1. Introduction

In the fields of industrial manufacturing and motion control, the plant’s frequency characteristics are often marked by complexity and diversity, for example, the prototype target table positioning system adopted in [

1], the electric injection molding machine used in [

2], the hybridized city bus tested in [

3], and the ABB IRB 1400 type robot utilized in [

4]. These plants exhibit multiple resonant modes across different frequency ranges, each characterized by distinct magnitudes and phases. When resonant modes appear in the low-frequency region, the closed-loop bandwidth of the system can be severely restricted. This results in increased system complexity and diversity. In the context of linear control theory, when designing controller parameters for the systems corresponding to the controlled plants in [

1,

2,

3,

4], traditional tuning strategies based on plant modeling and parameter identification may become ineffective. This is because the diversity and complexity of the frequency characteristics exhibited by general controlled plants often lead to low model accuracy and poor identification reliability. Therefore, the development of automatic tuning algorithms for controller parameter computation is essential.

Some controller tuning strategies focus on time-domain metrics (such as overshoot, rise and settling time, etc.) derived from experimental results, represented by the Ziegler–Nichols (ZN) method [

5,

6,

7]. The ZN method is not commonly used in practice as it is time-consuming, labor-intensive, and requires close attention from the operator. To this end, Rad et al. [

8] designed an iterative PI parameter-tuning algorithm based on the Newton–Raphson method. While the designed algorithm is computationally efficient, its convergence and robustness exhibit some degree of uncertainty. In Ref. [

9], a genetic algorithm was used, with overshoot and the integral of weighted time absolute error as cost functions, to achieve the optimized design of the PID controller. Cheng et al. [

10] combined gradient optimization with fuzzy step-sizing techniques, using time-domain metrics such as overshoot and tracking error as predefined objective functions to design an optimal controller. Similarly, Tursini et al. [

11] proposed a real-time, model-free tuning method for the PI speed controller based on the integral error (IE) between the actual and ideal overshoot. These methods face challenges in converting time-domain metrics into intuitive constraints on the open-loop transfer function, often relying on iterative or trial-and-error tuning procedures. As a result, they may lead to issues such as high computational burden, system instability, and poor convergence.

Model-based tuning methods are the most common in the field of linear control, among which the zero-pole cancellation (ZPC) method optimizes dynamic performance by canceling the plant dominant pole with the controller zero [

12,

13,

14]. Yang et al. [

15] modeled both the current- and speed-loop of the servo system as simple first-order models, and based on this, performed offline identification of electrical and mechanical parameters to achieve ZPC. Erturk et al. [

16] proposed a voltage injection method to estimate a spatial inductance map, and the inductance parameter was then used to tune the PI controller of the current loop based on ZPC. Model predictive control (MPC) includes two main strategies: model predictive torque control (MPTC) and model predictive current control (MPCC) [

17]. MPTC requires the joint regulation of torque and flux linkage, making it necessary to design a cost function with suitable weighting factors to balance these variables [

18]. In contrast, MPCC focuses solely on current control. Since its cost function deals with variables of the same dimension, MPCC eliminates the need for weighting factors, resulting in a simpler implementation than MPTC [

19,

20]. For the first-order current-loop system, Shang et al. [

21] introduced the normalized gain as the sole variable in the PI controller and achieved ZPC in the form of parameter correction. In second-order speed servo systems, a strategy known as ‘double ratio’ is widely used for tuning PI controllers [

22]. Similar to ZPC, this tuning method relies on model parameters, namely the motor and load inertia values, and the resulting PI controller has only a single adjustable variable. Although both ZPC and the double ratio method offer strong control performance for the system, they rely on high-precision parameter identification or self-correction processes. Moreover, the designed controller features a single tuning variable, limiting its flexibility and making it challenging to adapt to multiple resonant modes (high-order) systems.

Apart from ZPC, another category of strategies emphasizes the frequency-domain specifications of the system. Refs. [

23,

24] employed gain and phase margins for PID controller tuning. In [

25], a fractional-order PID with multiple adjustable variables is employed, with its parameters sequentially adjusted based on five frequency-domain specifications. Tuning using multiple frequency-domain specifications in [

23,

24,

25] can increase the number of adjustable parameters in the controller. The quantitative feedback theory (QFT) [

26,

27] enables the visualization of preset frequency-domain specifications in the Nichols plot, thereby facilitating the design of the controller. However, the resulting controllers may lack practicality due to their potentially high order, and both the controller structure and parameter design require manual intervention. In [

28,

29,

30,

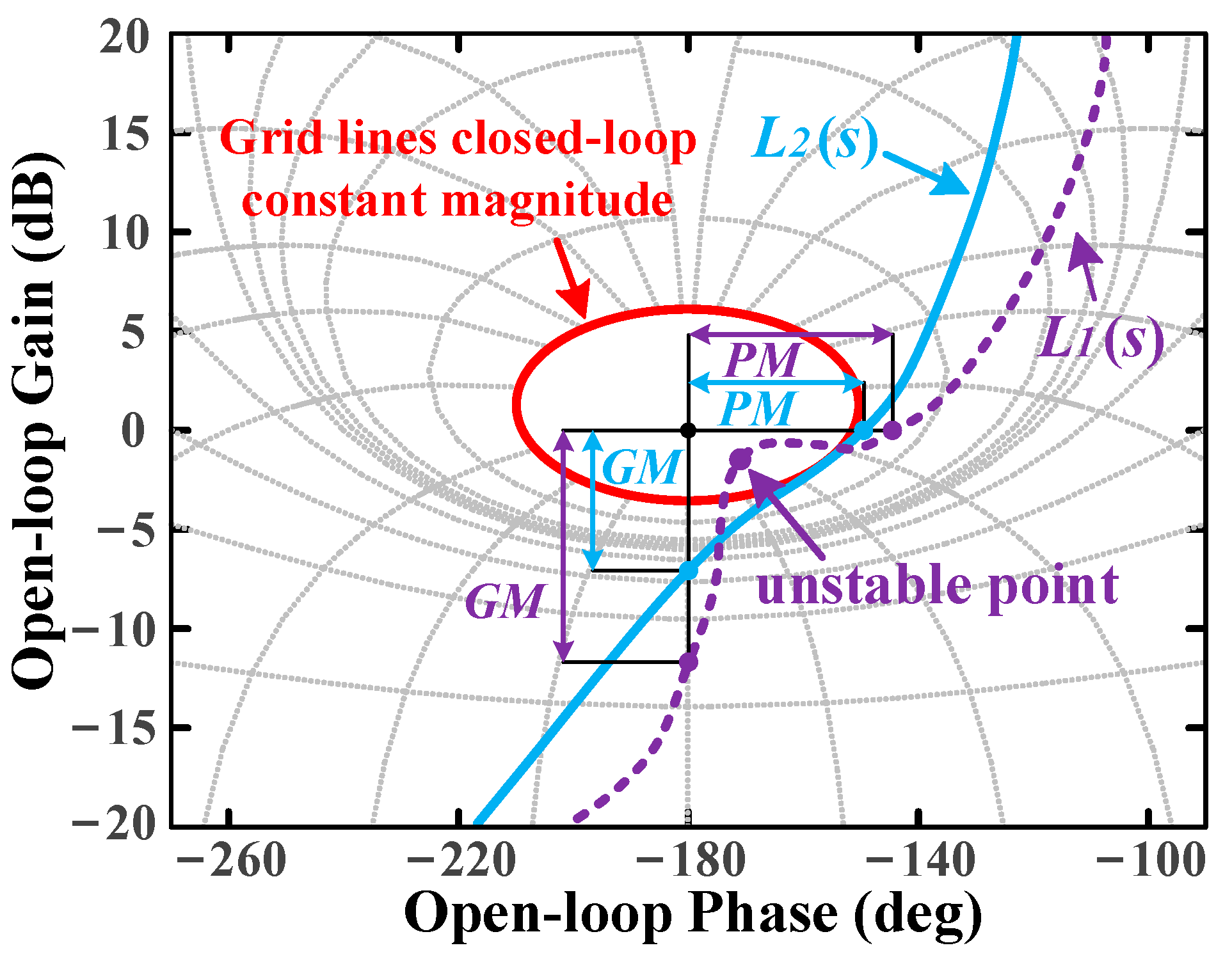

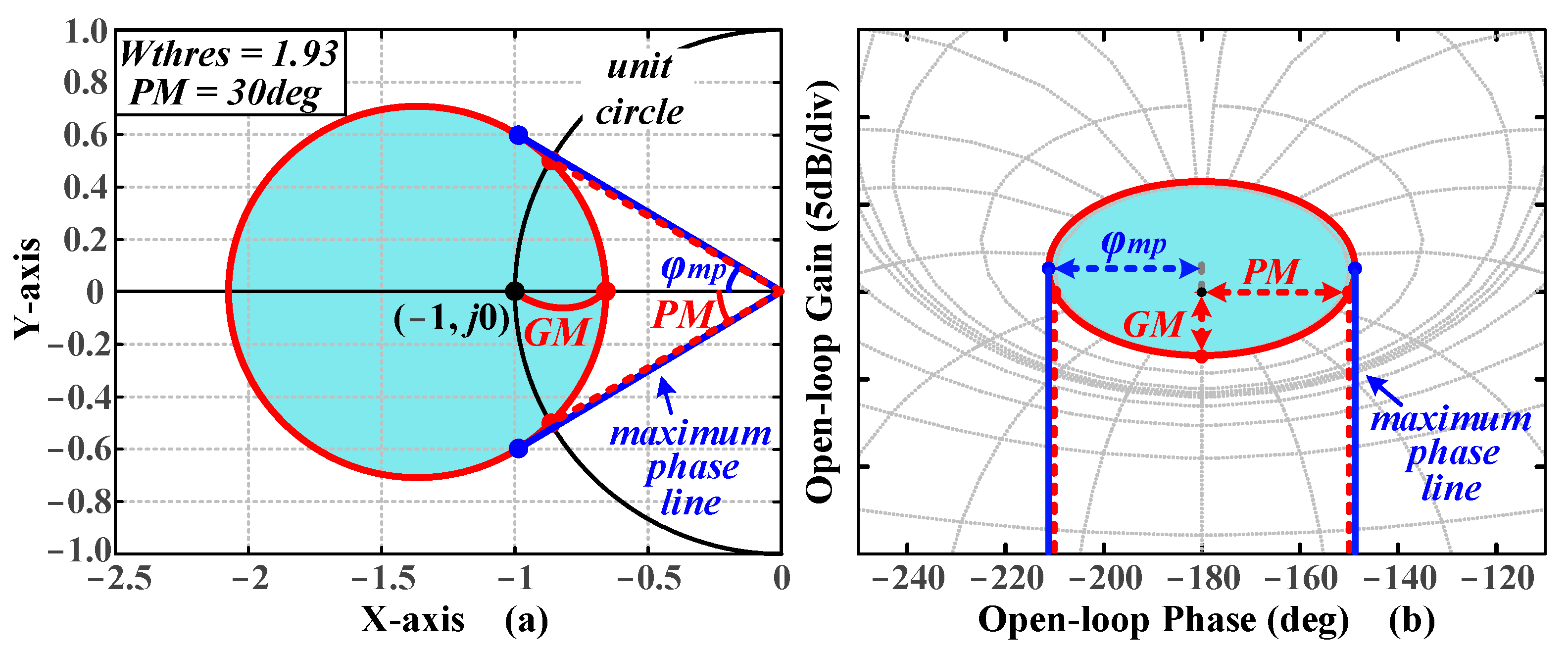

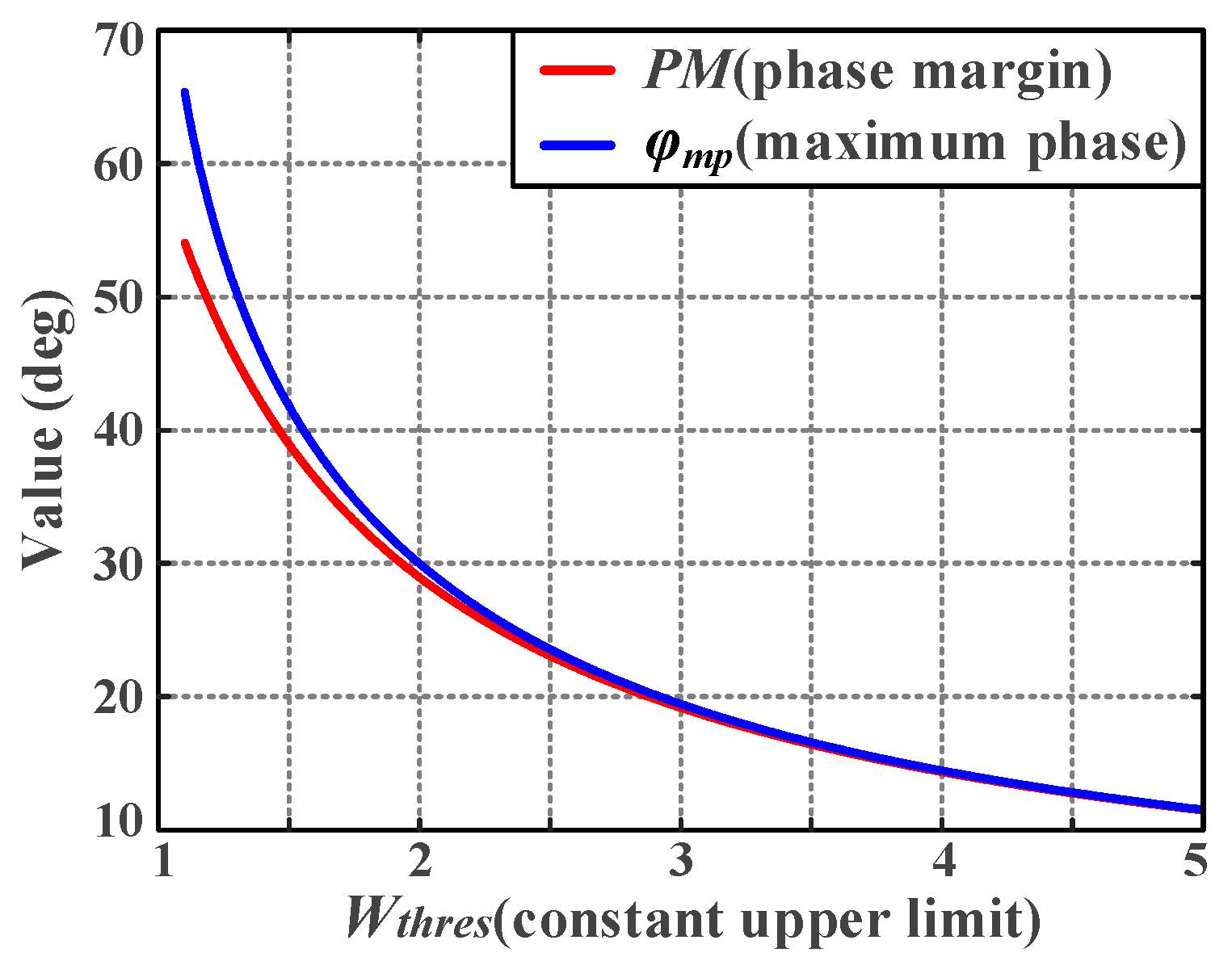

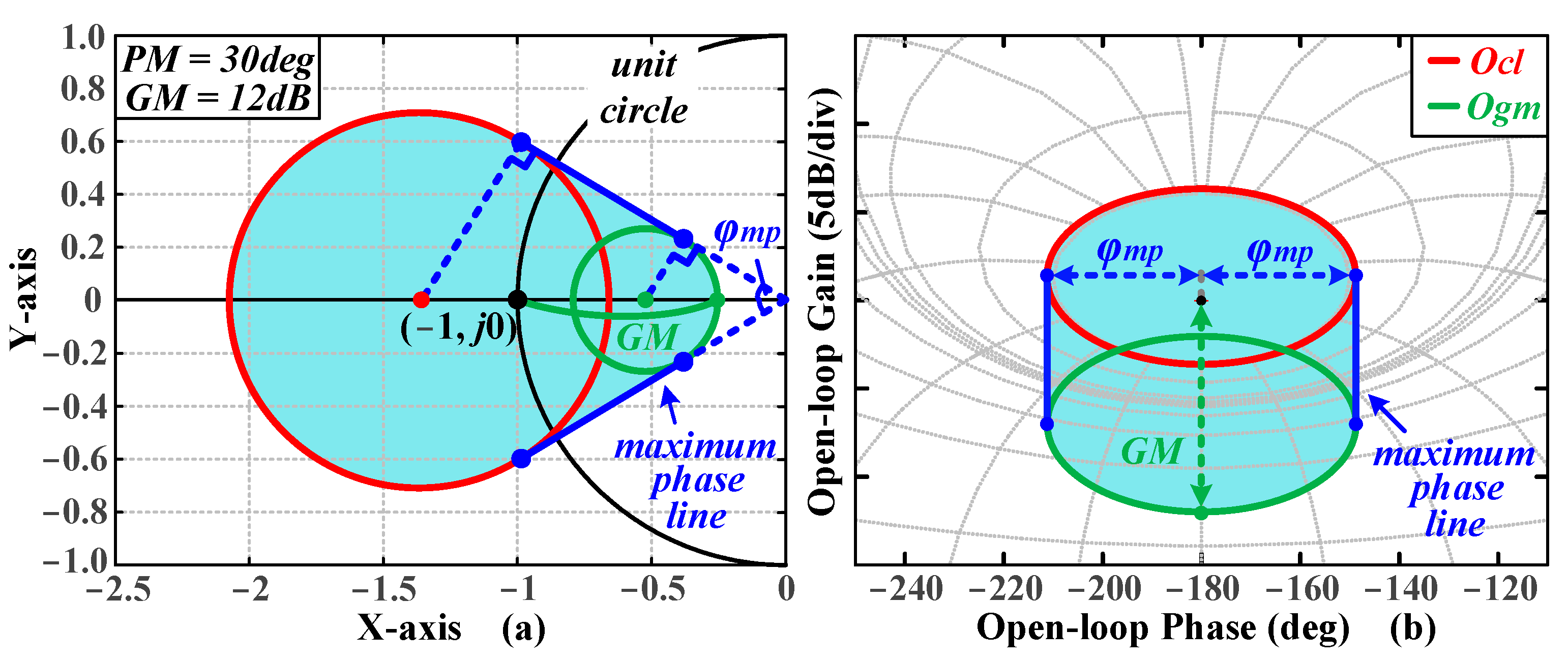

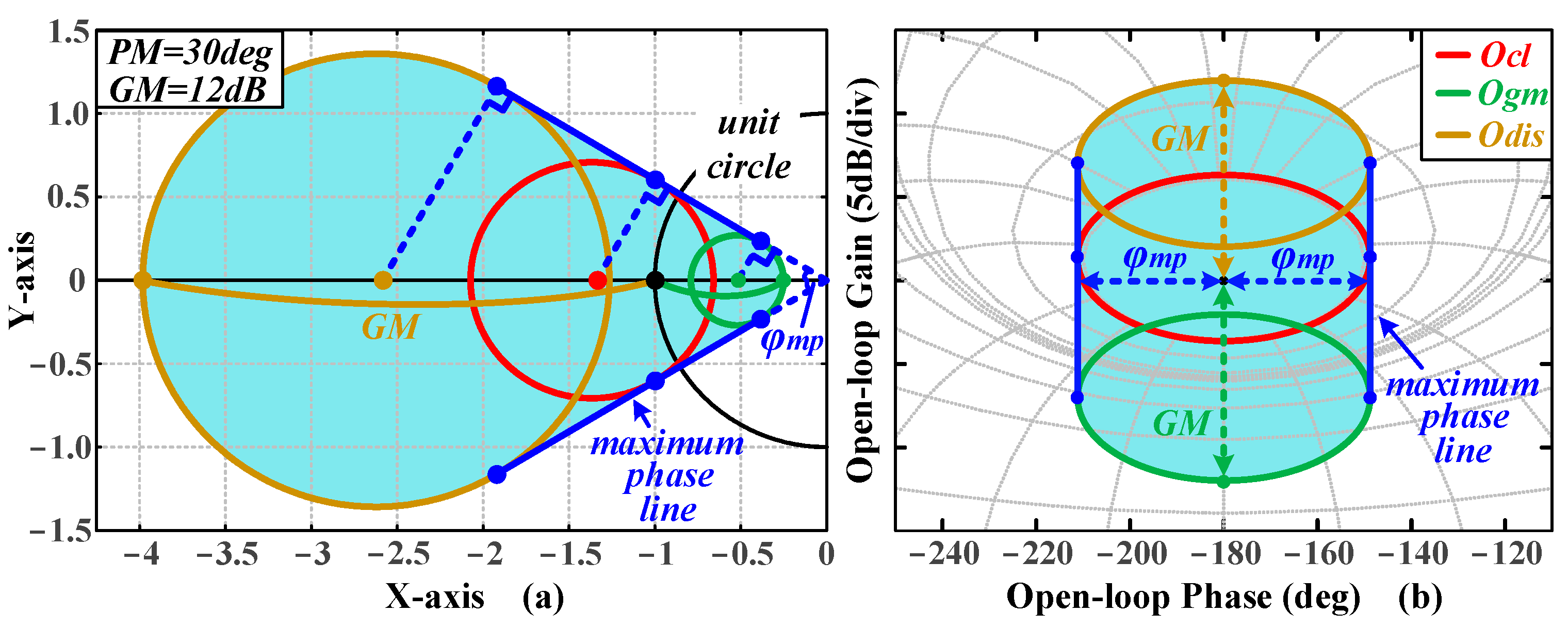

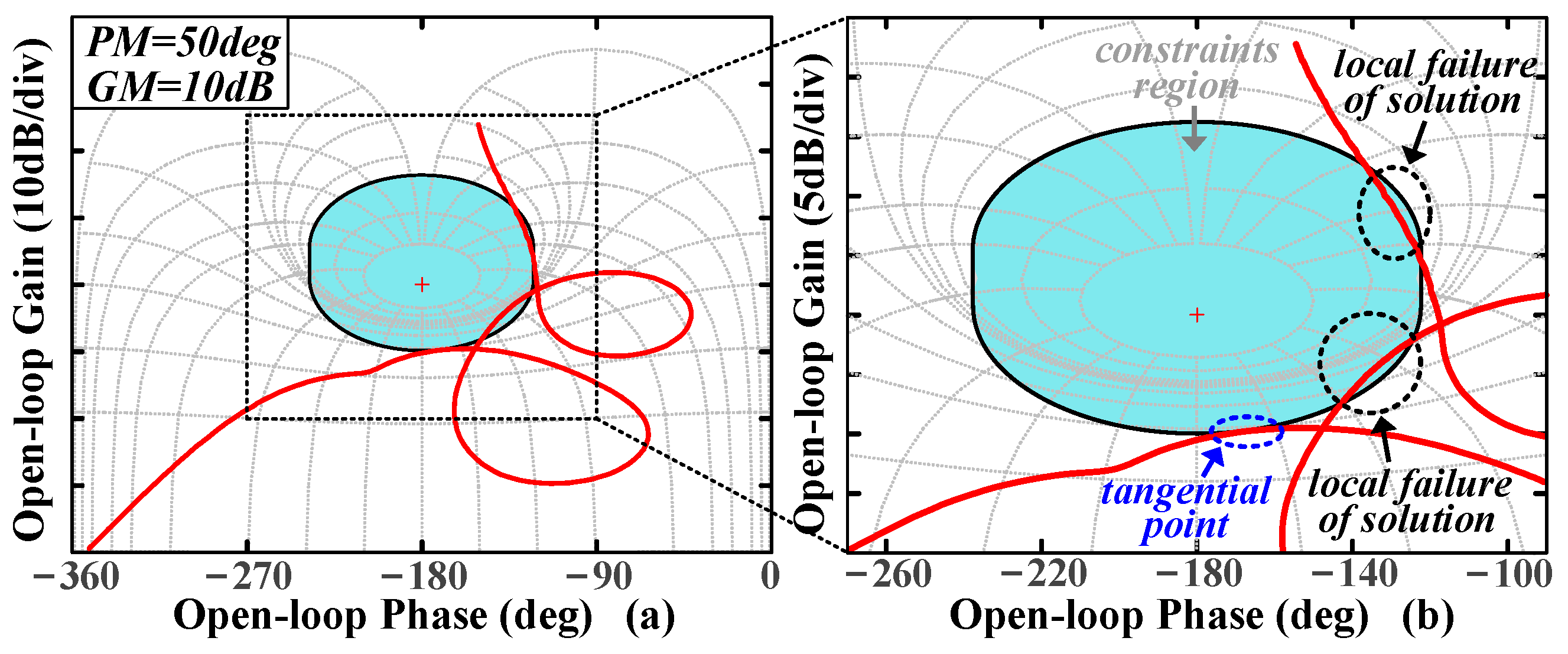

31], a strategy called ‘circle-condition’ is adopted to quantify and visualize gain and phase margins as graphical elements in the Nyquist plot. Unlike QFT, this approach can facilitate the analytical computation of loop shaping, which reduces the need for manual operation. ‘Circle-condition’ treats gain and phase margins as a single adjustable variable, making it difficult to impose performance constraints on high-order systems. Building on the ‘circle-condition’, this paper treats gain and phase margins as two independent variables, quantifies and visualizes multiple frequency-domain specifications in the complex plane, and proposes a non-parametric, versatile tuning algorithm that adapts to multi-order systems, reducing the need for manual intervention.

Addressing the limitations of traditional tuning methods, which are constrained by specific models and lack general applicability, the proposed non-parametric tuning algorithm presents the following features and contributions:

The algorithm is applicable to plants with multiple resonant points (multi-order), ensuring a certain degree of versatility. The plant data can be measured or pre-recorded;

By presetting the frequency-domain specifications, the algorithm ensures that the system exhibits desired dynamic characteristics within a specific frequency range, such as low overshoot, fast response time, and excellent disturbance rejection performance;

Since the mathematical and graphical representations of the constraint boundary in the complex plane are well-defined and visible, the algorithmic design process based on the boundary is highly transparent;

The tuning results of the algorithm exhibit consistency for identical types of plants, as reflected in similar time-domain metrics, such as overshoot and speed drop.

This paper is organized as follows. In

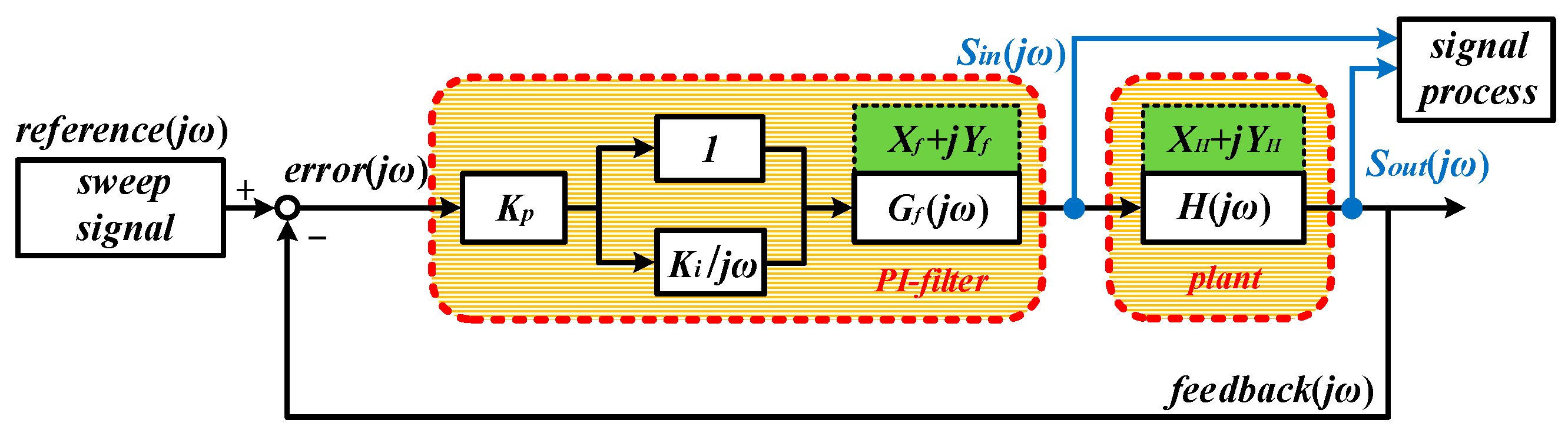

Section 2, the system structure and frequency sweep strategy employed in this paper are introduced. Based on preset frequency-domain specifications, the stability and disturbance rejection constraints are sequentially constructed, ultimately forming a constraint boundary that covers the entire frequency range in a linear coordinate system. In

Section 3, a search algorithm is proposed to obtain a set of controller parameters that ensure both excellent system stability and dynamic performance. Furthermore, a validation algorithm is introduced to address the issue of local failure. Finally, the experiments and conclusions are presented in

Section 4 and

Section 5, respectively.

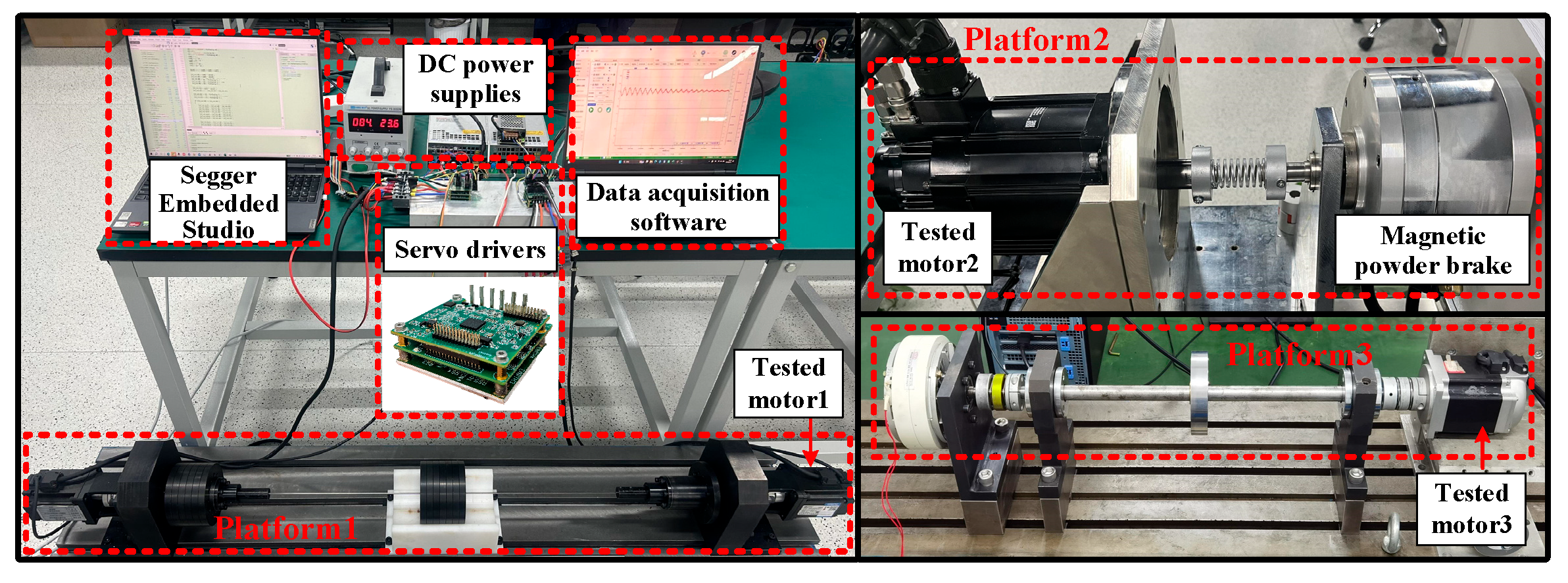

4. Experimental Validation on Different Platforms

The subsequent experiments are carried out within the framework of the servo speed-loop system. To thoroughly validate the effectiveness of the algorithm, three mechanical platforms are utilized. The key parameters of the controller and tested motors are shown in

Table 1 and

Table 2, respectively.

Figure 10 illustrates the experimental platform utilized in this paper, which includes two PCs, two self-developed servo drivers, multiple DC power supplies, and a magnetic powder brake. The self-developed servo drivers are based on the RISC-V microcontroller HPM6264 (HPMicro, Shanghai, China). Input commands are provided by the PC-side software (Xien Servo Driver Studio V1.1.071), while output data are collected by the upper computer software via RS-232.

A zero-DC offset chirp signal is injected as the speed input for the frequency sweep, with the key parameter values of the software platforms recorded in

Table 1. This results in the frequency set Ω containing 498 data points. The raw data collected are smoothed by the Hample filter, the Savitzky–Golay filter, and the Gaussian filter [

34]. The resulting frequency characteristics of the plant are shown in

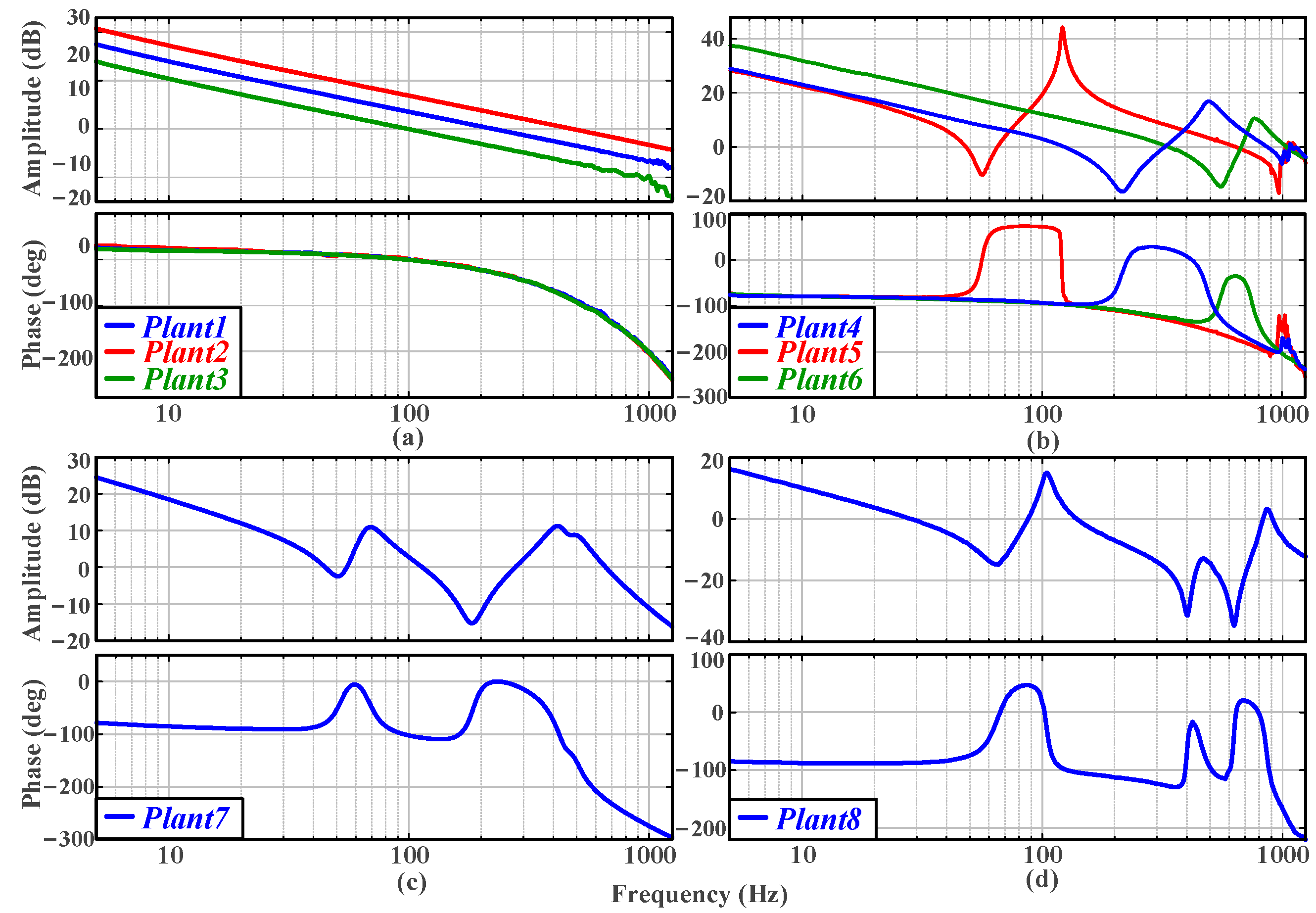

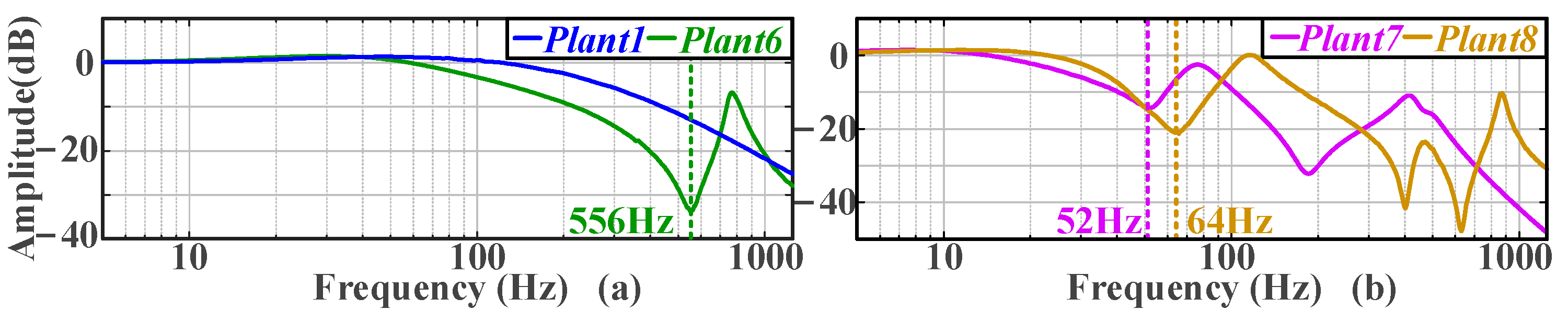

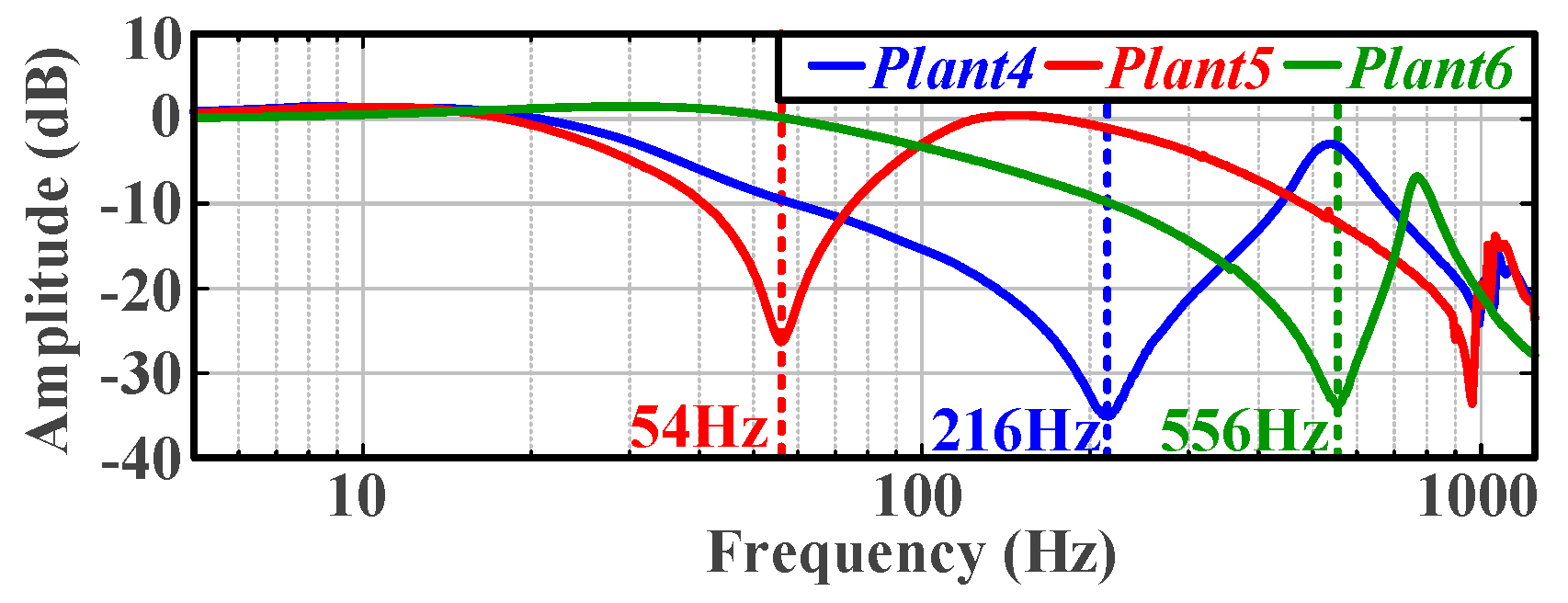

Figure 11.

In Platform 1, both the tested motor and the load motor are implemented using Motor 1 in

Table 2, and they are connected via a flexible shaft. By attaching different numbers of inertia disks to the motor and load sides, three distinct frequency characteristics of the plants are obtained, as illustrated in

Figure 11b. In Platform 2, the tested motor is Motor 2 listed in

Table 2, and the load side consists of a magnetic powder brake. The two components are connected via an elastic shaft. The frequency characteristic of the plant in Platform 2 is shown in

Figure 11c. In Platform 3, the tested motor is Motor 3 listed in

Table 2, and it is connected to the load side through multiple couplings and inertia disks. The frequency characteristic of the plant in Platform 3 is shown in

Figure 11d.

Figure 11a presents the frequency characteristics of Motors 1–3.

4.1. Comparison of Time-Domain Metrics Under Varying Preset Frequency-Domain Specifications

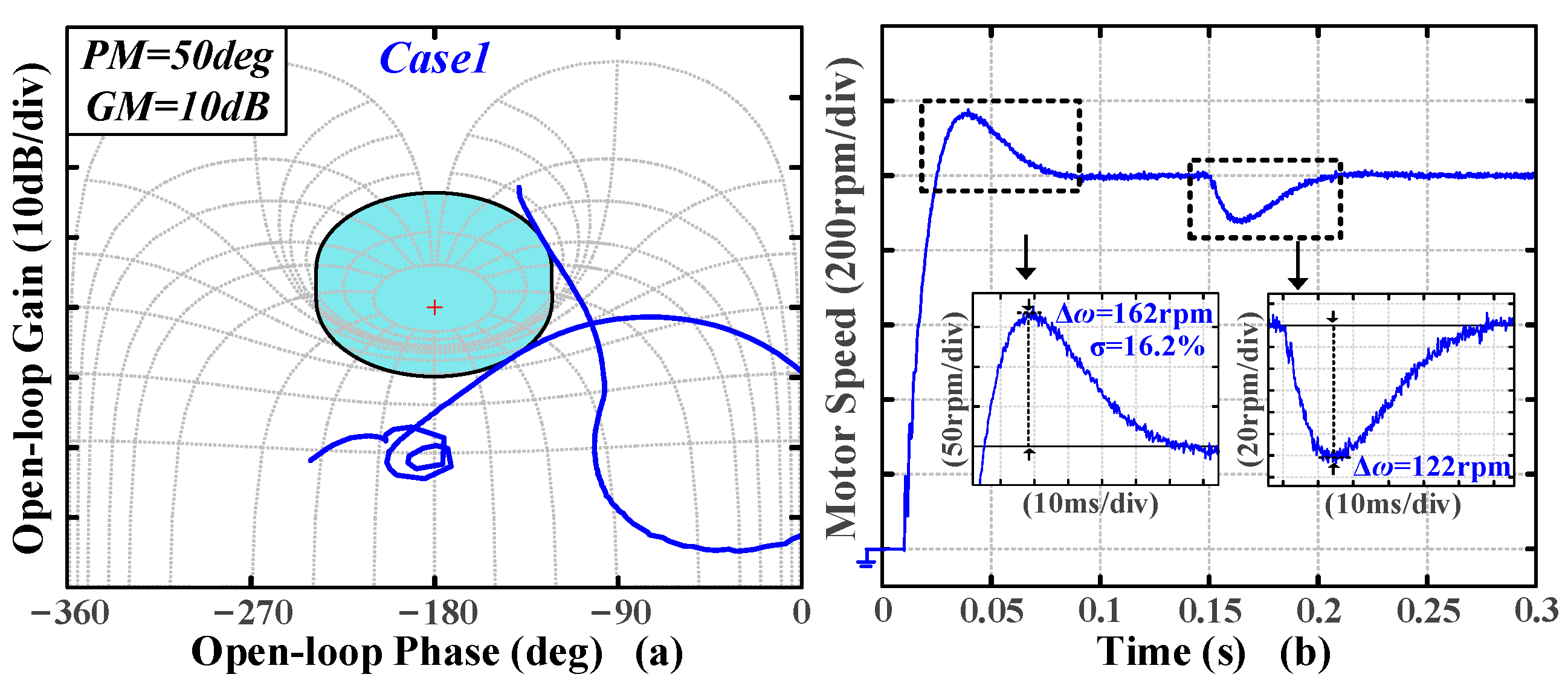

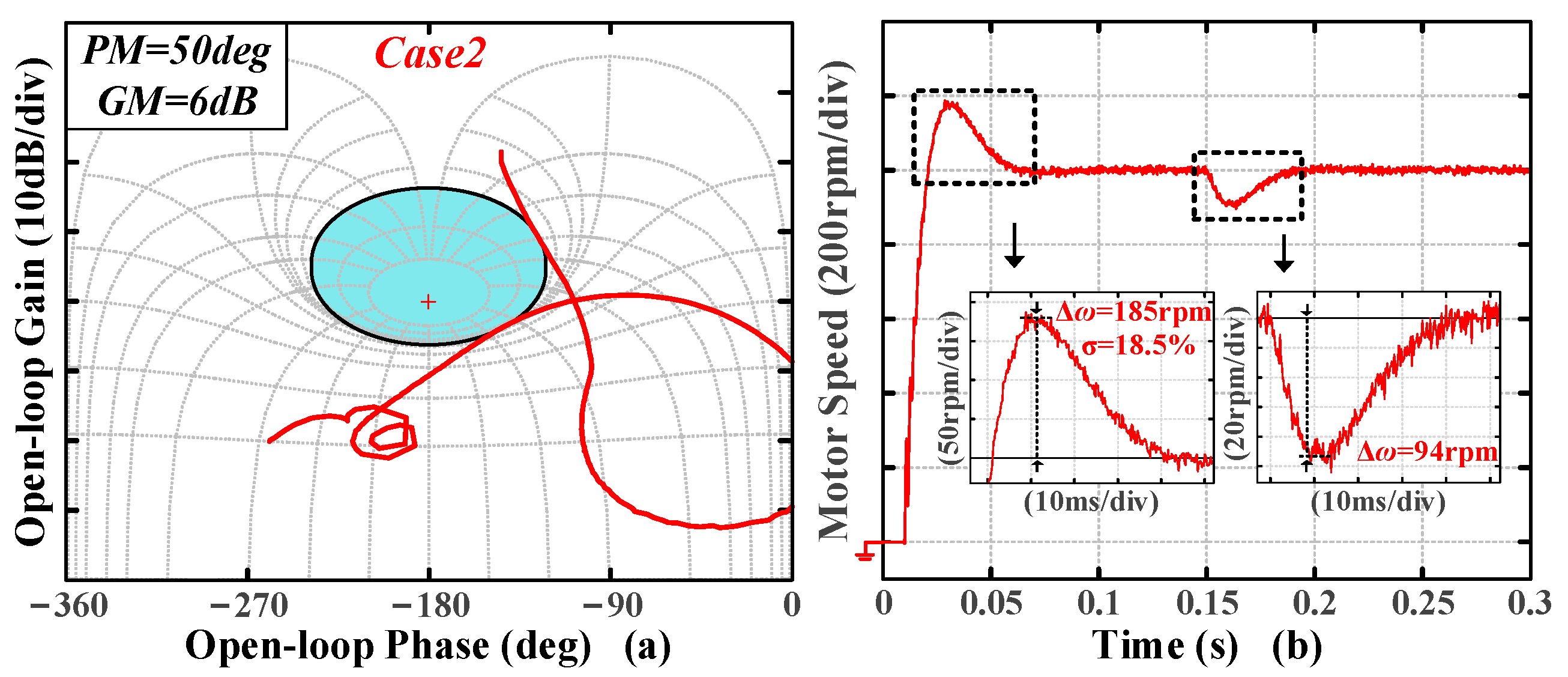

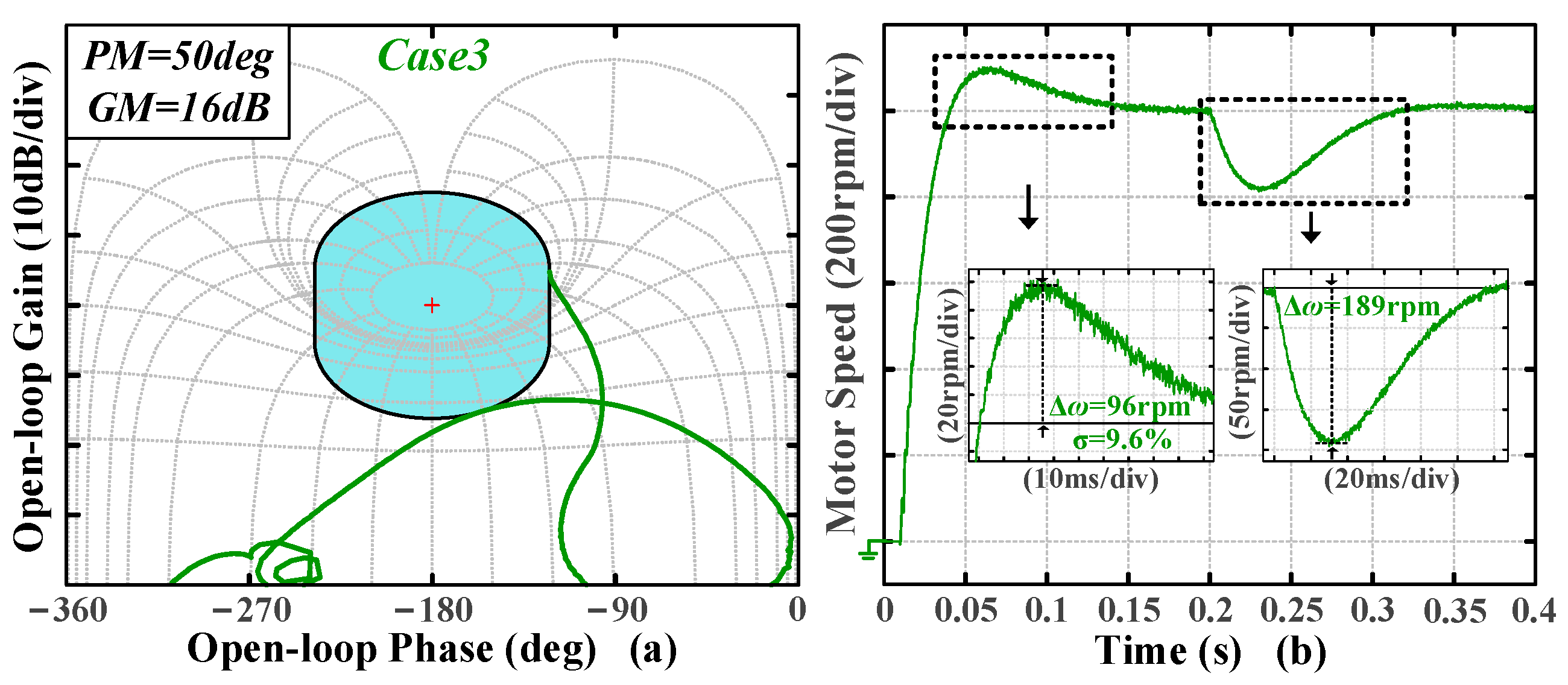

Plant 4 in

Figure 11b is selected for the experiment. Different margin groups are set as the search algorithm inputs, with

Case 1: PM = 50 degree and GM = 10 dB serving as the benchmark. Based on the benchmark,

Case 2 and

Case 3 reduce and increase the GM, respectively, while

Case 4 and

Case 5 reduce and increase the PM, respectively (

Table 3). The Nichols plots of the tuning results under different cases are shown in

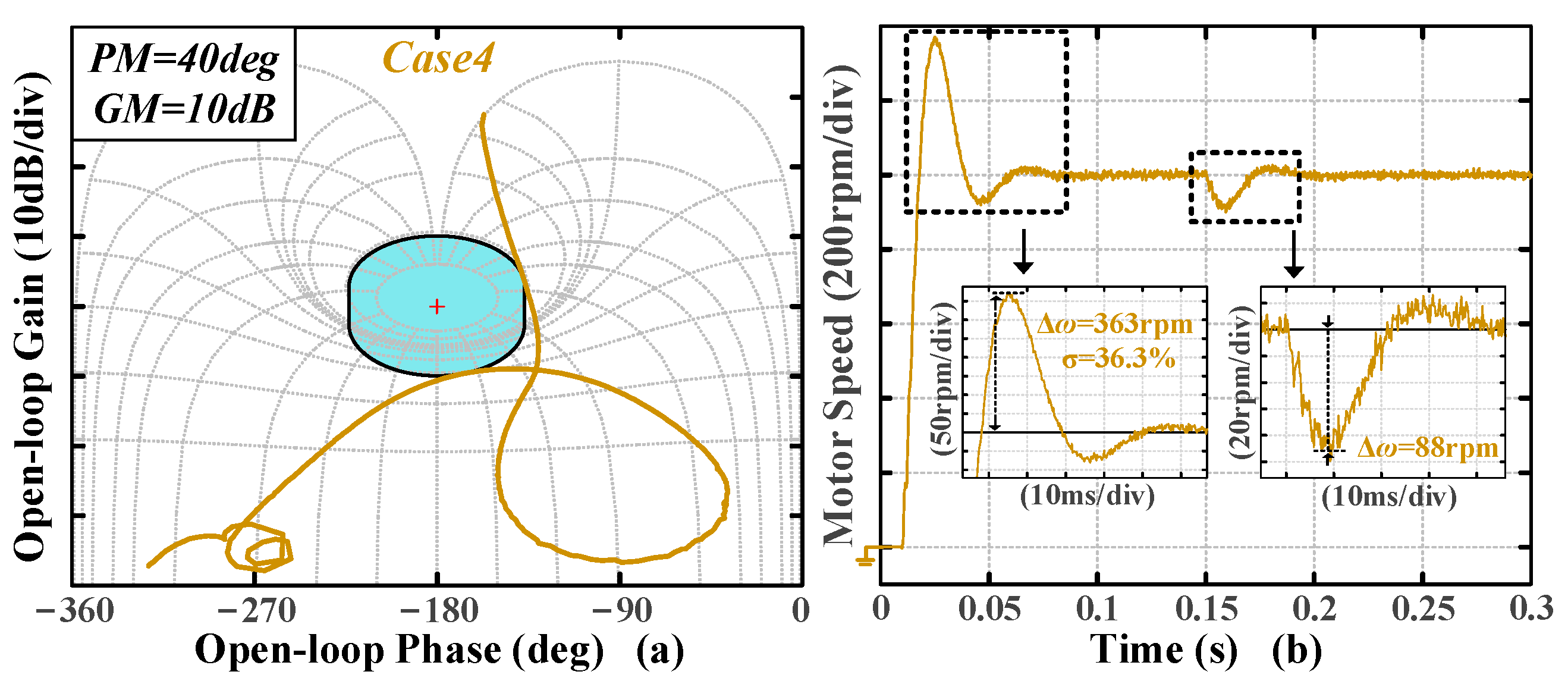

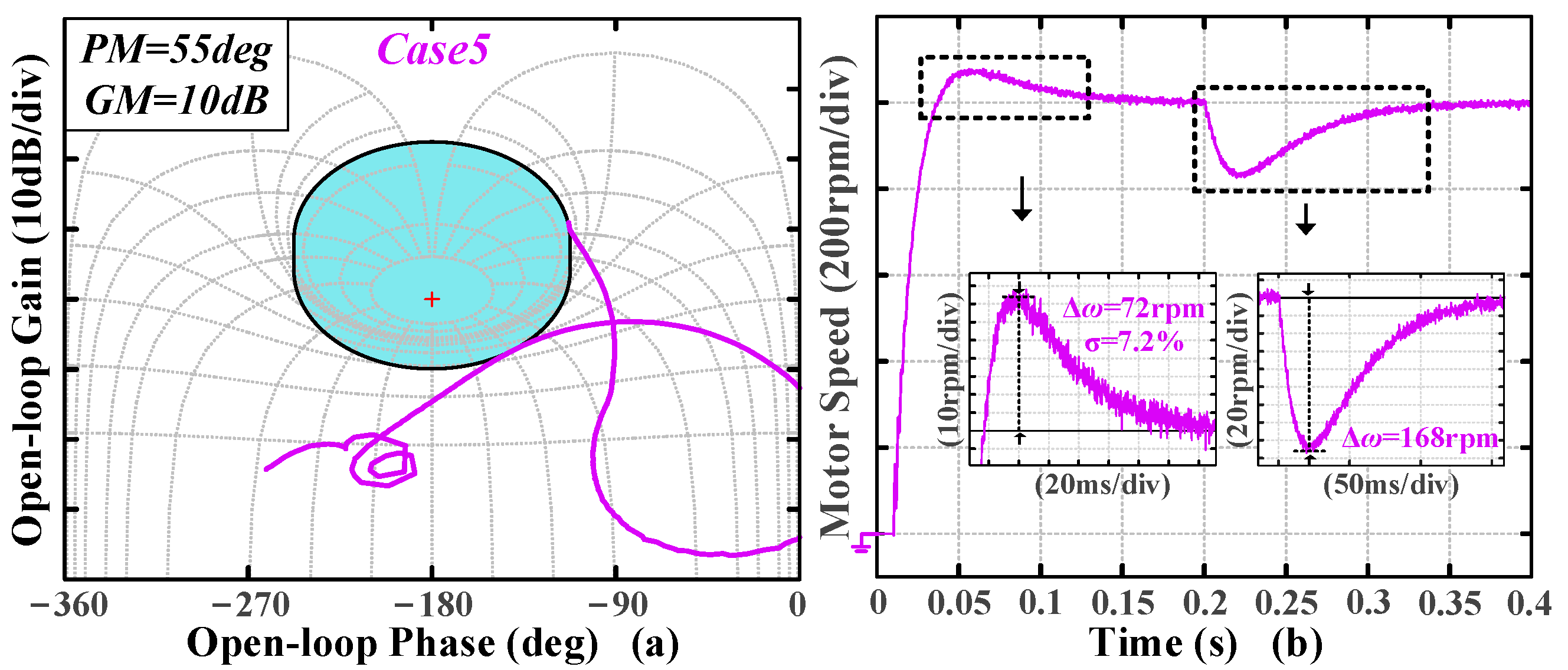

Figure 12a,

Figure 13a,

Figure 14a,

Figure 15a and

Figure 16a.

The tuning results are presented in

Table 4. To acquire the corresponding time-domain metrics, transient experiments are conducted: a 1000 rpm step signal is applied at 0.01 s, followed by an abrupt torque of 0.3 pu load. The speed response waveforms under different cases are shown in

Figure 12b,

Figure 13b,

Figure 14b,

Figure 15b and

Figure 16b. For ease of comparison,

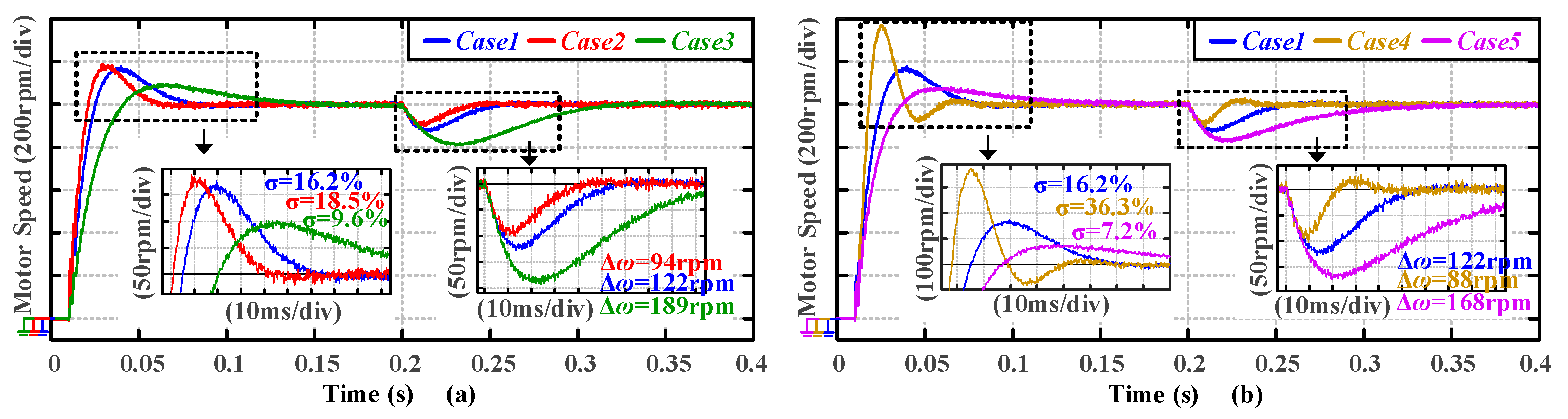

Figure 17 summarizes the speed response waveforms, categorizing them into varying gain margin groups and varying phase margin groups.

As shown in

Table 4 and

Figure 12b,

Figure 13b,

Figure 14b,

Figure 15b and

Figure 16b, an increase in either PM or GM individually results in a decrease in system overshoot, an increase in speed drop, and longer settling and recovery times. In addition, the corresponding closed-loop bandwidth is also reduced. In

Figure 17, it is obvious that the time-domain metrics are influenced by both PM and GM, with their trends remaining consistent; specifically, a notable reduction in overshoot occurs with changes to either PM or GM independently. The experimental results indicate that the algorithm effectively transforms the preset stability and disturbance rejection specifications into the desired time-domain response.

4.2. Comparison of Time-Domain Metrics Under Different Types of Plants

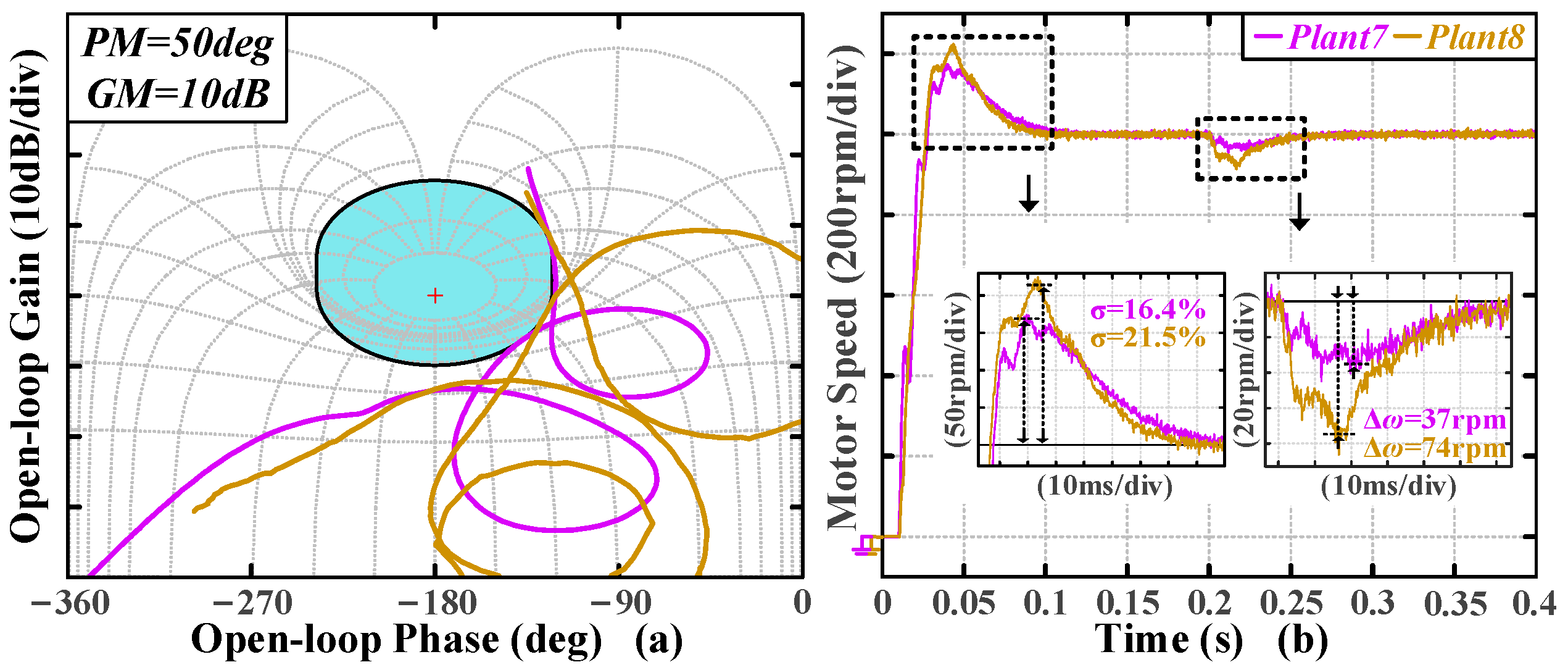

To validate the versatility of the algorithm, different types of plants—plant 1, plant 5, plant 7, and plant 8 in

Figure 11—are selected for the experiments. The experiments are conducted based on the benchmark. The Nichols plots of the tuning results are shown in

Figure 18a and

Figure 19a. The same transient experiments as the last part are conducted to obtain the time-domain metrics. The speed waveforms are shown in

Figure 18b and

Figure 19b.

Figure 20 presents the corresponding closed-loop magnitude Bode plot.

As shown in

Figure 18b and

Figure 19b, the tested plants—plant 1, plant 6, plant 7, and plant 8—exhibit distinct time-domain metrics under the same Case1 margin inputs. This is primarily attributed to the significant differences in their frequency characteristics, as these plants differ in system order, leading to variations in overshoot, speed drop, settling, and recovery time. The tuning results for different plants are summarized in

Table 5. It is obvious that the closed-loop bandwidth of the obtained system is limited by the inherent anti-resonance frequencies of the plants, leading to variations in the settling and recovery times. Despite the differences, the settling and recovery times of different plants are consistent with their anti-resonance frequencies. Inertial systems (plants 1–3) exhibit higher closed-loop bandwidths compared to other systems.

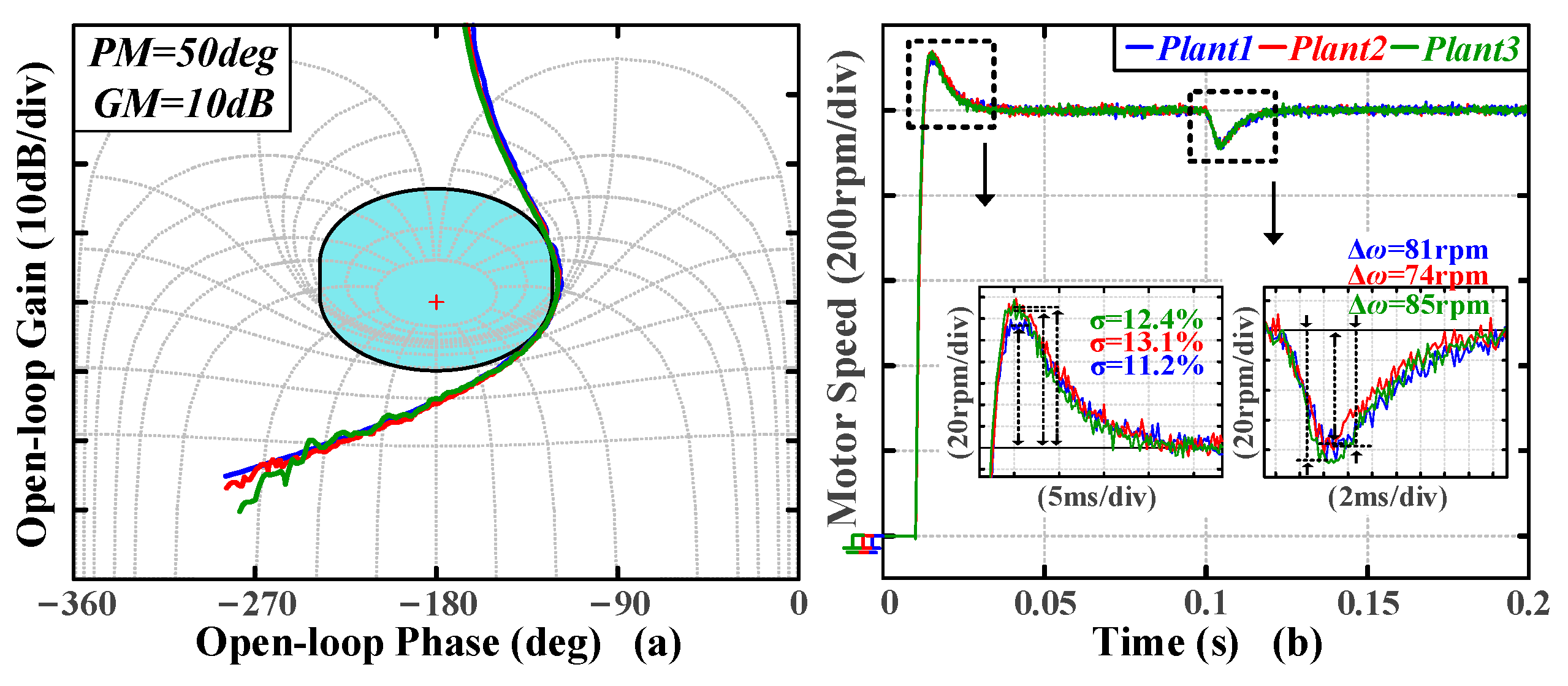

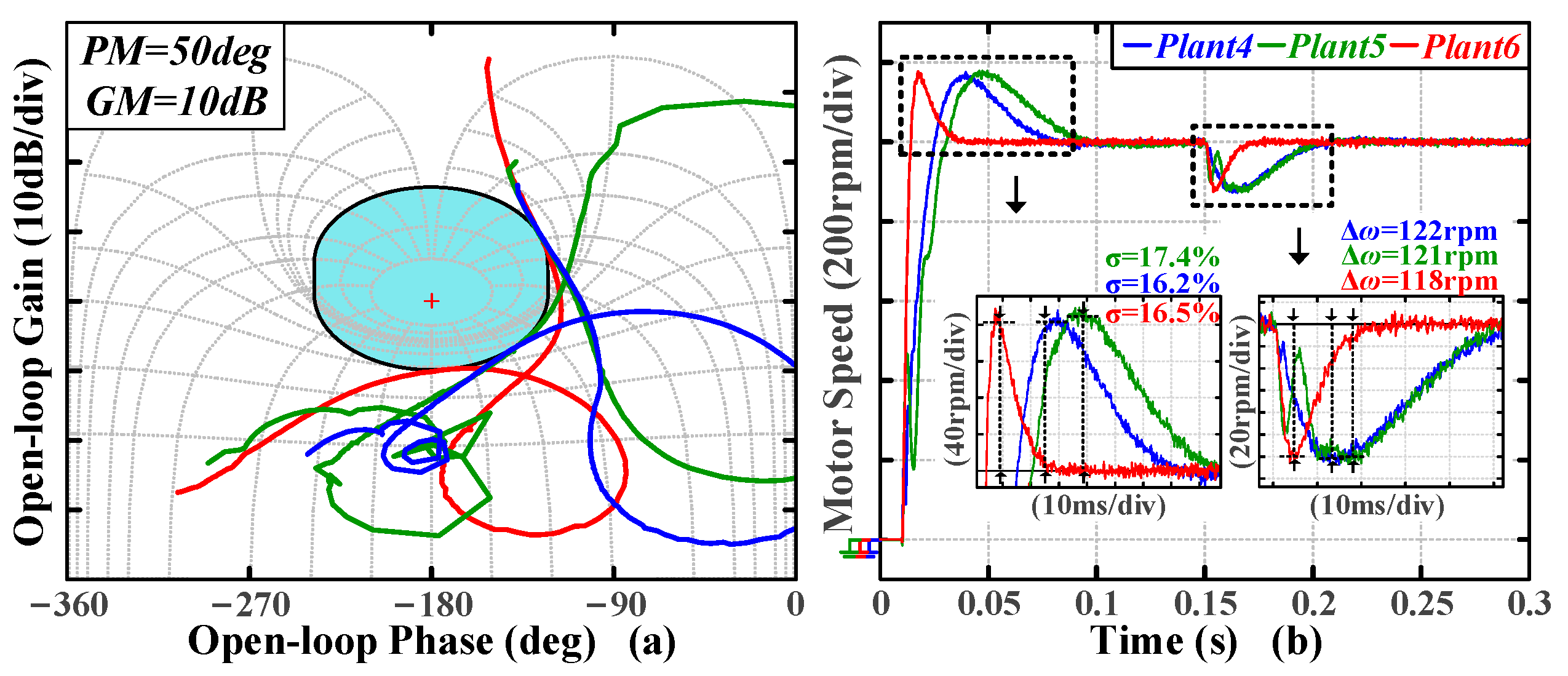

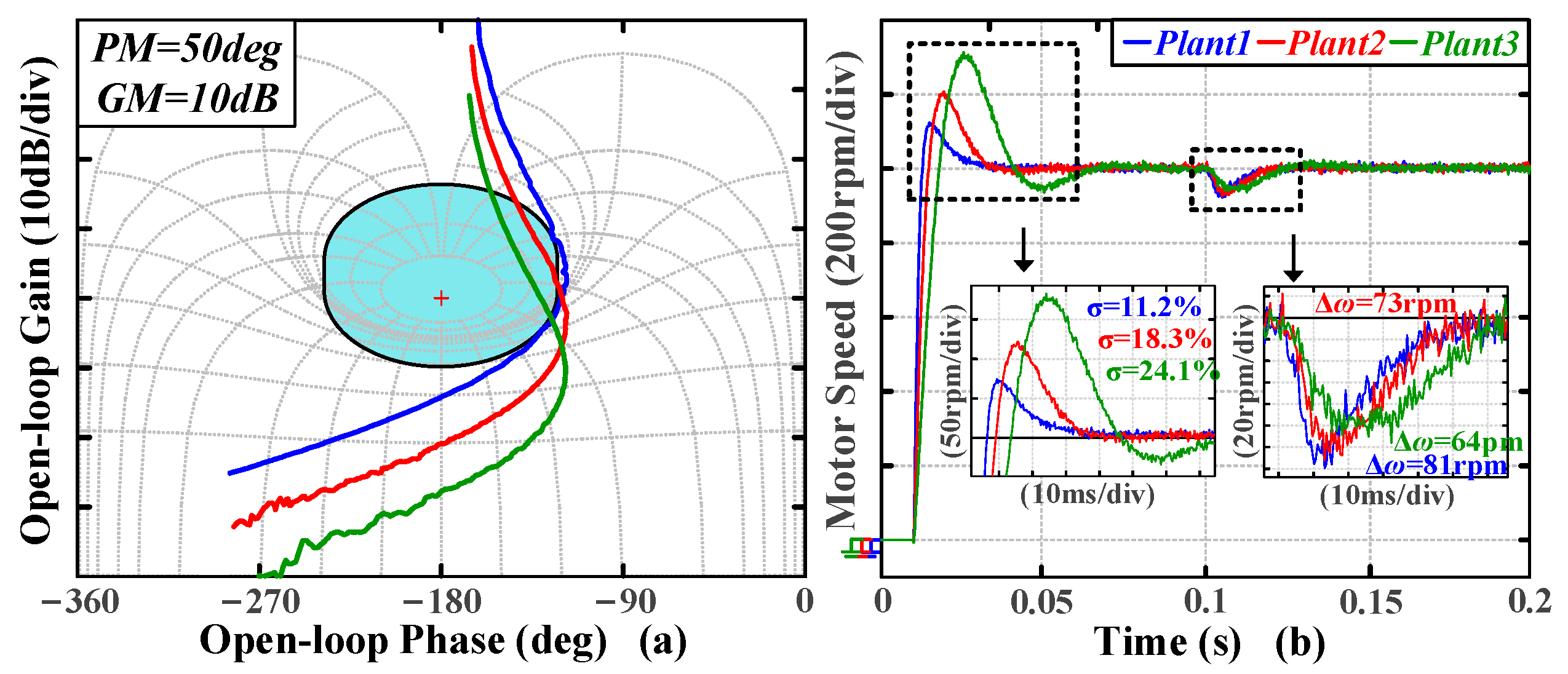

4.3. Comparison of Time-Domain Metrics Under Identical Types of Plants

To further explore the relationship between frequency-domain and time-domain metrics under different plants, three inertial systems in

Figure 11a and three single resonance point systems in

Figure 11b are used for experiments, respectively. The experiments are conducted based on the benchmark. The Nichols plots of the tuning results are shown in

Figure 21a and

Figure 22a. The same transient experiments as the last part are conducted to obtain the time-domain metrics. The speed waveforms are shown in

Figure 21b and

Figure 22b.

In

Figure 21b, the time-domain metrics for inertial systems exhibit consistency: the maximum differences in overshoot and speed drop are 1.9% and 1.1%, respectively. In

Figure 22b, the maximum differences in overshoot and speed drop are 1.2% and 0.4%, respectively. Given the differences in the inherent anti-resonant points of the single-resonance point systems, which limit the closed-loop bandwidth in

Figure 23, settling and recovery times are consistent with anti-resonance frequencies.

In summary, the proposed algorithm converts the preset PM and GM into the desired dynamic performance, as validated by the experimental time-domain metrics, which vary with changes in PM and GM. In addition, the algorithm presents compatibility with different types of plants, with the tuned systems exhibiting excellent transient performance. Furthermore, for plants with the same number of resonance points, the tuning results exhibit a certain degree of consistency in overshoot and speed drop. The differences in settling and recovery times can be correlated with the anti-resonance frequencies of the plants.

4.4. Comparison of Time-Domain Metrics with Systems Tuned by ZPC

To demonstrate the advantages of the proposed tuning algorithm, a comparison is conducted between the proposed method and the zero-pole cancellation (ZPC) strategy, where ZPC is implemented following reference [

35]. As a foundation, the speed servo block diagram and calculation formulas used for ZPC are first introduced.

In

Figure 24,

Ksp and

Ksi represent the proportional and integral gains of the speed controller, respectively, while

Kcp and

Kci represent the proportional and integral gains of the current loop controller, respectively.

L and

R denote the stator inductance and q-axis resistance of the motor, respectively;

J represents the motor inertia; and

KT denotes the torque constant. When the current loop bandwidth is sufficiently high, its closed-loop transfer function can be approximated as 1.

where

Gsc(

s) and

Gsc(

s) denote the open-loop and closed-loop transfer functions of the speed control system, respectively.

where

ωsc denotes the speed loop gain crossover frequency and

u denotes the preset phase margin. According to reference [

35], by specifying the gain crossover frequency and phase margin of the open-loop transfer function of the system, along with the motor inertia, the parameters of the PI controller can be determined. With the gain crossover frequency set at 100 rad/s and the phase margin specified as 50 deg, the resulting PI controller parameters for Motors 1–3 are summarized in

Table 6.

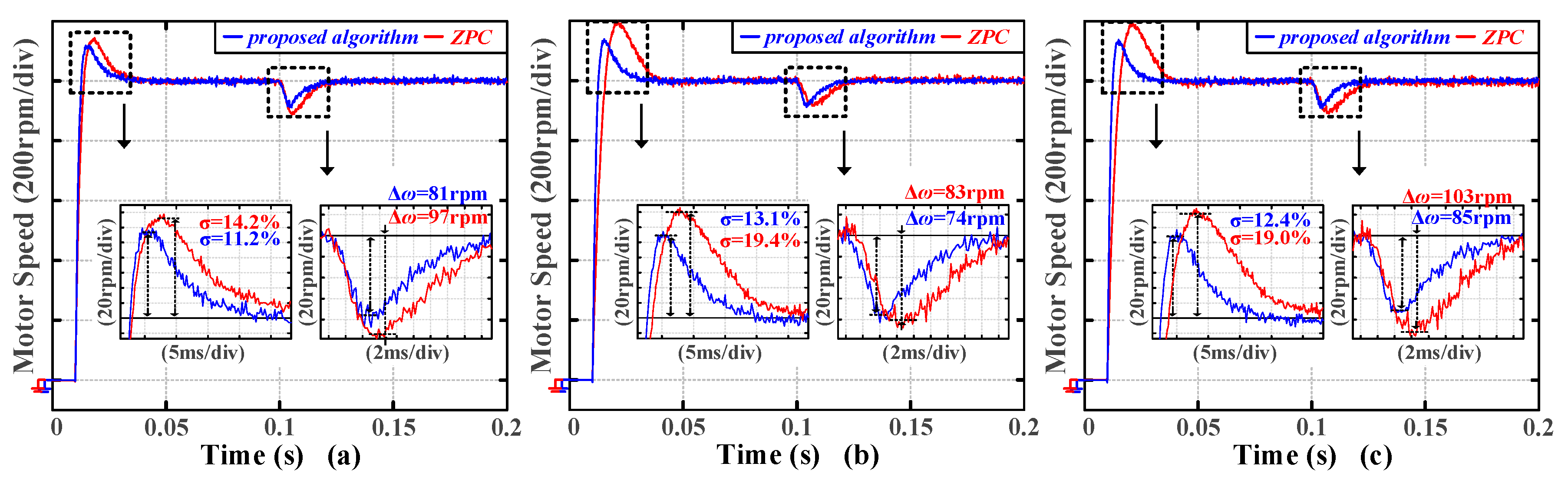

In order to conduct a quantitative comparison with the tuning algorithm proposed in this paper, the stability margins used as inputs for the proposed algorithm are Case 1: PM = 50 deg, GM = 10 dB. To acquire the corresponding time-domain metrics, transient experiments are conducted: a 1000 rpm step signal is applied at 0.01 s, followed by an abrupt torque of 0.3 pu load at 0.1 s. The speed response curves of the experiment are shown in

Figure 25.

As shown in

Figure 25a–c, the system tuned using the ZPC-based method exhibits a larger overshoot and speed drop, as well as longer settling and recovery times compared to the proposed method. The comparison of the four time-domain performance metrics demonstrates that the tuning approach presented in this paper provides superior performance. The ZPC method is primarily designed for relatively simple PI controllers, which involve only two tunable parameters. In contrast, the controller employed in this paper adopts a PI filter structure with three tunable parameters. Therefore, the ZPC and the tuning algorithm proposed in this manuscript are developed for different controller structures, each requiring distinct types of input parameters.

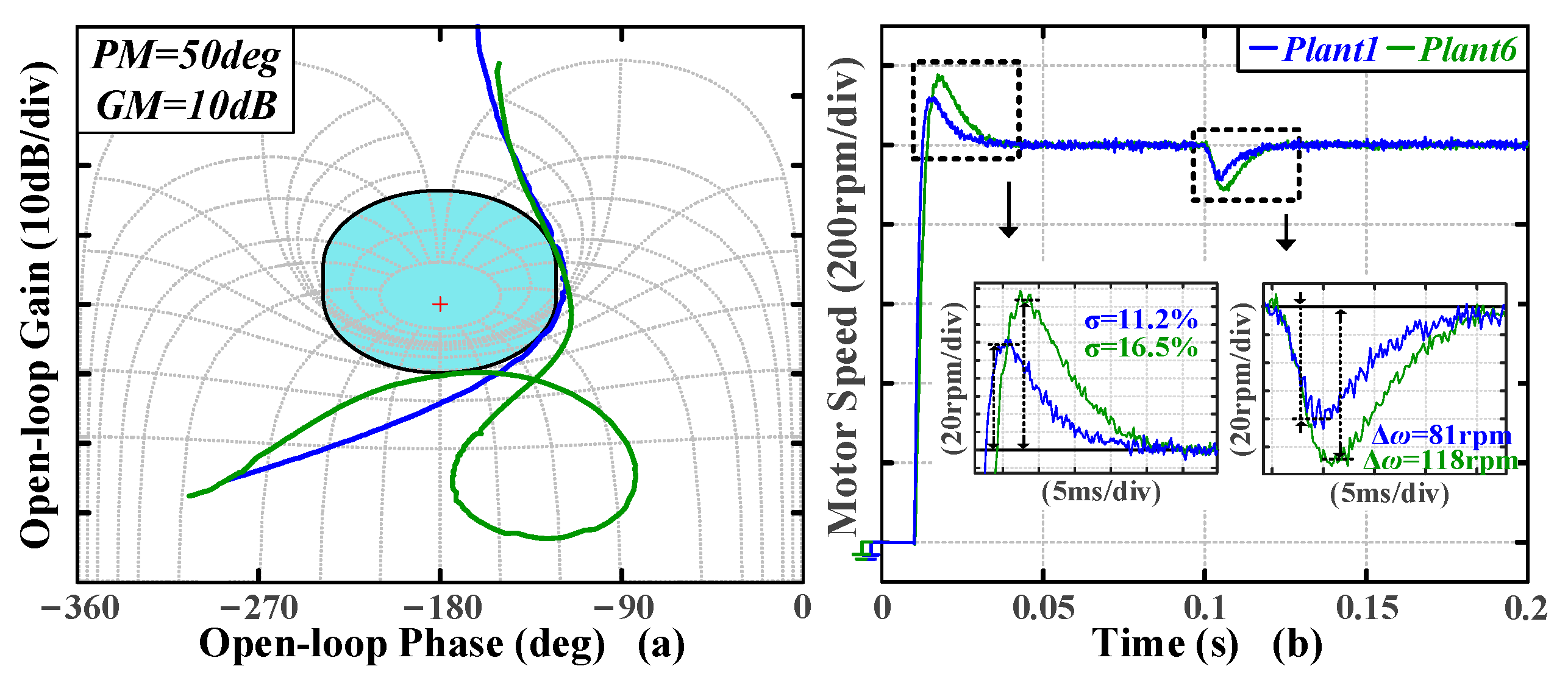

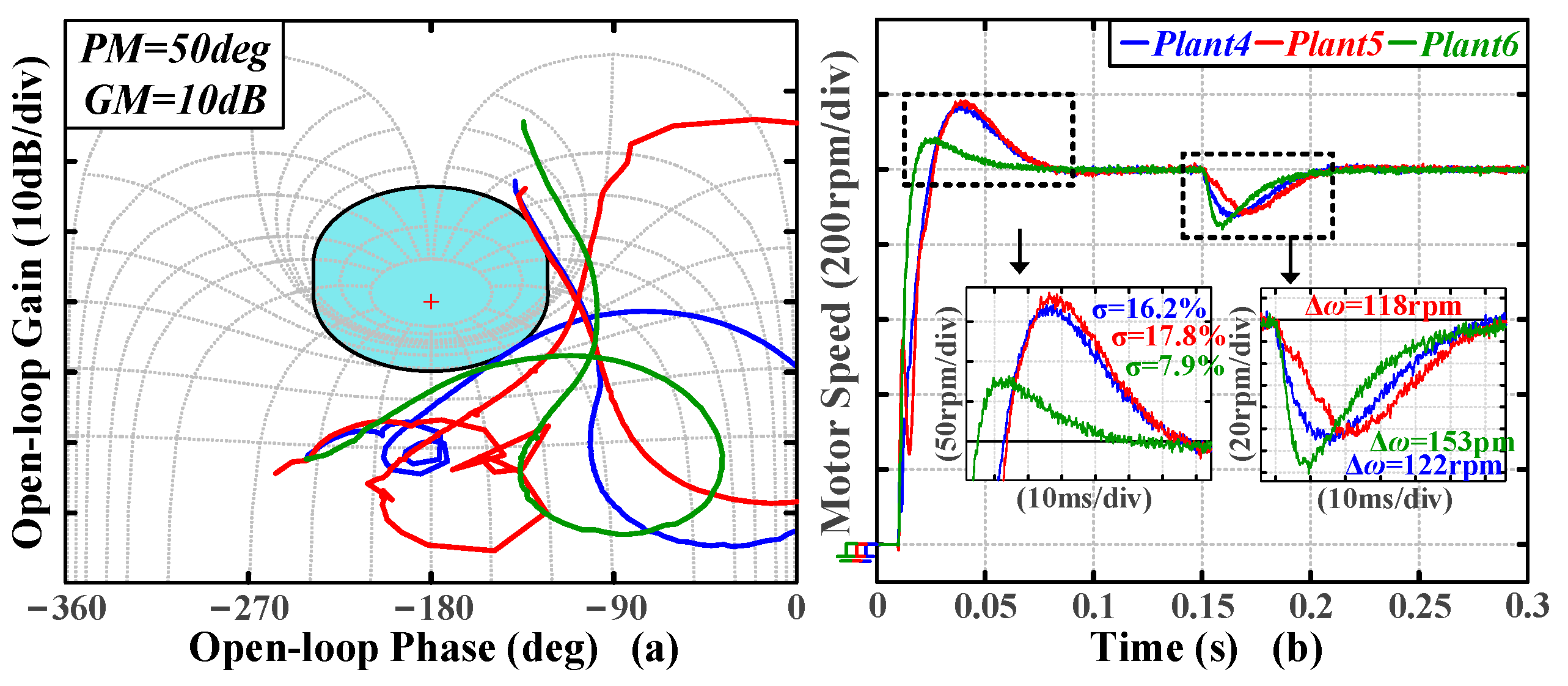

4.5. Comparison of the Time-Domain Metrics of Different Order Systems Under Load Variation

To investigate the robustness of the proposed tuning algorithm against load variations, plant1 and plant4, representing two different types of systems, are, respectively, selected as the initial plants for tuning. Plants 2–3 and plants 5–6 are used as the plants after the inertia changes. The result for plant1’s controller parameters (Kp, Ki, and ω0) is (0.242, 144, 6097); the result for plant4’s controller parameters is (0.121, 57, 31,501).

When the load of the inertia system changes, the corresponding open-loop curves are shown in

Figure 26a. The curves cross the preset boundary, indicating that the stability and disturbance rejection constraints are no longer satisfied. The corresponding speed response waveforms are shown in

Figure 26b, where the overshoot increases from 11.2% to 24.1%, and the settling time also changes accordingly. In contrast, when the load of the single-resonant system changes, the open-loop curve moves away from the boundary, resulting in excessive stability margins. As shown in

Figure 27 and

Table 7, the proposed tuning method exhibits a certain degree of sensitivity to load variations.