A Review of Mycelium Bio-Composites as Energy-Efficient Sustainable Building Materials

Abstract

1. Introduction

2. Review Methodology

- (i)

- Material and fabrication technologies: mycelium-based building materials, extrusion, 3D printing, robotic manufacturing, modular growth;

- (ii)

- Performance and characterization: thermal conductivity, thermal resistance, thermal effusivity, moisture buffering, vapor permeability, mechanical strength, fire resistance, durability;

- (iii)

- Sustainability and application context: embodied energy, low-carbon materials, energy efficiency, regenerative design, life cycle assessment (LCA), scalability, and standardization.

- Titles and abstracts of the retrieved studies are screened, focusing on embedded concepts, keywords, and specific terms. The 80 reviewed references were retrieved primarily from peer-reviewed databases, with the majority published by MDPI (25%) and Elsevier (16.25%). Additional sources include ACS, Springer, Nature Publishing Group, IEEE, Wiley, and Taylor & Francis, with 37.5% of sources categorized as grey literature or unclassified.

- Then, the full texts of the selected studies from Step 1 were reviewed to extract detailed data, considering parameters including physical characteristics, replacement of traditional energy-intensive building materials, and their contribution to regenerative design and waste valorization. A short and relevant description and a reference for each contribution were written at that stage. Numerous mycological and biological references pertain to mycelium, yet they fall outside the purview of this review, and, as such, are omitted from the study’s scope.

- At the final step, a qualitative assessment of the data extracted from stage 2 was conducted to identify common themes, trends, and knowledge gaps. The reviewed literature was synthesized under two main topics: Fabrication of Mycelium Bio-Composites, which includes lab-scale processes, industrial production methods, additive manufacturing, and scalability; and Performance Characterization of MBCs, covering mechanical properties, hygrothermal behavior, durability, fire resistance, and environmental impact.

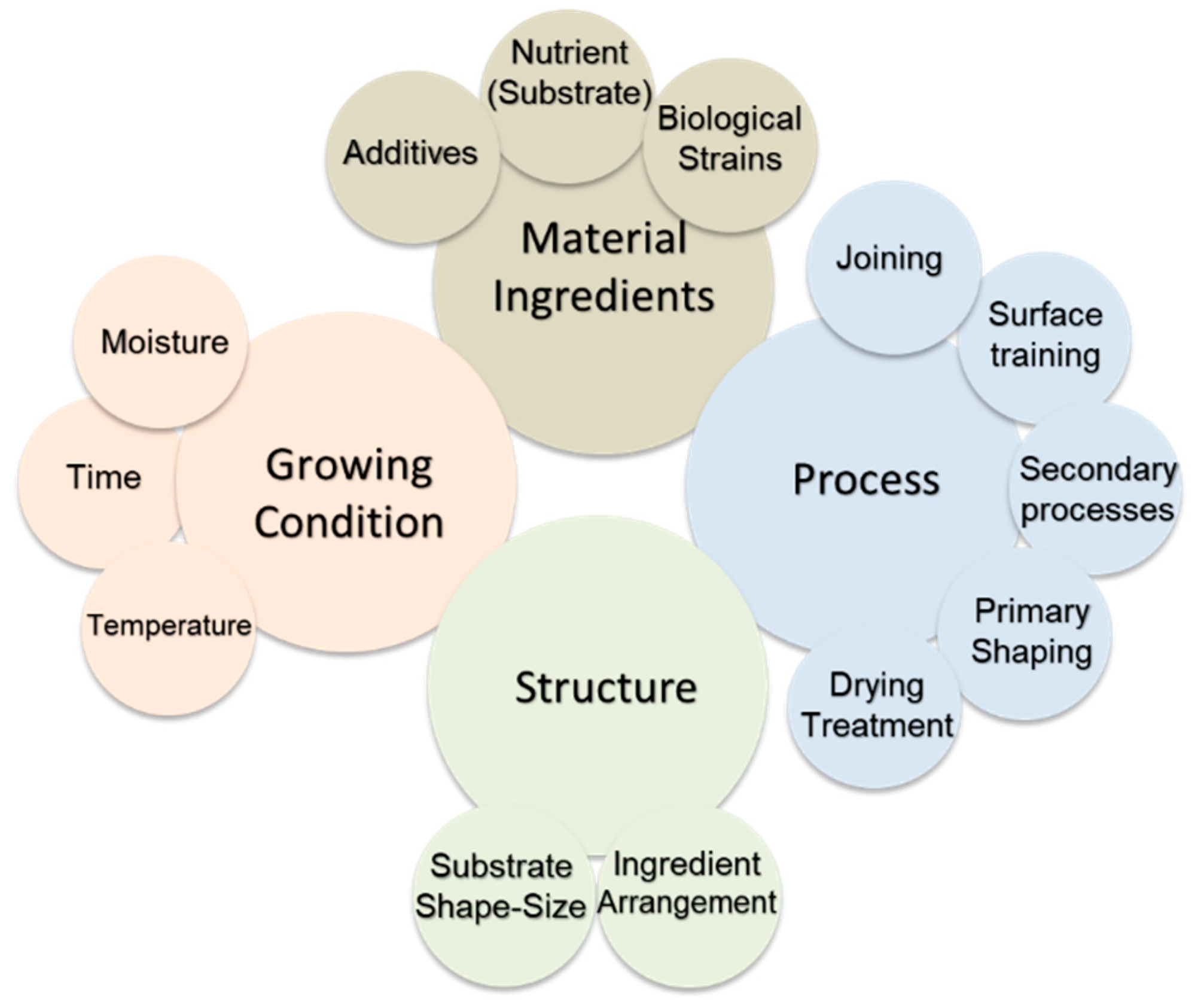

3. Fabrication of Mycelium Bio-Composites: From Lab to Industry

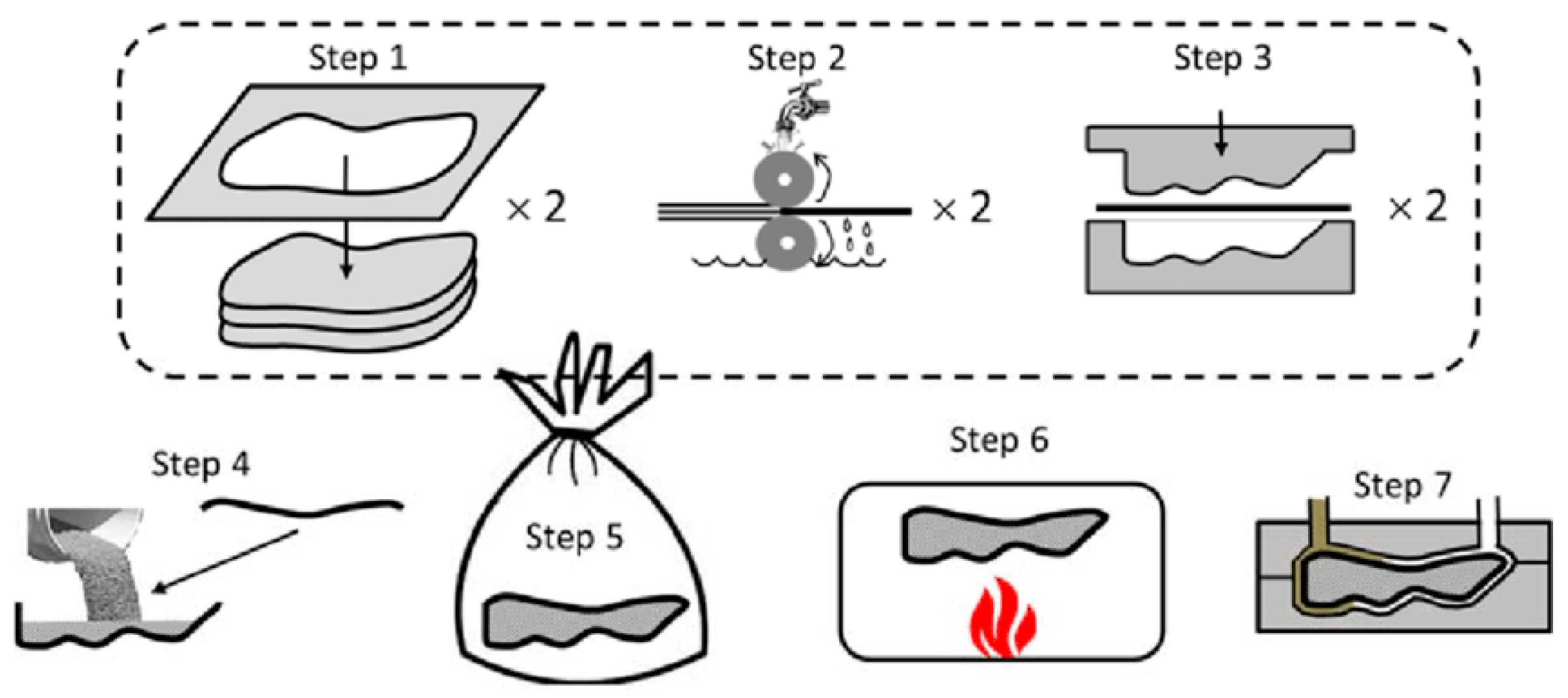

3.1. Laboratory Methods

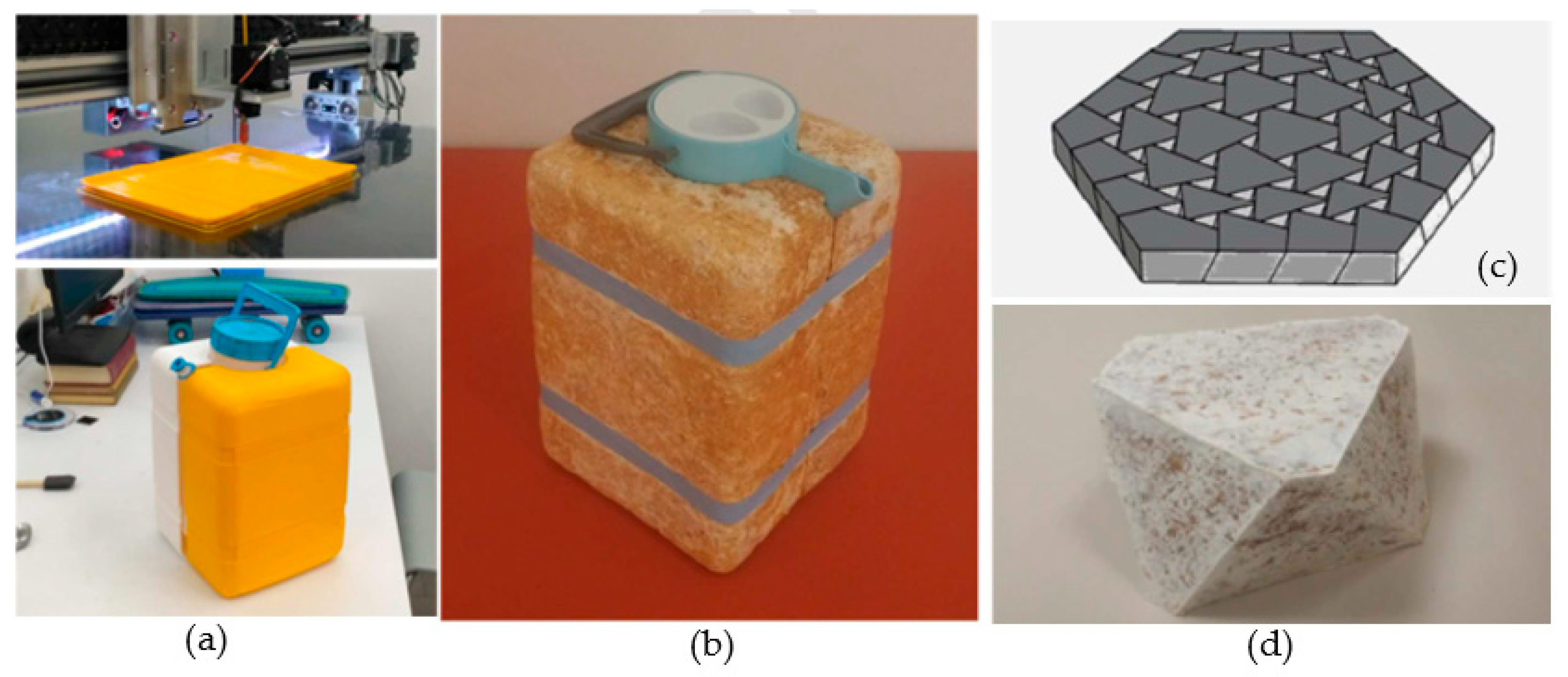

3.2. Additive Manufacturing

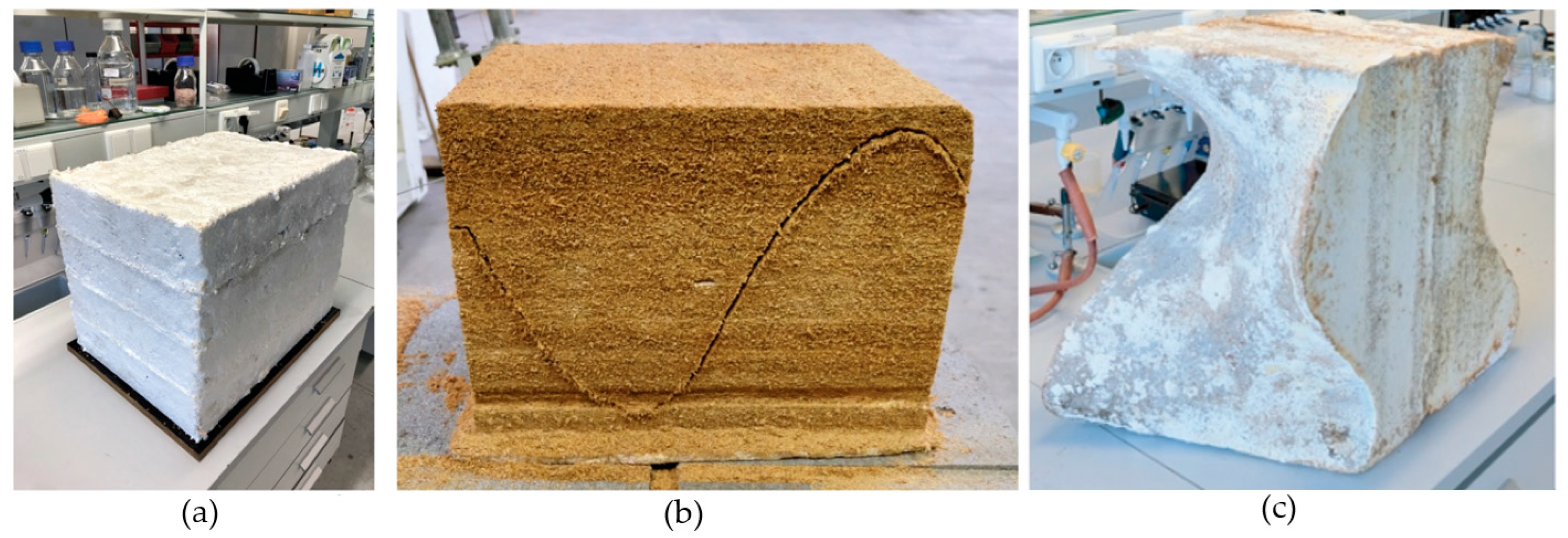

3.3. Industrial-Scale Production

3.4. Scalability of Production

3.5. Durability

3.6. Real-World Demonstrations

- MBCs can be fabricated through mold-based, additive manufacturing, and industrial hybrid methods, each with trade-offs between reproducibility and geometric complexity.

- Substrate type, fungal strain, and incubation protocols significantly affect mycelial growth and material performance.

- Additive manufacturing offers design flexibility but presents challenges in contamination control and material consistency.

- Industrial-scale production methods increasingly use composite layering, textile reinforcement, and CNFs to enhance structure and moisture resistance.

- Scalability remains constrained by biological variability, IP protection, and lack of standardized growth protocols.

4. Performance Characterization of MBCs

4.1. Mechanical Response to Processing Methods

4.2. Hygrothermal Behavior

4.3. Environmental Impact of MBCs

4.4. Fire Resistance and Safety of MBCs

4.5. Influence of Microstructure on the Hygrothermal Performance of MBCs

- Mechanical performance improves significantly with densification techniques such as hot pressing, which reduce porosity and enhance strength.

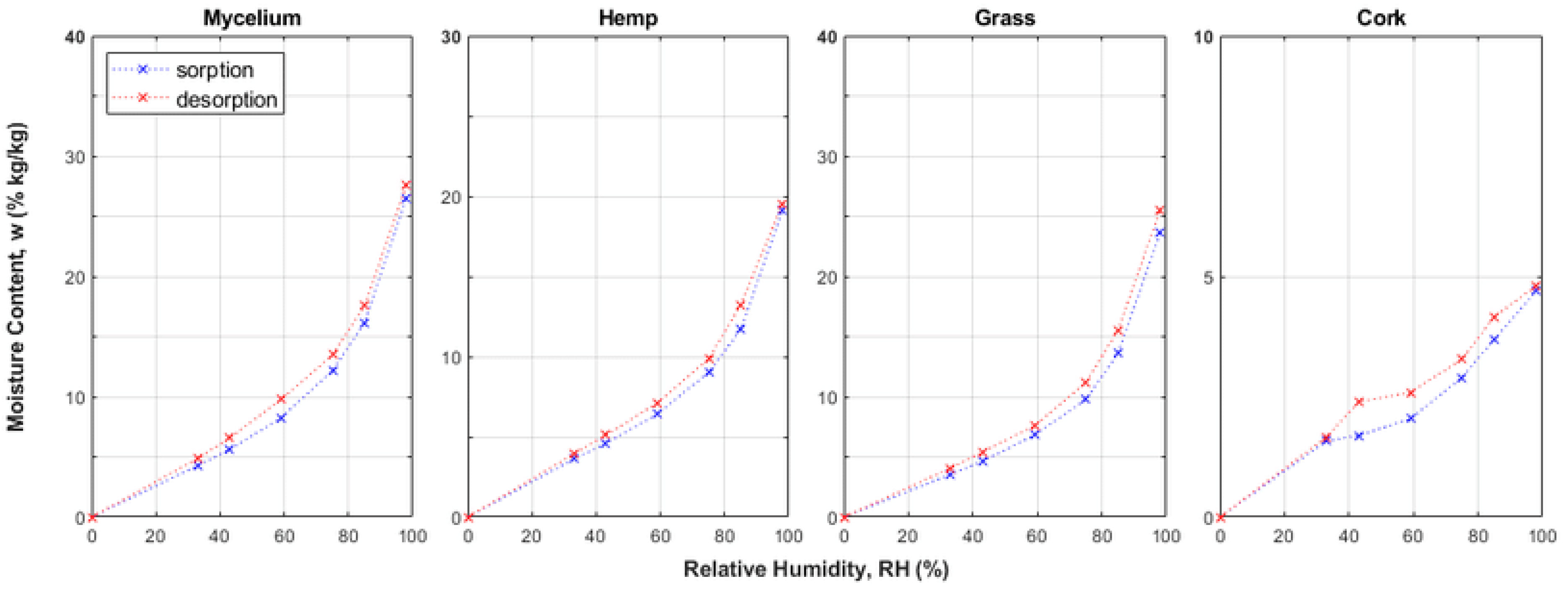

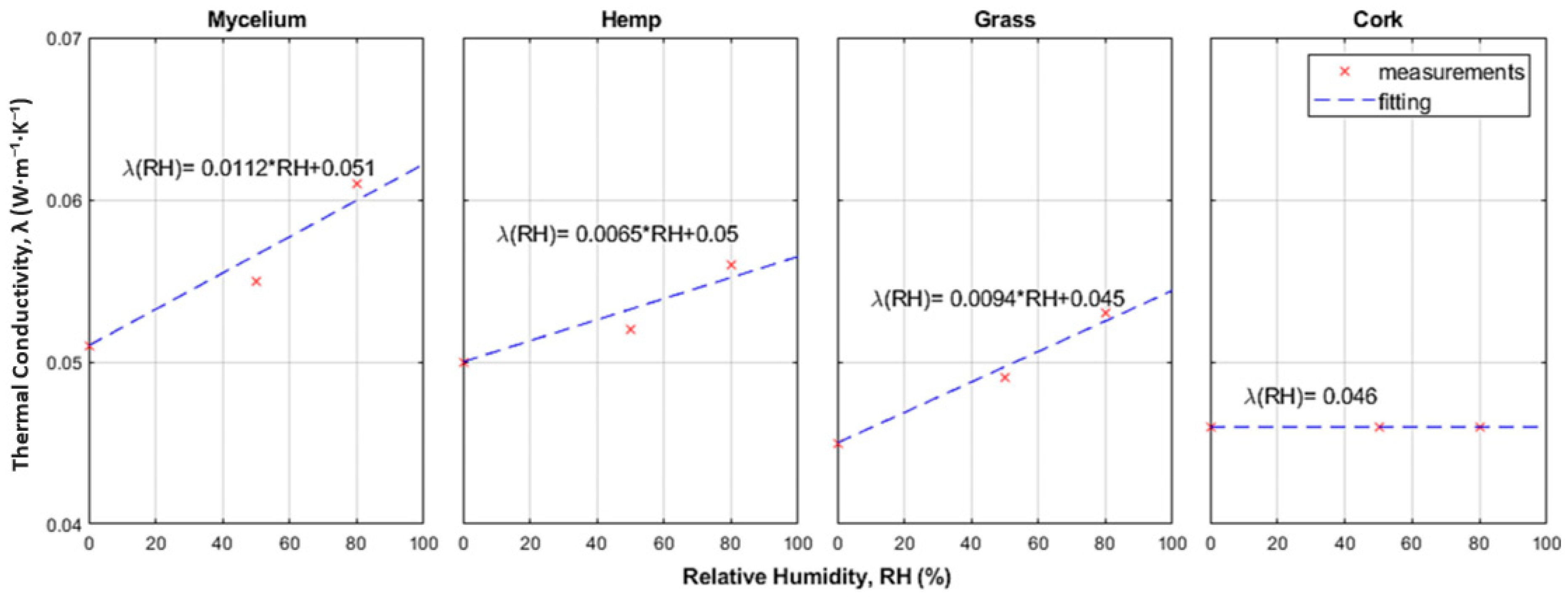

- Hygrothermal performance is strongly influenced by fungal strain, substrate, and microstructure; denser mycelial networks yield better insulation and lower water uptake.

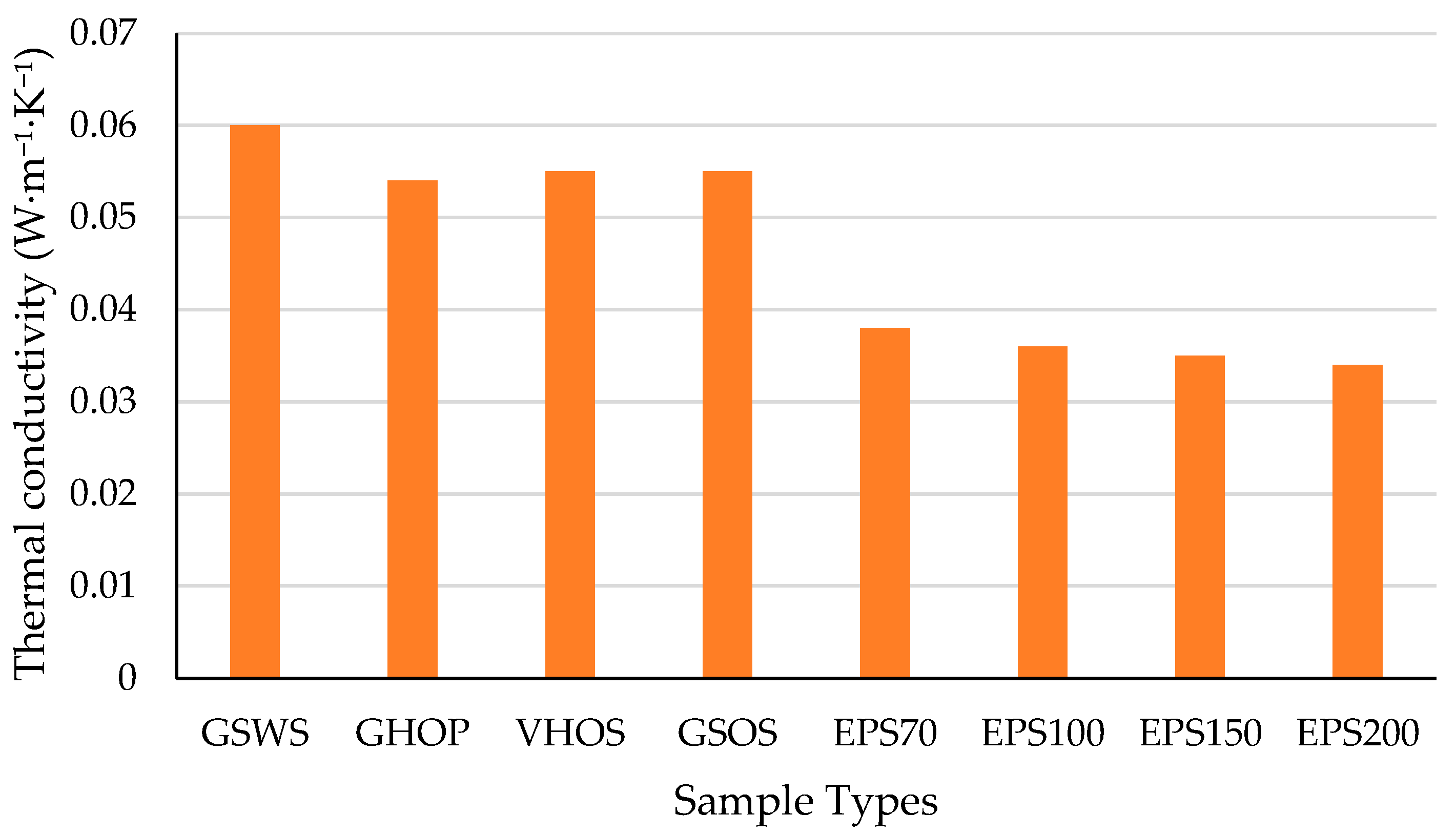

- MBCs exhibit thermal conductivities (0.036–0.048 W·m−1·K−1) comparable to commercial insulation while offering biodegradability and carbon negativity.

- Life cycle assessments confirm MBCs’ low embodied carbon, though results vary based on region, energy sourcing, and end-of-life treatment.

- MBCs demonstrate promising fire resistance and self-extinguishing behavior due to char formation and low combustion rates, enhancing safety for building applications.

5. Discussion

5.1. Fabrication Methods

5.2. Mechanical and Hygrothermal Properties

5.3. Environmental Impact and Life Cycle Performance

5.4. Fire Resistance and Safety

5.5. Durability and Long-Term Performance

5.6. Scalability and Real-World Implementation

5.7. Innovation Landscape

5.8. Comparative Bio-Based Materials

6. Conclusions

- Environmental performance is promising, with several LCA studies confirming low or even negative embodied carbon under optimized conditions.

- Durability remains a critical limitation, especially under prolonged humidity; however, post-treatment and material hybridization strategies show potential.

- Fire resistance is generally favorable due to high char formation and low smoke release, making MBCs safer than many synthetic insulations.

- Standardizing fabrication protocols to enable reproducibility and certification, especially for 3D printing and modular assembly.

- Advancing bio-hybrid strategies, including robotic manufacturing and self-healing systems, to improve scalability and reliability.

- Extending durability studies across diverse climates and building types, focusing on long-term moisture, UV, and biodegradation performance.

- Quantitative coupling of microstructure with thermal and moisture behavior, to enable predictive material design.

- Comprehensive LCA and end-of-life studies in various regional contexts to inform policy and market adoption.

Funding

Conflicts of Interest

Nomenclature

| Units: | |

| % | Percent (relative humidity, energy savings) |

| °C | Degrees Celsius (temperature) |

| W/m·K | Watts per meter-Kelvin (thermal conductivity) |

| MPa | Mega Pascal |

| Abbreviations: | |

| AKD | Alkyl Ketene Dimer |

| ANOVA | Analysis of Variance |

| CAD | Computer-Aided Design |

| CNF | Cellulose Nanofibrils |

| CO2-eq | Carbon Dioxide Equivalent |

| DIW | Direct Ink Writing |

| EU | European Union |

| EPS | Expanded Polystyrene |

| GHG | Greenhouse Gas |

| GHOP | Ganoderma lucidum + Hemp + Without Additive + Pasteurized Substrate |

| GSOS | Ganoderma lucidum + Straw + Without Additive + Sterilized Substrate |

| GSWS | Ganoderma lucidum + Straw + With Additive + Sterilized Substrate |

| LCA | Life Cycle Assessment |

| LCZEB | Life-Cycle Zero Energy Building |

| MBC | Mycelium Bio-Composite |

| MDF | Medium Density Fiberboard |

| PHBH | Poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) |

| PIR | Polyisocyanurate |

| PLA | Polylactic Acid |

| PVA | Polyvinyl Alcohol |

| PVC | Polyvinyl Chloride |

| RH | Relative Humidity |

| SEM | Scanning Electron Microscopy |

| UTS | Ultimate Tensile Strength |

| UV | Ultraviolet |

| VHOS | Trametes versicolor + Hemp + Without Additive + Sterilized Substrate |

| XPS | Extruded Polystyrene |

| ZEB | Zero Energy Building |

References

- Moussa, T.; Maalouf, C.; Ingrao, C.; Scrucca, F.; Costantine, G.; Asdrubali, F. Bio-based and recycled-waste materials in buildings: A study of energy performance of hemp-lime concrete and recycled-polyethylene terephthalate façades for office facilities in France and Italy. Sci. Technol. Built Environ. 2018, 24, 492–501. [Google Scholar] [CrossRef]

- Khasreen, M.M.; Banfill, P.F.; Menzies, G.F. Life-cycle assessment and the environmental impact of buildings: A review. Sustainability 2009, 1, 674–701. [Google Scholar] [CrossRef]

- Jansson, G.; Schade, J.; Olofsson, T. Requirements management for the design of energy efficient buildings. J. Inf. Technol. Constr. 2013, 18, 321–337. [Google Scholar]

- Pan, J.; Jain, R.; Paul, S.; Vu, T.; Saifullah, A.; Sha, M. An internet of things framework for smart energy in buildings: Designs, prototype, and experiments. IEEE Internet Things J. 2015, 2, 527–537. [Google Scholar] [CrossRef]

- Takano, A.; Hughes, M.; Winter, S.A. multidisciplinary approach to sustainable building material selection: A case study in a Finnish context. Build. Environ. 2014, 82, 526–535. [Google Scholar] [CrossRef]

- Jones, D.; Brischke, C. Performance of Bio-Based Building Materials; Woodhead Publishing: Cambridge, UK, 2017. [Google Scholar]

- Canada Energy Regulator. Canada’s Energy Future 2023: Energy Supply and Demand Projections to 2050; Canada Energy Regulator: Calgary, AB, Canada, 2023; Available online: https://www.cer-rec.gc.ca/en/data-analysis/canada-energy-future/2023/ (accessed on 23 July 2025).

- Beccali, M.; Cellura, M.; Fontana, M.; Longo, S.; Mistretta, M. Energy retrofit of a single-family house: Life cycle net energy saving and environmental benefits. Renew. Sustain. Energy Rev. 2013, 27, 283–293. [Google Scholar] [CrossRef]

- Lawrence, M. Reducing the environmental impact of construction by using renewable materials. J. Renew. Mater. 2015, 3, 163–174. [Google Scholar] [CrossRef]

- Cuéllar-Franca, R.M.; Azapagic, A. Environmental impacts of the UK residential sector: Life cycle assessment of houses. Build. Environ. 2012, 54, 86–99. [Google Scholar] [CrossRef]

- Joseph, P.; Tretsiakova-McNally, S. Sustainable non-metallic building materials. Sustainability 2010, 2, 400–427. [Google Scholar] [CrossRef]

- Dutil, Y.; Rousse, D.; Quesada, G. Sustainable buildings: An ever evolving target. Sustainability 2011, 3, 443–464. [Google Scholar] [CrossRef]

- Motamedi, S.; Rousse, D.R.; Promis, G. The evolution of crop-based materials in the built environment: A review of the applications, performance, and challenges. Energies 2023, 16, 5252. [Google Scholar] [CrossRef]

- Es-sakali, N.; Pfafferott, J.; Mghazli, M.O.; Cherkaoui, M. Towards climate-responsive net zero energy rural schools: A multi-objective passive design optimization with bio-based insulations, shading, and roof vegetation. Sustain. Cities Soc. 2025, 120, 106142. [Google Scholar] [CrossRef]

- Cerimi, K.; Akkaya, K.C.; Pohl, C.; Schmidt, B.; Neubauer, P. Fungi as source for new bio-based materials: A patent review. Fungal Biol. Biotechnol. 2019, 6, 17. [Google Scholar] [CrossRef]

- Stelzer, L.; Hoberg, F.; Bach, V.; Schmidt, B.; Pfeiffer, S.; Meyer, V.; Finkbeiner, M. Life cycle assessment of fungal-based composite bricks. Sustainability 2021, 13, 11573. [Google Scholar] [CrossRef]

- Gorse, C.; Thomas, F.; Glew, D.; Shenton, D.M. Achieving sustainability in new build and retrofit: Building performance and life cycle analysis. In Building Sustainable Futures; Springer: Berlin/Heidelberg, Germany, 2016; pp. 183–207. [Google Scholar]

- Elsacker, E.; Vandelook, S.; Brancart, J.; Peeters, E.; De Laet, L. Mechanical, physical and chemical characterisation of mycelium-based composites with different types of lignocellulosic substrates. PLoS ONE 2019, 14, e0213954. [Google Scholar] [CrossRef] [PubMed]

- Motamedi, S.; Rousse, D.R.; Promis, G. Microstructure-Driven Hygrothermal Behavior of Mycelium-Based Composites for Bio-Based Insulation. Energies 2025, 18, 2864. [Google Scholar] [CrossRef]

- Meyer, V.; Schmidt, B.; Pohl, C.; Cerimi, K.; Schubert, B.; Weber, B.; Volpato, A. Mind the Fungi; Universitätsverlag der Technischen Universität Berlin: Berlin, Germany, 2020. [Google Scholar]

- Escobar, N.; Laibach, N. Sustainability check for bio-based technologies: A review of process-based and life cycle approaches. Renew. Sustain. Energy Rev. 2021, 135, 110213. [Google Scholar] [CrossRef]

- Barta, D.G.; Simion, I.; Tiuc, A.E.; Vasile, O. Mycelium-based composites as a sustainable solution for waste management and circular economy. Materials 2024, 17, 404. [Google Scholar] [CrossRef]

- Nussbaumer, M.; Van Opdenbosch, D.; Engelhardt, M.; Briesen, H.; Benz, J.P.; Karl, T. Material characterization of pressed and unpressed wood–mycelium composites derived from two Trametes species. Environ. Technol. Innov. 2023, 30, 103063. [Google Scholar] [CrossRef]

- Camilleri, E.; Narayan, S.; Lingam, D.; Blundell, R. Mycelium-based composites: An updated comprehensive overview. Biotechnol. Adv. 2025, 79, 108517. [Google Scholar] [CrossRef]

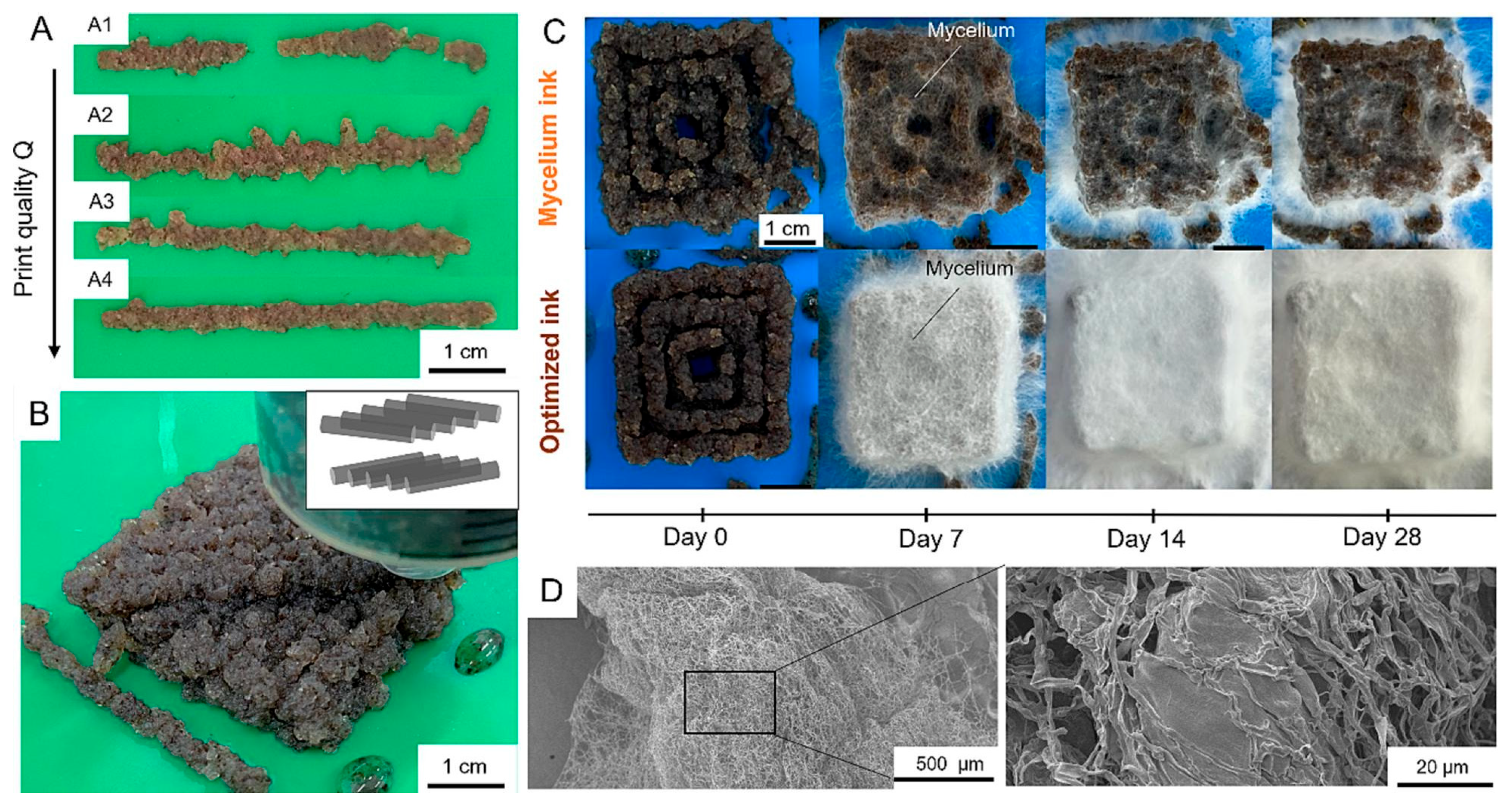

- Mohseni, A.; Vieira, F.R.; Pecchia, J.A.; Gürsoy, B. Three-dimensional printing of living mycelium-based composites: Material compositions, workflows, and ways to mitigate contamination. Biomimetics 2023, 8, 257. [Google Scholar] [CrossRef]

- Scott, J.; Kaiser, R.; Ozkan, D.; Hoenerloh, A.; Agraviador, A.; Elsacker, E.; Bridgens, B. Knitted Cultivation: Textiling a Multi-Kingdom Bio Architecture, in Structures and Architecture a Viable Urban Perspective? CRC Press: Boca Raton, FL, USA, 2022; pp. 3–10. [Google Scholar]

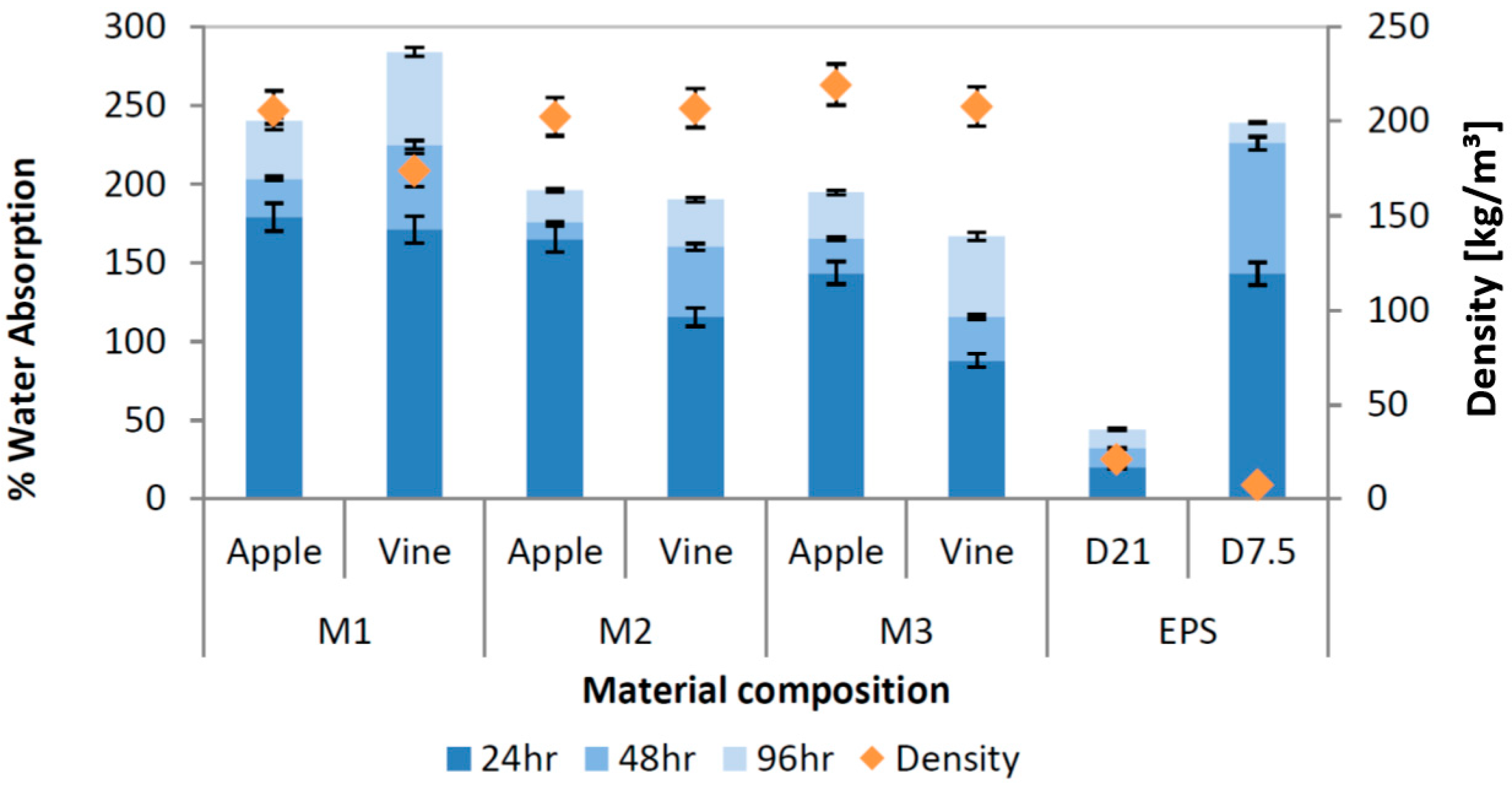

- Attias, N.; Danai, O.; Abitbol, T.; Tarazi, E.; Ezov, N.; Pereman, I.; Grobman, Y.J. Mycelium bio-composites in industrial design and architecture: Comparative review and experimental analysis. J. Clean. Prod. 2020, 246, 119037. [Google Scholar] [CrossRef]

- Elsacker, E.; Søndergaard, A.; Van Wylick, A.; Peeters, E.; De Laet, L. Growing living and multifunctional mycelium composites for large-scale formwork applications using robotic abrasive wire-cutting. Constr. Build. Mater. 2021, 283, 122732. [Google Scholar] [CrossRef]

- Jones, M.; Huynh, T.; Dekiwadia, C.; Daver, F.; John, S. Mycelium composites: A review of engineering characteristics and growth kinetics. J. Bionanosci. 2017, 11, 241–257. [Google Scholar] [CrossRef]

- Teoh, J.H.; Soh, E.; Le Ferrand, H. Manipulating fungal growth in engineered living materials through precise deposition of nutrients. Int. J. Bioprinting 2024, 10, 3939. [Google Scholar] [CrossRef]

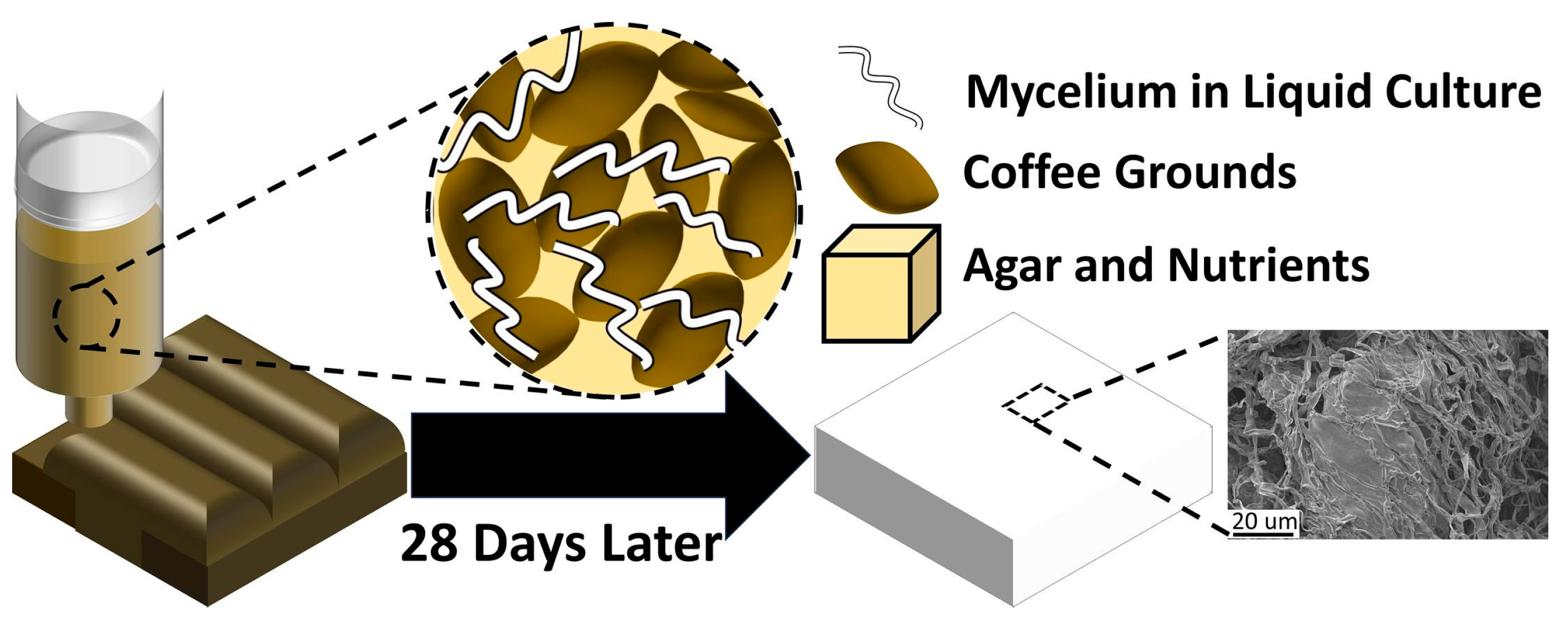

- Soh, E.; Teoh, J.H.; Leong, B.; Xing, T.; Le Ferrand, H. 3D printing of mycelium engineered living materials using a waste-based ink and non-sterile conditions. Mater. Des. 2023, 236, 112481. [Google Scholar] [CrossRef]

- Luo, D.; Yang, J.; Peek, N. 3D-Printed Mycelium Biocomposites: Method for 3D Printing and Growing Fungi-Based Composites. 3D Print. Addit. Manuf. 2025, 12, 98–111. [Google Scholar] [CrossRef]

- Rahman, A.M.; Bhardwaj, A.; Pei, Z.; Ufodike, C.; Castell-Perez, E. The 3D printing of biomass–fungi composites: Effects of waiting time after mixture preparation on mechanical properties, rheological properties, minimum extrusion pressure, and print quality of the prepared mixture. J. Compos. Sci. 2022, 6, 237. [Google Scholar] [CrossRef]

- Soh, E.; Chew, Z.Y.; Saeidi, N.; Javadian, A.; Hebel, D.; Le Ferrand, H. Development of an extrudable paste to build mycelium-bound composites. Mater. Des. 2020, 195, 109058. [Google Scholar] [CrossRef]

- Bhardwaj, A.; Vasselli, J.; Lucht, M.; Pei, Z.; Shaw, B.; Grasley, Z.; Wei, X.; Zou, N. 3D printing of biomass-fungi composite material: A preliminary study. Manuf. Lett. 2020, 24, 96–99. [Google Scholar] [CrossRef]

- Chen, H.; Klemm, S.; Dönitz, A.G.; Ou, Y.; Schmidt, B.; Fleck, C.; Simon, U.; Völlmecke, C. Tailoring the Mechanical Properties of Fungal Mycelium Mats with Material Extrusion Additive Manufacturing of PHBH and PLA Biopolymers. ACS Omega 2024, 9, 49609–49617. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Tao, J.; Wu, Z.; Weiland, K.; Wang, Z.; Masania, K.; Wang, B. Fabrication of living entangled network composites enabled by mycelium. Adv. Sci. 2024, 11, 2309370. [Google Scholar] [CrossRef]

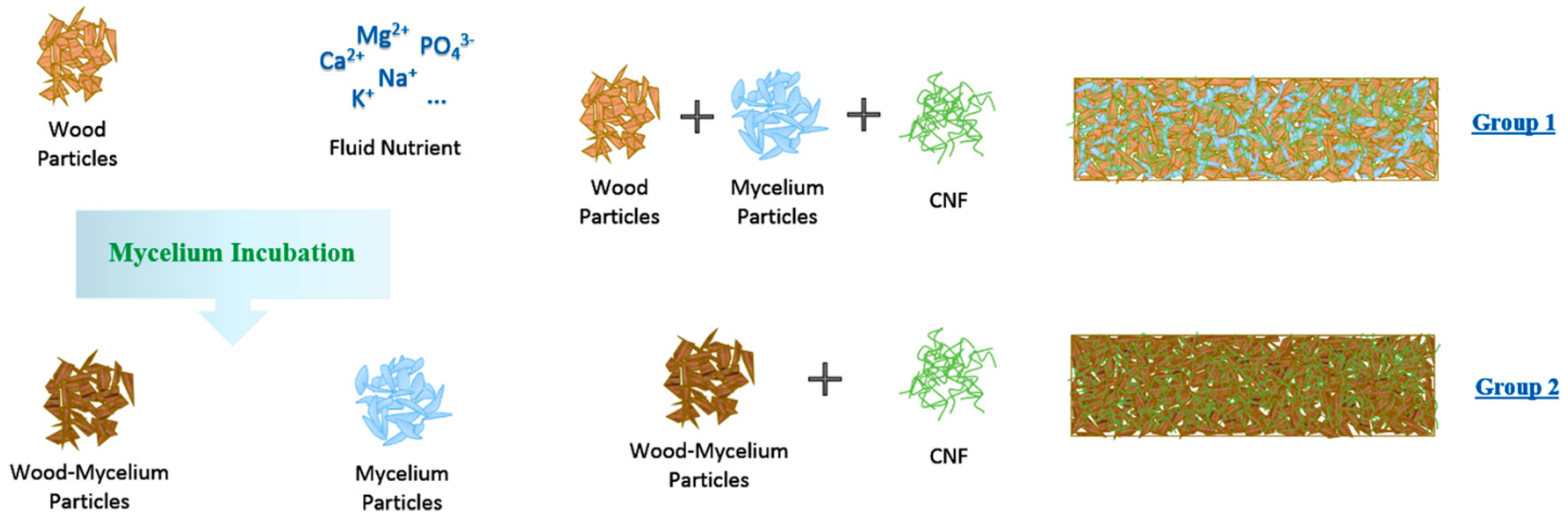

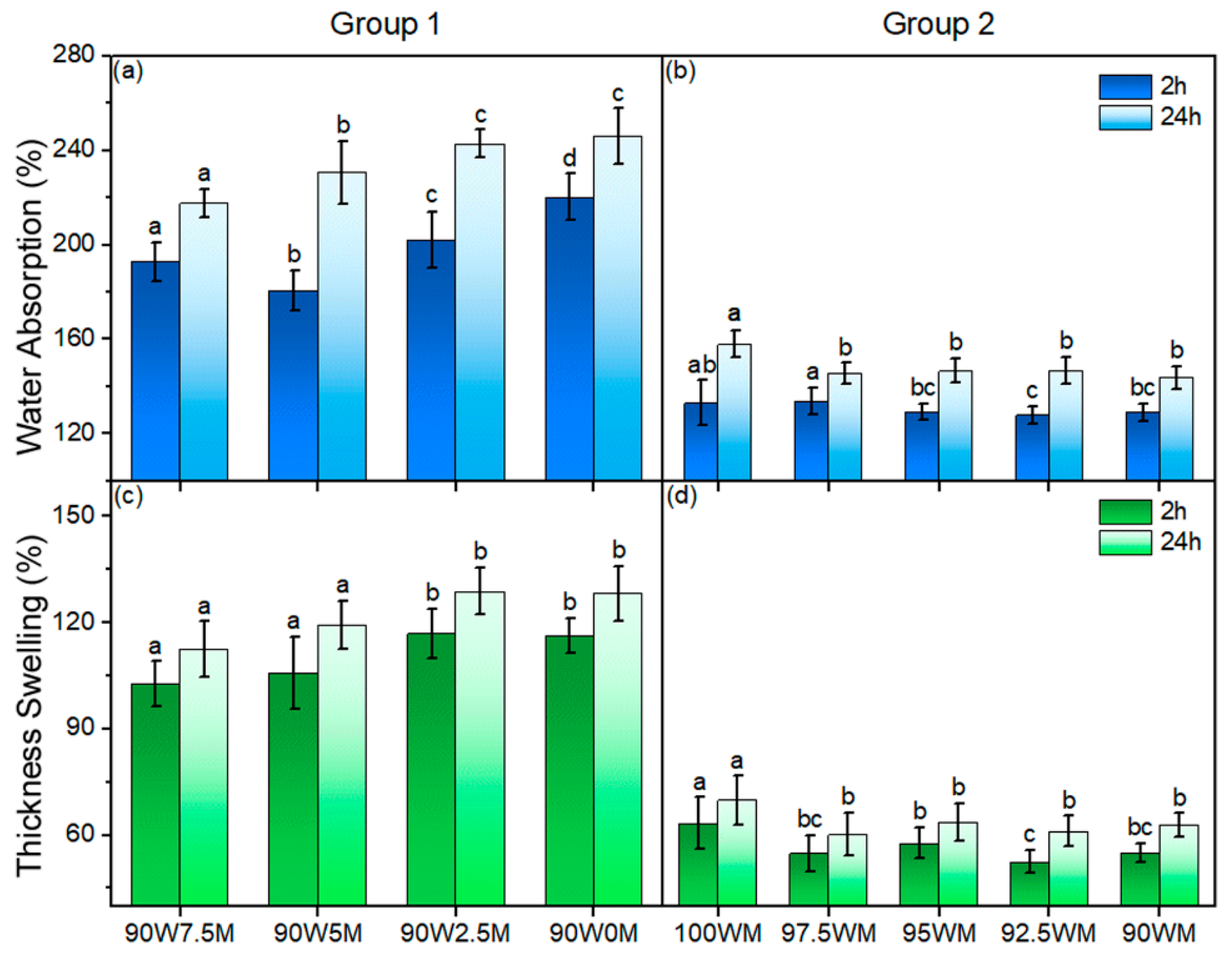

- Sun, W.; Tajvidi, M.; Hunt, C.G.; McIntyre, G.; Gardner, D.J. Fully bio-based hybrid composites made of wood, fungal mycelium and cellulose nanofibrils. Sci. Rep. 2019, 9, 3766. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Walczyk, D.; McIntyre, G.; Bucinell, R.; Tudryn, G. Manufacturing of biocomposite sandwich structures using mycelium-bound cores and preforms. J. Manuf. Process. 2017, 28, 50–59. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Anaele, J.U.; Oke, T.M.; Kareem, S.A.; Adediran, M.; Ajibuwa, O.A.; Anabaranze, Y.O. Mycelium based composites: A review of their bio-fabrication procedures, material properties and potential for green building and construction applications. Alex. Eng. J. 2023, 83, 234–250. [Google Scholar] [CrossRef]

- Bitting, S.; Derme, T.; Lee, J.; Van Mele, T.; Dillenburger, B.; Block, P. Challenges and opportunities in scaling up architectural applications of mycelium-based materials with digital fabrication. Biomimetics 2022, 7, 44. [Google Scholar] [CrossRef]

- Wattanavichean, N.; Phanthuwongpakdee, J.; Koedrith, P.; Laoratanakul, P.; Thaithatgoon, B.; Somrithipol, S.; Kwantong, P.; Nuankaew, S.; Pinruan, U.; Chuaseeharonnachai, C.; et al. Mycelium-Based Breakthroughs: Exploring Commercialization, Research, and Next-Gen Possibilities. Circ. Econ. Sustain. 2025. [Google Scholar] [CrossRef]

- Shin, H.J.; Ro, H.S.; Kawauchi, M.; Honda, Y. Review on mushroom mycelium-based products and their production process: From upstream to downstream. Bioresour. Bioprocess. 2025, 12, 3. [Google Scholar] [CrossRef]

- Schultz, N.; Fazli, A.; Piros, S.; Barranco-Origel, Y.; DeLa Cruz, P.; Schneider, D.Y. Characterization of Mycelium Biocomposites under Simulated Weathering Conditions. ACS Appl. Bio Mater. 2024, 7, 8408–8422. [Google Scholar] [CrossRef]

- Gan, J.K.; Soh, E.; Saeidi, N.; Javadian, A.; Hebel, D.E.; Le Ferrand, H. Temporal characterization of biocycles of mycelium-bound composites made from bamboo and Pleurotus ostreatus for indoor usage. Sci. Rep. 2022, 12, 19362. [Google Scholar] [CrossRef] [PubMed]

- Van Wylick, A.; Elsacker, E.; Yap, L.L.; Peeters, E.; De Laet, L. Mycelium composites and their biodegradability: An exploration on the disintegration of mycelium-based materials in soil. Constr. Technol. Archit. 2022, 1, 652–659. [Google Scholar]

- Gauvin, F.; Vette, I.J. Characterization of Mycelium-Based Composites as Foam-Like Wall Insulation Material. Master’s Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2020. [Google Scholar]

- Farrahnoor, A.; Sazali, N.A.A.; Yusoff, H.; Zhou, B.T. Effect of beeswax and coconut oil as natural coating agents on morphological, degradation behaviour, and water barrier properties of mycelium-based composite in modified controlled environment. Prog. Org. Coat. 2024, 196, 108763. [Google Scholar] [CrossRef]

- Elsacker, E.; Vandelook, S.; Damsin, B.; Van Wylick, A.; Peeters, E.; De Laet, L. Mechanical characteristics of bacterial cellulose-reinforced mycelium composite materials. Fungal Biol. Biotechnol. 2021, 8, 18. [Google Scholar] [CrossRef] [PubMed]

- Alemu, D.; Tafesse, M.; Mondal, A.K. Mycelium-based composite: The future sustainable biomaterial. Int. J. Biomater. 2022, 2022, 8401528. [Google Scholar] [CrossRef] [PubMed]

- Kuribayashi, T.; Lankinen, P.; Hietala, S.; Mikkonen, K.S. Dense and continuous networks of aerial hyphae improve flexibility and shape retention of mycelium composite in the wet state. Compos. Part A Appl. Sci. Manuf. 2022, 152, 106688. [Google Scholar] [CrossRef]

- Karana, E.; Blauwhoff, D.; Hultink, E.J.; Camere, S. When the material grows: A case study on designing (with) mycelium-based materials. Int. J. Des. 2018, 12, 119–136. Available online: https://research.tudelft.nl/en/publications/when-the-material-grows-a-case-study-on-designing-with-mycelium-b (accessed on 23 July 2025).

- Es-sakali, N.; Charai, M.; Kaitouni, S.I.; Ait Laasri, I.; Mghazli, M.O.; Cherkaoui, M.; Pfafferott, J.; Ukjoo, S. Energy efficiency and hygrothermal performance of hemp clay walls for Moroccan residential buildings: An integrated lab-scale, in-situ and simulation-based assessment. Appl. Energy 2023, 352, 121967. [Google Scholar] [CrossRef]

- Appels, F.V.; Camere, S.; Montalti, M.; Karana, E.; Jansen, K.M.; Dijksterhuis, J.; Krijgsheld PWösten, H.A. Fabrication factors influencing mechanical, moisture-and water-related properties of mycelium-based composites. Mater. Des. 2019, 161, 64–71. [Google Scholar] [CrossRef]

- Lingam, D.; Narayan, S.; Mamun, K.; Charan, D. Engineered mycelium-based composite materials: Comprehensive study of various properties and applications. Constr. Build. Mater. 2023, 391, 131841. [Google Scholar] [CrossRef]

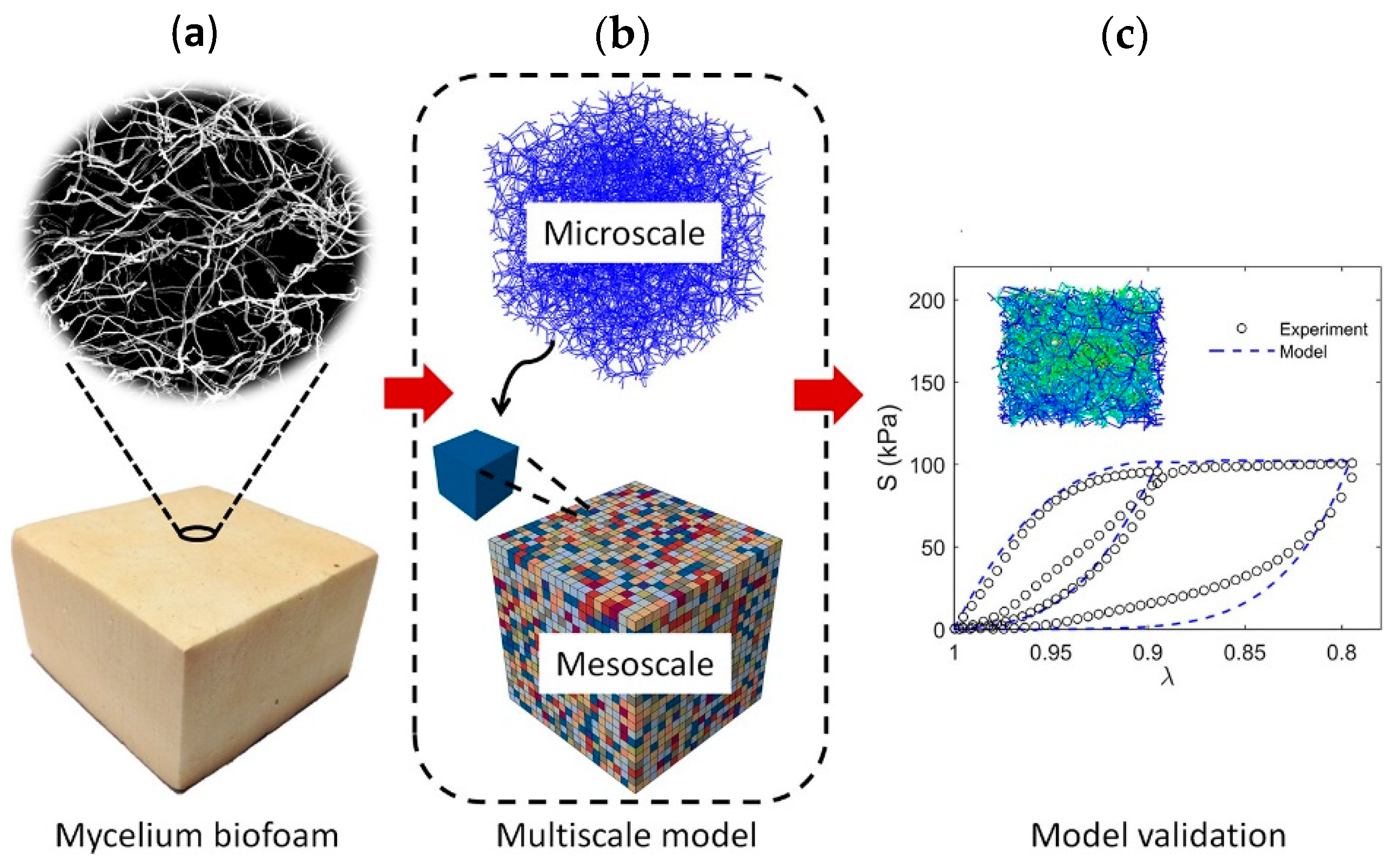

- Islam, M.R.; Tudryn, G.; Bucinell, R.; Schadler, L.; Picu, R.C. Stochastic continuum model for mycelium-based bio-foam. Mater. Des. 2018, 160, 549–556. [Google Scholar] [CrossRef]

- Attias, N.; Danai, O.; Tarazi, E.; Pereman, I.; Grobman, Y.J. Implementing bio-design tools to develop mycelium-based products. Des. J. 2019, 22, 1647–1657. [Google Scholar] [CrossRef]

- Yang, L.; Park, D.; Qin, Z. Material function of mycelium-based bio-composite: A review. Front. Mater. 2021, 8, 737377. [Google Scholar] [CrossRef]

- Nguyen, D.M.; Grillet, A.C.; Diep, T.M.H.; Thuc, C.N.H.; Woloszyn, M. Hygrothermal properties of bio-insulation building materials based on bamboo fibers and bio-glues. Constr. Build. Mater. 2017, 155, 852–866. [Google Scholar] [CrossRef]

- Farrera-Vázquez, N.; Aviles-Trujilo, L.; Moreira-Acosta, J.; García-Ramos, O.; Velazquez-Gurrola, A.; Aguilar-Castillejos, A.; Vargas-Estrada, L.; Sebastian, P.J. Development of an insulating material based on Trametes elegans mycelium and the study of its hygrothermal properties. Green Mater. 2022, 11, 28–36. [Google Scholar] [CrossRef]

- Pittau, F.; Carcassi, O.G.; Servalli, M.; Pellegrini, S.; Claude, S. Hygrothermal Characterization of Bio-Based Thermal Insulation Made of Fibres from Invasive Alien Lake Plants Bounded with Mycelium. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Beijing, China, 23–25 September 2020; IOP Publishing: Bristol, UK; Philadelphia, PA, USA, 2022; Volume 1078, p. 012069. [Google Scholar] [CrossRef]

- Babenko, M.; Kononets, Y.; Bartos, P.; Pont, U.; Spalek, F.; Zoubek, T.; Kriz, P. Perspectives of Insulating Biodegradable Composites Derived from Agricultural Lignocellulosic Biomass and Fungal Mycelium: A Comprehensive Study of Thermal Conductivity and Density Characteristics. Biomimetics 2024, 9, 707. [Google Scholar] [CrossRef] [PubMed]

- Sağlam, S.S.; Özgünler, S.A. Production of mycelium-based composite materials and evaluation of thermal insulation performance. J. Green Build. 2024, 19, 193–222. [Google Scholar] [CrossRef]

- Jin, Q.; Zhang, Z.; Chen, J. A study on the thermal performance of Pleurotus Ostreatus/Straw mycelium composites and its application in building envelopes. J. Build. Eng. 2024, 92, 109646. [Google Scholar] [CrossRef]

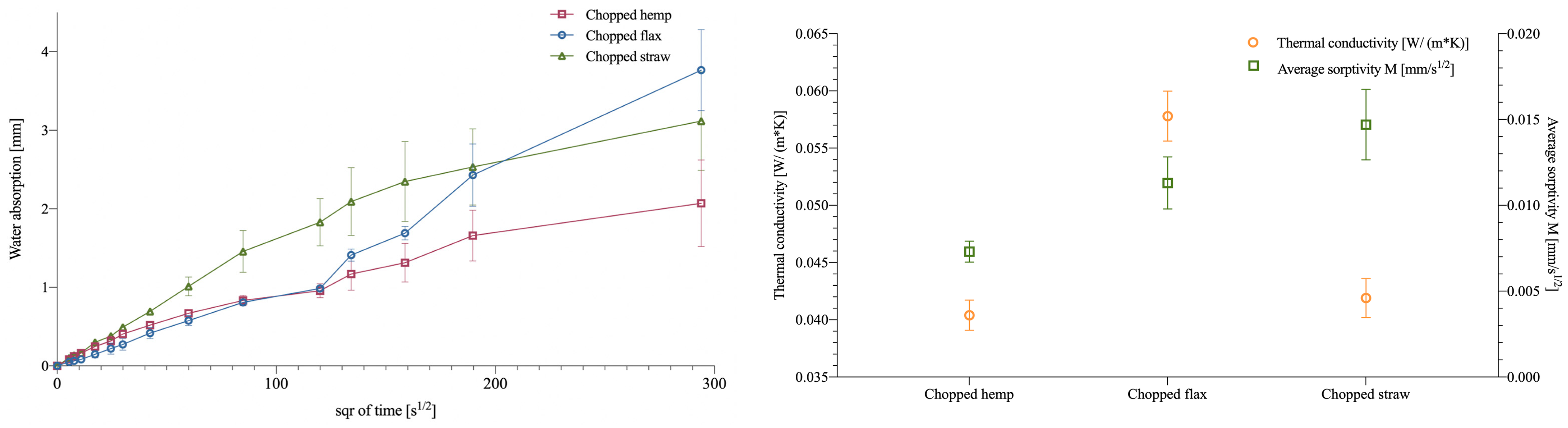

- Koh, C.H.; Gauvin, F.; Schollbach, K.; Brouwers, H.J.H. Investigation of material characteristics and hygrothermal performances of different bio-based insulation composites. Constr. Build. Mater. 2022, 346, 128440. [Google Scholar] [CrossRef]

- Shea, A.; Wildman, J.; Walker, P.; Henk, D. Extrinsic and intrinsic determinants of thermal conductivity in mycelium composites. Build. Serv. Eng. Res. Technol. 2024, 46, 317–338. [Google Scholar]

- Song, H.; Hon, K.C.; Gauvin, F.; Pantaleo, S.; Berger, F.; Chen, W.; Brouwers, H.J.H. Durability assessment of alkyl ketene dimer hydrophobic treatment of bio-based thermal insulation materials. Resour. Conserv. Recycl. 2025, 212, 107983. [Google Scholar] [CrossRef]

- Volk, R.; Schröter, M.; Saeidi, N.; Steffl, S.; Javadian, A.; Hebel, D.E.; Schultmann, F. Life cycle assessment of mycelium-based composite materials. Resour. Conserv. Recycl. 2024, 205, 107579. [Google Scholar] [CrossRef]

- Alaux, N.; Vašatko, H.; Maierhofer, D.; Saade, M.R.M.; Stavric, M.; Passer, A. Environmental potential of fungal insulation: A prospective life cycle assessment of mycelium-based composites. Int. J. Life Cycle Assess. 2024, 29, 255–272. [Google Scholar] [CrossRef]

- Livne, A.; Wösten, H.A.; Pearlmutter, D.; Gal, E. Fungal mycelium bio-composite acts as a CO2-sink building material with low embodied energy. ACS Sustain. Chem. Eng. 2022, 10, 12099–12106. [Google Scholar] [CrossRef]

- Akromah, S.; Chandarana, N.; Rowlandson, J.L.; Eichhorn, S.J. Potential environmental impact of mycelium composites on African communities. Sci. Rep. 2024, 14, 11867. [Google Scholar] [CrossRef]

- Irbe, I.; Kirpluks, M.; Kampuss, M.; Andze, L.; Milbreta, U.; Filipova, I. Assessing the Conformity of Mycelium Biocomposites for Ecological Insulation Solutions. Materials 2024, 17, 6111. [Google Scholar] [CrossRef]

- Jones, M.; Bhat, T.; Kandare, E.; Thomas, A.; Joseph, P.; Dekiwadia, C.; Yuen, R.; John, S.; Ma, J.; Wang, C.-H.; et al. Thermal degradation and fire properties of fungal mycelium and mycelium-biomass composite materials. Sci. Rep. 2018, 8, 17583. [Google Scholar] [CrossRef] [PubMed]

- Chulikavit, N.; Wang, C.; Huynh, T.; Yuen, A.C.Y.; Khatibi, A.; Kandare, E. Fireproofing flammable composites using mycelium: Investigating the effect of deacetylation on the thermal stability and fire reaction properties of mycelium. Polym. Degrad. Stab. 2023, 215, 110419. [Google Scholar] [CrossRef]

- Jones, M. Waste-Derived Mycelium Materials for Non-Structural and Semi-Structural Applications. Ph.D. Thesis, RMIT University, Melbourne, VIC, Australia, 2019. [Google Scholar]

- Zhang, M.; Zhang, Z.; Zhang, R.; Peng, Y.; Wang, M.; Cao, J. Lightweight, thermal insulation, hydrophobic mycelium composites with hierarchical porous structure: Design, manufacture and applications. Compos. Part B Eng. 2023, 266, 111003. [Google Scholar] [CrossRef]

- Verhelst, J.; Vandersanden, S.; Nouwen, O.; Rineau, F. Fungal Strain Influences Thermal Conductivity, Hydrophobicity, Color Homogeneity, and Mold Contamination of Mycelial Composites. Materials 2024, 17, 6050. [Google Scholar] [CrossRef] [PubMed]

- Chutimanukul, P.; Sukdee, S.; Prajuabjinda, O.; Thepsilvisut, O.; Panthong, S.; Athinuwat, D.; Poomipan, P.; Vachirayagorn, V. The Effects of Soybean Meal on Growth, Bioactive Compounds, and Antioxidant Activity of Hericium erinaceus. Horticulturae 2023, 9, 693. [Google Scholar] [CrossRef]

- Holt, G.A.; Mcintyre, G.; Flagg, D.; Bayer, E.; Wanjura, J.D.; Pelletier, M.G. Fungal mycelium and cotton plant materials in the manufacture of biodegradable molded packaging material: Evaluation study of select blends of cotton byproducts. J. Biobased Mater. Bioenergy 2012, 6, 431–439. [Google Scholar] [CrossRef]

- Sisti, L.; Gioia, C.; Totaro, G.; Verstichel, S.; Cartabia, M.; Camere, S.; Celli, A. Valorization of wheat bran agro-industrial byproduct as an upgrading filler for mycelium-based composite materials. Ind. Crops Prod. 2021, 170, 113742. [Google Scholar] [CrossRef]

| Category | Lab-Scale Methods | Industrial-Scale Methods |

|---|---|---|

| Typical Techniques | Mold growth, hot pressing, 3D printing | Panel pressing, sandwich composites, modular units |

| Control & Consistency | High variability; limited standardization | Moderate consistency; early-stage standardization |

| Microstructural Tuning | High potential (custom molds, SEM studies) | SEM studies Limited but improving (pressing, additives) |

| Thermal Conductivity | 0.036–0.048 W·m−1·K−1 (depending on substrate) | ~0.040–0.060 W·m−1·K−1 (less optimized) |

| Scalability | Low (manual processes, contamination risks) | Moderate (batch production, robotic cutting) |

| Limitations | Inconsistency, contamination, shape limits | Cost, IP protection, production speed |

| Insulating Material | Thermal Conductivity [W/(m·K)] | Density [kg/m3] |

|---|---|---|

| Mycelium–flax composite—a | 0.0578 ± 0.002 ᵇᶜ | 135 |

| Mycelium–hemp composite—b | 0.0404 ± 0.001 ᵃ | 99 |

| Mycelium–straw composite—c | 0.0419 ± 0.0002 ᵇ | 94 |

| Rock wool | 0.044 | 470–2250 |

| Glass wool | 0.033–0.045 | 13–100 |

| Extruded polystyrene | 0.025–0.035 | 18–50 |

| Kenaf | 0.034–0.043 | 30–180 |

| Sheep wool plates | 0.038–0.054 | 10–25 |

| Author | Type | Fiber | Fungi | Technology/Initiative/Novelty |

|---|---|---|---|---|

| Appels et al. [54] | Article | Rapeseed straw Beech sawdust Cotton | T. multi-color P. Ostreatus | Non-pressed Heat-pressed Cold-pressed |

| Attias et al. [57] | Article | Vine and apple woodchips (residues of pruning) | Colorius sp. Trametes sp. Gonoderma sp. | The effect of further inoculation inside perforated bags on the quality of the material |

| Babenko et al. [62] | Article | Wheat straw Hemp straw Flax straw | Ganoderma lucidum | Comparative study on thermal performance and biodegradability |

| Bhardwaj et al. [35] | Article | Rice straw Hemp | Not mentioned | 3d Printing |

| Cerimi et al. [15] | Patent review | Wheat straw, wheat bran, maize straw, rice straw bagasse, wood, saw dust, wood chips, wool, hemp, silk, corncobs, | Agrocybe aegerita, Agrocybe brasiliensis, Coprinus comatus, Flammulina velutipes, Hypholoma capnoides, Hypholoma, Sublateritium, Lentinula edodes, Macrolepiota procera, Pleurotus djamor, Pleurotus eryngii, Pleurotus ostreatus, Pleurotus ostreatus var. columbines, Polyporales, Fomes fomentarius, Ganoderma tsugae, Ganoderma lucidum, Ganoderma orogenese, Grifola frondesa, Piptoporous betulina, Polyporus mylittae, Pycnoporus cinnabarinus, Trametes versicolor, Russulales Hericium erinaceus, Ascomycota, Pezizales, Morchella Angusticeps, Xylariales Xylaria Polymorpha, Xylaria hypoxylon, Xylaria filiformis, Xylaria longipes | Organic packaging material, fireproof composites, dehydrated mycelium elements, mycelium panels for construction, dehydrated mycelium elements using molding system, stiff engineered composite, roll-to-roll production of dehydrated mycelium, vehicle interieur outfit, bulk fungal materials (fillings), self-supporting composites, ultrasonic treatment, vehicle parts, sound attenuating materials, electric circuits composed of fungal mycelium |

| Chutimanukul et al. [78] | Article | soybean meal | H. erinaceus | Medical applications |

| Elsacker et al. (2021) [28] | Article | Hemp hurd Beachwood sawdust | Ganoderma resinaceum Trametes versicolor | Scalability of the fabrication practices - Growing large blocks - on-site robotic wire cutting - multi-functional framework usage of mycelium - Self healing of fungal organisms |

| Elsacker et al. (2019) [18] | Article | Hemp Flax Flax waste Soft wood Wheat straw | Trametes versicolor | The effect of substrate type and pre-processing of the substrate on the hygrothermal properties |

| Farrera-Vázquez et al. [60] | Article | Corn stalk | Trametes elegans | Development of bio-insulation from T. elegans and cornstalk with hygrothermal testing |

| Gauvin and Vette [47] | Thesis | Rapeseed straw Cellulose | G. lucidum | Prolonging inoculation phase |

| Holt et al. [79] | Article | Cotton plant biomass (CPB) | Proprietary information of Ecovative | |

| Islam et al. [56] | Article | Ecovative supplied bio composite | Multi-scale stochastic analysis | |

| Jiang et al. [39] | Article | Jute Hemp Cellulose | Mycelium-bound agricultural waste (core) Bioresin (matrix) | Manufacturing of biocomposite sandwich structure |

| Karana et al. [52] | Product design journey | Fiber Grain | Not Mentioned | Non-pressed Heat-pressed Cold-pressed |

| Koh et al. [65] | Article | Straw Miscanthus Flax | Not mentioned | - Hygrothermal characterization - comparison of mycelium-based composites with other type of bio-based building materials |

| Pittau et al. [61] | Conference | Hemp shiv Lagarosiphon major fibres | Not mentioned | Use of invasive aquatic plant fibres with mycelium for insulation |

| Rahman et al. [33] | Article | Not mentioned | Not mentioned | 3d Printing |

| Scott et al. [26] | Article | Mixed fiber (straw, wood shavings, plain flour) | Pleurotus ostreatus | - Knitting living textiles as scaffolds - Incorporation of bacteria and mycelium |

| Sisti et al. [80] | Article | bran/cotton, bran/hemp Additive: wheat bran | Proprietary information of Mogu | Investigation of wheat bran as an upgrading filler to the base substrate |

| Soh et al. (2020) [34] | Article | Bamboo culms | Ganoderma lucidum | 3d Printing |

| Soh et al. (2023) [31] | Article | Coffee grounds | Pleurotus ostreatus | 3d Printing |

| Song et al. [67] | Article | Grass | Not mentioned | Application of AKD hydrophobization to reduce water uptake |

| Stelzer et al. [16] | Article | Hemp shiv | Fomes fomentarius | LCA for fungal-based composite bricks |

| Sun et al. [38] | Article | Soft wood | White-rot basidiomycete | Cellulose nanofabrils |

| Verhelst et al. [77] | Article | Mixture of hemp shives and flax shives | Ganoderma lucidum Pleurotus ostreatus Trametes versicolor Trametes hirsuta Schizophyllum commune Coprinus comatus Lentinula edodes Hericium erinaceus Fomes fomentarius | Comparative study of fungal strain impact on insulation properties |

| Zhang et al. [76] | Article | Poplar and birch sawdust | Trametes versicolor | Development of lightweight, hydrophobic mycelium composites with hierarchical porous structures for thermal insulation applications. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Motamedi, S.; Rousse, D.R.; Promis, G. A Review of Mycelium Bio-Composites as Energy-Efficient Sustainable Building Materials. Energies 2025, 18, 4225. https://doi.org/10.3390/en18164225

Motamedi S, Rousse DR, Promis G. A Review of Mycelium Bio-Composites as Energy-Efficient Sustainable Building Materials. Energies. 2025; 18(16):4225. https://doi.org/10.3390/en18164225

Chicago/Turabian StyleMotamedi, Sina, Daniel R. Rousse, and Geoffrey Promis. 2025. "A Review of Mycelium Bio-Composites as Energy-Efficient Sustainable Building Materials" Energies 18, no. 16: 4225. https://doi.org/10.3390/en18164225

APA StyleMotamedi, S., Rousse, D. R., & Promis, G. (2025). A Review of Mycelium Bio-Composites as Energy-Efficient Sustainable Building Materials. Energies, 18(16), 4225. https://doi.org/10.3390/en18164225