Low-Carbon Industrial Heating in the EU and UK: Integrating Waste Heat Recovery, High-Temperature Heat Pumps, and Hydrogen Technologies

Abstract

1. Introduction

1.1. Novelty and Contributions to the Field

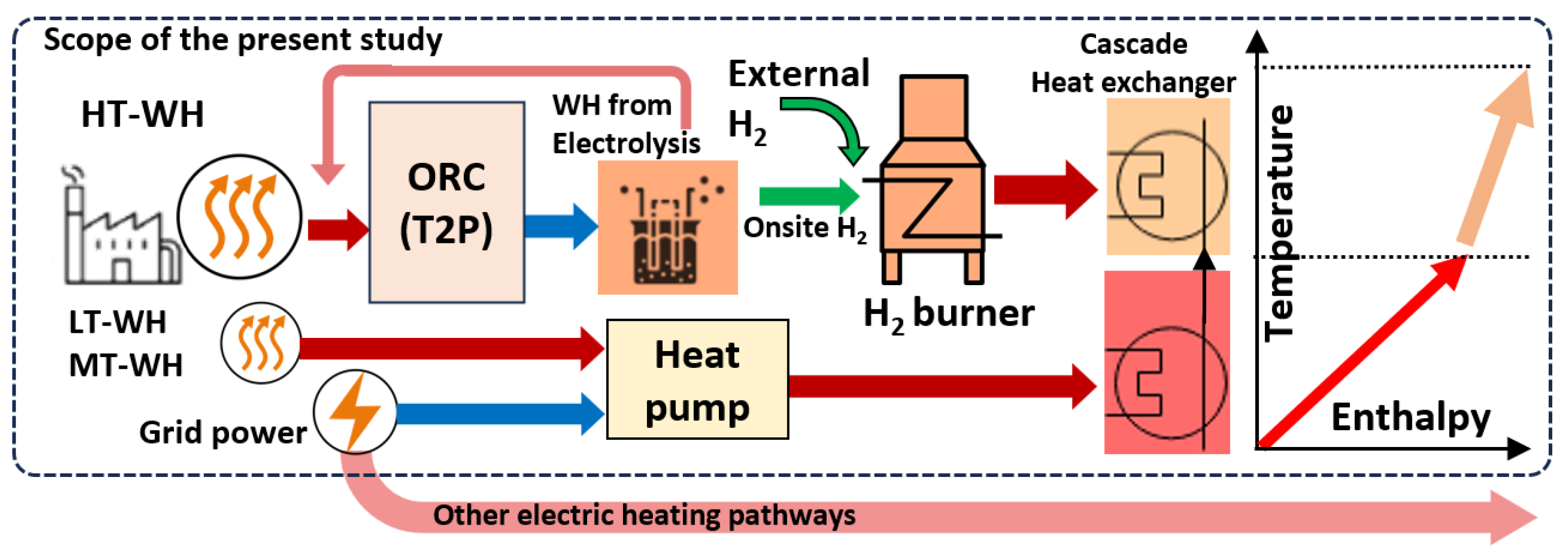

1.2. Research Framework and Case Study

2. Methodology

2.1. Waste Heat Potential

2.2. Two-Stage Heating

2.3. Levelised Cost of Heat

3. Results and Discussion

3.1. Technology Assessment Approach

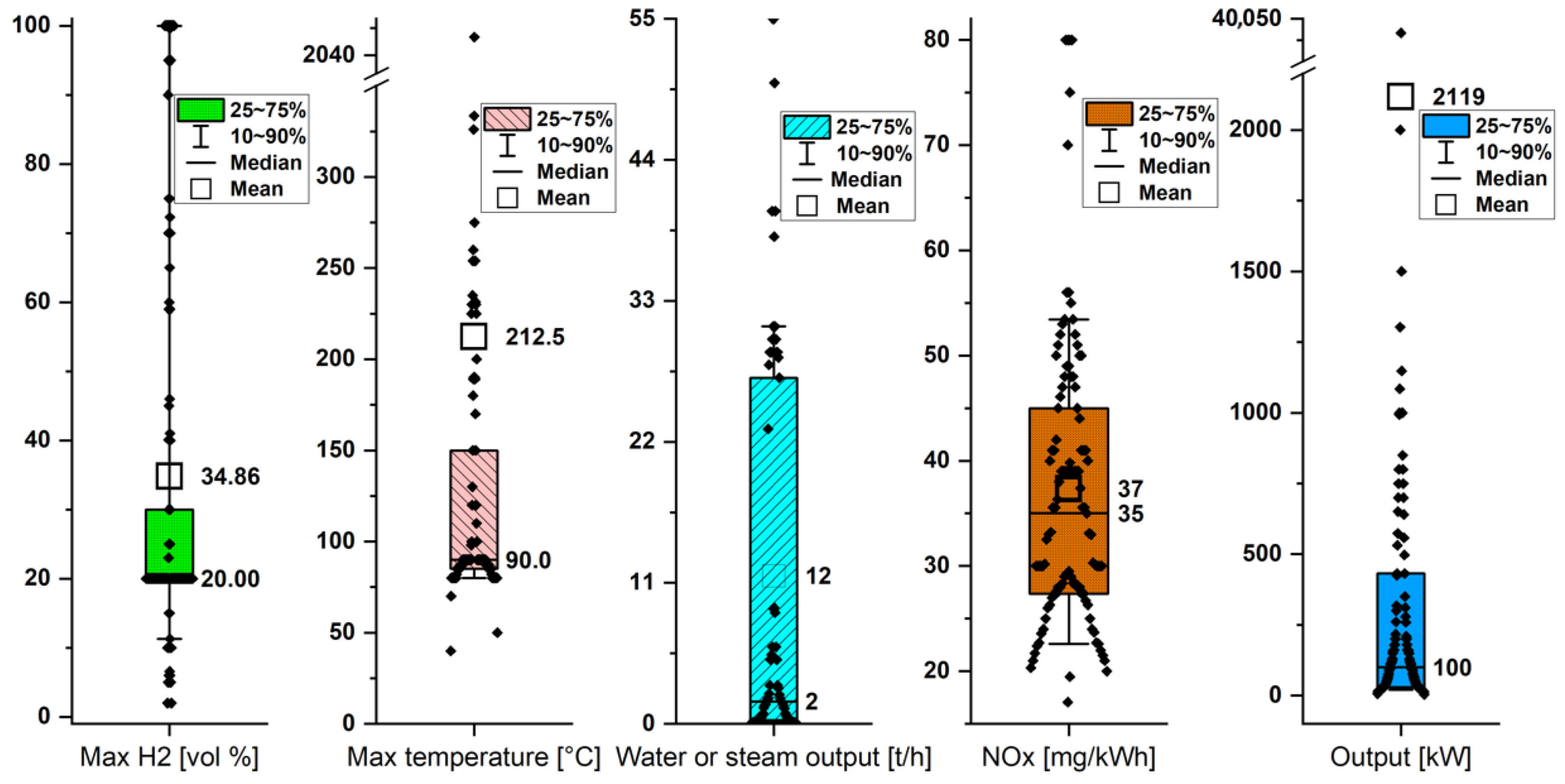

3.2. Technology Assessment—Hydrogen to Heat

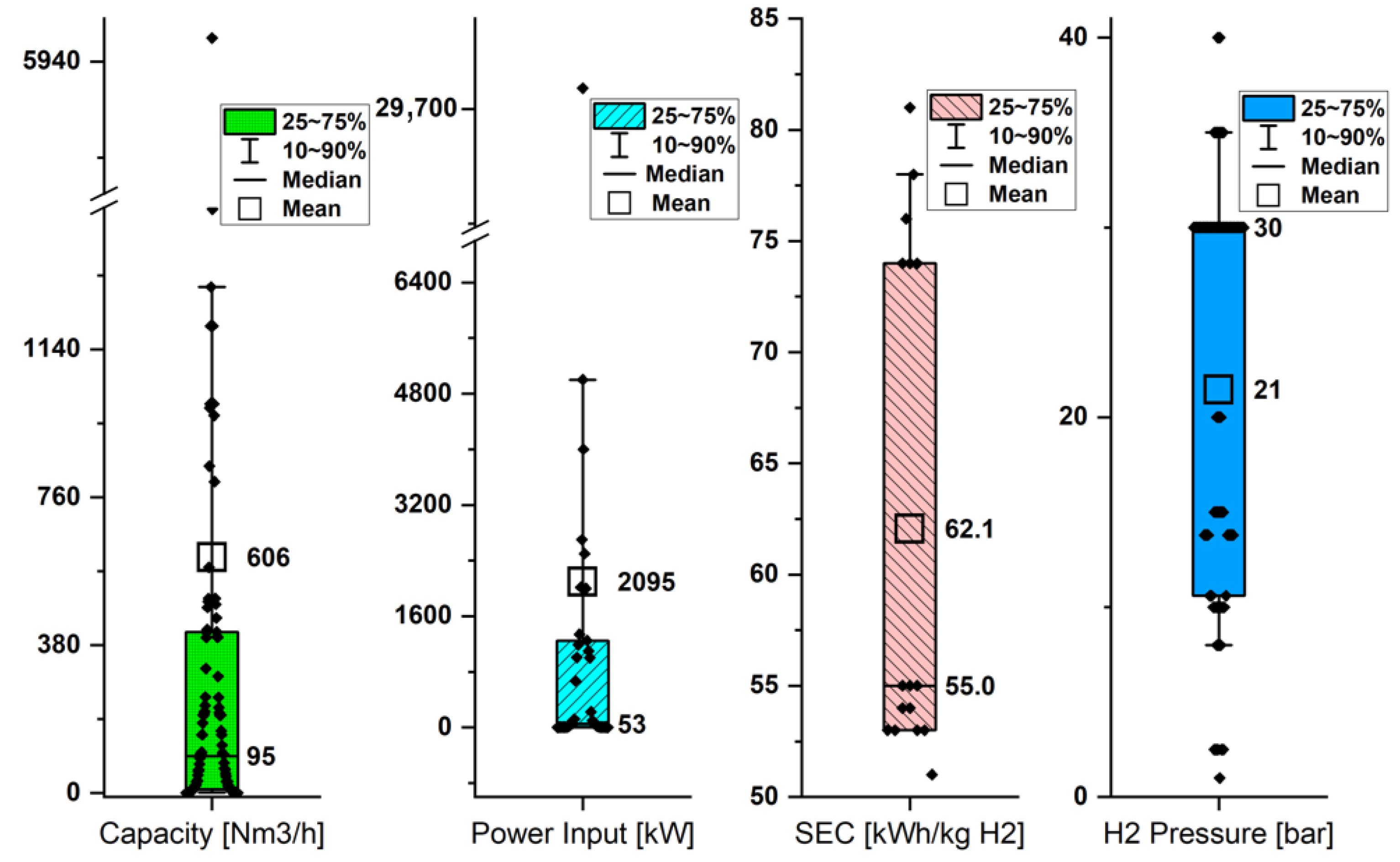

3.3. Technology Assessment—Power to Hydrogen

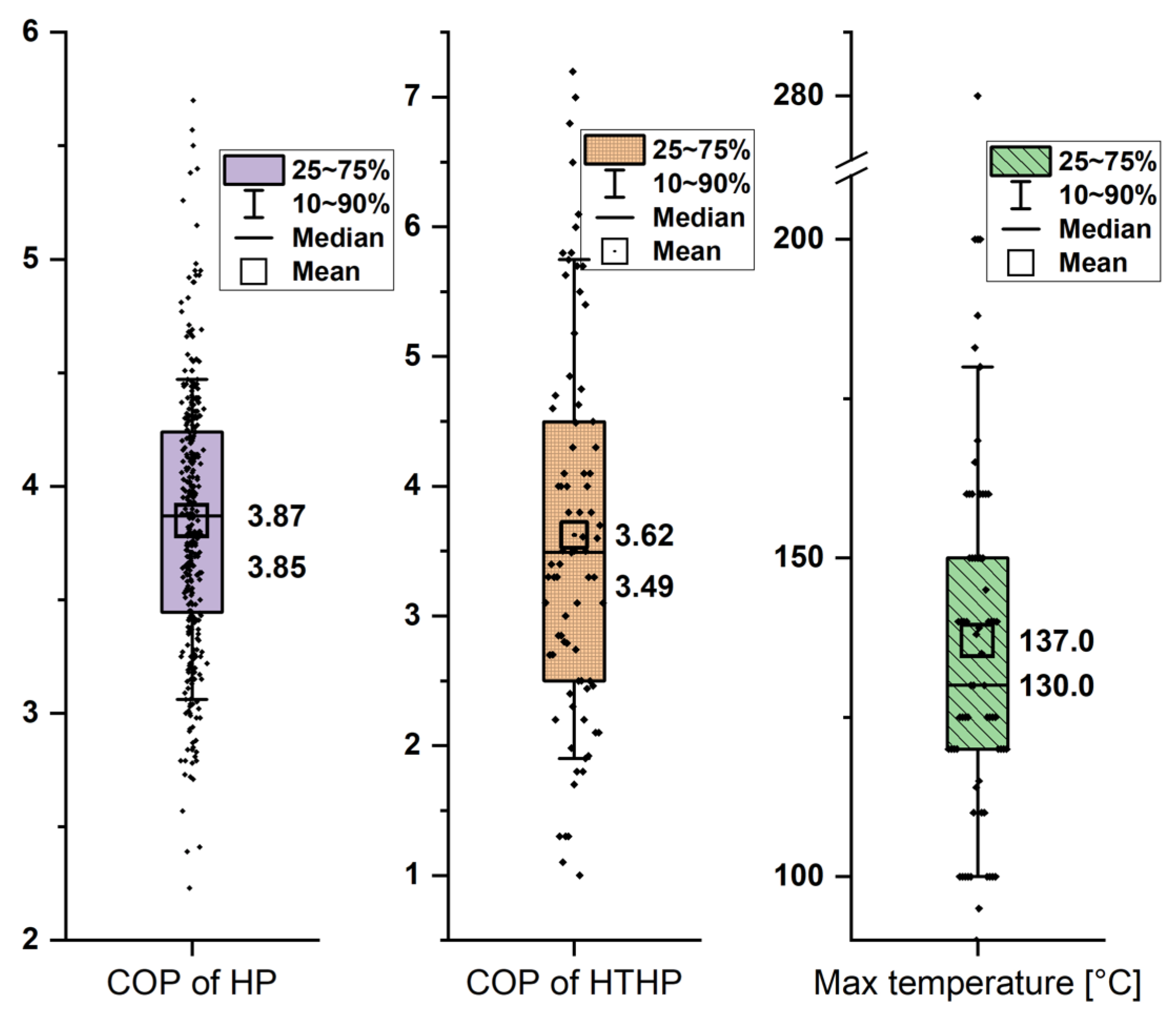

3.4. Technology Assessment—Heat Upgrading

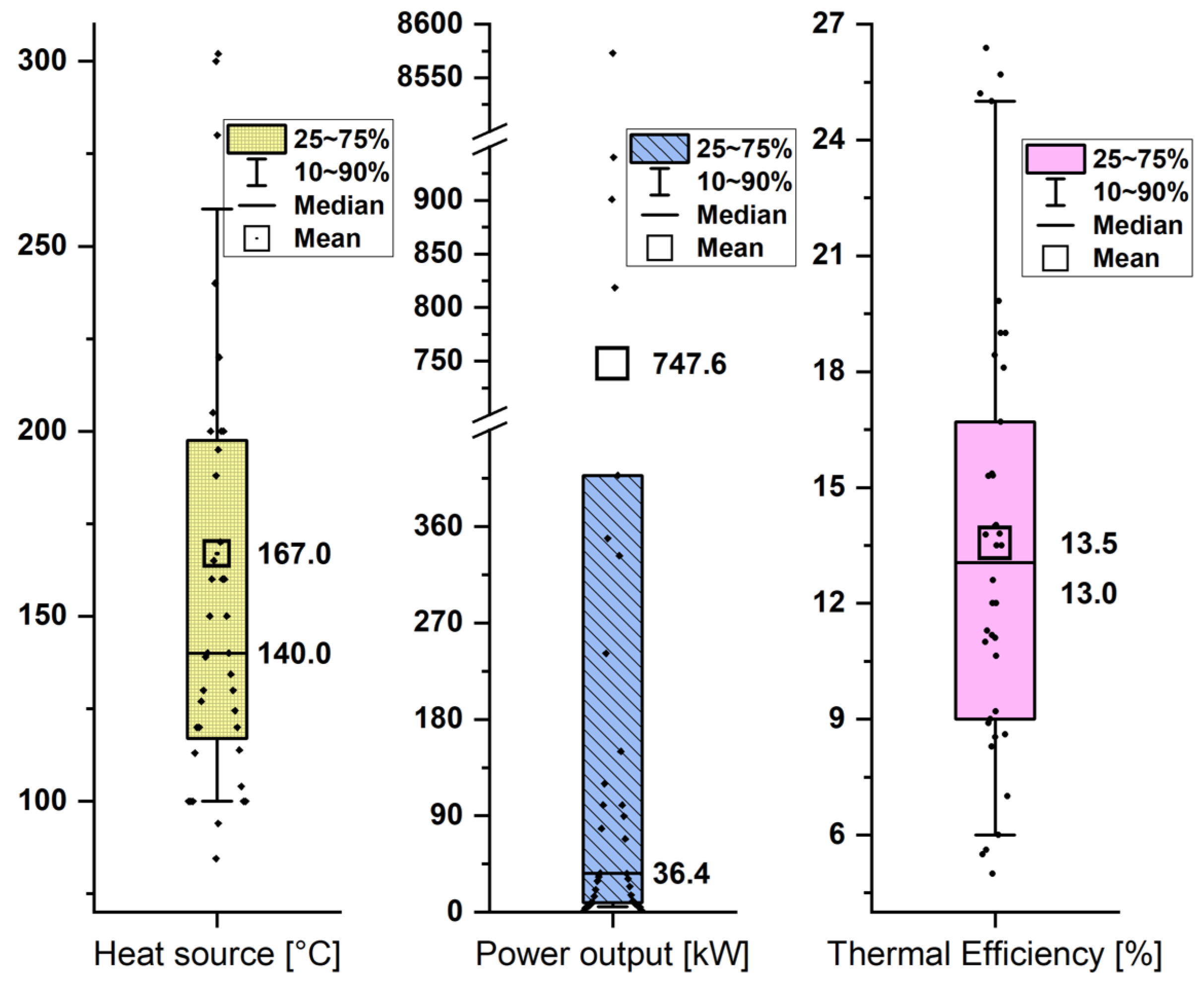

3.5. Technology Assessment—Heat to Power

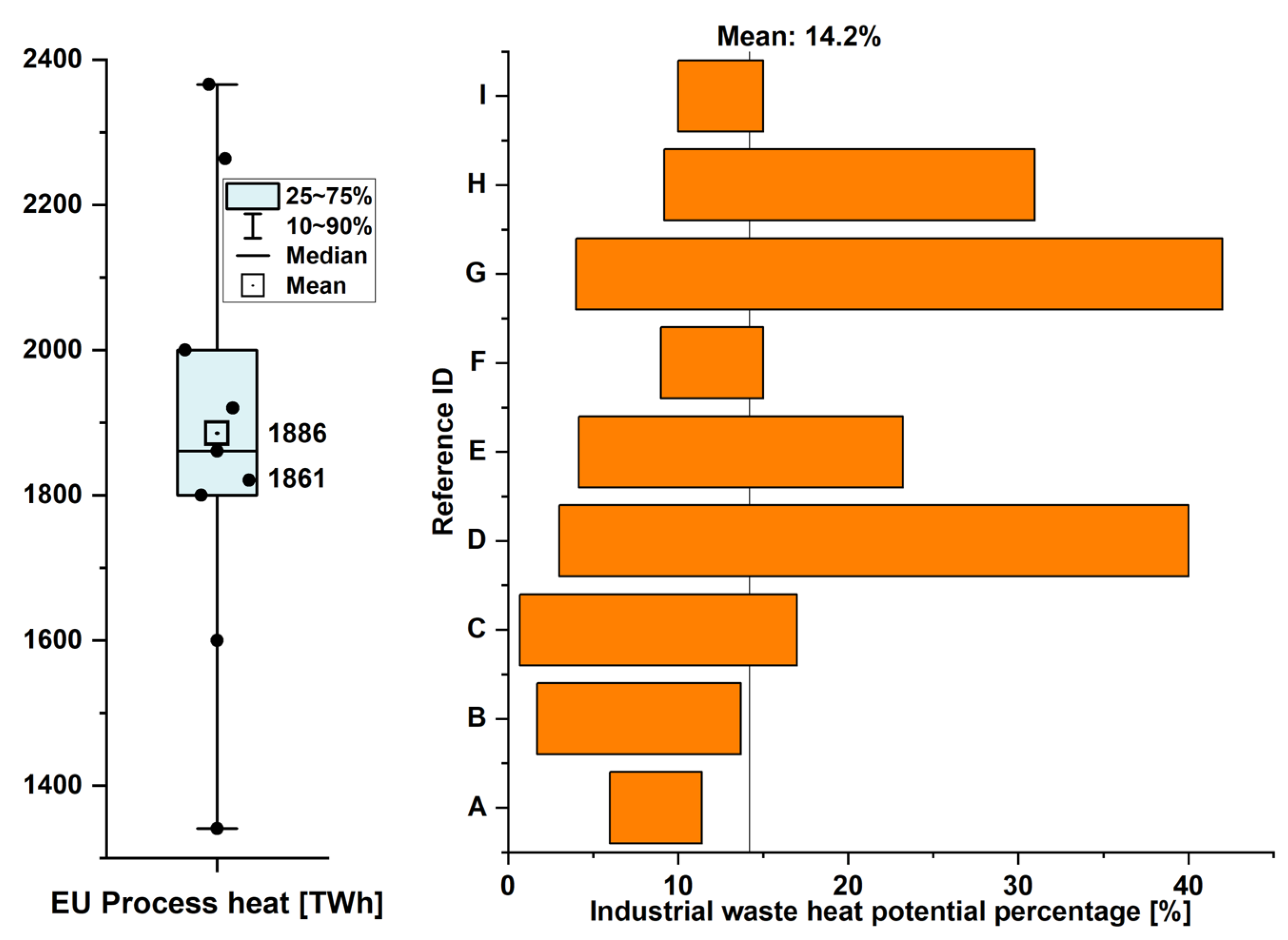

3.6. Industrial Heat and Waste Heat Assessment—EU Scale

3.7. System Assessment—Energy Flow Analysis

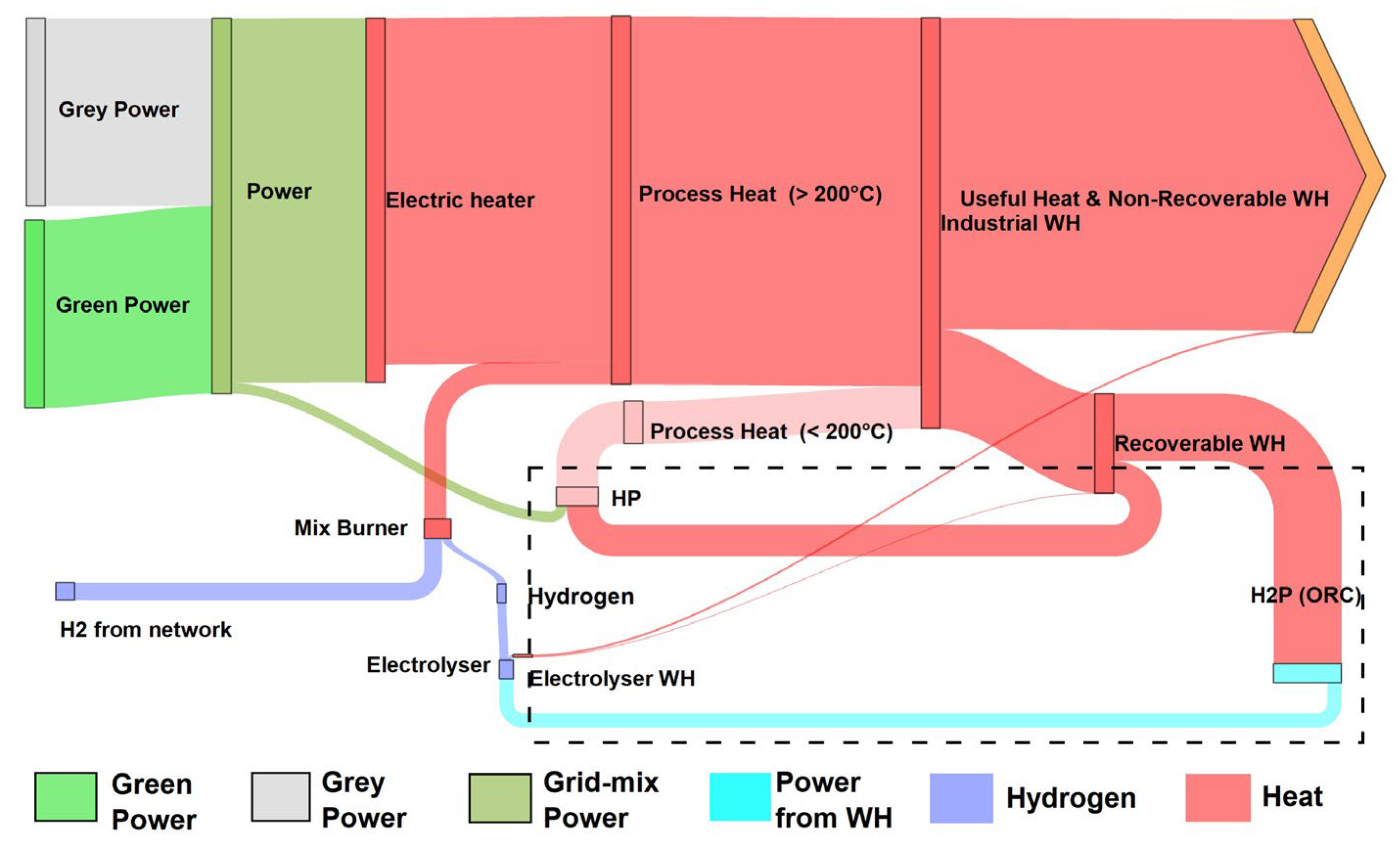

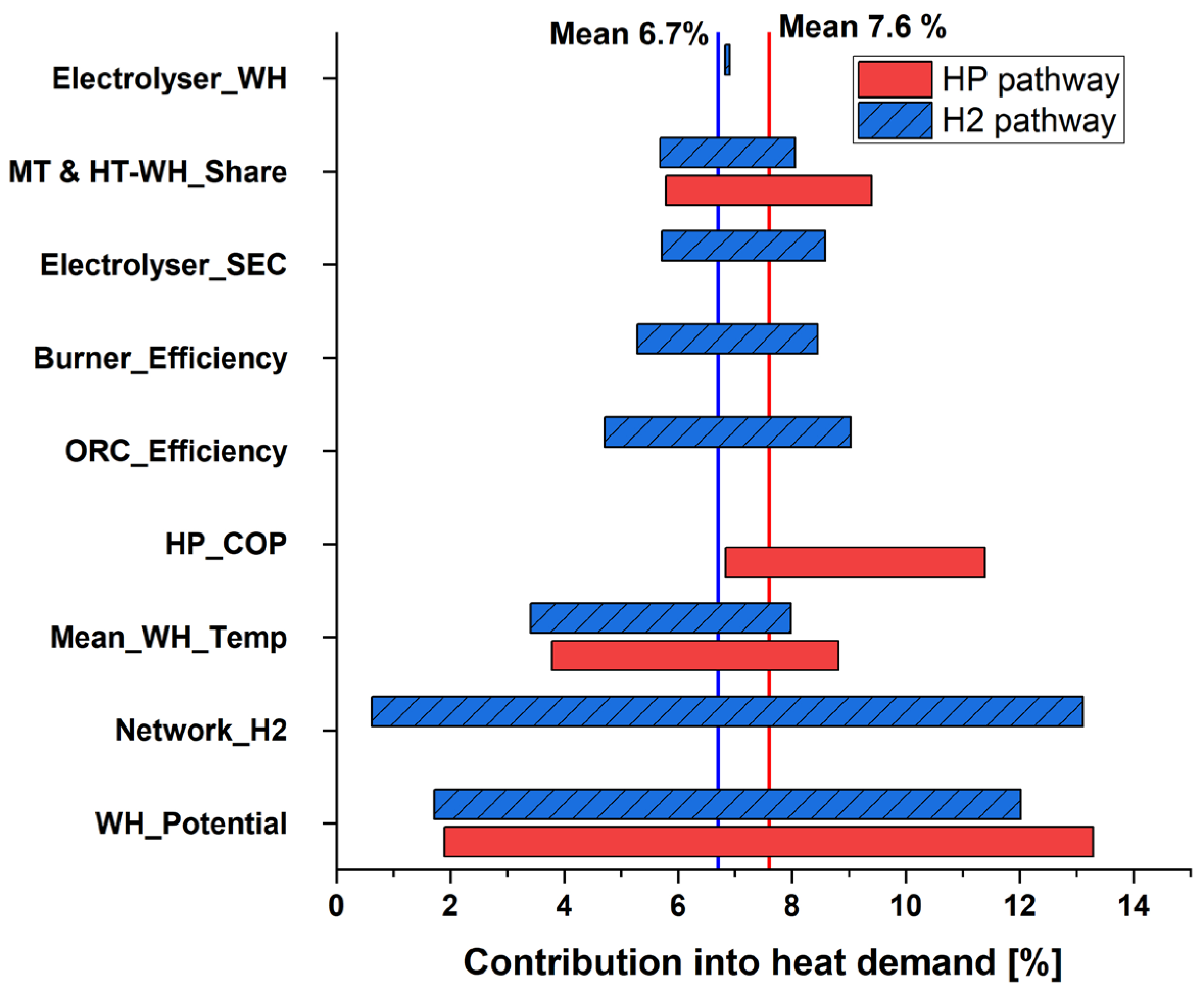

3.8. System Assessment—Sensitivity Analysis

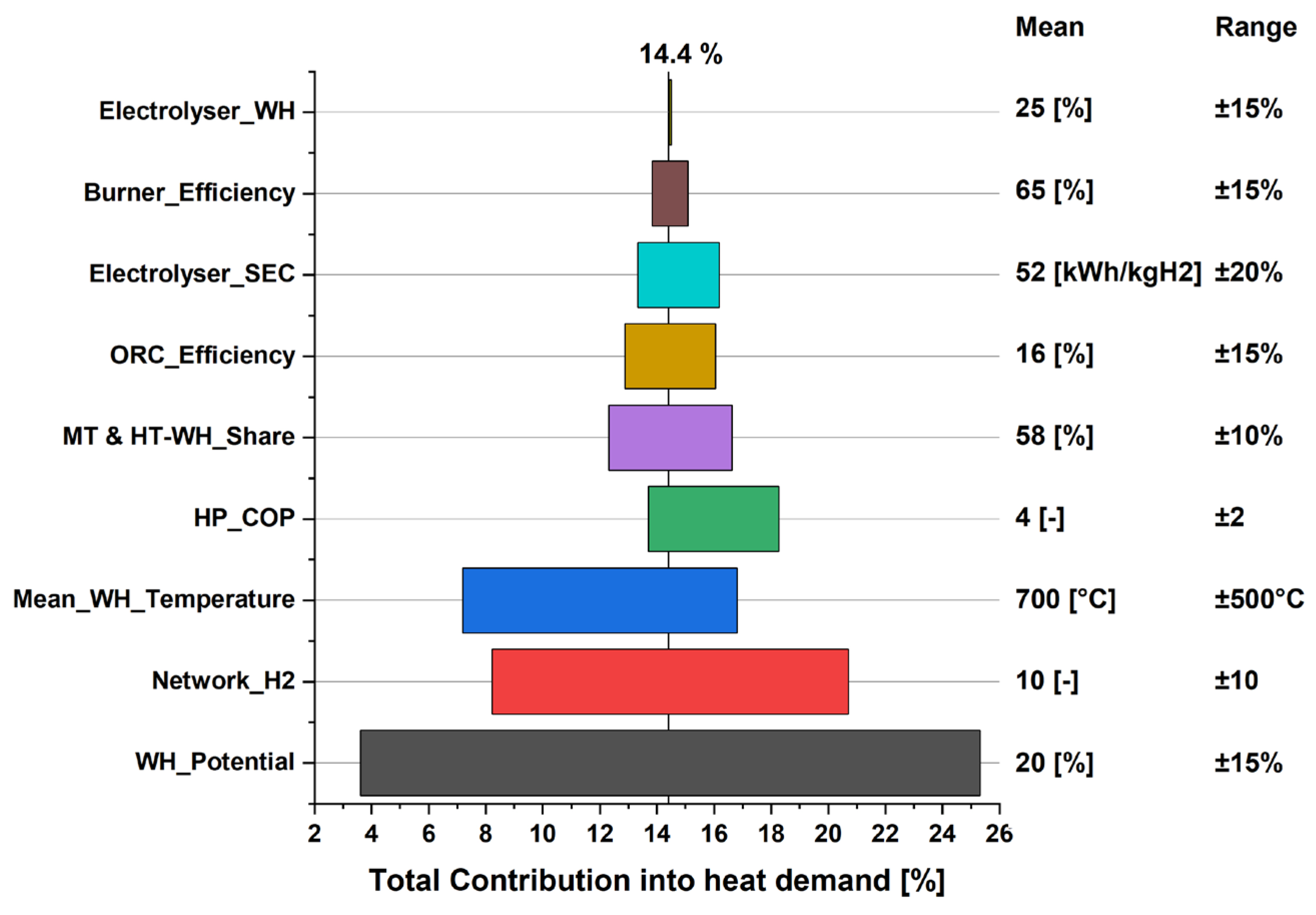

3.9. System Assessment—Policy Alignment

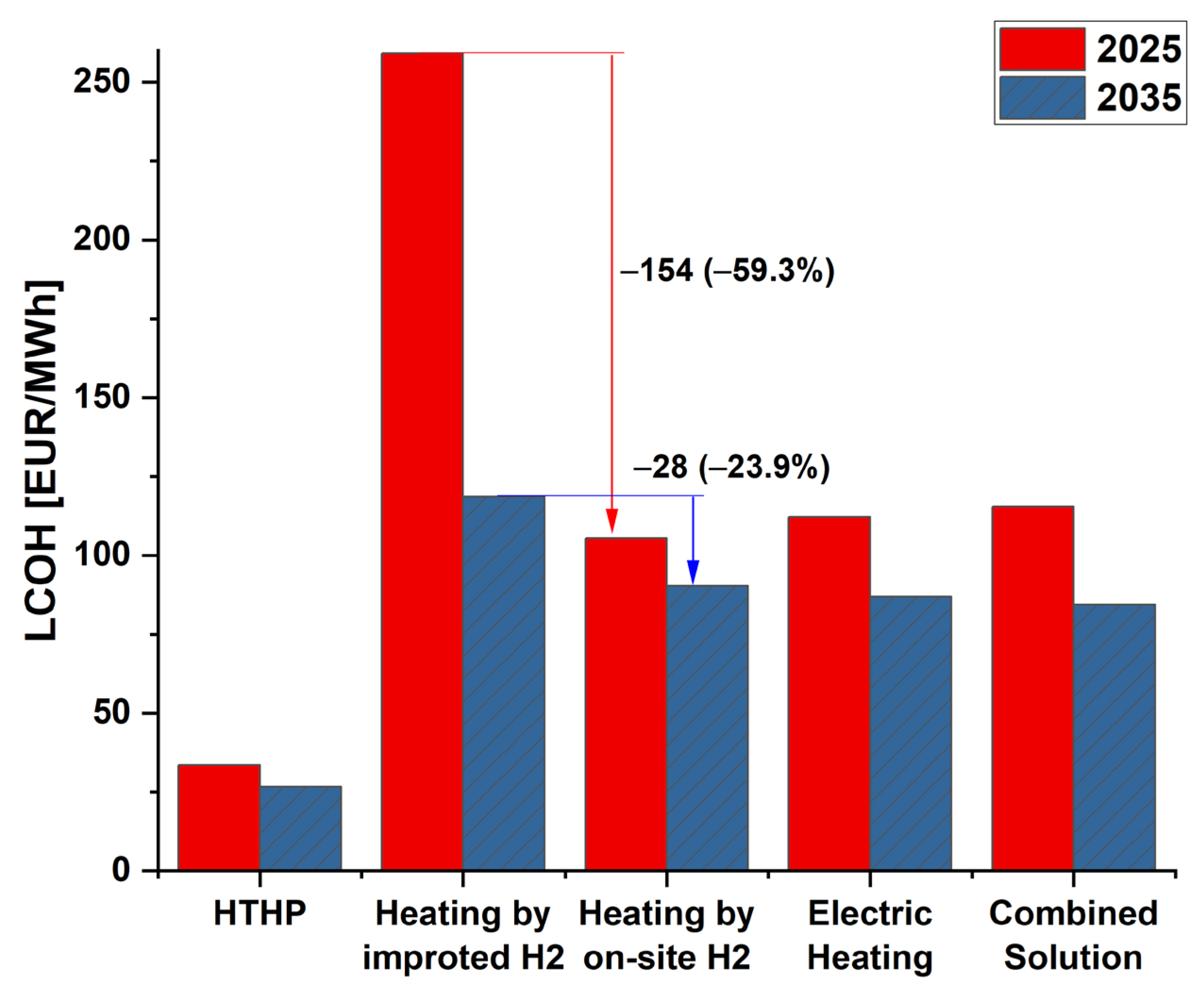

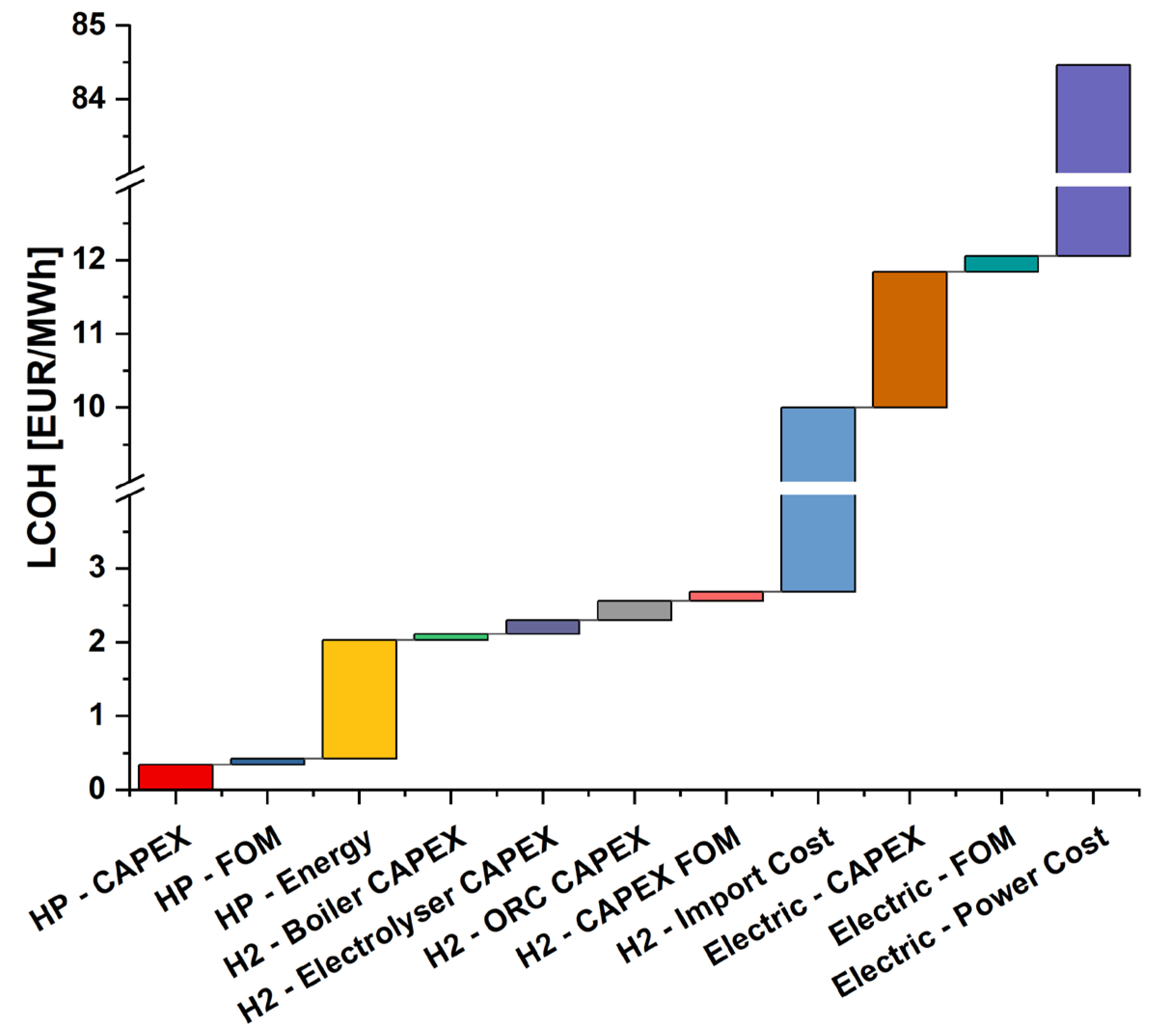

3.10. Economic Assessment

4. Conclusions

- The results point to a potential contribution of the low-carbon, WH-driven combined heating solution in meeting the process heating demand in EU industry of ~14%, with the following key findings:

- The analysis using the WHR model revealed that the breakdown of contribution is ~6.7% from the hydrogen pathway and ~7.6% from the HTHP. The contribution could support and accelerate progress in the electrification of heating. However, given the projected green hydrogen production capacity in the EU by 2035 and 2050, this solution cannot offer a replacement for electrification, though it can play a key complementary role.

- The most critical parameters through the combined solution, as found through the sensitivity analysis, are WH potential (highly dependent on the nature of the process and industrial sector), temperature of the WH, COP of the heat pump, and share of high-grade WH within the total WH.

- The hydrogen pathway benefits from the hydrogen intake from the future hydrogen infrastructure, supporting the achievement of higher temperatures. The base scenario integrates an HTHP for heat upgrading of low- and medium-temperature WH and delivery up to ~200 °C, with the hydrogen burner providing top-up heat. Without hydrogen intake, the temperature can reach 210 °C; however, including green hydrogen uptake from the network allows the system to fully meet industrial requirements, reaching much higher temperatures—i.e., 700 °C.

- The solution offers industry flexibility in process heating, which stems from the diversity of energy sources (green hydrogen, renewable power, and WH). It is also a technically viable solution for the transition phase, since hydrogen-ready systems are compatible with natural gas, hydrogen, or their blends. As a result, the solution can be deployed under a business-as-usual gas supply scenario and gradually adapted as hydrogen infrastructure expands to reach industrial clusters, enabling a smooth energy transition towards a Net Zero industry.

- The LCOH of the combined solution is competitive with the direct electrification of heating; however, integrating a WHR-driven HTHP and on-site electrolysis enables industries requiring high-temperature heating to more effectively benefit from hydrogen heating technologies and also helps reduce costs.

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AEM | Anion exchange membrane |

| ALK | Alkaline water electrolysis |

| CAPEX | Capital expenditures |

| COP | Coefficient of performance |

| CRF | Capital recovery factor |

| CWHP | Carnot waste heat potential |

| FOM | Fixed operating and maintenance cost |

| H2P | Heat to power |

| HHV | Higher heating value |

| HP | Heat pump |

| HT | High temperature |

| HTF | Heat transfer fluid |

| HTHP | High-temperature heat pump |

| IH | Industrial Heat |

| KPI | Key performance indicator |

| LCOH | Levelised cost of heat |

| LHV | Lower heating value |

| LT | Low temperature |

| MT | Medium temperature |

| ORC | Organic Rankine cycle |

| PEM | Polymer electrolyte membrane |

| RES | Renewable energy source |

| sCO2 | Supercritical CO2 |

| SEC | Specific energy consumption |

| SOEC | Solid oxide electrolyser cell |

| TRL | Technology Readiness Level |

| WH | Waste heat |

| WHR | Waste heat recovery |

| WHP | Waste heat potential |

References

- UK Government. Hydrogen Heating Town Pilot: Letter to Gas Distribution Networks—Update; Department for Energy Security and Net Zero: London, UK, 2024. Available online: https://www.gov.uk/government/publications/hydrogen-heating-town-pilot-open-letter-to-gas-distribution-networks (accessed on 1 July 2025).

- Rosenow, J. A meta-review of 54 studies on hydrogen heating. Cell Rep. Sustain. 2024, 1, 100010. [Google Scholar] [CrossRef]

- Department for Energy Security and Net Zero (formerly BEIS). Hydrogen Heating Town Pilot: Letter to Gas Distribution Networks—Update (9 May 2024). Available online: https://gov.uk/government/publications/hydrogen-heating-town-pilot-open-letter-to-gas-distribution-networks (accessed on 1 July 2025).

- Department for Business, Energy & Industrial Strategy (BEIS). Industrial Decarbonisation Strategy. Presented to Parliament by the Secretary of State for Business, Energy & Industrial Strategy, March 2021; ID: CCS0221092964 03/21, CP 399. Available online: https://gov.uk/government/publications/industrial-decarbonisation-strategy (accessed on 1 July 2025).

- Paardekooper, S.; Lund, R.S.; Mathiesen, B.V.; Chang, M.; Petersen, U.R.; Grundahl, L.; David, A.; Dahlbæk, J.; Kapetanakis, I.A.; Lund, H.; et al. Heat Roadmap Europe: Quantifying the Impact of Low-Carbon Heating and Cooling Roadmaps; Deliverable 6.4, ID: H2020-EE-2015-3-MarketUptake/D6.4 PU; August 2018. Available online: https://vbn.aau.dk/ws/portalfiles/portal/288075507/Heat_Roadmap_Europe_4_Quantifying_the_Impact_of_Low_Carbon_Heating_and_Cooling_Roadmaps.pdf (accessed on 1 July 2025).

- Rosenow, J. Is heating homes with hydrogen all but a pipe dream? An evidence review. Joule 2022, 6, 2219–2239. [Google Scholar] [CrossRef]

- Knosala, K.; Langenberg, L.; Pflugradt, N.; Stenzel, P.; Kotzur, L.; Stolten, D. The role of hydrogen in German residential buildings. Energy Build. 2022, 276, 112480. [Google Scholar] [CrossRef]

- Ameli, H.; Strbac, G.; Pudjianto, D.; Ameli, M.T. A Review of the Role of Hydrogen in the Heat Decarbonization of Future Energy Systems: Insights and Perspectives. Energies 2024, 17, 1688. [Google Scholar] [CrossRef]

- Beccali, M.; Bonomolo, M.; Martorana, F.; Catrini, P.; Buscemi, A. Electrical hybrid heat pumps assisted by natural gas boilers: A review. Appl. Energy 2022, 322, 119466. [Google Scholar] [CrossRef]

- Martire, M.; Kaya, A.F.; Morselli, N.; Puglia, M.; Allesina, G.; Pedrazzi, S. Analysis and optimization of a hybrid system for the production and use of green hydrogen as fuel for a commercial boiler. Int. J. Hydrogen Energy 2024, 56, 769–779. [Google Scholar] [CrossRef]

- UK Research and Innovation (UKRI). Enabling Net Zero: A Plan for UK Industrial Cluster Decarbonisation; UKRI: Swindon, UK, 2023; Available online: https://www.ukri.org/publications/enabling-net-zero-a-plan-for-uk-industrial-decarbonisation/ (accessed on 1 July 2025).

- Niknam, P.H.; Barberis, S.; Sciacovelli, A. High Temperature Industrial Thermal Energy Storage—Assessment of Potential Applications and Benefits Toward Industrial Decarbonization. In Proceedings of the EUROTHERM 2023 Conference, Lleida, Spain, 24–26 May 2023. [Google Scholar]

- Niknam, P.H.; Fisher, R.; Ciappi, L.; Sciacovelli, A. Optimally integrated waste heat recovery through combined emerging thermal technologies: Modelling, optimization and assessment for onboard multi-energy systems. Appl. Energy 2024, 366, 123298. [Google Scholar] [CrossRef]

- Fisher, R.; Ciappi, L.; Niknam, P.H.; Braimakis, K.; Karellas, S.; Frazzica, A.; Sciacovelli, A. Innovative waste heat valorisation technologies for zero-carbon ships—A review. Appl. Therm. Eng. 2024, 253, 123740. [Google Scholar] [CrossRef]

- Jouhara, H.; Khordehgah, N.; Almahmoud, S.; Delpech, B.; Chauhan, A.; Tassou, S.A. Waste heat recovery technologies and applications. Therm. Sci. Eng. Prog. 2018, 6, 268–289. [Google Scholar] [CrossRef]

- Danfoss Impact. Green Hydrogen: A Critical Balancing Act, Issue No. 5, 2024. Available online: https://assets.danfoss.com/documents/latest/512571/BE512836614058en-000201.pdf (accessed on 1 July 2025).

- Zini, A.; Socci, L.; Vaccaro, G.; Rocchetti, A.; Talluri, L. Working Fluid Selection for High-Temperature Heat Pumps: A Comprehensive Evaluation. Energies 2024, 17, 1556. [Google Scholar] [CrossRef]

- Clean Hydrogen Monitors November 2023, Hydrogen Europe. Available online: https://hydrogeneurope.eu/wp-content/uploads/2023/10/Clean_Hydrogen_Monitor_11-2023_DIGITAL.pdf (accessed on 1 July 2025).

- Electrolytic Hydrogen Production Working Group, Electrolytic Hydrogen Production. 2023. Available online: https://hydrogen-uk.org/wp-content/uploads/2023/09/HUK-Electrolytic-Hydrogen-Production-Report.pdf (accessed on 1 July 2025).

- Government of the United Kingdom. Powering Up Britain: Net Zero Growth Plan. Policy Paper; UK Government: London, UK, 2023.

- Amendment 2023 of RED III, PE-CONS 36/23 WST/JGC/di. Available online: https://data.consilium.europa.eu/doc/document/PE-36-2023-INIT/en/pdf (accessed on 1 July 2025).

- European Commission. SET Plan Action 6 on Energy Efficiency in Industry: Implementation Plan, Revision 2021 (Final Version 07/12/2021). Endorsed by the SET Plan Steering Group. European Strategic Energy Technology Information System (SETIS), Publications Office of the European Union. 2021. Available online: https://setis.ec.europa.eu/system/files/2022-02/EE-in-industry_Implementation-Plan_Rev2021_Final-Endorsed.pdf (accessed on 1 July 2025).

- Daniarta, S. Techno-Economic Survey of Enhancing Power-to-Methane Efficiency via Waste Heat Recovery from Electrolysis and Biomethanation. Renew. Sustain. Energy Rev. 2024, 194, 114301. [Google Scholar] [CrossRef]

- Wieland, C. Innovations for Organic Rankine Cycle Power Systems: Current Trends and Future Perspectives. Appl. Therm. Eng. 2023, 225, 120201. [Google Scholar] [CrossRef]

- Zhao, P.; Wang, J.; Sun, L.; Li, Y.; Xia, H.; He, W. Optimal electrode configuration and system design of compactly-assembled industrial alkaline water electrolyzer. Energy Convers. Manag. 2024, 299, 117875. [Google Scholar] [CrossRef]

- IRENA. Green Hydrogen: A Guide to Policy Making—Cost Reduction; IRENA: Abu Dhabi, United Arab Emirates, 2020; Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2020/Dec/IRENA_Green_hydrogen_cost_2020.pdf (accessed on 1 July 2025).

- Bianchi, G.; Panayiotou, G.P.; Aresti, L.; Kalogirou, S.A.; Florides, G.A.; Tsamos, K.; Christodoulides, P. Estimating the waste heat recovery in the European Union Industry. Energy Ecol. Environ. 2019, 4, 211–221. [Google Scholar] [CrossRef]

- Turek, V.; Kilkovský, B.; Daxner, J.; Babička Fialová, D.; Jegla, Z. Industrial Waste Heat Utilization in the European Union—An Engineering-Centric Review. Energies 2024, 17, 2084. [Google Scholar] [CrossRef]

- Peconet, Inc. Eclipse ThermJet PCA Burner Datasheet (Bulletin 20600dga). 2007. Available online: http://peconet.com/products/EclipseBulletins/02%20Furnace%20Type%20Burners/206_ThermJetPCA/20600dga.pdf (accessed on 15 July 2025).

- Techrite Controls Australia. Eclipse ThermJet Burner Datasheet 3018; Edition 05.23 (EN); Techrite Controls: Springvale, Australia, 2023. Available online: https://techritecontrols.com.au/cms/uploads/Techrite-Controls-Product-Eclipse-Thermjet-Burner-3018.pdf (accessed on 15 July 2025).

- European Commission. 2040 Climate Target. Available online: https://climate.ec.europa.eu/eu-action/climate-strategies-targets/2040-climate-target_en (accessed on 14 July 2025).

- Obrist, M.D.; Kannan, R.; McKenna, R.; Schmidt, T.J.; Kober, T. High temperature heat pumps in climate pathways for selected industry sectors in Switzerland. Energy Policy 2023, 173, 113383. [Google Scholar] [CrossRef]

- Arpagaus, C.; Bless, F.; Bertsch, S.; Krummenacher, P.; Flórez Orrego, D.A.; Pina, E.A.; Maréchal, F.; Calame Darbellay, N.; Rognon, F.; Vesin, S.; et al. Integration of high temperature heat pumps in Swiss industrial processes (HTHP CH). In Proceedings of the 14th IEA Heat Pump Conference 2023, Chicago, IL, USA, 15–18 May 2023; Paper 494. Available online: https://www.hpc2023.org/wp-content/uploads/gravity_forms/3-7075ba8a16c5f78b321724d090fb2a34/2023/05/0494_HPC2023_Full_Paper_Arpagaus_v02.pdf (accessed on 14 July 2025).

- Sun, J.; Peng, B. Experimental Study on Steady-State Operation of Organic Rankine Cycle System under Different Operating Conditions. Sci. Rep. 2025, 15, 1041. [Google Scholar] [CrossRef] [PubMed]

- Astolfi, M.; Romano, M.C.; Bombarda, P.; Macchi, E. Binary ORC (Organic Rankine Cycles) Power Plants for the Exploitation of Low–Medium Enthalpy Geothermal Brines. Energy 2014, 66, 662–672. [Google Scholar] [CrossRef]

- Quoilin, S.; Declaye, S.; Tchanche, B.F.; Lemort, V. Thermo-Economic Optimization of Waste Heat Recovery Organic Rankine Cycles. Appl. Thermal Eng. 2011, 31, 2885–2893. [Google Scholar] [CrossRef]

- Pantaleo, A.M.; Simpson, M.; Rotolo, G.; Distaso, E.; Oyewunmi, O.; Sapin, P.; De Palma, P.; Markides, C.N. Thermoeconomic Optimisation of Small-Scale Organic Rankine Cycle Systems Based on Screw vs. Piston Expander Maps in Waste Heat Recovery Applications. Energy Convers. Manag. 2019, 200, 112053. [Google Scholar] [CrossRef]

- Tsiropoulos, I.; Tarvydas, D.; Zucker, A. Cost Development of Low Carbon Energy Technologies: Scenario Based Cost Trajectories to 2050. 2017 ed.; EUR 29034 EN; Publications Office of the European Union: Luxembourg, 2018; ISBN 9789279774799. [Google Scholar] [CrossRef]

- UK Department for Business, Energy & Industrial Strategy. International Energy Price Comparisons. Gov.UK Collection. Available online: https://gov.uk/government/collections/international-energy-price-comparisons (accessed on 21 July 2025).

- International Energy Agency. Net Zero by 2050: A Roadmap for the Global Energy Sector; IEA: Paris, France, 2021; (revised October 2021). [Google Scholar]

- Bolard, J.; Dolci, F.; Gryc, K.; Eynard, U.; Georgakaki, A.; Letout, S.; Mountraki, A.; Ince, E.; Shtjefni, D.; Rózsai, M.; et al. Clean Energy Technology Observatory: Water Electrolysis and Hydrogen in the European Union—2024 Status Report on Technology Development, Trends, Value Chains and Markets; Publications Office of the European Union: Luxembourg, 2024; EUR 40075, JRC 139364; ISBN 978-92-68-20995-0. ISSN 1831-9424. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Northwest European Hydrogen Monitor 2024; IEA: Paris, France, 2024; Licence CC BY 4.0; Available online: https://iea.org/reports/northwest-european-hydrogen-monitor-2024 (accessed on 21 July 2025).

- EY & Hyvolution. European Hydrogen Index—Hyvolution/EY: European Hydrogen Monitor 2025; EY & Hyvolution: Paris, France, 2025; Available online: https://ey.com/content/dam/ey-unified-site/ey-com/fr-fr/insights/climate-change-sustainability-services/documents/ey-hyvolution-ey-european-hydrogen-20250214.pdf (accessed on 21 July 2025).

- OFX. Historical Exchange Rates—Yearly Average Rates. Available online: https://ofx.com/en-gb/forex-news/historical-exchange-rates/yearly-average-rates/ (accessed on 15 July 2025).

- International Energy Agency; Nuclear Energy Agency. Projected Costs of Generating Electricity 2020; IEA & OECD Nuclear Energy Agency: Paris, France; Luxembourg, 2020. [Google Scholar]

- Jesper, M.; Juhani, H.; Petter, L.; Mats, R.; Erik, D. High temperature heat pumps for industrial heat demand. Energy 2018, 165, 968–978. [Google Scholar] [CrossRef]

- Madsen, J.; Martin, J.; Schlosser, F.; Vajen, K. Performance Evaluation of Heat Pumps in the European Market: A Comprehensive Survey of 58 Devices. Energies 2023, 16, 3733. [Google Scholar] [CrossRef]

- Mahajan, D.; Tan, K.; Venkatesh, T.; Kileti, P.; Clayton, C.R. Hydrogen blending in gas pipeline networks—A review. Energies 2022, 15, 3582. [Google Scholar] [CrossRef]

- Öztuna, S.; Büyükakın, M.K. Effects of hydrogen enrichment of methane on diffusion flame structure and emissions in a back-pressure combustion chamber. Int. J. Hydrogen Energy 2020, 45, 5971–5986. [Google Scholar] [CrossRef]

- Xin, Y.; Wang, K.; Zhang, Y.; Zeng, F.; He, X.; Takyi, S.A.; Tontiwachwuthikul, P. Numerical simulation of combustion of natural gas mixed with hydrogen in gas boilers. Energies 2021, 14, 6883. [Google Scholar] [CrossRef]

- Yilmaz, I.; Ilbas, M. An experimental study on hydrogen–methane mixtured fuels. Int. Commun. Heat Mass Transf. 2008, 35, 178–187. [Google Scholar] [CrossRef]

- İlbaş, M.; Yılmaz, İ. Experimental analysis of the effects of hydrogen addition on methane combustion. Int. J. Energy Res. 2012, 36, 643–647. [Google Scholar] [CrossRef]

- Cellek, M.S.; Pınarbaşı, A. Investigations on performance and emission characteristics of an industrial low swirl burner while burning natural gas, methane, hydrogen-enriched natural gas and hydrogen as fuels. Int. J. Hydrogen Energy 2018, 43, 1194–1207. [Google Scholar] [CrossRef]

- Büyükakın, M.K.; Öztuna, S. Numerical investigation on hydrogen-enriched methane combustion in a domestic back-pressure boiler and non-premixed burner system from flame structure and pollutants aspect. Int. J. Hydrogen Energy 2020, 45, 35246–35256. [Google Scholar] [CrossRef]

- Fang, Z.; Zhang, S.; Huang, X.; Hu, Y.; Xu, Q. Performance of three typical domestic gas stoves operated with methane-hydrogen mixture. Case Stud. Therm. Eng. 2023, 41, 102631. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, H.; Zhang, Y.; Wang, H.; Lyu, J.; Yue, G. Efficiency and emissions of gas-fired industrial boiler fueled with hydrogen-enriched nature gas: A case study of 108 t/h steam boiler. Int. J. Hydrogen Energy 2022, 47, 28188–28203. [Google Scholar] [CrossRef]

- Basso, G.L.; Nastasi, B.; Garcia, D.A.; Cumo, F. How to handle the Hydrogen enriched Natural Gas blends in combustion efficiency measurement procedure of conventional and condensing boilers. Energy 2017, 123, 615–636. [Google Scholar] [CrossRef]

- Ding, Y.; Durox, D.; Darabiha, N.; Schuller, T. Chemiluminescence based operating point control of domestic gas boilers with variable natural gas composition. Appl. Therm. Eng. 2019, 149, 1052–1060. [Google Scholar] [CrossRef]

- Schiro, F.; Stoppato, A.; Benato, A. Modelling and analyzing the impact of hydrogen enriched natural gas on domestic gas boilers in a decarbonization perspective. Carbon Resour. Convers. 2020, 3, 122–129. [Google Scholar] [CrossRef]

- Bălănescu, D.T.; Homutescu, V.M. Effects of hydrogen-enriched methane combustion on latent heat recovery potential and environmental impact of condensing boilers. Appl. Therm. Eng. 2021, 197, 117411. [Google Scholar] [CrossRef]

- Boulahlib, M.S.; Medaerts, F.; Boukhalfa, M.A. Experimental study of a domestic boiler using hydrogen methane blend and fuel-rich staged combustion. Int. J. Hydrogen Energy 2021, 46, 37628–37640. [Google Scholar] [CrossRef]

- Elco Hydrogen-Ready Products. Available online: https://elco.net/en/products.html (accessed on 29 July 2025).

- Intergas Hydrogen-Ready Boilers. Available online: https://intergasheating.co.uk/app/uploads/2023/02/Factsheet-Products.pdf (accessed on 29 July 2025).

- ACV Hydrogen-Ready Boilers. Available online: https://acv.com/gb/news/20-hydrogen-blend-ready-boilers (accessed on 29 July 2025).

- Accorroni Hydrogen-Ready Boilers. Available online: https://accorroni.it/public/downloads/499_en.pdf (accessed on 29 July 2025).

- Hoval Hydrogen-Ready Boilers. Available online: https://hoval.co.uk/en_GB/Heating-technology/Gas/c/G_gas (accessed on 29 July 2025).

- Remeha Hydrogen-Ready Boilers. Available online: https://remeha.de/produkte/gas-brennwertkessel (accessed on 29 July 2025).

- ETP Clean Energy Technology Guide. Available online: https://iea.org/data-and-statistics/data-tools/etp-clean-energy-technology-guide (accessed on 29 July 2025).

- Hydrogen. Available online: https://teledynees.com/what-we-do/markets/hydrogen (accessed on 29 July 2025).

- H2B2 Electrolysers. Available online: https://h2b2.es/electrolyzers/ (accessed on 29 July 2025).

- LONGi ALK Hi1. Available online: https://longi.com/en/products/hydrogen/alk-hi-1/ (accessed on 29 July 2025).

- EnapterAEM Electrolysers. Available online: https://www.enapter.com/en/enapter-products-aem/ (accessed on 29 July 2025).

- Cummins Electrolyzers Brochure. Available online: https://www.cummins.com/sites/default/files/2023-10/electrolyzer-brochure.pdf (accessed on 29 July 2025).

- McPhy Electrolyzers. Available online: https://mcphy.com/en/equipment-services/electrolyzers/ (accessed on 29 July 2025).

- Nel Hydrogen (Nel ASA). Water Electrolysers/Hydrogen Generators. Available online: https://nelhydrogen.com/water-electrolysers-hydrogen-generators/ (accessed on 29 July 2025).

- Giner Inc. Electrolyzers. Giner Labs. Available online: https://www.ginerinc.com/electrolyzers (accessed on 29 July 2025).

- GINERELX The Allagash Electrolyzer. Available online: https://www.messe.de/apollo/hannover_messe_2020/obs/Binary/A1014067/1014067_02199667.pdf (accessed on 29 July 2025).

- GINERELX The Merrimack Electrolyzer. Available online: https://www.messe.de/apollo/hannover_messe_2020/obs/Binary/A1014067/1014067_02199672.pdf (accessed on 29 July 2025).

- University of Queensland Dow Centre. Green Hydrogen Production from Treated Wastewater; University of Queensland: Brisbane, Australia, 2024; pp. 1–28. Available online: https://dow.centre.uq.edu.au/files/15402/Green%20Hydrogen%20Production%20from%20Treated%20Wastewater%20April%202024.pdf (accessed on 29 July 2025).

- Salvatore, A. Sustainable Hydrogen Production from Wastewater Treatment Plants. Master’s Thesis, Politecnico di Torino, Turin, Italy, 2021. Available online: https://webthesis.biblio.polito.it/17436/1/tesi.pdf (accessed on 29 July 2025).

- Yang, Y.; Wang, Y.; Xu, Z.; Xie, B.; Hu, Y.; Yu, J.; Chen, Y.; Zhang, T.; Lu, Z.; Gong, Y. Performance Comparison of High-Temperature Heat Pumps with Different Vapor Refrigerant Injection Techniques. Processes 2024, 12, 566. [Google Scholar] [CrossRef]

- Zhenyu Yang, M.; Sadeghi, M.; Petersen, T.; Zühlsdorf, B.; Madsen, K.S.; Arabkoohsar, A. Thermodynamic Analysis of a High-Temperature Heat Pump Using Low GWP Natural Working Fluids for Upgrading District Heating to Process Heating. In Proceedings of the 36th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems (ECOS 2023), Las Palmas de Gran Canaria, Spain, 25–30 June 2023; pp. 715–724. [Google Scholar] [CrossRef]

- Huang, M.; Liang, X.; Zhuang, R. Experimental investigation on the performance of a high temperature heat pump using scroll compressor. Paper P.3.3.1. In Proceedings of the 12th IEA Heat Pump Conference, Rotterdam, The Netherlands, 14–17 May 2017. [Google Scholar]

- National Renewable Energy Laboratory (NREL). High Temperature Heat Pump Model Documentation and Case Studies; NREL/TP 5700 84560; U.S. Department of Energy, National Renewable Energy Laboratory, Golden, CO, USA, 2023. Available online: https://docs.nrel.gov/docs/fy23osti/84560.pdf (accessed on 30 June 2025).

- Enertime. Very High Temperature Heat Pump and Steam Generation Heat Pump (HTHP). 2024. Available online: https://enertime.com/en/solutions/heat-pumps.html (accessed on 30 June 2025).

- SPH GmbH. High-Temperature Heat Pumps for Industry. 2024. Available online: https://spheat.de/blog-en/high-temperature-heat-pumps-for-industry?lang=en (accessed on 30 June 2025).

- Bever, P.-M.; Bless, F.; Arpagaus, C.; Bertsch, S.S. High-Temperature Heat Pumps for Industrial Use. Chem. Ing. Tech. 2024, 96, 1071–1084. [Google Scholar] [CrossRef]

- Fluorocarbons. High Temperature Heat Pumps. Available online: https://fluorocarbons.org/applications/high-temperature-heat-pumps/ (accessed on 30 June 2025).

- Lu, Z.; Gong, Y.; Yao, Y.; Luo, C.; Ma, W. Development of a high temperature heat pump system for steam generation using medium-low temperature geothermal water. Energy Procedia 2019, 158, 6046–6054. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Y.; Qin, Y.; Wang, G.; Liu, R.; Yang, Y. A Review of Super-High-Temperature Heat Pumps over 100 °C. Energies 2023, 16, 4591. [Google Scholar] [CrossRef]

- Bamigbetan, O.; Eikevik, T.M.; Nekså, P.; Bantle, M. Extending ammonia high-temperature heat pump using butane in a cascade system. In Proceedings of the 7th IIR Conference: Ammonia and CO2 Refrigeration Technologies, Ohrid, Nort Macedonia, 11–13 May 2017. [Google Scholar] [CrossRef]

- Bamigbetan, O.; Eikevik, T.M.; Nekså, P.; Bantle, M.; Banasiak, K. Extending hydrocarbon heat pumps to higher temperatures: Predictions from simulations. In Proceedings of the 30th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, San Diego, CA, USA, 2–6 July 2017. [Google Scholar]

- Dai, B.; Liu, C.; Liu, S.; Wang, D.; Wang, Q.; Zou, T.; Zhou, X. Life cycle techno-enviro-economic assessment of dual-temperature evaporation transcritical CO2 high-temperature heat pump systems for industrial waste heat recovery. Appl. Therm. Eng. 2023, 219, 119570. [Google Scholar] [CrossRef]

- Wu, D.; Hu, B.; Wang, R.Z.; Fan, H.B.; Wang, R. The performance comparison of high-temperature heat pump among R718 and other refrigerants. Renew. Energy 2020, 154, 715–722. [Google Scholar] [CrossRef]

- Chamoun, M.; Rulliere, R.; Haberschill, P.; Peureux, J.-L. Experimental investigation of a new high-temperature heat pump using water as refrigerant for industrial heat recovery. In Proceedings of the International Refrigeration and Air Conditioning Conference, Purdue University, West Lafayette, IN, USA, 18–21 July 2012. Paper No. 1165. [Google Scholar]

- Li, X.; Zhang, Y.; Ma, X.; Deng, N.; Jin, Z.; Yu, X.; Li, W. Performance analysis of high-temperature water-source cascade heat pump using BY3B/BY6 as refrigerants. Appl. Therm. Eng. 2019, 159, 113895. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Yu, X.; Guo, J.; Deng, N.; Dong, S.; Ma, X. Analysis of a high-temperature heat pump using BY-5 as refrigerant. Appl. Therm. Eng. 2017, 127, 1461–1468. [Google Scholar] [CrossRef]

- Yu, X.-H.; Zhang, Y.-F.; Zhang, Y.; He, Z.-L.; Dong, S.-M.; Ma, X.-L.; Yao, S. Intelligent prediction on performance of high-temperature heat pump systems using different refrigerants. J. Cent. South Univ. 2018, 25, 2754–2765. [Google Scholar] [CrossRef]

- Yu, X.; Yufeng, Z.; Na, D.; Chengmin, C.; Yan, Z. Experimental performance of high-temperature heat pump with near-azeotropic refrigerant mixture. Energy Build. 2014, 78, 43–49. [Google Scholar] [CrossRef]

- Deng, N.; Jing, X.; Cai, R.; Gao, J.; Shen, C.; Zhang, Y.; Sui, H. Molecular simulation and experimental investigation for thermodynamic properties of new refrigerant NBY-1 for high-temperature heat pump. Energy Convers. Manag. 2019, 179, 339–348. [Google Scholar] [CrossRef]

- Wu, D.; Jiang, J.; Hu, B.; Wang, R.Z. Experimental investigation on the performance of a very high temperature heat pump with water refrigerant. Energy 2020, 190, 116427. [Google Scholar] [CrossRef]

- Kimura, T.; Fuchikami, H.; Nishida, K.; Kudo, M.; Machida, A.; Saito, K.; Ohta, Y.; Katsuta, M. Development of a high-temperature heat pump using reusable heat as the heat source. In Proceedings of the JRAIA International Symposium 2018, Kobe, Japan, 6 December 2018. [Google Scholar]

- Suemitsu, R.; Sakai, M.; Togano, Y.; Kobayashi, N.; Yuki, H.; Wajima, K.; Ueda, K. Research and development for 200 °C compressed-water heat pump using exhaust heat with low GWP refrigerant for industrial use. In Proceedings of the 13th IEA Heat Pump Conference, Jeju, Korea, 26–29 April 2021. Paper No. 163. [Google Scholar]

- Kaida, T.; Sakuraba, I.; Hashimoto, K.; Hasegawa, H. Experimental performance evaluation of heat pump-based steam supply system. In Proceedings of the IOP Conference Series: Materials Science and Engineering, 9th International Conference on Compressors and Their Systems, London, UK, 7–9 September 2015; Volume 90, p. 012076. [Google Scholar] [CrossRef]

- Linuo Ritter. Cascade Air-Source High-Temp Heat Pump Water Heater. Available online: https://linuo-ritter.com/Cascade-Air-Source-High-Temp-Heat-Pump-Water-Heater-pd40742850.html (accessed on 30 June 2025).

- Gómez-Hernández, J.; Grimes, R.; Briongos, J.V.; Marugán-Cruz, C.; Santana, D. Carbon dioxide and acetone mixtures as refrigerants for industry heat pumps to supply temperature in the range 150–220 °C. Energy 2023, 269, 126821. [Google Scholar] [CrossRef]

- White, S.D.; Yarrall, M.G.; Cleland, D.J.; Hedley, R.A. Modelling the performance of a transcritical CO2 heat pump for high-temperature heating. Int. J. Refrig. 2002, 25, 479–486. [Google Scholar] [CrossRef]

- Pan, L.; Wang, H.; Chen, Q.; Chen, C. Theoretical and experimental study on several refrigerants of moderately high-temperature heat pump. Appl. Therm. Eng. 2011, 31, 1886–1893. [Google Scholar] [CrossRef]

- Reissner, F.; Gromoll, B.; Danov, V.; Schaefer, J.; Karl, J. Basic development of a novel high-temperature heat pump system using low GWP working fluids. In Proceedings of the 11th IEA Heat Pump Conference, Montréal, QC, Canada, 12–16 May 2014. Paper, O.2.3.4. [Google Scholar]

- Bamigbetan, O.; Eikevik, T.M.; Nekså, P.; Bantle, M.; Schlemminger, C. Theoretical analysis of suitable fluids for high-temperature heat pumps up to 125 °C heat delivery. Int. J. Refrig. 2018, 92, 185–195. [Google Scholar] [CrossRef]

- Arpagaus, C.; Bless, F.; Uhlmann, M.; Büchel, E.; Frei, S.; Schiffmann, J.; Bertsch, S. High-temperature heat pump using HFO and HCFO refrigerants—System design, simulation, and first experimental results. In Proceedings of the International Refrigeration and Air Conditioning Conference, Purdue University, West Lafayette, IN, USA, 11–14 July 2018. Paper No. 1875. [Google Scholar]

- Bellemo, L.; Gerritsen, J.; Hoffmann, K. High-temperature CO2 heat pump integration into the spray drying process. In Proceedings of the 2nd Conference on High Temperature Heat Pumps, Copenhagen, Denmark, 5–6 March 2019; pp. 158–160. [Google Scholar]

- Abi Chahla, G.; Beucher, Y.; Zoughaib, A.; De Carlan, F.; Pierucci, J. Transcritical industrial heat pump using HFOs for up to 150 °C hot air supply. In Proceedings of the 25th IIR International Congress of Refrigeration (ICR 2019), Montréal, QC, Canada, 24–30 August 2019. Paper ID 1184. [Google Scholar] [CrossRef]

- Bamigbetan, O.; Eikevik, T.M.; Nekså, P.; Bantle, M.; Schlemminger, C. The development of a hydrocarbon high-temperature heat pump for waste heat recovery. Energy 2019, 173, 1141–1153. [Google Scholar] [CrossRef]

- Bamigbetan, O.; Eikevik, T.M.; Nekså, P.; Bantle, M.; Schlemminger, C. Experimental investigation of a prototype R-600 compressor for high-temperature heat pump. Energy 2019, 169, 730–738. [Google Scholar] [CrossRef]

- Verdnik, M.; Rieberer, R. Experimental analysis of a R600 high-temperature heat pump in sub-critical and trans-critical operation. In Proceedings of the 14th IIR Gustav-Lorentzen Conference on Natural Refrigerants (GL 2020), Kyoto, Japan, 7–9 December 2020; pp. 500–505. [Google Scholar] [CrossRef]

- Verdnik, M.; Rieberer, R. Influence of operating parameters on the COP of an R600 high-temperature heat pump. Int. J. Refrig. 2022, 140, 103–111. [Google Scholar] [CrossRef]

- Wilk, V.; Helminger, F.; Lauermann, M.; Windholz, B. High-temperature heat pumps for drying—first results of operation in industrial environment. In Proceedings of the 13th IEA Heat Pump Conference 2020, Jeju, Republic of Korea, 26–29 April 2021. Paper No. 075. [Google Scholar]

- Dusek, S.; Lauermann, M.; Helminger, F.; Wilk, V. Analysis of a steam-generating high-temperature heat pump for industrial waste heat recovery. In Proceedings of the 13th IEA Heat Pump Conference, Jeju, Republic of Korea, 26–29 April 2021. Paper No. 097. [Google Scholar]

- Marina, A.; Smeding, S.F.; Wemmers, A.K.; Spoelstra, S.; Kremers, P. Design and experimental results of a two-stage steam producing industrial heat pump. In Proceedings of the 13th IEA Heat Pump Conference, Jeju, Republic of Korea, 26–29 April 2021. Paper No. 156. [Google Scholar]

- Arpagaus, C.; Bertsch, S. Experimental comparison of HCFO and HFO R1224yd(Z), R1233zd(E), R1336mzz(Z), and HFC R245fa in a high-temperature heat pump up to 150 °C supply temperature. In Proceedings of the International Refrigeration and Air Conditioning Conference, Purdue University, West Lafayette, IN, USA, 11–14 July 2021. Paper No. 2200. [Google Scholar]

- Tveit, T.M.; Johansson, M.; Zevenhoven, R. Environmentally friendly steam generation using VHTHPs at a pharmaceutical research facility. In Proceedings of the 13th IEA Heat Pump Conference, Jeju, Republic of Korea, 26–29 April 2021. Paper No. 004. [Google Scholar]

- Ramirez, M.; Trebilcock, F.; Peña, X.; Martinez-Urrutia, A.; Hassan, A.H. Development and lab-scale performance evaluation of a high-temperature heat pump for integration into a Power-to-Heat-to-Power system. In Proceedings of the 13th IEA Heat Pump Conference, Jeju, Republic of Korea, 26–29 April 2021. Paper No. 103. [Google Scholar]

- Bobelin, D.; Bourig, A. Experimental results of a newly developed very high temperature industrial heat pump (140 °C) equipped with scroll compressors and working with a new blend refrigerant. In Proceedings of the International Refrigeration and Air Conditioning Conference, Purdue University, West Lafayette, IN, USA, 10–14 July 2012. Paper No. 1299. [Google Scholar]

- Koundinya, S.; Seshadri, S. Energy, exergy, environmental, and economic (4E) analysis and selection of best refrigerant using TOPSIS method for industrial heat pumps. Therm. Sci. Eng. Prog. 2022, 36, 101491. [Google Scholar] [CrossRef]

- Mateu-Royo, C.; Navarro-Esbrí, J.; Mota-Babiloni, A.; Molés, F.; Amat-Albuixech, M. Experimental exergy and energy analysis of a novel high-temperature heat pump with scroll compressor for waste heat recovery. Appl. Energy 2019, 253, 113504. [Google Scholar] [CrossRef]

- Xu, C.; Yang, H.; Yu, X.; Ma, H.; Chen, M.; Yang, M. Performance analysis for binary mixtures based on R245fa using in high-temperature heat pumps. Energy Convers. Manag. X 2021, 12, 100123. [Google Scholar] [CrossRef]

- Zühlsdorf, B.; Bühler, F.; Bantle, M.; Elmegaard, B. Analysis of technologies and potentials for heat pump-based process heat supply above 150 °C. Energy Convers. Manag. X 2019, 2, 100011. [Google Scholar] [CrossRef]

- Zühlsdorf, B. Annex 58 High-Temperature Heat Pumps. Task 1—Technologies, Task Report; IEA Heat Pump Centre: Borås, Sweden, 2023. [Google Scholar]

- Pintoro, A. Performance analysis of low-temperature heat source of organic Rankine cycle for geothermal application. IOP Conf. Ser. Mater. Sci. Eng. 2018, 308, 012026. [Google Scholar] [CrossRef]

- Boydak, Ö.; Ekmekçi, I.; Yılmaz, M.; Köten, H. Thermodynamic investigation of organic Rankine cycle energy recovery system and recent studies. Therm. Sci. 2018, 22, 2679–2690. [Google Scholar] [CrossRef]

- Lin, C.-H.; Hsu, P.-P.; He, Y.-L.; Shuai, Y.; Hung, T.-C.; Feng, Y.-Q.; Chang, Y.-H. Investigations on experimental performance and system behavior of 10 kW organic Rankine cycle using scroll-type expander for low-grade heat source. Energy 2019, 177, 94–105. [Google Scholar] [CrossRef]

- Prasetyo, T.; Surindra, M.D.; Caesarendra, W.; Taufik; Glowacz, A.; Irfan, M.; Glowacz, W. Influence of superheated vapour in organic Rankine cycles with working fluid R123 utilizing low-temperature geothermal resources. Symmetry 2020, 12, 1463. [Google Scholar] [CrossRef]

- Abbas, W.K.; Linnemann, M.; Baumhögger, E.; Vrabec, J. Experimental Study of Two Cascaded Organic Rankine Cycles with Varying Working Fluids. Energy Convers. Manag. 2021, 230, 113818. [Google Scholar] [CrossRef]

- Tumen Ozdil, N.F.; Segmen, M.R. Investigation of the effect of the water phase in the evaporator inlet on economic performance for an Organic Rankine Cycle (ORC) based on industrial data. Appl. Therm. Eng. 2016, 100, 1042–1051. [Google Scholar] [CrossRef]

- Surindra, M.D.; Caesarendra, W.; Prasetyo, T.; Mahlia, T.M.I.; Taufik. Comparison of the Utilization of 110 °C and 120 °C Heat Sources in a Geothermal Energy System Using Organic Rankine Cycle (ORC) with R245fa, R123, and Mixed-Ratio Fluids as Working Fluids. Processes 2019, 7, 113. [Google Scholar] [CrossRef]

- Özkaraca, O.; Keçebaş, P.; Demircan, C.; Keçebaş, A. Thermodynamic Optimization of a Geothermal-Based Organic Rankine Cycle System Using an Artificial Bee Colony Algorithm. Energies 2017, 10, 1691. [Google Scholar] [CrossRef]

- Unverdi, M.; Cerci, Y. Thermodynamic analysis and performance improvement of Irem geothermal power plant in Turkey: A case study of Organic Rankine cycle. Energy Prog. Sustain. Energy 2018, 37, 1523–1539. [Google Scholar] [CrossRef]

- Landelle, A.; Tauveron, N.; Haberschill, P.; Revellin, R.; Colasson, S. Performance Evaluation and Comparison of Experimental Organic Rankine Cycle Prototypes from Published Data. Energy Procedia 2017, 105, 1706–1711. [Google Scholar] [CrossRef]

- Algieri, A.; Šebo, J. Energetic Investigation of Organic Rankine Cycles (ORCs) for the Exploitation of Low-Temperature Geothermal Sources—A possible application in Slovakia. Procedia Comput. Sci. 2017, 109, 833–840. [Google Scholar] [CrossRef]

- Canbolat, A.S.; Bademlioglu, A.H.; Kaynakli, O. A modelling of electricity generation by using geothermal-assisted Organic Rankine Cycle with internal heat recovery. Energy Sources Part A Recover. Util. Environ. Eff. 2019, 41, 212–228. [Google Scholar] [CrossRef]

- Zhang, C.; Fu, J.; Yuan, P.; Liu, J. Guidelines for Optimal Selection of Subcritical Low-Temperature Geothermal Organic Rankine Cycle Configuration Considering Reinjection Temperature Limits. Energies 2018, 11, 2878. [Google Scholar] [CrossRef]

- Uusitalo, A.; Honkatukia, J.; Turunen-Saaresti, T.; Grönman, A. Thermodynamic evaluation on the effect of working fluid type and fluids critical properties on design and performance of Organic Rankine Cycles. J. Clean. Prod. 2018, 188, 253–263. [Google Scholar] [CrossRef]

- Ali, M.A.; Khan, T.S.; Al Hajri, E.; Ayub, Z.H. A Computer Program for Working Fluid Selection of Low-Temperature Organic Rankine Cycle. In Proceedings of the ASME 2015 Power Conference (POWER 2015), San Diego, CA, USA, 28 June 2015. [Google Scholar] [CrossRef]

- Pezzuolo, A.; Benato, A.; Stoppato, A.; Mirandola, A. The ORC-PD: A versatile tool for fluid selection and Organic Rankine Cycle unit design. Energy 2016, 102, 605–620. [Google Scholar] [CrossRef]

- Agromayor, R.; Nord, L.O. Fluid Selection and Thermodynamic Optimization of Organic Rankine Cycles for Waste Heat Recovery Applications. Energy Procedia 2017, 129, 527–534. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, J.; Chen, S.; Pu, Y. Analysis of organic Rankine cycles using zeotropic mixtures as working fluids under different restrictive conditions. Energy Convers. Manag. 2016, 126, 704–715. [Google Scholar] [CrossRef]

- Imran, M.; Usman, M.; Park, B.-S.; Yang, Y. Comparative assessment of Organic Rankine Cycle integration for low temperature geothermal heat source applications. Energy 2016, 102, 473–490. [Google Scholar] [CrossRef]

- Wang, Y.Z.; Zhao, J.; Wang, Y.; An, Q.S. Multi-objective optimization and grey relational analysis on configurations of Organic Rankine Cycle. Appl. Therm. Eng. 2017, 114, 1355–1363. [Google Scholar] [CrossRef]

- Li, G. Organic Rankine cycle performance evaluation and thermoeconomic assessment with various applications part I: Energy and exergy performance evaluation. Renew. Sustain. Energy Rev. 2016, 53, 477–499. [Google Scholar] [CrossRef]

- Yang, M.-H.; Yeh, R.-H. Economic performances optimization of an organic Rankine cycle system with lower global warming potential working fluids in geothermal application. Renew. Sustain. Energy Rev. 2016, 85, 1201–1213. [Google Scholar] [CrossRef]

- Liu, C.; Gao, T.; Zhu, J.; Xu, J. Performance Optimization and Economic Analysis of Geothermal Power Generation by Subcritical and Supercritical Organic Rankine Cycles. In Proceedings of the ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition (GT 2016), Seoul, Republic of Korea, 13–17 June 2016. ASME Turbo Expo 2016: GT2016 56821. [Google Scholar] [CrossRef]

- Manente, G.; Da Lio, L.; Lazzaretto, A. Influence of axial turbine efficiency maps on the performance of subcritical and supercritical Organic Rankine Cycle systems. Energy 2016, 107, 761–772. [Google Scholar] [CrossRef]

- Moloney, F.; Almatrafi, E.; Goswami, D.Y. Working fluid parametric analysis for recuperative supercritical organic Rankine cycles for medium geothermal reservoir temperatures. Renew. Sustain. Energy Rev. 2020, 147, 2874–2881. [Google Scholar] [CrossRef]

- Lukawski, M.Z.; Tester, J.W.; DiPippo, R. Impact of molecular structure of working fluids on performance of organic Rankine cycles (ORCs). Sustain. Energy Fuels 2017, 1, 1098–1111. [Google Scholar] [CrossRef]

- Cakici, D.M.; Erdogan, A.; Colpan, C.O. Thermodynamic performance assessment of an integrated geothermal-powered supercritical regenerative Organic Rankine Cycle and parabolic trough solar collectors. Energy 2017, 120, 306–319. [Google Scholar] [CrossRef]

- Sun, Q.; Wang, Y.; Cheng, Z.; Wang, J.; Zhao, P.; Dai, Y. Thermodynamic optimization of a double-pressure organic Rankine cycle driven by geothermal heat source. Energy Procedia 2017, 129, 591–598. [Google Scholar] [CrossRef]

- Sun, Q.; Wang, Y.; Cheng, Z.; Wang, J.; Zhao, P.; Dai, Y. Thermodynamic and economic optimization of a double-pressure organic Rankine cycle driven by low-temperature heat source. Renew. Sustain. Energy Rev. 2020, 147, 2822–2832. [Google Scholar] [CrossRef]

- Manente, G.; Lazzaretto, A.; Bonamico, E. Design guidelines for the choice between single and dual pressure layouts in organic Rankine cycle (ORC) systems. Energy 2017, 123, 413–431. [Google Scholar] [CrossRef]

- Wang, S. Thermo-economic Evaluations of Dual Pressure Organic Rankine Cycle (DPORC) Driven by Geothermal Heat Source. J. Renew. Sustain. Energy 2018, 10, 063901. [Google Scholar] [CrossRef]

- Fontalvo, A.; Solano, J.; Pedraza, C.; Bula, A.; Gonzalez Quiroga, A.; Vasquez Padilla, R. Energy, Exergy and Economic Evaluation Comparison of Small-Scale Single and Dual Pressure Organic Rankine Cycles Integrated with Low-Grade Heat Sources. Entropy 2017, 19, 476. [Google Scholar] [CrossRef]

- Braimakis, K.; Karellas, S. Energetic Optimization of Regenerative Organic Rankine Cycle (ORC) Configurations. Energy Convers. Manag. 2018, 159, 353–370. [Google Scholar] [CrossRef]

- Braimakis, K.; Karellas, S. Exergetic optimization of double stage Organic Rankine Cycle (ORC) for waste heat recovery. Energy 2018, 149, 296–313. [Google Scholar] [CrossRef]

- Liu, G.; Wang, Q.; Xu, J.; Miao, Z. Exergy Analysis of Two-Stage Organic Rankine Cycle Power Generation System. Entropy 2021, 23, 43. [Google Scholar] [CrossRef]

- Li, T.; Yuan, Z.; Li, W.; Yang, J.; Zhu, J. Strengthening mechanisms of two-stage evaporation strategy on system performance for Organic Rankine Cycle. Energy 2016, 101, 532–540. [Google Scholar] [CrossRef]

- Li, T.; Yuan, Z.; Xu, P.; Zhu, J. Entransy dissipation/loss-based optimization of two-stage organic Rankine cycle (TSORC) with R245fa for geothermal power generation. Sci. China Technol. Sci. 2016, 59, 1524–1536. [Google Scholar] [CrossRef]

- Li, J.; Ge, Z.; Duan, Y.; Yang, Z.; Liu, Q. Parametric optimization and thermodynamic performance comparison of single-pressure and dual-pressure evaporation organic Rankine cycles. Appl. Energy 2018, 217, 409–421. [Google Scholar] [CrossRef]

- Wang, M.; Chen, Y.; Liu, Q.; Zhao, Y. Thermodynamic and thermo-economic analysis of dual-pressure and single-pressure evaporation organic Rankine cycles. Energy Convers. Manag. 2018, 177, 718–736. [Google Scholar] [CrossRef]

- Kazemi, N.; Samadi, F. Thermodynamic, economic and thermo-economic optimization of a new proposed organic Rankine cycle for energy production from geothermal resources. Energy Convers. Manag. 2016, 121, 391–401. [Google Scholar] [CrossRef]

- Samadi, F.; Kazemi, N. Exergoeconomic analysis of zeotropic mixture on the new proposed Organic Rankine cycle for energy production from geothermal resources. Renew. Sustain. Energy Rev. 2020, 152, 1250–1265. [Google Scholar] [CrossRef]

- Luo, X.; Huang, R.; Yang, Z.; Chen, J.; Chen, Y. Performance investigation of a novel zeotropic organic Rankine cycle coupling liquid separation condensation and multi-pressure evaporation. Energy Convers. Manag. 2018, 161, 112–127. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, S.; Sun, L.; Zhao, S.; Ashraf Talesh, S.S. Optimization and thermodynamic performance analysis of a power generation system based on geothermal flash and dual-pressure evaporation organic Rankine cycles using zeotropic mixtures. Energy 2020, 194, 116785. [Google Scholar] [CrossRef]

- Surendran, A.; Seshadri, S. Design and performance analysis of a novel Transcritical Regenerative Series Two-stage Organic Rankine Cycle for dual-source waste heat recovery. Energy 2020, 203, 117800. [Google Scholar] [CrossRef]

- Sadeghi, A.; Shokati, A.; Mohammadi-ivatloo, B. Thermodynamic Analysis and Multi-Objective Optimization of Various ORC (Organic Rankine Cycle) Configurations Using Zeotropic Mixtures. Energy 2016, 109, 791–805. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, J.; Li, T.; Meng, N. Techno-economic performance of two-stage series evaporation Organic Rankine cycle with dual-level heat sources. Appl. Therm. Eng. 2020, 171, 115078. [Google Scholar] [CrossRef]

- Xu, B.; Rathod, D.; Yebi, A.; Filipi, Z.; Onori, S.; Hoffman, M. A comprehensive review of organic Rankine cycle waste heat recovery systems in heavy-duty diesel engine applications. Renew. Sustain. Energy Rev. 2019, 107, 145–170. [Google Scholar] [CrossRef]

- Falciai, A. The New Industrial Age Tailored Electrification Pathways for Europe’s Industrial Competitiveness. Power Summit 2025 Report; Eurelectric: Brussels, Belgium, 2025; Available online: http://powersummit2025.eurelectric.org/wp-content/uploads/2025/06/Industrial-electrification-competitiveness.pdf (accessed on 1 July 2025).

- Cleantech Reality Check: Electrification—The Electrification Mirage for Europe? Breakthrough Energy; Cleantech for Europe; Systemiq. December 2024. Available online: http://Breakthroughenergy.org/wp-content/uploads/2024/12/EIH_CleantechReality_Serie2-compressed_2.pdf (accessed on 1 July 2025).

- Naegler, T.; Simon, S.; Klein, M.; Gils, H.C. Quantification of the European industrial heat demand by branch and temperature level. Int. J. Energy Res. 2015, 39, 2019–2030. [Google Scholar] [CrossRef]

- Papapetrou, M.; Kosmadakis, G.; Cipollina, A.; La Commare, U.; Micale, G. Industrial waste heat: Estimation of the technically available resource in the EU per industrial sector, temperature level and country. Appl. Therm. Eng. 2018, 138, 207–216. [Google Scholar] [CrossRef]

- Tannous, H.; Stojceska, V.; Tassou, S.A. The Use of Solar Thermal Heating in SPIRE and Non-SPIRE Industrial Processes. Sustainability 2023, 15, 7807. [Google Scholar] [CrossRef]

- Heat Roadmap Europe: Combined Heat and Power and District Heating—A Vision Towards 2020 and Beyond. Heat Roadmap Europe, February 2019. Available online: http://heatroadmap.eu/wp-content/uploads/2019/02/HRE_Final-Brochure_web.pdf (accessed on 1 July 2025).

- Directorate General for Energy. Mapping and Analyses of the Current and Future (2020–2030) Heating/Cooling Fuel Deployment (Fossil/Renewables): Executive Summary. European Commission, 10 September 2016. Available online: http://energy.ec.europa.eu/document/download/3418e3a4-5e11-45d3-aac2-059b279bfda3_en?filename=mapping-hc-excecutivesummary.pdf (accessed on 1 July 2025).

- Kim, S.T.; Hegner, R.; Özuylasi, G.; Stathopoulos, P.; Nicke, E. Performance analysis of multistage high-temperature heat pump cycle. Energy Sci. Eng. 2023, 11, 3500–3511. [Google Scholar] [CrossRef]

- Agathokleous, R.; Bianchi, G.; Panayiotou, G.; Aresti, L.; Argyrou, M.C.; Georgiou, G.S.; Tassou, S.A.; Jouhara, H.; Kalogirou, S.A.; Florides, G.A.; et al. Waste Heat Recovery in the EU Industry and Proposed New Technologies. Energy Procedia 2019, 161, 489–496. [Google Scholar] [CrossRef]

- Ates, F.; Ozcan, H. Turkey’s industrial waste heat recovery potential with power and hydrogen conversion technologies: A techno-economic analysis. Int. J. Hydrogen Energy 2020, 47, 7421–7438. [Google Scholar] [CrossRef]

- Brunke, J.C.; Johansson, M.; Thollander, P. Empirical investigation of barriers and drivers to the adoption of energy conservation measures, energy management practices and energy services in the Swedish iron and steel industry. J. Clean. Prod. 2014, 84, 509–525. [Google Scholar] [CrossRef]

- Hochschule Osnabrück; Kompetenzzentrum Energie; Landkreis Osnabrück. ReWIn—Regionales Wärmekataster Industrie. Projektlaufzeit November 2013–April 2014; Hochschule Osnabrück: Osnabrück, Germany, 2014. Available online: http://kompetenzzentrum-energie.de/fileadmin/HSOS/Homepages/Kompetenzzentrum-Energie/ZBH/PDf/ReWIn__2014.pdf (accessed on 1 July 2025).

- Investigation Report on Industrial Waste Heat. NEDO (New Energy and Industrial Technology Development Organization), Japan, March 2019. Available online: https://www.nedo.go.jp/content/100957934.pdf (accessed on 1 July 2025).

- Aydemir, A.; Doderer, H.; Hoppe, F.; Braungardt, S.; Fraunhofer Institut für System und Innovationsforschung ISI. Abwärmenutzung in Unternehmen; Fraunhofer ISI: Karlsruhe, Germany, 2021; Available online: https://www.isi.fraunhofer.de/content/dam/isi/dokumente/ccx/2021/Abwärmenutzung_in_Unternehmen.pdf (accessed on 1 July 2025).

- Bestimmung der Abwärmepotenziale in Berlin: Schlussbericht (Determination of Waste Heat Potentials in Berlin: Final Report). Institute for Ecological Economy Research (IÖW) & ifeu—Institut für Energie- und Umweltforschung Heidelberg, Germany, September 2022. Available online: http://Ioew.de/fileadmin/user_upload/IOEW_ifeu_Bestimmung_der_Abwaermepotenziale_in_Berlin_Schlussbericht.pdf (accessed on 1 July 2025).

- Fernández, A.G.; Soler, D.; Miró, L.; Labidi, J.; Cabeza, L.F. Industrial waste heat estimation for the manufacturing industry in Chile. Int. J. Environ. Sci. Technol. 2024, 21, 4331–4342. [Google Scholar] [CrossRef]

- U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy. Waste Heat Recovery Systems. In Quadrennial Technology Review 2015; Chapter 6M (Technology Assessment); U.S. DOE: Washington, DC, USA, 2016. Available online: http://energy.gov/sites/prod/files/2016/02/f30/QTR2015-6M-Waste-Heat-Recovery.pdf (accessed on 1 July 2025).

- Lyons, L.; Kavvadias, K.; Carlsson, J. Defining and Accounting for Waste Heat and Cold; EUR 30869 EN; Publications Office of the European Union: Luxembourg, 2021; ISBN 978-92-76-42588-5. ISSN 1831-9424. [Google Scholar] [CrossRef]

- Hydrogen Council; McKinsey & Company. Hydrogen for Net Zero; Hydrogen Council: Brussels, Belgium, 2021; Available online: http://hydrogencouncil.com/wp-content/uploads/2021/11/Hydrogen-for-Net-Zero.pdf (accessed on 1 July 2025).

- European Commission. Net-Zero Industry Act Explained. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal/green-deal-industrial-plan/net-zero-industry-act_en (accessed on 1 July 2025).

- Northern Gas Networks. East Coast Hydrogen Feasibility Report; Northern Gas Networks: Sunderland, UK, 2021; Available online: https://cadentgas.com/nggdwsdev/media/FRoG/ResourcesHub/East-Coast-Hydrogen-Feasibility-Report_online.pdf (accessed on 1 July 2025).

- International Energy Agency (IEA). Global Hydrogen Review 2023; IEA: Paris, France, 2023; Available online: https://iea.org/reports/global-hydrogen-review-2023 (accessed on 1 July 2025).

- Erbach, G.; Svensson, S. EU Rules for Renewable Hydrogen; European Parliamentary Research Service (EPRS), PE 747.085: Brussels, Belgium, 2023; Available online: https://europarl.europa.eu/RegData/etudes/BRIE/2023/747085/EPRS_BRI(2023)747085_EN.pdf (accessed on 1 July 2025).

- Goldman Sachs Research. Carbonomics: The Clean Hydrogen Revolution; Goldman Sachs: New York, NY, USA, 2022; Available online: https://www.goldmansachs.com/intelligence/pages/carbonomics-the-clean-hydrogen-revolution.html (accessed on 1 July 2025).

- DNV. Hydrogen Forecast to 2050: Energy Transition Outlook 2022; DNV: Høvik, Norway, 2022; Available online: https://www.dnv.com/focus-areas/hydrogen/forecast-to-2050/ (accessed on 1 July 2025).

- European Commission. European Hydrogen Bank: Results of the First Auction Announced. Press Release, 30 April 2024. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_24_2333 (accessed on 1 July 2025).

- Fraunhofer IS. Direct Electrification of Industrial Process Heat: An Assessment of Technologies, Potentials and Future Prospects for the EU. Study on Behalf of Agora Industry, 2024. Available online: https://www.agora-industry.org/fileadmin/Projects/2023/2023-20_IND_Electrification_Industrial_Heat/A-IND_329_04_Electrification_Industrial_Heat_WEB.pdf (accessed on 1 July 2025).

- Deloitte and Renewable Thermal Collaborative. Assessment of Green Hydrogen for Industrial Heat. 2023. Available online: https://deloitte.com/content/dam/Deloitte/us/Documents/Advisory/us-advisory-assessment-of-green-hydrogen-for-industrial-heat.pdf (accessed on 21 July 2025).

| Parameter [Unit] | Value | Reference |

|---|---|---|

| Electric heater efficiency [%] | 85–95 | - |

| Burner efficiency [%] | 45–80 | [29,30] |

| ORC efficiency | Refer to Section 3.5 | - |

| Electrolysis efficiency | Refer to Section 3.3 | - |

| Electrolysis WH [%] | 13.2 to 25.3 | [13] |

| H2 LHV [kWh/kg] | 33.3 | [19] |

| H2 HHV [kWh/kg] | 39.4 | [19] |

| Technology | CAPEX [EUR/kW] | FOM |

|---|---|---|

| Decentralised electrolysis | 1837, 1548, 928 (year of 2025, 2030 and 2050) [31] | 1.5–3% of CAPEX [31] |

| boiler | 114, 124, 124 (year of 2025, 2030, 2050) [31] | |

| HTHP | 465 [32,33] | |

| ORC | 2122 [34], 1800–2500 [35], 2136 [36], 1630 [37] ~6% cost drop by 2030 [38] | |

| Electric boiler/heater | 110, 100, 95, 90 (year of 2025, 2030, 2040, 2050) [31] | 1.1 EUR/kW [31] |

| Item | Value |

|---|---|

| Power cost (3-year average from 2022 to 2024 EU27 + UK) | Current: 10.99 EUR/MWh excluding taxes and levies, and VAT [39] 23% reduction in 2030 [40] |

| Hydrogen price | 6.6 [41] ~3 EUR/kg in year 2035 [41,42,43] |

| Currency exchange rate (per EUR) | USD/EUR 0.933 | GBP/EUR 1.168 [44] |

| EU-average discount rate | 7% [45] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niknam, P.H. Low-Carbon Industrial Heating in the EU and UK: Integrating Waste Heat Recovery, High-Temperature Heat Pumps, and Hydrogen Technologies. Energies 2025, 18, 4313. https://doi.org/10.3390/en18164313

Niknam PH. Low-Carbon Industrial Heating in the EU and UK: Integrating Waste Heat Recovery, High-Temperature Heat Pumps, and Hydrogen Technologies. Energies. 2025; 18(16):4313. https://doi.org/10.3390/en18164313

Chicago/Turabian StyleNiknam, Pouriya H. 2025. "Low-Carbon Industrial Heating in the EU and UK: Integrating Waste Heat Recovery, High-Temperature Heat Pumps, and Hydrogen Technologies" Energies 18, no. 16: 4313. https://doi.org/10.3390/en18164313

APA StyleNiknam, P. H. (2025). Low-Carbon Industrial Heating in the EU and UK: Integrating Waste Heat Recovery, High-Temperature Heat Pumps, and Hydrogen Technologies. Energies, 18(16), 4313. https://doi.org/10.3390/en18164313