1. Introduction

As a result of the large-scale invasion of Ukraine and the shelling of energy infrastructure facilities, especially in the 2022–2023 heating season, many problems have arisen in the country’s unified energy system, which has led to the introduction of forced schedules of alternating disconnection of consumers from electricity or so-called “blackouts” [

1]. In this regard, the issue of alternative sources of electricity has become acute for both enterprises, institutions and organizations, as well as for individual households [

2]. The huge demand for electric generators in recent years was the reason for unjustified and sometimes even speculative prices for them [

3].

A power generator allows you to achieve autonomy in terms of power supply, providing electricity to devices and equipment. In modern conditions of low-quality electricity supply and its parts, turning off generators is a must for every household.

Although the situation looks better and more predictable, given that the energy industry and the population are already aware of the challenges they may face, it is also necessary to understand that there is a huge uncertainty about what exactly can happen in this area. Uncertainty itself—the situation is quite difficult to make a decision. Generally, the task of justifying the decision in such a case comes down to narrowing the initial set of alternatives based on the information available to the decision-maker (DM) [

4].

When making a decision, it is necessary to make a forecast of future conditions; develop a list of possible alternatives; evaluate the results of alternatives; evaluate alternatives according to selected criteria; determine the solution. However, it should be remembered that the DM is unable to objectively assess the probabilities of the occurrence of various conditions, and the forecast may not inspire confidence. Thus, creating a model for choosing an electric generator is an urgent problem.

It is impossible to solve the problem of appropriate selection of any technical system without taking into account its technical, economic, operational and ergonomic characteristics.

The values of these characteristics declared by the manufacturer or supplier of the technical system in many cases do not coincide with the real ones, or there is no information about these values at all. That is, the choice has to be made in conditions of uncertainty, which requires the use of selection methods that can take this uncertainty into account, in particular, methods of expert evaluations.

In conditions of uncertainty, different approaches can be used to make decisions, for example, on the selection of generators.

It is known that the main groups of decision-making methods are axiomatic, heuristic and verbal. The first group includes such approaches as the multi-criteria theory of utility, the theory of fuzzy sets and others. The heuristic approach corresponds to complex situations that are repeated and are not amenable to direct mathematical analysis. The process of choice and decision is modeled in such a way as to reproduce the course of human reasoning.

Contradictions are observed in both approaches, to overcome which some authors suggest using verbal (ordinal) decision analysis. This type includes the well-known Analytic Hierarchy Process (AHP), which consists of the decomposition of a general problem by building a hierarchical structural model [

5,

6], and is used to select alternatives in a wide range of problems. In particular, this method was applied when building models for the selection of various machines and their systems [

7,

8,

9].

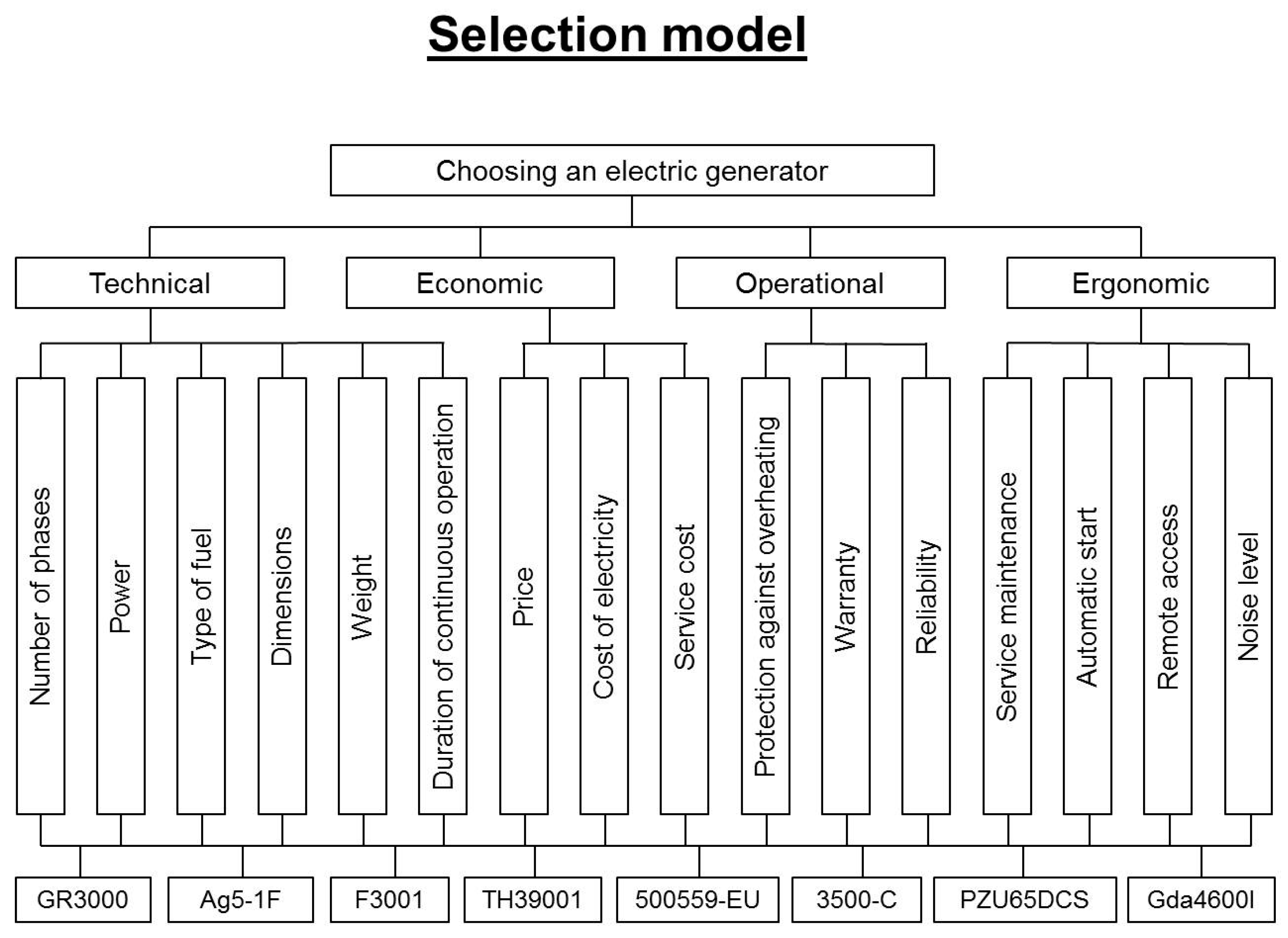

The main stage of the AHP is the construction of a hierarchical structural model of the choice problem.

At the top of the hierarchy in this structural model is the problem itself. If the hierarchy has four levels, then, at the second level of the hierarchy, there are groups of criteria, and, at the third, the selection criteria themselves. For a hierarchy with three levels, there is no criterion group level.

Alternatives, that is, specific examples of technical systems, are located at the lowest level of the model. It is from a set of alternatives that an appropriate option is chosen, taking into account the entire set of criteria and the relative importance of the criteria themselves and their groups.

To develop a hierarchical structural model, first of all, it is necessary to decide on a list of criteria.

For most technical systems, there are four most important groups of criteria [

7]:

- -

Technical;

- -

Economic;

- -

Operational;

- -

Ergonomic.

The groups listed above may have different specific weights depending on the specific conditions in which the selection is made. Specific values of this weight are determined by experts when constructing a matrix of pairwise comparisons of individual groups of criteria [

6].

The determination of alternatives takes place, as a rule, on the basis of market analysis and the stable reputation of manufacturers. In particular, it is possible to apply rating assessments of experts.

However, the majority of researchers use the AHP or its combination with other methods to solve the problem of choice.

On the basis of a bibliometric study of decision-making methods based on many criteria, the classic variant of the AHP was chosen and used in work [

10] for the selection of a medium-sized warship. A commercial aircraft selection model combining the fuzzy Analytical Hierarchical Process of the interval type (IT2FAHP) and the hybrid methods of the fuzzy technique of order preference by similarity to the ideal solution (IT2FTOPSIS) was developed in [

11]. The classic AHP model was used in work [

12] to select a fighter aircraft based on many criteria and in work [

13] to assess the risks of introducing electric vehicles to the market and in work [

14] to select the best hosting for a company’s website. The model of the introduction of ground electrical equipment of airports using the analytical network process (ANP) and Super Decisions software tools is presented in [

15]. A combination of the AHP and the Weighted Additive Fuzzy Goal Programming (WAFGP) method was used to select information systems projects in work [

16].

A review study [

17] provided an analysis of the experience of using AHP and Analytic Network Process (ANP) models over two decades of our century and found that the AHP tends to produce more accurate results than the ANP.

Thus, to solve the problem of choice, it is advisable to use the AHP.

The purpose of this work is to develop a model for choosing an electric generator for consumers with comprehensive consideration of a set of technical, economic, operational and ergonomic criteria in conditions of uncertainty.

2. Materials and Methods

The AHP was used to develop the electric generator selection model.

To achieve this goal, the following tasks must be solved:

- -

Conduct an analysis of the subject area;

- -

Justify the criteria for choosing an electric generator;

- -

Build a hierarchical structural model of the problem of choosing an electric generator;

- -

Build matrices of pairwise comparisons and calculate weighting coefficients;

- -

Calculate generalized weighting factors and choose an appropriate alternative.

An electricity generator is characterized by a significant number of parameters that have a significant impact on the choice of a certain model.

First of all, it is necessary to take into account the power of the generator. To calculate the required power, it is necessary to take into account the aggregate indicators of all devices that will be connected to the network. Considering this total power, it is necessary to take into account both ordinary household appliances and electrical appliances that work with some important elements of life support (for example, water pumps and heating systems). Thus, the required generator power values are in the range of 3 kW to 5 kW.

Secondly, the choice is influenced by the number of phases of the generator. There are single-phase, three-phase devices and combined generators. The choice should depend on the network from which the equipment works. A three-phase consumer will be able to work only from the corresponding station, but single-phase consumers can be connected to one phase of a 3-phase generator. A single-phase generator is enough for a small house.

Thirdly, the type of fuel also has a significant impact on the choice of an appropriate alternative. The advantages of gasoline generators are low noise level, moderate cost, compactness, relatively low weight and easy start-up at low temperatures. However, there are certain disadvantages, namely, limited time of continuous operation, relatively high cost of electricity and limited motor resource. The advantages of diesel generators include resistance to significant loads, a long time of continuous operation and economical fuel consumption. Disadvantages of diesel generators are a high level of noise and a higher price than gasoline generators with the same power.

Fourthly, the dimensions of the generator are important for the user, which can become a limitation for its appropriate placement in the limited space of the residence.

Fifth, the weight of the generator should be taken into account as, from time to time, there may be a need to move it, so this parameter can become important.

Sixthly, it is impossible not to take into account the time of continuous operation of the generator because it greatly affects the convenience of its use.

When choosing a generator, you cannot ignore its cost parameters. In particular, the price of the generator can become an obstacle in its selection, the constant increase in fuel prices requires taking into account the cost of generating a unit of power by the generator, and the cost of spare parts and consumables also affects the choice of a certain alternative.

Generator performance should also be considered when evaluating generator options. In particular, the absence or imperfection of the overheating protection system can accidentally disable the generator. The overall reliability of the generator is also valued by consumers and should be taken into account. It will significantly facilitate the operation of the generator and the availability of a sufficient warranty service period.

Even with a warranty, the problem may be the lack of convenient access to the service center, so the convenience of service should be taken into account when choosing.

The starter used to start the generator can be manual, electric or automatic. The first is the cheapest, but its use can cause complications in cold conditions; the second is more expensive, but the start-up process is greatly simplified; the third is the most expensive but ensures continuous operation of the equipment. Therefore, the type of starter should also be taken into account when choosing.

Considering the growing popularity of the use of intelligent home management, when choosing a generator, you should also take into account the possibility of connecting remote access, which significantly affects the level of consumer comfort. The impact of the noise level from the operation of the generator must also be taken into account because it affects the comfort of the consumer and can limit the location of the generator.

Thus, after analyzing the criteria for the selection of generators, we can come to the conclusion that we have four main groups of criteria. It is proposed to include the following in the technical group of criteria: number of phases, power, type of fuel, dimensions, weight and duration of continuous operation.

The economic group of indicators consists of the following: the cost of the generator, the cost of electricity and the cost of maintenance.

Operational criteria include the following: protection against overheating, warranty and reliability.

And finally, the ergonomic group includes convenience of service, automatic start, the possibility of connecting remote access and noise level.

As an alternative, it was decided to choose several options of household generators with a capacity of 2.5–5 kW.

In particular, these are the following models: Grupel GR3000 [

18], Cedrus Ag5-1F [

19], Fogo F3001 [

20], Kruzer TH 3900 [

21], Champion 500559-EU [

22], AL-KO 3500-C [

23], Oleo-Mac PZU65DCS [

24] and Daewoo Power Products Gda 4600I [

25]. All these generators were selected by the authors from the popular Polish site ceneo.pl because Poland is the main hub through which aid goes to Ukraine. The model proposed by the authors is not limited to the selected generators but can be applied with appropriate modifications to any number of them. The only limitation in this case is the laboriousness of expert evaluations in pairwise comparisons at the lower level of many alternatives among themselves.

3. Results and Discussion

3.1. Development of a Hierarchical Structural Model and Matrices of Pairwise Comparisons

A hierarchical structural model of the generator selection problem was created, containing four levels of hierarchy. The model is shown in

Figure 1.

On the basis of this model, we will form matrices of pairwise comparisons, using the judgments of experts, presented in the form of a numerical assessment according to the scale of comparisons [

6].

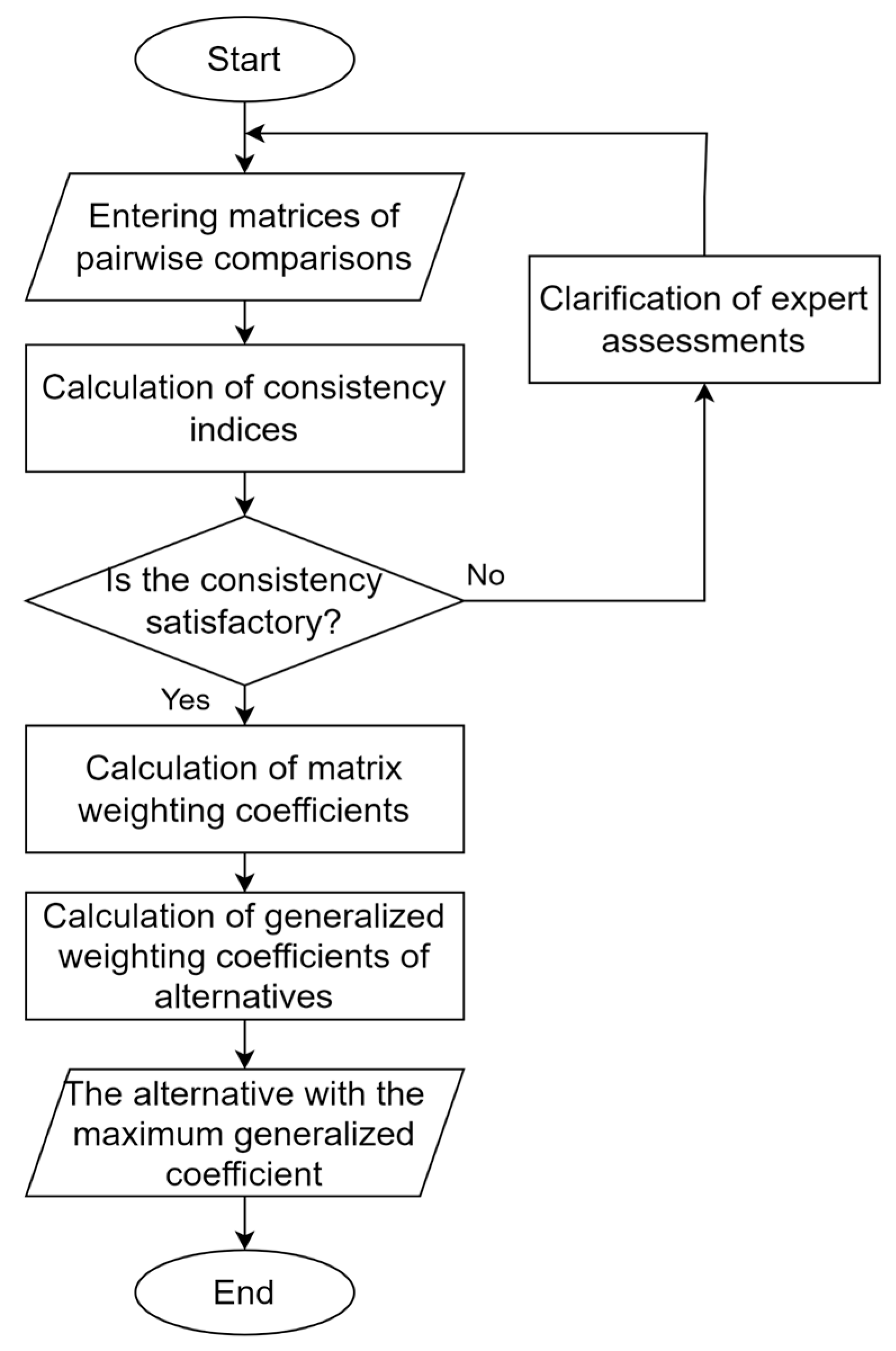

After obtaining experts’ evaluations, further software implementation of calculations using the AHP was carried out according to the algorithm shown in

Figure 2.

Five experts were engaged to create the pairwise comparison matrix for the AHP method. All experts possessed the following competencies:

- -

Higher technical education;

- -

At least 7 years of practical experience in the field of energy, operation of energy equipment or technical support for autonomous energy sources.

The experts were trained in the use of the Saati scale and the AHP methodology. The competency index included the following:

- -

Assessment of expertise in a given field;

- -

Assessment of analytical skills;

- -

Assessment of market knowledge and generator model knowledge.

Each expert exceeded the 0.75 threshold, indicating a high level of credibility for the expert opinions obtained.

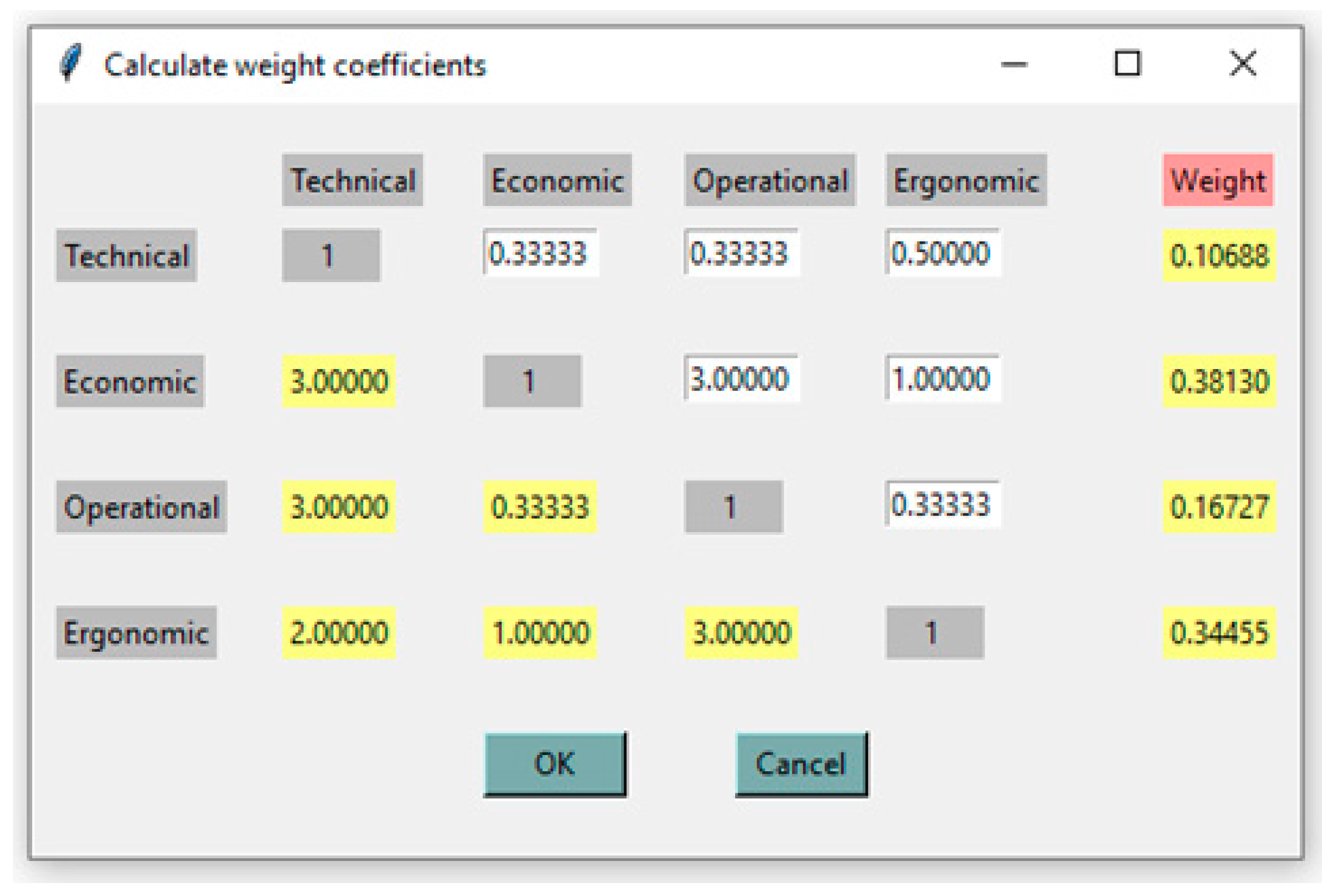

First, a matrix of pairwise comparisons of groups of criteria is formed in relation to the generator selection problem itself; this is presented in

Table 1.

The consistency of the estimates was calculated for each row by summing the products of the elements by their corresponding column weights, dividing the result by the row weight, and then calculating the arithmetic mean. The resulting value (1) is as follows:

Then, for

n = 4, the consistency index (2) was calculated:

The consistency coefficient (3) is as follows:

The consistency level (4) was achieved:

which indicates acceptability.

In addition to the square matrix itself, the figure presents the values of the weight coefficients of the groups in the additional right column. These weighting coefficients were calculated by calculating the geometric means for the rows of the matrix and their further normalization by the total sum of the geometric means [

6].

Then, matrices of pairwise comparisons are formed, reflecting the importance of criteria within each of the four groups of criteria.

An example of such a matrix for the operational group of criteria is presented in

Table 2, which also shows an additional column of weighting factors.

Considering

Table 2, it should be concluded that the expert opinions contained in this matrix are logical and acceptable for further analysis within the AHP framework. This is evidenced by the fact that the consistency calculation results for

Table 2 are λ

max ≈ 3.054, CI ≈ 0.027 and CR ≈ 0.046 (or 4.6%). Since CR < 10%, the matrix is consistent.

At the lowest level, pairwise comparisons of alternatives are carried out among each other according to each criterion. An example of such a comparison together with the calculation of the weighting factors of the alternatives according to the operational criterion of reliability is presented in

Table 3.

The consistency indices from

Table 3 are λmax ≈ 8.828, CI ≈ 0.118 and CR ≈ 0.084 (i.e., 8.4%). CR index < 10%, it means that the matrix is consistent.

For all formed matrices, according to the requirements of the AHP, the agreement index and the agreement ratio were determined, which are within 10%, that is, the values are acceptable.

3.2. Choosing an Appropriate Alternative

The final stage of the implementation of the AHP is the calculation of generalized weighting factors for each of the alternatives.

For its implementation, the operation of sequential weighting of weighting factors is performed, namely, the weighting factors of the lower levels of the structural hierarchical model are weighted by the components of the vector of weighting factors of the upper levels [

6].

Therefore, the generalized weighting coefficients of the alternatives according to all criteria for each group are determined first. Thus, the matrix for calculating the generalized weighting coefficients of alternatives according to all criteria of the operational group is presented in

Table 4.

Then, the generalized weighting coefficients of the alternatives according to all the criteria of the structural model are determined, as shown in

Table 5. The alternative, which will have the largest value of the generalized weighting coefficient according to the entire set of criteria, is considered the appropriate choice. As we can see, in this case, it is an alternative to F3001.

The assessment of reliability and overheating protection had the greatest influence on its selection. This was justified based on an analysis of existing methods for decision-making under uncertainty and their application to the selection of technical systems. The feasibility of using the AHP to solve the given problem was justified by the selection criteria for the electric generator. A hierarchical structural model of the selection problem was constructed. The AHP procedure was implemented by constructing a pairwise comparison matrix and calculating generalized weighting factors. A suitable alternative was determined in the class of electric generators for households. The F3001 model has the highest generalized weighting factor value of 0.136 for the entire set of criteria. The electric generator has the highest generalized weighting factor value for the economic group criteria of 0.143 and the highest generalized weighting factor value for the operational group criteria of 0.147. The assessment of reliability and overheating protection for the engine had the greatest influence on the selection. The advantage of the selected alternative over the two others, i.e., 3500-C with a generalized weighting factor of 0.128 and PZU65DCS with a generalized weighting factor of 0.127, is insignificant, which indicates the potential sensitivity of the results to changes in the initial data.

In

Table 5, the difference between the best and worst ratings (0.136 and 0.119) is only 12.5% relative, confirming that the choice is made among alternatives with very similar characteristics. This indicates the potential sensitivity of the results to changes in the initial data. It is advisable to explain the final choice by taking into account additional practical considerations.

The software implementation of the AHP was performed using the Python 3.13.3 programming language. The user interface is developed using the library “tkinter”. The dialog box for inputting expert assessments and calculating weighting coefficients is presented in

Figure 3.

4. Application of a Cogeneration Unit in Future Research

Representatives of Woodward Poland and EPS System, in cooperation with representatives of the Institute of Technology and Life Sciences, National Research Institute, Poznań Branch, carried out the start-up of the AG20P cogeneration unit powered by biogas from a research agricultural biogas plant in Ocieszyn (Poland).

The main scope of work performed included is below.

The AG20P biogas generator was prepared for start-up by the following:

- -

Installing a Marelli Mark V AVR controller, designed for parallel operation with the grid and interoperability with the easYgen 2500 controller (Woodward INC, Fort Collins, CO, USA), in the generator;

- -

Connecting the generator to the generator’s electrical cabinet and connecting the generator’s electrical cabinet to the biogas plant’s electrical system;

- -

Installing a test air intake to the engine on the generator’s air filter;

- -

Checking the correct connection of the generator’s exhaust gas outlet to the biogas plant’s exhaust gas cooling system and the excess biogas combustion system.

The AG20P biogas generator was started and calibrated at idle speed by the following:

- -

Programming the Woodward easYgen 2500 controller settings;

- -

Updating the controller software;

- -

Adjusting the Woodward easYgen 2500 generator controller and the Marelli Mark V generator’s AVR controller. The generator was synchronized with the grid in consultation with ENEA Operator of the Energy Post in Oborniki. Initial calibration of the cogenerator’s operation under load in parallel with the grid was performed.

The generator was prepared for parallel operation with the grid with an active load of 10 kW and a test run until the biogas in the fermentation tank was depleted.

The AG20P-modernization (EPS System Sp. z o. o., Trzebinia, Poland) cogeneration unit was confirmed to operate correctly when powered by biogas generated during the fermentation of farm manure.

The AG20P biogas unit’s start-up, synchronization and parallel operation with the ENEA Operator grid were correct when powered by biogas with typical biogas plant parameters (methane content ≥60%, biogas pressure at the unit’s connection ≥2 kPa). When the AG20P biogas generator operated in parallel with the grid with an active power of up to 11.7 kW, the electricity produced by the generator met the adopted assumptions and requirements.

The electricity was used entirely (without feeding any surplus into the ENEA Operator grid) by the farm where the research biogas plant is installed. Current measurements on the farm did not indicate any surplus was fed into the ENEA Operator grid. No voltage exceedances were observed at ENEA Operator.

Following the commissioning and trial operation of the AG20P cogeneration unit at the research agricultural biogas plant, it is recommended to implement additional changes to better adapt the biogas plant to the farm and to demonstrate its operation for future commercialization.

Install the AG20P automatic start and synchronization button on the door of the automation cabinet (the controller has already been programmed to operate this button) in accordance with the connection description provided by Woodward Poland, simplifying the operation of the unit by farm staff.

Construct and connect the lambda sensor heating harness, which will enable better control of the air–gas mixture composition by the AFR system in the unit. Configure the AFR throttle valve for use with a Woodward P/N 1689-1249 lambda sensor (Woodward INC, Fort Collins, CO, USA)-LSF 4.2 transducer, Bosch heated exhaust gases, oxygen, 460 mm.

Mount the target engine air intake port on the unit’s air filter.

Install a biogas pressure gauge upstream of the Dungs shut-off solenoid valve (incorrectly installed, i.e., downstream of the Dungs shut-off solenoid valve).

Provide safety devices and their programmed settings, as well as a certificate of compliance for the Woodward easYgen 2500 controller with the following requirements:

- -

NC RfG Network Code (including General Application Requirements in accordance with URE decision No. DRE.7128.550.2.2018.ZJ); ENEA Operator’s set of requirements for type A energy generation modules (including micro-installations), enabling the formal submission to ENEA Operator of a micro-installation with an AG20P generator as the generation source (energy generation module). Combined electricity and heat generation takes place in a cogeneration unit burning biogas generated in the research biogas installation during the methane fermentation of pig manure. The test stand consisted of a two-cylinder diesel engine. The engine was equipped with an indirect fuel injection system with an injection pump section. The engine was permanently connected via the power take-off shaft to an asynchronous motor controlled by an automatic control and measurement system.

5. Conclusions

- (1)

In modern conditions of martial law in Ukraine, ensuring reliable energy supply to households is one of the important factors of economic stability and economic security of our country. The use by consumers of autonomous power sources with appropriate characteristics, and, in particular, electric generators, contributes to the solution of this problem. For a justified choice of an electric generator, taking into account the entire set of its characteristics, it is necessary to build a model that provides the possibility of choosing an appropriate alternative in conditions of uncertainty.

- (2)

The Analytical Hierarchy Process procedure is implemented by constructing matrices of pairwise comparisons and calculating generalized weight coefficients, and a suitable alternative in the class of electric generators for households is determined—model F3001, which has the highest value of the generalized weighting factor for the entire set of criteria—0.136.

- (3)

For the first time, the AHP method was used to select power generators for households, taking into account reliability indicators in war conditions. Thus, the Analytic Hierarchy Process was further developed by extending it to a new subject area—the choice of an electric generator for a household under conditions of uncertainty.

- (4)

In future studies, it is advisable to evaluate the interdependencies of the proposed selection criteria and, if necessary, develop a model for the selection of electric generators based on the analytical network process (ANP) using Super Decisions software tools.