Fault Diagnosis of Rolling Bearings Under Variable Speed for Energy Conversion Systems: An ACMD and SP-DPS Clustering Approach with Traction Motor Validation

Abstract

1. Introduction

- (1)

- An ACMD-based order tracking method is developed to enhance fault feature extraction under variable speed conditions.

- (2)

- A robust diagnosis framework combining ACMD and SP-DPS is proposed, tailored to the energy-critical scenario of traction systems.

- (3)

- Experiments on variable speed bearing datasets validate the proposed method’s effectiveness and practical applicability.

2. Related Methodologies

2.1. ACMD-Based Order Tracking Method

2.1.1. Review of the ACMD Algorithm

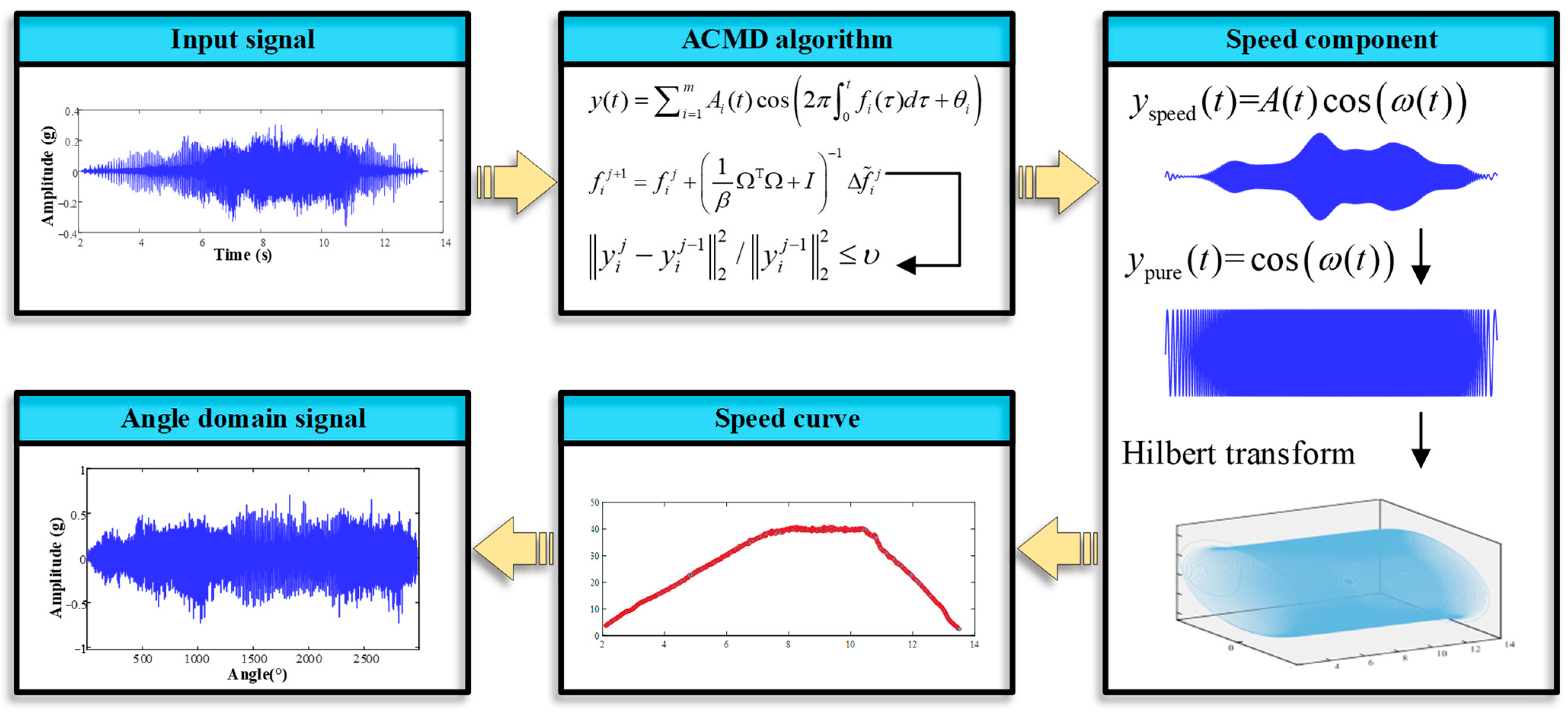

2.1.2. ACMD-Based Order Tracking

- (1)

- Signal Acquisition: The original vibration signal is acquired from an acceleration sensor.

- (2)

- ACMD Decomposition: The acquired signal is processed using the ACMD algorithm. Following the procedure described in Section 2.1.1, the rotational speed component and several Amplitude Modulation–Frequency Modulation (AM–FM) signal components are extracted. Suppose the obtained AM–FM signal is as follows:

- (3)

- FM Signal Conversion and Hilbert Transform: The AM–FM component corresponding to the rotational speed is converted into a purely frequency-modulated (FM) signal. This FM signal is subsequently processed using the Hilbert transform to obtain its analytic form. Suppose the obtained FM signal is as follows:Then, applying the Hilbert transform to Equation (11):

- (4)

- Instantaneous Frequency Extraction: The instantaneous phase of the analytic signal is differentiated to obtain the instantaneous frequency, representing the rotational speed curve.

- (5)

- Angular Domain Resampling: Finally, the derived speed curve is used to resample the original vibration signal, thereby converting it into an angular domain signal suitable for further analysis. The key premise of angular domain resampling is to determine the resampling time. In this study, the resampling time is obtained by solving the integral equation of the speed curve:

2.2. Shortest Paths Density Peak Search

3. The Proposed Intelligent Fault Diagnosis Framework

- (1)

- Data Acquisition: Vibration signals are directly collected from machinery operating under variable speed conditions, such as traction motors. These raw signals reflect the dynamic load and speed fluctuations typical of real-world energy conversion environments, making them valuable for fault detection.

- (2)

- Signal Processing: The collected vibration signals are processed using the proposed ACMD-based order tracking technique to improve diagnostic precision under these complex conditions. Specifically, the Adaptive Chirp Mode Decomposition (ACMD) algorithm extracts instantaneous speed information, which is then applied in the order tracking process to transform non-stationary time domain signals into stationary angular domain signals. This transformation enhances feature stability and provides a more informative representation for subsequent diagnosis, enabling better support for proactive maintenance and operational decision-making.

- (3)

- Fault Identification: In the final stage, discriminative features are extracted from the stationary signals in both the time and frequency domains, recognizing that bearing faults can exhibit multi-domain signatures.

4. Experimental Verification

4.1. Experiment 1: Bearing Fault Under Variable Speed Without Load

4.2. Experiment 2: Bearing Fault Under Variable Speed with Load

5. Conclusions

- (1)

- Reliable signal transformation for energy-critical systems: The ACMD-based order tracking method effectively transforms nonstationary time domain signals into stationary angular domain signals, providing a robust foundation for fault feature extraction even under fluctuating speed conditions. This enhances the reliability of condition monitoring in dynamic operating environments, contributing to improved energy efficiency and reduced unexpected failures.

- (2)

- Enhanced diagnostic robustness: By leveraging a global path-guided clustering mechanism, the SP-DPS algorithm overcomes the limitations of traditional clustering methods, particularly in handling complex, long-tailed, and nonlinearly separable fault features. The higher fault identification precision, which supports earlier and more accurate maintenance decisions critical for reducing downtime and lowering operational costs in high-demand energy applications.

- (3)

- Validated performance in realistic energy scenarios: Experimental validation across two platforms—including a metro traction motor bearing testbed—demonstrates that the proposed method consistently delivers superior diagnostic accuracy (up to 97.3% and 96.0%, respectively). These results affirm the framework’s effectiveness in safeguarding the reliability and safety of energy systems.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qi, L.; Song, J.; Wang, Y.; Yi, M.; Zhang, Z.; Yan, J. Mechanical motion rectification-based electromagnetic vibration energy harvesting technology: A review. Energy 2024, 289, 130030. [Google Scholar] [CrossRef]

- Zhao, Z.; Chen, F.; He, X.; Lan, P.; Chen, D.; Yin, X.; Yang, J. A universal hydraulic-mechanical diagnostic framework based on feature extraction of abnormal on-field measurements: Application in micro pumped storage system. Appl. Energy 2024, 357, 122478. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, Y.; Jiang, Y.; Zhao, T.; Xu, H.; Qian, P.; Li, C. A novel wind turbine rolling element bearing fault diagnosis method based on CEEMDAN and improved TFR demodulation analysis. Energies 2024, 17, 819. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, G.; Huang, X. Adaptive two-dimensional coupled unsaturated asymmetric combined Gaussian potential stochastic resonance energy gain model and application of bearing fault diagnosis. J. Energy Storage 2024, 103, 114239. [Google Scholar] [CrossRef]

- Szweda, S.; Głuszek, G.; Szyguła, M.; Grzegorzek, W.; Adamecki, D.; Mikuła, J.; Mikuła, S. Functionality of bearings in the shafts of a vertical-axis wind turbine. Energies 2024, 17, 5189. [Google Scholar] [CrossRef]

- Kumar, S.; Raj, K.K.; Cirrincione, M.; Cirrincione, G.; Franzitta, V.; Kumar, R.R. A comprehensive review of remaining useful life estimation approaches for rotating machinery. Energies 2024, 17, 5538. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, Q.; Wang, S.; Ma, T.; Gao, S.; Kong, Y.; Han, Q.; Chu, F. Hybrid triboelectric-variable reluctance generator assisted wireless intelligent condition monitoring of aero-engine main bearings. Nano Energy 2025, 136, 110721. [Google Scholar] [CrossRef]

- He, D.; Xu, Y.; Jin, Z.; Liu, Q.; Zhao, M.; Chen, Y. A zero-shot model for diagnosing unknown composite faults in train bearings based on label feature vector generated fault features. Appl. Acoust. 2025, 232, 110563. [Google Scholar] [CrossRef]

- Wang, J.; Liu, K.; Wei, D.; Chen, Y.; Chen, J.; Li, R.; Luan, H.; Li, K.; Zhou, S. Bearing fault diagnosis in permanent magnet synchronous machine based on signature analysis of encoder signal under variable speed conditions. IEEE Trans. Energy Convers. 2025, 40, 1538–1553. [Google Scholar] [CrossRef]

- Sawalhi, N. Improved order tracking in vibration data utilizing variable frequency drive signature. Sensors 2025, 25, 815. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, H.; Li, Q.; Wang, X.; Zhou, Z.; Xu, H.; Zhang, D.; Qian, P. Overview of condition monitoring technology for variable-speed offshore wind turbines. Energies 2025, 18, 1026. [Google Scholar] [CrossRef]

- Mosquera, F.D.; Faedo, N.; Evangelista, C.A.; Ringwood, J.V.; Puleston, P.F. Wave energy optimal control structure with second-order sliding mode tracking: Hardware-in-the-loop assessment. IEEE Trans. Sustain. Energy 2023, 15, 1341–1350. [Google Scholar] [CrossRef]

- Nosheen, T.; Ali, A.; Chaudhry, M.U.; Nazarenko, D.; Shaikh, I.U.H.; Bolshev, V.; Iqbal, M.M.; Khalid, S.; Panchenko, V. a fractional order controller for sensorless speed control of an induction motor. Energies 2023, 16, 1901. [Google Scholar] [CrossRef]

- He, D.; Wu, J.; Jin, Z.; Huang, C.; Wei, Z.; Yi, C. AGFCN: A bearing fault diagnosis method for high-speed train bogie under complex working conditions. Reliab. Eng. Syst. Saf. 2025, 258, 110907. [Google Scholar] [CrossRef]

- Chen, S.; Yang, Y.; Peng, Z.; Wang, S.; Zhang, W.; Chen, X. Detection of rub-impact fault for rotor-stator systems: A novel method based on adaptive chirp mode decomposition. J. Sound Vib. 2019, 440, 83–99. [Google Scholar] [CrossRef]

- Yuzgec, U.; Dokur, E.; Balci, M. A novel hybrid model based on Empirical Mode Decomposition and Echo State Network for wind power forecasting. Energy 2024, 300, 131546. [Google Scholar] [CrossRef]

- Matthew, D.E.; Cao, H.; Shi, J. Advancing chatter detection: Harnessing the strength of wavelet synchrosqueezing transform and Hilbert-Huang transform techniques. J. Manuf. Process. 2024, 127, 613–630. [Google Scholar] [CrossRef]

- Wang, X.; He, Y.; Wang, H.; Hu, A.; Zhang, X. A novel hybrid approach for damage identification of wind turbine bearing under variable speed condition. Mech. Mach. Theory 2022, 169, 104629. [Google Scholar] [CrossRef]

- Song, C.; Cheng, W.; Chen, X.; Wang, J.; Qiao, B.; Ge, X.; Gao, L.; Huang, H. Identification and separation of coupled vibration sources in multi-rotor gas turbines under time-varying speed conditions. Mech. Syst. Signal Process. 2023, 188, 110037. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, Y.; Wang, X. Two-step adaptive chirp mode decomposition for time-varying bearing fault diagnosis. IEEE Trans. Instrum. Meas. 2021, 70, 3511510. [Google Scholar] [CrossRef]

- Ma, Z.; Lu, F.; Liu, S.; Li, X. A parameter-adaptive ACMD method based on particle swarm optimization algorithm for rolling bearing fault diagnosis under variable speed. J. Mech. Sci. Technol. 2021, 35, 1851–1865. [Google Scholar] [CrossRef]

- Huang, J.; Li, C.; Xiao, X.; Yu, T.; Yuan, X.; Zhang, Y. Adaptive multivariate chirp mode decomposition. Mech. Syst. Signal Process. 2023, 186, 109897. [Google Scholar] [CrossRef]

- Ding, H.; Tian, R.; Wang, J.; Yang, X. Power measurement using adaptive chirp mode decomposition for electrical vehicle charging load. Energies 2023, 16, 5305. [Google Scholar] [CrossRef]

- Chen, S.; Guo, L.; Fan, J.; Yi, C.; Wang, K.; Zhai, W. Bandwidth-aware adaptive chirp mode decomposition for railway bearing fault diagnosis. Struct. Health Monit. 2024, 23, 876–902. [Google Scholar] [CrossRef]

- Leiria, D.; Johra, H.; Anoruo, J.; Praulins, I.; Piscitelli, M.S.; Capozzoli, A.; Marszal-Pomianowska, A.; Pomianowski, M.Z. Is it returning too hot? Time series segmentation and feature clustering of end-user substation faults in district heating systems. Appl. Energy 2025, 381, 125122. [Google Scholar] [CrossRef]

- Wei, X.; Peng, M.; Huang, H.; Zhou, Y. An overview on density peaks clustering. Neurocomputing 2023, 554, 126633. [Google Scholar] [CrossRef]

- Park, J.H.; Cho, H.; Gil, S.M.; Choo, K.-B.; Kim, M.; Huang, J.; Jung, D.; Yun, C.; Choi, H.S. Research on clustering-based fault diagnosis during rov hovering control. Appl. Sci. 2024, 14, 5235. [Google Scholar] [CrossRef]

- He, D.; Zhao, J.; Jin, Z.; Huang, C.; Zhang, F.; Wu, J. Prediction of bearing remaining useful life based on a two-stage updated digital twin. Adv. Eng. Inform. 2025, 65, 103123. [Google Scholar] [CrossRef]

- Agayan, S.M.; Bogoutdinov, S.R.; Dzeboev, B.A.; Dzeranov, B.V.; Kamaev, D.A.; Osipov, M.O. DPS Clustering: New Results. Appl. Sci. 2022, 12, 9335. [Google Scholar] [CrossRef]

- Sun, H.; Fu, X.; Zhong, S. A weakly supervised gas-path anomaly detection method for civil aero-engines based on mapping relationship mining of gas-path parameters and improved density peak clustering. Sensors 2021, 21, 4526. [Google Scholar] [CrossRef]

- Luo, S.; Liu, H.; Qi, E. Recognition and labeling of faults in wind turbines with a density-based clustering algorithm. Data Technol. Appl. 2021, 55, 841–868. [Google Scholar] [CrossRef]

- Pass, R.Z.; Wetter, M.; Piette, M. A thermodynamic analysis of a novel bidirectional district heating and cooling network. Energy 2018, 144, 20–30. [Google Scholar] [CrossRef]

- Shi, L.; Yang, X.; Chang, X.; Wu, J.; Sun, H. An improved density peaks clustering algorithm based on k nearest neighbors and turning point for evaluating the severity of railway accidents. Reliab. Eng. Syst. Saf. 2023, 233, 109132. [Google Scholar] [CrossRef]

- Pizzagalli, D.U.; Gonzalez, S.F.; Krause, R. A trainable clustering algorithm based on shortest paths from density peaks. Sci. Adv. 2019, 5, eaax3770. [Google Scholar] [CrossRef]

- Chen, S.; Dong, X.; Peng, Z.; Zhang, W.; Meng, G. Nonlinear chirp mode decomposition: A variational method. IEEE Trans. Signal Process. 2017, 65, 6024–6037. [Google Scholar] [CrossRef]

- Motallebi, H.; Malakoutifar, N. An efficient clustering algorithm based on searching popularity peaks. Pattern Anal. Appl. 2024, 27, 67. [Google Scholar] [CrossRef]

- Liu, Z.; Cheng, Z.; Xiong, Y. Fault diagnosis of tooth surface spalling based on variational mode decomposition and maximum correlation kurtosis method. Eng. Res. Express 2024, 6, 015510. [Google Scholar] [CrossRef]

- Liu, S.; Chen, J.; He, S.; Shi, Z.; Zhou, Z. Few-shot learning under domain shift: Attentional contrastive calibrated transformer of time series for fault diagnosis under sharp speed variation. Mech. Syst. Sig. Process. 2023, 189, 110071. [Google Scholar] [CrossRef]

- Sarmas, E.; Fragkiadaki, A.; Marinakis, V. Explainable ai-based ensemble clustering for load profiling and demand response. Energies 2024, 17, 5559. [Google Scholar] [CrossRef]

- Du, B.; Narusue, Y.; Furusawa, Y.; Nishihara, N.; Indo, K.; Morikawa, H.; Iida, M. Clustering wind turbines for SCADA data-based fault detection. IEEE Trans. Sustain. Energy 2022, 14, 442–452. [Google Scholar] [CrossRef]

- Yin, X.; Mu, Z.; Cui, Q.; Sun, T. Interpretable and spatio-distributed settlement related multimode process monitoring for Metro tunnels excavated by TBM. Adv. Eng. Inform. 2025, 66, 103464. [Google Scholar] [CrossRef]

| Step | Description |

|---|---|

| Input | Time domain vibration signal ; instantaneous rotational speed signal (or angular signal ); |

| 1 | Apply ACMD to to extract the dominant mode(s) representing the fault-related signal component; |

| 2 | Estimate the instantaneous angular position (if only is available); |

| 3 | Define a uniform angular grid over ; |

| 4 | Interpolate the extracted signal from the time domain to the angular domain: Use and to obtain via interpolation; |

| 5 | Perform spectral analysis (e.g., FFT) on to extract order components or construct an order spectrum; |

| Output | Angular domain signal ; order spectrum or features for subsequent fault diagnosis. |

| Step | Description |

|---|---|

| Input | Data points set X; distance function ; estimated density ; density peak thresholds , ; path cost function (e.g., minimax); |

| 1 | Construct a graph where and edge weights (fully connected or k-nearest neighbors); |

| 2 | Estimate the density for each point (e.g., using a Gaussian kernel or neighborhood count); |

| 3 | For each point , compute ; |

| 4 | Identify the set of density peaks: ; |

| 5 | Add a virtual source node s and connect it to each density peak with a negligible edge cost D; |

| 6 | Apply Dijkstra’s single-source shortest path (SSSP) algorithm from s to all other nodes:Use to evaluate the path from s to each node x:

|

| 7 | Assign each node x to the cluster associated with the density peak that its shortest path passes through; |

| 8 | Noise handling: if the path cost to a point exceeds a threshold (e.g., Otsu-based), mark it as noise; |

| Output | Cluster labels for all data points in X. |

| Feature | Expression | Feature | Expression |

|---|---|---|---|

| Feature | Expression | Feature | Expression |

|---|---|---|---|

| Type of Fault | Area of Failure (mm2) | Depth of Damage (mm) |

|---|---|---|

| IF | 4 | 0.5 |

| IF | 8 | 4 |

| IF | 12 | 2 |

| OF | 4 | 4 |

| OF | 8 | 8 |

| OF | 12 | 12 |

| Experiment | Approach | Correct/Total | Accuracy | Real Fault/Identified |

|---|---|---|---|---|

| Experiment 1 | SP-DPS | 342/350 | 97.7% | 7/7 |

| DPS | 252/350 | 72.0% | 7/12 | |

| ATDPS | 211/350 | 60.3% | 7/14 | |

| K-medoids | 205/350 | 58.5% | 7/7 | |

| DAP | 209/350 | 59.7% | 7/17 | |

| DBSCAN | 266/350 | 76.0% | 7/5 | |

| Experiment 2 | SP-DPS | 311/320 | 97.2% | 4/4 |

| DPS | 198/320 | 61.9% | 4/8 | |

| ATDPS | 204/320 | 63.7% | 4/14 | |

| K-medoids | 254/320 | 79.4% | 4/4 | |

| DAP | 237/320 | 74.1% | 4/14 | |

| DBSCAN | 262/320 | 81.8% | 4/4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, S.; Xu, E.; Zhuang, Y.; Jian, H.; Jin, Z.; Wei, Z. Fault Diagnosis of Rolling Bearings Under Variable Speed for Energy Conversion Systems: An ACMD and SP-DPS Clustering Approach with Traction Motor Validation. Energies 2025, 18, 4254. https://doi.org/10.3390/en18164254

Peng S, Xu E, Zhuang Y, Jian H, Jin Z, Wei Z. Fault Diagnosis of Rolling Bearings Under Variable Speed for Energy Conversion Systems: An ACMD and SP-DPS Clustering Approach with Traction Motor Validation. Energies. 2025; 18(16):4254. https://doi.org/10.3390/en18164254

Chicago/Turabian StylePeng, Shunyan, Enyong Xu, Yuan Zhuang, Hanqing Jian, Zhenzhen Jin, and Zexian Wei. 2025. "Fault Diagnosis of Rolling Bearings Under Variable Speed for Energy Conversion Systems: An ACMD and SP-DPS Clustering Approach with Traction Motor Validation" Energies 18, no. 16: 4254. https://doi.org/10.3390/en18164254

APA StylePeng, S., Xu, E., Zhuang, Y., Jian, H., Jin, Z., & Wei, Z. (2025). Fault Diagnosis of Rolling Bearings Under Variable Speed for Energy Conversion Systems: An ACMD and SP-DPS Clustering Approach with Traction Motor Validation. Energies, 18(16), 4254. https://doi.org/10.3390/en18164254