Gasification Processes of Portuguese Biomass: Theoretical Analysis of Hydrogen Production Potential

Abstract

1. Introduction

2. Literature Review

2.1. Biomass Gasification Fundamentals

2.2. Hydrogen Production from Biomass Gasification

2.3. Portuguese Biomass Resources

2.4. Biomass Characterization for Gasification

2.5. Research Gaps in Biomass Gasification for Hydrogen Production in Portugal

3. Materials and Methods

3.1. Biomass Sample Collection and Preparation

3.2. Characterization Methods

3.3. Theoretical Calculations

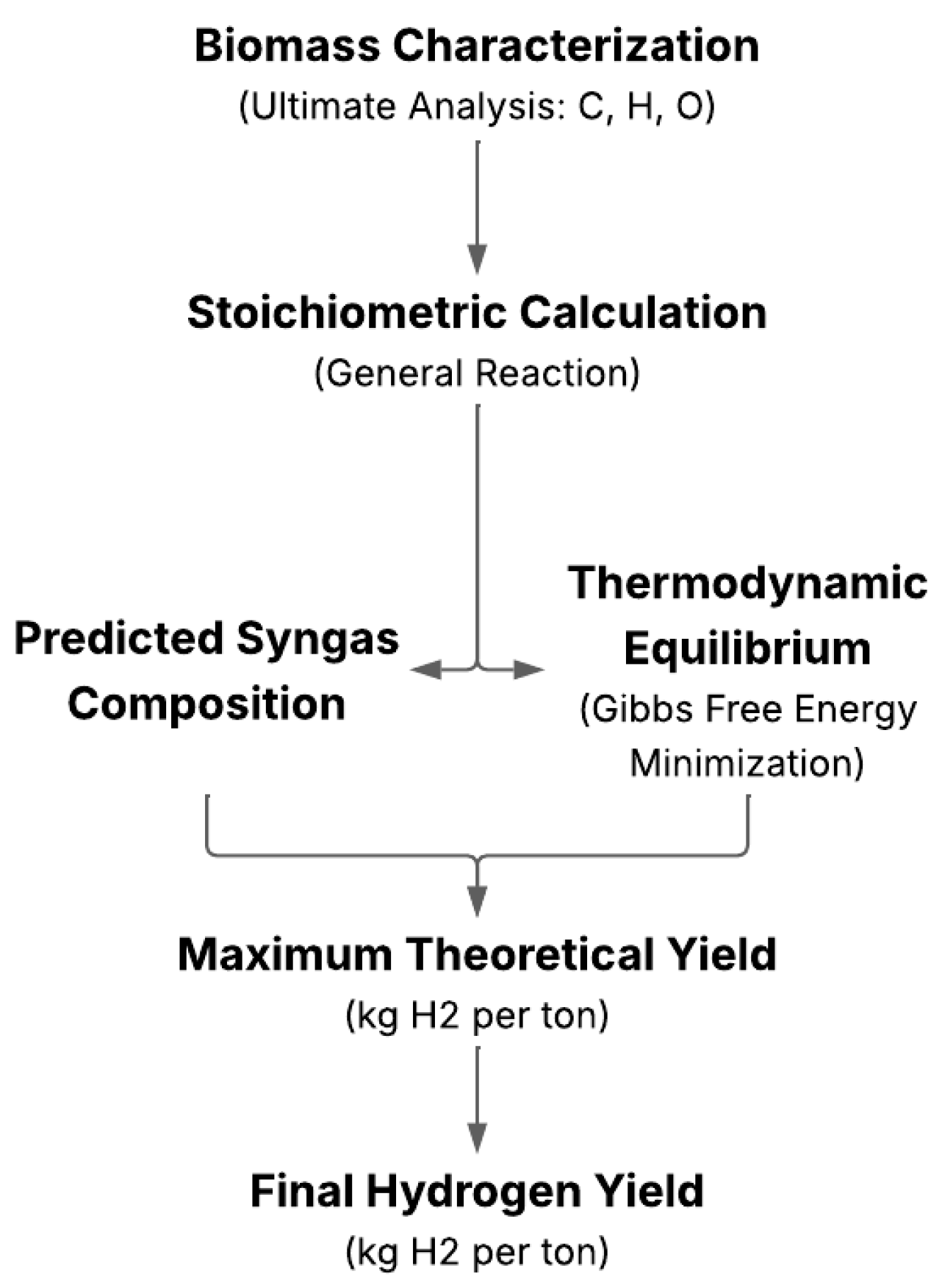

4. Results and Discussion

4.1. Biomass Characterization Results

4.2. Ultimate Analysis and Heating Values

4.3. Metal Content Analysis and Ash Composition

4.4. Theoretical Hydrogen Production Potential

4.5. Model Validation

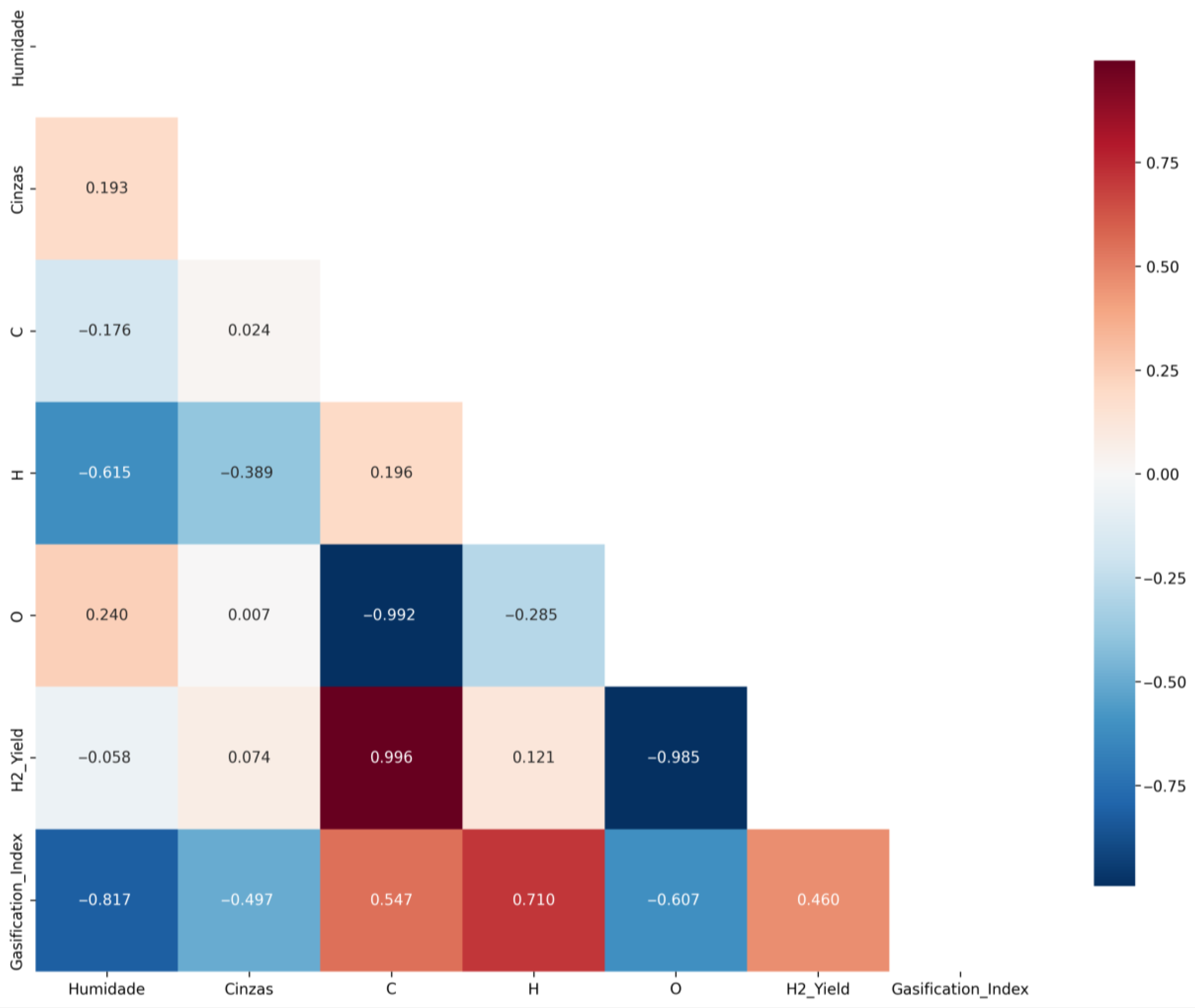

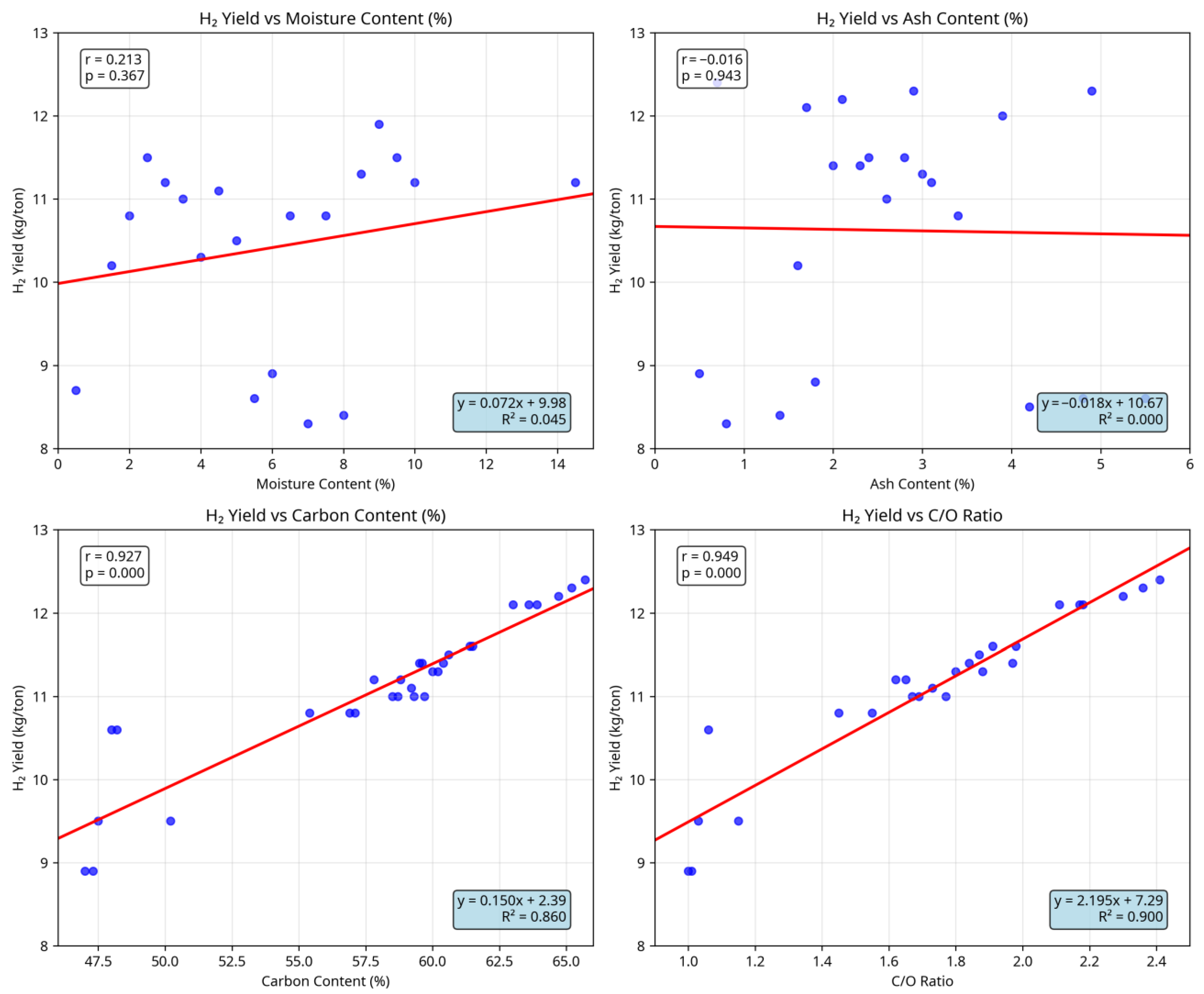

4.6. Statistical Analysis and Species Grouping

4.7. Comparison with International Biomass Types

4.8. Regional Distribution and Availability Assessment

5. Hydrogen Production Potential

5.1. National Biomass Resource Assessment

5.2. Regional Production Capacity Analysis

5.3. Economic and Environmental Implications

5.4. Integration with Renewable Energy Systems

5.5. Sensitivity Analysis

- Low Scenario (40–50% realization): Accounts for significant logistical barriers and conservative sustainability restrictions. Potential hydrogen production: 32,000–47,500 tons annually.

- Medium Scenario (50–60% realization): Represents moderate improvements in collection efficiency through better infrastructure and management practices. Potential hydrogen production: 40,000–57,000 tons annually.

- High Scenario (60–70% realization): Assumes optimized supply chains, technological advancements in harvesting, and strong policy incentives. Potential hydrogen production: 48,000–66,500 tons annually.

5.6. Comparative Life Cycle Assessment with Alternative Pathways

6. Future Directions and Recommendations

6.1. Research and Development Priorities

6.2. Policy and Regulatory Recommendations

6.3. Infrastructure Development Needs

6.4. International Collaboration Opportunities

6.5. Limitations of the Study

7. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dincer, I.; Aydin, M.I. New paradigms in sustainable energy systems with hydrogen. Energy Convers. Manag. 2023, 283, 116950. [Google Scholar] [CrossRef]

- Teixeira, B.; Brito, M.C.; Mateus, A. Strategic raw material requirements for large-scale hydrogen production in Portugal and European Union. Energy Rep. 2024, 12, 5133–5144. [Google Scholar] [CrossRef]

- Alptekin, F.M.; Celiktas, M.S. Review on catalytic biomass gasification for hydrogen production as a sustainable energy form and social, technological, economic, environmental, and political analysis of catalysts. ACS Omega 2022, 7, 24918–24941. [Google Scholar] [CrossRef]

- Barreiro, S.; Ferreira, P.G.; Azevedo, A.; Tomppo, E. 28.1 Development of Portugal’s National Forest Inventory. In National Forest Inventories; Springer Science Business Media B.V.: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Bełdycka-Bórawska, A.; Silva, J. Forest management in Portugal. Sj-Econ. Sci. J. 2024, 53, 2–10. [Google Scholar] [CrossRef]

- Abreu, M.; Reis, A.; Moura, P.; Fernando, A.L.; Luís, A.; Quental, L.; Patinha, P.; Gírio, F. Evaluation of the Potential of Biomass to Energy in Portugal—Conclusions from the CONVERTE Project. Energies 2020, 13, 937. [Google Scholar] [CrossRef]

- Abreu, M.; Reis, A.; Moura, P.; Fernando, A.L.; Luís, A.; Quental, L.; Patinha, P.; Gírio, F. Energies MDPI. In Proceedings of the Selected Papers from 27th European Biomass Conference & Exhibition (EUBCE 2019), Lisbon, Portugal, 27–30 May 2019; p. 27. [Google Scholar]

- Crujeira, A.T.; Trancoso, M.A.; Eusébio, A.; Oliveira, A.C.; Passarinho, P.C.; Abreu, M.; Marques, I.P.; Marques, P.A.; Marques, S.; Albergaria, H. Admissibility Grid to Support the Decision for the Preferential Routing of Portuguese Endogenous Waste Biomass for the Production of Biogas, Advanced Biofuels, Electricity and Heat. Biomass 2023, 3, 336–366. [Google Scholar] [CrossRef]

- Alves, C.T.; Onwudili, J.A.; Ghorbannezhad, P.; Kumagai, S. A review of the thermochemistries of biomass gasification and utilisation of gas products. Sustain. Energy Fuels 2023, 7, 3505–3540. [Google Scholar] [CrossRef]

- Demirbaş, A. Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Convers. Manag. 2001, 42, 1357–1378. [Google Scholar] [CrossRef]

- Thijs, B.; Houlleberghs, M.; Hollevoet, L.; Heremans, G.; Rongé, J.; Martens, J.A. Hydrogen, fueling the future: Introduction to hydrogen production and storage techniques. In Hydrogen Production, Storage and Utilization; De Gruyter Brill: Berlin/Heidelberg, Germany, 2021; Volume 2, pp. 159–194. [Google Scholar]

- Rajasekhar Reddy, B.; Vinu, R. Feedstock characterization for pyrolysis and gasification. In Coal and Biomass Gasification: Recent Advances and Future Challenges; Springer: Berlin/Heidelberg, Germany, 2017; pp. 3–36. [Google Scholar]

- Sharma, G.; Dewangan, A.K.; Yadav, A.K.; Ahmad, A. Feasibility of waste-to-hydrogen generation system based on gasification/pyrolysis: A comprehensive review of experimental studies. J. Therm. Anal. Calorim. 2024, 149, 13629–13651. [Google Scholar] [CrossRef]

- Tuluhong, A.; Chang, Q.; Xie, L.; Xu, Z.; Song, T. Current Status of Green Hydrogen Production Technology: A Review. Sustainability 2024, 16, 9070. [Google Scholar] [CrossRef]

- Makepa, D.C.; Chihobo, C.H. Sustainable pathways for biomass production and utilization in carbon capture and storage—A review. Biomass Convers. Biorefin. 2025, 15, 11397–11419. [Google Scholar] [CrossRef]

- Nunes, L.J.; Raposo, M.A.; Meireles, C.I.; Gomes, C.J.P.; Ribeiro, N.M.A. Energy recovery of shrub species as a path to reduce the risk of occurrence of rural fires: A case study in serra da estrela natural park (portugal). Fire 2021, 4, 33. [Google Scholar] [CrossRef]

- Domingos, T.; Kalapodis, N.; Sakkas, G.; Chandramouli, K.; Gama, I.; Proença, V.; Ribeiro, I.; Pio, M. Advancing Integrated Fire Management and Closer-to-Nature Forest Management: A Holistic Approach to Wildfire Risk Reduction and Ecosystem Resilience in Quinta da França, Portugal. Forests 2025, 16, 1306. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, C.C.; Champagne, P. Overview of recent advances in thermo-chemical conversion of biomass. Energy Convers. Manag. 2010, 51, 969–982. [Google Scholar] [CrossRef]

- Wang, X.; Chen, H.; Luo, K.; Shao, J.; Yang, H. The influence of microwave drying on biomass pyrolysis. Energy Fuels 2008, 22, 67–74. [Google Scholar] [CrossRef]

- Mahamulkar, S.; Yin, K.; Agrawal, P.K.; Davis, R.J.; Jones, C.W.; Malek, A.; Shibata, H. Formation and oxidation/gasification of carbonaceous deposits: A review. Ind. Eng. Chem. Res. 2016, 55, 9760–9818. [Google Scholar] [CrossRef]

- Haghighi, M.; Sun, Z.-q.; Wu, J.-h.; Bromly, J.; Wee, H.L.; Ng, E.; Wang, Y.; Zhang, D.-k. On the reaction mechanism of CO2 reforming of methane over a bed of coal char. Proc. Combust. Inst. 2007, 31, 1983–1990. [Google Scholar] [CrossRef]

- Snoeck, J.-W.; Froment, G.; Fowles, M. Steam/CO2 reforming of methane. Carbon filament formation by the Boudouard reaction and gasification by CO2, by H2, and by steam: Kinetic study. Ind. Eng. Chem. Res. 2002, 41, 4252–4265. [Google Scholar] [CrossRef]

- Pen, M.; Gomez, J.; Fierro, J.G. New catalytic routes for syngas and hydrogen production. Appl. Catal. A Gen. 1996, 144, 7–57. [Google Scholar] [CrossRef]

- Kuttin, K.W.; Kuttin, A.W.; Salem, A.M.; Wang, Y.; Ding, L. Spatial comprehensive comparative analysis of updraft and downdraft fixed bed gasification reactors by computational fluid dynamics approach with industrial data validation. Appl. Energy 2025, 400, 126612. [Google Scholar] [CrossRef]

- Gómez-Barea, A.; Ollero, P.; Leckner, B. Optimization of char and tar conversion in fluidized bed biomass gasifiers. Fuel 2013, 103, 42–52. [Google Scholar] [CrossRef]

- Henrich, E.; Weirich, F. Pressurized entrained flow gasifiers for biomass. Environ. Eng. Sci. 2004, 21, 53–64. [Google Scholar] [CrossRef]

- Couto, N.; Rouboa, A.; Silva, V.; Monteiro, E.; Bouziane, K. Influence of the biomass gasification processes on the final composition of syngas. Energy Procedia 2013, 36, 596–606. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, Q.; Du, J.; Chen, J. Oxygen-enriched air gasification of biomass materials for high-quality syngas production. Energy Convers. Manag. 2019, 199, 111628. [Google Scholar] [CrossRef]

- Babatabar, M.A.; Saidi, M. Hydrogen production via integrated configuration of steam gasification process of biomass and water-gas shift reaction: Process simulation and optimization. Int. J. Energy Res. 2021, 45, 19378–19394. [Google Scholar] [CrossRef]

- Lang, C.; Sécordel, X.; Kiennemann, A.; Courson, C. Water gas shift catalysts for hydrogen production from biomass steam gasification. Fuel Process. Technol. 2017, 156, 246–252. [Google Scholar] [CrossRef]

- Pathania, A.; Pathania, A.R. Animal Wastes: Fundamentals, Classification, Properties, and Applications. In Biomass Wastes for Sustainable Industrial Applications; CRC Press: Boca Raton, FL, USA, 2025; pp. 140–183. [Google Scholar]

- Wang, F.; Zhang, Y.; Zeng, X.; Yue, J.; Zhang, G.; Hu, D.; Adamu, M.H.; Lai, X.; Xu, G. Insight into tar thermal cracking and catalytic cracking by char: Characteristics and kinetics. Fuel 2022, 326, 124929. [Google Scholar] [CrossRef]

- Nemmour, A.; Inayat, A.; Janajreh, I.; Ghenai, C. New performance correlations of municipal solid waste gasification for sustainable syngas fuel production. Biomass Convers. Biorefin. 2022, 12, 4271–4289. [Google Scholar] [CrossRef]

- Khan, M.J.; Al-attab, K.A. Steam gasification of biomass for hydrogen production—A review and outlook. J. Adv. Res. Fluid. Mech. Therm. Sci. 2022, 98, 175–204. [Google Scholar] [CrossRef]

- Dziva, G.; Cheng, Q.; Liu, K.; Zeng, L. Hydrogen production through two-stage sorption-enhanced biomass gasification: Process design and thermodynamic analysis. Int. J. Hydrogen Energy 2023, 48, 38602–38616. [Google Scholar] [CrossRef]

- Castro, J.; Leaver, J.; Pang, S. Simulation and techno-economic assessment of hydrogen production from biomass gasification-based processes: A review. Energies 2022, 15, 8455. [Google Scholar] [CrossRef]

- Ebrahimi, P.; Kumar, A.; Khraisheh, M. A review of recent advances in water-gas shift catalysis for hydrogen production. Emergent Mater. 2020, 3, 881–917. [Google Scholar] [CrossRef]

- Ladebeck, J.; Wagner, J. Catalyst development for water-gas shift. In Handbook of Fuel Cells-Fundamentals, Technology and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2003; Volume 3, pp. 190–201. [Google Scholar]

- Chen, W.-H.; Lin, M.-R.; Jiang, T.L.; Chen, M.-H. Modeling and simulation of hydrogen generation from high-temperature and low-temperature water gas shift reactions. Int. J. Hydrogen Energy 2008, 33, 6644–6656. [Google Scholar] [CrossRef]

- Hofbauer, H.; Rauch, R. Biomass to liquid (BtL). In Energy from Organic Materials (Biomass); Springer: Berlin/Heidelberg, Germany, 2019; pp. 1047–1063. [Google Scholar]

- Peng, W.; Wang, L.; Mirzaee, M.; Ahmadi, H.; Esfahani, M.; Fremaux, S. Hydrogen and syngas production by catalytic biomass gasification. Energy Convers. Manag. 2017, 135, 270–273. [Google Scholar] [CrossRef]

- Teixeira, P.; Bacariza, C.; Correia, P.; Pinheiro, C.; Cabrita, I. Hydrogen Production with In Situ CO2 Capture at High and Medium Temperatures Using Solid Sorbents. Energies 2022, 15, 4039. [Google Scholar] [CrossRef]

- Guan, G.; Hao, X.; Abudula, A. Heterogeneous catalysts from natural sources for tar removal: A mini review. J. Adv. Catal. Sci. Technol. 2014, 1, 20–28. [Google Scholar] [CrossRef]

- Hughes, A.E.; Haque, N.; Northey, S.A.; Giddey, S. Platinum group metals: A review of resources, production and usage with a focus on catalysts. Resources 2021, 10, 93. [Google Scholar] [CrossRef]

- Shayan, E.; Zare, V.; Mirzaee, I. Hydrogen production from biomass gasification; a theoretical comparison of using different gasification agents. Energy Convers. Manag. 2018, 159, 30–41. [Google Scholar] [CrossRef]

- Kalinci, Y.; Hepbasli, A.; Dincer, I. Biomass-based hydrogen production: A review and analysis. Int. J. Hydrogen Energy 2009, 34, 8799–8817. [Google Scholar] [CrossRef]

- Kan, T.; Strezov, V. Hydrogen production from biomass. In Renewable Energy Systems from Biomass; CRC Press: Boca Raton, FL, USA, 2018; pp. 207–224. [Google Scholar]

- Abuadala, A.; Dincer, I. A review on biomass-based hydrogen production and potential applications. Int. J. Energy Res. 2012, 36, 415–455. [Google Scholar] [CrossRef]

- de Jong, W. Sustainable hydrogen production by thermochemical biomass processing. In Hydrogen Fuel; CRC Press: Boca Raton, FL, USA, 2008; pp. 197–238. [Google Scholar]

- Mohanty, P.; Pant, K.K.; Mittal, R. Hydrogen generation from biomass materials: Challenges and opportunities. In Advances in Bioenergy: The Sustainability Challenge; John Wiley & Sons: Hoboken, NJ, USA, 2016; pp. 93–108. [Google Scholar]

- Tavares Borges, P.; Silva Lora, E.E.; Venturini, O.J.; Errera, M.R.; Yepes Maya, D.M.; Makarfi Isa, Y.; Kozlov, A.; Zhang, S. A comprehensive technical, environmental, economic, and bibliometric assessment of hydrogen production through biomass gasification, including global and brazilian potentials. Sustainability 2024, 16, 9213. [Google Scholar] [CrossRef]

- Chen, D.; He, L. Towards an efficient hydrogen production from biomass: A review of processes and materials. Chem. Cat Chem. 2011, 3, 490–511. [Google Scholar] [CrossRef]

- Demirbas, A.; Arin, G. Hydrogen from biomass via pyrolysis: Relationships between yield of hydrogen and temperature. Energy Sources 2004, 26, 1061–1069. [Google Scholar] [CrossRef]

- Akulinin, E.I.; Golubyatnikov, O.O.; Dvoretsky, S.I. Pressure swing adsorption for recovery hydrogen, oxygen and nitrogen from gas mixtures: Mathematical modeling, optimization and units design. Izv. Vyss. Uchebnykh Zaved. Khimiya Khimicheskaya Tekhnologiya 2021, 64, 8–29. [Google Scholar] [CrossRef]

- Al-Mufachi, N.; Rees, N.; Steinberger-Wilkens, R. Hydrogen selective membranes: A review of palladium-based dense metal membranes. Renew. Sustain. Energy Rev. 2015, 47, 540–551. [Google Scholar] [CrossRef]

- Naquash, A.; Qyyum, M.A.; Chaniago, Y.D.; Riaz, A.; Yehia, F.; Lim, H.; Lee, M. Separation and purification of syngas-derived hydrogen: A comparative evaluation of membrane-and cryogenic-assisted approaches. Chemosphere 2023, 313, 137420. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, S.; Monteiro, E.; Brito, P.; Vilarinho, C. Biomass resources in Portugal: Current status and prospects. Renew. Sustain. Energy Rev. 2017, 78, 1221–1235. [Google Scholar] [CrossRef]

- Ribeiro, A.P.; Bertani, R.; Mozzon, M.; Sgarbossa, P.; Conte, P. Bioenergy in Portugal. In Synthesis and Applications in Chemistry and Materials: Volume 14: Biomass and Waste Valorisation, Functional Materials, Energy Conversion and Supercritical Systems; World Scientific: Singapore, 2024; pp. 3–62. [Google Scholar]

- Nunes, L.; Álvarez-González, J.; Alberdi, I.; Silva, V.; Rocha, M.; Rego, F.C. Analysis of the occurrence of wildfires in the Iberian Peninsula based on harmonised data from national forest inventories. Ann. For. Sci. 2019, 76, 27. [Google Scholar] [CrossRef]

- da Costa, T.P.; Quinteiro, P.; Arroja, L.; Dias, A.C. Environmental comparison of forest biomass residues application in Portugal: Electricity, heat and biofuel. Renew. Sustain. Energy Rev. 2020, 134, 110302. [Google Scholar] [CrossRef]

- Fernandes, U.; Costa, M. Potential of biomass residues for energy production and utilization in a region of Portugal. Biomass Bioenergy 2010, 34, 661–666. [Google Scholar] [CrossRef]

- Simões, C.L.; Simoes, R.; Gonçalves, A.S.; Nunes, L.J. Environmental analysis of the valorization of Woody biomass residues: A comparative study with vine pruning leftovers in Portugal. Sustainability 2023, 15, 14950. [Google Scholar] [CrossRef]

- Nunes, L.; Moreno, M.; Alberdi, I.; Álvarez-González, J.G.; Godinho-Ferreira, P.; Mazzoleni, S.; Castro Rego, F. Harmonized classification of forest types in the Iberian Peninsula based on national forest inventories. Forests 2020, 11, 1170. [Google Scholar] [CrossRef]

- Viana, H.; Cohen, W.B.; Lopes, D.; Aranha, J. Assessment of forest biomass for use as energy. GIS-based analysis of geographical availability and locations of wood-fired power plants in Portugal. Appl. Energy 2010, 87, 2551–2560. [Google Scholar] [CrossRef]

- Portugal-Pereira, J.; Carvalho, F.; Rathmann, R.; Szklo, A.; Rochedo, P.; Schaeffer, R. The potential of biomass. In Handbook on the Geopolitics of the Energy Transition; Edward Elgar Publishing: Cheltenham, UK; Northampton, MA, USA, 2023; pp. 334–350. [Google Scholar]

- Viegas, M.; Batista, P.; Cordovil, F. The portuguese forest and the common agricultural policy. Landsc. Ecol. 2023, 38, 3637–3656. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Meireles, C.I.R.; Pinto Gomes, C.J.; de Almeida Ribeiro, N.M.C. Socioeconomic aspects of the forests in Portugal: Recent evolution and perspectives of sustainability of the resource. Forests 2019, 10, 361. [Google Scholar] [CrossRef]

- Casau, M.; Dias, M.F.; Matias, J.C.; Nunes, L.J. Residual biomass: A comprehensive review on the importance, uses and potential in a circular bioeconomy approach. Resources 2022, 11, 35. [Google Scholar] [CrossRef]

- Batra, G. Renewable energy economics: Achieving harmony between environmental protection and economic goals. Soc. Sci. Chron. 2023, 2, 1–32. [Google Scholar] [CrossRef]

- Abreu, M.; Reis, A.; Fernando, A.L. Marginal soils for bioenergy production—How to identify these soils in Portugal? In WASTES: Solutions, Treatments and Opportunities IV; CRC Press: Boca Raton, FL, USA, 2023; pp. 368–373. [Google Scholar]

- Iglesias, M.C.; Hermoso, V.; Azevedo, J.C.; Campos, J.C.; Salgado-Rojas, J.; Sil, Â.; Regos, A. Integrating multiple landscape management strategies to optimise conservation under climate and planning scenarios: A case study in the Iberian Peninsula. Ecosyst. Serv. 2025, 74, 101742. [Google Scholar] [CrossRef]

- Carvalho-Ribeiro, S.; Lovett, A.; O’Riordan, T. Multifunctional forest management in Northern Portugal: Moving from scenarios to governance for sustainable development. Land Use Policy 2010, 27, 1111–1122. [Google Scholar] [CrossRef]

- Valente, S.; Coelho, C.; Ribeiro, C.; Marsh, G. Sustainable Forest Management in Portugal: Transition from global policies to local participatory strategies. Int. For. Rev. 2015, 17, 368–383. [Google Scholar] [CrossRef]

- Cai, J.; He, Y.; Yu, X.; Banks, S.W.; Yang, Y.; Zhang, X.; Yu, Y.; Liu, R.; Bridgwater, A.V. Review of physicochemical properties and analytical characterization of lignocellulosic biomass. Renew. Sustain. Energy Rev. 2017, 76, 309–322. [Google Scholar] [CrossRef]

- Teh, J.S.; Teoh, Y.H.; How, H.G.; Sher, F. Thermal analysis technologies for biomass feedstocks: A state-of-the-art review. Processes 2021, 9, 1610. [Google Scholar] [CrossRef]

- McPhail, A.; Griffin, R.; El-Halwagi, M.; Medlock, K.; Alvarez, P.J. Environmental, economic, and energy assessment of the ultimate analysis and moisture content of municipal solid waste in a parallel co-combustion process. Energy Fuels 2014, 28, 1453–1462. [Google Scholar] [CrossRef]

- Dong, J.; Chi, Y.; Tang, Y.; Ni, M.; Nzihou, A.; Weiss-Hortala, E.; Huang, Q. Effect of operating parameters and moisture content on municipal solid waste pyrolysis and gasification. Energy Fuels 2016, 30, 3994–4001. [Google Scholar] [CrossRef]

- Bailis, R.; Berrueta, V.; Chengappa, C.; Dutta, K.; Edwards, R.; Masera, O.; Still, D.; Smith, K.R. Performance testing for monitoring improved biomass stove interventions: Experiences of the Household Energy and Health Project. Energy Sustain. Dev. 2007, 11, 57–70. [Google Scholar] [CrossRef]

- Chuayboon, S.; Abanades, S.; Rodat, S. Insights into the influence of biomass feedstock type, particle size and feeding rate on thermochemical performances of a continuous solar gasification reactor. Renew. Energy 2019, 130, 360–370. [Google Scholar] [CrossRef]

- Sirous, R.; da Silva, F.J.N.; da Cruz Tarelho, L.A.; Martins, N.A.D. Mixed biomass pelleting potential for Portugal, step forward to circular use of biomass residues. Energy Rep. 2020, 6, 940–945. [Google Scholar] [CrossRef]

- Nunes, L.; Matias, J.; Catalão, J. Biomass in the generation of electricity in Portugal: A review. Renew. Sustain. Energy Rev. 2017, 71, 373–378. [Google Scholar] [CrossRef]

- Yao, X.; Zhao, Z.; Xu, K.; Zhou, H. Determination of ash forming characteristics and fouling/slagging behaviours during gasification of masson pine in a fixed-bed gasifier. Renew. Energy 2020, 160, 1420–1430. [Google Scholar] [CrossRef]

- Ahmad, A.A.; Zawawi, N.A.; Kasim, F.H.; Inayat, A.; Khasri, A. Assessing the gasification performance of biomass: A review on biomass gasification process conditions, optimization and economic evaluation. Renew. Sustain. Energy Rev. 2016, 53, 1333–1347. [Google Scholar] [CrossRef]

- Mlonka-Mędrala, A.; Magdziarz, A.; Gajek, M.; Nowińska, K.; Nowak, W. Alkali metals association in biomass and their impact on ash melting behaviour. Fuel 2020, 261, 116421. [Google Scholar] [CrossRef]

- He, Z.-M.; Cao, J.-P.; Zhao, X.-Y. Review of biomass agglomeration for fluidized-bed gasification or combustion processes with a focus on the effect of alkali salts. Energy Fuels 2022, 36, 8925–8947. [Google Scholar] [CrossRef]

- Nunes, L.J.; Casau, M.; Matias, J.C.; Ferreira Dias, M. Characterization of Portuguese woody biomass: Alignment with the ENPlus® standard for the certification of wood pellets. Biofuels 2024, 15, 259–270. [Google Scholar] [CrossRef]

- Li, C.-Z. Importance of volatile–char interactions during the pyrolysis and gasification of low-rank fuels–a review. Fuel 2013, 112, 609–623. [Google Scholar] [CrossRef]

- Han, J.; Kim, H. The reduction and control technology of tar during biomass gasification/pyrolysis: An overview. Renew. Sustain. Energy Rev. 2008, 12, 397–416. [Google Scholar] [CrossRef]

- Thakur, A.; Kumar, A.; Somya, A. Forestry and Agricultural Residues-Based Wastes: Fundamentals, Classification, Properties, and Applications. In Biomass Wastes for Sustainable Industrial Applications; CRC Press: Boca Raton, FL, USA, 2025; pp. 95–139. [Google Scholar]

- Li, Y.; Wang, Z.; He, Z.; Luo, S.; Su, D.; Jiang, H.; Zhou, H.; Xu, Q. Effects of temperature, hydrogen/carbon monoxide ratio and trace element addition on methane production performance from syngas biomethanation. Bioresour. Technol. 2020, 295, 122296. [Google Scholar] [CrossRef] [PubMed]

- Katyal, S.; Thambimuthu, K.; Valix, M. Carbonisation of bagasse in a fixed bed reactor: Influence of process variables on char yield and characteristics. Renew. Energy 2003, 28, 713–725. [Google Scholar] [CrossRef]

- Phang, F.J.F.; Soha, M.; Khaerudini, D.S.; Timuda, G.E.; Chew, J.J.; How, B.S.; Loh, S.K.; Yusup, S.; Sunarso, J. Catalytic wet torrefaction of lignocellulosic biomass: An overview with emphasis on fuel application. S. Afr. J. Chem. Eng. 2023, 43, 162–189. [Google Scholar] [CrossRef]

- Tomlin, A.S. Air quality and climate impacts of biomass use as an energy source: A review. Energy Fuels 2021, 35, 14213–14240. [Google Scholar] [CrossRef]

- Tian, H.; Wei, Y.; Cheng, S.; Huang, Z.; Qing, M.; Chen, Y.; Yang, H.; Yang, Y. Optimizing the gasification reactivity of biochar: The composition, structure and kinetics of biochar derived from biomass lignocellulosic components and their interactions during gasification process. Fuel 2022, 324, 124709. [Google Scholar] [CrossRef]

- Maksimuk, Y.; Antonava, Z.; Krouk, V.; Korsakova, A.; Kursevich, V. Prediction of higher heating value (HHV) based on the structural composition for biomass. Fuel 2021, 299, 120860. [Google Scholar] [CrossRef]

- Nunes, L.J.; Casau, M.; Dias, M.F.; Matias, J.; Teixeira, L.C. Agroforest woody residual biomass-to-energy supply chain analysis: Feasible and sustainable renewable resource exploitation for an alternative to fossil fuels. Results Eng. 2023, 17, 101010. [Google Scholar] [CrossRef]

- Volchyn, I.; Haponych, L.; Mokretskyy, V. Estimation and Forecasting of Carbon Dioxide Emissions from Coal-Fired Thermal Power Plants in Ukraine. In Natsional’nyi Hirnychyi Universytet. Naukovyi Visnyk; 2022; pp. 80–88. Available online: https://www.researchgate.net/publication/364982360_Estimation_and_forecasting_of_carbon_dioxide_emissions_from_coal-fired_thermal_power_plants_in_Ukraine (accessed on 18 August 2025).

- Adegoke, I.; Ige, A.; Adejoba, O.; Aruwajoye, D.; James, J. Roles of biomass in the absorption of heavy metals. Eur. J. Energy Res. 2022, 2, 9–13. [Google Scholar] [CrossRef]

- Lin, F.; Xu, M.; Ramasamy, K.K.; Li, Z.; Klinger, J.L.; Schaidle, J.A.; Wang, H. Catalyst deactivation and its mitigation during catalytic conversions of biomass. ACS Catal. 2022, 12, 13555–13599. [Google Scholar] [CrossRef]

- Cao, X.; Ge, Z.; Liu, X.; Wu, H.; Yu, G. Enhancement of ash properties on alkali and alkaline earth metal retention by coal additives in the gasification condition. Fuel 2023, 341, 127023. [Google Scholar] [CrossRef]

- Rodrigues, A.; Gonçalves, A.B.; Maçãs, B.; Cordeiro, A.; Brito, P. A GIS-Based Estimation of Bioenergy Potential from Cereal and Legume Straw Biomasses in Alentejo, Portugal. Appl. Sci. 2025, 15, 868. [Google Scholar] [CrossRef]

- Fontes, A.V.; João, I.M.; Silva, J.M. Multicriteria evaluation of biomass residues in Portugal to second generation bioethanol production. Production 2021, 31, e20210060. [Google Scholar] [CrossRef]

- Nunes, L.J.; Casau, M.; Matias, J.C.; Dias, M.F. Assessment of woody residual biomass generation capacity in the Central region of Portugal: Analysis of the power production potential. Land 2022, 11, 1722. [Google Scholar] [CrossRef]

- Nunes, L.J.; Casau, M.; Matias, J.C.; Dias, M.F. Coal to biomass transition as the path to sustainable energy production: A hypothetical case scenario with the conversion of Pego Power Plant (Portugal). Appl. Sci. 2023, 13, 4349. [Google Scholar] [CrossRef]

- Casau, M.; Cancela, D.C.; Matias, J.C.; Dias, M.F.; Nunes, L.J. Coal to biomass conversion as a path to sustainability: A hypothetical scenario at pego power plant (Abrantes, Portugal). Resources 2021, 10, 84. [Google Scholar] [CrossRef]

- Moura, P.; Henriques, J.; Alexandre, J.; Oliveira, A.C.; Abreu, M.; Gírio, F.; Catarino, J. Sustainable value methodology to compare the performance of conversion technologies for the production of electricity and heat, energy vectors and biofuels from waste biomass. Clean. Waste Syst. 2022, 3, 100029. [Google Scholar] [CrossRef]

- Cardoso, J.S.; Silva, V.; Chavando, J.A.M.; Eusébio, D.; Hall, M.J.; Costa, M. Small-scale biomass gasification for green ammonia production in Portugal: A techno-economic study. Energy Fuels 2021, 35, 13847–13862. [Google Scholar] [CrossRef]

- Segurado, R.; Pereira, S.; Correia, D.; Costa, M. Techno-economic analysis of a trigeneration system based on biomass gasification. Renew. Sustain. Energy Rev. 2019, 103, 501–514. [Google Scholar] [CrossRef]

- Ferreira, S.; Moreira, N.A.; Monteiro, E. Bioenergy overview for Portugal. Biomass Bioenergy 2009, 33, 1567–1576. [Google Scholar] [CrossRef]

- Enes, T.; Aranha, J.; Fonseca, T.; Lopes, D.; Alves, A.; Lousada, J. Thermal properties of residual agroforestry biomass of northern portugal. Energies 2019, 12, 1418. [Google Scholar] [CrossRef]

- Borges, R.; Franco, F.; Serralha, F.; Cabrita, I. Green Hydrogen Production at the Gigawatt Scale in Portugal: A Technical and Economic Evaluation. Energies 2024, 17, 1638. [Google Scholar] [CrossRef]

- Thurner, F.; Mann, U. Kinetic investigation of wood pyrolysis. Ind. Eng. Chem. Process Des. Dev. 1981, 20, 482–488. [Google Scholar] [CrossRef]

- Khalil, M.; Dincer, I. Investigation of a New Holistic Energy System for a Sustainable Airport with Green Hydrogen Fuels. Sustain. Cities Soc. 2024, 113, 105624. [Google Scholar] [CrossRef]

- Khonde, R.; Hedaoo, S.; Deshmukh, S. Prediction of product gas composition from biomass gasification by the method of Gibbs free energy minimization. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 43, 371–380. [Google Scholar] [CrossRef]

- Spycher, N.F.; Reed, M.H. Fugacity coefficients of H2, CO2, CH4, H2O and of H2O-CO2-CH4 mixtures: A virial equation treatment for moderate pressures and temperatures applicable to calculations of hydrothermal boiling. Geochim. Cosmochim. Acta 1988, 52, 739–749. [Google Scholar] [CrossRef]

- Mark, M.F.; Maier, W.F. CO2-reforming of methane on supported Rh and Ir catalysts. J. Catal. 1996, 164, 122–130. [Google Scholar] [CrossRef]

- Dias, J.; Azevedo, J. Evaluation of biomass residuals in Portugal Mainland. In New and Renewable Energy Technologies for Sustainable Development; CRC Press: Boca Raton, FL, USA, 2020; pp. 215–228. [Google Scholar]

- Avwioroko, A.; Ibegbulam, C.; Afriyie, I.; Fesomade, A.T. Smart grid integration of solar and biomass energy sources. Eur. J. Comput. Sci. Inf. Technol. 2024, 12, 1–14. [Google Scholar] [CrossRef]

- Zhu, M.; Fang, J.; Ai, X.; Cui, S.; Zhong, Z.; Wen, J. Real-Time Energy Management of Hydrogen Energy Hub-Based Industrial Integrated Energy Distribution System. IEEE Trans. Ind. Appl. 2024, 61, 1779–1789. [Google Scholar] [CrossRef]

- Ishaq, H.; Dincer, I. A new energy system based on biomass gasification for hydrogen and power production. Energy Rep. 2020, 6, 771–781. [Google Scholar] [CrossRef]

- Elkhatat, A.; Al-Muhtaseb, S. Combined “Renewable Energy–Thermal Energy Storage (RE–TES)” Systems: A Review. Energies 2023, 16, 4471. [Google Scholar] [CrossRef]

- Sousa, J.; Lagarto, J.; Barata, F. Impact of demand flexibility on renewable energy integration, backup capacity, storage use and dispatchable generation: A case study for Portugal’s 2030 National Energy plan. Energy 2025, 320, 135270. [Google Scholar] [CrossRef]

- Qazi, U.Y. Future of hydrogen as an alternative fuel for next-generation industrial applications; challenges and expected opportunities. Energies 2022, 15, 4741. [Google Scholar] [CrossRef]

- Frenette, G.; Forthoffer, D. Economic & commercial viability of hydrogen fuel cell vehicles from an automotive manufacturer perspective. Int. J. Hydrogen Energy 2009, 34, 3578–3588. [Google Scholar]

- Ala, G.; Colak, I.; Di Filippo, G.; Miceli, R.; Romano, P.; Schettino, G.; Silva, C.; Valtchev, S.; Viola, F. Forecasts on the development of Hydrogen Refuelling Infrastructures in Portugal. In Proceedings of the 2021 9th International Conference on Smart Grid (icSmartGrid), Online, 29 June–1 July 2021; pp. 112–117. [Google Scholar]

- Wang, J.; Ma, C.; Wu, J. Thermodynamic analysis of a combined cooling, heating and power system based on solar thermal biomass gasification. Appl. Energy 2019, 247, 102–115. [Google Scholar] [CrossRef]

- Hess, J.R.; Ray, A.E.; Rials, T.G. Advancements in biomass feedstock preprocessing: Conversion ready feedstocks. Front. Energy Res. 2019, 7, 140. [Google Scholar] [CrossRef]

- Adeleke, A.A.; Odusote, J.K.; Ikubanni, P.P.; Lasode, O.A.; Malathi, M.; Paswan, D. Essential basics on biomass torrefaction, densification and utilization. Int. J. Energy Res. 2021, 45, 1375–1395. [Google Scholar] [CrossRef]

- Liu, W.; Xue, T.; Adam, N.A.; Jero, A.; Yang, H. Hydrogen economy in China: Integrating biomass for renewable ernergy transition and economic growth. Int. J. Hydrogen Energy 2025, 121, 171–188. [Google Scholar] [CrossRef]

- Samuel, S.A. Carbon pricing mechanisms for reducing greenhouse gas emissions and encouraging sustainable industrial practices. World J. Adv. Res. Rev. 2025, 25, 1–24. [Google Scholar] [CrossRef]

- Alhajj Ali, S.; Tallou, A.; Vivaldi, G.A.; Camposeo, S.; Ferrara, G.; Sanesi, G. Revitalization potential of marginal areas for sustainable rural development in the Puglia Region, Southern Italy: Part I: A Review. Agronomy 2024, 14, 431. [Google Scholar] [CrossRef]

- Patel, P.; Vaezi, M.; Sebastian, R.M.; Kumar, A. The development of a GIS-Based framework to locate biomass and municipal solid waste collection points for an optimal waste conversion facility. Trans. ASABE 2021, 64, 1671–1691. [Google Scholar] [CrossRef]

- de Santana Filho, J.J.; Gaspar, P.D.; do Paço, A.; Marcelino, S.M. Governance-Centred Industrial Symbiosis for Circular Economy Transitions: A Rural Forest Biomass Hub Framework Proposal. Sustainability 2025, 17, 5659. [Google Scholar] [CrossRef]

- Nunes, L.J. Exploring the present and future of biomass recovery units: Technological innovation, policy incentives and economic challenges. Biofuels 2024, 15, 375–387. [Google Scholar] [CrossRef]

- Hess, J.R.; Tumuluru, J.S. Biomass supply chain logistics: Challenges and technological advancements. In Handbook of Biorefinery Research and Technology: Biomass Logistics to Saccharification; Springer: Berlin/Heidelberg, Germany, 2024; pp. 3–24. [Google Scholar]

- Sakib, A.N.; Mehjabin, F.; Schmidt, J.B.; Haque, M.; Saha, K.; Bhuiyan, M.M.H. Harnessing hydrogen: A comprehensive literature review on strategic launching initiatives in the global energy market. Int. J. Energy Res. 2024, 2024, 3265065. [Google Scholar] [CrossRef]

- Abdin, Z. Bridging the energy future: The role and potential of hydrogen co-firing with natural gas. J. Clean. Prod. 2024, 436, 140724. [Google Scholar] [CrossRef]

- Ebini, O.H. Fostering Workforce Readiness for the Green Hydrogen Economy through People-Centric Training Programs. Int. J. Innov. Sci. Res. Technol. 2024, 9, 773–788. [Google Scholar] [CrossRef]

| Species | Moisture (%) | Ash (%) | Volatile Matter (%) | Fixed Carbon (%) |

|---|---|---|---|---|

| Adenocarpus cumplicatus | 2.65 | 2.33 | 77.69 | 17.33 |

| Arbutus unedo | 7.12 | 3.90 | 68.73 | 20.25 |

| Calluna vulgaris | 4.82 | 2.28 | 74.33 | 18.56 |

| Cistus populifolius | 14.95 | 2.98 | 63.58 | 18.49 |

| Cistus psilosepalus | 2.50 | 1.94 | 75.96 | 19.60 |

| Cistus salviifolius | 4.47 | 2.92 | 71.87 | 20.74 |

| Crataegus monogyna | 5.00 | 2.59 | 74.45 | 17.97 |

| Cytisus multiflorus | 2.56 | 1.75 | 78.34 | 17.34 |

| Cytisus striatus | 7.43 | 2.00 | 73.25 | 17.32 |

| Daphne gnidium | 9.66 | 2.84 | 70.06 | 17.45 |

| Erica arborea | 5.66 | 1.81 | 71.97 | 20.56 |

| Erica australis | 5.68 | 1.37 | 73.61 | 19.35 |

| Erica lusitanica | 8.52 | 1.73 | 69.99 | 19.76 |

| Erica scoparia | 3.69 | 4.94 | 70.38 | 20.99 |

| Erica umbellata | 3.99 | 2.13 | 73.43 | 20.45 |

| Genista falcata | 4.15 | 1.61 | 76.60 | 17.64 |

| Halimium lasianthum | 3.05 | 2.87 | 71.48 | 22.60 |

| Ilex aquifolium | 13.45 | 4.15 | 70.63 | 11.77 |

| Lavandula luisieri | 6.51 | 4.32 | 72.23 | 16.93 |

| Lithodora prustrata | 5.21 | 5.52 | 71.10 | 18.18 |

| Phillyrea angustifolia | 9.75 | 2.59 | 72.49 | 15.17 |

| Prunus lusitanica | 2.52 | 2.43 | 77.61 | 17.45 |

| Pterospartum tridentatum | 2.44 | 1.37 | 74.34 | 21.85 |

| Rhamnus alaternus | 5.37 | 5.47 | 73.00 | 16.17 |

| Rubus ulmifolius | 8.72 | 3.40 | 69.90 | 17.98 |

| Ruscus aculeatus | 6.65 | 4.84 | 73.48 | 15.03 |

| Ulex minor | 8.17 | 2.08 | 71.38 | 18.37 |

| Viburnum tinus | 6.09 | 3.10 | 73.62 | 17.18 |

| Hakea sericea | 6.41 | 1.70 | 73.92 | 17.97 |

| Eucalyptus globulus | 8.24 | 0.85 | 75.49 | 15.42 |

| Acacia dealbata | 7.01 | 0.48 | 76.46 | 16.04 |

| Acacia melanoxylon | 8.49 | 0.74 | 73.75 | 17.02 |

| Robinia pseudoacacia | 7.07 | 4.78 | 71.57 | 16.59 |

| Pinus pinaster | 6.04 | 0.58 | 76.03 | 17.35 |

| Ailanthus altissima | 8.29 | 2.96 | 71.89 | 16.86 |

| PBT (Torrefied Pine Biomass) | 0.50 | 1.91 | 72.27 | 25.32 |

| Olive Pomace | 0.52 | 1.30 | 73.20 | 24.99 |

| Vineyard Pruning | 3.67 | 1.42 | 77.80 | 19.58 |

| Species | C (%) | H (%) | N (%) | O (%) | HHV (MJ/kg) | C/O Ratio |

|---|---|---|---|---|---|---|

| Adenocarpus cumplicatus | 60.40 | 6.53 | 2.40 | 30.67 | 20.43 | 1.97 |

| Arbutus unedo | 57.10 | 5.07 | 0.95 | 36.88 | 21.24 | 1.55 |

| Calluna vulgaris | 60.20 | 5.69 | 0.68 | 33.43 | 20.78 | 1.80 |

| Cistus populifolius | 59.60 | 5.18 | 1.05 | 34.17 | 19.47 | 1.74 |

| Cistus psilosepalus | 56.90 | 5.21 | 1.24 | 36.65 | 18.52 | 1.55 |

| Cistus salviifolius | 59.20 | 5.84 | 0.69 | 34.27 | 19.21 | 1.73 |

| Crataegus monogyna | 58.70 | 5.75 | 0.89 | 34.66 | 19.46 | 1.69 |

| Cytisus multiflorus | 61.50 | 6.45 | 2.87 | 29.18 | 20.68 | 2.11 |

| Cytisus striatus | 59.50 | 5.70 | 2.41 | 32.39 | 21.26 | 1.84 |

| Daphne gnidium | 60.60 | 5.64 | 1.43 | 32.33 | 17.52 | 1.87 |

| Erica arborea | 63.90 | 5.98 | 0.83 | 29.29 | 21.73 | 2.18 |

| Erica australis | 65.70 | 6.21 | 0.78 | 27.31 | 22.92 | 2.41 |

| Erica lusitanica | 61.50 | 5.65 | 0.71 | 32.14 | 21.22 | 1.91 |

| Erica scoparia | 65.20 | 6.23 | 0.97 | 27.60 | 22.98 | 2.36 |

| Erica umbellata | 64.70 | 6.25 | 0.93 | 28.12 | 22.49 | 2.30 |

| Genista falcata | 61.40 | 6.18 | 1.44 | 30.98 | 20.93 | 1.98 |

| Halimium lasianthum | 59.20 | 5.41 | 1.93 | 33.46 | 19.53 | 1.77 |

| Ilex aquifolium | 58.80 | 4.95 | 0.53 | 35.72 | 20.36 | 1.65 |

| Lavandula luisieri | 58.50 | 5.48 | 0.93 | 35.09 | 20.40 | 1.67 |

| Lithodora prustrata | 55.40 | 5.44 | 0.88 | 38.28 | 18.14 | 1.45 |

| Phillyrea angustifolia | 63.00 | 5.94 | 1.20 | 29.86 | 21.72 | 2.11 |

| Prunus lusitanica | 59.30 | 5.62 | 0.80 | 34.28 | 20.77 | 1.73 |

| Pterospartum tridentatum | 63.60 | 5.97 | 1.16 | 29.27 | 21.71 | 2.17 |

| Rhamnus alaternus | 48.00 | 5.90 | 0.66 | 45.44 | 19.36 | 1.06 |

| Rubus ulmifolius | 59.20 | 5.45 | 1.15 | 34.20 | 19.97 | 1.73 |

| Ruscus aculeatus | 57.80 | 5.46 | 1.17 | 35.57 | 20.77 | 1.62 |

| Ulex minor | 60.60 | 5.50 | 1.60 | 32.30 | 21.50 | 1.88 |

| Viburnum tinus | 59.70 | 5.58 | 0.98 | 33.74 | 19.35 | 1.77 |

| Hakea sericea | 60.00 | 5.92 | 0.71 | 33.40 | 20.45 | 1.80 |

| Eucalyptus globulus | 47.30 | 5.67 | 0.10 | 46.93 | 19.39 | 1.01 |

| Acacia dealbata | 47.00 | 5.76 | 0.33 | 46.91 | 19.37 | 1.00 |

| Acacia melanoxylon | 47.00 | 5.61 | 0.31 | 47.07 | 19.35 | 1.00 |

| Robinia pseudoacacia | 48.20 | 5.81 | 0.58 | 45.37 | 19.54 | 1.06 |

| Pinus pinaster | 50.21 | 6.07 | 0.08 | 43.64 | 19.35 | 1.15 |

| Ailanthus altissima | 47.52 | 5.63 | 0.51 | 46.34 | 22.23 | 1.03 |

| Species | Al | Ca | Fe | Mg | K | Cu | Mn | Zn |

|---|---|---|---|---|---|---|---|---|

| Adenocarpus cumplicatus | 45.2 | 3247 | 89.4 | 1156 | 2847 | 3.2 | 18.7 | 25.0 |

| Arbutus unedo | 78.9 | 8945 | 156.7 | 2034 | 4523 | 5.8 | 45.2 | 41.0 |

| Calluna vulgaris | 23.4 | 1789 | 67.3 | 789 | 1234 | 2.1 | 12.4 | 13.7 |

| Cistus populifolius | 156.8 | 5678 | 234.5 | 1567 | 6789 | 8.9 | 67.8 | 104.8 |

| Erica arborea | 34.5 | 2456 | 78.9 | 1023 | 3456 | 4.2 | 23.4 | 34.5 |

| Erica australis | 28.7 | 2134 | 65.4 | 945 | 2987 | 3.8 | 19.8 | 28.9 |

| Eucalyptus globulus | 67.8 | 4567 | 123.4 | 1789 | 5234 | 6.7 | 34.5 | 56.7 |

| Pinus pinaster | 45.6 | 3456 | 98.7 | 1234 | 4123 | 5.2 | 28.9 | 45.6 |

| Species | H2 Yield (kg/ton) | Gasification Index | Category |

|---|---|---|---|

| Adenocarpus cumplicatus | 11.4 | 76.4 | Other |

| Arbutus unedo | 10.8 | 67.9 | Other |

| Calluna vulgaris | 11.3 | 73.4 | Other |

| Cistus populifolius | 11.4 | 63.2 | Woody Shrubland |

| Cistus psilosepalus | 10.8 | 74.1 | Woody Shrubland |

| Cistus salviifolius | 11.1 | 73.0 | Woody Shrubland |

| Crataegus monogyna | 11.0 | 72.5 | Other |

| Cytisus multiflorus | 11.7 | 77.2 | Woody Shrubland |

| Cytisus striatus | 11.4 | 71.4 | Woody Shrubland |

| Daphne gnidium | 11.5 | 68.6 | Other |

| Erica arborea | 12.1 | 74.1 | Woody Shrubland |

| Erica australis | 12.4 | 75.0 | Woody Shrubland |

| Erica lusitanica | 11.6 | 71.0 | Woody Shrubland |

| Erica scoparia | 12.3 | 72.9 | Woody Shrubland |

| Erica umbellata | 12.2 | 75.6 | Woody Shrubland |

| Genista falcata | 11.6 | 75.5 | Woody Shrubland |

| Halimium lasianthum | 11.3 | 74.0 | Other |

| Ilex aquifolium | 11.2 | 62.1 | Other |

| Lavandula luisieri | 11.0 | 68.8 | Other |

| Eucalyptus globulus | 8.9 | 65.2 | Forest Species |

| Pinus pinaster | 9.5 | 68.7 | Forest Species |

| Acacia dealbata | 8.9 | 66.1 | Forest Species |

| Category | Count | Moisture (%) | Ash (%) | Carbon (%) | H2 Yield (kg/ton) |

|---|---|---|---|---|---|

| Woody Shrubland | 15 | 5.2 ± 2.8 | 2.1 ± 1.0 | 61.8 ± 3.2 | 11.4 ± 0.6 |

| Forest Species | 8 | 7.1 ± 1.2 | 1.8 ± 1.5 | 48.2 ± 1.8 | 9.2 ± 0.8 |

| Other | 16 | 6.8 ± 3.5 | 3.2 ± 1.4 | 58.9 ± 4.1 | 10.9 ± 0.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nunes, L.J.R. Gasification Processes of Portuguese Biomass: Theoretical Analysis of Hydrogen Production Potential. Energies 2025, 18, 4453. https://doi.org/10.3390/en18164453

Nunes LJR. Gasification Processes of Portuguese Biomass: Theoretical Analysis of Hydrogen Production Potential. Energies. 2025; 18(16):4453. https://doi.org/10.3390/en18164453

Chicago/Turabian StyleNunes, Leonel J. R. 2025. "Gasification Processes of Portuguese Biomass: Theoretical Analysis of Hydrogen Production Potential" Energies 18, no. 16: 4453. https://doi.org/10.3390/en18164453

APA StyleNunes, L. J. R. (2025). Gasification Processes of Portuguese Biomass: Theoretical Analysis of Hydrogen Production Potential. Energies, 18(16), 4453. https://doi.org/10.3390/en18164453