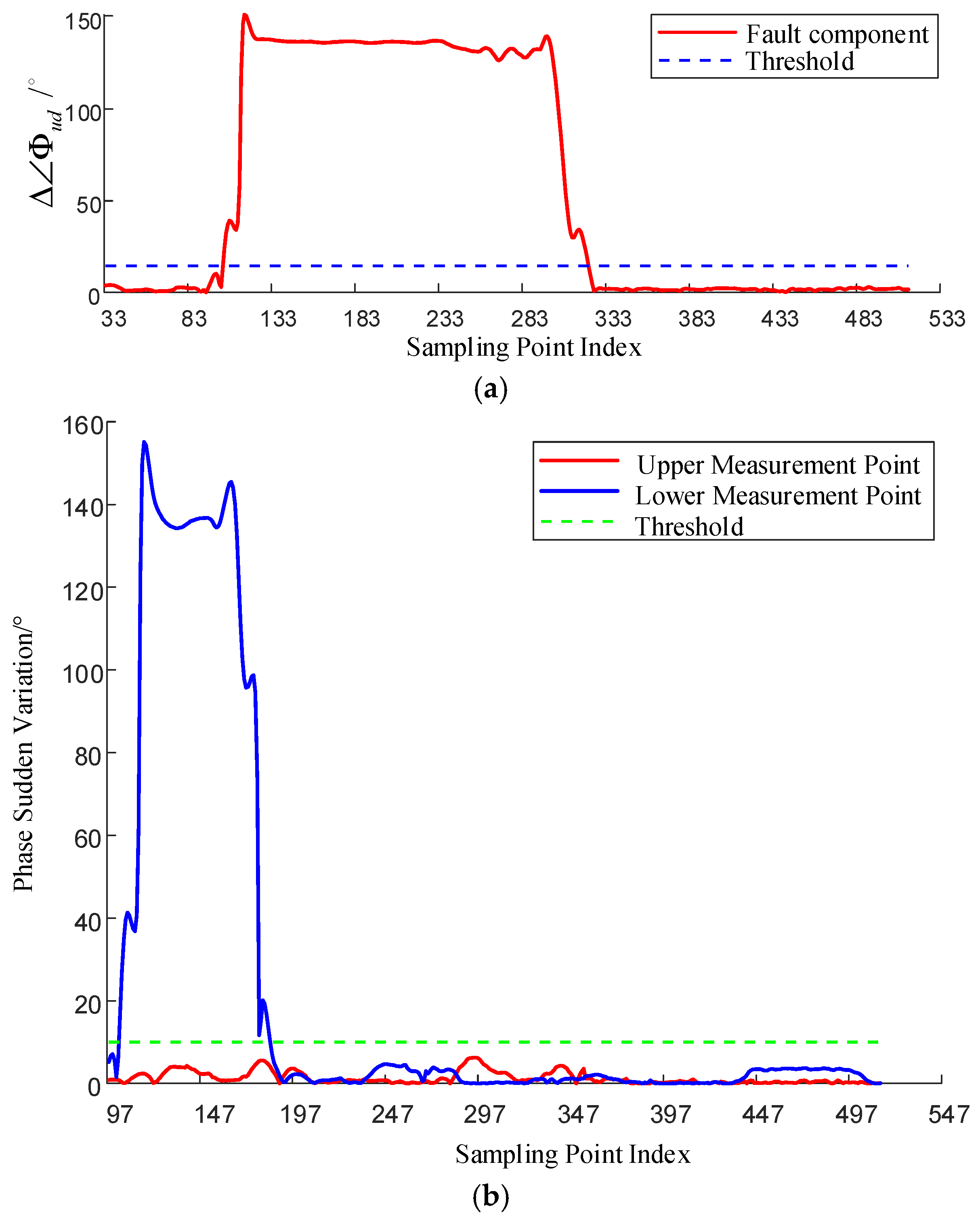

2.3.2. Analysis of the Differential Principle of Fiber Leakage Magnetic Field Spike Variation

- Leakage magnetic field distribution of interphase short circuit faults;

- Leakage magnetic field differential criterion;

2.3.3. Analysis of the Phase Difference Method for Measuring the Leakage Magnetic Field of Optical Fibers

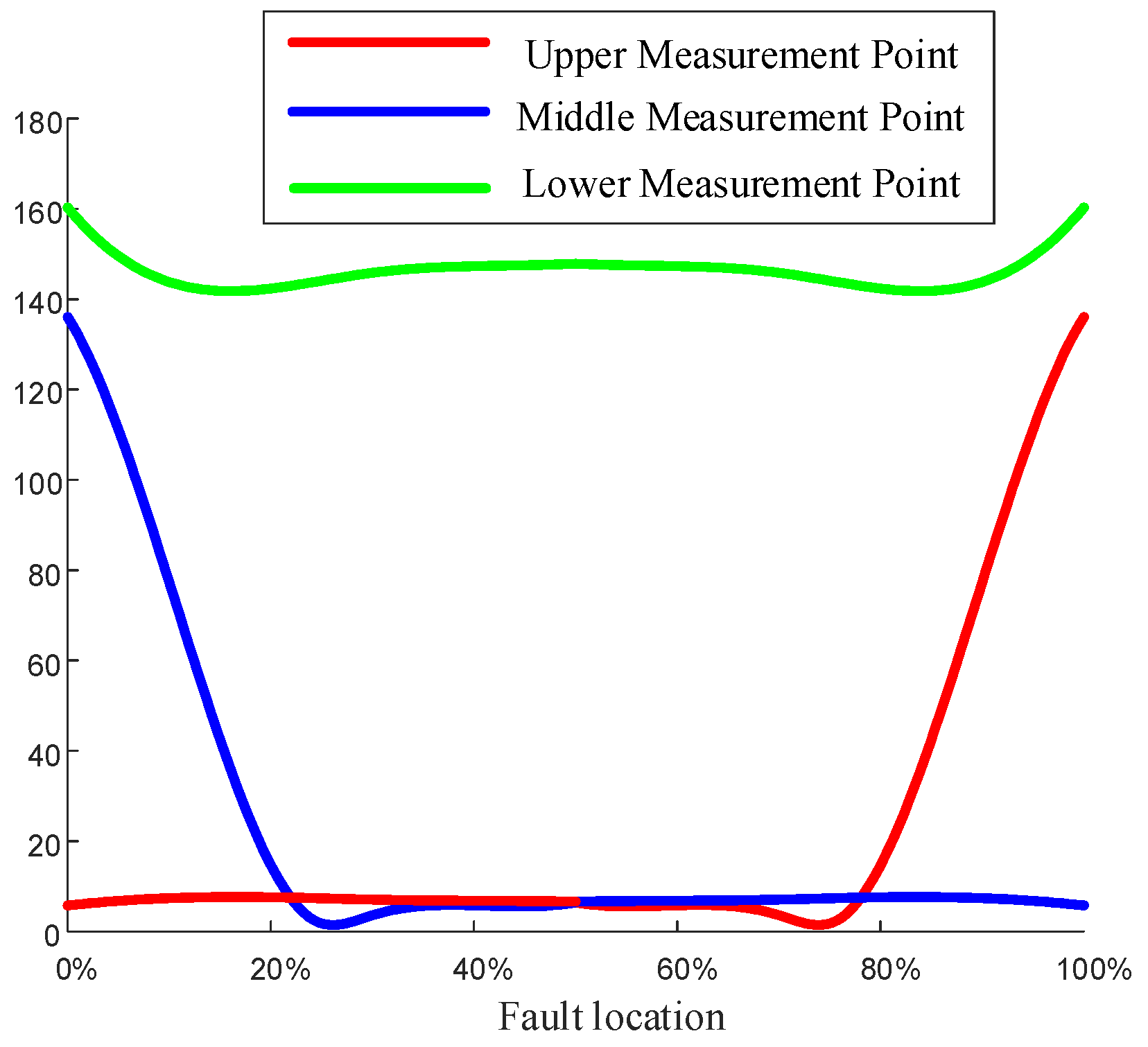

- Phase analysis of leakage magnetic field in inter-turn short circuit;

- Leakage magnetic field phase difference protection criterion;

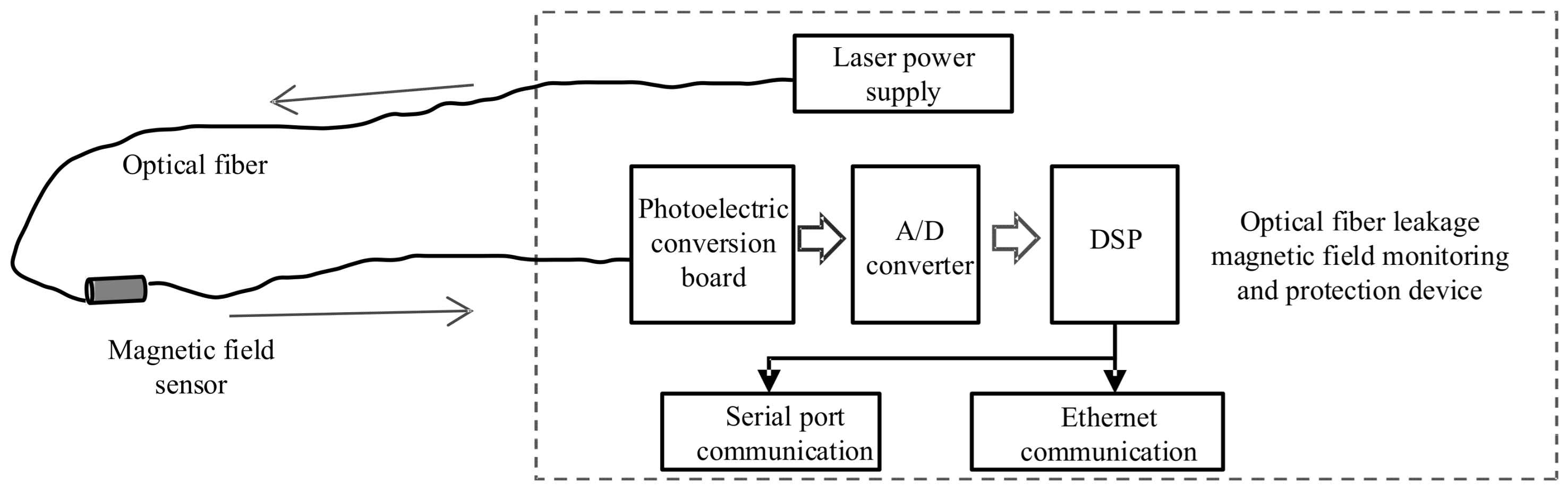

3. The Implementation Scheme of Optical Fiber Leakage Magnetic Field Balance Protection

4. Testing of the Early Fault Proactive Defense System

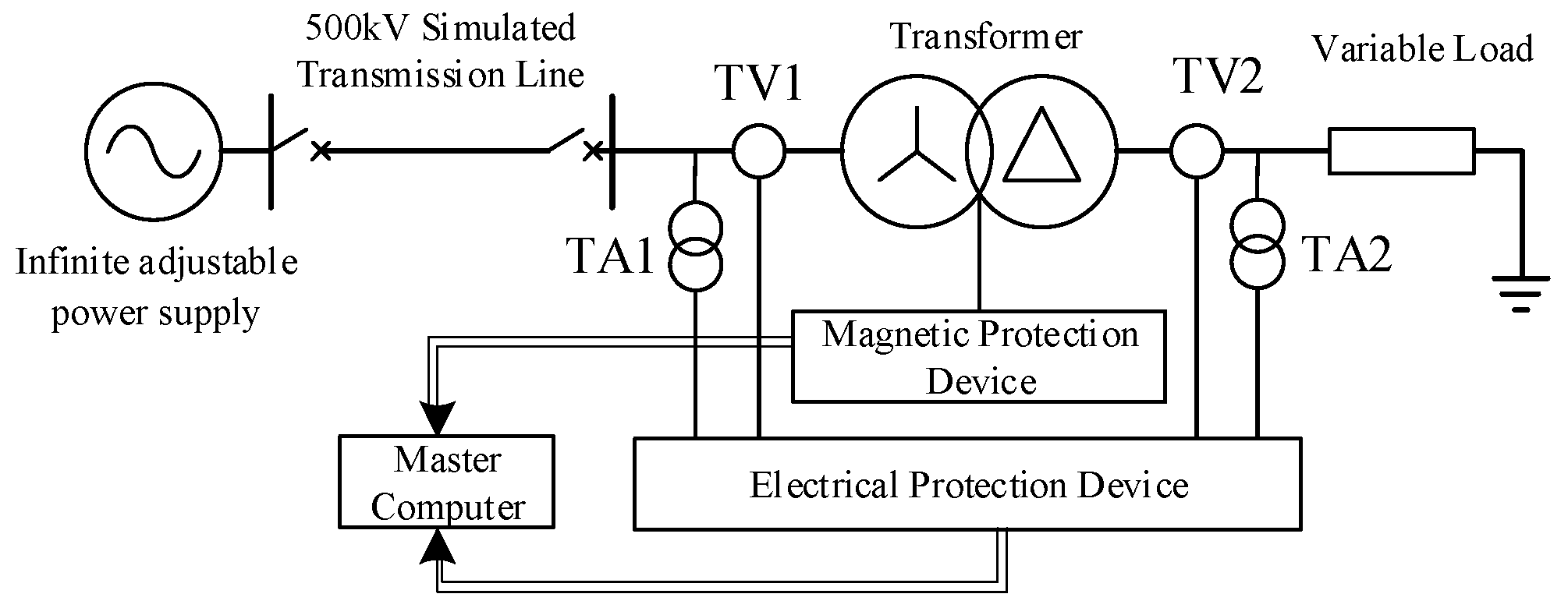

4.1. Dynamic Model Test

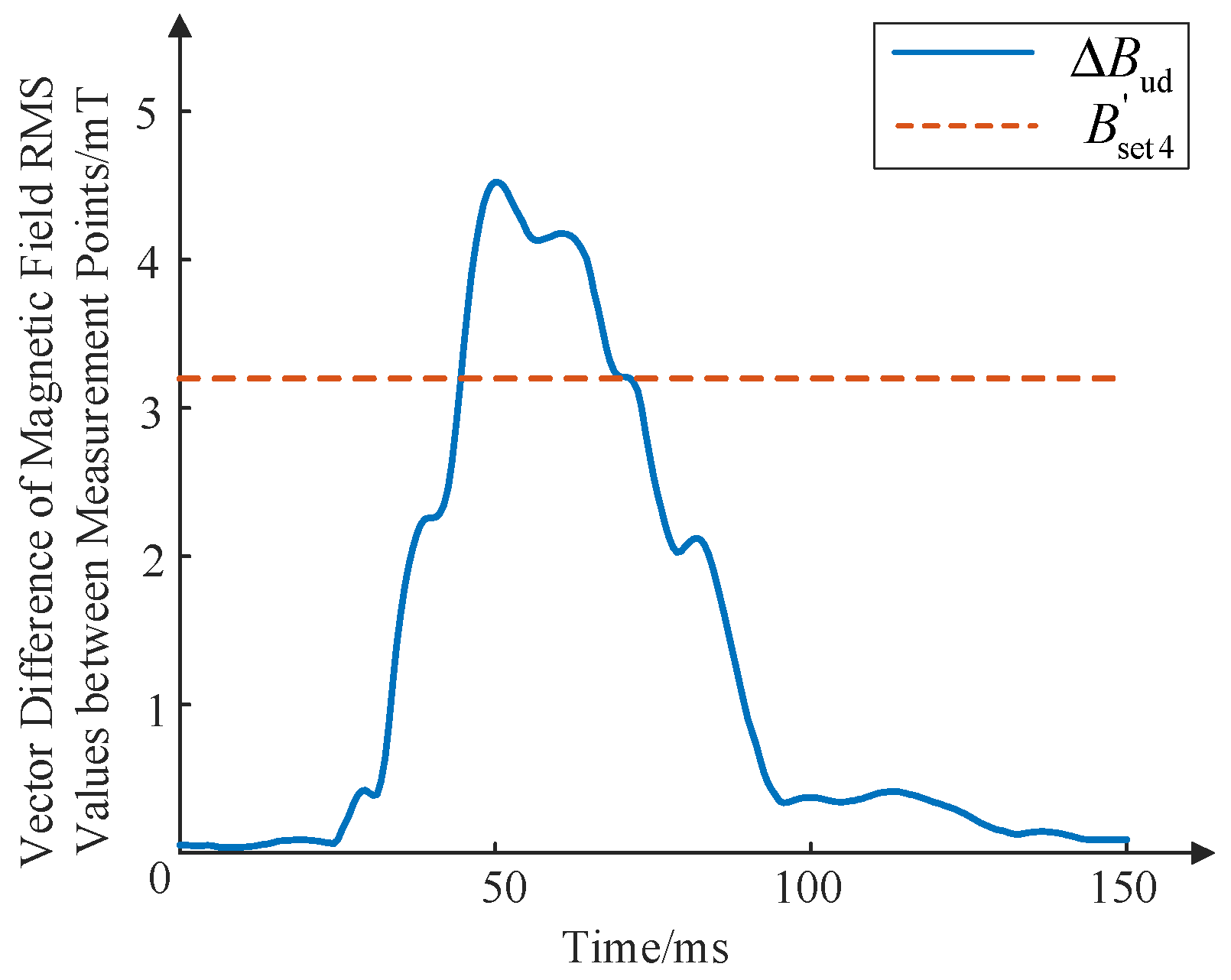

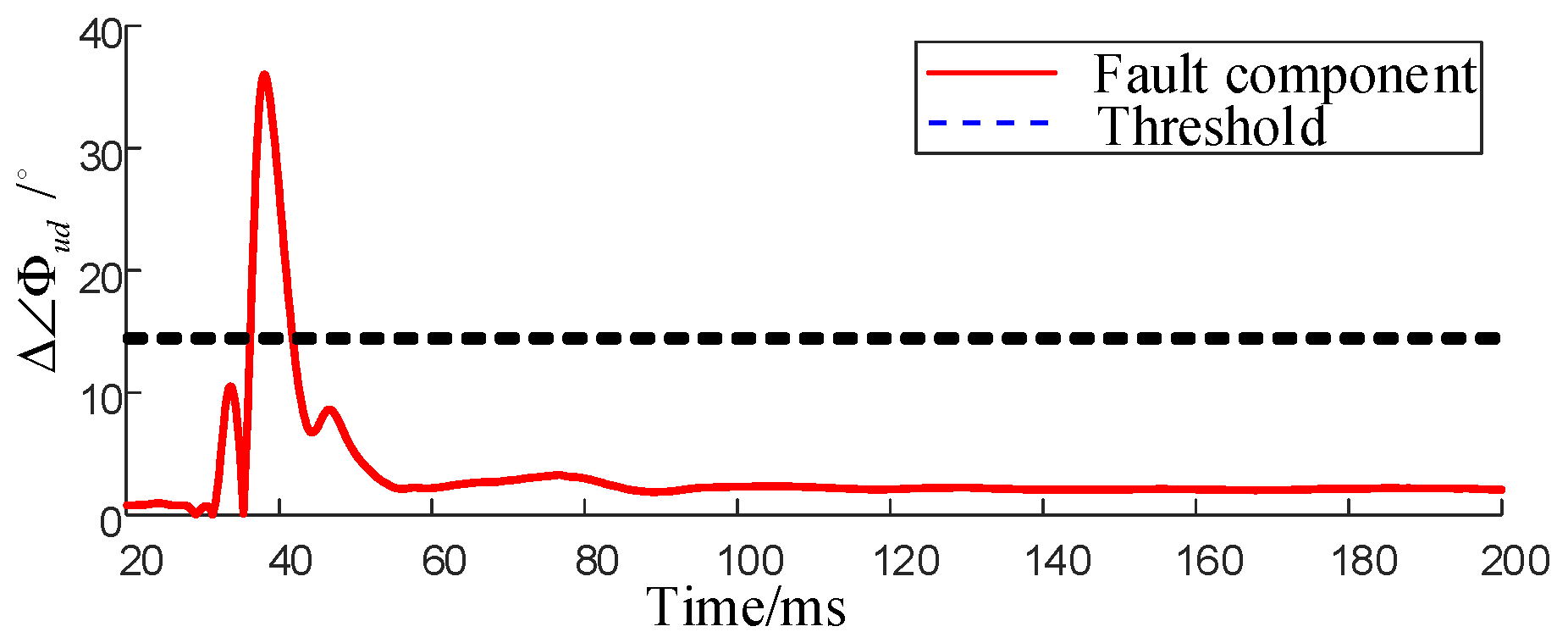

4.1.1. Transformer No−Load Closing

4.1.2. Turn-to-Turn Fault

4.1.3. Winding Discharge to Ground

4.1.4. Summary of the Dynamic Model Test

4.2. Field Engineering Application of the Early Fault Active Defense System

5. Conclusions

- (1)

- Using leakage magnetic fields as fault indicators, we proposed and validated both amplitude-differential and phase-differential protection principles, establishing comprehensive protection criteria.

- (2)

- Through comparative analysis of two sensor installation methods, we successfully developed an active defense system for early transformer fault detection based on fiber-optic leakage magnetic field monitoring.

- (3)

- Experimental verification using a purpose-built early fault simulation platform demonstrated the system’s effectiveness in accurately identifying incipient transformer faults while maintaining immunity to false operations during no-load switching operations.

- (4)

- The developed fiber-optic leakage magnetic field active protection system has been successfully deployed at the Wudongde Hydropower Plant, achieving highly efficient monitoring and protection against early-stage transformer faults.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jia, Y.; Ji, S.; Li, J.; Jia, S.; Luo, X.; Wang, K.; Sun, J. Overview on the Characteristics of Power Frequency Arc in Transformer Oil and Transformer Explosion Protection. Proc. CSEE 2024, 44, 2910–2927. [Google Scholar]

- Moradzadeh, A.; Pourhossein, K.; Mohammadi-Ivatloo, B.; Mohammadi, F. Locating Inter-Turn Faults in Transformer Windings Using Isometric Feature Mapping of Frequency Response Traces. IEEE Trans. Ind. Inform. 2021, 17, 6962–6970. [Google Scholar] [CrossRef]

- Ou, Q.; Luo, L.; Li, Y.; Yang, X.; Zhou, L. An Evaluation Method for Short-Circuit Cumulative Mechanical Damage of Power Transformer. Trans. China Electrotech. Soc. 2024, 39, 2578–2590. [Google Scholar]

- Zhang, F.; Li, X.; Zhu, X.; Zhuang, Z.; Shi, Y. Assessment of the Withstand Ability to Short Circuit of Inner Windings in Power Transformers Considering the Degree of Thermal Aging. Proc. CSEE 2022, 42, 3836–3846. [Google Scholar]

- Du, J.; Fan, Z.; Fan, Z.; Wang, Q.; Li, P. Research on Abnormal Data Identification and Content Prediction of Dissolved Gas in Power Transformer Oil. Power Syst. Technol. 2025, 49, 844–853. [Google Scholar]

- Wen, Y. Research on On-line Monitoring Device of Transformer Winding Deformation by Frequency Response Method. Master’s Thesis, North China Electric Power University, Beijing, China, 2024. [Google Scholar]

- Deng, X.; Zhang, Z.; Xia, Y.; Wang, L.; Wu, C.; Fan, J.; Wang, F. Vibration signal characteristic analysis of power transformer winding under deformation state. Adv. Technol. Electr. Eng. Energy 2024, 43, 13–23. [Google Scholar]

- Zhang, F.; Ji, S.; Shi, Y.; Lu, W.; Li, D.; Chen, L. Research on Transformer Winding Vibration and Propagation Characteristics. Proc. CSEE 2018, 38, 2790–2798, 2849. [Google Scholar]

- Xia, Y.; Li, M.; Xiang, T.; Qin, S.; Deng, Q.; Wang, X. Fault diagnosis of transformer winding and core based on SOM. J. Eiectric Power Sci. Technol. 2018, 33, 129–134. [Google Scholar]

- Ouyang, X.; Chen, M.H.; Zhou, Q.; Chen, W.G.; Zhang, Z.X.; Luo, Z.H. A Novel All-dielectric Optical Fiber Temperature-magnetic Field Dual-parameter Sensor. Proc. CSEE 2023, 43, 8114–8124. [Google Scholar]

- Li, D.; Liu, Y.; Fan, X.; Li, H.; Li, Y. Discrimination and Degree Detection of Axial and Radial Deformation in Transformer Windings Based on Distributed Sensing of Ribbon Optical Fibers. Proc. CSEE 2025, 45, 803–813. [Google Scholar]

- Liu, Y.; Li, H.; Gao, S.; Wang, J.; Fan, X. Research on Application of Distributed Optical Fiber Sensing in Monitoring of Temperature and Winding Deformation of Large Transformer. Proc. CSEE 2022, 42, 6126–6135, 6186. [Google Scholar]

- Deng, X.; Zhu, H.; Yan, K. Magnetic Balance Protection of Transformers Based on Optical Fiber Leakage Magnetic Field Measurement. Trans. China Electrotech. Soc. 2024, 39, 628–642. [Google Scholar]

- Zhou, Y.; Wang, X. The on-line monitoring method of transformer winding deformation based on magnetic field measurement. Electr. Meas. Instrum. 2017, 54, 58–63, 87. [Google Scholar]

- Wang, L. Research on a New Non Electric Quantity Protection Strategy of Oil Immersed Transformers. Master’s Thesis, Zhejiang University, Hangzhou, China, 2020. [Google Scholar]

- Haghjoo, F.; Mostafaei, M.; Mohammadi, H. A New Leakage Flux-Based Technique for Turn-to-Turn Fault Protection and Faulty Region Identification in Transformers. IEEE Trans. Power Deliv. 2018, 33, 671–679. [Google Scholar] [CrossRef]

- Zheng, Y.; Gong, X.; Pan, S.; Sun, J.; Deng, J. Analysis on Leakage Flux Characteristics of Turn-to-Turn Short-circuit Fault for Power Transformer. Autom. Electr. Power Syst. 2022, 46, 121–127. [Google Scholar]

- Xian, R.; Zhang, B.; Liu, X.; Jiang, X.; Chen, L. Application of finite element analysis to transient characteristics of interturn short circuit in power transformer windings. Electr. Mach. Control. 2021, 25, 130–138. [Google Scholar]

- Deng, X.; Zhang, Z.; Zhu, H.; Yan, K. Early fault diagnosis of transformer winding based on leakage magnetic field and DSAN learning method. Front. Energy Res. 2023, 10, 1058378. [Google Scholar] [CrossRef]

- Deng, X.; Zhu, H.; Yang, M.; Wu, W.; Liu, S. Research on Early Fault Protection Method of Transformer Winding Based on Multi-state Model. Proc. CSEE 2022, 42, 6704–6715. [Google Scholar]

- Liu, J.; Li, Z.; Zhou, Y. Transformer windings based on leakage field and ICOA-ResNet early fault diagnosis. Power Syst. Prot. Control. 2024, 52, 99–110. [Google Scholar]

- Deng, X.; Yan, K.; Zhu, H.; Zhu, H.; Zhang, Z. Transformer winding early fault protection based on circuit-magnetic leakage field multi-state analytical model. Power Syst. Technol. 2023, 47, 3808–3821. [Google Scholar]

- Ji, M.; Qi, B.; Zheng, W.; Huang, M.; Li, C.R.; Wang, J. Coding Diagnosis Method Based on Leakage Distribution Law UnderTypical Winding Defects of Transformers. Power Syst. Technol. 2024, 48, 2133–2142. [Google Scholar]

- Jia, Y.; Jia, S.; Luo, X.; Ji, S.; Li, S. Research on comparison on rapid detection methods of transformer internal arc fault. High Volt. Eng. 2024, 50, 2158–2165. [Google Scholar]

- Wu, S.; Ji, S.; Sun, J.; Liang, N.; Zhao, T.; Dai, S. Vibration Monitoring and Variation Law of Converter Transformer in Operation. High Volt. Eng. 2022, 48, 1561–1570. [Google Scholar]

| Differential Criterion Based on Sudden Change Quantity | Differential Criterion Based on Steady-State Quantity | Phase Difference Criterion | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Characteristic Quantity | Action and Positioning | Characteristic Quantity | Action and Positioning | Characteristic Quantity | Action and Positioning | ||||

| 1.49% inter-turn short circuit in the lower part of the winding | 0.267 | correct operation lower part | 1.352 | correct operation lower part | 151.475 | correct operation lower part | |||

| 105.511 | |||||||||

| 0.786 | 0.774 | 20.496 | |||||||

| 85.015 | |||||||||

| 1.478 | 0.933 | 130.977 | |||||||

| 0.995% inter-turn short circuit in the middle of the winding | 0.089 | correct operation middle part | 1.067 | correct operation middle part | 1.696 | correct operation middle part | |||

| 170.609 | |||||||||

| 0.531 | 0.393 | 15.085 | |||||||

| 155.524 | |||||||||

| 1.386 | 0.643 | 16.781 | |||||||

| no-load closing | - | non-operating | - | non-operating | 2.974 | non-operating | |||

| - | - | 50.735 | |||||||

| - | - | ||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Liu, Y.; Mao, J.; Liu, S.; Tong, Z.; Deng, X.; Tan, W. Research on Active Defense System for Transformer Early Fault Based on Fiber Leakage Magnetic Field Measurement. Energies 2025, 18, 4497. https://doi.org/10.3390/en18174497

Wang J, Liu Y, Mao J, Liu S, Tong Z, Deng X, Tan W. Research on Active Defense System for Transformer Early Fault Based on Fiber Leakage Magnetic Field Measurement. Energies. 2025; 18(17):4497. https://doi.org/10.3390/en18174497

Chicago/Turabian StyleWang, Junchao, Yaqi Liu, Jian Mao, Shaoyong Liu, Zhixiang Tong, Xiangli Deng, and Wenbin Tan. 2025. "Research on Active Defense System for Transformer Early Fault Based on Fiber Leakage Magnetic Field Measurement" Energies 18, no. 17: 4497. https://doi.org/10.3390/en18174497

APA StyleWang, J., Liu, Y., Mao, J., Liu, S., Tong, Z., Deng, X., & Tan, W. (2025). Research on Active Defense System for Transformer Early Fault Based on Fiber Leakage Magnetic Field Measurement. Energies, 18(17), 4497. https://doi.org/10.3390/en18174497