Comprehensive Review of Hydrogen and Tyre Pyrolysis Oil as Sustainable Fuels for HCCI Engines

Abstract

1. Introduction

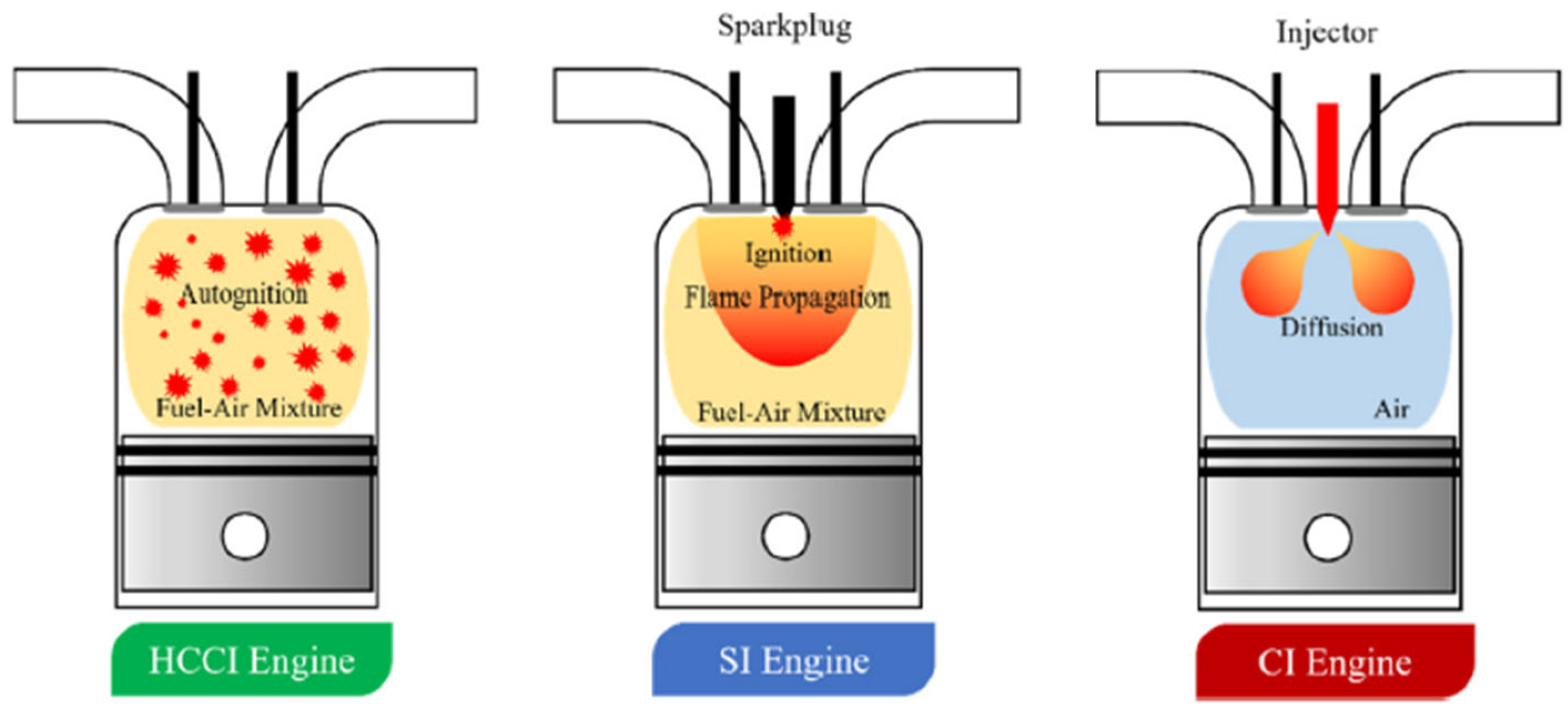

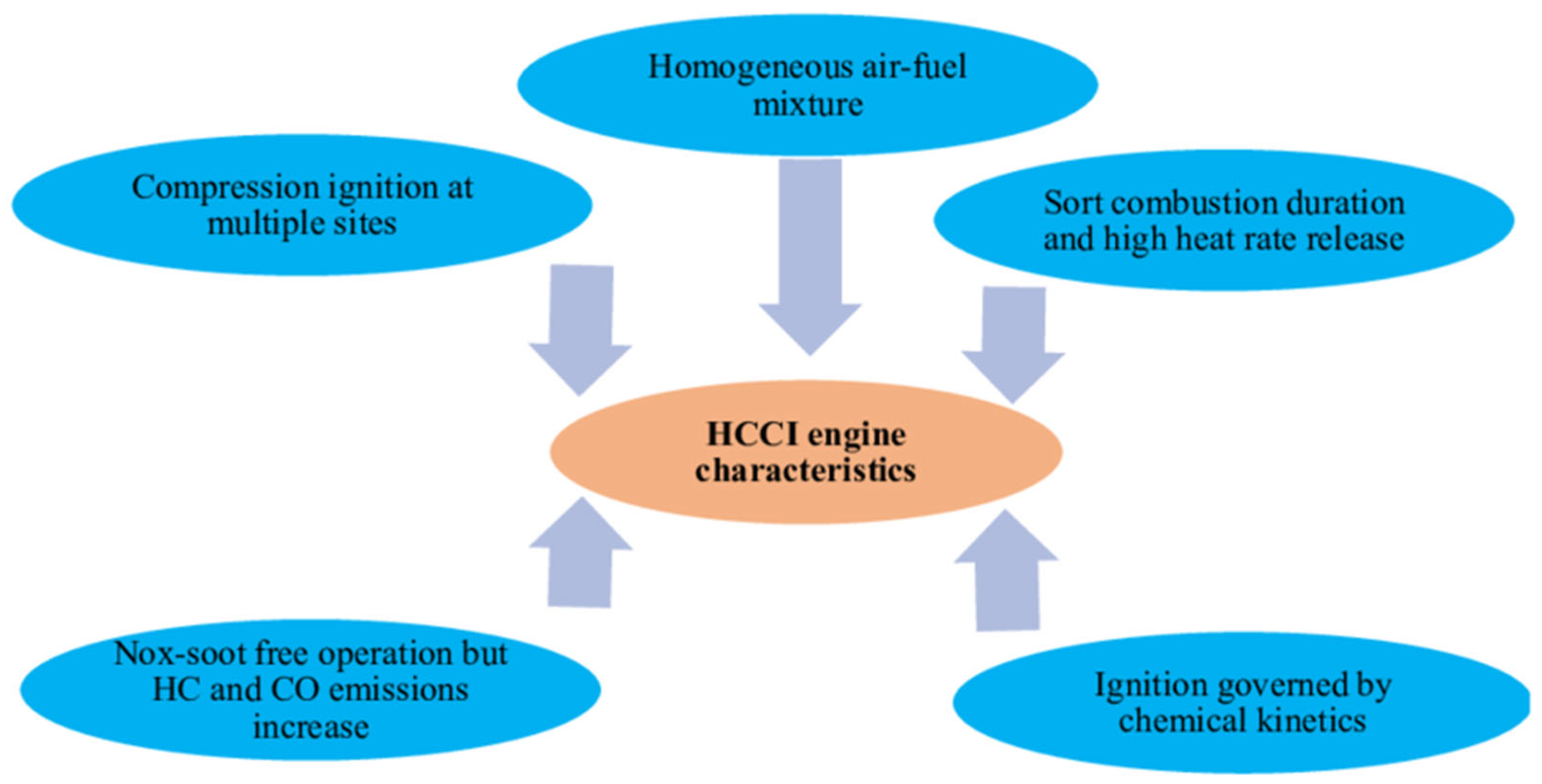

1.1. Background of Sustainable Fuels and Homogeneous Charge Compression Ignition Engines

1.2. Importance of Hydrogen and Tyre Pyrolysis Oil as Alternative Fuels

2. Hydrogen as a Sustainable Fuel for Homogeneous Charge Compression Ignition Engines

2.1. Properties of Hydrogen Relevant to Homogeneous Charge Compression Ignition Combustion

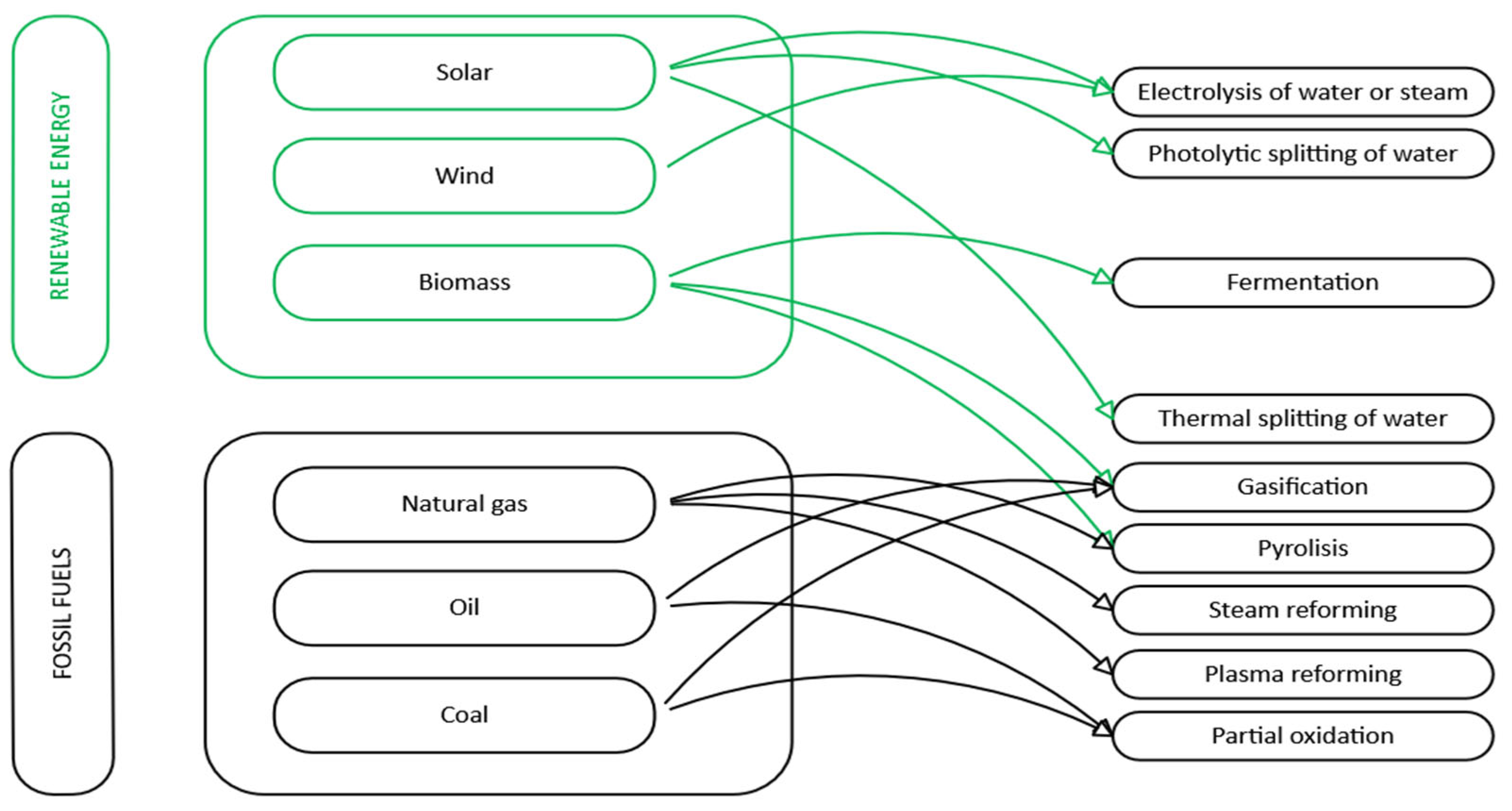

2.2. Production Methods and Sustainability Aspects

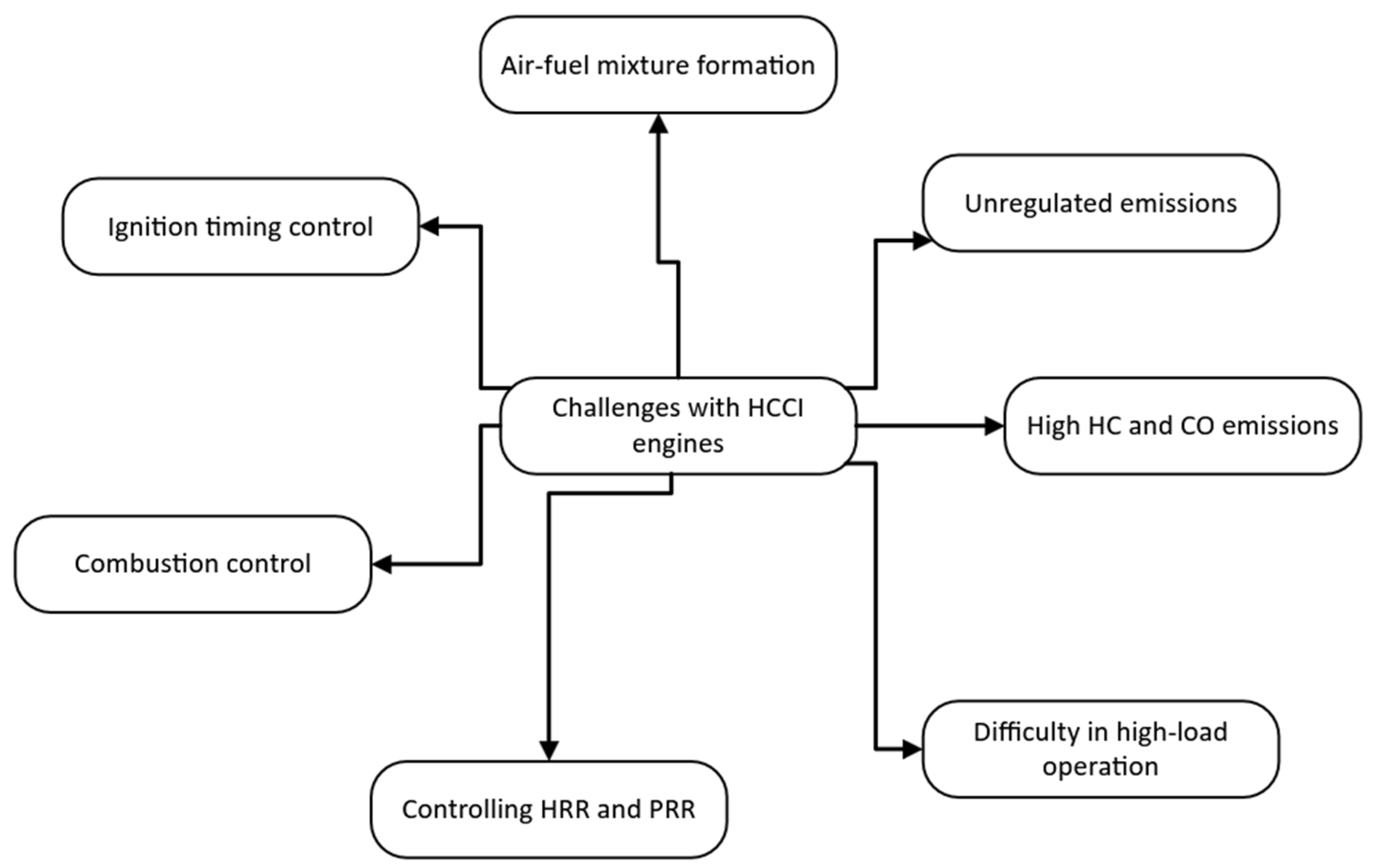

2.3. Advantages and Challenges of Hydrogen in Homogeneous Charge Compression Ignition Engines

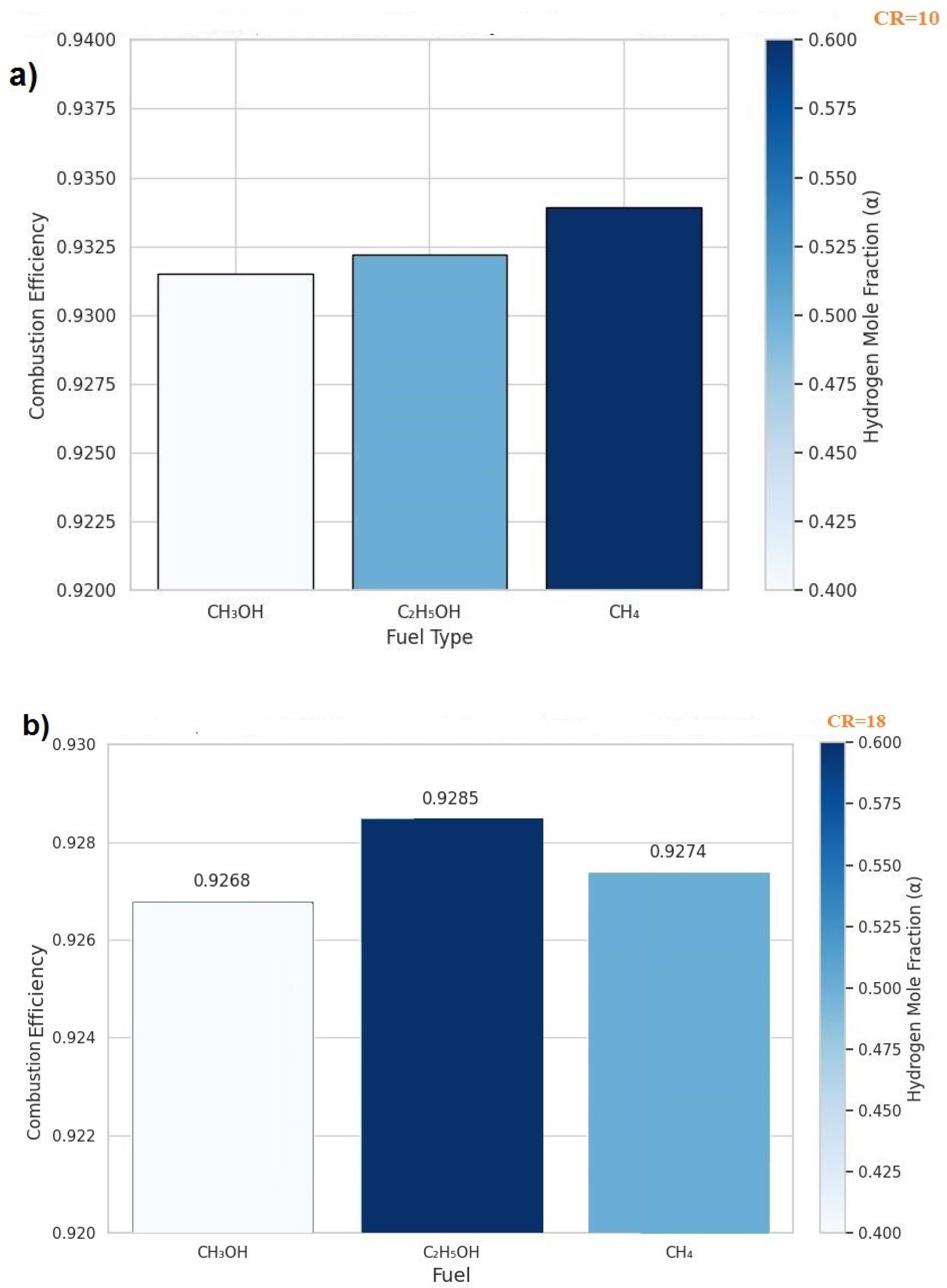

2.4. Performance Characteristics of Hydrogen-Fuelled Homogeneous Charge Compression Ignition Engines

2.5. Emissions Profile of Hydrogen Homogeneous Charge Compression Ignition Engines

3. Tyre Pyrolysis Oil as a Sustainable Fuel for Homogeneous Charge Compression Ignition Engines

3.1. Composition and Properties of Tyre Pyrolysis Oil

3.2. Production Process and Environmental Implications

3.3. Advantages and Challenges of Tyre Pyrolysis Oil in Homogeneous Charge Compression Ignition Engines

4. Comparative Analysis of Hydrogen and Tyre Pyrolysis Oil in Homogeneous Charge Compression Ignition Engines

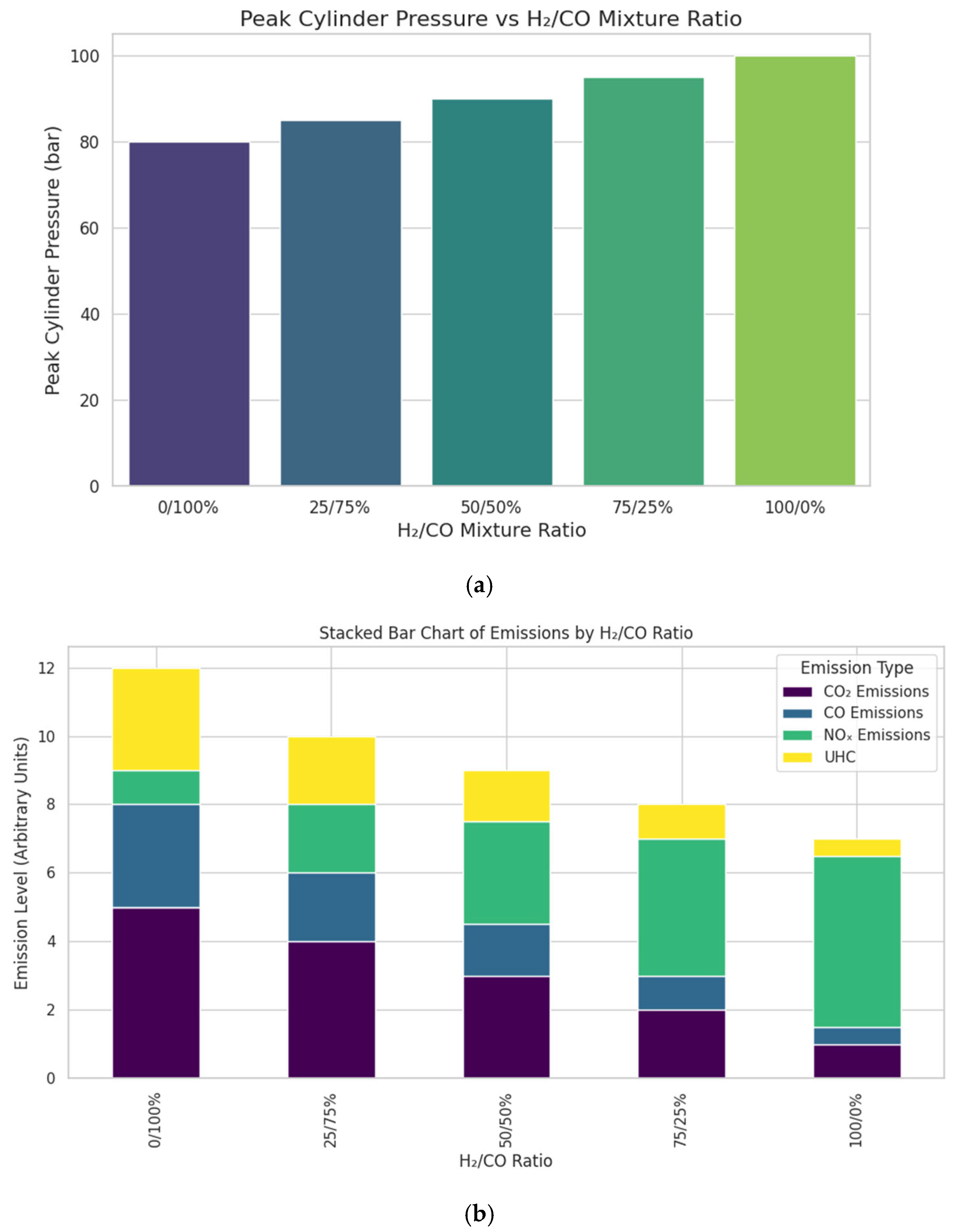

4.1. Engine Performance Metrics

4.2. Combustion Characteristics

4.3. Emission Comparison

4.4. Fuel Efficiency and Energy Density

4.5. Economic Feasibility and Scalability

5. Technological Advancements and Future Prospects

5.1. Recent Developments in Hydrogen and Tyre Pyrolysis Oil Production

5.2. Innovations in Homogeneous Charge Compression Ignition Engine Design for Alternative Fuels

5.3. Potential Synergies Between Hydrogen and Tyre Pyrolysis Oil

5.4. Research Gaps and Future Directions

6. Environmental and Sustainability Implications

6.1. Life-Cycle Assessments of Hydrogen and Tyre Pyrolysis Oil as Homogeneous Charge Compression Ignition Fuels

6.2. Contributions to the Circular Economy and Waste Management

6.3. Potential Impacts on Greenhouse Gas Emission Reduction

7. Regulatory Framework and Policy Considerations

7.1. Current Regulations on Alternative Fuels in Transportation

7.2. Incentives and Barriers for the Adoption of Sustainable Homogeneous Charge Compression Ignition Fuels

7.3. Policy Recommendations for Promoting Hydrogen and Tyre Pyrolysis Oil Adoption

8. Conclusions

- Each of the two fuels has particular merits and challenges that make them interesting options in the transition to cleaner combustion technologies.

- Hydrogen provides extremely high energy density, combustion without carbon emissions, rapid flame speed and a broad flammability range, which are all factors promoting greater efficiency and lower emissions in HCCI engines. Nevertheless, its use in the real world is restricted by the need for elaborate storage solutions, inadequate transport logistics solutions and the wide lack of refuelling infrastructure.

- TPO, obtained through waste-tyre pyrolysis, simultaneously addresses demands for alternative fuel and waste management solutions. TPO is capable of providing a performance comparable to diesel in HCCI engines while reducing emissions, especially PM and NOx. However, variable chemical composition may lead to unpredictable combustion and pollutant production. Improved standardisation and refining processes are needed in order to ensure fuel quality.

- Hydrogen fuel optimisation will require accurate mixture preparation, proper timing of auto-ignition and a controlled release rate to avoid engine knocking. TPO optimisation will require better fuel injection and EGR methods and fine-tuning of combustion timing.

- Combining hydrogen and TPO in a dual-fuel system could help counteract the shortcomings of both fuels. Such blends might combine the volatile nature of TPO combustion with the consistent and clean-burning nature of hydrogen, increasing combustion stability, improving efficiency and reducing emissions.

- Further research and development is required to maximise the potential of hydrogen and TPO use in HCCI engines. Above all, improvements are required in fuel production technologies and engine design. More effective technologies should also be developed to help control emissions. Such advancements will help eliminate the existing constraints in fuel scalability, engine performance and infrastructure preparedness.

- As systems with high intrinsic thermal efficiency and low emissions, HCCI engines provide an ideal platform to introduce sustainable fuels such as hydrogen, TPO, biofuels and waste-based synthetic fuels. These fuels can help achieve a cleaner and more secure energy future in the transportation sector alongside ongoing policy support, technological innovation and investment in research.

Funding

Conflicts of Interest

References

- Mofijur, M.; Ahmed, S.F.; Ahmed, B.; Mehnaz, T.; Mehejabin, F.; Shome, S.; Almomani, F.; Chowdhury, A.A.; Kalam, M.A.; Badruddin, I.A.; et al. Impact of nanoparticle-based fuel additives on biodiesel combustion: An analysis of fuel properties, engine performance, emissions, and combustion characteristics. Energy Convers. Manag. X 2024, 21, 100515. [Google Scholar] [CrossRef]

- Amba, G.; Rao, P.; Karthikeya Sharma, T. Prospects of Hydrogen in HCCI Engines—A Review. Int. J. Appl. Eng. Res. 2021, 16, 538–551. [Google Scholar]

- Hairuddin, A.A.; Yusaf, T.; Wandel, A.P. A review of hydrogen and natural gas addition in diesel HCCI engines. Renew. Sustain. Energy Rev. 2014, 32, 739–761. [Google Scholar] [CrossRef]

- Pulidindi, K. Tire Pyrolysis Oil Market—By Raw Material, By Process, By End Use and Forecast, 2025–2034. Global Market Insights. Available online: https://www.gminsights.com/industry-analysis/tire-pyrolysis-oil-market (accessed on 10 July 2025).

- Zerin, N.H.; Rasul, M.G.; Jahirul, M.I.; Sayem, A.S.M. End-of-life tyre conversion to energy: A review on pyrolysis and activated carbon production processes and their challenges. Sci. Total Environ. 2023, 905, 166981. [Google Scholar] [CrossRef] [PubMed]

- Singh, G.; Singh, A.P.; Agarwal, A.K. Experimental investigations of combustion, performance and emission characterization of biodiesel fuelled HCCI engine using external mixture formation technique. Sustain. Energy Technol. Assess. 2014, 6, 116–128. [Google Scholar] [CrossRef]

- Riyadi, T.W.B.; Spraggon, M.; Herawan, S.G.; Idris, M.; Paristiawan, P.A.; Putra, N.R.; Faizullizam R, M.; Silambarasan, R.; Veza, I. Biodiesel for HCCI engine: Prospects and challenges of sustainability biodiesel for energy transition. Results Eng. 2023, 17, 100916. [Google Scholar] [CrossRef]

- Ali, K.; Amna, R.; Ali, M.I.H. HCCI engine performance using fuel mixture of H2 and H2O2. Energy Convers. Manag. 2023, 276, 116588. [Google Scholar] [CrossRef]

- Khaliq, A.; Ahmad, F.; Khalid, F. Utilization of Bio-Hydrogen in HCCI Engines as a Most Renewable Fuel for Sustainable Transportation—A Thermodynamic Analysis. Encycl. Renew. Sustain. Mater. 2020, 3, 224–231. [Google Scholar] [CrossRef]

- Hassan Ali, M.I.; Ali, K. Exploring sustainable fuel alternatives: The role of NH3–H2–H2O2 blends in enhancing HCCI engine performance. Int. J. Hydrogen Energy 2024, 94, 782–794. [Google Scholar] [CrossRef]

- Hoang, A.T.; Murugesan, P.; PV, E.; Balasubramanian, D.; Parida, S.; Priya Jayabal, C.; Nachippan, M.; Kalam, M.A.; Truong, T.H.; Cao, D.N.; et al. Strategic combination of waste plastic/tire pyrolysis oil with biodiesel for natural gas-enriched HCCI engine: Experimental analysis and machine learning model. Energy 2023, 280, 128233. [Google Scholar] [CrossRef]

- Mariani, A.; Foucher, F.; Minale, M.; Masurier, J.B.; Unich, A.; Brequigny, P. An experimental study on the impact of hydrogen and carbon dioxide addition to methane on a HCCI engine performance and emissions. Int. J. Hydrogen Energy 2024, 90, 1411–1423. [Google Scholar] [CrossRef]

- Mikulski, M.; Ambrosewicz-Walacik, M.; Hunicz, J.; Nitkiewicz, S. Combustion engine applications of waste tyre pyrolytic oil. Prog. Energy Combust. Sci. 2021, 85, 100915. [Google Scholar] [CrossRef]

- Zhang, H. Research on technological innovation and application of modern diesel engines. Theor. Nat. Sci. 2023, 25, 286–292. [Google Scholar] [CrossRef]

- Rajendra Prasad, G.; Goud, S.C.; Maheswar, D. Alternative Fuels for Hcci Engine Techology and Recent Developments. Int. J. Adv. Res. Eng. Appl. Sci. 2012, 1, 1–19. [Google Scholar]

- Ramana, P.V.; Maheswar, D.; Gowd, B.U. Development of Alternative fuels for HCCI Engine Technology. IJEDR 2015, 3, 108–119. [Google Scholar]

- Djermouni, M.; Ouadha, A. Comparative thermodynamic analysis of LNG, LPG, methanol, ethanol, biodiesel, and hydrogen as alternative fuels in HCCI engines. Int. J. Thermodyn. 2021, 24, 111–123. [Google Scholar] [CrossRef]

- Djermouni, M.; Ouadha, A. Thermodynamic analysis of methanol, ammonia, and hydrogen as alternative fuels in HCCI engines. Int. J. Thermofluids 2023, 19, 100372. [Google Scholar] [CrossRef]

- Vinoth Kanna, I.; Paturu, P. A study of hydrogen as an alternative fuel. Int. J. Ambient Energy 2020, 41, 1433–1436. [Google Scholar] [CrossRef]

- Yaqoob, H.; Teoh, Y.H.; Sher, F.; Jamil, M.A.; Murtaza, D.; Al Qubeissi, M.; Ui Hassan, M.; Mujtaba, M.A. Current status and potential of tire pyrolysis oil production as an alternative fuel in developing countries. Sustainability 2021, 13, 3214. [Google Scholar] [CrossRef]

- Sharma, P.; Dhar, A. Effect of hydrogen supplementation on engine performance and emissions. Int. J. Hydrogen Energy 2018, 43, 7570–7580. [Google Scholar] [CrossRef]

- Rosati, M.F.; Aleiferis, P.G. Hydrogen SI and HCCI combustion in a Direct-Injection optical engine. In Proceedings of the SAE Technical Papers, Detroit, MI, USA, 20–23 April 2009. [Google Scholar]

- Wang, D.; Ji, C.; Wang, S.; Yang, J.; Wang, Z. Numerical study of the premixed ammonia-hydrogen combustion under engine-relevant conditions. Int. J. Hydrogen Energy 2021, 46, 2667–2683. [Google Scholar] [CrossRef]

- Hernández, J.J.; Salvador, J.B.; Cova-Bonillo, A. Autoignition of diesel-like fuels under dual operation with H2. Adv. Mech. Eng. 2019, 11, 1687814019856781. [Google Scholar] [CrossRef]

- Aydin, M.I.; Dincer, I. An assessment study on various clean hydrogen production methods. Energy 2022, 245, 123090. [Google Scholar] [CrossRef]

- Najafi, B.; Haghighatshoar, F.; Ardabili, S.; Band, S.S.; Chau, K.W.; Mosavi, A. Effects of low-level hydroxy as a gaseous additive on performance and emission characteristics of a dual fuel diesel engine fueled by diesel/biodiesel blends. Eng. Appl. Comput. Fluid Mech. 2021, 15, 236–250. [Google Scholar] [CrossRef]

- Yu, M.; Wang, K.; Vredenburg, H. Insights into low-carbon hydrogen production methods: Green, blue and aqua hydrogen. Int. J. Hydrogen Energy 2021, 46, 21261–21273. [Google Scholar] [CrossRef]

- Vostakola, M.F.; Salamatinia, B.; Horri, B.A. A Review on Recent Progress in the Integrated Green Hydrogen Production Processes. Energies 2022, 15, 1209. [Google Scholar] [CrossRef]

- Dash, S.K.; Chakraborty, S.; Roccotelli, M.; Sahu, U.K. Hydrogen Fuel for Future Mobility: Challenges and Future Aspects. Sustainability 2022, 14, 8285. [Google Scholar] [CrossRef]

- Laghlimi, C.; Moutcine, A.; Ziat, Y.; Koufi, A.; Bouyassan, S.; Belkhanchi, H. Hydrogen, chronology and electrochemical production. Sol. Energy Sustain. Dev. 2024, 14, 22–37. [Google Scholar] [CrossRef]

- Zhao, C.; Luo, Y. Introduction of HCCI for Hydrogen Fuel Engines. J. Sci. Res. Rep. 2020, 26, 127–132. [Google Scholar] [CrossRef]

- Chaudhari, V.D.; Deshmukh, D. Challenges in charge preparation and combustion in homogeneous charge compression ignition engines with biodiesel: A review. Energy Rep. 2019, 5, 960–968. [Google Scholar] [CrossRef]

- Das, S.; Debnath, B.K.; Negi, S.; Das, B.; Safari, S.; Reddy, B.V.; Debbarma, S.; Ehyaei, M.A. A comprehensive review into the effects of different parameters on the hydrogen-added HCCI diesel engine. Energy Sci. Eng. 2023, 11, 3928–3958. [Google Scholar] [CrossRef]

- Saxena, M.R.; Maurya, R.K. Exergy analysis and investigation on effect of inlet valve closing temperature and hydrogen enrichment in syngas composition in an HCCI engine. Int. J. Hydrogen Energy 2023, 48, 3269–3286. [Google Scholar] [CrossRef]

- Minh, T.N.; Minh, H.P.; Duy, V.N. A review of internal combustion engines powered by renewable energy based on ethanol fuel and HCCI technology. AIMS Energy 2022, 10, 1005–1025. [Google Scholar] [CrossRef]

- Dimitrova, I.D.; Megaritis, T.; Ganippa, L.C.; Tingas, E. Al Computational analysis of an HCCI engine fuelled with hydrogen/hydrogen peroxide blends. Int. J. Hydrogen Energy 2022, 47, 10083–10096. [Google Scholar] [CrossRef]

- Shere, A.; Subramanian, K.A. Effects of hydrogen and EGR on energy efficiency improvement with ultra low emissions in a common rail direct injection compression ignition engine fueled with dimethyl ether (DME) under HCCI mode. Int. J. Hydrogen Energy 2024, 52, 1447–1474. [Google Scholar] [CrossRef]

- Guo, H.; Neill, W.S. The effect of hydrogen addition on combustion and emission characteristics of an n-heptane fuelled HCCI engine. Int. J. Hydrogen Energy 2013, 38, 11429–11437. [Google Scholar] [CrossRef]

- Nguyen, D.; Turner, J.W.G. Effect of nitric oxide on the performance and emissions of a hydrogen-fueled HCCI engine. Fuel 2023, 349, 128611. [Google Scholar] [CrossRef]

- Öner, İ.V.; Atabani, A.E.; Durnagöl, T. Recycling of waste tires to crude pyrolytic oil: Engine performance, combustion characteristics and emissions analysis of diesel-butanol-crude pyrolytic oil blends in CI diesel engines. Sustain. Energy Technol. Assess. 2023, 56, 103023. [Google Scholar] [CrossRef]

- Arya, S.; Sharma, A.; Rawat, M.; Agrawal, A. Tyre pyrolysis oil as an alternative fuel: A review. Mater. Today Proc. 2020, 28, 2481–2484. [Google Scholar] [CrossRef]

- Vihar, R.; Seljak, T.; Rodman Oprešnik, S.; Katrašnik, T. Combustion characteristics of tire pyrolysis oil in turbo charged compression ignition engine. Fuel 2015, 150, 226–235. [Google Scholar] [CrossRef]

- Yaqoob, H.; Teoh, Y.H.; Jamil, M.A.; Gulzar, M. Potential of tire pyrolysis oil as an alternate fuel for diesel engines: A review. J. Energy Inst. 2021, 96, 205–221. [Google Scholar] [CrossRef]

- Alvarez, J.; Lopez, G.; Amutio, M.; Mkhize, N.M.; Danon, B.; van der Gryp, P.; Görgens, J.F.; Bilbao, J.; Olazar, M. Evaluation of the properties of tyre pyrolysis oils obtained in a conical spouted bed reactor. Energy 2017, 128, 463–474. [Google Scholar] [CrossRef]

- Zhang, G.; Chen, F.; Zhang, Y.; Zhao, L.; Chen, J.; Cao, L.; Gao, J.; Xu, C. Properties and utilization of waste tire pyrolysis oil: A mini review. Fuel Process. Technol. 2021, 211, 106582. [Google Scholar] [CrossRef]

- Li, D.; Lei, S.; Rajput, G.; Zhong, L.; Ma, W.; Chen, G. Study on the co-pyrolysis of waste tires and plastics. Energy 2021, 226, 120381. [Google Scholar] [CrossRef]

- Djandja, O.S.; Wang, Z.; Duan, P.; Wang, F.; Xu, Y. Hydrotreatment of pyrolysis oil from waste tire in tetralin for production of high-quality hydrocarbon rich fuel. Fuel 2021, 285, 119185. [Google Scholar] [CrossRef]

- Yarlagadda, J.; Ravuru, A.; Voduri, P.; Chaitanya, I.S.H.; Murali Manohar, P. A study on improving tire pyrolysis oil quality by blending it with biodiesels derived from edible oils. Int. J. Ambient Energy 2022, 43, 2775–2786. [Google Scholar] [CrossRef]

- Nabi, M.N.; Hussam, W.K.; Bin Rashid, A.; Islam, J.; Islam, S.; Afroz, H.M.M. Notable improvement of fuel properties of waste tire pyrolysis oil by blending a novel pumpkin seed oil–biodiesel. Energy Rep. 2022, 8, 112–119. [Google Scholar] [CrossRef]

- Alzahrani, N.; Nahil, M.A.; Williams, P.T. Co-pyrolysis of waste plastics and tires: Influence of interaction on product oil and gas composition. J. Energy Inst. 2024, 118, 101908. [Google Scholar] [CrossRef]

- Wu, Y.; Yuan, Y.; Xia, C.; Alahmadi, T.A.; Alharbi, S.A.; Sekar, M.; Pugazhendhi, A. Production of waste tyre pyrolysis oil as the replacement for fossil fuel for diesel engines with constant hydrogen injection via air intake manifold. Fuel 2024, 355, 129458. [Google Scholar] [CrossRef]

- Özer, S.; Gülcan, H.E.; Çelebi, S.; Demir, U. Assessment of waste tyre pyrolysis oil and oxy-hydrogen gas usage in a diesel engine in terms of energy, exergy, environmental, and enviroeconomic perspectives. Int. J. Hydrogen Energy 2024, 143, 862–881. [Google Scholar] [CrossRef]

- Martínez, J.D.; Puy, N.; Murillo, R.; García, T.; Navarro, M.V.; Mastral, A.M. Waste tyre pyrolysis—A review. Renew. Sustain. Energy Rev. 2013, 23, 179–213. [Google Scholar] [CrossRef]

- Williams, P.T. Pyrolysis of waste tyres: A review. Waste Manag. 2013, 33, 1714–1728. [Google Scholar] [CrossRef]

- Ali Ijaz Malik, M.; Zeeshan, S.; Khubaib, M.; Ikram, A.; Hussain, F.; Yassin, H.; Qazi, A. A review of major trends, opportunities, and technical challenges in biodiesel production from waste sources. Energy Convers. Manag. X 2024, 23, 100675. [Google Scholar] [CrossRef]

- Han, W.; Han, D.; Chen, H. Pyrolysis of Waste Tires: A Review. Polymers 2023, 15, 1604. [Google Scholar] [CrossRef]

- Prajapati, A.K.; Yadav, S.; Gomey, A.K.; Choubey, A.K.; Kumar, R. Assessment of performance and emission characteristics of CI engine using tyre pyrolysis oil and biodiesel blends by nano additives: An experimental study. J. Energy Inst. 2024, 117, 101825. [Google Scholar] [CrossRef]

- Nguyen, V.N.; Ganesan, N.; Ashok, B.; Balasubramanian, D.; Anabayan, K.; Lawrence, K.R.; Tamilvanan, A.; Le, D.T.N.; Truong, T.H.; Tran, V.D.; et al. Eco-friendly perspective of hydrogen fuel addition to diesel engine: An inclusive review of low-temperature combustion concepts. Int. J. Hydrogen Energy 2024, 104, 344–366. [Google Scholar] [CrossRef]

- Alias, M.S.M.; Hairuddin, A.A.; Hassan, M.K.; Rezali, K.A.M. A review of hydrogen addition in an HCCI engine fueled with biofuels. AIP Conf. Proc. 2019, 2059, 020045. [Google Scholar] [CrossRef]

- Soylu, S. Examination of combustion characteristics and phasing strategies of a natural gas HCCI engine. Energy Convers. Manag. 2005, 46, 101–119. [Google Scholar] [CrossRef]

- Mishra, S.; Naik, B.; Mallikarjuna, J.M. Effect of direct water injection timing and quantity on combustion, performance, and emission characteristics of a homogeneous charge compression ignition engine—A CFD analysis. Appl. Therm. Eng. 2024, 257, 124190. [Google Scholar] [CrossRef]

- Hunicz, J.; Gęca, M.S.; Ratajczyk, E.; Andwari, A.M.; Yang, L.; Mikulski, M. An analytical approach to converting vibration signal to combustion characteristics of homogeneous charge compression ignition engines. Energy Convers. Manag. 2023, 294, 117564. [Google Scholar] [CrossRef]

- Pandey, S.; Diwan, P.; Sahoo, P.K.; Thipse, S.S. A review of combustion control strategies in diesel HCCI engines. Biofuels 2016, 9, 61–74. [Google Scholar] [CrossRef]

- Ganesh, D.; Nagarajan, G.; Mohamed Ibrahim, M. Study of performance, combustion and emission characteristics of diesel homogeneous charge compression ignition (HCCI) combustion with external mixture formation. Fuel 2008, 87, 3497–3503. [Google Scholar] [CrossRef]

- Nazoktabar, M.; Jazayeri, S.A.; Parsa, M.; Ganji, D.D.; Arshtabar, K. Controlling the optimal combustion phasing in an HCCI engine based on load demand and minimum emissions. Energy 2019, 182, 82–92. [Google Scholar] [CrossRef]

- Murugan, S.; Ramaswamy, M.C.; Nagarajan, G. Performance, emission and combustion studies of a DI diesel engine using Distilled Tyre pyrolysis oil-diesel blends. Fuel Process. Technol. 2008, 89, 152–159. [Google Scholar] [CrossRef]

- Park, S.H.; Lee, Y.D.; Ahn, K.Y. Performance analysis of an SOFC/HCCI engine hybrid system: System simulation and thermo-economic comparison. Int. J. Hydrogen Energy 2014, 39, 1799–1810. [Google Scholar] [CrossRef]

- Zhu, P.; Yao, J.; Qian, C.; Yang, F.; Porpatham, E.; Zhang, Z.; Wu, Z. High-efficiency conversion of natural gas fuel to power by an integrated system of SOFC, HCCI engine, and waste heat recovery: Thermodynamic and thermo-economic analyses. Fuel 2020, 275, 117883. [Google Scholar] [CrossRef]

- Jeyaseelan, T.; Ekambaram, P.; Subramanian, J.; Shamim, T. A comprehensive review on the current trends, challenges and future prospects for sustainable mobility. Renew. Sustain. Energy Rev. 2022, 157, 112073. [Google Scholar] [CrossRef]

- Munyentwali, A.; Tan, K.C.; He, T. Advancements in the development of liquid organic hydrogen carrier systems and their applications in the hydrogen economy. Prog. Nat. Sci. Mater. Int. 2024, 34, 825–839. [Google Scholar] [CrossRef]

- Dewi, W.N.; Zhou, Q.; Mollah, M.; Yang, S.; Ilankoon, I.M.S.K.; Chaffee, A.; Zhang, L. Synergistic interaction between scrap tyre and plastics for the production of sulphur-free, light oil from fast co-pyrolysis. Waste Manag. 2024, 179, 99–109. [Google Scholar] [CrossRef]

- Yao, M.; Zheng, Z.; Liu, H. Progress and recent trends in homogeneous charge compression ignition (HCCI) engines. Prog. Energy Combust. Sci. 2009, 35, 398–437. [Google Scholar] [CrossRef]

- Sundararajan, K.; Janathanan, K.; Pandian, V.; Dhandapani, M.; Kanagara, K. A Performance, Combustion and Emission Study on HCCI Engine: Trends and Innovations. In Proceedings of the SAE Technical Papers, Detroit, MI, USA, 12–14 April 2016; Volume 2016-Febru. [Google Scholar]

- Constandinides, G. Thermal Management and control of a Homogeneous Charge Compression Ignition (HCCI) Engine. Ph.D. Thesis, University of Birmingham, Birmingham, UK, 2013. [Google Scholar]

- Martinez-Frias, J.; Aceves, S.M.; Flowers, D.; Smith, J.R.; Dibble, R. HCCI engine control by thermal management. In Proceedings of the SAE Technical Papers, Detroit, MI, USA, 6–9 March 2000. [Google Scholar]

- Al-Qadri, A.A.; Ahmed, U.; Ahmad, N.; Abdul Jameel, A.G.; Zahid, U.; Naqvi, S.R. A review of hydrogen generation through gasification and pyrolysis of waste plastic and tires: Opportunities and challenges. Int. J. Hydrogen Energy 2024, 77, 1185–1204. [Google Scholar] [CrossRef]

- Kodgire, P. Hydrogen-imminent clean and green energy: Hydrogen production technologies life cycle assessment review. Process Saf. Environ. Prot. 2025, 193, 483–500. [Google Scholar] [CrossRef]

- Tsangas, M.; Papamichael, I.; Loizia, P.; Voukkali, I.; Salman Raza, N.; Vincenzo, N.; Zorpas, A.A. Life cycle assessment of electricity generation by tire pyrolysis oil. Process Saf. Environ. Prot. 2024, 186, 376–387. [Google Scholar] [CrossRef]

- Mohanty, A.; Ajmera, S.; Chinnam, S.; Kumar, V.; Mishra, R.K.; Acharya, B. Pyrolysis of waste oils for biofuel production: An economic and life cycle assessment. Fuel Commun. 2024, 18, 100108. [Google Scholar] [CrossRef]

- Antoniou, N.A.; Zorpas, A.A. Quality protocol and procedure development to define end-of-waste criteria for tire pyrolysis oil in the framework of circular economy strategy. Waste Manag. 2019, 95, 161–170. [Google Scholar] [CrossRef] [PubMed]

- Tamizhdurai, P.; Arthi, P.; Mangesh, V.L.; Krishnan, P.S.; Kumar, N.S.; Saravanan, P.; Subramani, A.; Sasikumar, P.; Alotibi, M.F.; Alreshaidan, S.B.; et al. Clean energy technology: Hydro-processing of waste tyre pyrolysis oil (WTPO) to diesel fuel in a continuous reactor using Co/SBA-15 catalyst. Appl. Energy Combust. Sci. 2025, 21, 100305. [Google Scholar] [CrossRef]

- Lutsey, N. Regulatory and technology lead-time: The case of US automobile greenhouse gas emission standards. Transp. Policy 2012, 21, 179–190. [Google Scholar] [CrossRef]

- Hariharasudhan, S.; Sankarlal, P. A Study on homogeneous charge compression ignition (HCCI) engine with alternate fuels. In Proceedings of the International Conference on Current Research in Engineering Science and Technology (ICCREST-2016), Jayaram College of Engineering & Technology, Trichy, India, 4 May 2016. [Google Scholar]

- Fattah, I.M.R.; Mofijur, M.; Silitonga, A.S.; Kalam, M.A.; Mahlia, T.M.I.; Ampah, J.D. Blending Low Carbon Fuels for Sustainable Transportation. Encycl. Renew. Energy Sustain. Environ. 2024, 3, 773–788. [Google Scholar] [CrossRef]

- Benajes, J.; García, A.; Monsalve-Serrano, J.; Guzmán-Mendoza, M. A review on low carbon fuels for road vehicles: The good, the bad and the energy potential for the transport sector. Fuel 2024, 361, 130647. [Google Scholar] [CrossRef]

| Report Attribute | Details |

|---|---|

| Base year | 2024 |

| Tyre pyrolysis oil market size in 2024 | USD 363.2 million |

| Forecast period 2025–2034 CAGR | 5.4% |

| 2034 value projection | USD 611.9 million |

| Historical data period | 2021–2024 |

| Segments covered | Raw material, process, end use and region |

| Growth drivers |

|

| Pitfalls/challenges | Technological limitations and production efficiency |

| Properties | Values |

|---|---|

| Density at 15 °C (kg/m3) | 900 to 935 |

| Kinematic viscosity at 40 °C (cSt) | 2.81 to 6.3 |

| Calorific value (MJ/kg) | 42 to 43.27 |

| Flashpoint (°C) | 20 to 43 |

| H/C ratio | 1.28 to 1.6 |

| Moisture (wt.%) | 4.6 |

| Sulphur (wt.%) | 0.6 to 1.45 |

| Carbon residue (wt.%) | 2.14 to 2.2 |

| Aromatic content (wt.%) | 64 |

| Emission Type | H2 + TPO Blend | H2 + Diesel Blend | H2 + Petrol Blend |

|---|---|---|---|

| CO2 emissions | Reduced compared with pure TPO; exact reduction varies based on the blend ratio and engine conditions, up to 18–22% at 30% H2 blend (avg.) | Decreased by approximately 10–15% compared with diesel alone | Reduced by approximately 11.7% on average; up to 31.2% reduction at a 20% H2 blend |

| CO emissions | Lower than TPO alone; specific values depend on the operating conditions, reduced to 20–35% at moderate engine load | Significantly reduced; exact figures vary across studies, ranging between 50 and 60% at a 30% H2 blend | Decreased with increasing H2 content; specific reductions depend on the blend ratio, up to 40% reduction at a 25% blend ratio |

| Hydrocarbon emissions | Decreased compared with TPO alone; specific values depend on the blend and engine load, normally in the range of 30–45% | Reduced by approximately 50% at a 30% H2 blend compared with diesel | Decreased with higher H2 content; exact reductions vary by up to 35–50% at a high H2 blend ratio |

| NOx emissions | Increased by 6–9% compared with TPO alone | Results vary: some studies report increases of up to 10%, while others report decreases or minimal changes | Variable (–5% to +12%); some studies indicate reductions while others show increases depending on the blend ratio and engine conditions |

| Smoke opacity | Reduced by up to 15–25% compared with TPO alone; specific values depend on the blend ratio up to 20–30% | Decreased from 67% (diesel) to 38% at a 30% H2 blend | Not specified in the available studies |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borkar, D.S.; Satputaley, S.; Alone, S.; Dudek, M. Comprehensive Review of Hydrogen and Tyre Pyrolysis Oil as Sustainable Fuels for HCCI Engines. Energies 2025, 18, 4448. https://doi.org/10.3390/en18164448

Borkar DS, Satputaley S, Alone S, Dudek M. Comprehensive Review of Hydrogen and Tyre Pyrolysis Oil as Sustainable Fuels for HCCI Engines. Energies. 2025; 18(16):4448. https://doi.org/10.3390/en18164448

Chicago/Turabian StyleBorkar, Dilip S., Sushant Satputaley, Santosh Alone, and Magdalena Dudek. 2025. "Comprehensive Review of Hydrogen and Tyre Pyrolysis Oil as Sustainable Fuels for HCCI Engines" Energies 18, no. 16: 4448. https://doi.org/10.3390/en18164448

APA StyleBorkar, D. S., Satputaley, S., Alone, S., & Dudek, M. (2025). Comprehensive Review of Hydrogen and Tyre Pyrolysis Oil as Sustainable Fuels for HCCI Engines. Energies, 18(16), 4448. https://doi.org/10.3390/en18164448