Evolution of Shipboard Motor Failure Monitoring Technology: Multi-Physics Field Mechanism Modeling and Intelligent Operation and Maintenance System Integration

Abstract

1. Introduction

2. Fault Mechanisms and Characteristic Analysis of Shipboard Motors

2.1. Typical Fault Classification and Physical Modeling

- (1)

- Fault Mechanisms of Main Propulsion Motors

- 1)

- Bearing Electrical Erosion

- 2)

- Rotor Eccentricity (Propulsion Load Impact)

- (2)

- Auxiliary Motor Failure Mechanism

- (3)

- Propulsion Motor Failure Mechanisms

- 1)

- Permanent Magnet Demagnetization

- 2)

- Stator Winding Partial Discharge (PWM inverter stress)

2.2. Fault Feature Signal Extraction

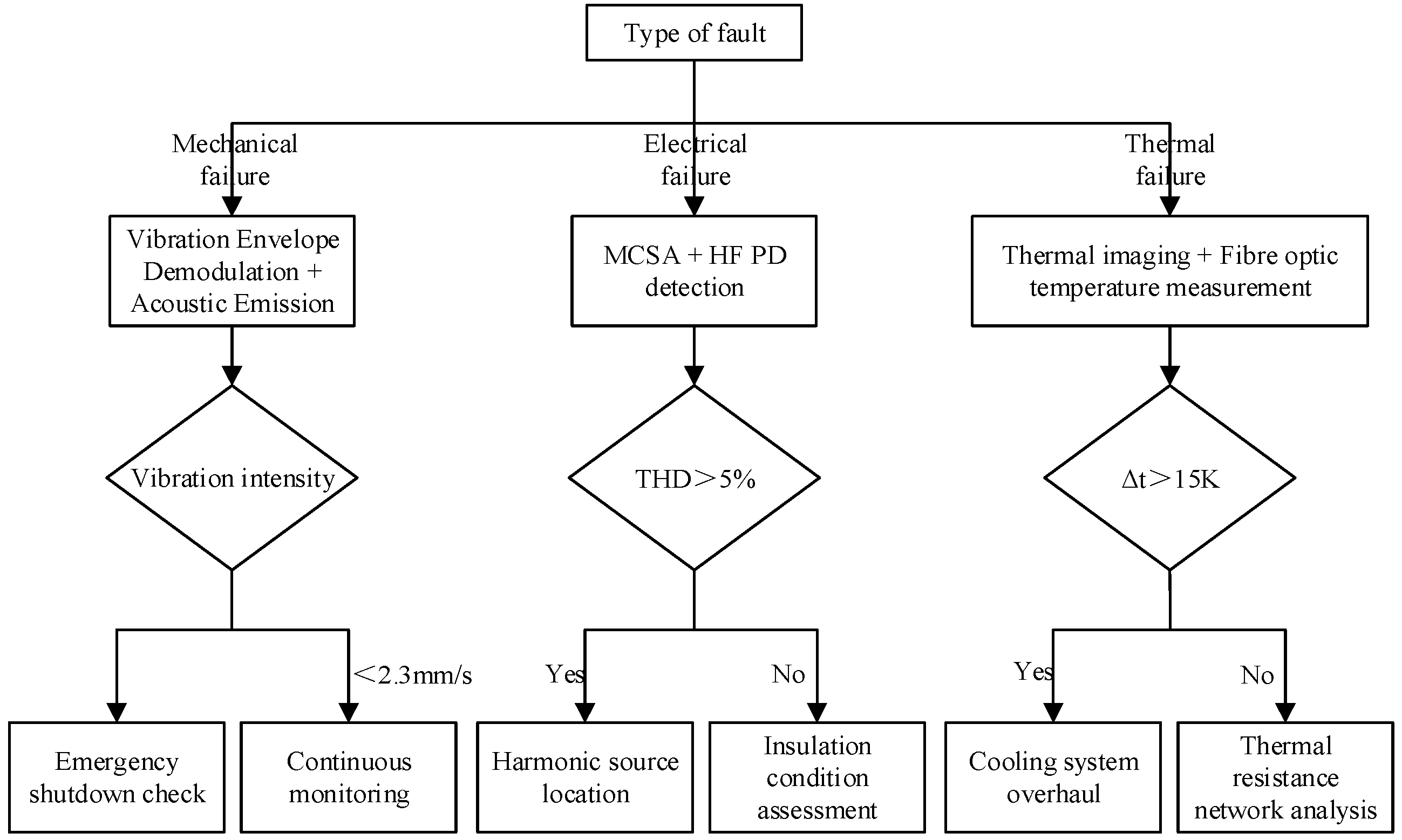

3. Key Technology for Shipboard Motor Fault Monitoring

3.1. Model-Driven Approach

3.2. Data-Driven Approach

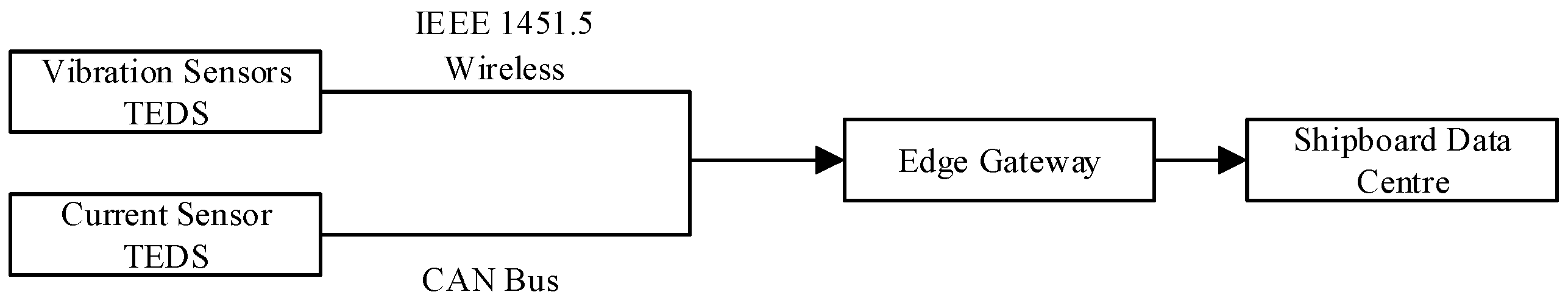

3.3. Edge Computing and Embedded Systems

3.3.1. Lightweight Fault Detection Platform

3.3.2. Smart Sensor Network Construction

4. Analysis of Technical Challenges in the Special Environment of Ships

4.1. Electromagnetic Compatibility Issues

4.2. Reliability Verification Criteria

5. Future Research Directions

5.1. Digital Twin

5.2. Self-Directed Health Management

5.3. New Sensor Technology

6. Conclusions and Recommendations

Author Contributions

Funding

Conflicts of Interest

References

- IEEE. IEEE Standard Test Procedure for Polyphase Induction Motors and Generators; IEEE: Piscataway, NJ, USA, 2018. [Google Scholar] [CrossRef]

- The Three Departments Jointly Issued the Action Plan for the Development of Intelligent Ships (2019–2021). Available online: https://www.gov.cn/xinwen/2018-12/30/content_5353550.htm (accessed on 18 April 2025).

- Vrijdag, A.; Martelli, M. Parameter Identification of a Model Scale Ship Drive Train. J. Mar. Sci. Eng. 2021, 9, 268. [Google Scholar] [CrossRef]

- Aizpurua, J.I.; Knutsen, K.E.; Heimdal, M.; Vanem, E. Integrated Machine Learning and Probabilistic Degradation Approach for Vessel Electric Motor Prognostics. Ocean Eng. 2023, 275, 114153. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, Z.; Cao, L.; Dong, F.; Zou, Y.; Wang, K.; Zhang, Y.; Sun, P. Marine Systems and Equipment Prognostics and Health Management: A Systematic Review from Health Condition Monitoring to Maintenance Strategy. Machines 2022, 10, 72. [Google Scholar] [CrossRef]

- Zamudio-Ramirez, I.; Osornio-Rios, R.A.; Antonino-Daviu, J.A.; Razik, H.; Romero-Troncoso, R. Magnetic Flux Analysis for the Condition Monitoring of Electric Machines: A Review. IEEE Trans. Ind. Inform. 2022, 18, 2895–2908. [Google Scholar] [CrossRef]

- Jaros, R.; Byrtus, R.; Dohnal, J.; Danys, L.; Baros, J.; Koziorek, J.; Zmij, P.; Martinek, R. Advanced Signal Processing Methods for Condition Monitoring. Arch. Comput. Methods Eng. 2023, 30, 1553–1577. [Google Scholar] [CrossRef]

- Akbar, S.; Vaimann, T.; Asad, B.; Kallaste, A.; Sardar, M.U.; Kudelina, K. State-of-the-Art Techniques for Fault Diagnosis in Electrical Machines: Advancements and Future Directions. Energies 2023, 16, 6345. [Google Scholar] [CrossRef]

- Kudelina, K.; Vaimann, T.; Asad, B.; Rassõlkin, A.; Kallaste, A.; Demidova, G. Trends and Challenges in Intelligent Condition Monitoring of Electrical Machines Using Machine Learning. Appl. Sci. 2021, 11, 2761. [Google Scholar] [CrossRef]

- Kudelina, K.; Asad, B.; Vaimann, T.; Rassõlkin, A.; Kallaste, A.; Khang, H.V. Methods of Condition Monitoring and Fault Detection for Electrical Machines. Energies 2021, 14, 7459. [Google Scholar] [CrossRef]

- Shang, L.; Niu, Y.; Mao, L.; Niu, H. Selection and Application of Vibration Acceptance Standards for Centrifugal Pumps GB/T 29531-2013 and ISO 10816-7. Pump Technol. 2017, 3, 26–28+33. [Google Scholar]

- Kumar, R.R.; Andriollo, M.; Cirrincione, G.; Cirrincione, M.; Tortella, A. A Comprehensive Review of Conventional and Intelligence-Based Approaches for the Fault Diagnosis and Condition Monitoring of Induction Motors. Energies 2022, 15, 8938. [Google Scholar] [CrossRef]

- Mazaheri-Tehrani, E.; Faiz, J. Airgap and Stray Magnetic Flux Monitoring Techniques for Fault Diagnosis of Electrical Machines: An Overview. IET Electr. Power Appl. 2022, 16, 277–299. [Google Scholar] [CrossRef]

- MSC.1/Circular.1580—Guidelines for Vessels and Units with Dynamic Positioning (DP) Systems. Available online: https://imorules.com/MSCCIRC_1580.html (accessed on 18 April 2025).

- Long-Range Identification and Tracking (LRIT). Available online: https://www.imo.org/en/OurWork/Safety/Pages/LRIT.aspx (accessed on 18 April 2025).

- Abad, H.B.B.; Ojaghi, M.; Taheri, A. Extra Freedom Degrees of Six-Phase Induction Motors Used to Diagnose Stator Inter-Turn Faults. Electr. Power Compon. Syst. 2021, 49, 294–307. [Google Scholar] [CrossRef]

- Abbasi, M.A.; Huang, S.; Khan, A.S. Fault Detection and Classification of Motor Bearings under Multiple Operating Conditions. ISA Trans. 2025, 156, 61–69. [Google Scholar] [CrossRef] [PubMed]

- Song, M.; Yan, P.; Wang, X.; Yang, Y.; Xie, R. Exploration of maximum unbalance of a turboshaft engine according to airworthiness requirements. J. Aerosp. Power 2023, 38, 1467–1473. [Google Scholar]

- Li, J.; Li, Z.; Zhang, J.; Zhao, S.; Cheng, F.; Qian, C.; Hu, X.; Zhou, G. Automated Monitoring of the Uniform Demagnetization Faults in Permanent-Magnet Synchronous Motors: Practical Methods and Challenges. Sustainability 2023, 15, 16326. [Google Scholar] [CrossRef]

- Du, Z.; Huang, Y.; Zhang, Z.; Wu, L.; Su, W.; Li, W. Method of Maintenance Cycle Prediction for Smart Electricity Meters Based on Hybrid Weibull Distribution. Electr. Meas. Instrum. Chin. 2025, 62, 217–224. [Google Scholar]

- Song, X.; Liao, Z.; Jia, B. Marine Fire Pump Motor Bearings Fault Feature Enhancement and Diagnosis Based on Adaptive SSA and Improved TEO. Chin. J. Ship Res. 2025, 20, 47–55. [Google Scholar]

- Ge, C.; Yan, Z.; Shang, J.; Xue, H. Fault Diagnosis of Ship Motor Bearings Based on Multi-Domain Information Fusion and Improved ELM. Chin. J. Ship Res. 2025, 20, 68–76. [Google Scholar]

- Zhu, R.; Song, E.; Yao, C.; Ke, Y. Marine Motor Fault Diagnosis Based on CEEMDAN and BRECANunder Strong Noise Conditions. Chin. J. Ship Res. 2025, 20, 20–29. [Google Scholar]

- Zhang, Z. Research on Diagnosis Technology Based on Typical Fault of Marine Generator. Master’s Thesis, Harbin Engineering University, Harbin, China, 2025. [Google Scholar]

- Fu, C.; Shi, W. Intelligent Fault Diagnosis of Marine Generator Stator Windings Combined with Attention Mechanism. Control Eng. China 2025, in press. [Google Scholar]

- Jang, J.-G.; Noh, C.-M.; Kim, S.-S.; Shin, S.-C.; Lee, S.-S.; Lee, J.-C. Vibration Data Feature Extraction and Deep Learning-Based Preprocessing Method for Highly Accurate Motor Fault Diagnosis. J. Comput. Des. Eng. 2023, 10, 204–220. [Google Scholar] [CrossRef]

- Shu, R.; Wei, J.; Tan, R.; Wu, X.; Fu, B. Investigation of Dynamic and Synchronization Properties of a Multi-Motor Driving System: Theoretical Analysis and Experiment. Mech. Syst. Signal Process. 2021, 153, 107496. [Google Scholar] [CrossRef]

- Feldman, M. Hilbert Transform in Vibration Analysis. Mech. Syst. Signal Process. 2011, 25, 735–802. [Google Scholar] [CrossRef]

- Xu, X.; Huang, W.; Zhang, X.; Zhang, Z.; Liu, F.; Brunauer, G. An Evidential Reasoning-Based Information Fusion Method for Fault Diagnosis of Ship Rudder. Ocean Eng. 2025, 318, 120082. [Google Scholar] [CrossRef]

- Nesser, H.; Mahmoud, H.A.; Lubineau, G. High-Sensitivity RFID Sensor for Structural Health Monitoring. Adv. Sci. 2023, 10, 2301807. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Song, M.; Kim, D.; Lee, D. An Adaptive Kalman Filter-Based Condition-Monitoring Technique for Induction Motors. IEEE Access 2023, 11, 46373–46381. [Google Scholar] [CrossRef]

- Sardar, M.U.; Vaimann, T.; Kütt, L.; Kallaste, A.; Asad, B.; Akbar, S.; Kudelina, K. Inverter-Fed Motor Drive System: A Systematic Analysis of Condition Monitoring and Practical Diagnostic Techniques. Energies 2023, 16, 5628. [Google Scholar] [CrossRef]

- Huang, K.; Li, W.; Fang, H.; Wu, X.; Wang, L.; Peng, H. IPORF: A Combined Improved Parrot Optimizer Algorithm and Random Forest for Fault Diagnosis in AUV. Ocean Eng. 2024, 313, 119665. [Google Scholar] [CrossRef]

- Ma, C.; He, X.; Xie, B.; Sun, W.; Zhao, D.; Liao, W. Backstepping Sliding Mode Fault-Tolerant Control for the Wind Turbine System with Disturbance Observer. Proc. Inst. Mech. Eng. Part J. Syst. Control Eng. 2022, 236, 1667–1678. [Google Scholar] [CrossRef]

- Hou, Y.; Wang, J.; Chen, Z.; Ma, J.; Li, T. Diagnosisformer: An Efficient Rolling Bearing Fault Diagnosis Method Based on Improved Transformer. Eng. Appl. Artif. Intell. 2023, 124, 106507. [Google Scholar] [CrossRef]

- Cureño-Osornio, J.; Díaz-Saldaña, G.; Osornio-Rios, R.A.; Dunai, L.; Sava, L.; Antonino-Daviu, J.A.; Zamudio-Ramírez, I. Detection of Contamination and Failure in the Outer Race on Ceramic, Metallic, and Hybrid Bearings through AI Using Magnetic Flux and Current. Machines 2024, 12, 505. [Google Scholar] [CrossRef]

- Huang, K.; Li, W.; Gao, F. Barabási-Albert Model-Enhanced Genetic Algorithm for Optimizing LGBM in Ship Power Grid Fault Diagnosis. Measurement 2025, 249, 116954. [Google Scholar] [CrossRef]

- Guo, Q.; Li, Y.; Song, Y.; Wang, D.; Chen, W. Intelligent Fault Diagnosis Method Based on Full 1-D Convolutional Generative Adversarial Network. IEEE Trans. Ind. Inform. 2020, 16, 2044–2053. [Google Scholar] [CrossRef]

- Guo, Y.; Gao, C.; Jin, Y.; Li, Y.; Wang, J.; Li, Q.; Wang, H. A Transfer Learning-Based Method for Marine Machinery Diagnosis with Small Samples in Noisy Environments. J. Ocean Eng. Sci. 2023, 10, 593–601. [Google Scholar] [CrossRef]

- Xie, F.; Li, G.; Hu, W.; Fan, Q.; Zhou, S. Intelligent Fault Diagnosis of Variable-Condition Motors Using a Dual-Mode Fusion Attention Residual. J. Mar. Sci. Eng. 2023, 11, 1385. [Google Scholar] [CrossRef]

- Ayyappan, G.S.; Ramesh Babu, B.; Srinivas, K.; Raja Raghavan, M.; Poonthalir, R. Mathematical Modelling and IoT Enabled Instrumentation for Simulation & Emulation of Induction Motor Faults. IETE J. Res. 2023, 69, 1829–1841. [Google Scholar] [CrossRef]

- Yao, Z.; Zhu, Q.; Zhang, Y.; Huang, H.; Luo, M. Minimizing Long-Term Energy Consumption in RIS-Assisted AAV-Enabled MEC Network. IEEE Internet Things J. 2025, 12, 20942–20958. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, Z.; Li, J.; Wei, C.; Chen, Q. Intelligent Sensing Technology for Power Equipment State Parameters. Proc. CSEE 2020, 20, 323–342. [Google Scholar]

- Ge, Y.; Lei, X.; Zhang, Y.; Fang, Z.; Lu, Z. Analysis and Test on Permissible Residual Unbalance of Rotors. J. Vib. Meas. Diagn. 2023, 43, 371–377+414–415. [Google Scholar]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y.C. Digital Twins and Cyber–Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Fera, F.; Spandonidis, C. A Fault Diagnosis Approach Utilizing Artificial Intelligence for Maritime Power Systems within an Integrated Digital Twin Framework. Appl. Sci. 2024, 14, 8107. [Google Scholar] [CrossRef]

- Hu, W.; Wang, T.; Chu, F. Novel Ramanujan Digital Twin for Motor Periodic Fault Monitoring and Detection. IEEE Trans. Ind. Inform. 2023, 19, 11564–11572. [Google Scholar] [CrossRef]

- Zhang, Q.; Song, H.; Li, L.; Song, Z.; Li, Z. Marine Power System Intelligent Operation and Maintenance Platform Based on Digital Twin. Chin. J. Ship Res. 2022, 17, 73–80. [Google Scholar]

- Yang, Q.; Liu, Y.; Chen, T.; Tong, Y. Federated Machine Learning: Concept and Applications. ACM Trans. Intell. Syst. Technol. 2019, 10, 1–19. [Google Scholar] [CrossRef]

- Huang, C.; Bu, S.; Lee, H.H.; Chan, K.W.; Yung, W.K.C. Prognostics and Health Management for Induction Machines: A Comprehensive Review. J. Intell. Manuf. 2024, 35, 937–962. [Google Scholar] [CrossRef]

- Yang, F.; Habibullah, M.S.; Shen, Y. Remaining Useful Life Prediction of Induction Motors Using Nonlinear Degradation of Health Index. Mech. Syst. Signal Process. 2021, 148, 107183. [Google Scholar] [CrossRef]

- Kim, S.; Kim, N.H.; Choi, J.-H. A Study Toward Appropriate Architecture of System-Level Prognostics: Physics-Based and Data-Driven Approaches. IEEE Access 2021, 9, 157960–157972. [Google Scholar] [CrossRef]

- Russell, M.; Wang, P. Maximizing Model Generalization for Machine Condition Monitoring with Self-Supervised Learning and Federated Learning. J. Manuf. Syst. 2023, 71, 274–285. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, F.; Zhang, C.; Wen, C.; Hu, X.; Wang, T. A Personalized Federated Learning-Based Fault Diagnosis Method for Data Suffering from Network Attacks. Appl. Intell. 2023, 53, 22834–22849. [Google Scholar] [CrossRef]

- Jenkel, L.; Jonas, S.; Meyer, A. Privacy-Preserving Fleet-Wide Learning of Wind Turbine Conditions with Federated Learning. Energies 2023, 16, 6377. [Google Scholar] [CrossRef]

- Chan, T.H.T.; Yu, L.; Tam, H.Y.; Ni, Y.Q.; Liu, S.Y.; Chung, W.H.; Cheng, L.K. Fiber Bragg Grating Sensors for Structural Health Monitoring of Tsing Ma Bridge: Background and Experimental Observation. Eng. Struct. 2006, 28, 648–659. [Google Scholar] [CrossRef]

- Kumar, P.; Yao, C.-K.; Augustine Arockiyadoss, M.; Mulatie Dehnaw, A.; Chang, C.-Y.; Peng, P.-C. YOLO-v7 Improved with Adan Optimizer: Realizing Orphaned Fiber Bragg Grating to Sense Superimposed Personalized Dynamic Strain. IEEE Sens. J. 2024, 24, 39923–39933. [Google Scholar] [CrossRef]

- Vaddadi, V.S.C.S.; Parne, S.R.; Parambil, V.V.; Panda, S.S.S.; Gandi, S. Design of Fiber Bragg Grating Sensor for Eccentricity Measurements in Ball Bearings. IEEE Trans. Instrum. Meas. 2023, 72, 7000309. [Google Scholar] [CrossRef]

| Fault Category | Failure Mode | Main Reason | Characteristic Signal | Generator Type |

|---|---|---|---|---|

| Mechanical breakdown | Bearing galvanic corrosion | Shaft current discharge | Current high-frequency harmonics, peak vibration envelope spectrum | Mainframe motor, Propulsion motor |

| Dynamic rotor eccentricity | Push load shock/Shaft misalignment | Rotational vibration, unbalanced magnetic tension | Mainframe motor | |

| Malfunction | Broken bar | Start-up shock, electro-thermal fatigue, casting defects | Low-frequency harmonic amplification, 2sf frequency sidebands | Asynchronous propulsion motor |

| Stator winding partial discharge | High Frequency Voltage Stress | High-frequency current pulse, insulation resistance drop | Propulsion motor | |

| Permanent Magnet Demagnetization | High temperature + harmonic magnetic field | Decrease in reaction potential and increase in torque fluctuation | Permanent magnet propulsion motors | |

| Insulation failure | Ageing of insulation | Hot and humid environments + thermal cycling stress | Rise in dielectric loss angle, increase in partial discharges | Auxiliary motors |

| Cooling System Failure | Clogged cooling channels | Seawater biofouling/corrosion product build-up | ΔT > 15 K (inlet and outlet), infrared thermal image hot spot | Pump/blower drive motors |

| Type of Fault | Eigenfrequency Formula | Typical Frequency Bands | Detection Methods |

|---|---|---|---|

| Bearing galvanic corrosion | 500 Hz~10 kHz | Vibration envelope demodulation + current harmonic analysis | |

| Rotor Broken Strip | 45~55 Hz | Current spectrum analysis | |

| Stator winding partial discharge | 100 kHz~10 MHz | High frequency current transformer + PRPD model analysis | |

| Rotor eccentricity | 25~75 Hz | Vibration acceleration spectroscopy + air gap magnetic density monitoring |

| Hierarchy | Type of Fault | Average Repair Time | Potential Consequence |

|---|---|---|---|

| I | Irreversible demagnetization of permanent magnets | >72 h | Loss of 30 to 50 percent of thrust in the propulsion system, requiring return to the factory for repair |

| II | Stator winding turn-to-turn short circuit | 24~48 h | Causes a short circuit fault in the grid, triggering the main circuit breaker to trip |

| III | Bearing galvanic corrosion (medium term) | 8~12 h | Vibration exceeds the standard (>7.1 mm/s), need to stop the machine to replace the bearing |

| IV | Partial failure of the cooling system | 2~4 h | Motor temperature rise limiting power operation (20%~30% derating) |

| Technical Means | Optimal Detection of Faults | Shipboard Environmental Adaptability | Directions for Improvement |

|---|---|---|---|

| Current Harmonic Analysis | Rotor breaks/eccentricity | Weak resistance to electromagnetic interference (need to add a magnetic ring) | Development of wide-band MCSA (0~50 kHz) based on SiC devices |

| Vibration envelope demodulation | Bearing damage/mechanical loosening | Highly disturbed by hull vibration (requires adaptive filtering) | Automatic extraction of time-frequency features combined with deep learning |

| Infrared thermal imaging | Insulation deterioration/poor contact | Affected by cabin airflow (requires dynamic temperature compensation) | Multi-view 3D temperature field reconstruction |

| High Frequency Partial Discharge Detection | Winding insulation defects | PWM noise suppression needs to be addressed | Based on data enhancement methods |

| Case | Type of Fault | Key Data/Thresholds | Root Cause | Improvement Measures | Monitoring Technology Insights |

|---|---|---|---|---|---|

| British Type 45 Destroyer Loses Power to Entire Ship | Electrical corrosion + cooling failure of mainframe motor bearings | Axial current density 0.28 A/m2 (180 per cent over limit) Bearing temperature jump 45 K | Failure to install shaft current monitoring device Lubricant salt spray corrosion | Addition of ceramic-insulated bearings Deployment of real-time shaft current sensors | Current-temperature multi-parameter coupled early warning models need to be developed |

| Demagnetization of the propulsion motor of a domestic destroyer | High Temperature Harmonic Demagnetization of Permanent Magnets | Harmonic THD = 8.7 per cent. Reverse electromotive force decreased by 22 per cent. Hdemag/Hcj = 1.15 | SiC Inverter High Frequency Harmonics Insufficient margin for cooling system design | PWM strategy optimization Adoption of dual-circulation oil cooling system | Harmonic magnetic field online monitoring and dynamic suppression system needs to be developed |

| Norwegian cruise ship auxiliary motor insulation breakdown | Stator winding partial discharge | Partial discharge > 500 pC tanδ rises to 0.12 | Cabin humidity > 95 per cent for extended periods Insulation coating process defects | Nano-modified insulating materials Cabin Dehumidification System Upgrade | Prediction of insulation status in conjunction with humidity sensors is required |

| Failure of propulsion motor bearings on a research vessel | Bearing spalling caused by rotor eccentricity | Vibration speed 8.7 mm/s (ISO 10816-3 overrun [11]) Eccentricity δ = 0.3 mm | Shaft system mounting tolerances exceeded Load shock not filtered | Laser Aligner Calibration Addition of torsional vibration dampers | Joint diagnosis of vibration envelope spectra and current harmonics required |

| U.S. LCS Ship Motor Cooling Failure | Sea water pump motor biofouling clogging | The flow rate decreased by 37% Temperature difference ΔT = 18 K | Microbiological corrosion of copper-nickel alloy pipework Long backwash intervals | Titanium line replacement Ultraviolet sterilization unit | Infrared cameras need to add dirt thermal resistance compensation algorithms |

| Fault Type | Detection Methods | Accuracy/Error |

|---|---|---|

| Bearing galvanic corrosion | MCSA + Envelope Demodulation | 92.3% |

| Ageing of insulation | Temperature field + Arrhenius | ±7.5% |

| Permanent Magnet Demagnetization | Harmonic analysis + critical modeling | 89.1% |

| Type of Fault | Current Sensor Confidence | Vibration Sensor Confidence | Temperature Sensor Confidence | Synthetic Confidence Level | Conflict Factor K |

|---|---|---|---|---|---|

| Bearing galvanic corrosion | 0.65 | 0.72 | 0.58 | 0.81 | 0.12 |

| Permanent Magnet Demagnetization | 0.83 | 0.15 | 0.76 | 0.79 | 0.34 |

| Conflict Alert | - | - | - | - | 0.61 |

| Methodologies | Capacity to Deal with Uncertainty | Computational Efficiency | Vessel Suitability |

|---|---|---|---|

| D-S Theory of Evidence | ★★★★★ | ★★☆ | Suitable for uncertain reasoning in the presence of strong disturbances (e.g., electromagnetic disturbances causing some sensors to fail) |

| Bayesian inference | ★★★☆☆ | ★★★★☆ | Requires a priori probability, performs poorly when data are missing |

| Fuzzy logic | ★★★★☆ | ★★★★★ | Weak capacity to deal with conflicting evidence |

| Methodologies | Applicable Fault Types | Parameterization | Advantage | Limitations | Ship Environmental Adaptation Improvements |

|---|---|---|---|---|---|

| Current Harmonic Analysis | Rotor Broken Strip Air Gap Eccentricity | Eigenfrequency: Equation (8) Harmonic distortion rate | Non-intrusive detection Sensitive to electrical faults | Vulnerable to grid harmonics Poor low frequency resolution (<5 Hz) | Add EMI filter Adoption of adaptive sliding window STFT |

| Vibration envelope demodulation | Bearing damage Mechanical loosening | Envelope spectrum peak frequency: Crag Indicator | Sensitive to early mechanical failure Can locate damage | Highly disturbed by hull vibration Requires high dynamic range sensors | Installation of shock-resistant sensors Combined with deep learning time-frequency analysis |

| Infrared Thermal Analysis | Ageing of insulation loose or defective contact | Hot spot temperature difference ΔT Temperature gradient ∇T | Intuitive visualization Contact measurement | Surface temperature detection only Subject to ambient airflow | Multi-perspective 3D reconstruction Dynamic calibration of emissivity |

| High Frequency Partial Discharge Detection | Winding insulation defects Short circuit between turns | Discharge q Discharge repetition rate n (cycles/sec) | Nanoscale defect detection Predictive Maintenance | Requires shielding from PWM noise (>80 dB) High sensor bandwidth requirements (>50 MHz) | Noise suppression Embedded Sensors |

| Magnetic flux density monitoring | Permanent Magnet Demagnetization Rotor Eccentricity | Air Gap Magnetic Density Bgap Harmonic distortion factor | Direct reflection of the electromagnetic state No sensor implantation | Affected by rotor position Complicated calibration | Hall Array Integration Combined Kalman filter estimation |

| Environmental Disturbance | Methods with the Most Severe Impacts | Prescription | Verify the Effectiveness |

|---|---|---|---|

| Electromagnetic interference | MCSA/HF PD detection | Fiber optic current sensors replace conventional CTs | Signal-to-noise ratio improved by 26 dB |

| Hull Vibration | Vibration analysis | IMU-based vibration compensation algorithm | 68 per cent reduction in false alarm rate |

| Salt spray corrosion | Thermal imaging | Corrosion-resistant infrared windows | Transmission decay <5%/year |

| Space limitation | Flux detection | Miniature TMR Magnetic Array | 80% volume reduction (Ø20 mm) |

| Characterisation | Learnable Bandpass Filters | Fixed Parameter Filters |

|---|---|---|

| Frequency adaptability | Automatic tracking of speed changes | Need to manually retune parameters |

| Anti-interference capability | Suppression of non-fault band noise (e.g., PWM switching frequency) | Fixed resistance bands may miss detecting faults |

| Computational complexity | Increase in reasoning time by approximately 15 per cent | No additional burden |

| Suitability for shipboard environments | Adaptation to different ship types/conditions (e.g., submarine low speed vs. destroyer high speed) | Individual design for each motor type is required |

| Norm | STM32H743 | NI Compact RIO | Advantage Statement |

|---|---|---|---|

| Computational delay | <10 ms | ~5 ms | Meeting the real-time needs of ships |

| Power wastage | 3.8 W | 22 W | Suitable for long-term deployment |

| Environmental adaptation | −40~85 °C | Requires additional protection | Direct exposure to the cabin environment |

| Project | MIL-STD-167-1A (US Army Standard) [44] | DNV GL (Det Norske Veritas) |

|---|---|---|

| Vibration testing | 5–100 Hz sweep, 20 g peak acceleration | Broadband random vibration (0.1–1 kHz) |

| Salt spray corrosion | 720 h neutral salt spray | Cyclic salt spray (alternating wet and dry) |

| Electromagnetic pulse (EMP) | 50 kV/m transient field immunity test | Not mandatory |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Sun, P.; Lin, B.; Li, W. Evolution of Shipboard Motor Failure Monitoring Technology: Multi-Physics Field Mechanism Modeling and Intelligent Operation and Maintenance System Integration. Energies 2025, 18, 4336. https://doi.org/10.3390/en18164336

Sun J, Sun P, Lin B, Li W. Evolution of Shipboard Motor Failure Monitoring Technology: Multi-Physics Field Mechanism Modeling and Intelligent Operation and Maintenance System Integration. Energies. 2025; 18(16):4336. https://doi.org/10.3390/en18164336

Chicago/Turabian StyleSun, Jun, Pan Sun, Boyu Lin, and Weibo Li. 2025. "Evolution of Shipboard Motor Failure Monitoring Technology: Multi-Physics Field Mechanism Modeling and Intelligent Operation and Maintenance System Integration" Energies 18, no. 16: 4336. https://doi.org/10.3390/en18164336

APA StyleSun, J., Sun, P., Lin, B., & Li, W. (2025). Evolution of Shipboard Motor Failure Monitoring Technology: Multi-Physics Field Mechanism Modeling and Intelligent Operation and Maintenance System Integration. Energies, 18(16), 4336. https://doi.org/10.3390/en18164336