A Review on Perovskite/Silicon Tandem Solar Cells: Current Status and Future Challenges

Abstract

1. Introduction

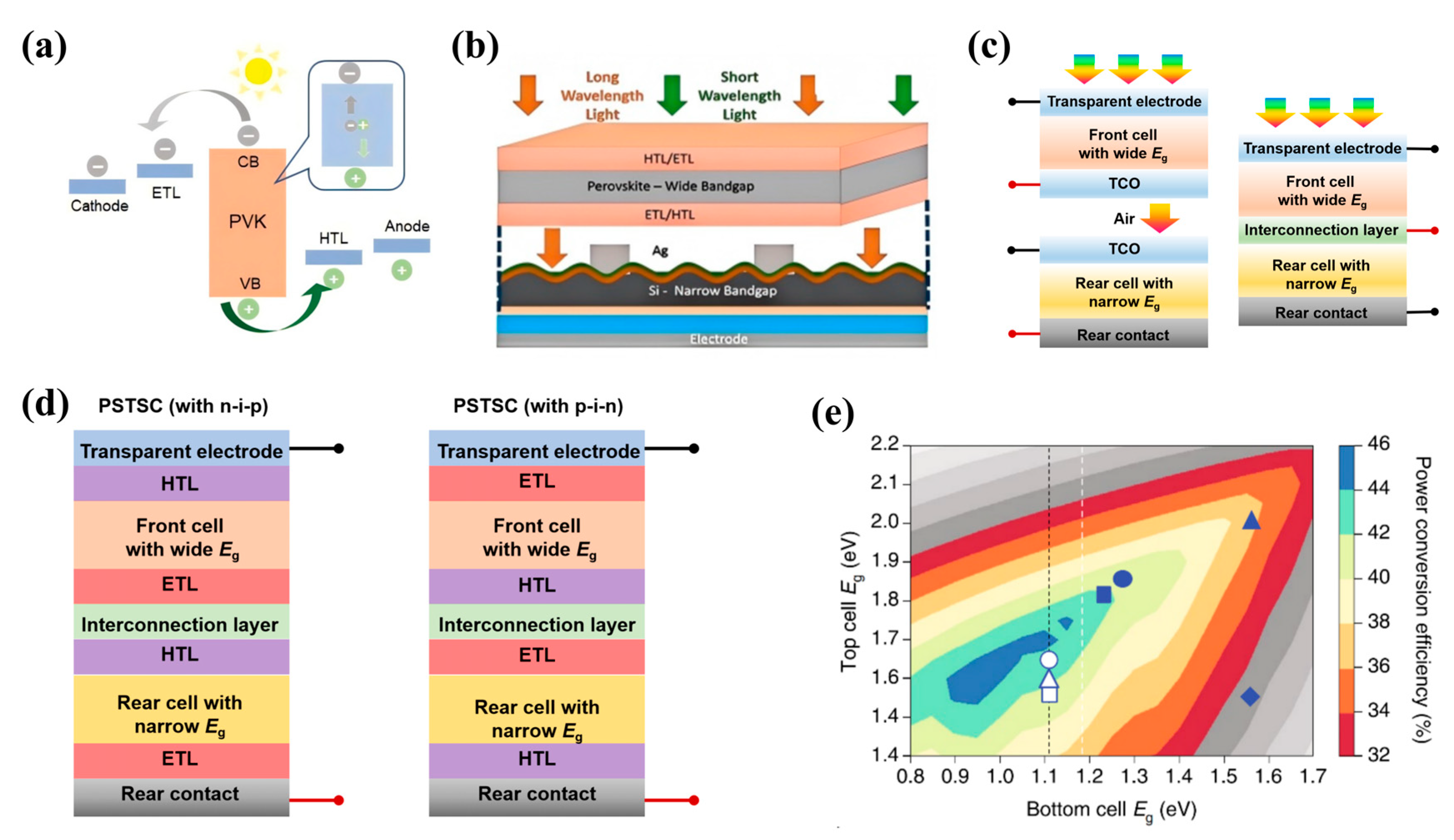

2. Fundamental Mechanisms of the Tandem Photovoltaic Device

| Year | Device Structure | Absorber | Si-Type | Eg (eV) | VOC (V) | JSC (mAcm−2) | PCE (%) | Ref |

|---|---|---|---|---|---|---|---|---|

| 2016 | n-i-p | FAxMA1−xPbyI3−yBr | SHJ | none | 1.78 | 14 | 18 | [27] |

| 2016 | n-i-p | MAPbI3 | SHJ | 1.6 | 1.703 | 15.8 | 21.4 | [28] |

| 2017 | p-i-n | Cs0.17FA0.83Pb(Br0.17I0.83)3 (CsFA) | SHJ | 1.63 | 1.65 | 18.1 | 23.6 | [29] |

| 2018 | n-i-p | MAPbI3 | TOPcon | 1.6 | 1.68 | 16.2 | 21 | [30] |

| 2018 | n-i-p | Cs0.05Rb0.05FA0.765MA0.135PbI2.55Br0.45 | SHJ | 1.63 | 1.763 | 17.8 | 24.5 | [31] |

| 2018 | p-i-n | CsxFA1−xPb(Br1−yIy) | SHJ | 1.6 | 1.78 | 19.5 | 25.2 | [32] |

| 2019 | p-i-n | (FAPbI3)0.8(MAPbBr3)0.2 | BSF | 1.64 | 1.645 | 16.13 | 21.19 | [33] |

| 2020 | p-i-n | Cs0.1MA0.9Pb(I0.9Br0.1)3 | SHJ | none | 1.82 | 19.2 | 26 | [34] |

| 2020 | p-i-n | Cs0.05(FA0.77MA0.23)0.95Pb(I0.77Br0.23)3 | SHJ | 1.68 | 1.92 | 19.26 | 29.15 | [9] |

| 2020 | p-i-n | Peroviskite | SHJ | 1.67 | 1.886 | 19.12 | 27.04 | [35] |

| 2020 | p-i-n | Cs0.05MA0.15FA0.8PbBr0.75I2.25 | SHJ | 1.68 | 1.7 | 19.8 | 25.7 | [36] |

| 2021 | p-i-n | Cs0.05(MA0.23FA0.77)0.95Pb(Br0.23I0.77)3 | SHJ | 1.68 | 1.89 | 19.13 | 28.2 | [37] |

| 2021 | p-i-n | Cs0.1FA0.9PbBr0.13I2.8 | SHJ | none | 1.808 | 19.79 | 27.48 | [38] |

| 2022 | p-i-n | Cs0.22FA0.78Pb(Br0.15I0.85)3 | TOPcon | 1.68 | 1.794 | 19.68 | 27.6 | [39] |

| 2022 | p-i-n | Cs0.05(FA0.79MA0.21)0.95Pb(I0.79Br0.21)3 | SHJ | 1.66 | 1.9 | 19.45 | 29.83 | [40] |

| 2022 | p-i-n | Cs0.1FA0.1MA0.7Pb(Br0.15I0.85)3 | SHJ | 1.65 | 1.92 | 18.95 | 28.6 | [41] |

| 2022 | n-i-p | CsPb(IxBr1−x)3 | SHJ | 1.8 | 2.04 | 14.34 | 22.95 | [42] |

| 2022 | p-i-n | Cs0.05FA0.8MA0.15Pb(Br0.255I0.755)3 | SHJ | 1.69 | 1.92 | 19.8 | 29.3 | [43] |

| 2022 | n-i-p | Cs0.05FA0.8MA0.15PbI2.5Br0.45 | TOPcon | 1.62 | 1.783 | 14.4 | 17.3 | [44] |

| 2022 | p-i-n | Cs0.22FA0.78Pb(Cl0.03Br0.15I0.85)3 | TOPcon | 1.68 | 1.79 | 19.68 | 27.63 | [45] |

| 2022 | p-i-n | FA0.78Cs0.22Pb(I0.85Br0.15)3 | PERC | 1.68 | 1.91 | 19.29 | 28.81 | [46] |

| 2022 | p-i-n | Cs0.05(FA0.83MA0.17)0.95Pb(Br0.17I0.83)3 | TOPcon | 1.63 | 1.8 | 19.2 | 28.2 | [47] |

| 2023 | p-i-n | CsPbBr0.15I2.85 | SHJ | 1.71 | 1.84 | 17.95 | 25.31 | [48] |

| 2023 | p-i-n | Cs0.22FA0.78Pb(I0.85Br0.15)3 + 5%MAPbI3 | SHJ | 1.68 | 2 | 20.24 | 32.5 | [49] |

| 2023 | p-i-n | Peroviskite | SHJ | none | 1.82 | 20.4 | 28.4 | [50] |

| 2023 | n-i-p | (FAPbI3)0.83(MAPbBr3)0.17 | SHJ | none | 1.82 | 18.1 | 27.2 | [51] |

| 2023 | p-i-n | Cs0.05(FA0.83MA0.17)0.95Pb(I0.83Br0.17)3 | TOPcon | none | 1.83 | 19.7 | 29.2 | [52] |

| 2023 | p-i-n | CsxFA1−xPbI3−yBry | SHJ | none | 1.68 | 19.47 | 23.22 | [53] |

| 2023 | p-i-n | Cs0.05MA0.14FA0.81Pb(I0.8Br0.2)3 | SHJ | 1.68 | 1.85 | 19.7 | 28.4 | [54] |

| 2024 | p-i-n | Cs0.05FA0.8MA0.15Pb(I0.75Br0.25)3 | SHJ | 1.67 | 1.941 | 20.1 | 29.6 | [55] |

| 2024 | p-i-n | Peroviskite | SHJ | 1.69 | 1.98 | 20.86 | 33.89 | [56] |

| 2024 | p-i-n | Cs0.05FA0.95−xMAxPb(I1−yBry)3 | SHJ | 1.67 | 1.869 | 20.32 | 30.52 | [57] |

| 2024 | n-i-p | Cs0.05FA0.8MA0.15Pb(I0.75Br0.25)3 | TOPCon | none | 1.9 | 18.82 | 28.2 | [58] |

| 2024 | p-i-n | Cs0.05(FA0.9MA0.1)0.95Pb(I0.8Br0.2)3 | SHJ | none | 1.954 | 18.92 | 30.22 | [59] |

| 2025 | p-i-n | Perovskite | TOPcon | 1.68 | 1.931 | 19.89 | 31.32 | [60] |

| 2025 | p-i-n | Cs0.17FA0.83Pb(I0.83Br0.17)3 | TOPCon | 1.68 | 1.977 | 19.41 | 30.36 | [61] |

| 2025 | p-i-n | Cs0.05(FA0.77MA0.23)0.95Pb(I0.77Br0.23)3 | SHJ | 1.68 | 1.92 | 20.3 | 31.5 | [62] |

| 2025 | p-i-n | perovskite | SHJ | 1.68 | 1.912 | 19.92 | 32.19 | [63] |

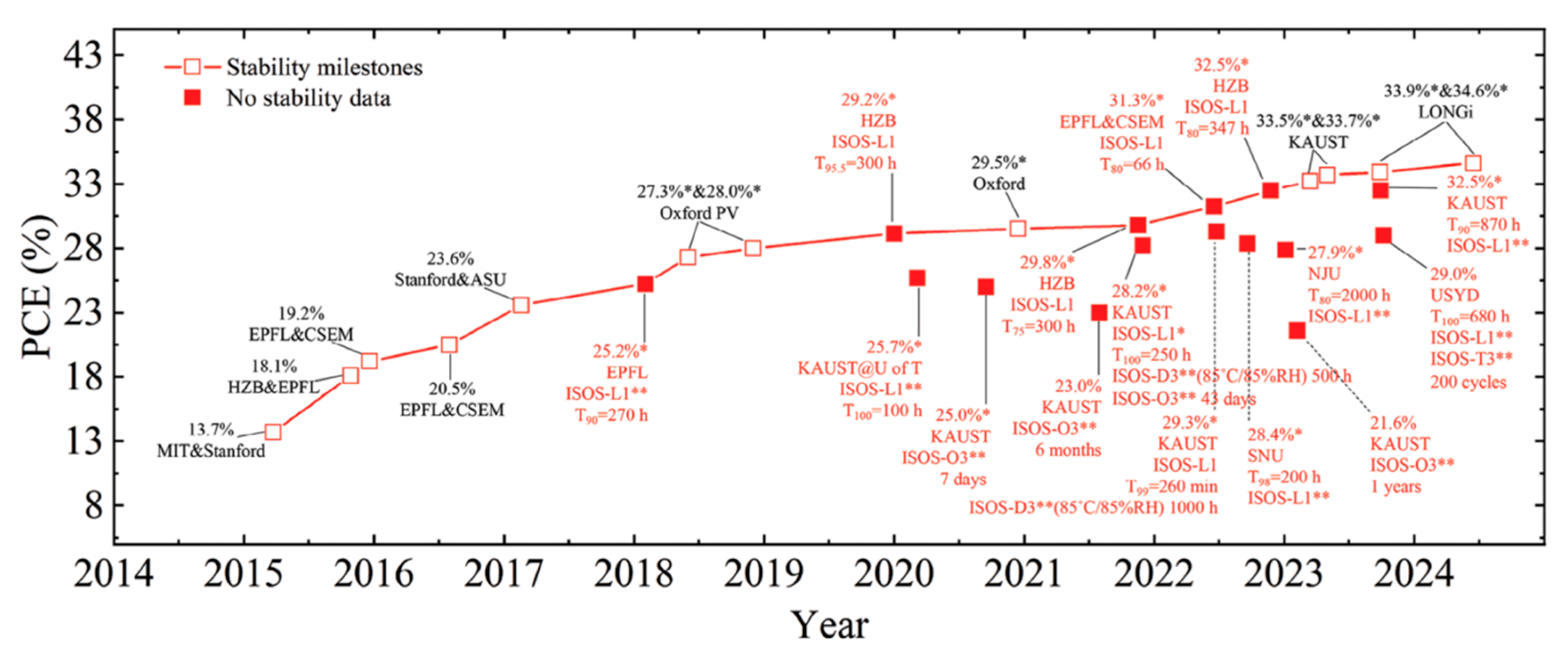

3. Present Status of Monolithic Perovskite/Silicon TSCs

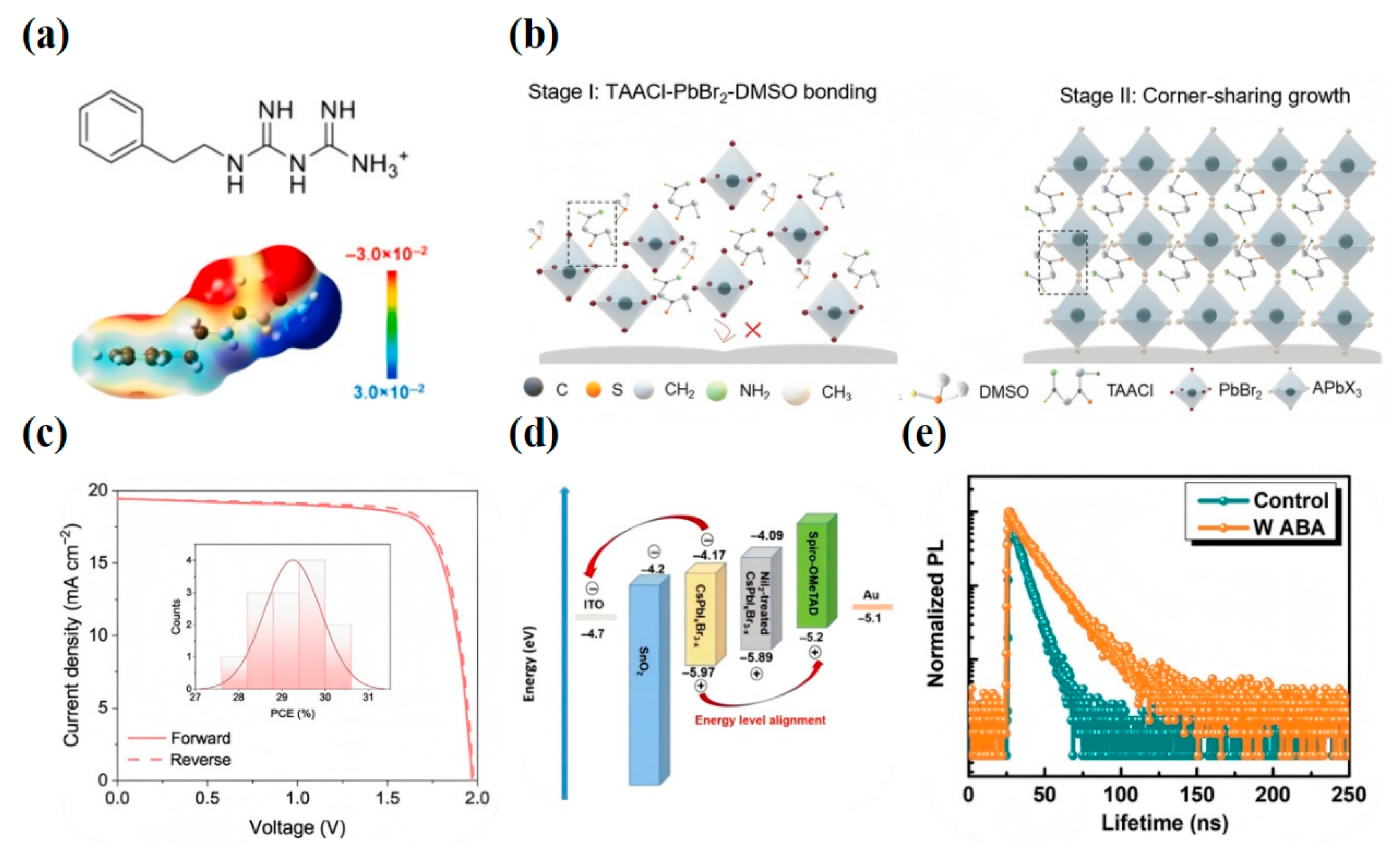

3.1. Perovskite Top Cell

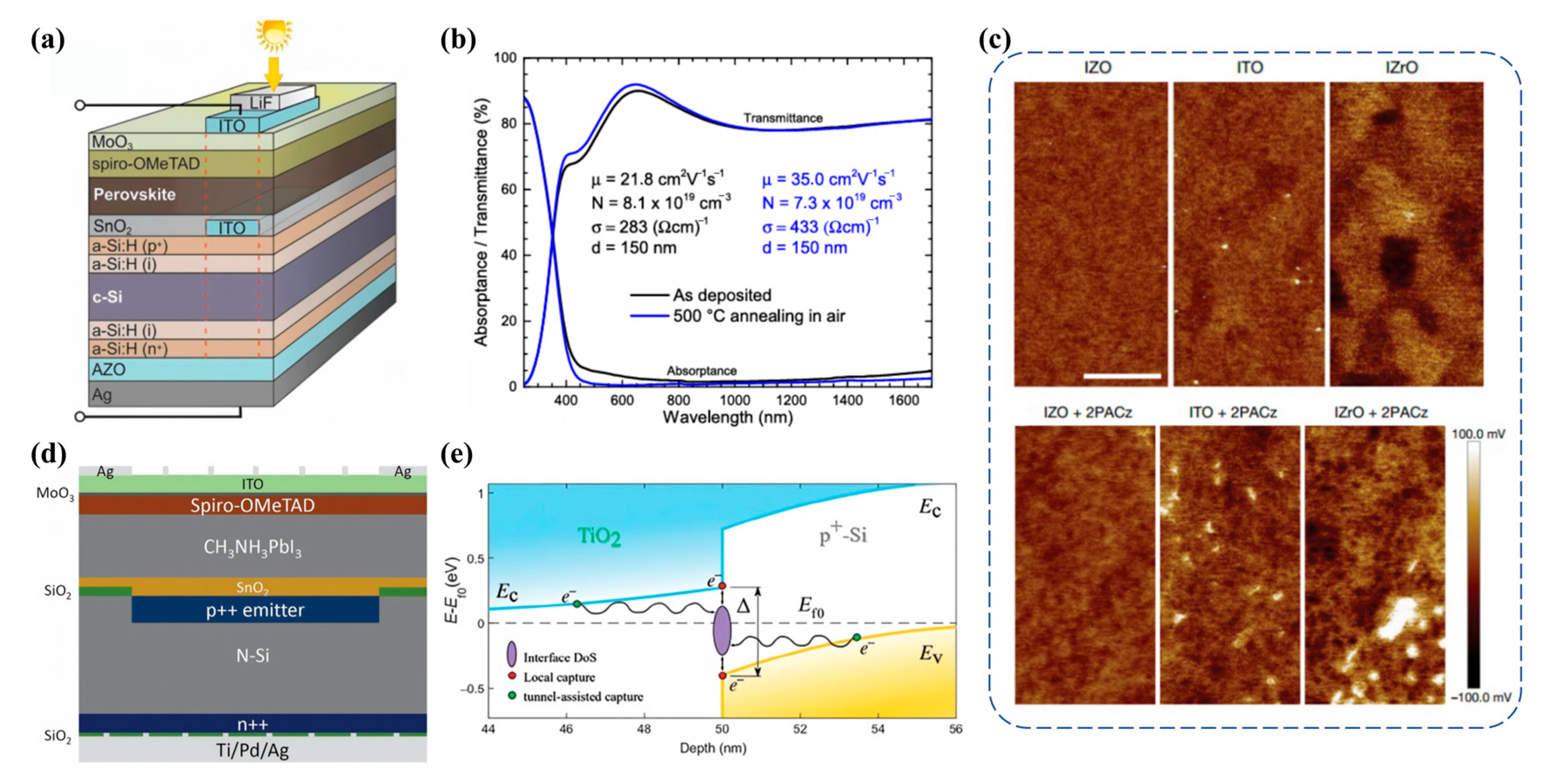

3.2. Interconnecting Layer

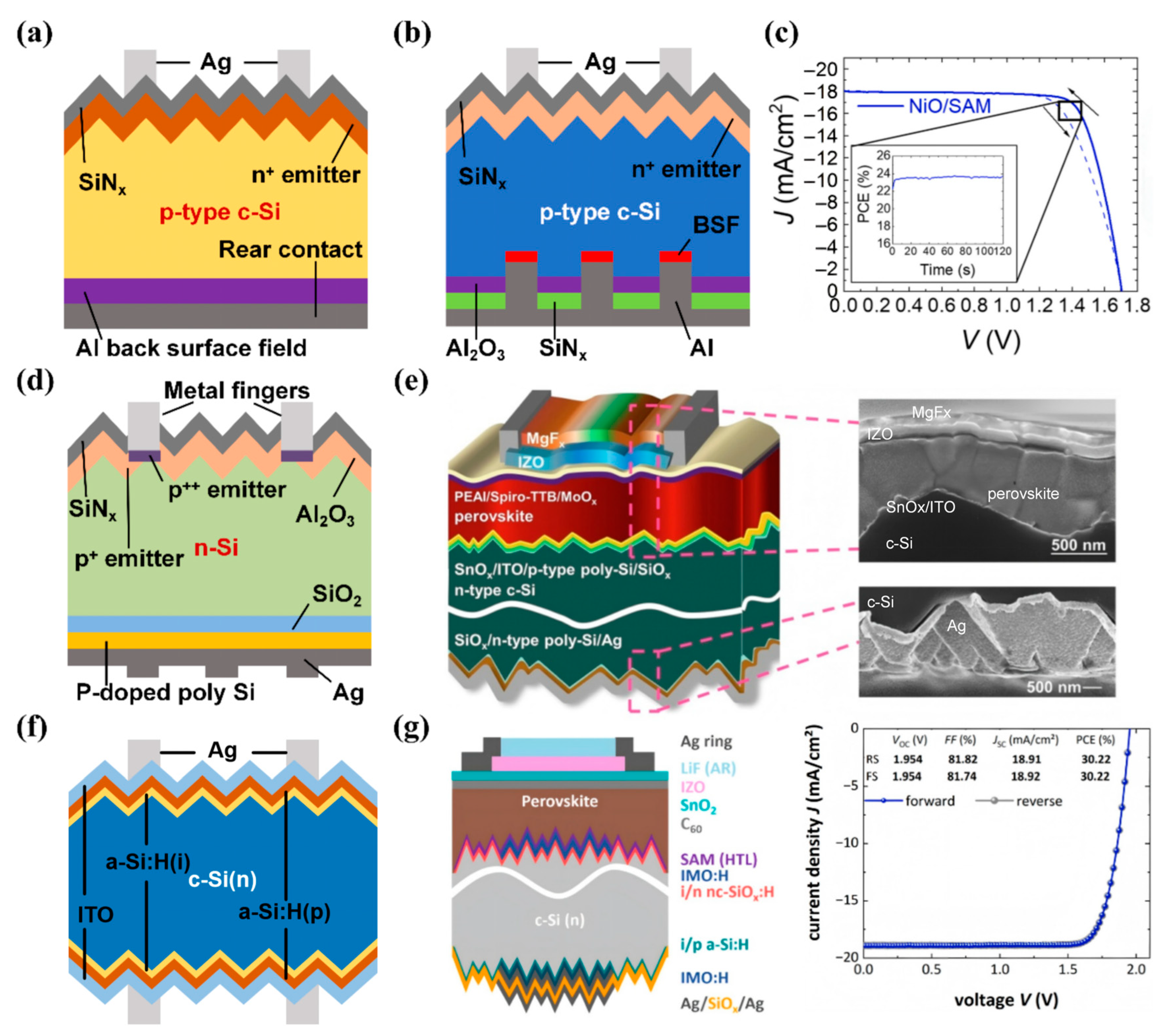

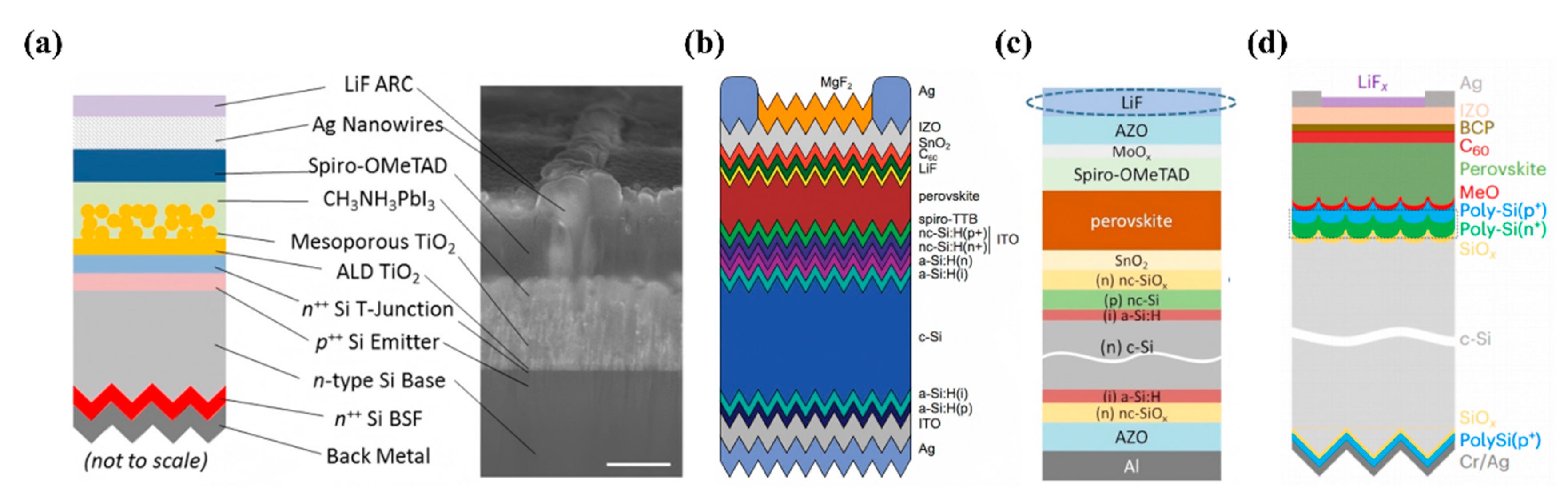

3.3. Si Bottom Cell

4. Challenges of PSTSCs

4.1. Stability of Perovskite and PSTSCs

4.2. Conformal Coating of Perovskite on Textured Silicon

4.3. Simplified ETL Architecture

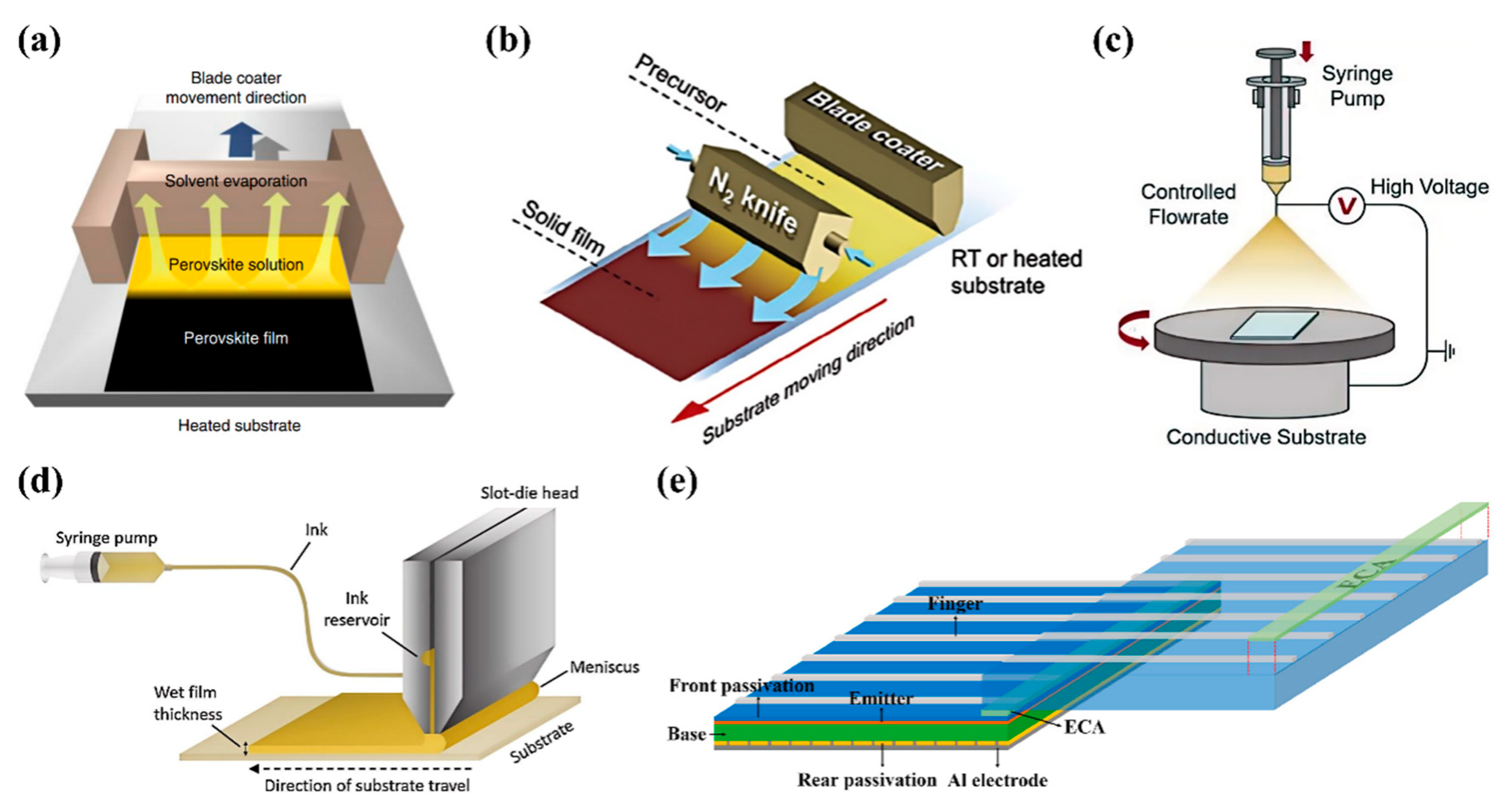

4.4. Fabricaition of PSTSCs Based on Full-Sized Silicon Cell

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Green, M.A.; Dunlop, E.D.; Yoshita, M.; Kopidakis, N.; Bothe, K.; Siefer, G.; Hao, X.; Jiang, J.Y. Solar cell efficiency tables (version 65). Prog. Photovolt. 2025, 33, 3–15. [Google Scholar] [CrossRef]

- Duan, L.; Walter, D.; Chang, N.; Bullock, J.; Kang, D.; Phang, S.P.; Weber, K.; White, T.; Macdonald, D.; Catchpole, K.; et al. Stability challenges for the commercialization of perovskite-silicon tandem solar cells. Nat. Rev. Mater. 2023, 8, 261–281. [Google Scholar] [CrossRef]

- Green, M.A.; Dunlop, E.D.; Yoshita, M.; Kopidakis, N.; Bothe, K.; Siefer, G.; Hinken, D.; Rauer, M.; Hohl-Ebinger, J.; Hao, X. Solar cell efficiency tables (version 64). Prog. Photovolt. 2024, 32, 425–441. [Google Scholar] [CrossRef]

- Yu, Y.; Bai, X.; Li, S.; Shi, J.; Wang, L.; Xi, F.; Ma, W.; Deng, R. Review of silicon recovery in the photovoltaic industry. Curr. Opin. Green Sustain. Chem. 2023, 44, 100870. [Google Scholar] [CrossRef]

- Green, M.A.; Dunlop, E.D.; Yoshita, M.; Kopidakis, N.; Bothe, K.; Siefer, G.; Hao, X.; Jiang, J.Y. Solar cell efficiency tables (version 66). Prog. Photovolt. 2025, 33, 795–810. [Google Scholar] [CrossRef]

- Richter, A.; Hermle, M.; Glunz, S.W. Reassessment of the limiting efficiency for crystalline silicon solar cells. IEEE J. Photovolt. 2013, 3, 1184–1191. [Google Scholar] [CrossRef]

- Park, J.; Kim, J.; Yun, H.-S.; Paik, M.J.; Noh, E.; Mun, H.J.; Kim, M.G.; Shin, T.J.; Seok, S.I. Controlled growth of perovskite layers with volatile alkylammonium chlorides. Nature 2023, 616, 724–730. [Google Scholar] [CrossRef]

- Chen, H.; Liu, C.; Xu, J.; Maxwell, A.; Zhou, W.; Yang, Y.; Zhou, Q.; Bati, A.S.R.; Wan, H.; Wang, Z.; et al. Improved charge extraction in inverted perovskite solar cells with dual-site-binding ligands. Science 2024, 384, 189–193. [Google Scholar] [CrossRef]

- Al-Ashouri, A.; Köhnen, E.; Li, B.; Magomedov, A.; Hempel, H.; Caprioglio, P.; Márquez, J.A.; Morales Vilches, A.B.; Kasparavicius, E.; Smith, J.A.; et al. Monolithic perovskite/silicon tandem solar cell with >29% efficiency by enhanced hole extraction. Science 2020, 370, 1300–1309. [Google Scholar] [CrossRef]

- Duan, Y.; Chen, Y.; Wu, Y.; Liu, Z.; Liu, S.; Peng, Q. A comprehensive review of organic hole-transporting materials for highly efficient and stable inverted perovskite solar cells. Adv. Funct. Mater. 2024, 34, 2315604. [Google Scholar] [CrossRef]

- Li, S.; Jiang, Y.; Xu, J.; Wang, D.; Ding, Z.; Zhu, T.; Chen, B.; Yang, Y.; Wei, M.; Guo, R.; et al. High-efficiency and thermally stable FACsPbI3 perovskite photovoltaics. Nature 2024, 635, 82–88. [Google Scholar] [CrossRef]

- Liu, S.; Li, J.; Xiao, W.; Chen, R.; Sun, Z.; Zhang, Y.; Lei, X.; Hu, S.; Kober-Czerny, M.; Wang, J.; et al. Buried interface molecular hybrid for inverted perovskite solar cells. Nature 2024, 632, 536–542. [Google Scholar] [CrossRef]

- Mailoa, J.P.; Bailie, C.D.; Johlin, E.C.; Hoke, E.T.; Akey, A.J.; Nguyen, W.H.; McGehee, M.D.; Buonassisi, T. A 2-terminal perovskite/silicon multijunction solar cell enabled by a silicon tunnel junction. Appl. Phys. Lett. 2015, 106, 121105. [Google Scholar] [CrossRef]

- Futscher, M.H.; Ehrler, B. Efficiency limit of perovskite/si tandem solar cells. ACS Energy Lett. 2016, 1, 863–868. [Google Scholar] [CrossRef]

- Wang, R.; Huang, T.; Xue, J.; Tong, J.; Zhu, K.; Yang, Y. Prospects for metal halide perovskite-based tandem solar cells. Nat. Photonics 2021, 15, 411–425. [Google Scholar] [CrossRef]

- Li, H.; Li, F.; Shen, Z.; Han, S.-T.; Chen, J.; Dong, C.; Chen, C.; Zhou, Y.; Wang, M. Photoferroelectric perovskite solar cells: Principles, advances and insights. Nano Today 2021, 37, 101062. [Google Scholar] [CrossRef]

- Sadhukhan, S.; Acharyya, S.; Panda, T.; Mandal, N.C.; Das, G.; Maity, S.; Chaudhuri, P.; Chakraborty, S.; Saha, H. TOPerc solar cell: An integral approach of tunnel oxide passivated contact (TOPCon) and passivated emitter and rear contact (PERC) architectures for achieving efficiency beyond 25%. Energy Technol. 2023, 11, 2300200. [Google Scholar] [CrossRef]

- Raza, E.; Ahmad, Z. Review on two-terminal and four-terminal crystalline-silicon/perovskite tandem solar cells; progress, challenges, and future perspectives. Energy Rep. 2022, 8, 5820–5851. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, Y.; Wang, X.; Sun, Y.; Zhao, Z.; Li, Y.; Zhou, H.; Chen, Q. Cost analysis of perovskite tandem photovoltaics. Joule 2018, 2, 1559–1572. [Google Scholar] [CrossRef]

- Cordell, J.J.; Woodhouse, M.; Warren, E.L. Technoeconomic analysis of perovskite/silicon tandem solar modules. Joule 2024, 9, 101781. [Google Scholar] [CrossRef]

- Park, I.J.; Park, J.H.; Ji, S.G.; Park, M.-A.; Jang, J.H.; Kim, J.Y. A three-terminal monolithic perovskite/si tandem solar cell characterization platform. Joule 2019, 3, 807–818. [Google Scholar] [CrossRef]

- Zhu, P.; Chen, C.; Dai, J.; Zhang, Y.; Mao, R.; Chen, S.; Huang, J.; Zhu, J. Toward the commercialization of perovskite solar modules. Adv. Mater. 2024, 36, 2307357. [Google Scholar] [CrossRef]

- Aydin, E.; Allen, T.G.; De Bastiani, M.; Razzaq, A.; Xu, L.; Ugur, E.; Liu, J.; De Wolf, S. Pathways toward commercial perovskite/silicon tandem photovoltaics. Science 2024, 383, eadh3849. [Google Scholar] [CrossRef]

- Han, M.; Zhou, R.; Chen, G.; Li, Q.; Li, P.; Sun, C.; Zhang, Y.; Song, Y. Unveiling the potential of two-terminal perovskite/organic tandem solar cells: Mechanisms, status, and challenges. Adv. Mater. 2024, 36, 2402143. [Google Scholar] [CrossRef]

- Chi, W.; Banerjee, S.K.; Jayawardena, K.G.D.I.; Silva, S.R.P.; Seok, S.I. Perovskite/silicon tandem solar cells: Choice of bottom devices and recombination layers. ACS Energy Lett. 2023, 8, 1535–1550. [Google Scholar] [CrossRef]

- Leijtens, T.; Bush, K.A.; Prasanna, R.; McGehee, M.D. Opportunities and challenges for tandem solar cells using metal halide perovskite semiconductors. Nat. Energy 2018, 3, 828–838. [Google Scholar] [CrossRef]

- Albrecht, S.; Saliba, M.; Correa Baena, J.P.; Lang, F.; Kegelmann, L.; Mews, M.; Steier, L.; Abate, A.; Rappich, J.; Korte, L.; et al. Monolithic perovskite/silicon-heterojunction tandem solar cells processed at low temperature. Energy Environ. Sci. 2016, 9, 81–88. [Google Scholar] [CrossRef]

- Werner, J.; Weng, C.-H.; Walter, A.; Fesquet, L.; Seif, J.P.; De Wolf, S.; Niesen, B.; Ballif, C. Efficient monolithic perovskite/silicon tandem solar cell with cell area >1 cm2. J. Phys. Chem. Lett. 2016, 7, 161–166. [Google Scholar] [CrossRef] [PubMed]

- Bush, K.A.; Palmstrom, A.F.; Yu, Z.J.; Boccard, M.; Cheacharoen, R.; Mailoa, J.P.; McMeekin, D.P.; Hoye, R.L.Z.; Bailie, C.D.; Leijtens, T.; et al. 23.6%-efficient monolithic perovskite/silicon tandem solar cells with improved stability. Nat. Energy 2017, 2, 17009. [Google Scholar] [CrossRef]

- Zheng, J.; Lau, C.F.J.; Mehrvarz, H.; Ma, F.-J.; Jiang, Y.; Deng, X.; Soeriyadi, A.; Kim, J.; Zhang, M.; Hu, L.; et al. Large area efficient interface layer free monolithic perovskite/homo-junction-silicon tandem solar cell with over 20% efficiency. Energy Environ. Sci. 2018, 11, 2432–2443. [Google Scholar] [CrossRef]

- Shen, H.; Omelchenko, S.T.; Jacobs, D.A.; Yalamanchili, S.; Wan, Y.; Yan, D.; Phang, P.; Duong, T.; Wu, Y.; Yin, Y.; et al. In situ recombination junction between p-Si and TiO2 enables high-efficiency monolithic perovskite/Si tandem cells. Sci. Adv. 2018, 4, eaau9711. [Google Scholar] [CrossRef]

- Sahli, F.; Werner, J.; Kamino, B.A.; Bräuninger, M.; Monnard, R.; Paviet-Salomon, B.; Barraud, L.; Ding, L.; Diaz Leon, J.J.; Sacchetto, D.; et al. Fully textured monolithic perovskite/silicon tandem solar cells with 25.2% power conversion efficiency. Nat. Mater. 2018, 17, 820–826. [Google Scholar] [CrossRef]

- Kim, C.U.; Yu, J.C.; Jung, E.D.; Choi, I.Y.; Park, W.; Lee, H.; Kim, I.; Lee, D.-K.; Hong, K.K.; Song, M.H.; et al. Optimization of device design for low cost and high efficiency planar monolithic perovskite/silicon tandem solar cells. Nano Energy 2019, 60, 213–221. [Google Scholar] [CrossRef]

- Chen, B.; Yu, Z.J.; Manzoor, S.; Wang, S.; Weigand, W.; Yu, Z.; Yang, G.; Ni, Z.; Dai, X.; Holman, Z.C.; et al. Blade-coated perovskites on textured silicon for 26%-efficient monolithic perovskite/silicon tandem solar cells. Joule 2020, 4, 850–864. [Google Scholar] [CrossRef]

- Xu, J.; Boyd, C.C.; Yu, Z.J.; Palmstrom, A.F.; Witter, D.J.; Larson, B.W.; France, R.M.; Werner, J.; Harvey, S.P.; Wolf, E.J.; et al. Triple-halide wide-band gap perovskites with suppressed phase segregation for efficient tandems. Science 2020, 367, 1097–1104. [Google Scholar] [CrossRef]

- Hou, Y.; Aydin, E.; De Bastiani, M.; Xiao, C.; Isikgor, F.H.; Xue, D.-J.; Chen, B.; Chen, H.; Bahrami, B.; Chowdhury, A.H.; et al. Efficient tandem solar cells with solution-processed perovskite on textured crystalline silicon. Science 2020, 367, 1135–1140. [Google Scholar] [CrossRef]

- Köhnen, E.; Wagner, P.; Lang, F.; Cruz, A.; Li, B.; Roß, M.; Jošt, M.; Morales-Vilches, A.B.; Topič, M.; Stolterfoht, M.; et al. 27.9% efficient monolithic perovskite/silicon tandem solar cells on industry compatible bottom cells. Sol. RRL 2021, 5, 2100244. [Google Scholar] [CrossRef]

- Li, Y.; Shi, B.; Xu, Q.; Yan, L.; Ren, N.; Chen, Y.; Han, W.; Huang, Q.; Zhao, Y.; Zhang, X. Wide bandgap interface layer induced stabilized perovskite/silicon tandem solar cells with stability over ten thousand hours. Adv. Energy Mater. 2021, 11, 2102046. [Google Scholar] [CrossRef]

- Wu, Y.; Zheng, P.; Peng, J.; Xu, M.; Chen, Y.; Surve, S.; Lu, T.; Bui, A.D.; Li, N.; Liang, W.; et al. 27.6% perovskite/c-si tandem solar cells using industrial fabricated TOPCon device. Adv. Energy Mater. 2022, 12, 2200821. [Google Scholar] [CrossRef]

- Tockhorn, P.; Sutter, J.; Cruz, A.; Wagner, P.; Jäger, K.; Yoo, D.; Lang, F.; Grischek, M.; Li, B.; Li, J.; et al. Nano-optical designs for high-efficiency monolithic perovskite-silicon tandem solar cells. Nat. Nanotechnol. 2022, 17, 1214–1221. [Google Scholar] [CrossRef]

- Yang, G.; Ni, Z.; Yu, Z.J.; Larson, B.W.; Yu, Z.; Chen, B.; Alasfour, A.; Xiao, X.; Luther, J.M.; Holman, Z.C.; et al. Defect engineering in wide-bandgap perovskites for efficient perovskite-silicon tandem solar cells. Nat. Photonics 2022, 16, 588–594. [Google Scholar] [CrossRef]

- Wang, S.; Wang, P.; Chen, B.; Li, R.; Ren, N.; Li, Y.; Shi, B.; Huang, Q.; Zhao, Y.; Grätzel, M.; et al. Suppressed recombination for monolithic inorganic perovskite/silicon tandem solar cells with an approximate efficiency of 23%. eScience 2022, 2, 339–346. [Google Scholar] [CrossRef]

- Liu, J.; De Bastiani, M.; Aydin, E.; Harrison, G.T.; Gao, Y.; Pradhan, R.R.; Eswaran, M.K.; Mandal, M.; Yan, W.; Seitkhan, A.; et al. Efficient and stable perovskite-silicon tandem solar cells through contact displacement by MgFx. Science 2022, 377, 302–306. [Google Scholar] [CrossRef]

- Hyun, J.Y.; Yeom, K.M.; Lee, S.-W.; Bae, S.; Choi, D.; Song, H.; Kang, D.; Hwang, J.-K.; Lee, W.; Lee, S.; et al. Perovskite/silicon tandem solar cells with a VOC of 1784 mV based on an industrially feasible 25 cm2 TOPCon silicon cell. ACS Appl. Energy Mater. 2022, 5, 5449–5456. [Google Scholar] [CrossRef]

- Mariotti, S.; Jäger, K.; Diederich, M.; Härtel, M.S.; Li, B.; Sveinbjörnsson, K.; Kajari-Schröder, S.; Peibst, R.; Albrecht, S.; Korte, L.; et al. Monolithic perovskite/silicon tandem solar cells fabricated using industrial p-type polycrystalline silicon on oxide/passivated emitter and rear cell silicon bottom cell technology. Sol. RRL 2022, 6, 2101066. [Google Scholar] [CrossRef]

- Sveinbjörnsson, K.; Li, B.; Mariotti, S.; Jarzembowski, E.; Kegelmann, L.; Wirtz, A.; Frühauf, F.; Weihrauch, A.; Niemann, R.; Korte, L.; et al. Monolithic perovskite/silicon tandem solar cell with 28.7% efficiency using industrial silicon bottom cells. ACS Energy Lett. 2022, 7, 2654–2656. [Google Scholar] [CrossRef]

- Ying, Z.; Yang, Z.; Zheng, J.; Wei, H.; Chen, L.; Xiao, C.; Sun, J.; Shou, C.; Qin, G.; Sheng, J.; et al. Monolithic perovskite/black-silicon tandems based on tunnel oxide passivated contacts. Joule 2022, 6, 2644–2661. [Google Scholar] [CrossRef]

- Wang, S.; Wang, P.; Shi, B.; Sun, C.; Sun, H.; Qi, S.; Huang, Q.; Xu, S.; Zhao, Y.; Zhang, X. Inorganic perovskite surface reconfiguration for stable inverted solar cells with 20.38% efficiency and its application in tandem devices. Adv. Mater. 2023, 35, 2300581. [Google Scholar] [CrossRef]

- Mariotti, S.; Köhnen, E.; Scheler, F.; Sveinbjörnsson, K.; Zimmermann, L.; Piot, M.; Yang, F.; Li, B.; Warby, J.; Musiienko, A.; et al. Interface engineering for high-performance, triple-halide perovskite-silicon tandem solar cells. Science 2023, 381, 63–69. [Google Scholar] [CrossRef]

- Zhang, F.; Tu, B.; Yang, S.; Fan, K.; Liu, Z.; Xiong, Z.; Zhang, J.; Li, W.; Huang, H.; Yu, C.; et al. Buried-interface engineering of conformal 2D/3D perovskite heterojunction for efficient perovskite/silicon tandem solar cells on industrially textured silicon. Adv. Mater. 2023, 35, 2303139. [Google Scholar] [CrossRef]

- Zheng, J.; Duan, W.; Guo, Y.; Zhao, Z.C.; Yi, H.; Ma, F.-J.; Granados Caro, L.; Yi, C.; Bing, J.; Tang, S.; et al. Efficient monolithic perovskite-Si tandem solar cells enabled by an ultra-thin indium tin oxide interlayer. Energy Environ. Sci. 2023, 16, 1223–1233. [Google Scholar] [CrossRef]

- Zheng, J.; Ying, Z.; Yang, Z.; Lin, Z.; Wei, H.; Chen, L.; Yang, X.; Zeng, Y.; Li, X.; Ye, J. Polycrystalline silicon tunnelling recombination layers for high-efficiency perovskite/tunnel oxide passivating contact tandem solar cells. Nat. Energy 2023, 8, 1250–1261. [Google Scholar] [CrossRef]

- He, Y.; Tang, Z.; He, B.; Han, C.; Ding, L.; Gu, X.; Zhang, Y.; Yan, H.; Xu, X. Composition engineering of perovskite absorber assisted efficient textured monolithic perovskite/silicon heterojunction tandem solar cells. RSC Adv. 2023, 13, 7886–7896. [Google Scholar] [CrossRef]

- De Bastiani, M.; Jalmood, R.; Liu, J.; Ossig, C.; Vlk, A.; Vegso, K.; Babics, M.; Isikgor, F.H.; Selvin, A.S.; Azmi, R.; et al. Monolithic perovskite/silicon tandems with >28% efficiency: Role of silicon-surface texture on perovskite properties. Adv. Funct. Mater. 2023, 33, 2205557. [Google Scholar] [CrossRef]

- Liu, Z.; Li, H.; Chu, Z.; Xia, R.; Wen, J.; Mo, Y.; Zhu, H.; Luo, H.; Zheng, X.; Huang, Z.; et al. Reducing perovskite/C60 interface losses via sequential interface engineering for efficient perovskite/silicon tandem solar cell. Adv. Mater. 2024, 36, 2308370. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; He, Y.; Ding, L.; Zhang, H.; Li, Q.; Jia, L.; Yu, J.; Lau, T.W.; Li, M.; Qin, Y.; et al. Perovskite/silicon tandem solar cells with bilayer interface passivation. Nature 2024, 635, 596–603. [Google Scholar] [CrossRef]

- Pei, F.; Wang, Q.; Wei, Z.; Zhuang, X.; Cheng, X.; Li, K.; Cui, Y.; Wang, L.; Huang, Z.; Zhang, Z.; et al. Tailoring perovskite/C60 interface by reactive passivators for stable tandem solar cells. Adv. Funct. Mater. 2024, 34, 2410737. [Google Scholar] [CrossRef]

- Ding, Z.; Kan, C.; Jiang, S.; Zhang, M.; Zhang, H.; Liu, W.; Liao, M.; Yang, Z.; Hang, P.; Zeng, Y.; et al. Highly passivated TOPCon bottom cells for perovskite/silicon tandem solar cells. Nat. Commun. 2024, 15, 8453. [Google Scholar] [CrossRef]

- Harter, A.; Artuk, K.; Mathies, F.; Karalis, O.; Hempel, H.; Al-Ashouri, A.; Albrecht, S.; Schlatmann, R.; Ballif, C.; Stannowski, B.; et al. Perovskite/silicon tandem solar cells above 30% conversion efficiency on submicron-sized textured czochralski-silicon bottom cells with improved hole-transport layers. ACS Appl. Mater. Interfaces 2024, 16, 62817–62826. [Google Scholar] [CrossRef]

- Wang, L.; Wang, N.; Wu, X.; Liu, B.; Liu, Q.; Li, B.; Zhang, D.; Kalasariya, N.; Zhang, Y.; Yan, X.; et al. Highly efficient monolithic perovskite/TOPCon silicon tandem solar cells enabled by “halide locking”. Adv. Mater. 2025, 37, 2416150. [Google Scholar] [CrossRef] [PubMed]

- Ye, T.; Qiao, L.; Wang, T.; Wang, P.; Zhang, L.; Sun, R.; Kong, W.; Xu, M.; Yan, X.; Yang, J.; et al. Molecular bridge in wide-bandgap perovskites for efficient and stable perovskite/silicon tandem solar cells. Adv. Funct. Mater. 2025, 35, 2419391. [Google Scholar] [CrossRef]

- Li, X.; Ying, Z.; Li, S.; Chen, L.; Zhang, M.; Liu, L.; Guo, X.; Wu, J.; Sun, Y.; Xiao, C.; et al. Top-down dual-interface carrier management for highly efficient and stable perovskite/silicon tandem solar cells. Nano-Micro Lett. 2025, 17, 141. [Google Scholar] [CrossRef]

- Li, C.; Chen, Y.; Li, Y.; Zhang, Z.; Yang, J.; Wang, Y.; Gong, L.; Yuan, Z.; Liang, L.; Liu, S.; et al. Achieving 32% efficiency in perovskite/silicon tandem solar cells with bidentate-anchored superwetting self-assembled molecular layers. Angew. Chem. Int. Ed. 2025, 64, e202502730. [Google Scholar] [CrossRef]

- McMeekin, D.P.; Sadoughi, G.; Rehman, W.; Eperon, G.E.; Saliba, M.; Hörantner, M.T.; Haghighirad, A.; Sakai, N.; Korte, L.; Rech, B.; et al. A mixed-cation lead mixed-halide perovskite absorber for tandem solar cells. Science 2016, 351, 151–155. [Google Scholar] [CrossRef]

- Jeong, M.; Choi, I.W.; Go, E.M.; Cho, Y.; Kim, M.; Lee, B.; Jeong, S.; Jo, Y.; Choi, H.W.; Lee, J.; et al. Stable perovskite solar cells with efficiency exceeding 24.8% and 0.3-V voltage loss. Science 2020, 369, 1615–1620. [Google Scholar] [CrossRef]

- Fang, Z.; Yan, N.; Liu, S. Modulating preferred crystal orientation for efficient and stable perovskite solar cells-From progress to perspectives. InfoMat 2022, 4, e12369. [Google Scholar] [CrossRef]

- He, A.; Wang, Y.; Tang, P.; Zhang, Z.; Zeng, Z.; Zhang, Y.; Hao, X.; Wu, L.; So, S.K.; Tsang, S.-W.; et al. Unraveling the impact of bromine incorporation on the hybrid perovskite film phase evolution mechanism by in situ characterization. Adv. Energy Mater. 2023, 13, 2300957. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Z.; Ma, J.; Han, M.; Gao, P.; Cai, M.; Zhang, Y.; Song, Y.; Peng, S. Unveiling the surface-interface properties of perovskite crystals and pivotal regulation strategies. Nano Res. 2024, 17, 3950–3981. [Google Scholar] [CrossRef]

- Zhou, Y.; Jia, Y.-H.; Fang, H.-H.; Loi, M.A.; Xie, F.-Y.; Gong, L.; Qin, M.-C.; Lu, X.-H.; Wong, C.-P.; Zhao, N. Composition-tuned wide bandgap perovskites: From grain engineering to stability and performance improvement. Adv. Funct. Mater. 2018, 28, 1803130. [Google Scholar] [CrossRef]

- Tan, H.; Che, F.; Wei, M.; Zhao, Y.; Saidaminov, M.I.; Todorović, P.; Broberg, D.; Walters, G.; Tan, F.; Zhuang, T.; et al. Dipolar cations confer defect tolerance in wide-bandgap metal halide perovskites. Nat. Commun. 2018, 9, 3100. [Google Scholar] [CrossRef]

- He, Y.; Tang, Z.; Mao, L.; Yang, S.; Yang, T.; Xie, M.; Chang, Q.; Ding, L.; He, B.; Peng, C.; et al. Minimizing open-circuit voltage loss in perovskite/si tandem solar cells via exploring the synergic effect of cations and anions. Phys. Status Solidi RRL 2021, 15, 2100119. [Google Scholar] [CrossRef]

- Ren, N.; Wang, P.; Jiang, J.; Li, R.; Han, W.; Liu, J.; Zhu, Z.; Chen, B.; Xu, Q.; Li, T.; et al. Multifunctional additive CdAc2 for efficient perovskite-based solar cells. Adv. Mater. 2023, 35, 2211806. [Google Scholar] [CrossRef]

- Isikgor, F.H.; Furlan, F.; Liu, J.; Ugur, E.; Eswaran, M.K.; Subbiah, A.S.; Yengel, E.; De Bastiani, M.; Harrison, G.T.; Zhumagali, S.; et al. Concurrent cationic and anionic perovskite defect passivation enables 27.4% perovskite/silicon tandems with suppression of halide segregation. Joule 2021, 5, 1566–1586. [Google Scholar] [CrossRef]

- Chen, B.; Yu, Z.; Liu, K.; Zheng, X.; Liu, Y.; Shi, J.; Spronk, D.; Rudd, P.N.; Holman, Z.; Huang, J. Grain engineering for perovskite/silicon monolithic tandem solar cells with efficiency of 25.4%. Joule 2019, 3, 177–190. [Google Scholar] [CrossRef]

- Kim, D.H.; Muzzillo, C.P.; Tong, J.; Palmstrom, A.F.; Larson, B.W.; Choi, C.; Harvey, S.P.; Glynn, S.; Whitaker, J.B.; Zhang, F.; et al. Bimolecular additives improve wide-band-gap perovskites for efficient tandem solar cells with CIGS. Joule 2019, 3, 1734–1745. [Google Scholar] [CrossRef]

- Bush, K.A.; Frohna, K.; Prasanna, R.; Beal, R.E.; Leijtens, T.; Swifter, S.A.; McGehee, M.D. Compositional engineering for efficient wide band gap perovskites with improved stability to photoinduced phase segregation. ACS Energy Lett. 2018, 3, 428–435. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Gao, F.; Yang, D. Efficient monolithic perovskite/silicon tandem photovoltaics. Energy Environ. Mater. 2024, 7, e12639. [Google Scholar] [CrossRef]

- Aydin, E.; Ugur, E.; Yildirim, B.K.; Allen, T.G.; Dally, P.; Razzaq, A.; Cao, F.; Xu, L.; Vishal, B.; Yazmaciyan, A.; et al. Enhanced optoelectronic coupling for perovskite/silicon tandem solar cells. Nature 2023, 623, 732–738. [Google Scholar] [CrossRef]

- Werner, J.; Walter, A.; Rucavado, E.; Moon, S.-J.; Sacchetto, D.; Rienaecker, M.; Peibst, R.; Brendel, R.; Niquille, X.; De Wolf, S.; et al. Zinc tin oxide as high-temperature stable recombination layer for mesoscopic perovskite/silicon monolithic tandem solar cells. Appl. Phys. Lett. 2016, 109, 233902. [Google Scholar] [CrossRef]

- Hyun, J.; Yeom, K.M.; Lee, H.E.; Kim, D.; Lee, H.-S.; Noh, J.H.; Kang, Y. Efficient n-i-p monolithic perovskite/silicon tandem solar cells with tin oxide via a chemical bath deposition method. Energies 2021, 14, 7614. [Google Scholar] [CrossRef]

- Mercaldo, L.V.; Bobeico, E.; De Maria, A.; Della Noce, M.; Ferrara, M.; La Ferrara, V.; Lancellotti, L.; Rametta, G.; Sannino, G.V.; Usatii, I.; et al. Monolithic perovskite/silicon-heterojunction tandem solar cells with nanocrystalline Si/SiOx tunnel junction. Energies 2021, 14, 7684. [Google Scholar] [CrossRef]

- Park, N.-G. Perovskite solar cell: Research direction for next 10 years. ACS Energy Lett. 2019, 4, 2983–2985. [Google Scholar] [CrossRef]

- Messmer, C.; Goraya, B.S.; Nold, S.; Schulze, P.S.C.; Sittinger, V.; Schön, J.; Goldschmidt, J.C.; Bivour, M.; Glunz, S.W.; Hermle, M. The race for the best silicon bottom cell: Efficiency and cost evaluation of perovskite-silicon tandem solar cells. Prog. Photovolt. Res. Appl. 2021, 29, 744–759. [Google Scholar] [CrossRef]

- Jung, E.D.; Kim, C.U.; Noh, Y.W.; Seo, S.K.; Noh, Y.I.; Choi, K.J.; Song, M.H. Aesthetic and efficient perovskite/Si tandem solar cells using luminescent down-shifting textured anti-reflection films. EcoMat 2023, 5, e12399. [Google Scholar] [CrossRef]

- Lee, S.; Kim, C.U.; Bae, S.; Liu, Y.; Noh, Y.I.; Zhou, Z.; Leu, P.W.; Choi, K.J.; Lee, J.-K. Improving light absorption in a perovskite/Si tandem solar cell via light scattering and uv-down shifting by a mixture of SiO2 nanoparticles and phosphors. Adv. Funct. Mater. 2022, 32, 2204328. [Google Scholar] [CrossRef]

- Wu, Y.; Yan, D.; Peng, J.; Duong, T.; Wan, Y.; Phang, S.P.; Shen, H.; Wu, N.; Barugkin, C.; Fu, X.; et al. Monolithic perovskite/silicon-homojunction tandem solar cell with over 22% efficiency. Energy Environ. Sci. 2017, 10, 2472–2479. [Google Scholar] [CrossRef]

- Phung, N.; Zhang, D.; van Helvoirt, C.; Verhage, M.; Verheijen, M.; Zardetto, V.; Bens, F.; Weijtens, C.H.L.; Geerligs, L.J.; Kessels, W.M.M.; et al. Atomic layer deposition of NiO applied in a monolithic perovskite/PERC tandem cell. Sol. Energy Mater. Sol. Cells 2023, 261, 112498. [Google Scholar] [CrossRef]

- Hermle, M.; Feldmann, F.; Bivour, M.; Goldschmidt, J.C.; Glunz, S.W. Passivating contacts and tandem concepts: Approaches for the highest silicon-based solar cell efficiencies. Appl. Phys. Rev. 2020, 7, 021305. [Google Scholar] [CrossRef]

- Sun, Z.; Chen, X.; He, Y.; Li, J.; Wang, J.; Yan, H.; Zhang, Y. Toward efficiency limits of crystalline silicon solar cells: Recent progress in high-efficiency silicon heterojunction solar cells. Adv. Energy Mater. 2022, 12, 2200015. [Google Scholar] [CrossRef]

- Walter, A.; Kamino, B.A.; Moon, S.-J.; Wyss, P.; Diaz Leon, J.J.; Allebé, C.; Descoeudres, A.; Nicolay, S.; Ballif, C.; Jeangros, Q.; et al. Rear textured p-type high temperature passivating contacts and their implementation in perovskite/silicon tandem cells. Energy Adv. 2023, 2, 1818–1822. [Google Scholar] [CrossRef]

- Ibarra Michel, J.; Dréon, J.; Boccard, M.; Bullock, J.; Macco, B. Carrier-selective contacts using metal compounds for crystalline silicon solar cells. Prog. Photovolt. Res. Appl. 2023, 31, 380–413. [Google Scholar] [CrossRef]

- Boccard, M.; Ballif, C. Influence of the subcell properties on the fill factor of two-terminal perovskite–silicon tandem solar cells. ACS Energy Lett. 2020, 5, 1077–1082. [Google Scholar] [CrossRef]

- Ren, Q.; Li, S.; Zhu, S.; Ren, H.; Yao, X.; Wei, C.; Yan, B.; Zhao, Y.; Zhang, X. High near-infrared wavelength response planar silicon-heterojunction solar cells. Sol. Energy Mater. Sol. Cells 2018, 185, 124–129. [Google Scholar] [CrossRef]

- Ying, Z.; Yang, X.; Wang, X.; Ye, J. Towards the 10-year milestone of monolithic perovskite/silicon tandem solar cells. Adv. Mater. 2024, 36, 2311501. [Google Scholar] [CrossRef]

- Philippe, B.; Park, B.-W.; Lindblad, R.; Oscarsson, J.; Ahmadi, S.; Johansson, E.M.J.; Rensmo, H. Chemical and electronic structure characterization of lead halide perovskites and stability behavior under different exposures-a photoelectron spectroscopy investigation. Chem. Mater. 2015, 27, 1720–1731. [Google Scholar] [CrossRef]

- Hoke, E.T.; Slotcavage, D.J.; Dohner, E.R.; Bowring, A.R.; Karunadasa, H.I.; McGehee, M.D. Reversible photo-induced trap formation in mixed-halide hybrid perovskites for photovoltaics. Chem. Sci. 2015, 6, 613–617. [Google Scholar] [CrossRef]

- Brennan, M.C.; Draguta, S.; Kamat, P.V.; Kuno, M. Light-induced anion phase segregation in mixed halide perovskites. ACS Energy Lett. 2018, 3, 204–213. [Google Scholar] [CrossRef]

- Wang, J.; Chen, Y.; Liang, M.; Ge, G.; Zhou, R.; Sun, Z.; Xue, S. A new thermal-stable truxene-based hole-transporting material for perovskite solar cells. Dyes Pigments 2016, 125, 399–406. [Google Scholar] [CrossRef]

- Eames, C.; Frost, J.M.; Barnes, P.R.F.; O’Regan, B.C.; Walsh, A.; Islam, M.S. Ionic transport in hybrid lead iodide perovskite solar cells. Nat. Commun. 2015, 6, 7497. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Mujahid, M.; Duan, Y.; Wang, Z.-K.; Xue, J.; Yang, Y. A review of perovskites solar cell stability. Adv. Funct. Mater. 2019, 29, 1808843. [Google Scholar] [CrossRef]

- Chu, Q.-Q.; Sun, Z.; Wang, D.; Cheng, B.; Wang, H.; Wong, C.-P.; Fang, B. Encapsulation: The path to commercialization of stable perovskite solar cells. Matter 2023, 6, 3838–3863. [Google Scholar] [CrossRef]

- Lou, Q.; Lou, G.; Guo, H.; Sun, T.; Wang, C.; Chai, G.; Chen, X.; Yang, G.; Guo, Y.; Zhou, H. Enhanced efficiency and stability of n-i-p perovskite solar cells by incorporation of fluorinated graphene in the Spiro-OMeTAD hole transport layer. Adv. Energy Mater. 2022, 12, 2201344. [Google Scholar] [CrossRef]

- Ni, Z.; Jiao, H.; Fei, C.; Gu, H.; Xu, S.; Yu, Z.; Yang, G.; Deng, Y.; Jiang, Q.; Liu, Y.; et al. Evolution of defects during the degradation of metal halide perovskite solar cells under reverse bias and illumination. Nat. Energy 2022, 7, 65–73. [Google Scholar] [CrossRef]

- Saliba, M.; Matsui, T.; Domanski, K.; Seo, J.-Y.; Ummadisingu, A.; Zakeeruddin, S.M.; Correa-Baena, J.-P.; Tress, W.R.; Abate, A.; Hagfeldt, A.; et al. Incorporation of rubidium cations into perovskite solar cells improves photovoltaic performance. Science 2016, 354, 206–209. [Google Scholar] [CrossRef]

- Lee, J.-W.; Kim, D.-H.; Kim, H.-S.; Seo, S.-W.; Cho, S.M.; Park, N.-G. Formamidinium and cesium hybridization for photo-and moisture-stable perovskite solar cell. Adv. Energy Mater. 2015, 5, 1501310. [Google Scholar] [CrossRef]

- Zhu, H.; Teale, S.; Lintangpradipto, M.N.; Mahesh, S.; Chen, B.; McGehee, M.D.; Sargent, E.H.; Bakr, O.M. Long-term operating stability in perovskite photovoltaics. Nat. Rev. Mater. 2023, 8, 569–586. [Google Scholar] [CrossRef]

- Li, Q.; Zheng, Y.; Wang, H.; Liu, X.; Lin, M.; Sui, X.; Leng, X.; Liu, D.; Wei, Z.; Song, M.; et al. Graphene-polymer reinforcement of perovskite lattices for durable solar cells. Science 2025, 387, 1069–1077. [Google Scholar] [CrossRef]

- Kim, H.; Choi, K.; Yoon, G.W.; Kim, D.; Lee, D.H.; Choi, Y.; Jung, H.S.; Song, S.; Park, T. Modulating molecular interaction of zwitterion toward rational interface engineering of perovskite solar cells. Adv. Energy Mater. 2024, 14, 2401263. [Google Scholar] [CrossRef]

- Li, H.; Zhang, C.; Gong, C.; Zhang, D.; Zhang, H.; Zhuang, Q.; Yu, X.; Gong, S.; Chen, X.; Yang, J.; et al. 2D/3D heterojunction engineering at the buried interface towards high-performance inverted methylammonium-free perovskite solar cells. Nat. Energy 2023, 8, 946–955. [Google Scholar] [CrossRef]

- Sun, X.; Shi, W.; Liu, T.; Cheng, J.; Wang, X.; Xu, P.; Zhang, W.; Zhao, X.; Guo, W. Vapor-assisted surface reconstruction enables outdoor-stable perovskite solar modules. Science 2025, 388, 957–963. [Google Scholar] [CrossRef]

- Gong, C.; Chen, X.; Zeng, J.; Wang, H.; Li, H.; Qian, Q.; Zhang, C.; Zhuang, Q.; Yu, X.; Gong, S.; et al. Functional-group-induced single quantum well dion-jacobson 2D perovskite for efficient and stable inverted perovskite solar cells. Adv. Mater. 2024, 36, 2307422. [Google Scholar] [CrossRef]

- Zang, X.; Xiong, S.; Jiang, S.; Li, D.; Wu, H.; Ren, H.; Cao, A.; Li, B.; Ma, Z.; Chen, J.; et al. Passivating dipole layer bridged 3D/2D perovskite heterojunction for highly efficient and stable p-i-n solar cells. Adv. Mater. 2024, 36, 2309991. [Google Scholar] [CrossRef]

- Zhang, F.; Park, S.Y.; Yao, C.; Lu, H.; Dunfield, S.P.; Xiao, C.; Uličná, S.; Zhao, X.; Du Hill, L.; Chen, X.; et al. Metastable dion-jacobson 2D structure enables efficient and stable perovskite solar cells. Science 2022, 375, 71–76. [Google Scholar] [CrossRef]

- Azmi, R.; Utomo, D.S.; Vishal, B.; Zhumagali, S.; Dally, P.; Risqi, A.M.; Prasetio, A.; Ugur, E.; Cao, F.; Imran, I.F.; et al. Double-side 2D/3D heterojunctions for inverted perovskite solar cells. Nature 2024, 628, 93–98. [Google Scholar] [CrossRef]

- Wang, Y.; Zheng, D.; Wang, K.; Yang, Q.; Qian, J.; Zhou, J.; Liu, S.; Yang, D. Lattice mismatch at the heterojunction of perovskite solar cells. Angew. Chem. Int. Ed. 2024, 63, e202405878. [Google Scholar] [CrossRef]

- De Bastiani, M.; Armaroli, G.; Jalmood, R.; Ferlauto, L.; Li, X.; Tao, R.; Harrison, G.T.; Eswaran, M.K.; Azmi, R.; Babics, M.; et al. Mechanical reliability of fullerene/tin oxide interfaces in monolithic perovskite/silicon tandem cells. ACS Energy Lett. 2022, 7, 827–833. [Google Scholar] [CrossRef]

- Dai, Z.; Padture, N.P. Challenges and opportunities for the mechanical reliability of metal halide perovskites and photovoltaics. Nat. Energy 2023, 8, 1319–1327. [Google Scholar] [CrossRef]

- Subbiah, A.S.; Isikgor, F.H.; Howells, C.T.; De Bastiani, M.; Liu, J.; Aydin, E.; Furlan, F.; Allen, T.G.; Xu, F.; Zhumagali, S.; et al. High-performance perovskite single-junction and textured perovskite/silicon tandem solar cells via slot-die-coating. ACS Energy Lett. 2020, 5, 3034–3040. [Google Scholar] [CrossRef]

- Du, S.; Yang, J.; Qu, S.; Lan, Z.; Sun, T.; Dong, Y.; Shang, Z.; Liu, D.; Yang, Y.; Yan, L.; et al. Impact of precursor concentration on perovskite crystallization for efficient wide-bandgap solar cells. Materials 2022, 15, 3185. [Google Scholar] [CrossRef]

- Jones, T.W.; Osherov, A.; Alsari, M.; Sponseller, M.; Duck, B.C.; Jung, Y.-K.; Settens, C.; Niroui, F.; Brenes, R.; Stan, C.V.; et al. Lattice strain causes non-radiative losses in halide perovskites. Energy Environ. Sci. 2019, 12, 596–606. [Google Scholar] [CrossRef]

- Liu, D.; Luo, D.; Iqbal, A.N.; Orr, K.W.P.; Doherty, T.A.S.; Lu, Z.-H.; Stranks, S.D.; Zhang, W. Strain analysis and engineering in halide perovskite photovoltaics. Nat. Mater. 2021, 20, 1337–1346. [Google Scholar] [CrossRef]

- Tennyson, E.M.; Frohna, K.; Drake, W.K.; Sahli, F.; Chien-Jen Yang, T.; Fu, F.; Werner, J.; Chosy, C.; Bowman, A.R.; Doherty, T.A.S.; et al. Multimodal microscale imaging of textured perovskite–silicon tandem solar cells. ACS Energy Lett. 2021, 6, 2293–2304. [Google Scholar] [CrossRef]

- Er-raji, O.; Rustam, L.; Kore, B.P.; Glunz, S.W.; Schulze, P.S.C. Insights into perovskite film formation using the hybrid evaporation/spin-coating route: An in situ xrd study. ACS Appl. Energy Mater. 2023, 6, 6183–6193. [Google Scholar] [CrossRef]

- Heiderhoff, R.; Haeger, T.; Pourdavoud, N.; Hu, T.; Al-Khafaji, M.; Mayer, A.; Chen, Y.; Scheer, H.-C.; Riedl, T. Thermal conductivity of methylammonium lead halide perovskite single crystals and thin films: A comparative study. J. Phys. Chem. C 2017, 121, 28306–28311. [Google Scholar] [CrossRef]

- Okada, Y.; Tokumaru, Y. Precise determination of lattice parameter and thermal expansion coefficient of silicon between 300 and 1500 k. J. Appl. Phys. 1984, 56, 314–320. [Google Scholar] [CrossRef]

- Er-raji, O.; Mahmoud, M.A.A.; Fischer, O.; Ramadan, A.J.; Bogachuk, D.; Reinholdt, A.; Schmitt, A.; Kore, B.P.; Gries, T.W.; Musiienko, A.; et al. Tailoring perovskite crystallization and interfacial passivation in efficient, fully textured perovskite silicon tandem solar cells. Joule 2024, 8, 2811–2833. [Google Scholar] [CrossRef]

- Ye, F.; Zhang, S.; Warby, J.; Wu, J.; Gutierrez-Partida, E.; Lang, F.; Shah, S.; Saglamkaya, E.; Sun, B.; Zu, F.; et al. Overcoming C60-induced interfacial recombination in inverted perovskite solar cells by electron-transporting carborane. Nat. Commun. 2022, 13, 7454. [Google Scholar] [CrossRef] [PubMed]

- Said, A.A.; Aydin, E.; Ugur, E.; Xu, Z.; Deger, C.; Vishal, B.; Vlk, A.; Dally, P.; Yildirim, B.K.; Azmi, R.; et al. Sublimed C60 for efficient and repeatable perovskite-based solar cells. Nat. Commun. 2024, 15, 708. [Google Scholar] [CrossRef] [PubMed]

- Warby, J.; Zu, F.; Zeiske, S.; Gutierrez-Partida, E.; Frohloff, L.; Kahmann, S.; Frohna, K.; Mosconi, E.; Radicchi, E.; Lang, F.; et al. Understanding performance limiting interfacial recombination in pin perovskite solar cells. Adv. Energy Mater. 2022, 12, 2103567. [Google Scholar] [CrossRef]

- Yang, Q.; Bittkau, K.; Klingebiel, B.; Kirchartz, T.; Rau, U.; Ding, K. Toward the working mechanisms of tin oxide as buffer layer in perovskite/silicon tandem solar cells. Appl. Phys. Rev. 2025, 12, 021403. [Google Scholar] [CrossRef]

- Aydin, E.; Altinkaya, C.; Smirnov, Y.; Yaqin, M.A.; Zanoni, K.P.S.; Paliwal, A.; Firdaus, Y.; Allen, T.G.; Anthopoulos, T.D.; Bolink, H.J.; et al. Sputtered transparent electrodes for optoelectronic devices: Induced damage and mitigation strategies. Matter 2021, 4, 3549–3584. [Google Scholar] [CrossRef]

- Li, B.; Härtel, M.; Al-Ashouri, A.; Simmonds, M.; Taupitz, I.; Kegelmann, L.; Jarzembowski, E.; Frühauf, F.; Köhnen, E.; Korte, L.; et al. Atomic-layer-deposition-free monolithic perovskite/silicon tandem solar cell reaching 29.91% power conversion on industrial PERX/TOPCon-like silicon bottom cells. ACS Energy Lett. 2024, 9, 4550–4556. [Google Scholar] [CrossRef]

- Magliano, E.; Di Giacomo, F.; Sathy, H.R.; Pourmotlagh, S.M.; Giliberti, G.; Becerril Rodriguez, D.; Ammirati, G.; Mariani, P.; Zarotti, F.; Matteocci, F.; et al. Solution-processed metal-oxide nanoparticles to prevent the sputtering damage in perovskite/silicon tandem solar cells. ACS Appl. Mater. Interfaces 2025, 17, 17599–17610. [Google Scholar] [CrossRef]

- Han, X.-J.; Yang, J.; Zhang, J.-L.; Liu, D.-X.; Shi, B.; Wang, P.-Y.; Zhao, Y.; Zhang, X.-D. Electron transport layer of tin dioxide deposited by reactive plasma and its application in perovskite solar cells. Acta Phys. Sin. 2023, 72, 178401–178409. [Google Scholar] [CrossRef]

- Li, W.; Liu, X.; Zhang, J.; Wang, H.; Yuan, C.; Lin, S.; Chen, C.; Shen, C.; Tang, J.; Li, J.; et al. Reactive plasma deposition of ITO as an efficient buffer layer for inverted perovskite solar cells. Adv. Mater. 2025, 37, 2417094. [Google Scholar] [CrossRef]

- Lu, Z.; Meng, F.; Cui, Y.; Shi, J.; Feng, Z.; Liu, Z. High quality of IWO films prepared at room temperature by reactive plasma deposition for photovoltaic devices. J. Phys. D Appl. Phys. 2013, 46, 075103. [Google Scholar] [CrossRef]

- Song, C.; Yan, Z.; Zhang, R.; Zhang, L.; Du, W.; Liu, Z.; Zhang, Y. Room temperature deposition of iwo electrodes on Spiro-OMeTAD without buffer layers for semi-transparent perovskite solar cells. Mater. Lett. 2023, 347, 134612. [Google Scholar] [CrossRef]

- Michelmore, A.; Whittle, J.D.; Bradley, J.W.; Short, R.D. Where physics meets chemistry: Thin film deposition from reactive plasmas. Front. Chem. Sci. Eng. 2016, 10, 441–458. [Google Scholar] [CrossRef]

- Yuan, C.; Liu, X.; Ge, C.; Li, W.; Li, K.; Fu, L.; Zeng, X.; Song, H.; He, Y.; Xiao, X.; et al. Stable indium tin oxide with high mobility. ACS Appl. Mater. Interfaces 2022, 14, 49937–49944. [Google Scholar] [CrossRef] [PubMed]

- Yin, R.; Wu, Y.; Huang, Z.; Vasenko, A.S.; Xu, S.; Zhou, H. Fabricating perovskite films for solar modules from small to large scale. Adv. Funct. Mater. 2025, 35, 2419184. [Google Scholar] [CrossRef]

- Fu, F.; Li, J.; Yang, T.C.-J.; Liang, H.; Faes, A.; Jeangros, Q.; Ballif, C.; Hou, Y. Monolithic perovskite-silicon tandem solar cells: From the lab to fab? Adv. Mater. 2022, 34, 2106540. [Google Scholar] [CrossRef]

- Li, X.; Ying, Z.; Wang, X.; Zeng, Y.; Yang, X.; Ye, J. How to enable highly efficient and large-area fabrication on specific textures for monolithic perovskite/silicon tandem solar cells? Inf. Funct. Mater. 2024, 1, 160–180. [Google Scholar] [CrossRef]

- Lu, C.-A.; Lin, P.; Lin, H.-C.; Wang, S.-F. Characterization of the low-curing-temperature silver paste with silver 2-ethylhexanoate addition. Jpn. J. Appl. Phys. 2007, 46, 251. [Google Scholar] [CrossRef]

- da Silva Filho, J.M.C.; de Morais, A.; Cesar, R.R.; Joanni, E.; Teixeira, R.C.; Marques, F.C.; de Freitas, J.N. Investigation of the stability of metallic grids for large-area perovskite solar cells. Sol. Energy Mater. Sol. Cells 2024, 276, 113043. [Google Scholar] [CrossRef]

- Kamino, B.A.; Paviet-Salomon, B.; Moon, S.-J.; Badel, N.; Levrat, J.; Christmann, G.; Walter, A.; Faes, A.; Ding, L.; Diaz Leon, J.J.; et al. Low-temperature screen-printed metallization for the scale-up of two-terminal perovskite-silicon tandems. ACS Appl. Energy Mater. 2019, 2, 3815–3821. [Google Scholar] [CrossRef]

- Rehman, A.u.; Van Kerschaver, E.P.; Aydin, E.; Raja, W.; Allen, T.G.; De Wolf, S. Electrode metallization for scaled perovskite/silicon tandem solar cells: Challenges and opportunities. Prog. Photovolt. Res. Appl. 2023, 31, 429–442. [Google Scholar] [CrossRef]

- Deng, Y.; Zheng, X.; Bai, Y.; Wang, Q.; Zhao, J.; Huang, J. Surfactant-controlled ink drying enables high-speed deposition of perovskite films for efficient photovoltaic modules. Nat. Energy 2018, 3, 560–566. [Google Scholar] [CrossRef]

- Niu, X.; Li, N.; Cui, Z.; Li, L.; Pei, F.; Lan, Y.; Song, Q.; Du, Y.; Dou, J.; Bao, Z.; et al. Anion confinement for homogeneous mixed halide perovskite film growth by electrospray. Adv. Mater. 2023, 35, 2305822. [Google Scholar] [CrossRef]

- Patidar, R.; Burkitt, D.; Hooper, K.; Richards, D.; Watson, T. Slot-die coating of perovskite solar cells: An overview. Mater. Today Commun. 2020, 22, 100808. [Google Scholar] [CrossRef]

- Oh, W.; Jee, H.; Bae, J.; Lee, J. Busbar-free electrode patterns of crystalline silicon solar cells for high density shingled photovoltaic module. Sol. Energy Mater. Sol. Cells 2022, 243, 111802. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, J.; Mao, L. A Review on Perovskite/Silicon Tandem Solar Cells: Current Status and Future Challenges. Energies 2025, 18, 4327. https://doi.org/10.3390/en18164327

Huang J, Mao L. A Review on Perovskite/Silicon Tandem Solar Cells: Current Status and Future Challenges. Energies. 2025; 18(16):4327. https://doi.org/10.3390/en18164327

Chicago/Turabian StyleHuang, Jingyu, and Lin Mao. 2025. "A Review on Perovskite/Silicon Tandem Solar Cells: Current Status and Future Challenges" Energies 18, no. 16: 4327. https://doi.org/10.3390/en18164327

APA StyleHuang, J., & Mao, L. (2025). A Review on Perovskite/Silicon Tandem Solar Cells: Current Status and Future Challenges. Energies, 18(16), 4327. https://doi.org/10.3390/en18164327