Self-Sustaining Operations with Energy Harvesting Systems

Abstract

1. Introduction

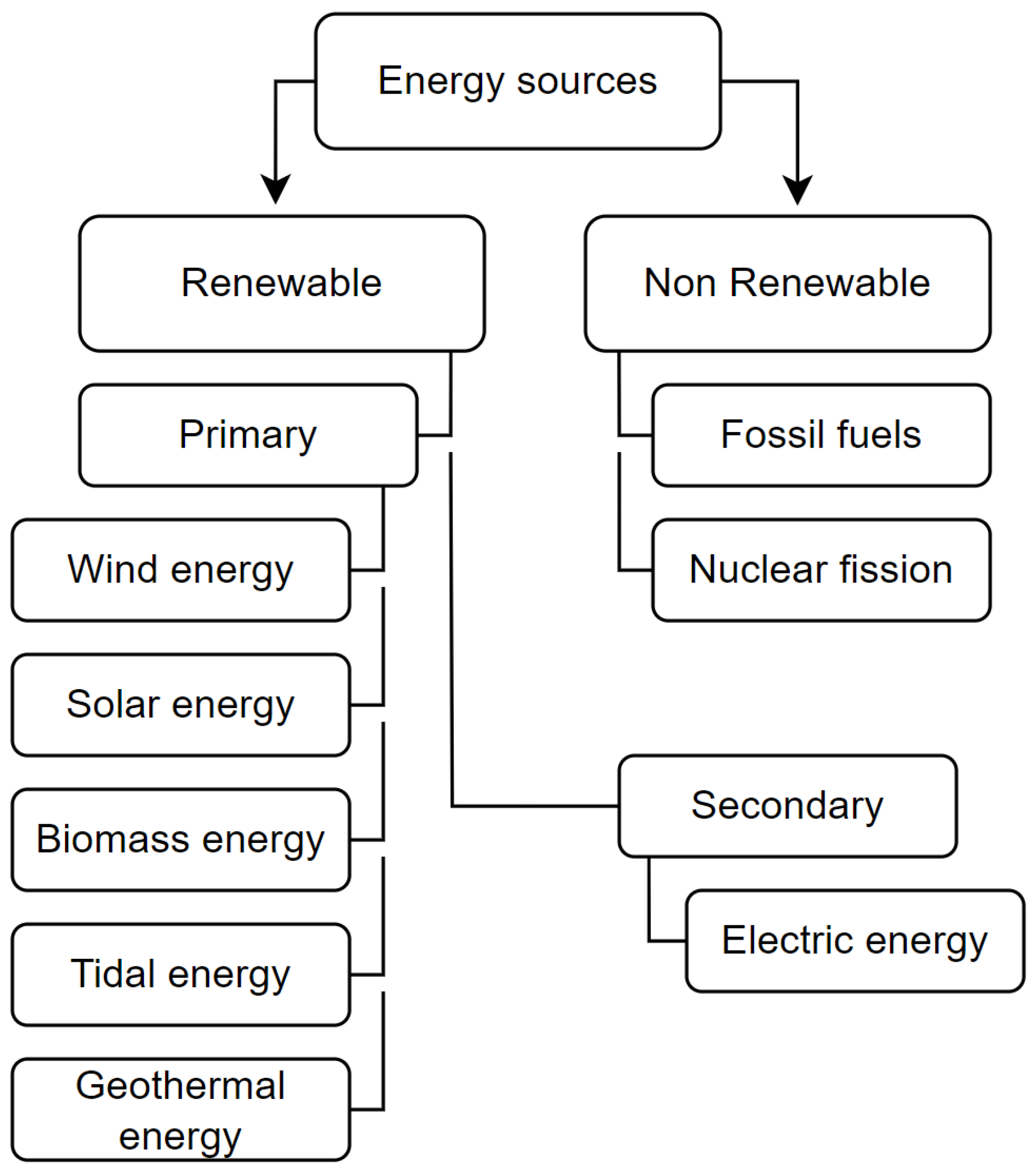

- Fossil fuel power plants generate electrical energy by burning fossil fuels, which generates heat that changes the pressurized water into steam, which is used to power the steam turbine used for electrical energy generation.Their primary disadvantage is the pollution caused by the burning of fossil fuels, which releases into the atmosphere large quantities of greenhouse gases, which cause global warming, and other health-damaging substances.Furthermore, fossil fuels are a non-renewable energy source, at least on the human time scale, since their creation takes millions of years. As a consequence, the fossil fuel power plant does not represent a long-term solution to the energy generation problem.

- Nuclear power plants use the process of nuclear fission, in which a heavier atom accepts a neutron into its atomic structure, which leads to a change in its state from stable to unstable—it becomes a different isotope of the same chemical element whose nucleus is unstable. The unstable isotopes are capable of only a short time of existence, after which the heavy atom (its unstable nucleus) splits into two lighter atoms (two different stable nuclei). During nuclear fission, a large amount of thermal energy is released, which is used to heat the pressurized water. From now on, the energy generation process is the same as with fossil fuel power plants. The primary difference is in the source of thermal energy.The nuclear power plants do not cause problems with pollution like fossil fuel power plants. However, during their operation, the radioactive waste, primarily in the form of spent (burned-out) nuclear fuel, is produced.In the past, the primary problems were the long-term storage and transportation of the spent nuclear fuel, which stays highly radioactive after the nuclear fission. And the catastrophic consequences associated with nuclear catastrophes, such as the ones in Chernobyl and Fukushima.The current solution for the long-term storage of spent nuclear fuel uses disused mining shafts or similar underground cavities, usually located in remote areas where radioactive material can be safely stored. For transportation, specialized, highly durable containers that prevent the contamination of the environment in the case of an accident are used.Furthermore, the new generation of nuclear reactors and highly improved security standards and regulations limit the possibility of another nuclear catastrophe.

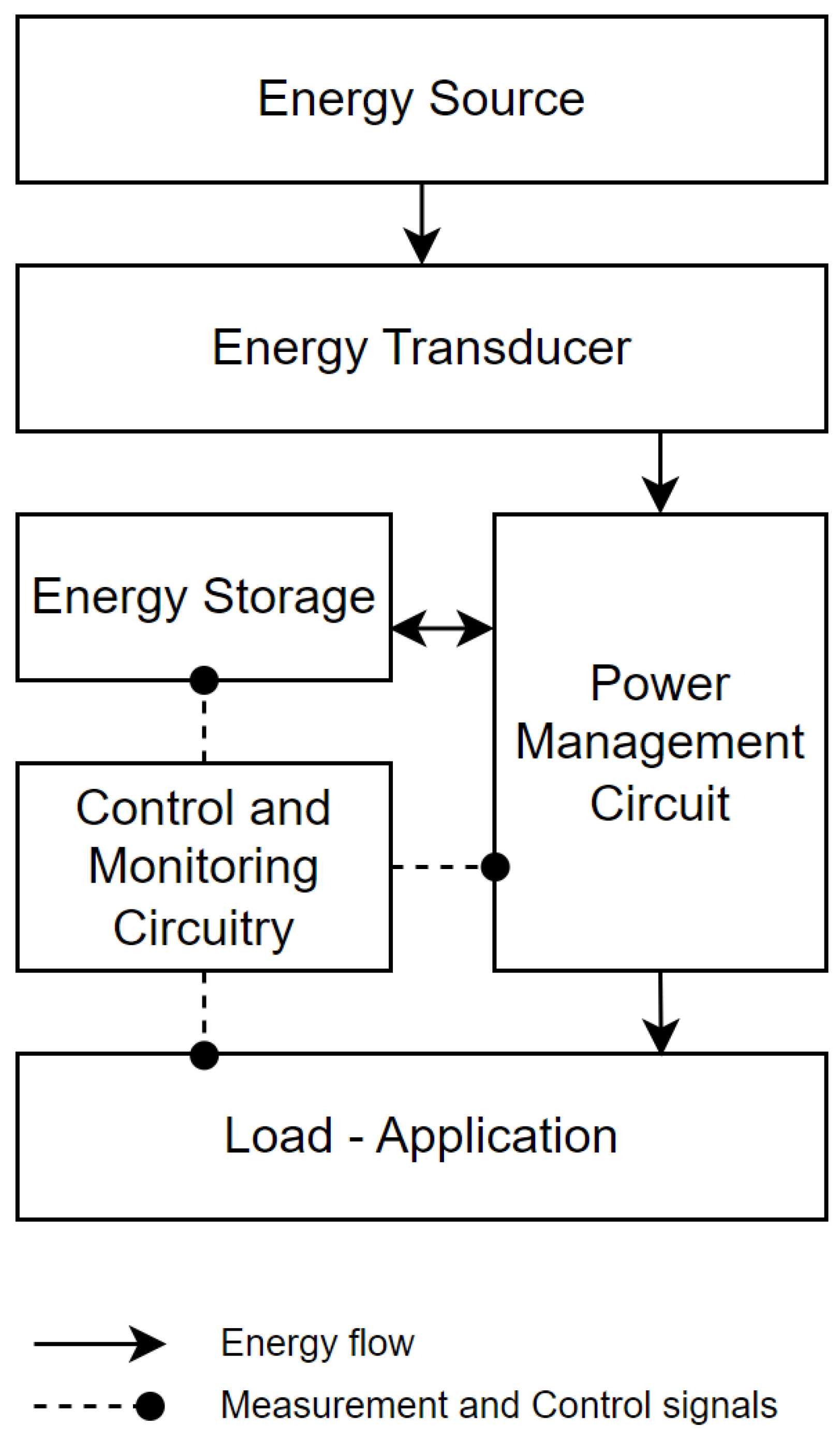

2. Energy Harvesting System

- Energy transducer,

- Energy storage,

- Power management circuit,

- Control and monitoring circuitry,

- Load (end-use application).

Artificial Intelligence and Machine Learning in Energy Harvesting

3. Energy Sources

3.1. Non-Renewable Energy

3.2. Renewable Energy

3.3. Ambient Energy

3.4. Ambient vs. Renewable Energy

3.5. Energy Sources Usage in the Past and Future

4. Energy Transducer

- Conversion efficiency—the proportion of input energy that is successfully converted to electrical energy.

- Power density—the amount of power generated per unit of volume or weight of the transducer mechanism. Most important for wearable implementations.

- Response time—the time that the transducer takes to respond to changes in the input energy.

- Durability—the ability of the transducer to resist conditions in the environment where it is supposed to be used.

- Operation time—can be determined in consideration of durability and maintenance cycles.

- Sensitivity—magnitude of the change in output quantity in response to a known change in the input quantity.

- Scalability—how easily the transducer can be used on a large scale.

- Environmental impact—mostly evaluated based on the materials used and the interference of the transducer with the environment, such as noise and vibrations.

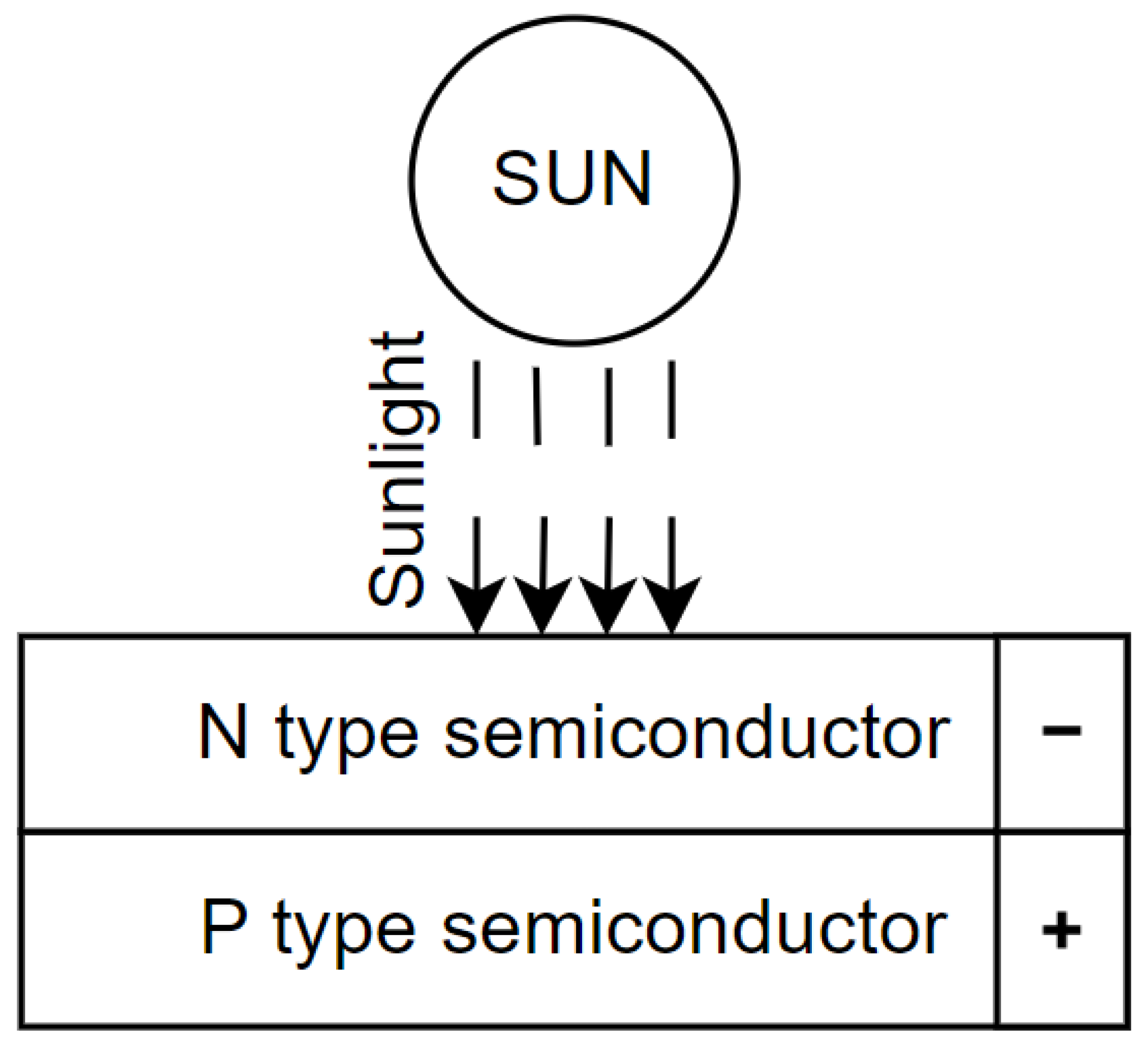

4.1. Photovoltaic Cell

4.1.1. Working Principle of Photovoltaic Cells

4.1.2. Conversion Efficiency and Power Density of Solar Energy

4.1.3. Types of Photovoltaic Cells

- Made with the Czochralski process [35],

- Composed of a single, continuous crystal lattice with no grain boundaries,

- More efficient because of the uniform structure, which allows the electrons inside the silicon ingots to move more freely,

- Mostly black in color,

- More expensive to produce because of the complex manufacturing process,

- Commonly used in high-efficiency solar panels,

- Have a long lifespan, reaching up to 40 years,

- Have a conversion efficiency between 15% and 24%,

- Have a power density ranging from 150 to 200 ,

- Have a 0.14% drop in efficiency per year of their operation (as 100% efficiency was considered the normal efficiency for this type of solar cell), based on tests performed by NREL,

- The most commonly used type of crystalline photovoltaic cells and photovoltaic cells in general.

- Made with the chemical vaporization deposition process,

- Made of multiple small silicon crystals or grains, which can create grain boundaries,

- Less efficient than single-crystal silicon ingots because of the presence of grain boundaries that decrease the flow of electrons inside the silicon ingot,

- Mostly blue in color,

- Less expensive to produce thanks to the simpler manufacturing process,

- Commonly used in low-efficiency solar panels,

- More sensitive to high temperatures, at which their efficiency decreases compared to monocrystalline silicon photovoltaic cells,

- Have a lower lifespan, reaching up to 35 years,

- Have a conversion efficiency between 13% and 16%,

- Have a power density ranging from 150 to 180 ,

- Have a 1% drop in efficiency per year of their operation (as 100% efficiency was considered the normal efficiency for this type of solar cell), based on tests performed by NREL.

- The most widely used type of thin-film photovoltaic cells is the second most widely used type of photovoltaic cell in general.

- They have a conversion efficiency between 12% and 13%.

- They have a lifespan reaching 25 to 30 years.

- Based on tests performed by NREL, these cells have a 0.45% drop in efficiency per year of their operation (as 100% efficiency was considered the normal efficiency of this type of solar cell).

- Commercially used cadmium telluride photovoltaic cells have a power density ranging from 100 to 150 .

- They have a conversion efficiency between 6% and 9%.

- They have a useful life of 10 to 20 years.

- Based on tests performed by NREL, these cells have a 1 to 2% drop in efficiency per year of their operation (as 100% efficiency was considered the normal efficiency of this type of solar cell).

- Commercially used amorphous silicon photovoltaic cells have a power density ranging from 60 to 100 .

4.1.4. Concentrated Photovoltaic Cells

4.1.5. Solar Farms

4.1.6. Advantages of Photovoltaic Cells

4.1.7. Disadvantages of Photovoltaic Cells

4.1.8. Current Research Goals

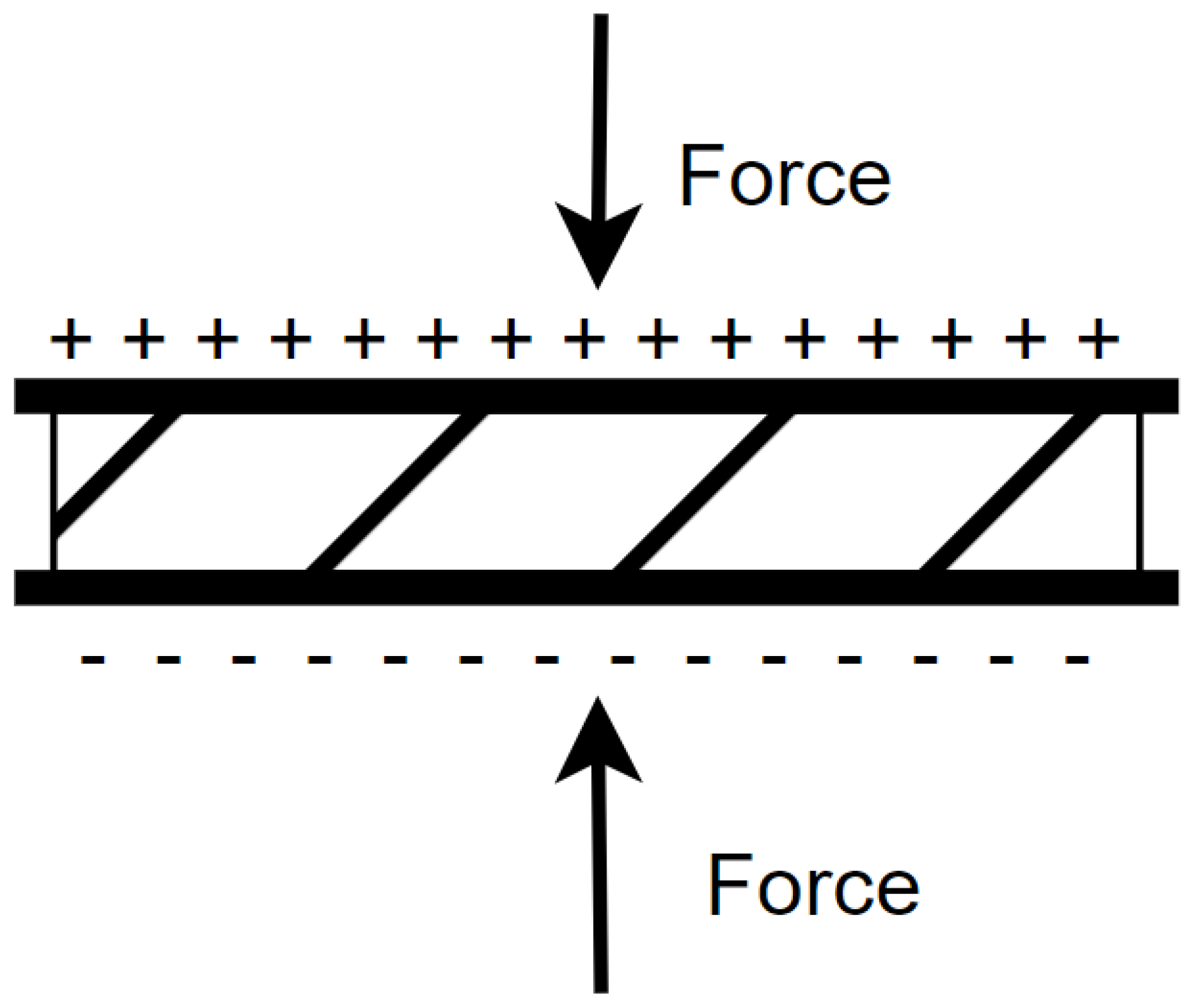

4.2. Piezoelectric Transducer

4.2.1. Working Principle of Piezoelectric Transducer

4.2.2. Conversion Efficiency and Power Density of Piezoelectricity

4.2.3. Types of Piezoelectric Materials

4.2.4. Applications of Piezoelectric Transducers

4.2.5. Advantages of Piezoelectric Transducer

- Quick response time—Piezoelectric transducers can generate electrical energy even from short-lasting mechanical stress. This makes them suitable for applications where the frequency of the harvested mechanical stress is high.

- Long lifespan and high durability—These transducers can withstand significant mechanical stress, vibrations, and extreme weather conditions, making them reliable for long-term use.

- Compact and lightweight—Piezoelectric materials are small and lightweight, allowing for good scalability, even in large-area applications.

- High conversion efficiency—With an efficiency ranging from 60% to 80%, piezoelectric transducers can effectively harvest energy even from small mechanical stresses.

4.2.6. Disadvantages of Piezoelectric Transducer

- Inability to generate energy from constant mechanical stress—Piezoelectric materials produce voltage proportional to the rate of change in applied mechanical stress. This means that when exposed to a constant mechanical force, regardless of its magnitude, they do not generate electrical energy.

- Inconsistent output voltage—The intensity and frequency of the applied mechanical stress are often irregular in real-world applications, leading to fluctuations in the generated output voltage. A prime example is harvesting energy from vehicles on roadways, where variations in vehicle weight and speed result in inconsistent mechanical stress.

- Limited direct use for continuous power supply—Piezoelectric transducers cannot directly power devices requiring a continuous energy source. However, they are well-suited for recharging primary power sources, such as batteries, thereby extending operational time without frequent replacements.

- High material costs—Some piezoelectric materials are expensive, making large-scale implementation of this energy-harvesting system costly when using these materials.

4.2.7. Current Research Goals

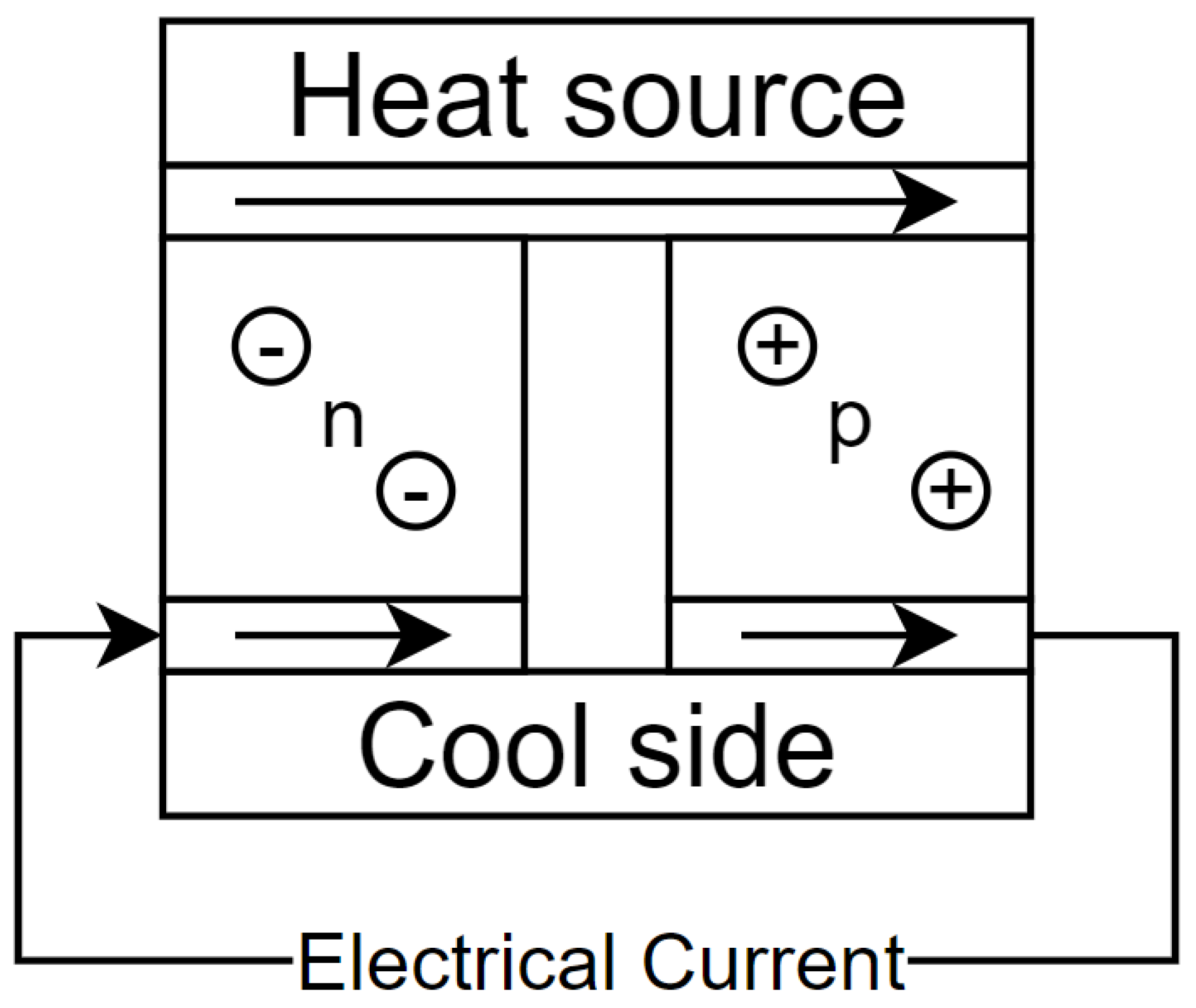

4.3. Thermoelectric Transducer

4.3.1. Working Principle of Thermoelectric Transducer

4.3.2. Conversion Efficiency and Power Density

4.3.3. Types of Thermoelectric Materials

- The E-type thermoelectric transducer—The transducer is made from the Chromel (nickel-chromium alloy) and the Constantan (nickel-constantan alloy). It can handle temperatures in the range °C to °C. Its Seebeck coefficient is at °C. It has high resistance to corrosion and oxidation.

- The J-type thermoelectric transducer—The transducer is made from iron and Constantan (nickel-constantan alloy). It can handle temperatures in the range °C to °C. Its Seebeck coefficient is at °C. It has good resistance to corrosion and oxidation.

- The T-type thermoelectric transducers—The transducer is made from copper and Constantan (nickel-constantan alloy). It can handle temperatures in the range °C to °C. Its Seebeck coefficient is at °C. It has good resistance to corrosion and oxidation.

- The K-type thermoelectric transducers—The transducer is made from Chromel (nickel-chromium alloy) and Alumel (nickel-aluminum alloy). It can handle temperatures in the range °C to °C. Its Seebeck coefficient is at °C. It has good resistance to corrosion and oxidation.

- The R-type thermoelectric transducer—The transducer is made from platinum-rhodium and platinum. It can handle temperatures in the range °C to °C. Its Seebeck coefficient is at °C. It has good resistance to corrosion and oxidation.

- The B-type thermoelectric transducer—The transducer is made from platinum-rhodium and platinum. It can handle temperatures in the range °C to °C. Its Seebeck coefficient is at 25 °C. It has high resistance to corrosion and oxidation.

4.3.4. Applications of Thermoelectric Transducers

4.3.5. Advantages of Thermoelectric Transducer

4.3.6. Disadvantages of Thermoelectric Transducer

4.3.7. Current Research Goals

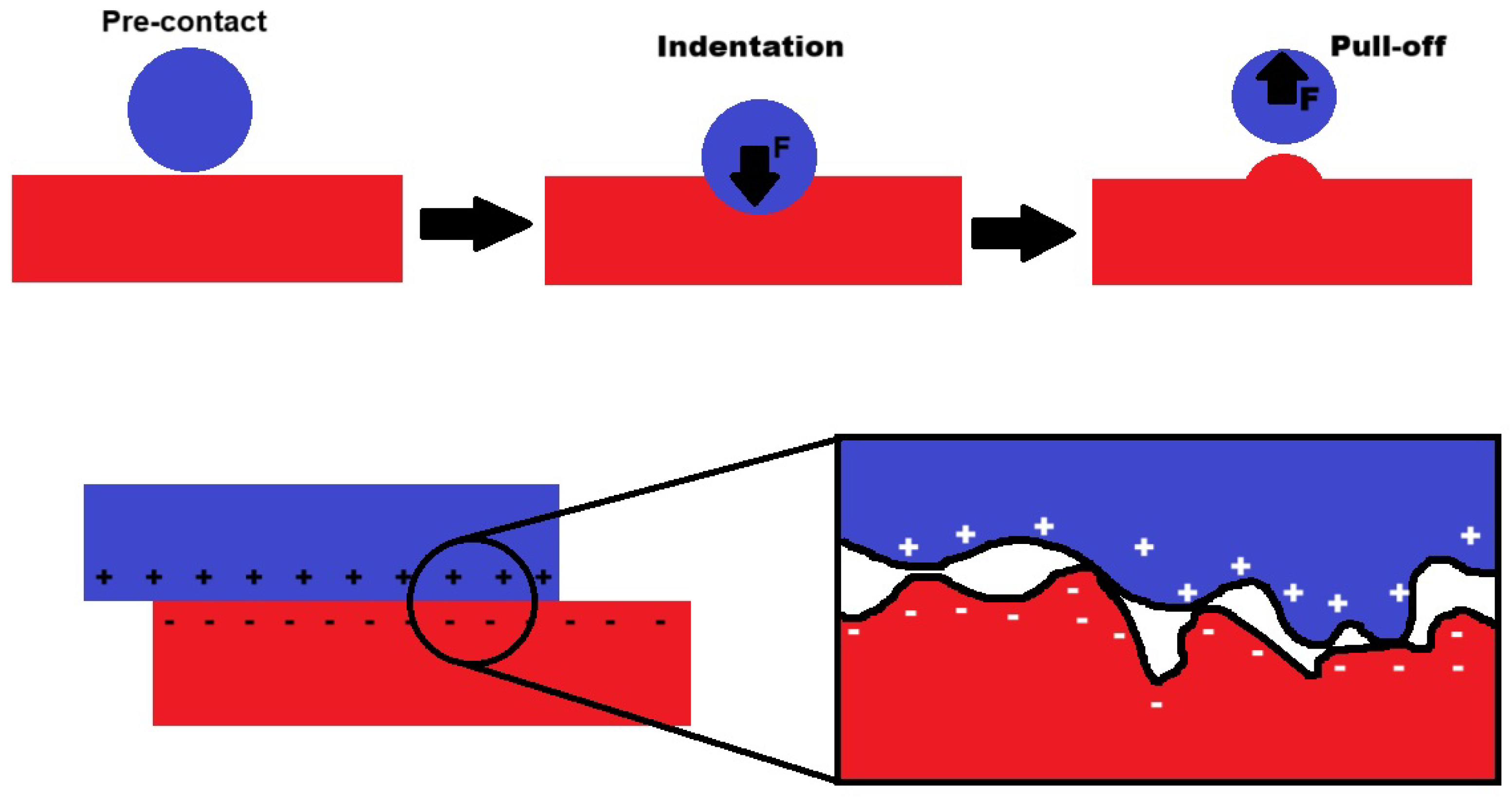

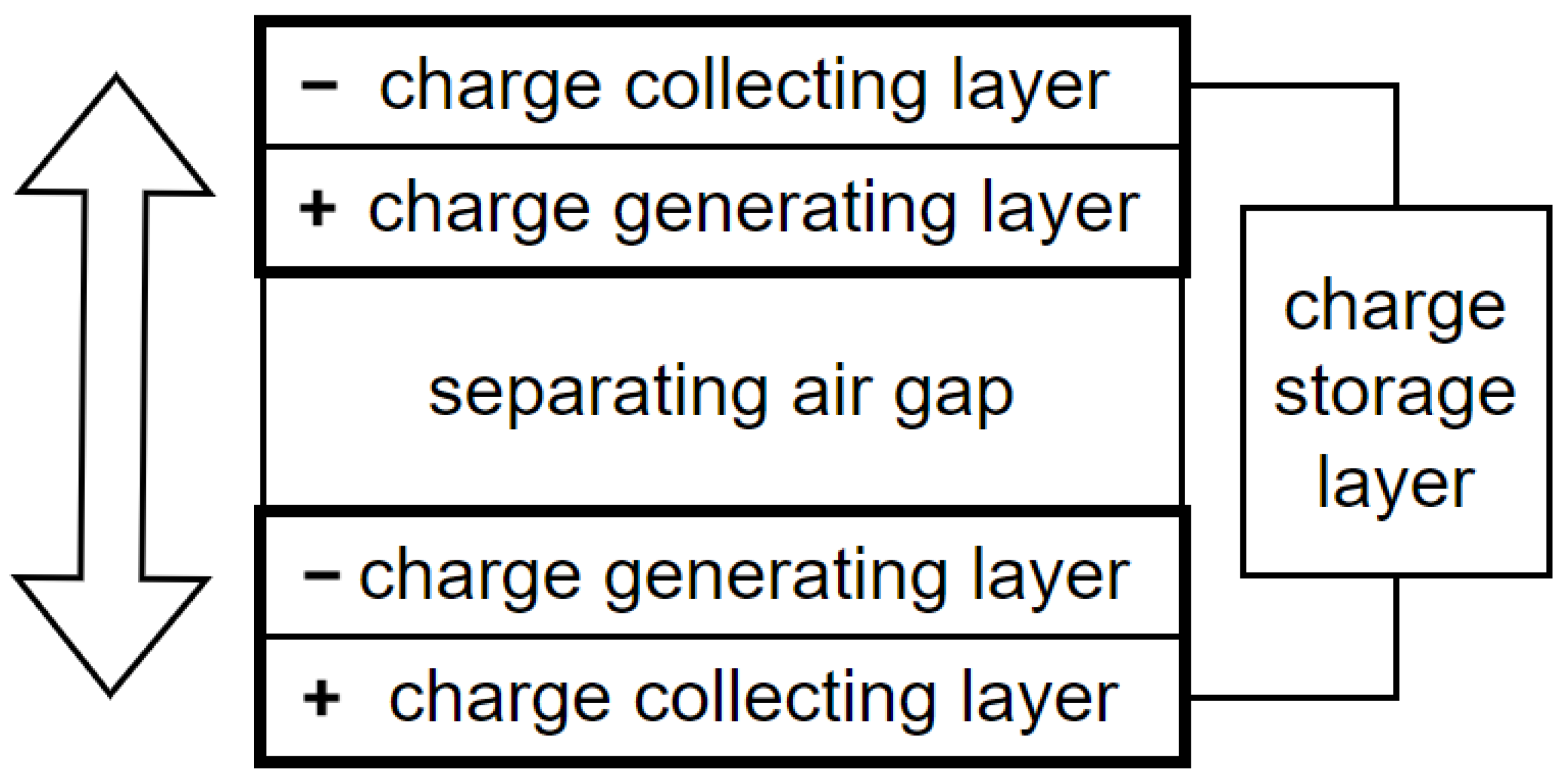

4.4. Triboelectric Transducer

4.4.1. Working Principle of Triboelectric Transducer

4.4.2. Conversion Efficiency and Power Density

4.4.3. Types of Triboelectric Materials

4.4.4. Applications of Triboelectric Transducers

- Wearable textiles—Textile Triboelectric Nanogenerators (tTENGs) are sewn into the fabric from which clothes are made. During human motion, these tTENGs generate a small amount of energy, which can be used, for example, to partially recharge small electronic devices [99,100].The first tTENG used in wearable textiles was created in 2014. This Woven-structured TENG (W-TENG) was constructed using two triboelectric materials, nylon and polyester, with Ag fabric serving as the conductive material. When the W-TENG is subjected to stretching or compression due to human movement, electrical energy is generated.Since this year, more efficient and complicated tTENGs have been designed. The triboelectric materials used in the wearable textile need to be flexible, comfortable during wear, and durable. Because of that, materials such as polytetrafluoroethylene, polydimethylsiloxane, polyethylene cotton, and silk are often used.

- Water wave energy—which falls under the category of so-called blue energy—is energy generated from water bodies. In this context, TENGs are used to harvest energy from waves in oceans or rivers. These waves are driven by the gravitational forces of the Sun and Moon acting on the Earth [101,102,103].TENGs are placed inside marine buoys, and the movement of the waves causes the buoys to move as well. Consequently, TENGs generate energy from this motion. This energy could power various marine devices, including smart buoys, night lights, floating weather stations, and maritime surveillance equipment.The triboelectric materials used need to have good durability against corrosion caused by salty water. Because of that, the combinations polytetrafluoroethylene and aluminium, polydimethylsiloxane and copper, and polyethylene and graphite are often used.

- Wind energy harvesting—electromagnetic generators, typically in the form of wind turbines, are commonly used to convert the kinetic energy of the wind into electricity, they struggle to generate energy from low-speed winds [104,105,106].This is where TENGs excel, offering high efficiency even in low-speed wind conditions. Incorporating TENG devices into existing wind turbine farms could increase their overall energy production.The triboelectric materials used need to be durable and capable of withstanding extreme outdoor conditions. Because of that, materials such as polytetrafluoroethylene, polydimethylsiloxane, polyethylene aluminium, and graphite are often used.

- Transportation. In this area, there are two major applications for TENGs.The first application is the collection of wind energy caused by the movement of vehicles.The second application is the collection of energy from the contact between the tires and the road surface. The TENGs are placed on car tires, and thanks to the friction against the road, they can generate electrical energy. TENGs have already been experimentally used in Advanced Driving Assistance Systems (ADAS), where they power sensors that monitor tire conditions such as pressure, road contact, and tire direction [107,108,109].The triboelectric materials used need to be durable against the mechanical stress to which they are exposed in these applications. Because of that, materials such as polytetrafluoroethylene, polydimethylsiloxane, polyethylene aluminium, and graphite are often used.

4.4.5. Advantages of the Triboelectric Transducers

4.4.6. Disadvantages of the Triboelectric Transducers

- Durability—only a limited number of tests have been conducted with specific TENGs outside of laboratory conditions. As a result, it remains uncertain how well they will endure extreme environmental conditions, such as high or low temperatures, corrosion caused by salty water in wave energy applications, or repeated machine washing of wearable textiles. Due to these environmental factors, materials with the best triboelectric properties for a given application cannot always be used. Instead, a compromise between the device’s durability and its energy generation efficiency must be made [110,111].

- Wear—TENGs generate energy through friction between two different materials, leading to wear. As a result, the lifespan of TENGs that use nanomaterials can be short if the problem with friction is not properly solved [112].

- Manufacturing processes—so far, certain TENGs have been produced in small series for testing purposes. However, if they were to be used on a commercial scale, a considerable investment in the necessary technology would be required. Additionally, due to constant technological improvements, this technology could quickly become obsolete and need upgrading. Another issue related to manufacturing and electrical output is that many modern TENGs are made from complex materials that require multiple processing steps. Consequently, the cost efficiency of some TENGs solutions may be low [95].

- Electrical output—despite significant progress in conversion efficiency since their inception, TENGs still suffer from low electrical output. This problem is magnified by the fact that they are generating on their output Alternating Current (AC), which needs to be rectified to be used by the final device. During this rectification process, another voltage loss occurs, which further decreases their energy production. This limitation is particularly pronounced for TENGs used in wearable textiles, where the generated energy reaches a maximum of 9 , which is more than 50 times less than more conventional non-textile TENGs, which are capable of generating up to 500 [113,114,115].

- The amount of power generated by some of the TENGs in real-world conditions is not yet well known, since a big part of the test was performed under laboratory conditions.

4.4.7. Current Research Goals

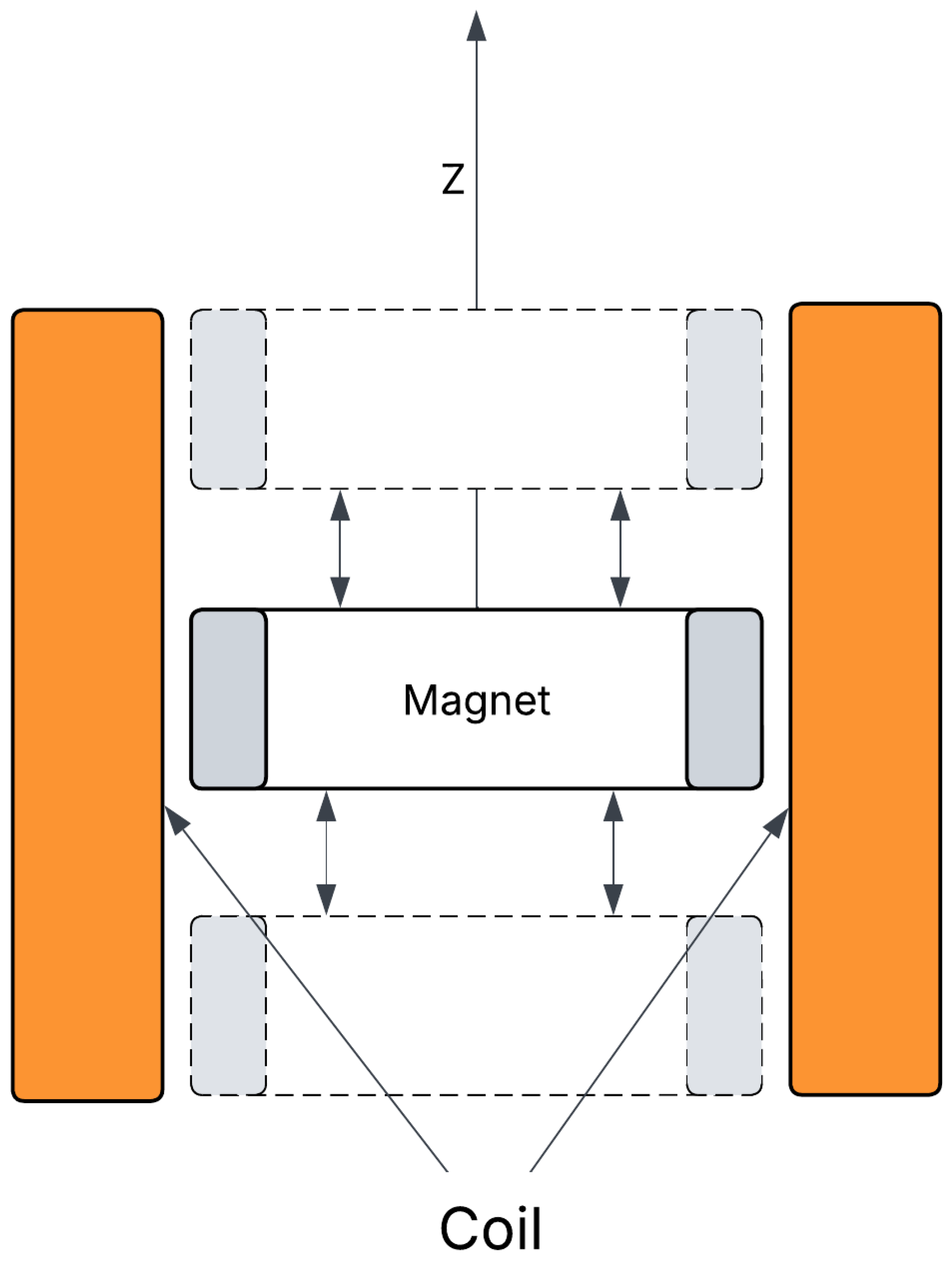

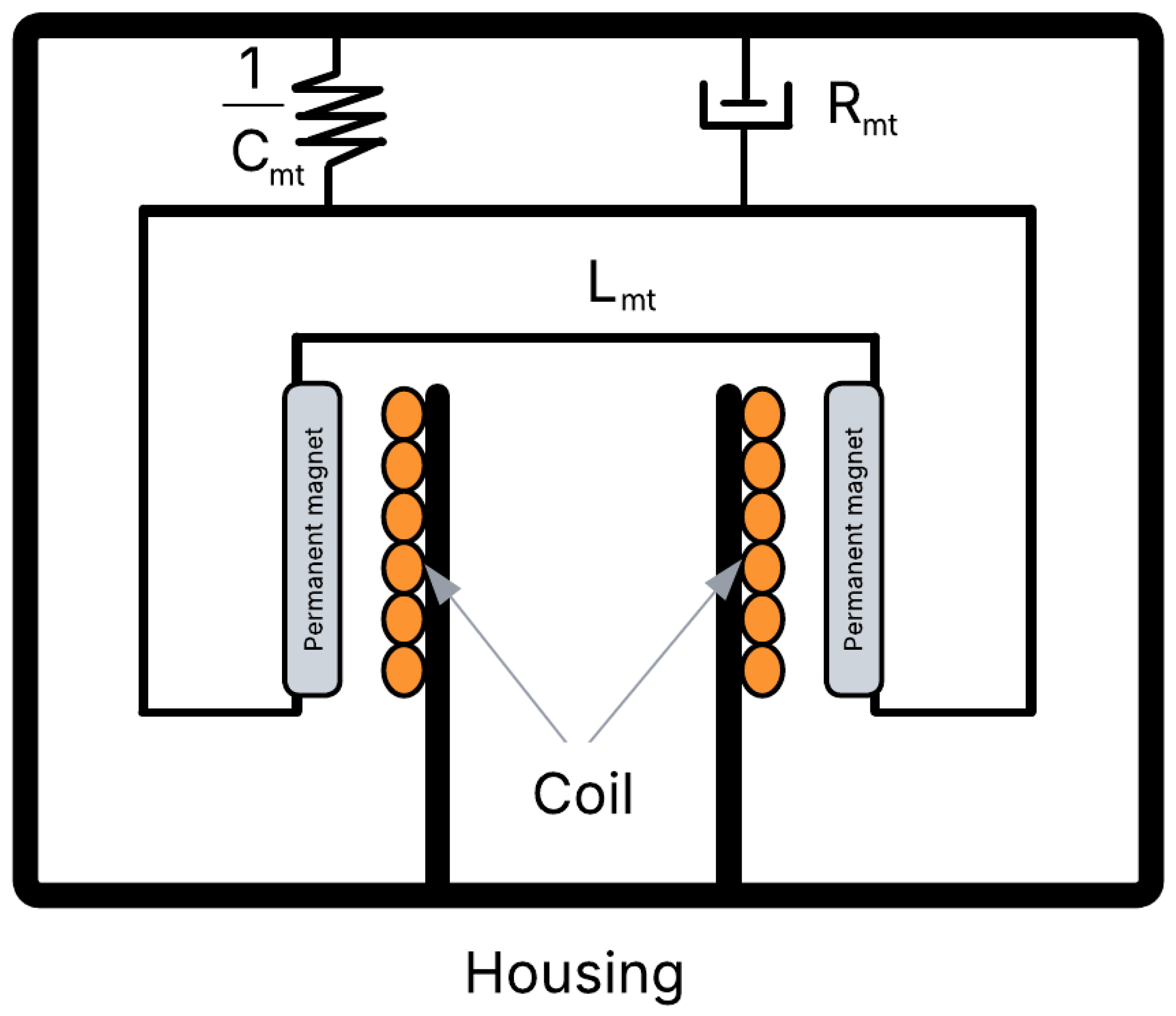

4.5. Electromagnetic Transducer

4.5.1. Working Principle of Electromagnetic Transducer

4.5.2. Conversion Efficiency and Power Density

4.5.3. Materials Inside of Electromagnetic Transducers

- Ferrite—It is made from iron oxide and other metallic elements. It has high corrosion resistance, and it can operate even in temperatures reaching °C. Ferrite is used in many applications thanks to its low cost, since its main component is cheap iron. It is capable of generating magnetic fields ranging from 0.1 to 0.5 T (Tesla). Its coercivity is between 100 and 300 . Its magnetic strength decreases by approximately −0.2% per °C above ambient temperature ( °C).

- Alnico—It is an alloy of aluminium, nickel, and cobalt. It has a high corrosion resistance, and it can operate even in high temperatures, reaching °C. It has good temperature stability. It is capable of generating a magnetic field of 0.15 T. Its coercivity is between 50 and 150 . Its magnetic strength decreases by approximately −0.02% per °C above ambient temperature ( °C).

- Neodymium-iron-boron (NdFeB)—It is made from rare earth elements. It is capable of generating a magnetic field ranging from 1 to 1.3 tesla. It can be used up to °C. Its coercivity is between 750 and 2000 . Its magnetic strength decreases by approximately −0.12% per °C above ambient temperature ( °C).

- Samarium-cobalt (SmCo)—It is made from rare earth elements. It has high corrosion resistance, and it can operate even at high temperatures reaching °C without a significant decrease in its magnetic field. It is capable of generating a magnetic field ranging from 0.8 to 1.16 tesla. Its coercivity is between 600 and 2400 . Its magnetic strength decreases by approximately −0.04% per °C above ambient temperature ( °C).

4.5.4. Applications of Electromagnetic Transducers

4.5.5. Advantages of the Electromagnetic Transducers

4.5.6. Disadvantages of the Electromagnetic Transducers

4.5.7. Current Research Goals

5. Energy Storage

- Energy density—refers to the amount of energy stored per unit of volume or weight. Higher energy density means that the same amount of energy can be stored in smaller systems.

- Power density measures the rate at which energy can be delivered by the storage system. Higher power density means that the system can give quick bursts of energy and thus supply bigger currents to the rest of the system.

- Efficiency is the ratio of the energy output to the energy input of the system. Higher efficiency means less energy is lost in the energy storage process.

- Cycle stability refers to how well the system maintains its efficiency and capacity over many charge and discharge cycles.

- Charge rate determines how fast the energy storage can be fully charged from a fully discharged state by an energy source with certain parameters.

- Discharge rate determines how fast the energy storage can be fully discharged from a fully charged state by the load with a certain power consumption.

- Response time refers to the speed at which the storage system can respond to energy demand changes.

- Environmental impact refers to the materials used in the energy storage system both from the point of view of the environmental impact caused during the mining and processing of the materials and the environmental impact if the energy storage system is not properly disposed of.

- Safety is a very important parameter when it comes to energy storage. Different types of energy storage have different conditions under which they become unsafe. For example, if we throw rechargeable batteries into the fire, they will explode. Therefore, in each application in which there is a possible fire hazard, we must make sure the batteries will not get exposed to the flames. Therefore, if we use rechargeable batteries in electric cars, we must put them into a fireproof box that will prevent their explosion in the case that the car will catch fire.

5.1. Mechanical Storage

5.1.1. Pumped Hydroelectric Storage (PHS)

5.1.2. Compressed Air Energy Storage (CAES)

5.1.3. Flywheel Energy Storage (FES)

5.1.4. Gravitational Energy Storage

5.2. Electrochemical Storage

5.3. Thermal Storage

Thermochemical Storage

5.4. Electrical Storage

5.5. Electrical Energy Storage Used in the IoT Applications

6. Power Management Circuit

7. Control and Monitoring Circuitry

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kiziroglou, M.; Yeatman, E. 17—Materials and techniques for energy harvesting. In Functional Materials for Sustainable Energy Applications; Kilner, J.A., Skinner, S.J., Irvine, S.J., Edwards, P.P., Eds.; Woodhead Publishing Series in Energ; Woodhead Publishing: Sawston, UK, 2012; pp. 541–572. [Google Scholar] [CrossRef]

- Lu, C.; Raghunathan, V.; Roy, K. Efficient Design of Micro-Scale Energy Harvesting Systems. IEEE J. Emerg. Sel. Top. Circuits Syst. 2011, 1, 254–266. [Google Scholar] [CrossRef]

- Sah, D.K.; Amgoth, T. Renewable energy harvesting schemes in wireless sensor networks: A Survey. Inf. Fusion 2020, 63, 223–247. [Google Scholar] [CrossRef]

- Liu, H.; Fu, H.; Sun, L.; Lee, C.; Yeatman, E.M. Hybrid energy harvesting technology: From materials, structural design, system integration to applications. Renew. Sustain. Energy Rev. 2021, 137, 110473. [Google Scholar] [CrossRef]

- Iturralde Carrera, L.A.; Garcia-Barajas, M.G.; Constantino-Robles, C.D.; Álvarez Alvarado, J.M.; Castillo-Alvarez, Y.; Rodríguez-Reséndiz, J. Efficiency and Sustainability in Solar Photovoltaic Systems: A Review of Key Factors and Innovative Technologies. Eng 2025, 6, 50. [Google Scholar] [CrossRef]

- Xiang, H.; Li, X.; Liao, X.; Cui, W.; Liu, F.; Li, D. Artificial Intelligence in Renewable Energy Systems: Applications and Security Challenges. Energies 2025, 18, 1931. [Google Scholar] [CrossRef]

- Szczepaniuk, H.; Szczepaniuk, E.K. Applications of Artificial Intelligence Algorithms in the Energy Sector. Energies 2023, 16, 347. [Google Scholar] [CrossRef]

- Alajingi, R.; R, M. Novel classification of energy sources, with implications for carbon emissions. Energy Strategy Rev. 2023, 49, 101146. [Google Scholar] [CrossRef]

- Dirner, V.; Pavelek, Z. Aspects of classification of energy sources in terms of their position in the sector of the economy. Acta Montan. Slovaca 2016, 21, 287–297. [Google Scholar]

- Žarković, M.; Lakić, S.; Ćetković, J.; Pejović, B.; Redzepagic, S.; Vodenska, I.; Vujadinović, R. Effects of Renewable and Non-Renewable Energy Consumption, GHG, ICT on Sustainable Economic Growth: Evidence from Old and New EU Countries. Sustainability 2022, 14, 9662. [Google Scholar] [CrossRef]

- Brożyna, J.; Mentel, G.; Ivanová, E.; Sorokin, G. Classification of Renewable Sources of Electricity in the Context of Sustainable Development of the New EU Member States. Energies 2019, 12, 2271. [Google Scholar] [CrossRef]

- Yu, C.; Moslehpour, M.; Tran, T.K.; Trung, L.M.; Ou, J.P.; Tien, N.H. Impact of non-renewable energy and natural resources on economic recovery: Empirical evidence from selected developing economies. Resour. Policy 2023, 80, 103221. [Google Scholar] [CrossRef]

- Destek, M.A.; Sinha, A. Renewable, non-renewable energy consumption, economic growth, trade openness and ecological footprint: Evidence from organisation for economic Co-operation and development countries. J. Clean. Prod. 2020, 242, 118537. [Google Scholar] [CrossRef]

- Zhang, B.; Matchinski, E.J.; Chen, B.; Ye, X.; Jing, L.; Lee, K. Chapter 21—Marine Oil Spills—Oil Pollution, Sources and Effects. In World Seas: An Environmental Evaluation, 2nd ed.; Sheppard, C., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 391–406. [Google Scholar] [CrossRef]

- Ellwanger, J.H.; Chies, J.A.B. Brazil’s heavy metal pollution harms humans and ecosystems. Sci. One Health 2023, 2, 100019. [Google Scholar] [CrossRef] [PubMed]

- Lappi, P.; Lintunen, J. From cradle to grave? On optimal nuclear waste disposal. Energy Econ. 2021, 103, 105556. [Google Scholar] [CrossRef]

- Ang, T.Z.; Salem, M.; Kamarol, M.; Das, H.S.; Nazari, M.A.; Prabaharan, N. A comprehensive study of renewable energy sources: Classifications, challenges and suggestions. Energy Strategy Rev. 2022, 43, 100939. [Google Scholar] [CrossRef]

- Rahman, A.; Farrok, O.; Haque, M.M. Environmental impact of renewable energy source based electrical power plants: Solar, wind, hydroelectric, biomass, geothermal, tidal, ocean, and osmotic. Renew. Sustain. Energy Rev. 2022, 161, 112279. [Google Scholar] [CrossRef]

- Halkos, G.E.; Gkampoura, E.C. Reviewing Usage, Potentials, and Limitations of Renewable Energy Sources. Energies 2020, 13, 2906. [Google Scholar] [CrossRef]

- Cao, S.; Li, J. A survey on ambient energy sources and harvesting methods for structural health monitoring applications. Adv. Mech. Eng. 2017, 9. [Google Scholar] [CrossRef]

- Mishu, M.K.; Rokonuzzaman, M.; Pasupuleti, J.; Shakeri, M.; Rahman, K.S.; Hamid, F.A.; Tiong, S.K.; Amin, N. Prospective Efficient Ambient Energy Harvesting Sources for IoT-Equipped Sensor Applications. Electronics 2020, 9, 1345. [Google Scholar] [CrossRef]

- Liu, N.; Wan, Y.; Han, H.; Liu, T. A review on vibration energy harvesting. E3S Web Conf. 2021, 245, 01041. [Google Scholar] [CrossRef]

- Snyder, G.J. Thermoelectric Energy Harvesting. In Energy Harvesting Technologies; Priya, S., Inman, D.J., Eds.; Springer: New York, NY, USA, 2009; pp. 325–336. [Google Scholar] [CrossRef]

- Jabbar, H.; Jeong, T. Ambient Light Energy Harvesting and Numerical Modeling of Non-Linear Phenomena. Appl. Sci. 2022, 12, 2068. [Google Scholar] [CrossRef]

- Šarafin, P.; Formanek, L.; Chochul, M. Dynamic System Parameter Identification Based On The Acceleration Data. In Proceedings of the 2020 18th International Conference on Emerging eLearning Technologies and Applications (ICETA), Košice, Slovakia, 12–13 November 2020; pp. 570–573. [Google Scholar] [CrossRef]

- Popescu, C.; Hysa, E.; Panait, M.; Çela, A. Past, Present, and Future of Critical Issues in Energy: Poverty, Transition and Security—A Systematic Review. Energies 2023, 16, 5484. [Google Scholar] [CrossRef]

- Ahmad, T.; Zhang, D. A critical review of comparative global historical energy consumption and future demand: The story told so far. Energy Rep. 2020, 6, 1973–1991. [Google Scholar] [CrossRef]

- Chrifi-Alaoui, L.; Drid, S.; Ouriagli, M.; Mehdi, D. Overview of Photovoltaic and Wind Electrical Power Hybrid Systems. Energies 2023, 16, 4778. [Google Scholar] [CrossRef]

- Luque, A.; Hegedus, S. Handbook of Photovoltaic Science and Engineering; John Wiley and Sons, Ltd.: Hoboken, NJ, USA, 2010. [Google Scholar] [CrossRef]

- Zhou, X.; Cui, Y.; Xu, H. Analysis of photovoltaic cell output characteristic. In Proceedings of the 2023 IEEE International Conference on Sensors, Electronics and Computer Engineering (ICSECE), Jinzhou, China, 18–20 August 2023; pp. 1447–1451. [Google Scholar] [CrossRef]

- Pastuszak, J.; Węgierek, P. Photovoltaic Cell Generations and Current Research Directions for Their Development. Materials 2022, 15, 5542. [Google Scholar] [CrossRef]

- Parida, B.; Iniyan, S.; Goic, R. A review of solar photovoltaic technologies. Renew. Sustain. Energy Rev. 2011, 15, 1625–1636. [Google Scholar] [CrossRef]

- Yahyaoui, N.; Mansouri, S.; Al-Sehemi, A.G.; Dere, A.; Al-Ghamdi, A.; Yakuphanoglu, F. Electrical characterization of silicon PV- cell: Modeling. Appl. Phys. A Mater. Sci. Process. 2024, 130, 379. [Google Scholar] [CrossRef]

- Sugianto, S. Comparative Analysis of Solar Cell Efficiency between Monocrystalline and Polycrystalline. INTEK J. Penelit. 2020, 7, 92–100. [Google Scholar] [CrossRef]

- Uecker, R. The historical development of the Czochralski method. J. Cryst. Growth 2014, 401, 7–24. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhou, S.; Tsai, C.S.; Guo, X.; Zhou, H. An Analysis of Cadmium Telluride and Amorphous Silicon PV Cells. In Proceedings of the 2022 3rd International Conference on Clean and Green Energy Engineering (CGEE), Istanbul, Turkey, 28–30 August 2022; pp. 1–7. [Google Scholar] [CrossRef]

- AL-Rousan, N.; Isa, N.A.M.; Desa, M.K.M. Advances in solar photovoltaic tracking systems: A review. Renew. Sustain. Energy Rev. 2018, 82, 2548–2569. [Google Scholar] [CrossRef]

- Surya Prathap, N.; Chaurasia, H.; Reddy, K.S. Optimizing the Heat Sink for Concentrated Photovoltaic Systems for Different Heat Flux Conditions. In Proceedings of the 2023 IEEE 50th Photovoltaic Specialists Conference (PVSC), San Juan, PR, USA, 11–16 June 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Dada, M.; Popoola, P. Recent advances in solar photovoltaic materials and systems for energy storage applications: A review. Beni-Suef Univ. J. Basic Appl. Sci. 2023, 66, 1–15. [Google Scholar] [CrossRef]

- Preet, S.; Smith, S.T. A comprehensive review on the recycling technology of silicon based photovoltaic solar panels: Challenges and future outlook. J. Clean. Prod. 2024, 448, 141661. [Google Scholar] [CrossRef]

- Park, N.G. Perovskite solar cells: An emerging photovoltaic technology. Mater. Today 2015, 18, 65–72. [Google Scholar] [CrossRef]

- Holzhey, P.; Prettl, M.; Collavini, S.; Chang, N.; Saliba, M. Towards Commercialisation with Lightweight, Flexible Perovskite Solar Cells for Residential Photovoltaics. In Proceedings of the 2023 IEEE 50th Photovoltaic Specialists Conference (PVSC), San Juan, PR, USA, 11–16 June 2023. [Google Scholar] [CrossRef]

- Al-Ezzi, A.S.; Ansari, M.N.M. Photovoltaic Solar Cells: A Review. Appl. Syst. Innov. 2022, 5, 67. [Google Scholar] [CrossRef]

- Machín, A.; Márquez, F. Advancements in Photovoltaic Cell Materials: Silicon, Organic, and Perovskite Solar Cells. Materials 2024, 17, 1165. [Google Scholar] [CrossRef]

- Coakley, K.M.; McGehee, M.D. Conjugated Polymer Photovoltaic Cells. Chem. Mater. 2004, 16, 4533–4542. [Google Scholar] [CrossRef]

- Lv, S.; Zhang, M.; Lai, Y.; Wu, Y.; Deng, J.; Guo, Y.; Feng, M.; Shi, G.; Zhang, B.; Ren, J.; et al. Comparative analysis of photovoltaic thermoelectric systems using different photovoltaic cells. Appl. Therm. Eng. 2023, 235, 121356. [Google Scholar] [CrossRef]

- Chandel, R.; Chandel, S.S.; Prasad, D.; Dwivedi, R.P. Review on thermoelectric systems for enhancing photovoltaic power generation. Sustain. Energy Technol. Assess. 2022, 53, 102585. [Google Scholar] [CrossRef]

- Jin, Y.K.; Sarker, S.; Lee, K.S.; Seo, H.W.; Kim, D.M. Piezoelectric materials for high performance energy harvesting devices. In Proceedings of the 2016 Pan Pacific Microelectronics Symposium (Pan Pacific), Big Island, HI, USA, 25–28 January 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Anton, S.R.; Sodano, H.A. A review of power harvesting using piezoelectric materials (2003–2006). Smart Mater. Struct. 2007, 16, R1. [Google Scholar] [CrossRef]

- Batra, A.; Alomari, A.; Chilvery, A.; Bandyopadhyay, A.; Grover, K. Piezoelectric Power Harvesting Devices: An Overview. Adv. Sci. Eng. Med. 2016, 8, 1–12. [Google Scholar] [CrossRef]

- Sezer, N.; Koç, M. A comprehensive review on the state-of-the-art of piezoelectric energy harvesting. Nano Energy 2021, 80, 105567. [Google Scholar] [CrossRef]

- Isaf, M.L.; Rincón-Mora, G.A. Piezoelectric Transducers: Complete Electromechanical Model with Parameter Extraction. Sensors 2024, 24, 4367. [Google Scholar] [CrossRef]

- Lacerda, I.S.; Silva, A.A.; Fernandes, E.M.; Senko, R.; Oliveira, A.G.; Delgado, J.M.P.Q.; Diniz, D.D.S.; Figueiredo, M.J.; Lima, A.G.B. Comparative Analysis of Piezoelectric Transducers for Low-Power Systems: A Focus on Vibration Energy Harvesting. Appl. Sci. 2024, 14, 9451. [Google Scholar] [CrossRef]

- Chen, Y.; Ji, X.; Si, W.; Guo, Z.; Zhang, X.; Zhang, X.; haoyu, Z. Preparation and performance of piezoelectric transducer packaged with 3D printing. Energy Build. 2023, 291, 113097. [Google Scholar] [CrossRef]

- Agrawal, R.; Espinosa, H.D. Giant Piezoelectric Size Effects in Zinc Oxide and Gallium Nitride Nanowires. A First Principles Investigation. Nano Lett. 2011, 11, 786–790. [Google Scholar] [CrossRef] [PubMed]

- Covaci, C.; Gontean, A. Piezoelectric Energy Harvesting Solutions: A Review. Sensors 2020, 20, 3512. [Google Scholar] [CrossRef]

- Shaukat, H.; Ali, A.; Bibi, S.; Altabey, W.A.; Noori, M.; Kouritem, S.A. A Review of the Recent Advances in Piezoelectric Materials, Energy Harvester Structures, and Their Applications in Analytical Chemistry. Appl. Sci. 2023, 13, 1300. [Google Scholar] [CrossRef]

- Damjanovic, D. Piezoelectricity. In Encyclopedia of Condensed Matter Physics; Bassani, F., Liedl, G.L., Wyder, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2005; pp. 300–309. [Google Scholar] [CrossRef]

- Samal, N.; Shiney, J.; Patra, A. Study of Piezoelectric transducers used for Energy Harvesting Applications. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1085, 012031. [Google Scholar] [CrossRef]

- Ju, M.; Dou, Z.; Li, J.W.; Qiu, X.; Shen, B.; Zhang, D.; Yao, F.Z.; Gong, W.; Wang, K. Piezoelectric Materials and Sensors for Structural Health Monitoring: Fundamental Aspects, Current Status, and Future Perspectives. Sensors 2023, 23, 543. [Google Scholar] [CrossRef]

- Wu, Y.; Ma, Y.; Zheng, H.; Ramakrishna, S. Piezoelectric materials for flexible and wearable electronics: A review. Mater. Des. 2021, 211, 110164. [Google Scholar] [CrossRef]

- Zheng, H.; Wang, Y.; Liu, J.; wang, J.; Yan, K.; Zhu, K. Recent advancements in the use of novel piezoelectric materials for piezocatalytic and piezo-photocatalytic applications. Appl. Catal. B Environ. 2024, 341, 123335. [Google Scholar] [CrossRef]

- Das, K.K.; Basu, B.; Maiti, P.; Dubey, A.K. Piezoelectric nanogenerators for self-powered wearable and implantable bioelectronic devices. Acta Biomater. 2023, 171, 85–113. [Google Scholar] [CrossRef] [PubMed]

- Zhu, M.; Yi, Z.; Yang, B.; Lee, C. Making use of nanoenergy from human – Nanogenerator and self-powered sensor enabled sustainable wireless IoT sensory system. Nano Today 2021, 36, 101016. [Google Scholar] [CrossRef]

- Sawane, M.; Prasad, M. MEMS piezoelectric sensor for self-powered devices: A review. Mater. Sci. Semicond. Process. 2023, 158, 107324. [Google Scholar] [CrossRef]

- Gupta, S.; Kumar, M.; Singh, G.; Chanda, A. Development of a novel footwear based power harvesting system. e-Prime-Adv. Electr. Eng. Electron. Energy 2023, 3, 100115. [Google Scholar] [CrossRef]

- Venkatasubramanian, R.; Siivola, E.P.; Colpitts, T.; O’Quinn, B. Thin-film thermoelectric devices with high room-temperature figures of merit. Nature 2001, 413, 597–602. [Google Scholar] [CrossRef]

- Enescu, D. Thermoelectric Energy Harvesting: Basic Principles and Applications. In Green Energy Advances; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef]

- Feng, M.; Lv, S.; Deng, J.; Guo, Y.; Wu, Y.; Shi, G.; Zhang, M. An overview of environmental energy harvesting by thermoelectric generators. Renew. Sustain. Energy Rev. 2023, 187, 113723. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, L.D. Thermoelectric materials: Energy conversion between heat and electricity. J. Mater. 2015, 1, 92–105. [Google Scholar] [CrossRef]

- Ridwan, M.; Gasulla, M.; Reverter, F. Principle and Applications of Thermoelectric Generators: A Review. Sensors 2025, 25, 2484. [Google Scholar] [CrossRef] [PubMed]

- Xie, H.; Zhang, Y.; Gao, P. Thermoelectric-Powered Sensors for Internet of Things. Micromachines 2023, 14, 31. [Google Scholar] [CrossRef] [PubMed]

- Terasaki, I. 13—Introduction to thermoelectricity. In Materials for Energy Conversion Devices; Sorrell, C.C., Sugihara, S., Nowotny, J., Eds.; Woodhead Publishing Series in Electronic and Optical Materials; Woodhead Publishing: Sawston, UK, 2005; pp. 339–357. [Google Scholar] [CrossRef]

- Freire, L.O.; Navarrete, L.M.; Corrales, B.P.; Castillo, J.N. Efficiency in thermoelectric generators based on Peltier cells. Energy Rep. 2021, 7, 355–361. [Google Scholar] [CrossRef]

- Irfan, S.; Yan, Z.; Khan, S.B. Advancements in thermoelectric materials: A comprehensive review. Mater. Sci. Energy Technol. 2024, 7, 349–373. [Google Scholar] [CrossRef]

- Feng, T.; Zhou, Z.; Wang, P.; Liao, Z.; Wang, Y.; Zhao, H.; Zhang, W.; Liu, W. Transverse thermoelectric materials: Recent advances and challenges. Next Energy 2024, 3, 100105. [Google Scholar] [CrossRef]

- Ochieng, A.O.; Megahed, T.F.; Ookawara, S.; Hassan, H. Comprehensive review in waste heat recovery in different thermal energy-consuming processes using thermoelectric generators for electrical power generation. Process Saf. Environ. Prot. 2022, 162, 134–154. [Google Scholar] [CrossRef]

- Fernández-Yáñez, P.; Romero, V.; Armas, O.; Cerretti, G. Thermal management of thermoelectric generators for waste energy recovery. Appl. Therm. Eng. 2021, 196, 117291. [Google Scholar] [CrossRef]

- Alami, A.H.; Olabi, A.; Mdallal, A.; Rezk, A.; Radwan, A.; Rahman, S.M.A.; Shah, S.K.; Abdelkareem, M.A. Concentrating solar power (CSP) technologies: Status and analysis. Int. J. Thermofluids 2023, 18, 100340. [Google Scholar] [CrossRef]

- Sztekler, K.; Wojciechowski, K.; Komorowski, M. The thermoelectric generators use for waste heat utilization from conventional power plant. E3S Web Conf. 2017, 14, 01032. [Google Scholar] [CrossRef]

- Zhu, X.; Yu, Y.; Li, F. A review on thermoelectric energy harvesting from asphalt pavement: Configuration, performance and future. Constr. Build. Mater. 2019, 228, 116818. [Google Scholar] [CrossRef]

- Jiang, W.; Yuan, D.; Xu, S.; Hu, H.; Xiao, J.; Sha, A.; Huang, Y. Energy harvesting from asphalt pavement using thermoelectric technology. Appl. Energy 2017, 205, 941–950. [Google Scholar] [CrossRef]

- Sootsman, J.; Chung, D.; Kanatzidis, M. New and Old Concepts in Thermoelectric Materials. Angew. Chem. Int. Ed. 2009, 48, 8616–8639. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhao, L.D. Seeking new, highly effective thermoelectrics. Science 2020, 367, 1196–1197. [Google Scholar] [CrossRef]

- Nadtochiy, A.; Kuryliuk, V.; Korotchenkov, O.; Li, P.W.; Lee, S.W. Enhancing the Seebeck effect in Ge/Si through the combination of interfacial design features. Sci. Rep. 2019, 9, 16335. [Google Scholar] [CrossRef]

- Li, W.; Poudel, B.; Kishore, R.A.; Nozariasbmarz, A.; Liu, N.; Zhang, Y.; Priya, S. Toward High Conversion Efficiency of Thermoelectric Modules through Synergistical Optimization of Layered Materials. Adv. Mater. 2023, 35, 2210407. [Google Scholar] [CrossRef]

- Dharmasena, R.D.I.G.; Jayawardena, K.D.G.I.; Mills, C.A.; Deane, J.H.B.; Anguita, J.V.; Dorey, R.A.; Silva, S.R.P. Triboelectric nanogenerators: Providing a fundamental framework. Energy Environ. Sci. 2017, 10, 1801–1811. [Google Scholar] [CrossRef]

- Gao, Q.; Cheng, T.; Wang, Z.L. Triboelectric mechanical sensors—Progress and prospects. Extrem. Mech. Lett. 2021, 42, 101100. [Google Scholar] [CrossRef]

- Ibrahim, A.; Ramini, A.; Towfighian, S. Triboelectric energy harvester with large bandwidth under harmonic and random excitations. Energy Rep. 2020, 6, 2490–2502. [Google Scholar] [CrossRef]

- Triboelectricity. Available online: https://www.numis.northwestern.edu/Research/Projects/triboelectricity/ (accessed on 13 July 2025).

- Shi, Z.; Zhang, Y.; Gu, J.; Liu, B.; Fu, H.; Liang, H.; Ji, J. Triboelectric Nanogenerators: State of the Art. Sensors 2024, 24, 4298. [Google Scholar] [CrossRef] [PubMed]

- Si, J.; Duan, R.; Zhang, M.; Liu, X. Recent Progress Regarding Materials and Structures of Triboelectric Nanogenerators for AR and VR. Nanomaterials 2022, 12, 1385. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.; Lee, J.; Kim, J.; Jeong, U. Material aspects of triboelectric energy generation and sensors. NPG Asia Mater. 2020, 12, 6. [Google Scholar] [CrossRef]

- Wang, Y.; Jin, W.; Wang, L.; Zhu, Z. Triboelectric Nanogenerator-Based Electronic Sensor System for Food Applications. Electronics 2023, 12, 4880. [Google Scholar] [CrossRef]

- Walden, R.; Kumar, C.; Mulvihill, D.M.; Pillai, S.C. Opportunities and Challenges in Triboelectric Nanogenerator (TENG) based Sustainable Energy Generation Technologies: A Mini-Review. Chem. Eng. J. Adv. 2022, 9, 100237. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Y.; Wang, Z. Triboelectric nanogenerators as flexible power sources. npj Flex. Electron. 2017, 1, 10. [Google Scholar] [CrossRef]

- Pu, X.; Li, L.; Song, H.; Du, C.; Zhao, Z.; Jiang, C.; Cao, G.; Hu, W.; Wang, Z.L. A Self-Charging Power Unit by Integration of a Textile Triboelectric Nanogenerator and a Flexible Lithium-Ion Battery for Wearable Electronics. Adv. Mater. 2015, 27, 2472–2478. [Google Scholar] [CrossRef]

- Liu, W.; Shi, J. A dynamics model of triboelectric nanogenerator transducers. Nano Energy 2021, 89, 106479. [Google Scholar] [CrossRef]

- Walden, R.; Aazem, I.; Babu, A.; Pillai, S.C. Textile-Triboelectric nanogenerators (T-TENGs) for wearable energy harvesting devices. Chem. Eng. J. 2023, 451, 138741. [Google Scholar] [CrossRef]

- Neelakandan, S.; Srither, S.R.; Dhineshbabu, N.R.; Maloji, S.; Dahlsten, O.; Balaji, R.; Singh, R. Recent Advances in Wearable Textile-Based Triboelectric Nanogenerators. Nanomaterials 2024, 14, 1500. [Google Scholar] [CrossRef]

- Radhakrishnan, S.; Joseph, S.; Jelmy, E.; Saji, K.; Sanathanakrishnan, T.; John, H. Triboelectric nanogenerators for marine energy harvesting and sensing applications. Results Eng. 2022, 15, 100487. [Google Scholar] [CrossRef]

- Shan, B.; Ai, T.; Wang, K. Triboelectric nanogenerator for ocean energy harvesting: A review of technological advances and future perspectives. Int. J. Electrochem. Sci. 2024, 19, 100694. [Google Scholar] [CrossRef]

- Dip, T.M.; Arin, M.R.A.; Anik, H.R.; Uddin, M.M.; Tushar, S.I.; Sayam, A.; Sharma, S. Triboelectric Nanogenerators for Marine Applications: Recent Advances in Energy Harvesting, Monitoring, and Self-Powered Equipment. Adv. Mater. Technol. 2023, 8, 2300802. [Google Scholar] [CrossRef]

- Ren, Z.; Wu, L.; Pang, Y.; Zhang, W.; Yang, R. Strategies for effectively harvesting wind energy based on triboelectric nanogenerators. Nano Energy 2022, 100, 107522. [Google Scholar] [CrossRef]

- Choi, J.A.; Jeong, J.; Kang, M.; Pyo, S. Vertical Blinds-Inspired Triboelectric Nanogenerator for Wind Energy Harvesting and Self-Powered Wind Speed Monitoring. ACS Appl. Electron. Mater. 2024, 6, 2534–2543. [Google Scholar] [CrossRef]

- Okbaz, A. Triboelectric Nanogenerators Used for Wind Energy Harvesting. In Proceedings of the 4th International Conference on Applied Engineering and Natural Sciences, Konya, Turkey, 10–13 November 2022. [Google Scholar]

- Hu, Y.; Xu, C.; Zhang, Y.; Snyder, R.; Wang, Z. A Nanogenerator for Energy Harvesting from a Rotating Tire and its Application as a Self-Powered Pressure/Speed Sensor. Adv. Mater. 2011, 23, 4068–4071. [Google Scholar] [CrossRef]

- Kim, W.G.; Kim, J.K.; Kim, D.W.; Tcho, I.W.; Choi, Y.K. A triboelectric nanogenerator implemented with an acoustic foam for a self-driven silent tire. Nano Energy 2022, 96, 107090. [Google Scholar] [CrossRef]

- Pang, Y.; Zhu, X.; Jin, Y.; Yang, Z.; Liu, S.; Shen, L.; Li, X.; Lee, C. Textile-inspired triboelectric nanogenerator as intelligent pavement energy harvester and self-powered skid resistance sensor. Appl. Energy 2023, 348, 121515. [Google Scholar] [CrossRef]

- Zhao, J.; Shi, Y. Boosting the Durability of Triboelectric Nanogenerators: A Critical Review and Prospect. Adv. Funct. Mater. 2023, 33, 2213407. [Google Scholar] [CrossRef]

- Zhao, J.; Shi, Y. Improving the Durability of Triboelectric Nanogenerator. In Handbook of Triboelectric Nanogenerators; Springer: New York, NY, USA, 2023; pp. 1–37. [Google Scholar] [CrossRef]

- Zhao, K.; Sun, W.; Zhang, X.; Meng, J.; Zhong, M.; Qiang, L.; Liu, M.J.; Gu, B.N.; Chung, C.C.; Liu, M.; et al. High-performance and long-cycle life of triboelectric nanogenerator using PVC/MoS2 composite membranes for wind energy scavenging application. Nano Energy 2022, 91, 106649. [Google Scholar] [CrossRef]

- Cao, V.A.; Lee, S.; Kim, M.; Alam, M.M.; Park, P.; Nah, J. Output power density enhancement of triboelectric nanogenerators via ferroelectric polymer composite interfacial layers. Nano Energy 2020, 67, 104300. [Google Scholar] [CrossRef]

- Zhang, J.H.; Hao, X. Enhancing output performances and output retention rates of triboelectric nanogenerators via a design of composite inner-layers with coupling effect and self-assembled outer-layers with superhydrophobicity. Nano Energy 2020, 76, 105074. [Google Scholar] [CrossRef]

- Li, W.; Leng, B.; Hu, S.; Cheng, X. Improving the Output Efficiency of Triboelectric Nanogenerator by a Power Regulation Circuit. Sensors 2023, 23, 4912. [Google Scholar] [CrossRef]

- Larsen, J. An introduction to electromagnetic induction in the ocean. Phys. Earth Planet. Inter. 1973, 7, 389–398. [Google Scholar] [CrossRef]

- Saslow, W.M. Chapter 12—Faraday’s Law of Electromagnetic Induction. In Electricity, Magnetism, and Light; Saslow, W.M., Ed.; Academic Press: Cambridge, MA, USA, 2002; pp. 505–558. [Google Scholar] [CrossRef]

- Arfken, G.B.; Griffing, D.F.; Kelly, D.C.; Priest, J. Chapter 34—Electro-Magnetic Induction. In University Physics; Arfken, G.B., Griffing, D.F., Kelly, D.C., Priest, J., Eds.; Academic Press: Cambridge, MA, USA, 1984; pp. 650–666. [Google Scholar] [CrossRef]

- MARION, J.B. 12—Electro-Magnetism. In Physics in the Modern World, 2nd ed.; Marion, J.B., Ed.; Academic Press: Cambridge, MA, USA, 1981; pp. 309–340. [Google Scholar] [CrossRef]

- Beeby, S.P.; O’Donnell, T. Electromagnetic Energy Harvesting. In Energy Harvesting Technologies; Priya, S., Inman, D.J., Eds.; Springer: New York, NY, USA, 2009; pp. 129–161. [Google Scholar] [CrossRef]

- Eslamlou, A.D.; Ghaderiaram, A.; Schlangen, E.; Fotouhi, M. A review on non-destructive evaluation of construction materials and structures using magnetic sensors. Constr. Build. Mater. 2023, 397, 132460. [Google Scholar] [CrossRef]

- Zărnescu, G.C.; Pîslaru-Dănescu, L.; Tiliakos, A. Modular Electromagnetic Transducer for Optimized Energy Transfer via Electric and/or Magnetic Fields. Sensors 2023, 23, 1291. [Google Scholar] [CrossRef]

- Park, J.; Morgenthal, G.; Kim, K.; Kwon, S.D.; Law, K. Power evaluation of flutter-based electromagnetic energy harvesters using computational fluid dynamics simulations. J. Intell. Mater. Syst. Struct. 2014, 25, 1800–1812. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, X.; Yin, P.; Tang, L.; Wu, H.; Peng, Y.; Luo, J.; Xie, S.; Pu, H.; Wang, D. Towards self-powered technique in underwater robots via a high-efficiency electromagnetic transducer with circularly abrupt magnetic flux density change. Appl. Energy 2021, 302, 117569. [Google Scholar] [CrossRef]

- Hendijanizadeh, M.; Sharkh, S.M.; Elliott, S.J.; Moshrefi-Torbati, M. Output power and efficiency of electromagnetic energy harvesting systems with constrained range of motion. Smart Mater. Struct. 2013, 22, 125009. [Google Scholar] [CrossRef]

- Stachurski, Z.H.; Wang, G.; Tan, X. Chapter 6—Magnetic properties of amorphous metallic alloys. In An Introduction to Metallic Glasses and Amorphous Metals; Stachurski, Z.H., Wang, G., Tan, X., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 157–192. [Google Scholar] [CrossRef]

- Kotnala, R.; Shah, J. Chapter 4—Ferrite Materials: Nano to Spintronics Regime. In Handbook of Magnetic Materials; Elsevier: Amsterdam, The Netherlands, 2015; pp. 291–379. [Google Scholar] [CrossRef]

- Rodriguez-Sotelo, D.; Rodriguez-Licea, M.A.; Soriano-Sanchez, A.G.; Espinosa-Calderon, A.; Perez-Pinal, F.J. Advanced Ferromagnetic Materials in Power Electronic Converters: A State of the Art. IEEE Access 2020, 8, 56238–56252. [Google Scholar] [CrossRef]

- Sarma, D. A new class of magnetic materials: Sr2FeMoO6 and related compounds. Curr. Opin. Solid State Mater. Sci. 2001, 5, 261–268. [Google Scholar] [CrossRef]

- McKenna, R.; Ostman, v.d. Leye, P.; Fichtner, W. Key challenges and prospects for large wind turbines. Renew. Sustain. Energy Rev. 2016, 53, 1212–1221. [Google Scholar] [CrossRef]

- Pfaffel, S.; Faulstich, S.; Rohrig, K. Performance and Reliability of Wind Turbines: A Review. Energies 2017, 10, 1904. [Google Scholar] [CrossRef]

- Galdo, M.L.; Barros, J.C.; García, J.O.; García, J.R.; Casanova, A.C. Introduction to Wind Turbines. In Encyclopedia of Renewable Energy, Sustainability and the Environment, 1st ed.; Rahimpour, M.R., Ed.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 331–342. [Google Scholar] [CrossRef]

- Toghyani, M.; Abedi, A.; Barahoei, M. Solar and Wind-Based Hybrid Technologies. In Encyclopedia of Renewable Energy, Sustainability and the Environment, 1st ed.; Rahimpour, M.R., Ed.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 241–262. [Google Scholar] [CrossRef]

- Fatahian, H.; Fatahian, E.; Mohamed-Kassim, Z. Wind Turbine Standards. In Encyclopedia of Renewable Energy, Sustainability and the Environment, 1st ed.; Rahimpour, M.R., Ed.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 427–436. [Google Scholar] [CrossRef]

- de Lima Andrade, A.; dos Santos, M.A. Hydroelectric plants environmental viability: Strategic environmental assessment application in Brazil. Renew. Sustain. Energy Rev. 2015, 52, 1413–1423. [Google Scholar] [CrossRef]

- Sun, Y.; Yang, Z.; Zhou, Z. Hydroelectric Power Plants: Current Design Principles, Impacts and Development Prospects. In Proceedings of the ICEBI ’21: Proceedings of the 2021 5th International Conference on E-Business and Internet, Singapore, 15–17 October 2021; pp. 46–55. [Google Scholar] [CrossRef]

- Pereira, G. Design of Hydroelectric Power Plants—Step by Step; CRC Press: London, UK, 2021. [Google Scholar] [CrossRef]

- Tkac, S. Hydro power plants, an overview of the current types and technology. Sel. Sci. Pap.—J. Civ. Eng. 2018, 13, 115–126. [Google Scholar] [CrossRef]

- Barros, C.P. Efficiency analysis of hydroelectric generating plants: A case study for Portugal. Energy Econ. 2008, 30, 59–75. [Google Scholar] [CrossRef]

- Gonzalez-Gonzalez, J.J.; Arenas-López, J.P.; Badaoui, M. Advancing towards zero emissions: Integrating floating photovoltaic systems in hydroelectric power plant reservoirs. Results Eng. 2024, 23, 102742. [Google Scholar] [CrossRef]

- Siddique, A.R.M.; Mahmud, S.; Heyst, B.V. A comprehensive review on vibration based micro power generators using electromagnetic and piezoelectric transducer mechanisms. Energy Convers. Manag. 2015, 106, 728–747. [Google Scholar] [CrossRef]

- Ahmad, M.M.; Khan, F.U. Review of vibration-based electromagnetic–piezoelectric hybrid energy harvesters. Int. J. Energy Res. 2021, 45, 5058–5097. [Google Scholar] [CrossRef]

- Gonsalez-Bueno, C.; Franco, V.; Brennan, M.; da Silva, S.; Lopes Junior, V. Energy harvesting using piezoelectric and electromagnetic transducers. In Proceedings of the 9th Brazilian Conference on Dynamics, Control and their Applications, Serra Negra, SP, Brazil, 7–11 June 2010. [Google Scholar]

- Delattre, G.; Vigne, S.; Brenes, A.; Garraud, N.; Freychet, O.; Boisseau, S. A new approach to design electromagnetic transducers for wideband electrically-tuned vibration energy harvesting. J. Intell. Mater. Syst. Struct. 2023, 34, 1314–1329. [Google Scholar] [CrossRef]

- Rahimi, A.; Zorlu, Ö.; Muhtaroğlu, A.; Külah, H. An electromagnetic energy harvesting system for low frequency applications with a passive interface ASIC in standard CMOS. Sensors Actuators A Phys. 2012, 188, 158–166. [Google Scholar] [CrossRef]

- Yang, L.; Wang, W.; Zhao, X.; Li, H.; Xiang, Y. Design and Optimization of High-Power and Low-Frequency Broadband Transducer with Giant Magnetostrictive Material. Sensors 2023, 23, 108. [Google Scholar] [CrossRef]

- Valamontes, A.; Vasilaki, E. Review and Improving the Low-Frequency Electromagnetic Active Inertial Sensor. Demokritos Sci. J. 2024. [Google Scholar] [CrossRef]

- Mansour, N.A.; Shin, B.; Ryu, B.; Kim, Y. Development of a Novel Miniaturized Electromagnetic Actuator for a Modular Serial Manipulator. Actuators 2021, 10, 14. [Google Scholar] [CrossRef]

- Halim, M.A.; Cho, H.; Salauddin, M.; Park, J.Y. A miniaturized electromagnetic vibration energy harvester using flux-guided magnet stacks for human-body-induced motion. Sens. Actuators A Phys. 2016, 249, 23–31. [Google Scholar] [CrossRef]

- Sun, H.; Urayama, R.; Uchimoto, T.; Takagi, T.; Hashimoto, M. Small electromagnetic acoustic transducer with an enhanced unique magnet configuration. NDT E Int. 2020, 110, 102205. [Google Scholar] [CrossRef]

- Sayed, E.T.; Olabi, A.G.; Alami, A.H.; Radwan, A.; Mdallal, A.; Rezk, A.; Abdelkareem, M.A. Renewable Energy and Energy Storage Systems. Energies 2023, 16, 1415. [Google Scholar] [CrossRef]

- Nikolaos, P.C.; Marios, F.; Dimitris, K. A Review of Pumped Hydro Storage Systems. Energies 2023, 16, 4516. [Google Scholar] [CrossRef]

- Borri, E.; Tafone, A.; Comodi, G.; Romagnoli, A.; Cabeza, L.F. Compressed Air Energy Storage—An Overview of Research Trends and Gaps through a Bibliometric Analysis. Energies 2022, 15, 7692. [Google Scholar] [CrossRef]

- Xu, K.; Guo, Y.; Lei, G.; Zhu, J. A Review of Flywheel Energy Storage System Technologies. Energies 2023, 16, 6462. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, L.; Shi, C.; Zhao, C. A Review of Gravity Energy Storage. Energies 2025, 18, 1812. [Google Scholar] [CrossRef]

- Detka, K.; Górecki, K. Selected Technologies of Electrochemical Energy Storage—A Review. Energies 2023, 16, 5034. [Google Scholar] [CrossRef]

- Jurczyk, M.; Spietz, T.; Czardybon, A.; Dobras, S.; Ignasiak, K.; Bartela, L.; Uchman, W.; Ochmann, J. Review of Thermal Energy Storage Materials for Application in Large-Scale Integrated Energy Systems—Methodology for Matching Heat Storage Solutions for Given Applications. Energies 2024, 17, 3544. [Google Scholar] [CrossRef]

- Wang, D.; Zhong, D.; Souri, A. Energy management solutions in the Internet of Things applications: Technical analysis and new research directions. Cogn. Syst. Res. 2021, 67, 33–49. [Google Scholar] [CrossRef]

- Malik, F.H.; Hussain, G.A.; Alsmadi, Y.M.S.; Haider, Z.M.; Mansoor, W.; Lehtonen, M. Integrating Energy Storage Technologies with Renewable Energy Sources: A Pathway Toward Sustainable Power Grids. Sustainability 2025, 17, 4097. [Google Scholar] [CrossRef]

- Rafy, M.F.; Boateng, E.O.; Krishnan, V.V.G.; Srivastava, A.K. Cyber-Resilient IoT-Based Battery Energy Storage Systems in Power Distribution System. IEEE Trans. Ind. Appl. 2025, 61, 4566–4577. [Google Scholar] [CrossRef]

- Poyyamozhi, M.; Murugesan, B.; Rajamanickam, N.; Shorfuzzaman, M.; Aboelmagd, Y. IoT—A Promising Solution to Energy Management in Smart Buildings: A Systematic Review, Applications, Barriers, and Future Scope. Buildings 2024, 14, 3446. [Google Scholar] [CrossRef]

- Chochul, M.; Ševčík, P. A Survey of Low Power Wide Area Network Technologies. In Proceedings of the 2020 18th International Conference on Emerging eLearning Technologies and Applications (ICETA), Košice, Slovakia, 12–13 November 2020; pp. 69–73. [Google Scholar] [CrossRef]

- Hodoň, M.; Chovanec, M.; Čechovič, L.; Húdik, M.; Milanová, J.; Kochláň, M.; Jurečka, M.; Kapitulík, J.; Ševčík, P. Maximizing performance of low-power WSN node on the basis of event-driven-programming approach: Minimization of operational energy costs of WSN node control unit. In Proceedings of the 2015 IEEE Symposium on Computers and Communication (ISCC), Larnaca, Cyprus, 6–9 July 2015; pp. 204–209. [Google Scholar] [CrossRef]

- Hodon, M.; Šarafín, P.; Ševčík, P. Monitoring and recognition of bird population in protected bird territory. In Proceedings of the 2015 IEEE Symposium on Computers and Communication (ISCC), Larnaca, Cyprus, 6–9 July 2015; pp. 198–203. [Google Scholar] [CrossRef]

- Formanek, L.; Karpis, O.; Olešnaníková, V. Reducing number of nodes in WSN with neural network usage. In Proceedings of the 2020 Fourth International Conference on Intelligent Computing in Data Sciences (ICDS), Fez, Morocco, 21–23 October 2020; pp. 1–4. [Google Scholar]

- Ševčík, P.; Žák, S.; Hodoň, M. Wireless sensor network for smart power metering. Concurr. Comput. Pract. Exp. 2017, 29, e4247. [Google Scholar] [CrossRef]

- Karpiš, O.; Olešnaníková, V.; Formanek, L.; Hodoň, M.; Čechovič, L.; Šarafín, P.; Ševčík, P. Compressed sensing–A way to spare energy in WSN for UAV. In Proceedings of the 17th IFAC Conference on Programmable Devices and Embedded Systems PDES 2022, Sarajevo, Bosnia and Herzegovina, 17–19 May 2022; Volume 55, pp. 170–176. [Google Scholar] [CrossRef]

| Energy Source | Renewable | Main Input Energy | Efficiency [%] | Power Density | Enviromental Impact | Applications |

|---|---|---|---|---|---|---|

| Fossil fuels | No | Chemical reaction of combustion | 30–50 | High | High (CO2, pollution) | Fossil fuel power plants, combustion engines |

| Nuclear | No | Nuclear fission reaction | 33–37 | High | Nowadays Low-Medium (radioactive waste) | Nuclear power plants |

| Photovoltaic | Yes | Photovoltaic energy | 6–41 | 60–200 W/m2 | Low (toxic if mishandled) | Solar panels, farms |

| Piezoelectric | Yes | Mechanical stress | 60–80 | 10–1000 W/m2 | Low–Medium | Wearables, roads, lighters |

| Thermoelectric | Yes | Thermal gradient | 5–6 | 0.1–5 W/m2 | Low–Medium | Waste heat, sensors |

| Triboelectric | Yes | Mechanical motion | 70–85 | 100–11,130 W/m2 | Low–Medium | Wearables, sensors, buoys |

| Electromagnetic | Yes | Magnetic induction | Variable | Variable | Low | Generators, sensors |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sevcik, P.; Sumsky, J.; Baca, T.; Tupy, A. Self-Sustaining Operations with Energy Harvesting Systems. Energies 2025, 18, 4467. https://doi.org/10.3390/en18174467

Sevcik P, Sumsky J, Baca T, Tupy A. Self-Sustaining Operations with Energy Harvesting Systems. Energies. 2025; 18(17):4467. https://doi.org/10.3390/en18174467

Chicago/Turabian StyleSevcik, Peter, Jan Sumsky, Tomas Baca, and Andrej Tupy. 2025. "Self-Sustaining Operations with Energy Harvesting Systems" Energies 18, no. 17: 4467. https://doi.org/10.3390/en18174467

APA StyleSevcik, P., Sumsky, J., Baca, T., & Tupy, A. (2025). Self-Sustaining Operations with Energy Harvesting Systems. Energies, 18(17), 4467. https://doi.org/10.3390/en18174467