Structure/Aerodynamic Nonlinear Dynamic Simulation Analysis of Long, Flexible Blade of Wind Turbine

Abstract

1. Introduction

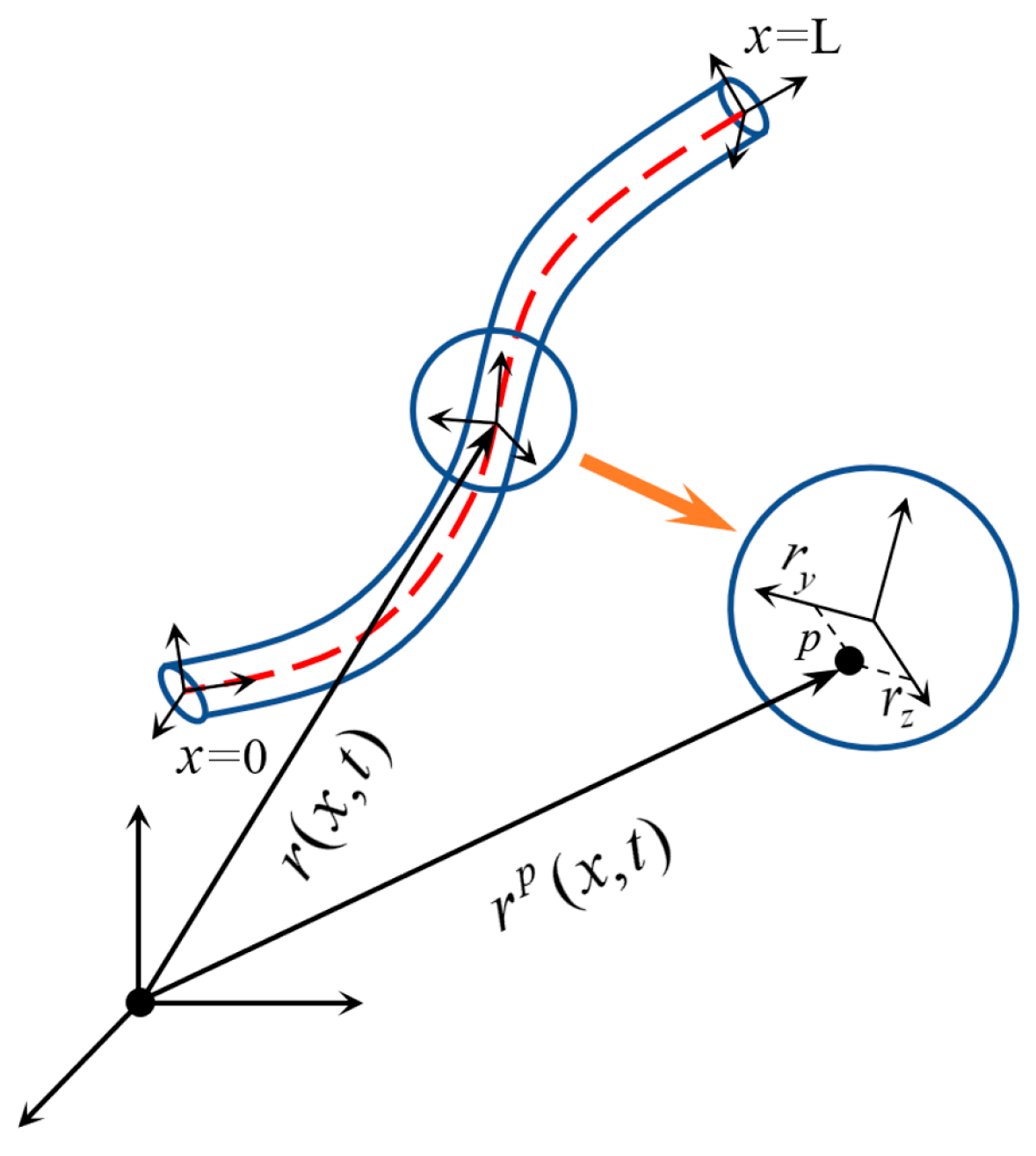

2. Absolute Nodal Coordinate Formulation

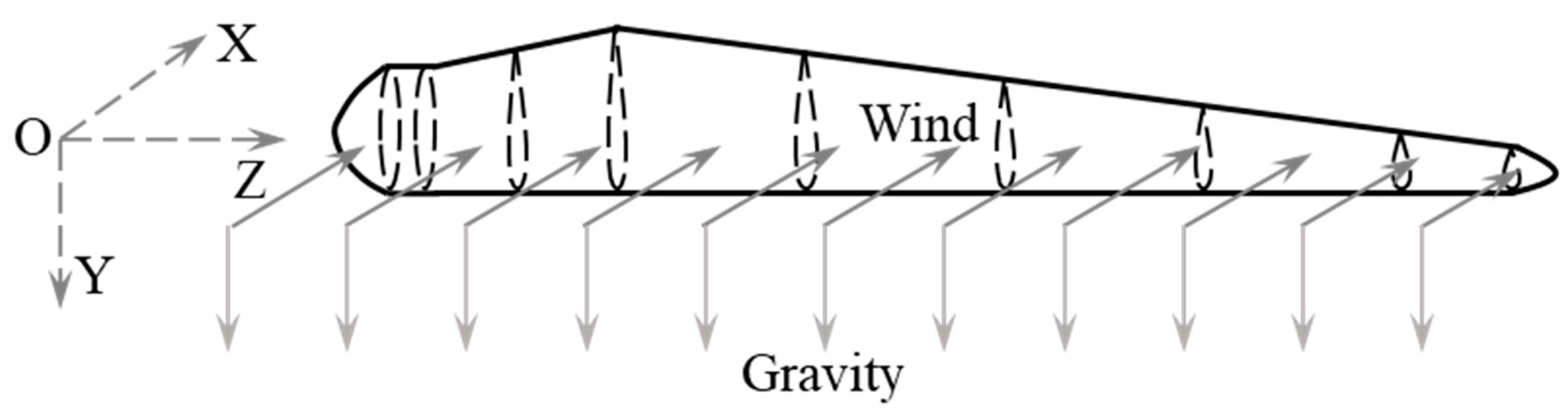

3. Aerodynamic Characteristics of Wind Turbine Blades

4. Simulation and Results

4.1. Model Simulation Settings

4.1.1. Construction of Constraint Equations

4.1.2. Working Condition Settings and Model Simulation Parameters

4.2. Comparison of Simulation Results of Blade Operating Conditions

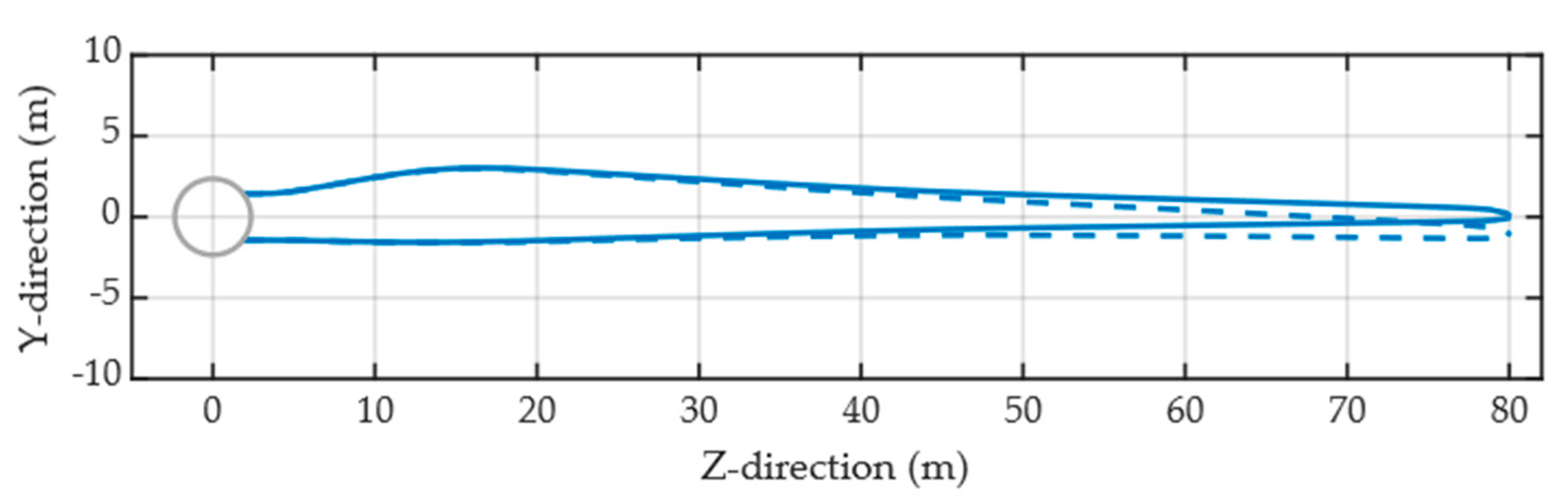

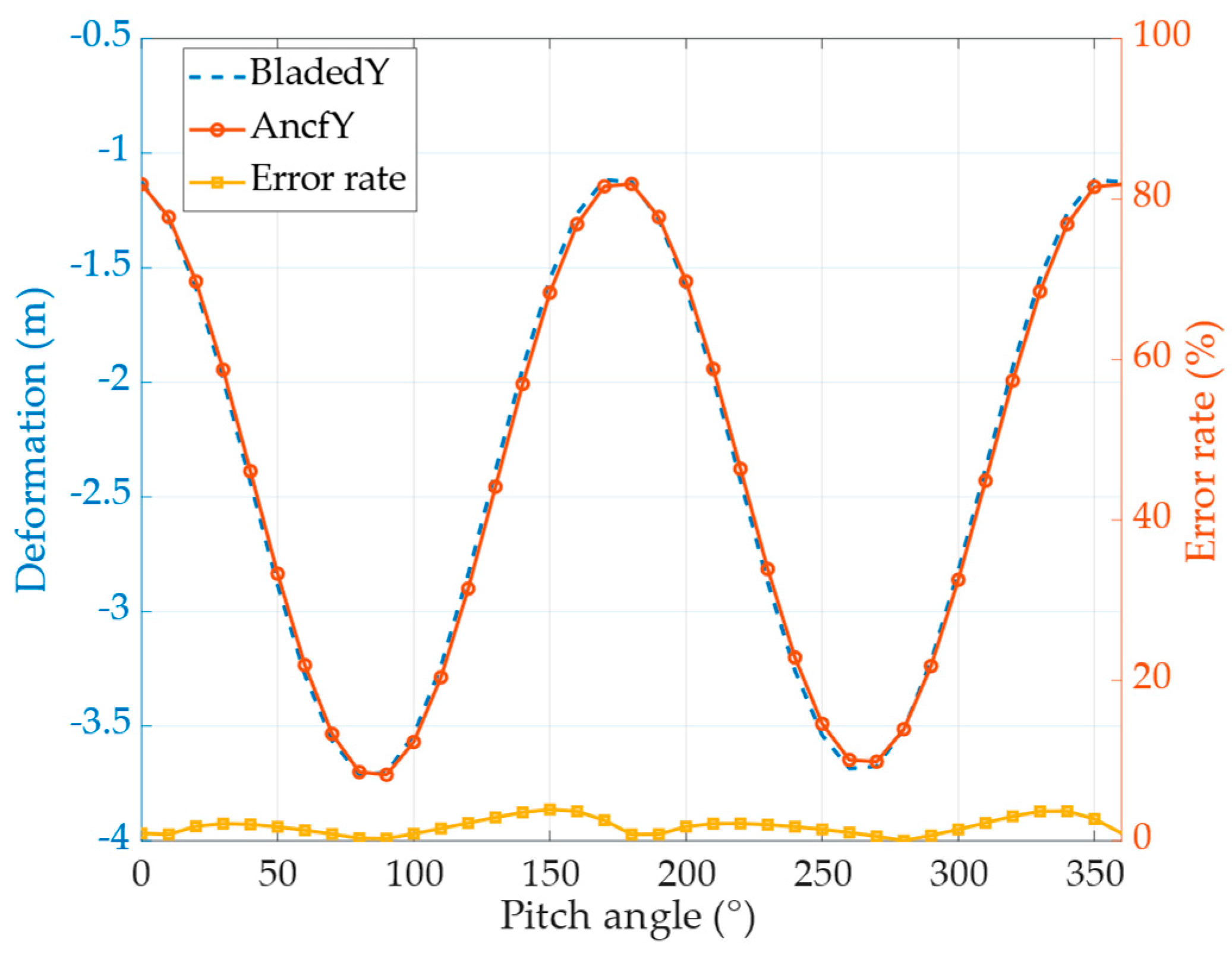

4.2.1. Condition 1: Horizontal Shutdown Condition Under Self-Weight

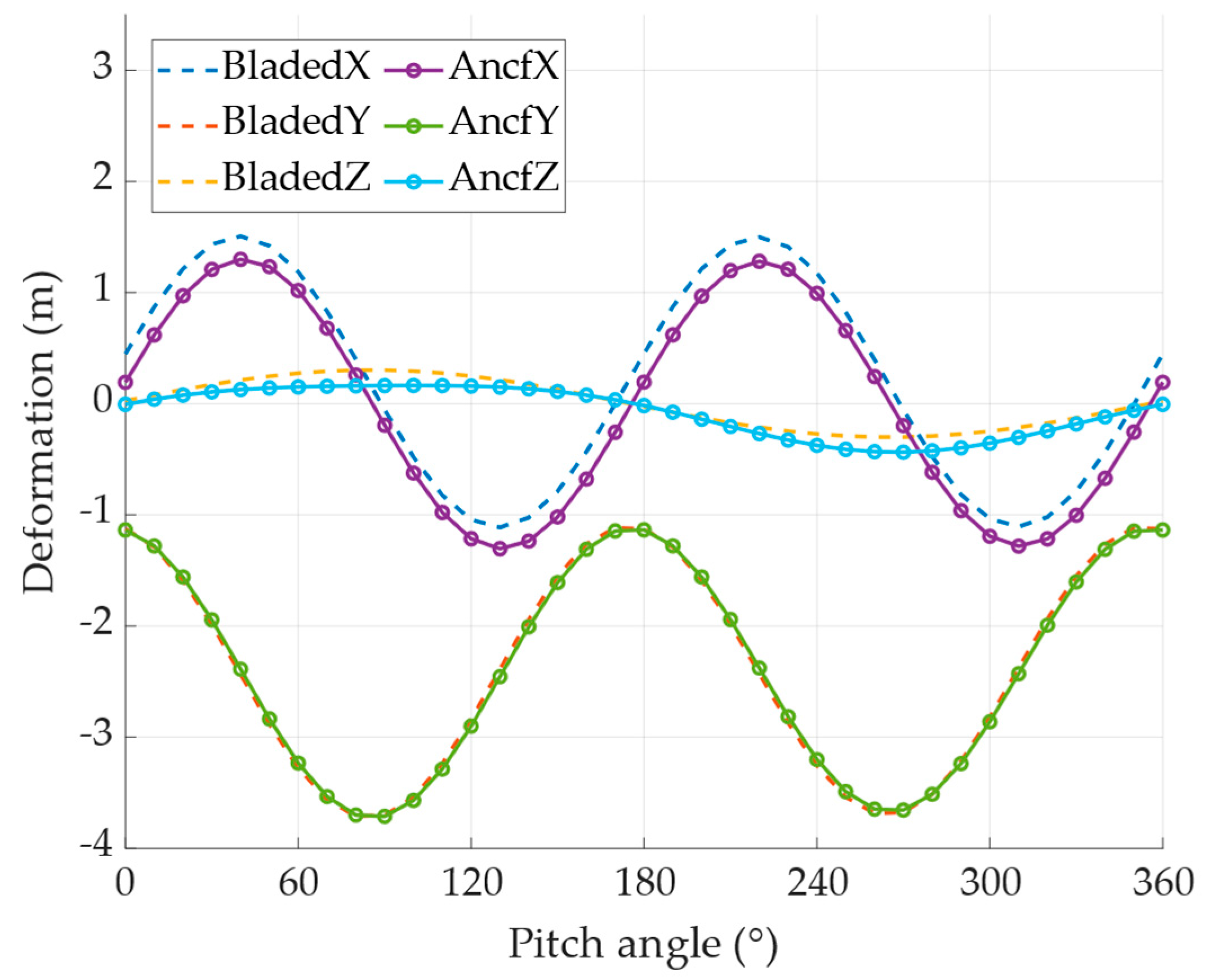

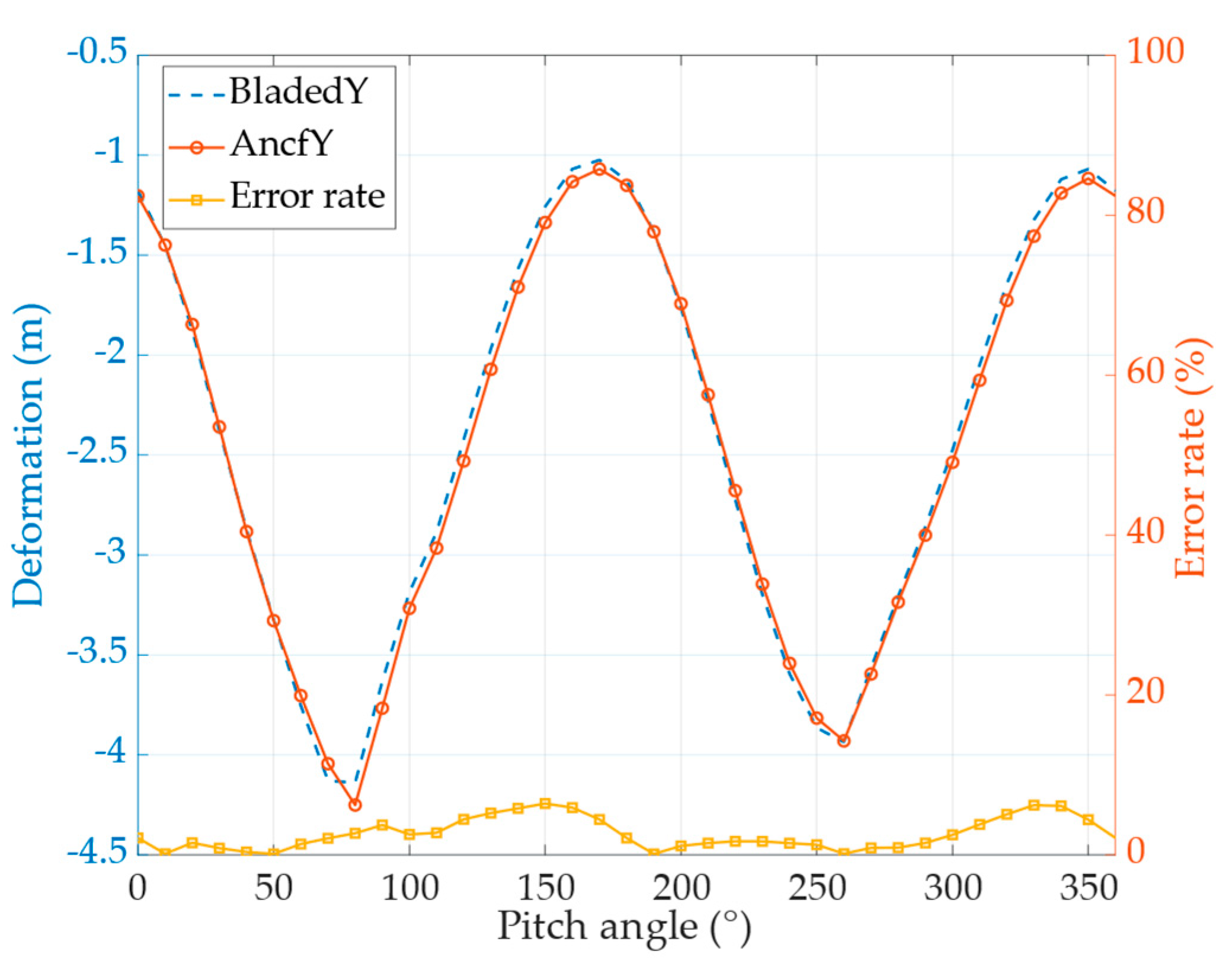

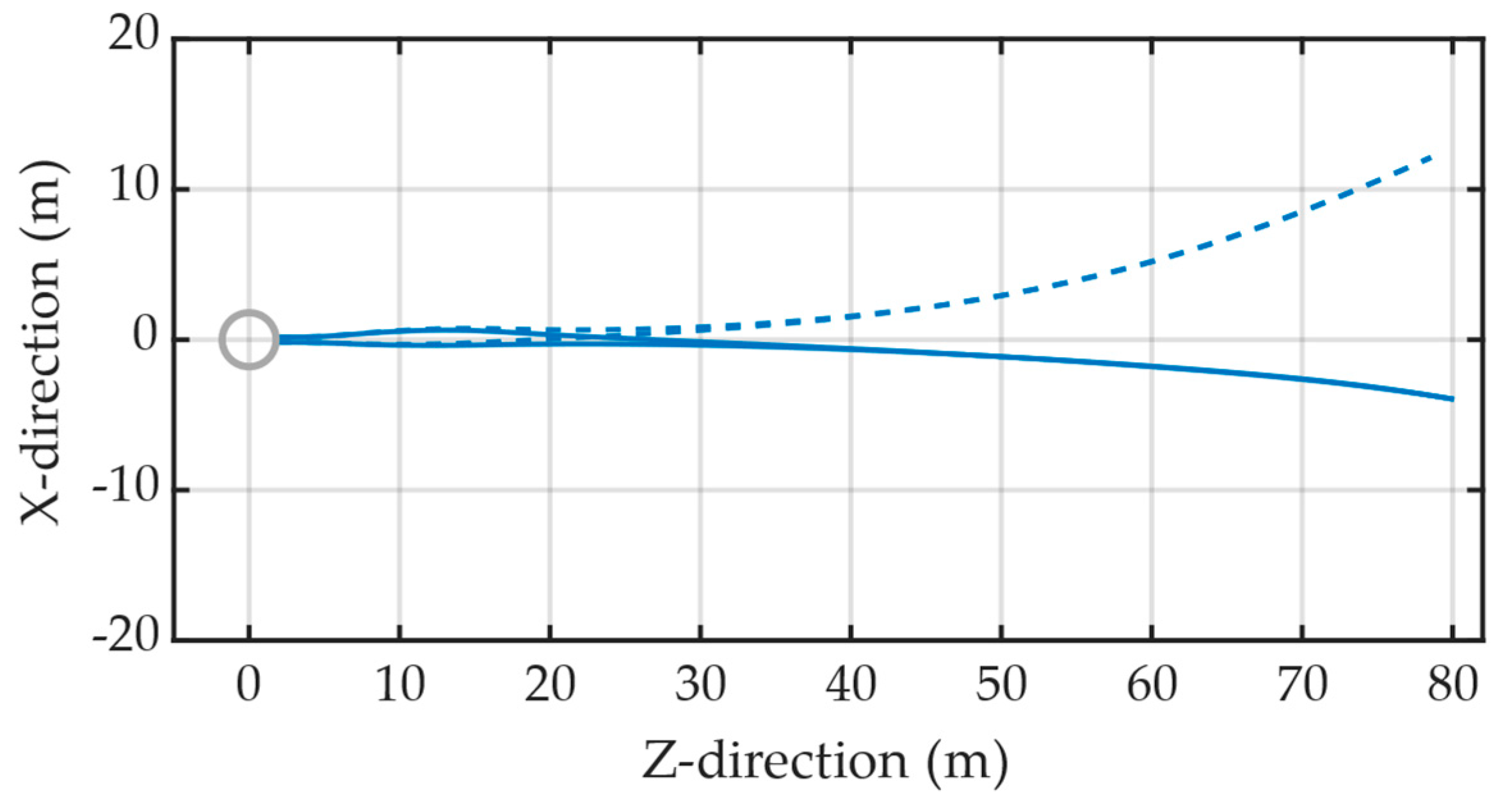

4.2.2. Condition 2: Horizontal Shutdown Condition Under Wind Load and Gravity

4.2.3. Condition 3: Operation Condition Under Wind Load and Gravity

5. Discussion

6. Conclusions

- (1)

- The results under shutdown conditions demonstrate that the dynamic model and aerodynamic load calculation method based on the Absolute Nodal Coordinate Formulation (ANCF) can accurately capture the nonlinear deformation behavior of wind turbine blades. (a). In the absence of wind load, the horizontally positioned shutdown blade is subjected solely to gravitational forces. The tip displacements computed at various pitch angles show good agreement with the results from the commercial software Bladed, with errors remaining within 5%. (b). Under wind loading, the correction of torsional stiffness through axis shifting introduces local errors whose influence becomes significant, resulting in a slightly larger discrepancy in the x-direction deformation compared to the Bladed results. The y-direction deformation error remains within 8%, indicating acceptable accuracy of the proposed model.

- (2)

- Under operating conditions, the aerodynamic force computed by the dynamic model is subject to reduced accuracy due to the use of simplified methods in the aerodynamic solution process. Additionally, the strong geometric nonlinearity of the blade structure, combined with the axial-shift correction of material properties, introduces multiple sources of deviation. These factors collectively contribute to notable differences in blade deformation predicted by the dynamic model across various wind speeds when compared to the results generated by the Bladed software. Nevertheless, the error in the x-direction—where the blade experiences the largest deformation compared to the other two directions—remains within 15%.

- (3)

- The proposed method proves to be both accurate and practical for the engineering-level analysis of large-scale wind turbine blades, providing a novel approach to blade dynamic modeling.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Della Posta, G.; Leonardi, S.; Bernardini, M. A two-way coupling method for the study of aeroelastic effects in large wind turbines. Renew. Energy 2022, 190, 971–992. [Google Scholar] [CrossRef]

- Liu, T.; Cui, Q.; Xu, D. Wind Turbine Composite Blades: A Critical Review of Aeroelastic Modeling and Vibration Control. FDMP-Fluid Dyn. Mater. Process 2025, 21, 1–36. [Google Scholar] [CrossRef]

- Wang, Y.; Cai, C.; Liao, C.; Hu, Z.; Zhang, L.; Sun, X.; Zhong, X.; Li, Q. Aeroelastic stability analysis of large-scale wind turbine blades under different operating conditions based on system identification and Floquet theory. Energy 2025, 326, 136279. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, L.; Li, X.; Li, S.; Yang, K. A study of dynamic response of a wind turbine blade based on the multi-body dynamics method. Renew. Energy 2020, 155, 358–368. [Google Scholar] [CrossRef]

- Navadeh, N.; Goroshko, I.O.; Zhuk, Y.A.; Etminan Moghadam, F.; Soleiman Fallah, A. Finite Element Analysis of Wind Turbine Blade Vibrations. Vibration 2021, 4, 310–322. [Google Scholar] [CrossRef]

- Chen, Y.; Zhou, S.; Cai, C.; Wang, W.; Hao, Y.; Zhou, T.; Wang, X.; Li, Q. Study on the Rotation Effect on the Modal Performance of Wind Turbine Blades. Energies 2023, 16, 1036. [Google Scholar] [CrossRef]

- Guo, S.X.; Li, Y.L.; Chen, W.M. Analysis on dynamic interaction between flexible bodies of large-sized wind turbine and its response to random wind loads. Renew. Energy 2021, 163, 123–137. [Google Scholar] [CrossRef]

- Abdullah, O.I.; Rakisheva, Z.B.; Jameel Al-Tamimi, A.N.; Majeed, M.H.; Khazem, E.A.; Schlattmann, J.; Mohammed, M.N.; Alfiras, M.; Alani, Z.N. Finite Element Analysis of Dynamic Behavior of NREL 5-MW Horizontal Axis Wind Turbine Blade. In Proceedings of the 2023 IEEE 8th International Conference on Engineering Technologies and Applied Sciences (ICETAS), Manama, Bahrain, 25–27 October 2023; pp. 1–6. [Google Scholar]

- Huang, H.S. Simulations of 10MW wind turbine under seismic loadings. Compos. Struct. 2022, 279, 114686. [Google Scholar] [CrossRef]

- Wang, Z.; Lu, Z.; Yi, W.; Hao, J.; Chen, Y. A study of nonlinear aeroelastic response of a long flexible blade for the horizontal axis wind turbine. Ocean Eng. 2023, 279, 113660. [Google Scholar] [CrossRef]

- Jiang, B.; Hui, Y.; Yang, Q.; Hua, X. Nonlinear dynamic analysis of parked large wind turbine blade considering harmonic inertial excitation using continuum mathematical model. Thin-Walled Struct. 2022, 181, 110128. [Google Scholar] [CrossRef]

- Arany, L.; Bhattacharya, S.; Adhikari, S.; Hogan, S.J.; Macdonald, J.H.G. An analytical model to predict the natural frequency of offshore wind turbines on three-spring flexible foundations using two different beam models. Soil Dyn. Earthq. Eng. 2015, 74, 40–45. [Google Scholar] [CrossRef]

- Yin, Y.; Liao, M.; Lyu, P. Analysis of Transient Response of Wind Turbine Blade Based Timoshenko Beam. Taiyangneng Xuebao/Acta Energiae Solaris Sin. 2017, 38, 2552–2558. [Google Scholar]

- Ma, H.; Lu, Y.; Wu, Z.; Tai, X.; Li, H.; Wen, B. A new dynamic model of rotor-blade systems. J. Sound Vib. 2015, 357, 168–194. [Google Scholar] [CrossRef]

- Otero, A.D.; Ponta, F.L. Structural Analysis of Wind-Turbine Blades by a Generalized Timoshenko Beam Model. J. Sol. Energy Eng. 2010, 132, 011015. [Google Scholar] [CrossRef]

- Zhou, X.; Huang, K.; Li, Z. Geometrically nonlinear beam analysis of composite wind turbine blades based on quadrature element method. Int. J. Non-Linear Mech. 2018, 104, 87–99. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, P.; Li, Y. Structural dynamic analysis of a tidal current turbine using geometrically exact beam theory. J. Offshore Mech. Arct. Eng. 2018, 140, 021903. [Google Scholar] [CrossRef]

- Leng, J.; Zhang, L.; Li, Y. Structural dynamic characteristics of vertical axis wind and tidal current turbines. Proc. R. Soc. A Math. Phys. Eng. Sci. 2024, 480, 20240234. [Google Scholar] [CrossRef]

- Rezaei, M.M.; Behzad, M.; Haddadpour, H.; Moradi, H. Aeroelastic analysis of a rotating wind turbine blade using a geometrically exact formulation. Nonlinear Dyn. 2017, 89, 2367–2392. [Google Scholar] [CrossRef]

- Saravia, C.M.; Gatti, C.D.; Ramirez, J.M. On the determination of the mechanical properties of wind turbine blades: Geometrical aspects of line based algorithms. Renew. Energy 2017, 105, 55–65. [Google Scholar] [CrossRef]

- Chen, J.; Shen, X.; Zhu, X.; Du, Z. Study on composite bend-twist coupled wind turbine blade for passive load mitigation. Compos. Struct. 2019, 213, 173–189. [Google Scholar] [CrossRef]

- Ma, X.; Peng, X.; Sun, J.; Chen, Y.; Huang, Z. A Comprehensive Investigation of Linear and Nonlinear Beam Models on Flexible Wind Turbine Blade Load Calculations. J. Mar. Sci. Eng. 2024, 12, 548. [Google Scholar] [CrossRef]

- Wan, C.; Hou, J.; Xue, S.; Zhang, G.; Xie, L.; Huang, G. Forced vibration of a novel beam model considering the shear deformation induced rotary inertia. Structures 2023, 47, 2541–2556. [Google Scholar] [CrossRef]

- Rangari, A.S.; Elishakoff, I.; Sarkar, K.; Amer Soc Mechanical, E. Slope-Inertia Model For Rotating Timoshenko-Ehrenfest Beams. In Proceedings of the ASME Aerospace Structures, Structural Dynamics, and Materials Conference (SSDM), San Diego, CA, USA, 19–21 June 2023. [Google Scholar]

- Panteli, A.N.; Manolas, D.I.; Riziotis, V.A.; Spiliopoulos, K.V. Comparative study of two geometrically non-linear beam approaches for the coupled wind turbine system. J. Wind Eng. Ind. Aerodyn. 2022, 231, 105231. [Google Scholar] [CrossRef]

- Tang, S.; Sweetman, B.; Gao, J. Nonlinear effects and dynamic coupling of floating offshore wind turbines using geometrically-exact blades and momentum-based methods. Ocean Eng. 2021, 229, 108866. [Google Scholar] [CrossRef]

- Wu, X.; Feng, K.; Li, Q. A Numerical Method for the Dynamics Analysis of Blade Fracture Faults in Wind Turbines Using Geometrically Exact Beam Theory and Its Validation. Energies 2024, 17, 824. [Google Scholar] [CrossRef]

- Lü, P.; Liao, M.; Xu, Y.; Yin, Y. Beam Finite Element for Wind Turbine Bladebased on Geometrically Exact Beam Theory. Acta Energiae Solaris Sin. 2015, 36, 2422–2428. [Google Scholar]

- Xiaohang, Q.; Zhiteng, G.; Tongguang, W.; Long, W.; Shitang, K. Nonlinear aeroelastic response analysis of 100-meter-scale flexible wind turbine blades. Acta Aerodyn. Sin. 2022, 40, 220–230. [Google Scholar]

- Chen, J.; Shen, X.; Liu, P.; Zhu, X.; Du, Z. Design tool for aeroelastic analysis of wind turbine blades based on geometrically exact beam theory and lifting surface method. In Proceedings of the 35th Wind Energy Symposium, Shanghai, China, 9–13 January 2017; p. 0450. [Google Scholar]

- Wang, L.; Liu, X.; Renevier, N.; Stables, M.; Hall, G.M. Nonlinear aeroelastic modelling for wind turbine blades based on blade element momentum theory and geometrically exact beam theory. Energy 2014, 76, 487–501. [Google Scholar] [CrossRef]

- Wang, Q.; Sprague, M.A.; Jonkman, J.; Johnson, N.; Jonkman, B. BeamDyn: A high-fidelity wind turbine blade solver in the FAST modular framework. Wind Energy 2017, 20, 1439–1462. [Google Scholar] [CrossRef]

- Leng, J.; Wang, Q.; Li, Y. A geometrically nonlinear analysis method for offshore renewable energy systems-Examples of offshore wind and wave devices. Ocean Eng. 2022, 250, 110930. [Google Scholar] [CrossRef]

- Wang, F.; Yang, Y.; Zeng, J.; Yang, Y. Research on dynamics of icing wind turbine blade based on geometrically exact beam theory. J. Sound Vib. 2025, 601, 118927. [Google Scholar] [CrossRef]

- Ren, H.; Weng, S.; Ke, S.; Zhao, K.; Tian, W. Investigation of wind-induced vibration evolution mechanisms in long-span flexible photovoltaic structures using three-dimensional digital image correlation method in aeroelastic wind tunnel tests. Phys. Fluids 2025, 37, 047126. [Google Scholar] [CrossRef]

- Lu, M.-m.; Ke, S.-t.; Wu, H.-x.; Tian, W.-x.; Wang, H.; Gao, M.-e. A novel forecasting method of flutter critical wind speed for the 15 MW wind turbine blade based on aeroelastic wind tunnel test. J. Wind. Eng. Ind. Aerodyn. 2022, 230, 105195. [Google Scholar] [CrossRef]

- Neunaber, I.; Danbon, F.; Soulier, A.; Voisin, D.; Guilmineau, E.; Delpech, P.; Courtine, S.; Taymans, C.; Braud, C. Wind tunnel study on natural instability of the normal force on a full-scale wind turbine blade section at Reynolds number 4.7 106. Wind Energy 2022, 25, 1332–1342. [Google Scholar] [CrossRef]

- Gao, R.; Yang, J.; Yang, H.; Wang, X. Wind-tunnel experimental study on aeroelastic response of flexible wind turbine blades under different wind conditions. Renew. Energy 2023, 219, 119539. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, L.; Amjad, A.; Yang, H.; Yang, J. Experimental investigation on Aeroelastic response of long flexible blades in turbulent flow. Appl. Energy 2024, 375, 124109. [Google Scholar] [CrossRef]

- Maktouf, R.; Yangui, M.; Fakhfekh, T.; Nasri, R.; Haddar, M.A. Non-linear dynamic analysis of a wind turbine blade. J. Chin. Inst. Eng. 2019, 42, 727–737. [Google Scholar] [CrossRef]

- Zhao, X.; Jiang, X.; Zhu, W.; Li, J. Semi-analytical solutions for steady-state bending-bending coupled forced vibrations of a rotating wind turbine blade by means of Green’s functions. J. Sound Vib. 2025, 596, 118714. [Google Scholar] [CrossRef]

- Jokar, H.; Mahzoon, M.; Vatankhah, R. Nonlinear dynamic characteristics of horizontal-axis wind turbine blades including pre-twist. Ocean Eng. 2022, 256, 111441. [Google Scholar] [CrossRef]

- Jokar, H.; Vatankhah, R.; Mahzoon, M. Nonlinear super-harmonic and sub-harmonic resonance analysis of the horizontal-axis wind turbine blades using multiple scale method including the pre-twist effects. Ocean Eng. 2022, 265, 112610. [Google Scholar] [CrossRef]

- Wu, H.; Ke, S.; Lu, M.; Gao, M.; Tian, W.; Liu, D.; Li, Y.; Wang, T. Research on vibration suppression effect and energy dissipation mechanism of wind turbine piezoelectric blade. J. Fluids Struct. 2023, 117, 103814. [Google Scholar] [CrossRef]

- Wu, H.; Ke, S.; Ren, H.; Tian, W.; Wang, H.; Zhu, S.; Wang, T. An efficient reduced-order modeling framework for spatiotemporal aerodynamic damping in flexible wind turbine blades. Phys. Fluids 2025, 37, 055149. [Google Scholar] [CrossRef]

- Jiang, T.; Guo, X.; Zhang, Y.; Li, D. Study and Quantitative Analysis of Mode Localization in Wind Turbine Blades. J. Mar. Sci. Eng. 2024, 12, 67. [Google Scholar] [CrossRef]

- Algolfat, A.; Wang, W.; Albarbar, A. Study of Centrifugal Stiffening on the Free Vibrations and Dynamic Response of Offshore Wind Turbine Blades. Energies 2022, 15, 6120. [Google Scholar] [CrossRef]

- Fan, W.; Zhu, W.D. An accurate singularity-free geometrically exact beam formulation using Euler parameters. Nonlinear Dyn. 2018, 91, 1095–1112. [Google Scholar] [CrossRef]

- Shabana, A.A. An Absolute Nodal Coordinate Formulation for the Large Rotation and Deformation Analysis of Flexible Bodies; UIC Dynamic Simulation Laboratory: Chicago, IL, USA, 1996. [Google Scholar]

- Ren, H. A Simple Absolute Nodal Coordinate Formulation for Thin Beams With Large Deformations and Large Rotations. J. Comput. Nonlinear Dyn. 2015, 10, 061005. [Google Scholar] [CrossRef]

- Otsuka, K.; Makihara, K.; Sugiyama, H. Recent Advances in the Absolute Nodal Coordinate Formulation: Literature Review From 2012 to 2020. J. Comput. Nonlinear Dyn. 2022, 17, 080803. [Google Scholar] [CrossRef]

- Nada, A.A. Use of B-spline surface to model large-deformation continuum plates: Procedure and applications. Nonlinear Dyn. 2013, 72, 243–263. [Google Scholar] [CrossRef]

- Bayoumy, A.H.; Nada, A.A.; Megahed, S.M. A Continuum Based Three-Dimensional Modeling of Wind Turbine Blades. J. Comput. Nonlinear Dyn. 2013, 8, 031004. [Google Scholar] [CrossRef]

- Hansen, M. Aerodynamics of Wind Turbines; Routledge: London, UK, 2015. [Google Scholar]

- Ponta, F.L.; Otero, A.D.; Lago, L.I.; Rajan, A. Effects of rotor deformation in wind-turbine performance: The Dynamic Rotor Deformation Blade Element Momentum model (DRD-BEM). Renew. Energy 2016, 92, 157–170. [Google Scholar] [CrossRef]

| Method | Accuracy | Efficiency | Relevant Literature | Relevant Software or Code |

|---|---|---|---|---|

| Solid or shell elements (FEM) | High | Low | [5,6,7,8,9] | Ansys, Abaqus |

| Euler–Bernoulli beam | Low | High | [10,11,12,22,23] | OpenFAST, Bladed, Modelica |

| Timoshenko beam | Medium | High | [13,14,15,16,24,25,26] | OpenFAST, Bladed |

| Geometrically exact beam | High | Medium | [17,18,19,20,21,27,28,29,30,31,32,33,34] | BEAMDyn |

| Number | Mass per Unit Length kg/m | Polar Inertia per Unit Length kgm | Bending Stiffness About z Nm2 | Bending Stiffness About y Nm2 |

|---|---|---|---|---|

| 1 | 3338.745 | 3717.804 | 331,868 × 105 | 3,306,347 × 104 |

| 2 | 855.8789 | 1724.239 | 1,646,356 × 104 | 1,631,844 × 104 |

| 3 | 529.8153 | 1038.684 | 9,198,995 × 103 | 8,925,694 × 103 |

| 4 | 464.9871 | 891.6566 | 7,225,307 × 103 | 7,075,645 × 103 |

| … | … | … | … | … |

| 45 | 151.5797 | 65.82533 | 9,218,432 × 102 | 1,888,861 × 102 |

| 46 | 159.885 | 65.04521 | 8,620,131 × 102 | 1,691,846 × 102 |

| 47 | 142.219 | 55.30613 | 8,088,488 × 102 | 1,547,374 × 102 |

| 48 | 135.4281 | 50.04884 | 7,424,591 × 102 | 1,349,393 × 102 |

| … | … | … | … | … |

| 79 | 5.688307 | 5.5037 × 10−2 | 277,481.2 | 2839.561 |

| 80 | 0.2554282 | 5.632 × 10−6 | 27.60785 | 0.165301 |

| Number | Hub Wind Speed [m/s] | Rotor Speed [rpm] | Pitch Angle [deg] |

|---|---|---|---|

| 1 | 5.0 | 13 | 0 |

| 2 | 5.5 | 13 | 0 |

| 3 | 6.0 | 13 | 0 |

| 4 | 6.5 | 13 | 0 |

| … | … | … | … |

| 9 | 9.0 | 13 | 0 |

| 10 | 9.5 | 13 | 0 |

| … | … | … | … |

| 14 | 11.5 | 13 | 0 |

| 15 | 12.0 | 13 | 0 |

| 16 | 12.5 | 13 | 0 |

| 17 | 13 | 13 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, X.; Yang, S.; Yang, Z.; Cai, C.; Zhang, L.; Li, Q.; Choi, J.-H. Structure/Aerodynamic Nonlinear Dynamic Simulation Analysis of Long, Flexible Blade of Wind Turbine. Energies 2025, 18, 4362. https://doi.org/10.3390/en18164362

Zhu X, Yang S, Yang Z, Cai C, Zhang L, Li Q, Choi J-H. Structure/Aerodynamic Nonlinear Dynamic Simulation Analysis of Long, Flexible Blade of Wind Turbine. Energies. 2025; 18(16):4362. https://doi.org/10.3390/en18164362

Chicago/Turabian StyleZhu, Xiangqian, Siming Yang, Zhiqiang Yang, Chang Cai, Lei Zhang, Qing’an Li, and Jin-Hwan Choi. 2025. "Structure/Aerodynamic Nonlinear Dynamic Simulation Analysis of Long, Flexible Blade of Wind Turbine" Energies 18, no. 16: 4362. https://doi.org/10.3390/en18164362

APA StyleZhu, X., Yang, S., Yang, Z., Cai, C., Zhang, L., Li, Q., & Choi, J.-H. (2025). Structure/Aerodynamic Nonlinear Dynamic Simulation Analysis of Long, Flexible Blade of Wind Turbine. Energies, 18(16), 4362. https://doi.org/10.3390/en18164362