Numerical Investigation of Clocking Effects on the Hydraulic Performance of Pump–Turbine in Pump Mode

Abstract

1. Introduction

2. Methodology

2.1. Local Hydraulic Loss Rate Theory

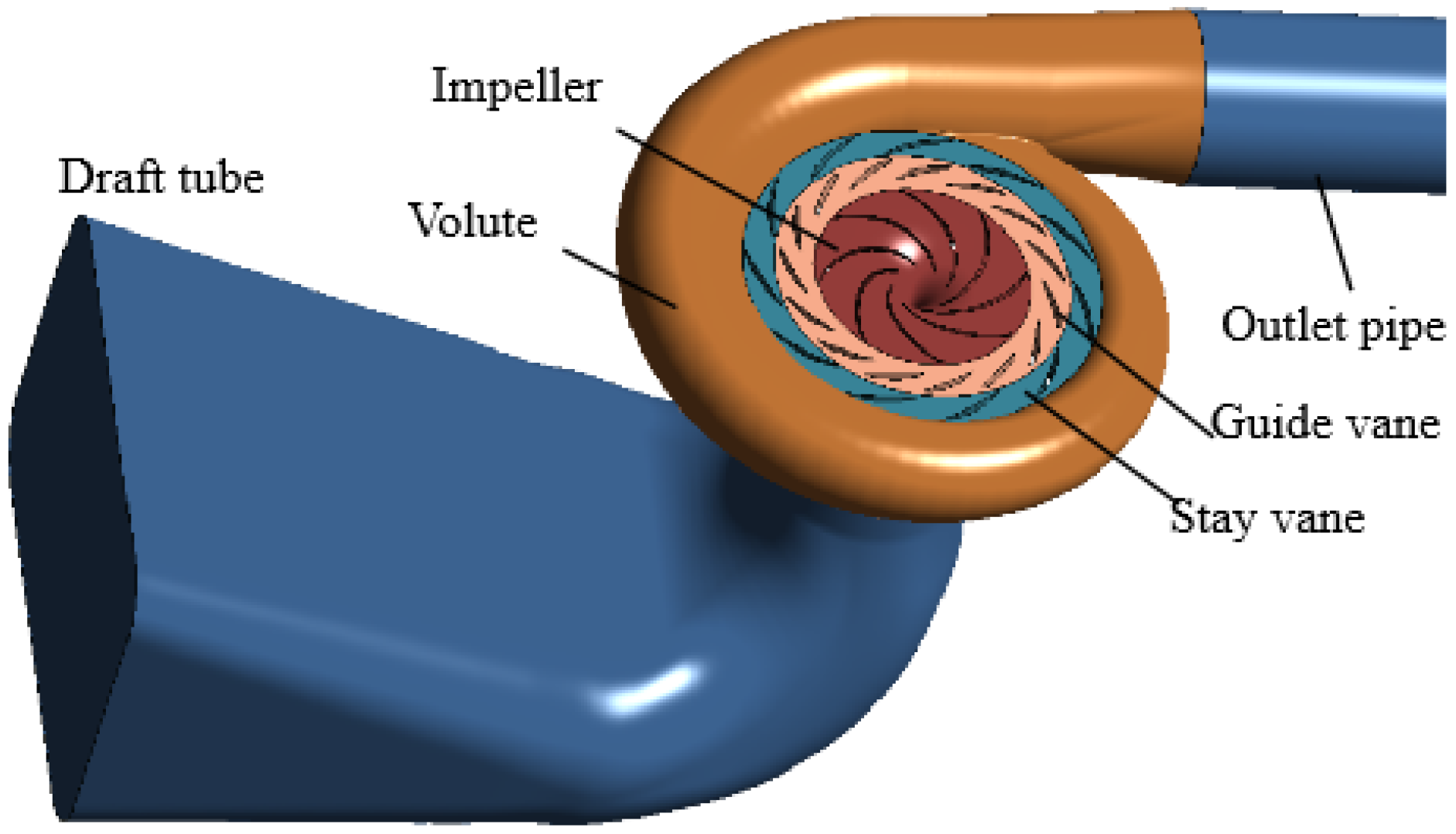

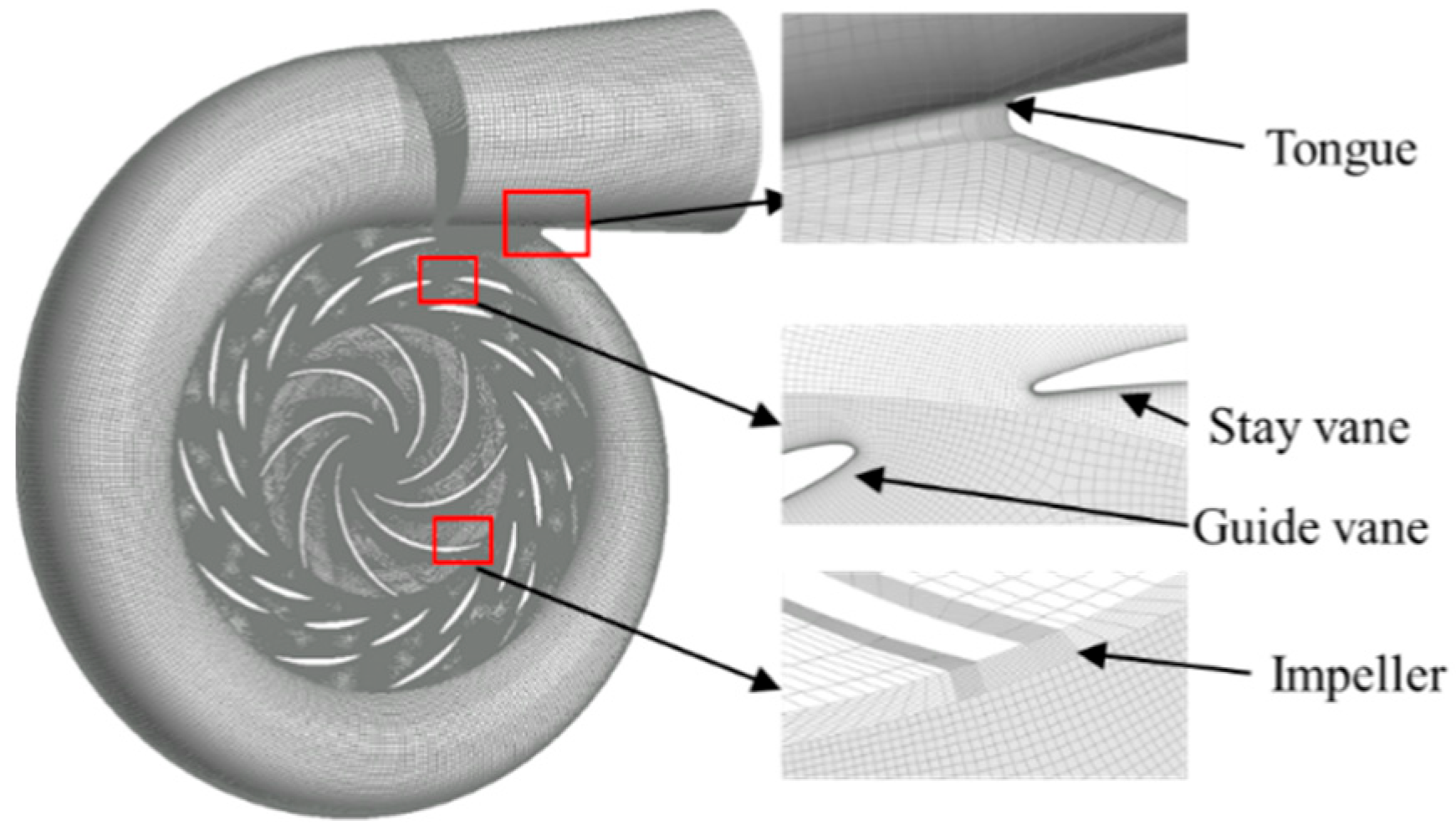

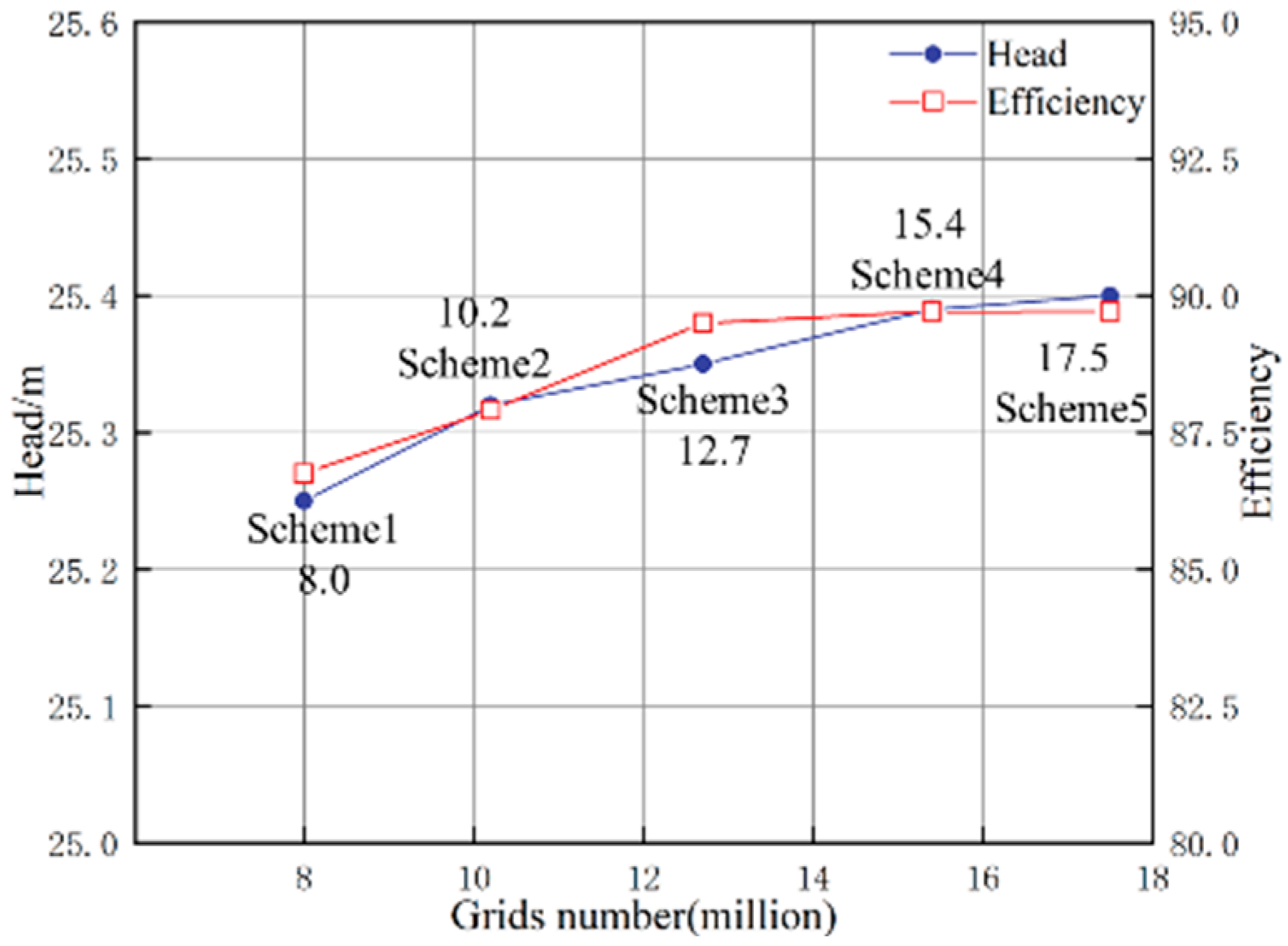

2.2. Model and Grid

2.3. Design Schemes and Experiment Verification

3. Result and Discussion

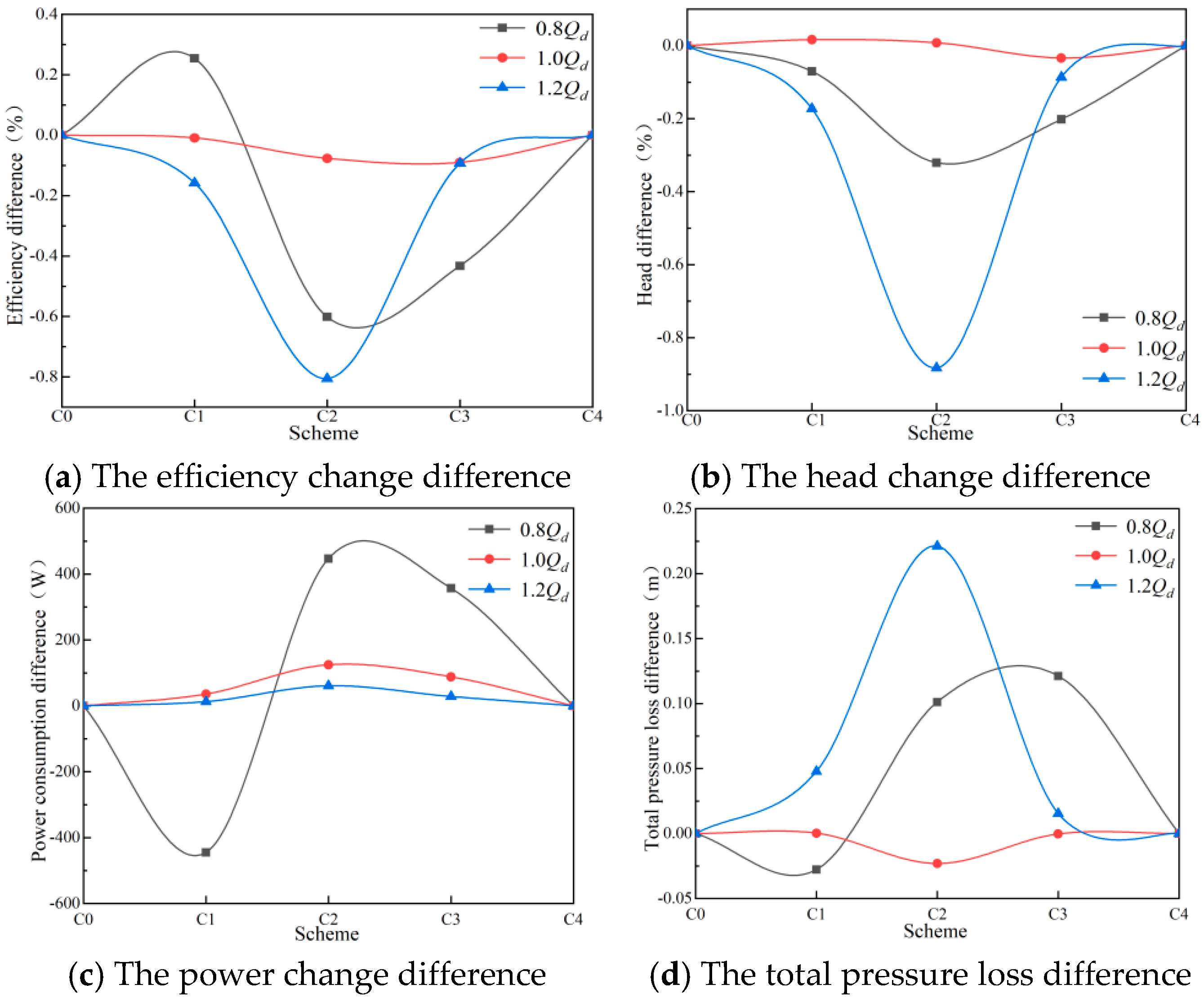

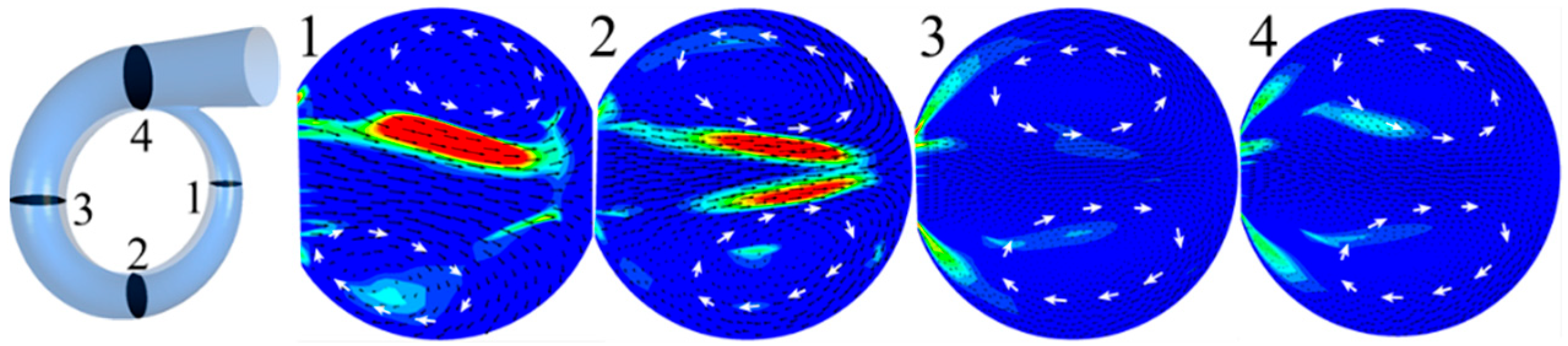

3.1. The Clocking Effect of the Stay Vane

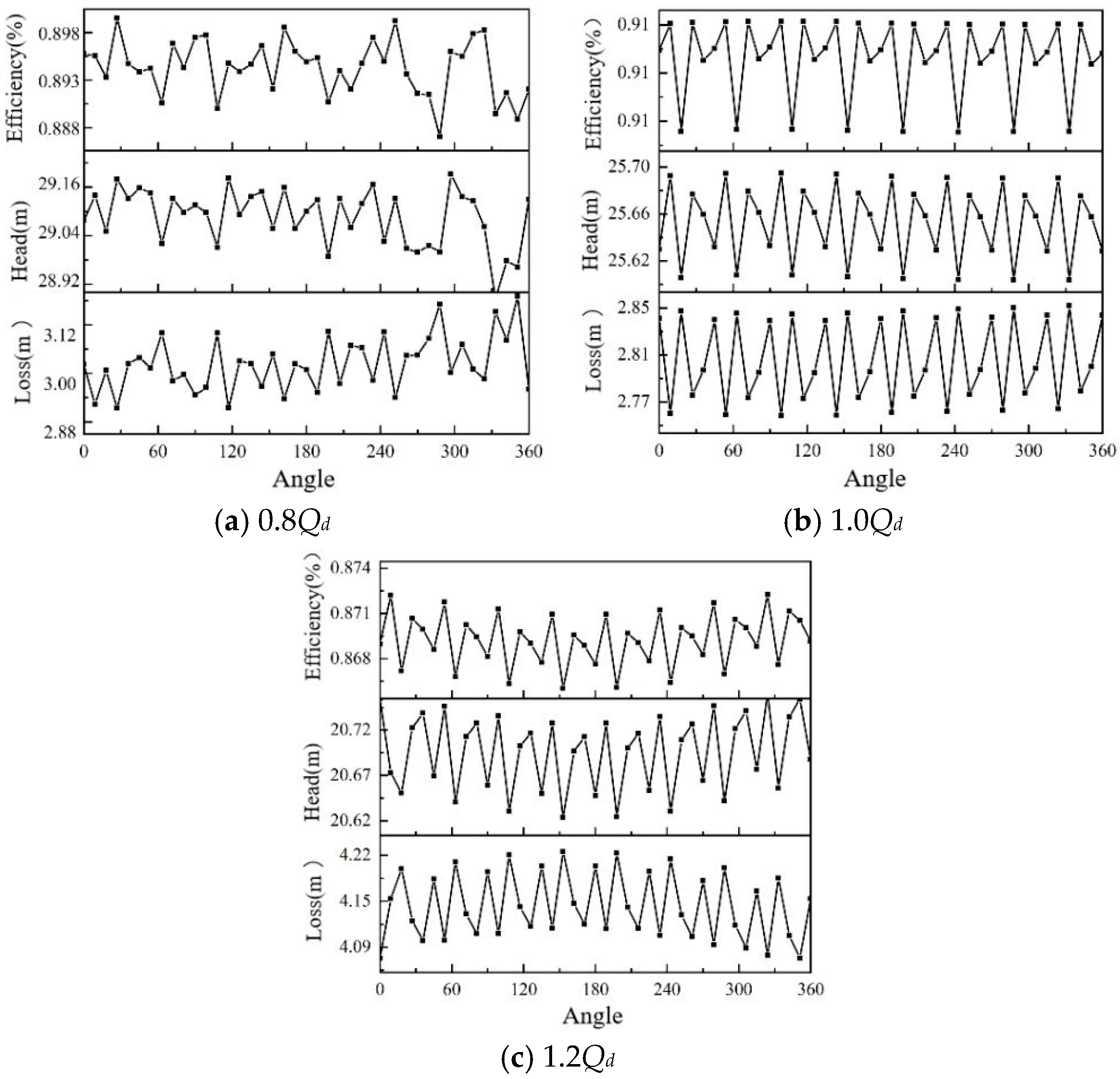

3.1.1. Analysis of Hydraulic Performance

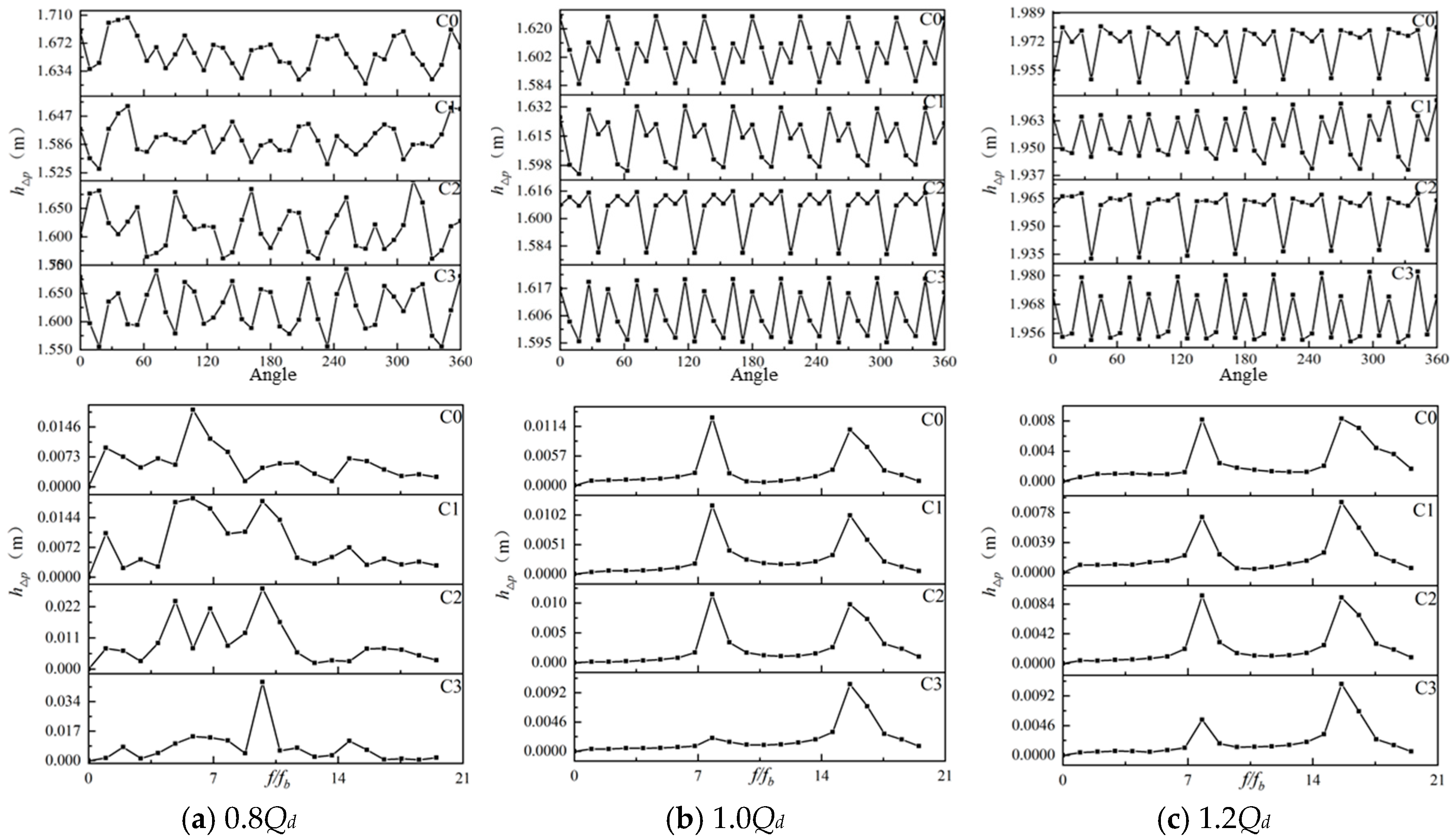

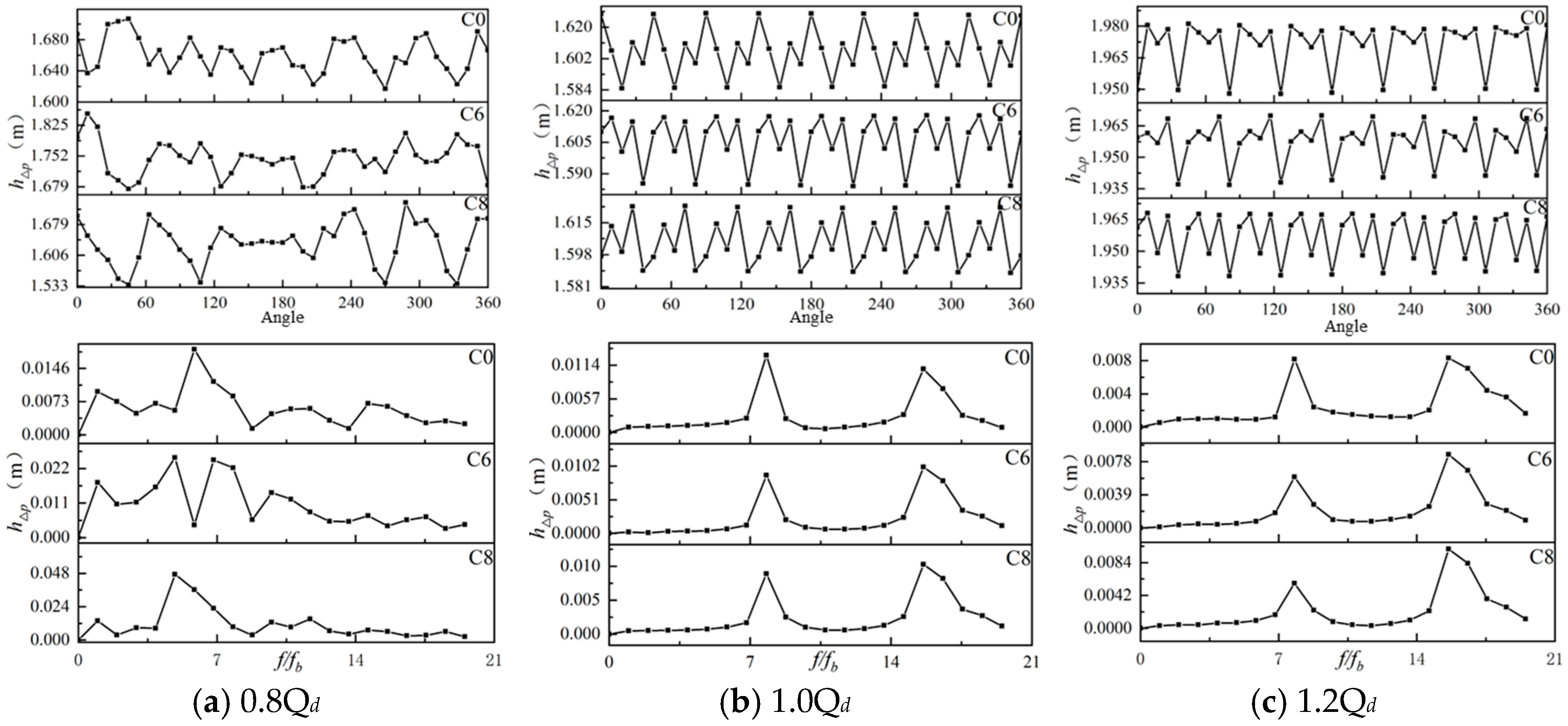

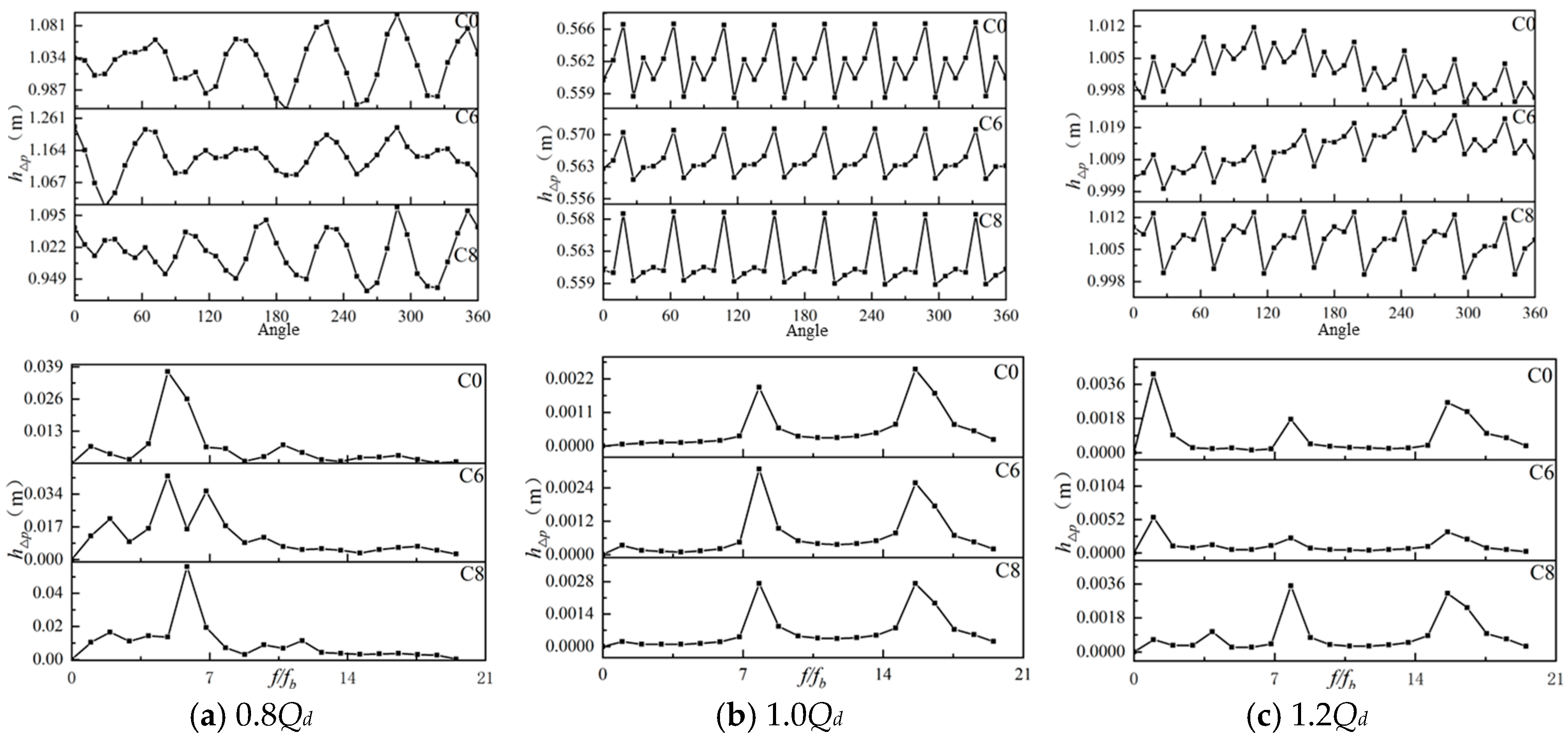

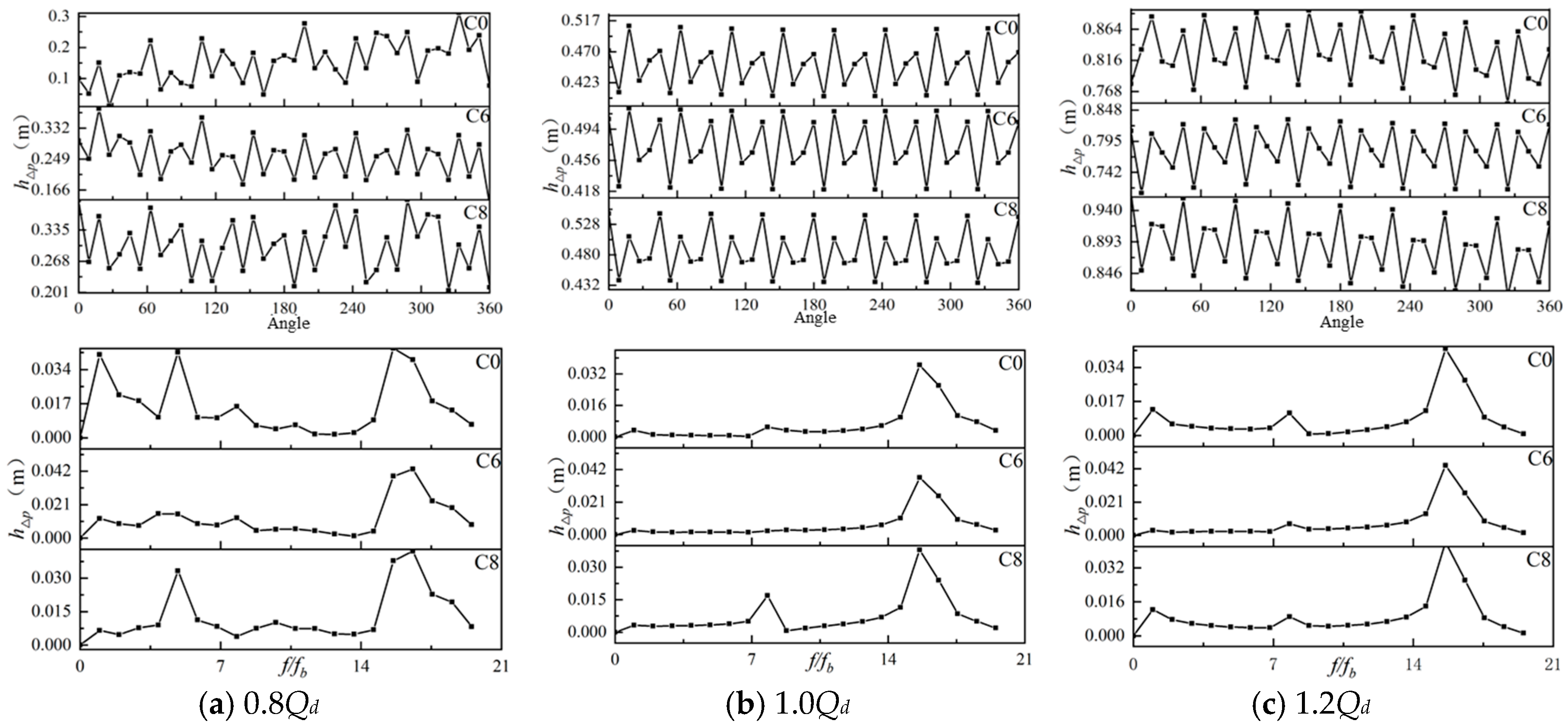

3.1.2. Analysis of Transient Characteristics

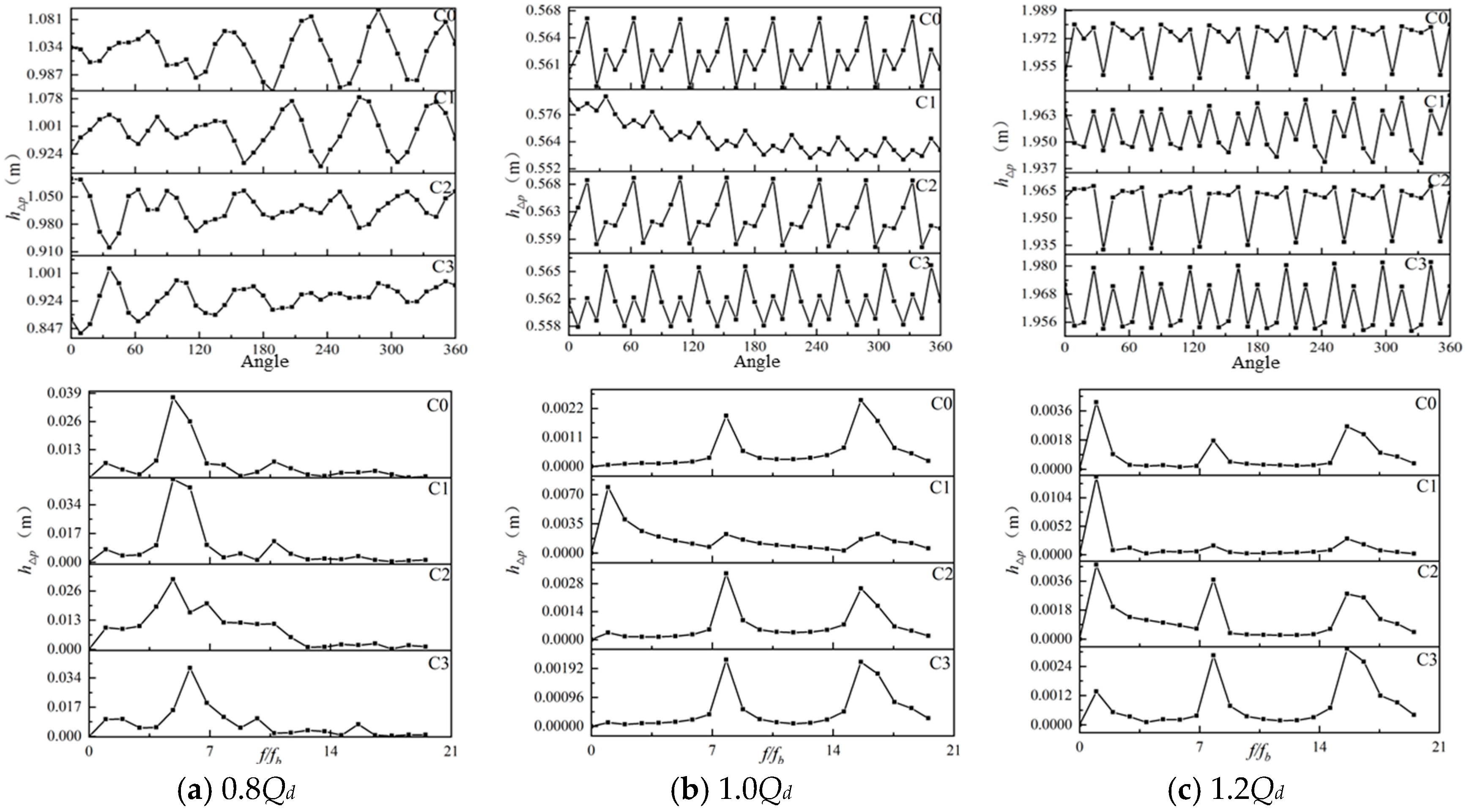

3.2. The Clocking Effect of the Guide Vane

3.2.1. Analysis of Hydraulic Performance

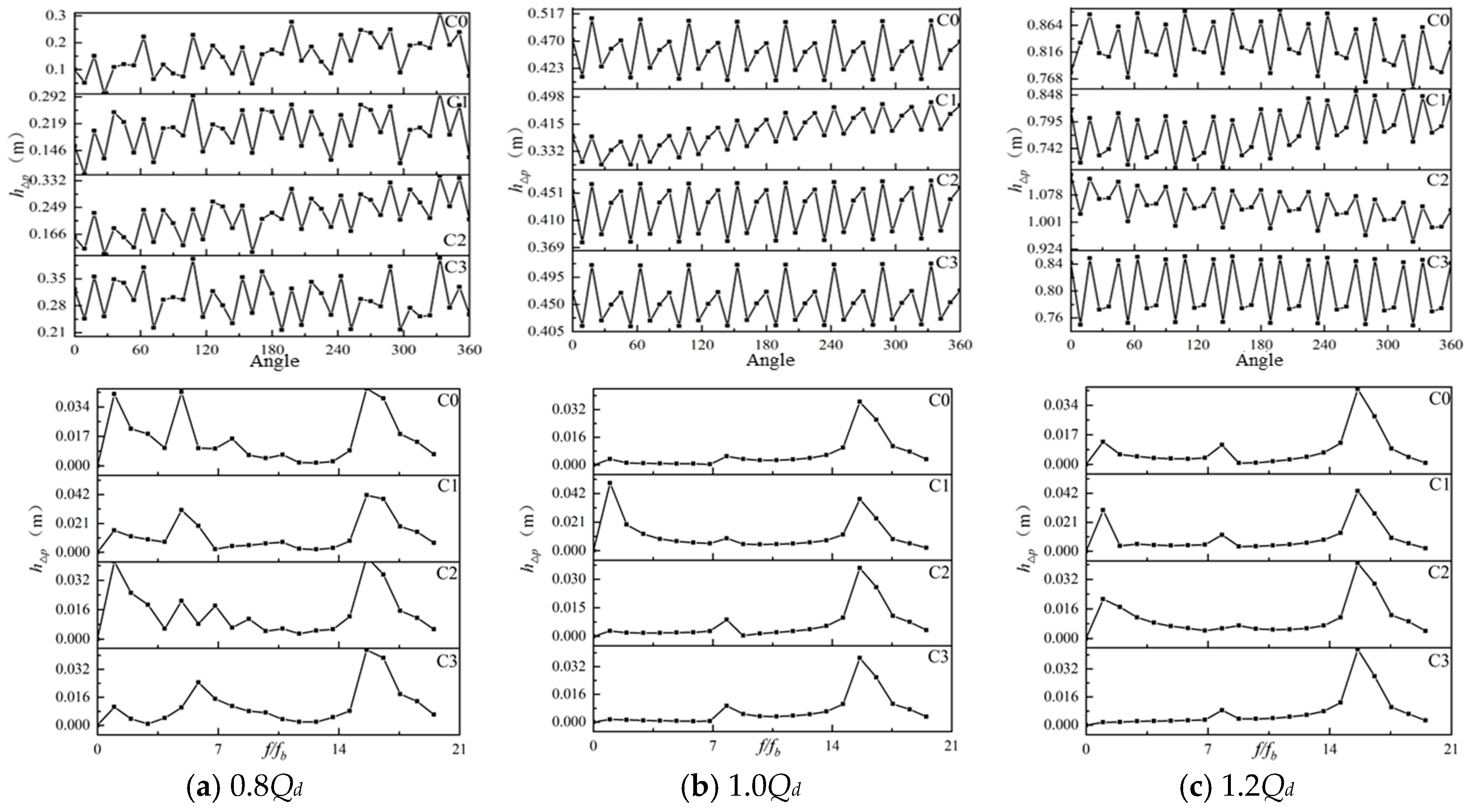

3.2.2. Analysis of Transient Characteristics

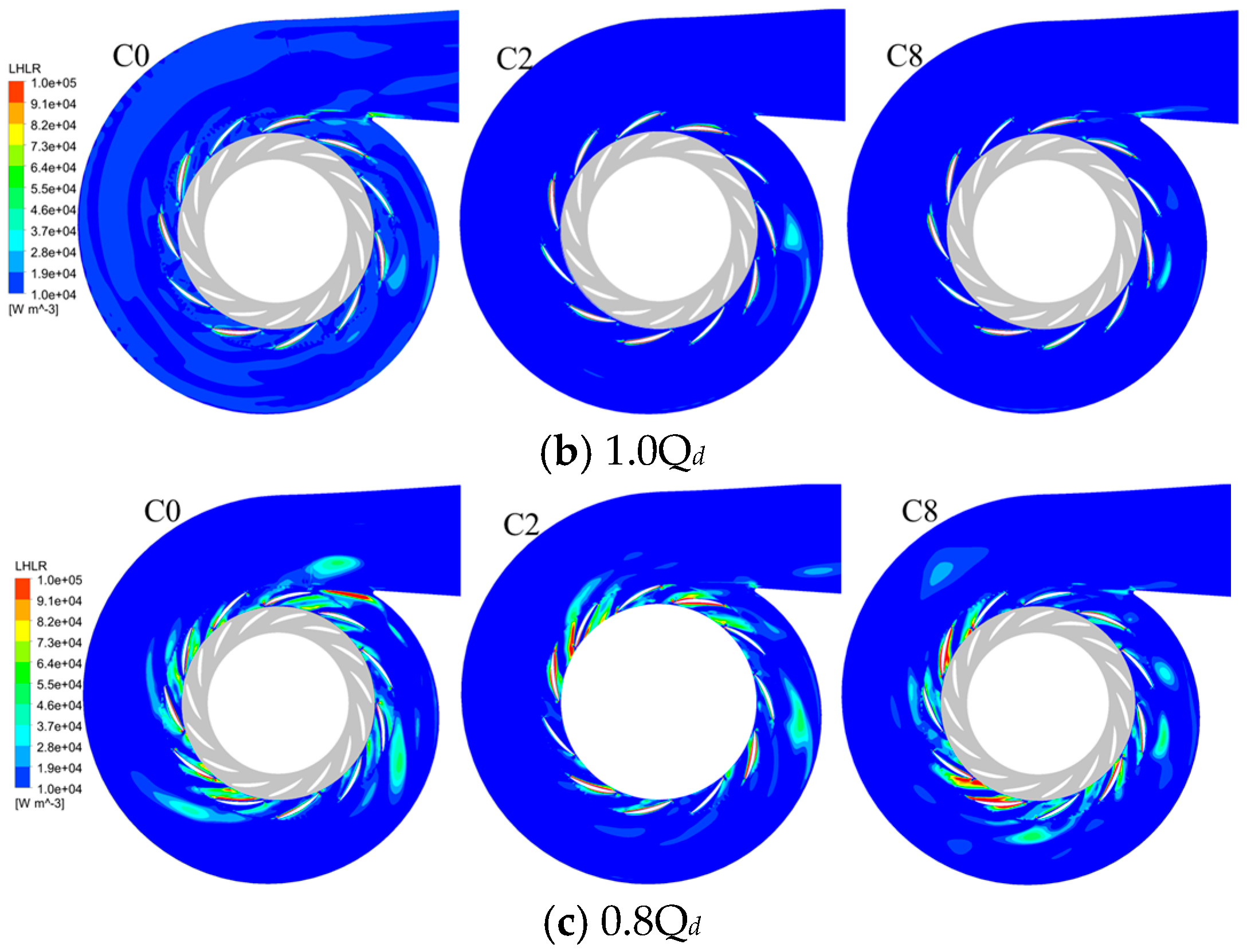

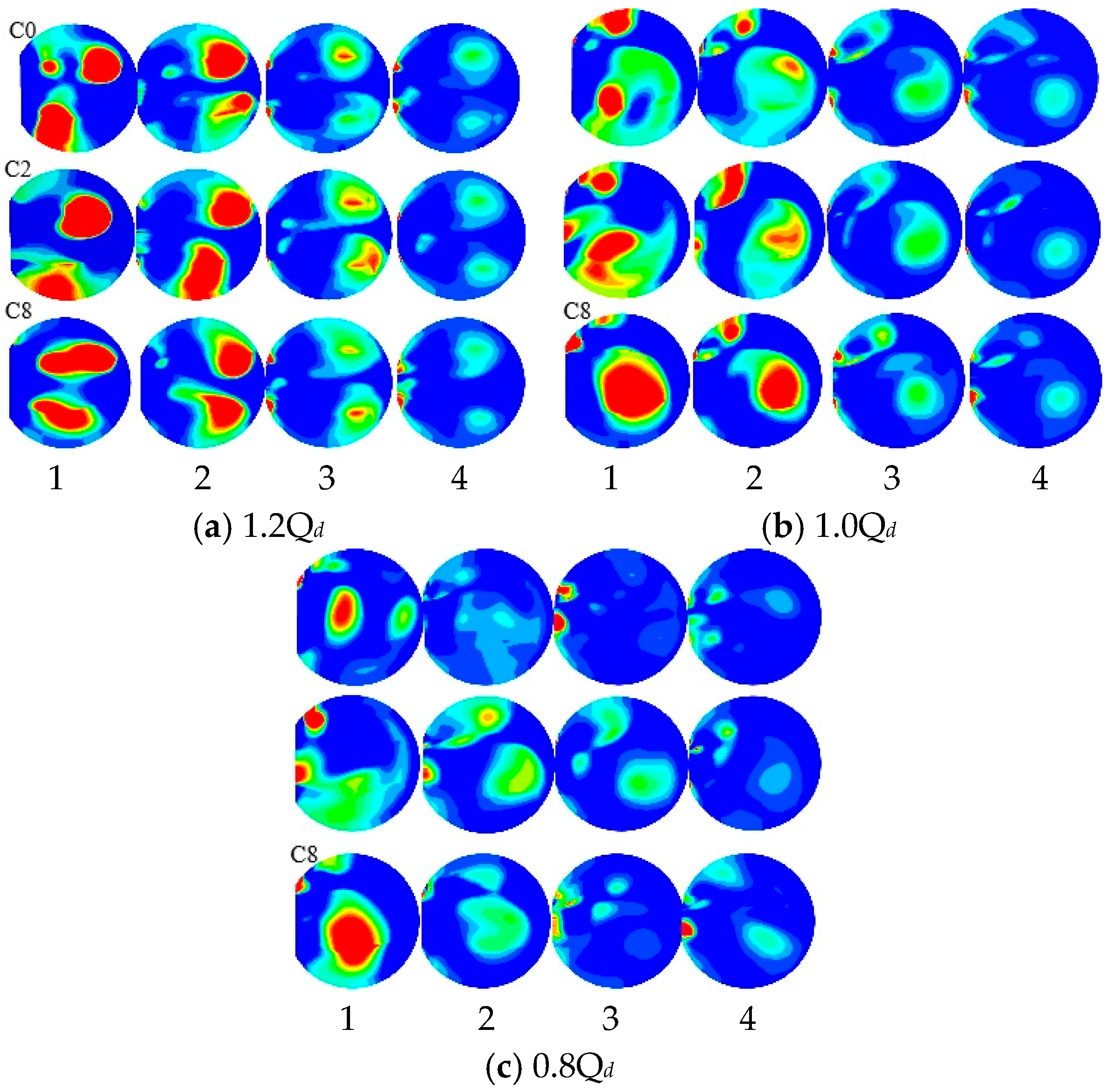

3.3. Analysis of Reasons for Changes in Losses

4. Conclusions

- (1)

- The clocking position of the stay vane exerts greater influence on off-design flow conditions. The maximum efficiency differences reach 0.855% and 0.805% at 0.8Qd and 1.2Qd conditions, respectively, while only 0.090% at the design condition. Although the impact of guide vane clocking position diminishes for off-design conditions, significant performance variations still occur at the 1.0Qd condition. Across increasing flow rates, the maximum efficiency differences between schemes are 0.641%, 0.330%, and 0.377%, respectively. Optimal hydraulic performance across all flow conditions is achieved when the tongue is positioned at the trailing edge of guide vanes and the 1/4 chord location of stay vane passages. When the angle between the stay vane trailing edge and tongue is 0°, instability emerges in losses for the guide vane, stay vane, and volute. In addition, positioning the tongue at the mid-passage of the stationary guide vanes enhances loss fluctuation stability across all components.

- (2)

- The time-domain analysis of external characteristics across various flow conditions reveals that the 0.8Qd condition represents an unstable operating regime, resulting in significant variations in component losses under different schemes. Regarding impeller and guide vane losses, all schemes demonstrate comparable time-averaged values under stable conditions. For stay vane and volute losses, the C0 scheme consistently exhibits the minimum time-averaged values across all conditions. The clocking effect proves most pronounced in the alteration of the proportion of volute losses, consequently exerting the dominant influence on pump mode performance variations.

- (3)

- The variation in volute hydraulic losses stems from the fact that different stay vane and guide vane clocking positions alter both the scale and intensity of the dual-vortex structure within the volute, thereby inducing significant changes in losses at the vortex interface region.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| P | Stress tensor |

| Sij | Shear strain tensor |

| U | Mean velocity in turbulent flow, m s−1 |

| μ | Viscosity, kg m−1 s−1 |

| u′ | Fluctuating velocity in turbulent flow, m s−1 |

| μeff | Effective viscosity, kg m−1 s−1 |

| LHLR | Local hydraulic loss rate |

| DIS | Dissipation term in local hydraulic loss rate |

| TRNS | Transportation term in local hydraulic loss rate |

| y+ | Dimensionless distance |

| yln+ | Intersection point from linear to logarithmic wall region |

| κ | Von Karman constant, 0.42 |

| τw | Wall shear stress, kg m s−2 |

| Qd | The flow rate at design condition |

| g | Local gravity acceleration, 9.8 m/s2 |

| By direct dissipation | |

| D′ | By turbulent dissipation |

| wall | Value is defined in the flow boundary layer |

References

- Zuo, Z.; Fan, H.; Liu, S.; Wu, Y. S-shaped characteristics on the performance curves of pump-turbines in turbine mode—A review. Renew. Sustain. Energy Rev. 2016, 60, 836–851. [Google Scholar] [CrossRef]

- Li, D.; Wang, H.; Qin, Y.; Wei, X.; Qin, D. Numerical simulation of hysteresis characteristic in the hump region of a pump-turbine model. Renew. Energy 2018, 115, 433–447. [Google Scholar] [CrossRef]

- Yang, S.; Chen, X.; Wu, D.; Yan, P. Dynamic analysis of the pump system based on MOC–CFD coupled method. Ann. Nucl. Energy 2015, 78, 60–69. [Google Scholar] [CrossRef]

- Zhang, X.X.; Cheng, Y.G. Simulation of hydraulic transients in hydropower systems using the 1-D-3-D coupling approach. J. Hydrodyn. B 2012, 24, 595–604. [Google Scholar] [CrossRef]

- Zhang, X.X.; Cheng, Y.G.; Yang, J.D.; Xia, L.S.; Lai, X. Simulation of the load rejection transient process of a francis turbine by using a 1-D-3-D coupling approach. J. Hydrodyn. B 2014, 26, 715–724. [Google Scholar] [CrossRef]

- Yang, J.; Feng, X.; Liu, X.; Peng, T.; Chen, Z.; Wang, Z. The Suppression of Hump Instability inside a Pump Turbine in Pump Mode Using Water Injection Control. Processes 2023, 11, 1647. [Google Scholar] [CrossRef]

- Zeng, Y.; Qian, Z.; Ye, W.; Geng, C.; Luo, X. Research on pressure pulsation characteristics of a pump-turbine in pump mode with rotating stall: Focus on the broadband frequency. Phys. Fluids 2024, 36, 047135. [Google Scholar] [CrossRef]

- Xiao, W.; Ren, S.; Chen, L.; Yan, B.; Zhu, Y.; Xiao, Y. Analysis of the Flow Behavior and Pressure Fluctuation of a Pump Turbine with Splitter Blades in Part-Load Pump Mode. Energies 2024, 17, 2402. [Google Scholar] [CrossRef]

- Li, D.; Gong, R.; Wang, H.; Xiang, G.; Wei, X.; Qin, D. Entropy production analysis for hump characteristics of a pump turbine model. Chin. J. Mech. Eng. 2016, 29, 803–812. (In English) [Google Scholar] [CrossRef]

- Yuan, Z.; Zhang, Y.; Zhang, J.; Zhu, J. Experimental studies of unsteady cavitation at the tongue of a pump-turbine in pump mode. Renew. Energy 2021, 177, 1265–1281. [Google Scholar] [CrossRef]

- Li, Q.; Xin, L.; Yao, L.; Zhang, S. Optimization of Guide Vane Airfoil Shape of Pump Turbine Based on SVM-MDMR Model. Arab. J. Sci. Eng. 2024, 49, 14949–14963. [Google Scholar] [CrossRef]

- Ji, Y.; Yang, Z.; Ran, J.; Li, H. Multi-objective parameter optimization of turbine impeller based on RBF neural network and NSGA-II genetic algorithm. Energy Rep. 2021, 7, 584–593. [Google Scholar] [CrossRef]

- Walker, G.J.; Oliver, A.R. The Effect of Interaction Between Wakes From Blade Rows in an Axial Flow Compressor on the Noise Generated by Blade Interaction. J. Eng. Power 1972, 94, 241–248. [Google Scholar] [CrossRef]

- Huber, F.W.; Johnson, P.D.; Sharma, O.P.; Staubach, J.B.; Gaddis, S.W. Performance Improvement Through Indexing of Turbine Airfoils: Part 1—Experimental Investigation. J. Turbomach. 1996, 118, 630–635. [Google Scholar] [CrossRef]

- Schennach, O.; Woisetschläger, J.; Paradiso, B.; Persico, G.; Gaetani, P. Three dimensional clocking effects in a one and a half stage transonic turbine. J. Turbomach. 2010, 132, 011019. [Google Scholar] [CrossRef]

- Jiang, W.; Li, G.; Liu, P.F.; Fu, L. Numerical investigation of influence of the clocking effect on the unsteady pressure fluctuations and radial forces in the centrifugal pump with vaned diffuser. Int. Commun. Heat Mass Transf. 2016, 71, 164–171. [Google Scholar] [CrossRef]

- Ye, C.; An, D.; Huang, W.; Heng, Y.; Zheng, Y. Investigation on Stall Characteristics of Centrifugal Pump with Guide Vanes. Water 2023, 15, 21. [Google Scholar] [CrossRef]

- Tan, M.; He, N.; Liu, H.; Wu, X.; Ding, J. Experimental test on impeller clocking effect in a multistage centrifugal pump. Adv. Mech. Eng. 2016, 8, 1687814016644376. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, W.; Feng, W.; Jia, Q.; Wang, Y.; Chen, D. Investigation of hydraulic losses in different clocking positions of pump-turbine in pump mode. J. Energy Storage 2024, 81, 110459. [Google Scholar] [CrossRef]

- Qin, Y.; Li, D.; Wang, H.; Liu, Z.; Wei, X.; Wang, X. Investigation on hydraulic loss component and distribution in hydraulic machinery: A case study of pump-turbine in pump mode. J. Energy Storage 2022, 52, 104932. [Google Scholar] [CrossRef]

- Kock, F.; Herwig, H. Local entropy production in turbulent shear flows: A high-Reynolds number model with wall functions. Int. J. Heat Mass Transf. 2004, 47, 2205–2215. [Google Scholar] [CrossRef]

- Melzer, S.; Pesch, A.; Schepeler, S.; Kalkkuhl, T.; Skoda, R. Three-dimensional simulation of highly unsteady and isothermal flow in centrifugal pumps for the local loss analysis including a wall function for entropy production. J. Fluids Eng. Trans. ASME 2020, 142, 111209. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, Z.; Han, S.; Zhu, B. Study on the Unsteady Flow Characteristics of a Pump Turbine in Pump Mode. Processes 2024, 12, 41. [Google Scholar] [CrossRef]

- Zhang, D.; Quan, Q.; Huang, X.; Wang, Z.; Wang, B.; Xiao, Y. Transient Flow-Induced Stress Investigation on a Prototype Reversible Pump–Turbine Runner. Energies 2024, 17, 3026. [Google Scholar] [CrossRef]

- Yin, X.; Huang, X.; Zhang, S.; Bi, H.; Wang, Z. Numerical Investigation of Flow and Structural Characteristics of a Large High-Head Prototype Pump–Turbine during Turbine Start-Up. Energies 2023, 16, 3743. [Google Scholar] [CrossRef]

- Ren, Y.; Qiao, R.; Wei, D.; Hou, S. Research on the Internal Flow Characteristics of Pump Turbines for Smoothing the Output Fluctuation of the Wind–Photovoltaic Complementary System. Front. Energy Res. 2022, 10, 914680. [Google Scholar] [CrossRef]

- Li, L.; Xu, P.; Li, Q.; Zheng, R.; Xu, X.; Wu, J.; He, B.; Bao, J.; Tan, D. A coupled LBM-LES-DEM particle flow modeling for microfluidic chip and ultrasonic-based particle aggregation control method. Appl. Math. Model. 2025, 143, 116025. [Google Scholar] [CrossRef]

- Xiuli, W.; Bin, L.; Yang, L.; Yan, Z.; Rongsheng, Z.; Yun, L.; Qiang, F. Hydraulic Optimization of Two-Way Counter-rotating Axial Flow Pump Turbine. Front. Energy Res. 2020, 8, 577232. [Google Scholar] [CrossRef]

- Liu, Y.; Ran, H.; Wang, D. Research on Groove Method to Suppress Stall in Pump Turbine. Energies 2020, 13, 3822. [Google Scholar] [CrossRef]

- Xiao, W.; Gui, Z.; Lu, Z.; Xiao, R.; Tao, R. Pressure pulsation of pump turbine at runaway condition based on Hilbert Huang transform. Front. Energy Res. 2024, 12, 1344676. [Google Scholar] [CrossRef]

- Li, Y.; Hao, P.; Zhang, Z.; Zhang, L.; Hai, H.; Zhang, H.; Wang, X.; Wang, J.; Zhao, Z.; Peng, P. Characterization of Pressure Pulsation Propagation in a Pump-Turbine Based on the Same-Frequency Tracking Method. Energy Sci. Eng. 2025, 13, 3588–3604. [Google Scholar] [CrossRef]

| Parameters | Symbol | Value |

|---|---|---|

| Runner blade number | Zr | 8 |

| Guide vane number | Zg | 15 |

| Stay vane number | Zs | 11 |

| Runner inlet diameter | D1 | 350 mm |

| Runner outlet diameter | D2 | 465 mm |

| Guide vane height | b0 | 84.2 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Li, Y.; Ma, M.; Kong, L.; Huang, Z.; Xu, L.; Wang, B. Numerical Investigation of Clocking Effects on the Hydraulic Performance of Pump–Turbine in Pump Mode. Energies 2025, 18, 4317. https://doi.org/10.3390/en18164317

Zhang L, Li Y, Ma M, Kong L, Huang Z, Xu L, Wang B. Numerical Investigation of Clocking Effects on the Hydraulic Performance of Pump–Turbine in Pump Mode. Energies. 2025; 18(16):4317. https://doi.org/10.3390/en18164317

Chicago/Turabian StyleZhang, Lisheng, Yongbo Li, Ming Ma, Lijun Kong, Zhenghai Huang, Lintao Xu, and Bofu Wang. 2025. "Numerical Investigation of Clocking Effects on the Hydraulic Performance of Pump–Turbine in Pump Mode" Energies 18, no. 16: 4317. https://doi.org/10.3390/en18164317

APA StyleZhang, L., Li, Y., Ma, M., Kong, L., Huang, Z., Xu, L., & Wang, B. (2025). Numerical Investigation of Clocking Effects on the Hydraulic Performance of Pump–Turbine in Pump Mode. Energies, 18(16), 4317. https://doi.org/10.3390/en18164317