Comparison of Production Processes and Performance Between Polypropylene-Insulated and Crosslinked-Polyethylene-Insulated Low-Voltage Cables

Abstract

1. Introduction

2. Materials and Methods

2.1. Insulated Core Preparation

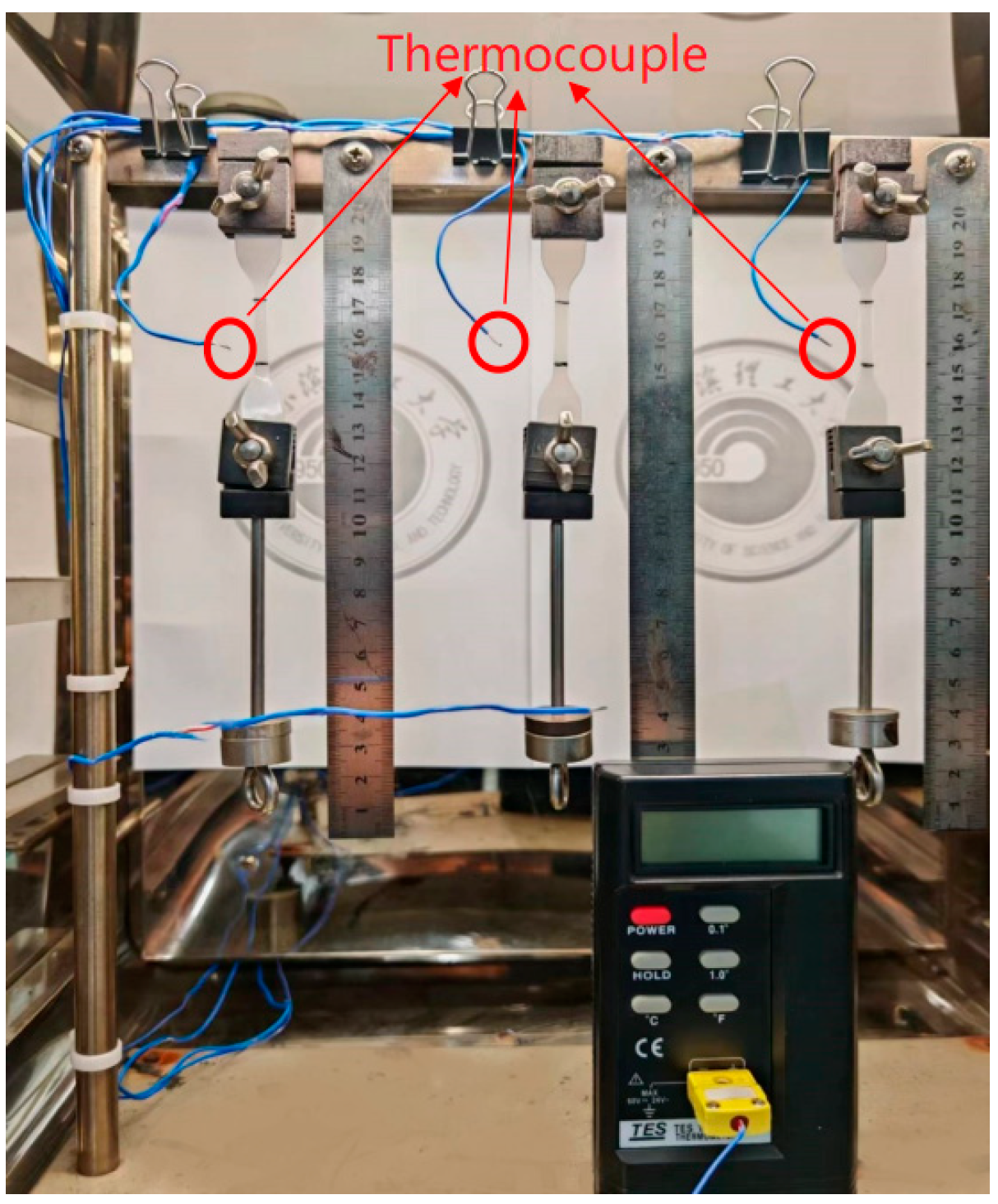

2.2. Mechanical Property Tests of Insulation Layers Before and After Thermal Aging

2.3. Thermal Extension and Crystallization Characteristic Testing

2.4. Electrical Performance Tests

3. Results

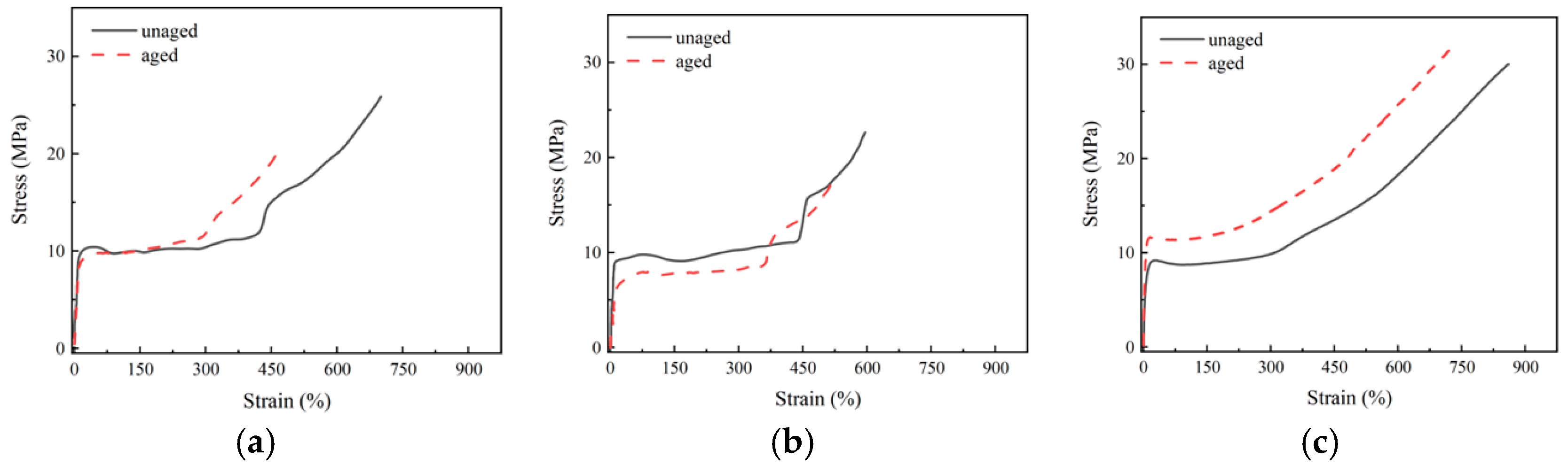

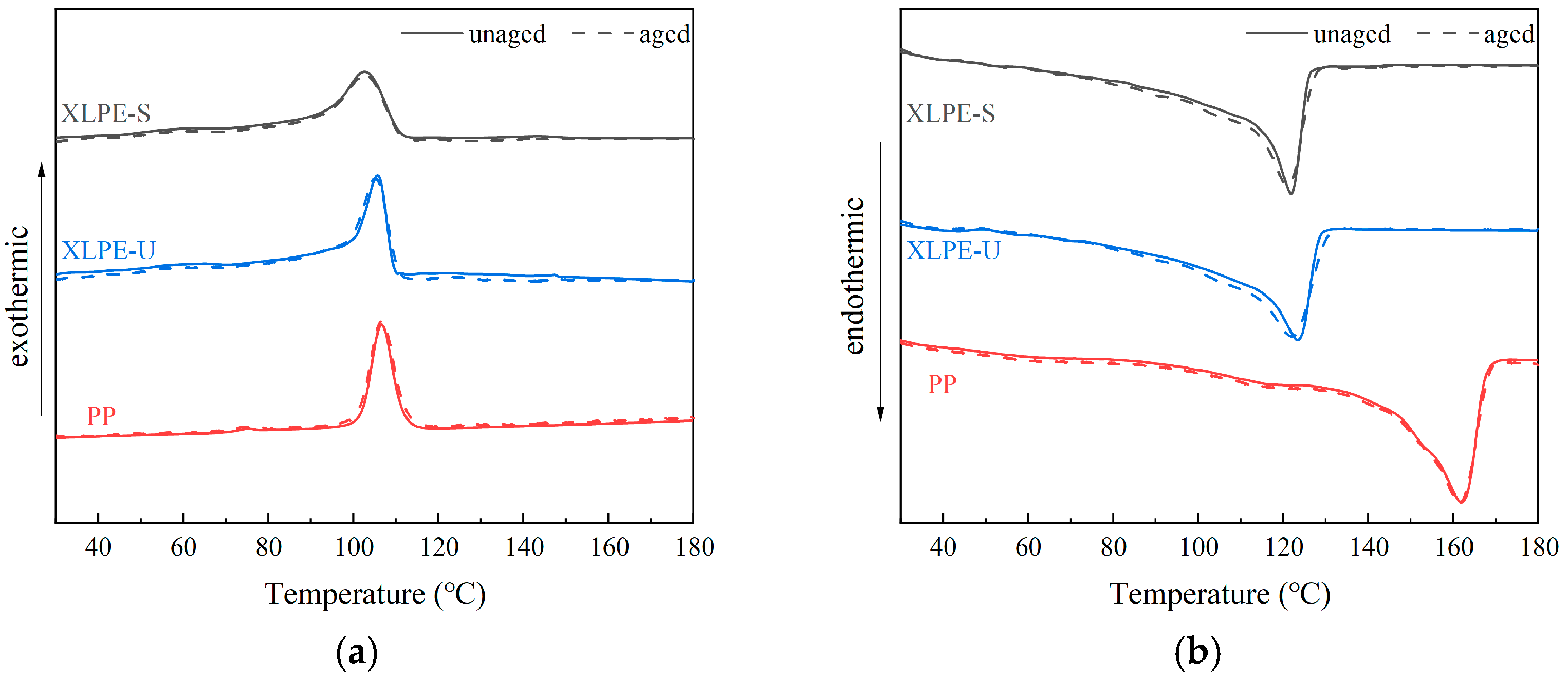

3.1. Mechanical Property Test Results of Insulation Layers Before and After Thermal Aging

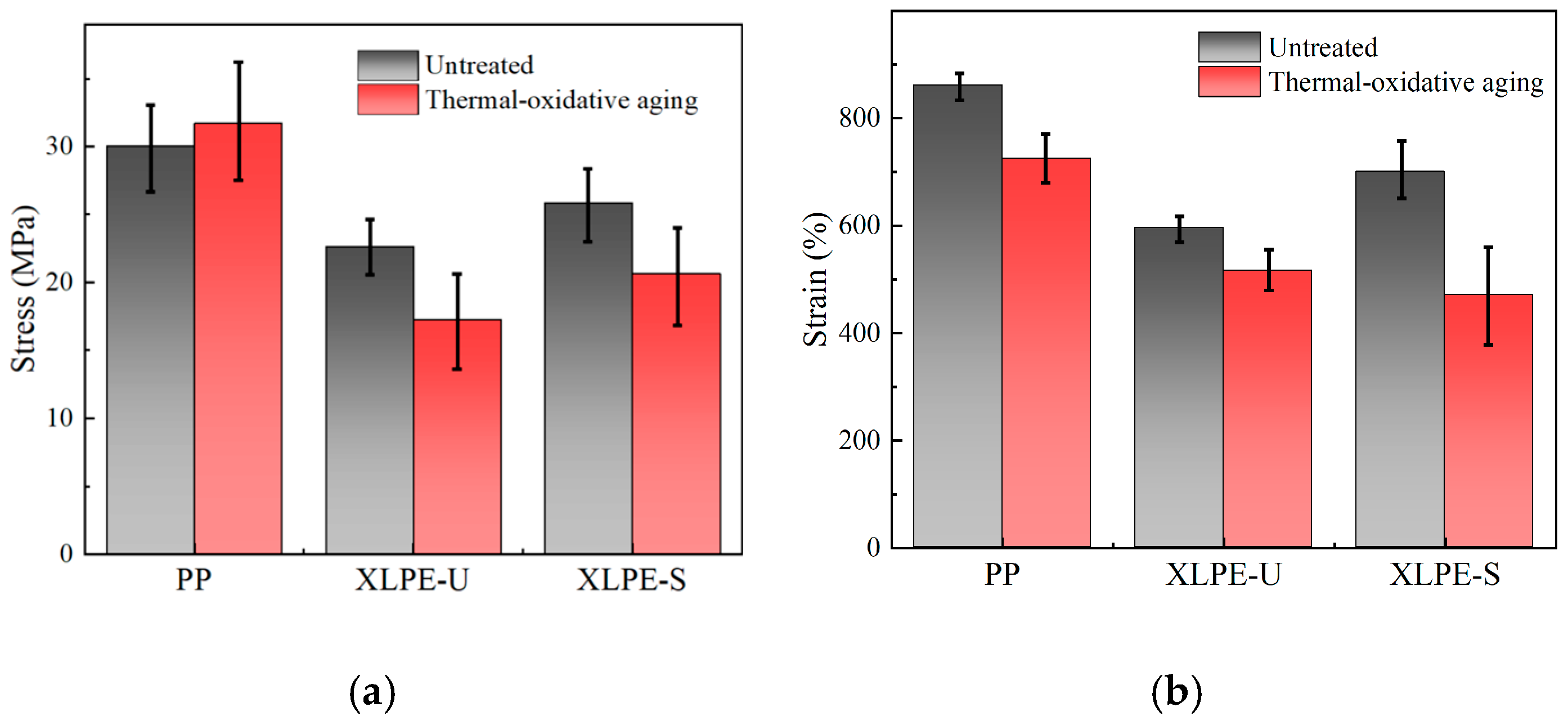

3.2. Hot Set Test Results of Insulation Layers

3.3. Electrical Performance Test Results

3.4. Production Process Parameters Comparison

4. Conclusions

- (1)

- Under the same extrusion process, PP low-voltage cable insulation exhibits the most excellent tensile properties. While XLPE-U and XLPE-S show stronger thermal load capacity due to their constructed physical crosslinking networks, PP insulation materials still meet the operational requirements of cables and maintain thermoplastic characteristics.

- (2)

- The PP insulation material maintains a high volume resistivity of 9.2 × 1015 Ω·m, ensuring no breakdown in the 4-h dielectric withstand test and sustaining excellent electrical insulation properties.

- (3)

- In full-process production and recycling, PP-insulated cables feature high production speed and short delivery cycle. Meanwhile, by eliminating the irradiation or high-temperature steaming process in insulation crosslinking, their production energy consumption and cost are significantly reduced. The thermoplastic properties of PP ensure green recycling after cable decommissioning.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qu, J.; Wang, S.; Li, S.; Wu, L.; Du, L.; Wang, Z.; Guo, L. The enhanced physical properties of XLPE insulation for high voltage cable based on LDPE/LLDPE or LDPE/HDPE blends. Polym. Degrad. Stab. 2023, 218, 110573. [Google Scholar] [CrossRef]

- Pourrahimi, A.; Pitois, C.; Abbasi, A. XLPE high voltage insulation; A link between DC conductivity and microstructure. Polym. Test. 2024, 131, 108330. [Google Scholar] [CrossRef]

- Ahmed, M.; Zhong, L.; Li, F.; Xu, N.; Gao, J. Improving the DC dielectric properties of XLPE with appropriate content of dicumyl peroxide for HVDC cables insulation. Materials 2022, 15, 5857. [Google Scholar] [CrossRef] [PubMed]

- Meng, F.; Chen, X.; Xu, X.; Dai, D.; Paramane, A.; Tanaka, Y. Effect of degassing treatment durations on physico-chemical and electrical properties of 500 kV extra HVDC XLPE cable insulation. Polym. Degrad. Stab. 2021, 188, 109566. [Google Scholar] [CrossRef]

- Li, Z.; Dong, Y.; Wu, Y.; Meng, Z.; Song, P.; Zhu, M.; Li, X.; Du, B. Breakdown performance evaluation and lifetime prediction of XLPE insulation in HVAC cables. Energies 2024, 17, 1337. [Google Scholar] [CrossRef]

- Sarkari, N.; Mohseni, M.; Ebrahimi, M. Examining impact of vapor-induced crosslinking duration on dynamic mechanical and static mechanical characteristics of silane-water crosslinked polyethylene compound. Polym. Test. 2021, 93, 106933. [Google Scholar] [CrossRef]

- Celina, M.; George, G. Characterisation and degradation studies of peroxide and silane crosslinked polyethylene. Polym. Degrad. Stab. 1995, 48, 297–312. [Google Scholar] [CrossRef]

- Huang, X.; Fan, Y.; Zhang, J.; Jiang, P. Polypropylene based thermoplastic polymers for potential recyclable HVDC cable insulation applications. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1446–1456. [Google Scholar] [CrossRef]

- Meng, P.; Zhou, Y.; Yuan, C.; Li, Q.; Liu, J.; Wang, H.; Hu, J.; He, J. Comparisons of different polypropylene copolymers as potential recyclable HVDC cable insulation materials. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 674–680. [Google Scholar] [CrossRef]

- Yang, K.; Liu, Y.; Yan, Z.; Tian, Z.; Liu, Y.; Jing, Z.; Li, J.; Li, S. Enhanced morphology-dependent tensile property and breakdown strength of impact polypropylene copolymer for cable insulation. Materials 2020, 13, 3935. [Google Scholar] [CrossRef]

- Hong, S.; Lee, S.; Han, J.; Ahn, M.; Park, H.; Han, S.; Lee, D.; Yu, S. Polypropylene-based soft ternary blends for power cable insulation at low-to-high temperature. J. Appl. Polym. Sci. 2022, 139, 51619. [Google Scholar] [CrossRef]

- Jiang, P.; Tanaka, T.; Zhang, J.; Huang, J. Material progress toward recyclable insulation of power cables part 2: Polypropylene-based thermoplastic materials. IEEE Electr. Insul. Mag. 2020, 36, 8–18. [Google Scholar]

- Mostofi, S.; Mohseni, M.; Ebrahimi, M. Crosslinkable Polyethylene Based Blends and Nanocomposites. In Risks and Limitations Associated with XLPE Nanocomposites and Blends; Springer: Singapore, 2021; pp. 411–456. [Google Scholar]

- Belli, S.; Perego, G.; Bareggi, A.; Caimi, L.; Donazzi, F.; Zaccone, E. P-Laser: Breakthrough in power cable systems. In Proceedings of the 2010 IEEE International Symposium on Electrical Insulation, San Diego, CA, USA, 16 August 2010. [Google Scholar]

- Gao, P.; Zhao, J.; Wang, Z. Research Progress of Polypropylene Materials in Application of Power Cables. Insul. Mater. 2023, 56, 1–10. [Google Scholar]

- Li, J.; Yang, K.; Wu, K.; Jing, Z.; Dong, J. Eco-friendly polypropylene power cable insulation: Present status and perspective. IET Nanodielectr. 2023, 6, 130–146. [Google Scholar] [CrossRef]

- Yu, S.; Lee, S.; Han, J.; Ahn, M.; Park, H.; Han, S.; Lee, D. Insulative ethylene-propylene copolymer-nanostructured polypropylene for high-voltage cable insulation applications. Polymer 2020, 202, 122674. [Google Scholar] [CrossRef]

- Pugach, V.; Polyakov, D.; Nikitin, K.; Zakharov, I.; Petukhova, N. Analysis of temperature conditions influence on cables insulation operation life. J. Phys. Conf. Ser. 2019, 1260, 052027. [Google Scholar] [CrossRef]

- Wruk, J.; Cibis, K.; Zdrallek, M. Economic benefit of preventive cable replacement in distribution networks based on the alignment with reinforcement measures. Electr. Power Syst. Res. 2022, 209, 107930. [Google Scholar] [CrossRef]

- IEC 60811-501:2012; Electric and Optical Fibre Cables—Test Methods for Non-Metallic Materials—Part 501: Mechanical Tests—Tests for Determining the Mechanical Properties of Insulating and Sheathing Compounds. IEC (International Electrotechnical Commission): Geneva, Switzerland, 2012.

- Liu, H.; Wang, S.; Li, S.; Wu, Y.; Jiang, L.; Lang, J.; Yuan, J.; Liu, J. Effect of thermo-oxidative aging on thermal elongation performance of XLPE insulation for high-voltage cables. Polym. Degrad. Stabil. 2023, 210, 110291. [Google Scholar] [CrossRef]

- Hosier, I.; Vaughan, A.; Swingler, S. An investigation of the potential of polypropylene and its blends for use in recyclable high voltage cable insulation systems. J. Mater. Sci. 2011, 46, 4058–4070. [Google Scholar] [CrossRef]

- IEC 60502-2:2014; Power Cables with Extruded Insulation and Their Accessories for Rated Voltages from 1 kV (Um = 1.2 kV) up to 30 kV (Um = 36 kV)—Part 2: Cables for Rated Voltages from 6 kV (Um = 7.2 kV) up to 30 kV (Um = 36 kV). IEC (International Electrotechnical Commission): Geneva, Switzerland, 2014.

- Barzin, J.; Azizi, H.; Morshedian, J. Preparation of silane-grafted and moisture cross-linked low density polyethylene: Part I: Factors affecting performance of grafting and cross-linking. Polym.-Plast. Technol. Eng. 2006, 45, 979–983. [Google Scholar] [CrossRef]

- Zamotaev, P.; Streltsova, Z.; Matisova-Rychla, L.; Chodak, I. Thermo-oxidation of crosslinked polyethylene: Influence of the antioxidant. Polym. Degrad. Stabil. 1993, 42, 167–174. [Google Scholar] [CrossRef]

- Zhu, Y.; Yoon, H.; Suh, K. Electrical properties of silane crosslinked polyethylene in comparison with DCP crosslinked polyethylene. IEEE Trns. Dielectr. Electr. Insul. 1999, 6, 164–168. [Google Scholar]

- Barzin, J.; Azizi, H.; Morshedian, J. Preparation of silane-grafted and moisture crosslinked low density polyethylene. Part II: Electrical, thermal and mechanical properties. Polym.-Plast. Technol. Eng. 2007, 46, 305–310. [Google Scholar] [CrossRef]

- Li, C.; Yang, Y.; Xu, G.; Zhou, Y.; Jia, M.; Zhong, S.; Gao, Y.; Park, C.; Liu, Q.; Wang, Y. Insulating materials for realising carbon neutrality: Opportunities, remaining issues and challenges. High Volt. 2022, 7, 610–632. [Google Scholar] [CrossRef]

- Meola, C.; Nele, L.; Giuliani, M.; Suriano, P. Chemical and irradiation cross-linking of polyethylene. Technological performance over costs. Polym.-Plast. Technol. Eng. 2004, 43, 631–648. [Google Scholar] [CrossRef]

- Hjertberg, T.; Palmlöf, M.; Sultan, B. Chemical reactions in crosslinking of copolymers of ethylene and vinyltrimethoxy silane. J. Appl. Polym. Sci. 1991, 42, 1185–1192. [Google Scholar] [CrossRef]

- Mazzanti, G.; Wurm, F.; Vergine, C.; Diban, B.; Ciroth, A.; Paajane, M.; Harjuhahto, J.; Lahti, K.; Pieroni, P.; Kannampuzha, M. The Horizon Europe NEWGEN Research Project: For a New Generation of High-Voltage DC Insulation Materials, Cables, and Systems after 24 Months since the Start of the Project. IEEE Ind. Appl. Mag. 2025, 31, 72–82. [Google Scholar] [CrossRef]

| Materials | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Zone 5 | Die Head |

|---|---|---|---|---|---|---|

| XLPE-S | 160 | 180 | 205 | 205 | 205 | 205 |

| XLPE-U | 160 | 180 | 205 | 205 | 205 | 205 |

| PP | 160 | 180 | 190 | 200 | 200 | 200 |

| Materials | Unaged | Aged | ||||

|---|---|---|---|---|---|---|

| Tm/°C | Tc/°C | Xc/% | Tm/°C | Tc/°C | Xc/% | |

| XLPE-S | 122.03 | 102.82 | 34.72 | 121.23 | 102.82 | 34.69 |

| XLPE-U | 123.65 | 105.73 | 32.89 | 122.36 | 105.24 | 32.81 |

| PP | 162.24 | 106.7 | 37.42 | 161.75 | 106.7 | 37.4 |

| Materials | Volume Resistivity (Ω·m) | 4-h Voltage-Withstand Test |

|---|---|---|

| PP | 9.2 × 1015 | No breakdown |

| XLPE-U | 3.9 × 1015 | No breakdown |

| XLPE-S | 3.0 × 1014 | No breakdown |

| Materials | PP | XLPE-U | XLPE-S |

|---|---|---|---|

| Extrusion Temperature (°C) | 200 | 180 | 180 |

| Production Speed (m/min) | 36 | 29 | 21 |

| Production Cycle (h) | 1 | 1 | 10 |

| Energy Consumption & Cost | Low | Medium | High |

| Environmental Protection | Easy | Medium | Difficult |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Y.; Pan, Z.; Song, H.; Ding, J.; Wang, K.; Yang, J.; Zhao, X. Comparison of Production Processes and Performance Between Polypropylene-Insulated and Crosslinked-Polyethylene-Insulated Low-Voltage Cables. Energies 2025, 18, 4371. https://doi.org/10.3390/en18164371

He Y, Pan Z, Song H, Ding J, Wang K, Yang J, Zhao X. Comparison of Production Processes and Performance Between Polypropylene-Insulated and Crosslinked-Polyethylene-Insulated Low-Voltage Cables. Energies. 2025; 18(16):4371. https://doi.org/10.3390/en18164371

Chicago/Turabian StyleHe, Yunping, Zeguo Pan, He Song, Junwang Ding, Kai Wang, Jiaming Yang, and Xindong Zhao. 2025. "Comparison of Production Processes and Performance Between Polypropylene-Insulated and Crosslinked-Polyethylene-Insulated Low-Voltage Cables" Energies 18, no. 16: 4371. https://doi.org/10.3390/en18164371

APA StyleHe, Y., Pan, Z., Song, H., Ding, J., Wang, K., Yang, J., & Zhao, X. (2025). Comparison of Production Processes and Performance Between Polypropylene-Insulated and Crosslinked-Polyethylene-Insulated Low-Voltage Cables. Energies, 18(16), 4371. https://doi.org/10.3390/en18164371